Vacuum decoration coating technique of high polymer material product

A technology of polymer materials and products, applied in the field of vacuum decorative coating of polymer electromechanical products, can solve the problems of poor metal texture, poor film-forming performance, easy to yellow color, etc., to improve ion density and ion energy, improve grade and added value, the effect of reducing the emission of large particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

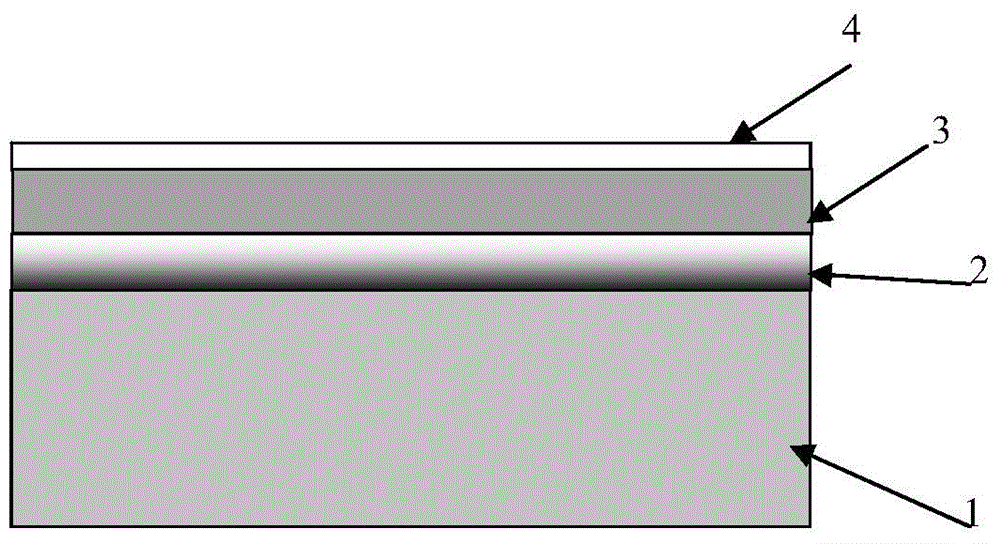

[0027] Such as figure 1 The processing procedure of the polymer material product shown is:

[0028] Hang the product and perform ultrasonic cleaning, mainly including degreasing, degreasing, deionization, drying and other processes. After the product is cleaned, it is to be coated. The cleaned polymer electromechanical products are sent into the coating vacuum chamber and vacuumed. At the same time, preheat to 120 degrees, and when the vacuum degree reaches 7*10e-3, enter the working gas between 0.3Pa and argon or nitrogen, and turn on the ion source to activate and modify the surface of the product. The processing time is 6 minutes. , to improve the state of the product surface, to be coated. The ion source is not turned off, the working gas argon pressure is adjusted to 0.5Pa, the high-power magnetron sputtering target Cr target is turned on, and the ion source is assisted to deposit Cr as the bottom layer. The coating time is 60 minutes. After 20 minutes of coating time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com