Patents

Literature

655 results about "Thermoelectric figure of merit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoelectric Figure of Merit. From an engineering perspective, the Seebeck coefficient is defined as the ratio of electric potential difference to temperature difference in the absence of electrical current flow.

Nanocomposites with high thermoelectric figures of merit

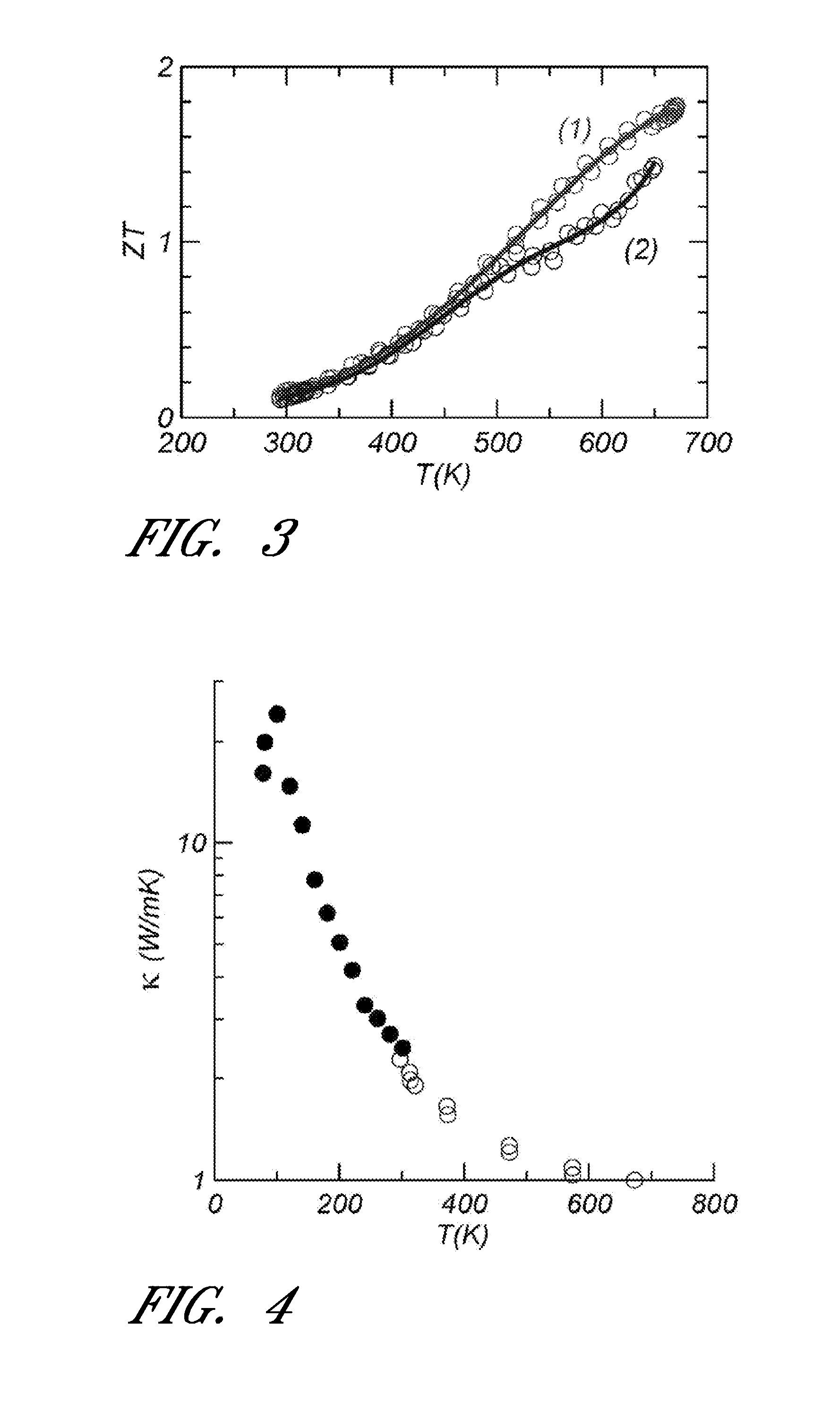

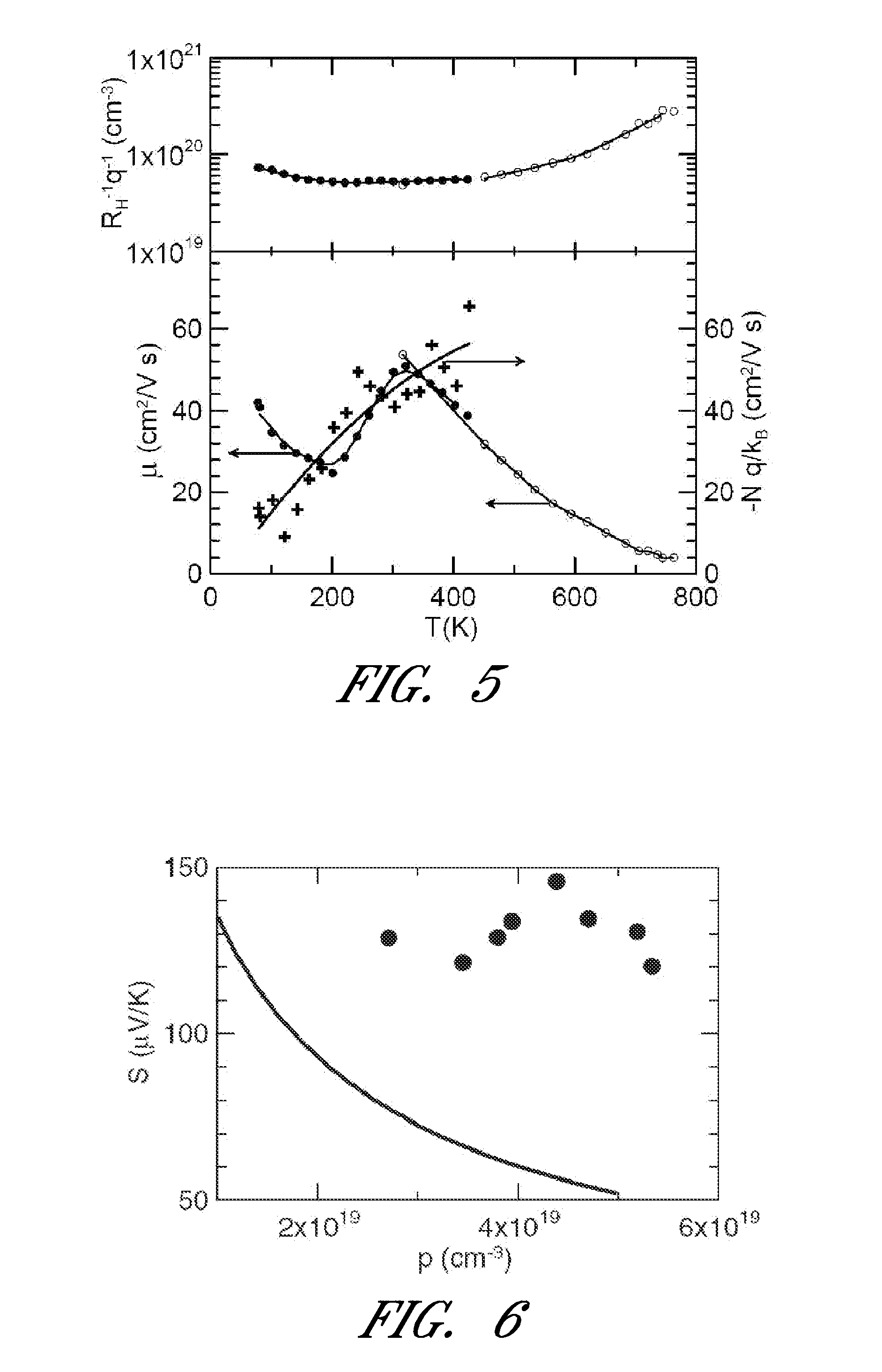

InactiveUS20060102224A1Improve thermoelectric performanceLow thermal conductivityMaterial nanotechnologyThermoelectric device with peltier/seeback effectValence bandConduction band

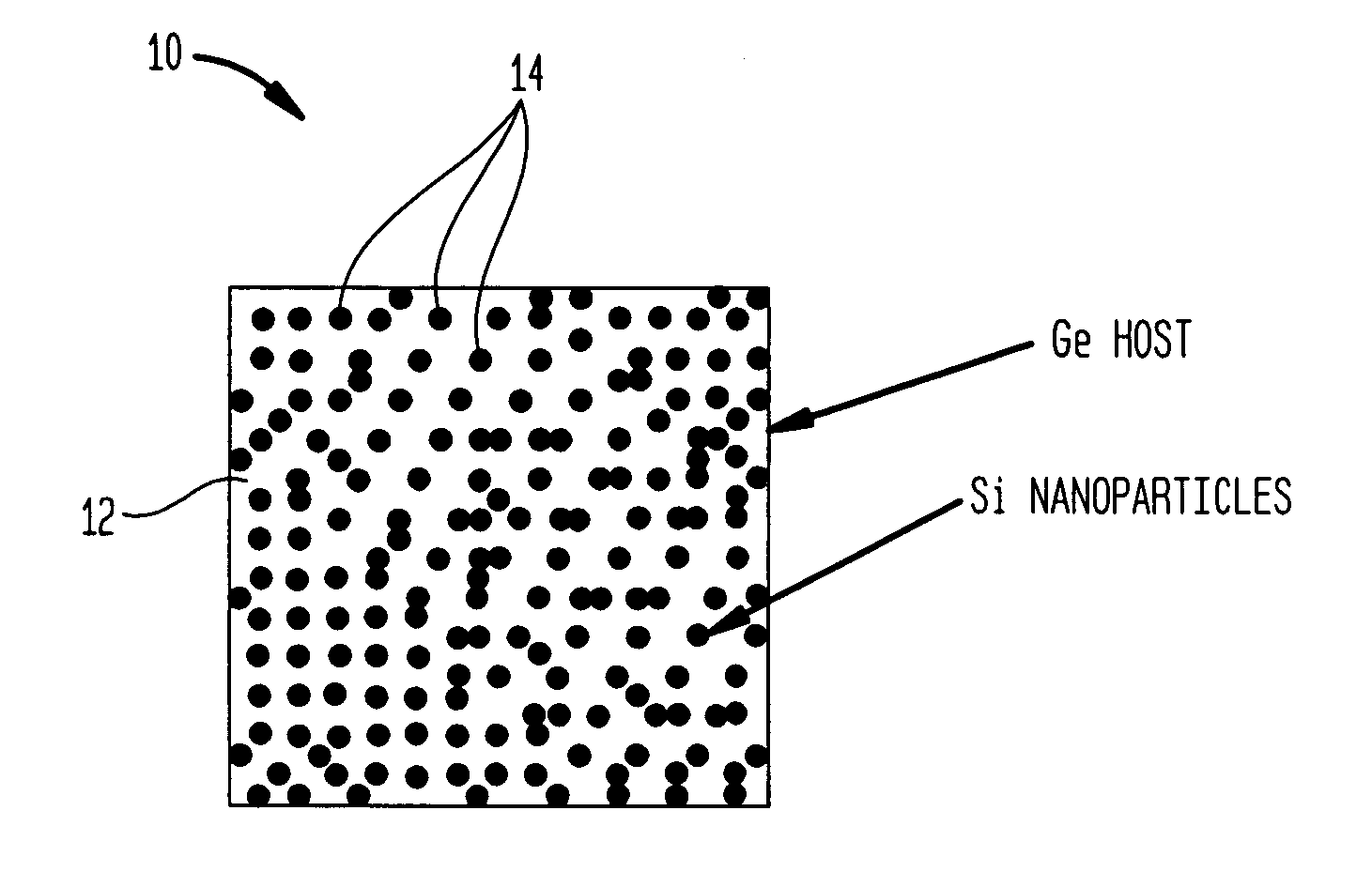

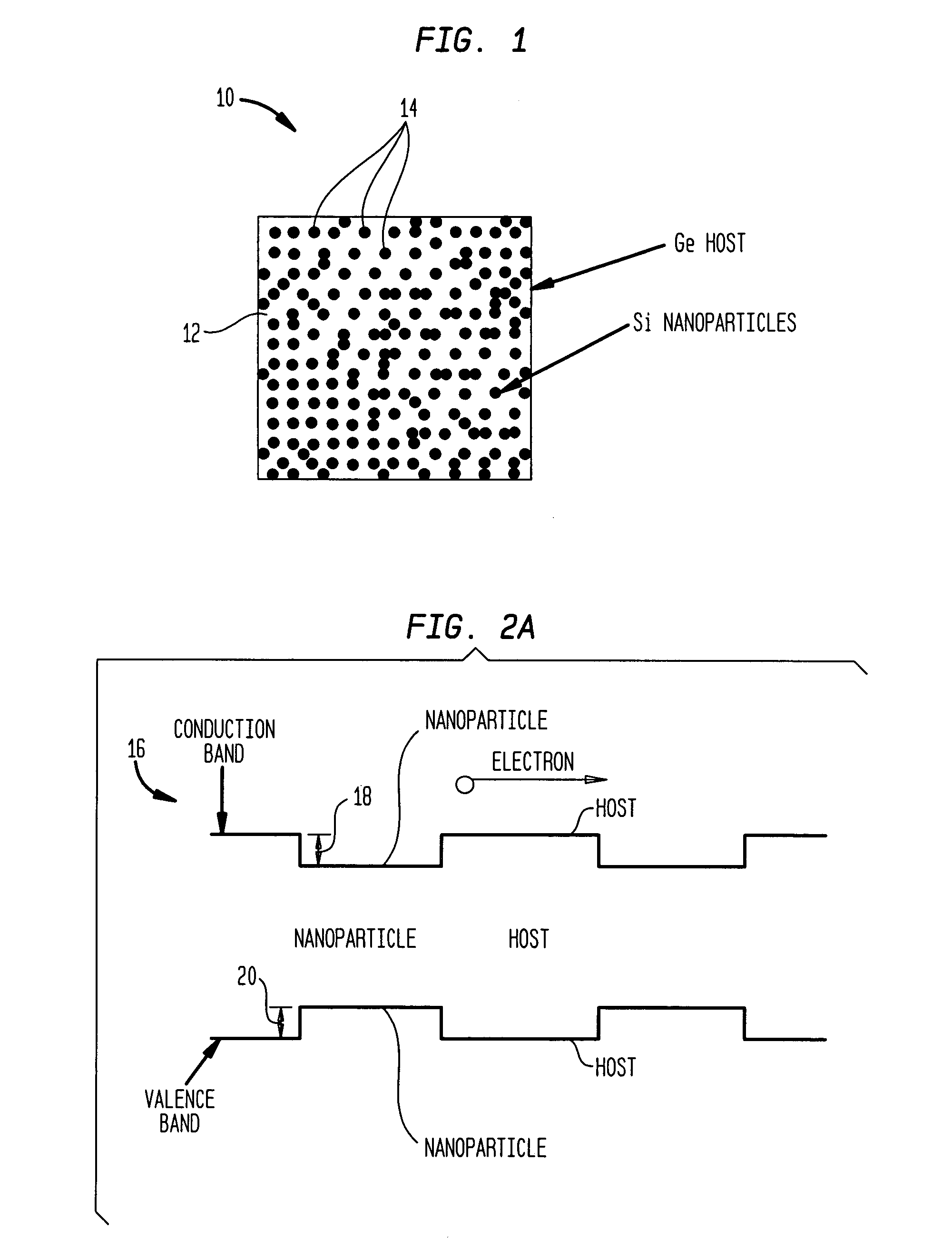

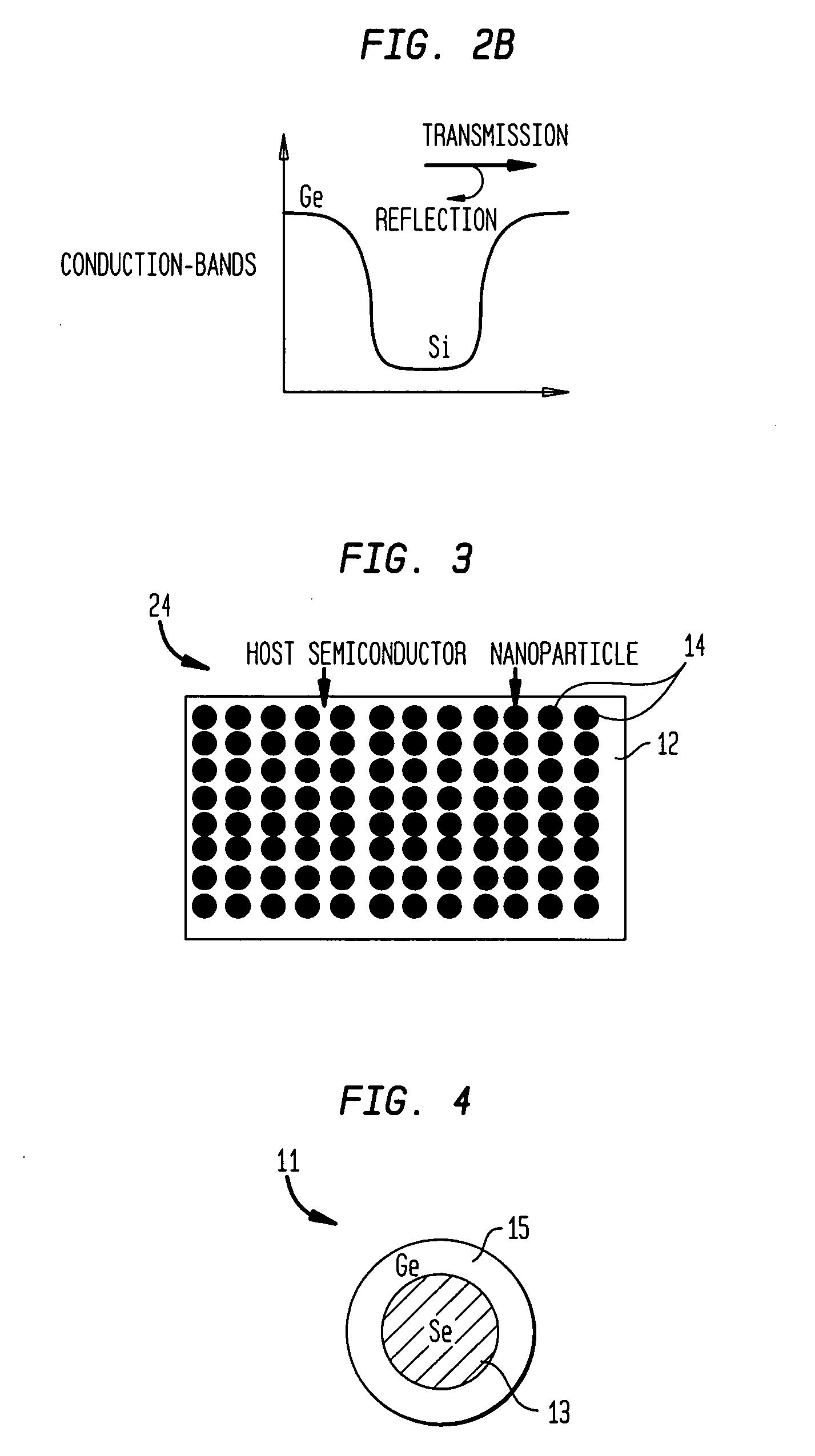

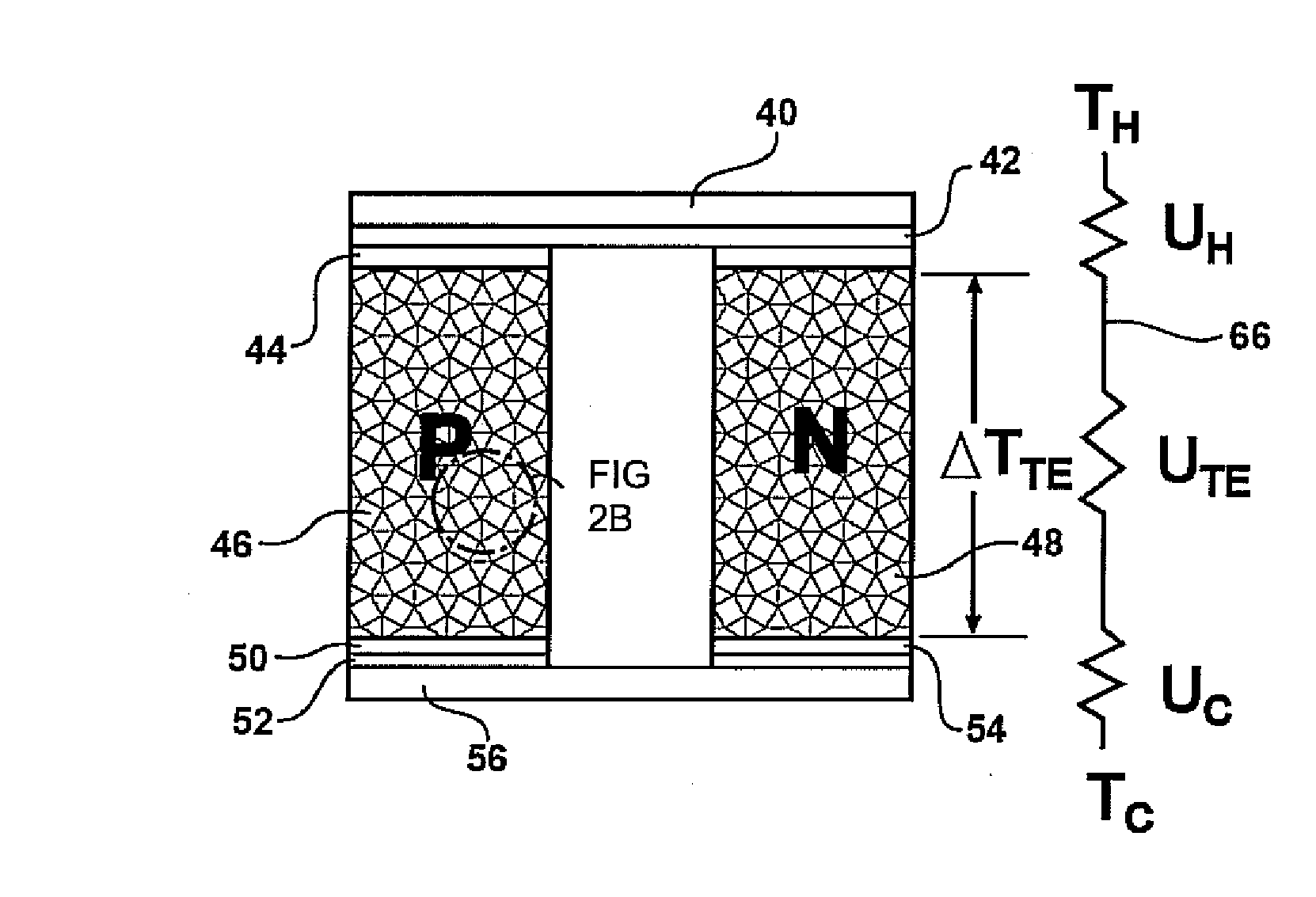

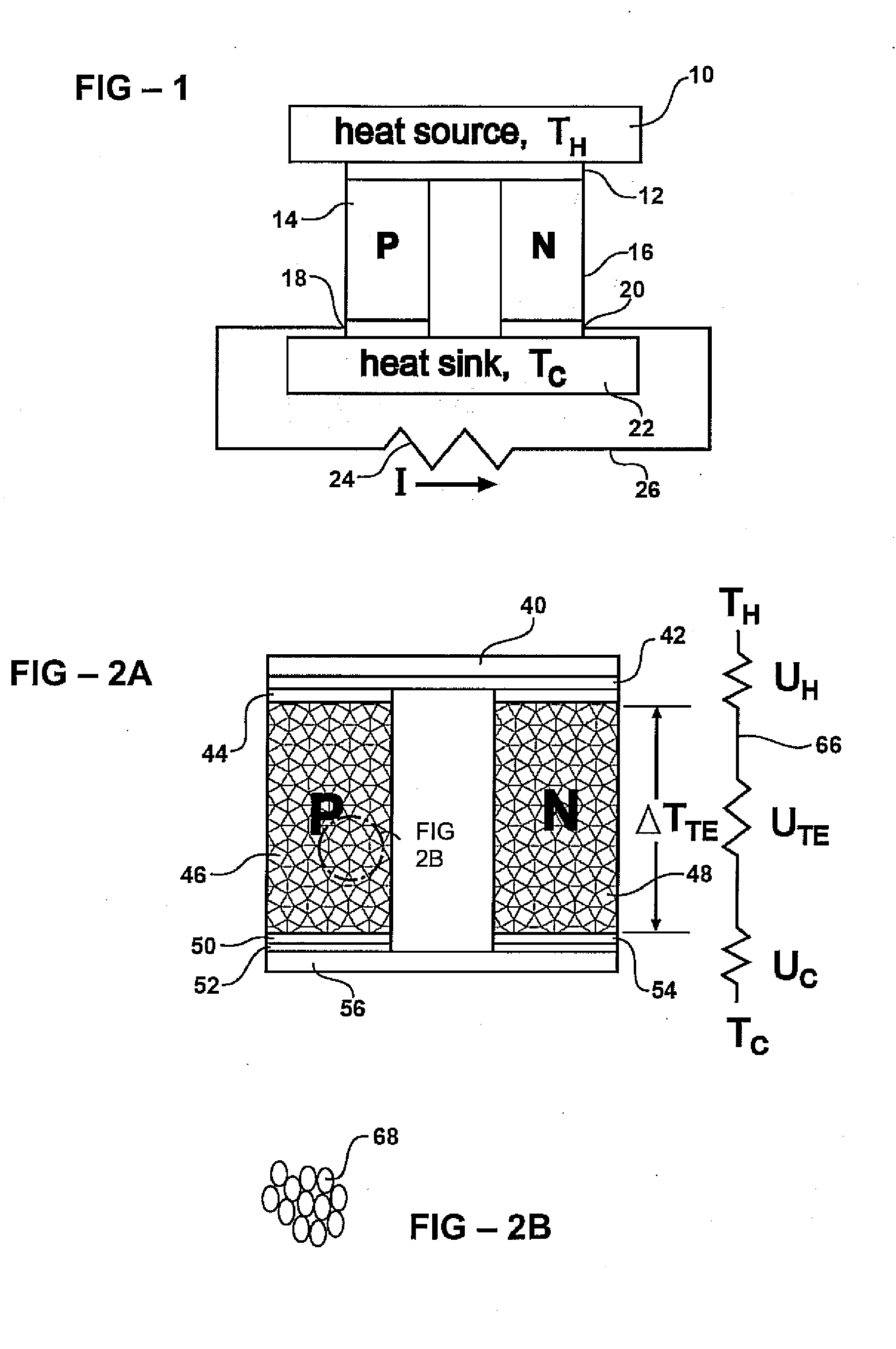

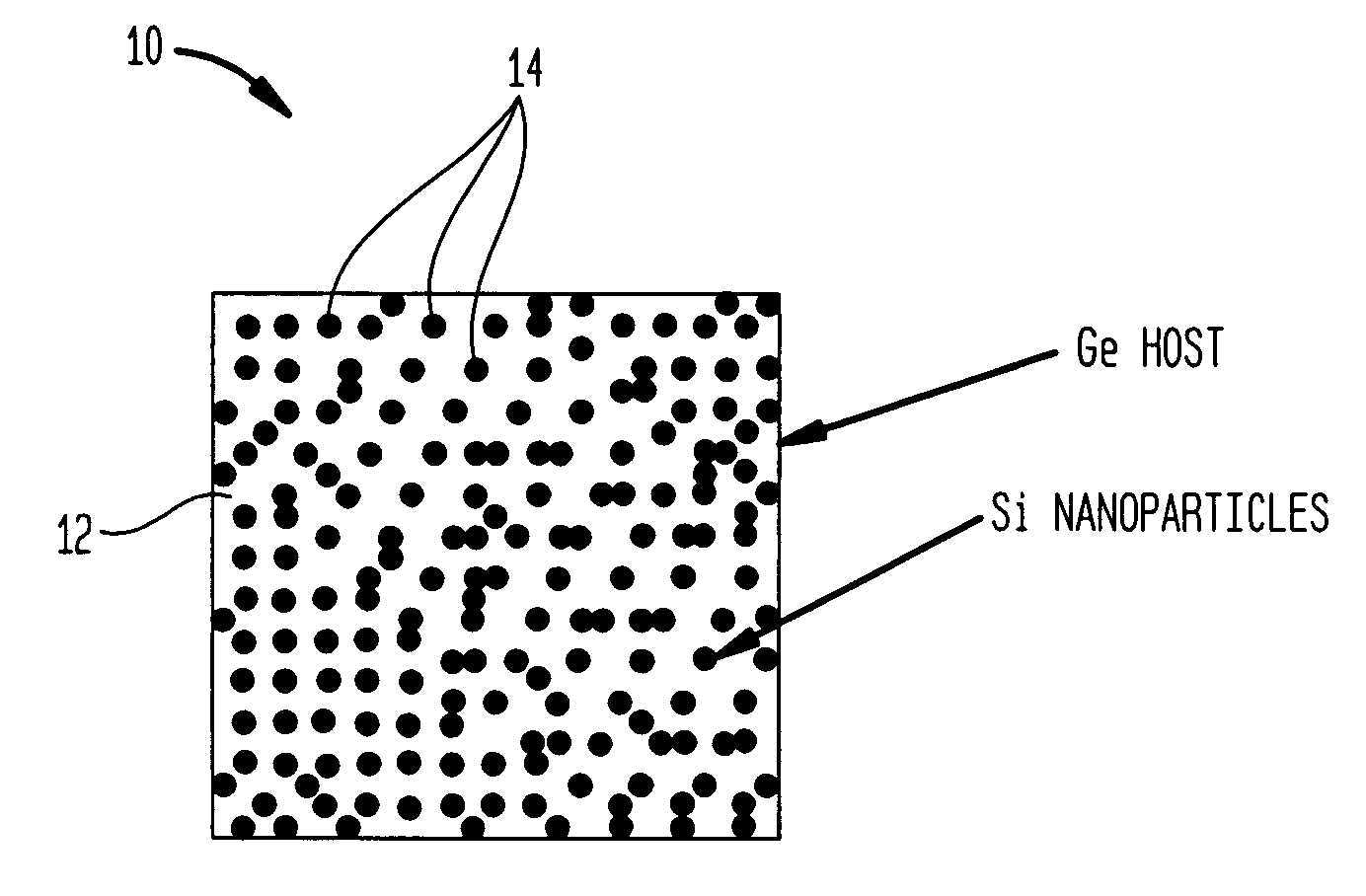

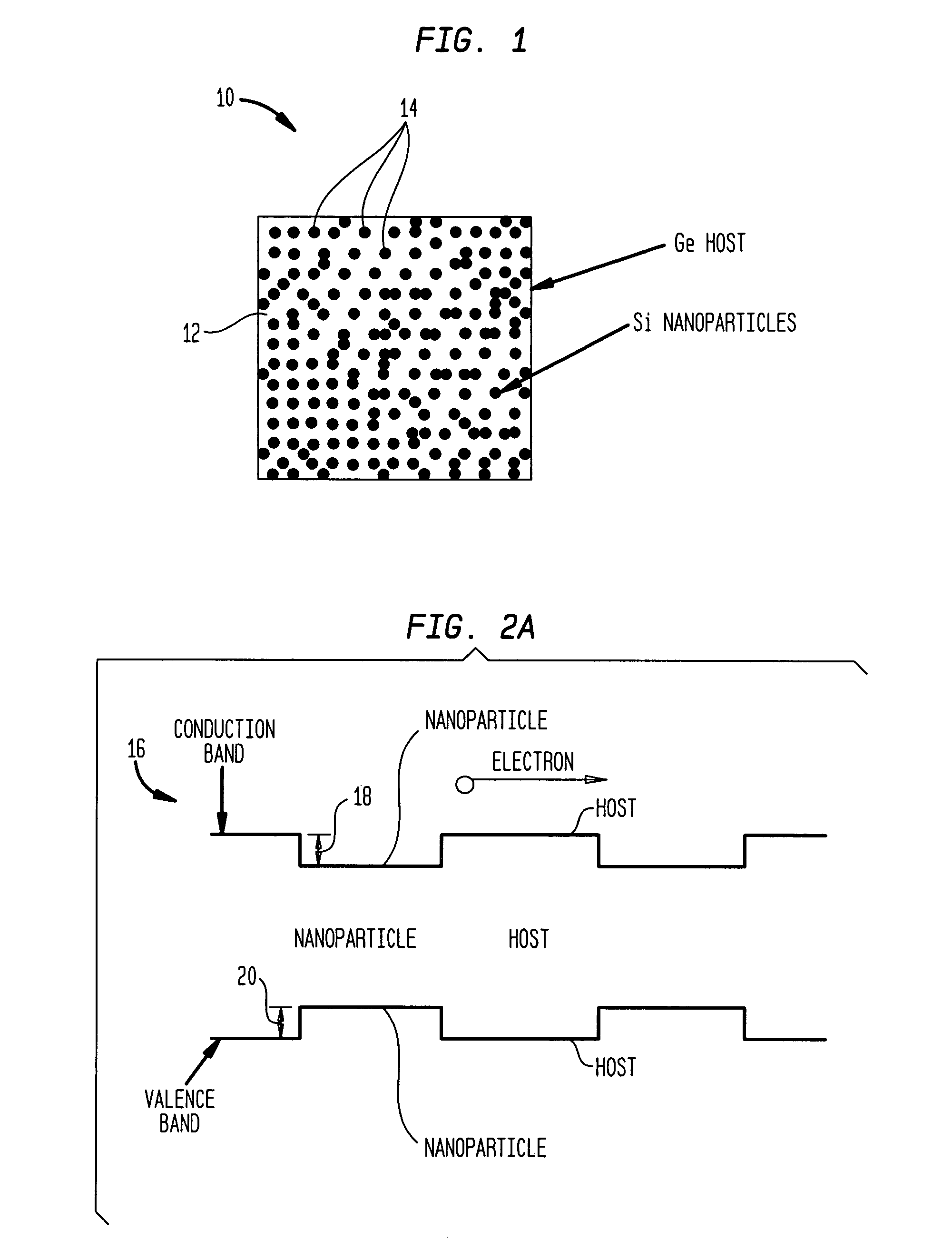

The present invention is generally directed to nanocomposite thermoelectric materials that exhibit enhanced thermoelectric properties. The nanocomposite materials include two or more components, with at least one of the components forming nano-sized structures within the composite material. The components are chosen such that thermal conductivity of the composite is decreased without substantially diminishing the composite's electrical conductivity. Suitable component materials exhibit similar electronic band structures. For example, a band-edge gap between at least one of a conduction band or a valence band of one component material and a corresponding band of the other component material at interfaces between the components can be less than about 5 kBT, wherein kB is the Boltzman constant and T is an average temperature of said nanocomposite composition.

