Patents

Literature

56results about How to "High ion energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

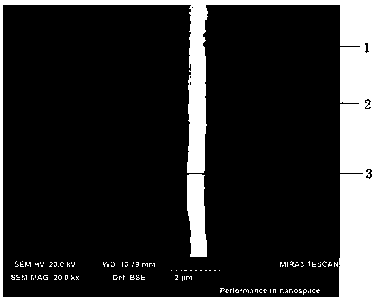

PVD chromium based ceramic composite coating piston ring and method for producing the same

InactiveCN101430004AOvercome the hardnessOvercome uniformity issuesPiston ringsVacuum evaporation coatingCeramic compositePiston ring

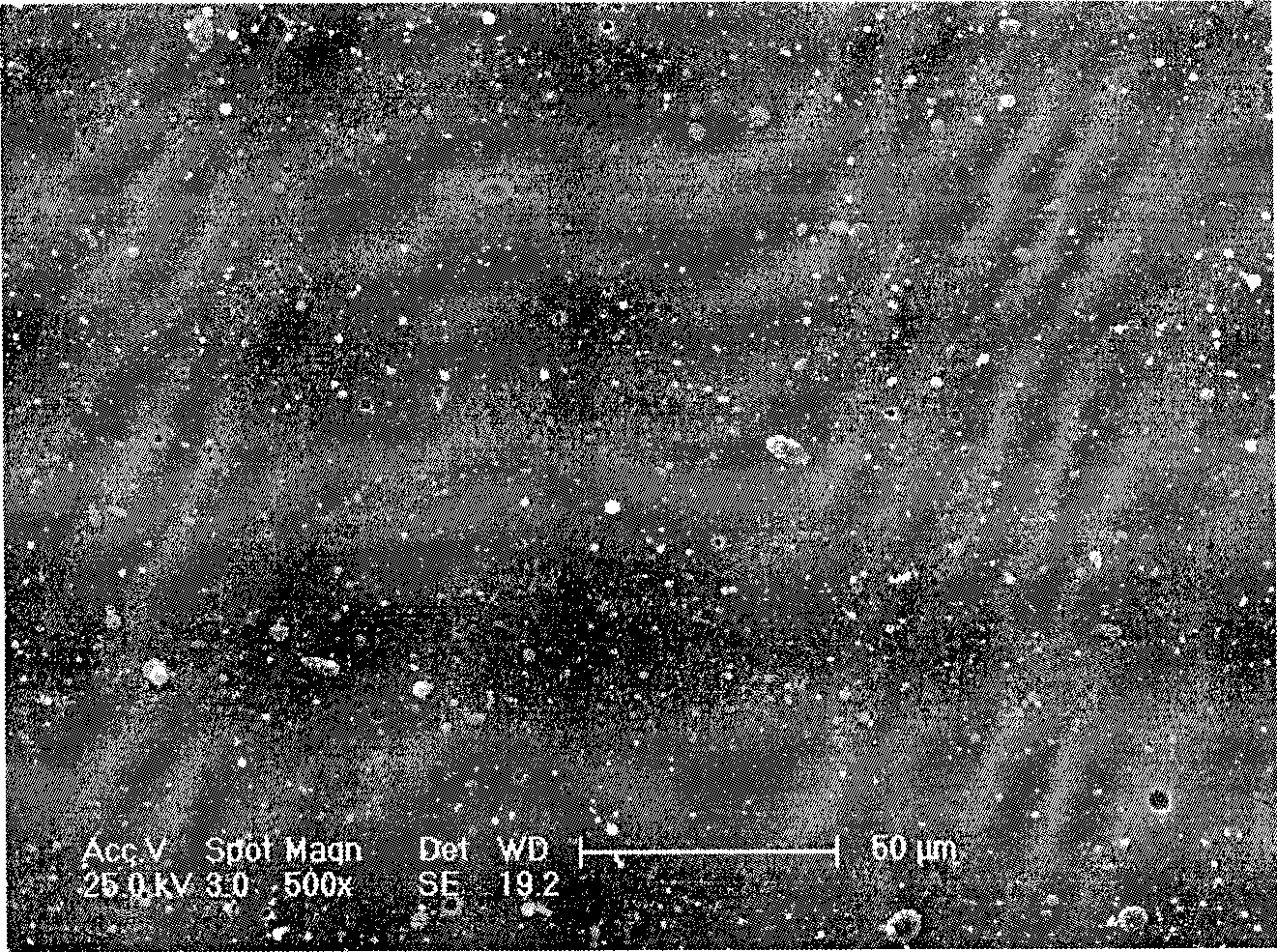

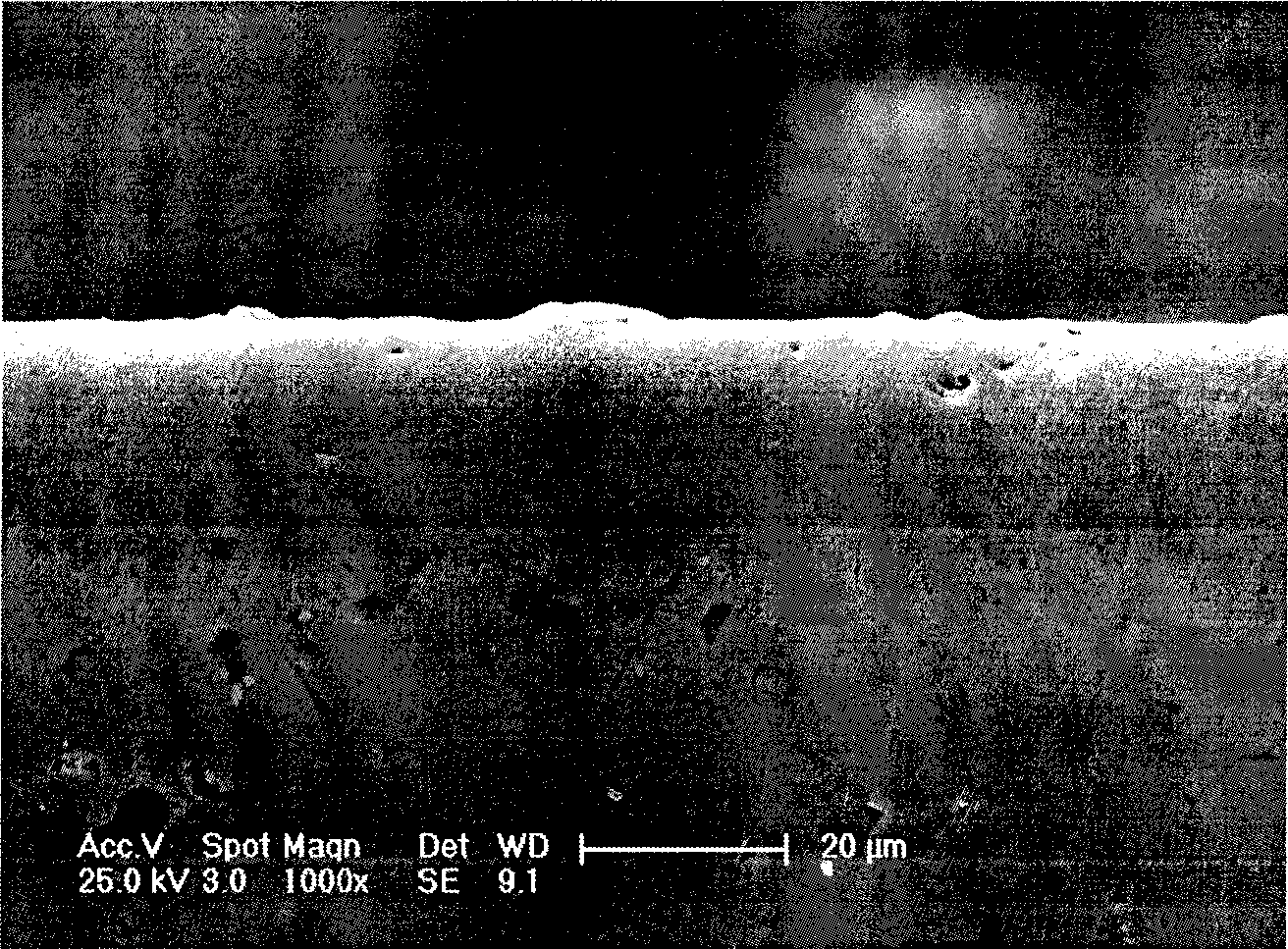

The invention discloses a PVD chromium base ceramic composite coating piston ring and a preparation method thereof, and the piston ring is manufactured by plating a chromium base ceramic composite coating on a basal body of the piston ring which is treated by nitriding by adopting high power electric arc discharge method; the chromium base ceramic composite coating is composed of a bonding layer, a main wearing layer and an anti-attrition layer, wherein, the bonding layer is binded with the basal body of the piston ring in a metallurgical way, the main wearing layer is arranged on the bonding layer, and the anti-attrition layer is positioned on the surface of the main wearing layer; the bonding layer is Cr, the main wearing layer is a Cr / CrN multilayer coating formed by the Cr and the CrN which are alternately arranged, and the anti-attrition layer is a Cr / Cr2O3 multilayer coating formed by the Cr and the Cr2O3 that are alternately arranged. The coating structure has reasonable design, and the manufactured coating has good cementing property, high hardness and good lubricating property. Furthermore, the method used for manufacturing the piston ring has no pollution in the preparation process, and overcomes the serious problem of environmental pollution of the conventional electrodeposited chromium; as the manufactured coating has better abrasion resistant and corrosion resistant performance compared with the electrodeposited chromium, the service life of the piston ring is greatly prolonged.

Owner:WUHAN UNIV

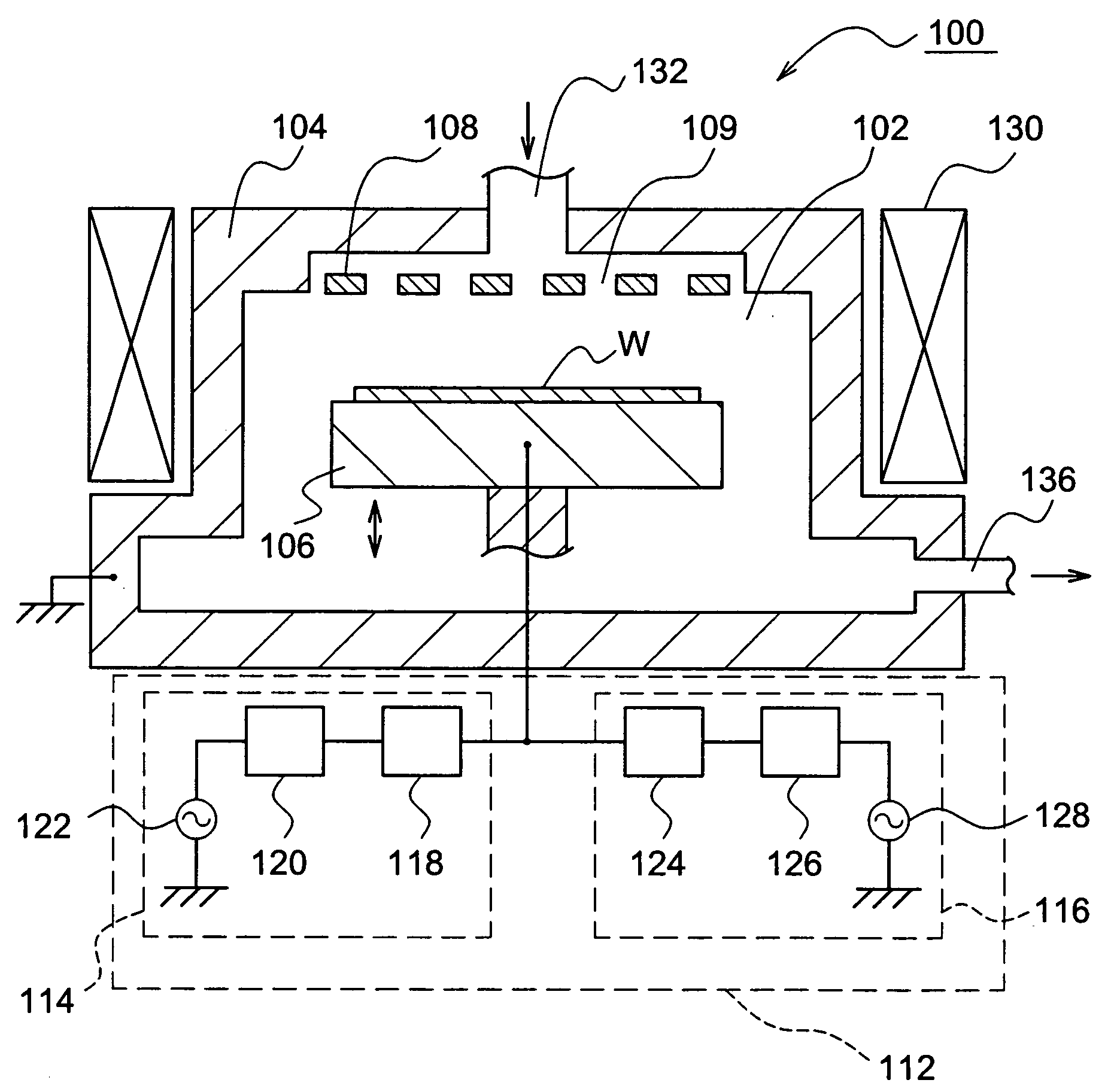

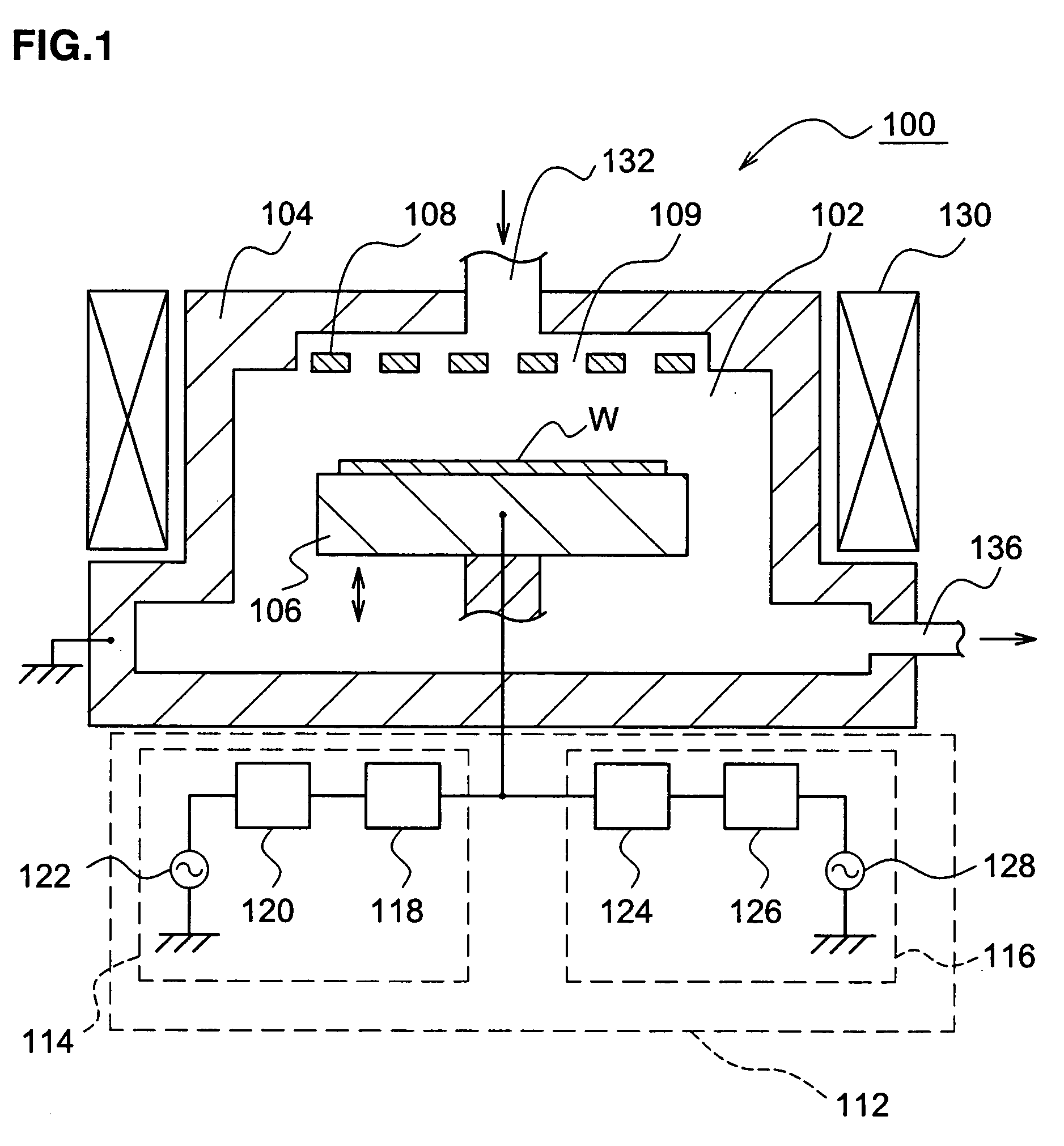

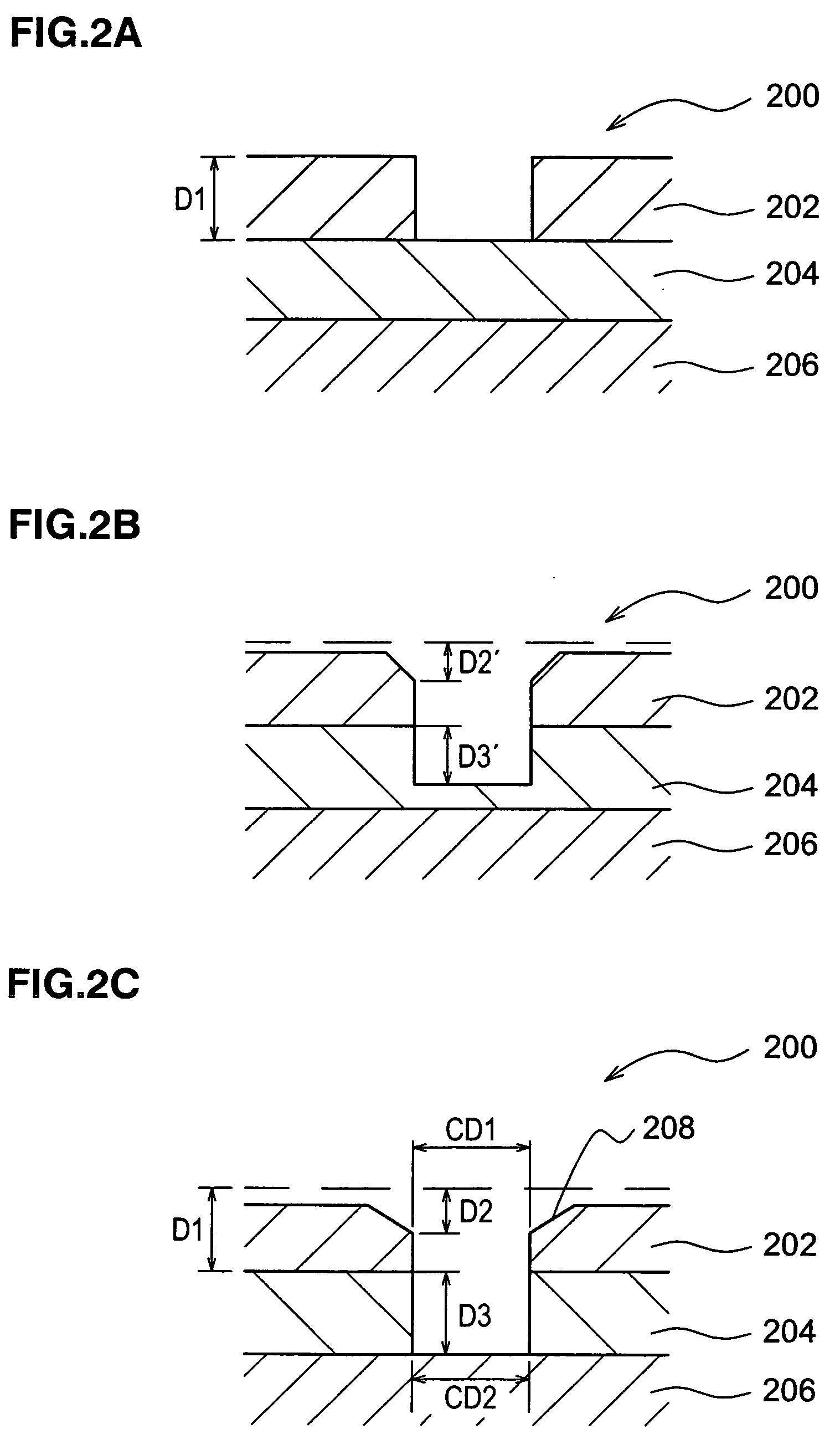

Etching method and plasma etching apparatus

InactiveUS20050103441A1Contribution of ion energyImprove etch selectivityElectric discharge tubesSemiconductor/solid-state device manufacturingOrganic filmHigh frequency power

There is provided an etching method and a plasma etching apparatus capable of taking a large etching selection ratio and of forming a hole having an appropriate shape. When etching an etching target film 204 by using an organic film 202 having a predetermined pattern as a mask, processing gas is introduced into an airtight processing container 104. There are provided a high frequency power source 122 of 40 MHz and a high frequency power source 128 of 3.2 MHz, by which two different kinds of high frequency powers are applied to a lower electrode 106. The power of each high frequency power is properly combined, thereby executing the etching process by using low plasma electron density Ne and high self-bias voltage Vdc which are generated by high frequency power.

Owner:TOKYO ELECTRON LTD +1

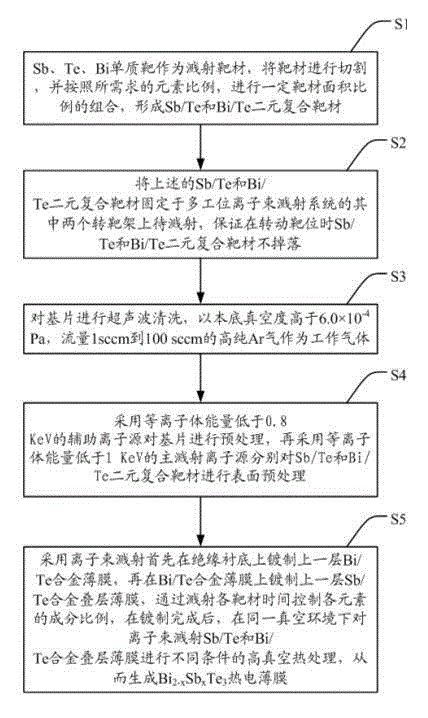

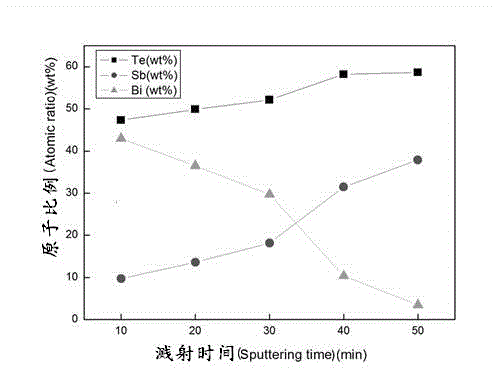

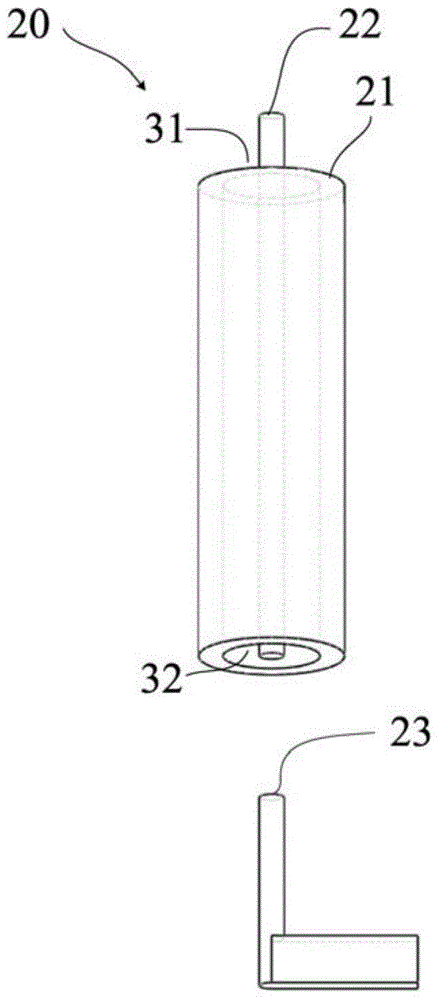

Method for preparing bismuth, antimony and telluride base thermoelectric film

ActiveCN103060750AHigh ion energyImprove qualityThermoelectric device manufacture/treatmentVacuum evaporation coatingRepeatabilityHot Temperature

The invention discloses a method for preparing a bismuth, antimony and telluride base thermoelectric film and particularly relates to a Bi[2-x]SbxTe3 base thermoelectric film. In the Bi[2-x]SbxTe3, x is not less than 0.1 and not more than 2.0. According to the method, the ion-beam sputtering depositing method is adopted, two binary complex targets which are Sb / Te and Bi / Te are used as sputtering target materials, the area proportions of the two target materials and the ion-beam sputtering parameters are controlled, and the high-temperature in situ heat treatment is carried out in the same vacuum environment to prepare the Bi[2-x]SbxTe3 thermoelectric film. The method has the advantages of simple process, good repeatability and high utilization rate of raw materials. Due to the adoption of the method, the high-precision controllable doping of elements of the Bi[2-x]SbxTe3 thermoelectric film can be realized, the structure of the Bi[2-x]SbxTe3 thermoelectric film can be optimized effectively, and the thermoelectric properties can be improved.

Owner:SHENZHEN UNIV

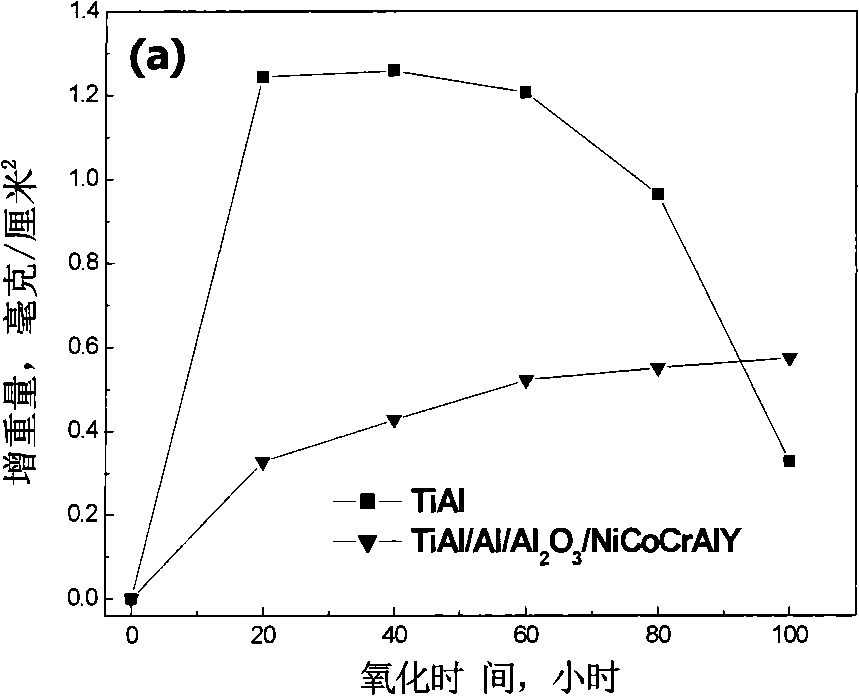

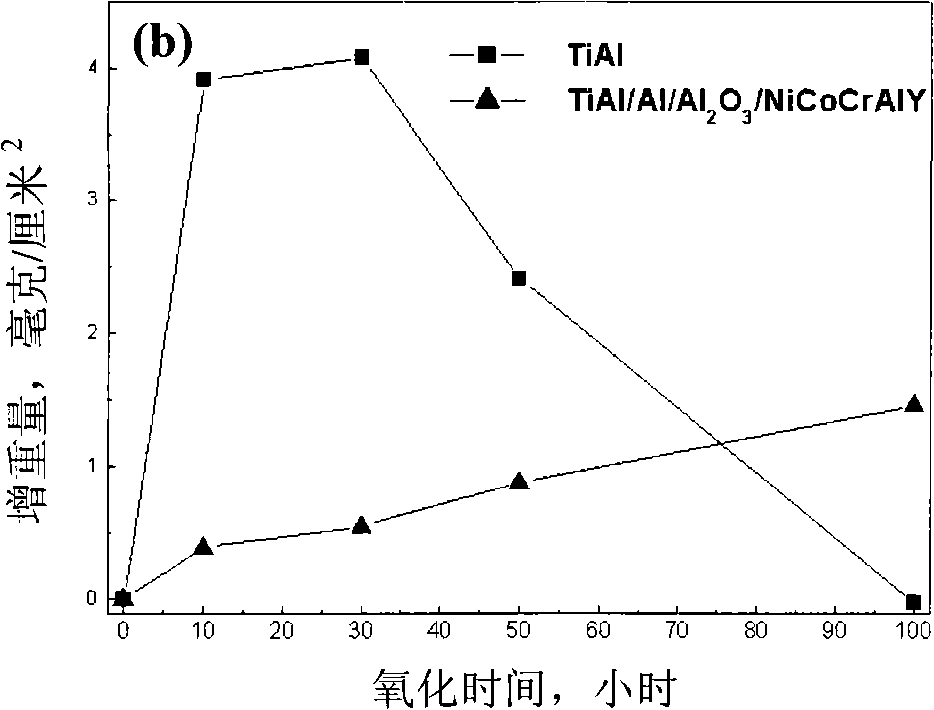

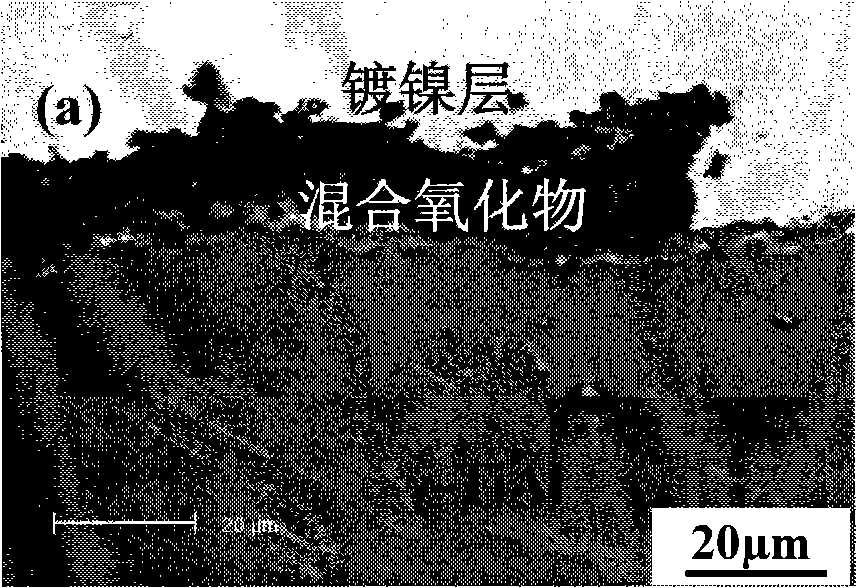

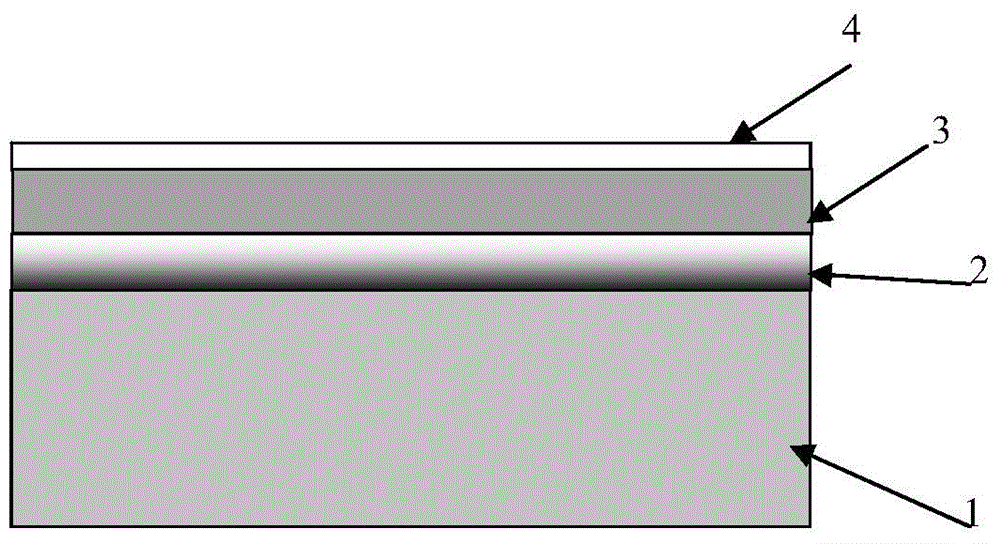

Aluminum/aluminum oxide/Ni-base superalloy composite coating for titanium-aluminum alloy and preparation method thereof

InactiveCN101310969AImprove high temperature stabilityBlocking interdiffusionVacuum evaporation coatingSputtering coatingSuperalloyIon plating

The invention relates to the coating technique, in particular to an Al / Al2O3 / MCrAlY composite coating used in Ti-Al alloy and a preparation method thereof, which aims at improving the high-temperature oxidation resistance of the Ti-Al alloy, guaranteeing the serviceability of the Ti-Al alloy in the high-temperature environment and solving the problem of non-matching between the MCrAlY coating and the Ti-Al alloy and is used for the high-temperature protection of the Ti-Al alloy. The composite coating comprises an Al / Al2O3 diffusion impervious layer and an MCrAlY alloy protective coating which are deposited on a substrate of the alloy in sequence; the thickness ratio among an Al film, an Al2O3 film and the MCrAlY protective coating is (1 to 5): (1 to 5): (20 to 50); in the MCrAlY alloy, M indicates Ni, Co or Ni plus Co. The arc ion plating technique is adopted to deposit the Al / Al2O3 diffusion impervious layer and then the MCrAlY coating on the substrate of the alloy. The composite coating of the invention has good high-temperature oxidation resistance as well as good bonding strength and high-temperature stability and can provide good high-temperature protection to the Ti-Al alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

