Method for preparing high-seebeck-coefficient tellurium/tellurium oxide nanocomposite with solvothermal

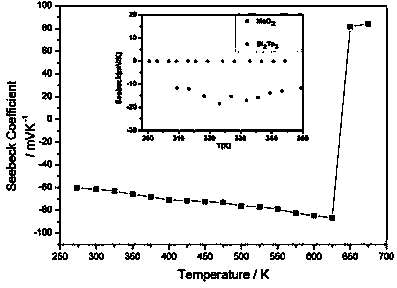

A nanocomposite material and tellurium oxide technology, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric device node lead-out materials, nanotechnology, etc., can solve problems such as inaccessibility, and achieve simple devices, high Seebeck coefficient, highly controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Pour 12.5mL of ethylene glycol solution into a 25mL polytetrafluoroethylene liner and place it in the middle of the magnetic stirrer. Add 0.041g of sodium acetate, 0.056g of sodium tellurite and 0.2g of PVP into the polytetrafluoroethylene liner in sequence, and stir magnetically at room temperature. After mixing evenly, close the autoclave and put it into a constant temperature oven.

[0024] (2) The above-mentioned constant temperature oven is heated from room temperature to 180 °C at a rate of 15 °C / min, kept at 180 °C for 8 hours, and then naturally cooled to room temperature to obtain uniform single crystal tellurium nanowires.

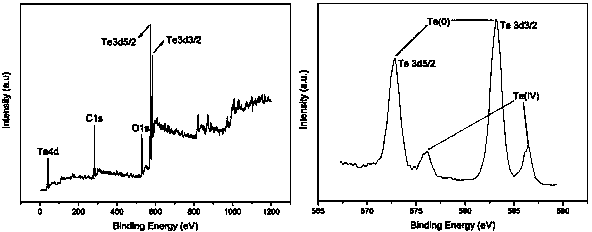

[0025] (3) After completing step (2), place the single crystal tellurium nanowires in a petri dish for 30 days, and the resulting product is Te / TeO 2 nanocomposites. The resulting product was directly observed under a scanning electron microscope and a transmission electron microscope, as figure 1 As shown, a large number of particle...

Embodiment 2

[0027] (1) Pour 12.5mL of ethylene glycol solution into a 25mL polytetrafluoroethylene liner and place it in the middle of the magnetic stirrer. Add 0.041g of sodium acetate, 0.056g of sodium tellurite and 0.2g of PVP into the polytetrafluoroethylene liner in sequence, and perform magnetic force at room temperature. After mixing evenly, close the autoclave and put it into a constant temperature oven.

[0028] (2) The above-mentioned constant temperature oven is heated from room temperature to 180 °C at a rate of 15 °C / min, kept at 180 °C for 6 hours, and then naturally cooled to room temperature to obtain uniform single crystal tellurium nanowires.

[0029] (3) After completing step (2), place the single crystal tellurium nanowires in a petri dish for 20 days, and the resulting product is Te / TeO 2 nanocomposites.

Embodiment 3

[0031] (1) Pour 12.5mL of ethylene glycol solution into a 25mL polytetrafluoroethylene liner and place it in the middle of the magnetic stirrer. Add 0.041g of sodium acetate, 0.056g of sodium tellurite and 0.2g of PVP into the polytetrafluoroethylene liner in sequence, and stir magnetically at room temperature. After mixing evenly, close the autoclave and put it into a constant temperature oven.

[0032] (2) The above-mentioned constant temperature oven is heated from room temperature to 160 °C at a rate of 15 °C / min, kept at 160 °C for 10 hours, and then naturally cooled to room temperature to obtain uniform single crystal tellurium nanowires.

[0033] (3) After completing step (2), place the single crystal tellurium nanowires in a petri dish for 25 days, and the resulting product is Te / TeO 2 nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com