Patents

Literature

45 results about "Wien filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

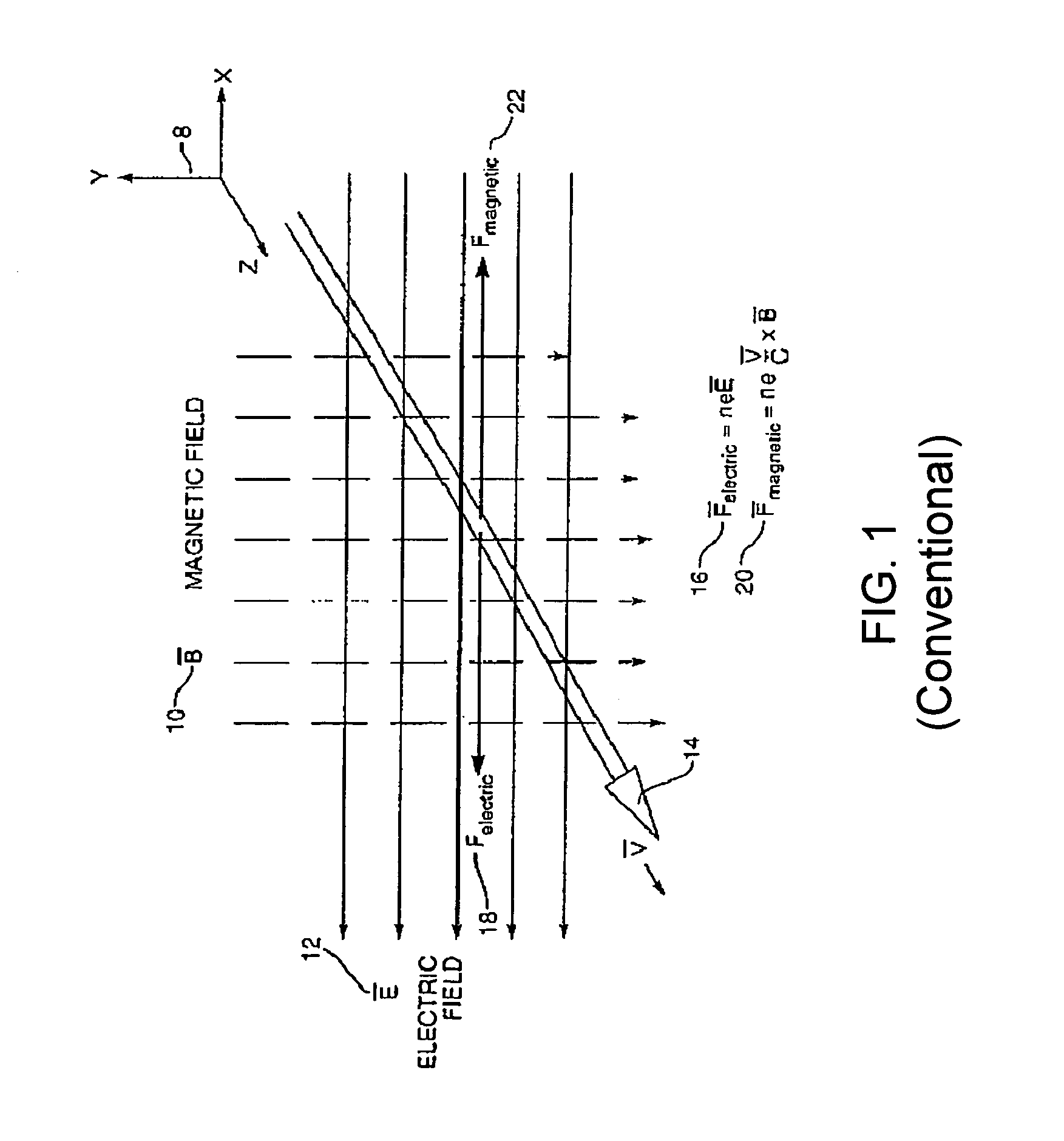

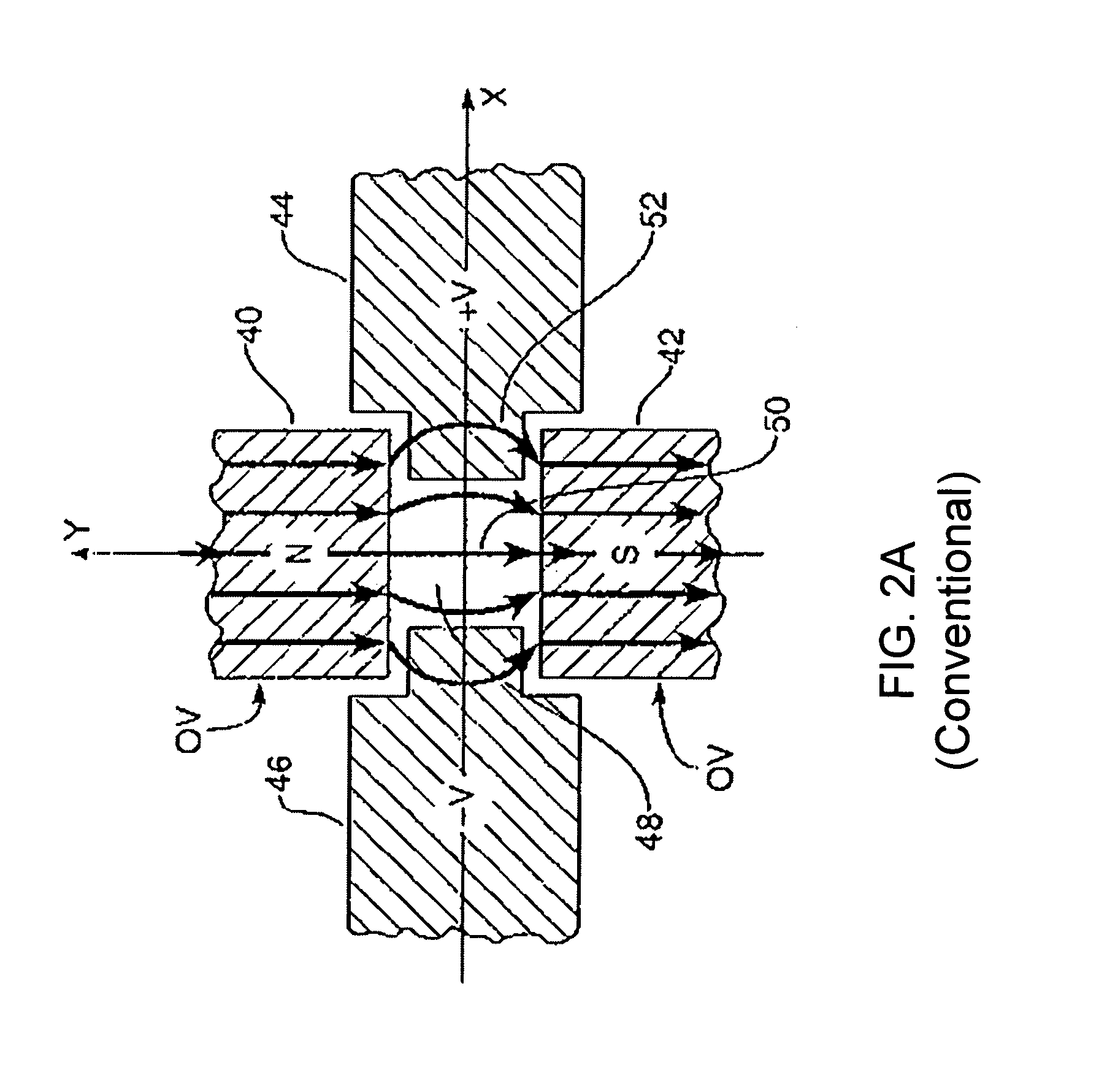

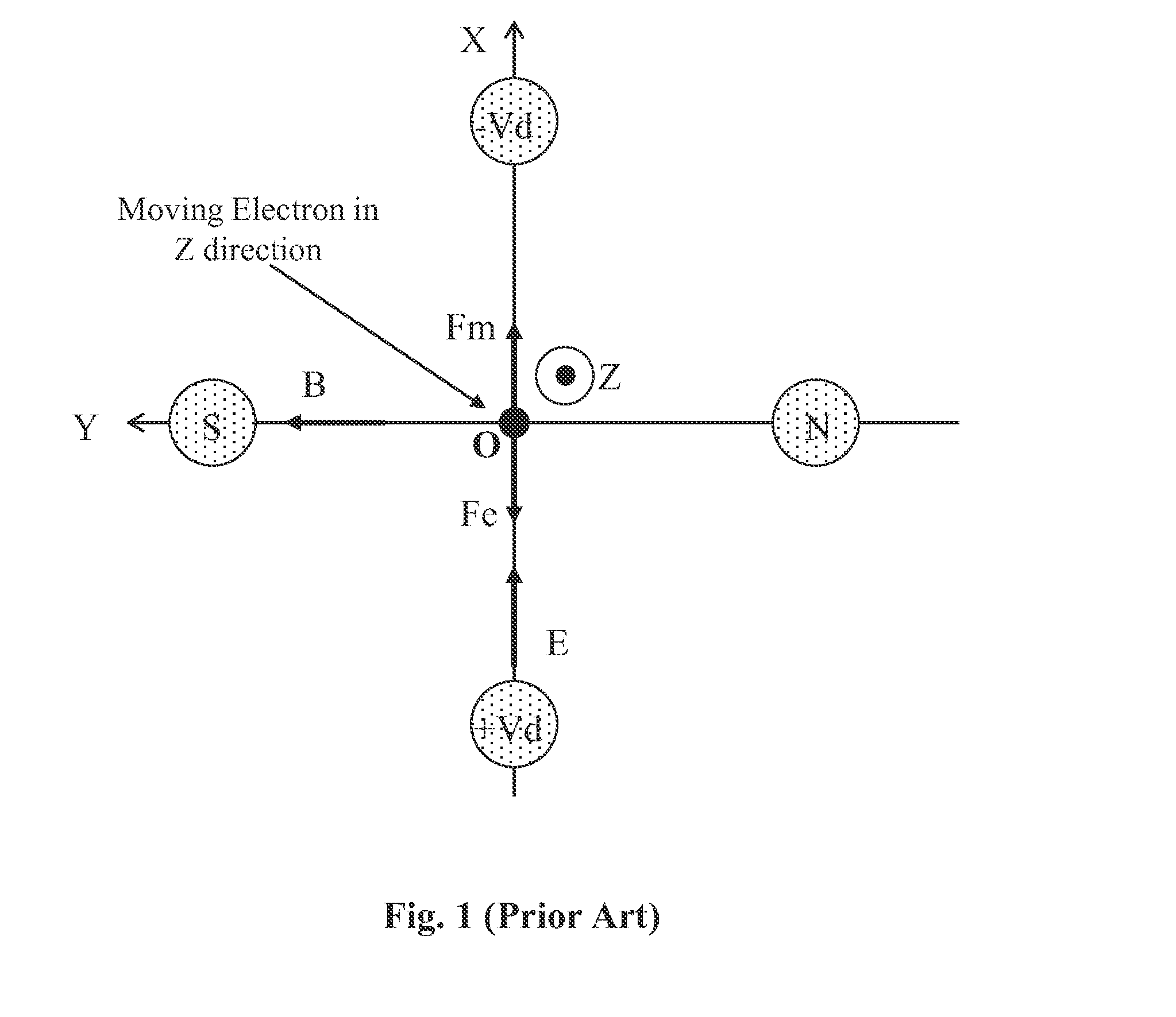

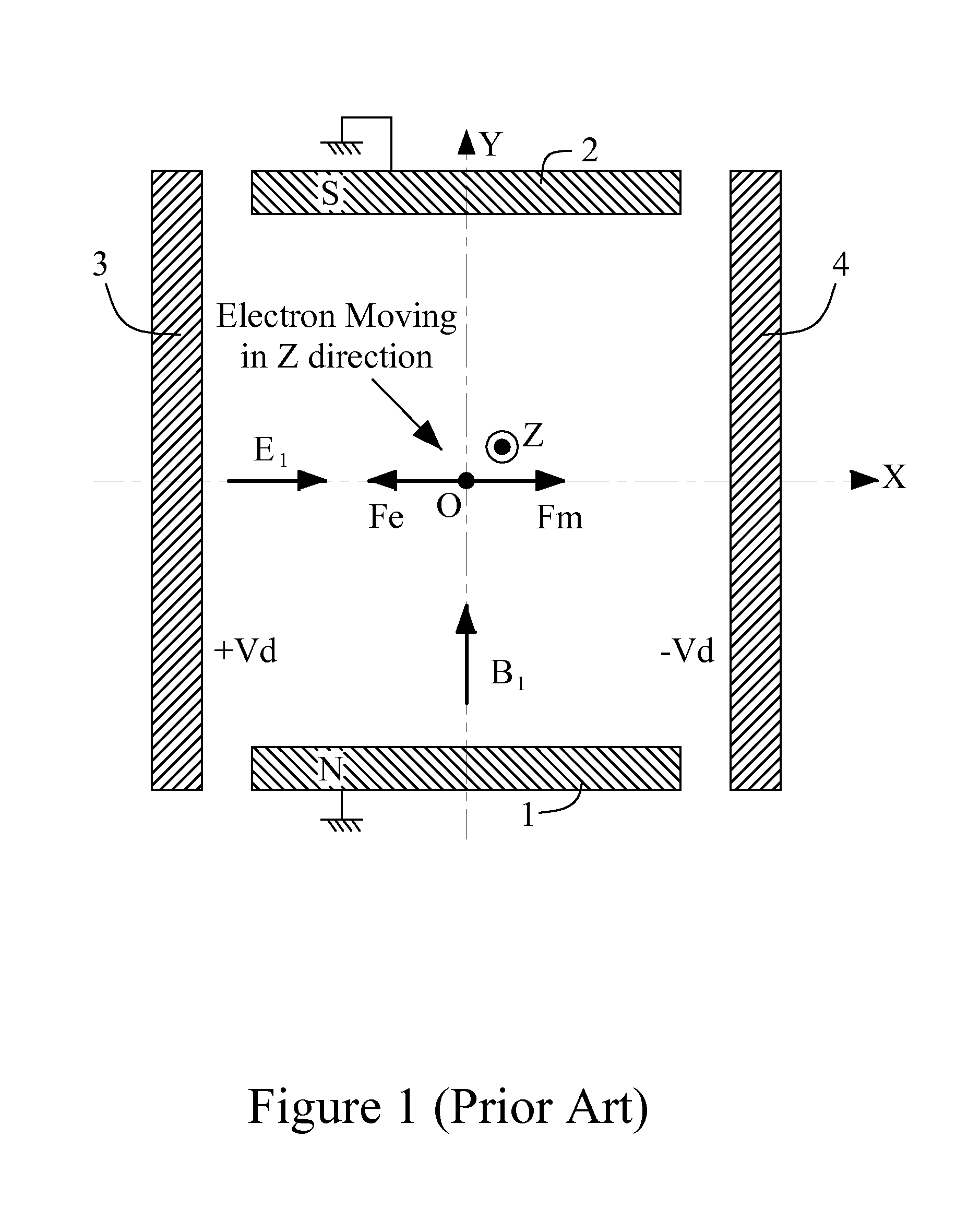

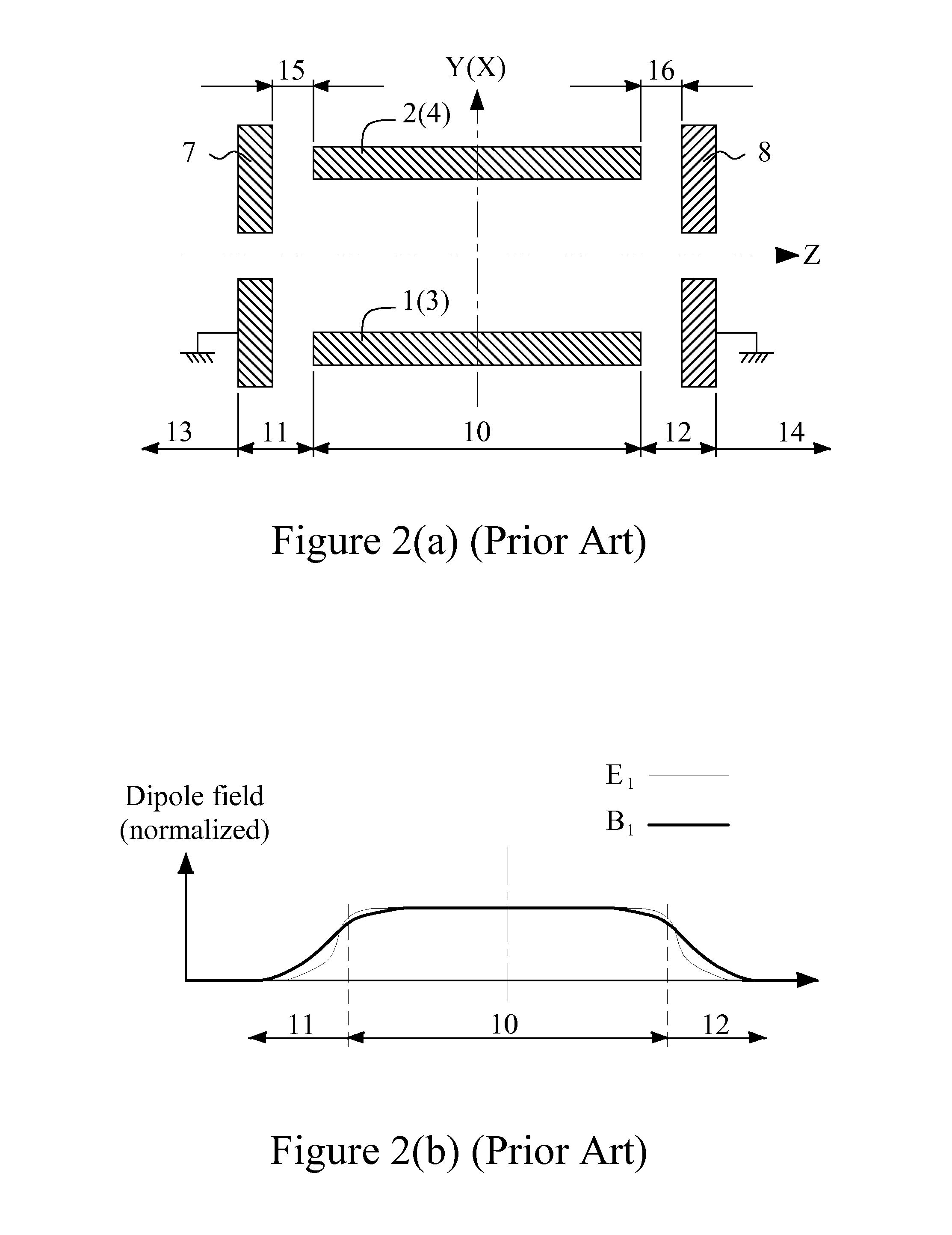

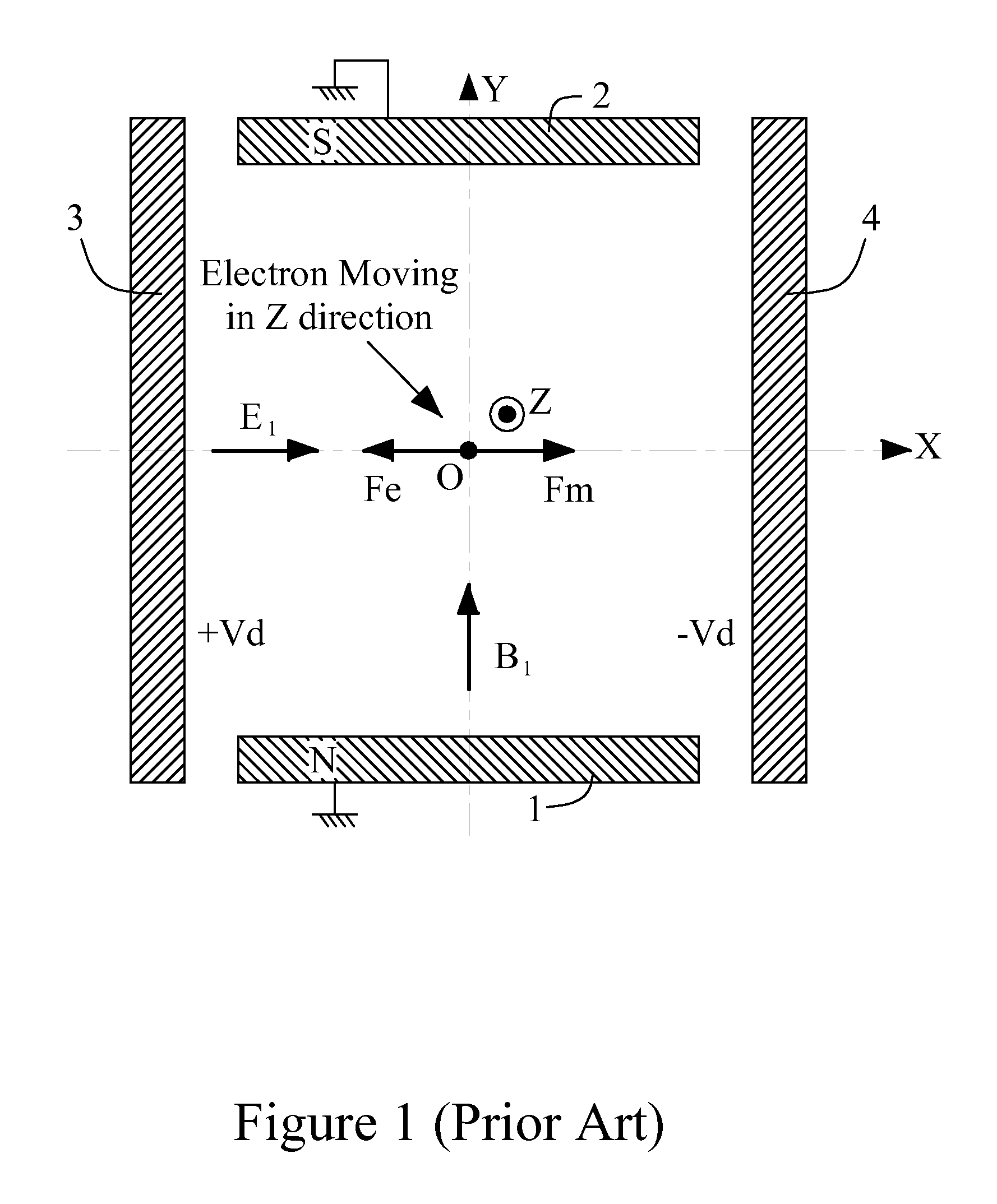

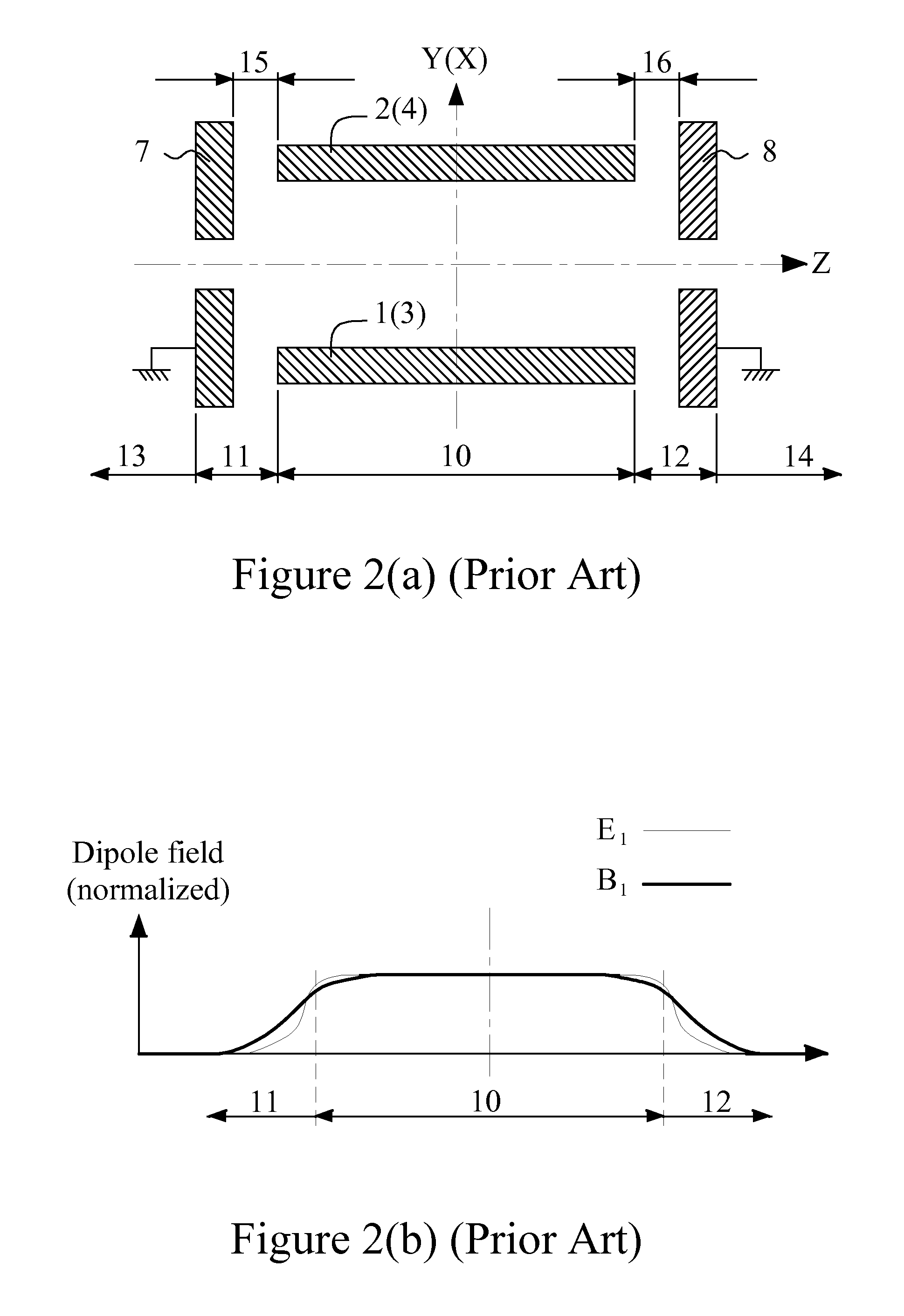

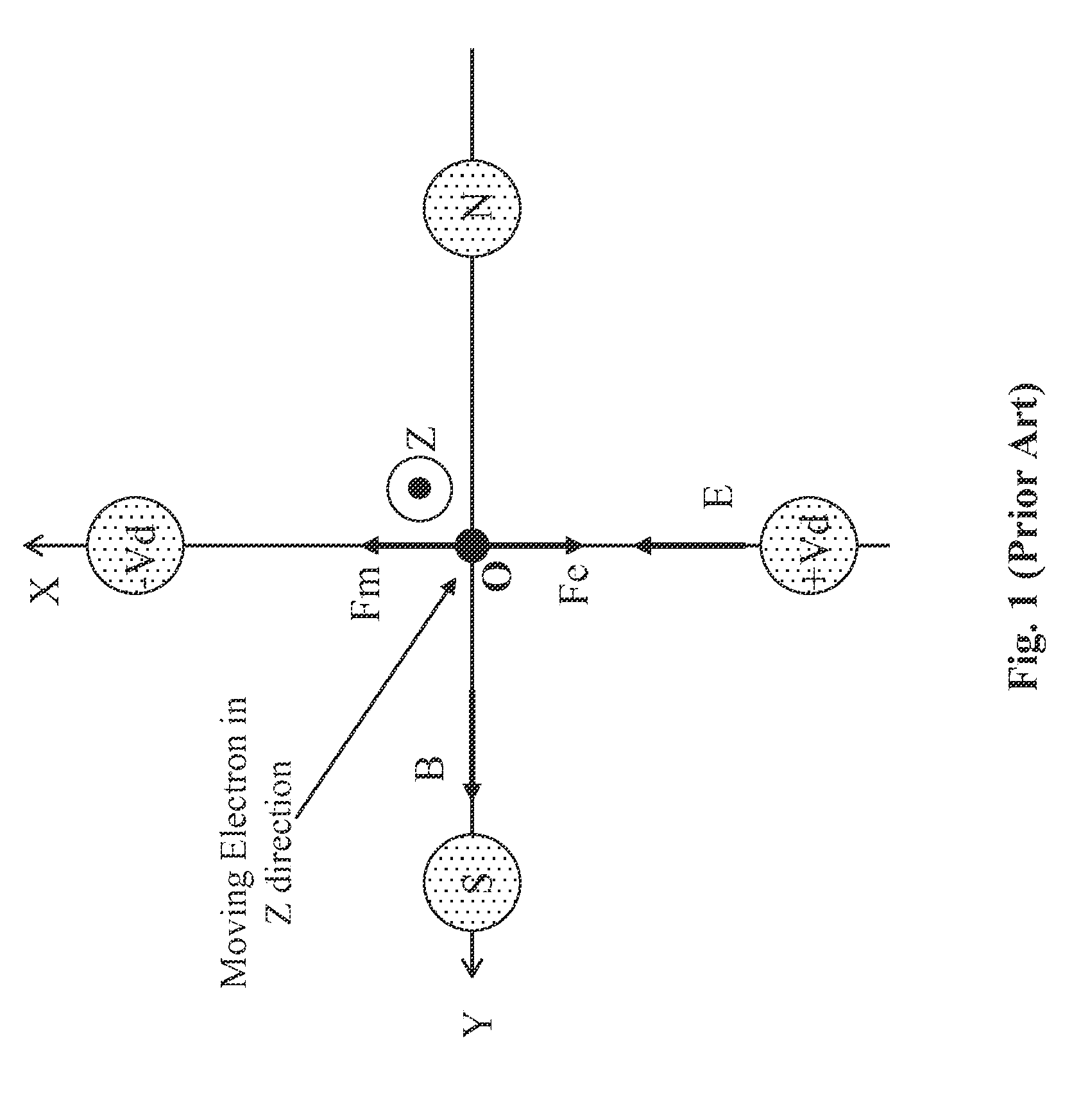

A Wien filter also known as velocity selector is a device consisting of perpendicular electric and magnetic fields that can be used as a velocity filter for charged particles, for example in electron microscopes and spectrometers. It is used in accelerator mass spectrometry to select particles based on their speed. The device is composed of orthogonal electric and magnetic fields, such that particles with the correct speed will be unaffected while other particles will be deflected. It is named for Wilhelm Wien who developed it in 1898 for the study of anode rays. It can be configured as a charged particle energy analyzer, monochromator, or mass spectrometer.

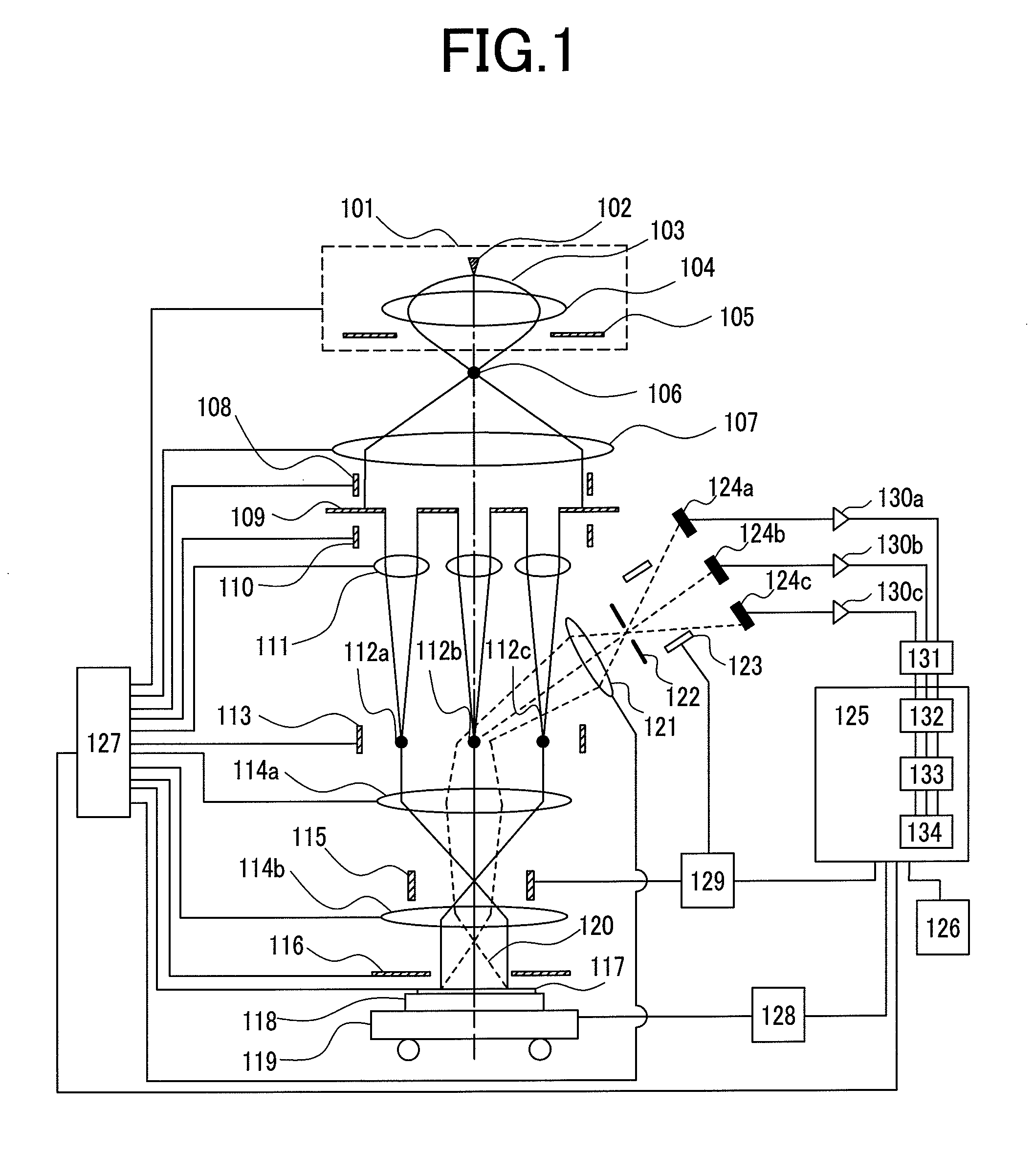

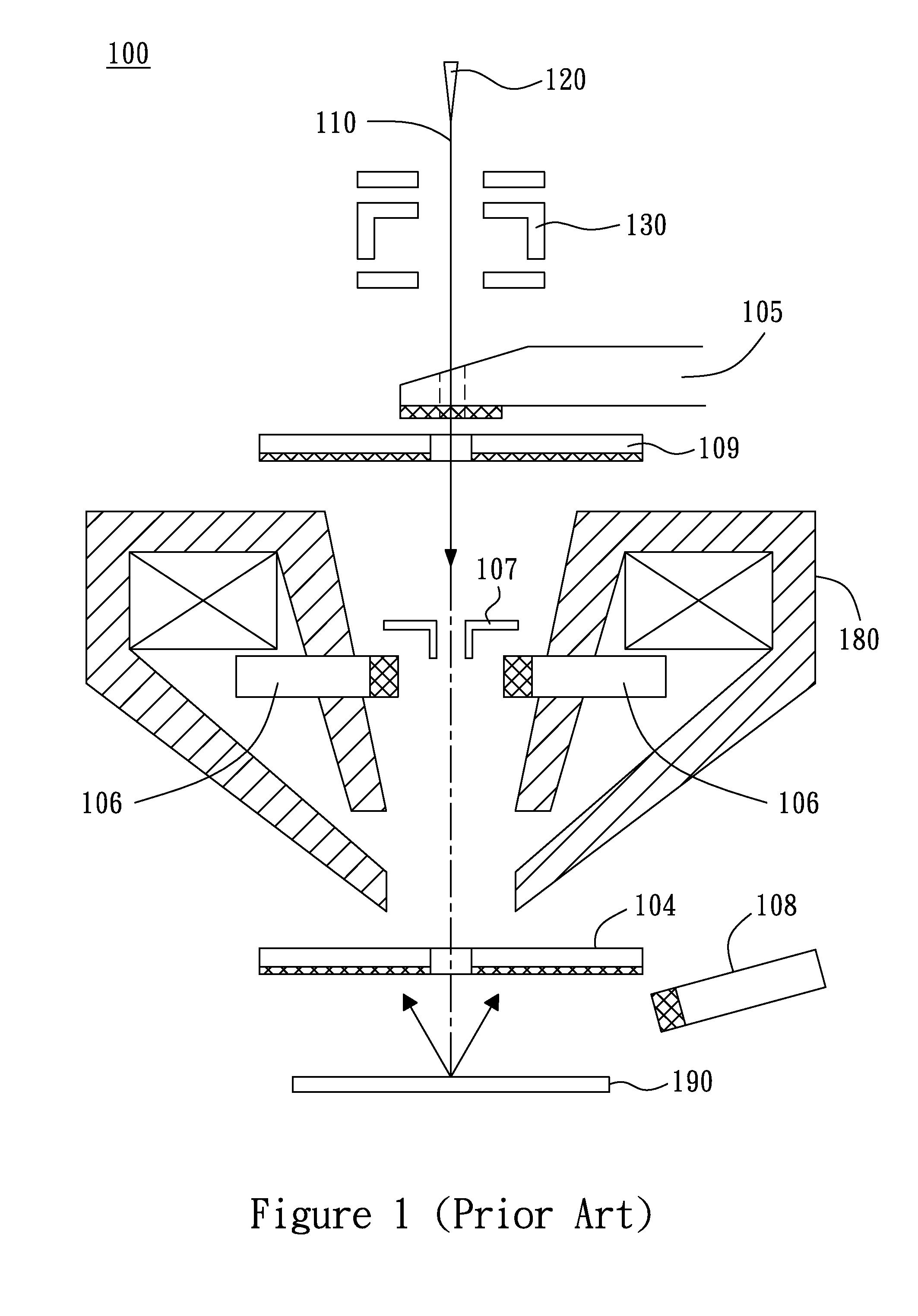

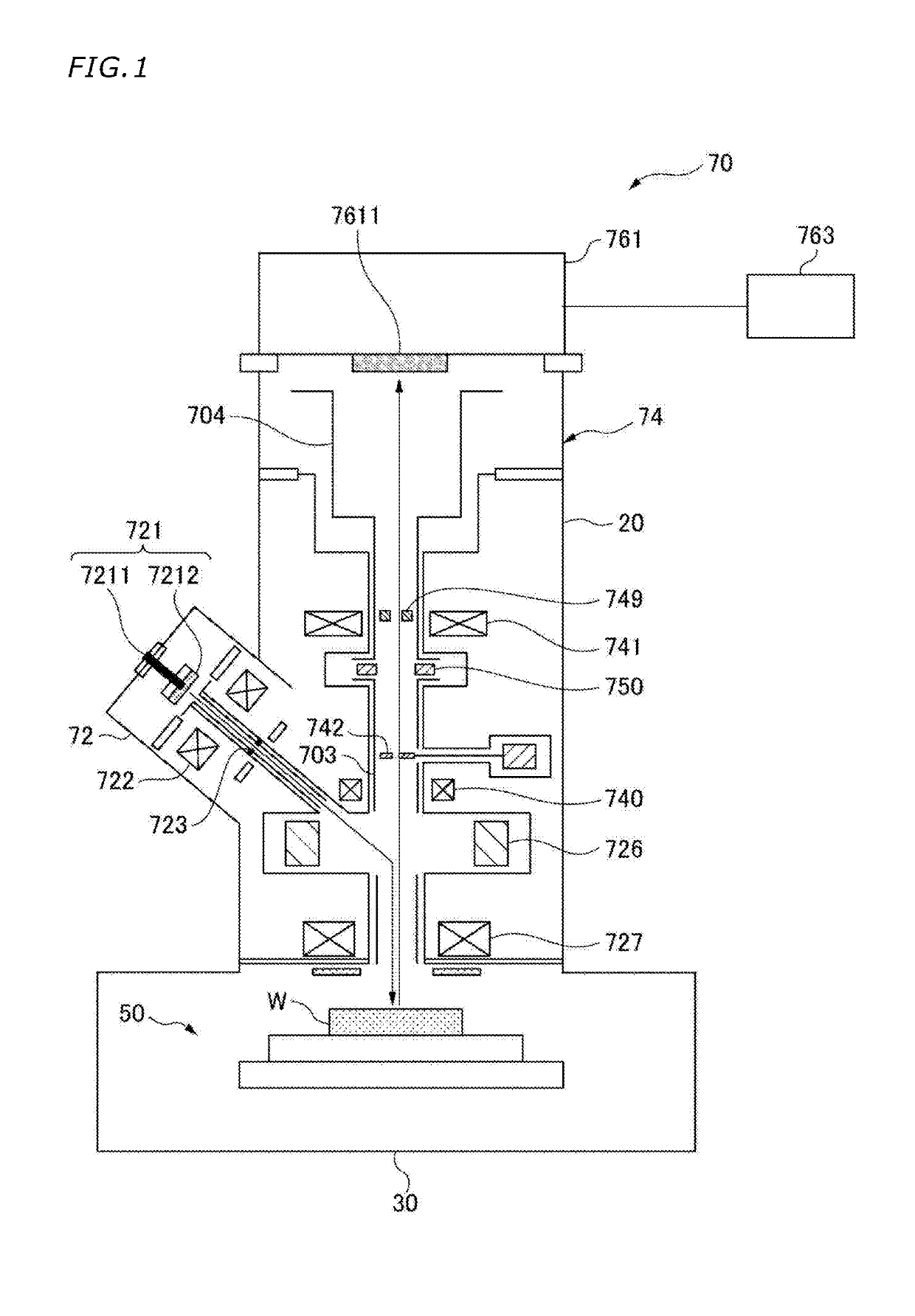

Projection electron beam apparatus and defect inspection system using the apparatus