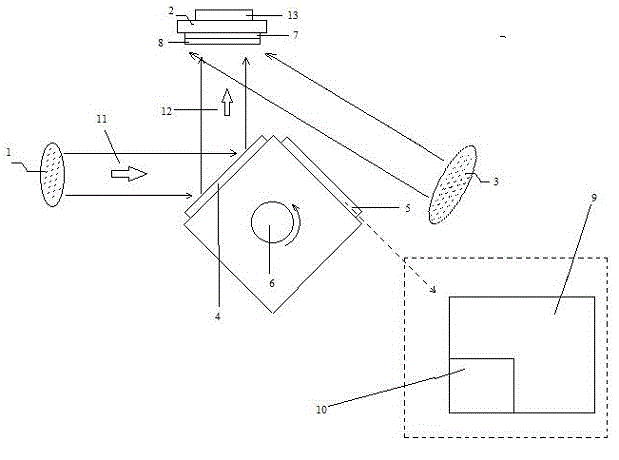

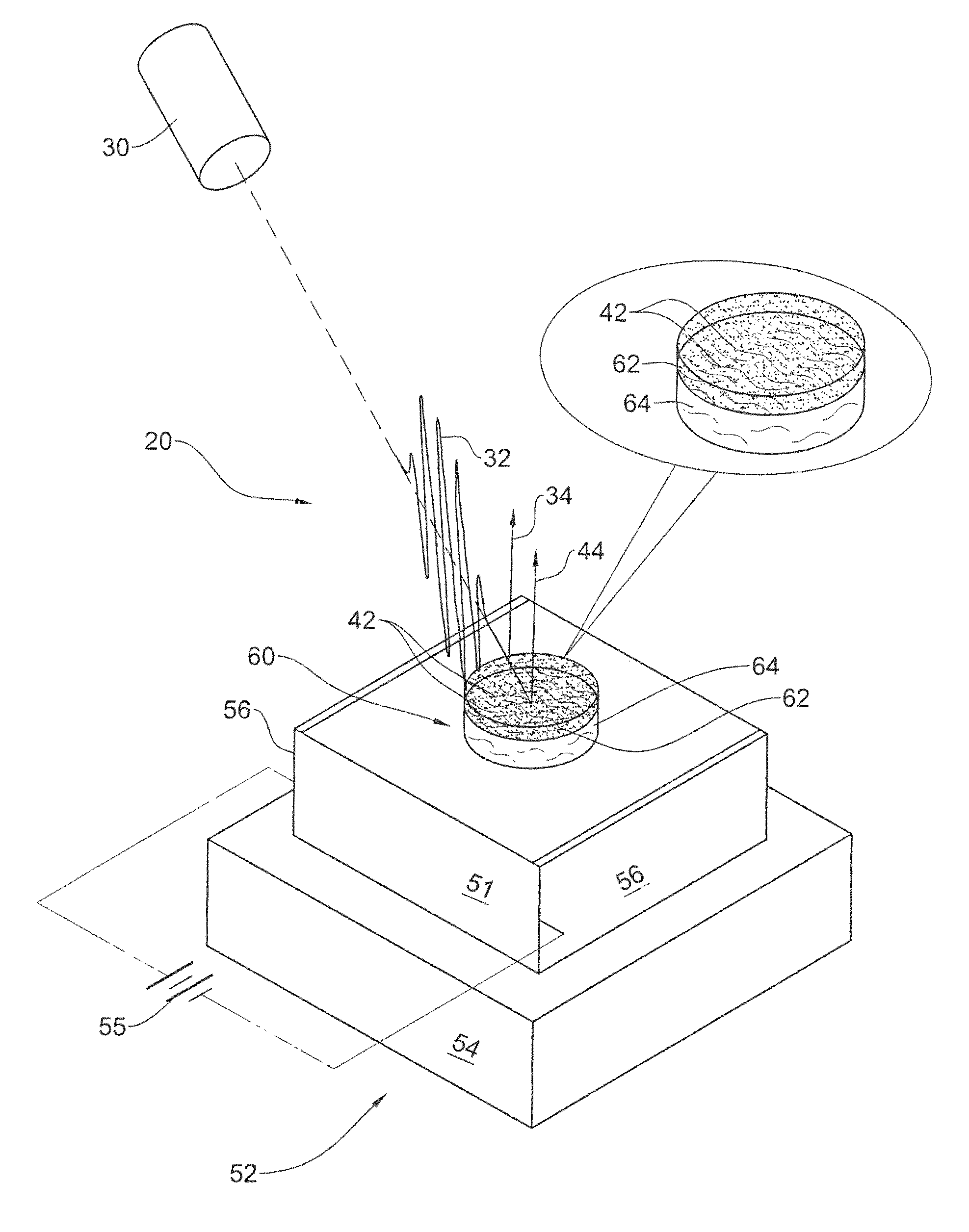

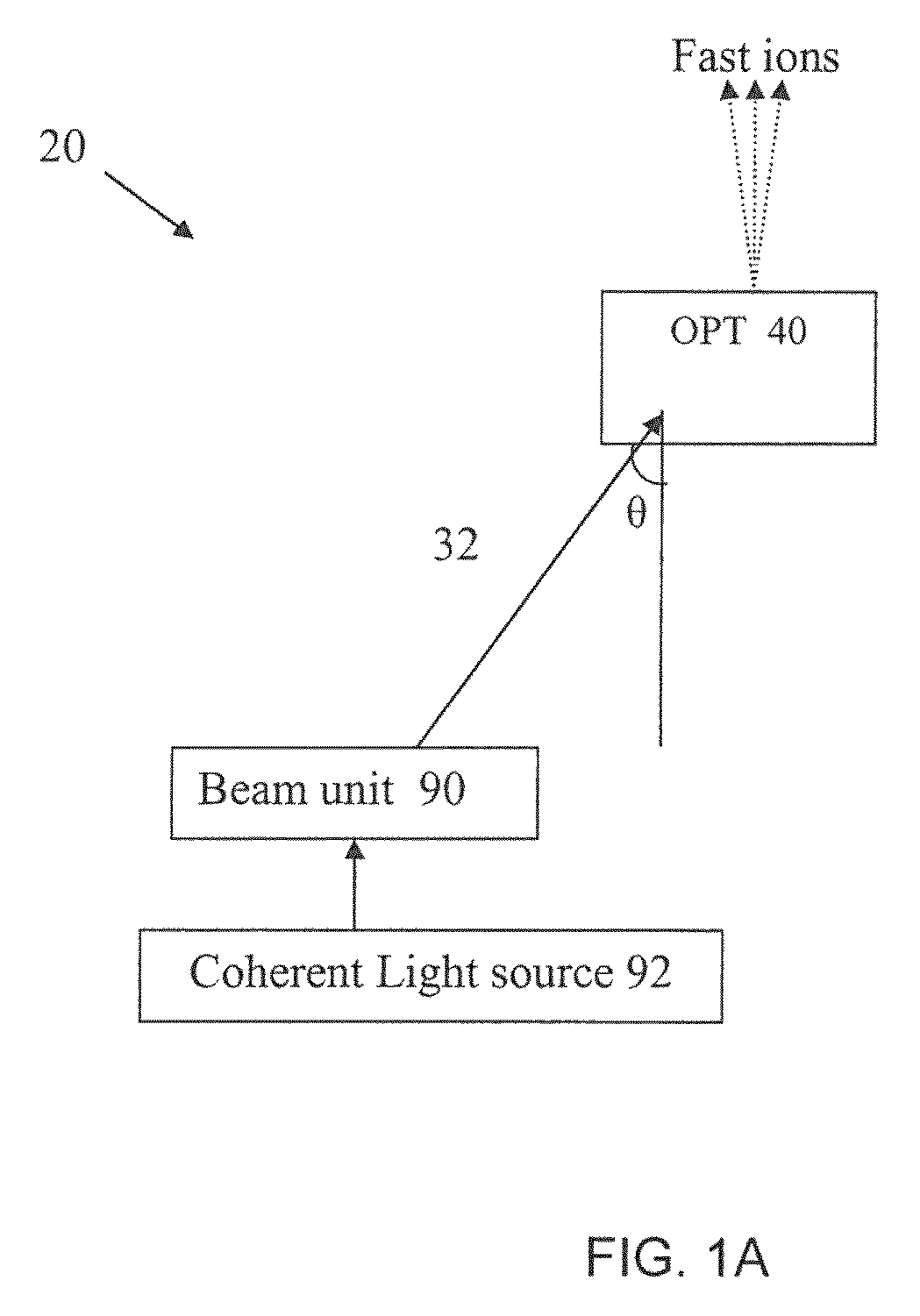

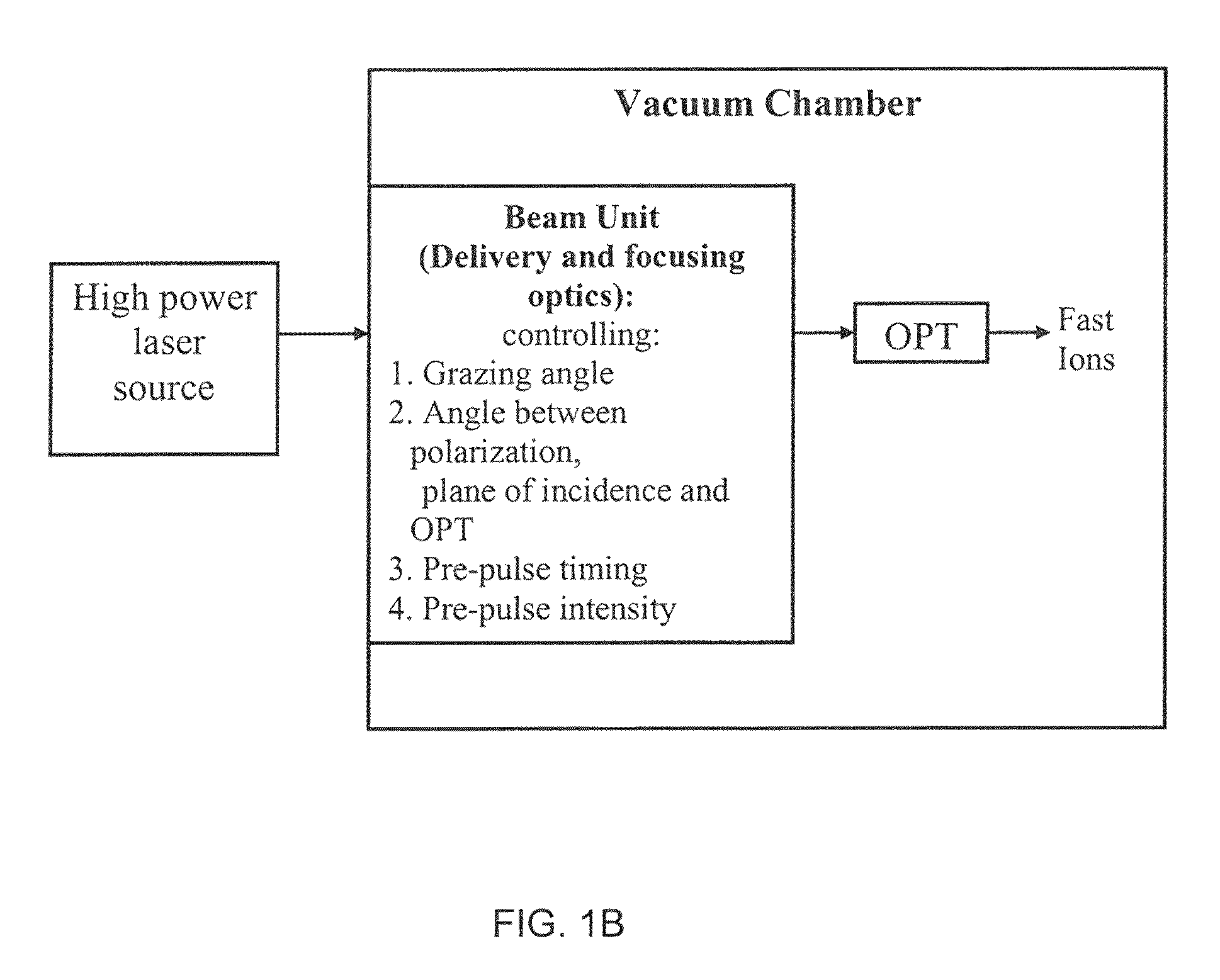

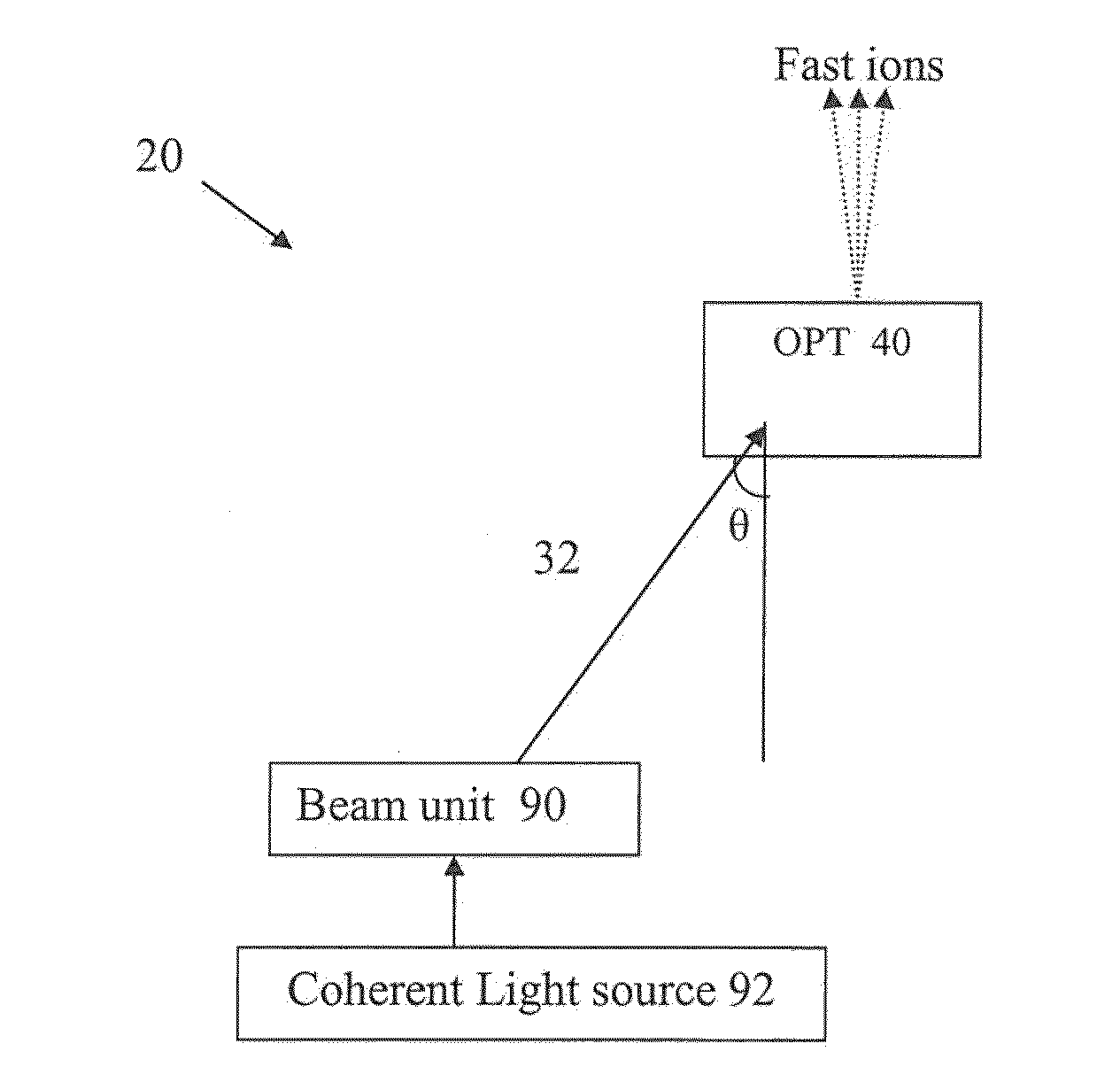

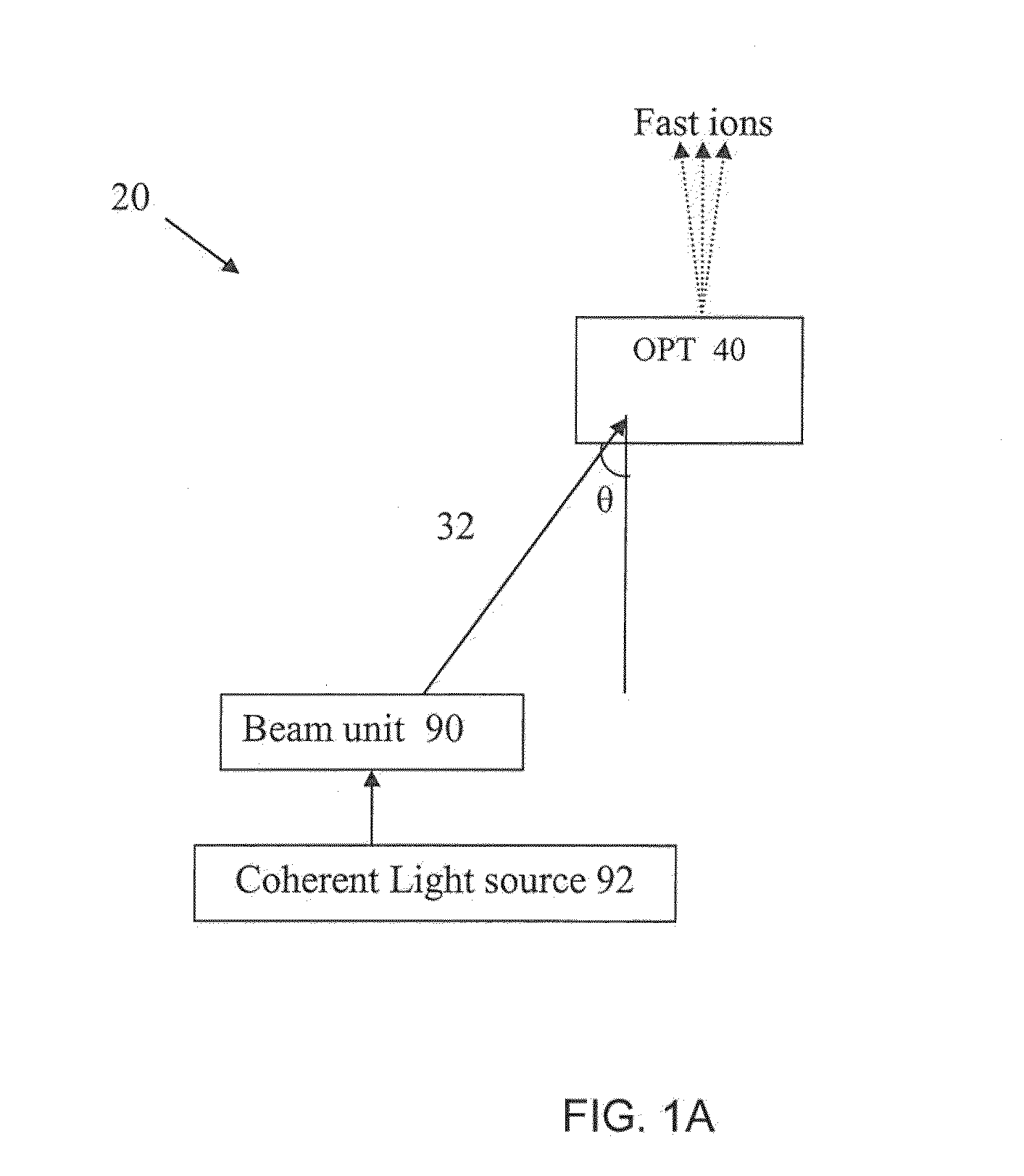

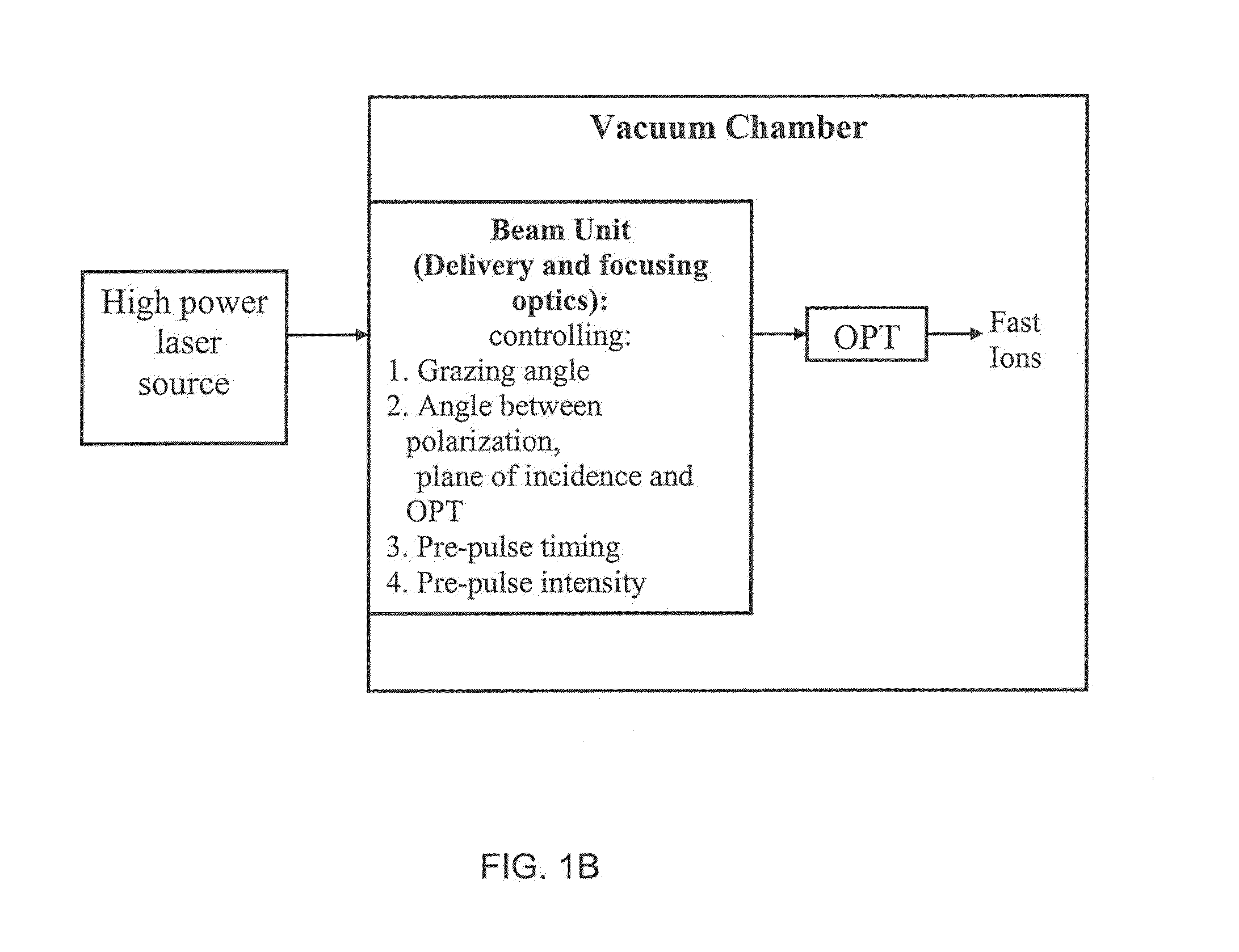

System for fast ions generation and a method thereof

ActiveUS9236215B2Improve efficiencyIncrease kinetic energyIon beam tubesElectromagnetic radiationRadiation beam

The present invention discloses a system and method for generating a beam of fast ions. The system comprising: a target substrate having a patterned surface, a pattern comprising nanoscale pattern features oriented substantially uniformly along a common axis; and; a beam unit adapted for receiving a high power coherent electromagnetic radiation beam and providing an electromagnetic radiation beam having a main pulse and a pre-pulse and focusing it onto said patterned surface of the target substrate to cause interaction between said radiation beam and said substrate enabling creation of fast ions.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD +1

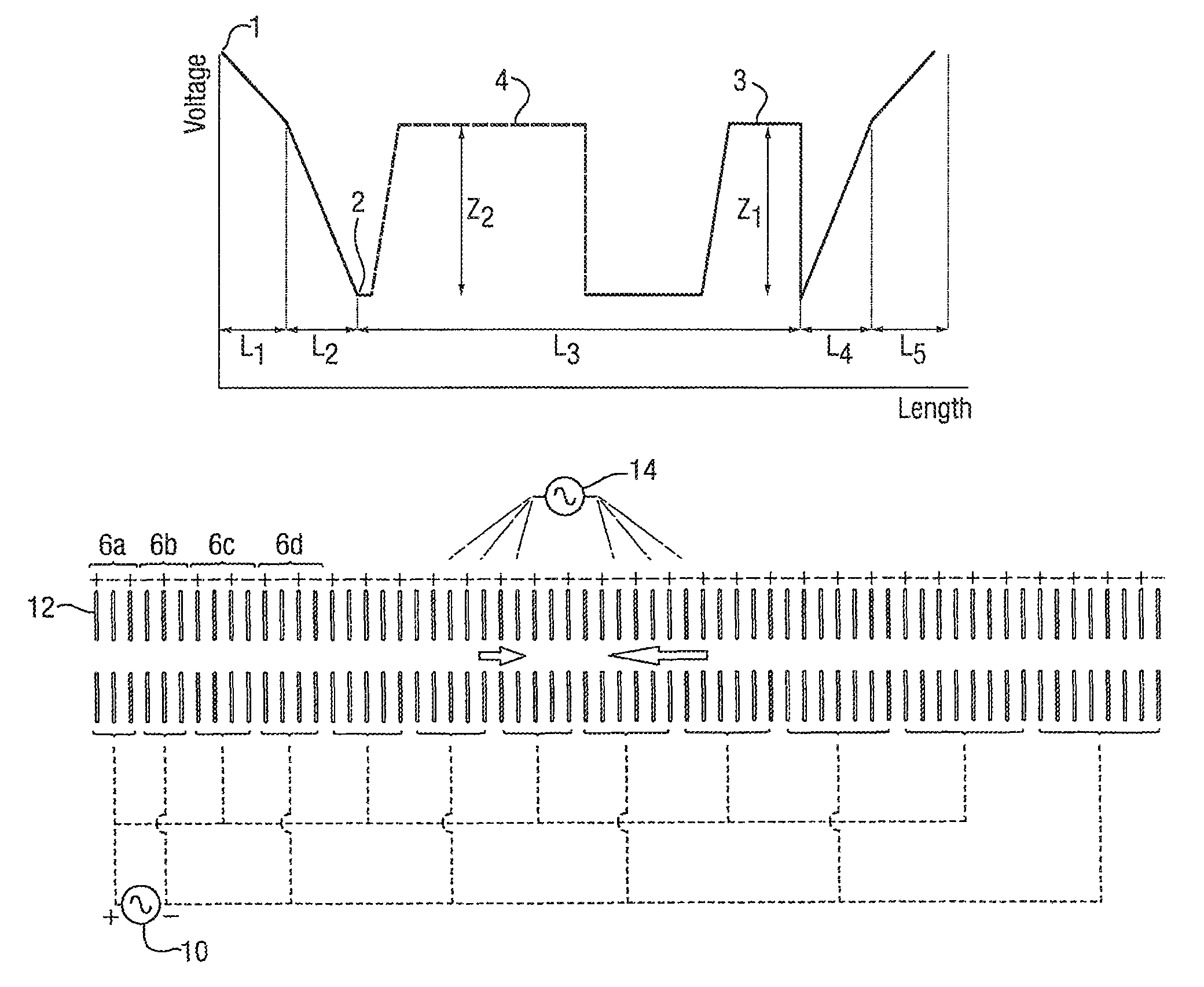

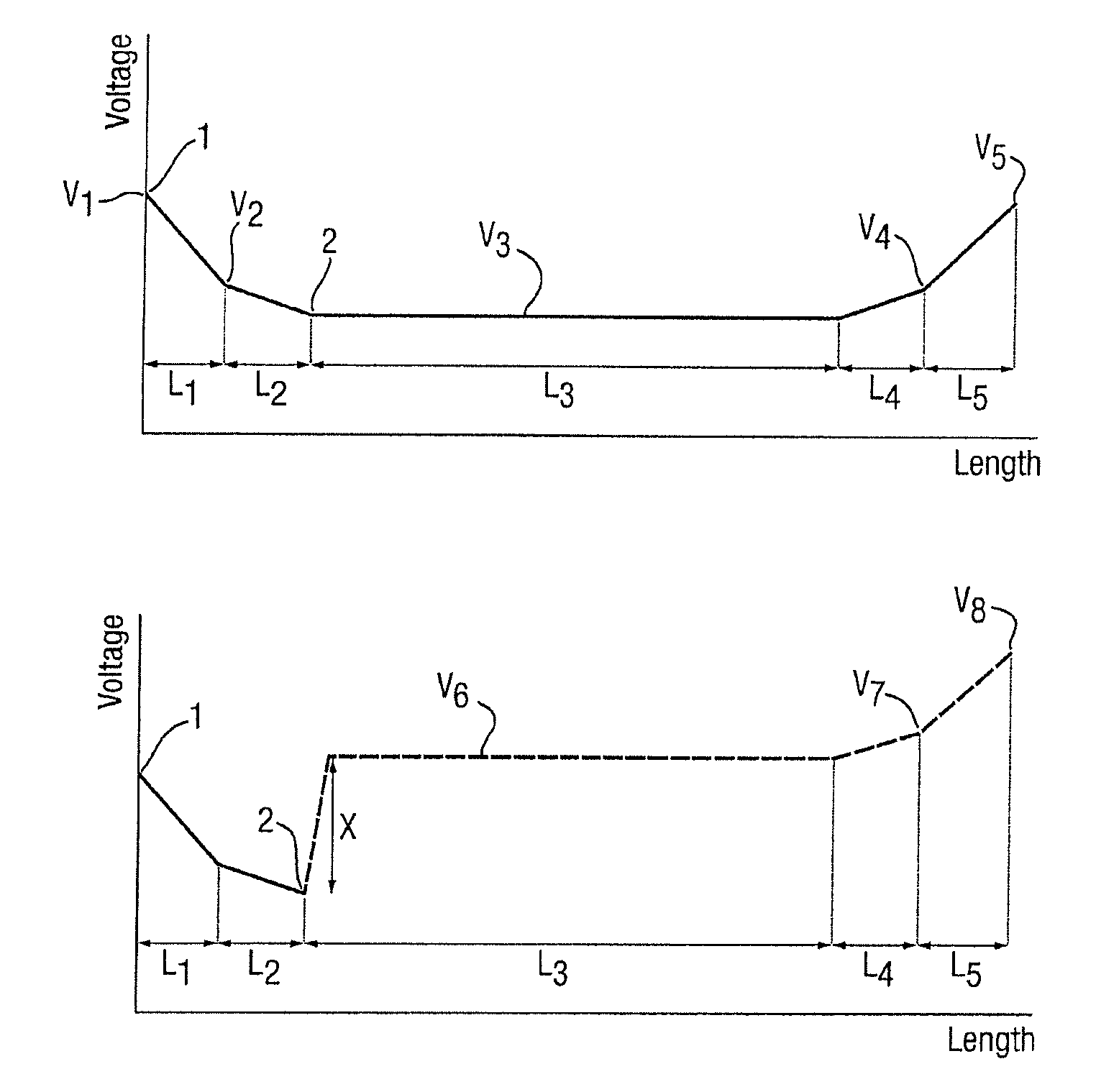

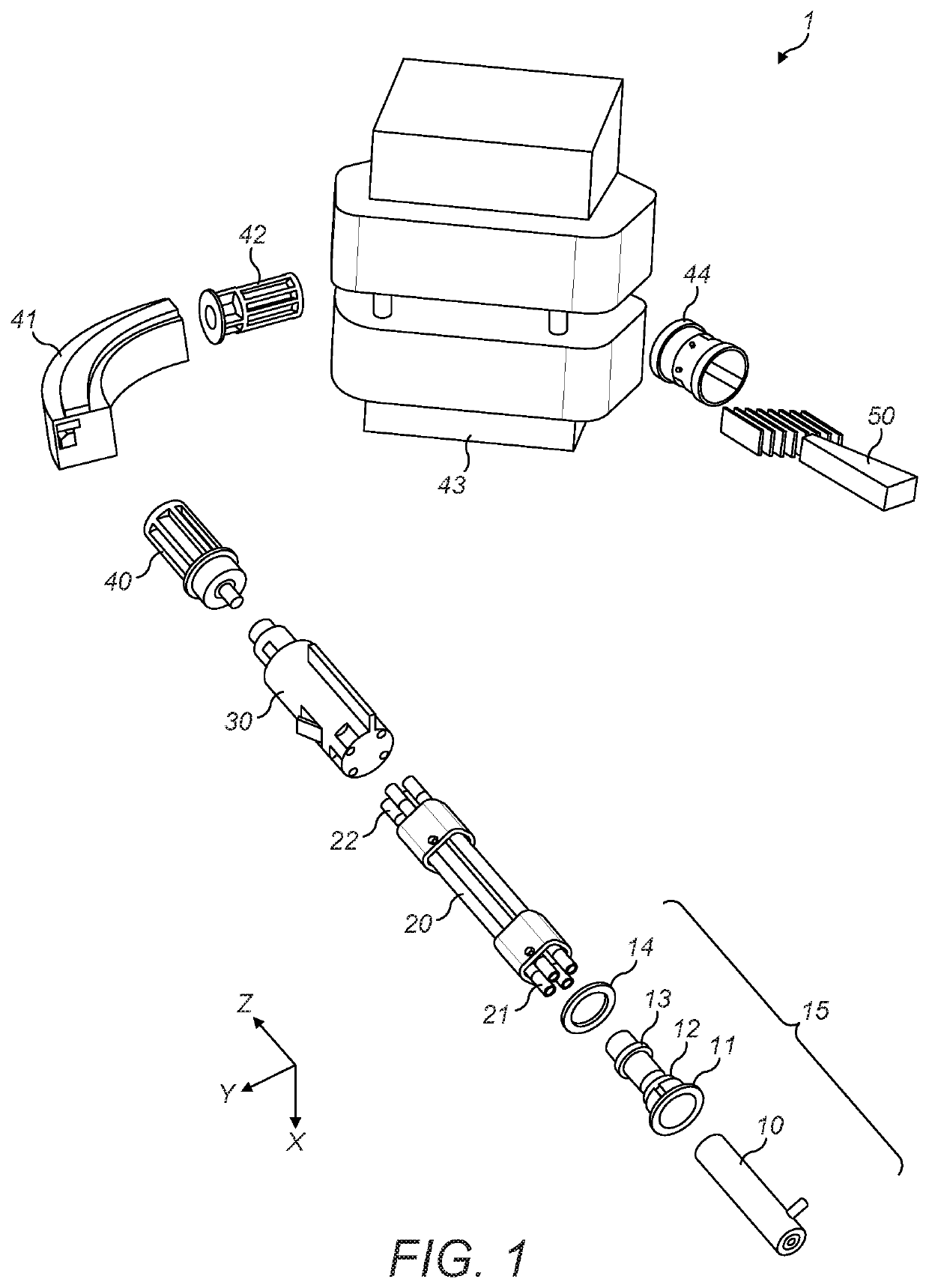

Mass spectrometers comprising accelerator devices

ActiveUS9318309B2High ion energySolve the low detection efficiencyTime-of-flight spectrometersElectron/ion optical arrangementsPotential differenceMass Spectrometry-Mass Spectrometry

