Method for preparing bismuth, antimony and telluride base thermoelectric film

A thermoelectric thin film, bismuth antimony tellurium technology, applied in the manufacture/processing of thermoelectric devices, vacuum evaporation plating, coating, etc., can solve the problems of easy side effects, low material utilization rate, and high requirements for reaction conditions, and achieve good Adhesion and repeatability, optimization of thermoelectric performance, effect of high ion energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

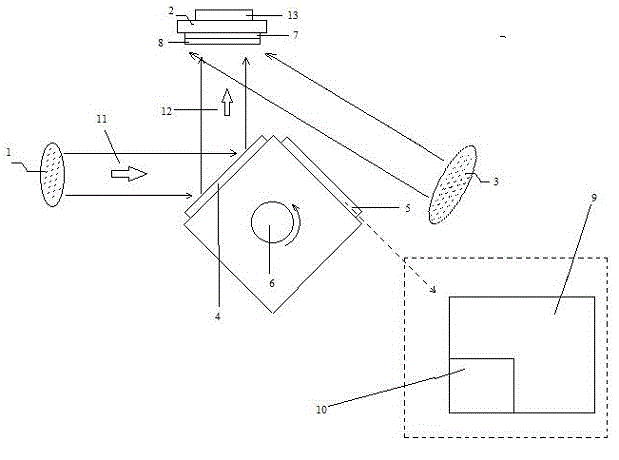

[0031] see figure 1 , which is the ion beam sputtering deposited Bi in the preparation method of bismuth antimony tellurium based thermoelectric thin film of the present invention 2-x Sb x Te 3 Schematic of a thermoelectric thin film. For ease of understanding, first the figure 1 The reference numbers in are explained as follows:

[0032] 1 main sputtering ion source; 2 insulating substrate; 3 auxiliary sputtering ion source; 4 Bi / Te binary composite target; 5 Sb / Te binary composite target; Te alloy film; 8 Sb / Te alloy film; 9 Te high-purity target; 10 Bi or Sb high-purity target; 11 ion beam; 12 sputtering atoms; 13 heating source.

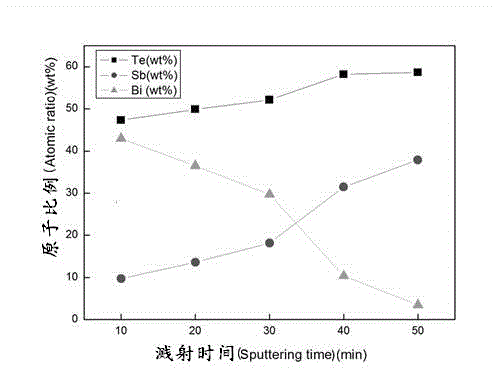

[0033] The Sb, Bi and Te targets with a purity of 99.99% are cut reasonably, and the targets are compounded according to the area ratio of the target as Sb:Te=1:3.5, Bi:Te=1:3 to form a binary Composite target, two binary composite targets of Sb / Te and Bi / Te are respectively fixed on the target frame of two stations; BK7 optical glass is us...

Embodiment 2

[0037] The difference from Example 1 is that the annealing time of the thermoelectric thin film is changed to 1H, 3H, 4H. Image 6 The sputtering time is 30 min for both BiTe / SbTe. Thin film thermoelectric performance characteristic curve with annealing time of 1H~4H.

Embodiment 3

[0039] The difference from Example 1 is that the annealing temperature of the thermoelectric thin film was changed to 150°C, 200°C, 250°C and 350°C. Figure 7 The thermoelectric performance characteristic curves of BiTe / SbTe films with the sputtering time of 30 min and the annealing temperature of 150°C~350°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com