InactiveUS20090212213A1Increase currentImprove throughputMaterial analysis using wave/particle radiationElectric discharge tubesWien filterTransmittance

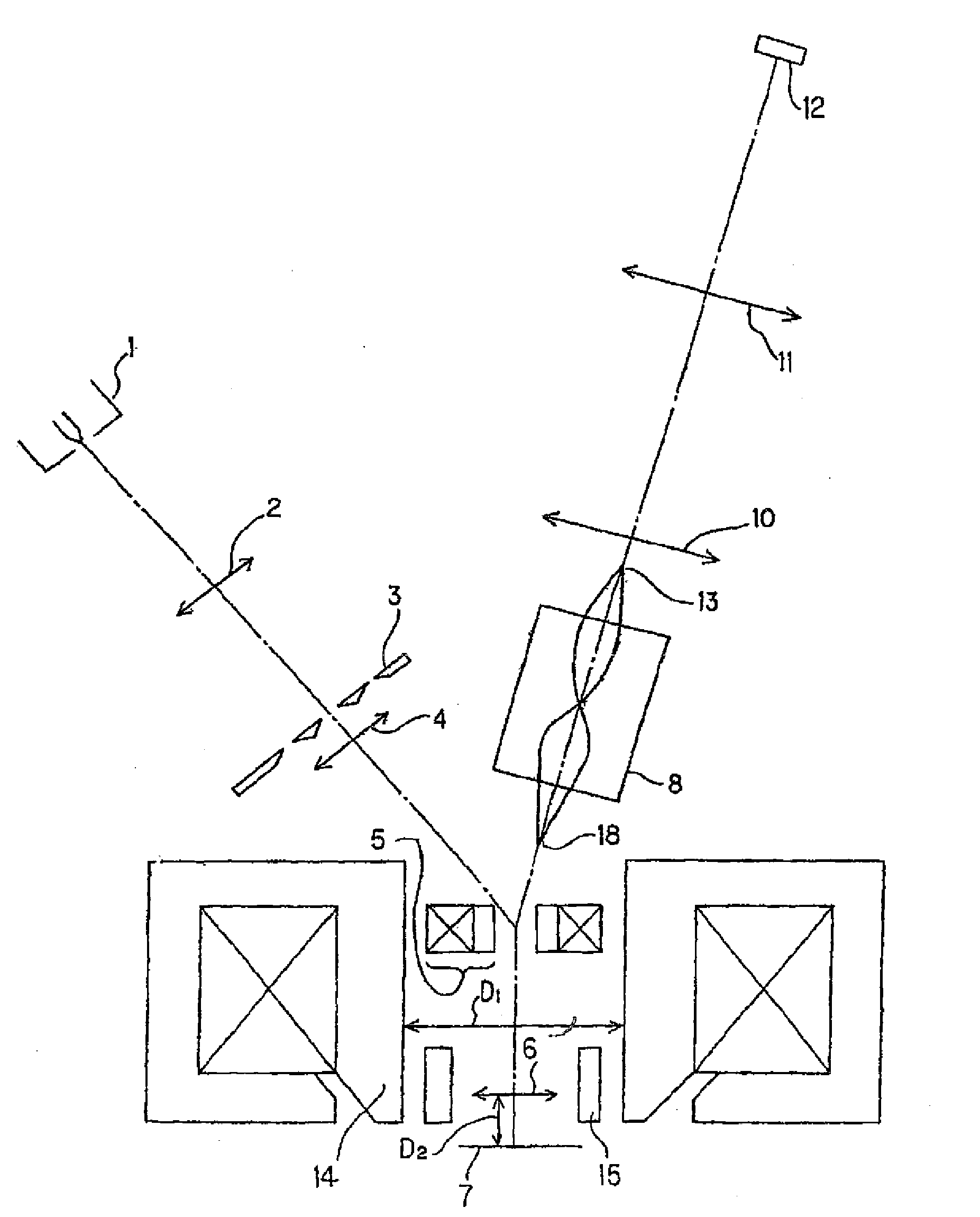

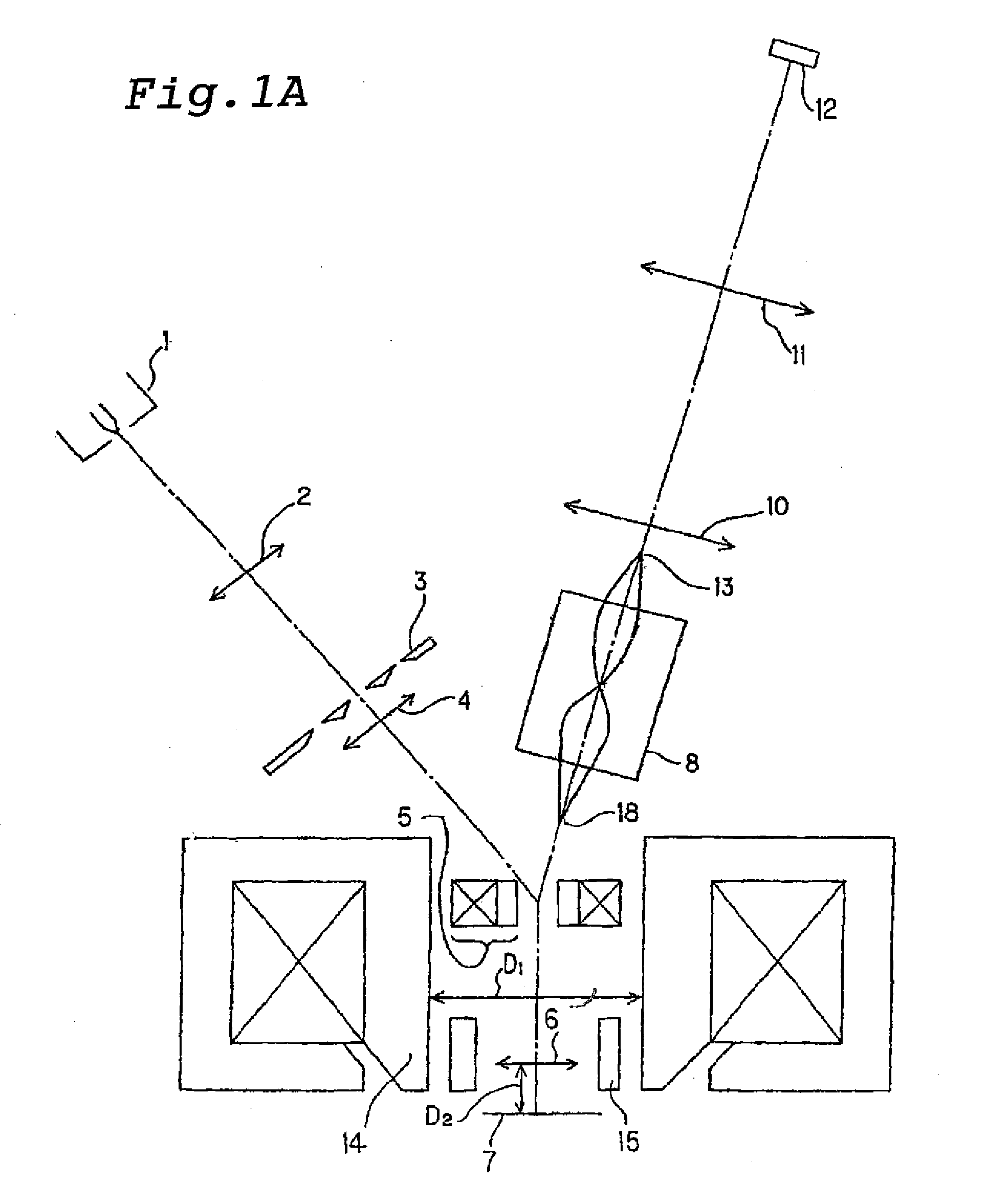

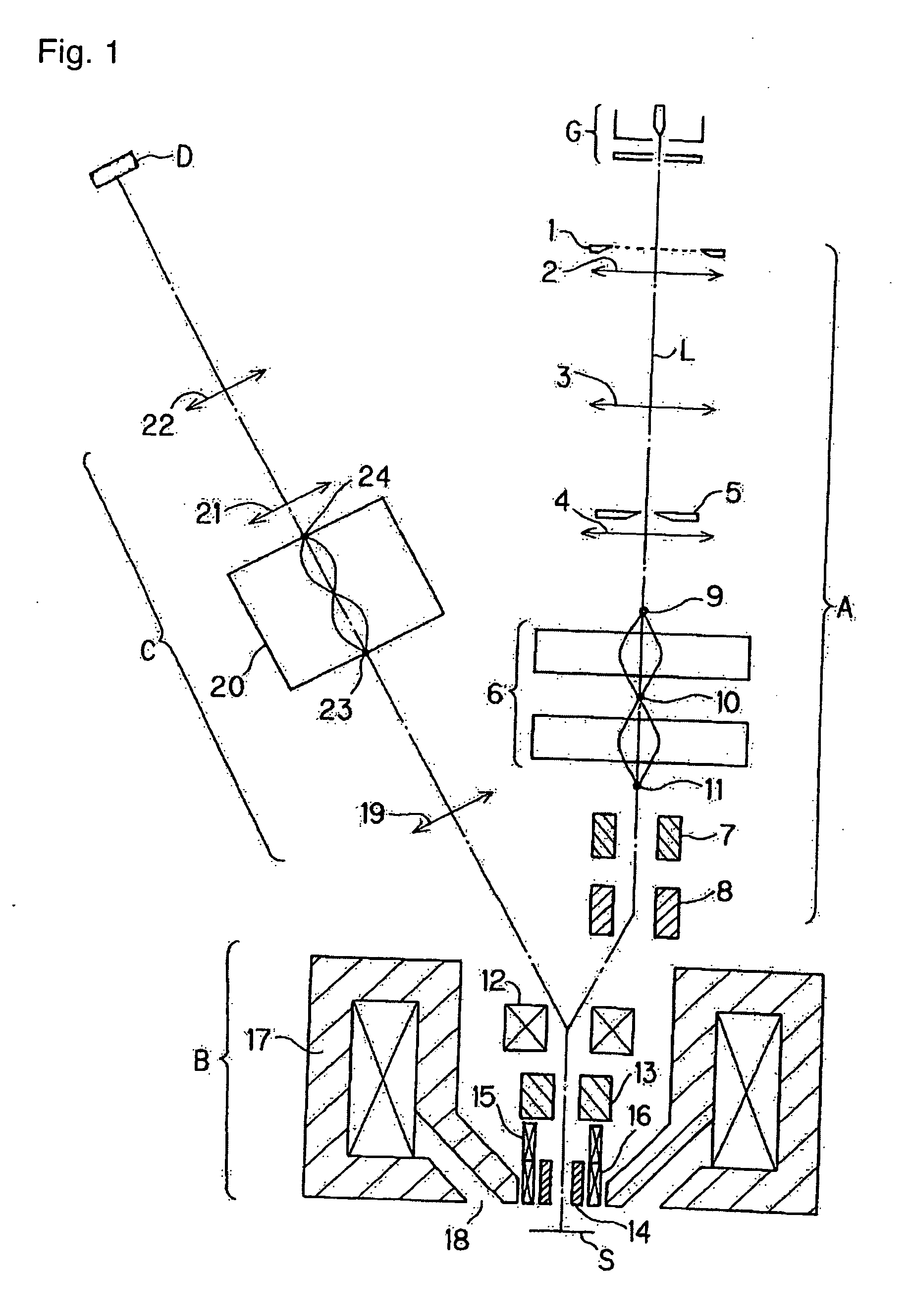

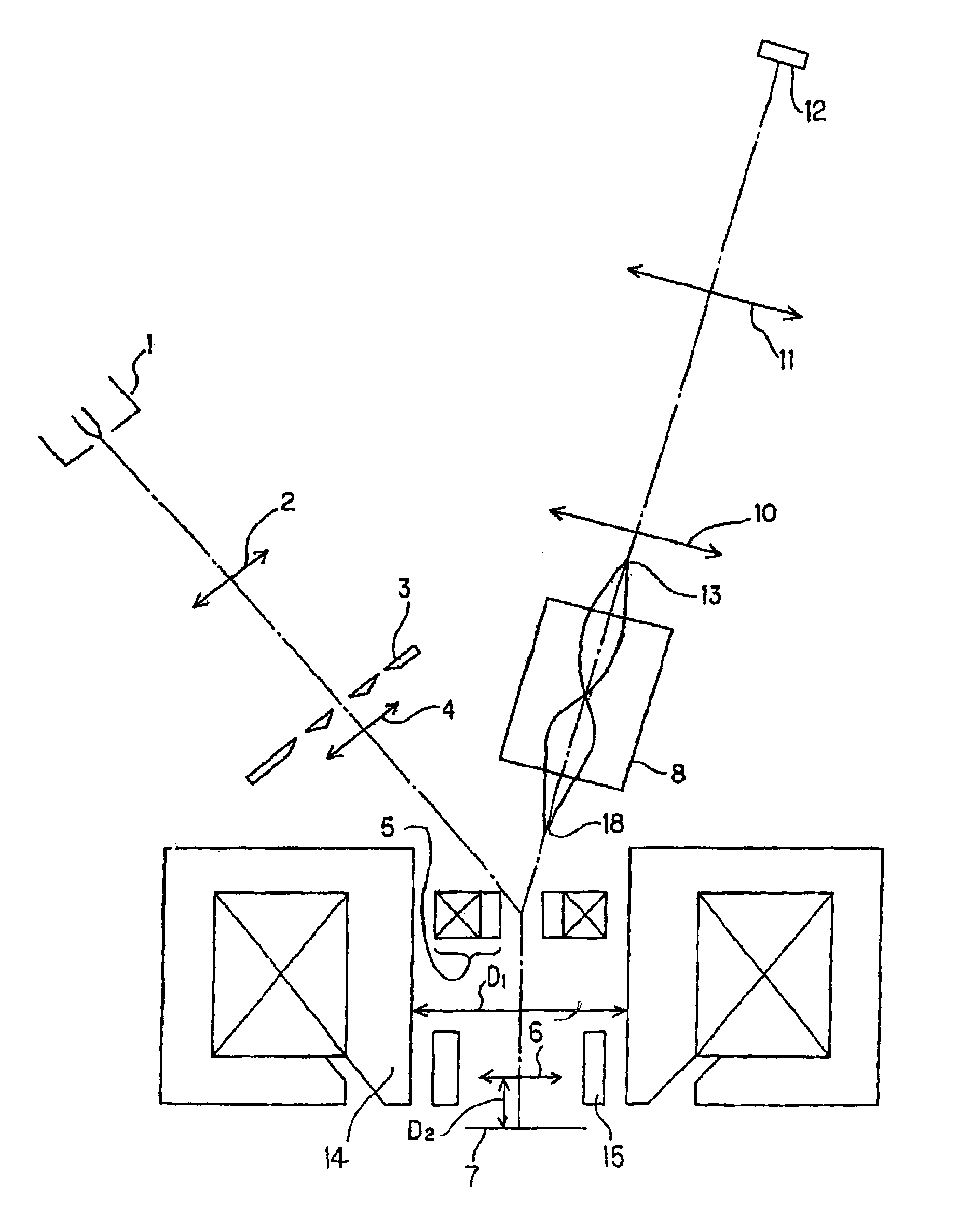

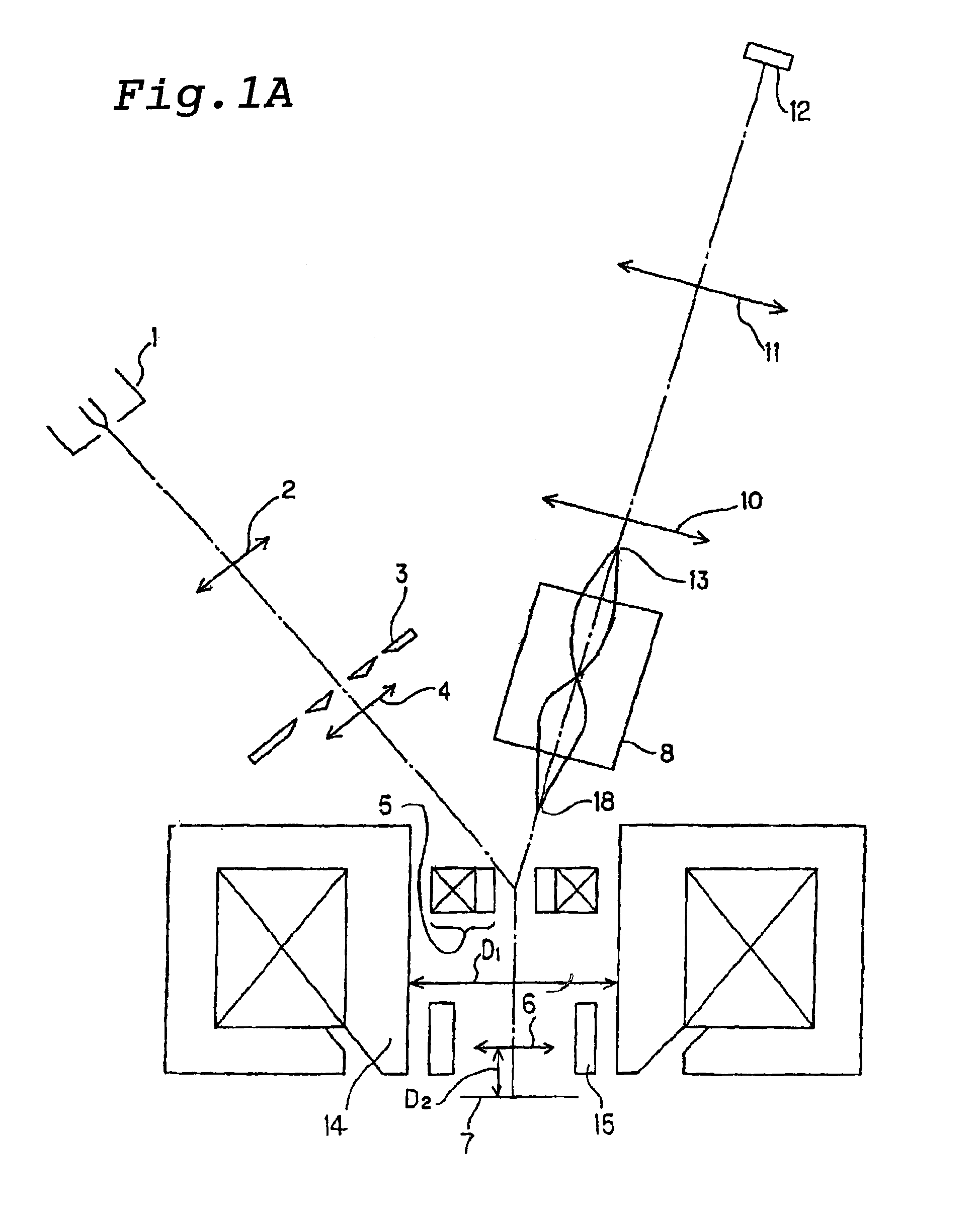

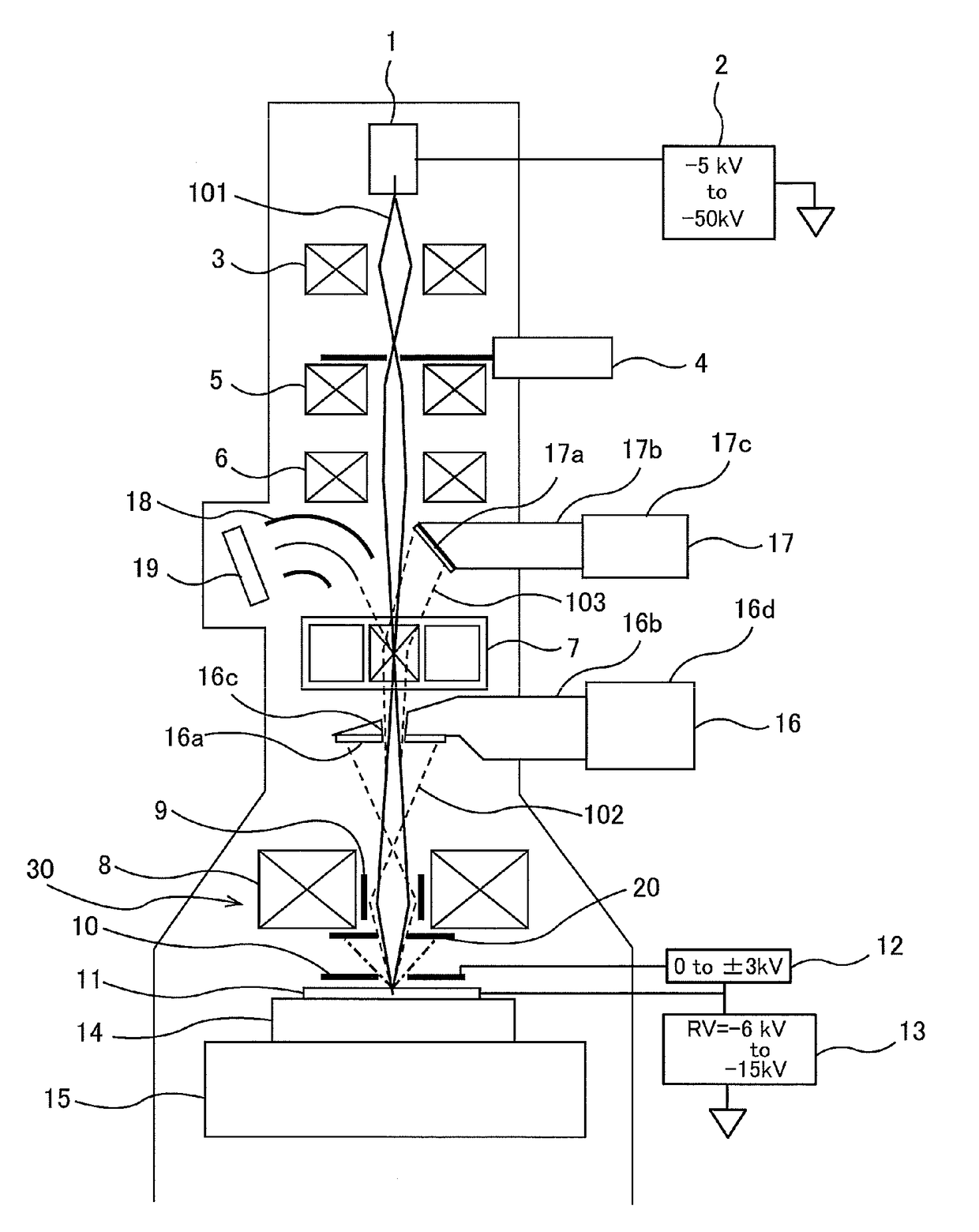

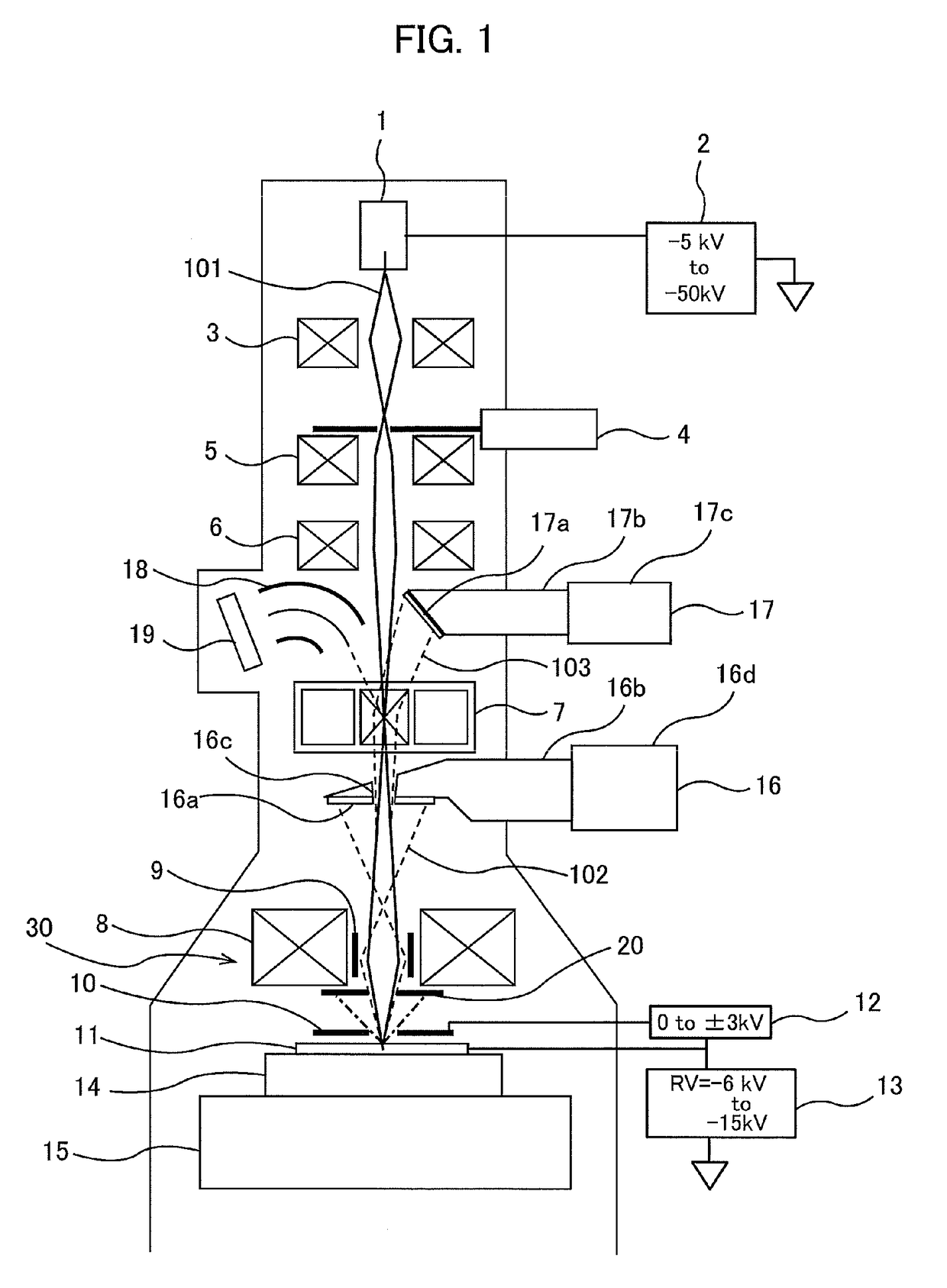

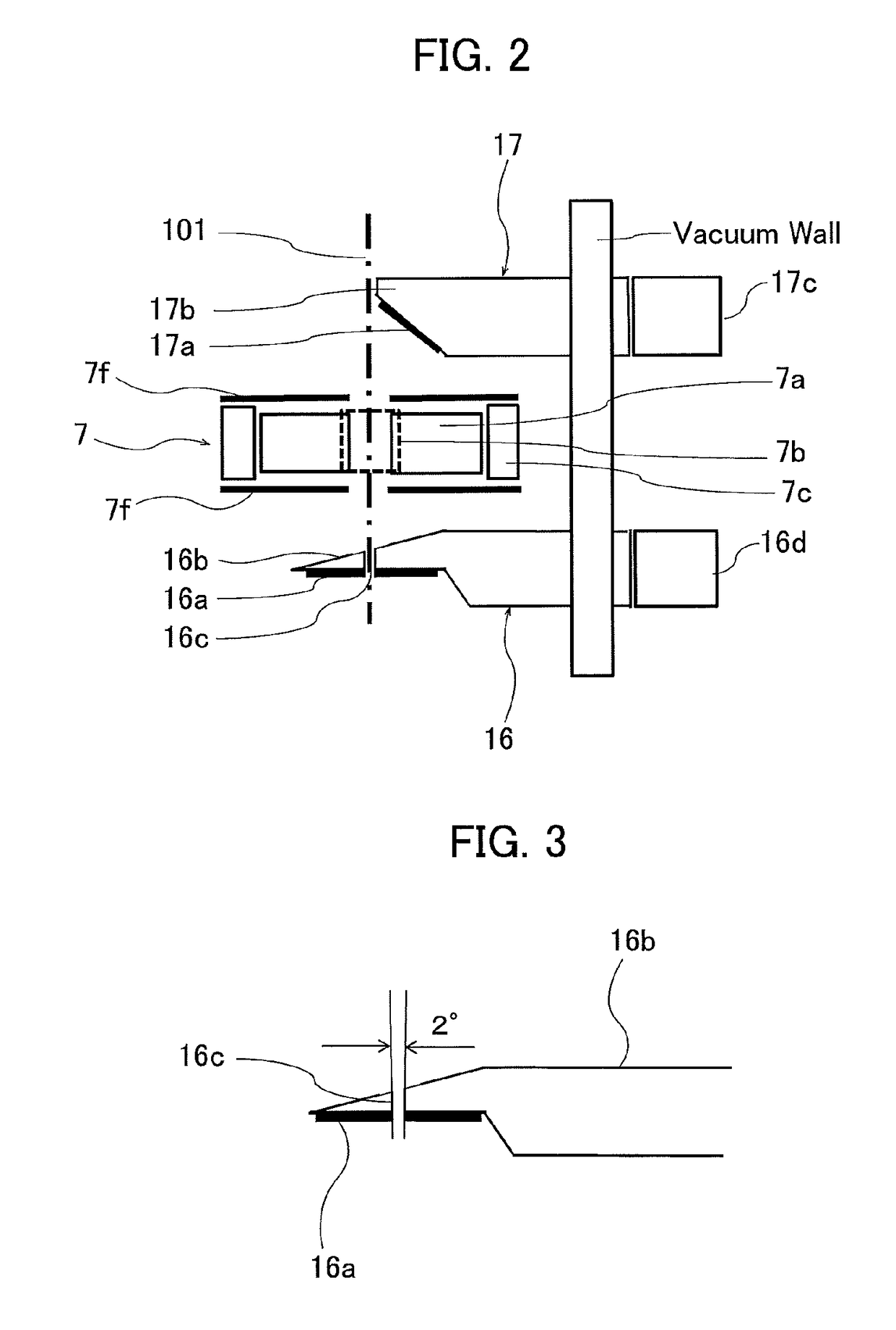

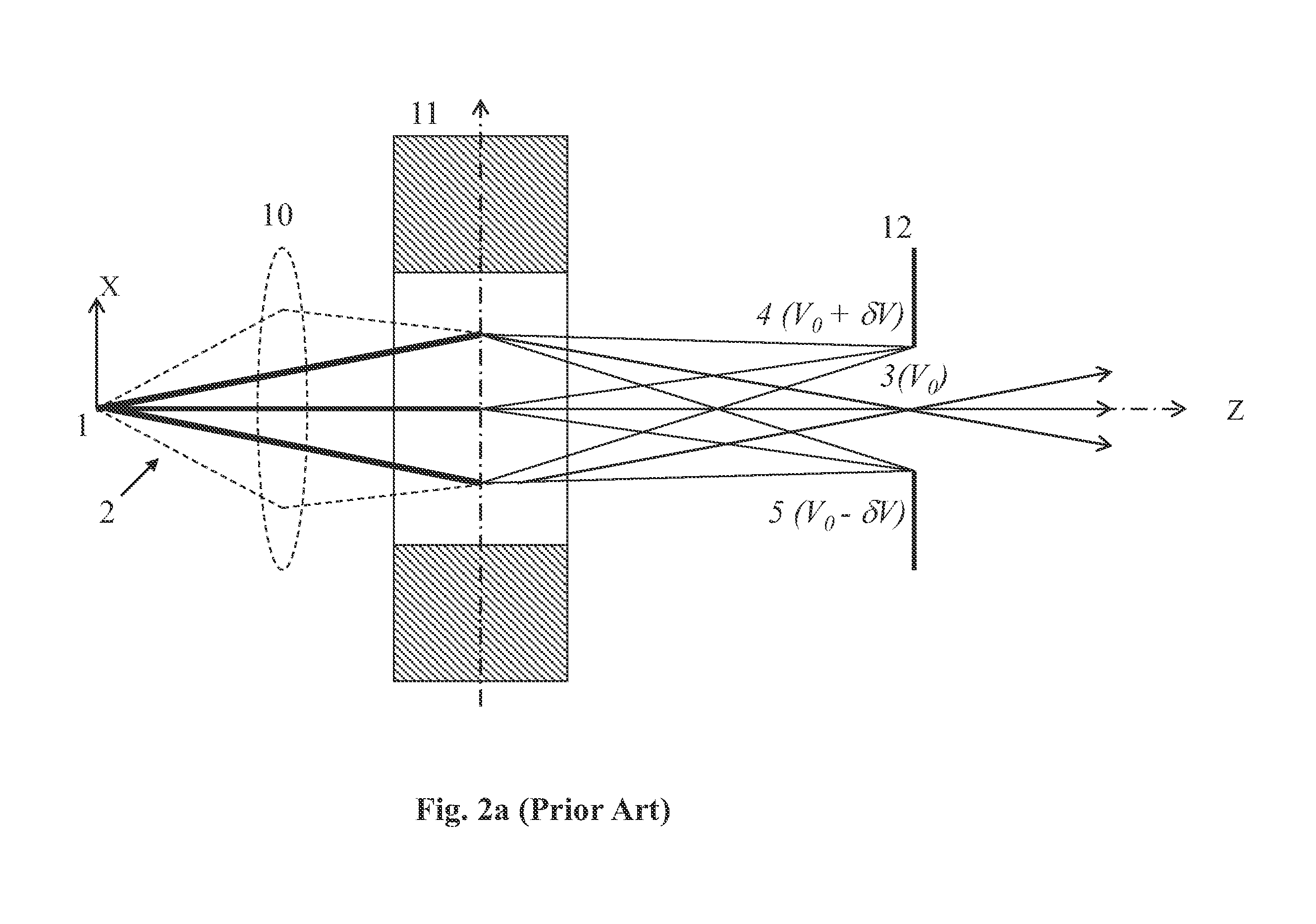

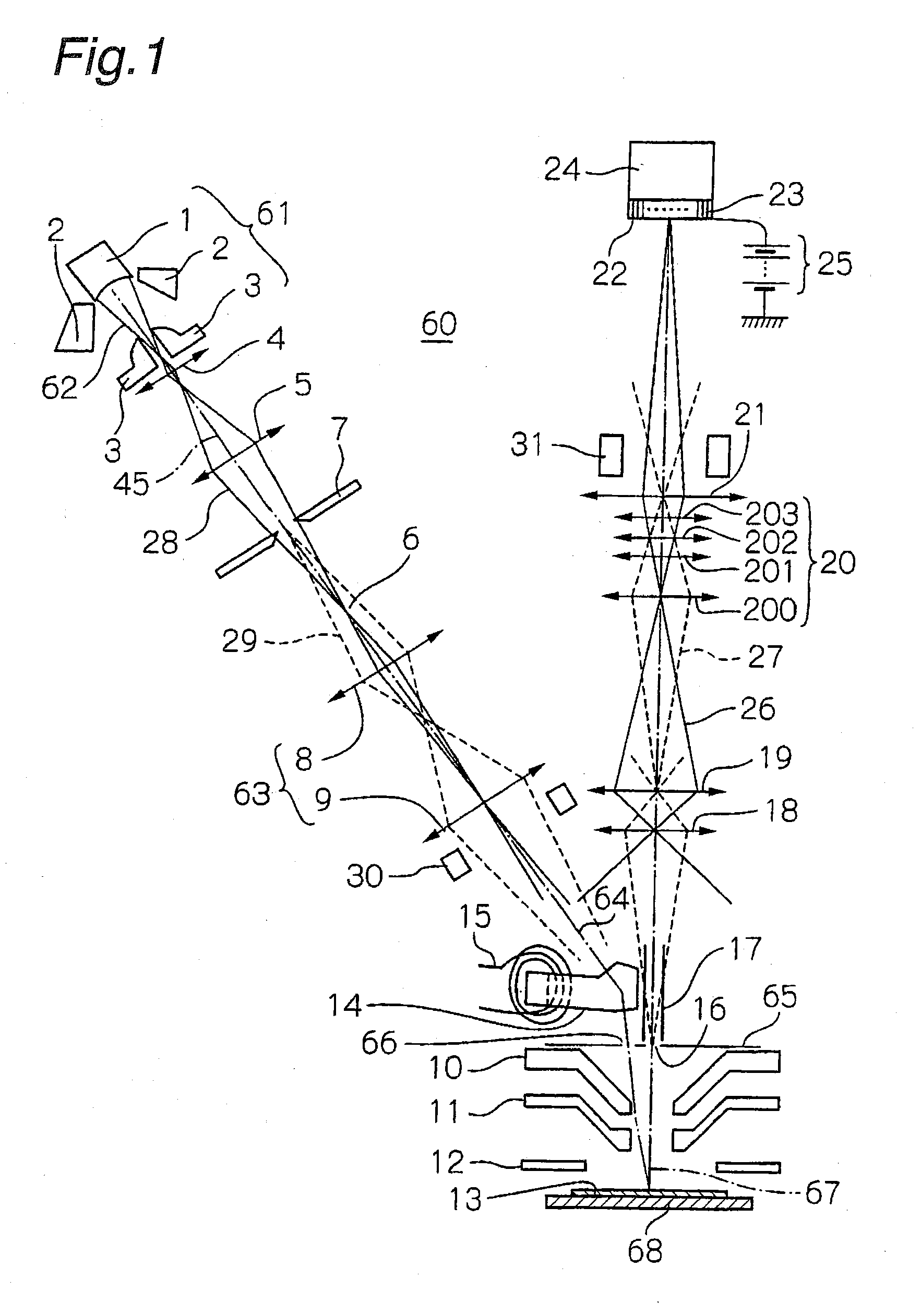

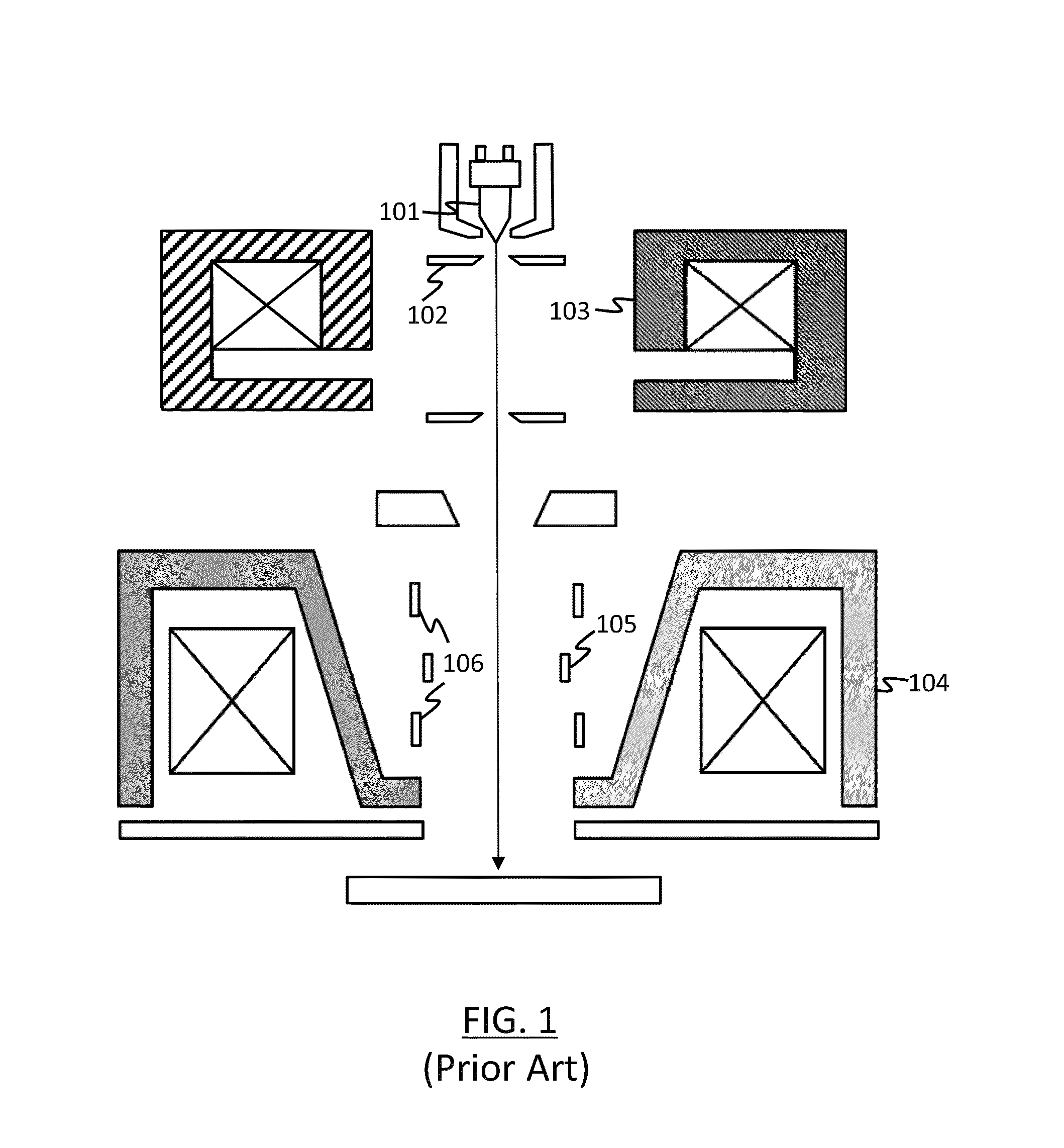

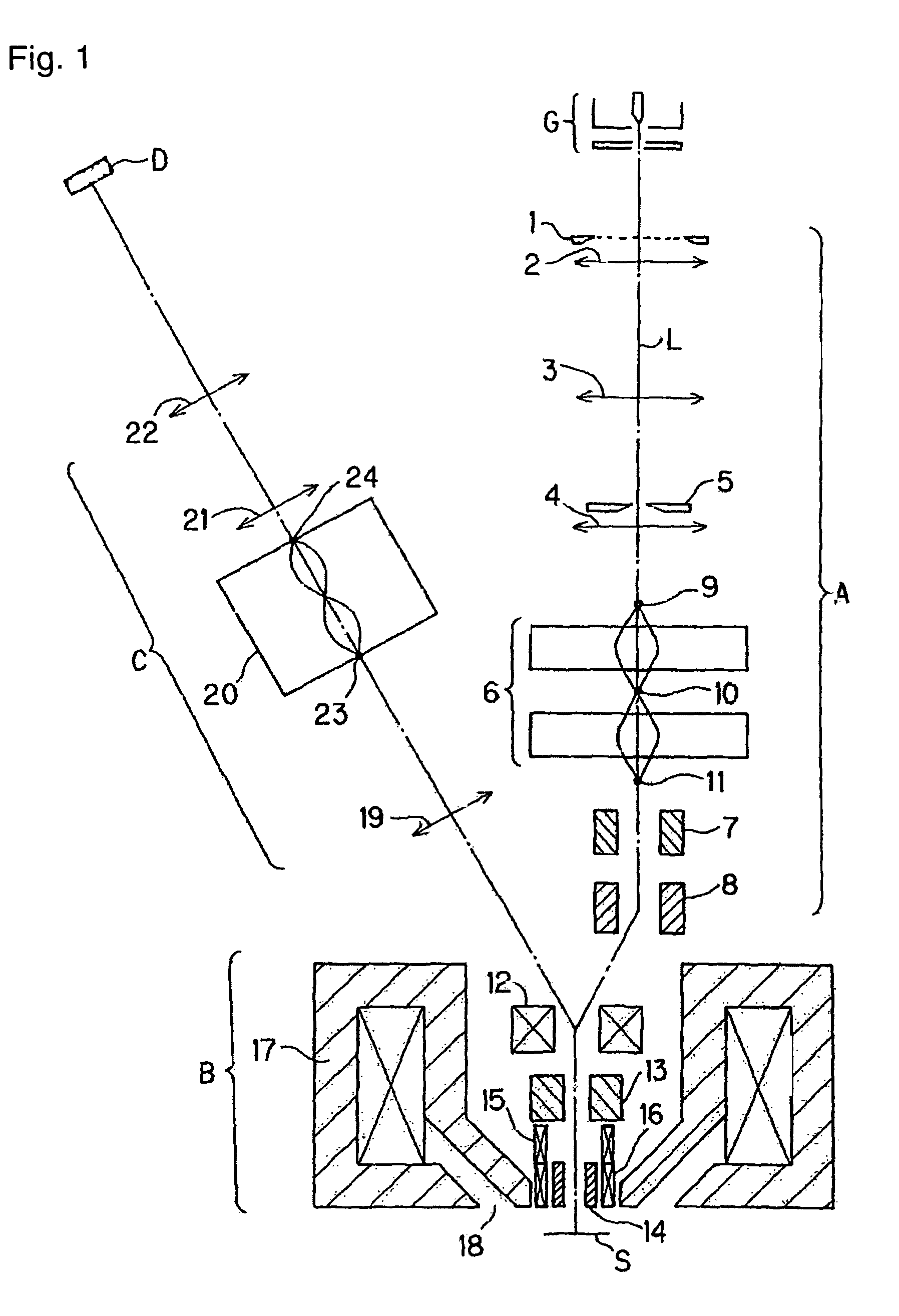

A sample is evaluated at a high throughput by reducing axial chromatic aberration and increasing the transmittance of secondary electrons. Electron beams emitted from an electron gun 1 are irradiated onto a sample 7 through a primary electro-optical system, and electrons consequently emitted from the sample are detected by a detector 12 through a secondary electro-optical system. A Wien filter 8 comprising a multi-pole lens for correcting axial chromatic aberration is disposed between a magnification lens 10 in the secondary electro-optical system and a beam separator 5 for separating a primary electron beam and a secondary electron beam, for correcting axial chromatic aberration caused by an objective lens 14 which comprises an electromagnetic lens having a magnetic gap defined on a sample side.

Owner:KK TOSHIBA

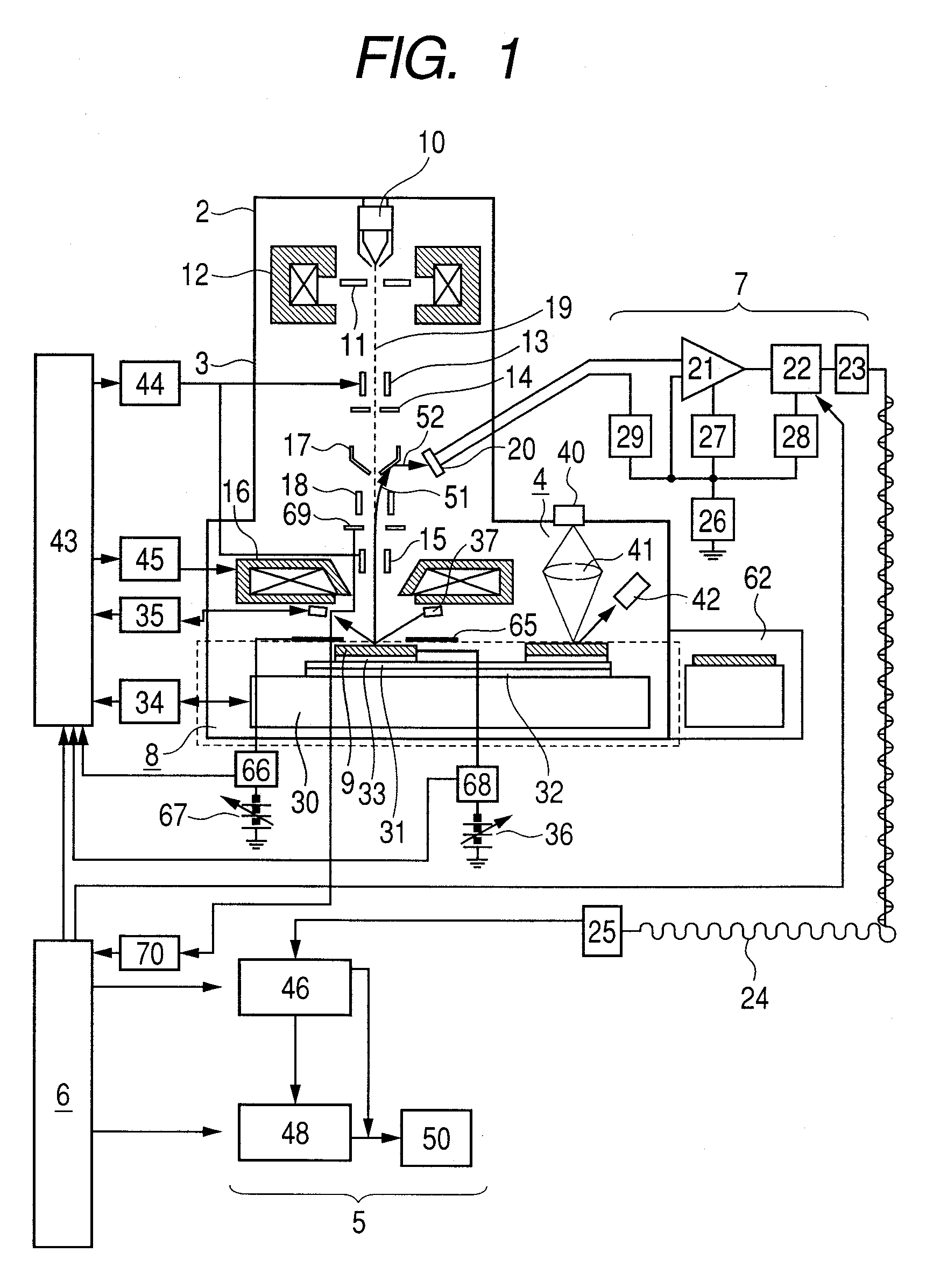