Owner:TRUSTEES OF BOSTON COLLEGE THE +1

Homogeneous thermoelectric nanocomposite using core-shell nanoparticles

ActiveUS20080087314A1Uniform and improved thermoelectricThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentBismuth tellurideSilicon dioxide

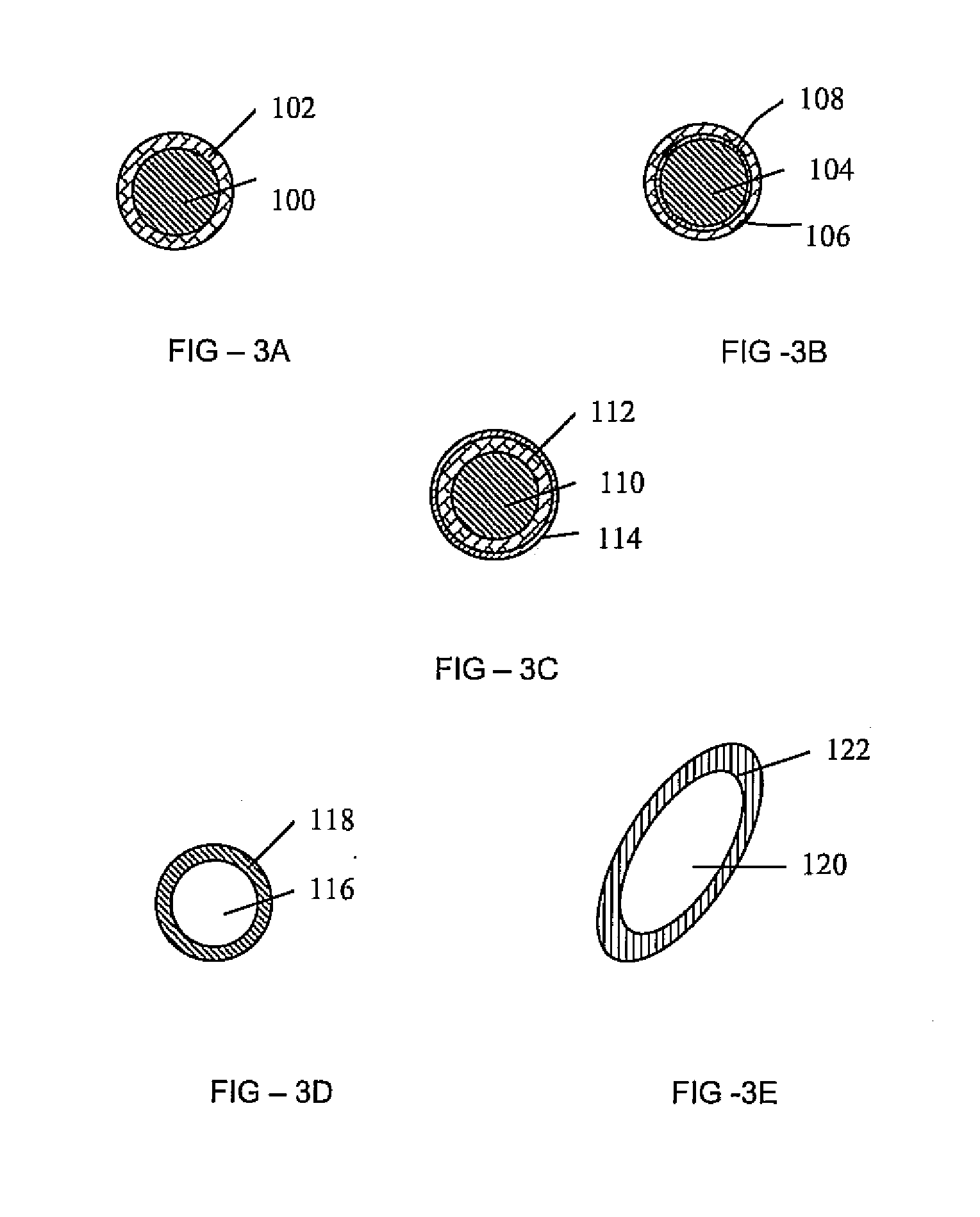

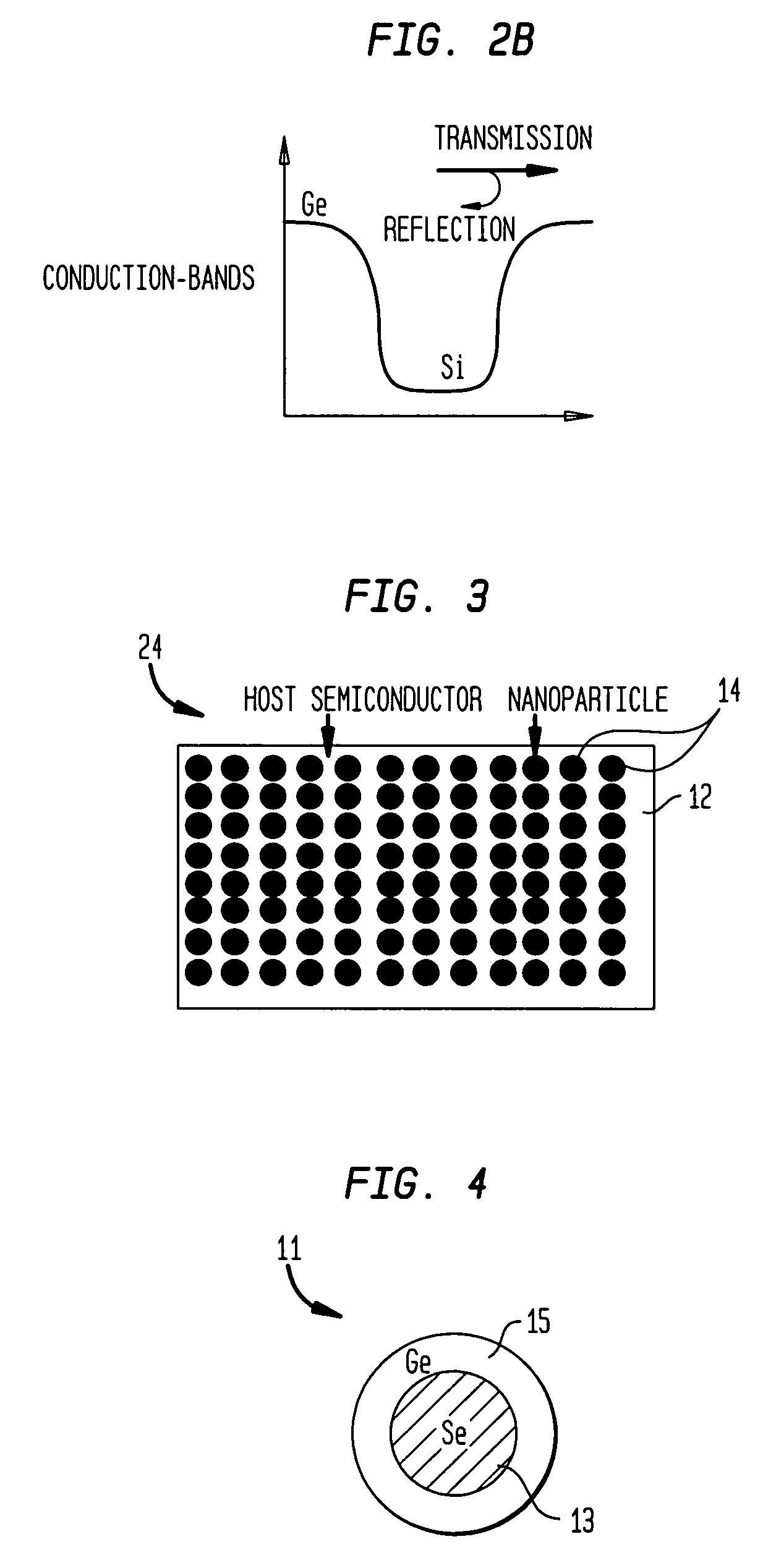

A thermoelectric material comprises core-shell particles having a core formed from a core material and a shell formed from a shell material. In representative examples, the shell material is a material showing an appreciable thermoelectric effect in bulk. The core material preferably has a lower thermal conductivity than the shell material. In representative examples, the core material is an inorganic oxide such as silica or alumina, and the shell material is a chalcogenide semiconductor such as a telluride, for example bismuth telluride. A thermoelectric material including such core-shell particles may have an improved thermoelectric figure of merit compared with a bulk sample of the shell material alone. Embodiments of the invention further include thermoelectric devices using such thermoelectric materials, and preparation techniques. The use of core-shell nanoparticles allows highly uniform nanocomposites to be formed, and embodiments of the invention also includes other materials and devices using core-shell particles.

Owner:TOYOTA MOTOR CO LTD +1

Thermoelectric conversion material and thermoelectric conversion module

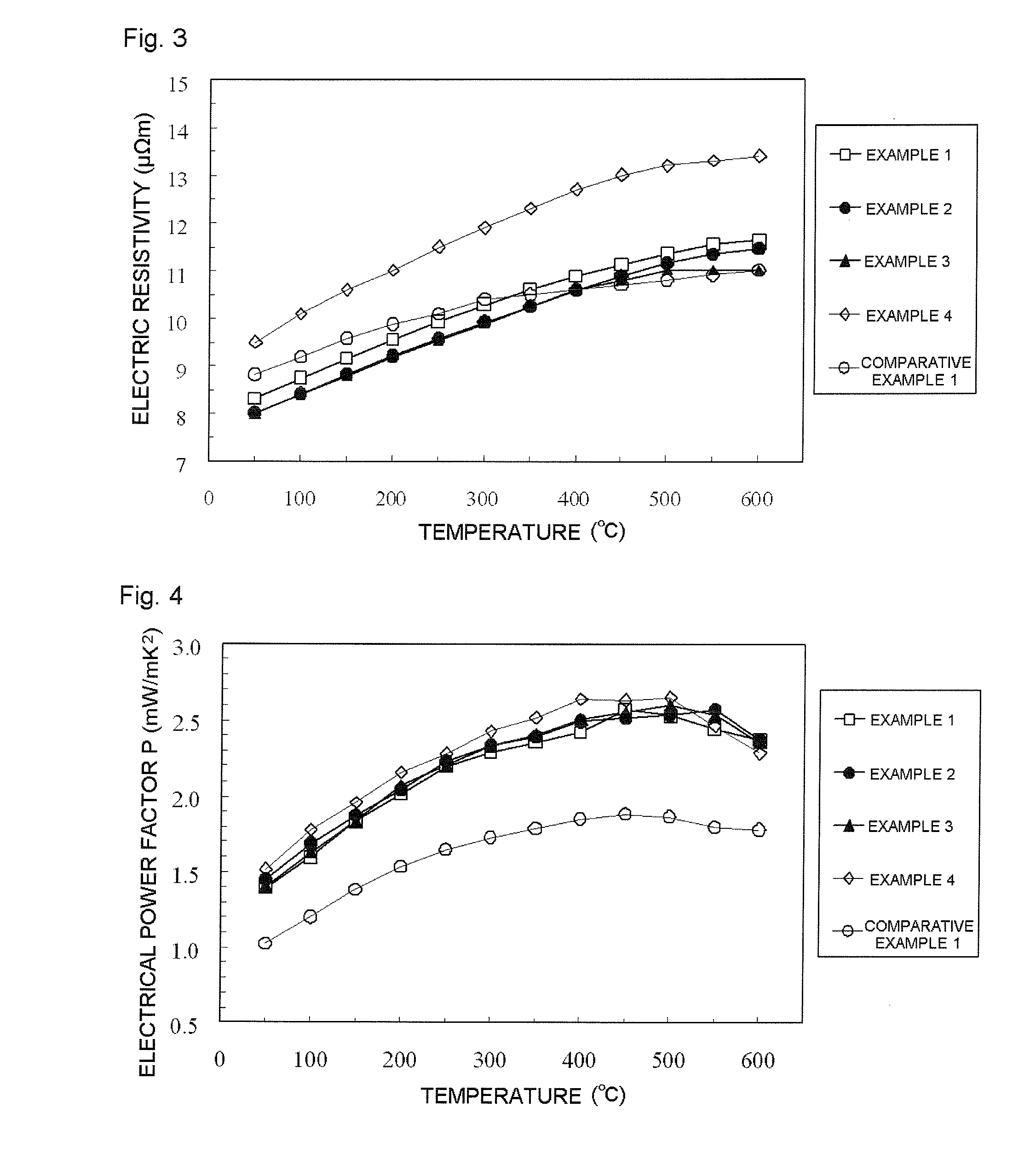

ActiveUS20100294326A1Improve thermoelectric performanceThermoelectric device junction materialsRare-earth elementAlkaline earth metal

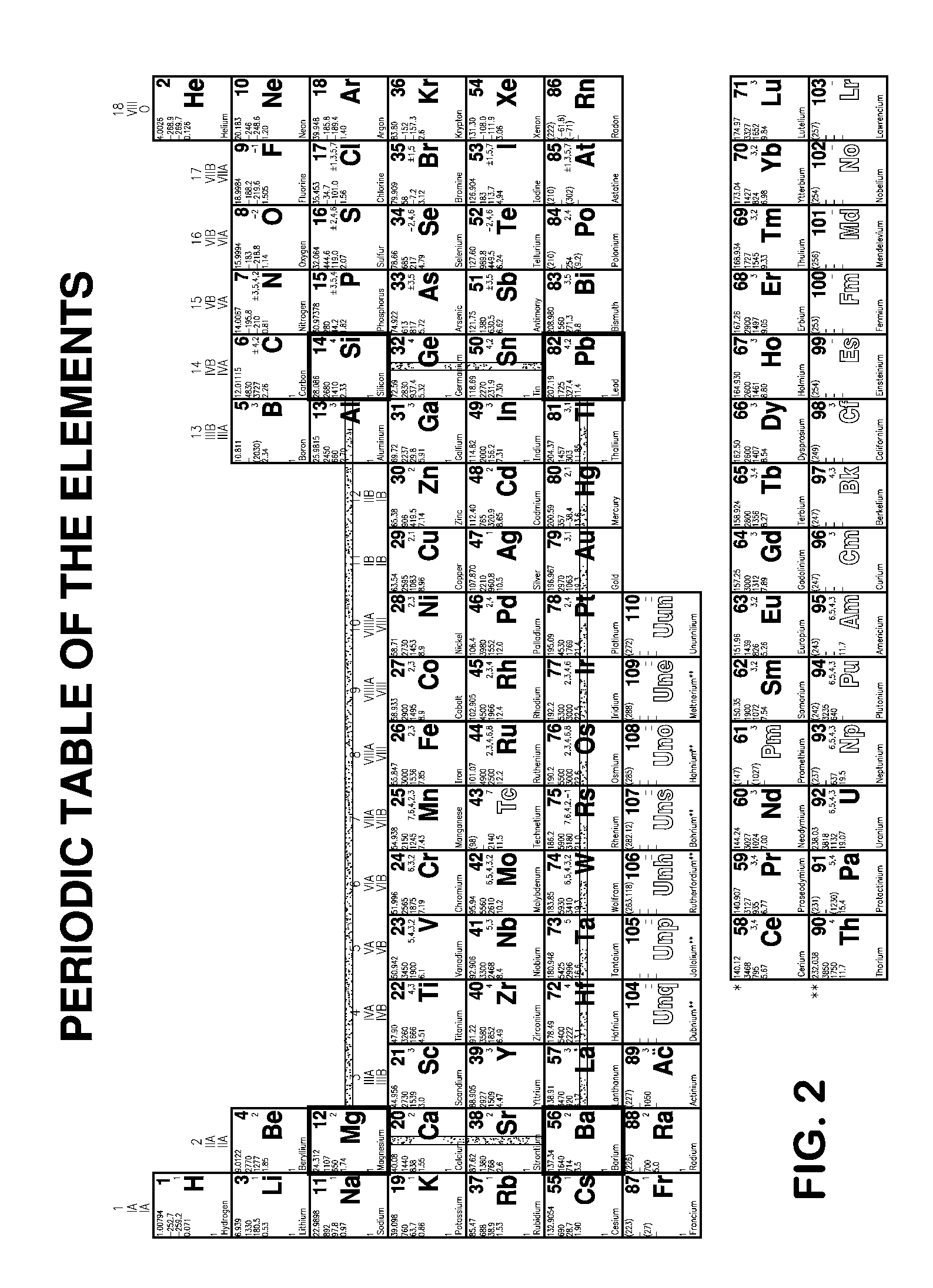

The present invention realizes a thermoelectric conversion material having excellent thermoelectric performance over a wide temperature range, and a thermoelectric conversion module providing excellent junctions between thermoelectric conversion materials and electrodes.The present invention provides an R-T-M-X-N thermoelectric conversion material that has a structure expressed by the following formula: RrTt−mMmXx−nNn (0<r≦1, 3≦t−m≦5, 0≦m≦0.5, 10≦x≦15, 0≦n≦2),where R represents three or more elements selected from the group consisting of rare earth elements, alkali metal elements, alkaline-earth metal elements, group 4 elements, and group 13 elements,T represents at least one element selected from Fe and Co,M represents at least one element selected from the group consisting of Ru, Os, Rh, Ir, Ni, Pd, Pt, Cu, Ag, and Au,X represents at least one element selected from the group consisting of P, As, Sb, and Bi, andN represents at least one element selected from Se and Te.

Owner:FURUKAWA COMPANY

Nanocomposites with high thermoelectric figures of merit

Owner:TRUSTEES OF BOSTON COLLEGE THE +1

Method for producing a device for direct thermoelectric energy conversion

InactiveUS20030110892A1Polycrystalline material growthThermoelectric device manufacture/treatmentJunction temperatureEngineering

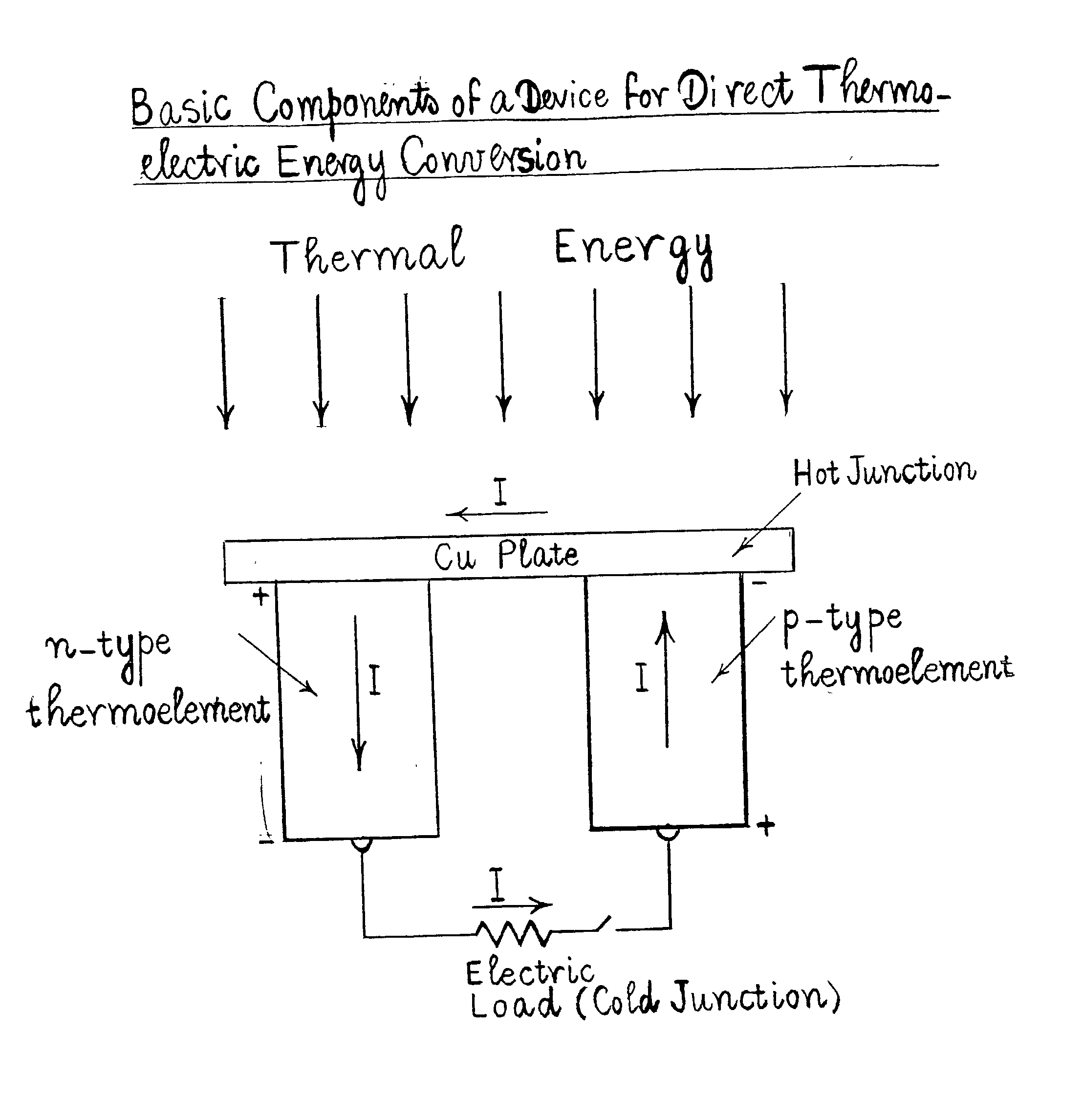

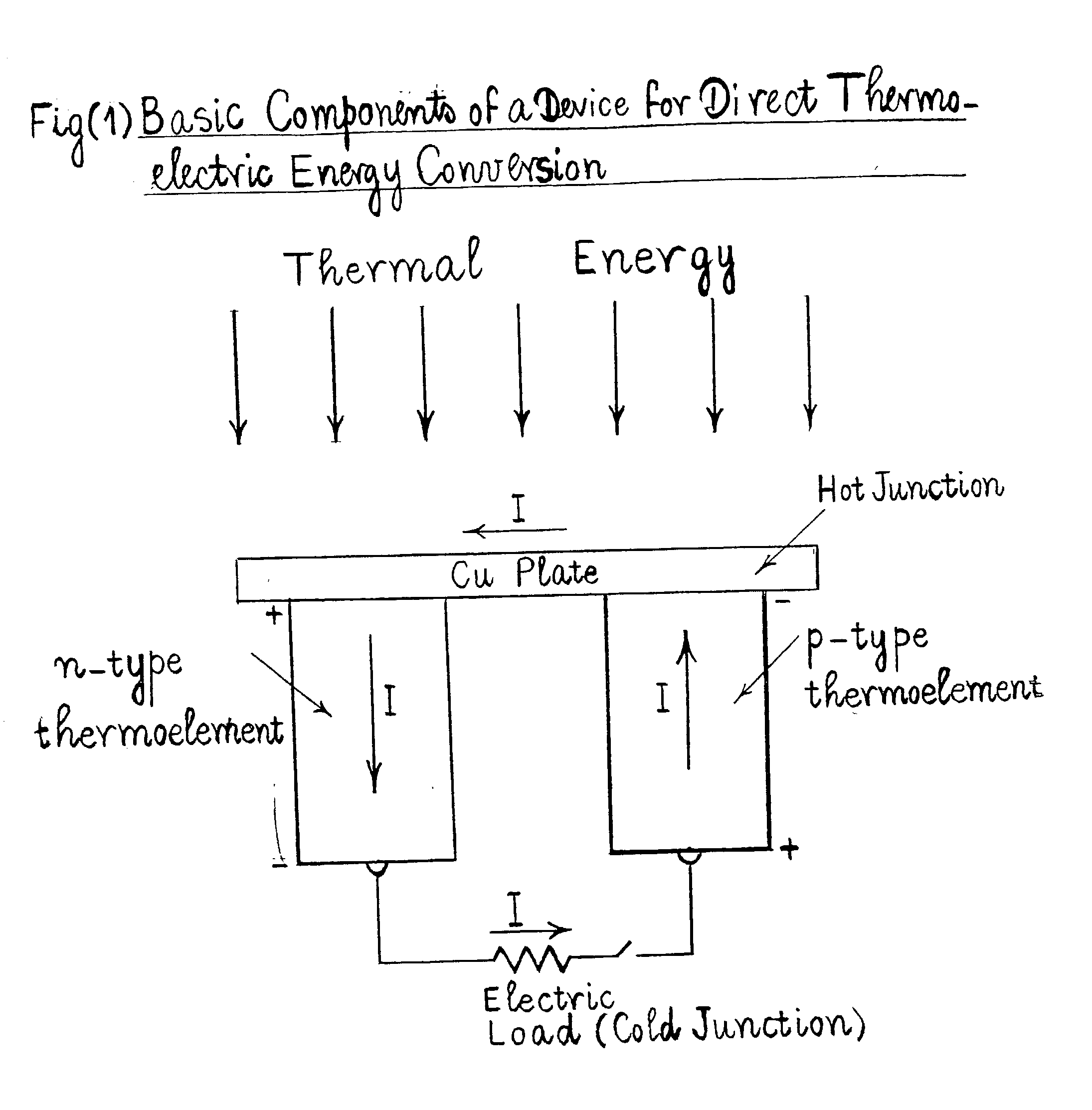

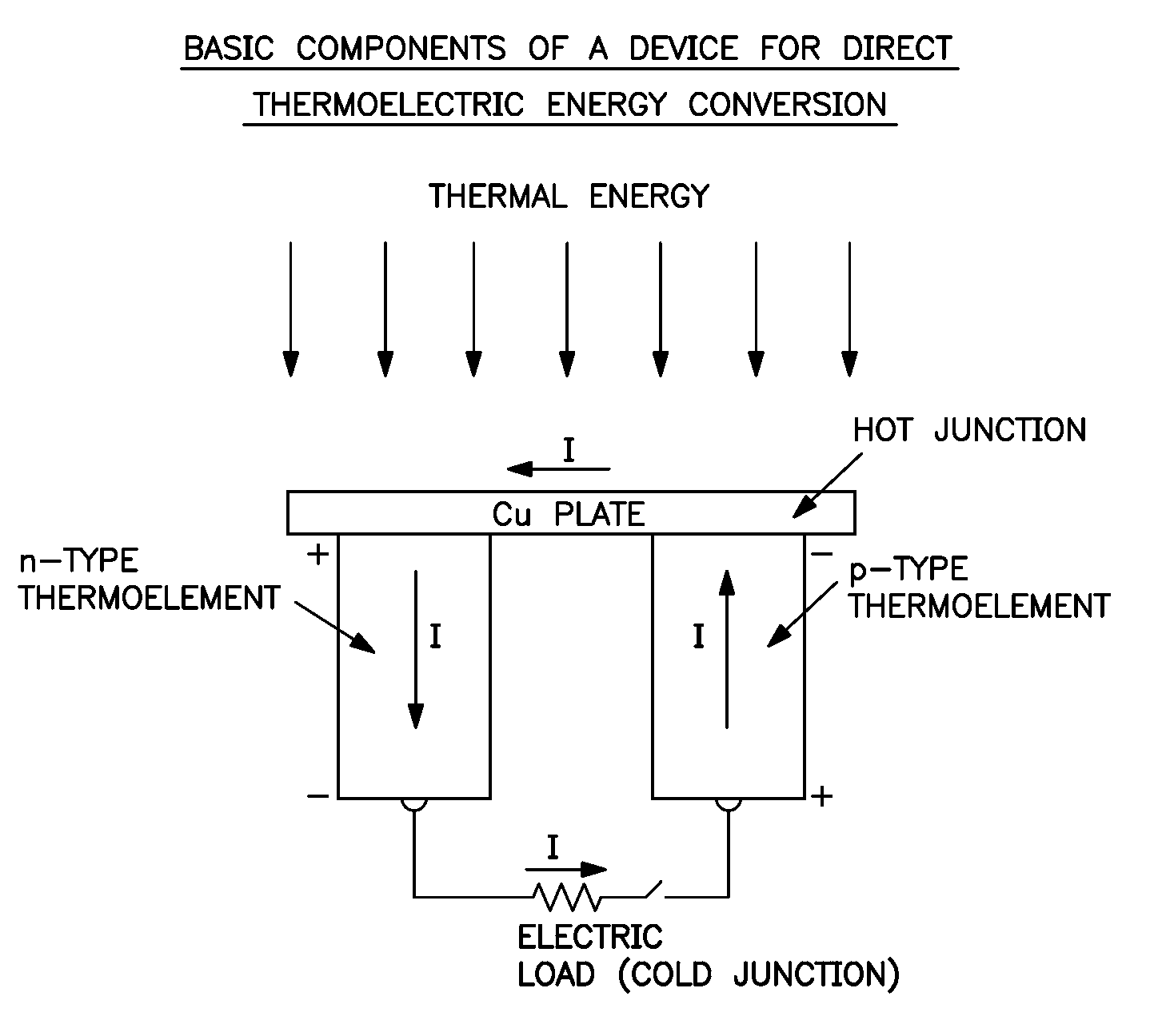

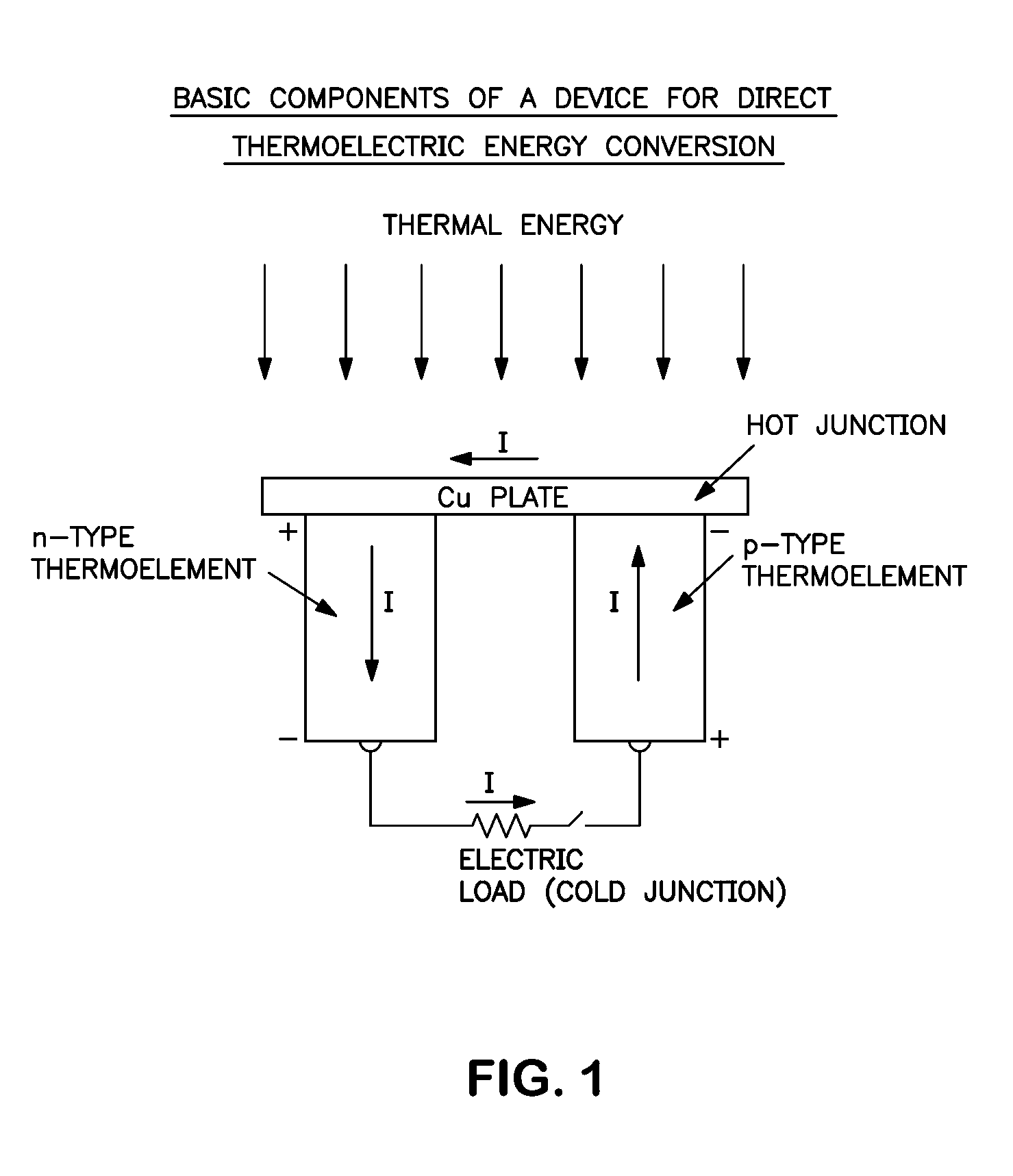

In devices used for the direct conversion of heat into electricity, or vice versa, known in the art as thermoelectric power generators, thermoelectric refrigerators and thermoelectric heat pumps, the efficiency of energy conversion and / or coefficient of performance have been considerably lower than those of conventional reciprocating or rotary, heat engines and / or vapor-compression systems, employing certain refrigerants. The energy conversion efficiency of power generating devices, for example, aside from the hot and cold junction temperatures, also depends on a parameter known in the art as the thermoelectric figure of merit Z=S2sigma / k, where S is the thermoelectric power, sigma is the electrical conductivity and k is the thermal conductivity, of the material that constitutes the p-type, and / or n-type, thermoelements, or branches, of the said devices. In order to achieve a considerable increase in the energy conversion efficiency, a thermoelectric figure of merit of the order of 10-2 K-1, or more, is needed. It is reasonably expected that such an order of magnitude, for the figure of merit, can be realized with a composition of matter, comprising magnesium, silicon, lead and barium, and optionally comprising one, or more, additional doping materials.

Owner:NICOLOAU MICHAEL C

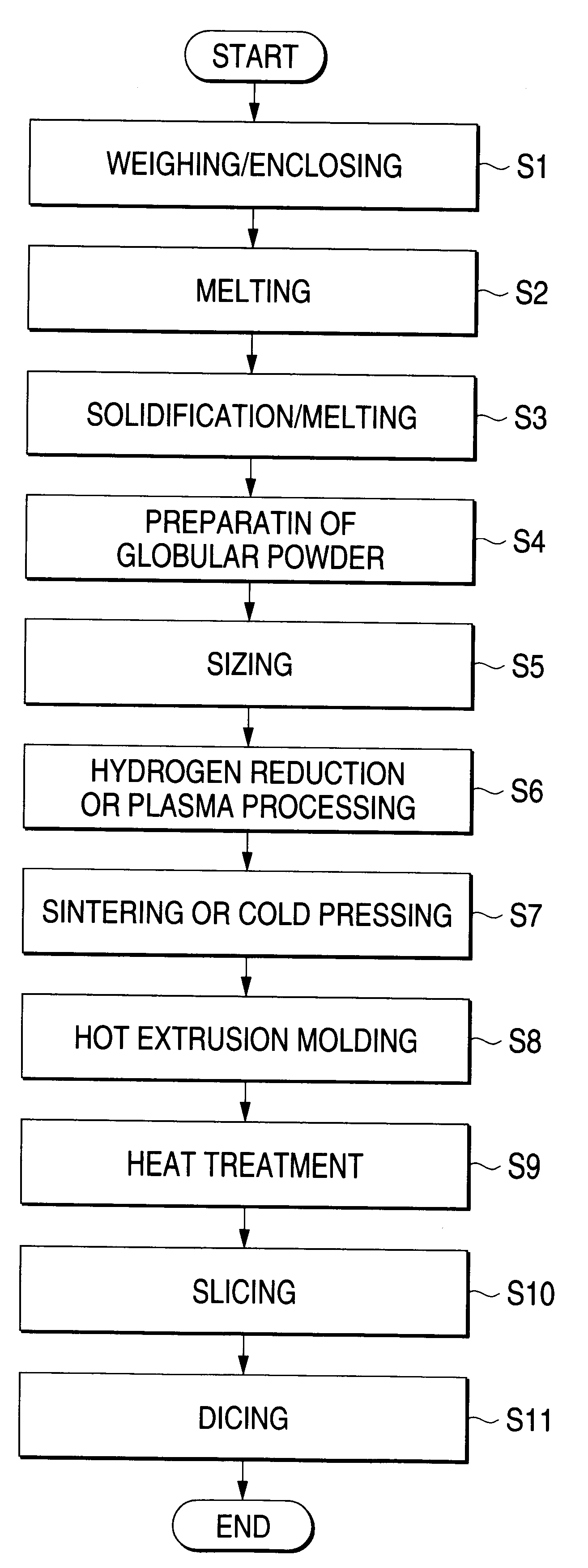

Method for manufacturing a thermoelectric semiconductor material or element and method for manufacturing a thermoelectric module

InactiveUS6319744B1Thermometers using electric/magnetic elementsSemiconductor/solid-state device manufacturingSemiconductor materialsMetallurgy

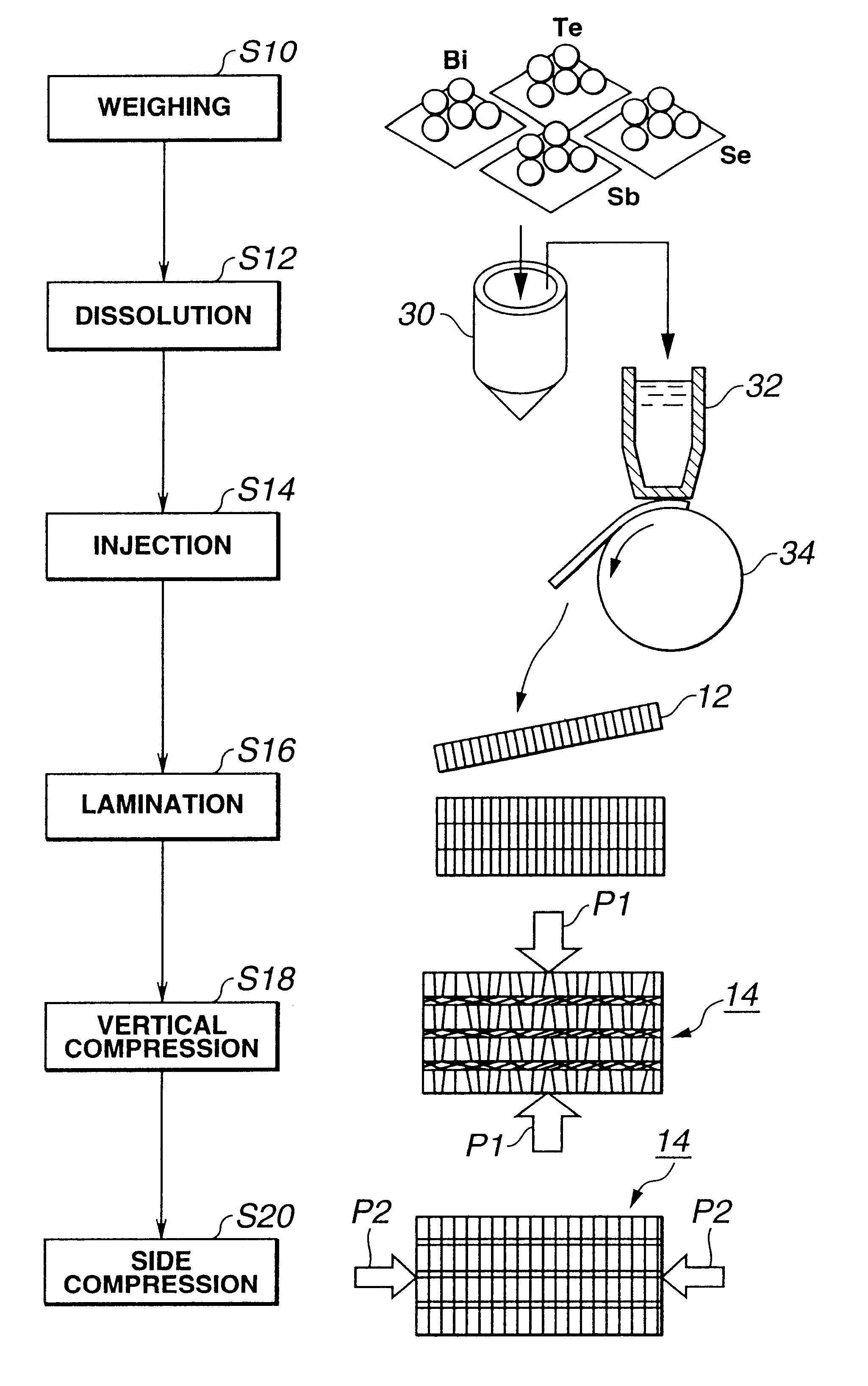

To provide a method for manufacturing a thermoelectric semiconductor material or a thermoelectric semiconductor element and method for manufacturing a thermoelectric module effective in improving thermoelectric performance. The thermoelectric semiconductor material is manufactured by producing a laminated body of thin powders manufactured by a quenching roller method, and compressing simultaneously the side surfaces of the laminated body using a secondary punch.

