Ag-Pb-Sb-Te thermoelectric materials and preparation process thereof

A thermoelectric material, ag-pb-sb-te technology, is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., and can solve the problem of long exposure time of materials, serious volatilization of components, long production cycle, etc. problems, achieve excellent thermoelectric performance, reduce volatilization, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

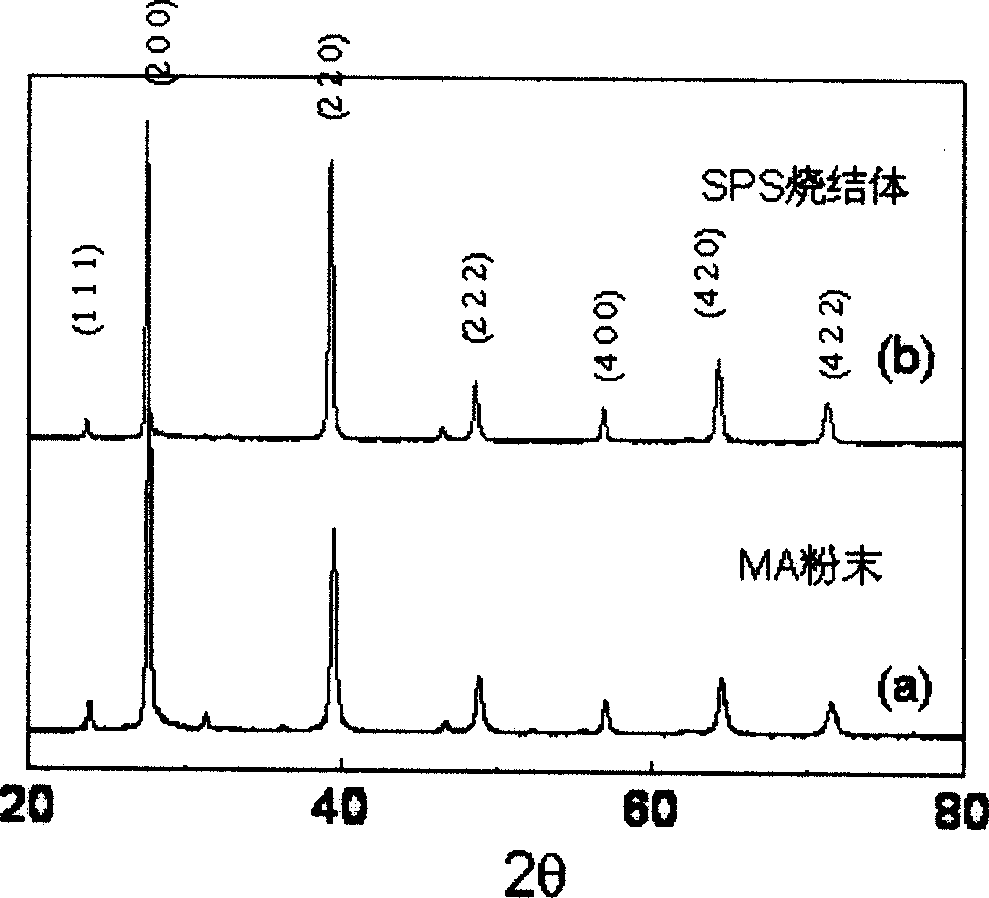

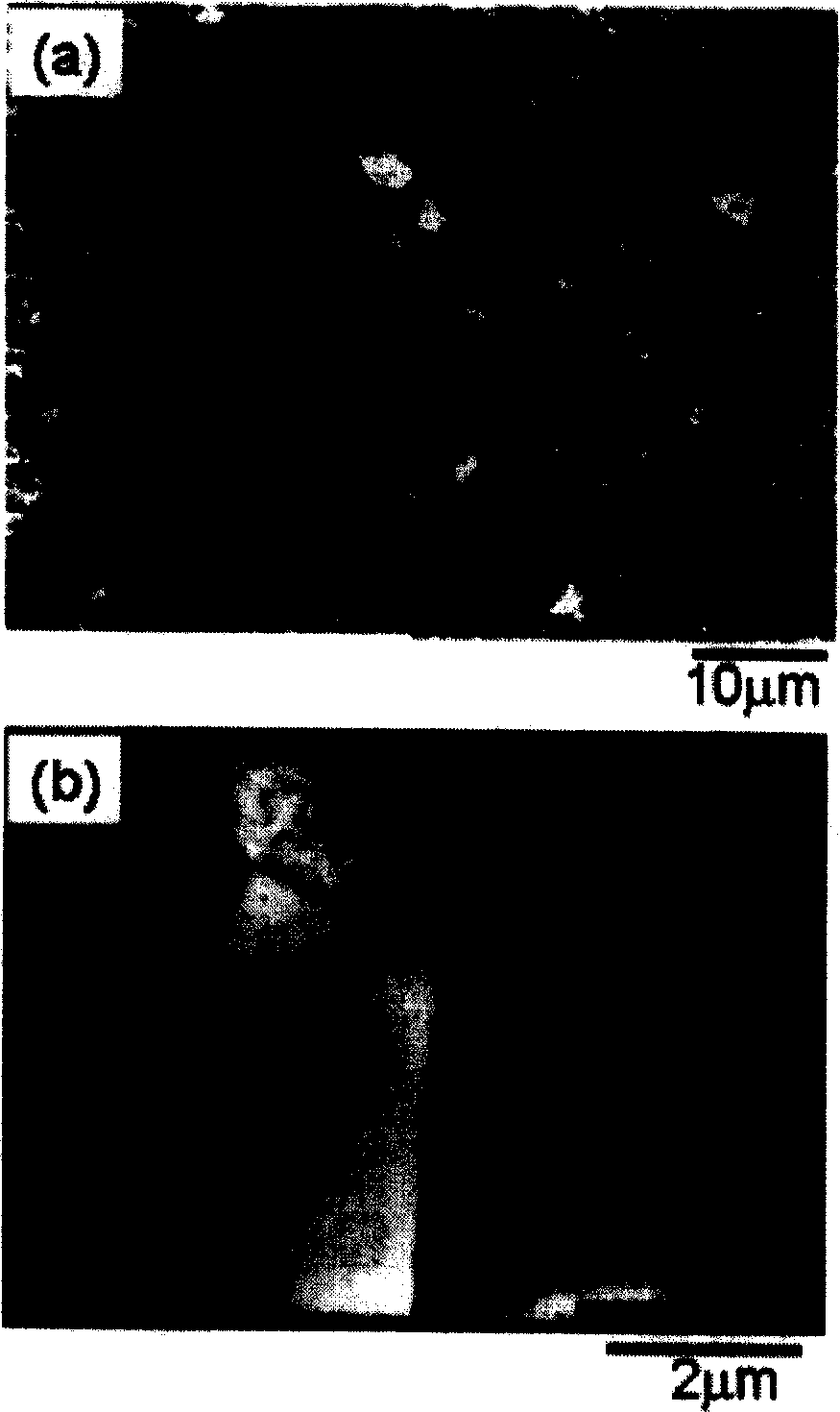

[0032] Using silver (Ag) powder, antimony (Sb) powder, lead (Pb) powder, tellurium (Te) powder as raw materials, according to Ag 0.8 Pb 22 SbT 20 Weigh a total of 20 g of powder, put it into a stainless steel ball mill jar (volume 250 mL), and add stainless steel balls with a diameter of 10 mm (the weight ratio of balls to powder is 18:1). The ball mill tank was filled with Ar as a protective gas, and Ag was prepared by mechanical alloying (MA) reaction in a planetary ball mill (QM-2, Nanjing University Instrument Factory) for 5 hours (rotation speed: 300r / min). 0.8 Pb 22 SbT 20 compound powder. Such as figure 1 As shown in (a), after the above MA treatment, the obtained powder becomes a single phase and has a cubic structure, and each diffraction peak can be calibrated according to the PbTe phase. The obtained powder is sintered at a pressure of 50Mpa at 400°C and kept for 2 minutes, and its relative density is all above 98% (see figure 2 SEM photo shown). Such as f...