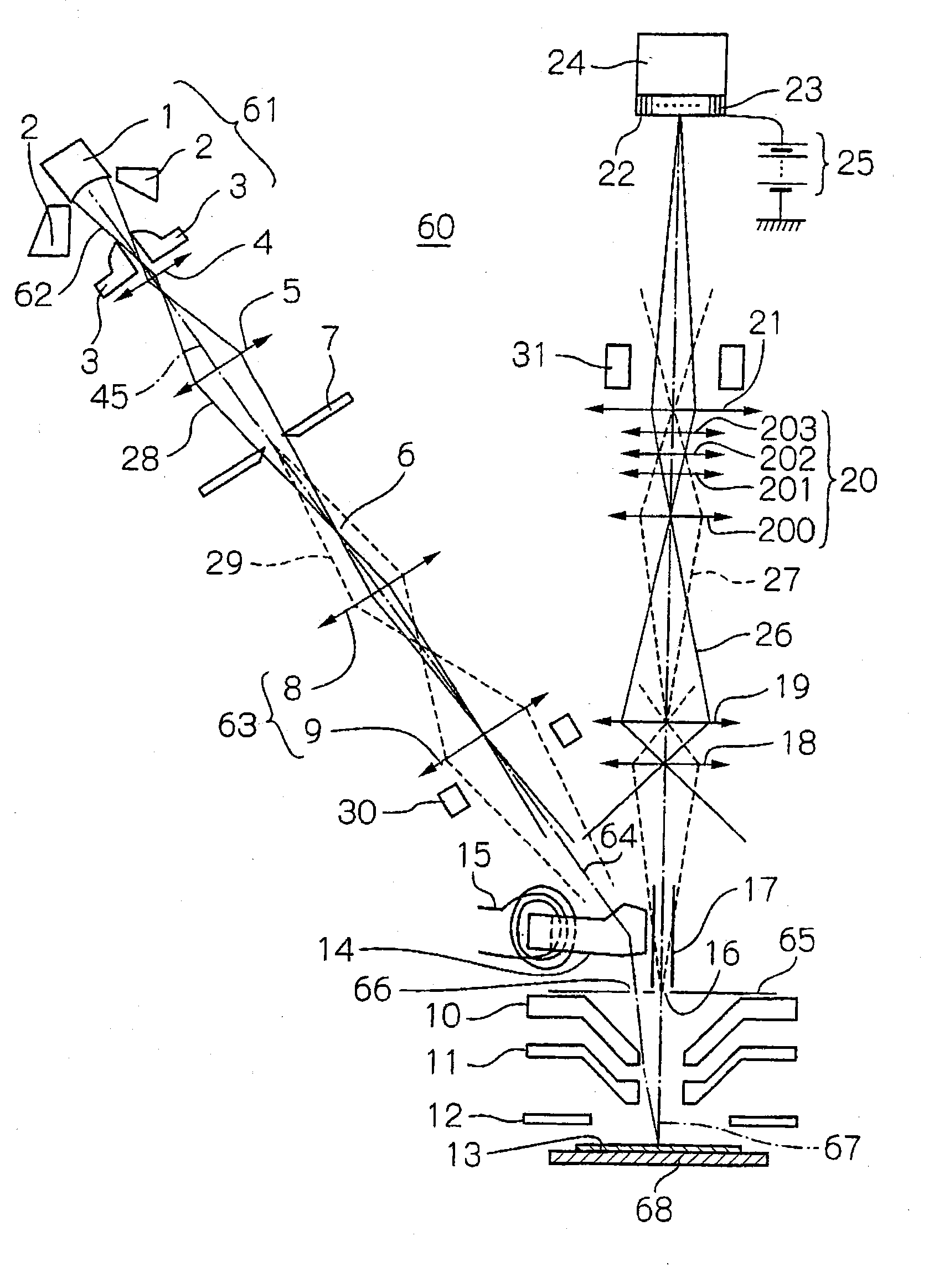

Electron beam apparatus

ActiveUS20090218506A1Improve throughputImprove processing speedStability-of-path spectrometersMaterial analysis using wave/particle radiationPath lengthWien filter

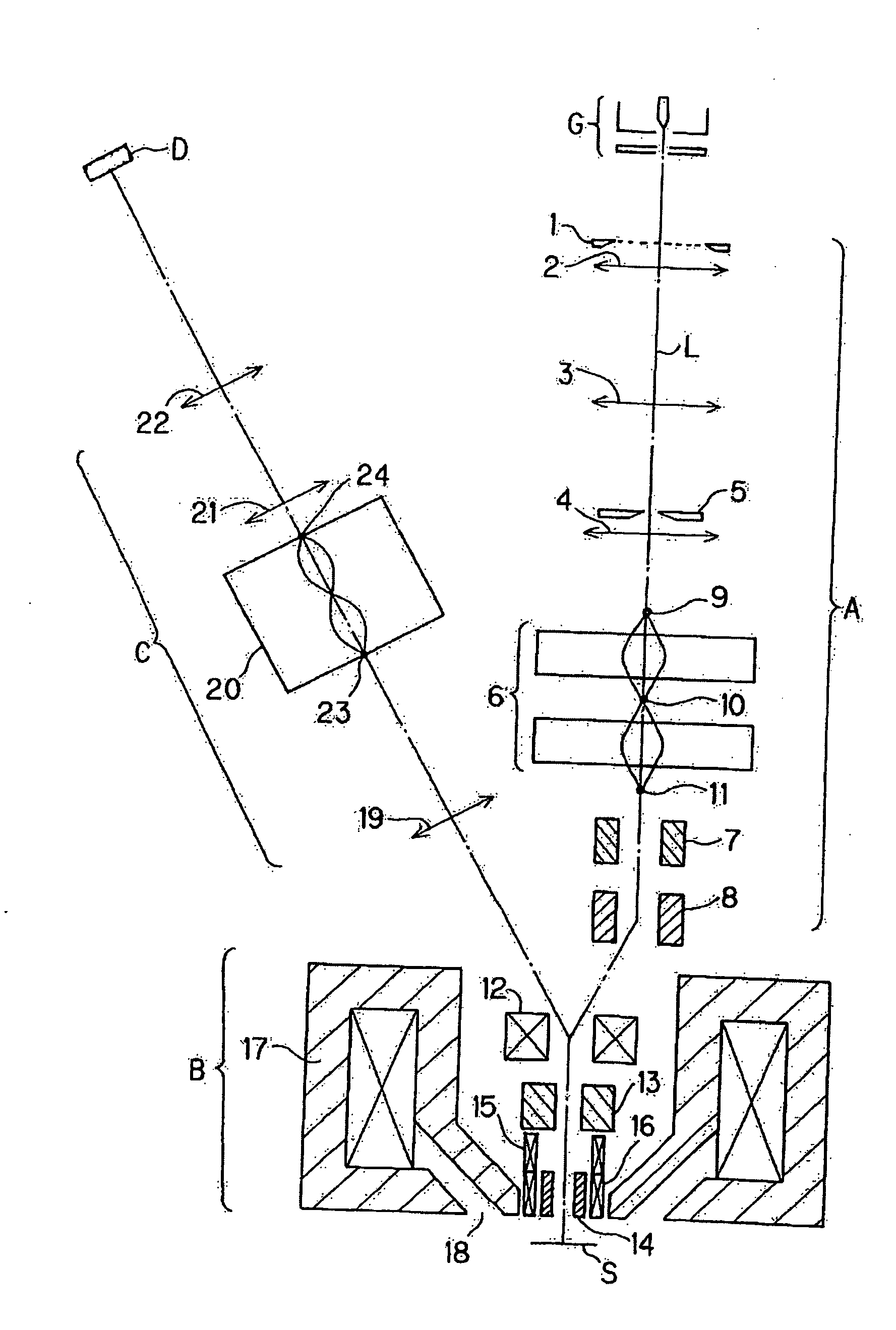

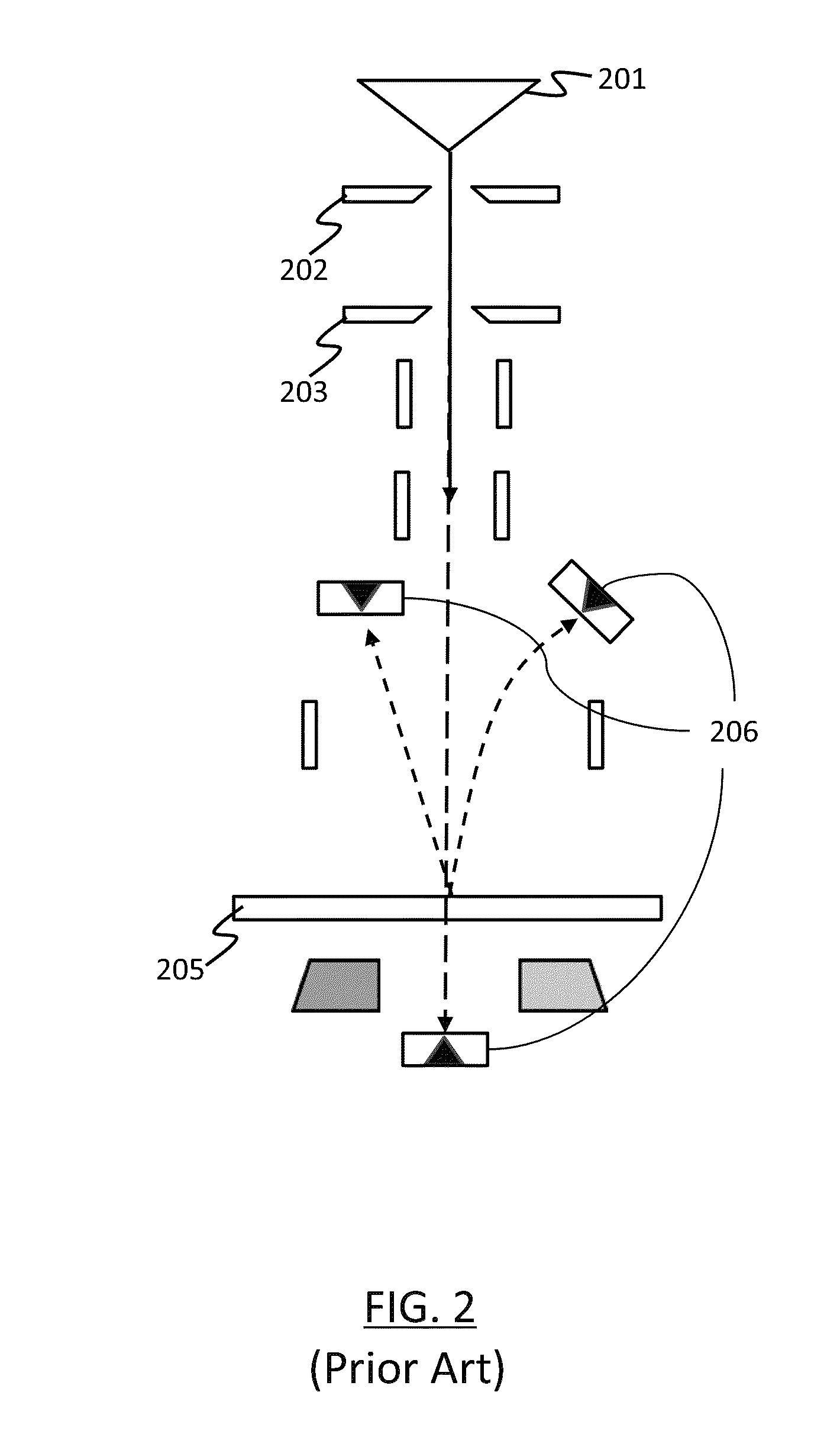

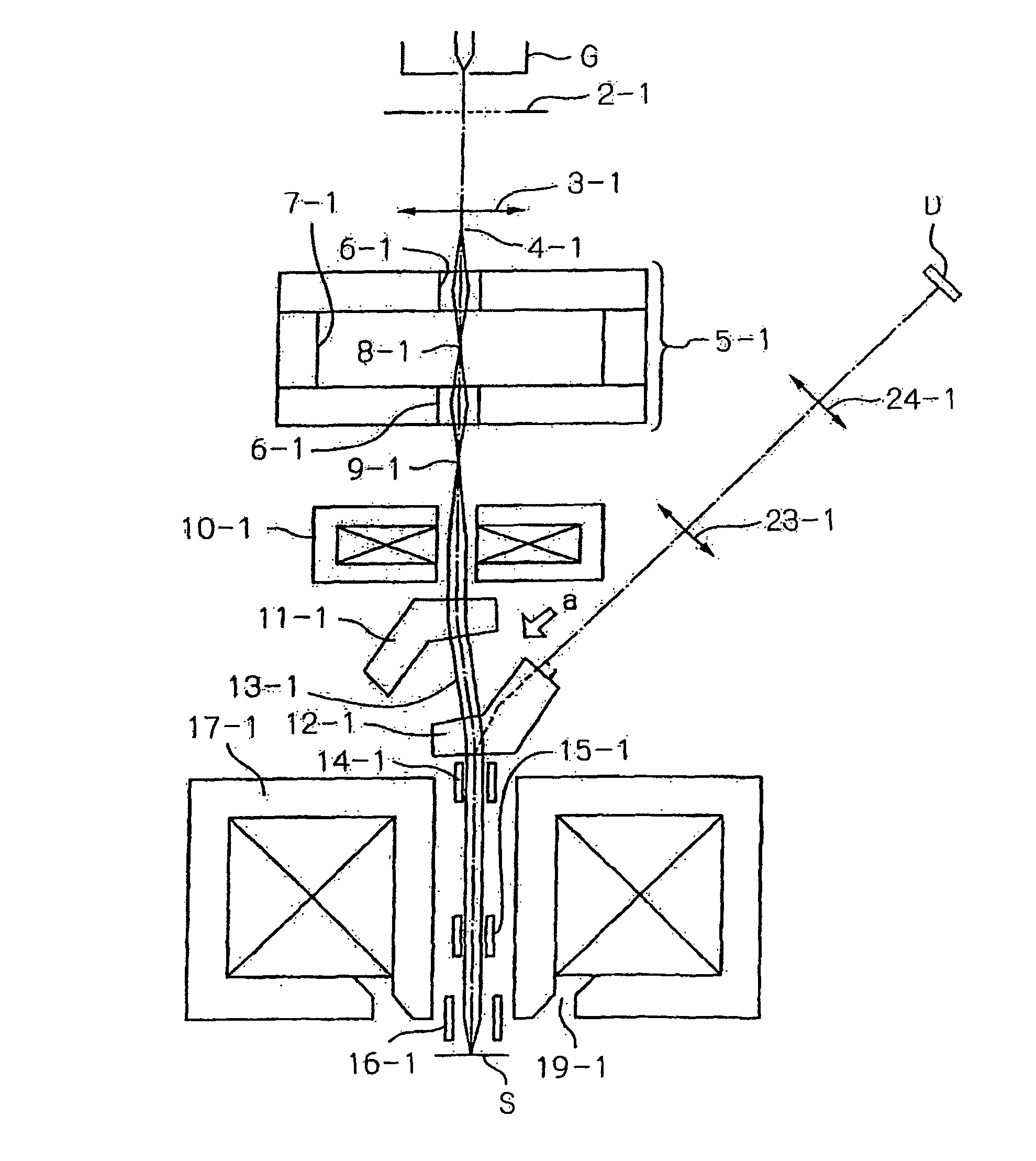

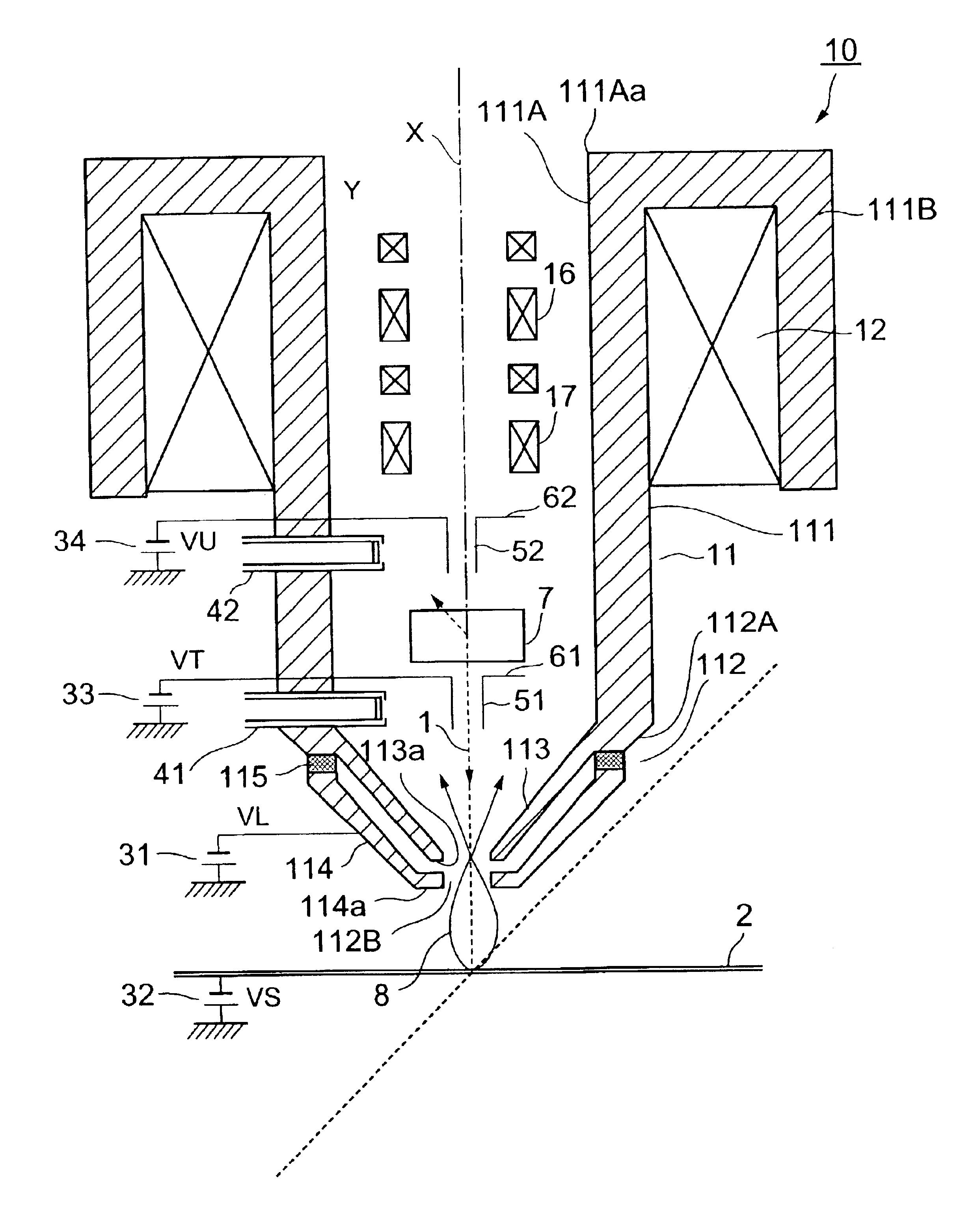

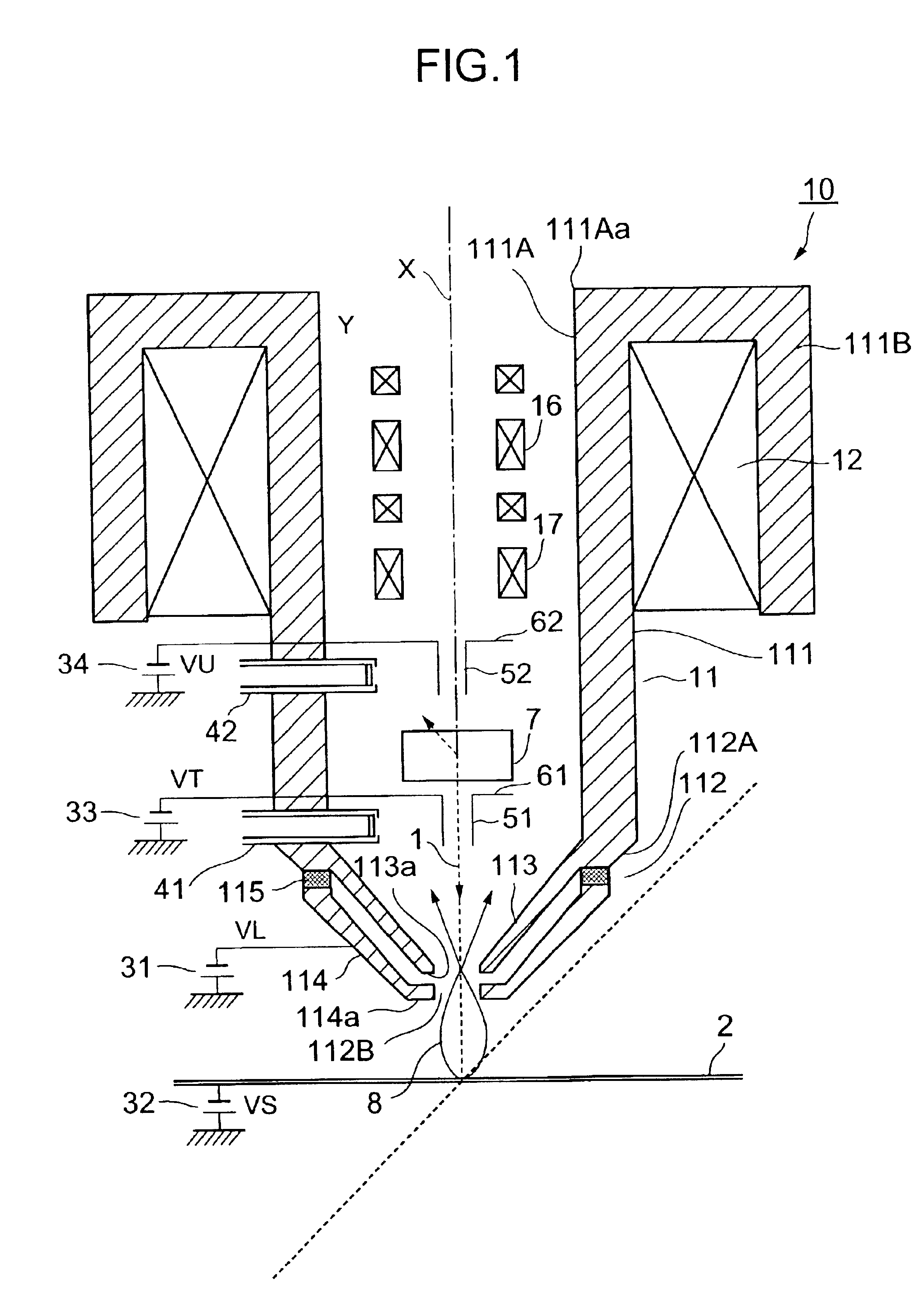

An electron beam emitted from an electron gun (G) forms a reduced image on a sample (S) through a non-dispersion Wien-filter (5-1), an electromagnetic deflector (11-1), a beam separator (12-1), and a tablet lens (17-1) as an objective lens. The beam separator (12-1) is configured such that a distance by which a secondary electron beam passes through the beam separator is approximately three times longer than a distance by which a primary electron beam passes through the beam separator. Therefore, even if a magnetic field in the beam separator is set to deflect the primary electron beam by a small angle equal to or less than approximately 10 degrees, the secondary electron beam can be deflected by approximately 30 degrees, so that the primary and secondary electron beams are sufficiently separated. Also, since the primary electron beam is deflected by a small angle, less aberration occurs in the primary electron beam. Accordingly, since a light path length of a primary electro-optical system, it is possible to reduce the influence of space charge and the occurrence of deflection aberration.