Owner:KOMATSU LTD

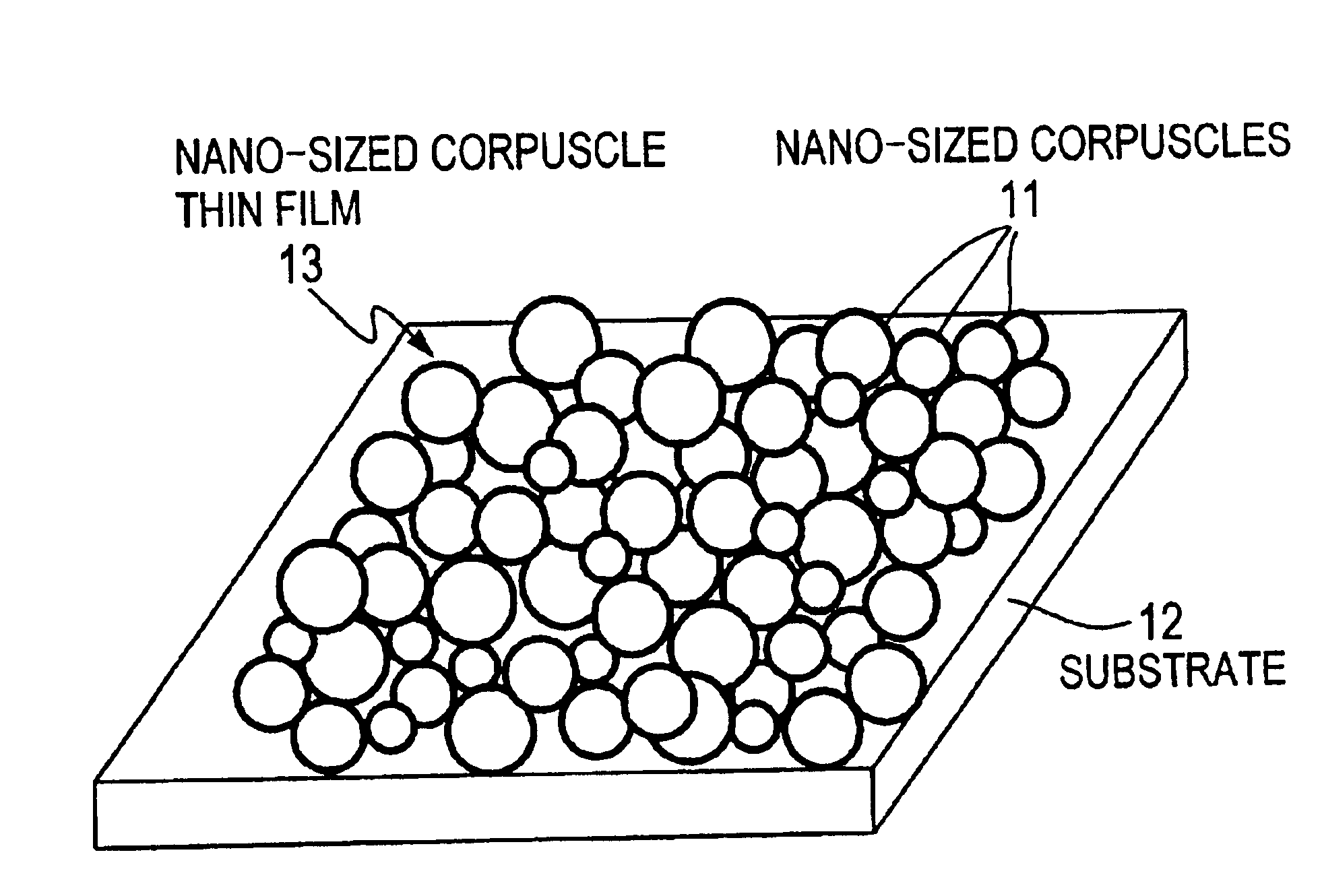

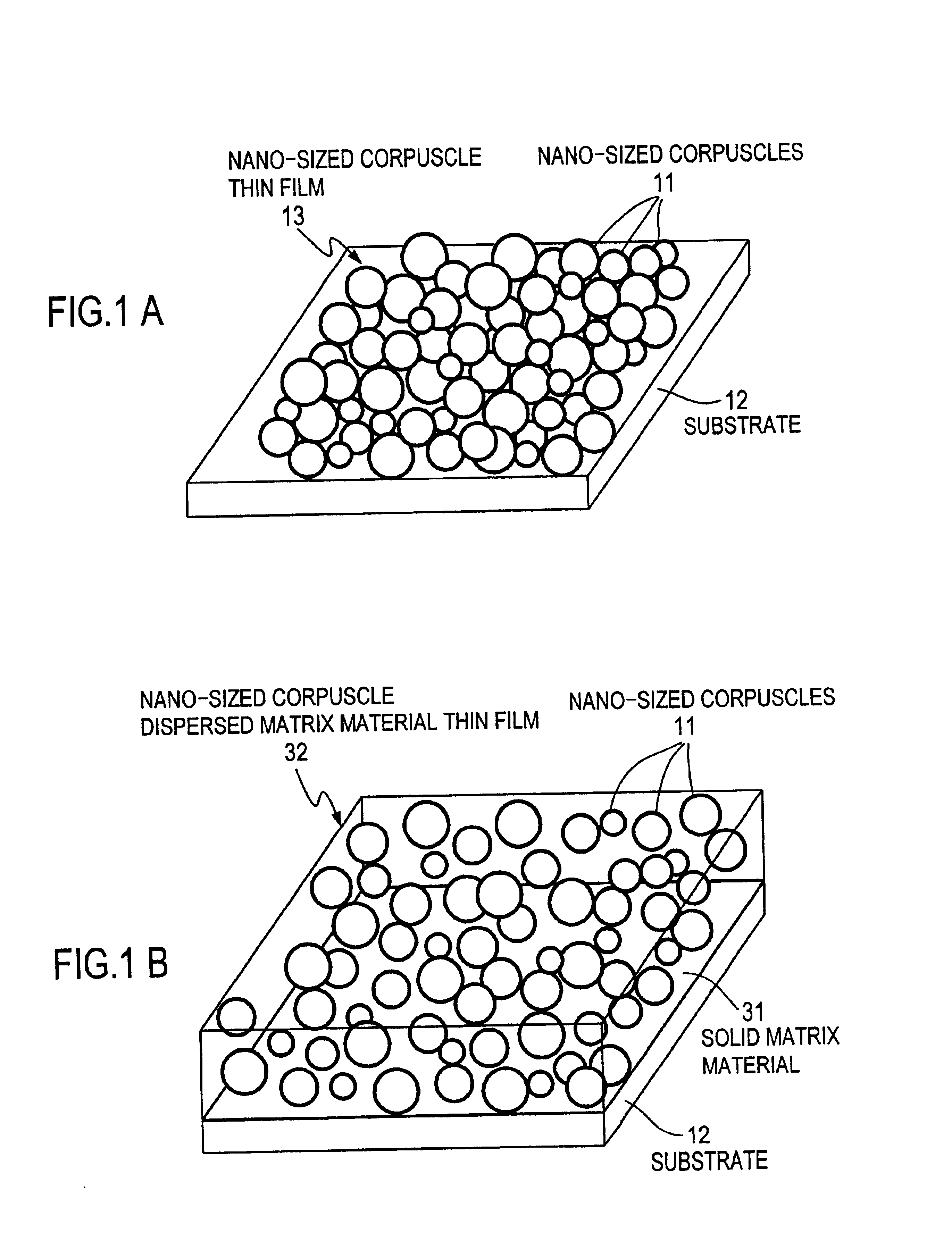

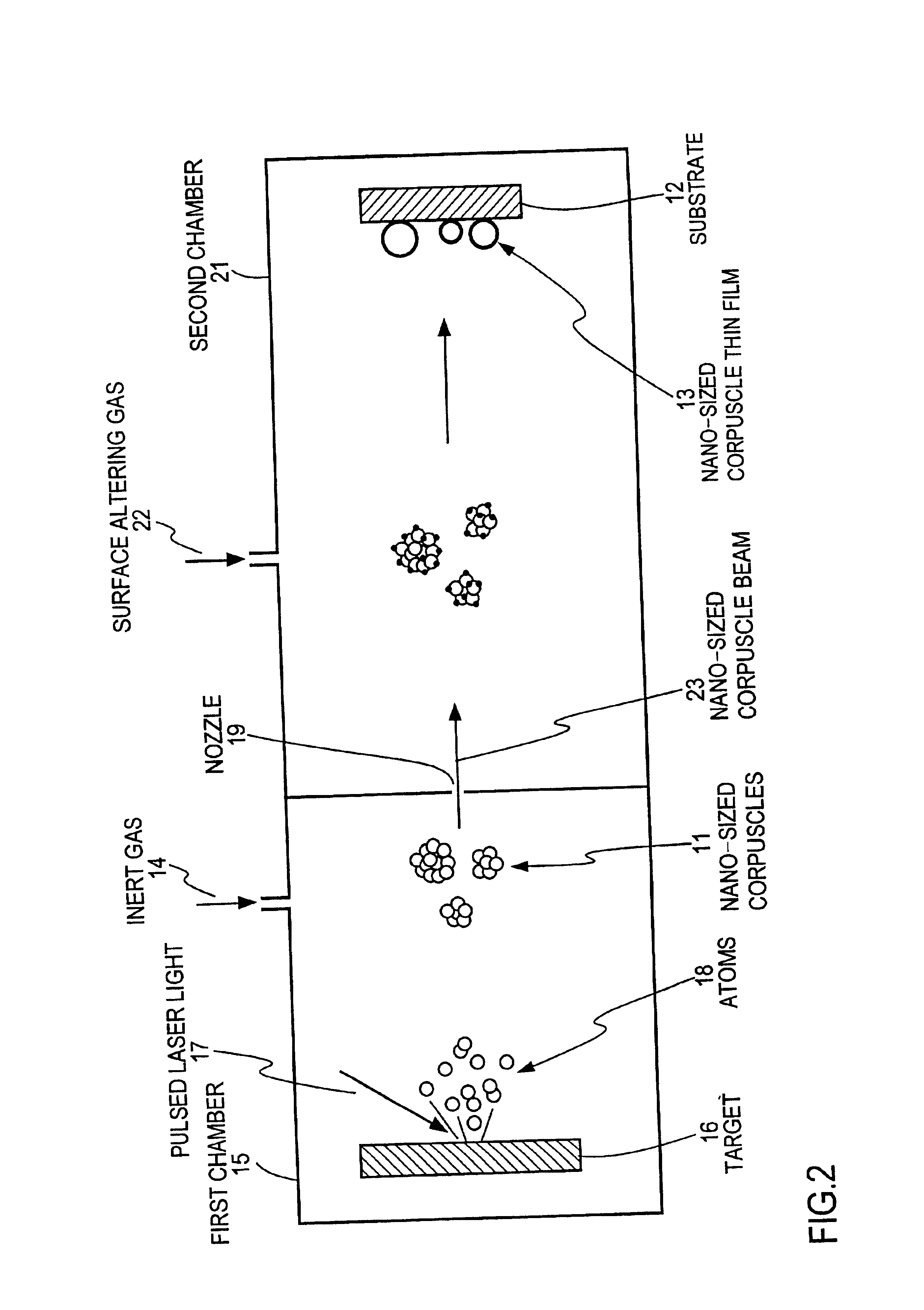

Thermoelectric material and method of manufacturing the same

InactiveUS6858154B2Low thermal conductivityThermoelectric device manufacture/treatmentConductive materialSolid massCharge carrier

A thermoelectric material having large thermoelectric figure of merit is provided. A thin film comprising nanometer-sized particles having their diameters distributing within the range of 0.5 nm though 100 nm both inclusive is formed by depositing the nanometer-sized particles on a substrate, or dispersing the particles in a solid matrix material or solution thereby to form a thin film. In the thin film, a band gap due to quantum confinement effect is generated in each of the particles and electrical conduction occurs by that at least a part of the particles supply carriers. Accordingly, thermal conductivity κ as well as electrical resistivity ρ and Seebeck coefficient S all of which are factors of thermoelectric figure of merit can be independently controlled, and it is possible to get a thermoelectric material having large dimensionless thermoelectric figure of merit ZT such as beyond 1.5.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

Method for producing a device for direct thermoelectric energy conversion

InactiveUS7166796B2Improve energy conversion efficiencyReduced dimensionPolycrystalline material growthThermoelectric device manufacture/treatmentJunction temperatureEngineering

In devices used for the direct conversion of heat into electricity, or vice versa, known in the art as thermoelectric power generators, thermoelectric refrigerators and thermoelectric heat pumps, the efficiency of energy conversion and / or coefficient of performance have been considerably lower than those of conventional reciprocating or rotary, heat engines and / or vapor-compression systems, employing certain refrigerants. The energy conversion efficiency of power generating devices, for example, aside from the hot and cold junction temperatures, also depends on a parameter known in the art as the thermoelectric figure of merit Z=S2σ / k, where S is the thermoelectric power, σ is the electrical conductivity and k is the thermal conductivity, of the material that constitutes the p-type, and / or n-type, thermoelements, or branches, of the said devices. In order to achieve a considerable increase in the energy conversion efficiency, a thermoelectric figure of merit of the order of 10−2 K−1, or more, is needed. It is reasonably expected that such an order of magnitude, for the figure of merit, can be realized with a composition of matter, comprising magnesium, silicon, lead and barium, and optionally comprising one, or more, additional doping materials.

Owner:NICOLOAU MICHAEL C

Uniwafer thermoelectric modules

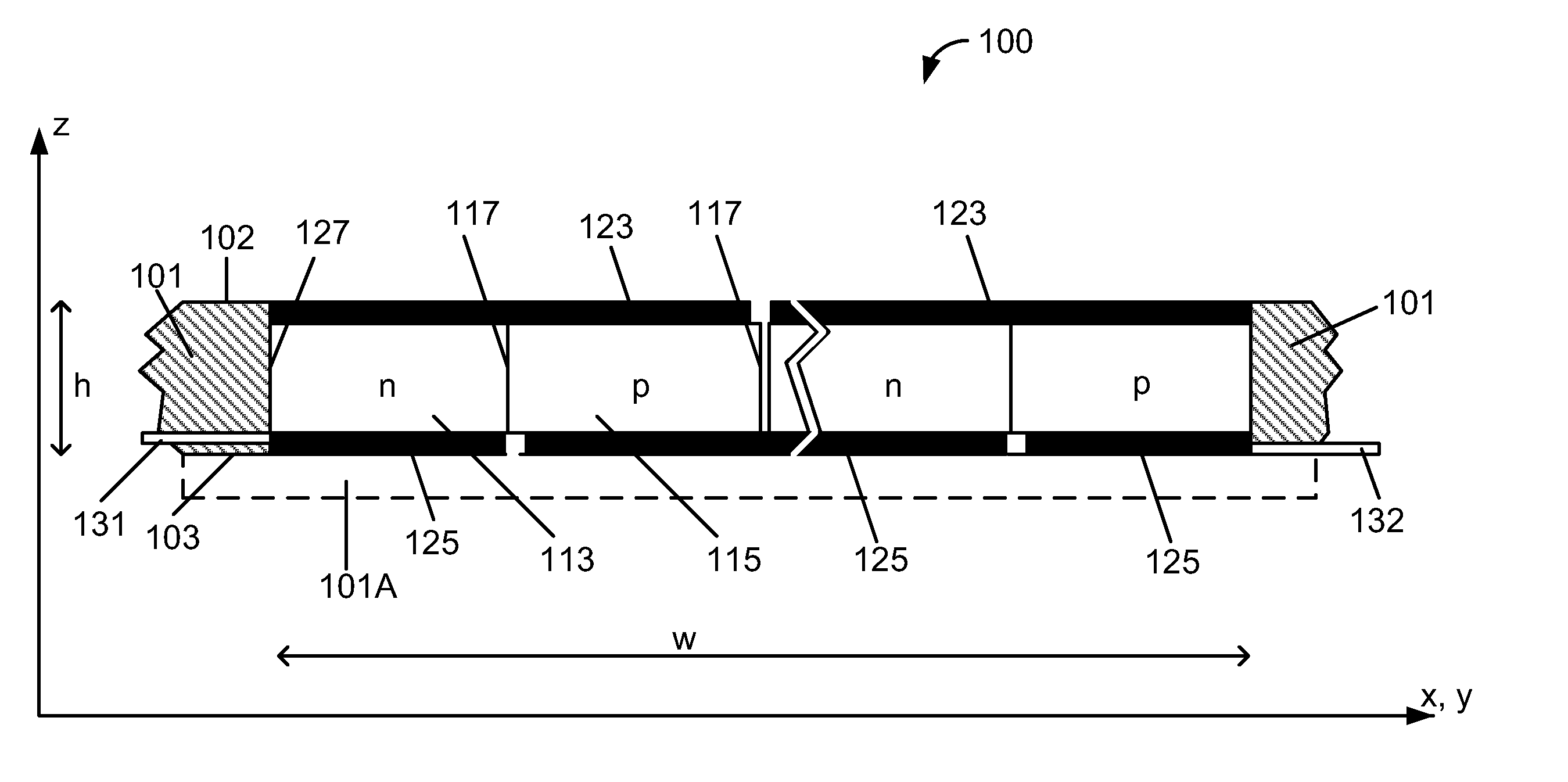

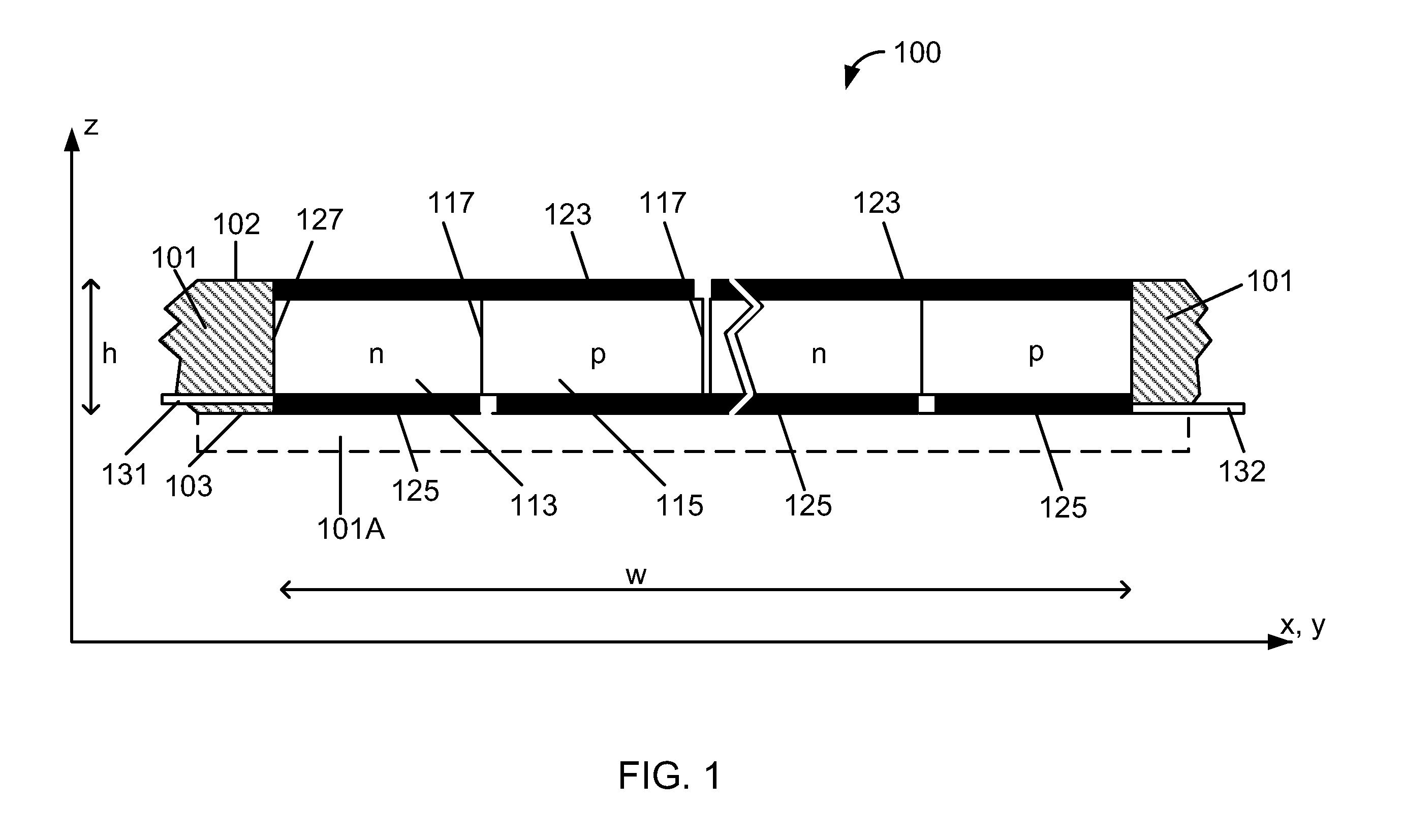

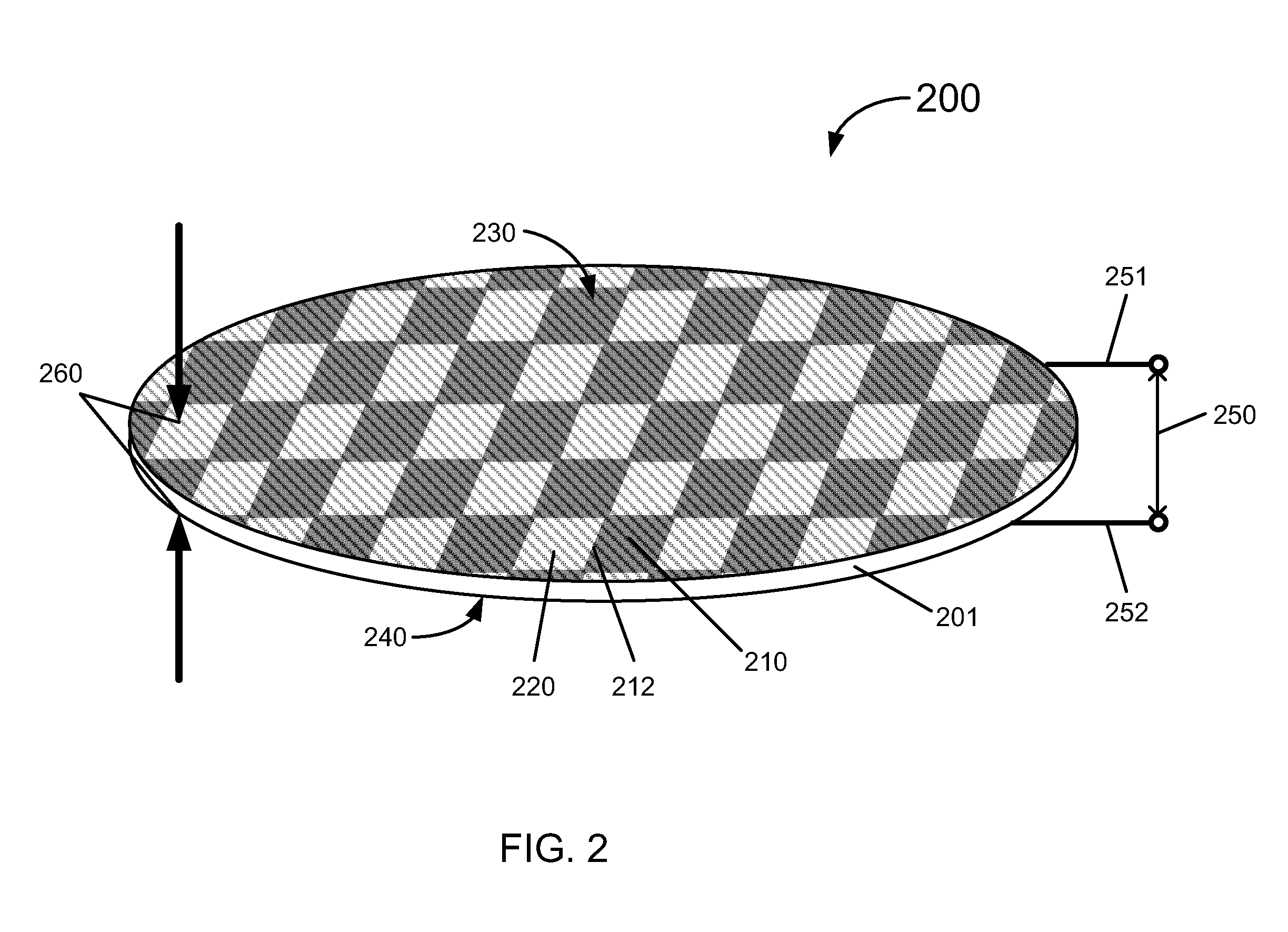

InactiveUS20110114146A1Enhancing thermoelectric figure of meritSimple processThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermal isolationHemt circuits

A uniwafer device for thermoelectric applications includes one or more first thermoelectric elements and one or more second thermoelectric elements comprising respectively a first and second patterned portion of a substrate material. Each first / second thermoelectric element is configured to be functionalized as an n- / p-type semiconductor with a thermoelectric figure of merit ZT greater than 0.2. The second patterned portion is separated from the first patterned portion by an intermediate region functionalized partially for thermal isolation and / or partially for electric interconnecting. The one or more first thermoelectric elements and the one or more second thermoelectric elements are spatially configured to allow formation of a first contact region and a second contact region respectively connecting to each of the one or more first thermoelectric elements and / or each of the one or more second thermoelectric elements to form a continuous electric circuit.

Owner:SYNERGY THERMOGEN INC +1

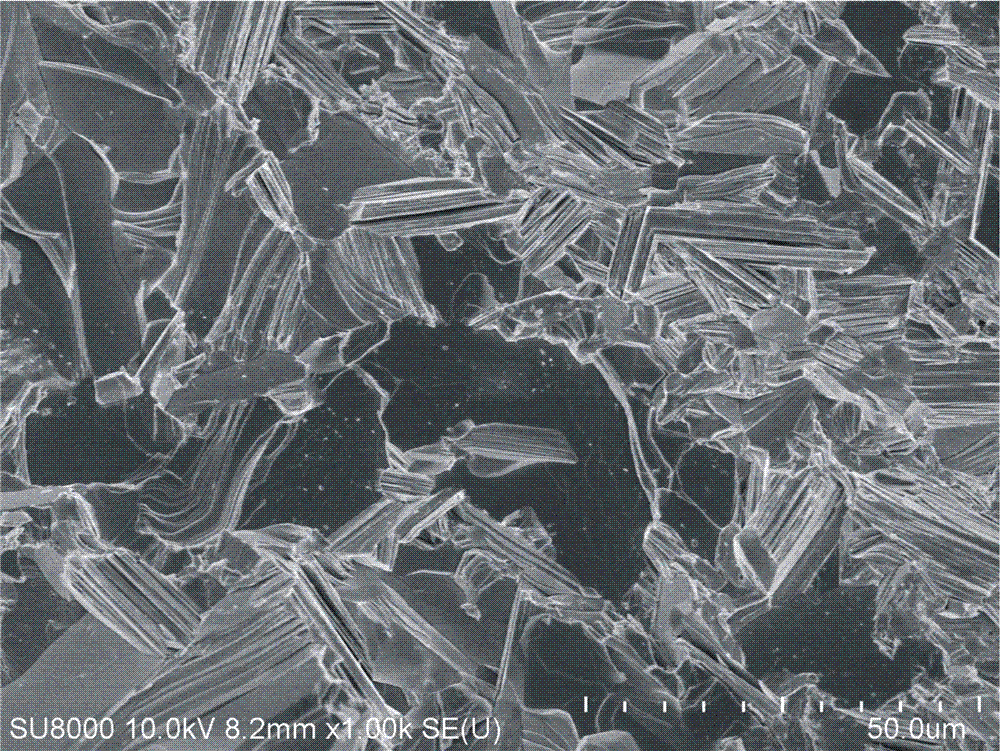

Bi2Te3 thin-piece/graphene composite material, preparation method and applications thereof

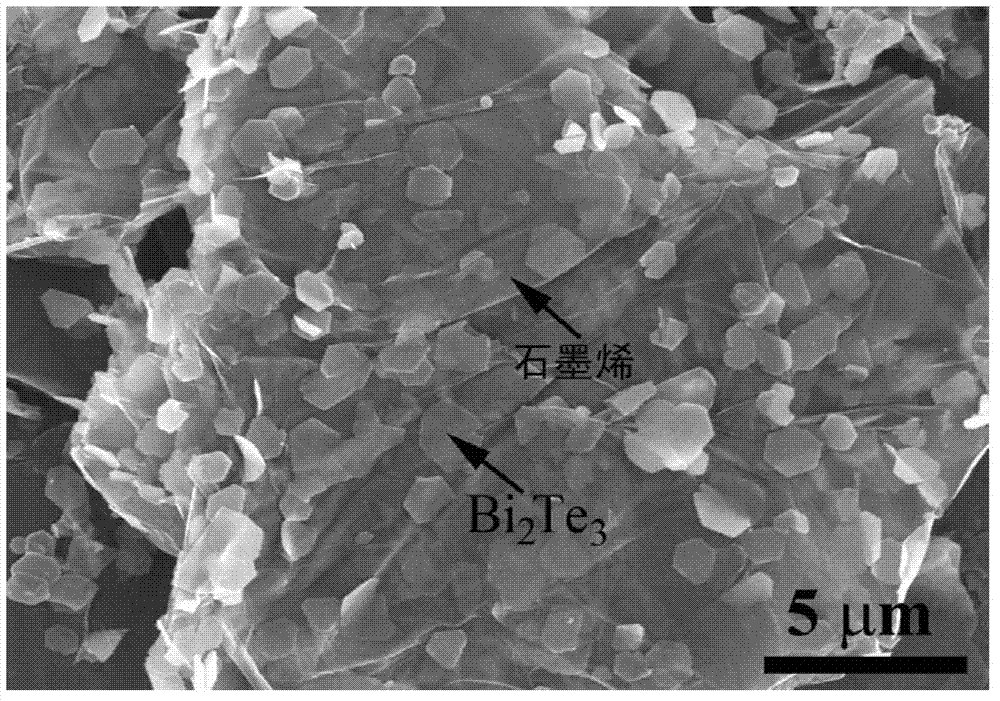

InactiveCN102760827AImprove thermoelectric performanceAvoid reunionGrapheneThermoelectric device junction materialsSolventCvd graphene

The invention discloses a Bi2Te3 thin-piece / graphene composite material. The Bi2Te3 thin-piece / graphene composite material consists of a micron-sized Bi2Te3 thin sheet and graphene. Due to the actions of dispersion, bearing and isolation of the graphene, the sintering of the micron-sized Bi2Te3 thin sheet in the heat-treatment process can be effectively prevented for maintaining effective scattering of the crystal boundary to phonons, and the great significance for improving the thermoelectric properties of the Bi2Te3 material is embodied. The composite material can be used as a thermoelectric material. The invention also discloses a preparation method of the composite material by a one-step hydrothermal method or a one-step solvothermal method, and has the advantages of simple process, low cost, short period and low energy consumption and the like.