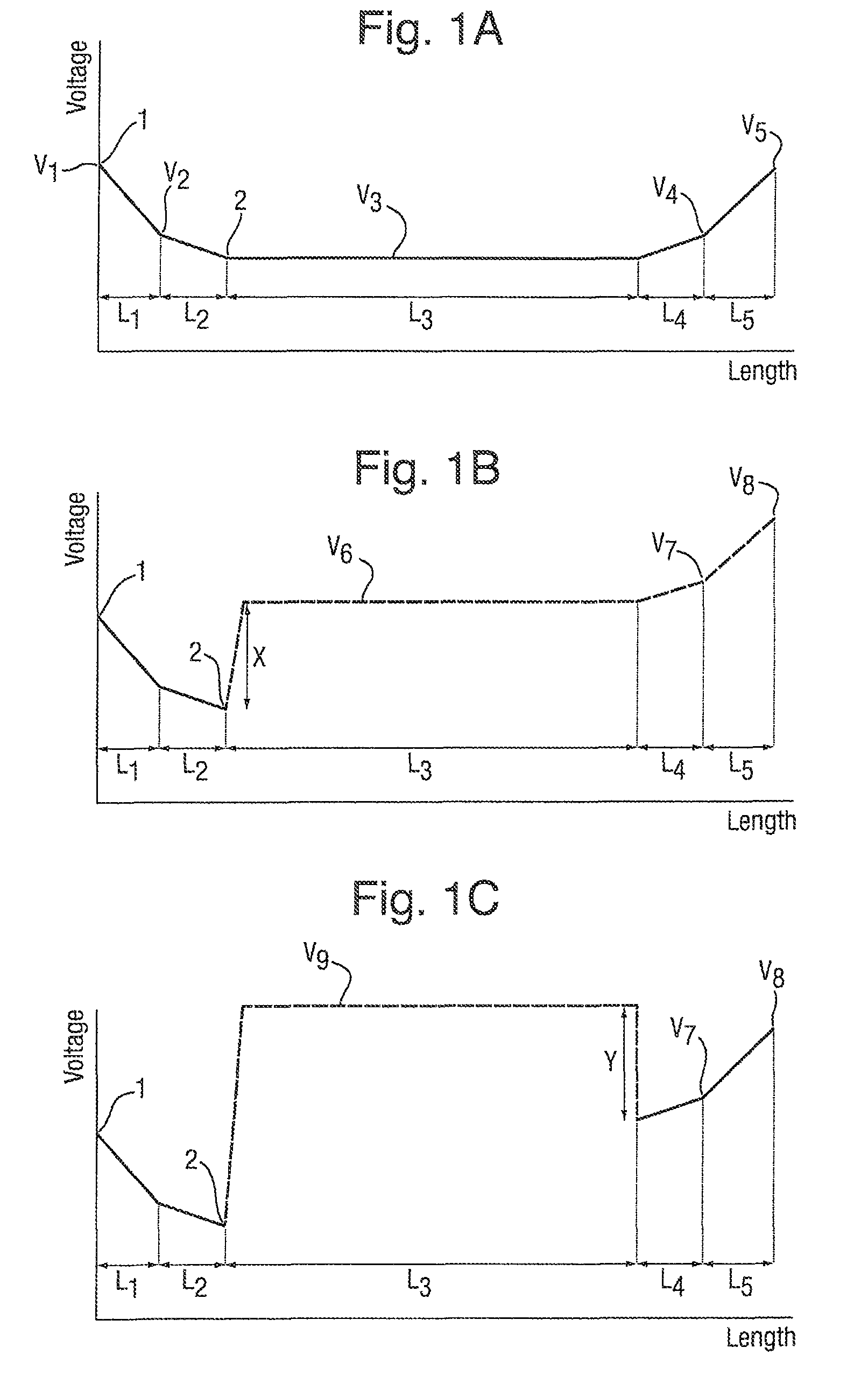

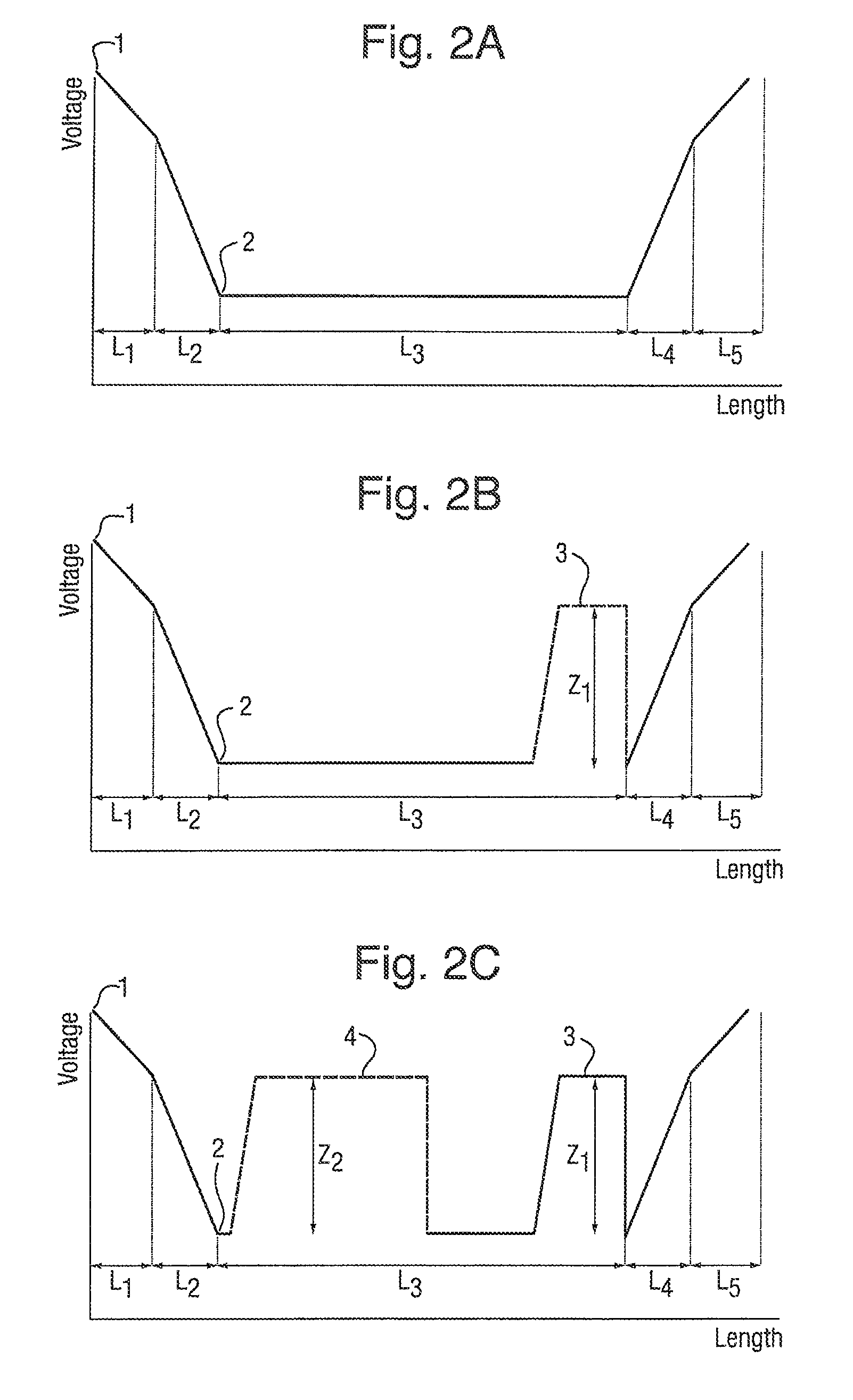

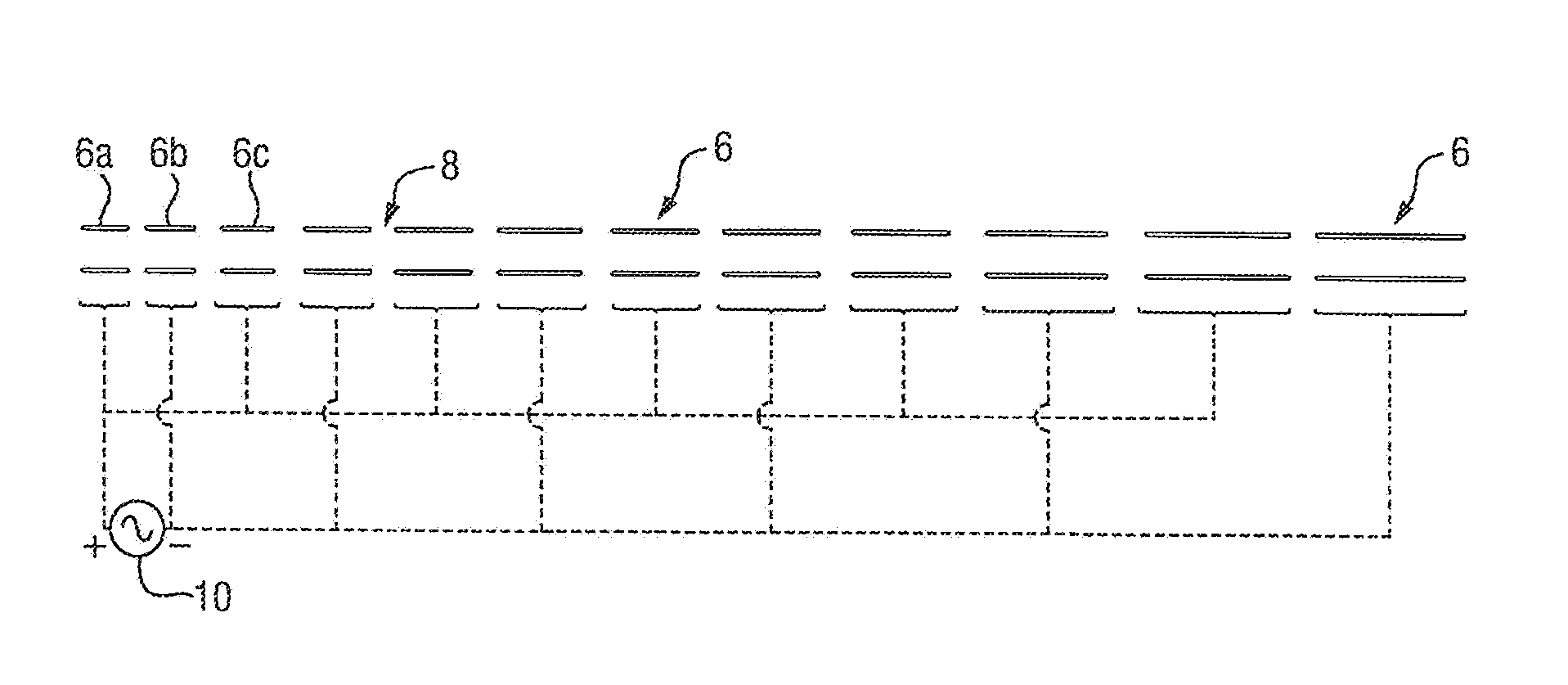

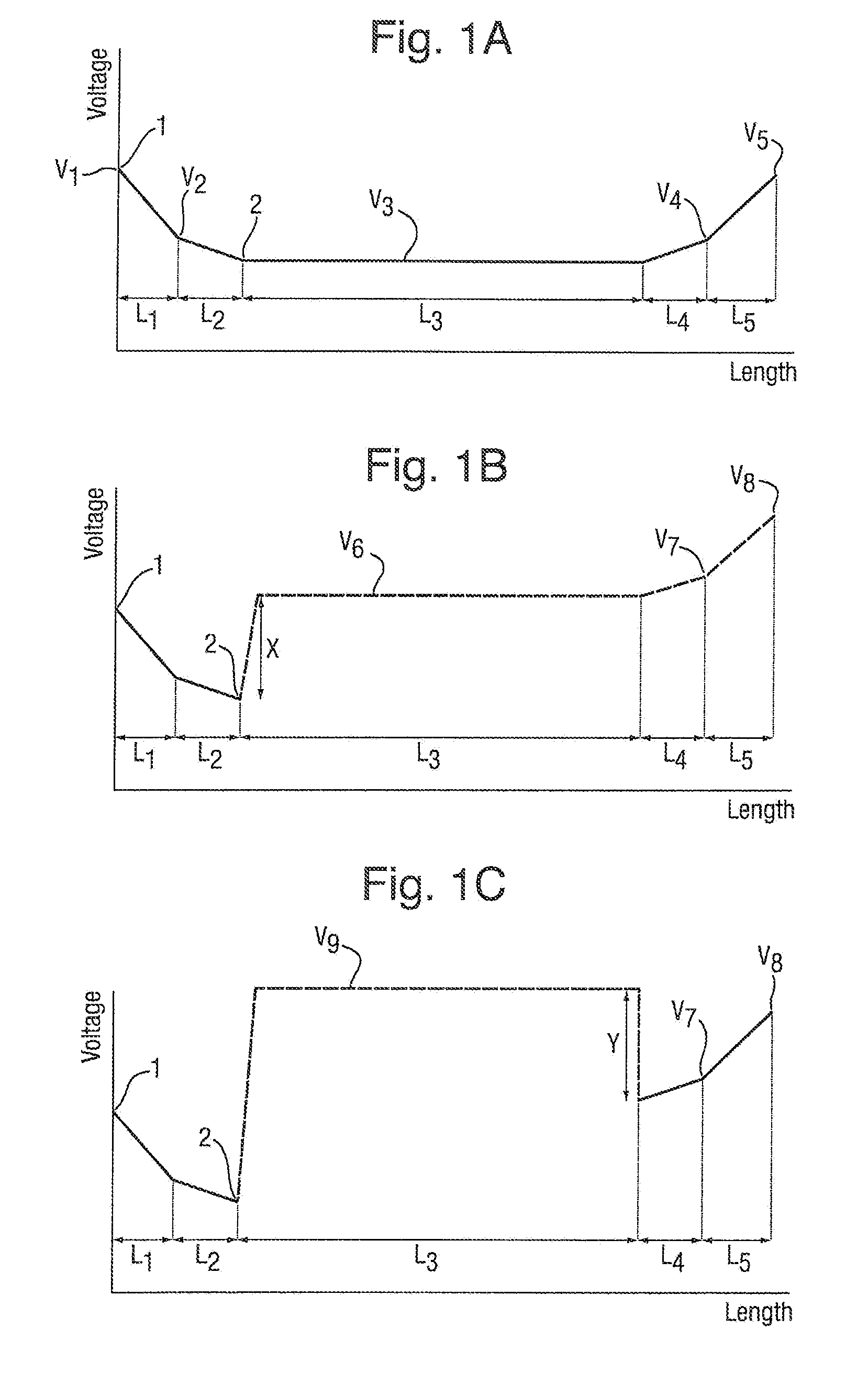

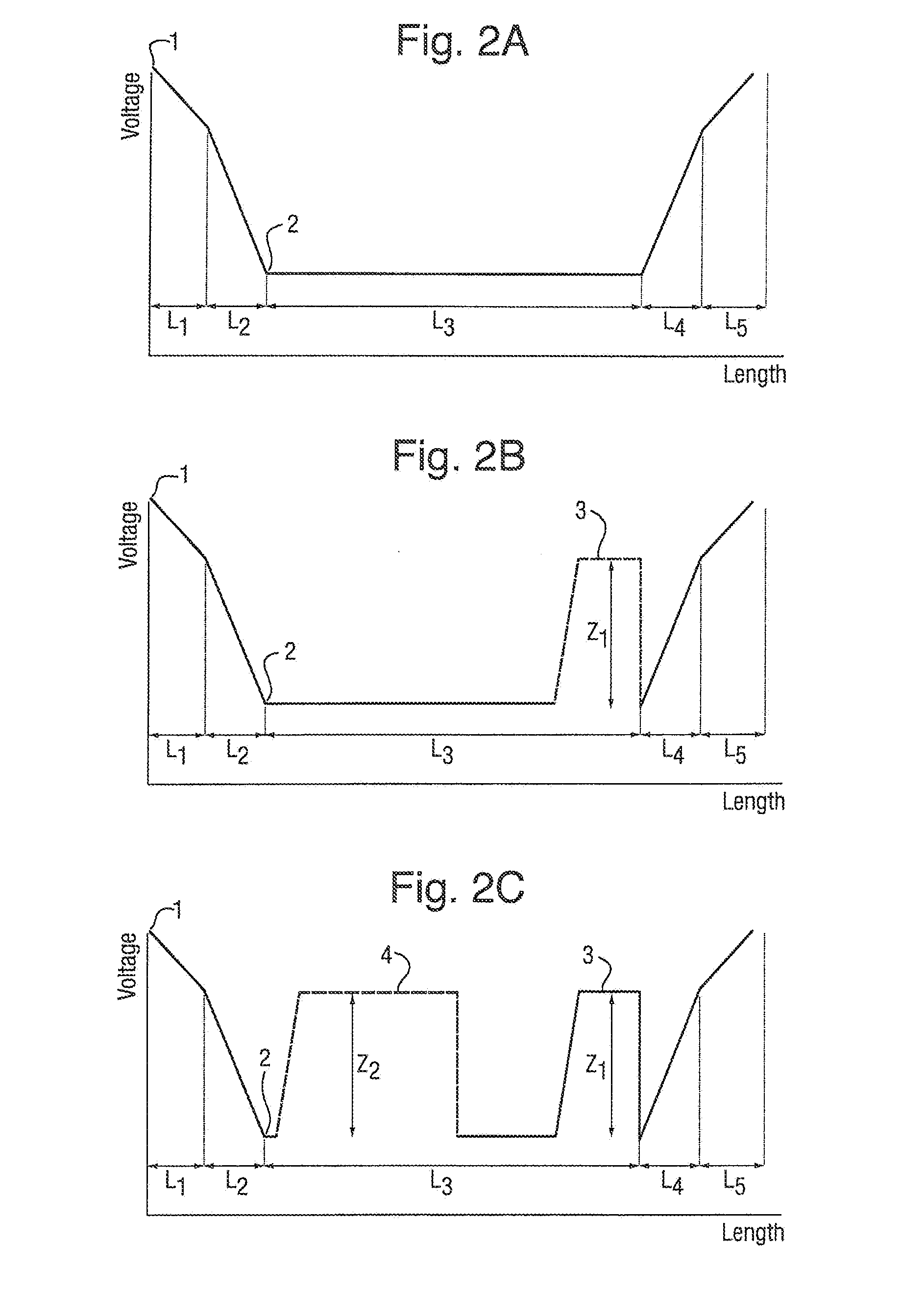

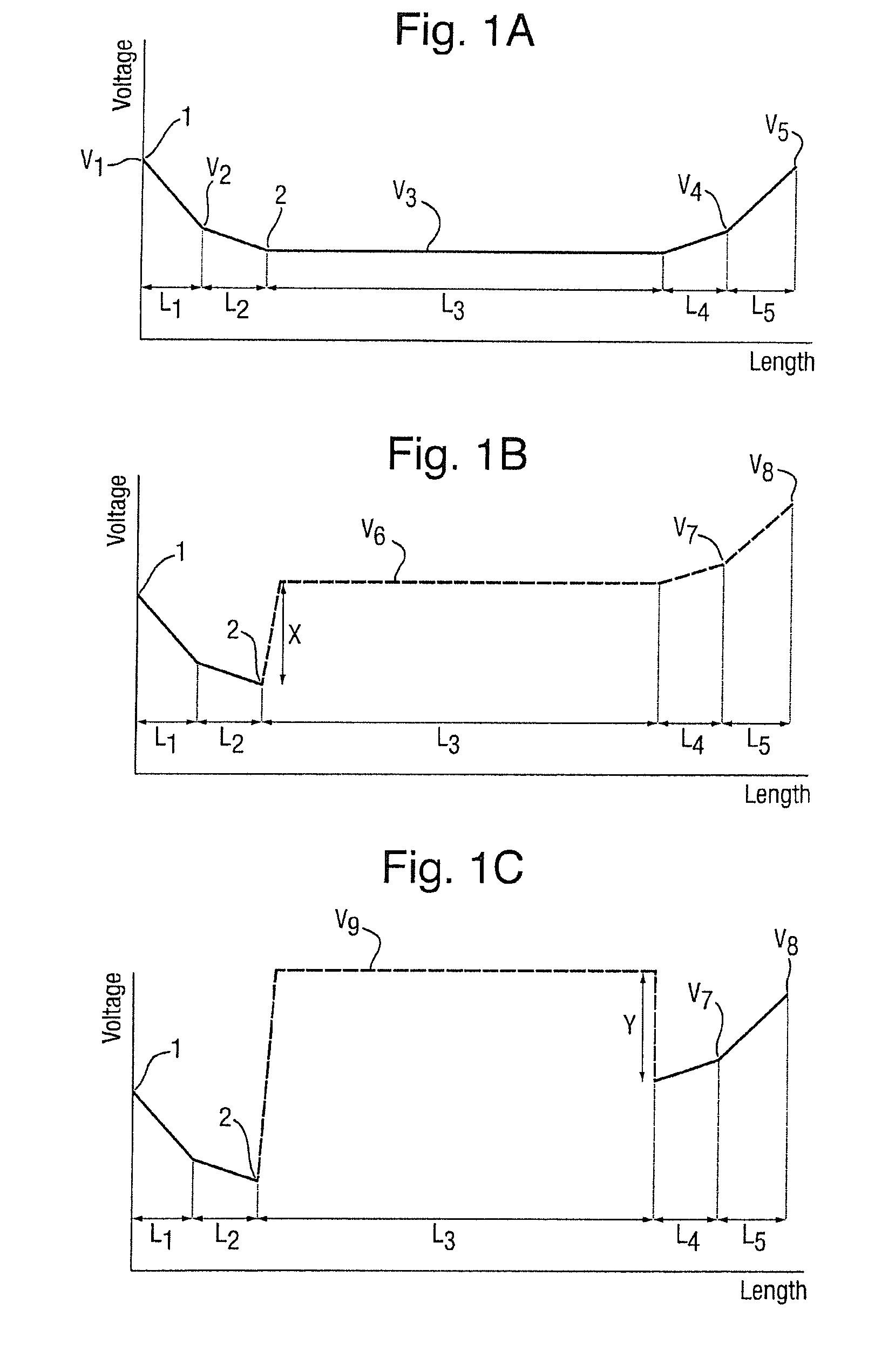

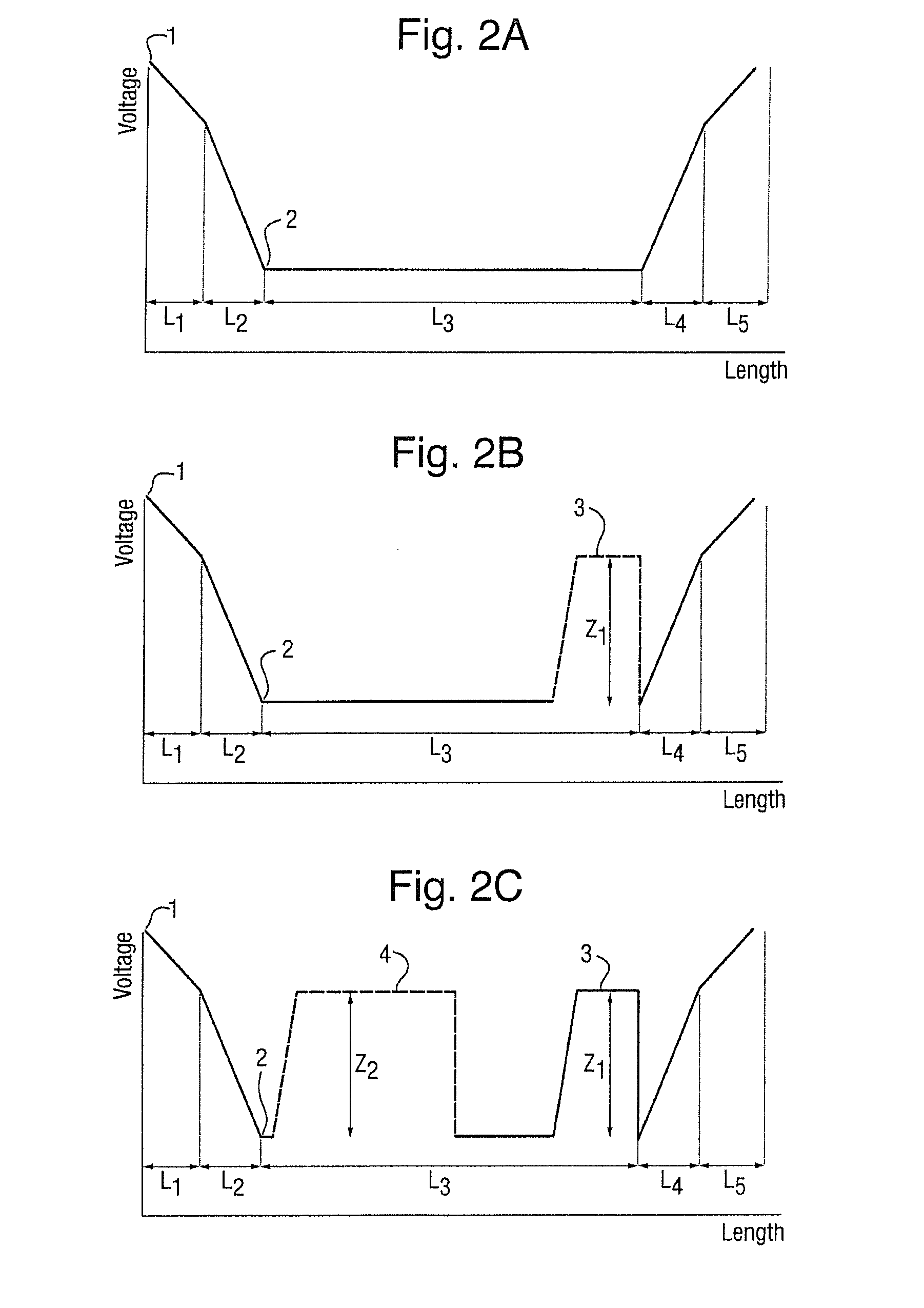

A method of mass spectrometry is disclosed comprising providing a flight region for ions to travel through and a detector or fragmentation device. A potential profile is maintained along the flight region such that ions travel towards the detector or fragmentation device. The potential at which a first length of the flight region is maintained is then changed from a first potential to a second potential while at least some ions are travelling within the first length of flight region. The changed potential provides a first potential difference at an exit of the length of flight region, through which the ions are accelerated as they leave the length of flight region. This increases the kinetic energy of the ions prior to them reaching the detector or fragmentation cell.

Owner:MICROMASS UK LTD

Mass Spectrometers Comprising Accelerator Devices

ActiveUS20140284471A1Increase ion energyIncrease energyTime-of-flight spectrometersElectron/ion optical arrangementsKinetic energySpectrometer

A method of mass spectrometry is disclosed comprising providing a flight region for ions to travel through and a detector or fragmentation device. A potential profile is maintained along the flight region such that ions travel towards the detector or fragmentation device. The potential at which a first length of the flight region is maintained is then changed from a first potential to a second potential whilst at least some ions are travelling within the first length of flight region. The changed potential provides a first potential difference at an exit of the length of flight region, through which the ions are accelerated as they leave the length of flight region. This increases the kinetic energy of the ions prior to them reaching the detector or fragmentation cell.

