Method for comprehensively recycling silver, selenium, tellurium and copper from telluride copper slag

A technology of copper telluride and copper tellurium, which is applied in the fields of selenium/tellurium compounds, chemical instruments and methods, inorganic chemistry, etc., and can solve the problems of comprehensive recovery with few considerations and single considerations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

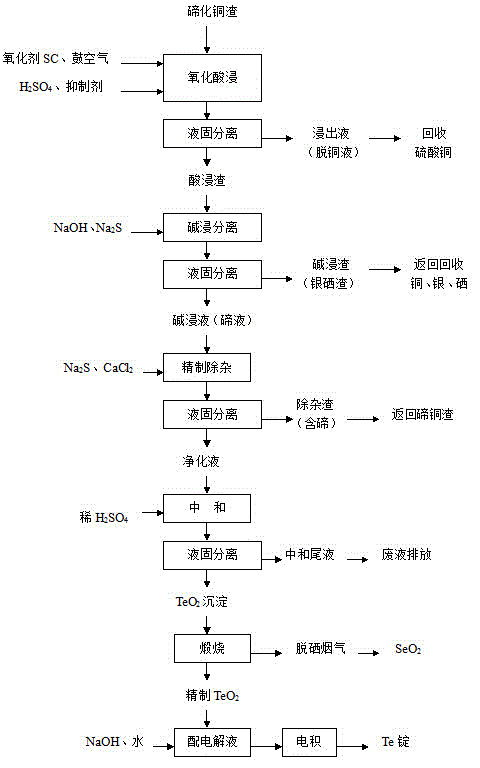

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Copper removal experiment by oxidative acid leaching of copper telluride slag

[0043] The copper telluride slag used in the experiment is the copper telluride slag wet material produced by the comprehensive workshop of the Copper Company of Baiyin Nonferrous Metals Group Co., Ltd., and its water content is 36-38%. In a 2000ml beaker, add 500g of wet telluride copper slag ( According to the drying capacity of 64%, the solid is 320g), add 800ml of water (the liquid-solid ratio is 3:1), and stir to form a slurry; then add 40ml of 93% industrial sulfuric acid and 32g of copper sulfate pentahydrate successively under stirring; heat When the temperature is above 90°C, air is continuously introduced into the reaction slurry and stirred, and the composite oxidant SC solution formed by dissolving 55g of oxidant, 25g of salt, and 250g of water is added dropwise within 2 hours, and then reacted for 1-1.5h after the drop is completed; while it is hot Filtrate, wash the ...

Embodiment 3

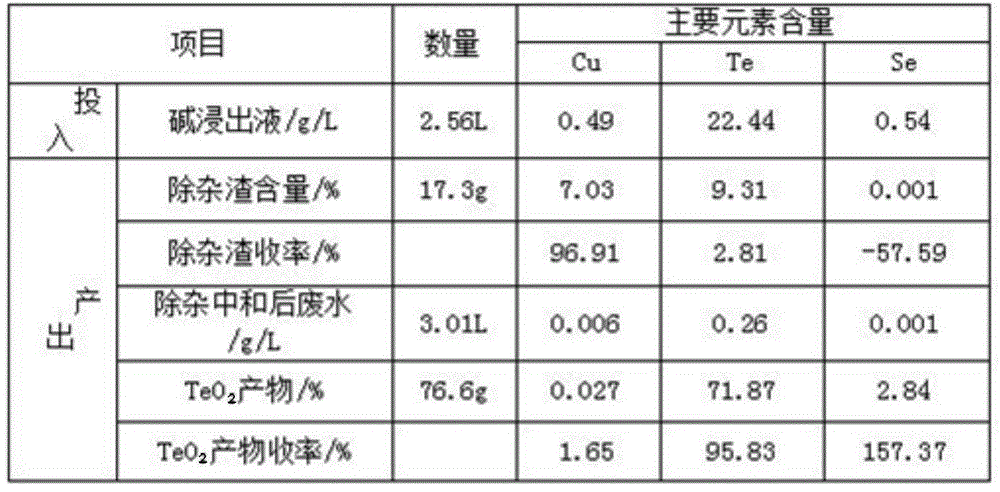

[0051] Example 3: Preparation of TeO by wet purification 2 product experiment

[0052] Put all the 2560ml alkali immersion solution obtained by the above reaction into a 3000ml beaker, and under stirring at room temperature, add 0.1g of EDTA solution, 5g of anhydrous calcium chloride powder, and 5g of sodium sulfide powder successively, continue to stir and react for 2h, and let it stand overnight. Let the sediment grow up and fully settle. The next day, all the impurity-removed solution was filtered to obtain 2570 ml of light yellow transparent solution. The filtered slag is impurity-removed slag, which is dried to obtain 17.3g, which can be returned to the high-pressure leaching process of the KALDO furnace for secondary recovery of copper and tellurium.

[0053] Put all the clarified liquid obtained after impurity removal and filtration into a 3000ml beaker, install a stirring device, heat to above 60°C, and slowly add 1+3 dilute sulfuric acid (1 part of 98% reagent grade...

Embodiment 4

[0059] Example 4: Tellurium electrowinning experiment

[0060] The tellurium electrowinning test is carried out in the laboratory, and the TeO used in the test 2 The product is the pilot test TeO obtained from the pilot test of the tellurium slag project 2 The product, its tellurium grade is 69.49%, two electrowinning experiments share wet TeO 2 Product 15kg (solid content 22-23%). The electrolytic cell used in the test is self-made with plexiglass plate, the volume of the electrowinning cell = length 28cm × width 12cm × depth 15cm = 5.0L, and the actual electrolyte solution is 4-4.5L. The anode plate for electrowinning is made of iron, and the cathode plate is made of stainless steel. The electrowinning area of a single cathode plate is 0.096m×0.100m×2≈0.02m 2 ; Power is provided by SDD-1250 electrolytic plating power supply.

[0061] Use an 8L stainless steel container as the reaction device, add 4.0L of the residual solution after the first electrodeposition, add wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com