Owner:KIOXIA CORP

Wien filter with reduced chromatic aberration

ActiveUS7164139B1Reduce or eliminate the chromatic aberration caused by the deviceMaterial analysis by optical meansIsotope separationMagnetic tension forceWien filter

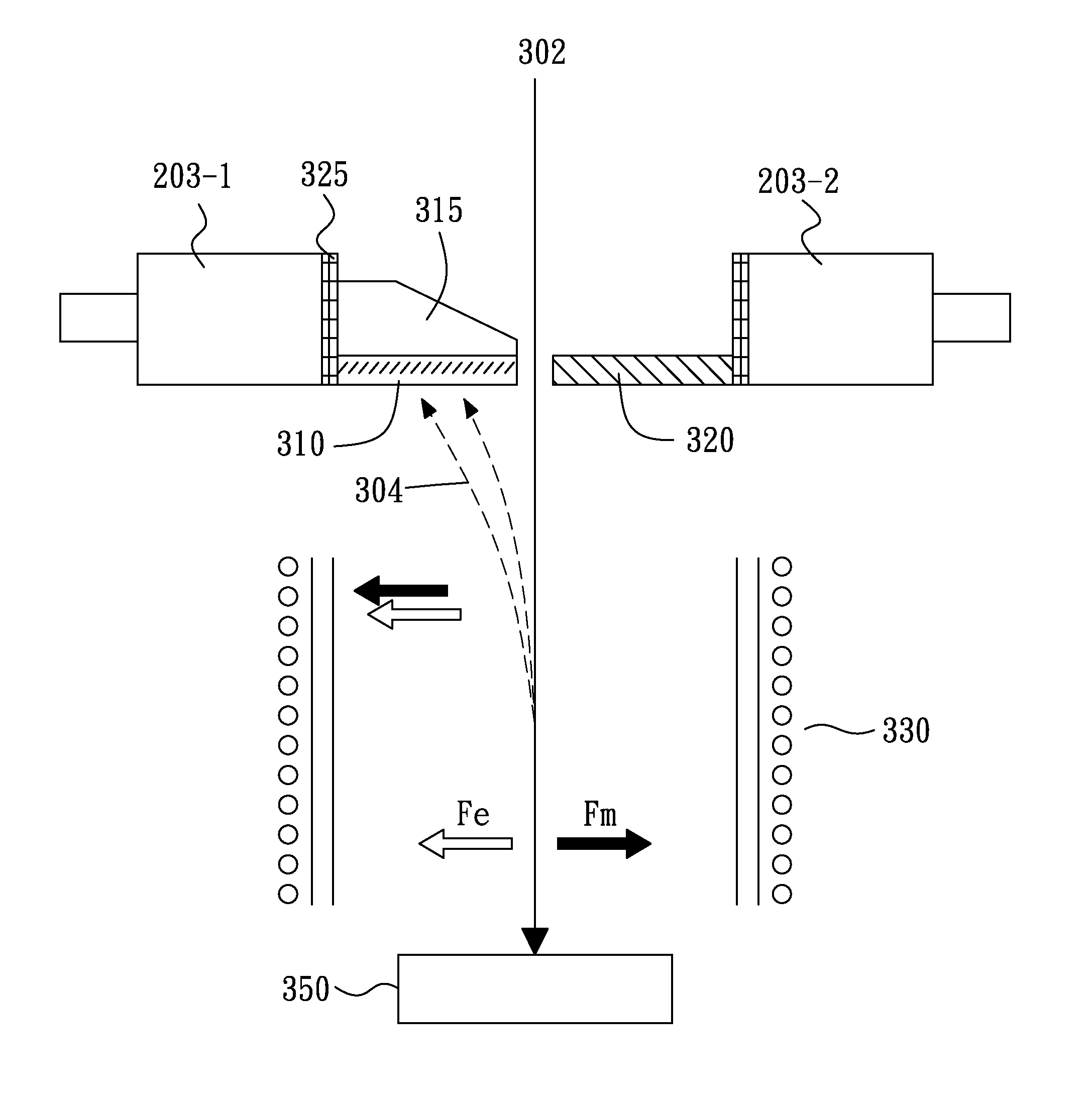

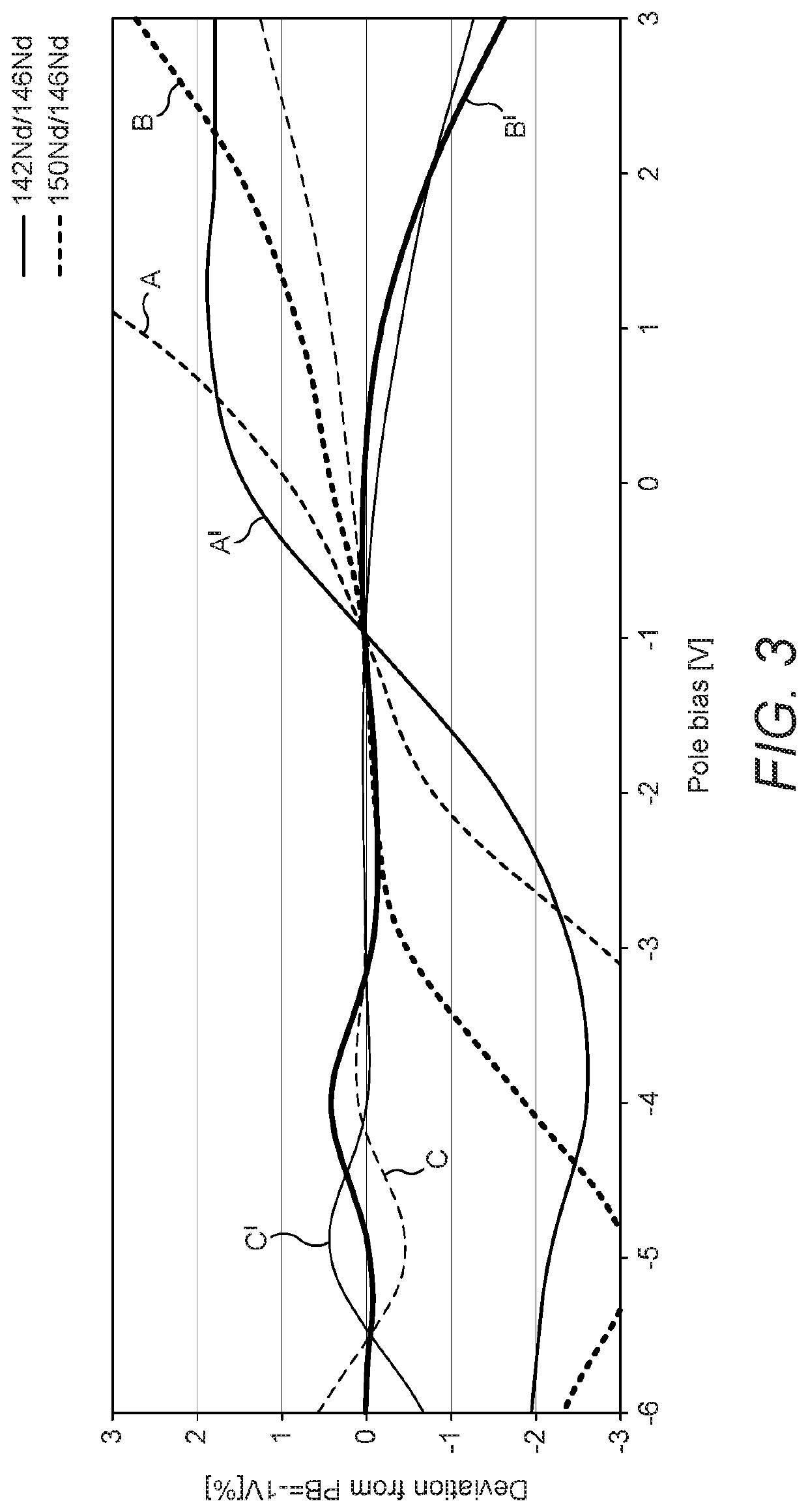

One embodiment disclosed relates to a Wien filter for a charged-particle beam apparatus. The charged-particle beam is transmitted through the Wien filter in a first direction. A magnetic field generation mechanism is configured to generate a magnetic field in a second direction which is perpendicular to the first direction, and an electrostatic field generation mechanism is configured to generate an electrostatic field in a third direction which is perpendicular to the first and second directions. The field generation mechanisms are further configured so as to have an offset between the positions of the magnetic and electrostatic fields along the first direction. Another embodiment disclosed relates to a Wien filter type device wherein the magnetic force is approximately twice in strength compared to the electrostatic force. Other embodiments are also disclosed.

Owner:KLA TENCOR TECH CORP

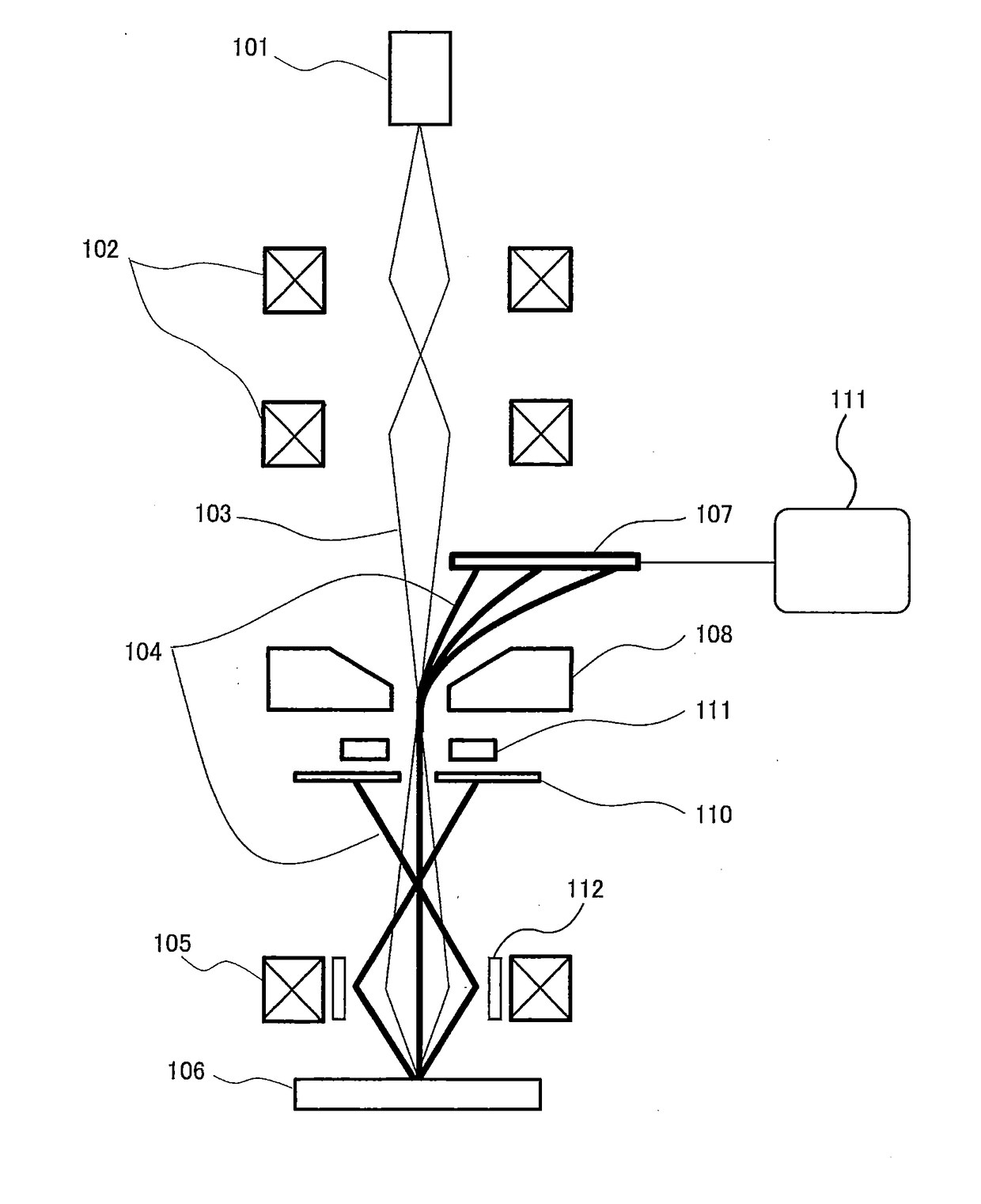

Projection electron beam apparatus and defect inspection system using the apparatus

ActiveUS20100096550A1Increase currentImprove throughputMaterial analysis using wave/particle radiationElectric discharge tubesWien filterTransmittance

A sample is evaluated at a high throughput by reducing axial chromatic aberration and increasing the transmittance of secondary electrons. Electron beams emitted from an electron gun 1 are irradiated onto a sample 7 through a primary electro-optical system, and electrons consequently emitted from the sample are detected by a detector 12 through a secondary electro-optical system. A Wien filter 8 comprising a multi-pole lens for correcting axial chromatic aberration is disposed between a magnification lens 10 in the secondary electro-optical system and a beam separator 5 for separating a primary electron beam and a secondary electron beam, for correcting axial chromatic aberration caused by an objective lens 14 which comprises an electromagnetic lens having a magnetic gap defined on a sample side.

Owner:KIOXIA CORP

Secondary particle detection system of scanning electron microscope

ActiveUS20170271124A1Reduce harmHigh resolutionElectric discharge tubesWien filterScanning tunneling microscope

A scanning electron microscope includes: a retarding power source configured to apply a retarding voltage to a specimen; a combined objective lens configured to focus the primary beam on a surface of the specimen; an electrostatic deflection system configured to deflect the primary beam to direct the primary beam to each point in a field of view on the surface of the specimen; a first scintillation detector having a first scintillator configured to emit light upon incidence of secondary electrons which have been emitted from the specimen; a Wien filter configured to deflect the secondary electrons in one direction without deflecting the primary beam; and a second scintillation detector having a second scintillator configured to detect the secondary electrons deflected by the Wien filter. The second scintillator has a distal end located away from the axis of the primary beam.

Owner:TASMIT INC

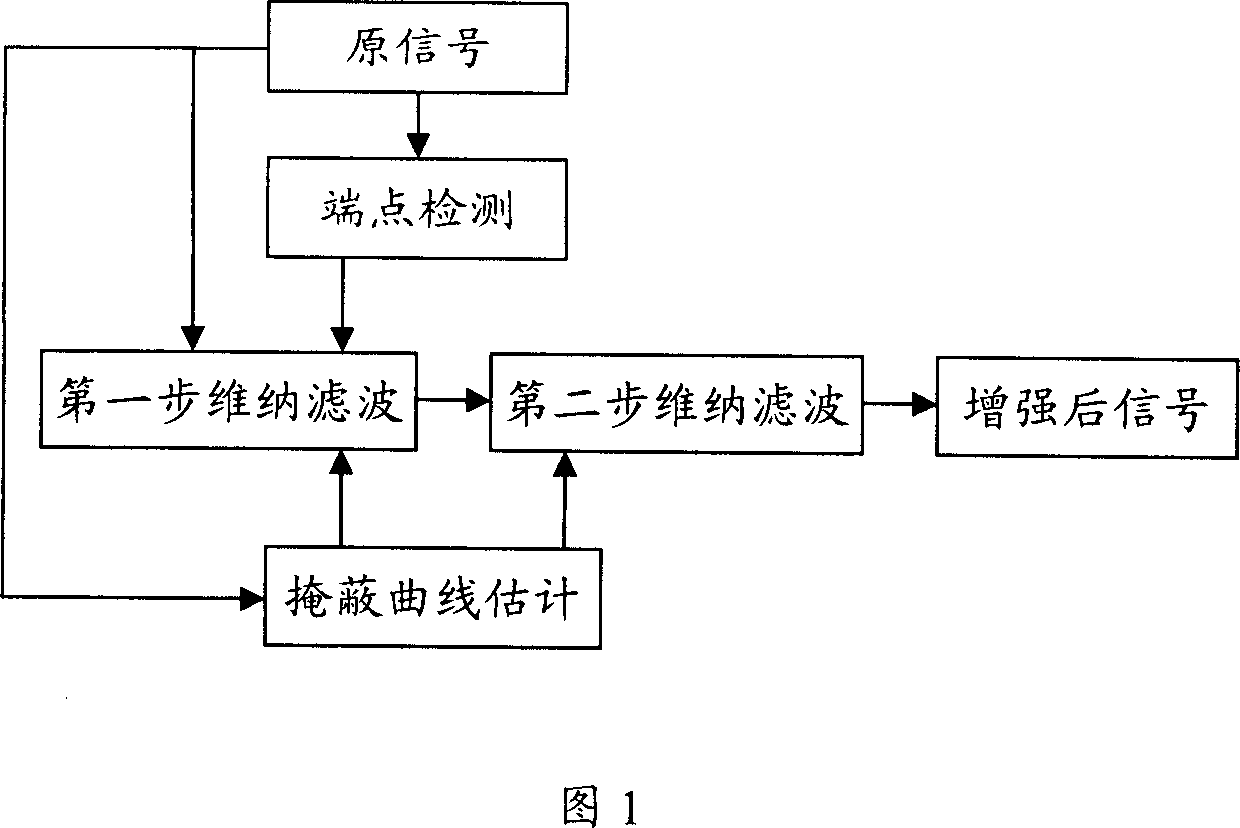

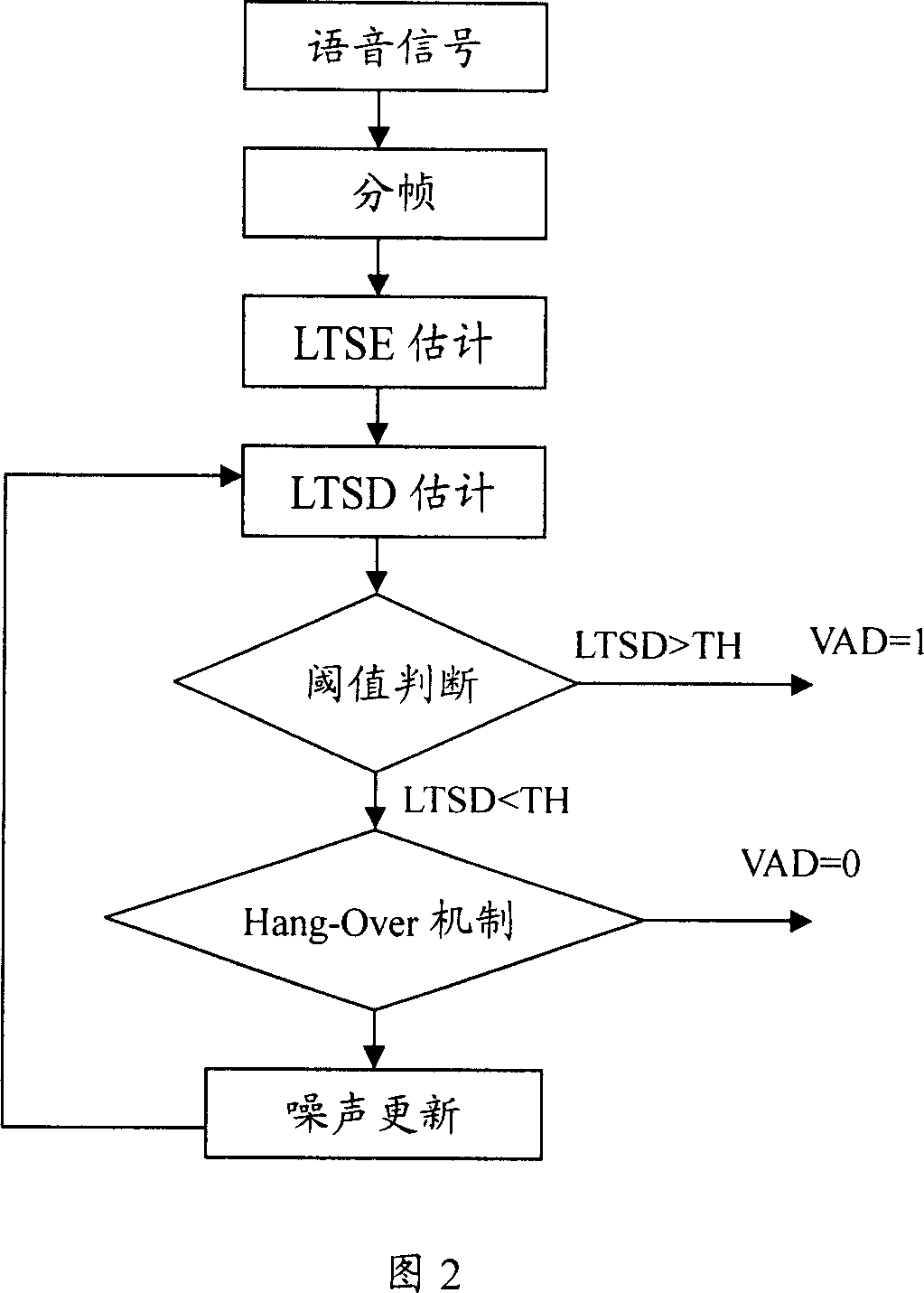

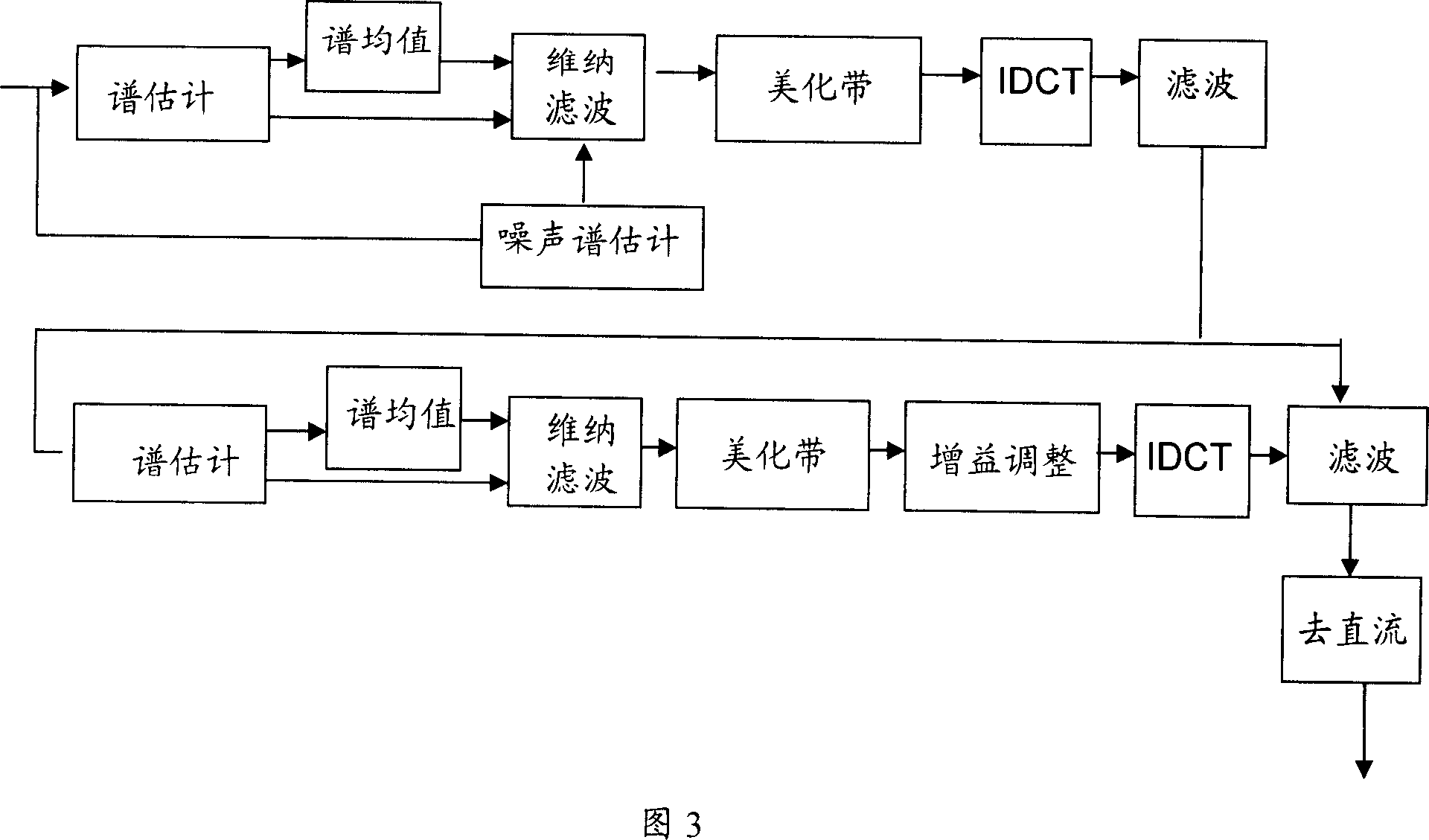

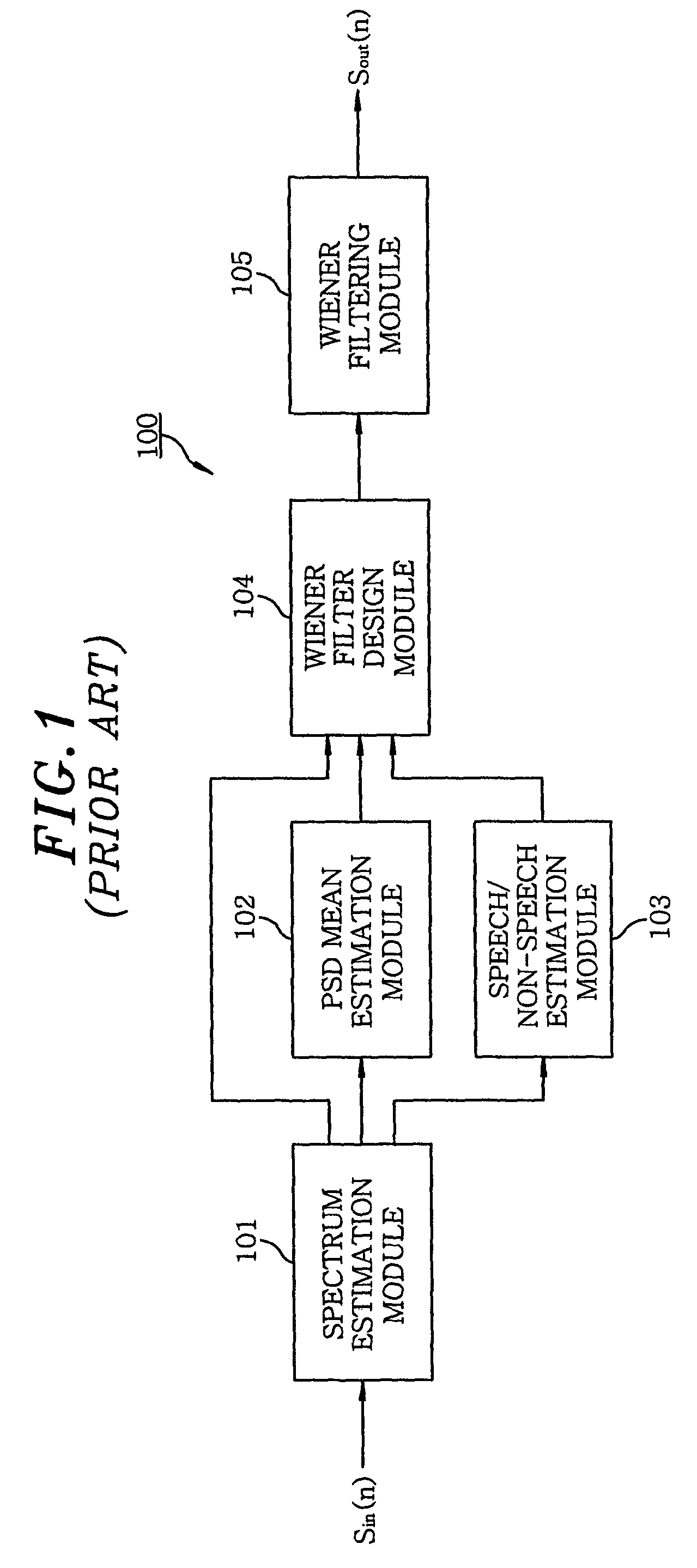

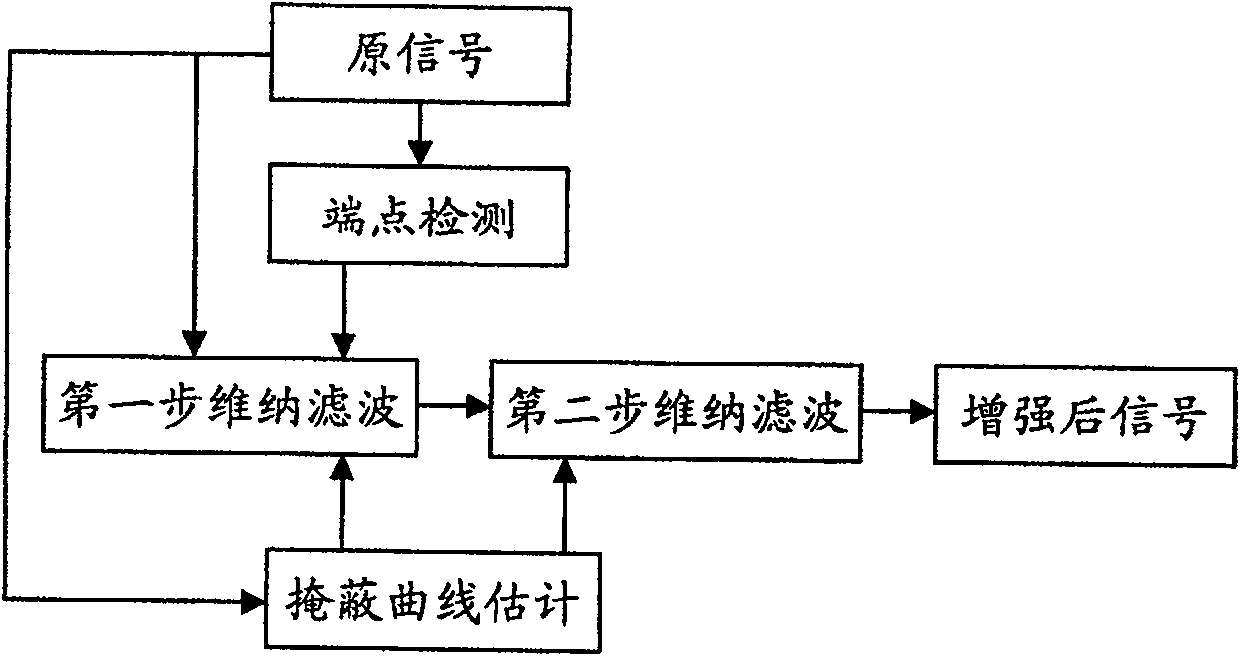

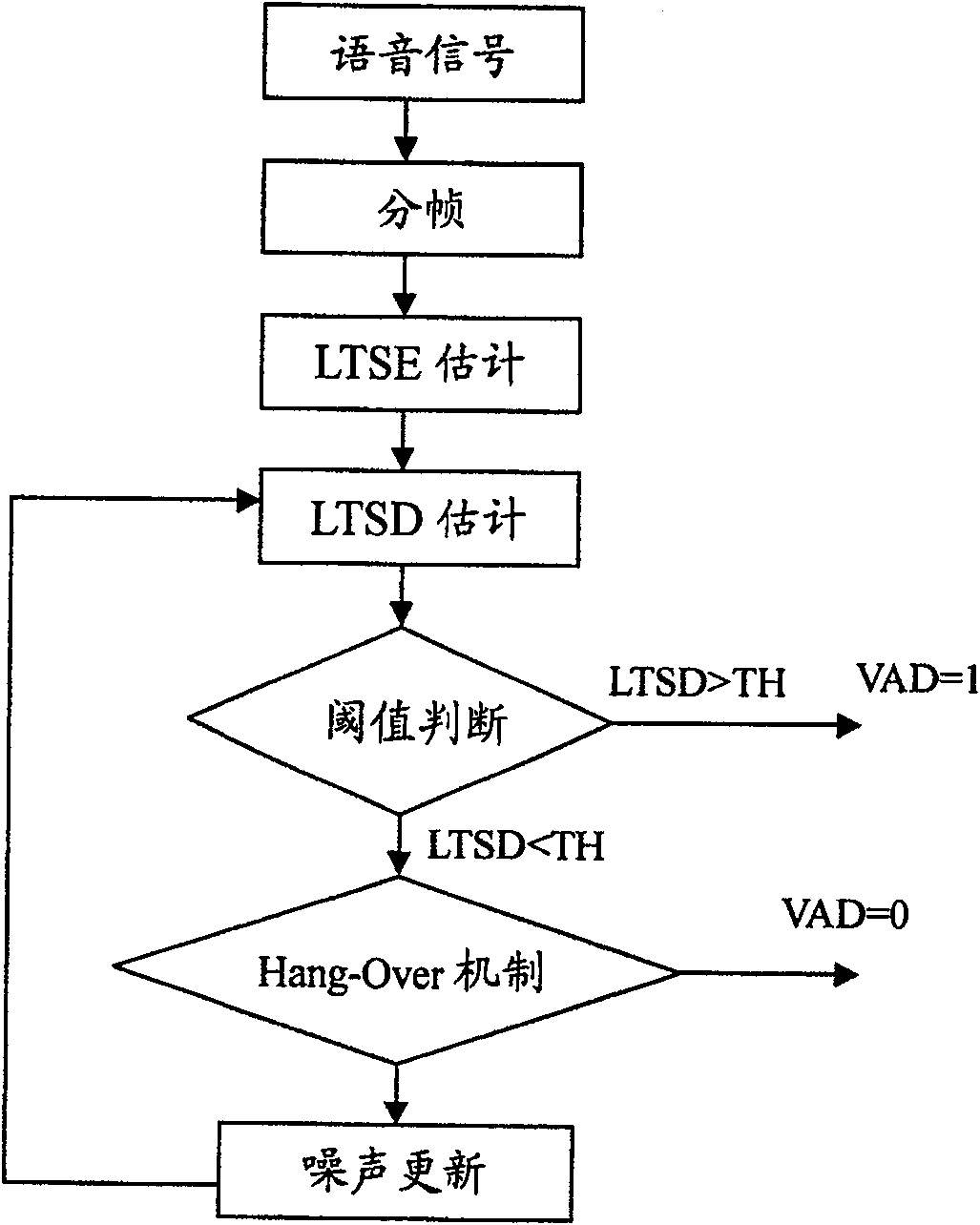

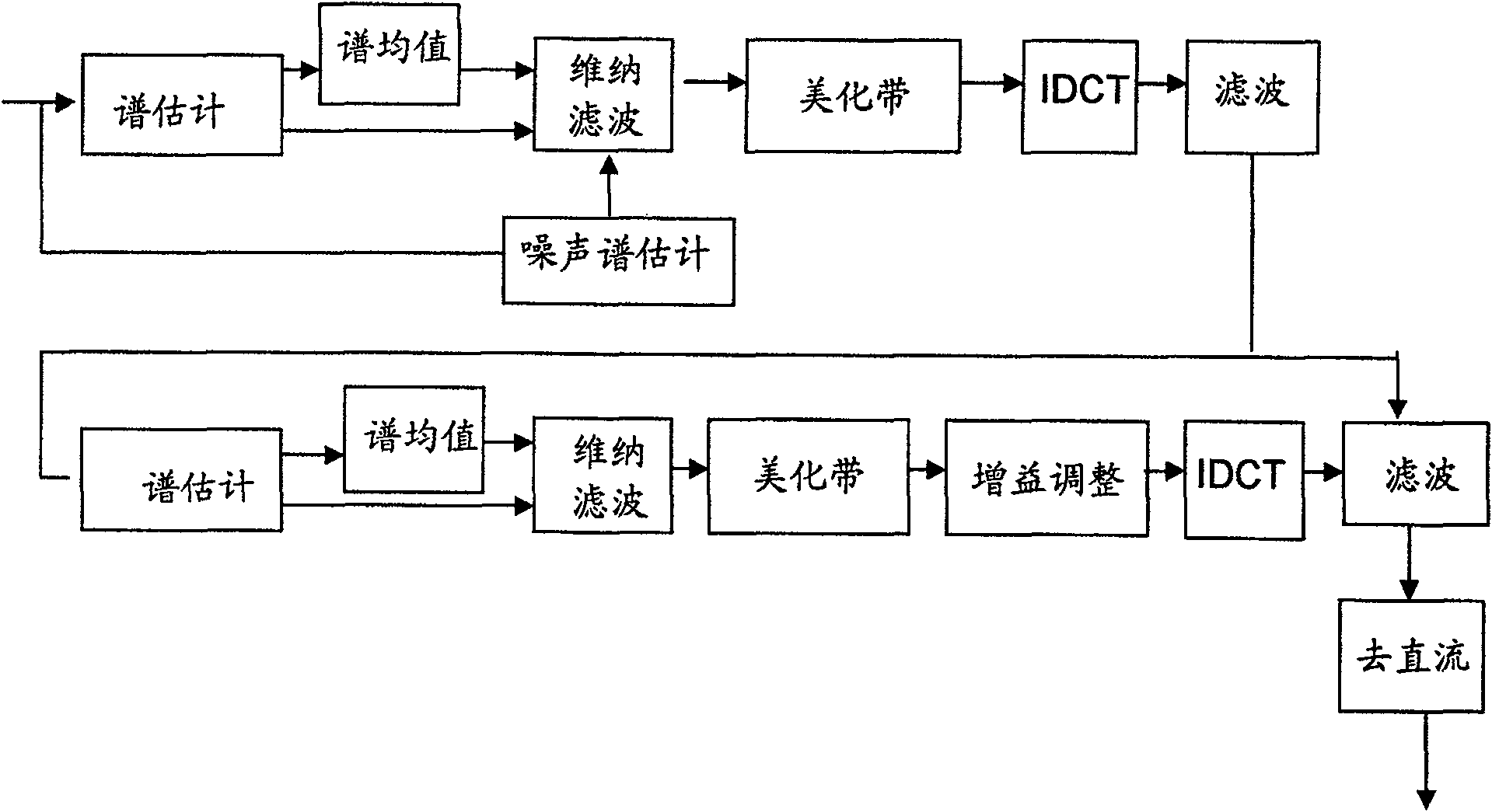

Speech enhancement method applied to deaf-aid

The invention provides a speech enhancement method that can restrain noise component in noisy voice and improve voice quality and intelligibility in noise environment. According to the method of the present invention, it specifically includes the following steps: 1) first, estimating the noise spectrum of the speech using endpoint detection technology; 2) removing noise using two-step Wiener filter technology; 3) meanwhile, adjusting the filter parameters according to auditory masking curve. The de-noising method in the invention has undertaken a thorough study and consideration on the signal level and perceptual level. For the estimation of noise, it uses the endpoint detection method, which has good robustness, to accurate estimate the noise spectrum as far as possible. Furthermore, it uses a two-step Wiener filter to solve this problem. Meanwhile, taking into account people's ears, by using auditory masking curve, it decreases the signal distortion. Thus, the eventually enhanced signal has a big increase on the voice quality and intelligibility.