Owner:MICROMASS UK LTD

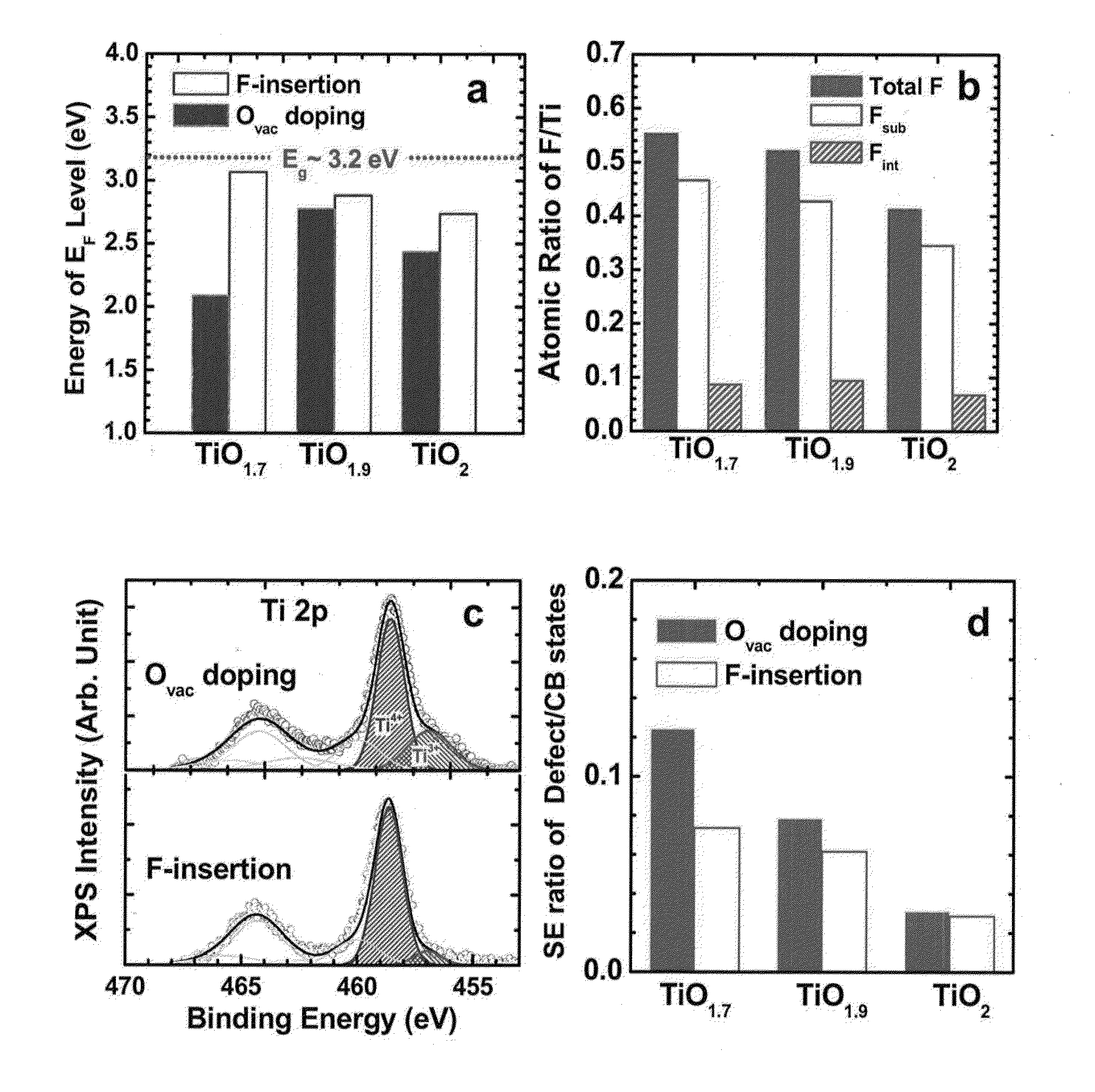

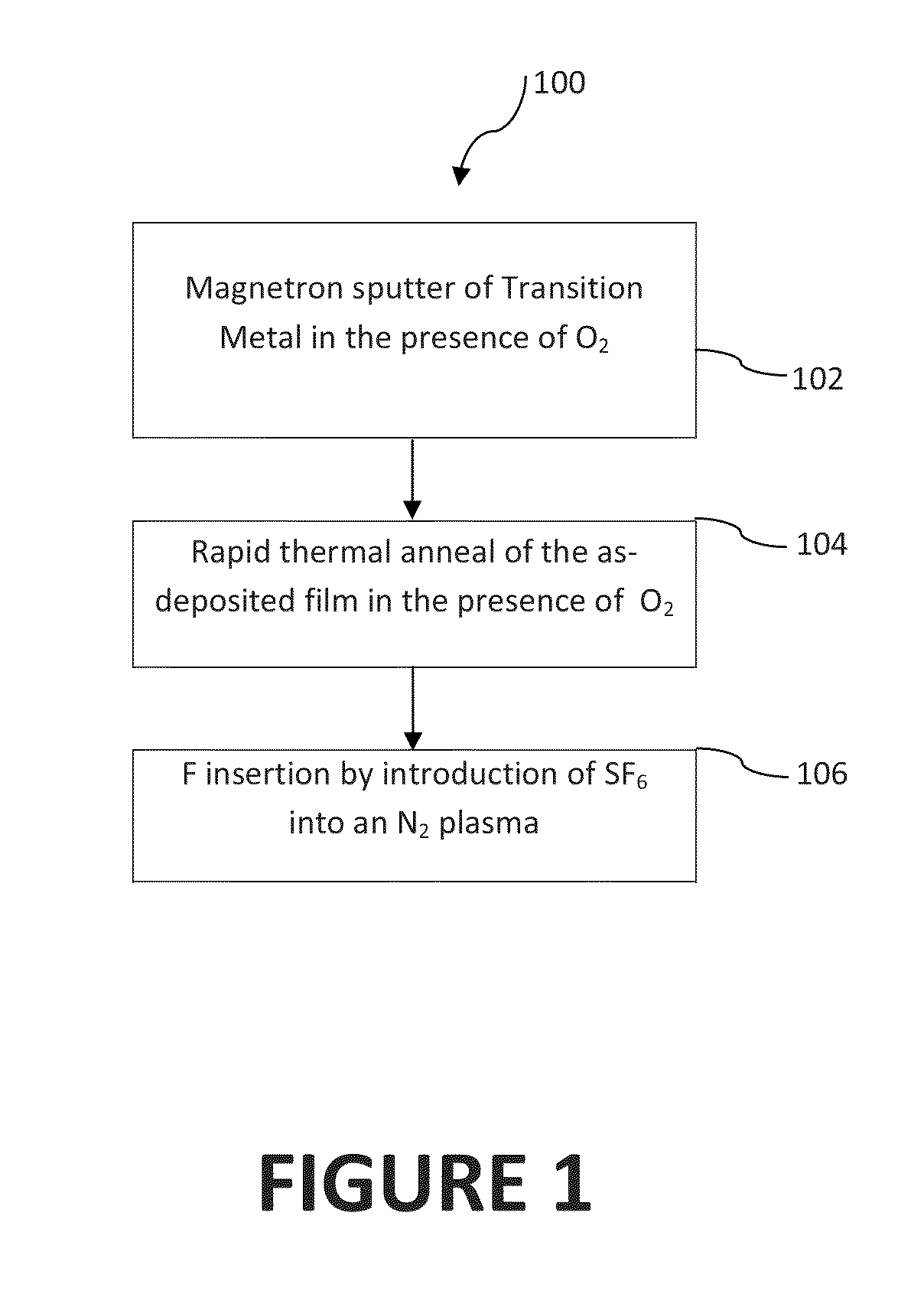

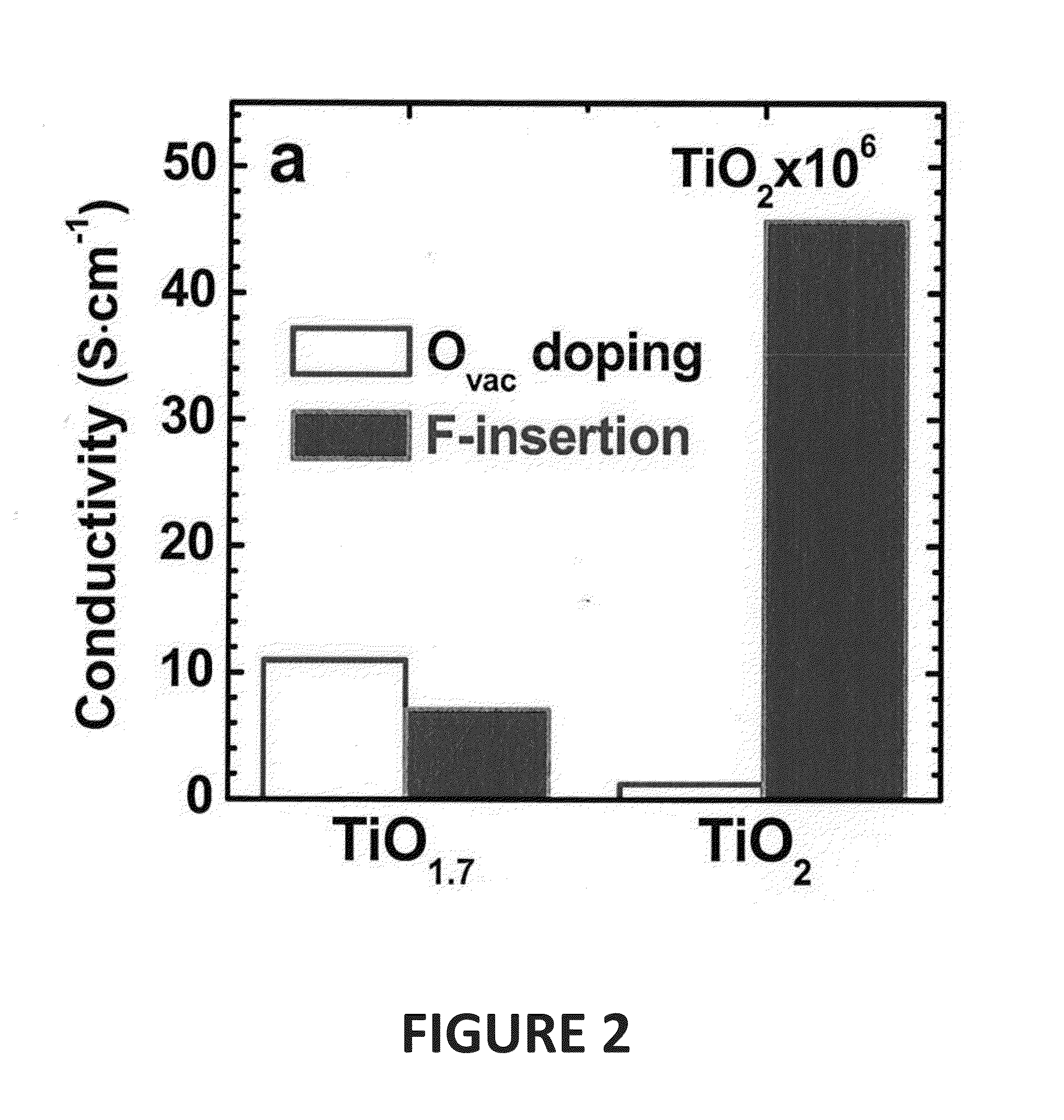

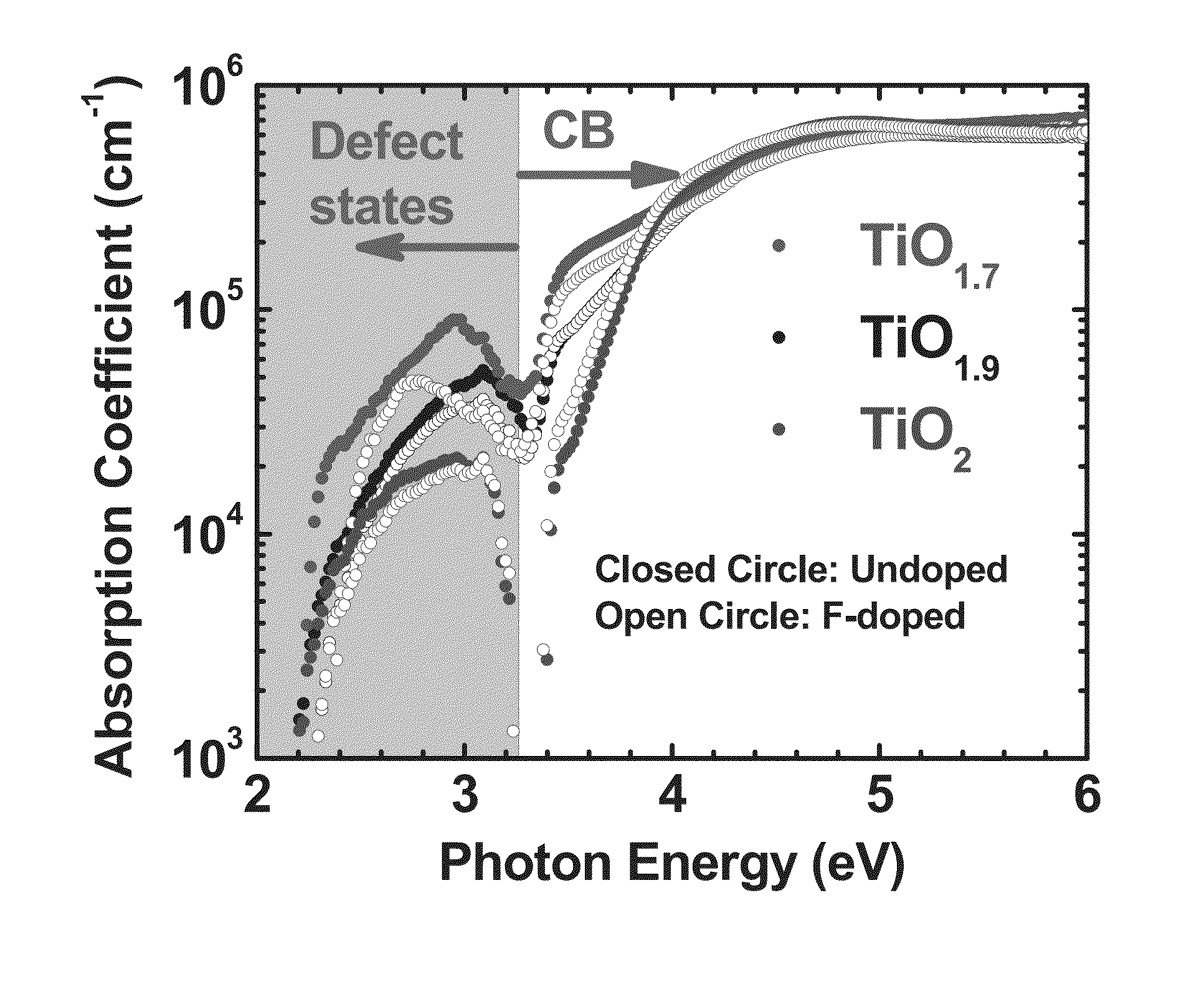

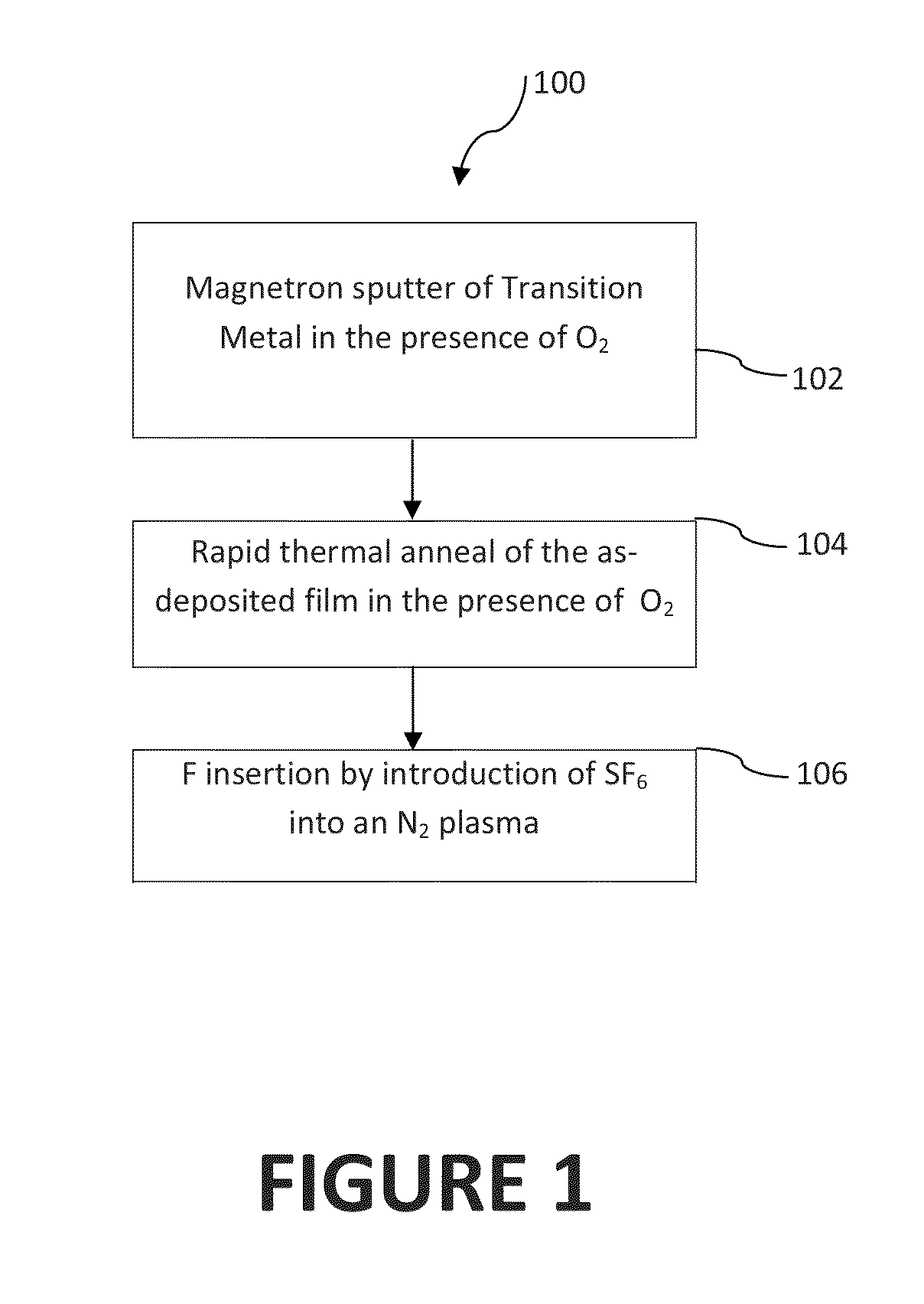

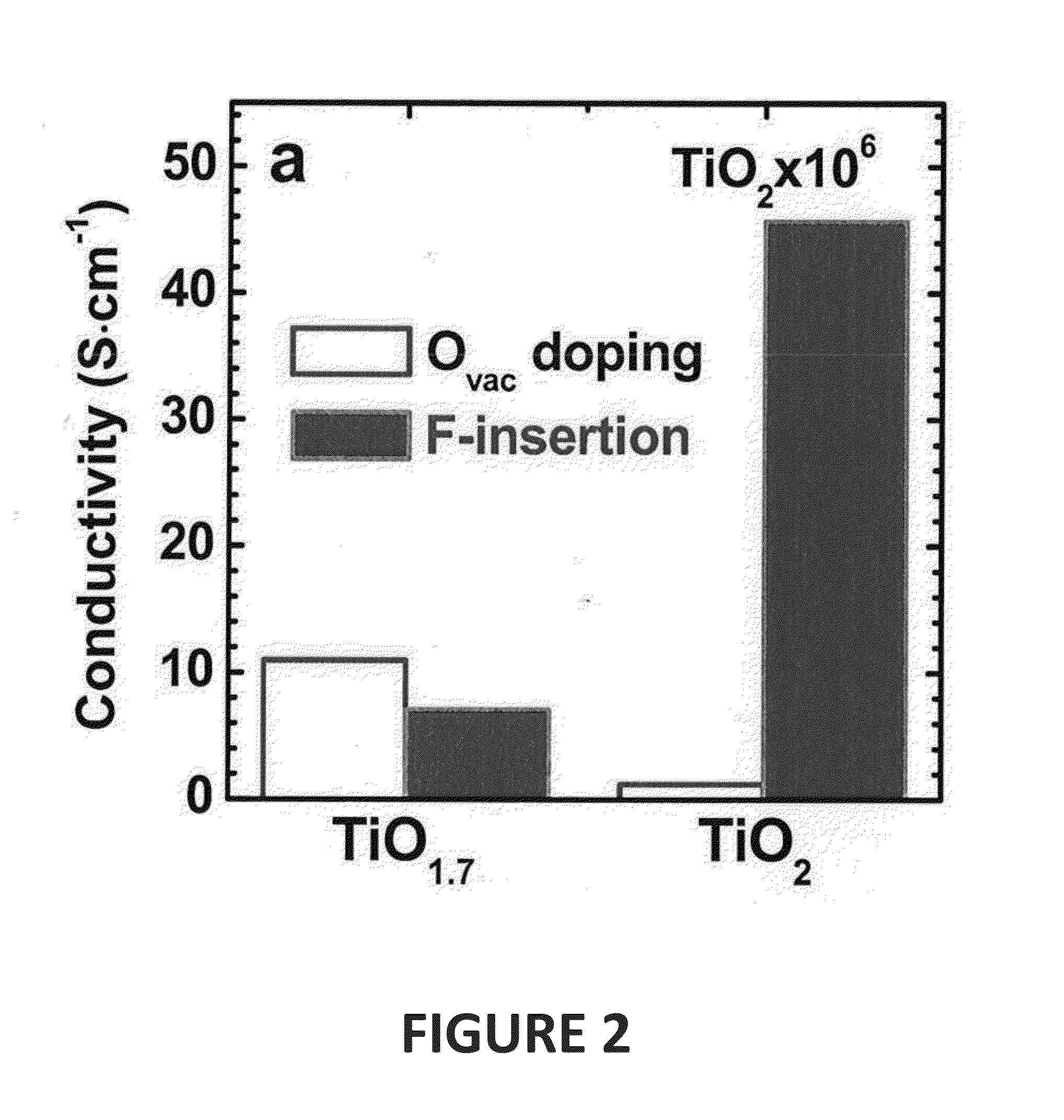

Generation of highly n-type, defect passivated transition metal oxides using plasma fluorine insertion

ActiveUS20140306215A1Reduce overpotentialIncrease ratingsSemiconductor/solid-state device manufacturingSemiconductor devicesOxygen atomOxygen vacancy

A new composition of matter is disclosed wherein oxygen vacancies in a semiconducting transition metal oxide such as titanium dioxide are filled with a halogen such as Fluorine, whereby the conductivity of the composition is greatly enhanced, while at the same time the chemical stability of the composition is greatly improved. Stoichiometric titanium dioxide having less than 3% oxygen vacancies is subject to fluorine insertion such that oxygen vacancies are filled, limited amounts of fluorine replace additional oxygen atoms and fluorine interstitially inserts into the body of the TiO2 composition.

Owner:RGT UNIV OF CALIFORNIA

System for fast ions generation and a method thereof

ActiveUS20130153783A1Improve efficiencyIncrease kinetic energyMaterial analysis by optical meansIon beam tubesLight beamElectromagnetic radiation

The present invention discloses a system and method for generating a beam of fast ions. The system comprising: a target substrate having a patterned surface, a pattern comprising nanoscale pattern features oriented substantially uniformly along a common axis; and; a beam unit adapted for receiving a high power coherent electromagnetic radiation beam and providing an electromagnetic radiation beam having a main pulse and a pre-pulse and focusing it onto said patterned surface of the target substrate to cause interaction between said radiation beam and said substrate enabling creation of fast ions.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD +1

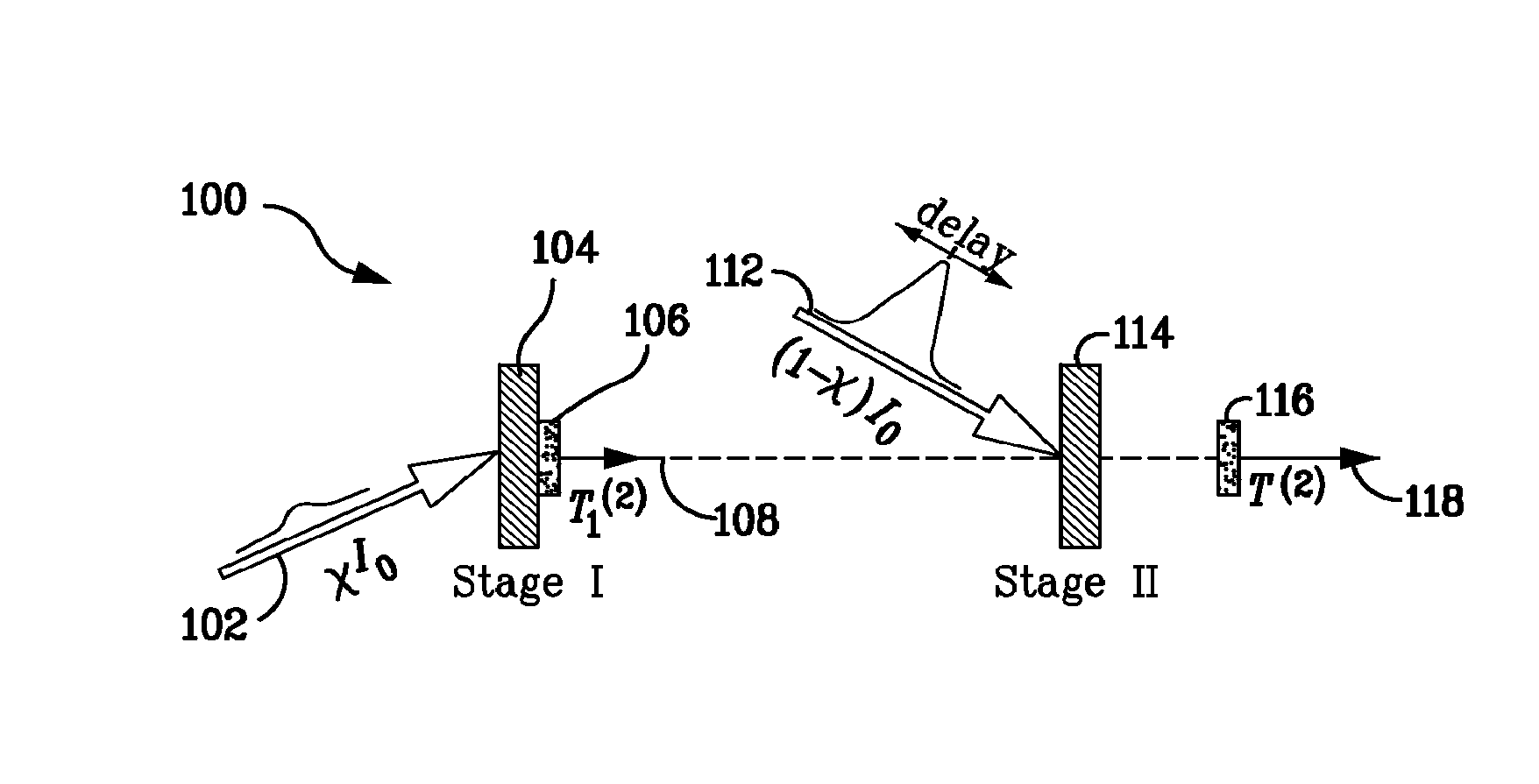

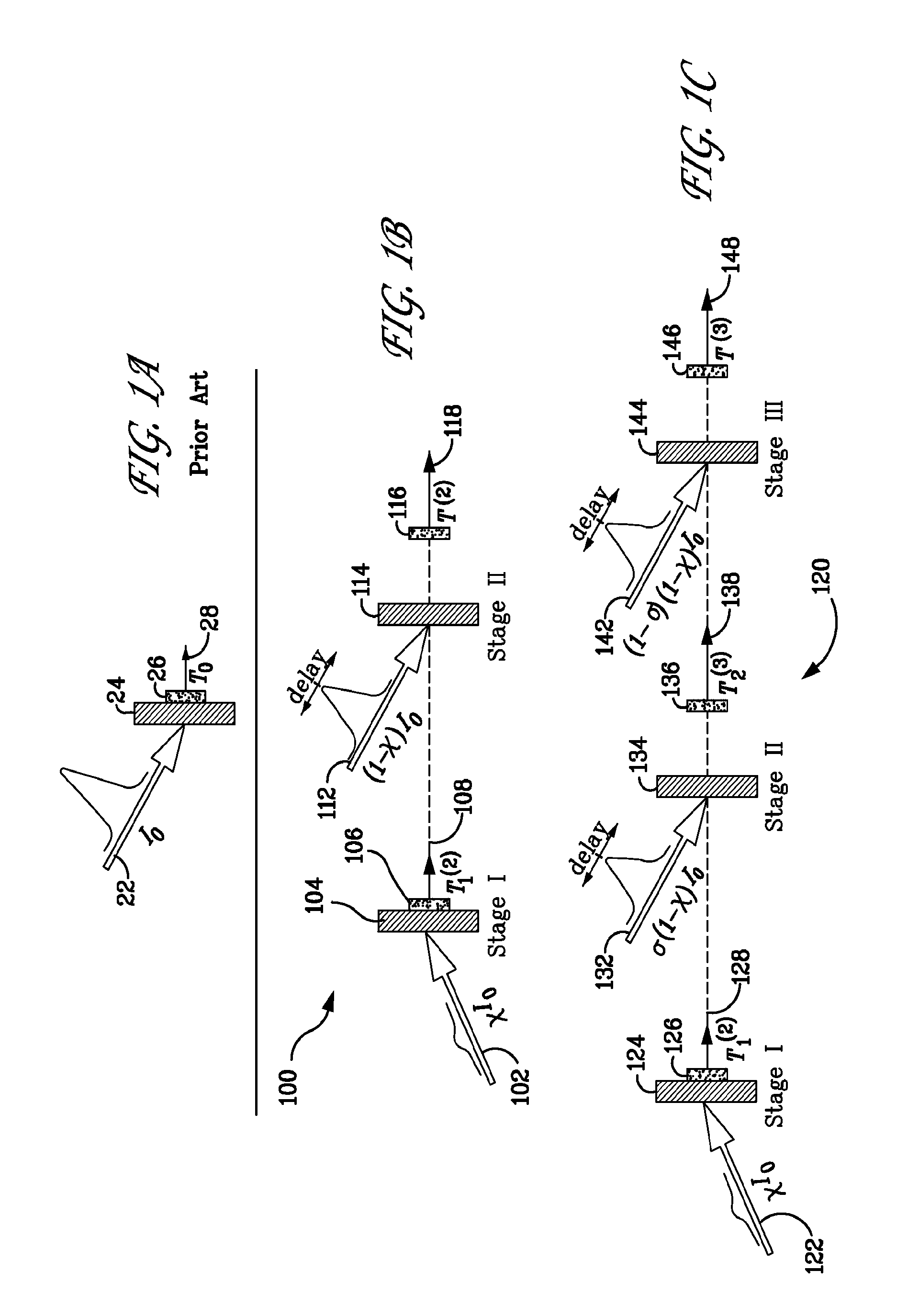

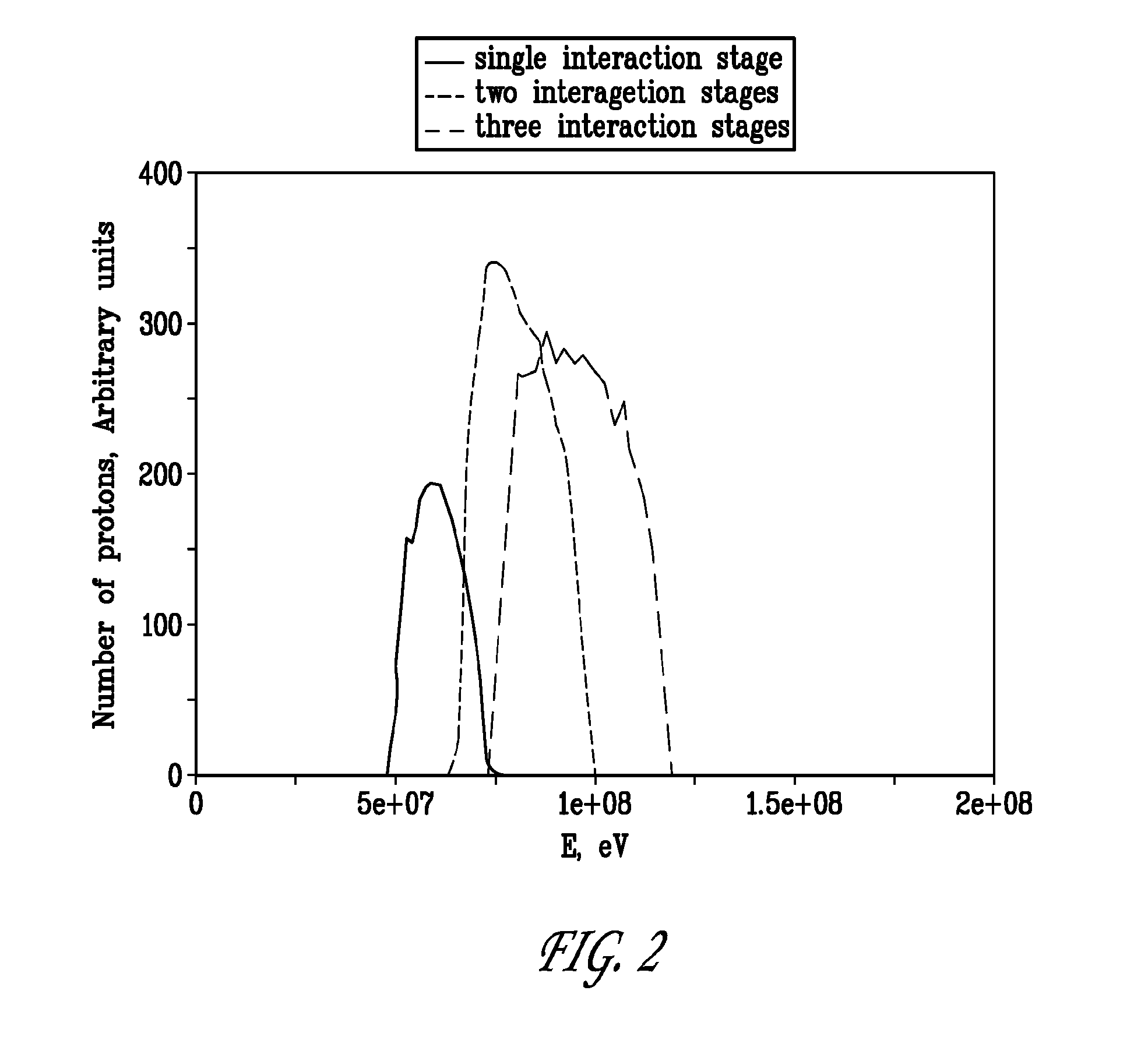

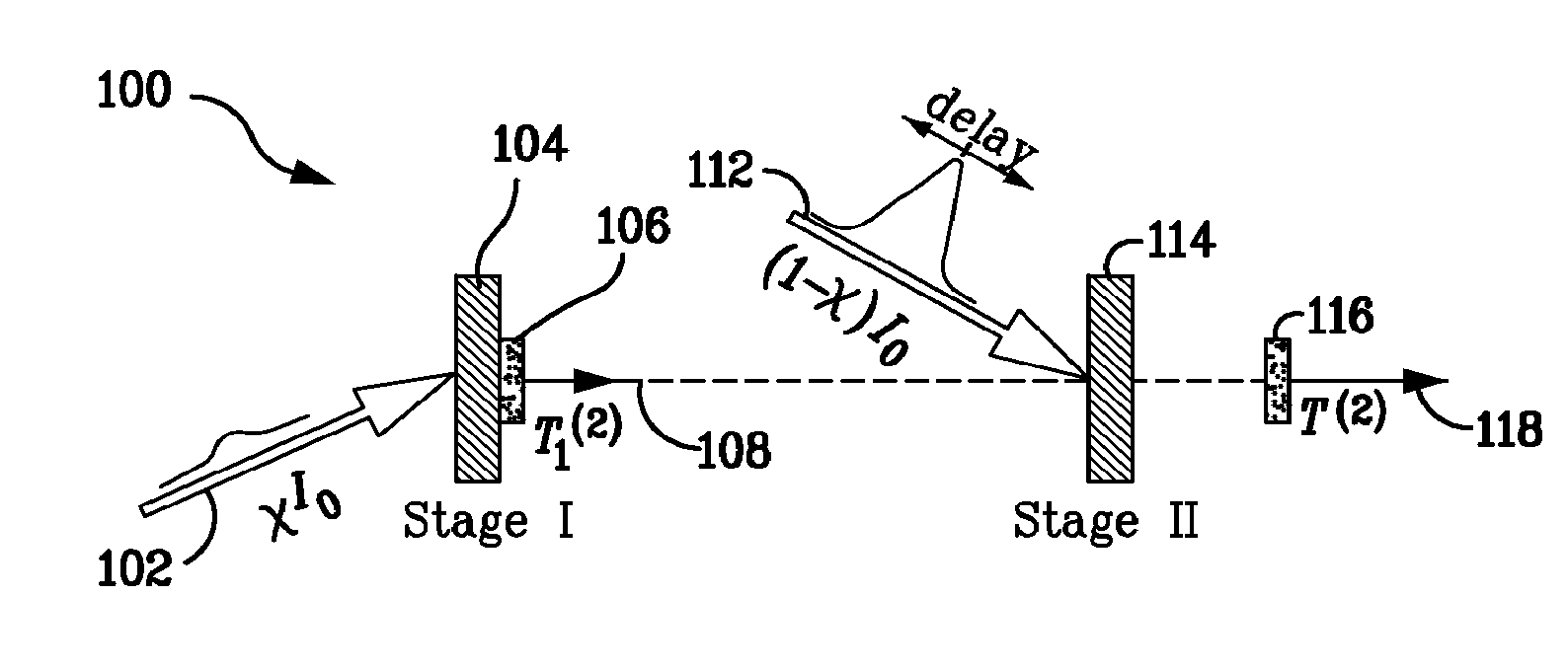

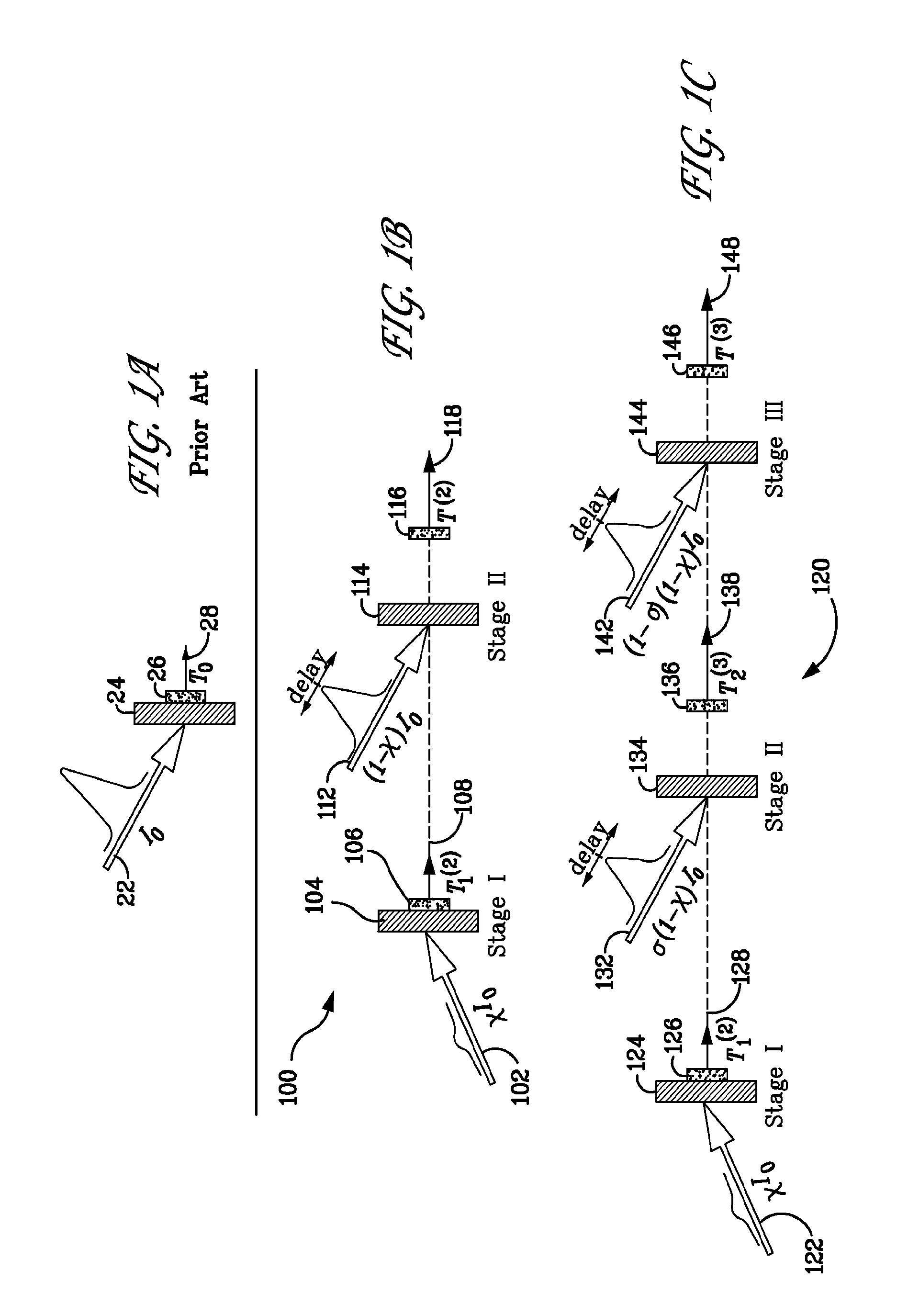

Methods and systems for increasing the energy of positive ions accelerated by high-power lasers

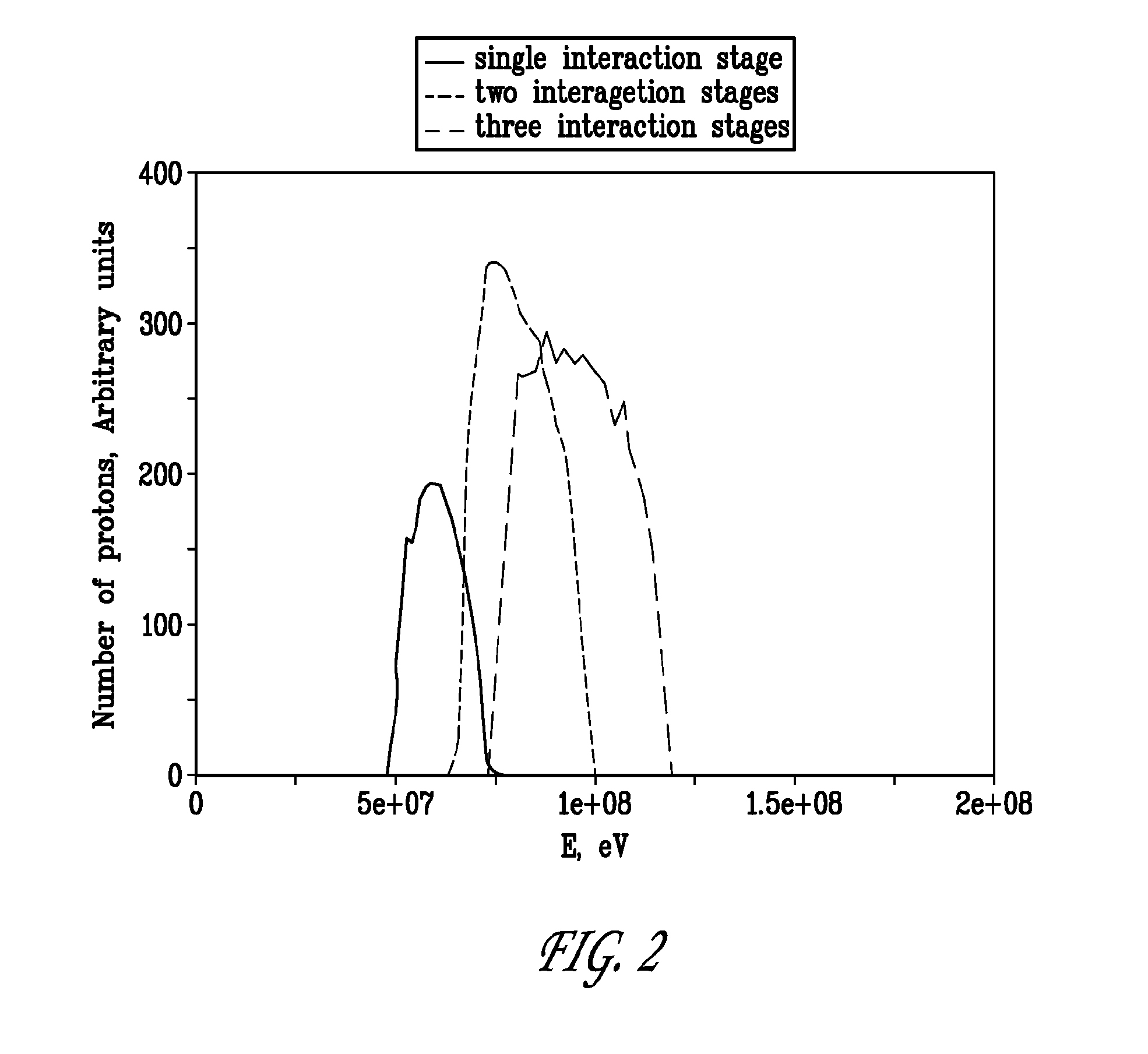

ActiveUS8269189B2Limiting abilityIncrease heightThermometer detailsBeam/ray focussing/reflecting arrangementsEnergy transferSingle stage

The energy of positive ions accelerated in laser-matter interaction experiments can be significantly increased by providing a plurality of laser pulses, e.g., through the process of splitting the incoming laser pulse, to form multiple laser-matter interaction stages. From a thermodynamic point of view, the splitting procedure can be viewed as an effective way of increasing the efficiency of energy transfer from the laser light to positive ions, which energy peaks for processes having the least amount of entropy gain. A 100% increase in the energy efficiency is achieved for a six-stage laser positive ion accelerator compared to a single-stage laser positive ion accelerator.