Owner:ZHEJIANG UNIV

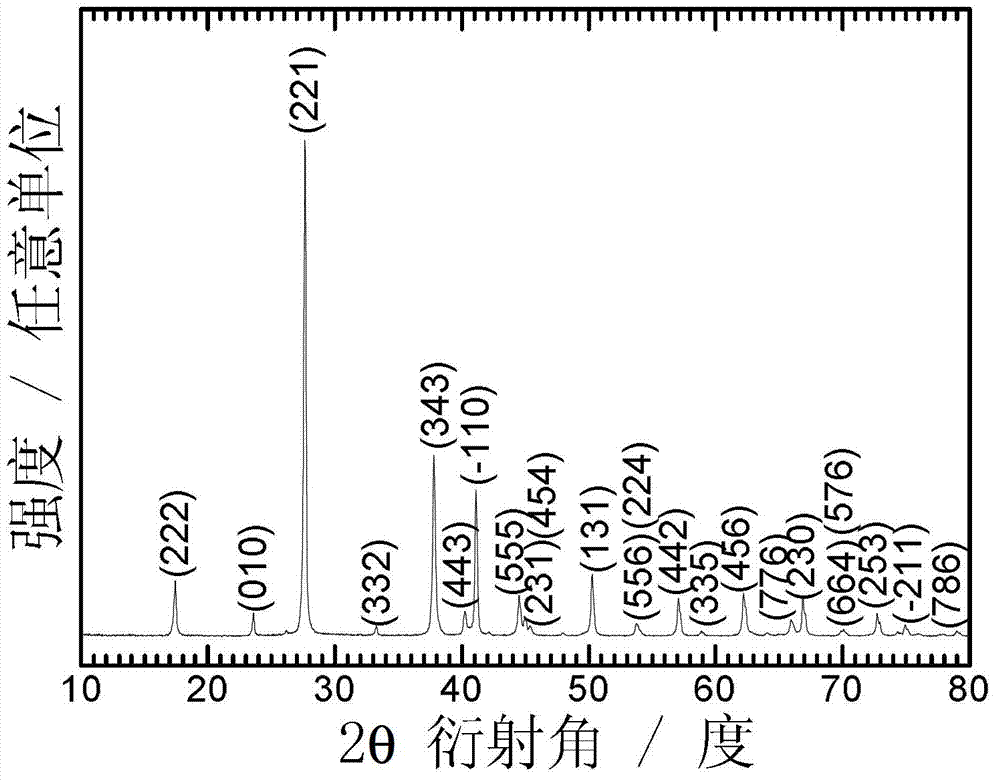

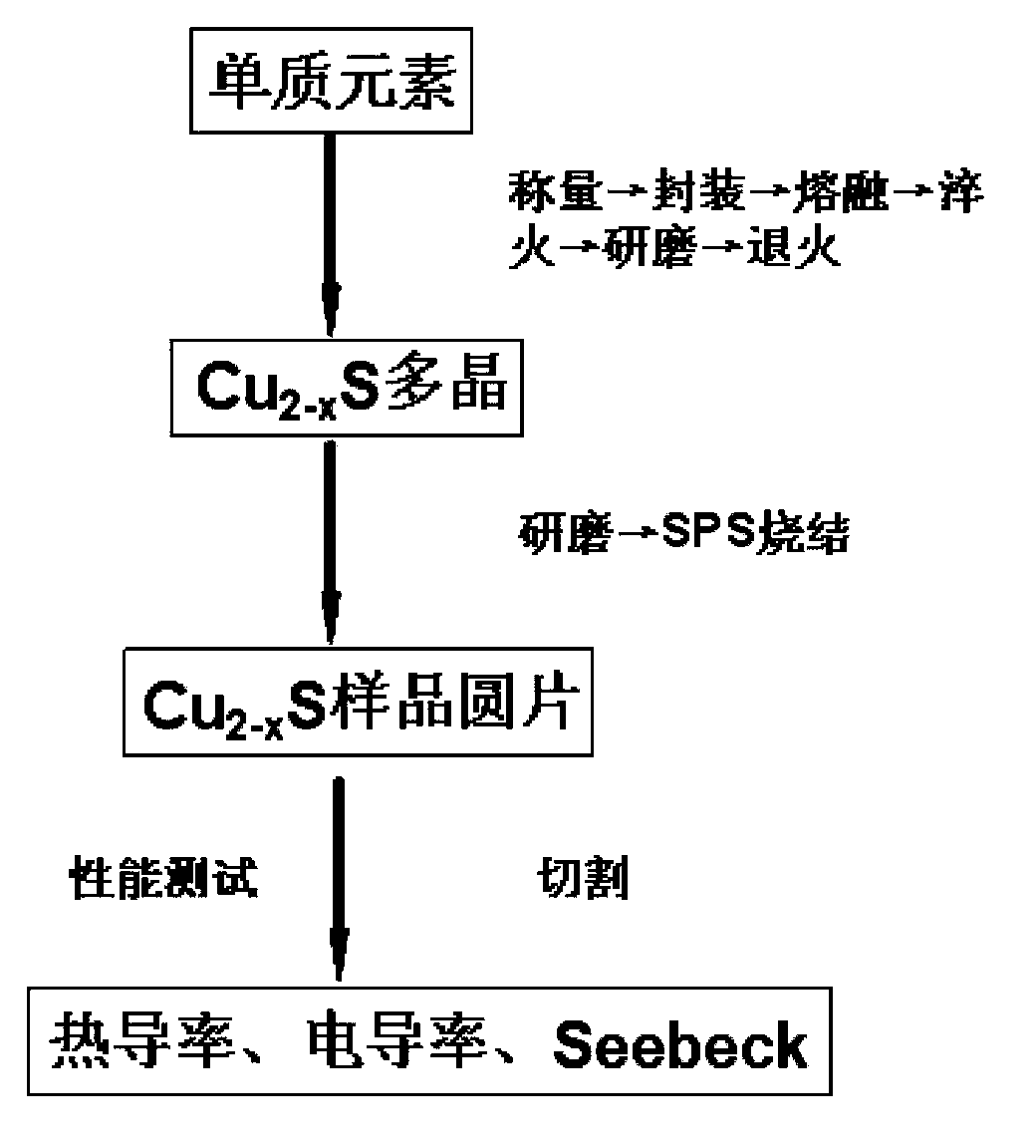

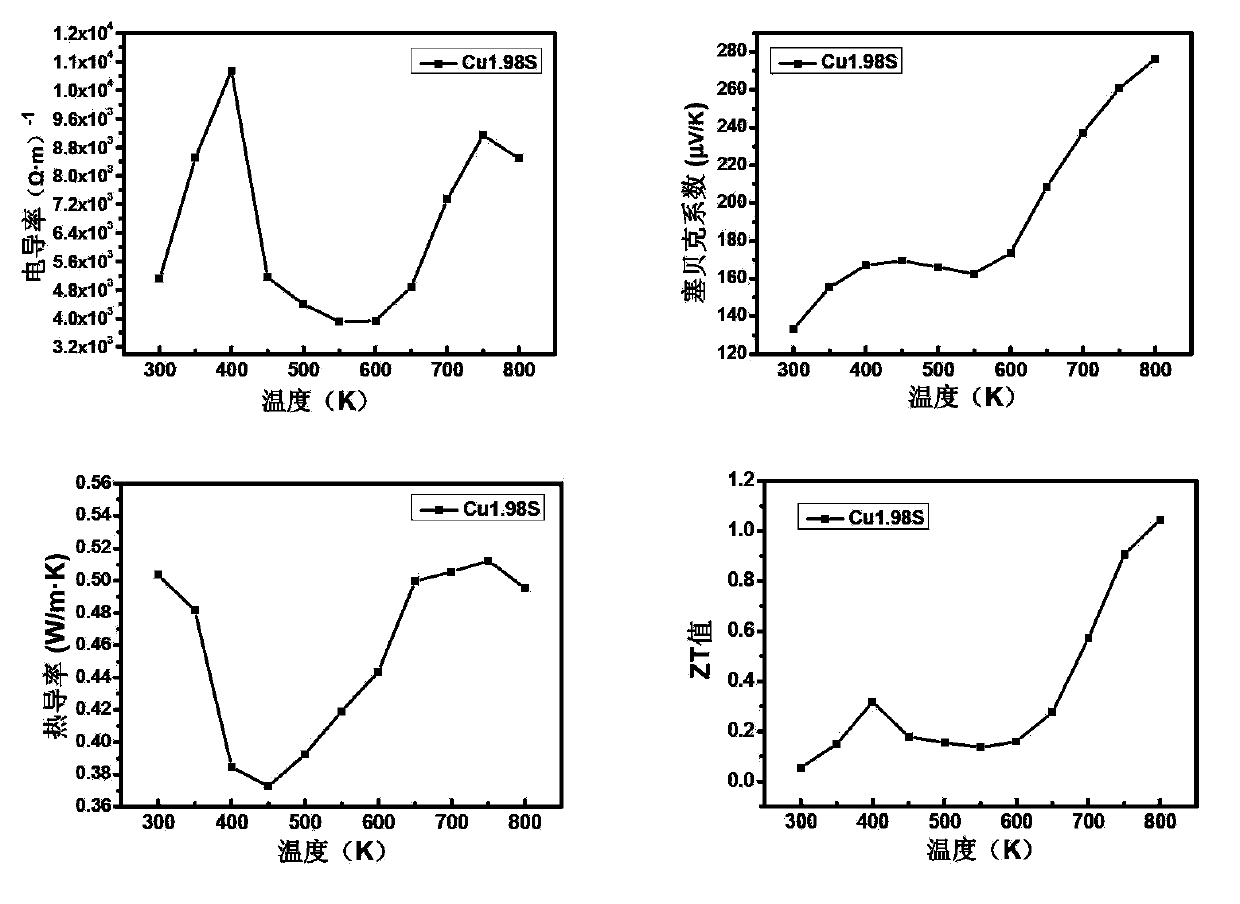

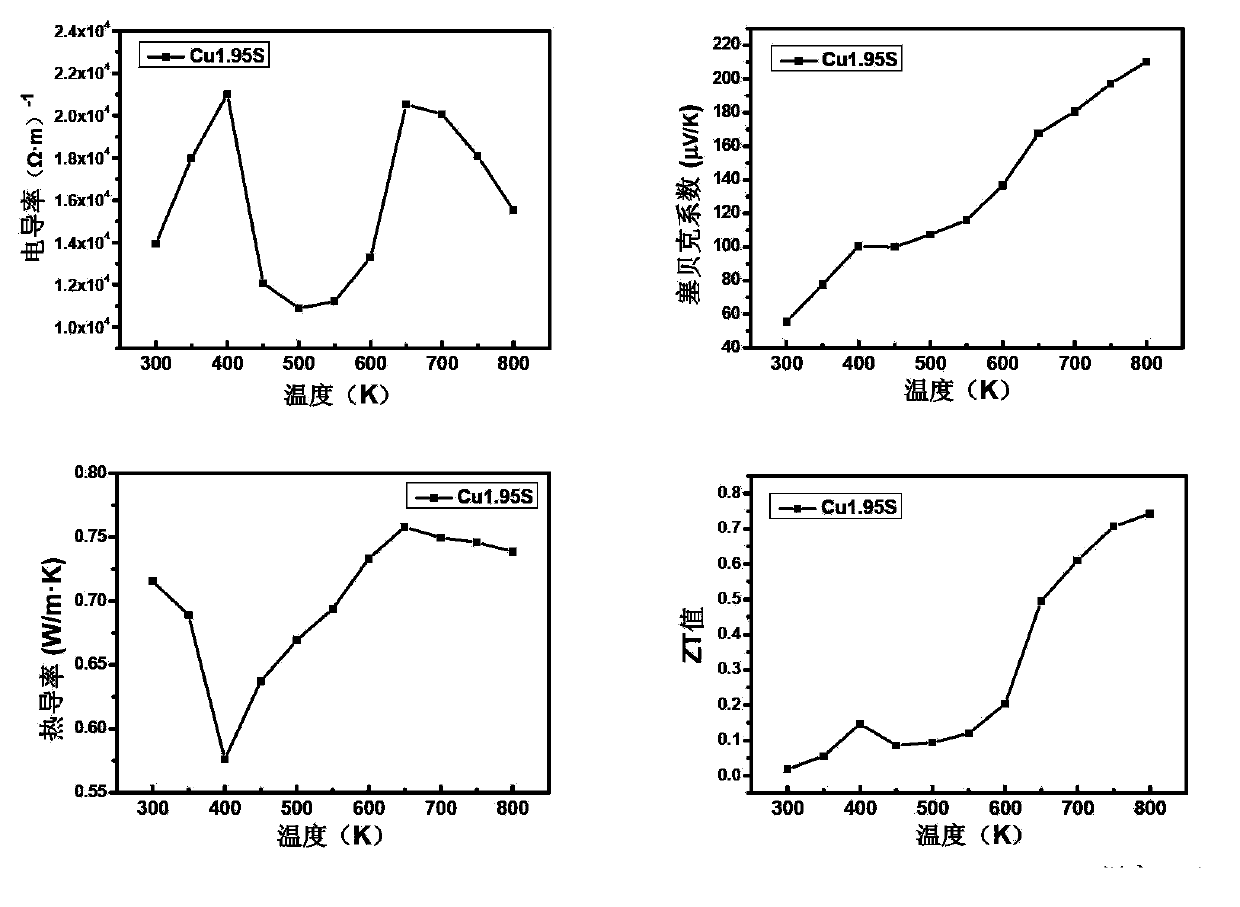

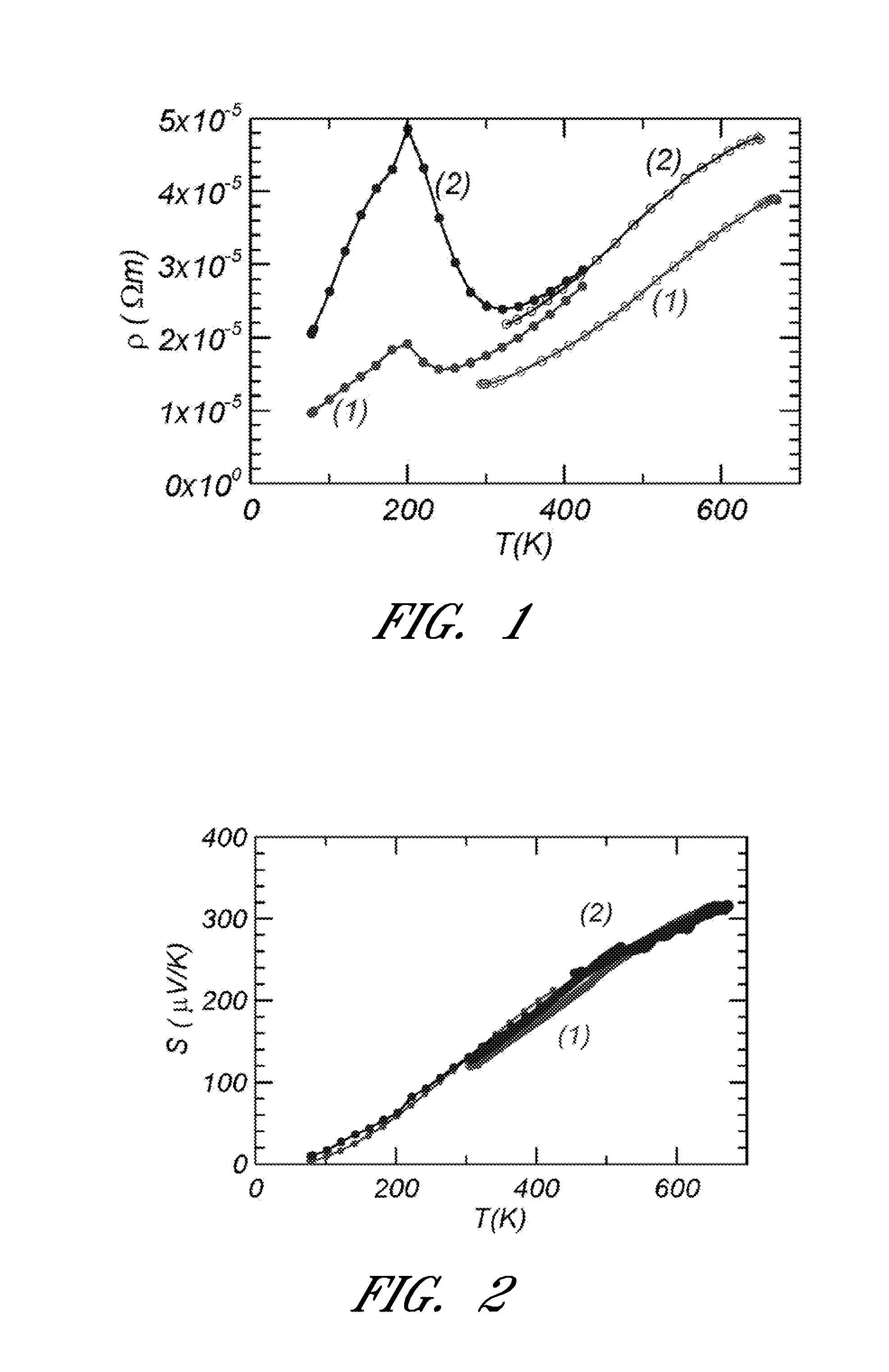

Copper-sulfur-based high-performance thermoelectric material and preparation method thereof

ActiveCN103872237ARich sourcesLow costThermoelectric device manufacture/treatmentThermoelectric device junction materialsMetallurgyElectric properties

The invention relates to a copper-sulfur-based high-performance thermoelectric material and a preparation method thereof, and particularly provides a novel p-type thermoelectric compound Cu(2-x)S or Cu2S(1-y)Ay (A is Se or Te) and a preparation method thereof. The compound is composed of Cu-S-(Se / Te), x equals 0.02-0.05, and y equals 0.2-0.4. The material is a semiconductor. Compared with traditional thermoelectric materials, the compound is simple, low in cost of raw materials, high in Seebeck coefficient, low in thermal conductivity, and excellent in thermal property, the thermoelectric figures of merit ZT of some components can reach 1 and above at 800K, and the compound has good thermoelectric application prospects.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

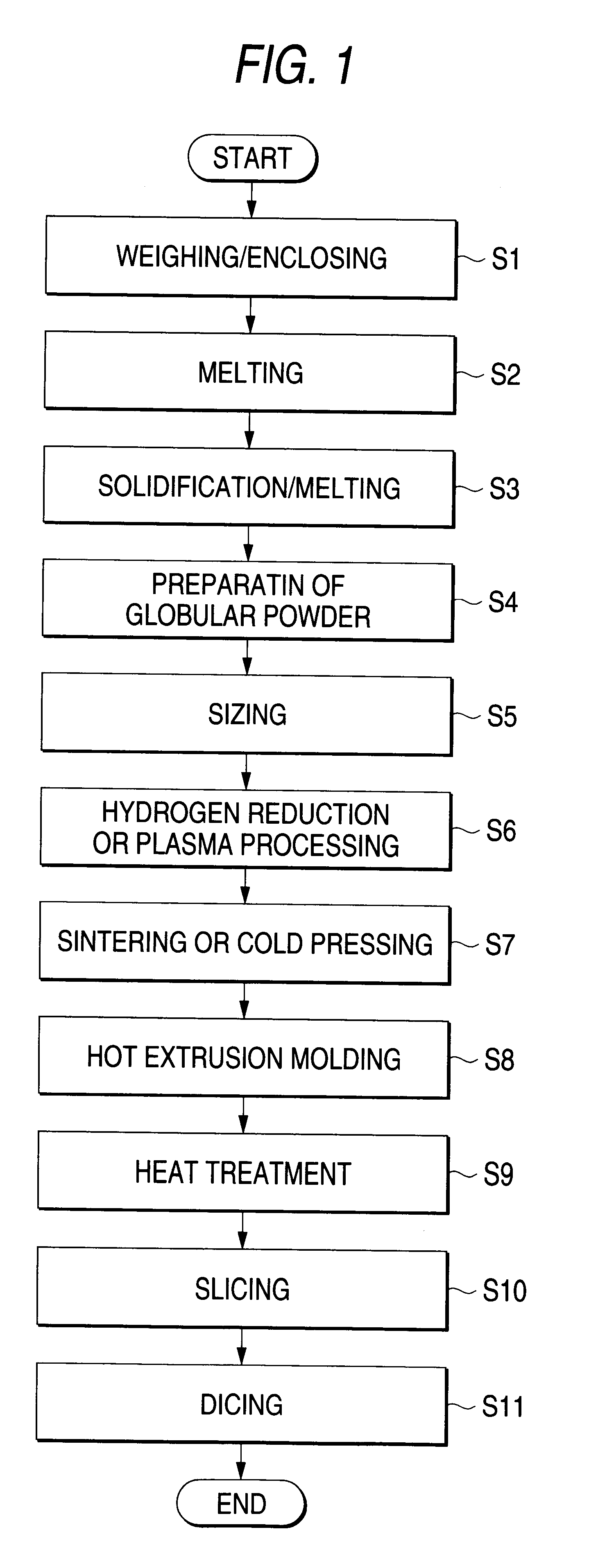

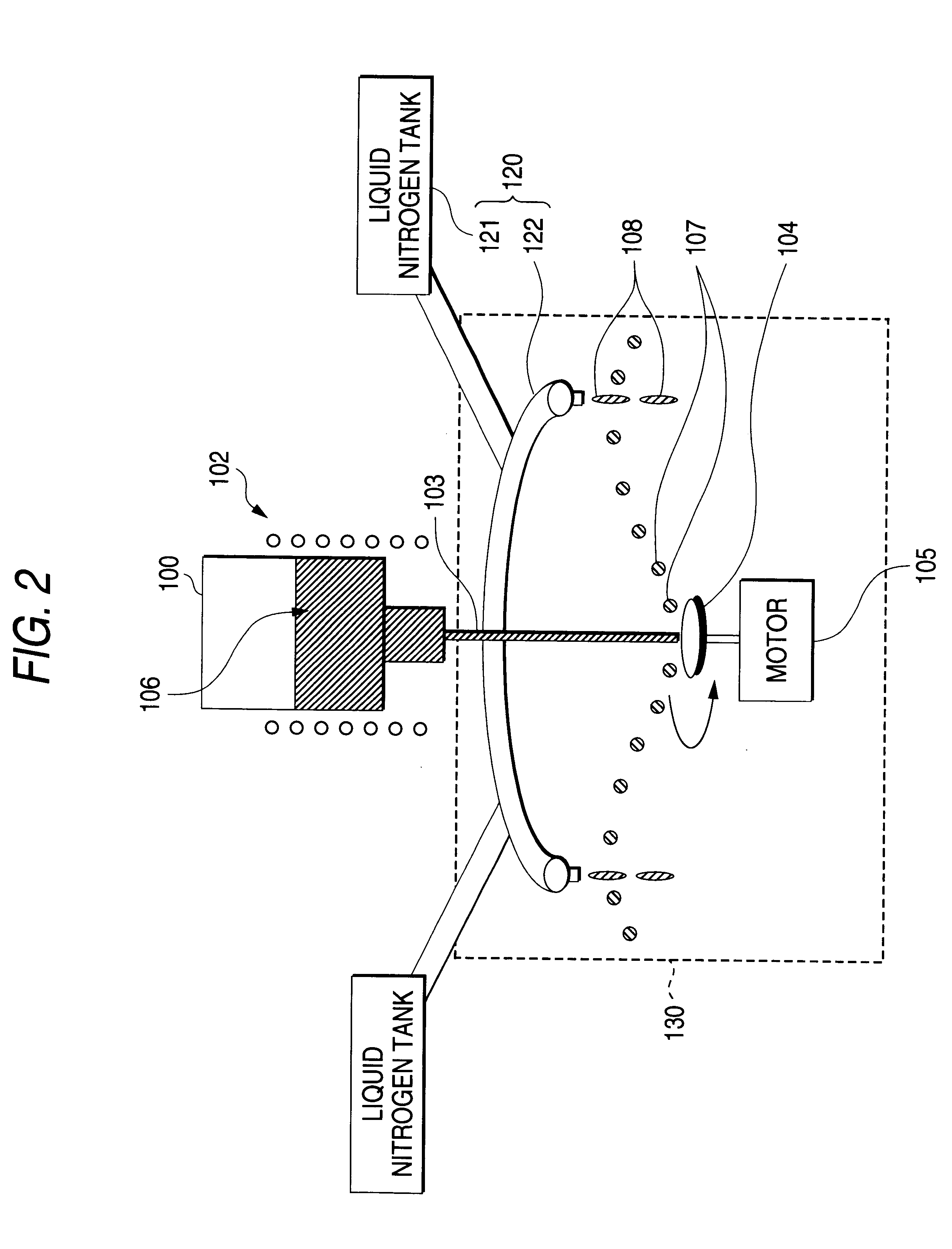

Thermoelectric element, method of fabricating the same, and thermoelectric module employing the same

InactiveUS6617504B2Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentCrystal orientationFigure of merit

A method of fabricating a thermoelectric element of enhanced thermoelectric performance is provided by improving the preparation of thermoelectric material and employing hot plastic working in combination. The method comprises the step (a) of mixing and heat-melting a raw material of a predetermined composition; the step (b) of turning the heat-melted material 106 into microglobules by either of scattering and spraying, and then quenching the microglobules, thereby providing a globular powdery thermoelectric material; and the step (c) of plastically deforming the thermoelectric material in a hot condition, thereby to bring crystal grains of the thermoelectric material into a crystal orientation affording an excellent figure of merit.

Owner:KOMATSU LTD

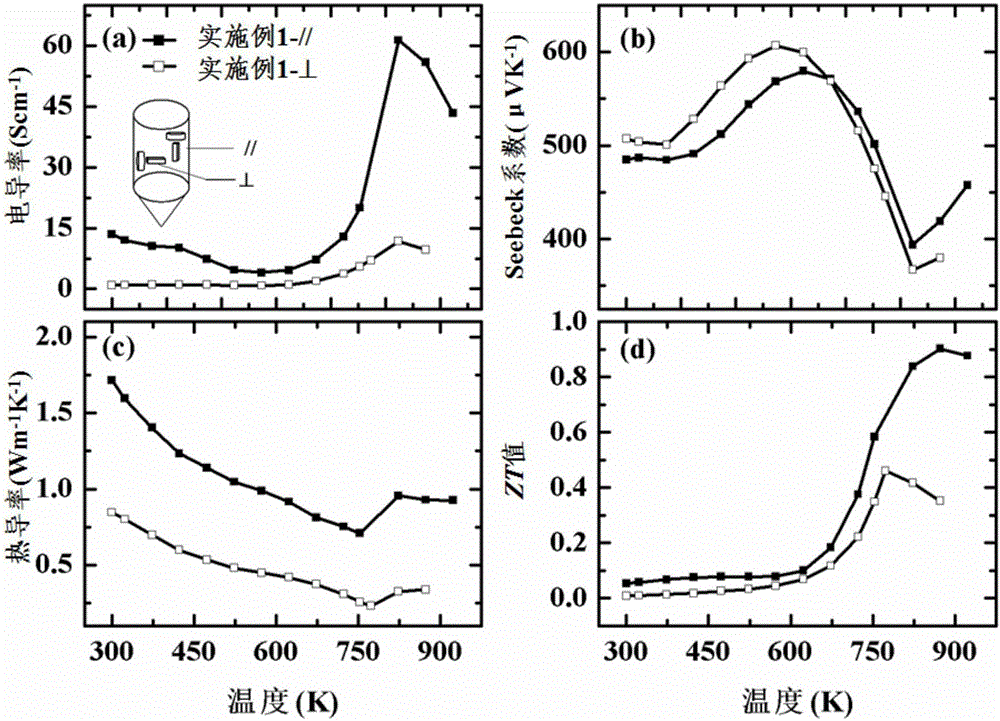

SnSe-based thermoelectric material and preparation method thereof

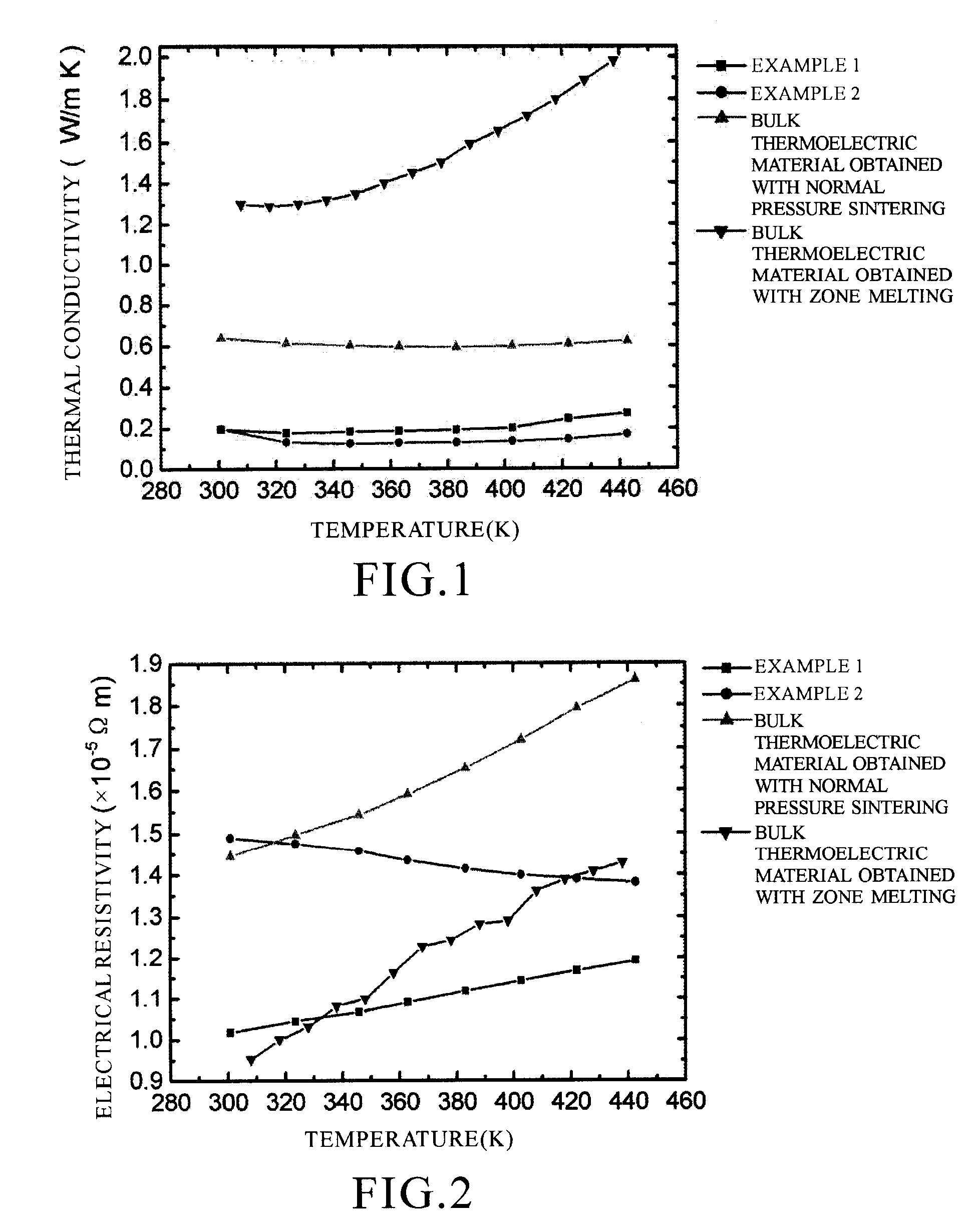

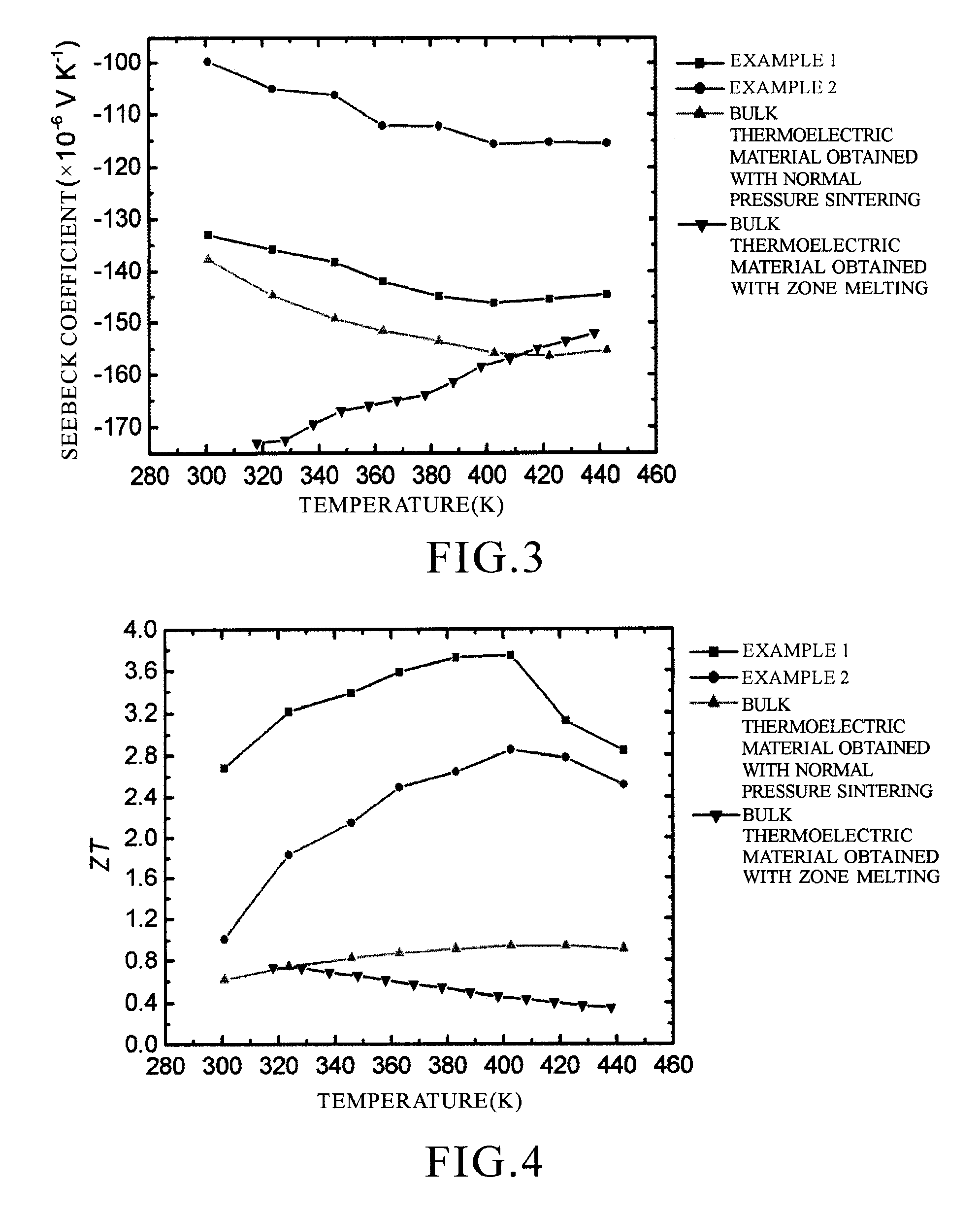

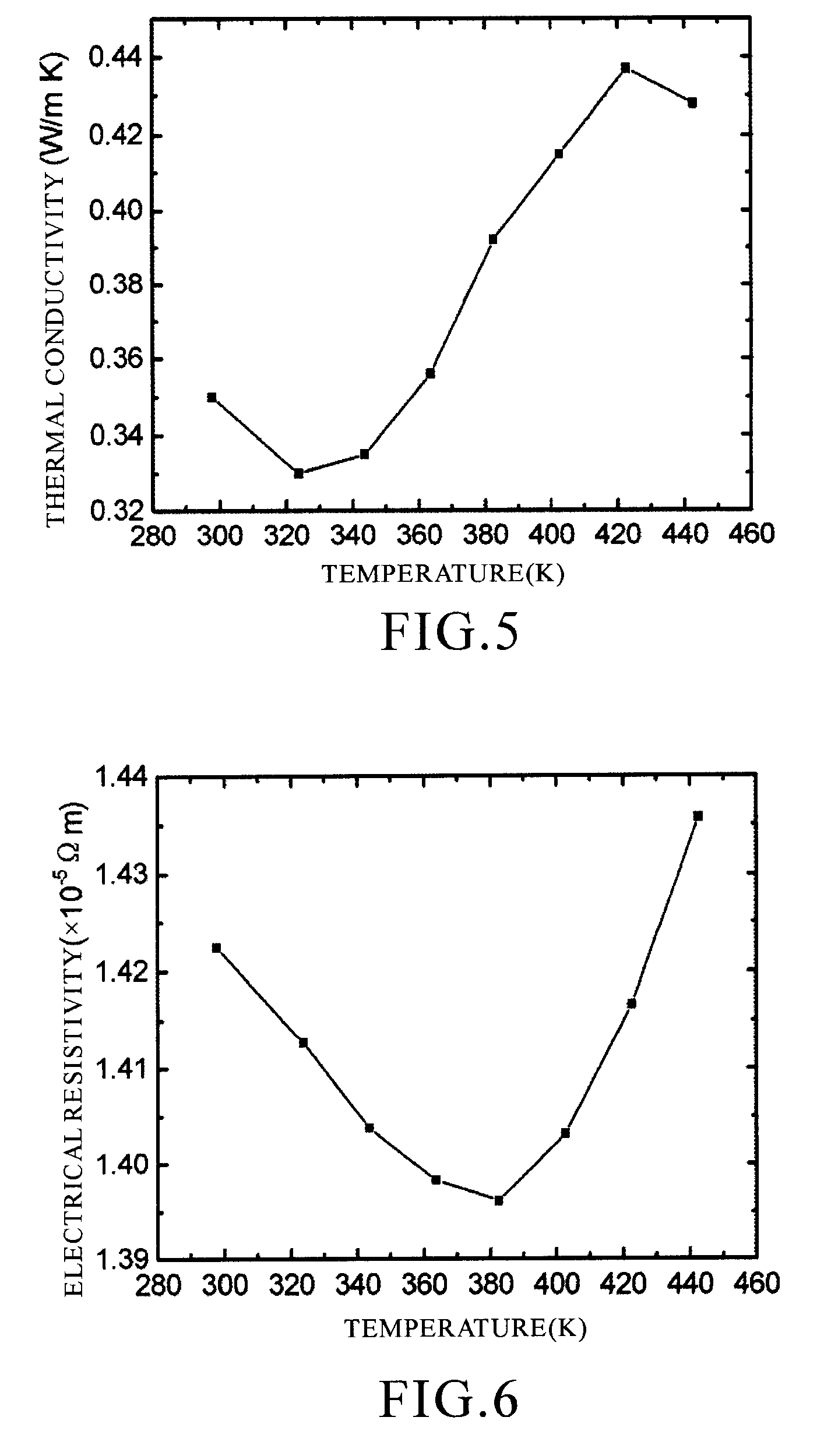

ActiveCN105047809AEasy to prepareShorten the growth cyclePolycrystalline material growthThermoelectric device manufacture/treatmentZone meltingIngot

The invention discloses an SnSe-based thermoelectric material and a preparation method thereof. The preparation method includes steps: S100 weighing reaction raw material according to the stoichiometric ratio of the SnSe-based thermoelectric material; S200 refining the reaction raw material through a melt-refining process to obtain SnSe-based thermoelectric material ingots; and S300 placing SnSe-based thermoelectric material ingots obtained from the S200 in a zone smelting furnace and growing polycrystalline SnSe-based thermoelectric material through a zone melting method. The SnSe-based thermoelectric material obtained through the method is preferential and has better thermoelectric performance. Compared with a method for preparing monocrystalline SnSe-based thermoelectric material, the method is simple and is short in growth period, low in cost, and suitable for mass industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