Embodiment 2

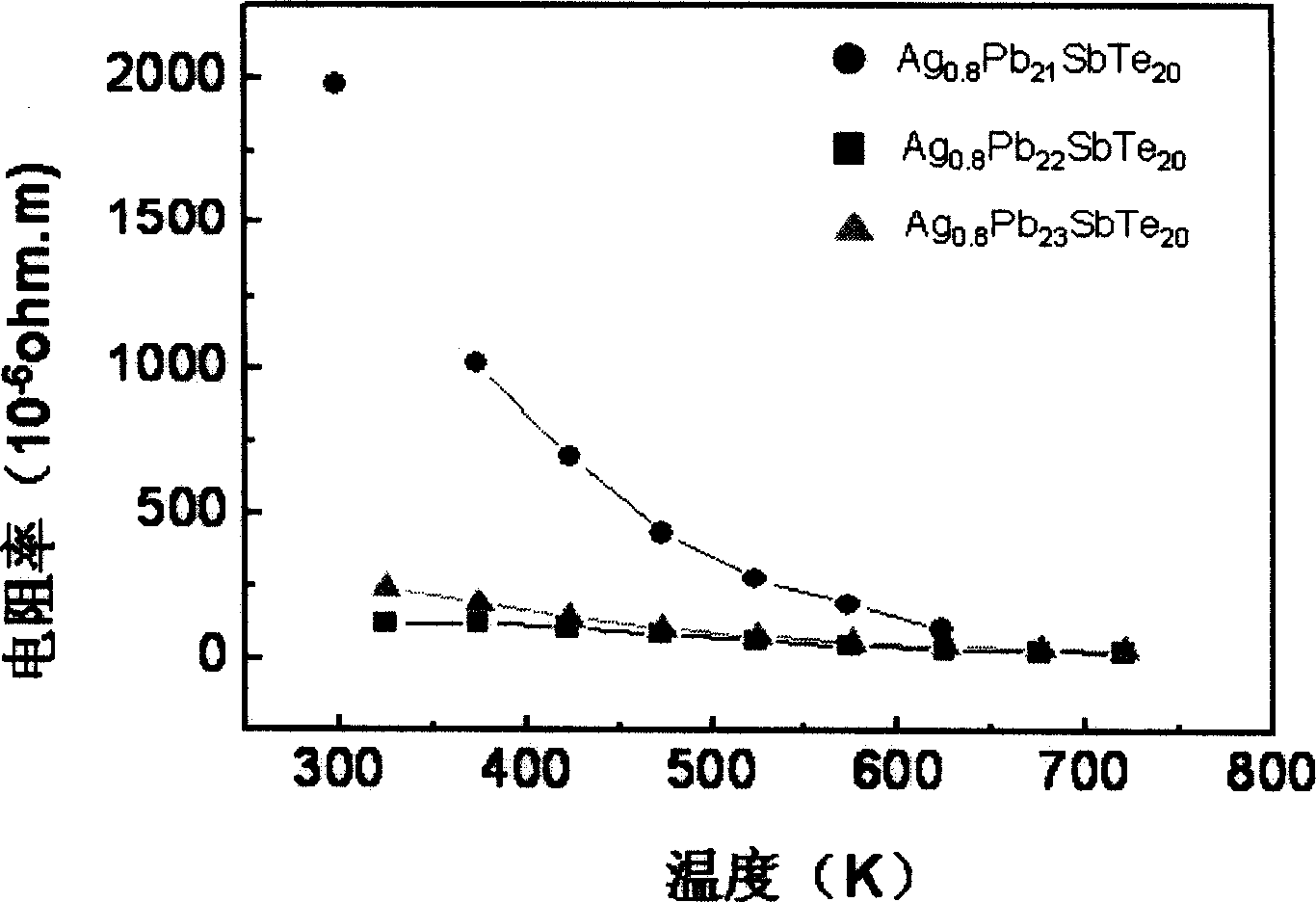

[0034] Using silver (Ag) powder, antimony (Sb) powder, lead (Pb) powder, tellurium (Te) powder as raw materials, according to Ag 0.8 Pb 21 SbT 20 , Ag 0.8 Pb 22 SbT 20 , Ag 0.8 Pb 23 SbT 20 Metering ratio A total of 20 g of powder was weighed to prepare three groups of samples with different Pb contents. Powder synthesis and SPS sintering conditions are the same as in Example 1. image 3 and 4 Comparing the three compositions of Ag 1-X Pb 18+Y SbT 20 Resistivity () and Seebeck coefficient (S) of the compound's SPS sintered samples versus temperature. Compared with the other two compositions, Ag 0.8 Pb 22 SbT 20 It has the lowest resistivity, and the absolute value of its Seebeck coefficient is between the two. Figure 5 is to use image 3 and 4 The power factor (S 2 / vs. temperature. As shown in the figure, Ag 0.8 Pb 22 SbT 20 The power factor of the composition is the highest, reaching 1766W / mK at 650K. Figure 6 is the composition (Ag 0.8 Pb 22 SbT...

Embodiment 3

[0036] Using silver (Ag) powder, antimony (Sb) powder, lead (Pb) powder, tellurium (Te) powder as raw materials, according to Ag 0.8 Pb 22 SbT 20 , Ag 0.8 Pb 22 SbT 20 and Ag 0.8 Pb 22 SbT 20 A total of 20 g of powder was weighed to prepare three groups of samples with different Ag contents. Powder synthesis and SPS sintering conditions are the same as in Example 1. The room temperature resistivities of samples with silver contents of 0.4, 0.6 and 0.8 are 0.125m, 0.185m, 0.175×10 -3 m. The resistivities of the two samples with Ag contents of 0.4 and 0.6 are too high, and the samples with Ag contents of about 0.8 have much lower resistivities than the other two compositions. Therefore, its comprehensive thermoelectric performance is high, and the dimensionless figure of merit ZT is as high as 1.37.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com