Owner:INST FOR CANCER RES

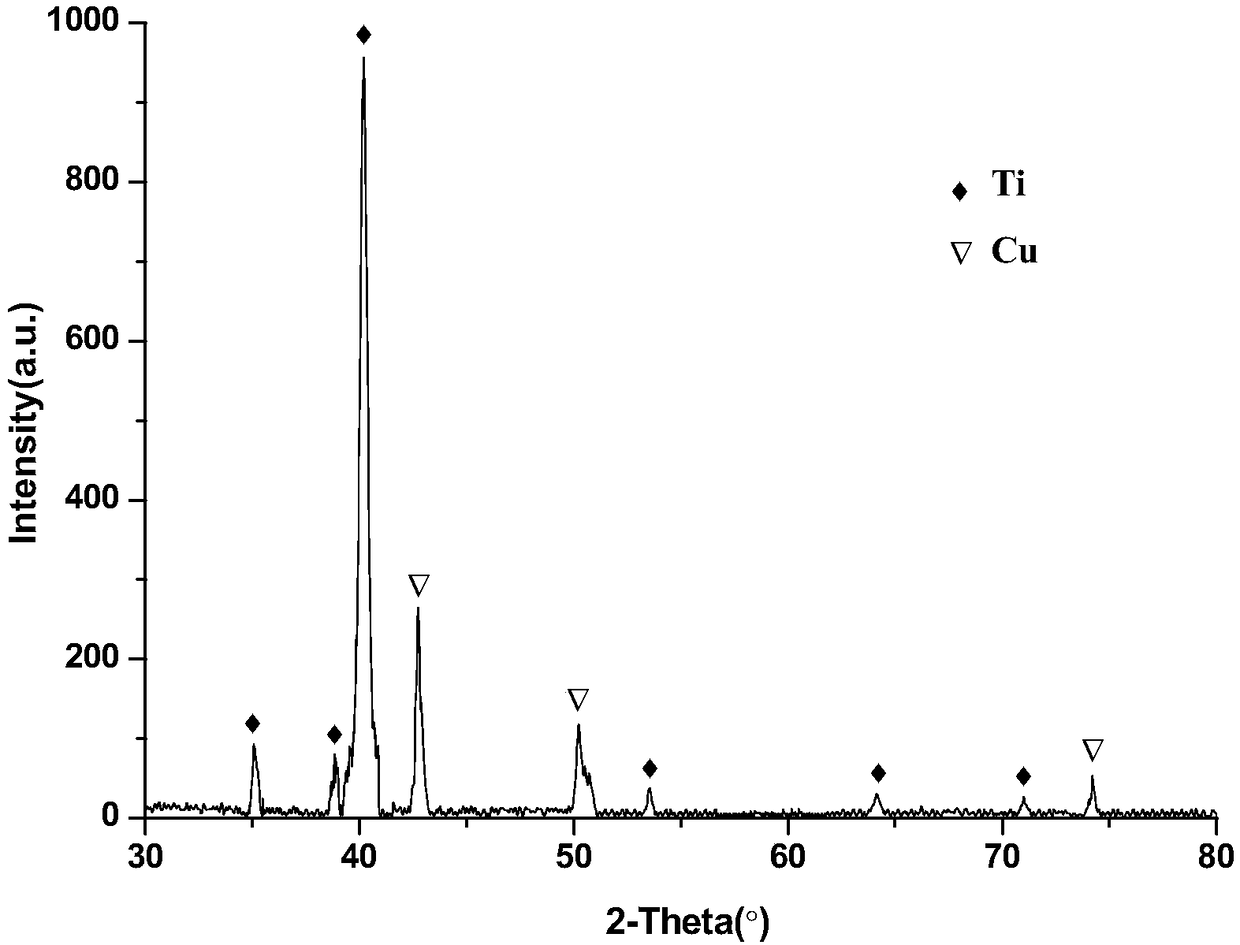

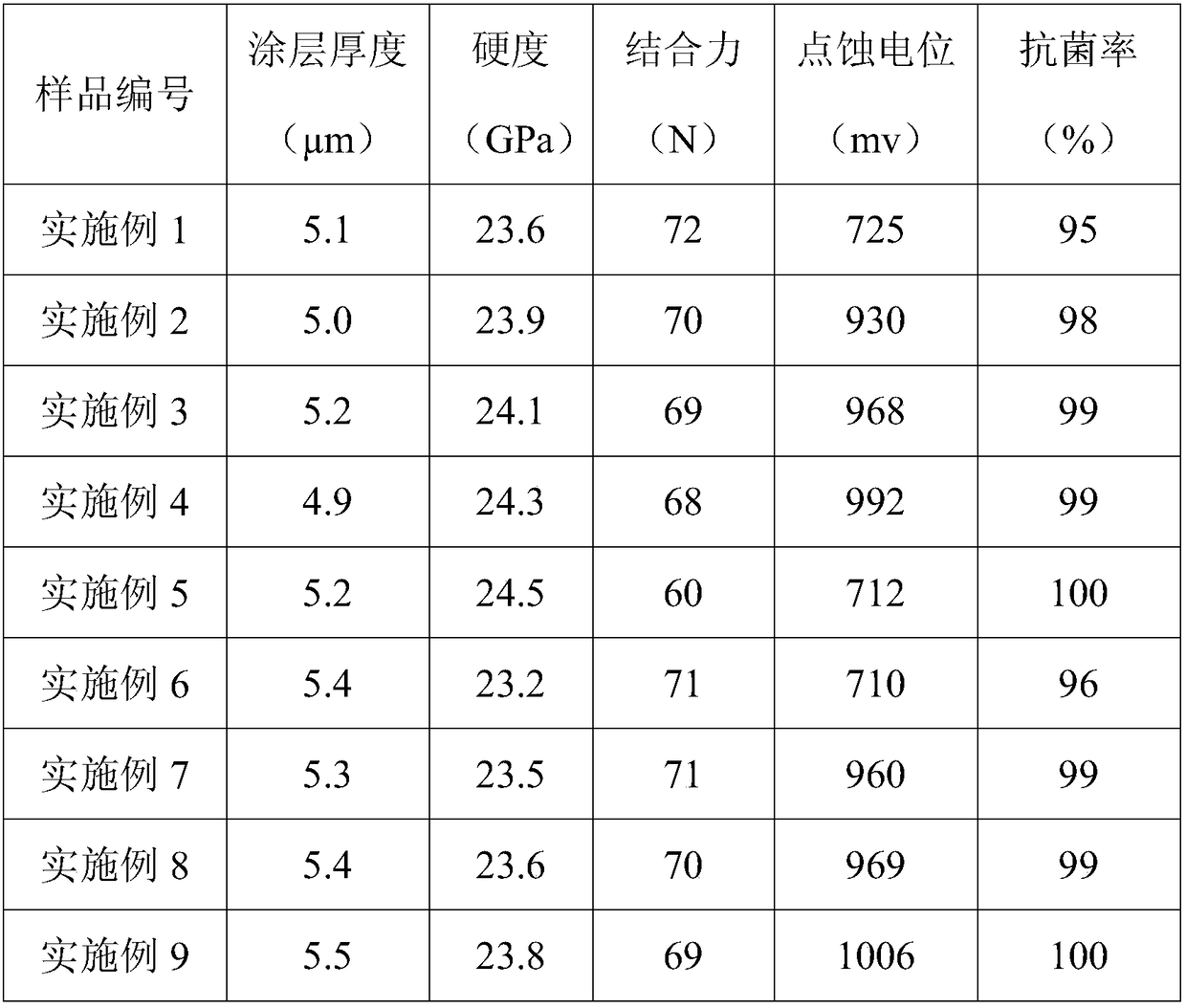

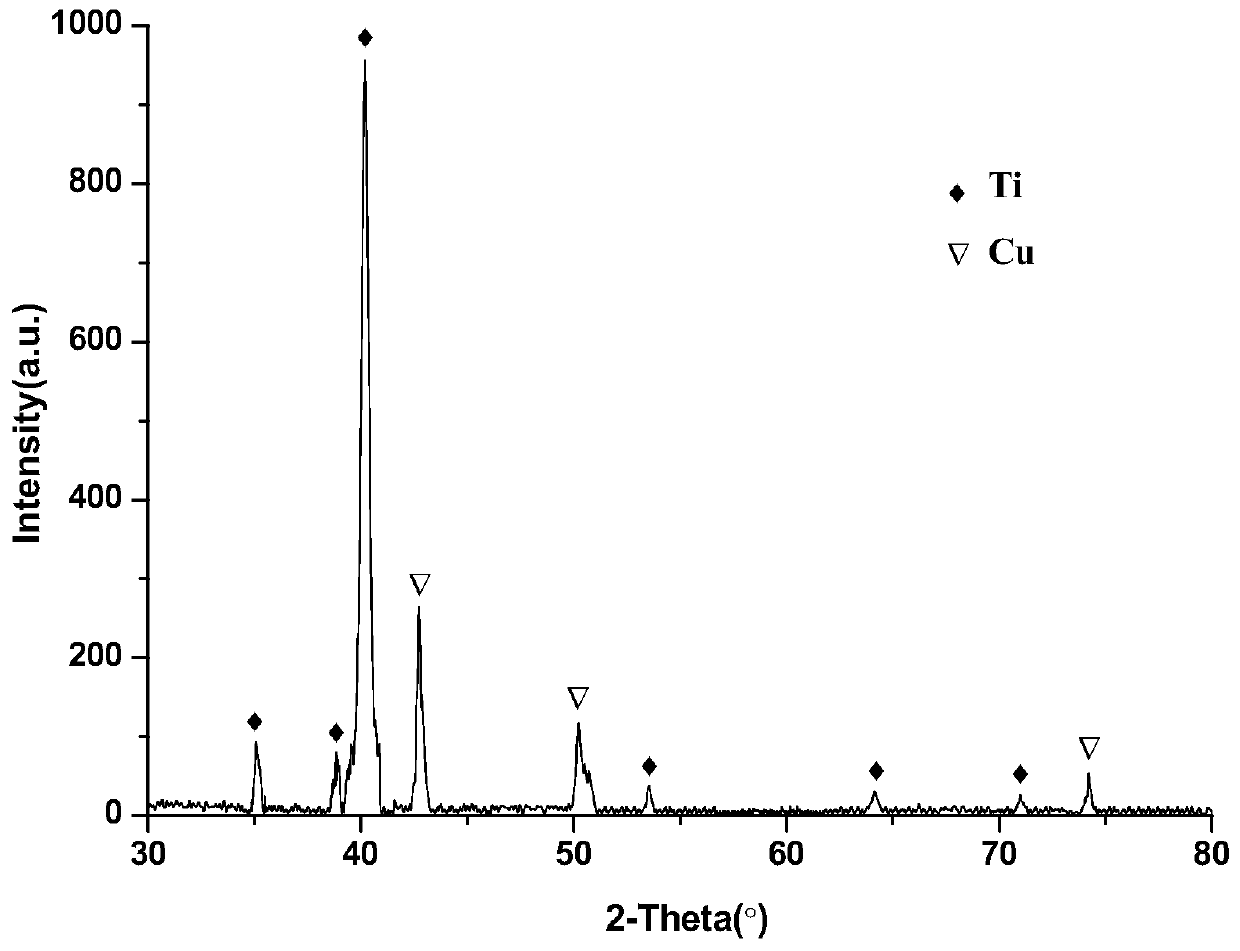

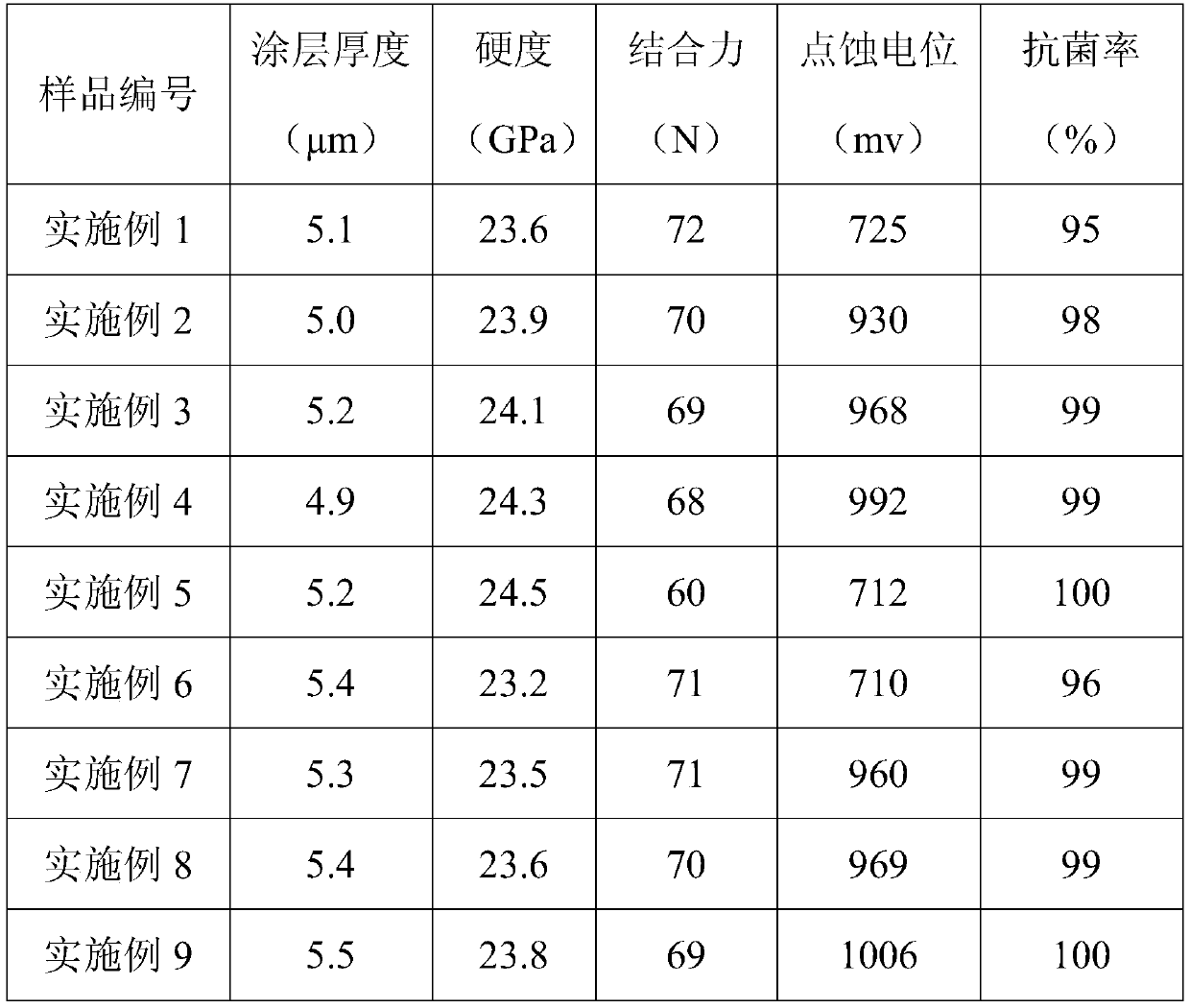

Titanium alloy nano-coating with antibacterial function and preparation method thereof

ActiveCN108866489AHas antibacterial functionHas broad-spectrum antibacterial functionVacuum evaporation coatingSputtering coatingChemical compositionCerium

The invention aims to provide a titanium alloy nano-coating with an antibacterial function and a preparation method thereof. The titanium alloy nano-coating is characterized by comprising the following chemical components of, by mass percent, 2-10% of Cu, 0.04-0.1% of Ce and the balance Ti, wherein the preferable range of the chemical components reaches the following standards that the Cu accountsfor 4-8%, the Ce accounts for 0.06-0.08%, and the balance is the Ti. According to the preparation method of the titanium alloy nano-coating, a titanium-copper-cerium nano-coating with the antibacterial function is formed on the surface of a substrate, so that the substrate can obtain a coating with the broad spectrum and the antibacterial function; and the coating has the excellent corrosion resistance in a biological medium and a corrosive solution.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

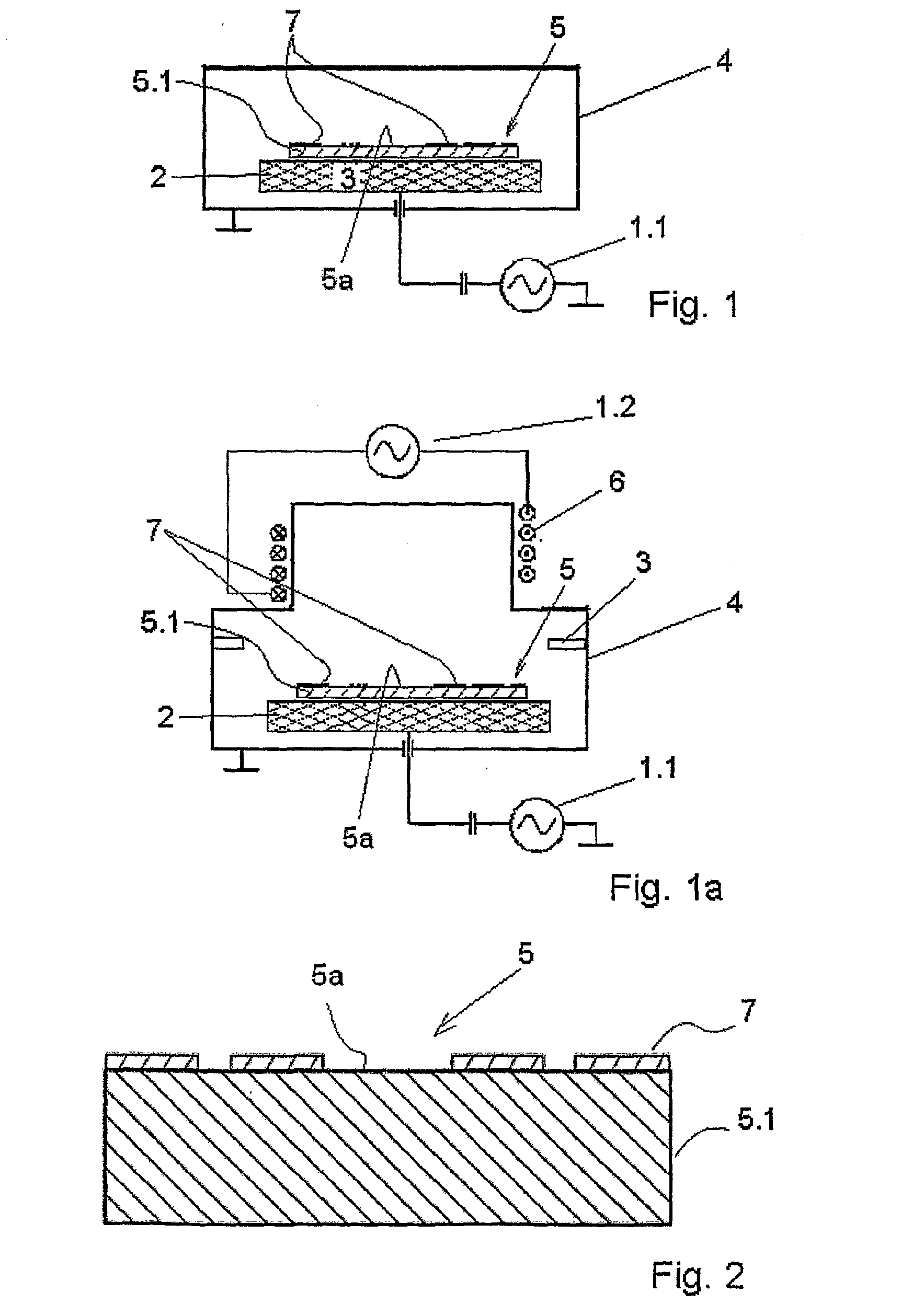

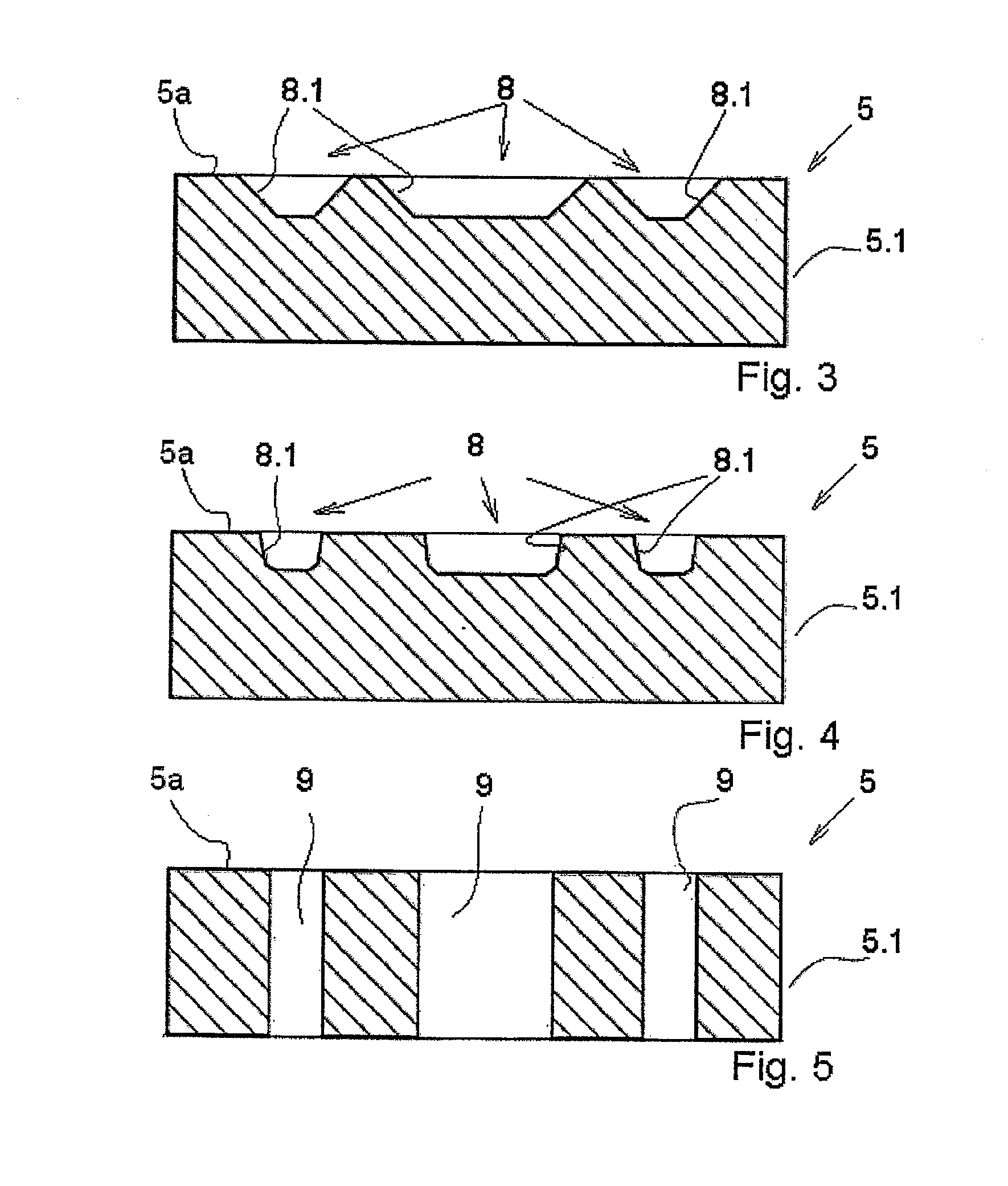

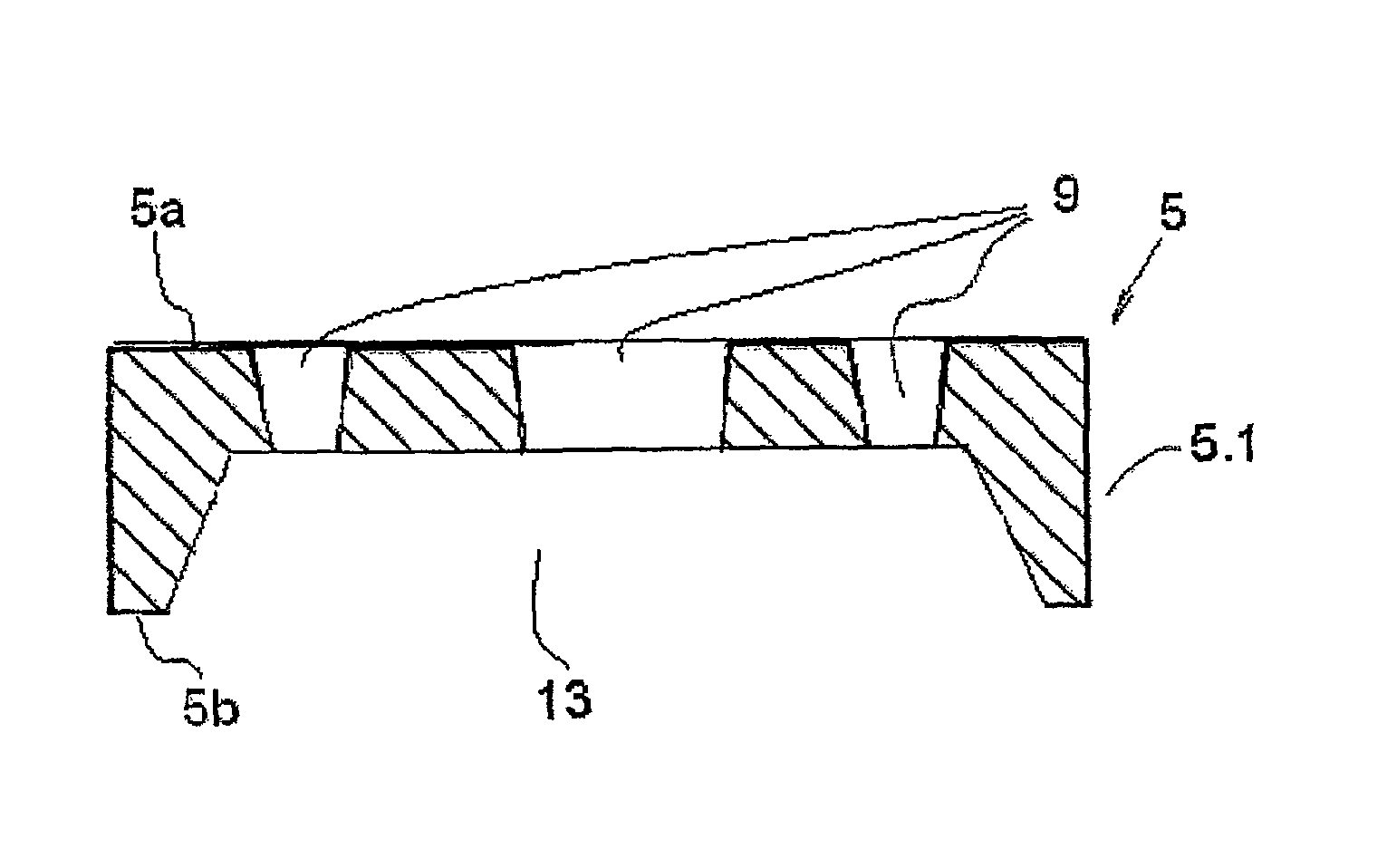

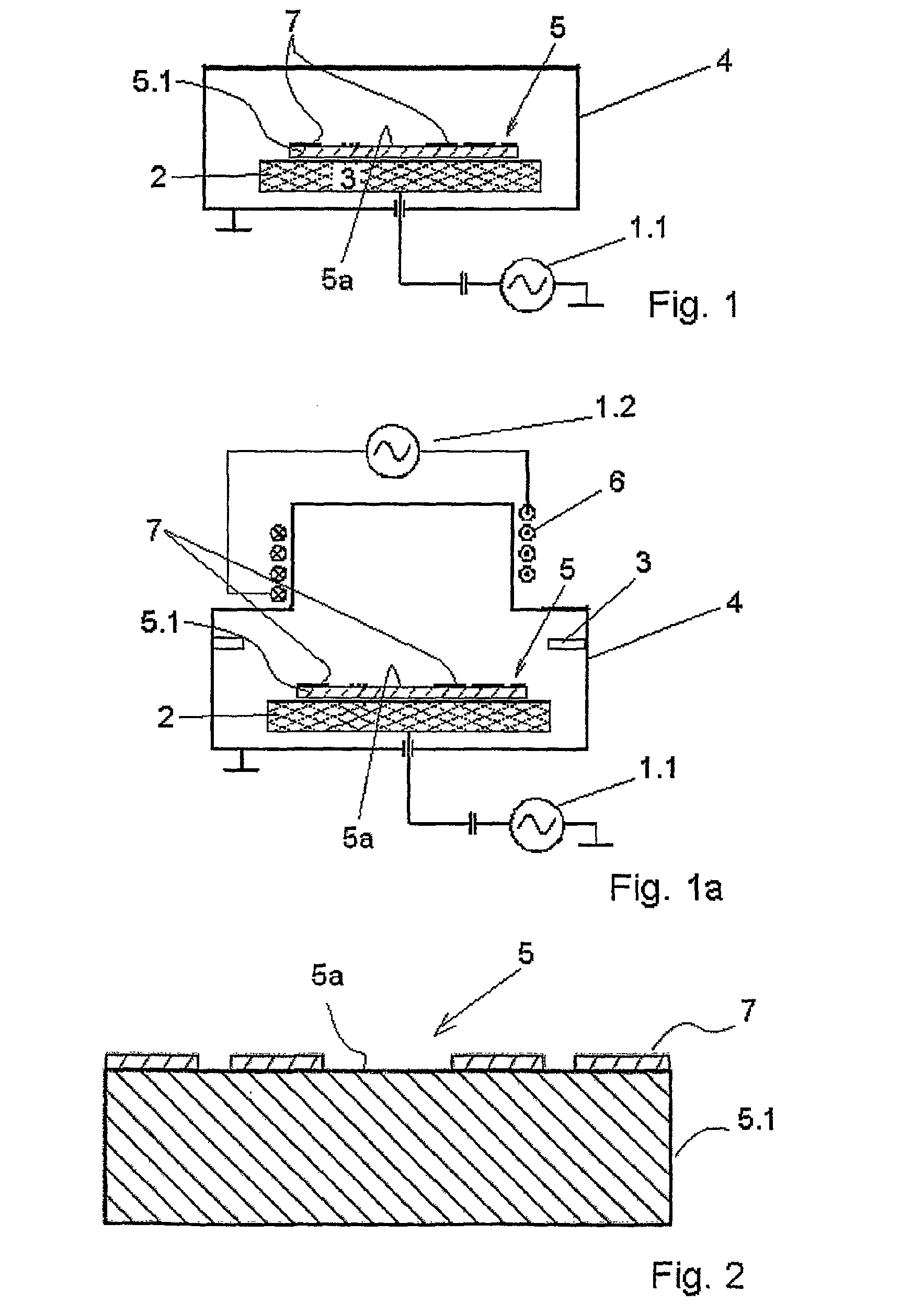

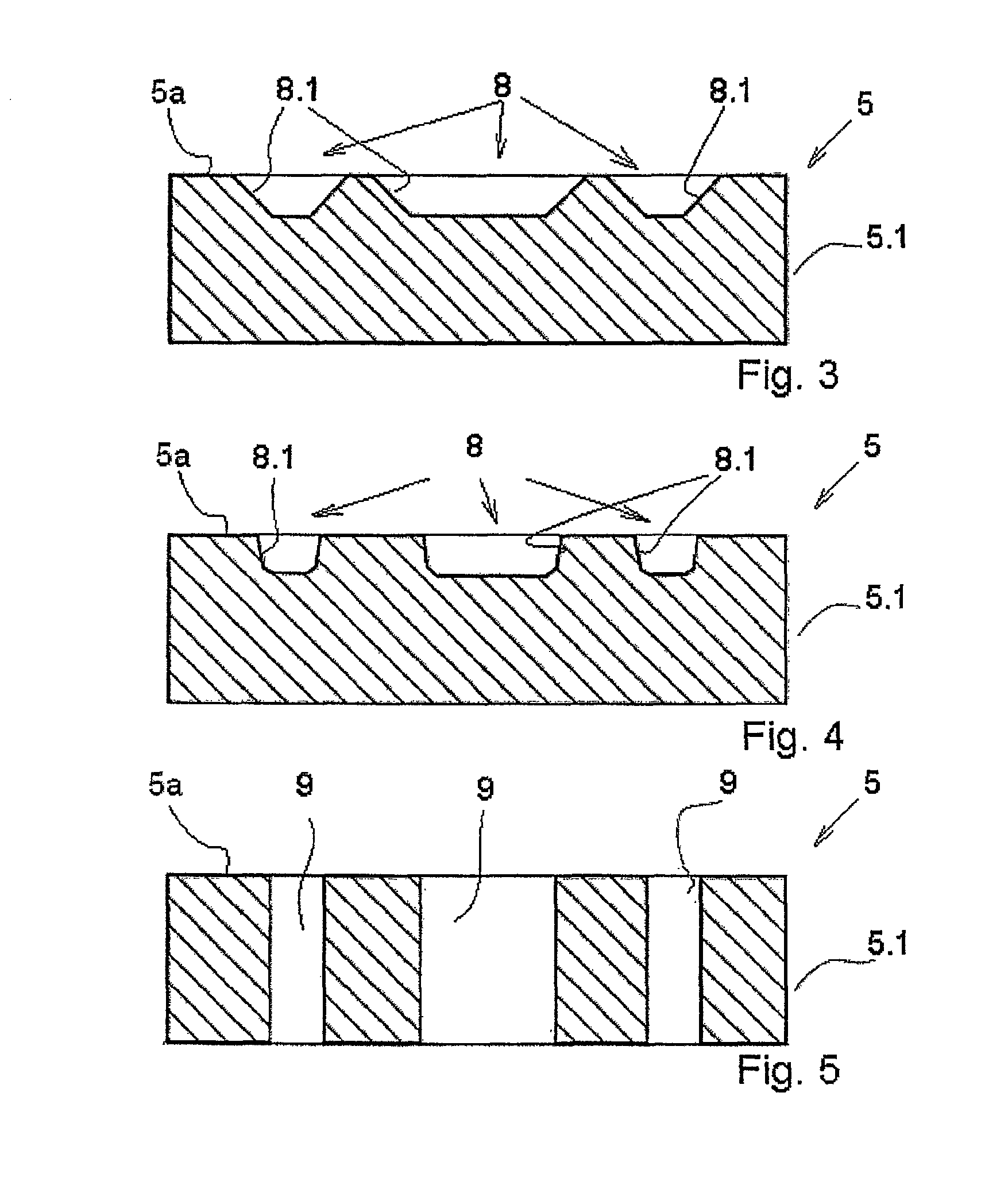

Method and Apparatus for Structuring Components Made of a Material Composed of Silicon Oxide

InactiveUS20090236311A1Good choiceIncrease variabilityDecorative surface effectsSemiconductor/solid-state device manufacturingSilicate glassSilicon oxide

A method and an apparatus for forming a structure on a component made of a material composed of silicon oxide, especially of silicate glass, glass ceramic or quartz, wherein in accordance with the process at least a first surface of the component a partial removal of the material by plasma etching takes place and during the plasma etching at least at the surface to be etched a substrate temperature is established which is substantially greater than 90° C. but less than the softening temperature of the material. The apparatus is equipped for this purpose with a heater for generating the substrate temperature.