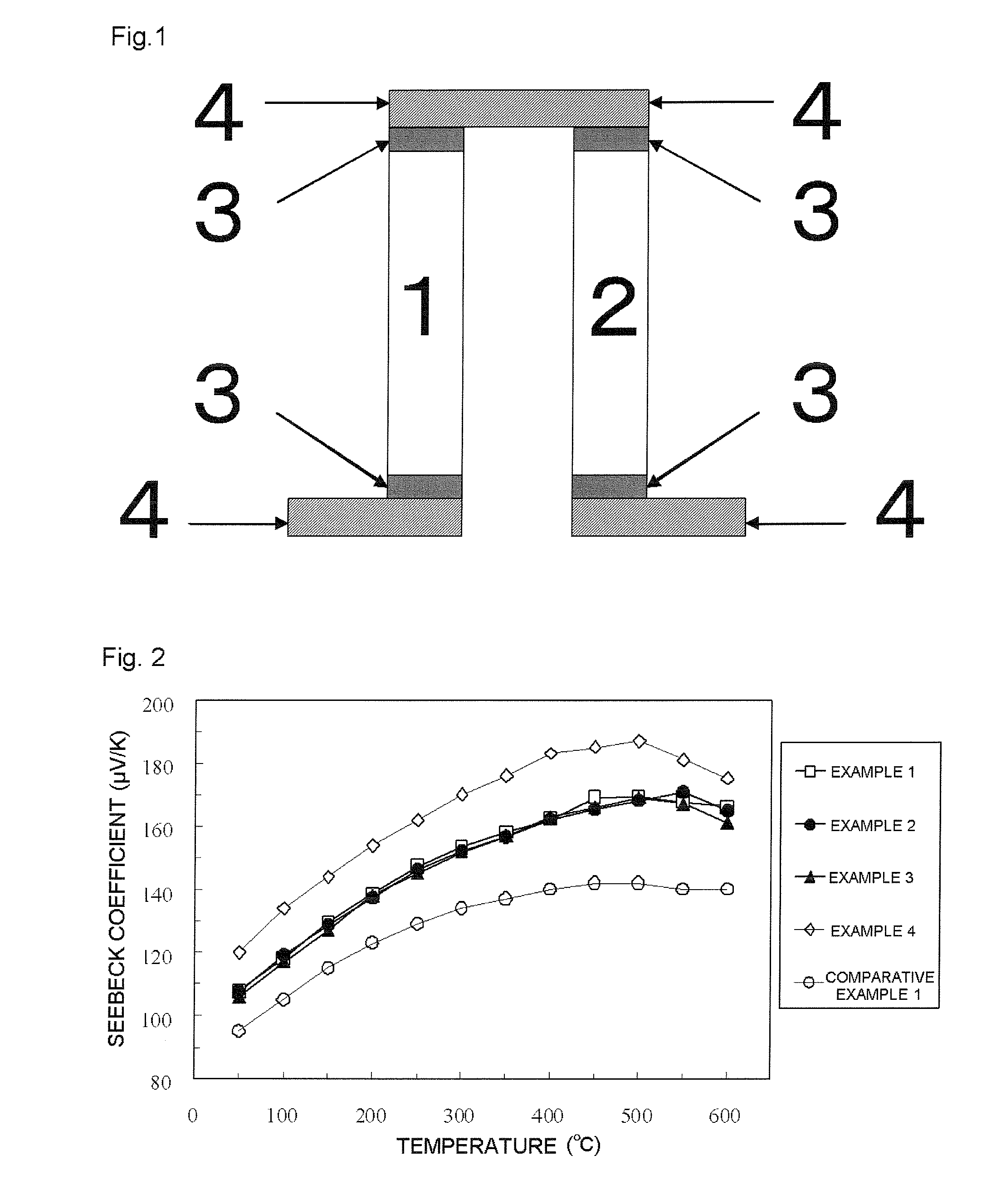

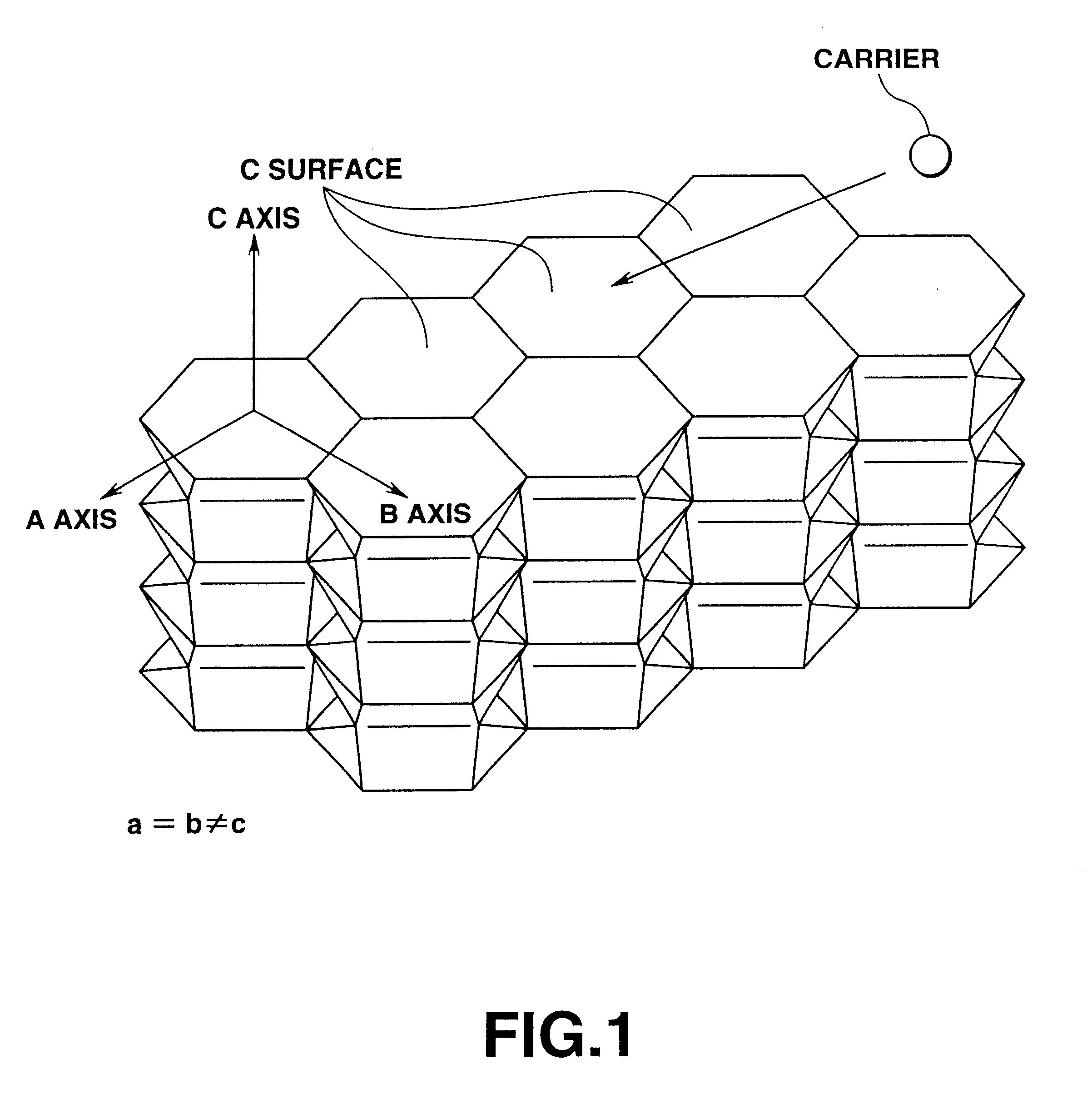

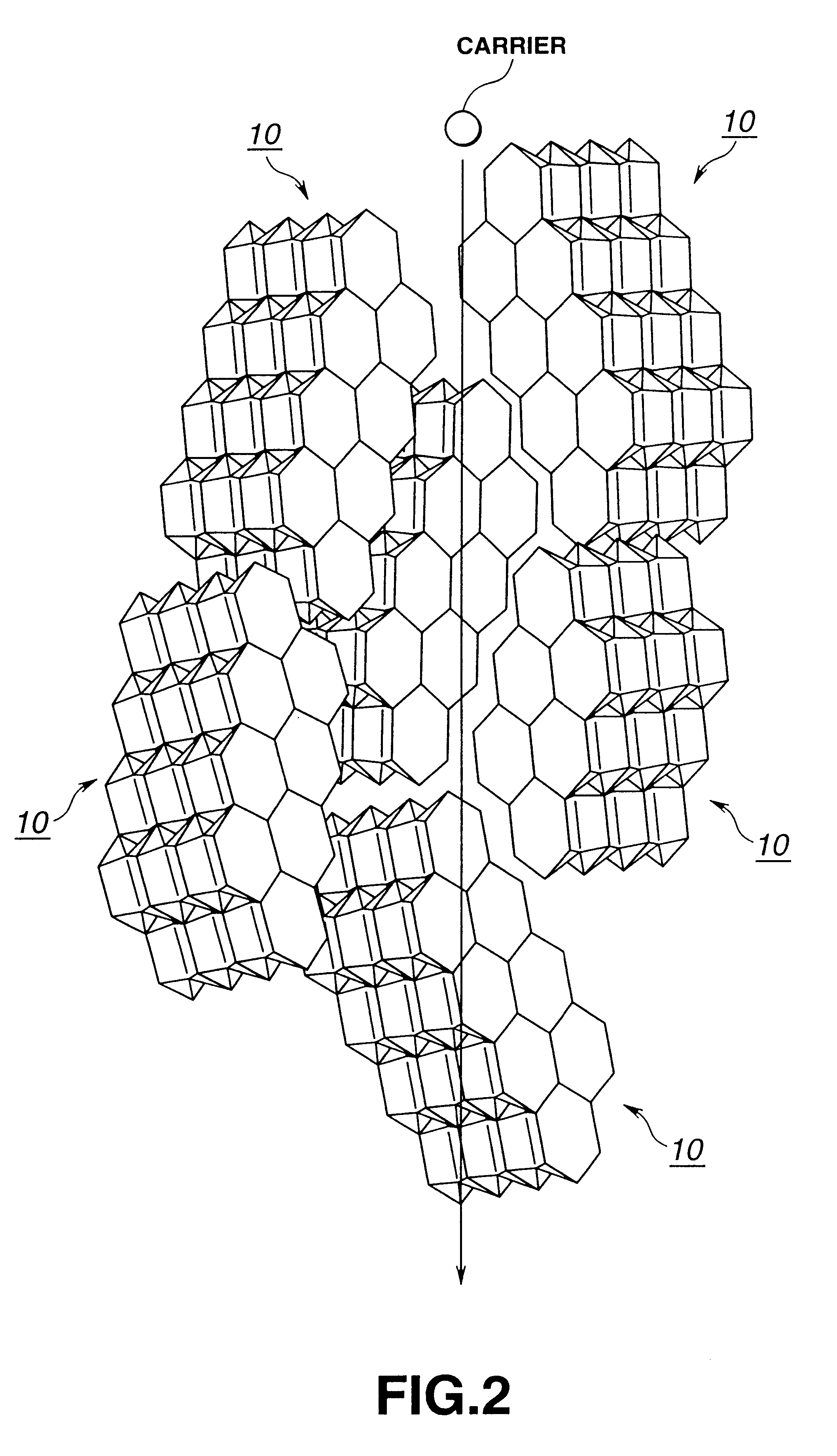

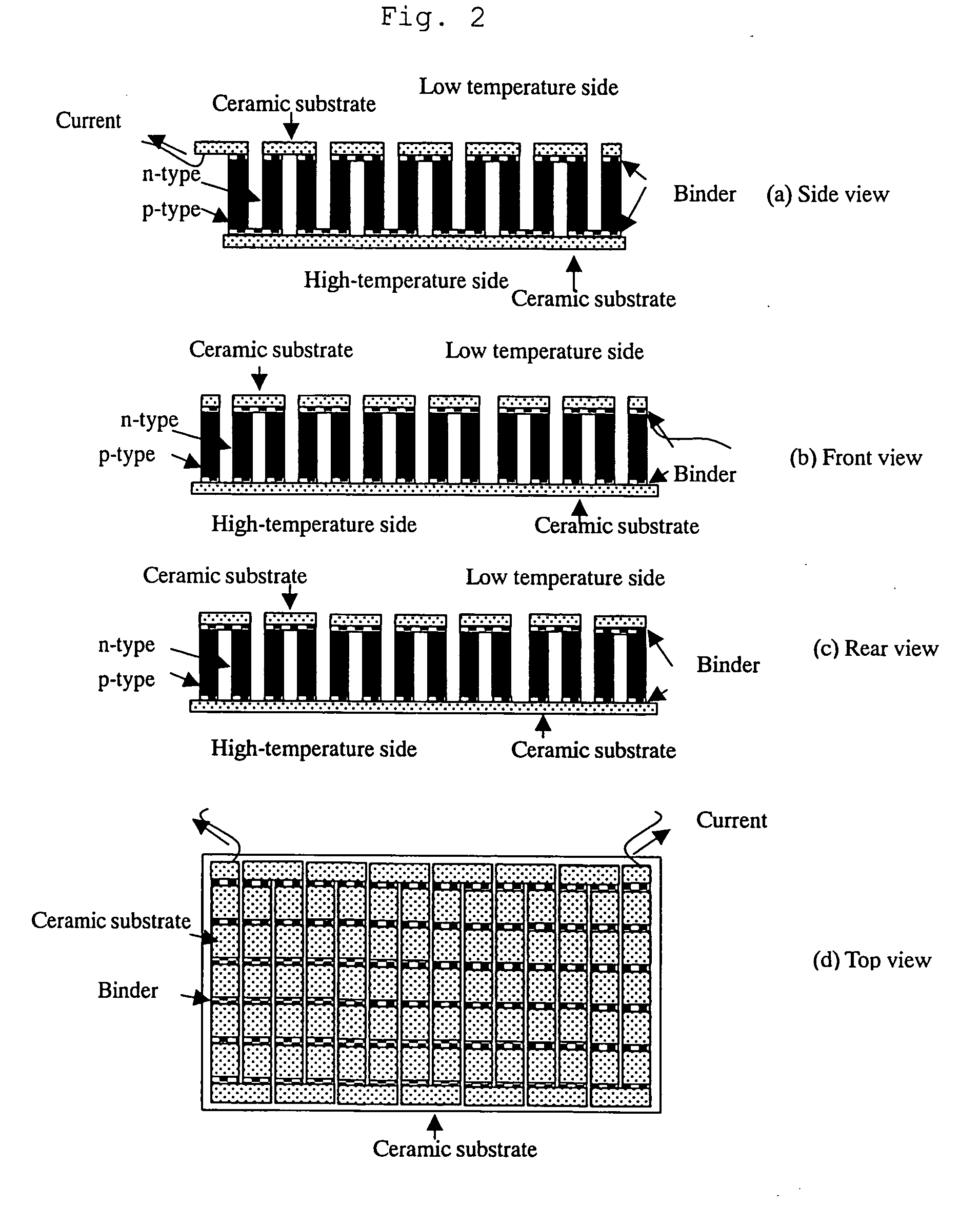

Thermoelectric semiconductor material, thermoelectric semiconductor element therefrom, thermoelectric module including thermoelectric semiconductor element and process for producing these

InactiveUS20060243314A1Increased junctionUniform deformation rateThermoelectric device manufacture/treatmentThermoelectric device junction materialsSemiconductor materialsCrystal orientation

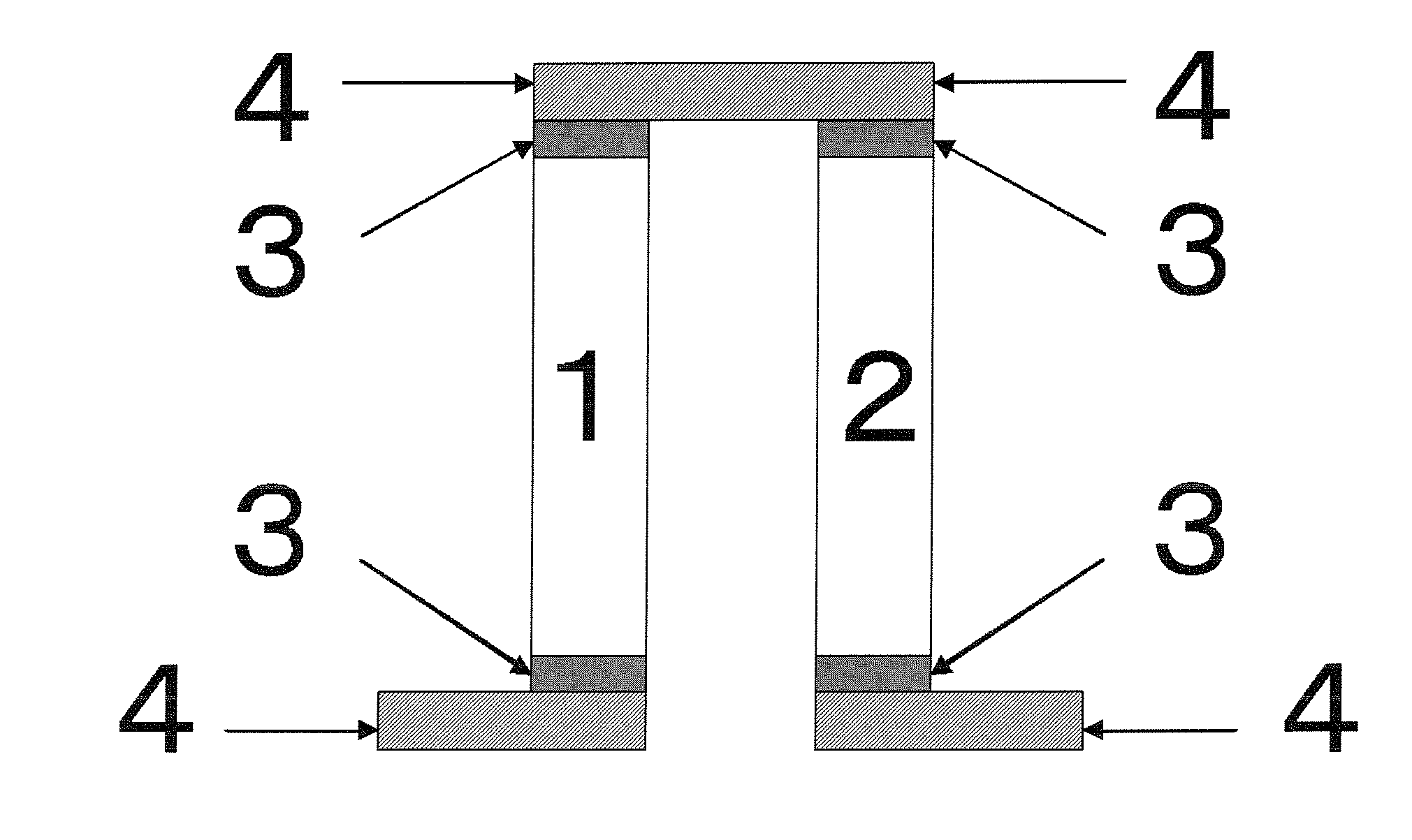

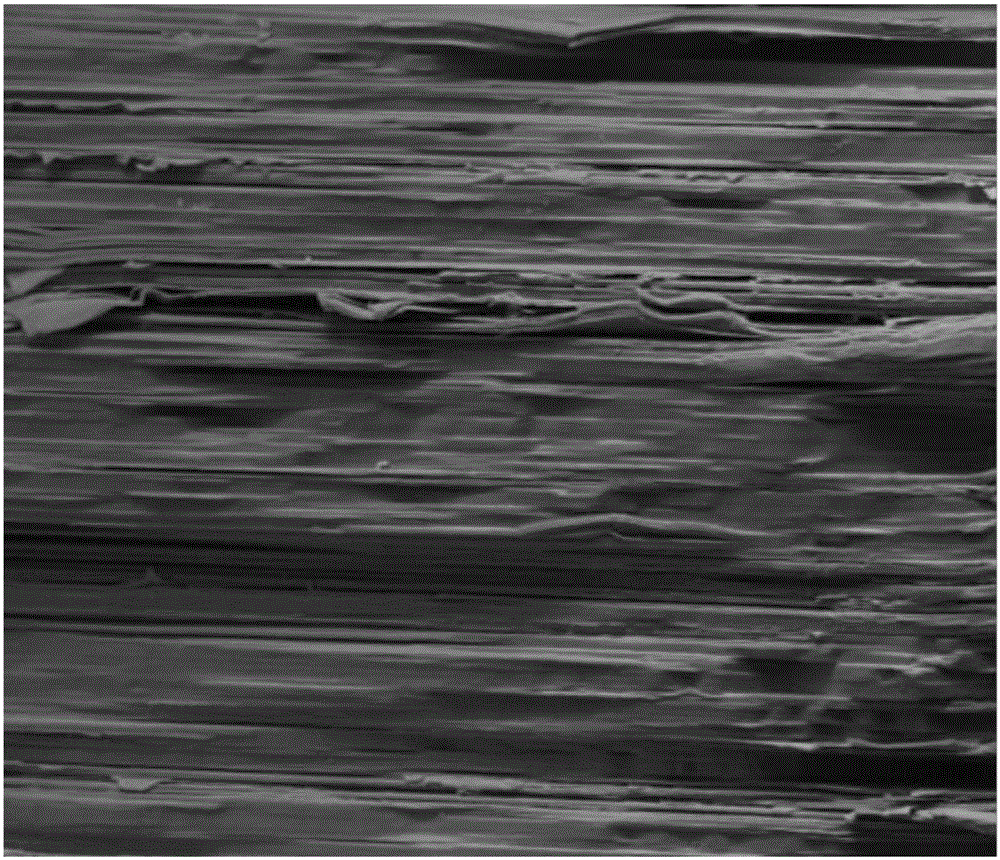

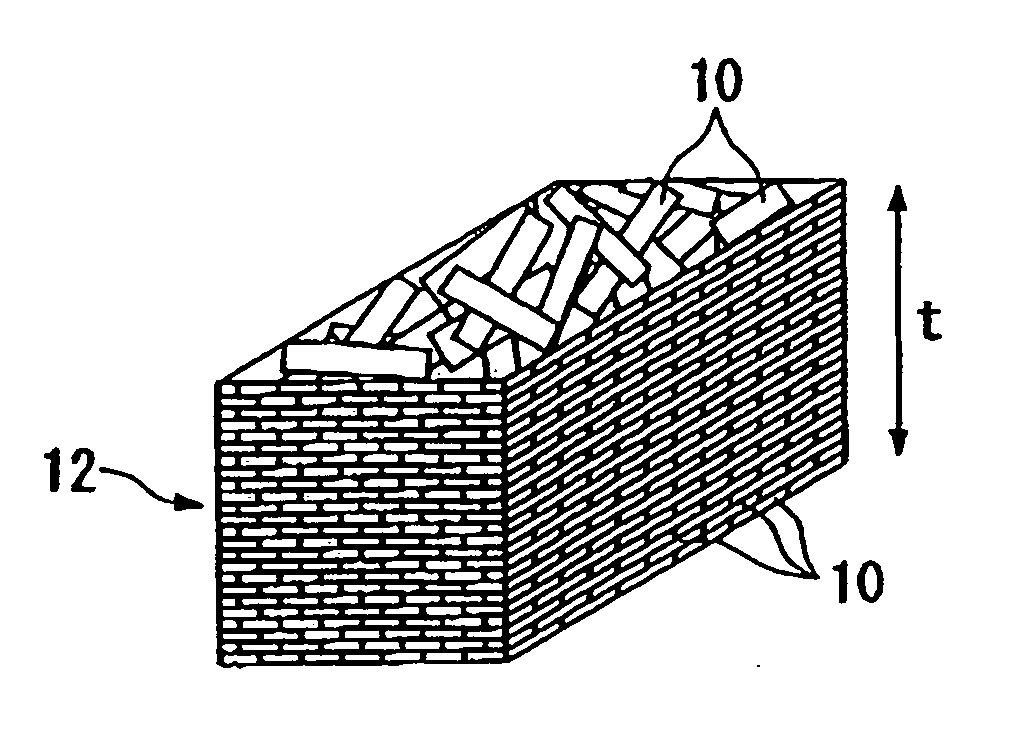

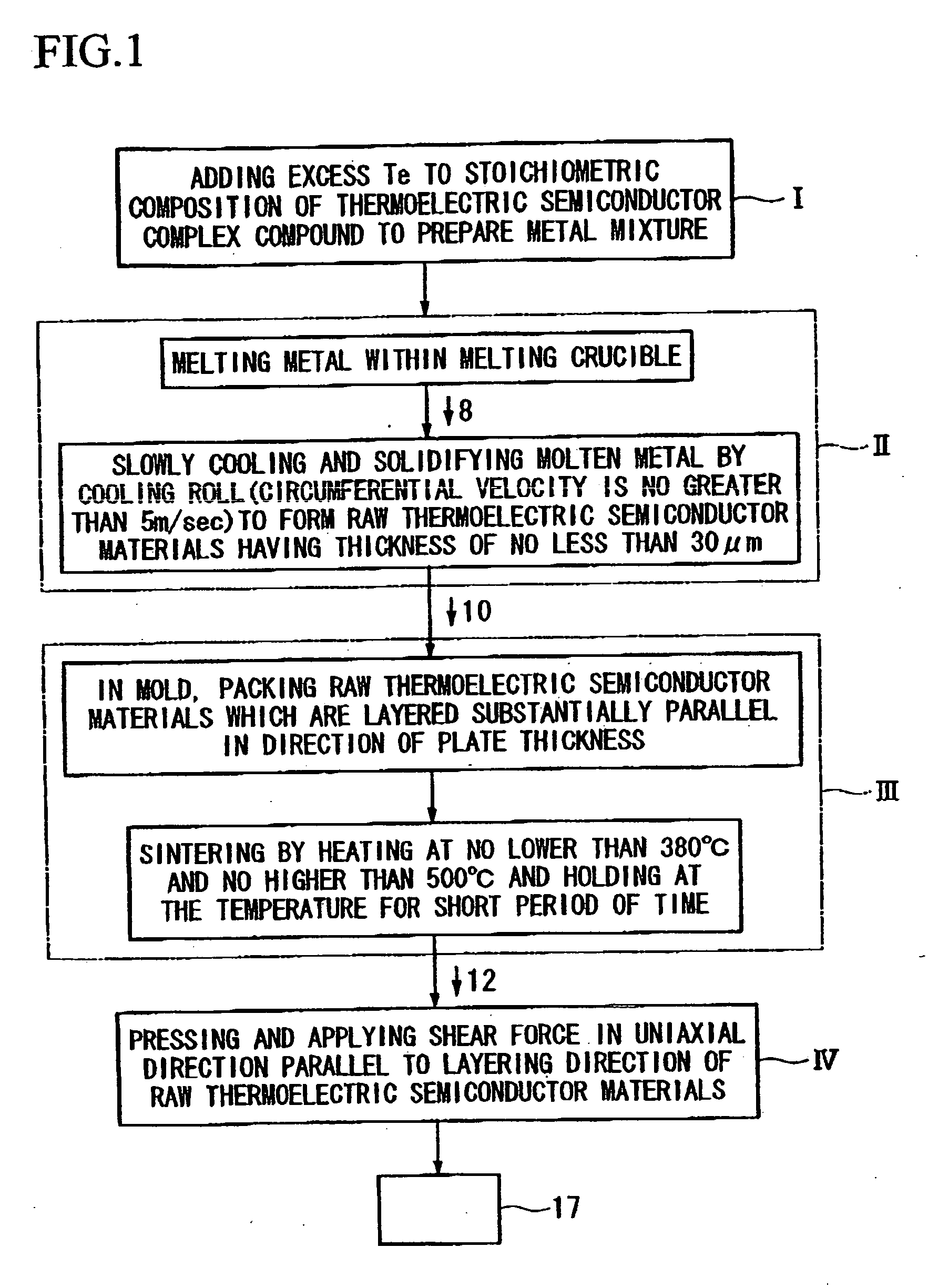

A metal mixture is prepared, in which an excess amount of Te is added to a (Bi—Sb)2Te3 based composition. After melting the metal mixture, the molten metal is solidified on a surface of a cooling roll of which the circumferential velocity is no higher than 5 m / sec, so as to have a thickness of no less than 30 μm. Thus, a plate shaped raw thermoelectric semiconductor materials 10 are manufactured, in which Te rich phases are microscopically dispersed in complex compound semiconductor phases, and extending directions of C face of most of crystal grains are uniformly oriented. The raw thermoelectric semiconductor materials 10 are layered in the direction of the plate thickness. And the layered body is solidified and formed to form a compact 12. After that, the compact 12 is plastically deformed in such a manner that a shear force is applied in a uniaxial direction that is approximately parallel to the main layering direction of the raw thermoelectric semiconductor materials 10. As a result, a thermoelectric semiconductor 17 having crystal orientation in which extending direction of C face and the don of c-axis of the hexagonal structure are approximately aligned. As a result, the crystalline orientation is improved, and the thermoelectric Figure-of-Merit is increased.

Owner:IHI CORP

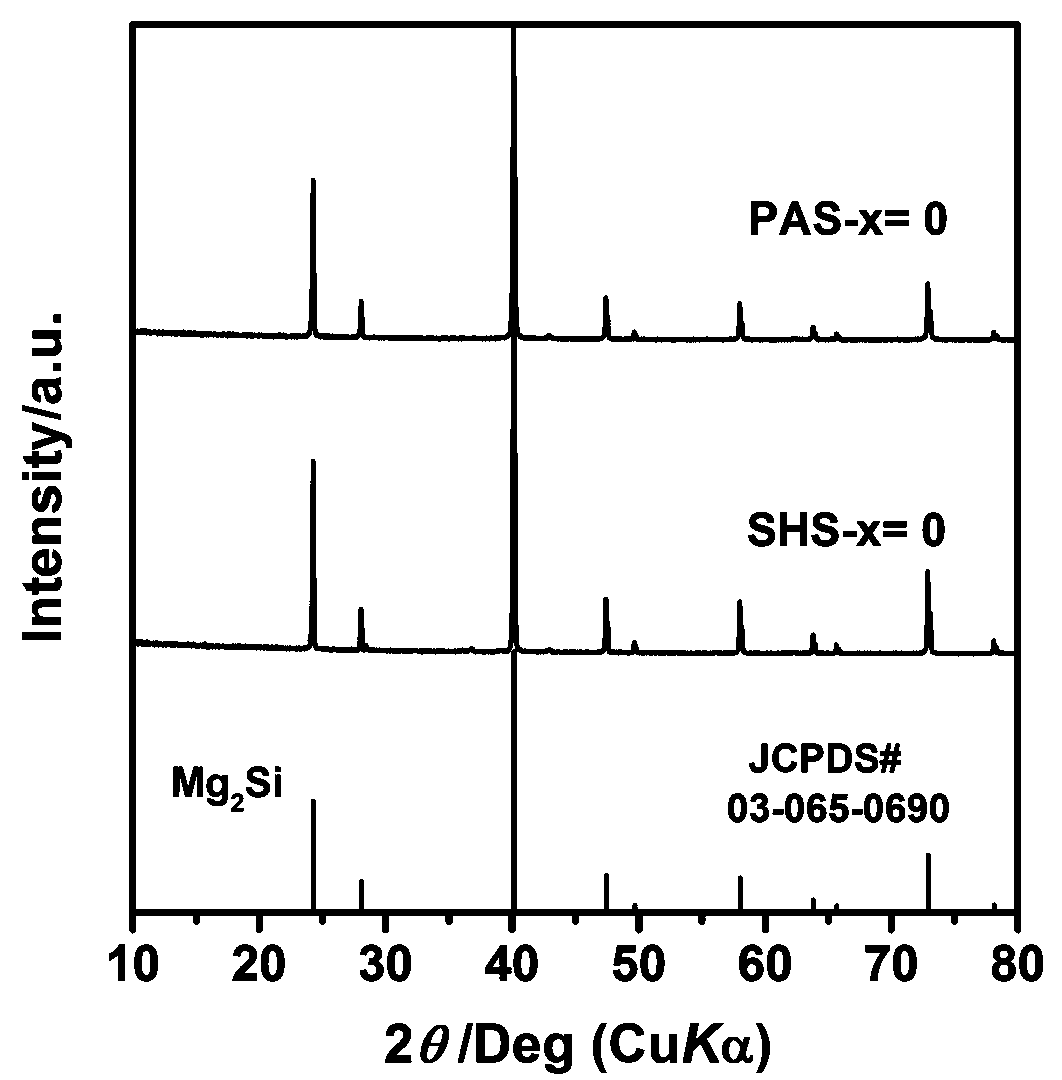

Method for quickly preparing high-performance Mg2Si-based thermoelectric material

ActiveCN103436723AQuick responseGood repeatabilityThermoelectric device junction materialsMetallurgyPlasma activated sintering

The invention relates to a method for quickly preparing a high-performance Mg2Si-based thermoelectric material. The method comprises the following steps: (1) weighing according to the stoichiometric proportion of all atoms in Mg2 (1+0.02) Si (1-x) Sbx (0<=x<=0.025), then grinding and uniformly mixing the atoms, and pressing the uniformly mixed powder into a block; (2) subjecting the block obtained in the step (1) to the self-propagating reaction, and then naturally cooling to obtain a single-phase Mg2 (1+0.02) Si (1-x) Sbx compound; (3) grinding the obtained product into powder, and performing discharge plasma activated sintering to obtain the high-performance Mg2Si-based thermoelectric material. The method provided by the invention has the advantages of quickness in reaction, simple process, high efficiency, energy saving, good repeatability and the like, the whole preparation process can be completed within 0.5 h, and the thermoelectric figure of merit ZT of the obtained block can reach 0.73 at 875K.

Owner:WUHAN UNIV OF TECH

Efficient thermoelectric device

InactiveUS20070235070A1Increasing thermoelectric figureImprove efficiencyThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentMetallic materialsFigure of merit

A high efficiency thermo electric device comprising a multi nanolayer structure of alternating insulator and insulator / metal material that is irradiated across the plane of the layer structure with ionizing radiation. The ionizing radiation produces nanocrystals in the layered structure that increase the electrical conductivity and decrease the thermal conductivity thereby increasing the thermoelectric figure of merit. Figures of merit as high as 2.5 have been achieved using layers of co-deposited gold and silicon dioxide interspersed with layers of silicon dioxide. The gold to silicon dioxide ratio was 0.04. 5 MeV silicon ions were used to irradiate the structure. Other metals and insulators may be substituted. Other ionizing radiation sources may be used. The structure tolerates a wide range of metal to insulator ratio.

Owner:AAMU RES INST

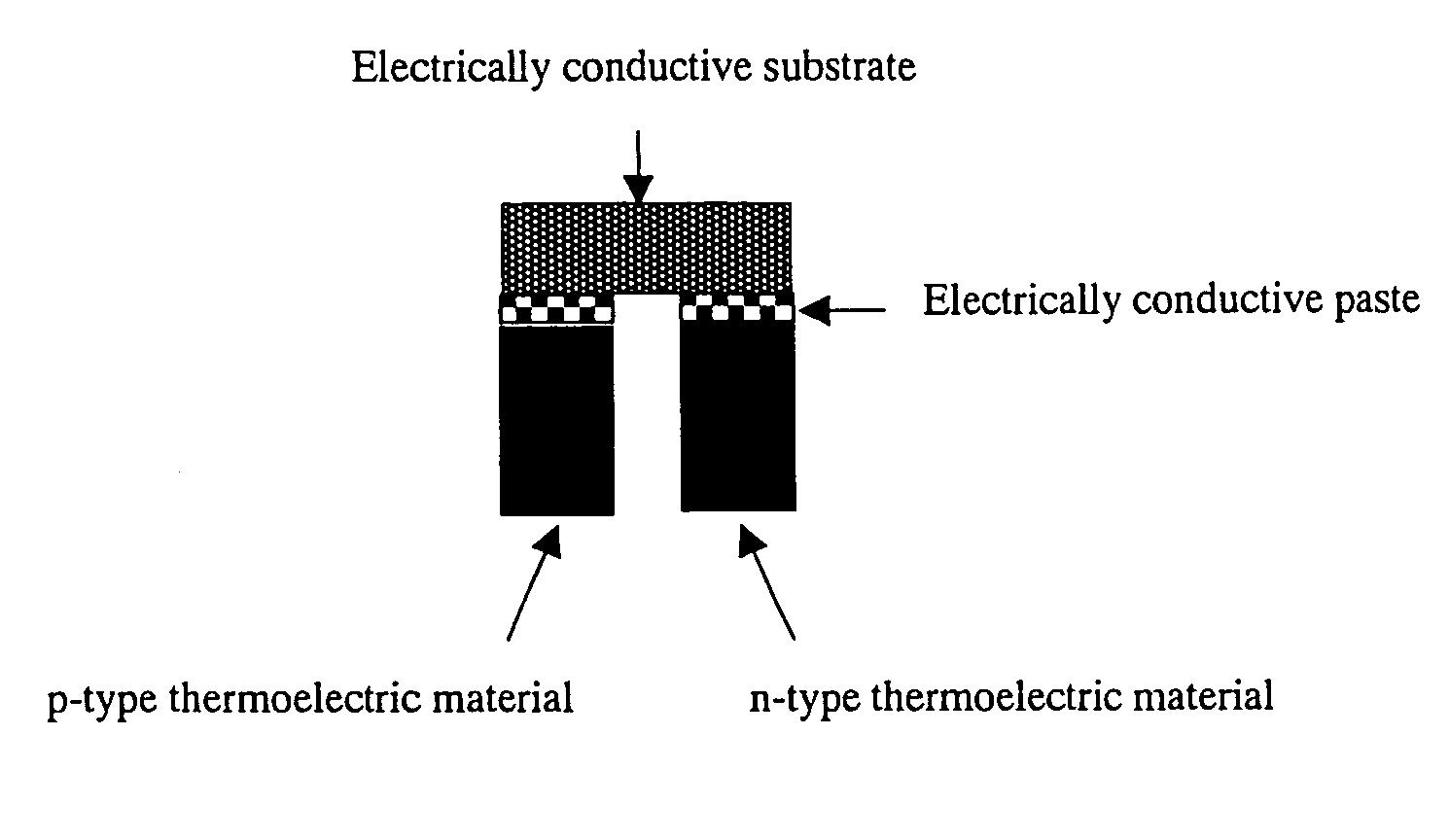

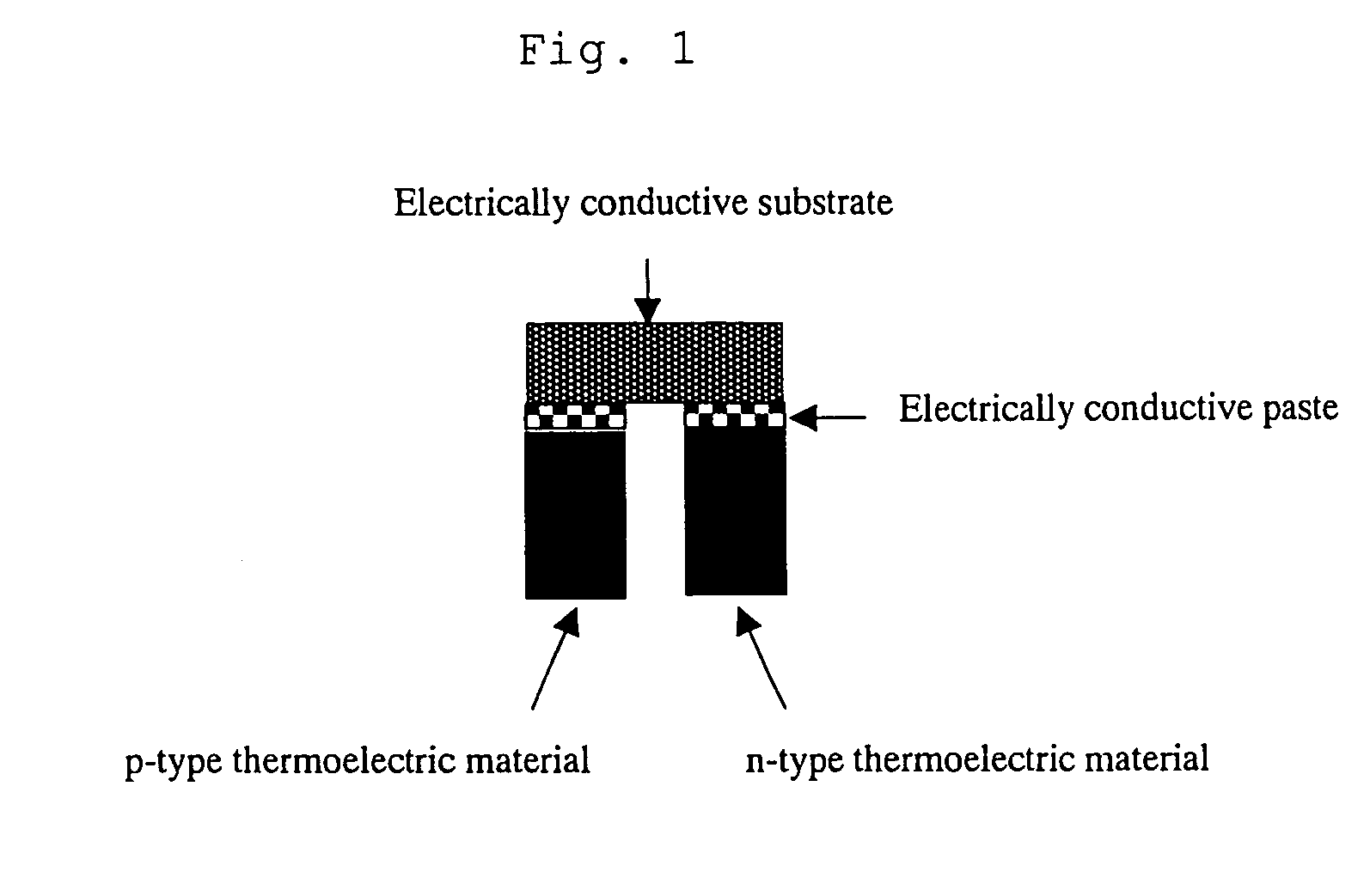

Conductive paste for connecting thermoelectric conversion material

InactiveUS20070125412A1Low electric resistanceHardly performance deteriorationThermoelectric device manufacture/treatmentOxide conductorsElectrically conductiveOxide

The present invention provides an electrically conductive paste for connecting thermoelectric materials, the paste comprising a specific powdery oxide and at least one powdery electrically conductive metal selected from the group consisting of gold, silver, platinum, and alloys containing at least one of these metals. By connecting a thermoelectric material to an electrically conductive substrate with the electrically conductive paste of the invention, a suitable electroconductivity is imparted to the connecting portion of the thermoelectric element. Further, the thermal expansion coefficient of the connecting portion can be made close to that of the thermoelectric material. Therefore, even when high-temperature power generation is repeated, separation at the connecting portion is prevented and a favorable thermoelectric performance can be maintained.

