Detecting system of therme generator thermoelectric property

A technology of thermoelectric generator and thermoelectric performance, which is applied in the direction of motor generator testing, machine/structural component testing, instruments, etc., and can solve problems affecting the application of thermoelectric generators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

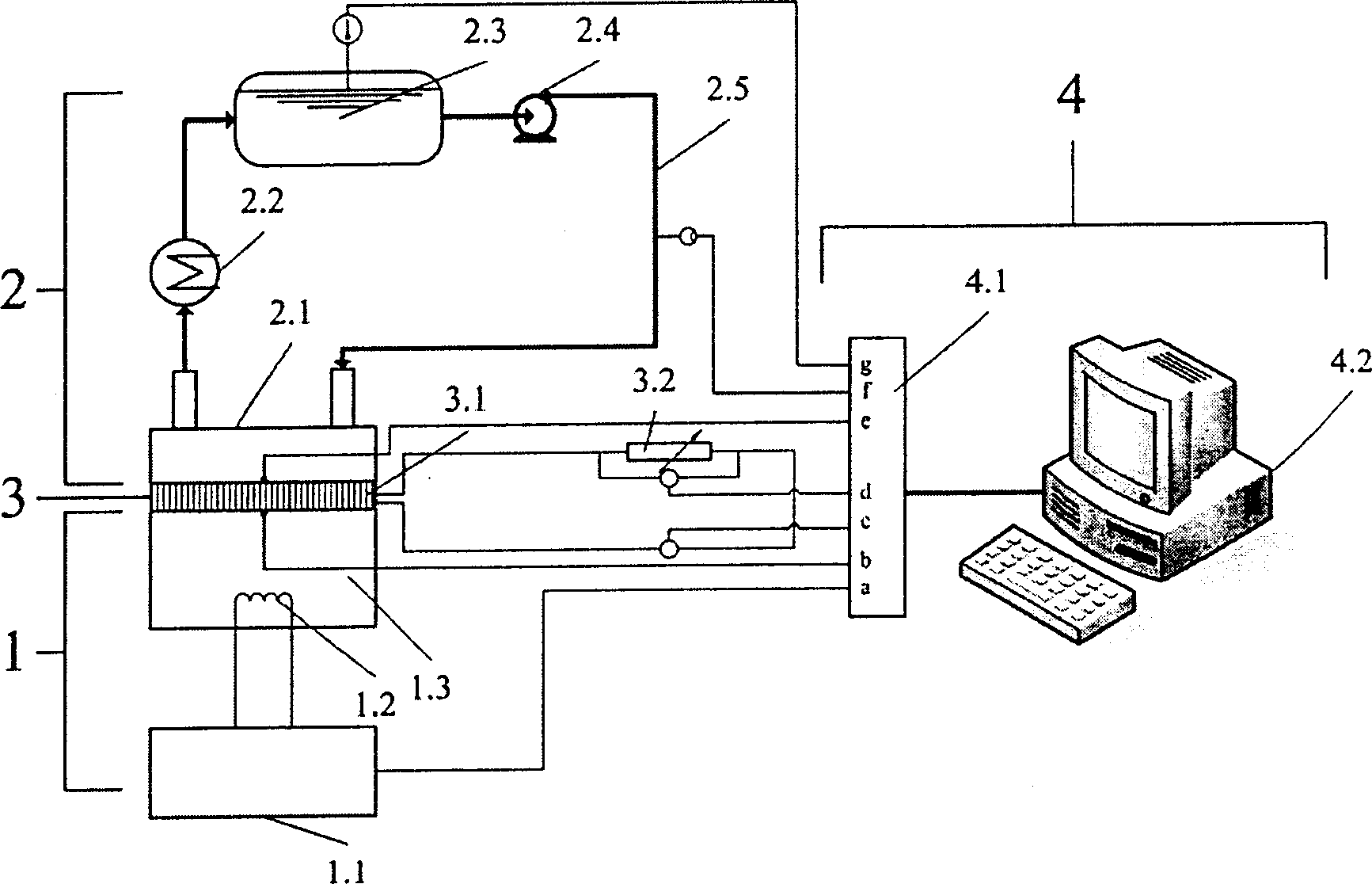

[0038] The main structural components of this test system are: (1) An electric heating heat source unit controlled by a computer. The heat source is well insulated except for one heat conduction surface, and the temperature distribution of the heat conduction surface is uniform. There is a (according to the heat conduction surface) (2) a circulating cooling water circuit heat sink unit, the heat sink unit is mainly composed of heat absorbing box, cooling water circulation The loop is mainly used to cool the cold surface of the thermoelectric generator. One end face of the cooling block is flat and has one (according to the size of the heat conduction surface, there can also be multiple) temperature measurement points and temperature sensors; (3) a set of data acquisition cards and control and data acquisition programs and data processing methods The processing unit can realize the temperature measurement and control of the heat source and heat sink unit described in (1) and (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com