Owner:北京大学科技开发有限公司

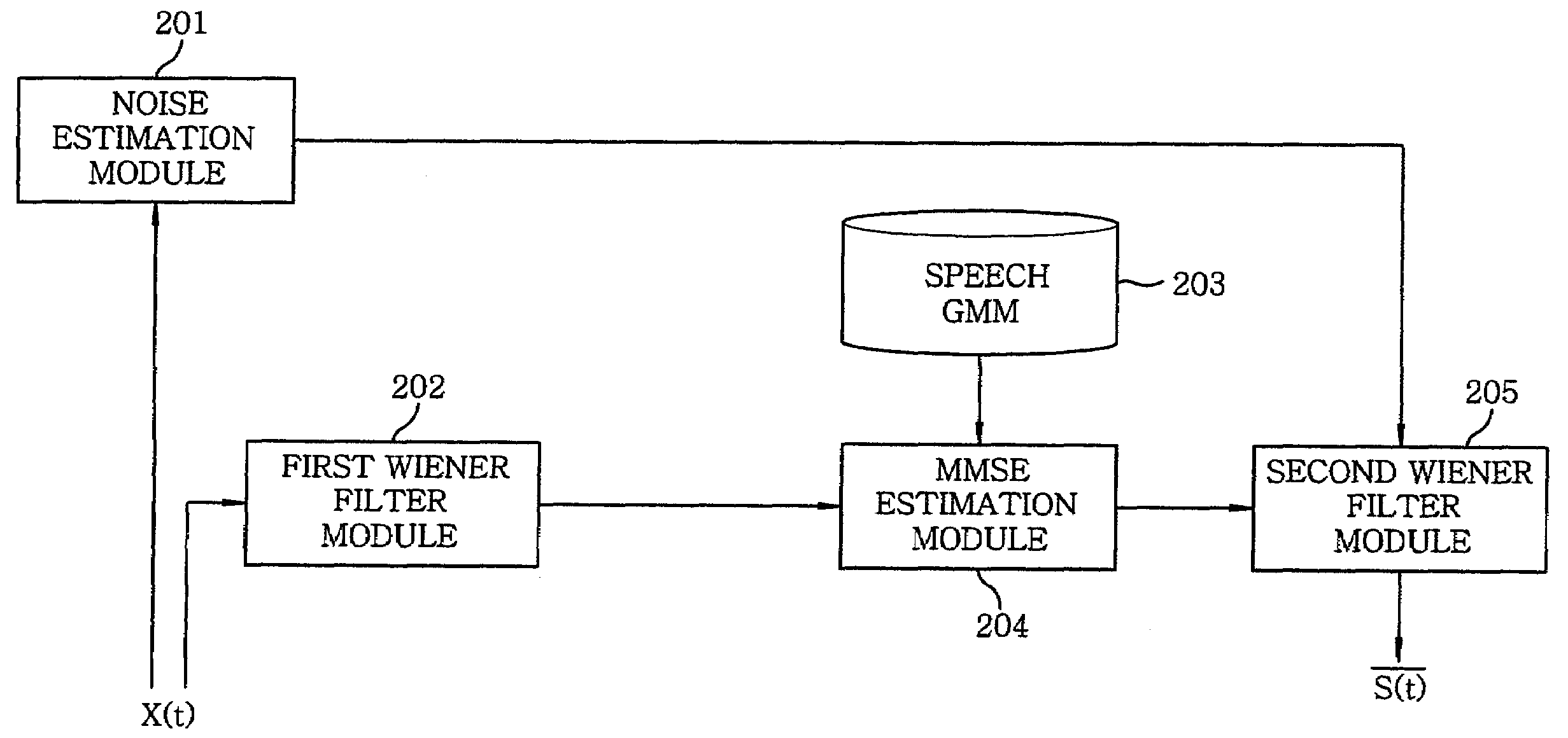

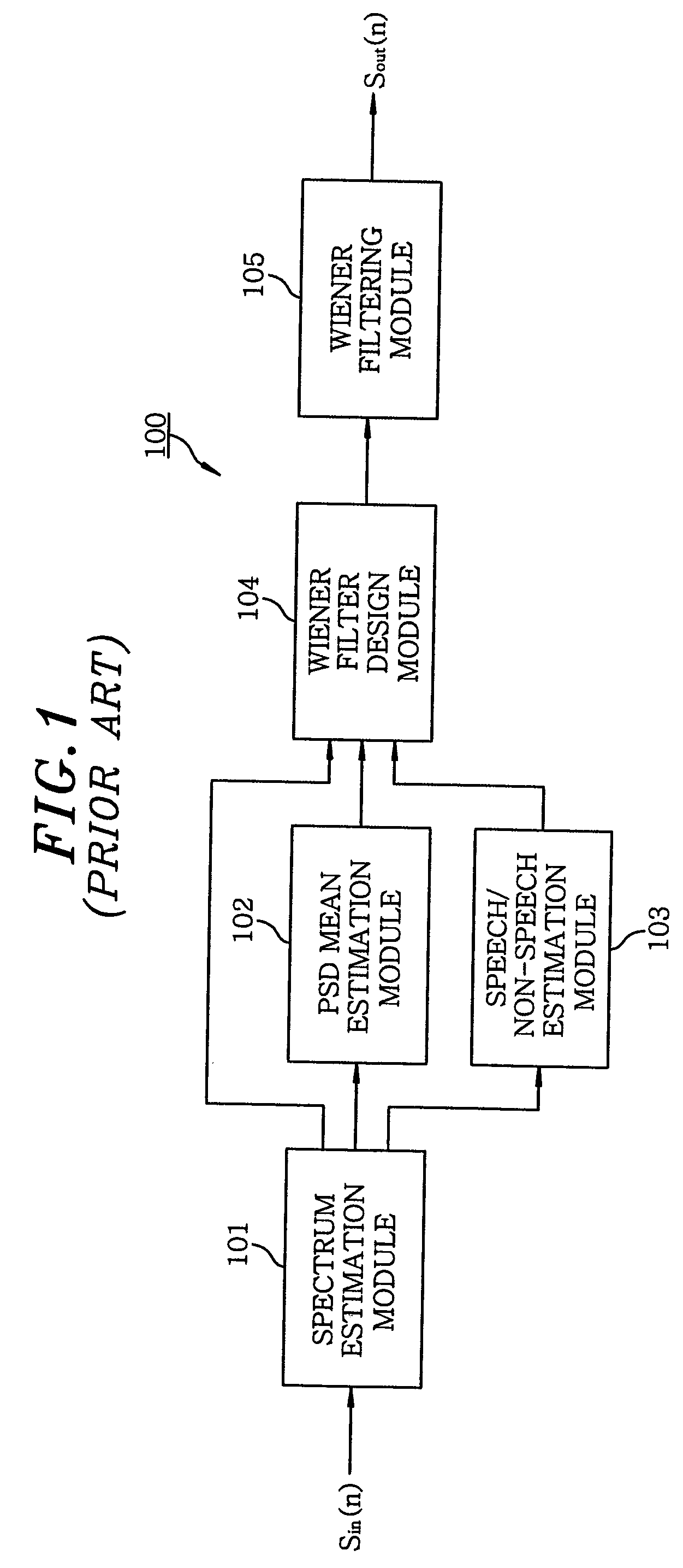

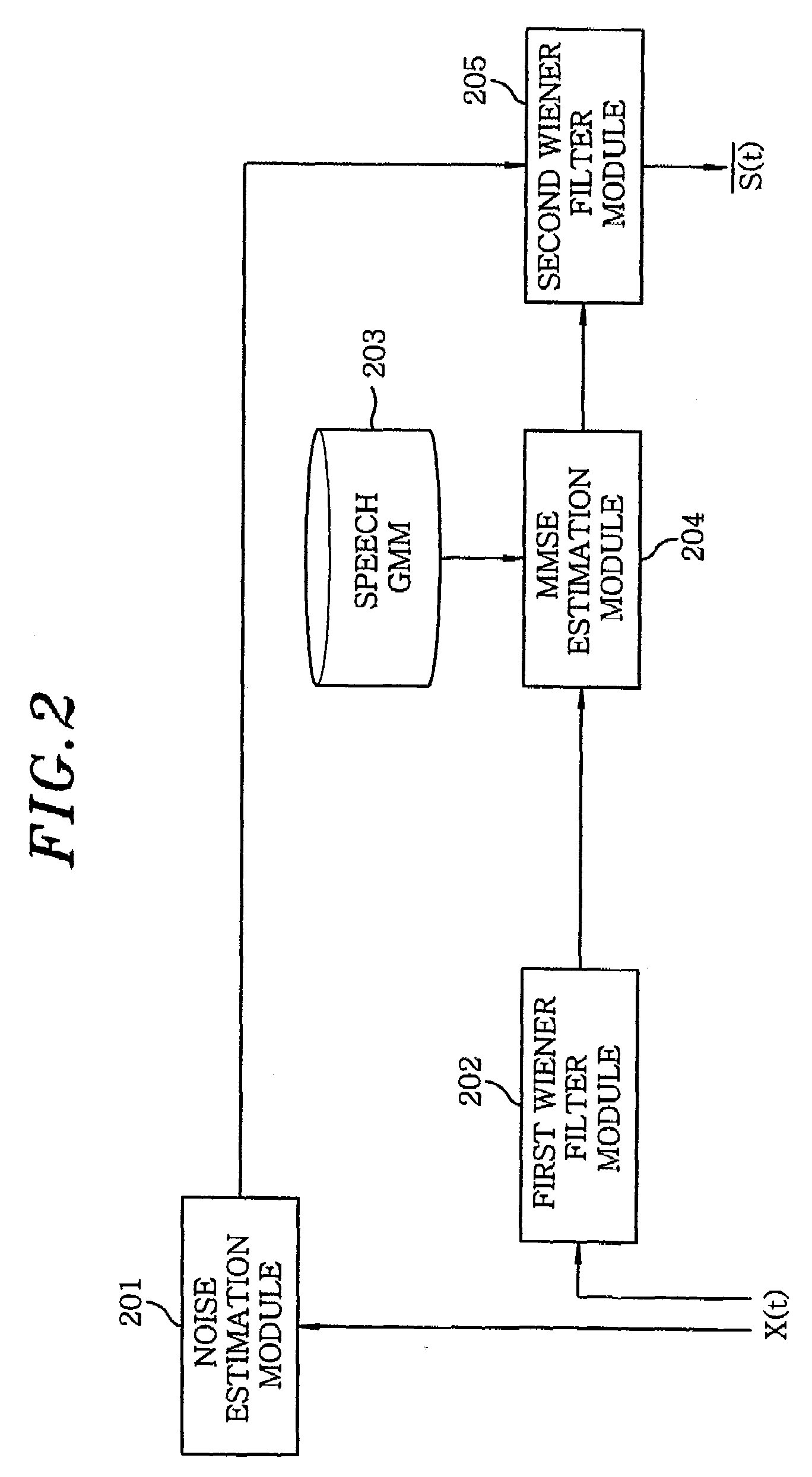

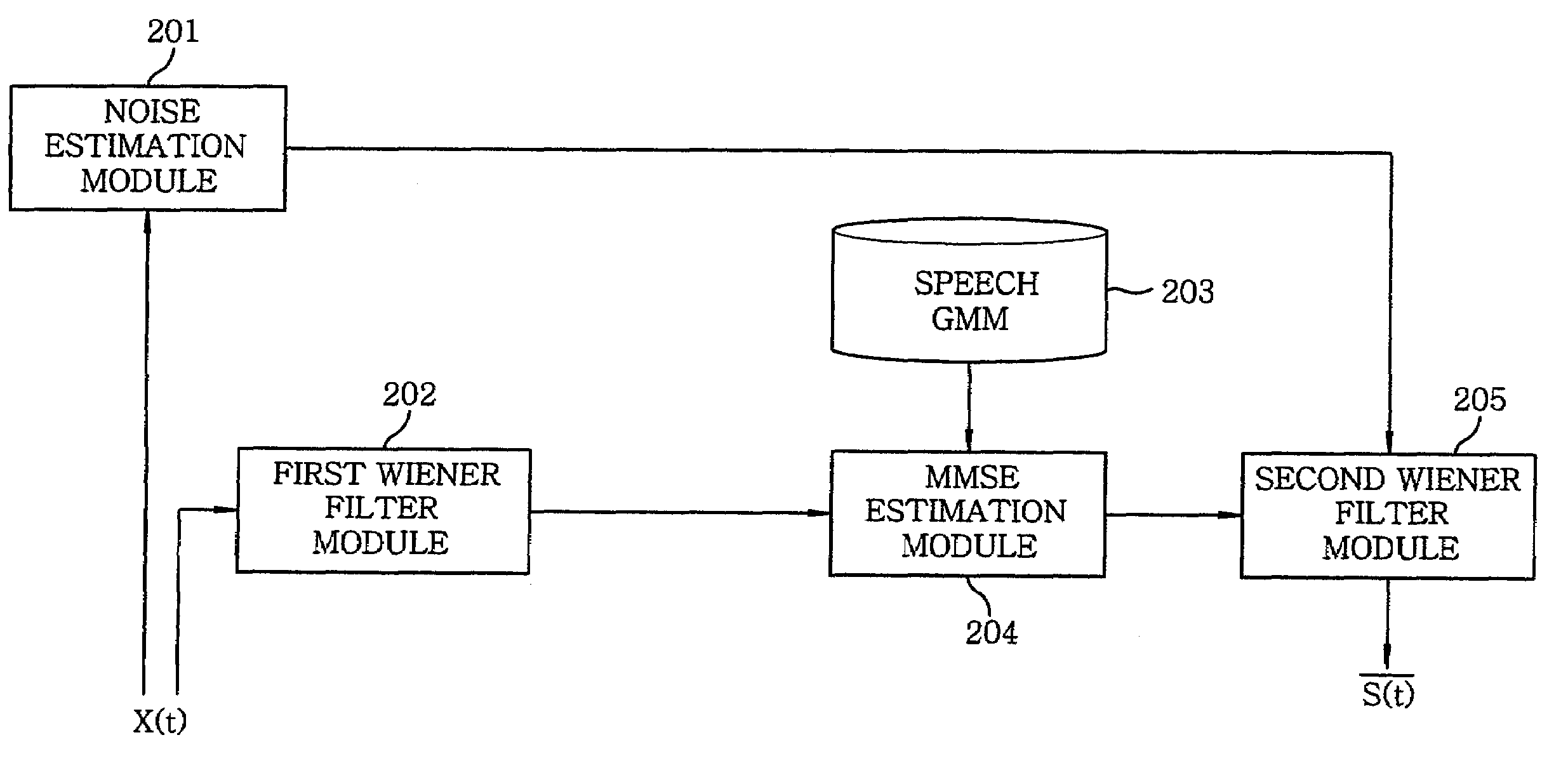

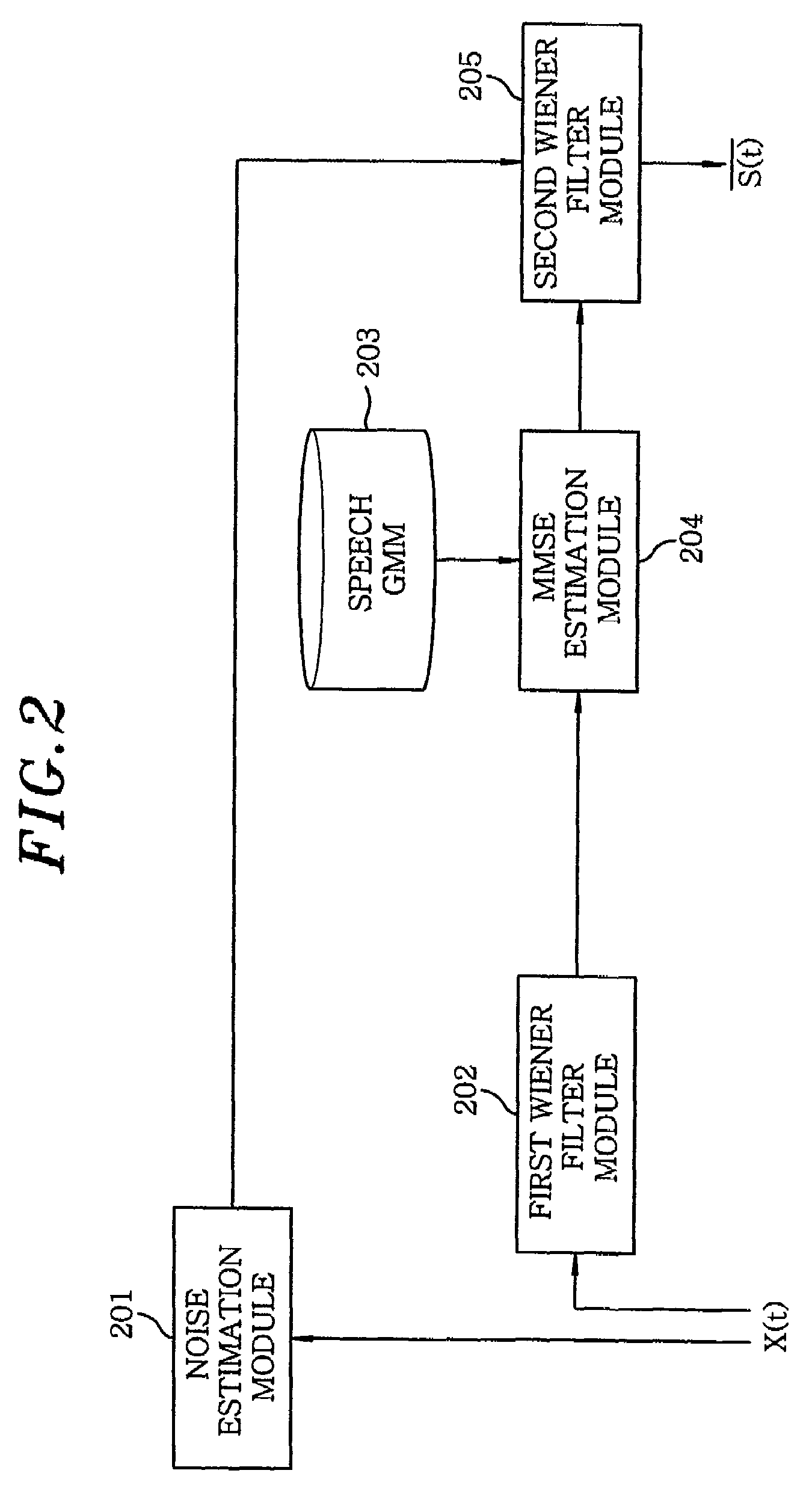

Noise cancellation system and method

InactiveUS20090265168A1Improve speech recognition performanceReduce noiseSpeech recognitionTransmission noise suppressionWien filterEngineering

A noise cancellation apparatus includes a noise estimation module for receiving a noise-containing input speech, and estimating a noise therefrom to output the estimated noise; a first Wiener filter module for receiving the input speech, and applying a first Wiener filter thereto to output a first estimation of clean speech; a database for storing data of a Gaussian mixture model for modeling clean speech; and an MMSE estimation module for receiving the first estimation of clean speech and the data of the Gaussian mixture model to output a second estimation of clean speech. The apparatus further includes a final clean speech estimation module for receiving the second estimation of clean speech from the MMSE estimation module and the estimated noise from the noise estimation module, and obtaining a final Wiener filter gain therefrom to output a final estimation of clean speech by applying the final Wiener filter gain.

Owner:ELECTRONICS & TELECOMM RES INST

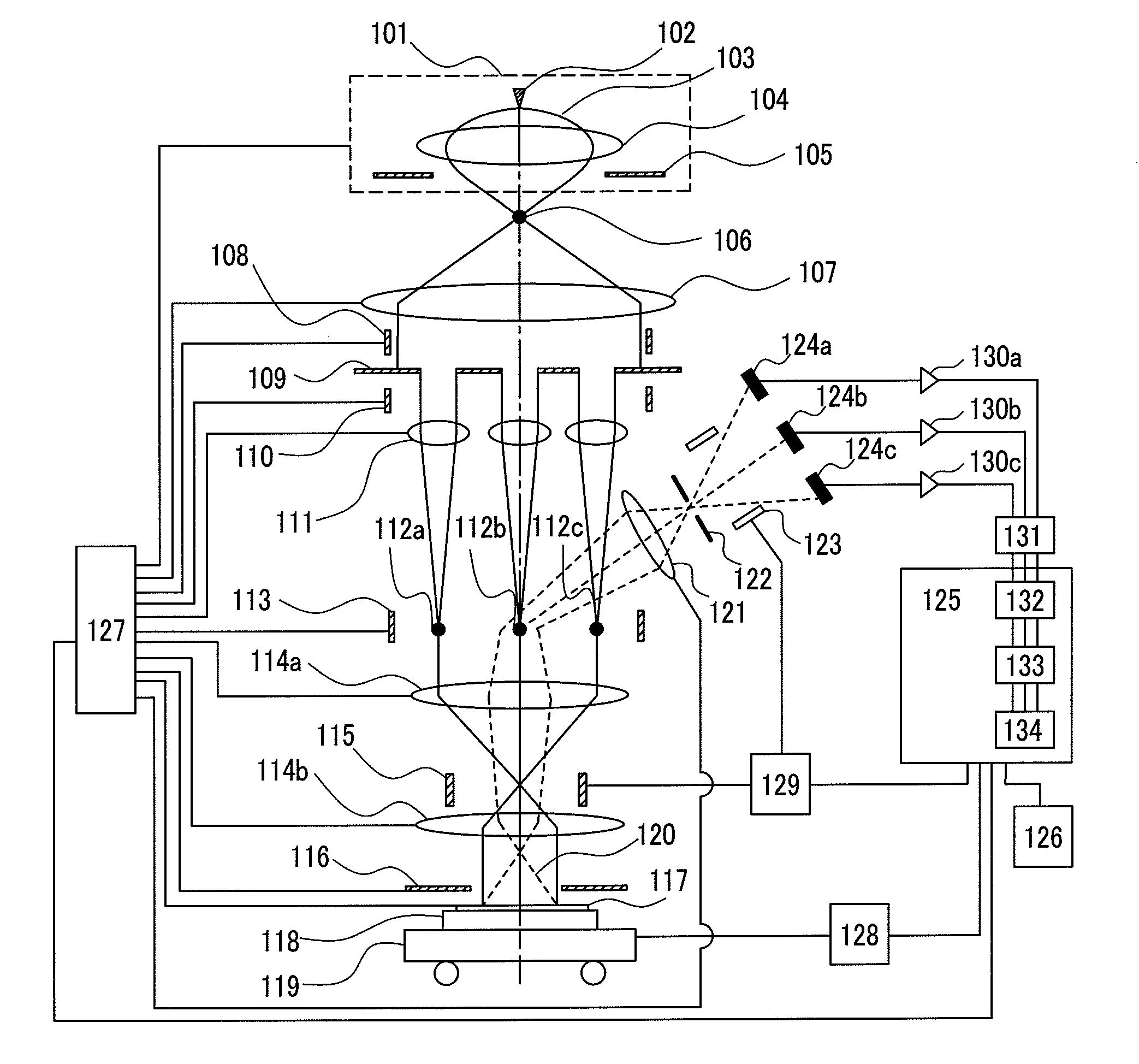

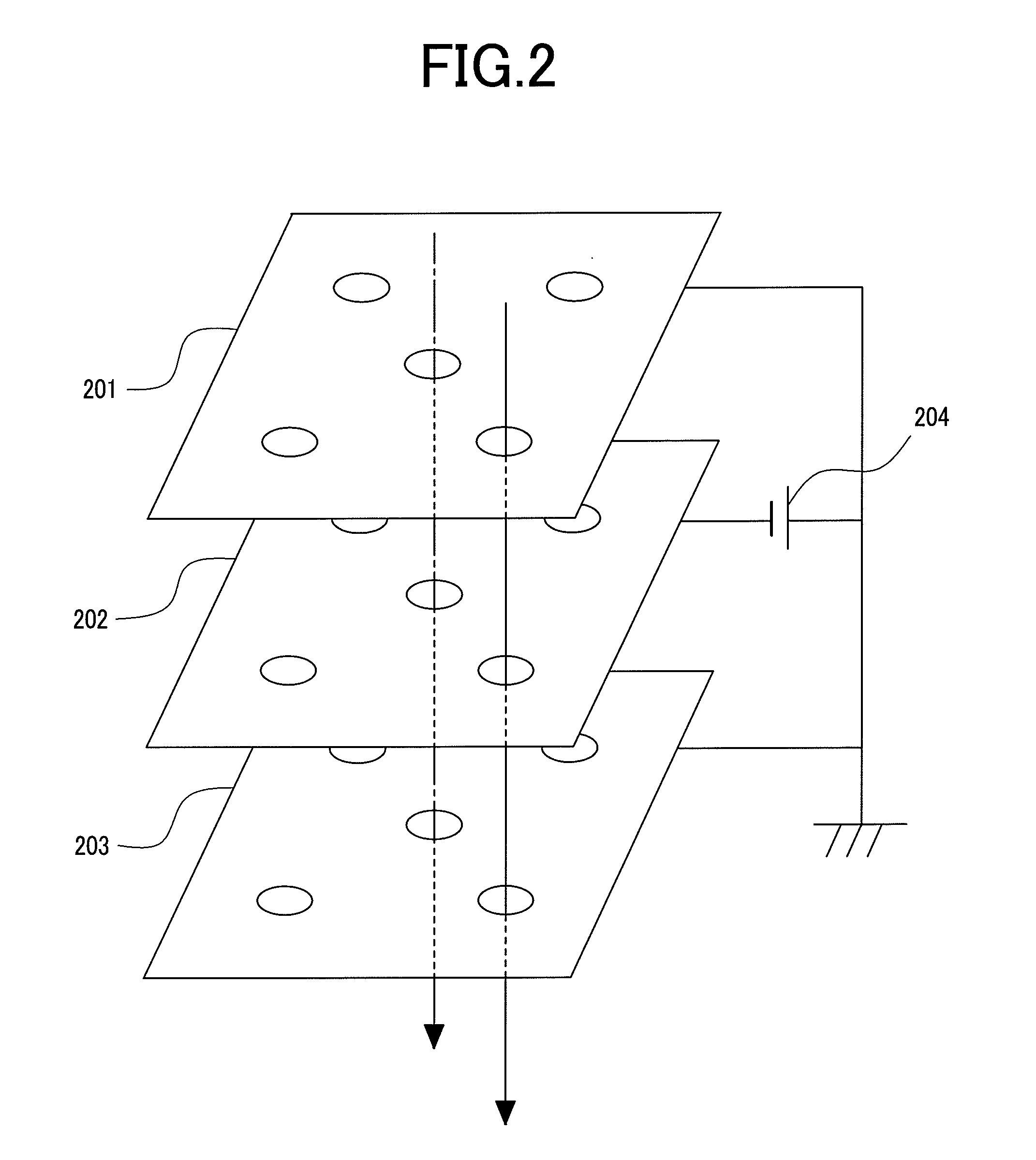

Charged particle beam apparatus

InactiveUS20080067376A1Reduce aberrationMaterial analysis using wave/particle radiationElectric discharge tubesParticle beamWien filter

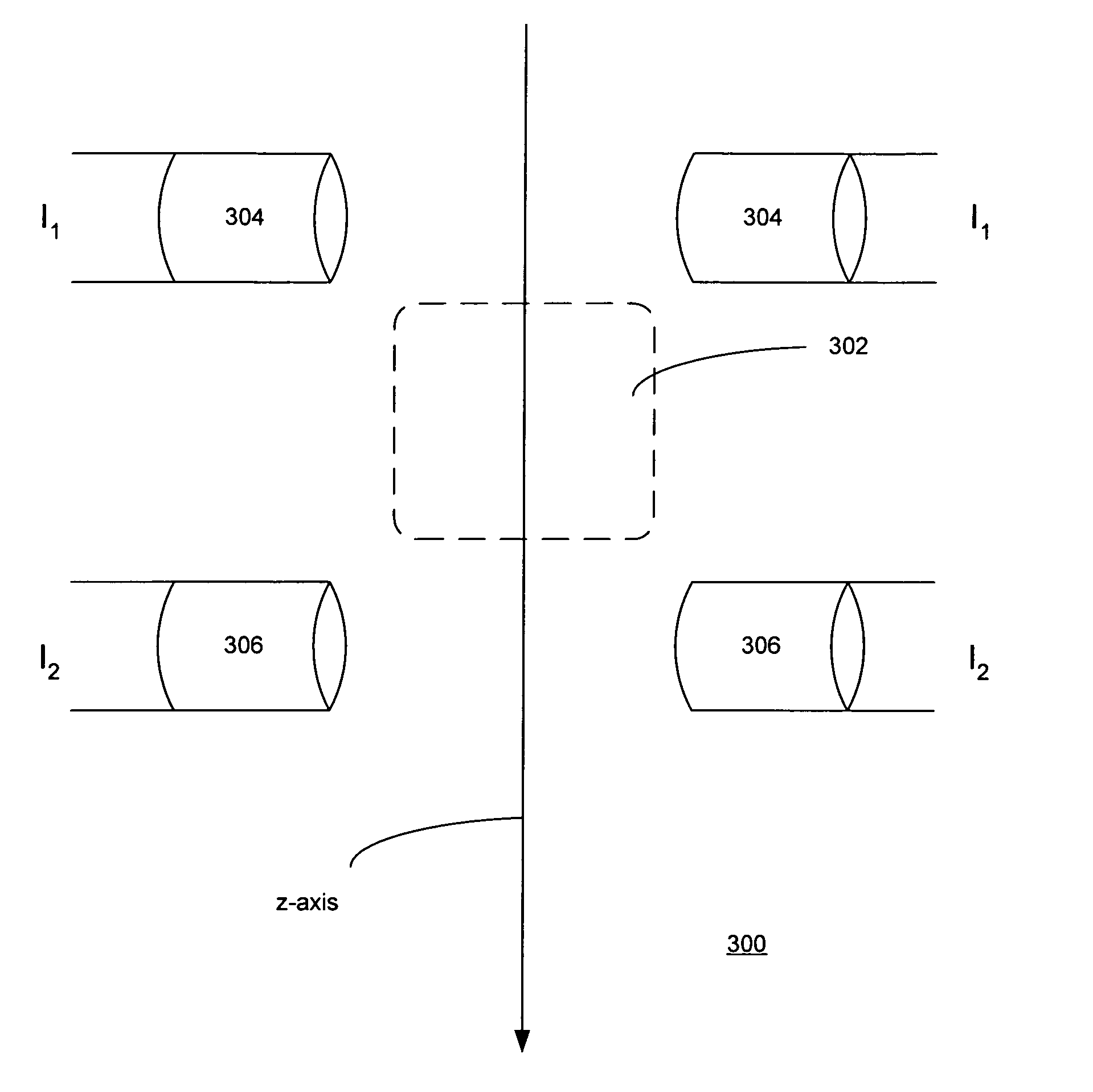

This invention provides a charged particle beam apparatus that can makes reduction in off axis aberration and separate detection of secondary beams to be compatible. The charged particle beam apparatus has: an electron optics that forms a plurality of primary charged particle beams, projects them on a specimen, and makes them scan the specimen with a first deflector; a plurality of detectors that individually detect a plurality of secondary charged particle beams produced from the plurality of locations of the specimen by irradiation of the plurality of primary charged particle beams; and a voltage source for applying a voltage to the specimen. The charged particle beam apparatus further has: a Wien filter for separating paths of the primary charged particle beams and paths of the secondary charged particle beams; a second deflector for deflecting the secondary charged particle beams separated by the Wien filter; and control means for controlling the first deflector and the second deflector in synchronization, wherein the plurality of detectors detect the plurality of secondary charged particle beams separated by the Wien filter individually.