Owner:NAT INST OF ADVANCED IND SCI & TECH

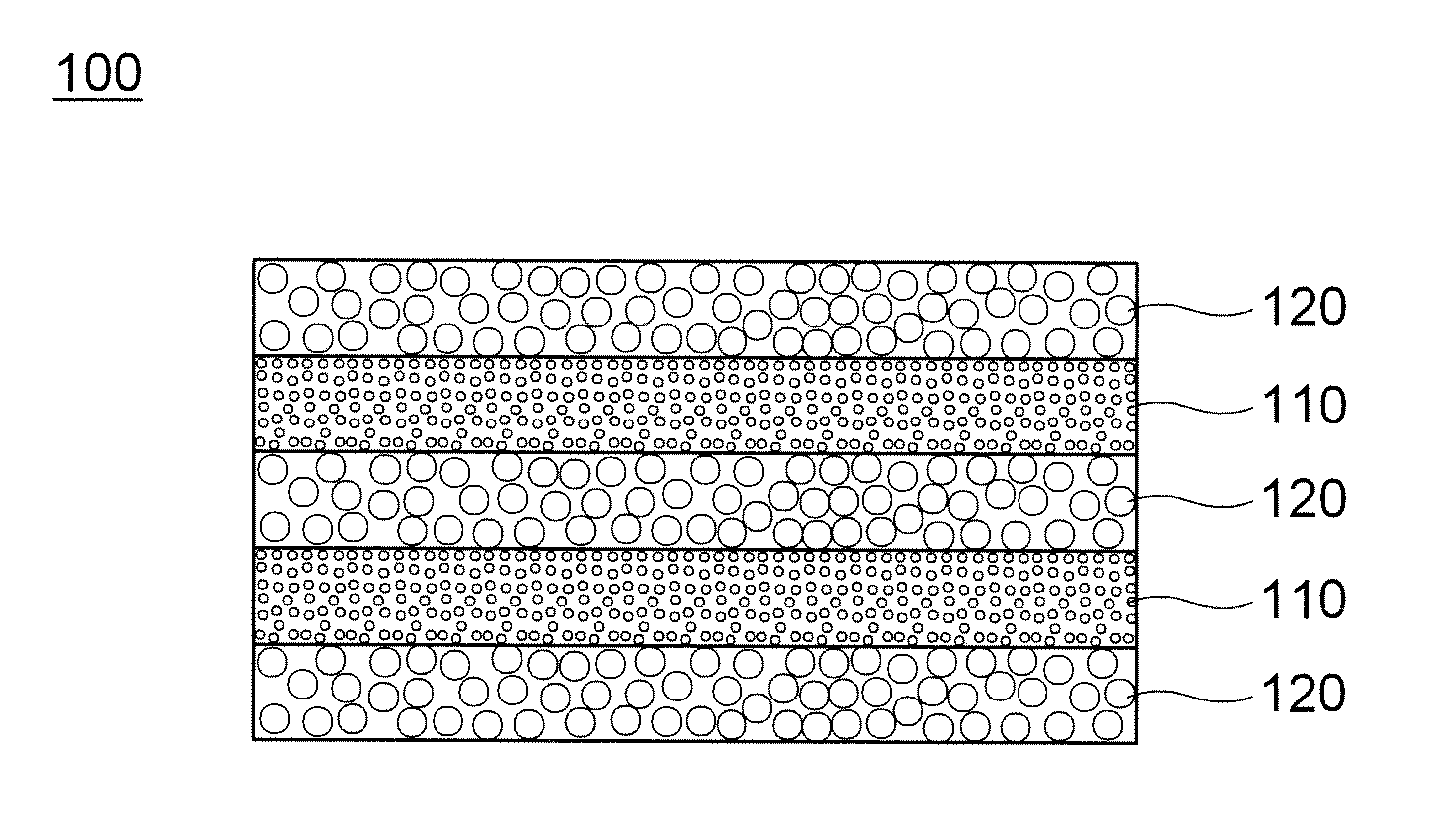

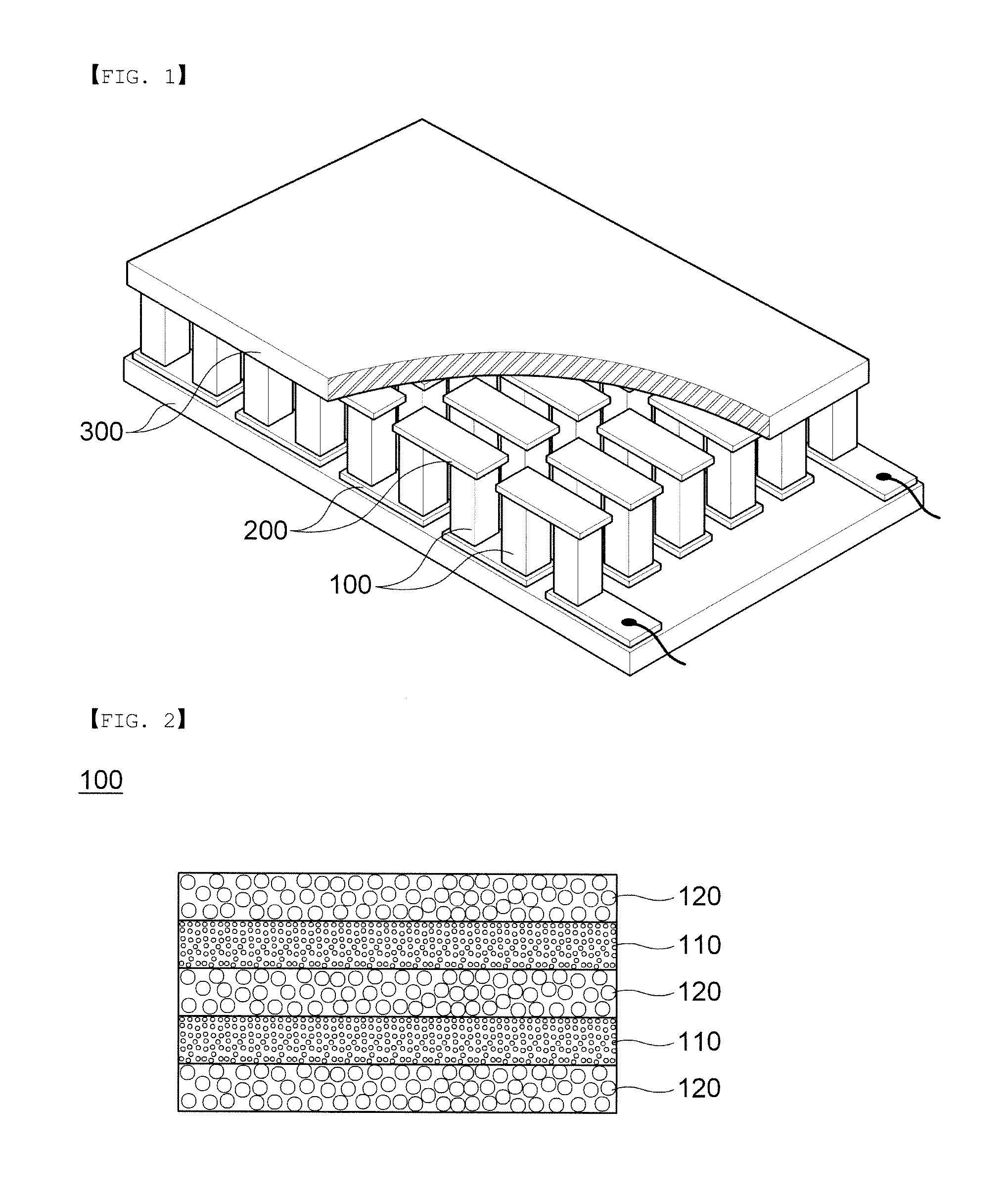

Thermoelectric element and thermoelectric module including the same

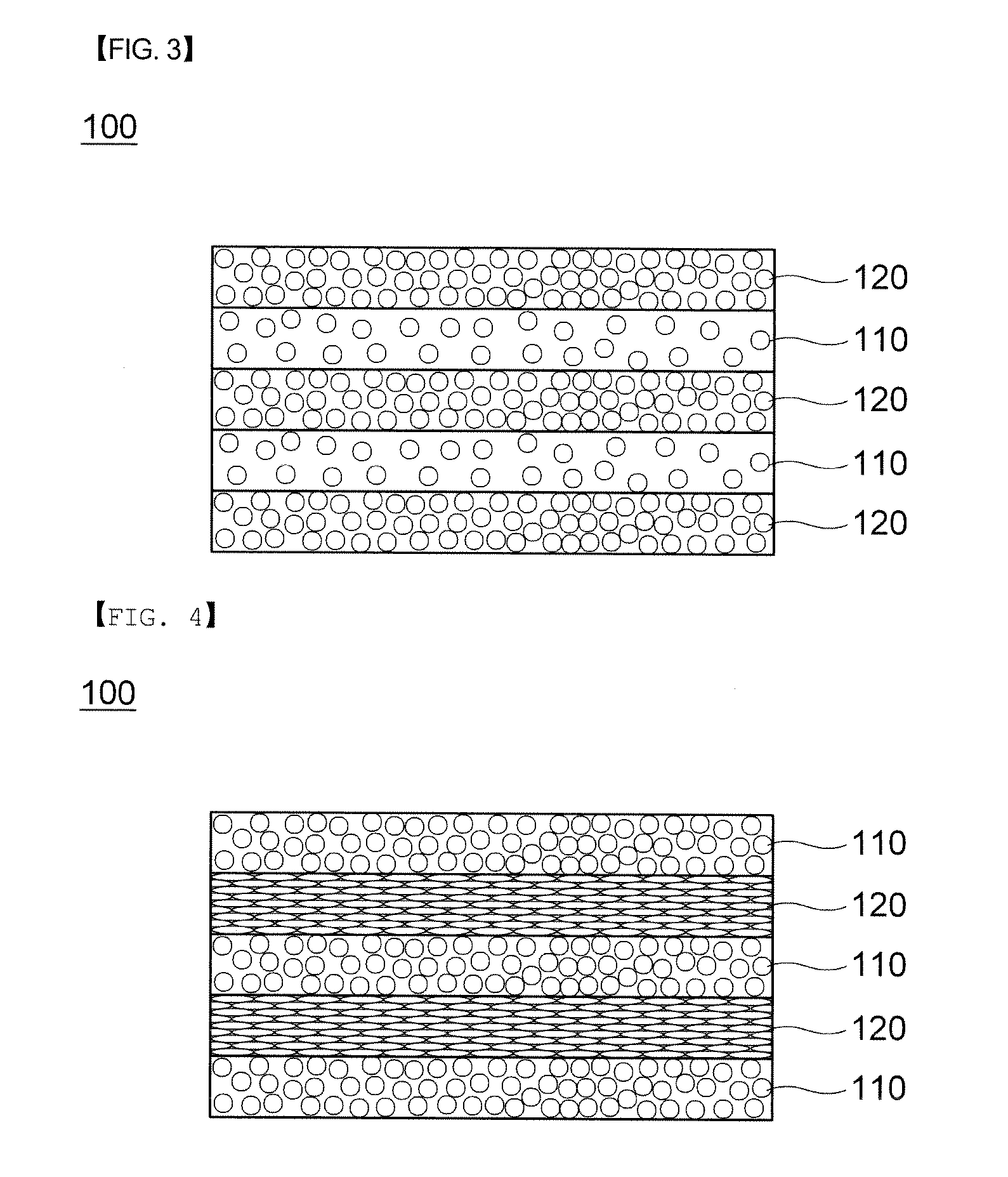

InactiveUS20120145209A1Improving thermoelectric figureImproving the thermoelectric figure of meritsThermoelectric device detailsThermoelectric device junction materialsMetallic materialsOptoelectronics

Disclosed herein are a thermoelectric element and a thermoelectric module including the same. The thermoelectric element is manufactured by differently setting diameter, density, and flatness, or laminating a plurality of sheets formed by mixing of metal or non-metal materials. Thus, thermoelectric figure of merit is improved in the thermoelectric module. Also, thermoelectric figure of merit, reliability, and efficiency of manufacturing process are improved in the thermoelectric module.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

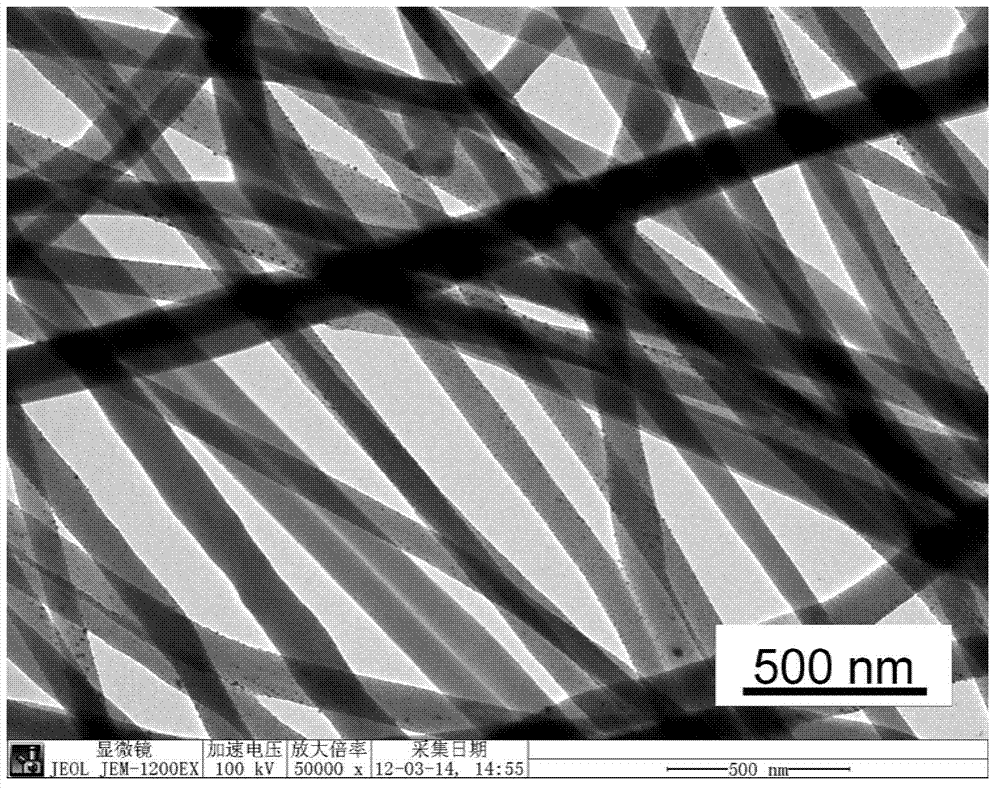

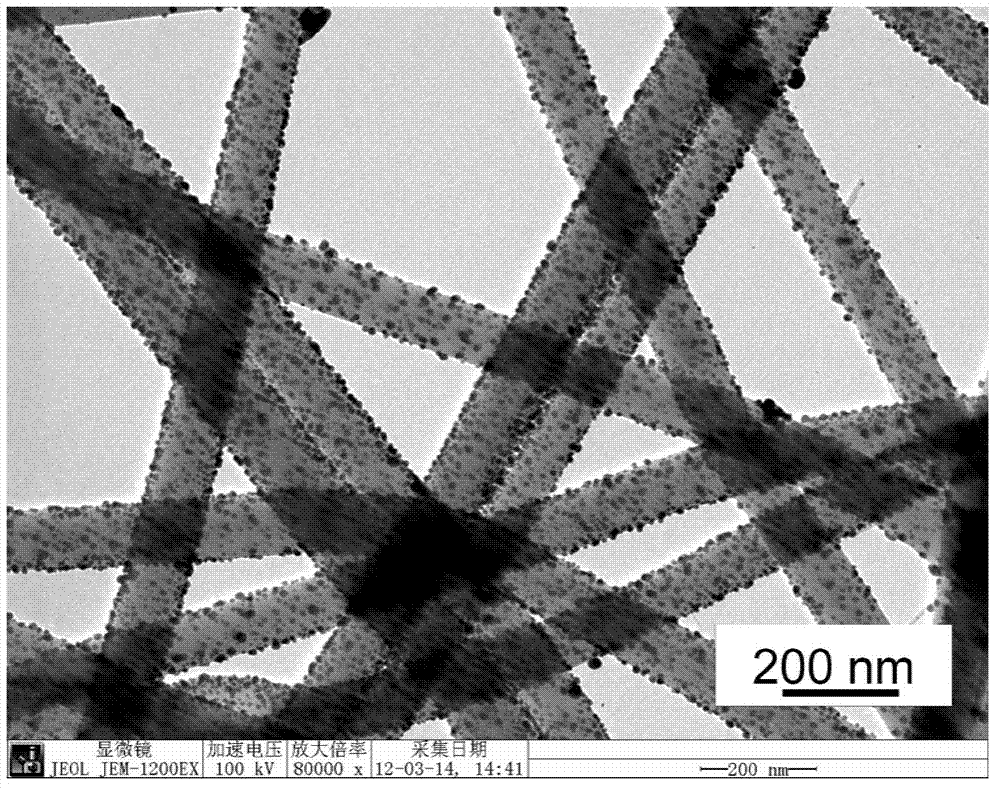

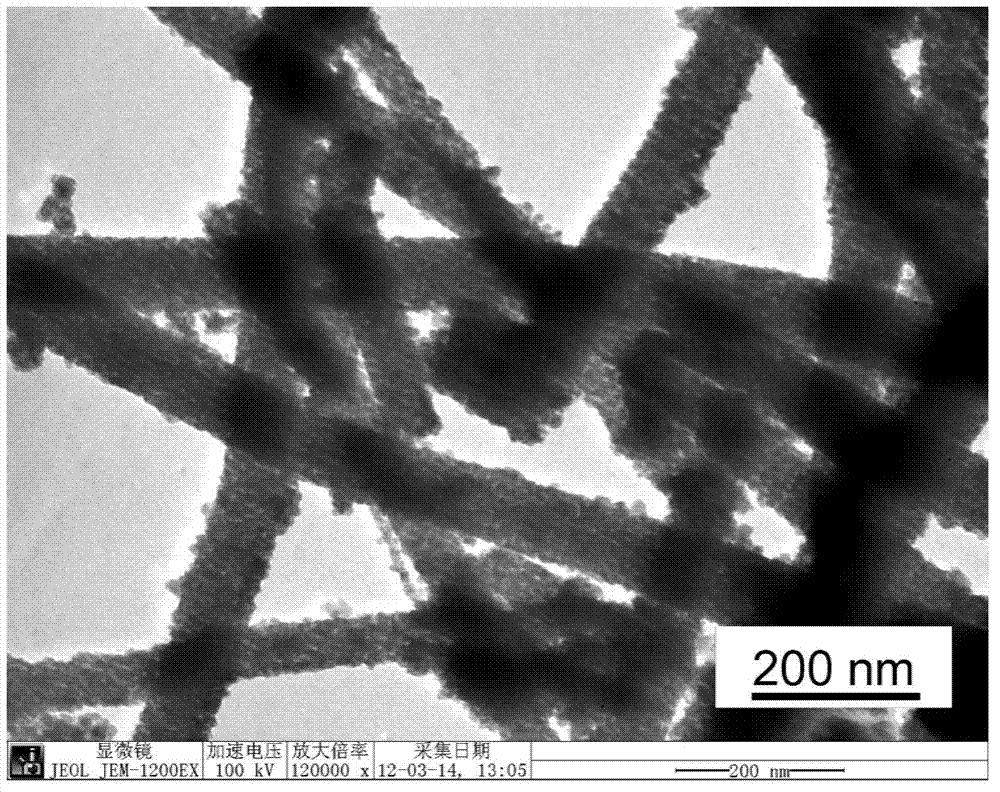

Nanofiber based flexible high performance thermoelectric material and preparation method thereof

InactiveCN102790166AFlexibleImprove performanceMaterial nanotechnologyThermoelectric device manufacture/treatmentVulcanizationOxidation reduction

The invention belongs to the technical field of a thermoelectric conversion material of novel energy, and in particular relates to a flexible semiconductor nanostructural material with high thermoelectric figure of merit based on electrostatic spun nanofiber and a preparation method of the material. The preparation method comprises the steps of taking high polymer and silver nitrate compound nanofiber as a substrate, depositing a silver shell on the surface of the fiber by an electroless method after reducing silver nitrate, and carrying oxidation reduction in situ and vulcanization to obtain a high polymer / silver sulfide nuclear shell nanofiber material. The nanofiber based thermoelectric material prepared by the method has ultrahigh Seebeck coefficient and thermoelectric figure of merit as well as good flexibility, which cannot be compared with conventional thermoelectric materials. For example, the Seebeck coefficient of polyacrylonitrile / silver sulfide nuclear shell nanofiber material reaches more than 103, the maximum thermoelectric figure of merit reaches 0.9 at temperature of 340K, and the original flexibility of the polyacrylonitrile nanofiber is maintained.

Owner:JILIN UNIV

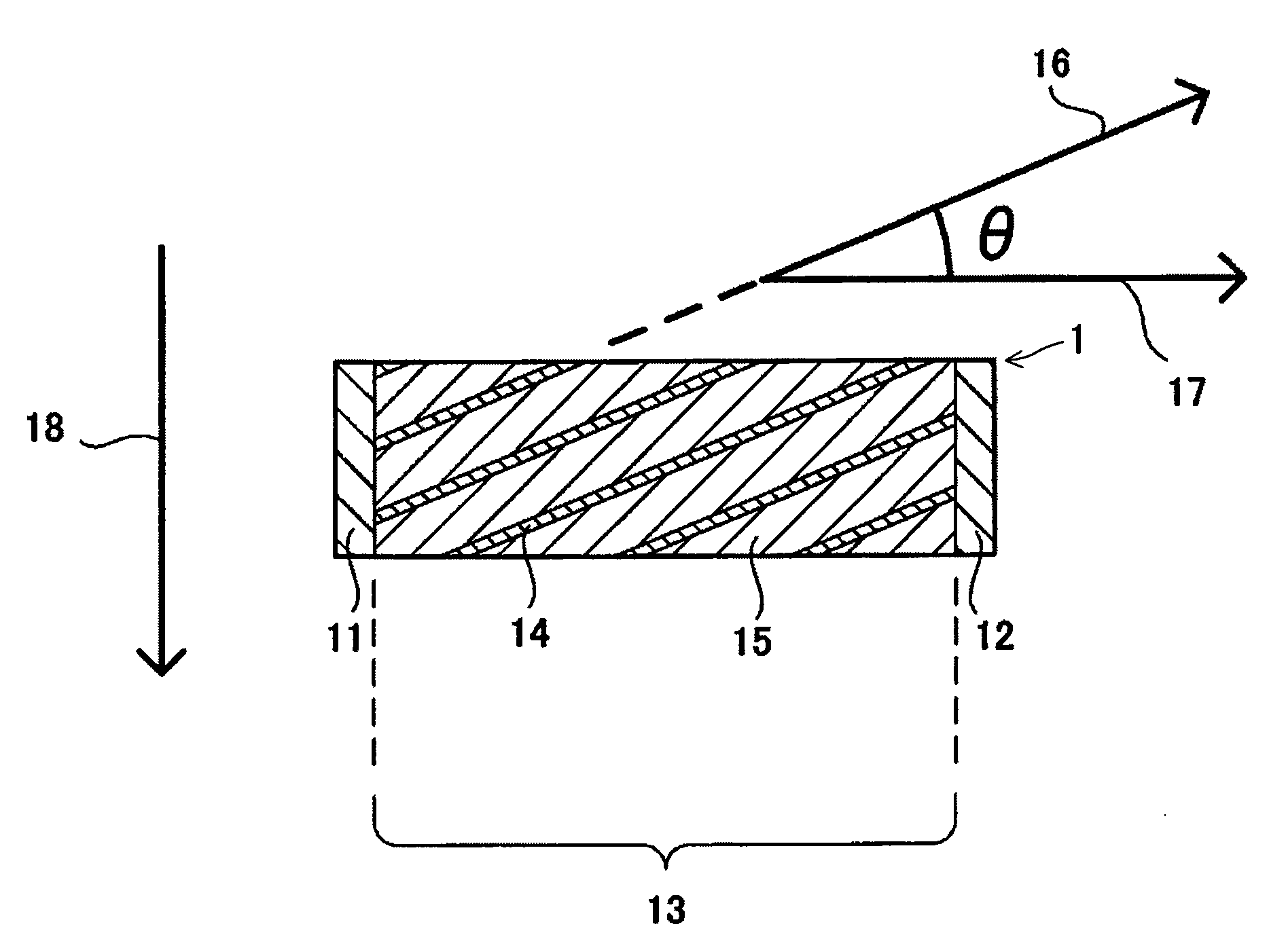

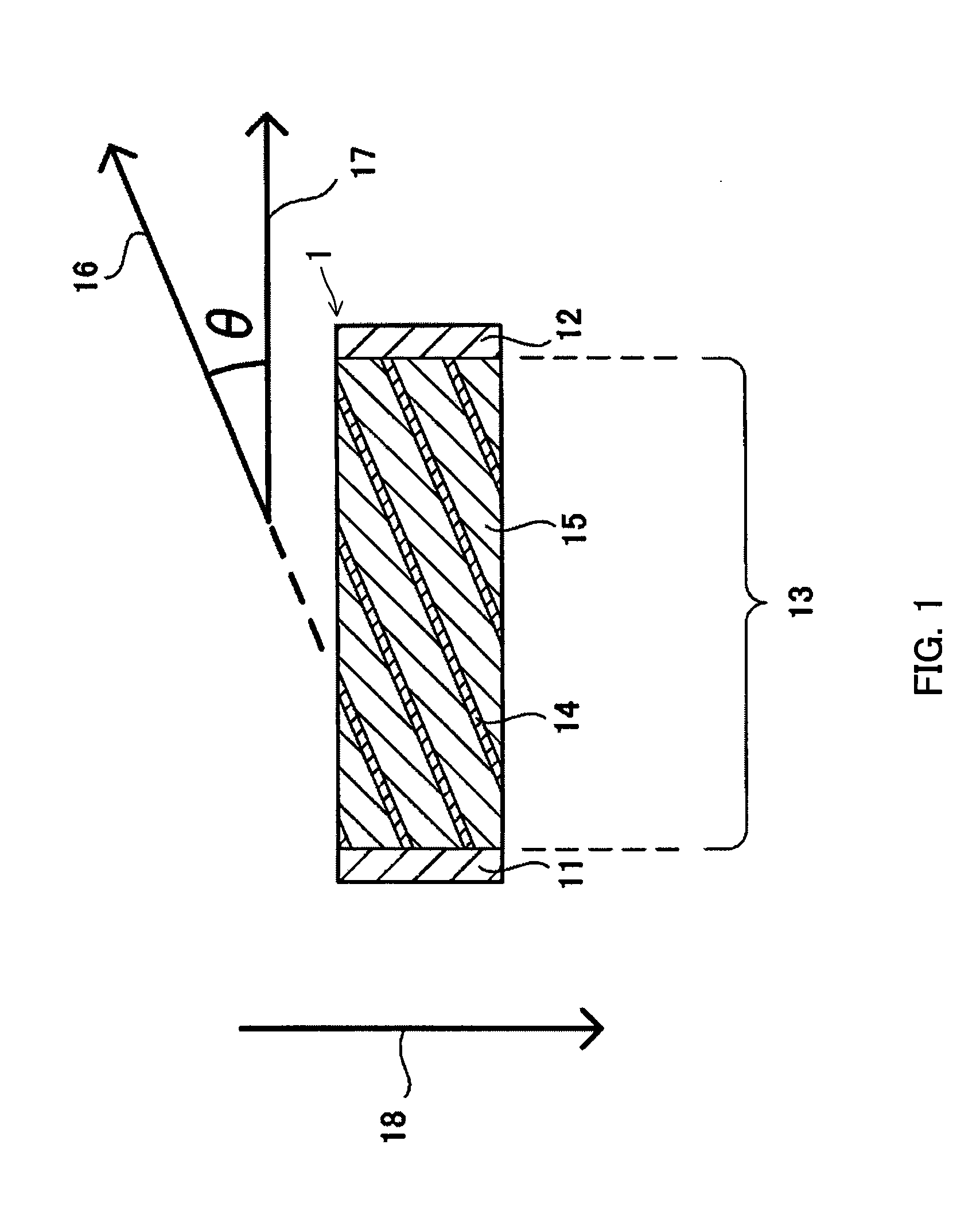

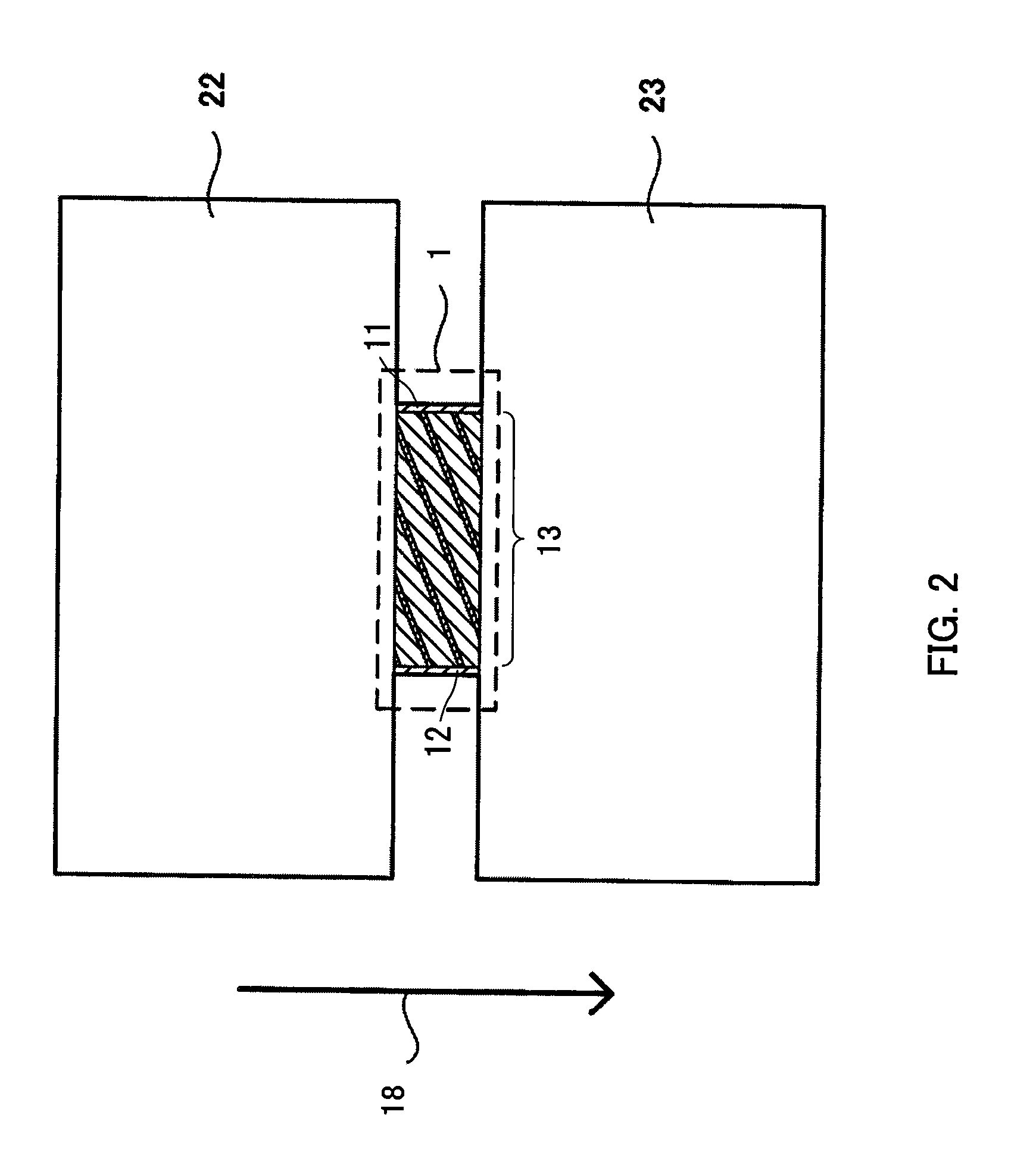

Power generation method using thermoelectric element, thermoelectric element and fabrication method thereof, and thermoelectric device

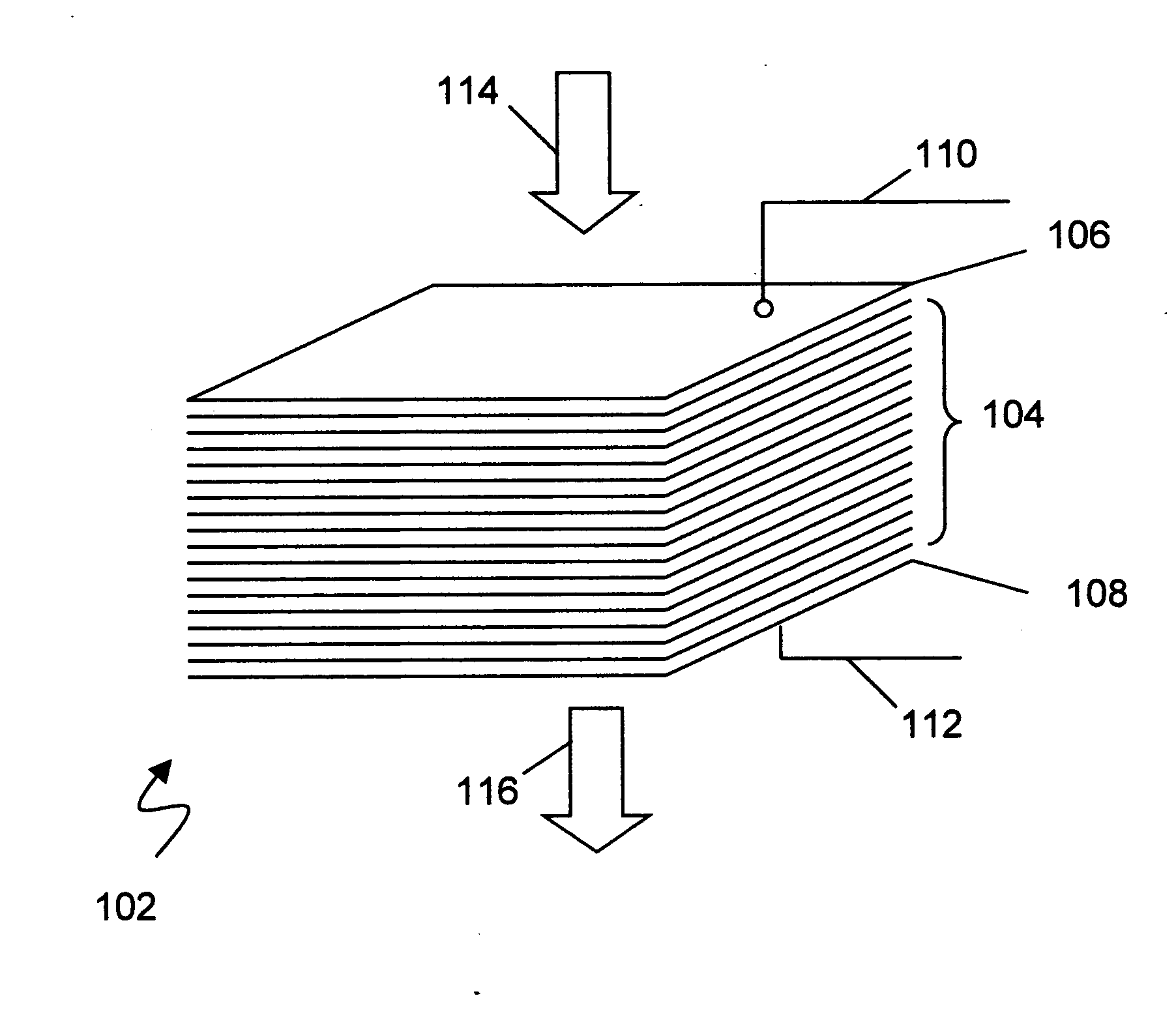

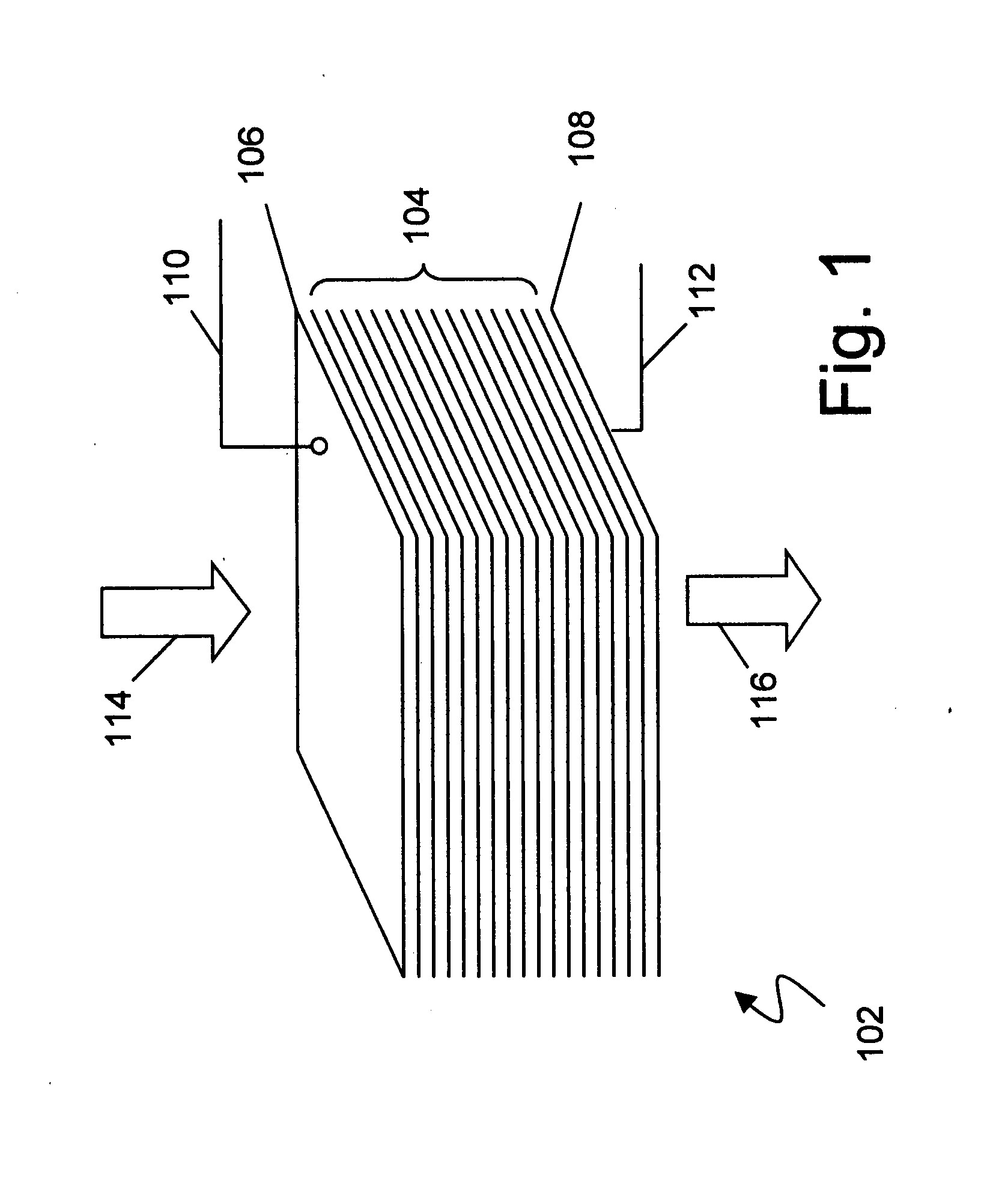

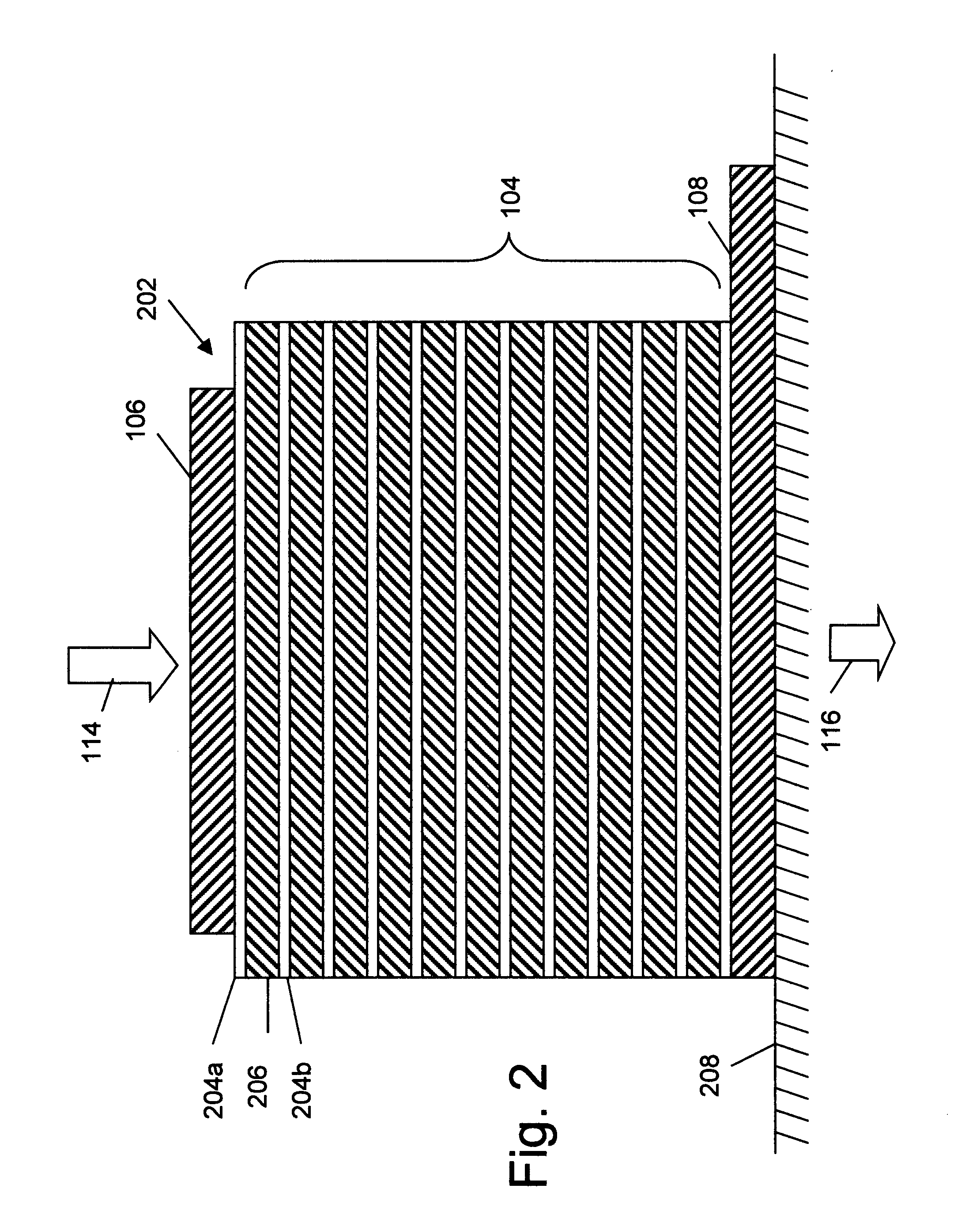

ActiveUS20080173343A1Improve energy conversion efficiencyImprove thermoelectric performanceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentPotential differenceTemperature difference

The invention provides a power generation method using a thermoelectric element, a thermoelectric element, and a thermoelectric device that excel in thermoelectric performance and are applicable to a wider range of applications over conventional counterparts. The element includes a first electrode and a second electrode that are disposed to oppose each other, and a laminate interposed between the first and second electrodes and electrically connected to both of the electrodes. The laminate has a structure in which a Bi layer and a metal layer made of a metal other than Bi are alternately layered, and the Bi layer and the metal layer having layer surfaces that are slanted with respect to a direction in which the first and second electrodes oppose each other. The element generates a potential difference between the electrodes by a temperature difference created along a direction perpendicular to the opposing direction of the first and second electrodes in the element. The power generation method and the thermoelectric device use this element.