Owner:FHR ANLAGENBAU GMBH

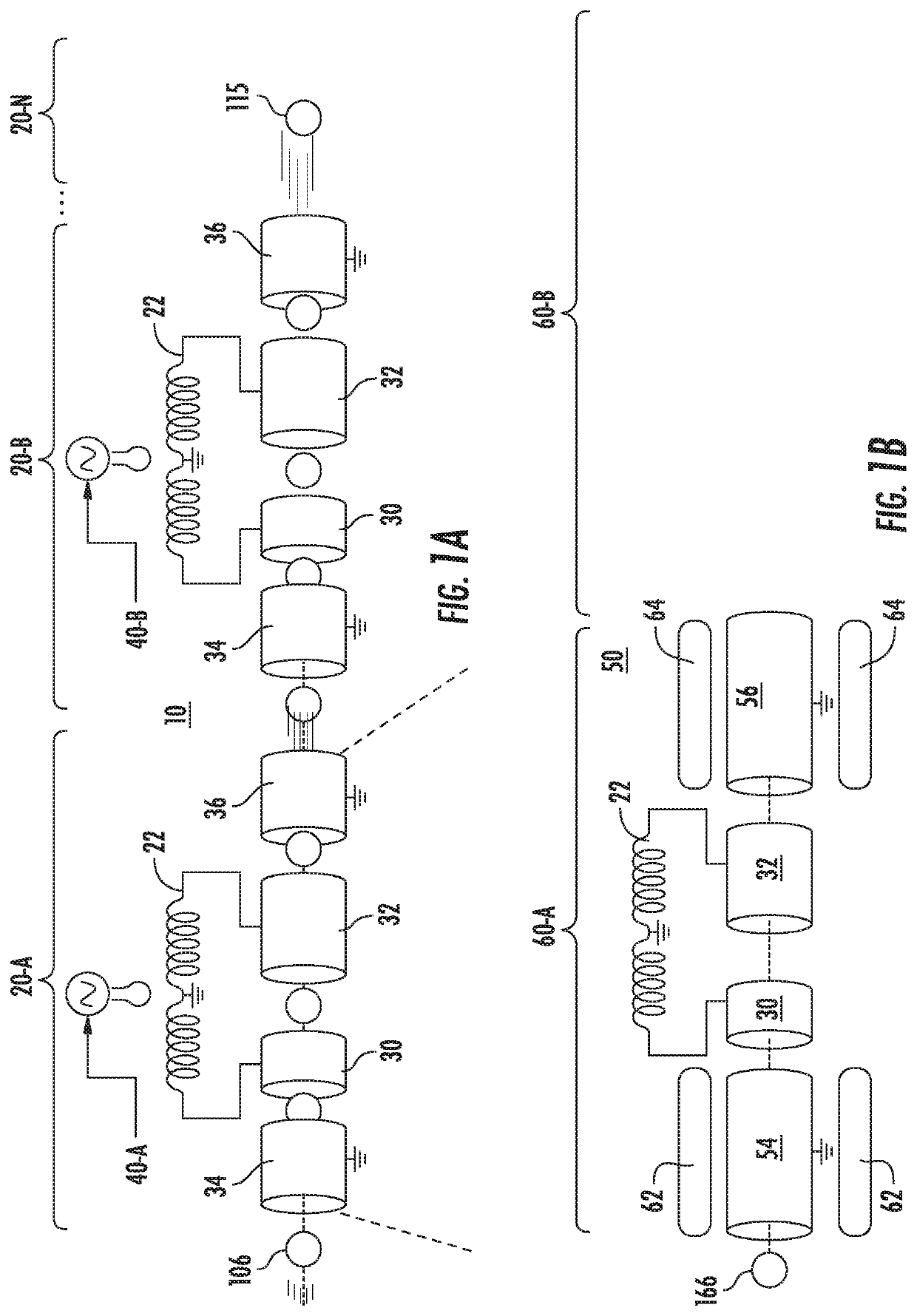

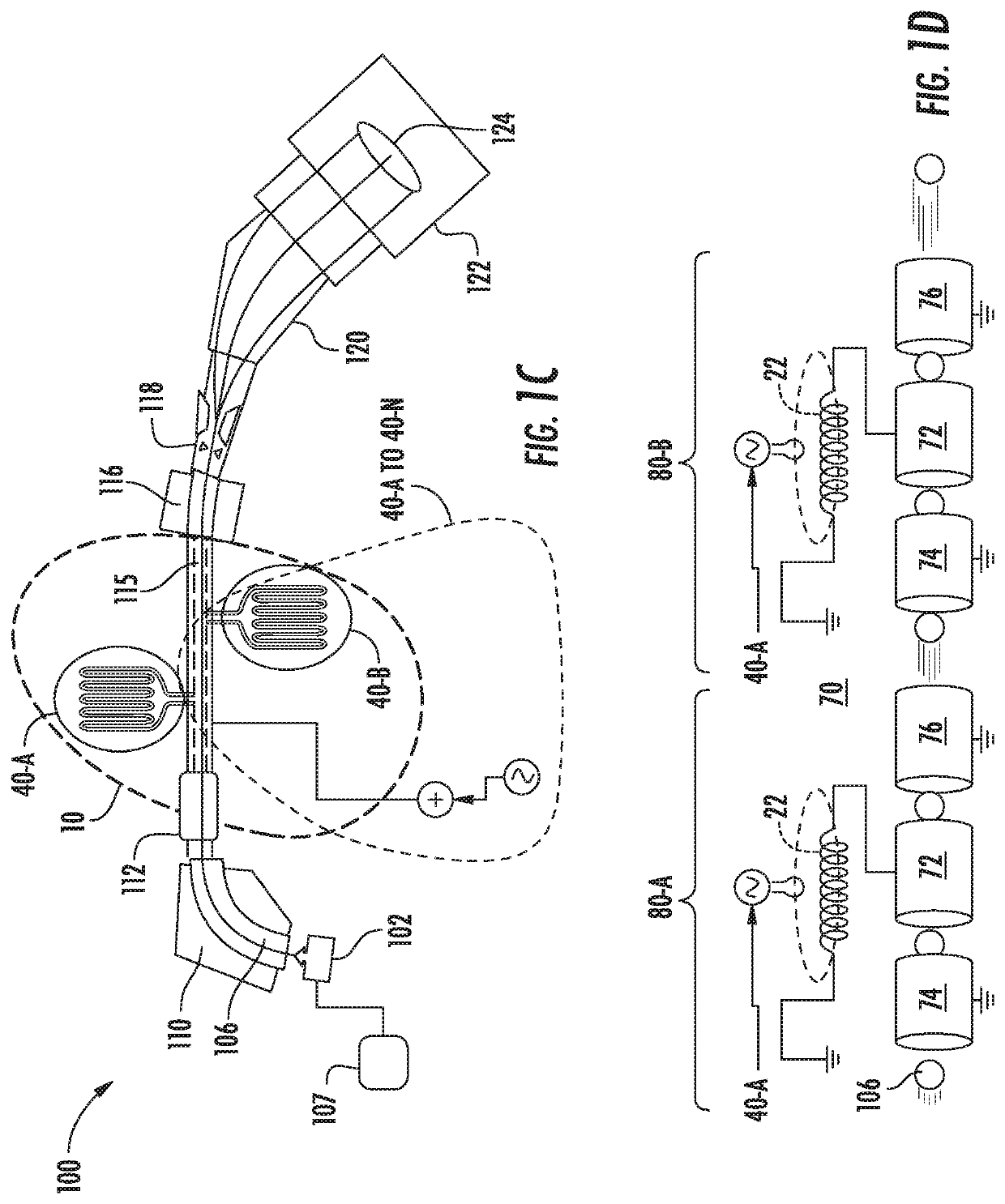

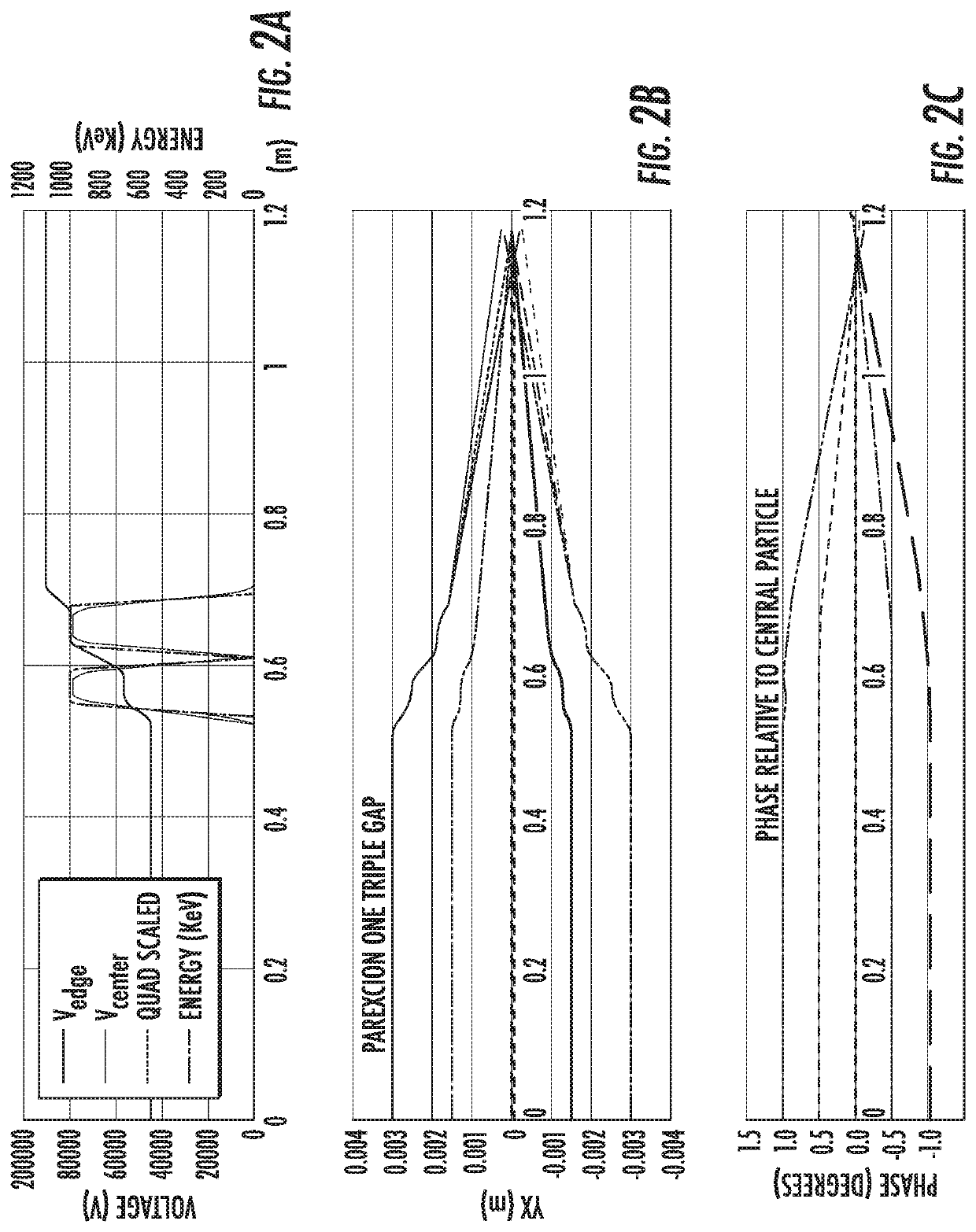

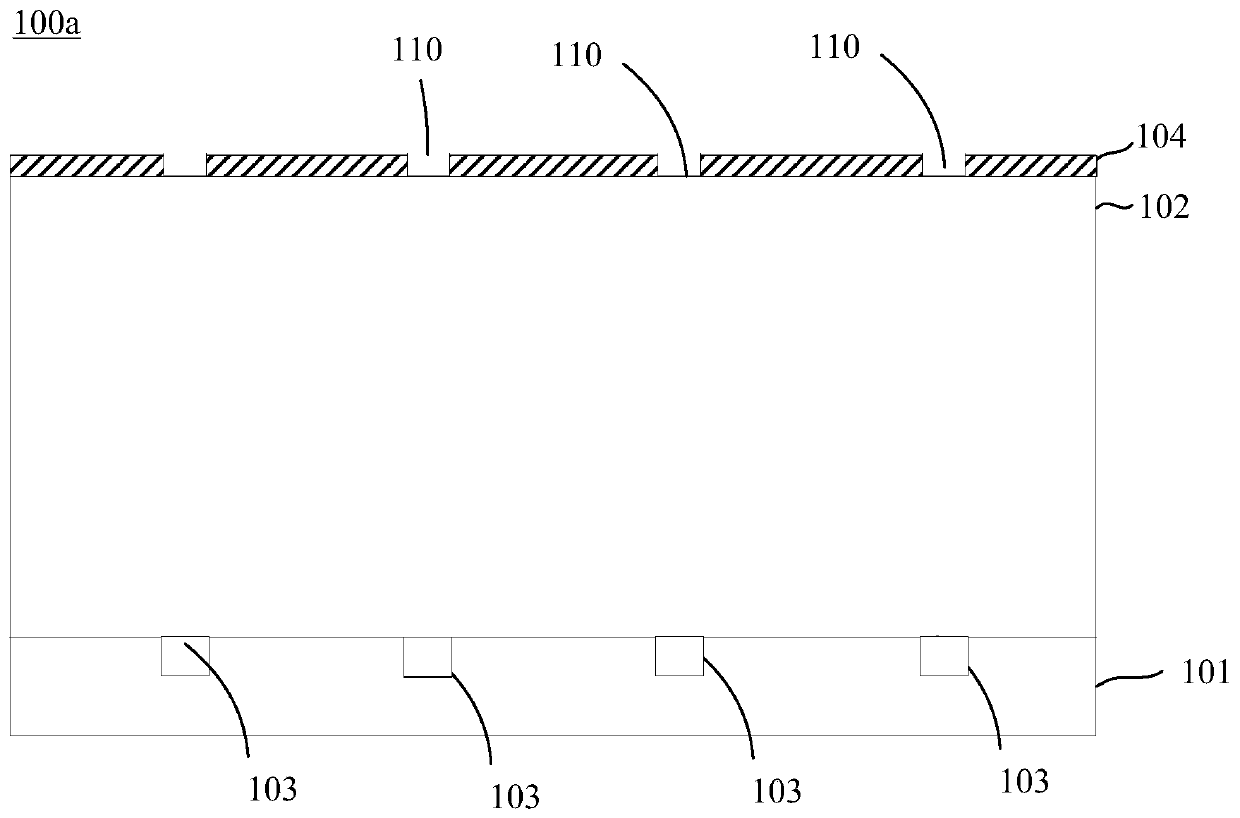

Ion implantation system and linear accelerator having novel accelerator stage configuration

ActiveUS20220037116A1High ion energyElectric discharge tubesLinear acceleratorsNuclear engineeringIon beam

An ion implantation system, including an ion source and extraction system, arranged to generate an ion beam at a first energy, and a linear accelerator, disposed downstream of the ion source, the linear accelerator arranged to receive the ion beam as a bunched ion beam accelerate the ion beam to a second energy, greater than the first energy. The linear accelerator may include a plurality of acceleration stages, wherein a given acceleration stage of the plurality of acceleration stages comprises: a drift tube assembly, arranged to conduct the ion beam; a resonator, electrically coupled to the drift tube assembly; and an RF power assembly, coupled to the resonator, and arranged to output an RF signal to the resonator. As such, the given acceleration stage does not include a quadrupole element.

Owner:APPLIED MATERIALS INC

PVD chromium based ceramic composite coating piston ring and method for producing the same

InactiveCN101430004BReduce coefficient of frictionImprove the lubrication effectPiston ringsVacuum evaporation coatingCeramic compositePiston ring

The invention discloses a PVD chromium base ceramic composite coating piston ring and a preparation method thereof, and the piston ring is manufactured by plating a chromium base ceramic composite coating on a basal body of the piston ring which is treated by nitriding by adopting high power electric arc discharge method; the chromium base ceramic composite coating is composed of a bonding layer,a main wearing layer and an anti-attrition layer, wherein, the bonding layer is binded with the basal body of the piston ring in a metallurgical way, the main wearing layer is arranged on the bondinglayer, and the anti-attrition layer is positioned on the surface of the main wearing layer; the bonding layer is Cr, the main wearing layer is a Cr / CrN multilayer coating formed by the Cr and the CrNwhich are alternately arranged, and the anti-attrition layer is a Cr / Cr2O3 multilayer coating formed by the Cr and the Cr2O3 that are alternately arranged. The coating structure has reasonable design,and the manufactured coating has good cementing property, high hardness and good lubricating property. Furthermore, the method used for manufacturing the piston ring has no pollution in the preparation process, and overcomes the serious problem of environmental pollution of the conventional electrodeposited chromium; as the manufactured coating has better abrasion resistant and corrosion resistant performance compared with the electrodeposited chromium, the service life of the piston ring is greatly prolonged.

Owner:WUHAN UNIV

Methods and systems for increasing the energy of positive ions accelerated by high-power lasers

ActiveUS20100320394A1Increase heightHigh final positive ion energyThermometer detailsBeam/ray focussing/reflecting arrangementsEnergy transferHigh power lasers

The energy of positive ions accelerated in laser-matter interaction experiments can be significantly increased by providing a plurality of laser pulses, e.g., through the process of splitting the incoming laser pulse, to form multiple laser-matter interaction stages. From a thermodynamic point of view, the splitting procedure can be viewed as an effective way of increasing the efficiency of energy transfer from the laser light to positive ions, which energy peaks for processes having the least amount of entropy gain. A 100% increase in the energy efficiency is achieved for a six-stage laser positive ion accelerator compared to a single-stage laser positive ion accelerator.

Owner:INST FOR CANCER RES

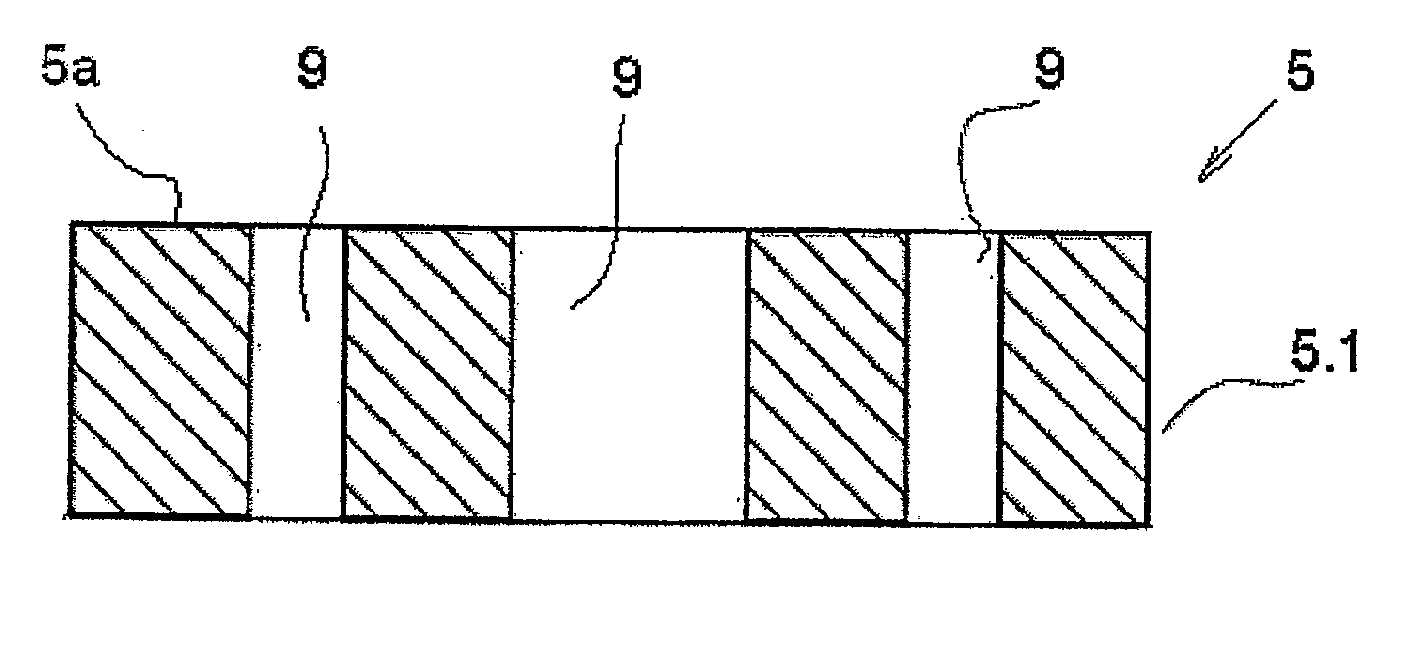

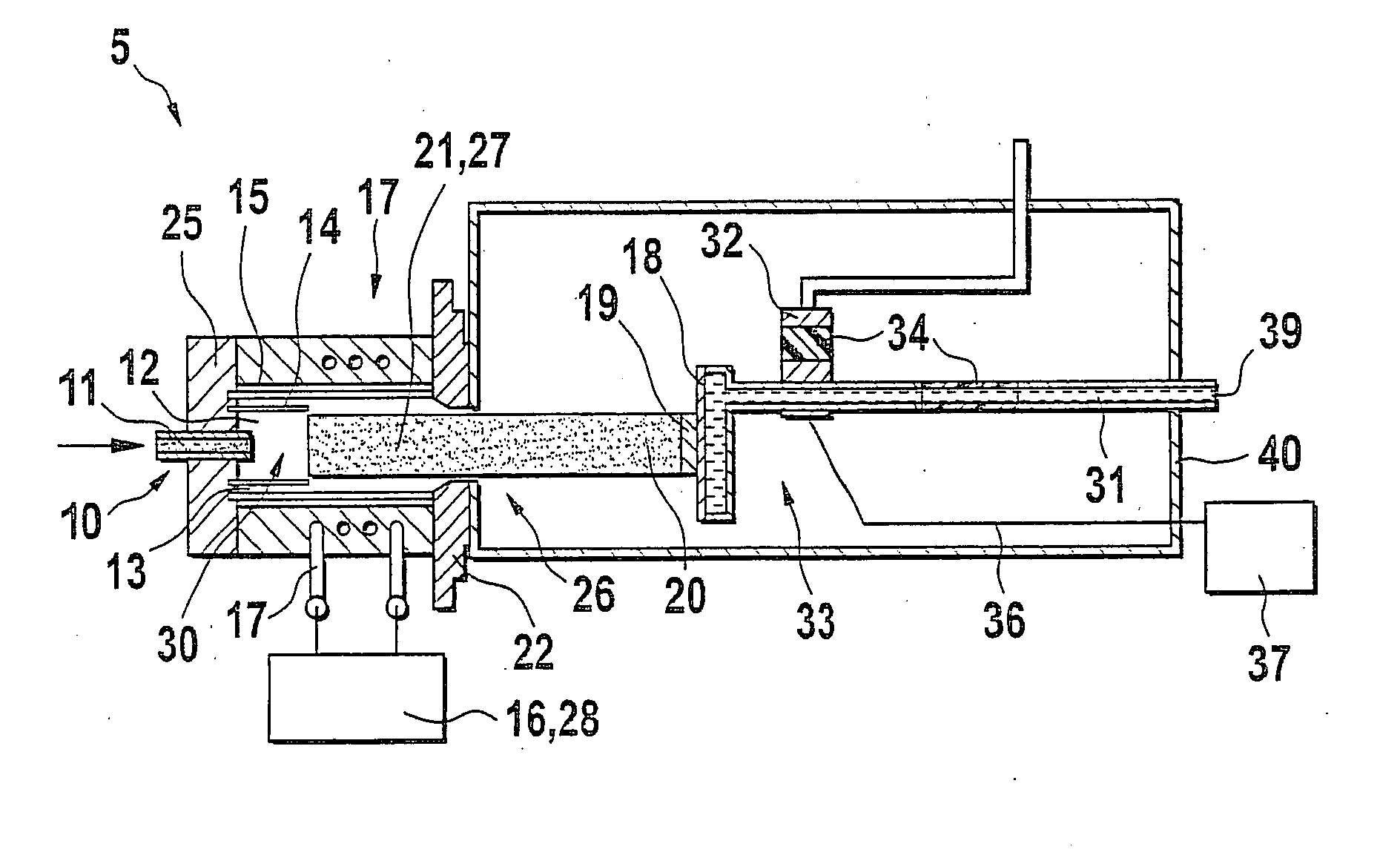

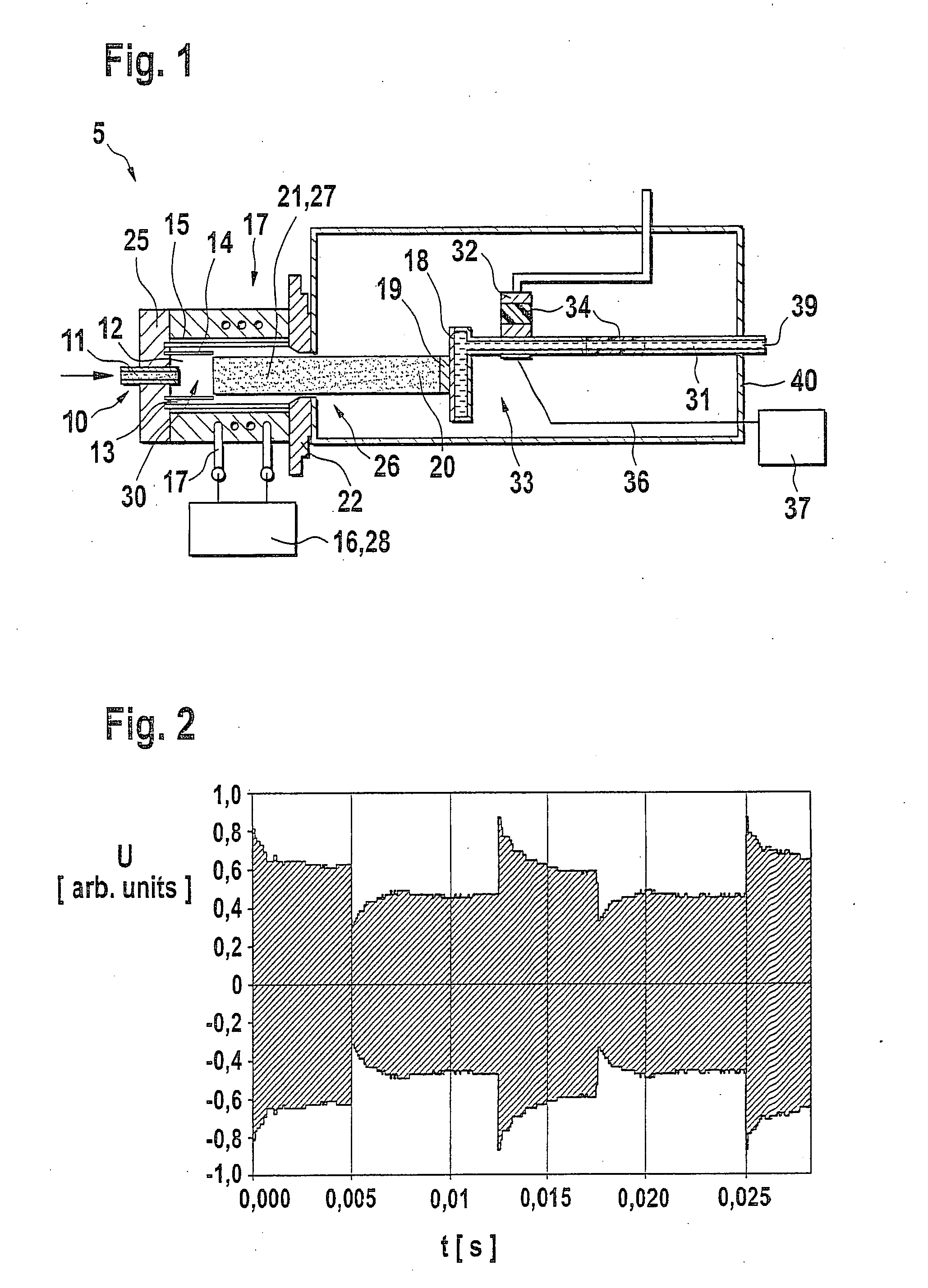

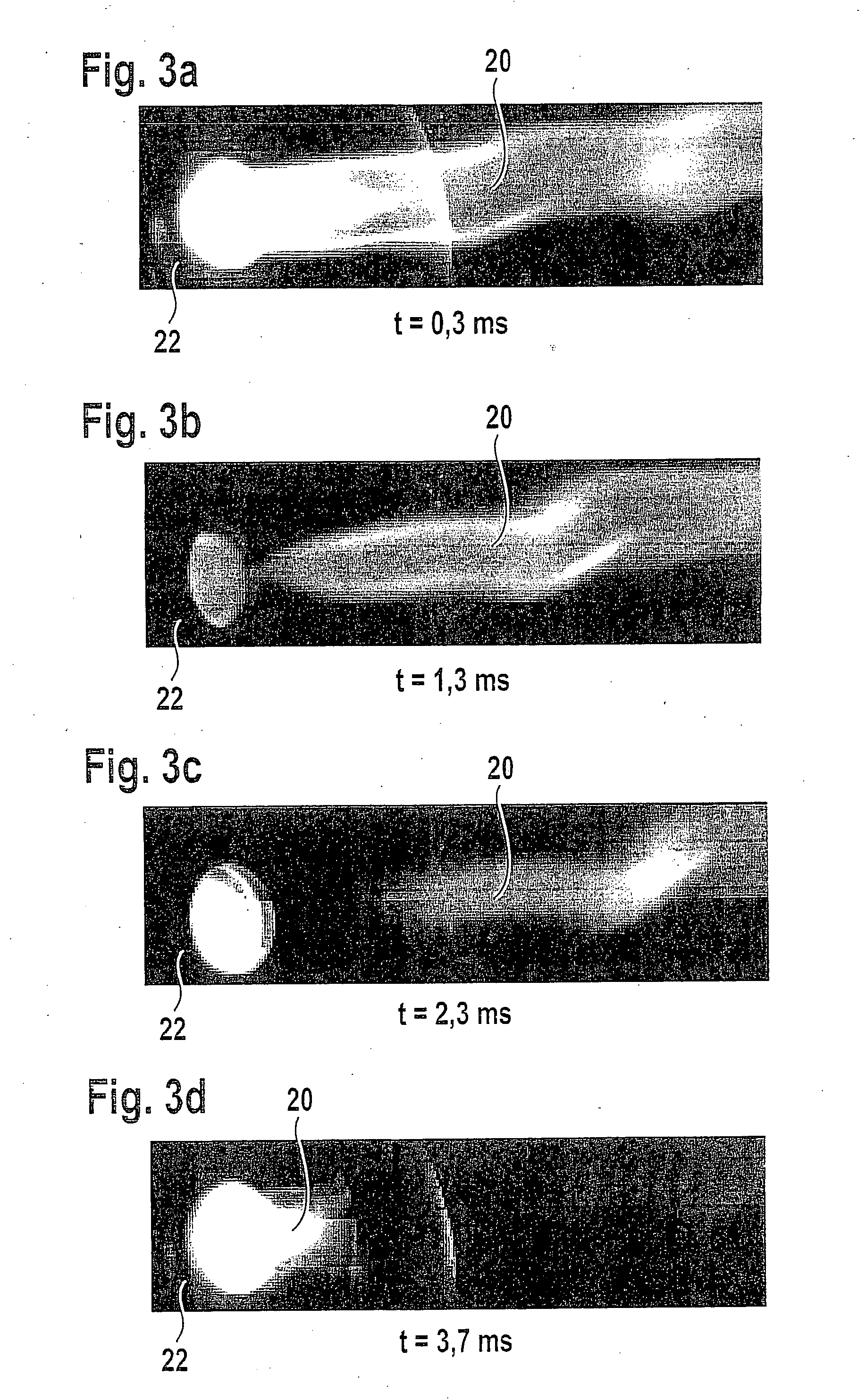

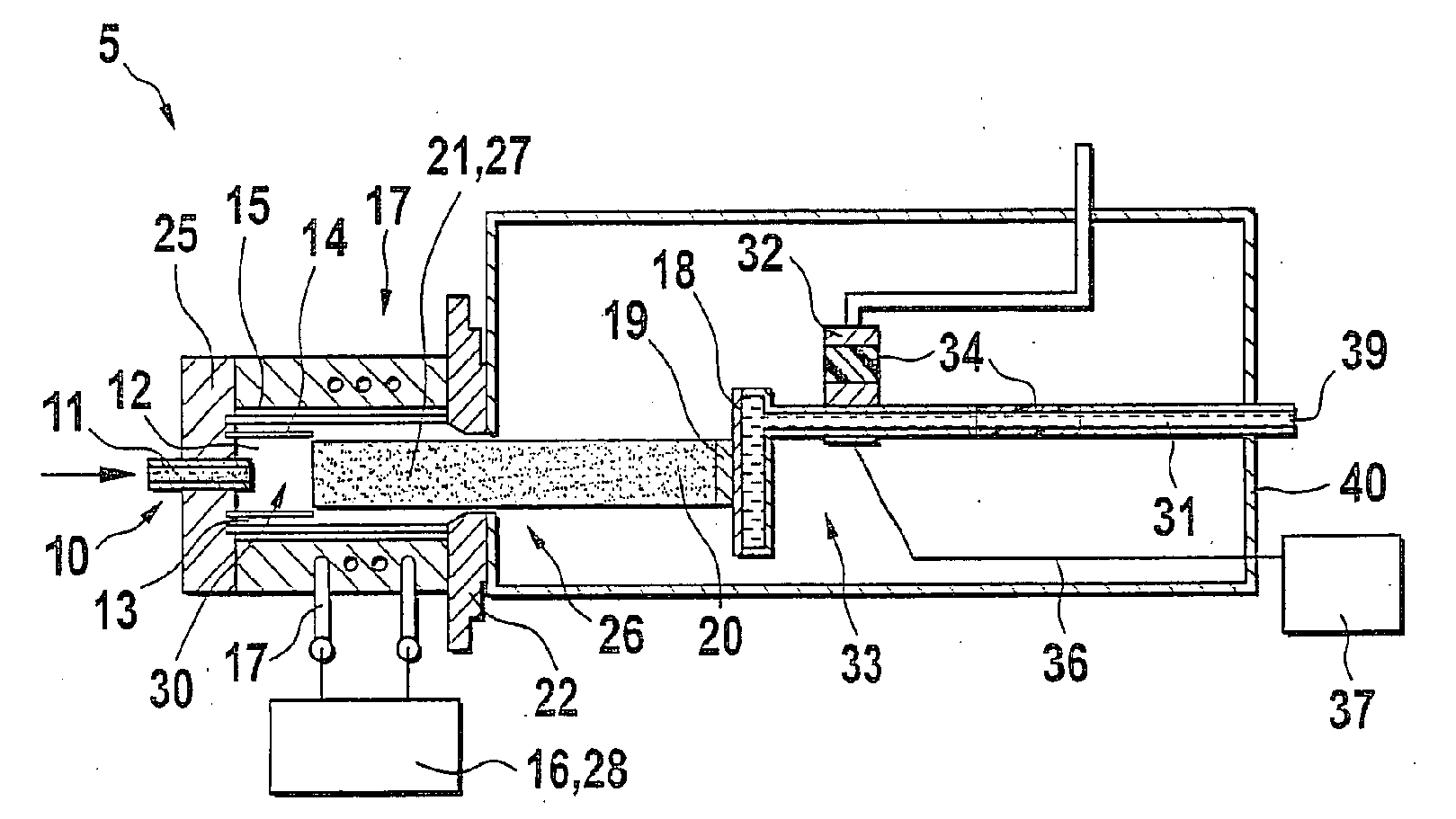

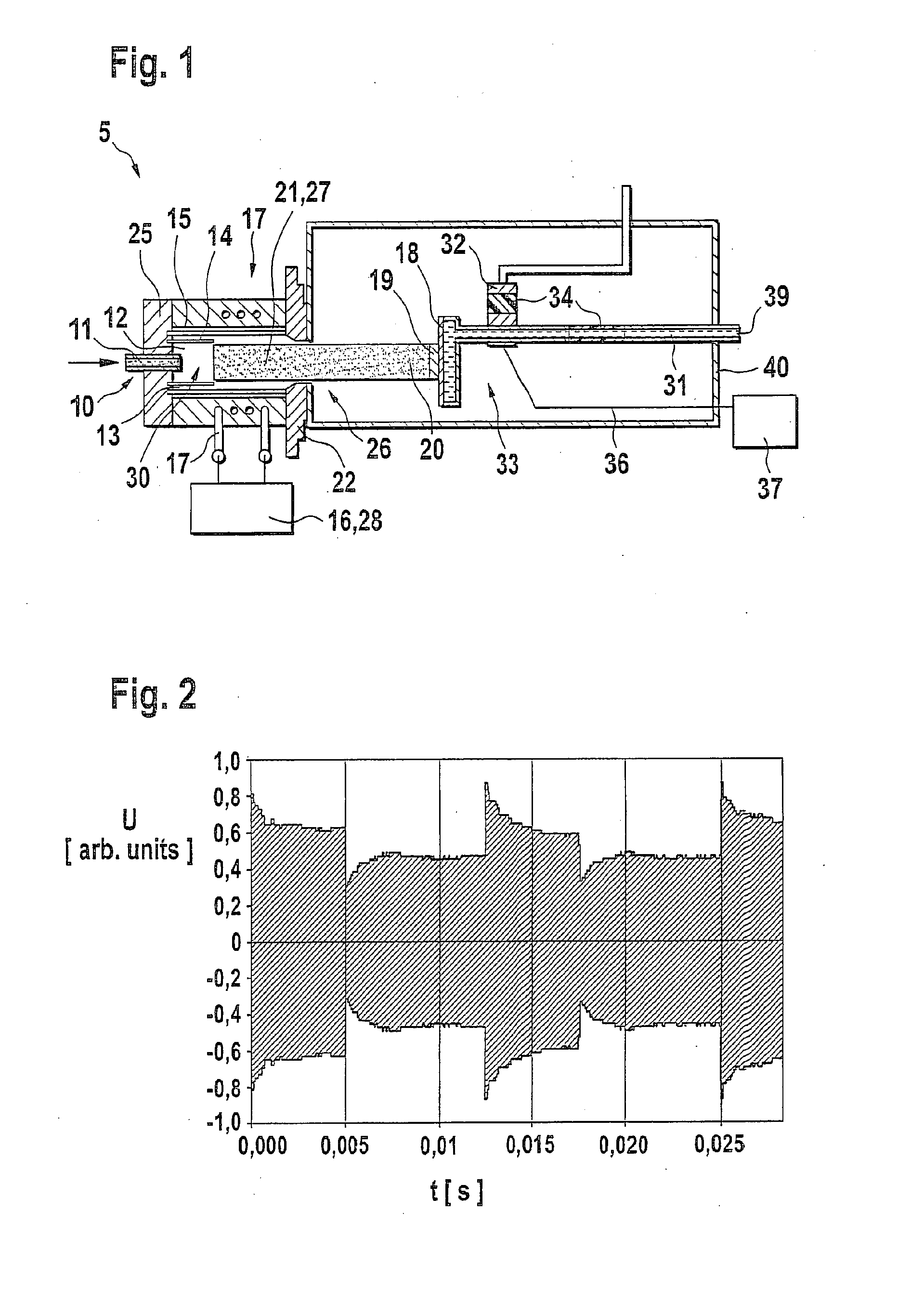

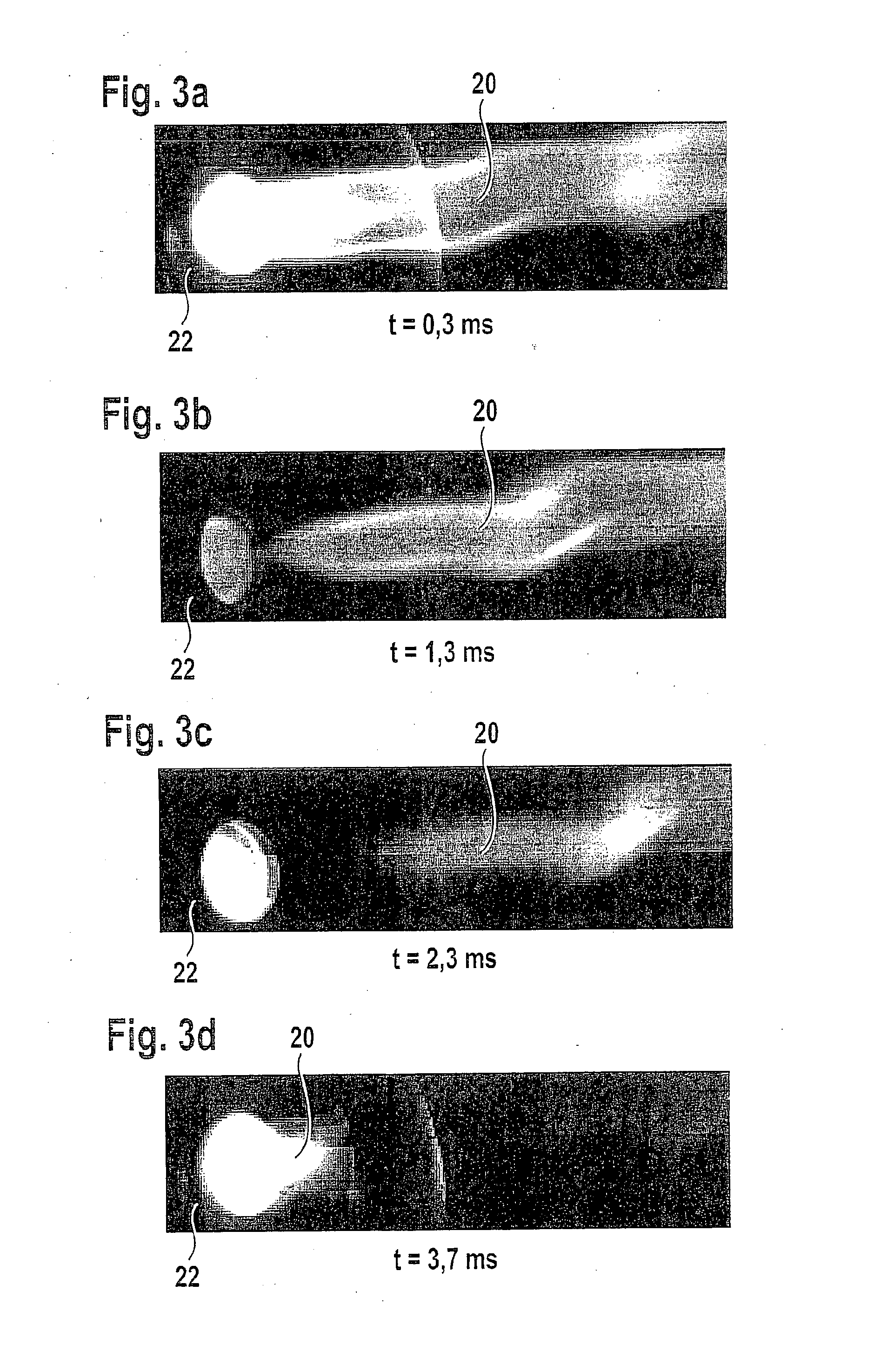

Plasma system and method of producing a functional coating

InactiveUS20100203253A1High ion energyReduce heat loadLiquid surface applicatorsMolten spray coatingPlasma jetCombustor