Owner:HITACHI HIGH-TECH CORP

Monochromator for Charged Particle Beam Apparatus

ActiveUS20120318978A1Energy spread can be reducedImprove imaging resolutionStability-of-path spectrometersMaterial analysis using wave/particle radiationElectron sourceWien filter

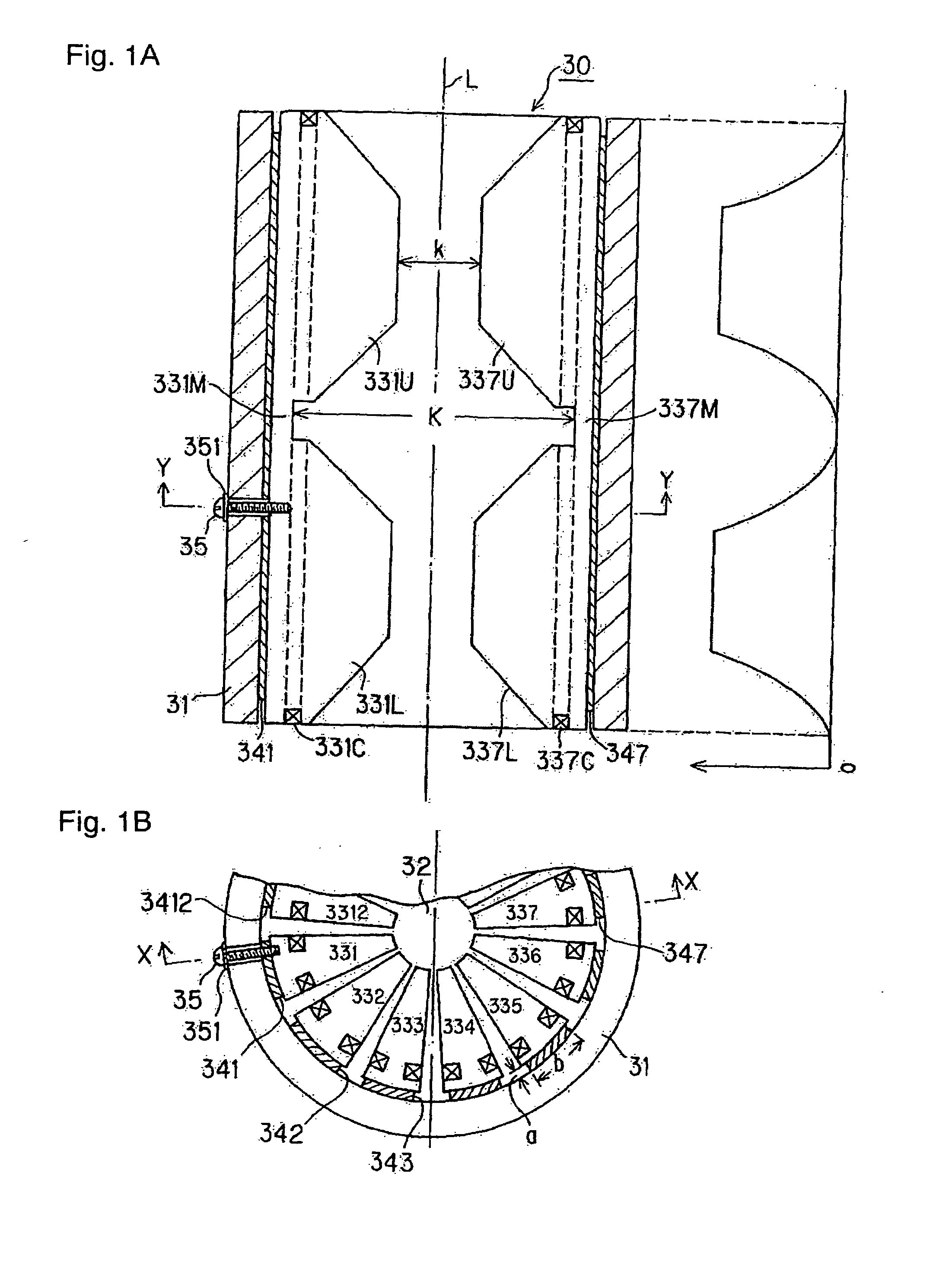

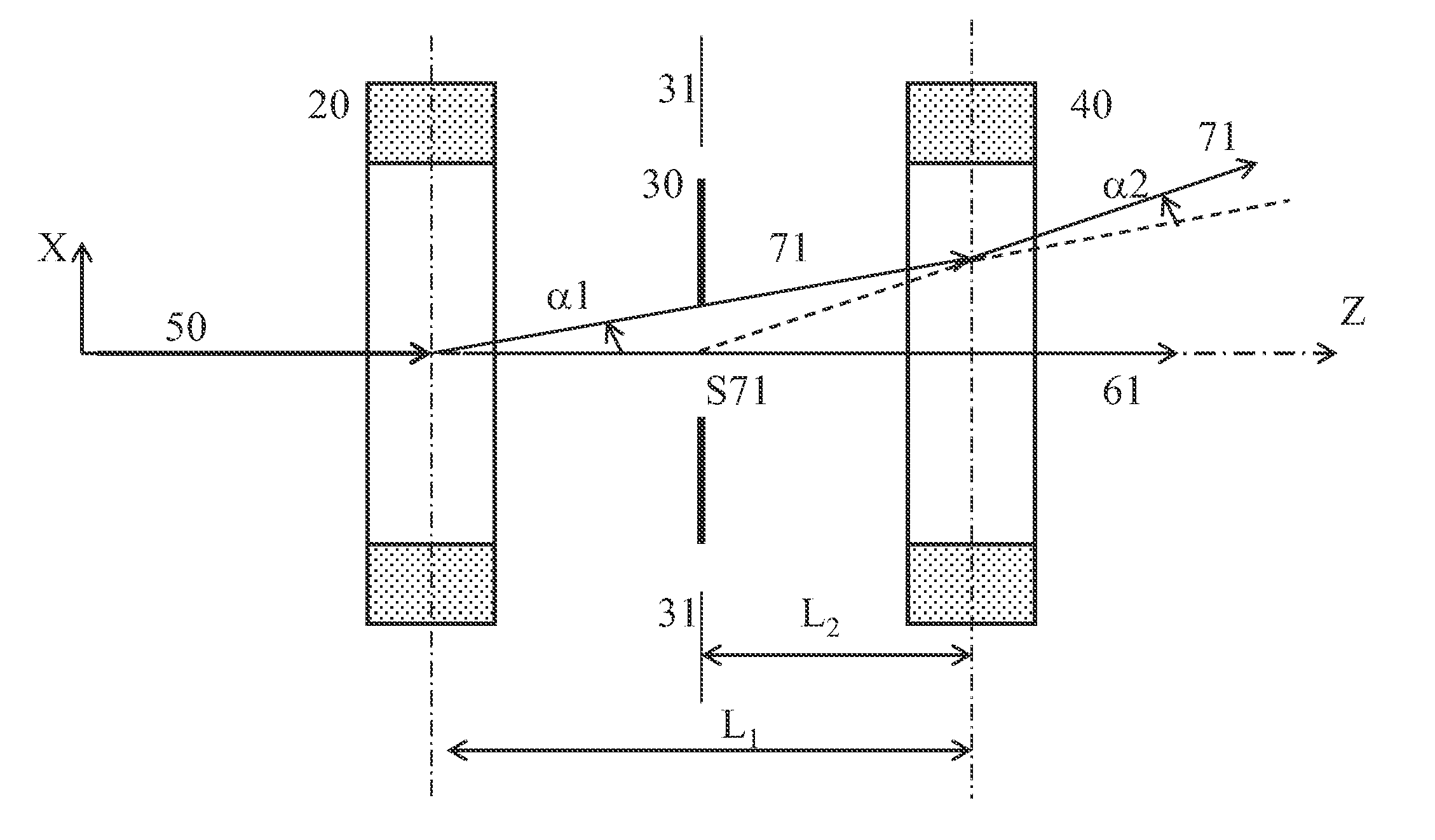

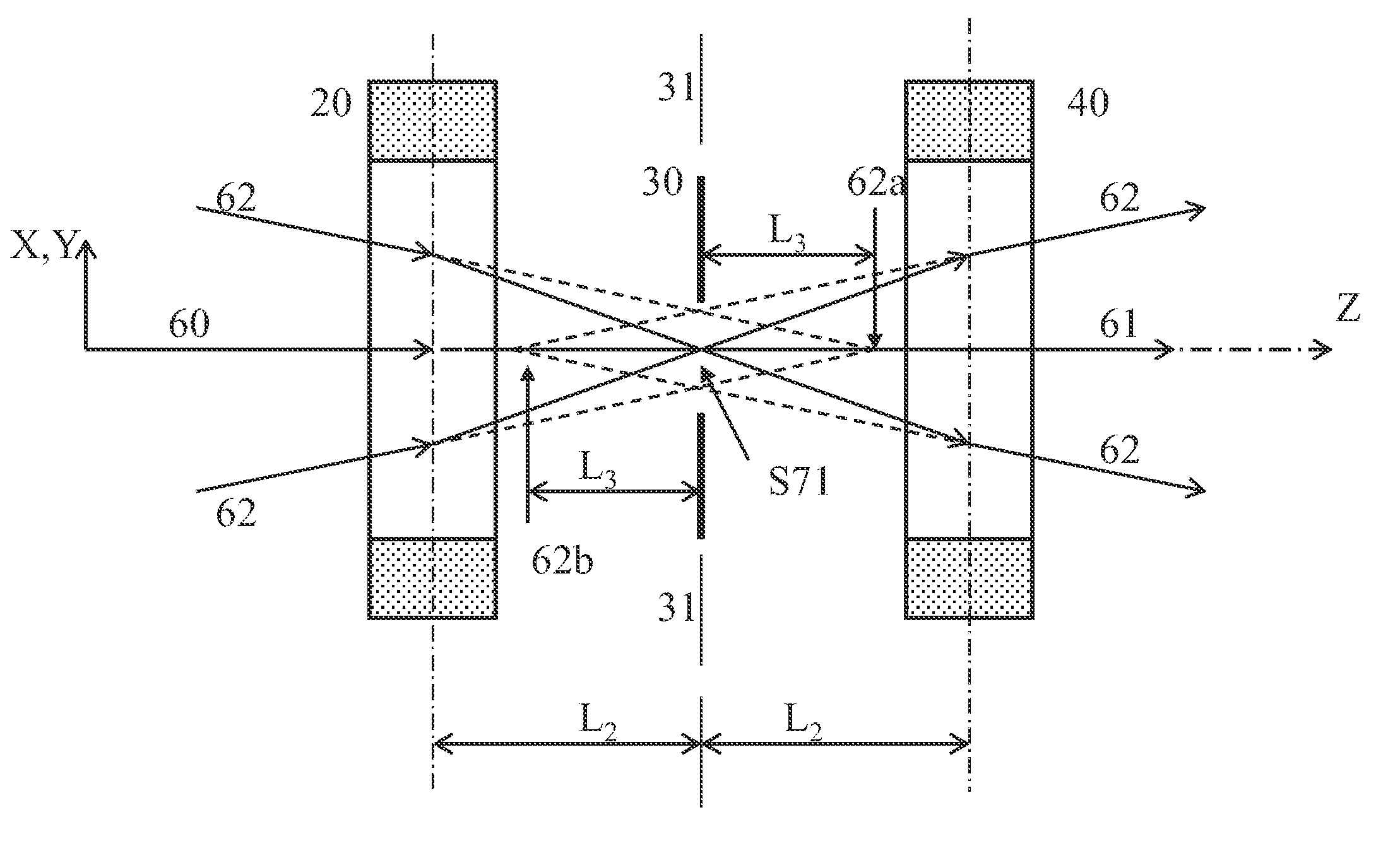

The monochromator for reducing energy spread of a primary charged particle beam in charged particle apparatus comprises a beam adjustment element, two Wien-filter type dispersion units and an energy-limit aperture. In the monochromator, a dual proportional-symmetry in deflection dispersion and fundamental trajectory along a straight optical axis is formed, which not only fundamentally avoids incurring off-axis aberrations that actually can not be compensated but also ensures the exit beam have a virtual crossover which is stigmatic, dispersion-free and inside the monochromator. The present invention also provides two ways to build a monochromator into a SEM, in which one is to locate a monochromator between the electron source and the condenser, and another is to locate a monochromator between the beam-limit aperture and the objective. The former provides an additional energy-angle depending filtering, and obtains a smaller effective energy spread.

Owner:ASML NETHERLANDS BV

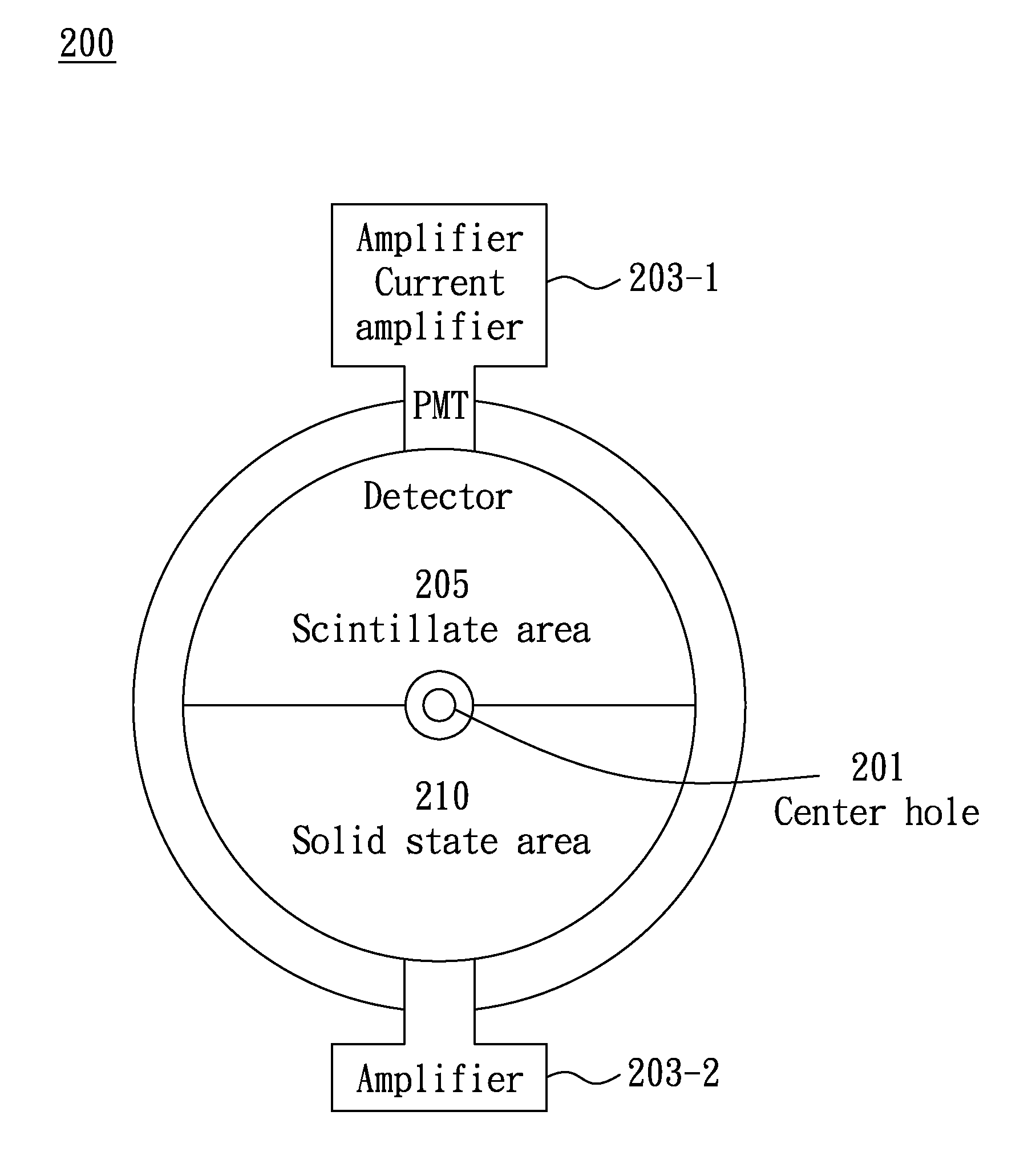

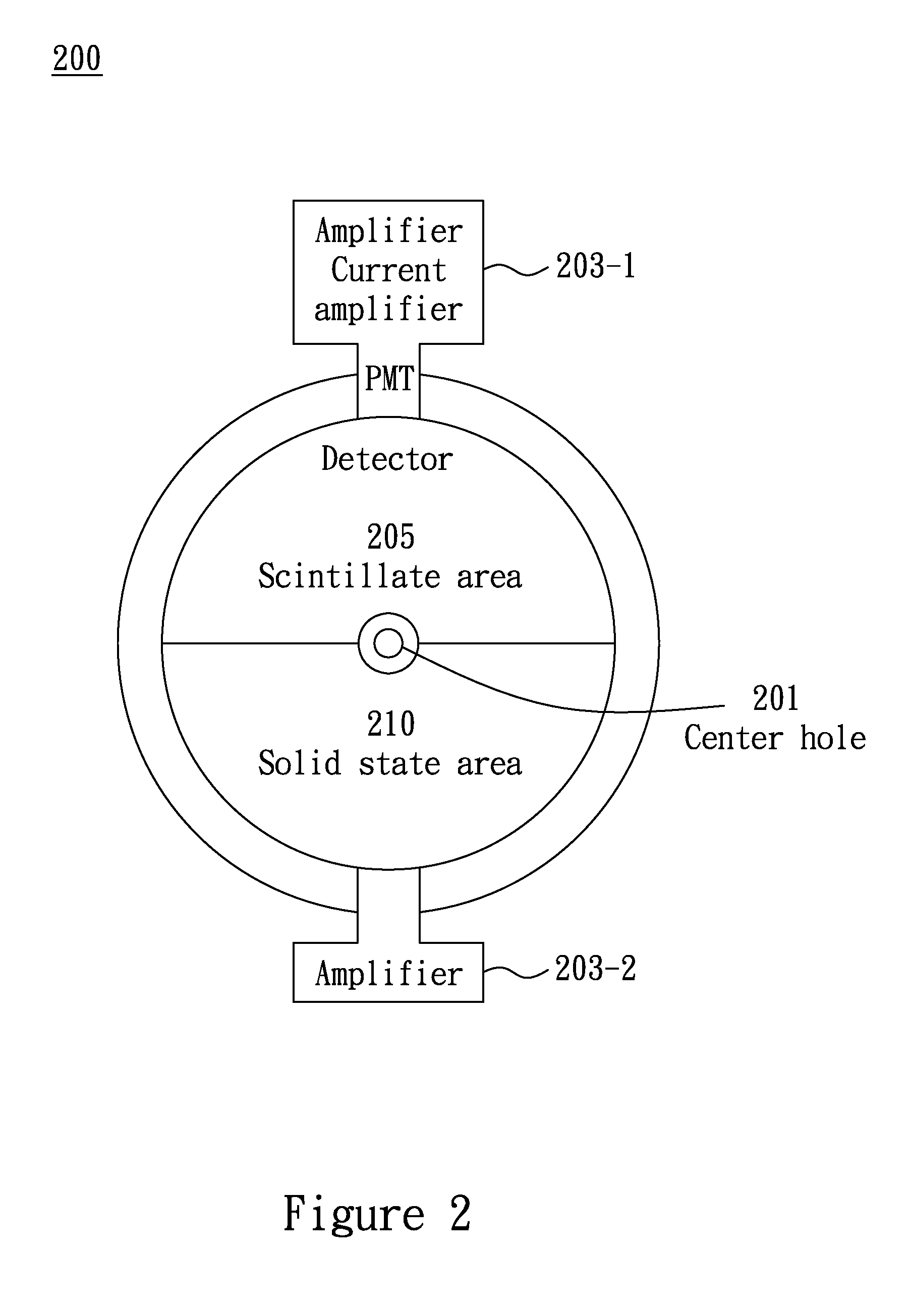

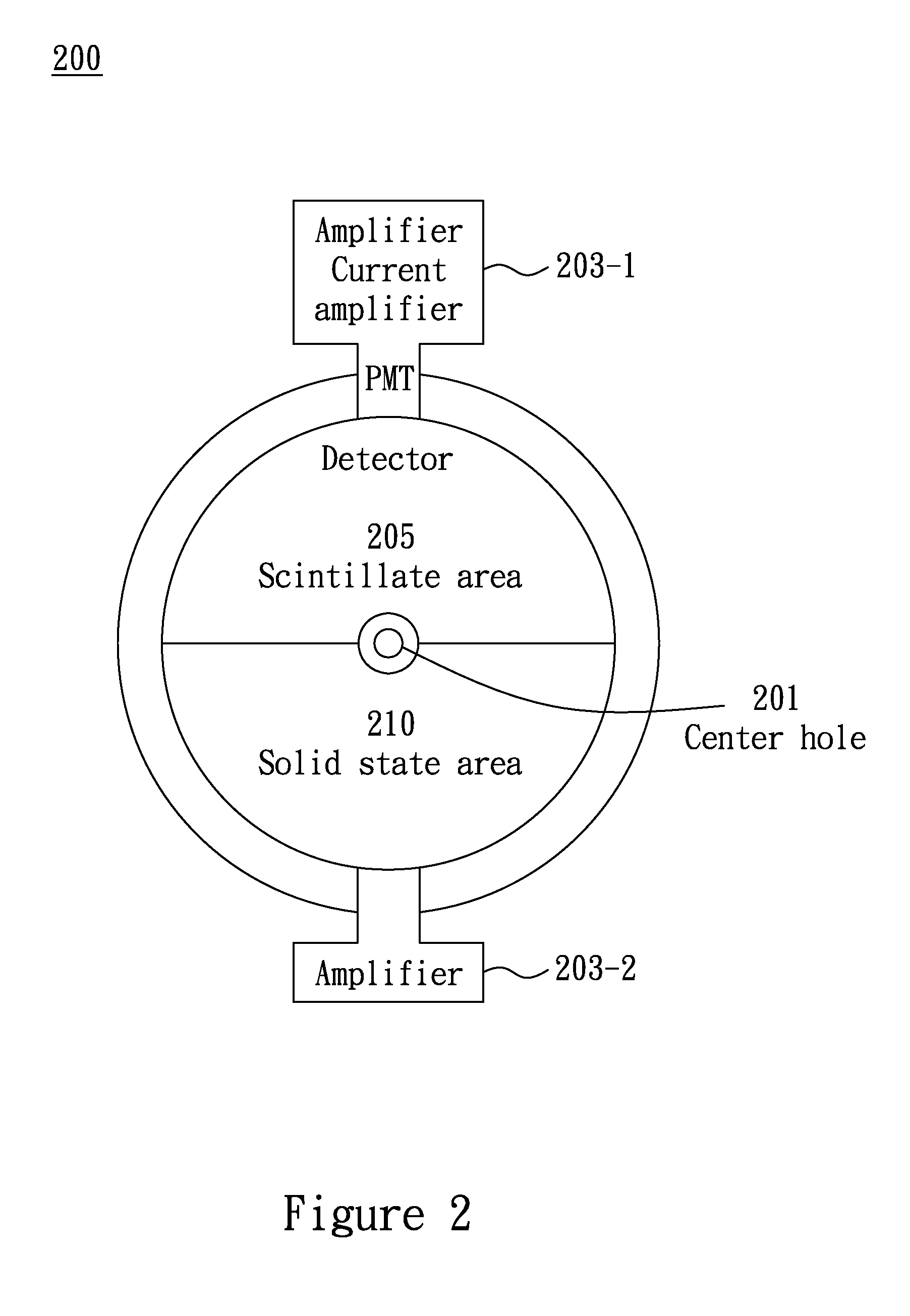

Charged Particle Beam Detection Unit with Multi Type Detection Subunits

ActiveUS20110215241A1Electric discharge tubesMaterial analysis by transmitting radiationPower flowWien filter

A detection unit of a charged particle imaging system includes a multi type detection subunit in the charged particle imaging system, with the assistance of a Wien filter (also known as an E×B charged particle analyzer). The imaging system is suitable for a low beam current, high resolution mode and a high beam current, high throughput mode. The unit can be applied to a scanning electron inspection system as well as to other systems that use a charged particle beam as an observation tool.

Owner:ASML NETHERLANDS BV

Pattern inspection and measurement apparatus

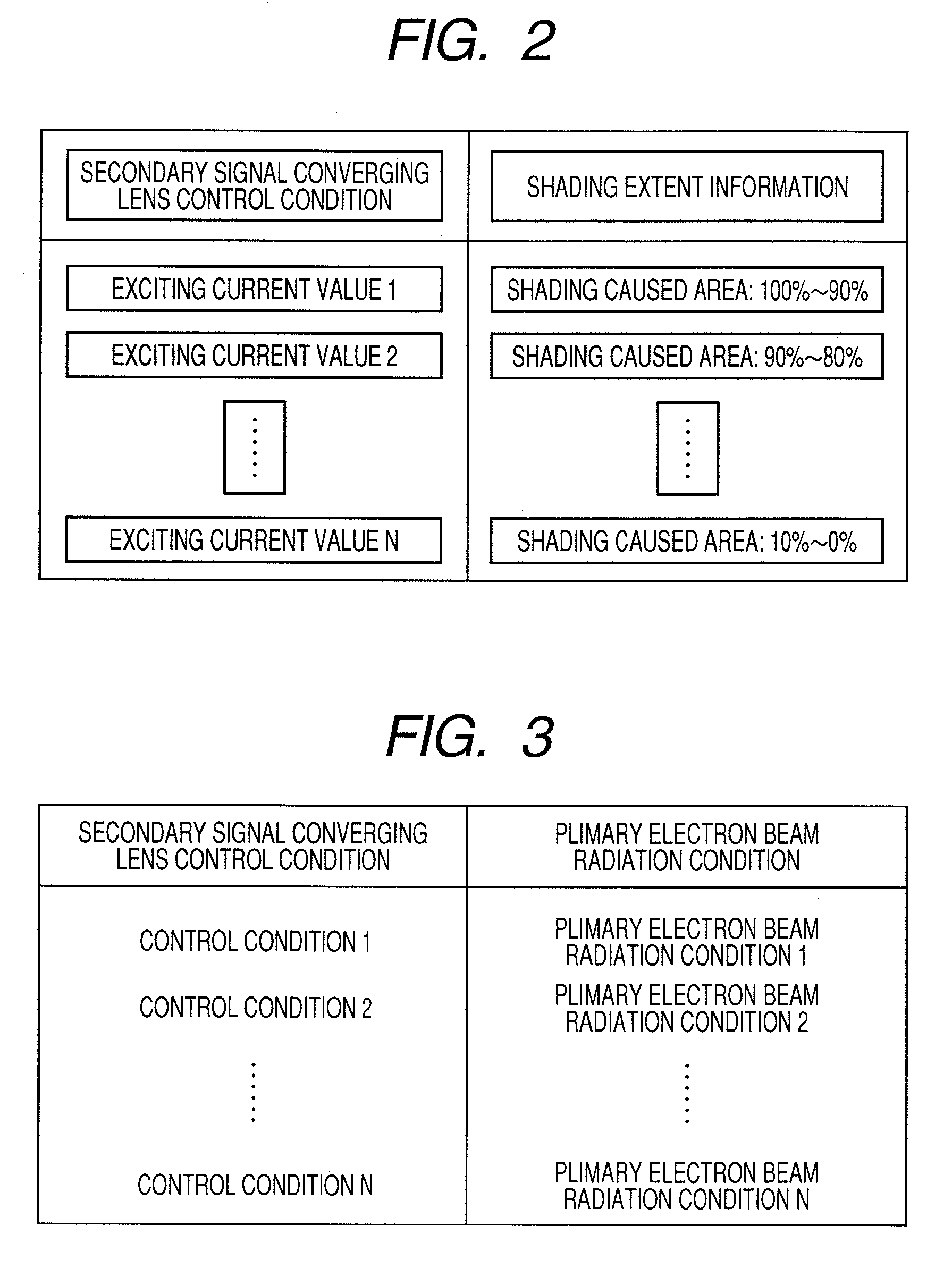

InactiveUS20080017797A1Improve accuracyGood repeatabilityMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementWien filterRepeatability

Pattern inspection and measurement technique where the failure of the detection of a secondary signal due to the variation of an optical condition of a primary electron beam or the occurrence of an electric field perpendicular to a traveling direction of the primary electron beam in a surface of a wafer is minimized, an SEM image the SN ratio of which is high and which hardly has shading in a field of view can be acquired and measurement such as measuring the dimensions and configuration of a measured object and inspecting a defect is enabled at high precision and high repeatability. A lens for converging a secondary signal is installed in a position which a traveling direction of the primary electron beam crosses or on a course of the secondary signal spatially separated from the primary electron beam by Wien filter. An SEM image always free of shading caused by the failure of the detection of a secondary signal in the field of view can be acquired by providing a unit that changes the setting of the lens according to the optical condition such as retarding voltage and an electrification control electrode of the primary electron beam.