Owner:PANASONIC CORP

Thermoelectric figure of merit enhancement by modification of the electronic density of states

InactiveUS20110248209A1Heat-exchange elementsSelenium/tellurium compounds with other elementsDopantChemical compound

A thermoelectric material and a method of using a thermoelectric material is provided. The thermoelectric material can include at least one compound. For example, the at least one compound may be a Group IV-VI compound such as lead telluride. The at least one compound may further include one or more dopants such as sodium, potassium, and thallium. The method of using a thermoelectric material can include exposing at least one portion of the at least one compound to a temperature greater than about 700 K.

Owner:THE OHIO STATES UNIV +1

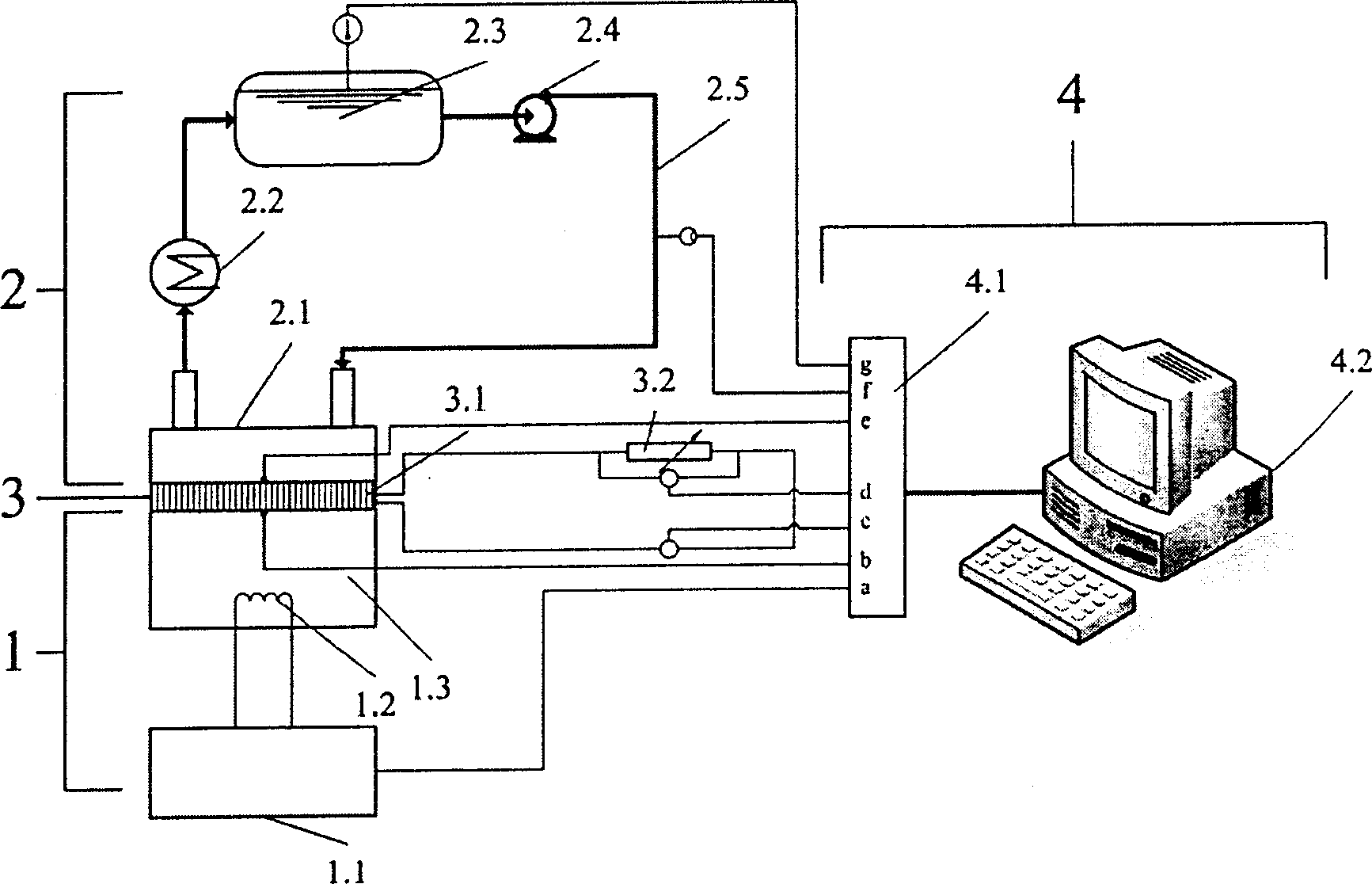

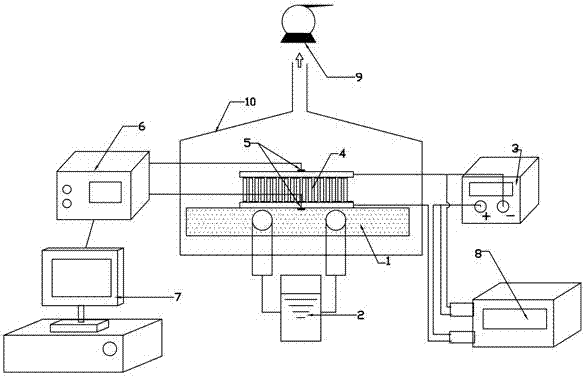

Detecting system of therme generator thermoelectric property

InactiveCN1821799AStructural/machines measurementDynamo-electric machine testingLiquid temperatureControl signal

This invention relates to a system for testing the thermoelectric performance of a temperature difference generator characterizing in including an electric heating source unit closing to the hot face of the generator to heat the hot face, a loop hot trap unit of circulation cooling water closing to the cold face to reduce the temperature of the cold face of the generator, collecting temperatures of the hot and cold faces of the temperature difference generator, its output current and voltage, the current flow and liquid temperature of the circulation cold water loop hot trap unit to be processed and analyzed to output a control signal and send it to the data collection and process unit of the hot source unit.

Owner:TSINGHUA UNIV

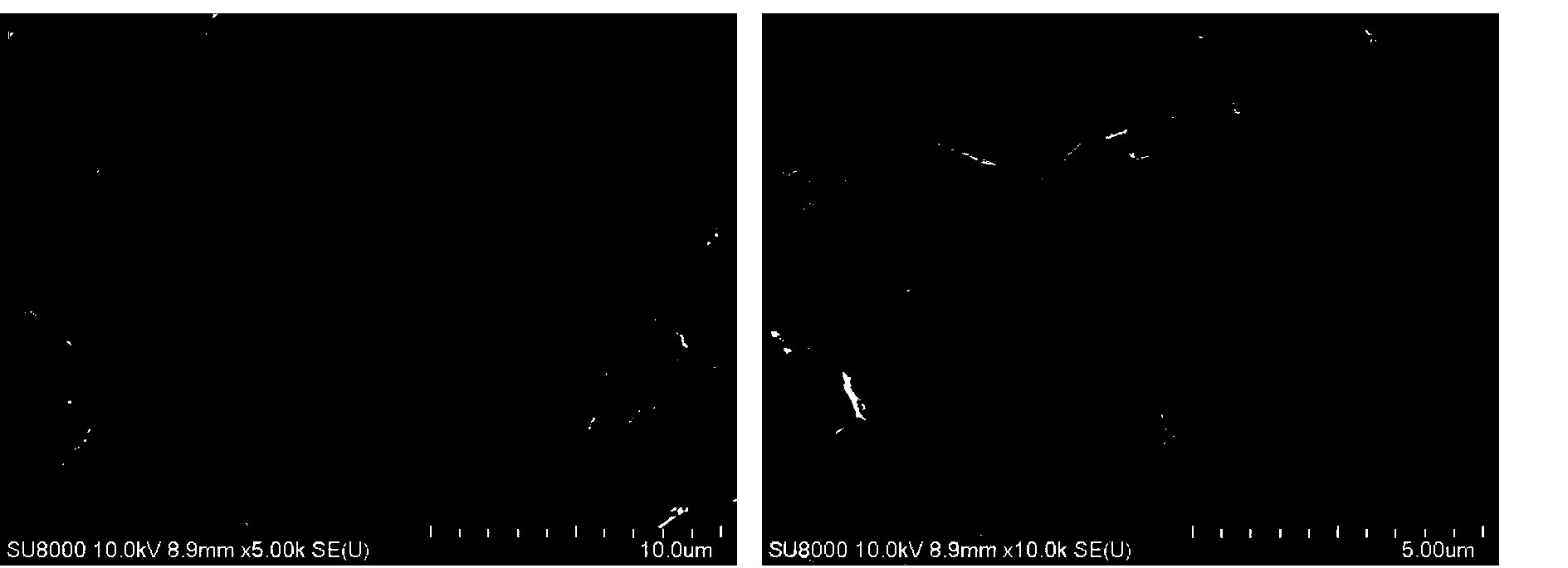

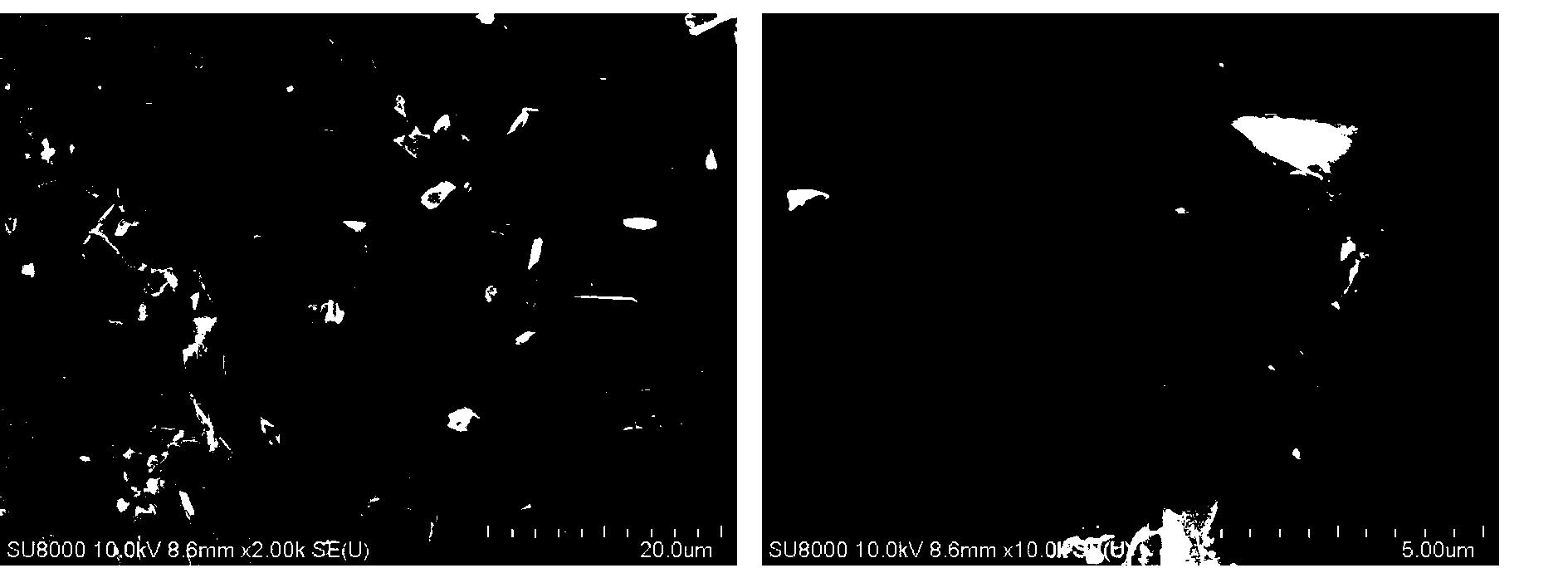

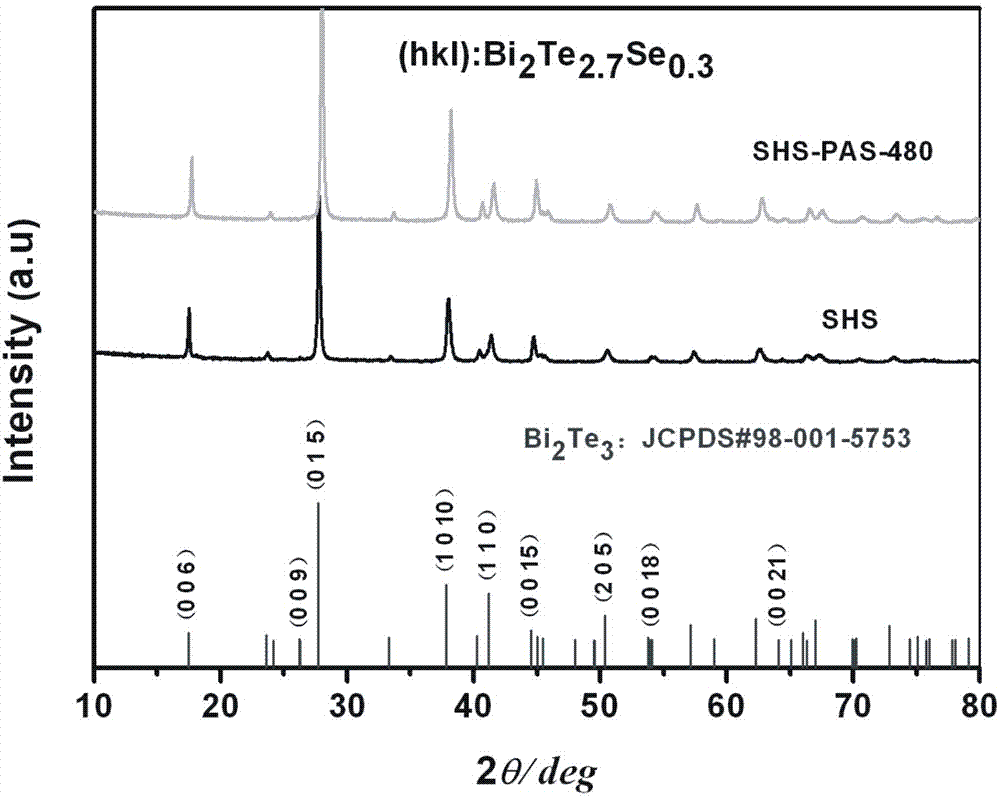

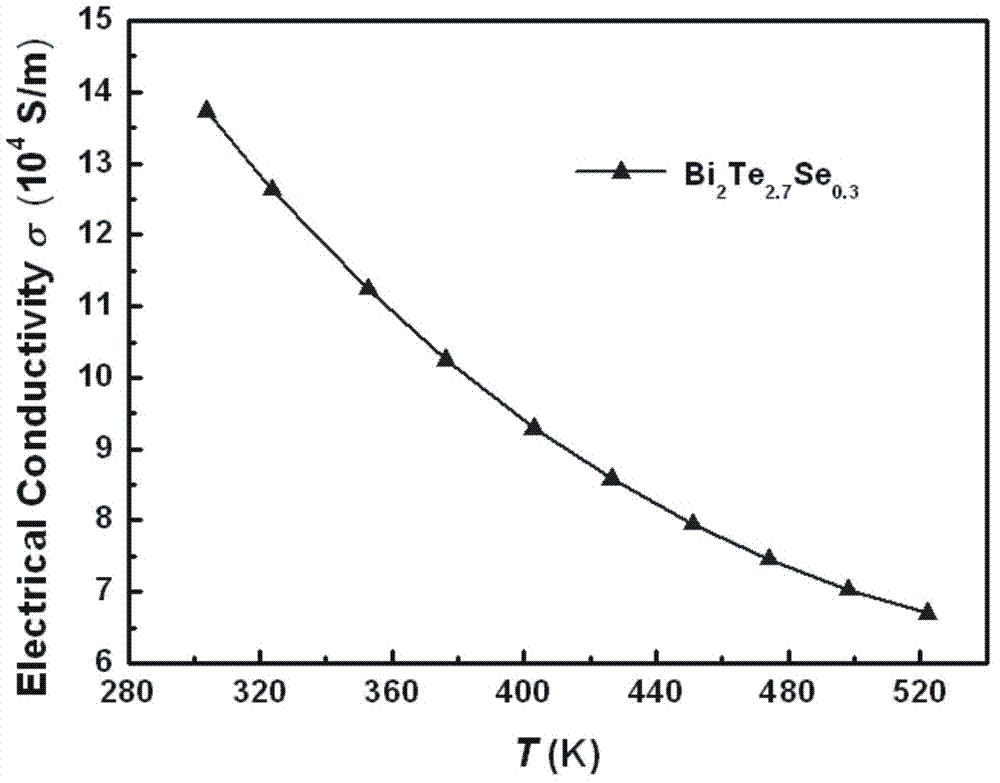

Method for fast manufacturing n-type bismuth telluride based high-performance thermoelectric materials

ActiveCN103928604AShort preparation timeSimple processThermoelectric device manufacture/treatmentThermoelectric device junction materialsMetallurgyBismuth telluride

The invention provides a method for fast manufacturing n-type bismuth telluride based high-performance thermoelectric materials. The method specifically comprises the steps that 1), Bi powder, Te powder and Se powder are weighed according to the stoichiometric ratio of all elements in Bi2Te3-xSex, 0=<x<=3, and the Bi powder, the Te powder and the Se powder are evenly mixed and pressed to be blocks; 2), a self-propagating reaction is generated on the blocks in the step 1), cooling is carried out after the reaction is completed, and a single-phase Bi2Te3-xSex compound is obtained; 3), the single-phase Bi2Te3-xSex compound obtained in the step 2) is ground to be powder, then plasma activation sintering is carried out, and the high-performance Bi2Te3-xSex thermoelectric materials are obtained. The technology with self-propagating combustion synthesis combined with plasma activation sintering is adopted, the n-type bismuth telluride block thermoelectric materials with the thermoelectric optimal value zT reaching 0.95 within 426 K are manufactured within 20 min, and the advantages of being short in manufacturing time, simple in technology, high in thermoelectric performance of the materials and the like are achieved.

Owner:武汉新赛尔科技有限公司

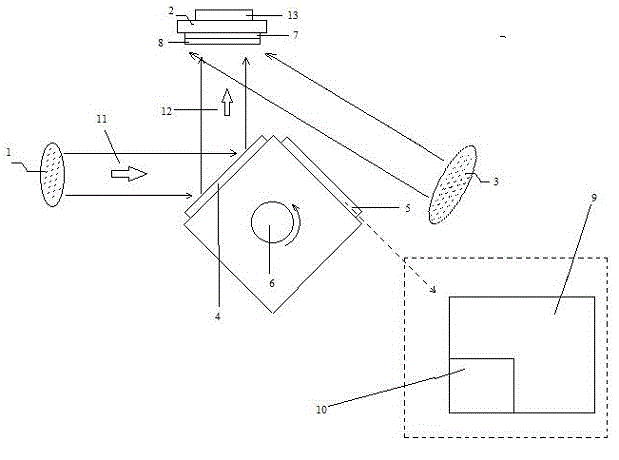

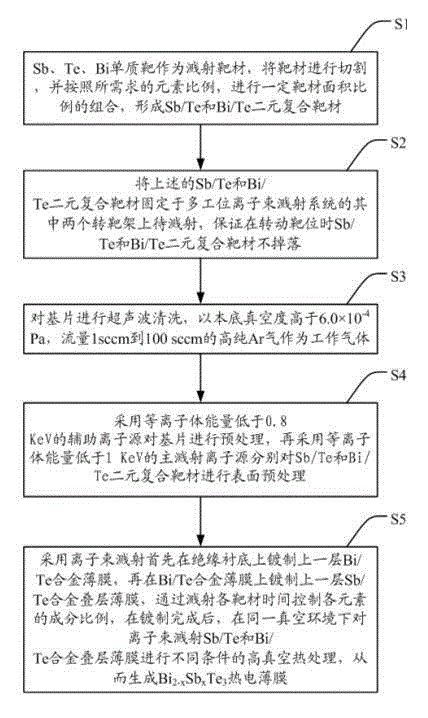

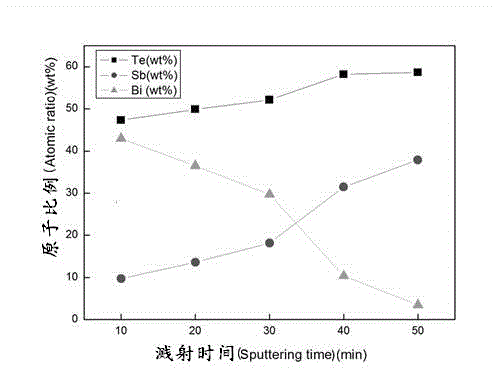

Method for preparing bismuth, antimony and telluride base thermoelectric film

ActiveCN103060750AHigh ion energyImprove qualityThermoelectric device manufacture/treatmentVacuum evaporation coatingRepeatabilityHot Temperature

The invention discloses a method for preparing a bismuth, antimony and telluride base thermoelectric film and particularly relates to a Bi[2-x]SbxTe3 base thermoelectric film. In the Bi[2-x]SbxTe3, x is not less than 0.1 and not more than 2.0. According to the method, the ion-beam sputtering depositing method is adopted, two binary complex targets which are Sb / Te and Bi / Te are used as sputtering target materials, the area proportions of the two target materials and the ion-beam sputtering parameters are controlled, and the high-temperature in situ heat treatment is carried out in the same vacuum environment to prepare the Bi[2-x]SbxTe3 thermoelectric film. The method has the advantages of simple process, good repeatability and high utilization rate of raw materials. Due to the adoption of the method, the high-precision controllable doping of elements of the Bi[2-x]SbxTe3 thermoelectric film can be realized, the structure of the Bi[2-x]SbxTe3 thermoelectric film can be optimized effectively, and the thermoelectric properties can be improved.