A plasma system has at least one inductively coupled high-frequency plasma jet source having a burner body delimiting a plasma generating space, having an outlet orifice for the plasma jet, and a chamber communicating with the plasma jet source through the outlet orifice, having a substrate situated in the chamber, where it is exposed to the plasma jet. The substrate is situated on a substrate electrode to which an electric voltage may be applied. In addition, a method of producing a functional coating on the substrate using such a plasma system is also described. In a preferred embodiment, during operation of the plasma system, both the plasma jet and the electric voltage on the substrate electrode are pulsed and / or a pressure gradient is maintained between the interior of the plasma jet source and the interior of the chamber.

Owner:ROBERT BOSCH GMBH

Method and apparatus for structuring components made of a material composed of silicon oxide

InactiveUS8652341B2Good choiceIncrease variabilityDecorative surface effectsSemiconductor/solid-state device manufacturingSilicate glassSilicon oxide

A method and an apparatus for forming a structure on a component made of a material composed of silicon oxide, especially of silicate glass, glass ceramic or quartz, wherein in accordance with the process at least a first surface of the component a partial removal of the material by plasma etching takes place and during the plasma etching at least at the surface to be etched a substrate temperature is established which is substantially greater than 90° C. but less than the softening temperature of the material. The apparatus is equipped for this purpose with a heater for generating the substrate temperature.

Owner:FHR ANLAGENBAU GMBH

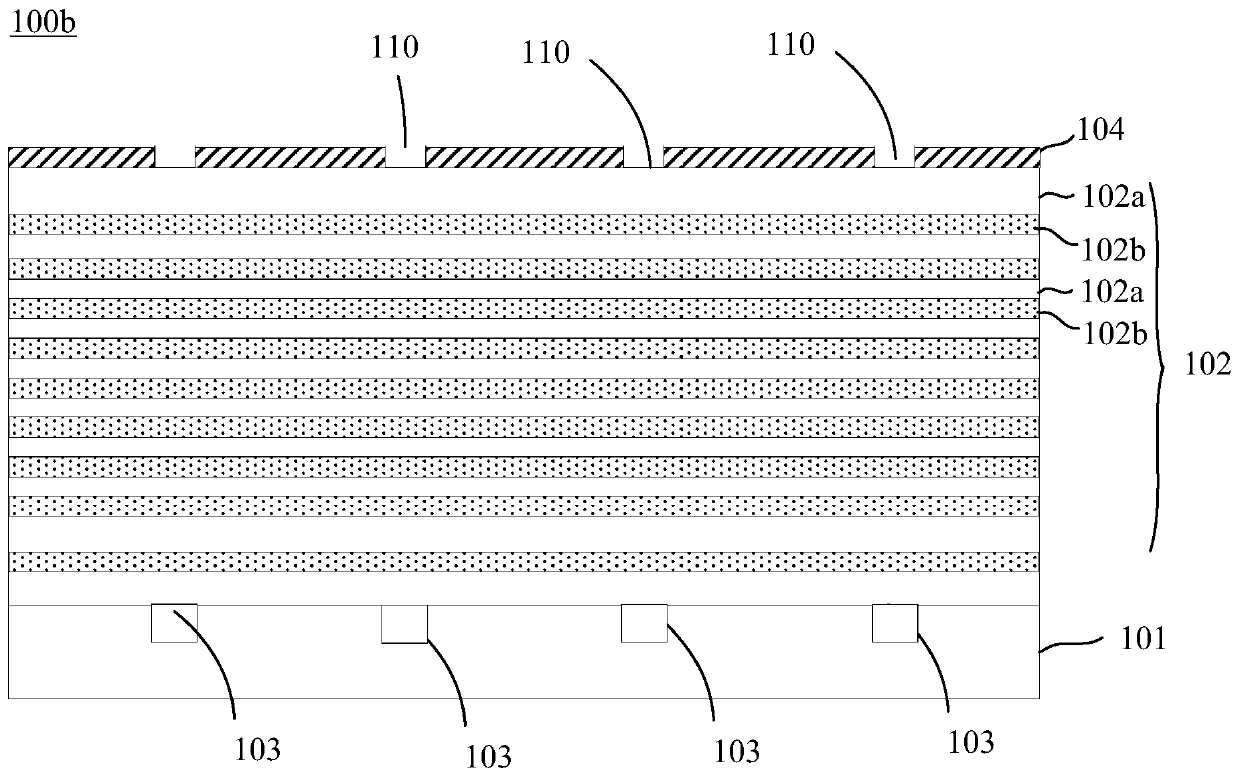

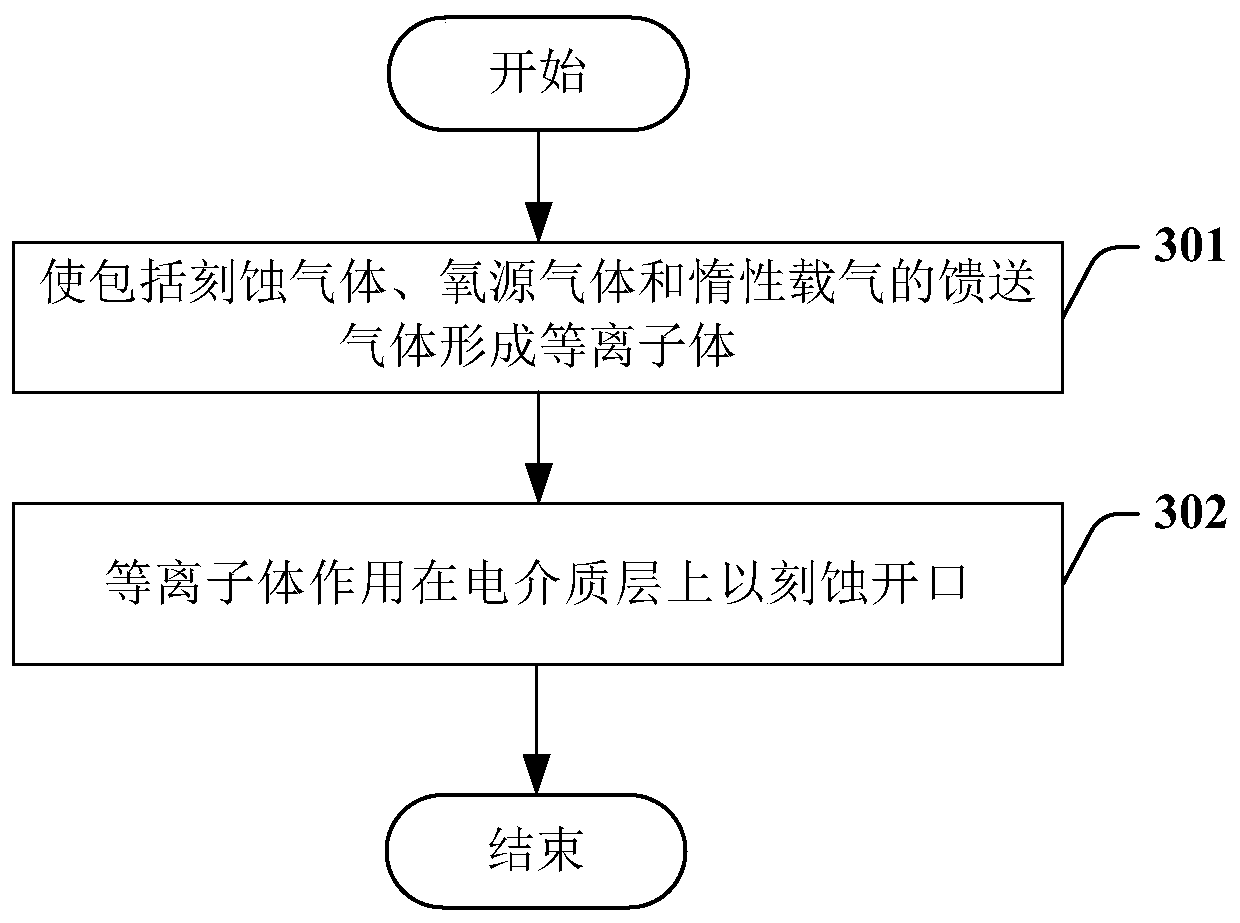

Etching method of opening with high depth-to-width ratio and semiconductor device

ActiveCN110571150AReduce ion concentrationReduce chance of swellingTransistorSolid-state devicesChemistryWidth ratio

The invention relates to an etching method of an opening with a high depth-to-width ratio and a semiconductor device. The etching method of an opening with a high depth-to-width ratio comprises the step of dry-etching a dielectric layer by using a feed gas including an etching gas, an oxygen source gas and an inert carrier gas to form an opening, wherein the flow proportion of the inert carrier gas in the feed gas is 4-21%.

Owner:YANGTZE MEMORY TECH CO LTD

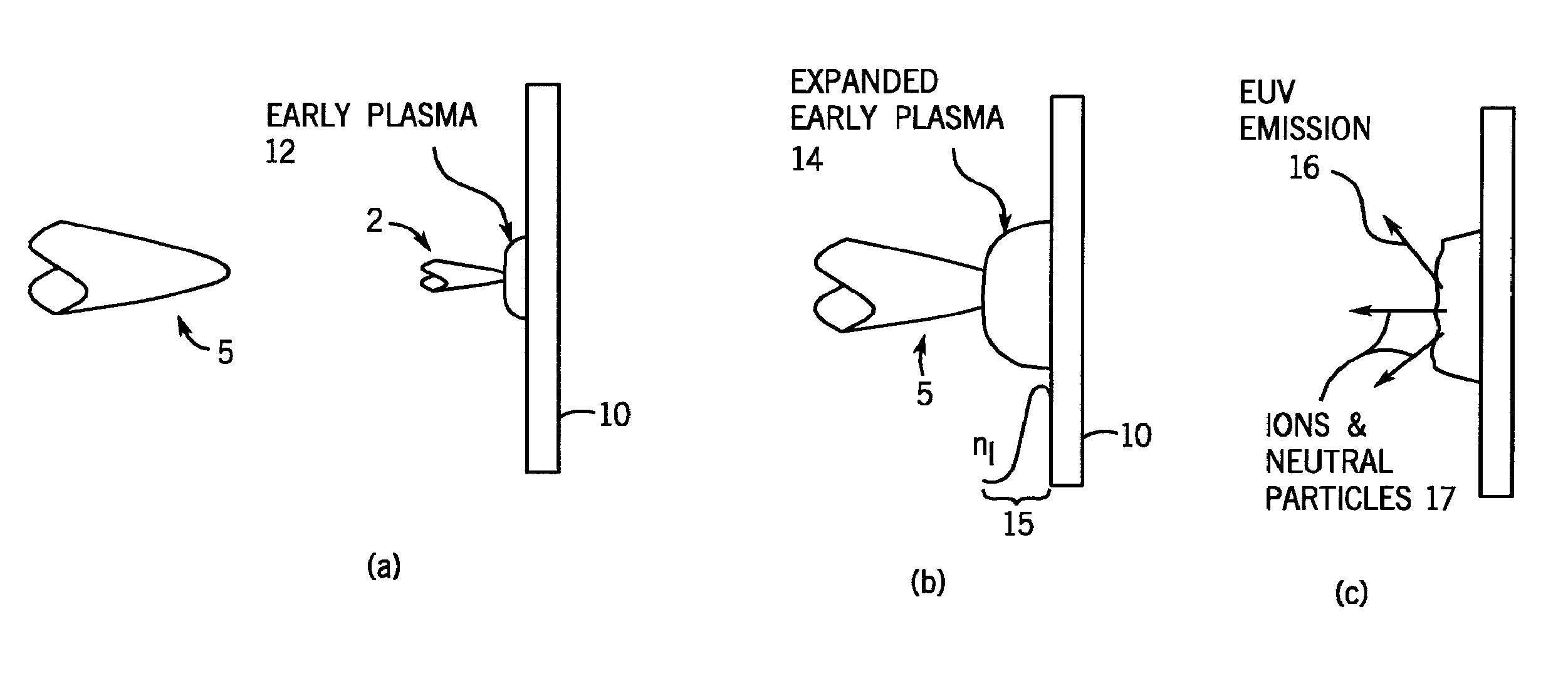

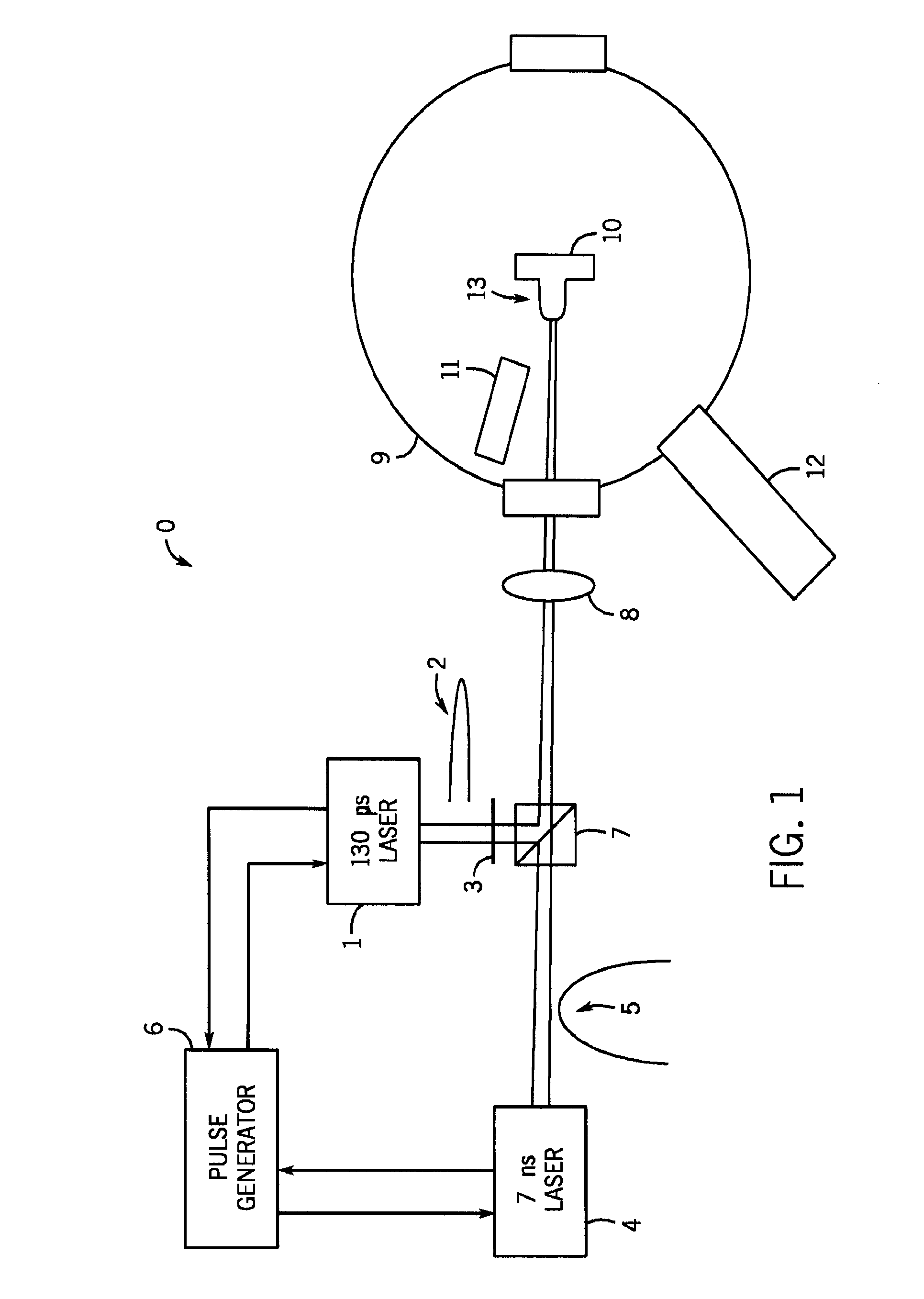

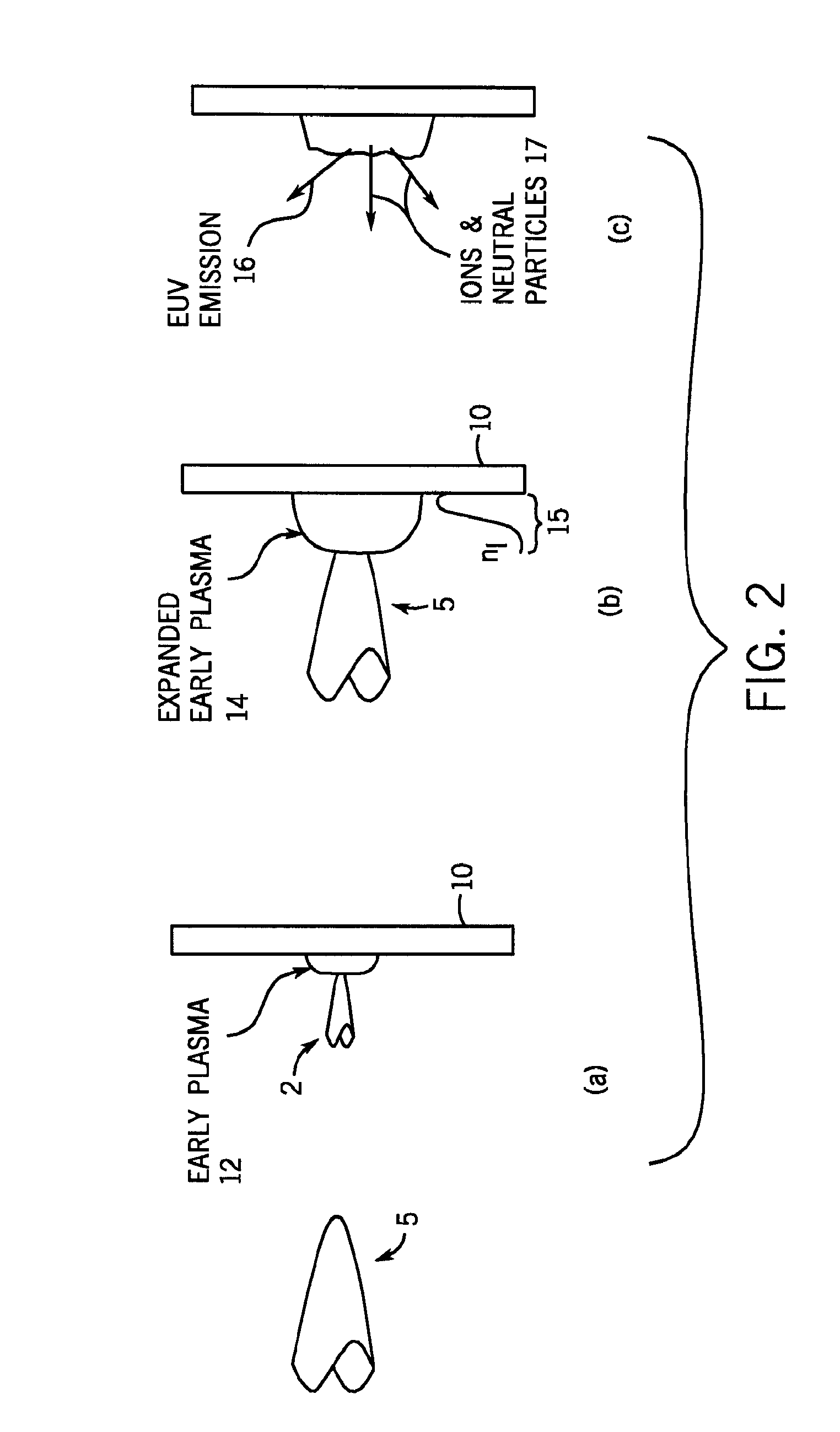

Light source employing laser-produced plasma

InactiveUS8536549B2Reduce generationNo loss of conversion efficiencyRadiation pyrometryElectric arc lampsSolid massTemporal succession

A system and a method of generating radiation and / or particle emissions are disclosed. In at least some embodiments, the system includes at least one laser source that generates a first pulse and a second pulse in temporal succession, and a target, where the target (or at least a portion the target) becomes a plasma upon being exposed to the first pulse. The plasma expand after the exposure to the first pulse, the expanded plasma is then exposed to the second pulse, and at least one of a radiation emission and a particle emission occurs after the exposure to the second pulse. In at least some embodiments, the target is a solid piece of material, and / or a time period between the first and second pulses is less than 1 microsecond (e.g., 840 ns).

Owner:RGT UNIV OF CALIFORNIA

High-temperature-oxidation-resistant aluminum-chromium-silicon-nitride and alumina multilayer composite coating and preparing method thereof

ActiveCN110643951AImprove bindingAvoid the problem of low high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingEtchingHigh entropy alloys

The invention discloses a high-temperature-oxidation-resistant aluminum-chromium silicon nitride and alumina multilayer composite coating which is a whole formed by sub-layers including a CrAlTiZrY high-entropy alloy bonding layer, an alpha-Cr2O3 oxide template layer, an alpha-Al2O3 oxide core layer and an AlCrSiN nitride surface layer which are arranged from inside to outside. The total thicknessof the coating is 1 micron to 3 microns. A preparation method of the coating comprises the steps that after a substrate is heated and is subjected to ion etching, the CrAlTiZrY layer is firstly deposited on the substrate by using an arc evaporation plating process; and then a cathode arc ion plating process is used, and then the alpha-Cr2O3 layer, the alpha-Al2O3 layer and the AlCrSiN layer are sequentially deposited. Due to the anti-oxidation synergistic effect of all sub-coatings, the high-temperature oxidation resistance of the aluminum-chromium-silicon-nitride and alumina multilayer composite coating is further improved, the abrasion resistance of the coating is good, the preparation process is simple, implementation is easy, and the coating is suitable for industrialized production and application.

Owner:SICHUAN UNIV

CrAlN thermal insulation coating for aluminum alloy piston combustor surface and preparation method thereof

ActiveCN108728804AIncrease ionization rateHigh ion energyVacuum evaporation coatingSputtering coatingCombustion chamberThermal insulation

The invention discloses a CrAlN thermal insulation coating for an aluminum alloy piston combustor surface and a preparation method thereof. The CrAlN thermal insulation coating comprises a transitionlayer and a thermal insulation layer from the inside out in order, the transition layer is a CrAl coating, and the thermal insulation layer is a CrAlN coating. The method adopts filtered cathodic vacuum arc technique, takes a CrAl alloy target material (Cr, Al metal target) as the cathode, performs deposition of the CrAl coating on the aluminum alloy surface to form a transition layer, then uses nitrogen as the working gas, and coats the transition layer surface with the CrAlN coating evenly to form the thermal insulation layer. The CrAlN thermal insulation coating provided by the invention not only solves the problem of poor binding force and bearing ability caused by large difference of basic physical properties between the CrAlN coating and the aluminum alloy substrate material, also the coating is uniform and compact, has good film-substrate combination state and hardness up to 40GPa, and shows good high temperature thermal insulation properties and thermal shock resistance in piston thermal load test. The CrAlN thermal insulation coating provided by the invention significantly improves the performance reliability and service life of the aluminum alloy piston, and can meet thehigh power and low emission development requirements of modern engines.

Owner:XIANGTAN UNIV

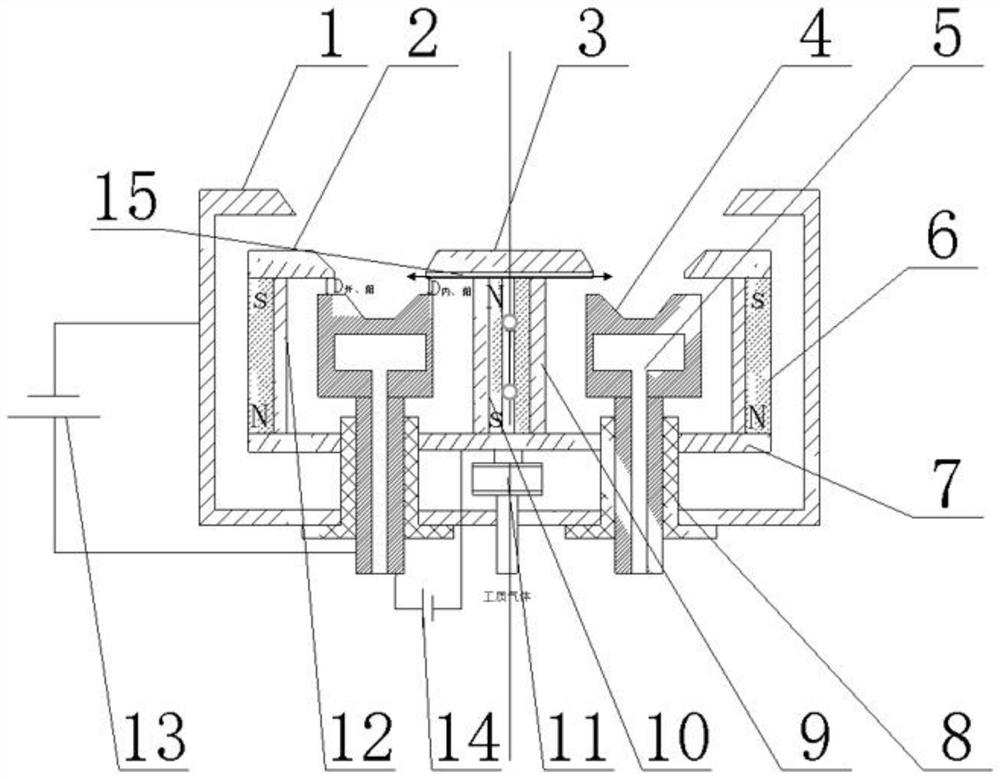

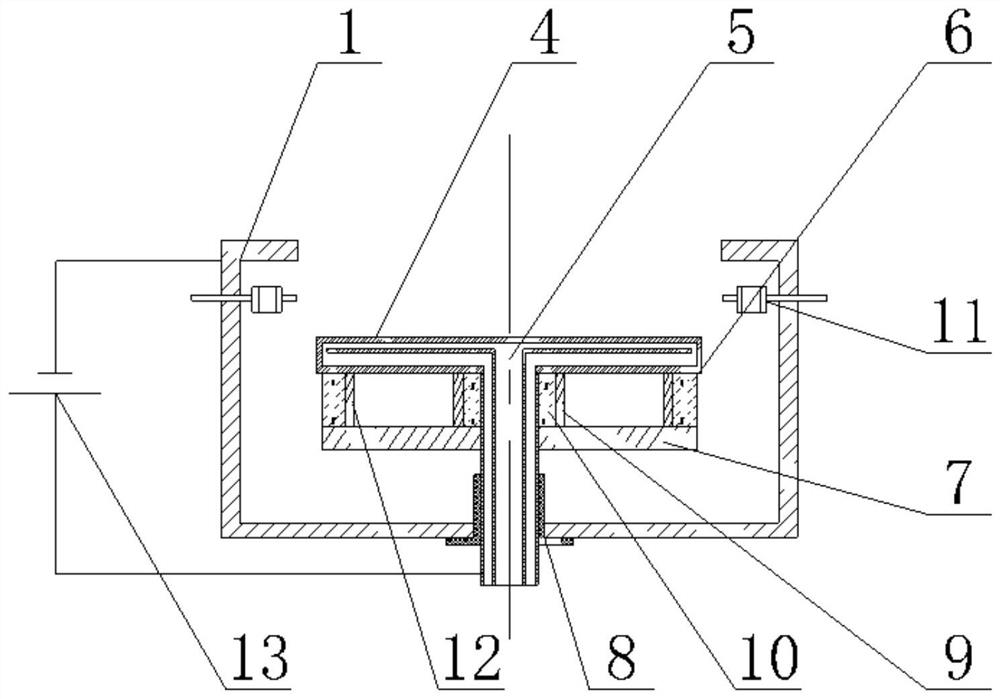

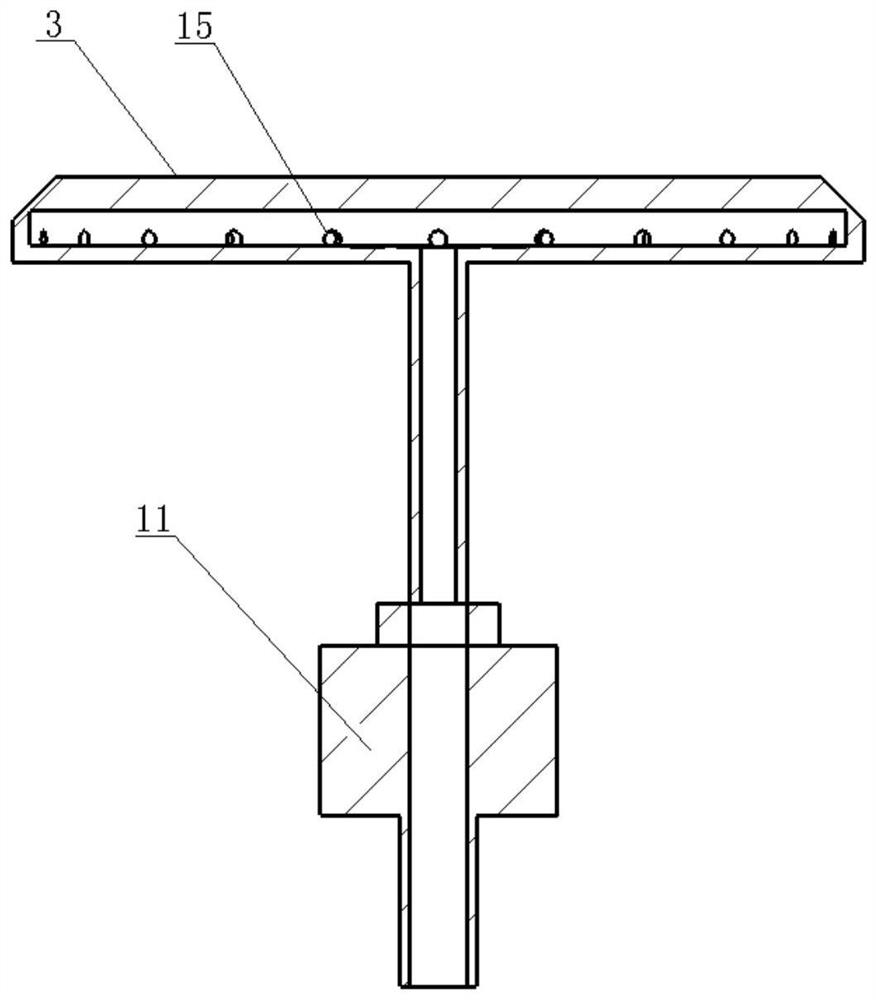

High-efficiency low-pollution plasma source

PendingCN114302546AIncrease profitReduce and control self-sputtering against the wallPlasma techniqueMagnetic tension forceSputtering

The invention belongs to the technical field of plasma sources, and particularly relates to a high-efficiency low-pollution plasma source which comprises a cathode, a water-cooled anode and a magnet yoke base which are coaxially arranged, inner magnetic steel arranged at the center of the magnet yoke base, an inner shield which sleeves the inner magnetic steel, and outer magnetic steel and an outer shield which are fixedly mounted above the outer edge of the magnet yoke base, the magnet yoke base is positioned in the cathode; the water-cooled anode is connected with the cathode in an insulating manner; the magnetic force directions of the inner magnetic steel and the outer magnetic steel are opposite; and a discharge power supply A is connected between the cathode and the water-cooling anode. The inner magnetic pole and the outer magnetic pole of the plasma source are located at the suspension potential or different bias voltages are applied to a workpiece or a vacuum chamber respectively, and the potential is distributed by designing a discharge channel, so that self-sputtering of discharge plasma to the wall can be reduced and controlled, and the purposes of improving the utilization rate of discharge current and leading out ion energy are achieved.