Owner:HITACHI HIGH-TECH CORP

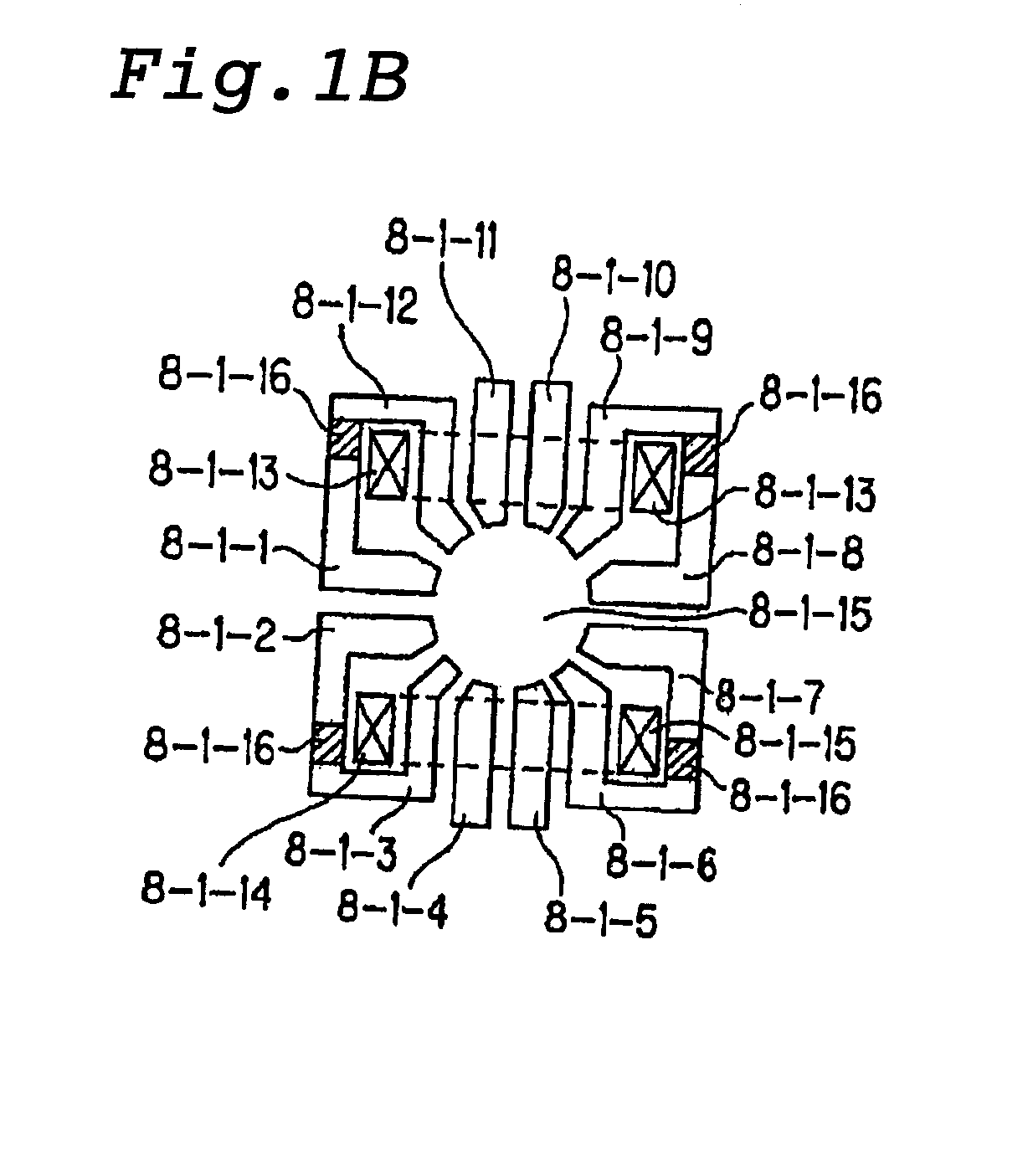

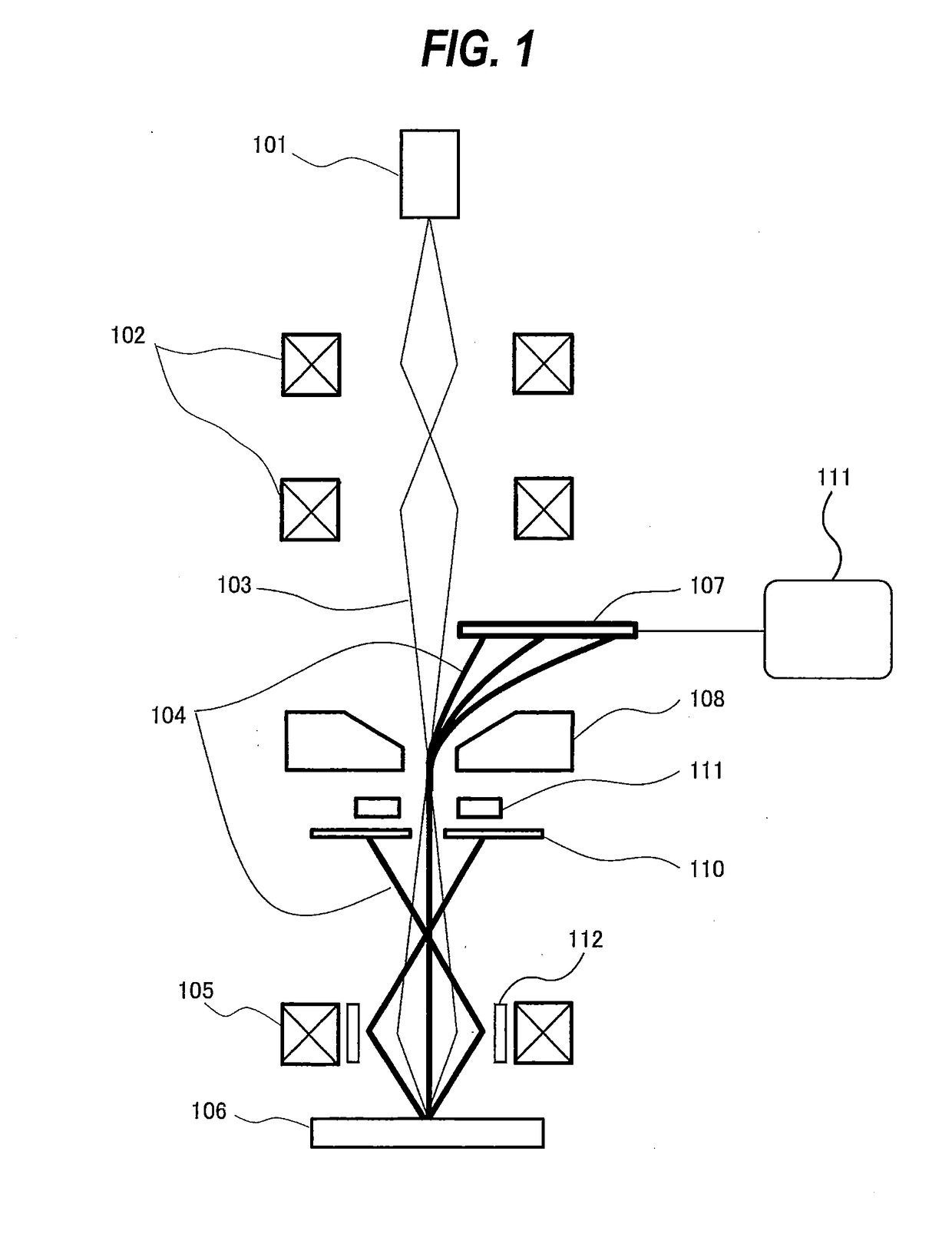

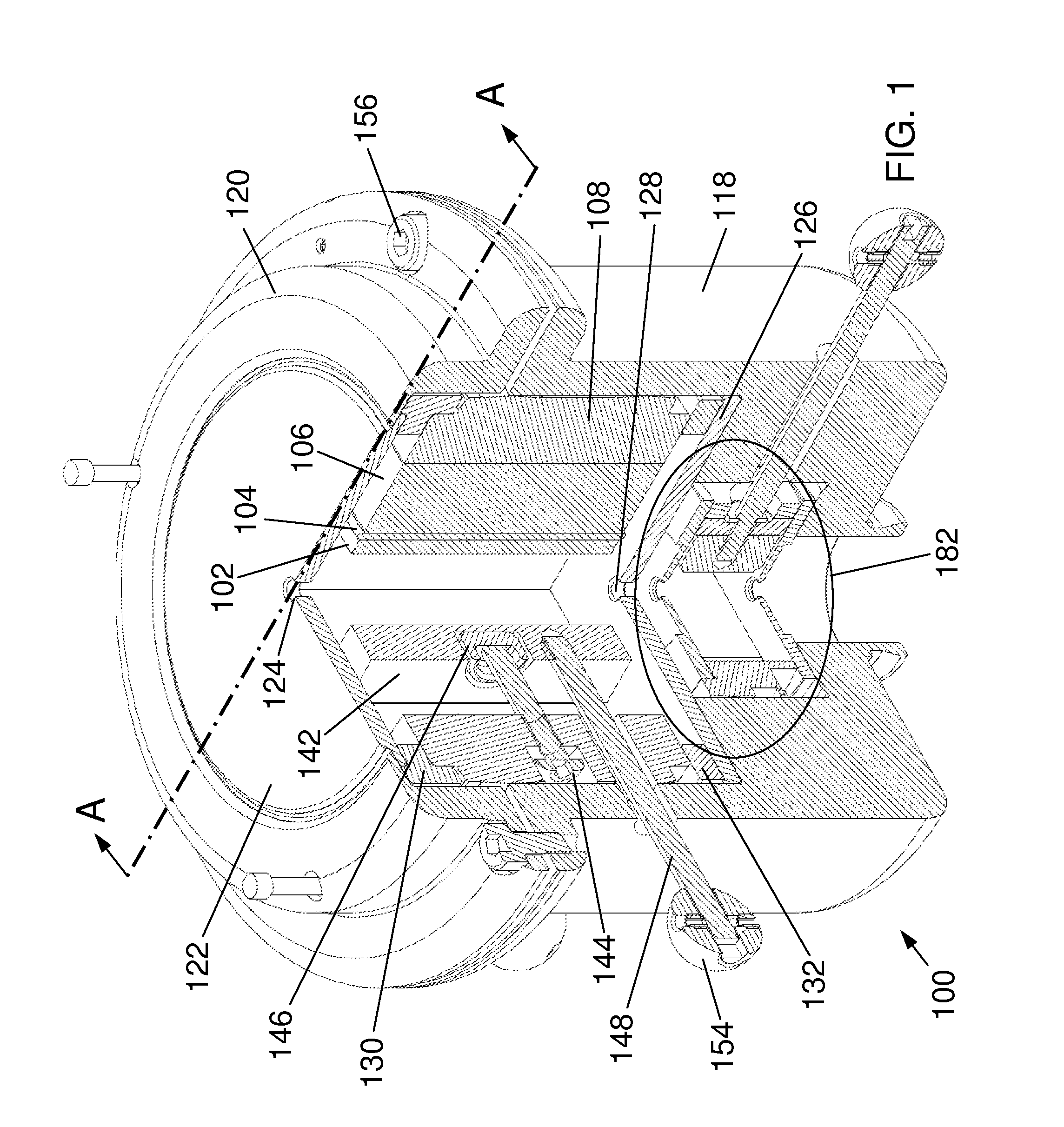

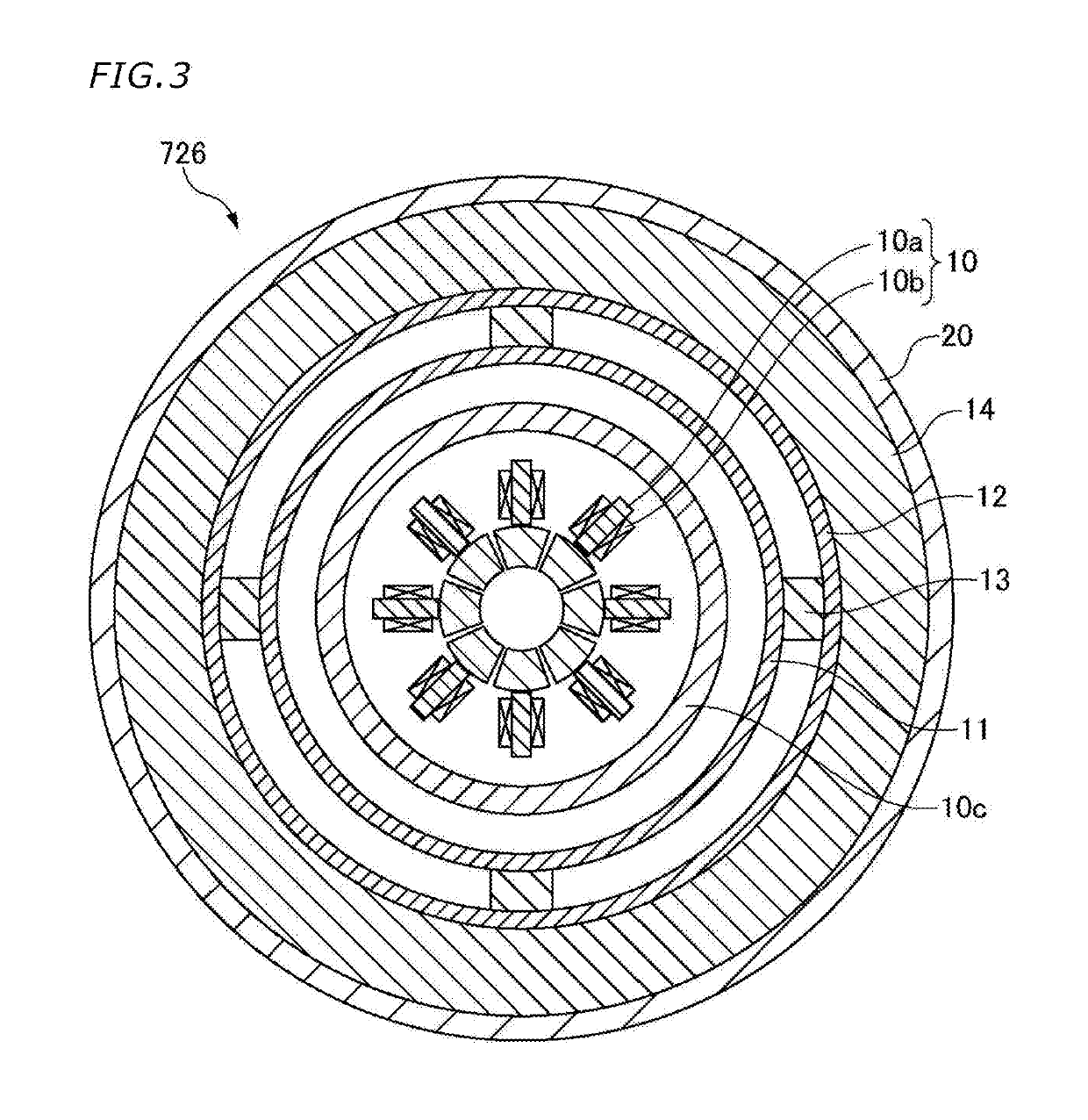

Wien filter

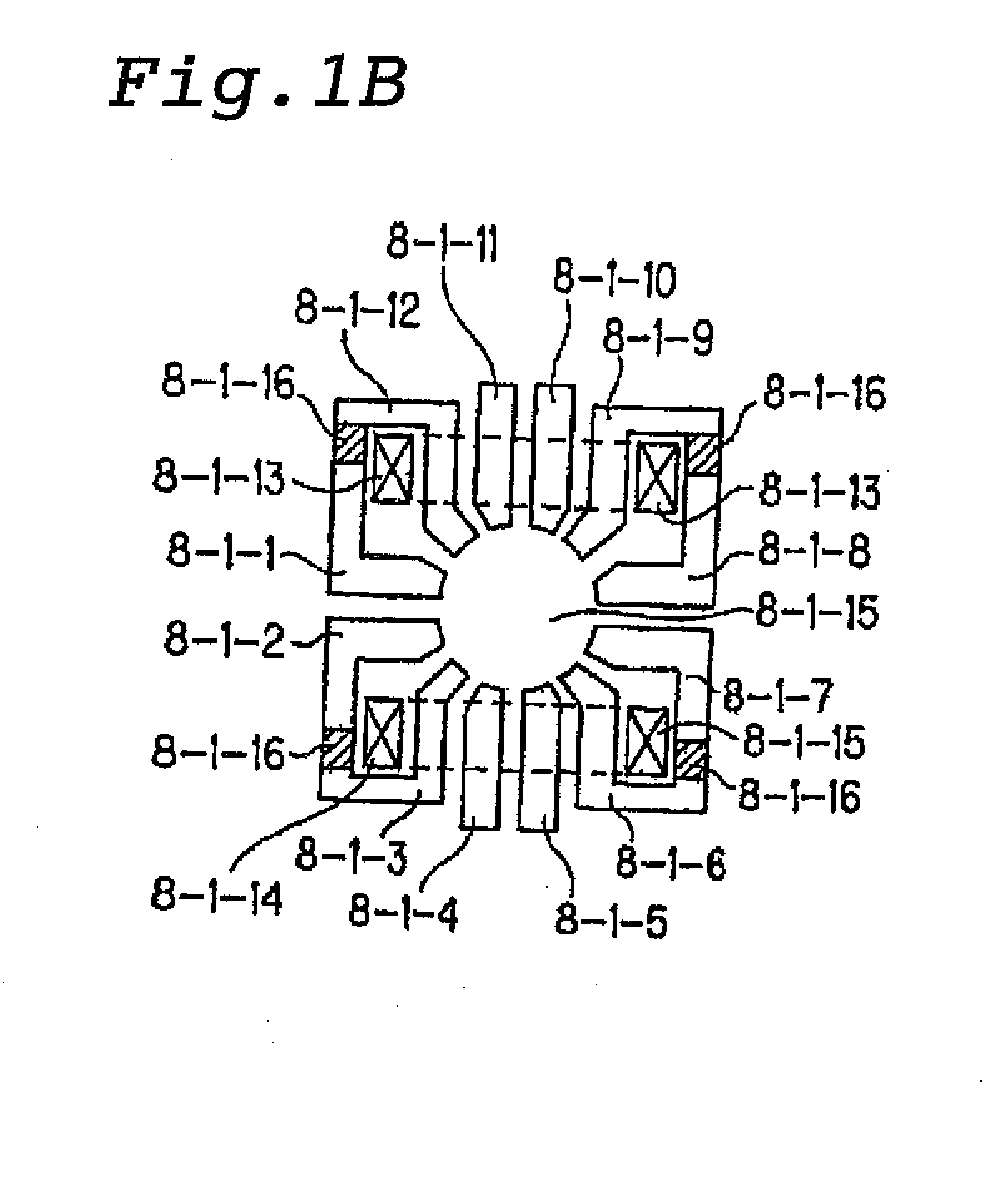

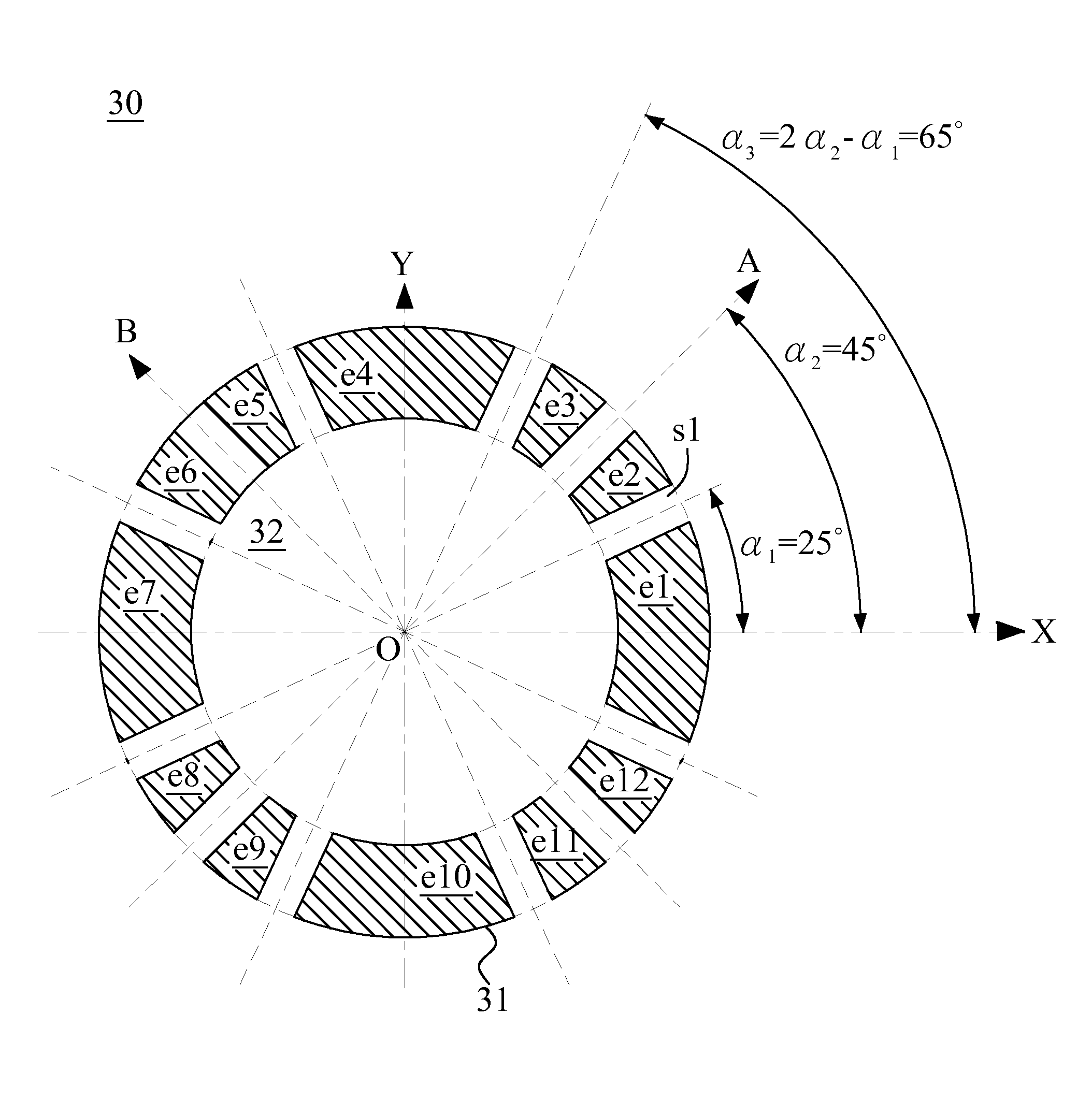

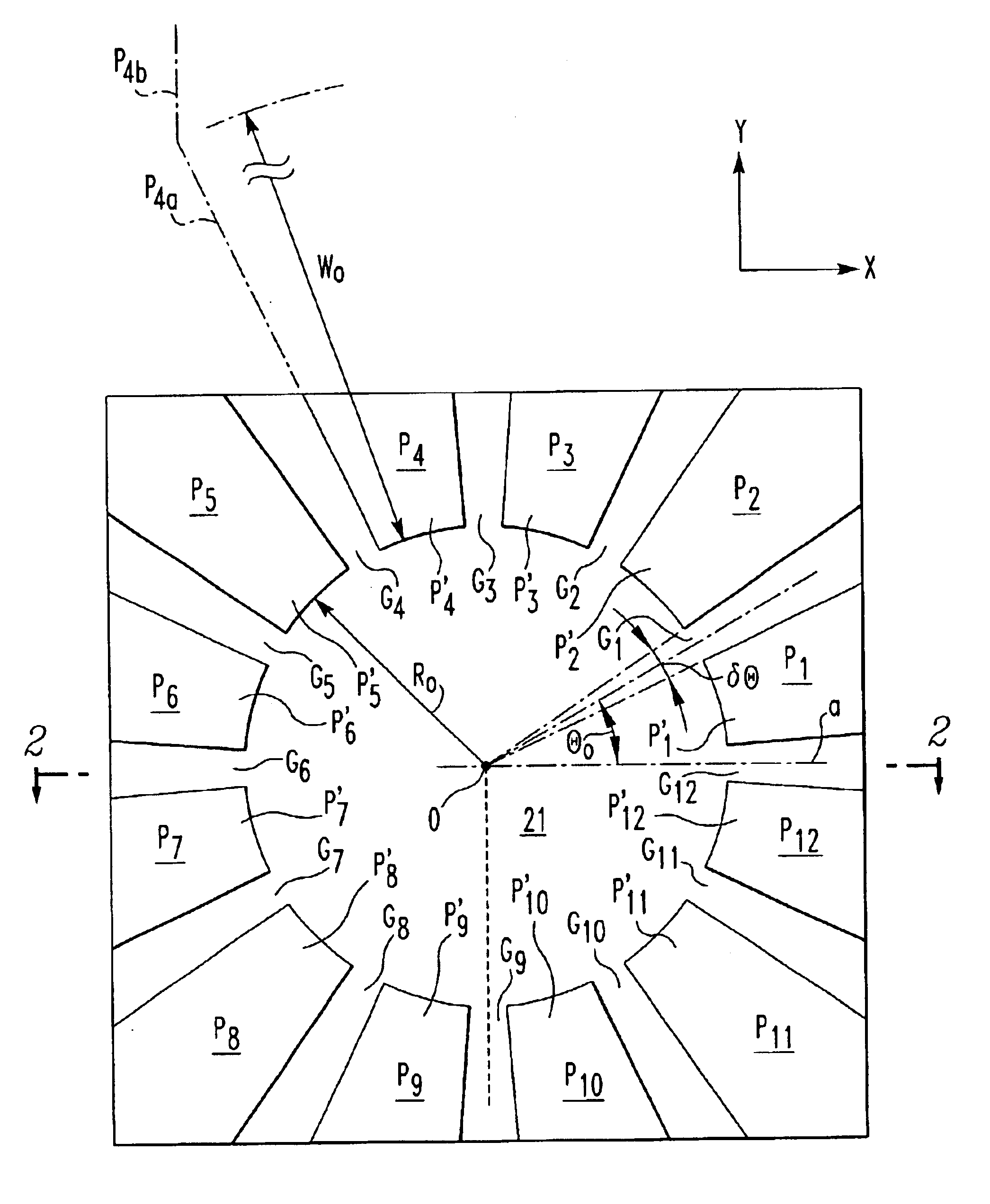

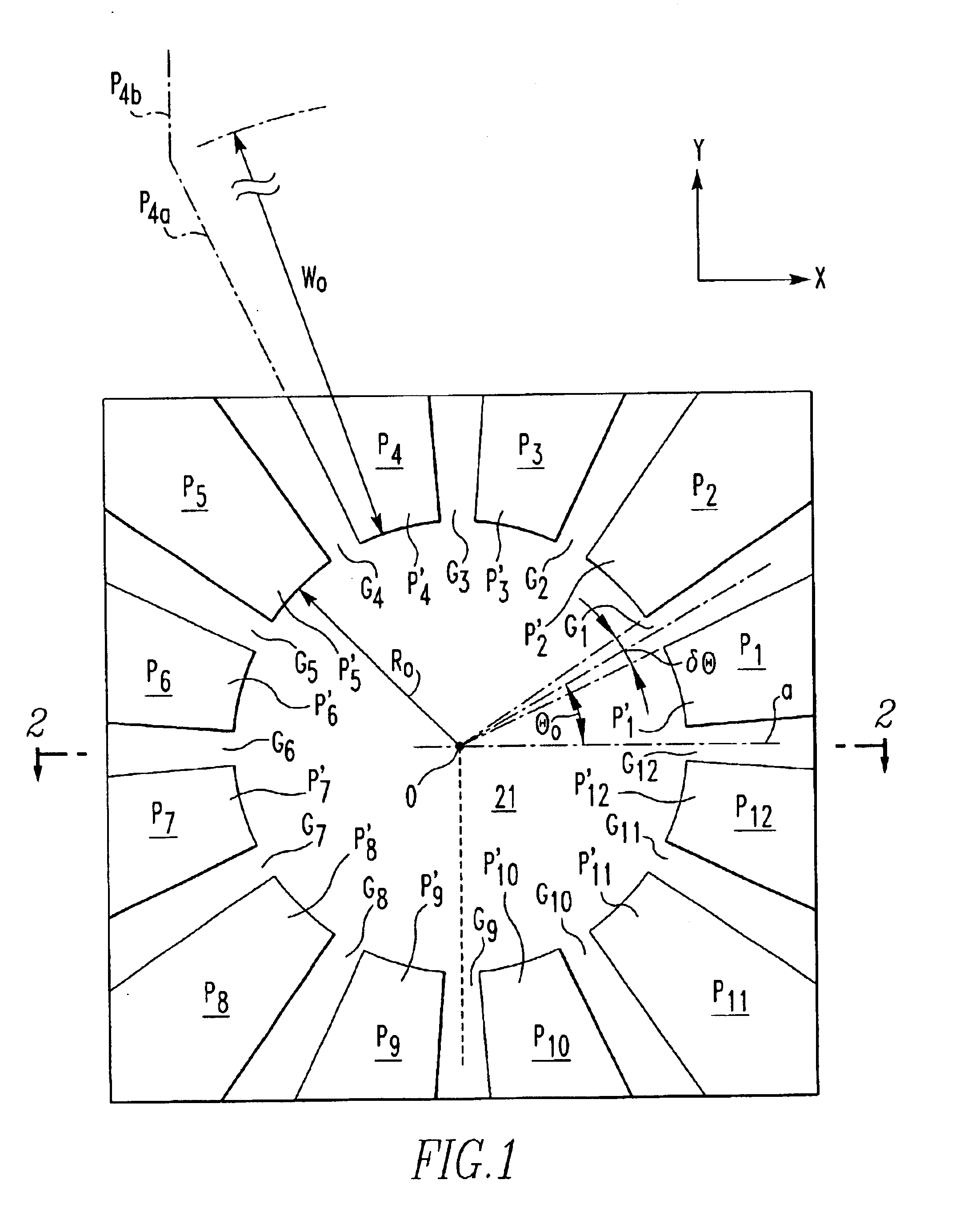

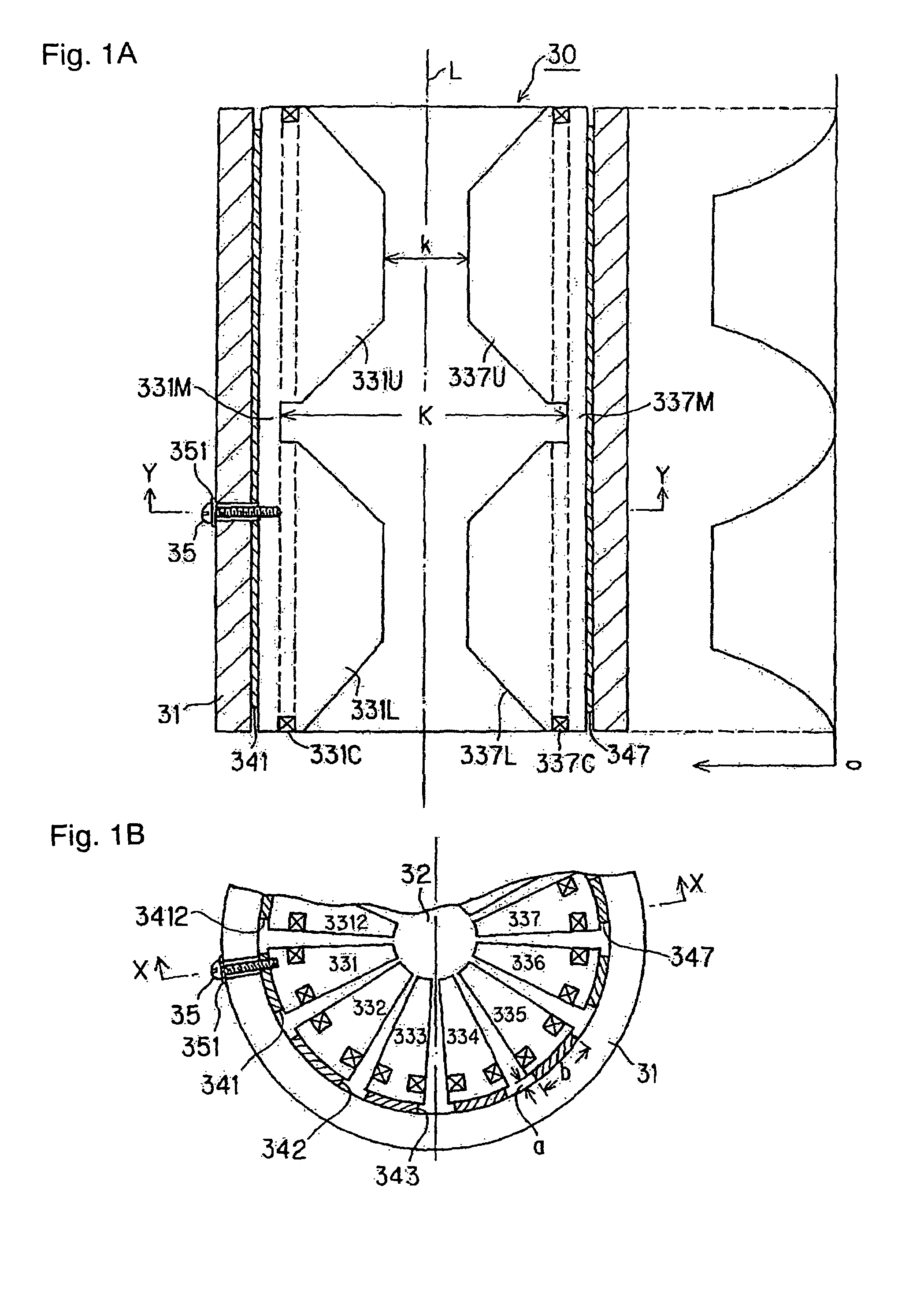

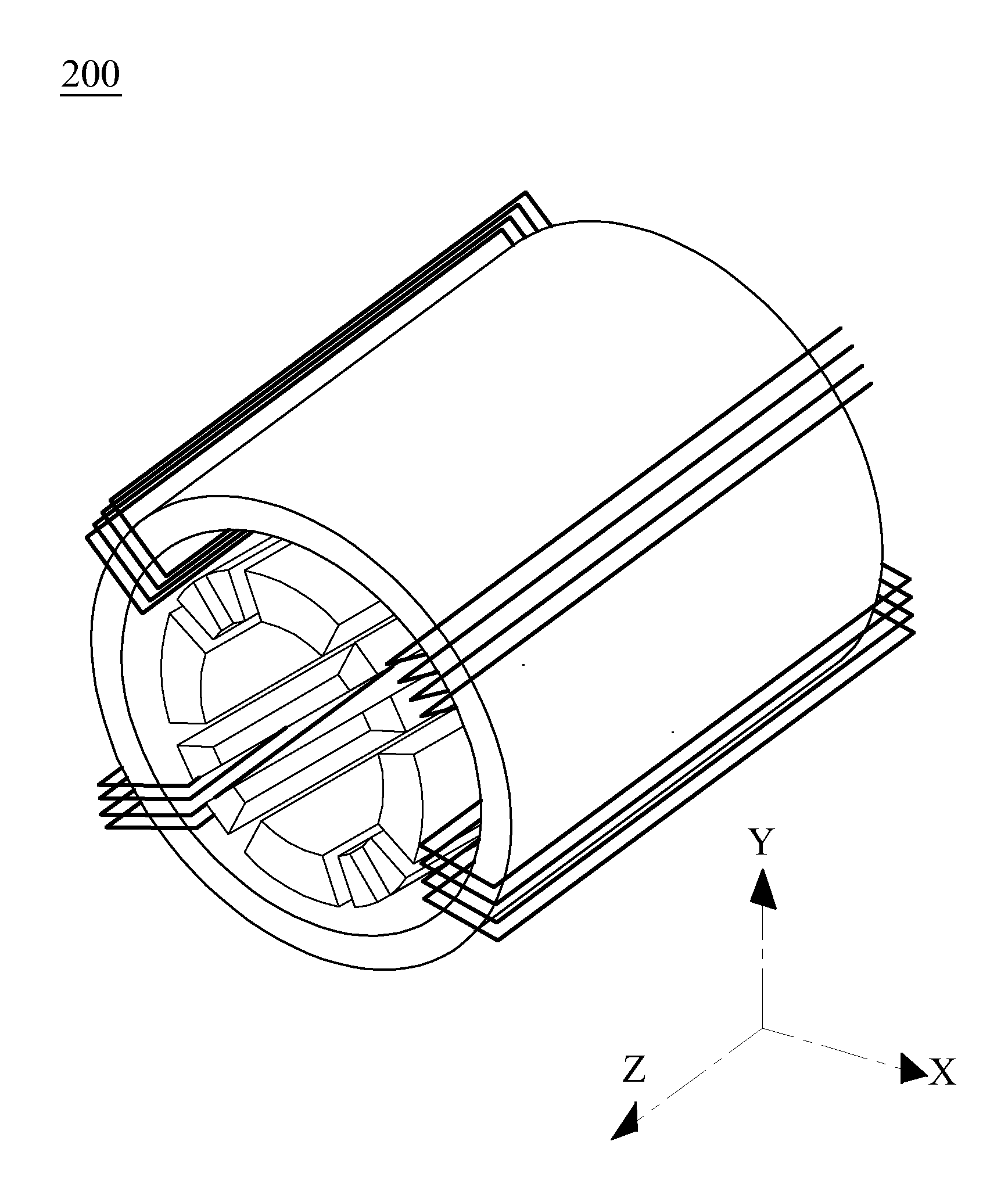

ActiveUS8436317B1Minimize aberrationReduced structureStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsHarmonicWien filter

This invention provides a multi-pole type Wien filter, which acts more purely approaching its fundamentally expected performance. A 12-electrode electric device acts as an electric deflector, or acts as an electric deflector and an electric stigmator together. A cylindrical 4-coil magnetic device with a magnetic core acts as a magnetic deflector. Both can produce a dipole field while only incurring a negligibly-small 3rd order field harmonic. The magnetic core enhances the strength and more preciously regulates the distribution of the magnetic field originally generated by the coils. Then two ways to construct a Wien filter are proposed. One way is based on both of the foregoing electric and magnetic devices, and the other way is based on the foregoing electric device and a conventional magnetic deflector. The astigmatism in each of such Wien filters can be compensated by the electric stigmator of the electric device.

Owner:ASML NETHERLANDS BV

Scanning electron microscope

InactiveUS20180005797A1Same energy resolutionWide range of energyElectric discharge tubesBeam sourceWien filter

A scanning electron microscope including: an electron beam source for generating a primary electron beam; an electron optical system configured to direct the primary electron beam to a specimen while focusing and deflecting the primary electron beam; and an energy analyzing system capable of performing parallel detection of an energy spectrum of back-scattered electrons emitted from the specimen is disclosed. The energy analyzing system includes: a Wien filter configured to separate the back-scattered electrons from a beam axis and analyze energies of the back-scattered electrons; and an array detector configured to detect the back-scattered electrons that have passed through the Wien filter. The Wien filter includes a plurality of electromagnetic poles, center-side ends of the plurality of electromagnetic poles have tapered surfaces, respectively, and the tapered surfaces form an exit of the Wien filter through which the back-scattered electrons pass out.