Owner:SHENZHEN UNIV

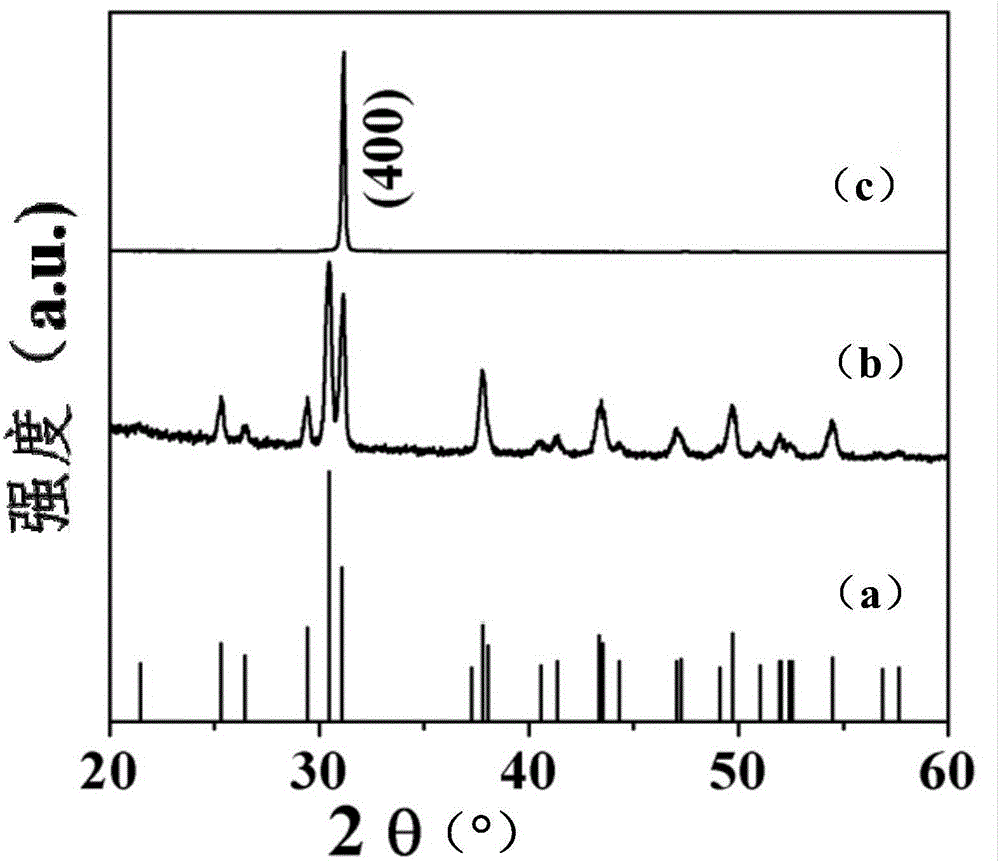

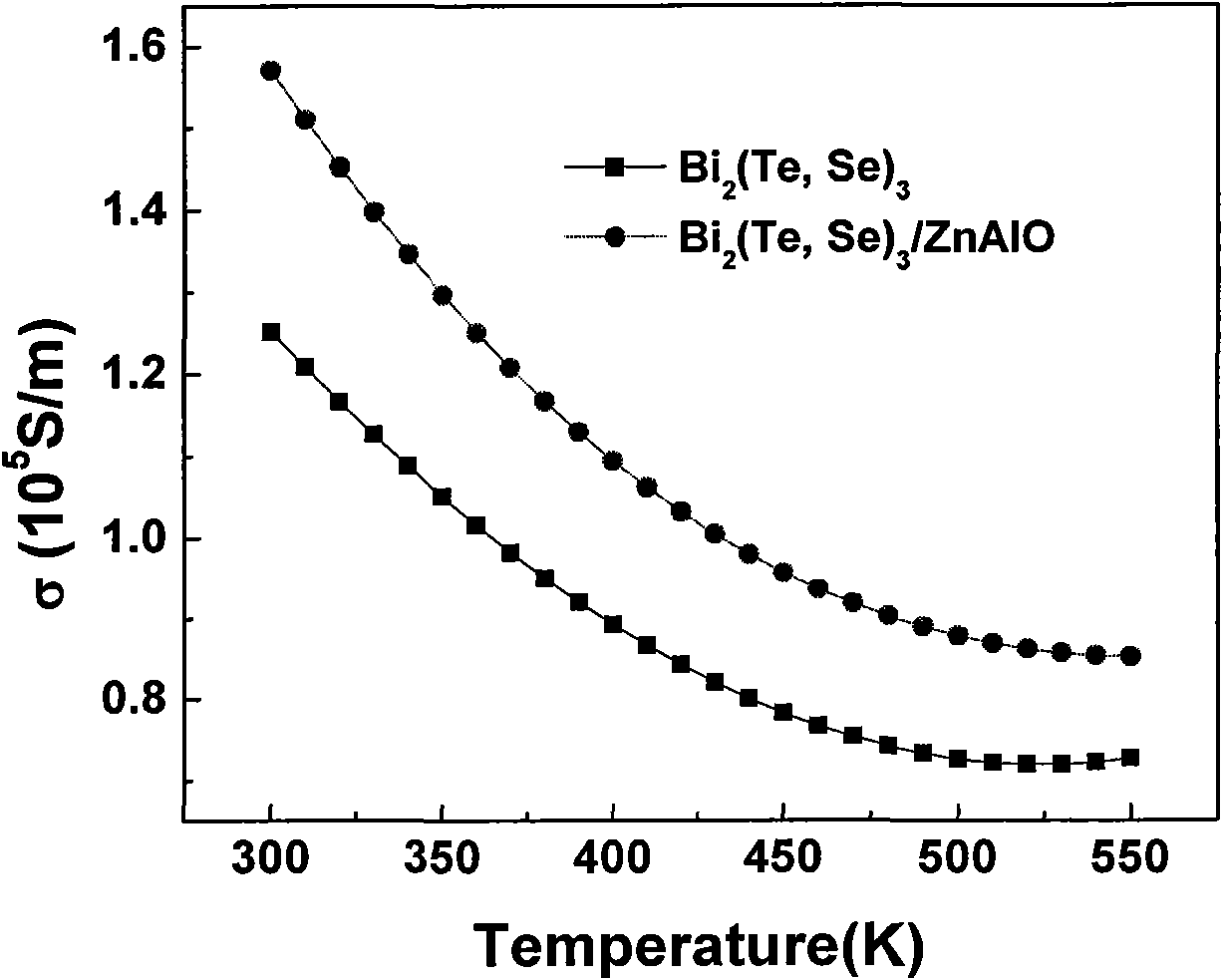

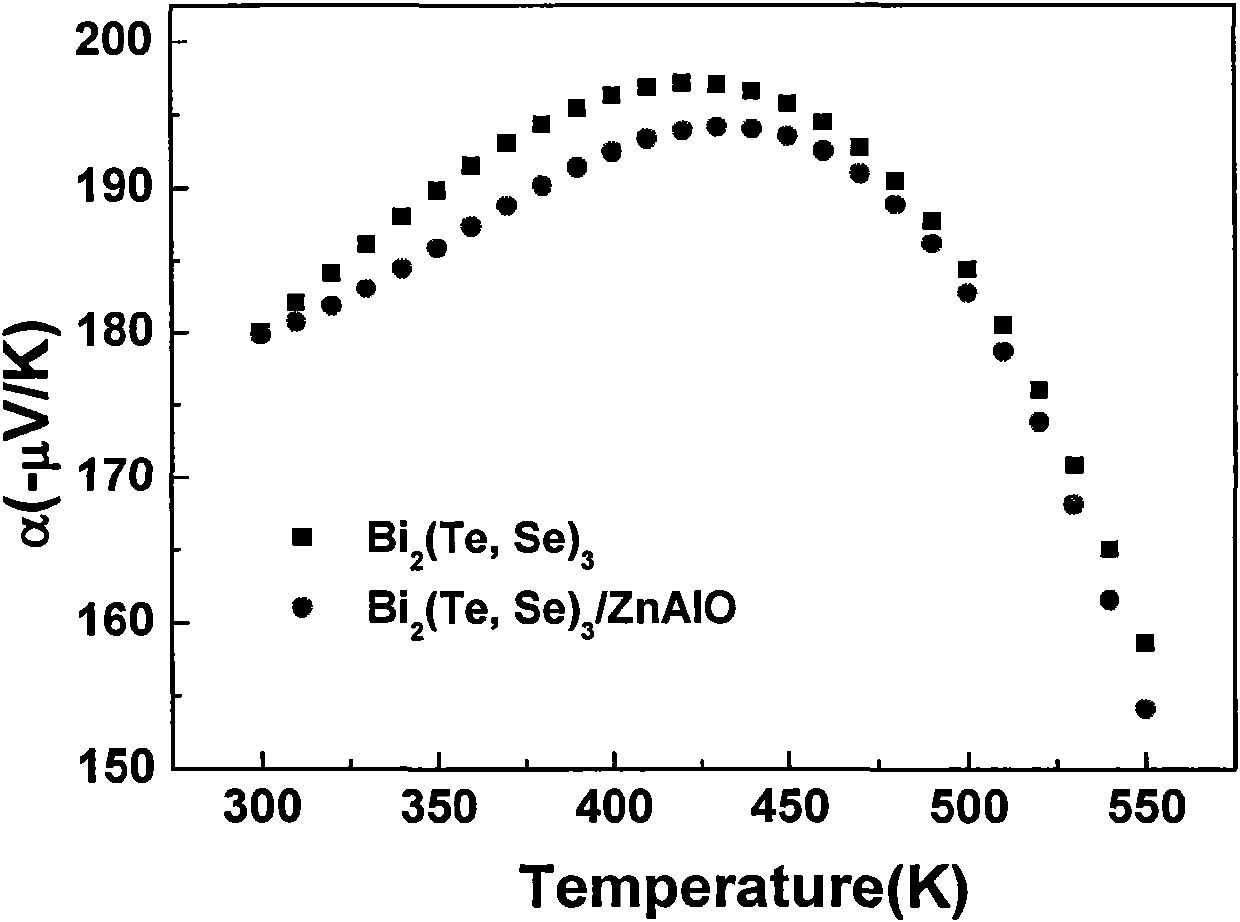

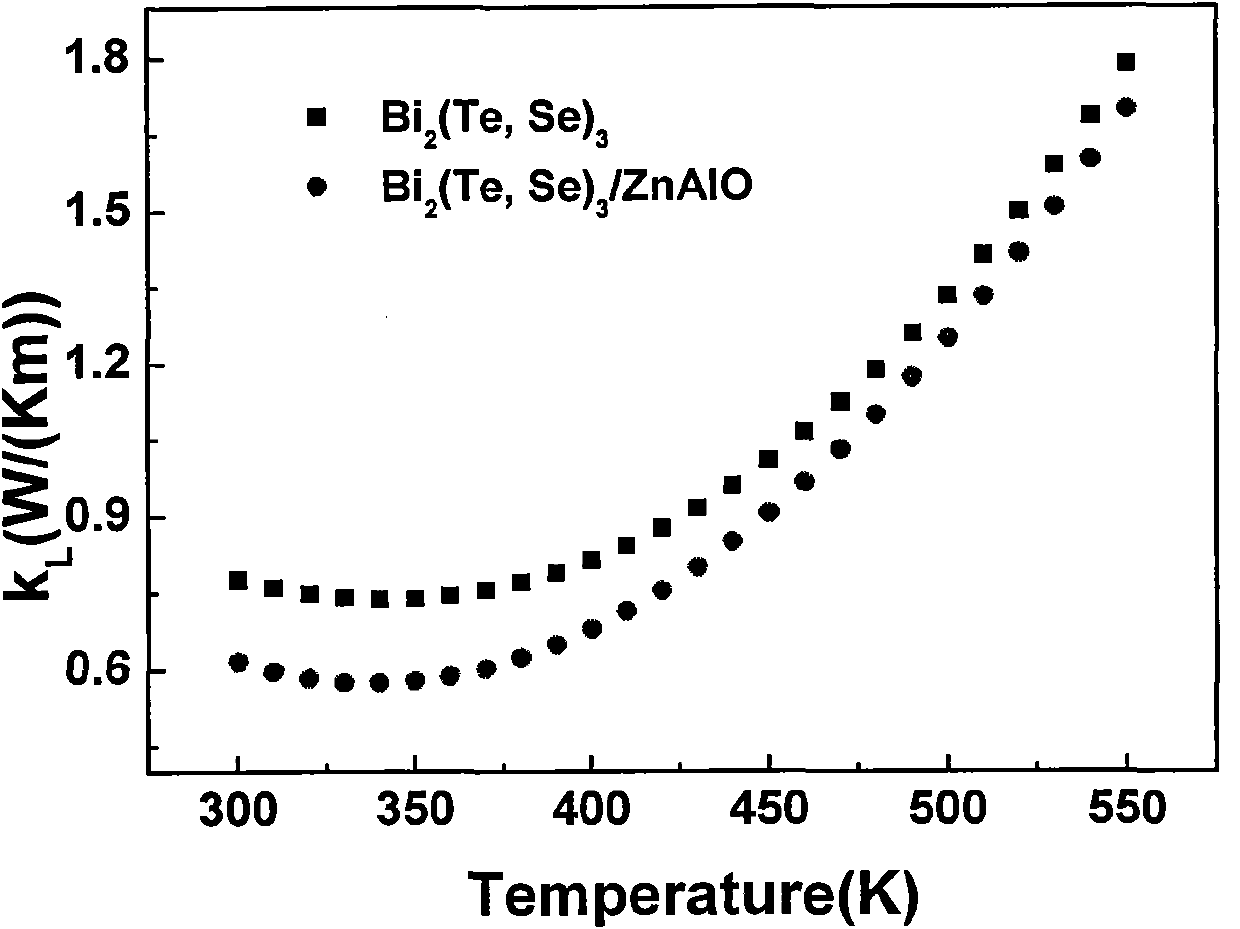

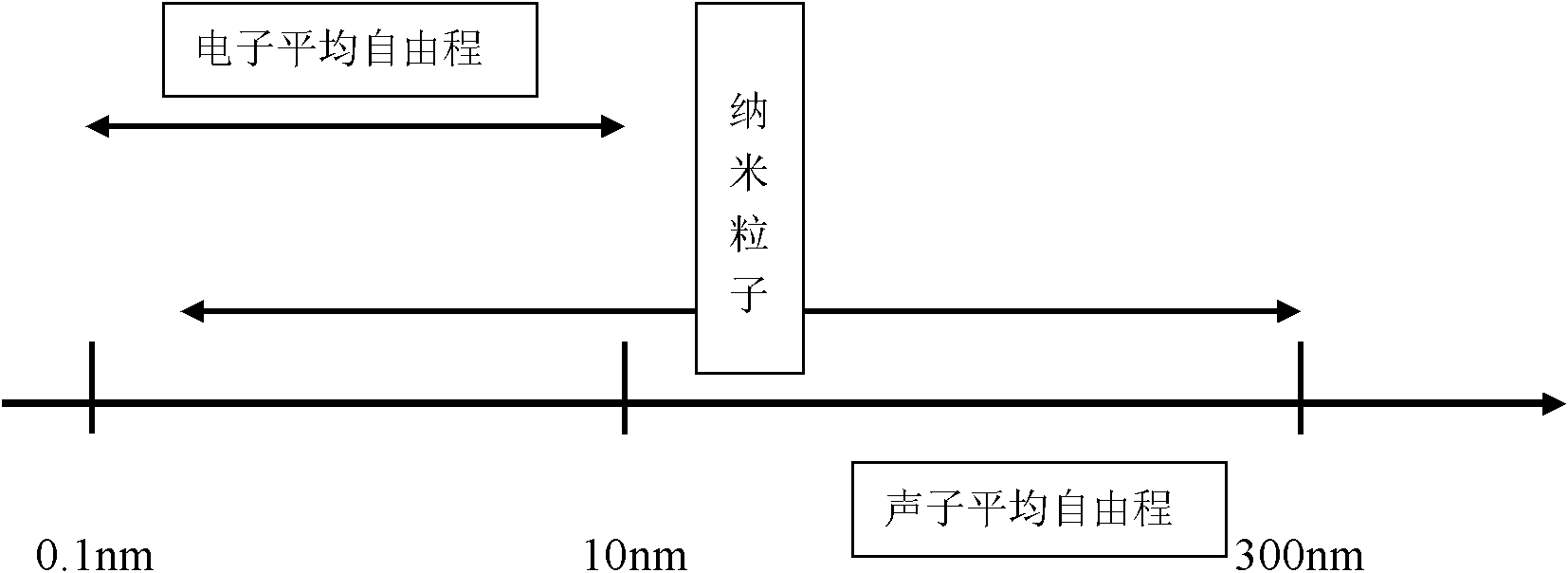

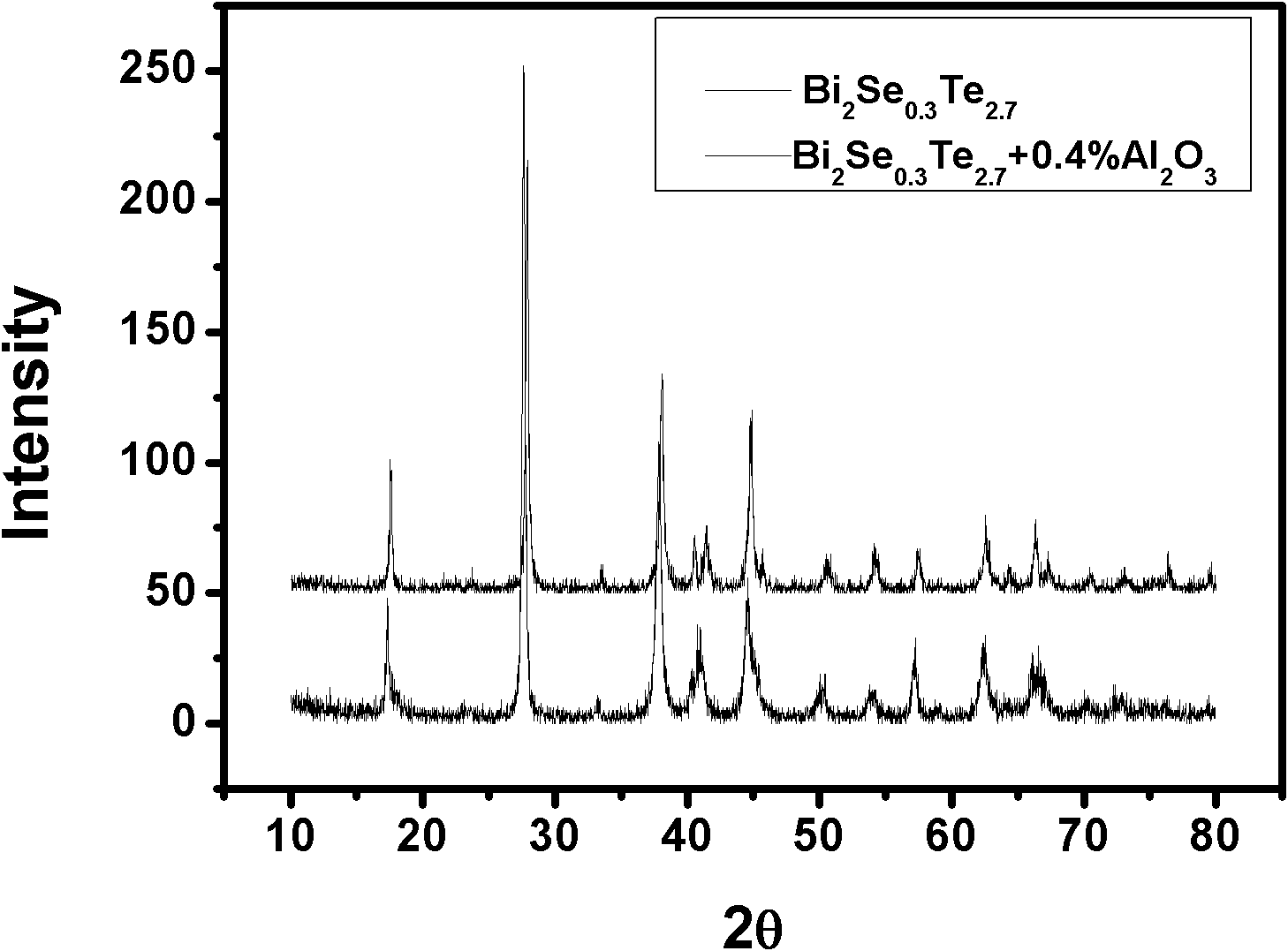

Nanoparticle composite bismuth telluride-based thermoelectric material and preparation method thereof

ActiveCN102024899ALower lattice thermal conductivityImprove thermoelectric figure of merit ZTThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideLattice thermal conductivity

The invention discloses a nanoparticle composite bismuth telluride-based thermoelectric material and a preparation method thereof. In the nanoparticle composite bismuth telluride-based thermoelectric material, a bismuth telluride thermoelectric material is used as a substrate, and nanoparticles are mixed in the substrate, wherein the nanoparticles are electrical-conduction oxide nanoparticles. Compared with the prior art, since the electrical-conduction oxide nanoparticles are used as a second phase and compounded with a bismuth telluride-based alloy substrate; on one hand, the electrical-conduction oxide nanoparticles can enhance the selective scattering to low-frequency phonons so that the crystal lattice heat conductivity of the bismuth telluride-based thermoelectric material can be effectively reduced, and on the other hand, the electrical-conduction oxide nanoparticles can improve the electrical conductivity of the material on the other hand, therefore, an integral regulation and control effect improves the thermoelectric figure of merit ZR of the bismuth telluride-based thermoelectric material so that the thermoelectric property of the bismuth telluride-based thermoelectric material is optimized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Fabrication of High Performance Densified Nanocrystalline Bulk Thermoelectric Materials Using High Pressure Sintering Technique

InactiveUS20100295202A1Low thermal conductivityIncrease valueMaterial nanotechnologyThermoelectric device manufacture/treatmentHigh densityAlloy

The present invention provides a method for the fabrication of high performance densified nanocrystalline bulk thermoelectric material, comprising: (1) preparing a thermoelectric alloy nanopowders by a ball milling process to achieve an average crystal size of 5-30 nm, and (2) preparing the nanocrystalline bulk thermoelectric material by high pressure sintering at a temperature of 0.25-0.8 Tm under a pressure of 0.8-6.0 GPa for 10-120 minutes, to achieve a relative density of 90-100% and an average grain size of 10-50 nm. The method is easy to operate and allows the production of a thermoelectric material with a ZT value higher than 2. In addition, the method can ensure both good thermoelectric properties and high density, and therefore have important applications for energy industry.

Owner:YANSHAN UNIV

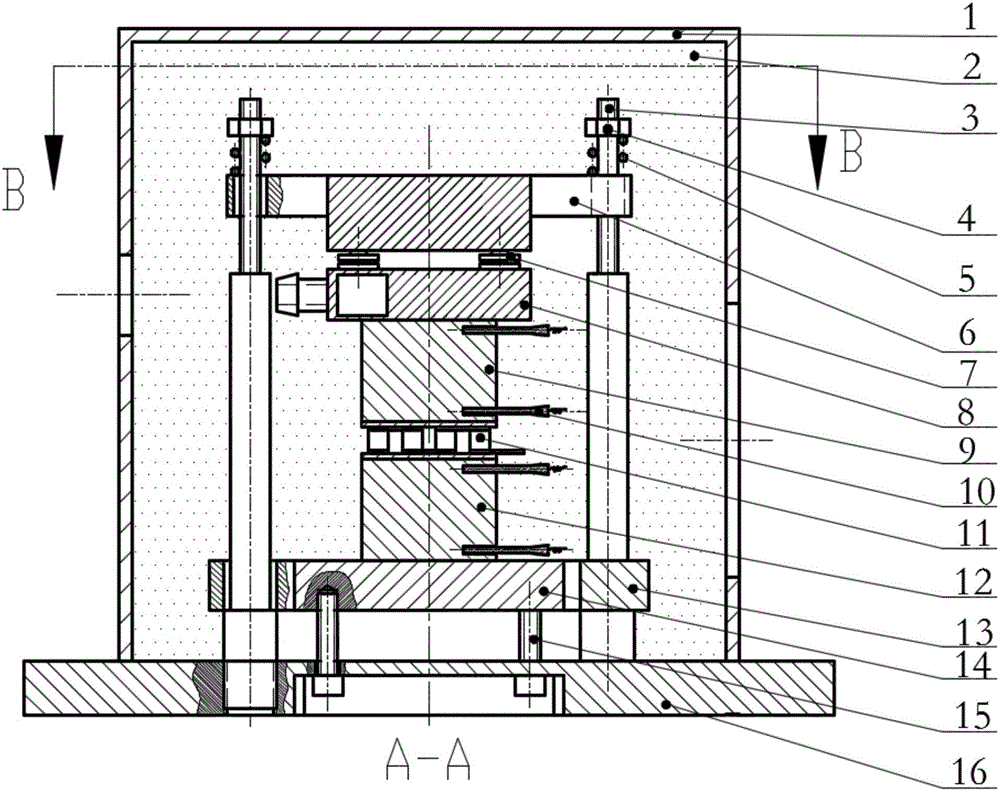

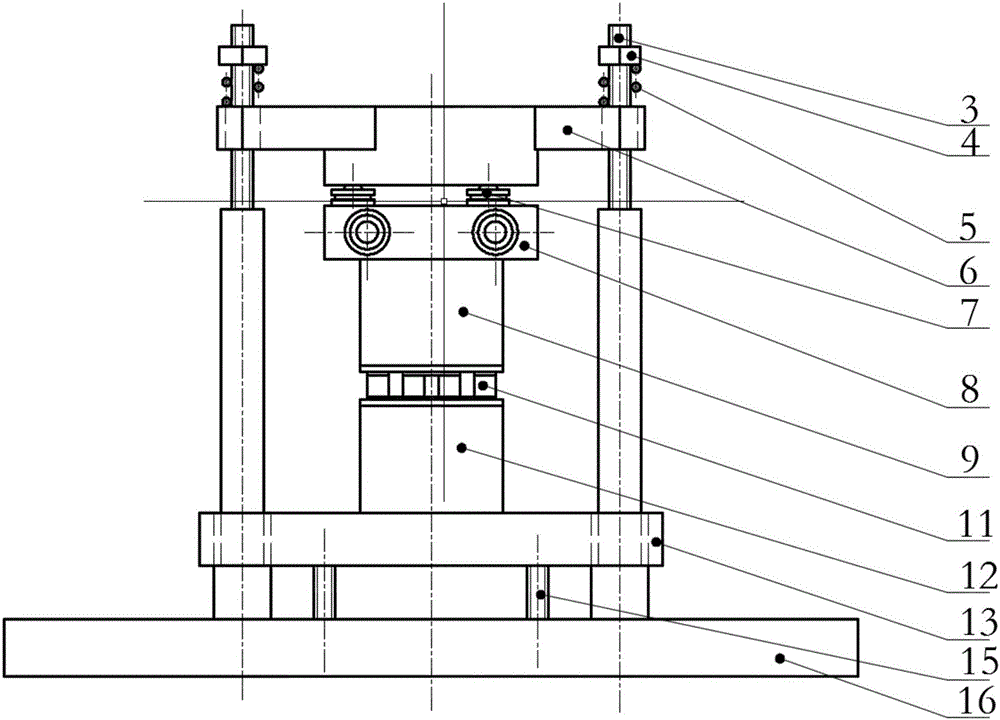

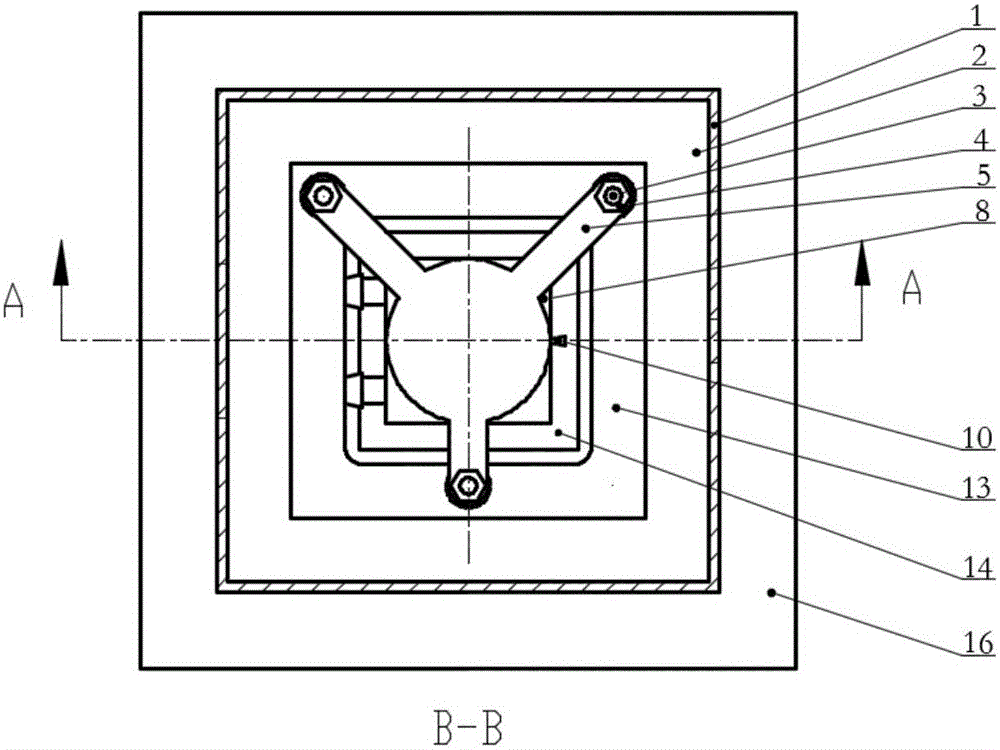

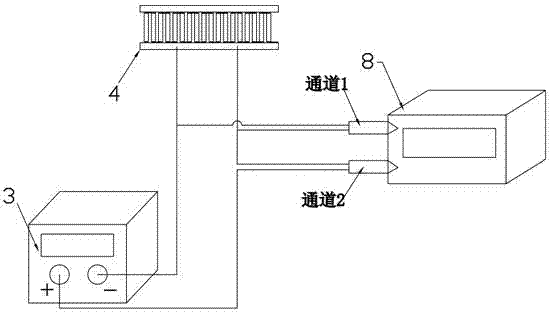

Testing apparatus and testing method of thermoelectric conversion efficiency of thermoelectric module group

PendingCN106093654AStable temperature differenceIncrease contactMaterial heat developmentElectrical testingElectricityHeat flow

The invention discloses a testing apparatus and testing method of a thermoelectric conversion efficiency of a thermoelectric module group. A heating bench protection fence encircles the side surface of an electric heating bench; a measuring assembly for installing a thermoelectric module group is installed on the electric heating bench; and a compression assembly for compressing the measuring assembly is fixed on upper sides of support rods. An outer cover is arranged on a base plate. A gap of internal space between the base plate and the outer cover is filled with a thermal insulation material. The thermoelectric module group is heated and a cold end of the thermoelectric module group is cooled. The compression device applies pressures to guarantee the good contact among all contact surfaces, so that a stable temperature difference between the two ends of the thermoelectric module group is kept and an electromotive force is generated. With a peripheral circuit, calculation is carried out based on temperature values measured by an upper standard measuring block and a lower standard measuring block, thereby obtaining input powers of the thermoelectric module group on different conditions and a heat flow rate inputted into a hot end and thus obtaining a conversion efficiency. According to the invention, various thermoelectric performance parameters of the thermoelectric module group under different pressures and different temperature differences can be tested comprehensively and thus a basis is provided for evaluating the performance of the thermoelectric module group comprehensively.

Owner:ZHEJIANG UNIV

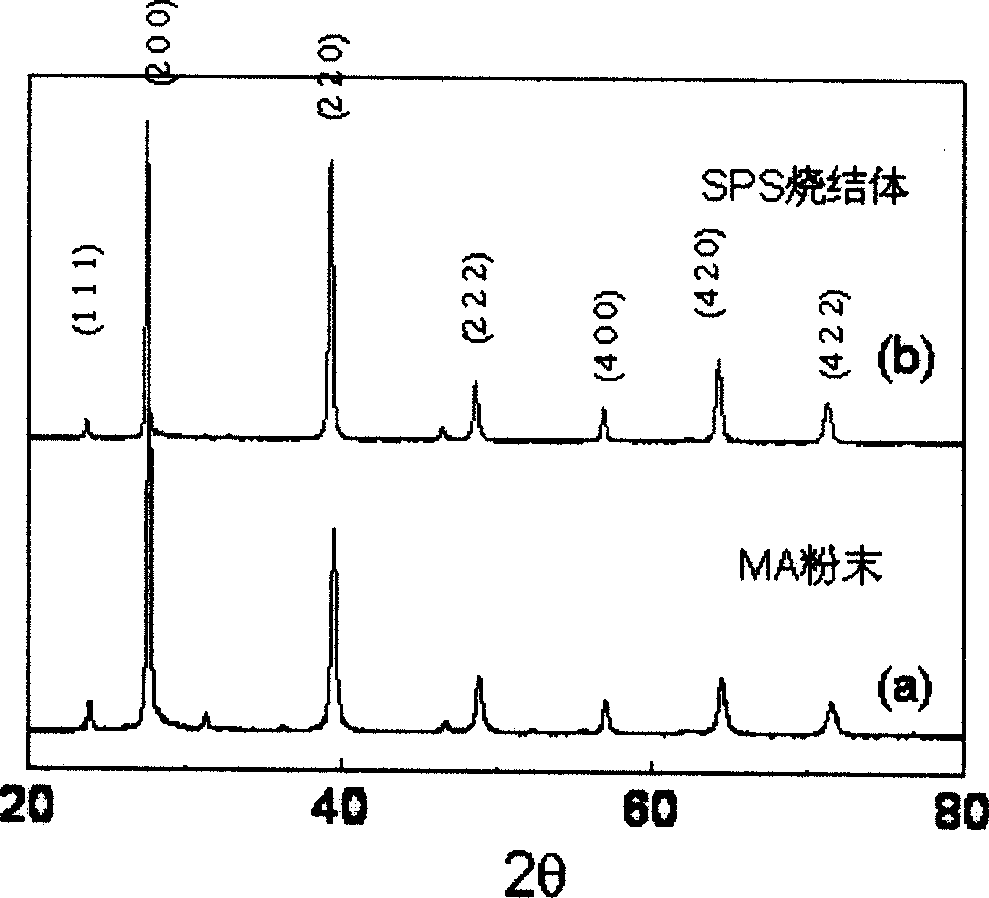

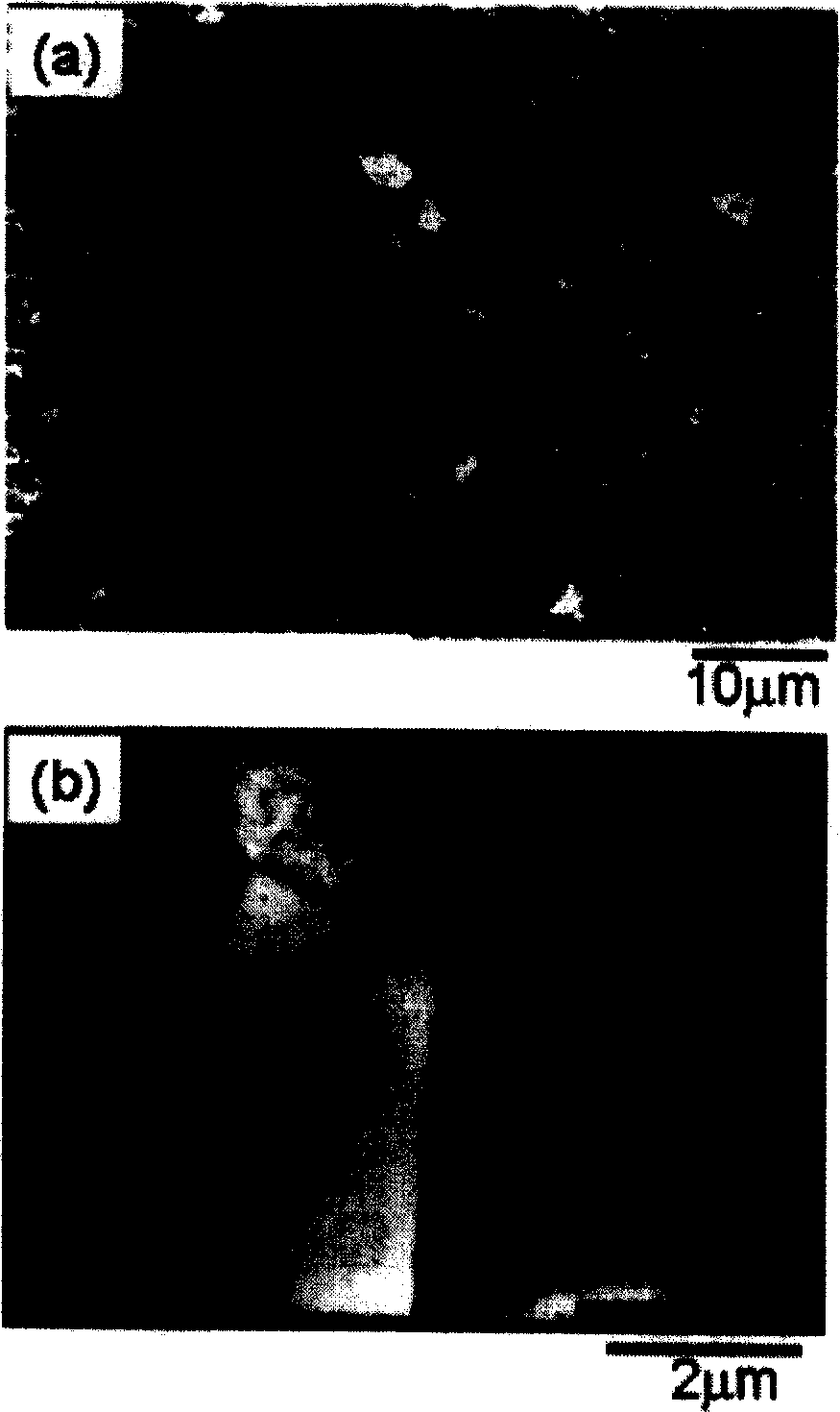

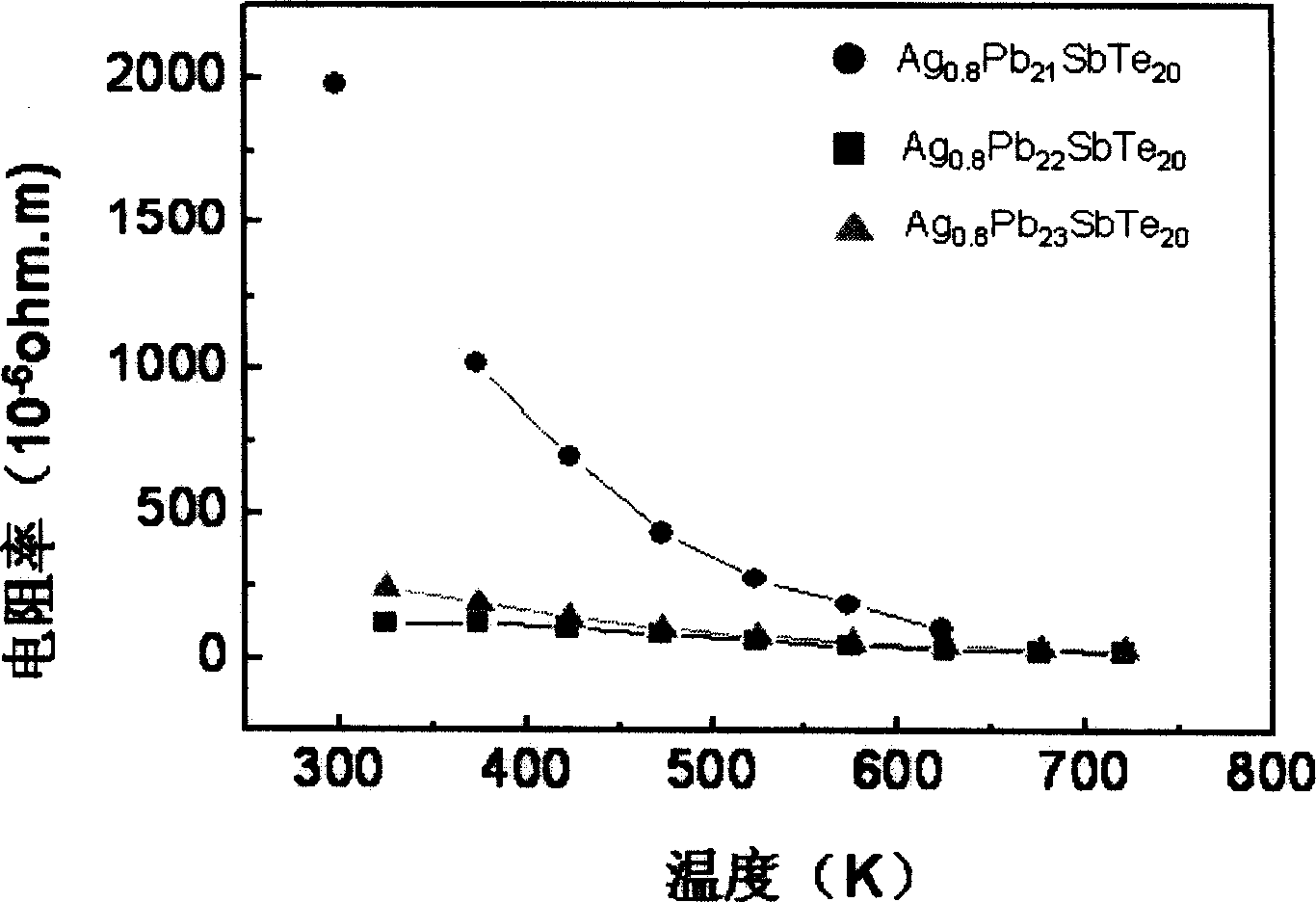

Ag-Pb-Sb-Te thermoelectric materials and preparation process thereof

ActiveCN1755961AFine grainImprove thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsNew energySemiconductor

The invention discloses new energy resource material and its preparing technique, relating to a Ag-Pb-Sb-Te thermoelectric material of thermoelectric semi-conductor compound with high thermoelectric effect and the relative preparing method. The invention utilizes the mechanical alloying (MA) combined with discharge plasma sinter (SPS) to prepare the PbTe high-performance thermoelectric material, which can be displayed as Ag1-XPb18+YSbTe20, wherein, the x is the amount of deviated Ag amount and y is amount that the raw material powder over the measurement rate of Pb. Compared to traditional powder metallurgy technology, the inventive MA+SPS process has the advantages of short process, high efficiency, lower energy consumption, and application to the industrial mass production and the attained thermoelectric material has better thermoelectric performance while the non-dimensional merit ZT of thermoelectric material of Ag1-XPb18+YSbTe20 prepared by MA and SPS can reach 1.37 in the temperature of 450 Deg. C.

Owner:TSINGHUA UNIV +1

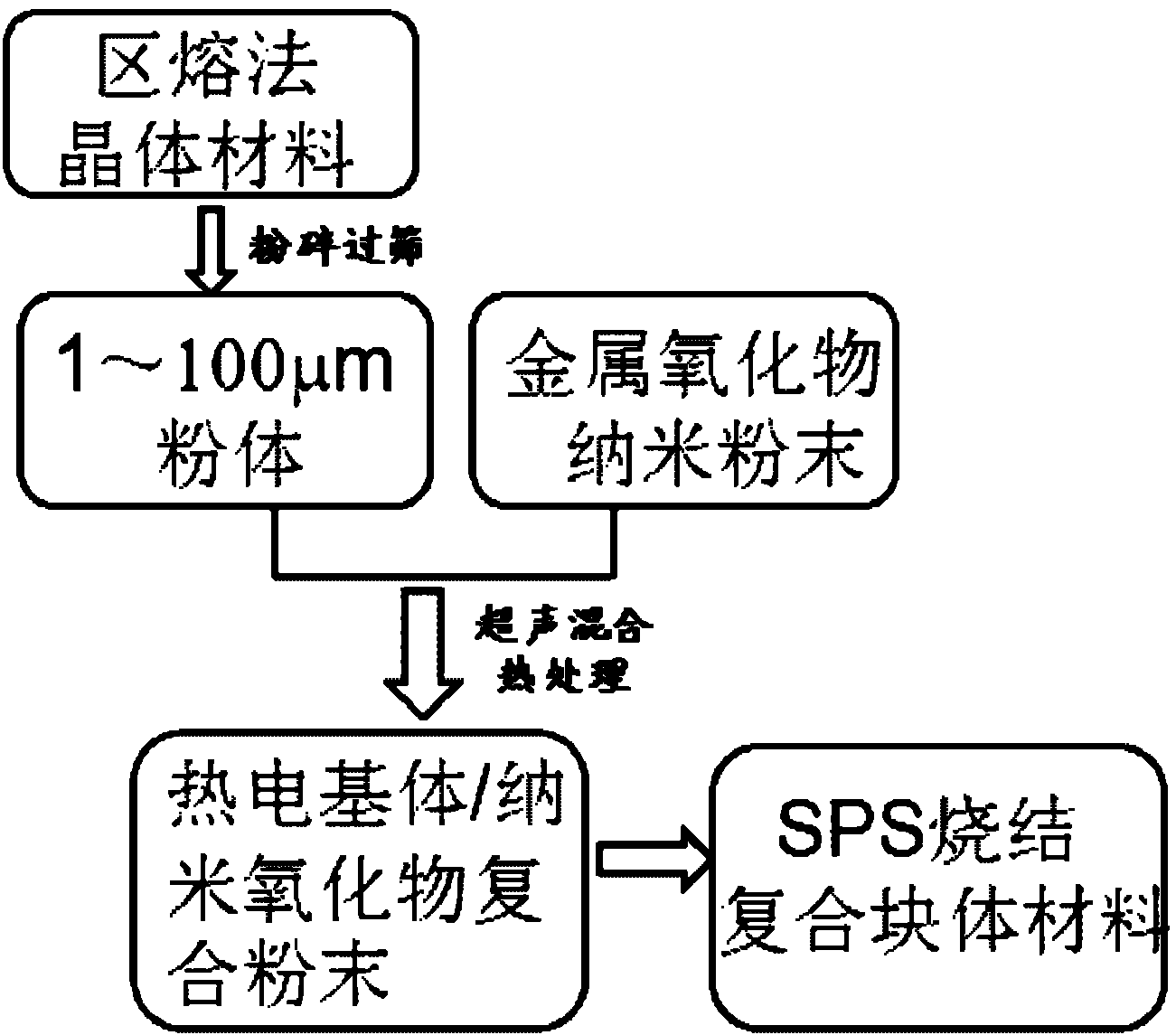

High-performance thermoelectric composite material and preparation method thereof

ActiveCN102339946AImprove Seeback coefficientLow thermal conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideLattice thermal conductivity

The invention relates to a high-performance thermoelectric composite material and a preparation method thereof, belonging to the field of thermoelectric materials. The composite material consists of two phases. A first phase is n-type Bi2Te3-Bi2Se3 or p-type Bi2Te3-Sb2Te3, and a second phase is nanometer powder of a metallic oxide. The nanometer powder of the metallic oxide accounts for 0.05-10% in terms of the total weight of the thermoelectric composite material. According to the preparation method provided by the invention, the n-type Bi2Te3-Bi2Se3 or p-type Bi2Te3-Sb2Te3 powder is ultrasonically mixed with the nanometer oxide, and discharge plasma sintering is carried out on the mixture to obtain a dense block material. Compared with the bismuth-telluride-based thermoelectric base material, under the condition that the electric conductivity of the thermoelectric base material is maintained to be unchanged basically in the invention, the high-performance thermoelectric composite material, provided by the invention, achieves the advantages of obviously reduced lattice heat conductivity and increased Seeback coefficient, and therefore the thermoelectric performance of the material can be greatly improved.

Owner:中科西卡思(苏州)科技发展有限公司

Thermoelectric performance measuring device and measuring method of thermoelectric refrigeration chip

ActiveCN103196947AThe testing process is simpleLow costMaterial heat developmentElectrical testingMeasurement deviceData acquisition

The invention relates to a thermoelectric performance measuring device and a measuring method of a thermoelectric refrigeration chip. The thermoelectric performance measuring device comprises a water cooling radiator, a constant temperature bath, a direct current voltage stabilizing and current stabilizing power supply, a thermoelectric refrigeration chip, platinum resistors, a data collector, a computer, a multichannel electric parameter measuring apparatus, a vacuum pump and a vacuum cover, wherein the hot end face of the thermoelectric refrigeration chip is adhered on the water cooling radiator, the water cooling radiator and the constant temperature bath are mutually connected to perform cold-heat exchange, the direct current voltage stabilizing and current stabilizing power supply is connected with the two electrodes of the thermoelectric refrigeration chip, the two platinum resistors are respectively adhered on the cold end face and the hot end face of the thermoelectric refrigeration chip, the platinum resistors are used for collecting temperature values and sending the temperature values to the data collector, and the data collector collects data and sends the data to the computer; the multichannel electric parameter measuring apparatus respectively collects the working voltage, the working current and the thermal electromotive force of the thermoelectric refrigeration chip and sends the data to the computer; and the water cooling radiator and the thermoelectric refrigeration chip are arranged in the vacuum cover, and the vacuum pump is used for pumping the air in the vacuum cover. The device is simple, the cost is low, the testing process is simple and the measuring precision is high.

Owner:江苏热声机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com