Owner:SOUTHWESTERN INST OF PHYSICS

Mass Spectrometers Comprising Accelerator Devices

ActiveUS20160233075A1High ion energySolve the low detection efficiencyTime-of-flight spectrometersElectron/ion optical arrangementsPotential differenceMass spectrometry

A method of mass spectrometry is disclosed comprising providing a flight region for ions to travel through and a detector or fragmentation device. A potential profile is maintained along the flight region such that ions travel towards the detector or fragmentation device. The potential at which a first length of the flight region is maintained is then changed from a first potential to a second potential whilst at least some ions are travelling within the first length of flight region. The changed potential provides a first potential difference at an exit of the length of flight region, through which the ions are accelerated as they leave the length of flight region. This increases the kinetic energy of the ions prior to them reaching the detector or fragmentation cell.

Owner:MICROMASS UK LTD

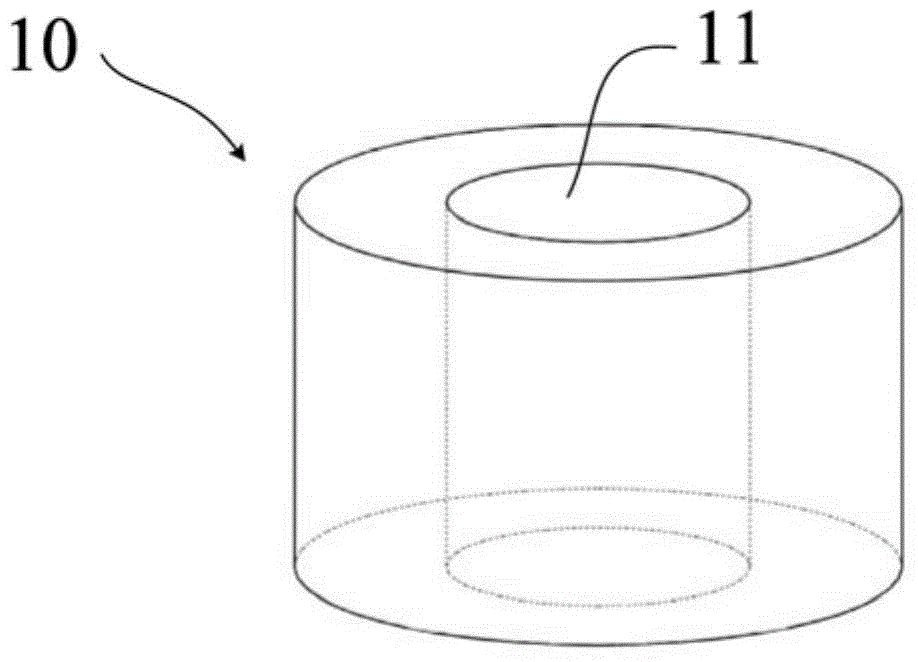

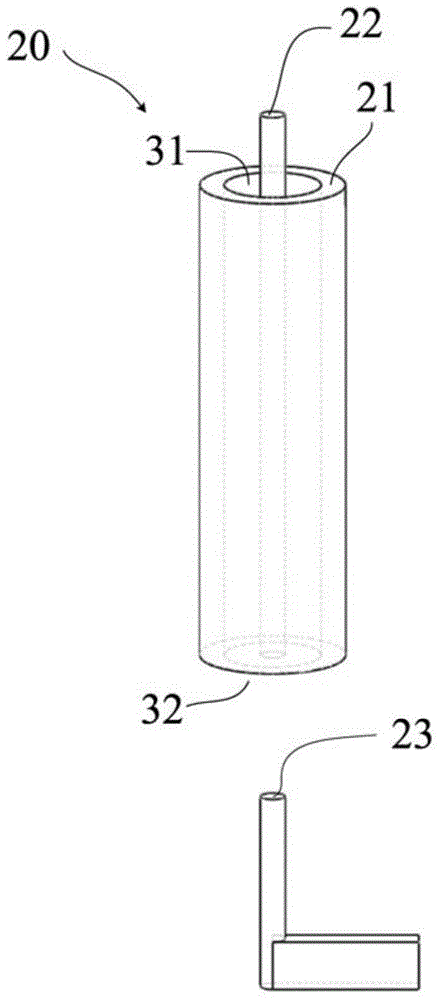

Atmospheric plasma jet generation device with hollow substrate and electrodes

The invention relates to an atmosphere plasma jet generation device with a hollow substrate and electrodes. The atmosphere plasma jet generation device comprises a DC discharge unit and a power supply used for supplying a discharge voltage to the DC discharge unit. The DC discharge unit comprises an air guide pipe and an electrode set. The electrode set comprises the cylindrical high-voltage electrode and the grounding electrode. The air guide pipe is a hollow pipe. The upper end and the lower end of the air guide pipe are provided with an air inlet port and an air outlet port respectively. The high-voltage electrode is arranged at the center of the air guide pipe in the axial direction. A hollow metal substrate unit used for forming a narrow airflow channel is further arranged at the grounding electrode. The hollow metal substrate unit is a cylinder and is provided with a through hole in the axial direction. The atmosphere plasma jet generation device with the hollow substrate and the electrodes is simple in operation process and low in running cost.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Vacuum decoration coating technique of high polymer material product

ActiveCN104694878AEmission reductionImprove arc spot dischargeVacuum evaporation coatingSputtering coatingSputteringSurface cleaning

The invention discloses a vacuum decoration coating technique of a high polymer material product, which comprises the following steps: product surface cleaning, product surface plasma activation, Cr layer plating by high-power magnetron sputtering, fine arc ion plating of functional layer, and high-power magnetron sputtering of protective layer. The film prepared by the technique mainly comprises a Cr base layer, an ion plating functional layer and an oxide protective layer. The technique is used for substituting electroplating treatment, avoids the pollution of three wastes, enhances the added value of the high polymer product, and can provide more colors and appearances.

Owner:WENZHOU UNIVERSITY

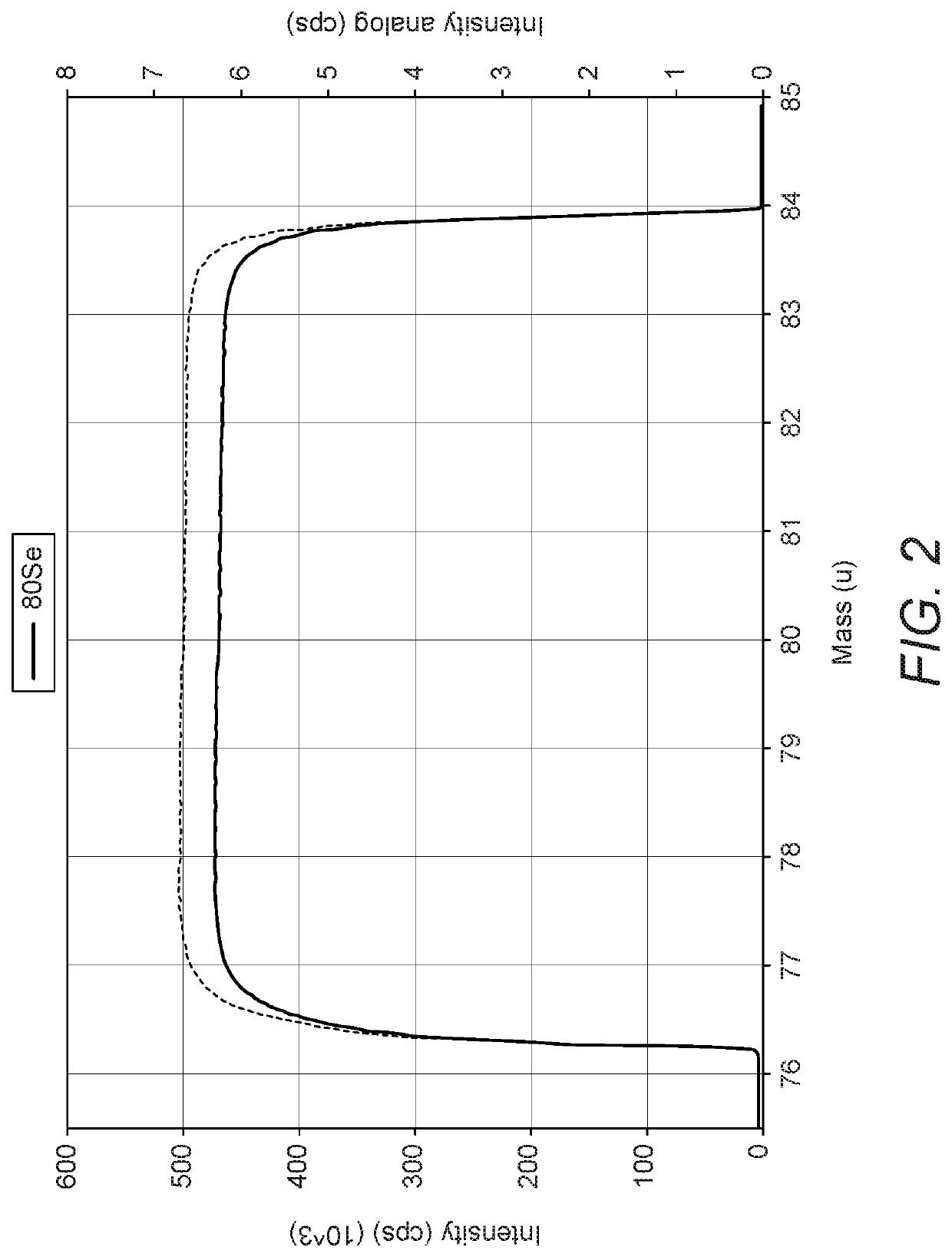

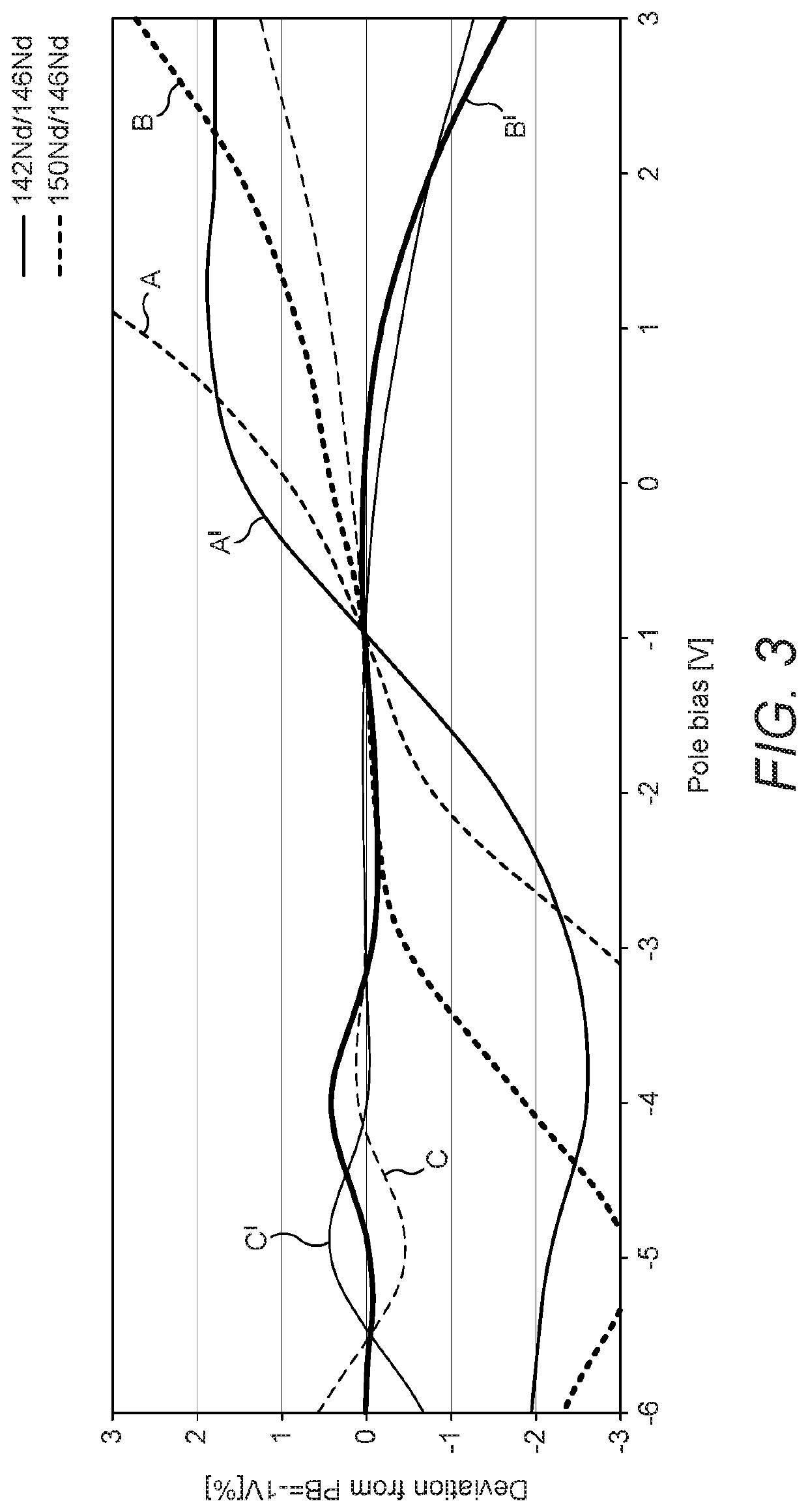

Mass Spectrometer

InactiveUS20210013017A1Improve transmittanceHigh sensitivityElectron/ion optical arrangementsIon sources/gunsWien filterOptical spectrometer

An isotope ratio mass spectrometer has an ion source, a static field mass filter, a reaction cell to induce a mass shift reaction, and a sector field mass analyser for spatially separating ions from the reaction cell according to their m / z. A detector platform detects a plurality of different ion species separated by the sector field mass analyser. The static field mass filter has a first Wien filter that deflects ions away from a longitudinal symmetry axis of the spectrometer in accordance with the ions' m / z, and a second Wien filter that deflects ions back towards the longitudinal symmetry axis in accordance with the ions' m / z. An inverting lens is positioned along the longitudinal axis between the Wien filters to invert the direction of deflection of the ions from the first Wien filter. The static field mass filter provides high transmission and improved spectrometer sensitivity. The first and second Wien filters permit simple tuning.

Owner:THERMO FISHER SCI BREMEN

Plasma system and method of producing a functional coating

InactiveUS20120222617A1High ion energyReduce heat loadElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma jetCombustor

A plasma system has at least one inductively coupled high-frequency plasma jet source having a burner body delimiting a plasma generating space, having an outlet orifice for the plasma jet, and a chamber communicating with the plasma jet source through the outlet orifice, having a substrate situated in the chamber, where it is exposed to the plasma jet. The substrate is situated on a substrate electrode to which an electric voltage may be applied. In addition, a method of producing a functional coating on the substrate using such a plasma system is also described. In a preferred embodiment, during operation of the plasma system, both the plasma jet and the electric voltage on the substrate electrode are pulsed and / or a pressure gradient is maintained between the interior of the plasma jet source and the interior of the chamber.

Owner:GROSSE STEFAN +2

Generation of highly N-type, defect passivated transition metal oxides using plasma fluorine insertion

ActiveUS9312342B2Greater the bias relative to the substrateHigh ion energySolid-state devicesSemiconductor/solid-state device manufacturingHalogenOxygen vacancy

A new composition of matter is disclosed wherein oxygen vacancies in a semiconducting transition metal oxide such as titanium dioxide are filled with a halogen such as Fluorine, whereby the conductivity of the composition is greatly enhanced, while at the same time the chemical stability of the composition is greatly improved. Stoichiometric titanium dioxide having less than 3 % oxygen vacancies is subject to fluorine insertion such that oxygen vacancies are filled, limited amounts of fluorine replace additional oxygen atoms and fluorine interstitially inserts into the body of the TiO2 composition.

Owner:RGT UNIV OF CALIFORNIA

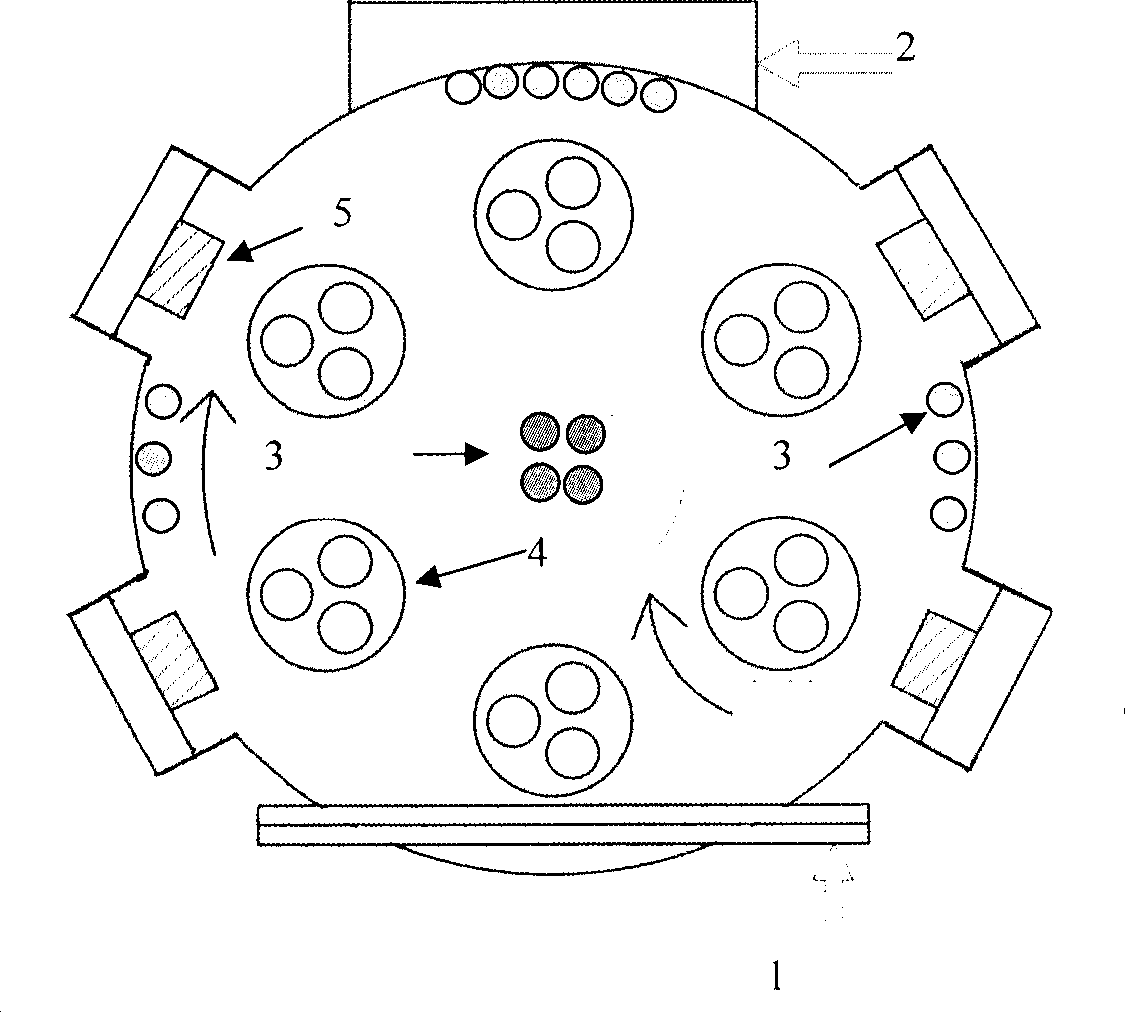

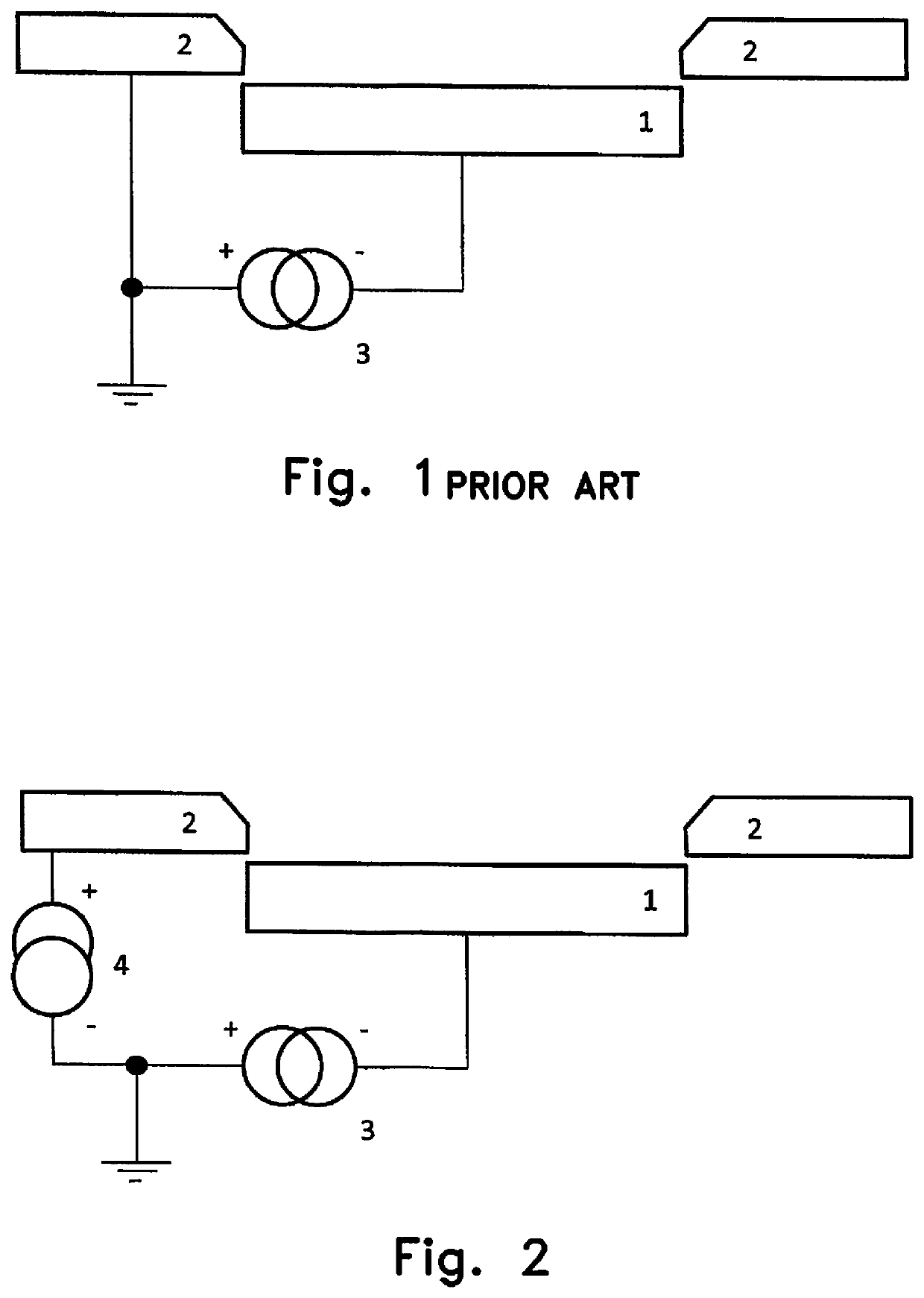

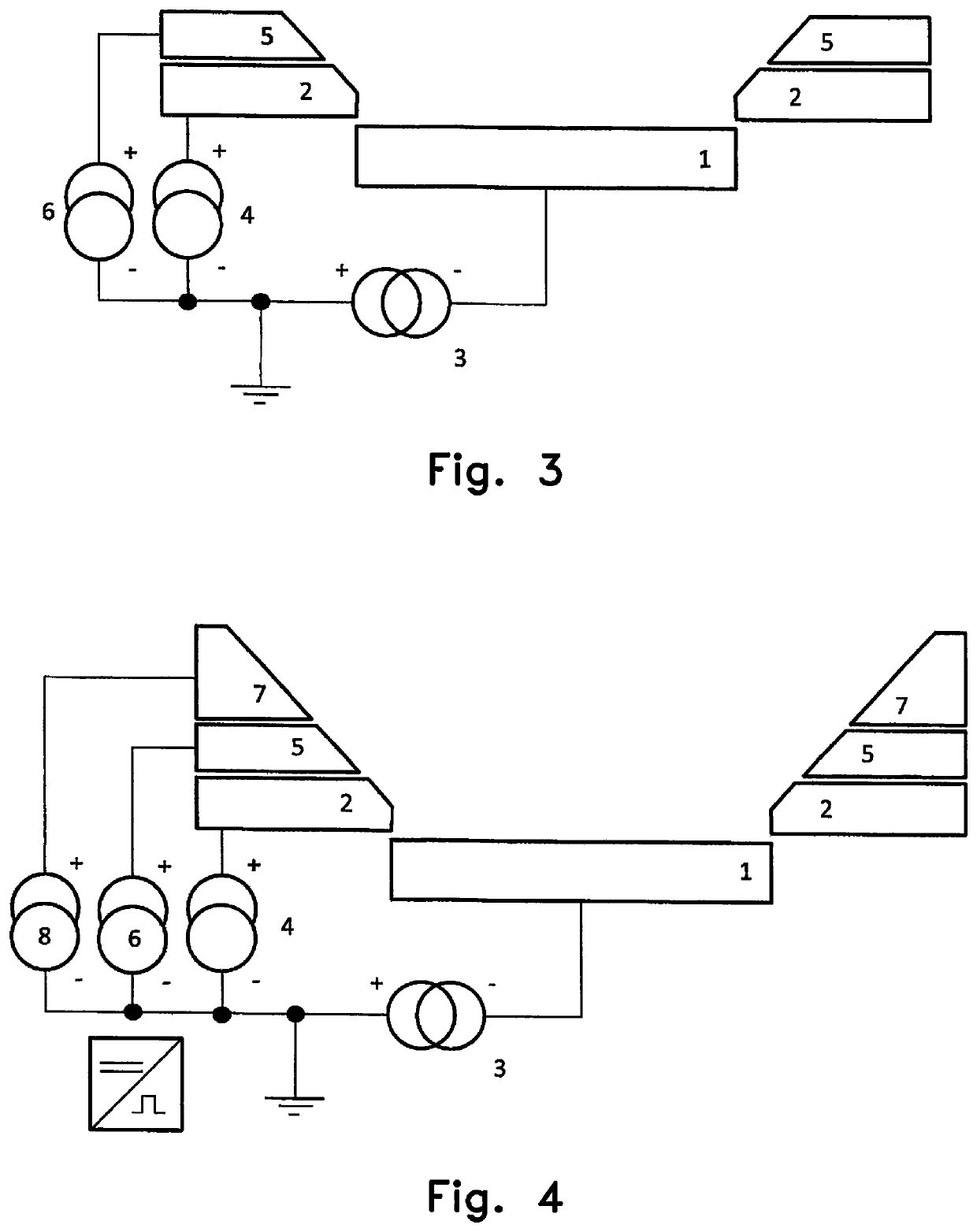

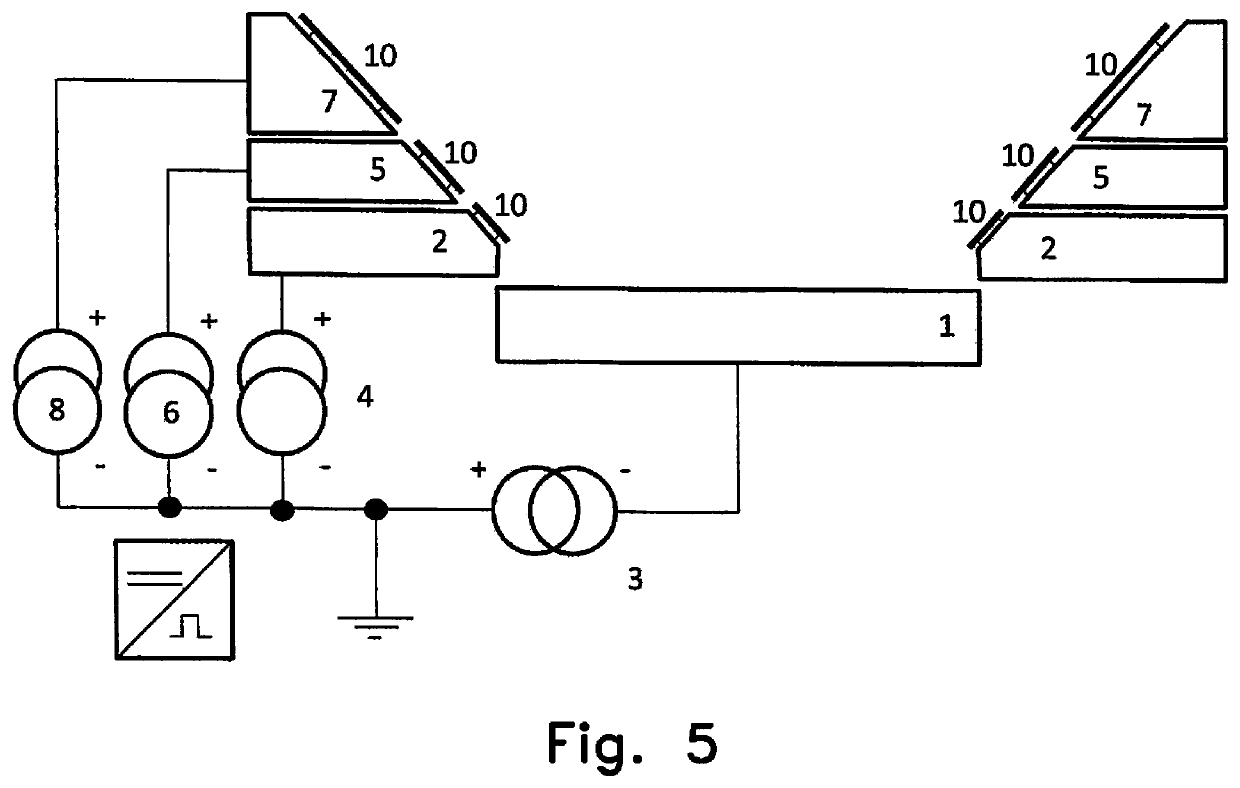

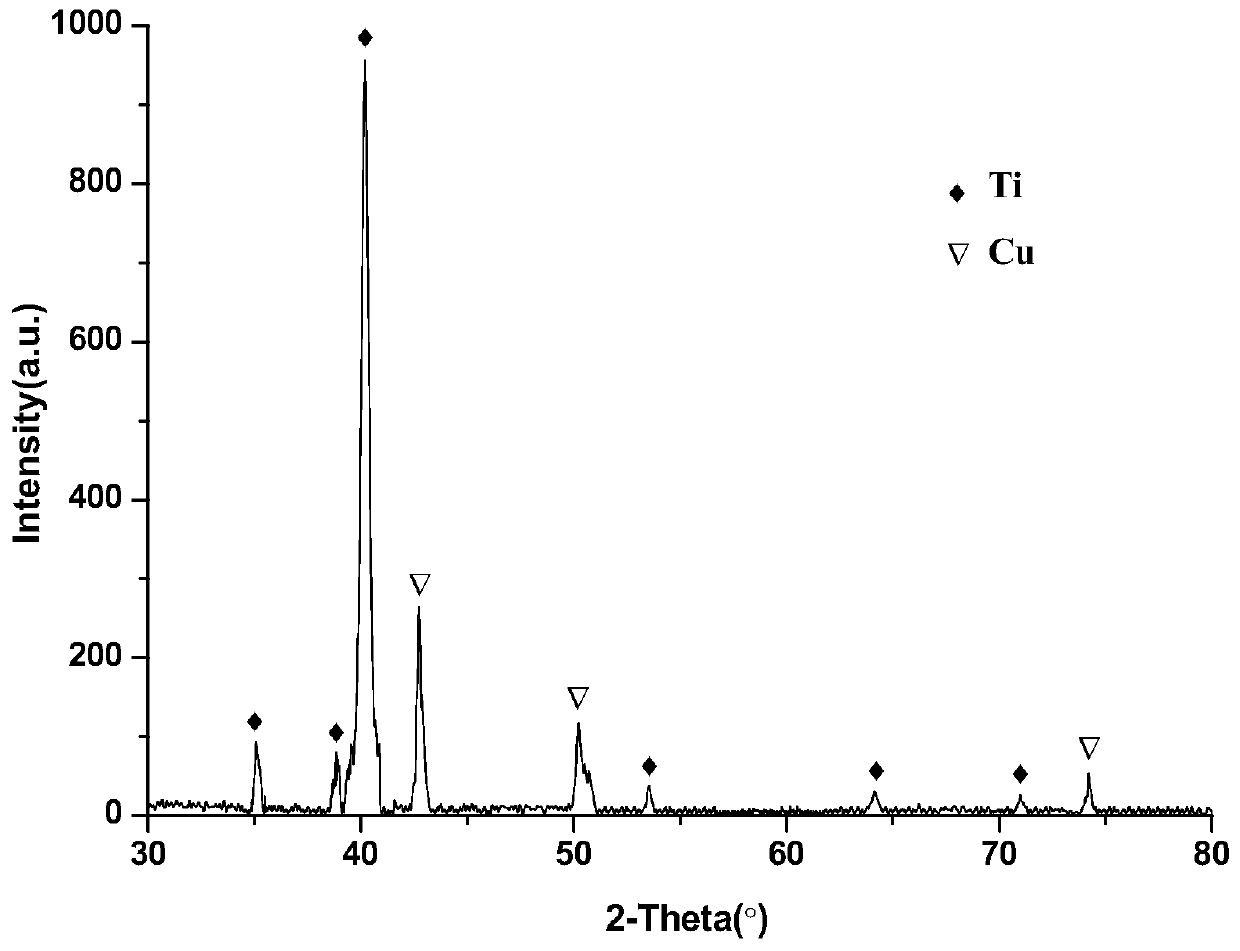

Arrangement for coating substrate surfaces by means of electric arc discharge

ActiveUS20200240002A1Constant layer thicknessReduce porosityElectric discharge tubesVacuum evaporation coatingMetallic materialsVacuum chamber

The invention relates to an arrangement for coating substrate surfaces by means of electric arc discharge in a vacuum chamber, wherein electric arc discharges between a target (1) which is electrically connected as a cathode and is formed from a metal material are used. Arranged at a distance from the target (1) is an anode (2), with which the electric arc discharges are ignited to form a plasma formed with metal material of the target (1). The target (1) is connected to a first electric power source (3) and the anode (2) to a second electric power source (4), wherein the absolute values of the electric voltages connected to the target (1) and to the anode (2) different from one another.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

A kind of titanium alloy nano-coating with antibacterial function and preparation method thereof

ActiveCN108866489BHas antibacterial functionHas broad-spectrum antibacterial functionVacuum evaporation coatingSputtering coatingChemical compositionTitanium

The invention aims to provide a titanium alloy nano-coating with an antibacterial function and a preparation method thereof. The titanium alloy nano-coating is characterized by comprising the following chemical components of, by mass percent, 2-10% of Cu, 0.04-0.1% of Ce and the balance Ti, wherein the preferable range of the chemical components reaches the following standards that the Cu accountsfor 4-8%, the Ce accounts for 0.06-0.08%, and the balance is the Ti. According to the preparation method of the titanium alloy nano-coating, a titanium-copper-cerium nano-coating with the antibacterial function is formed on the surface of a substrate, so that the substrate can obtain a coating with the broad spectrum and the antibacterial function; and the coating has the excellent corrosion resistance in a biological medium and a corrosive solution.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com