Semi-metal material Te nanowire/graphene hydrogel composite material as well as preparation method and application thereof

A graphene hydrogel, semi-metallic material technology, applied in the directions of gel preparation, botanical equipment and methods, applications, etc., can solve the problems of weak bactericidal effect, low photothermal conversion efficiency of photothermal catalysts, etc., and achieve simple sterilization. , Excellent photothermal conversion performance, sterilization and easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

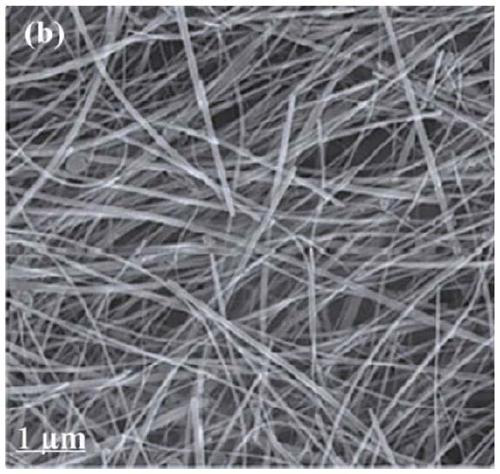

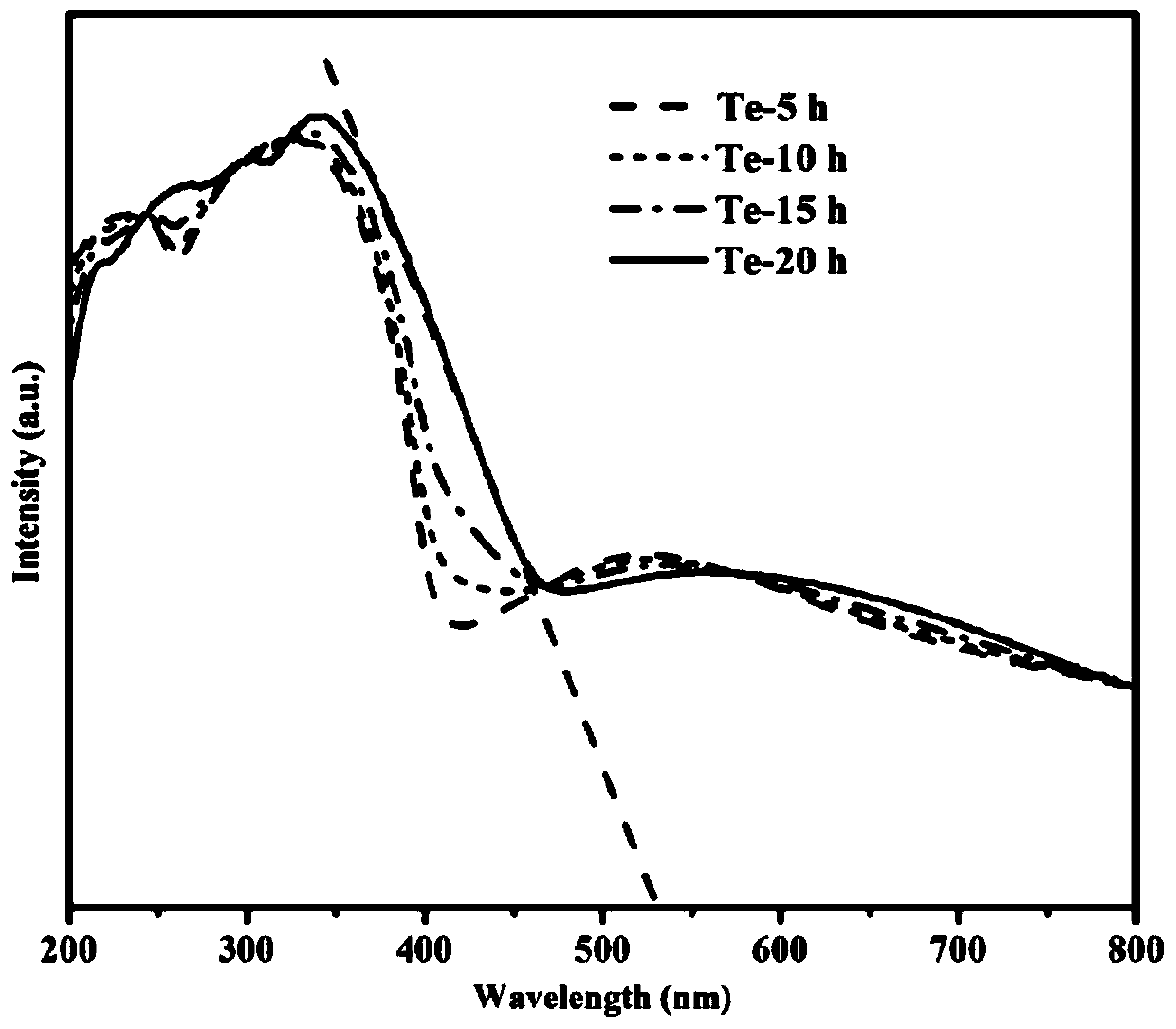

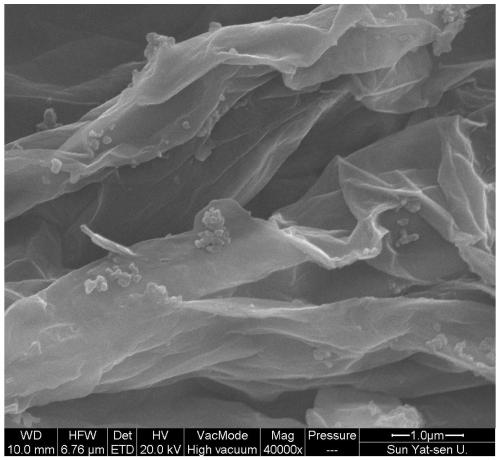

[0043] A kind of preparation method of half metal material Te nanowire / graphene hydrogel composite material, comprises the steps:

[0044] S1. Sodium tellurite (Na 2 TeO 3 ) and polyvinylpyrrolidone PVP were dissolved in deionized water, and gradually added hydrazine hydrate (N2 h 5 OH) solution as a reducing agent and ammonia water to control the pH, magnetically stir evenly, transfer the mixed solution to a hydrothermal reaction kettle with a polytetrafluoroethylene lining, and a hydrothermal synthesis reaction occurs in an oven, wherein the hydrothermal reaction temperature is 180 ℃, reaction time 10h, wherein the mass ratio of sodium tellurite to PVP is 1:5, the concentration of sodium tellurite is 2mg / mL, the mass percentage of hydrazine hydrate solution is 80%, the volume ratio of hydrazine hydrate to aqueous solution is 1:30, the volume ratio of hydrazine hydrate and ammonia water is 1:2;

[0045] S2. After the reaction, after cooling down to room temperature, centri...

Embodiment 2

[0050] A kind of preparation method of half metal material Te nanowire / graphene hydrogel composite material, comprises the steps:

[0051] S1. Sodium tellurite (Na 2 TeO 3 ) and polyvinylpyrrolidone PVP were dissolved in deionized water, and gradually added hydrazine hydrate (N 2 h 5 OH) solution as a reducing agent and ammonia water to adjust the PH, magnetically stir evenly, transfer the mixed solution to a hydrothermal reaction kettle with a polytetrafluoroethylene lining, and a hydrothermal synthesis reaction occurs in an oven, wherein the hydrothermal reaction temperature is 180 ℃, reaction time 5h, wherein the mass ratio of sodium tellurite to PVP is 1:5, the concentration of sodium tellurite is 2mg / mL, the mass percentage of hydrazine hydrate solution is 80%, the volume ratio of hydrazine hydrate to aqueous solution is 1:30, the volume ratio of hydrazine hydrate and ammonia water is 1:2;

[0052] S2. After the reaction, after cooling down to room temperature, centri...

Embodiment 3

[0056] A kind of preparation method of half metal material Te nanowire / graphene hydrogel composite material, comprises the steps:

[0057] S1. Sodium tellurite (Na 2 TeO 3 ) and polyvinylpyrrolidone PVP were dissolved in deionized water, and gradually added hydrazine hydrate (N 2 h 5 OH) solution as a reducing agent and ammonia water to adjust the PH, magnetically stir evenly, transfer the mixed solution to a hydrothermal reaction kettle with a polytetrafluoroethylene lining, and a hydrothermal synthesis reaction occurs in an oven, wherein the hydrothermal reaction temperature is 180 ℃, reaction time 10h, wherein the mass ratio of sodium tellurite to PVP is 1:5, the concentration of sodium tellurite is 2mg / mL, the mass percentage of hydrazine hydrate solution is 80%, the volume ratio of hydrazine hydrate to aqueous solution is 1:35, the volume ratio of hydrazine hydrate and ammonia water is 1:3;

[0058] S2. After the reaction, after cooling down to room temperature, centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com