Owner:NGR

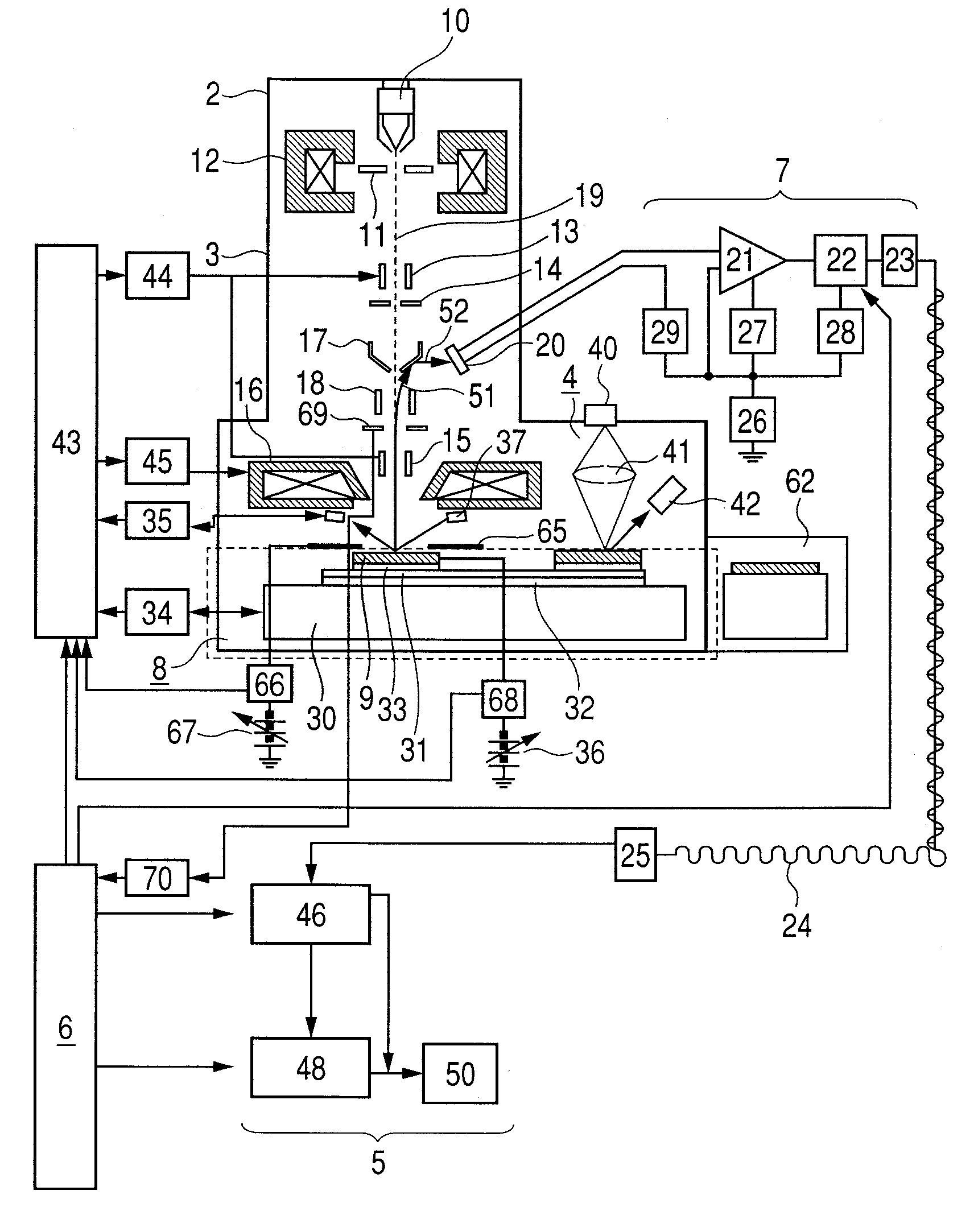

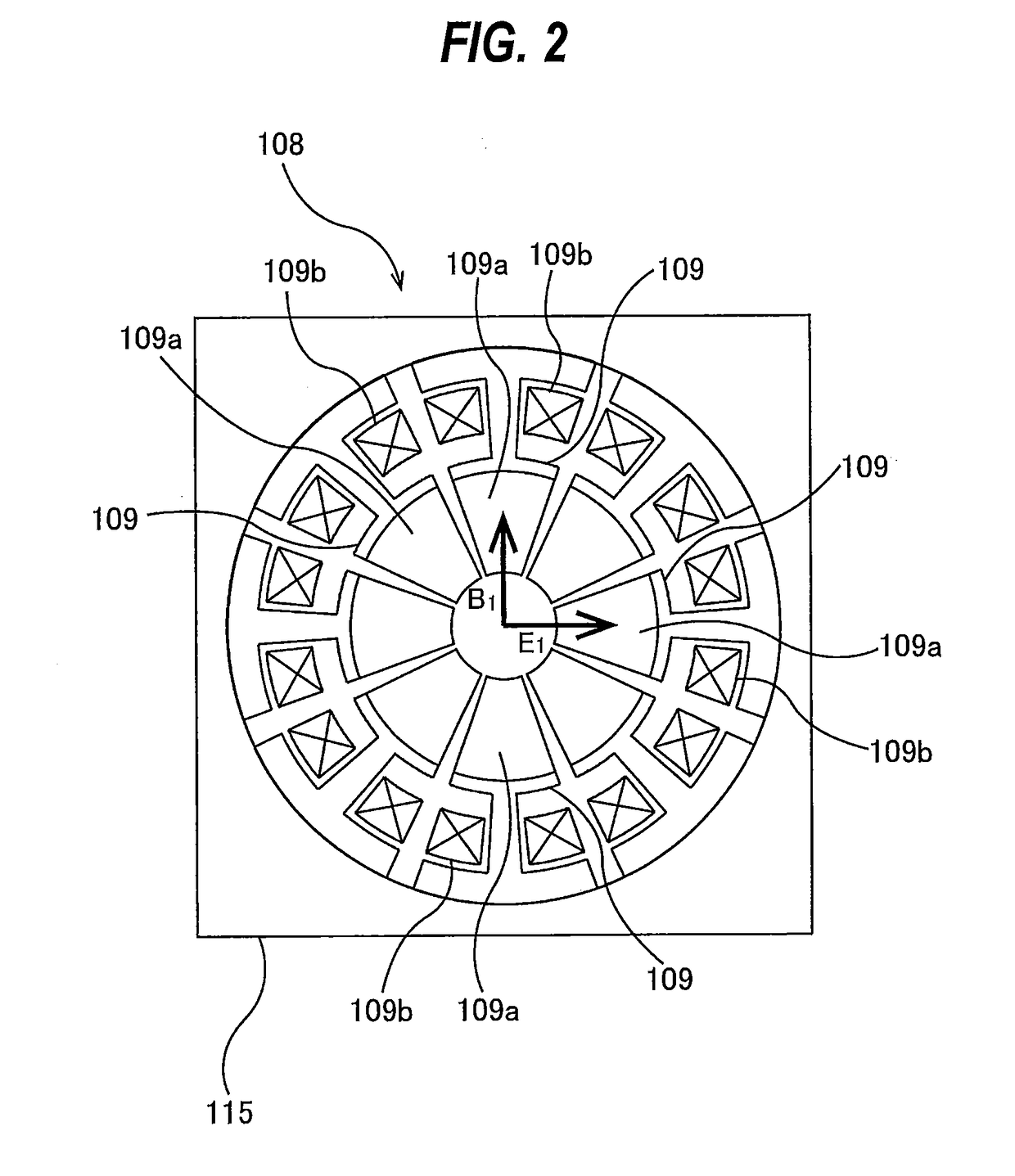

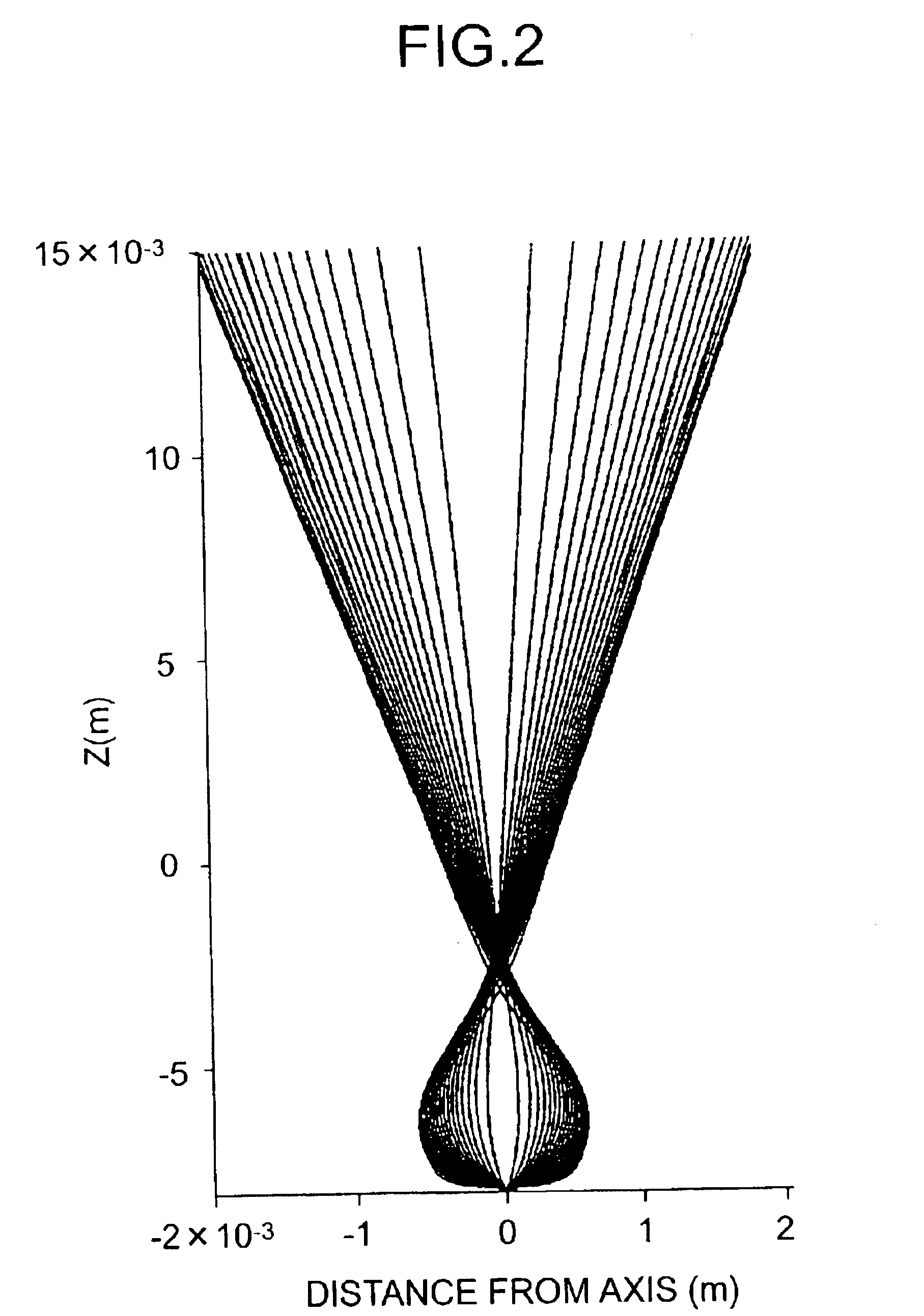

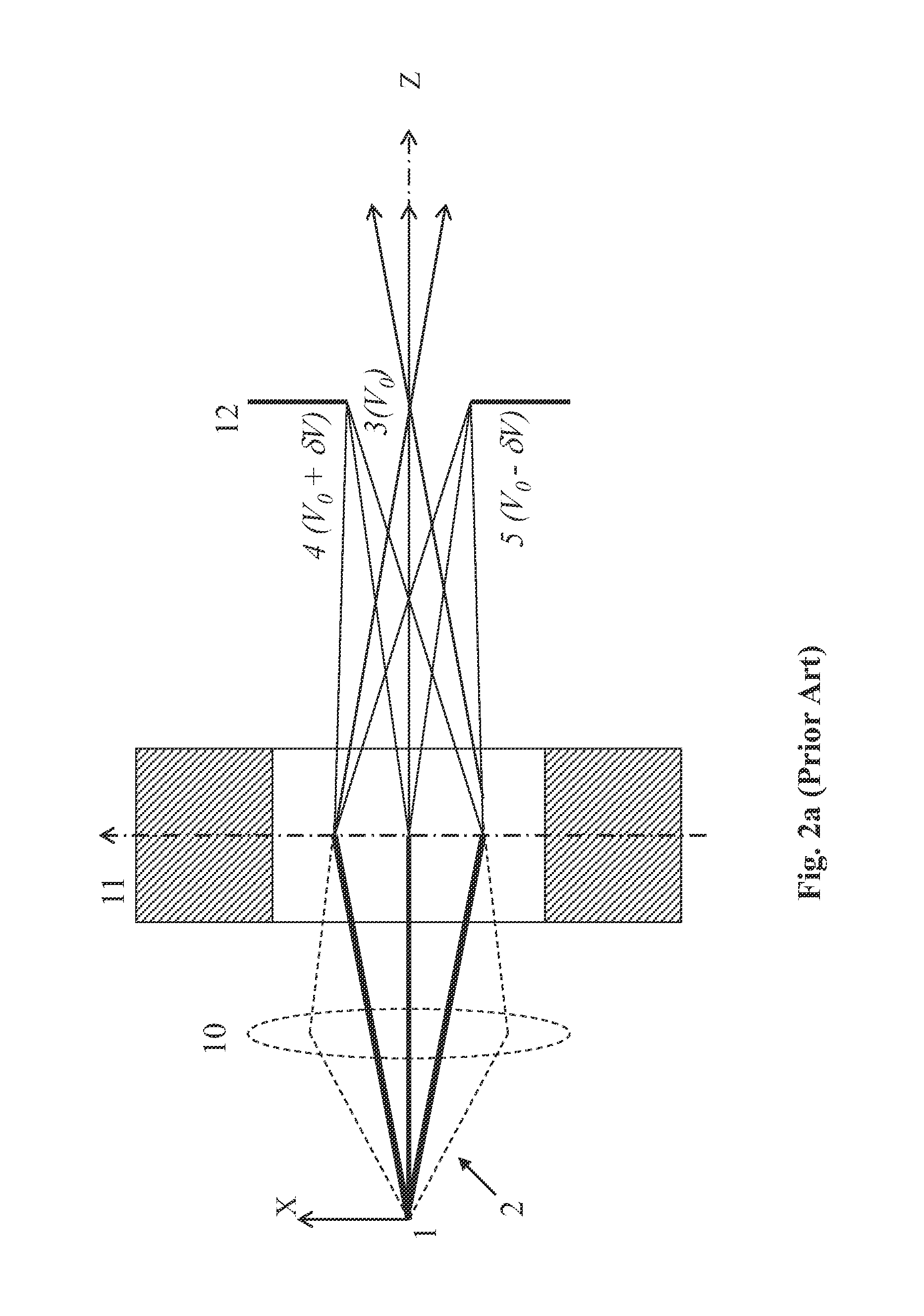

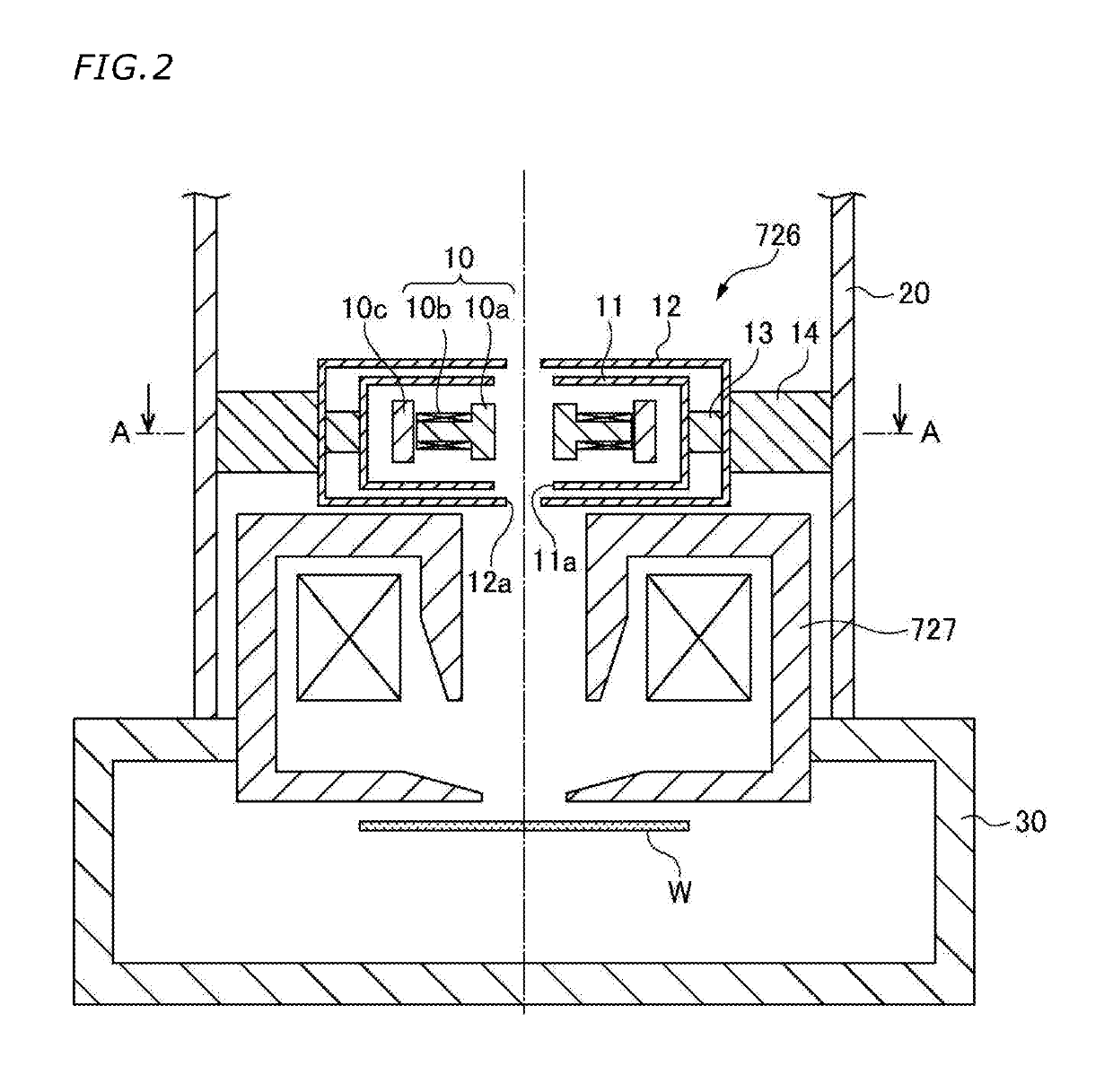

Electron beam apparatus and an aberration correction optical apparatus

ActiveUS20080067377A1High resolutionIncrease volumeMaterial analysis using wave/particle radiationSemiconductor/solid-state device manufacturingIntermediate imageWien filter

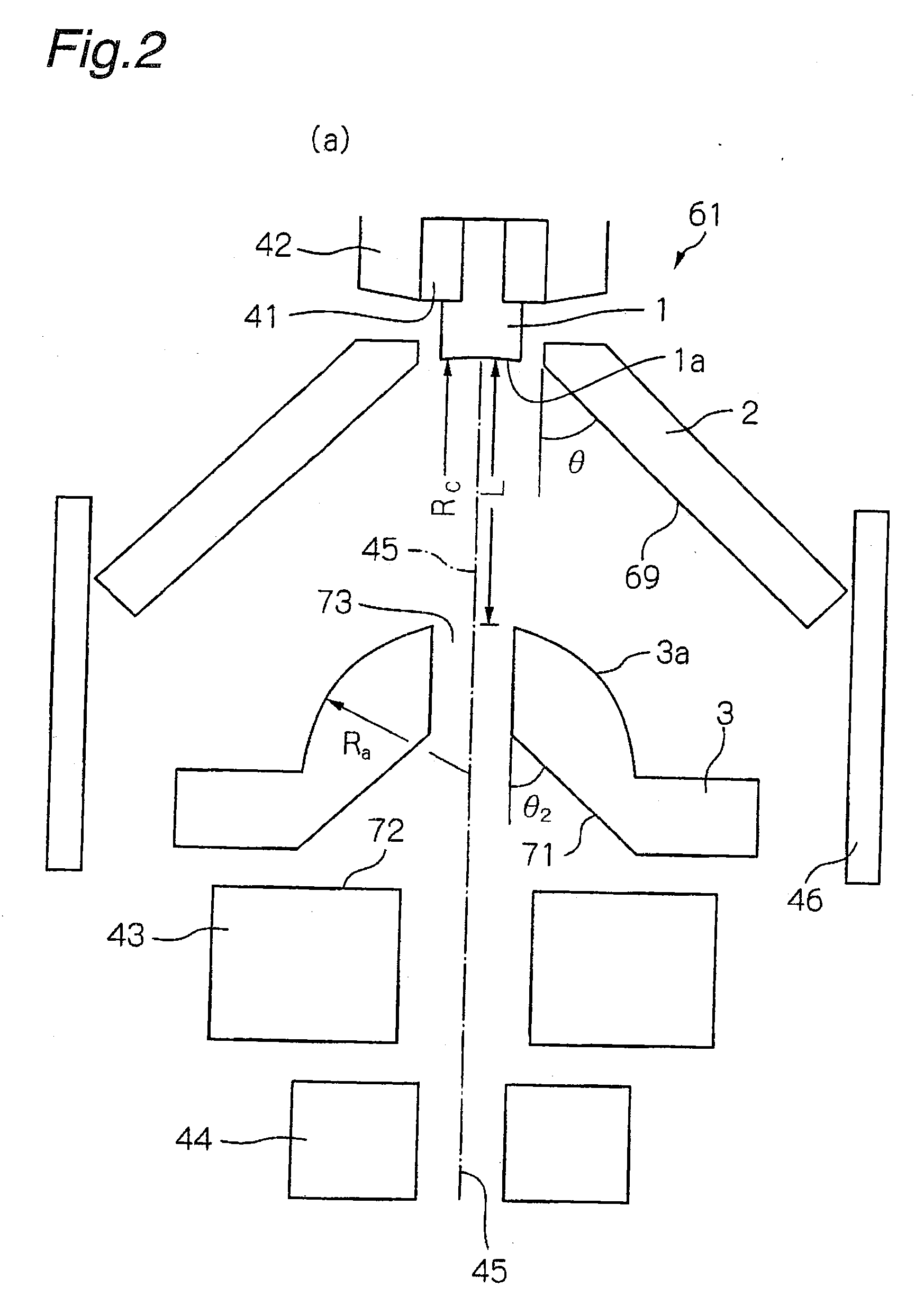

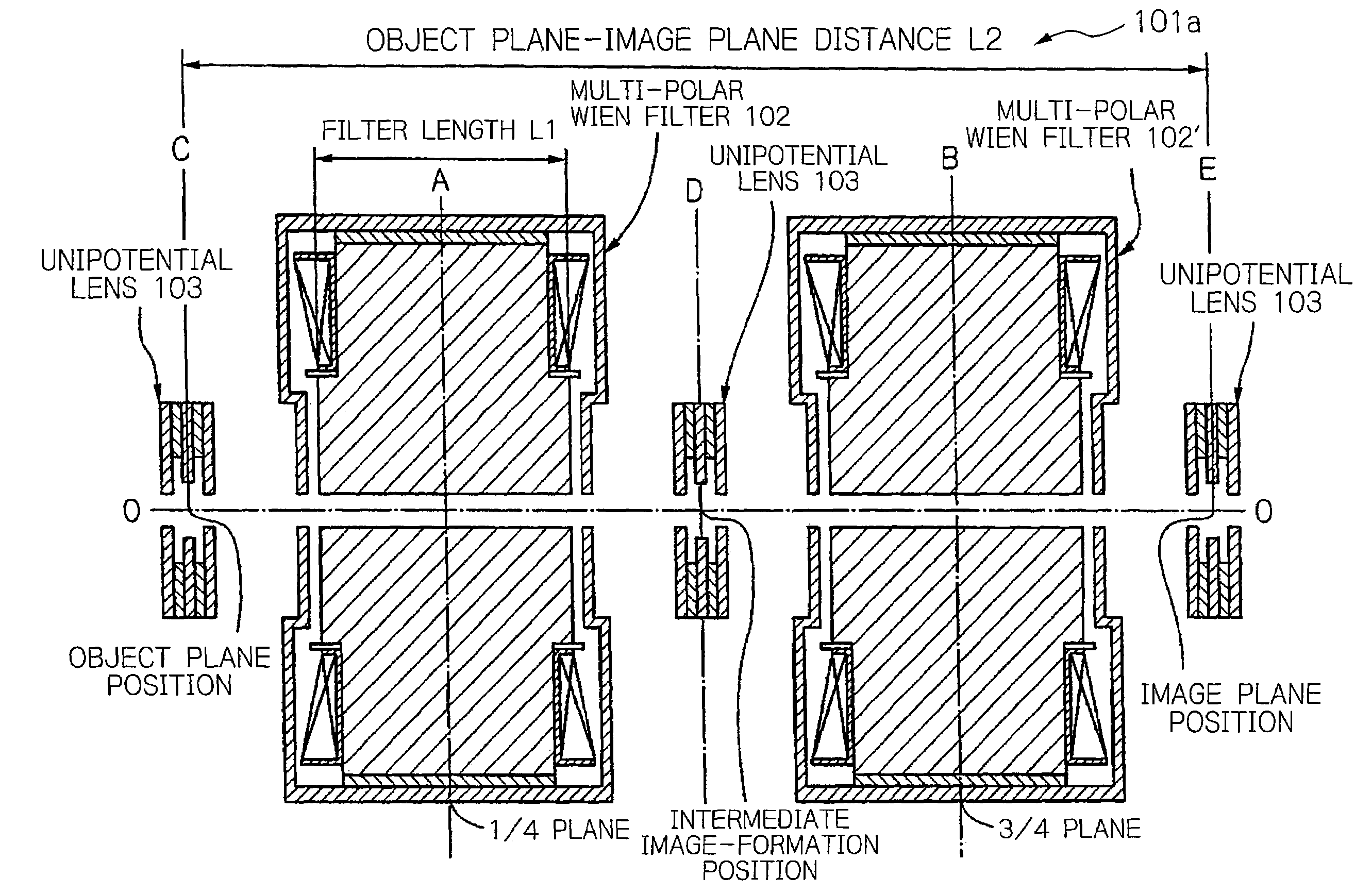

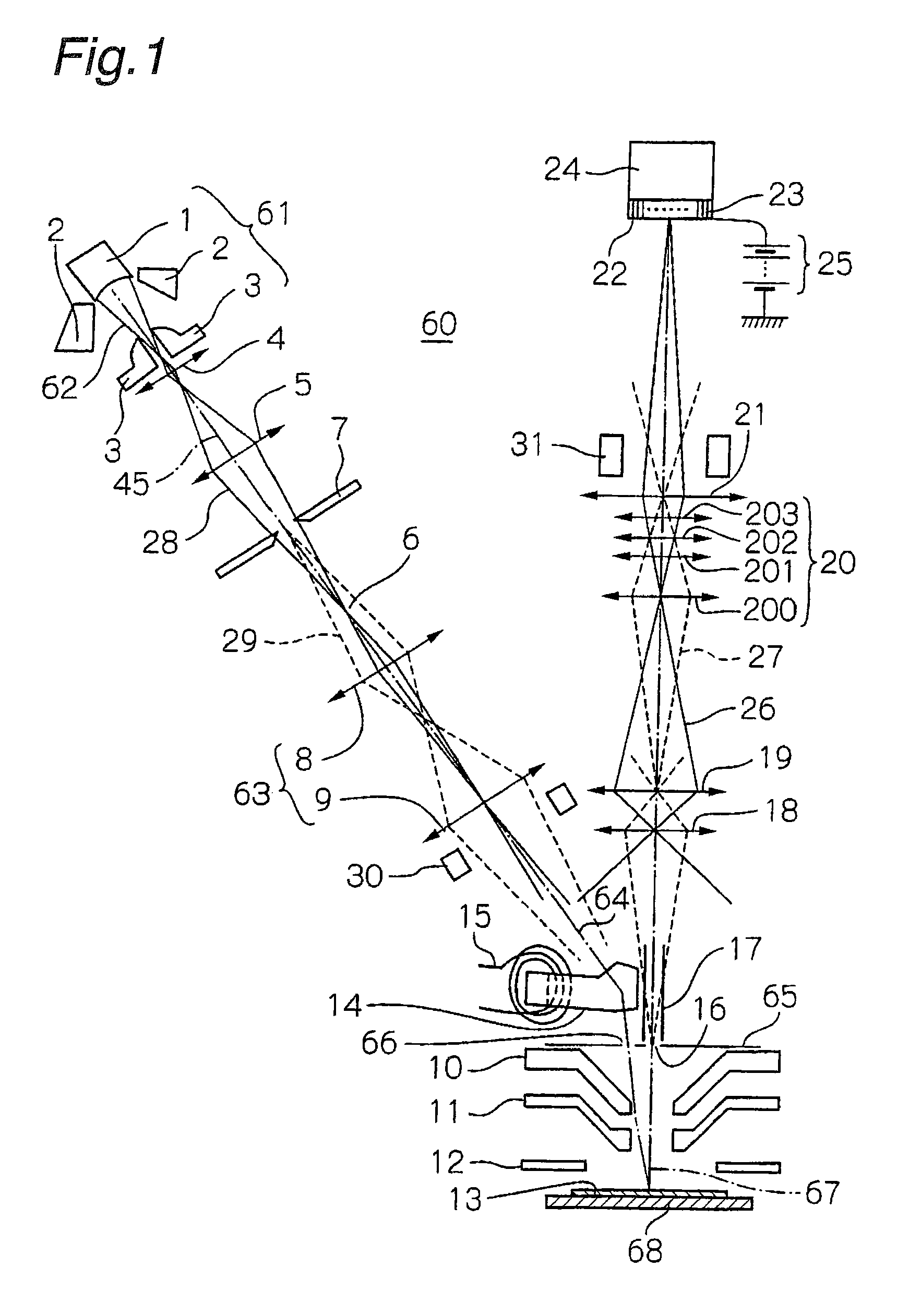

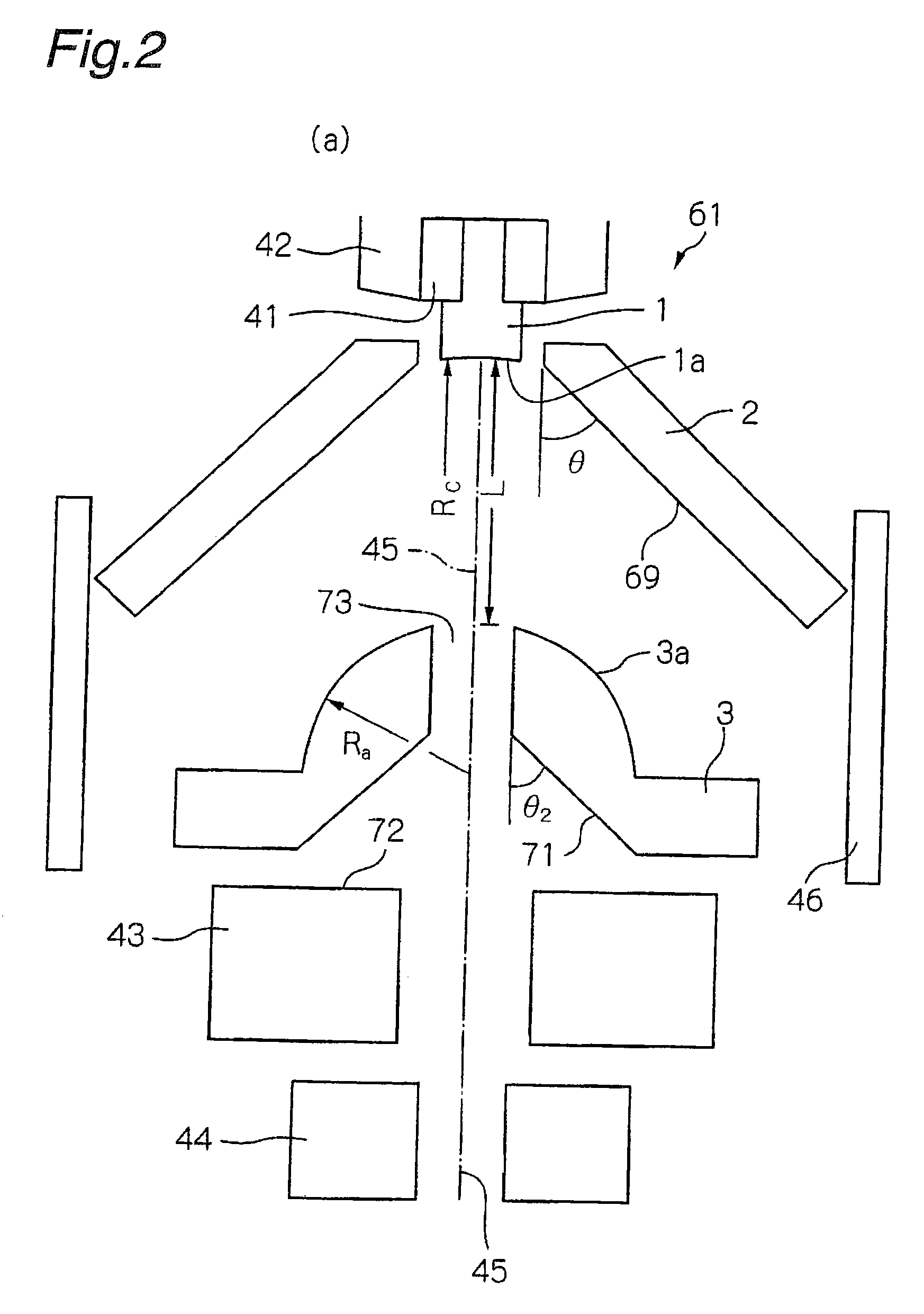

An electron beam apparatus for providing an evaluation of a sample, such as a semiconductor wafer, that includes a micro-pattern with a minimum line width not greater than 0.1 μm with high throughput. A primary electron beam generated by an electron gun is irradiated onto a sample and secondary electrons emanating from the sample are formed into an image on a detector by an image projection optical system. An electron gun 61 has a cathode 1 and a drawing electrode 3, and an electron emission surface 1a of the cathode defines a concave surface. The drawing electrode 3 has a convex surface 3a composed of a partial outer surface of a second sphere facing the electron emission surface 1a of the cathode and an aperture 73 formed through the convex surface for passage of the electrons. An aberration correction optical apparatus comprises two identically sized multi-polar Wien filters arranged such that their centers are in alignment with a 1 / 4 plane position and a ¾ plane position, respectively, along an object plane-image plane segment in the aberration correction optical apparatus, and optical elements having bidirectional focus disposed in an object plane position, an intermediate image-formation plane position and an image plane position, respectively, in the aberration correction optical apparatus.

Owner:EBARA CORP

Wien filter and electron microscope using same

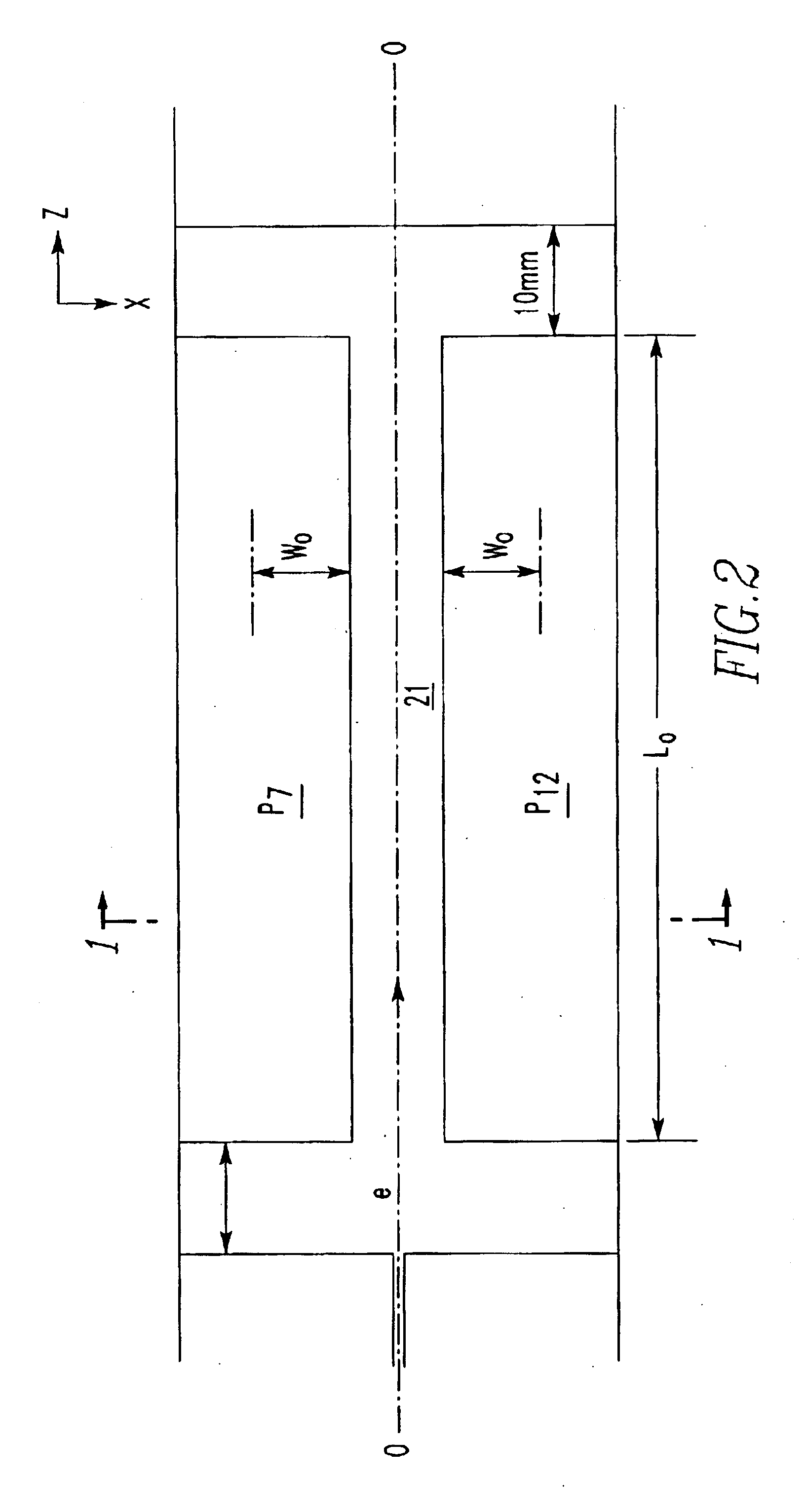

InactiveUS6844548B2Stability-of-path spectrometersMaterial analysis using wave/particle radiationOptical axisWien filter

A Wien filter is provided in which a less amount of secondary aberration is produced than conventional. This filter has 12 poles. These poles have front ends facing the optical axis. These front ends have a 12-fold rotational symmetry about the optical axis within the XY-plane perpendicular to the optical axis.

Owner:JEOL LTD

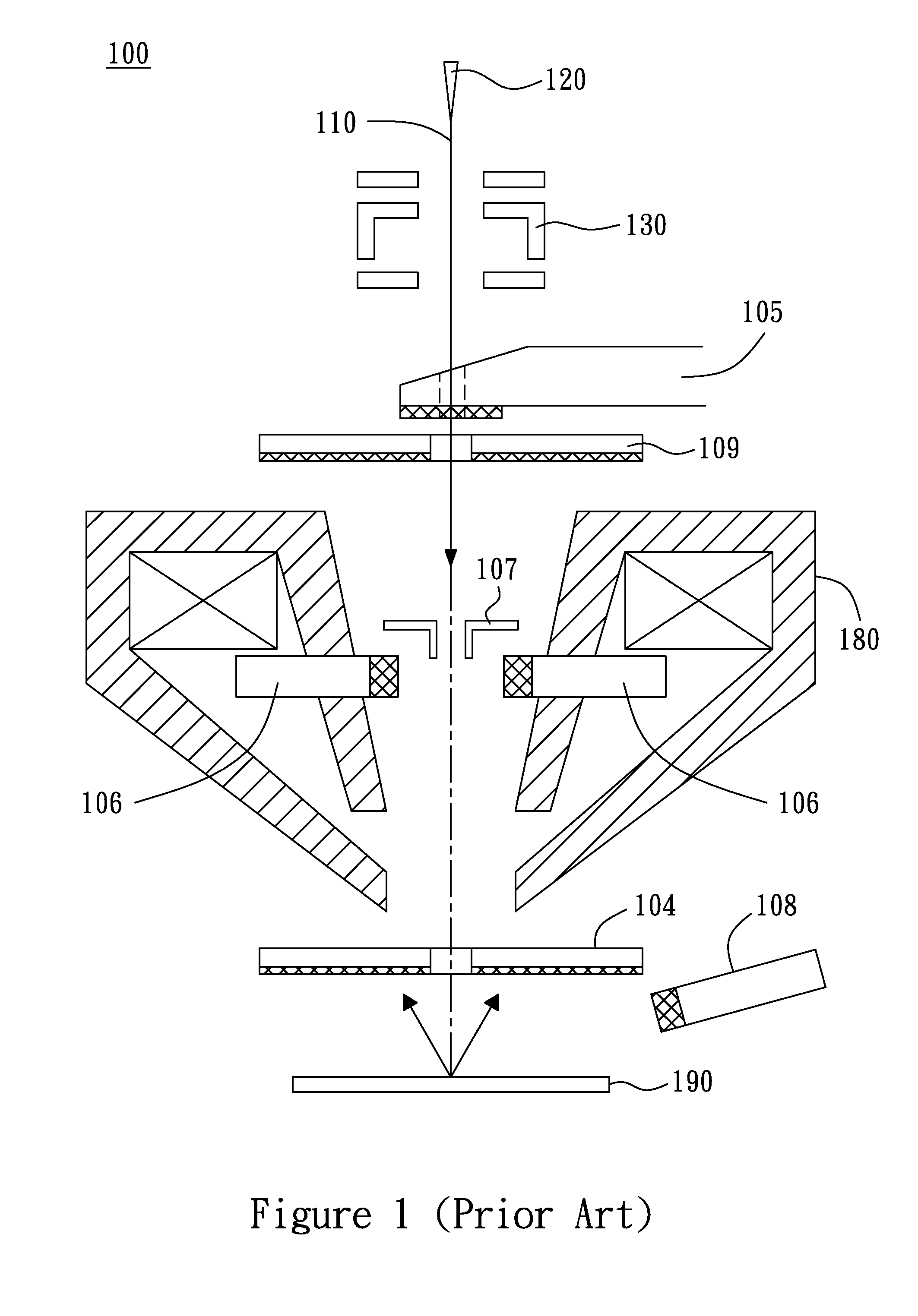

Method and Compound System for Inspecting and Reviewing Defects

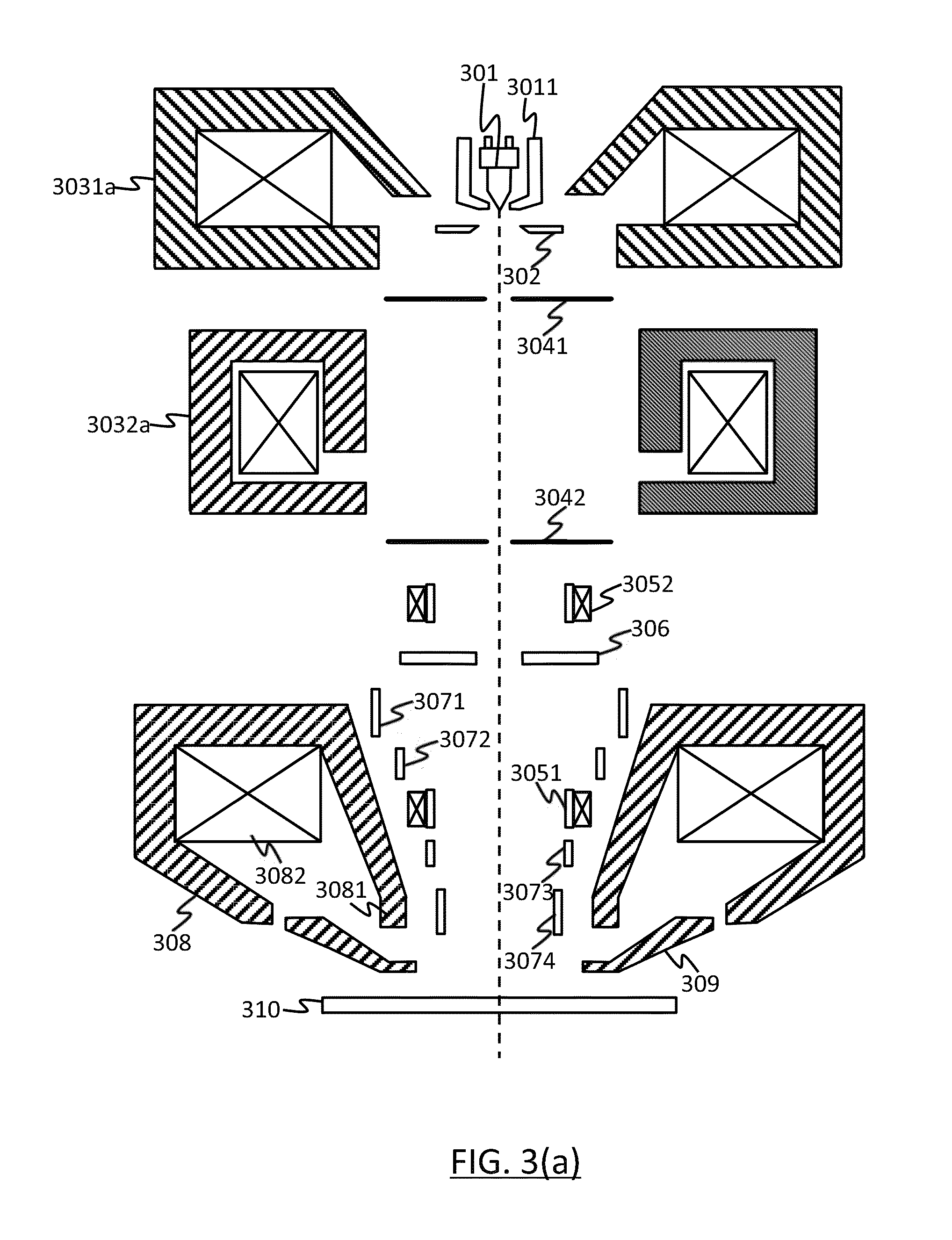

ActiveUS20160163502A1Small scanningLow costMaterial analysis using wave/particle radiationElectric discharge tubesWien filterLight beam

The present invention provides an improved electron-optical apparatus for the inspection and review of the specimen, and for the defect inspection, an inspection mode of operation is performed to generate inspection data, wherein the large beam current is formed by a magnetic immersion lens to scan the specimen, and preferably the objective lens system, a swing objective retarding immersion lens, focuses the beam current and generates the large scanning field, and for the defect review, the review mode of operation is performed to analyze the defects, wherein the large beam current is abandoned and the small beam current is adopted to examine the specimen without a large scanning field, and in order to properly select and detect signal charged particles excited from the specimen, a first Wien filter is utilized to select the acquired signal particles and a second Wien filter is used to compensate the aberrations induced when the signal particles pass through the first Wien filter.

Owner:ASML NETHERLANDS BV

Electron beam apparatus and an aberration correction optical apparatus

ActiveUS7863580B2Minimize blurred focusReduce brightnessStability-of-path spectrometersMaterial analysis using wave/particle radiationIntermediate imageWien filter

An electron beam apparatus for providing an evaluation of a sample, such as a semiconductor wafer, that includes a micro-pattern with a minimum line width not greater than 0.1 μm with high throughput. A primary electron beam generated by an electron gun is irradiated onto a sample and secondary electrons emanating from the sample are formed into an image on a detector by an image projection optical system. An electron gun 61 has a cathode 1 and a drawing electrode 3, and an electron emission surface 1a of the cathode defines a concave surface. The drawing electrode 3 has a convex surface 3a composed of a partial outer surface of a second sphere facing the electron emission surface 1a of the cathode and an aperture 73 formed through the convex surface for passage of the electrons. An aberration correction optical apparatus comprises two identically sized multi-polar Wien filters arranged such that their centers are in alignment with a ¼ plane position and a ¾ plane position, respectively, along an object plane-image plane segment in the aberration correction optical apparatus, and optical elements having bidirectional focus disposed in an object plane position, an intermediate image-formation plane position and an image plane position, respectively, in the aberration correction optical apparatus.

Owner:EBARA CORP

Electron beam apparatus

ActiveUS8067732B2Improve throughputImprove processing speedMaterial analysis using wave/particle radiationElectric discharge tubesPath lengthWien filter

An electron beam emitted from an electron gun (G) forms a reduced image on a sample (S) through a non-dispersion Wien-filter (5-1), an electromagnetic deflector (11-1), a beam separator (12-1), and a tablet lens (17-1) as an objective lens. The beam separator (12-1) is configured such that a distance by which a secondary electron beam passes through the beam separator is approximately three times longer than a distance by which a primary electron beam passes through the beam separator. Therefore, even if a magnetic field in the beam separator is set to deflect the primary electron beam by a small angle equal to or less than approximately 10 degrees, the secondary electron beam can be deflected by approximately 30 degrees, so that the primary and secondary electron beams are sufficiently separated. Also, since the primary electron beam is deflected by a small angle, less aberration occurs in the primary electron beam. Accordingly, since a light path length of a primary electro-optical system, it is possible to reduce the influence of space charge and the occurrence of deflection aberration.

Owner:KIOXIA CORP

Charged particle beam detection unit with multi type detection subunits

ActiveUS8350213B2Stability-of-path spectrometersBeam/ray focussing/reflecting arrangementsPower flowWien filter

A detection unit of a charged particle imaging system includes a multi type detection subunit in the charged particle imaging system, with the assistance of a Wien filter (also known as an E×B charged particle analyzer). The imaging system is suitable for a low beam current, high resolution mode and a high beam current, high throughput mode. The unit can be applied to a scanning electron inspection system as well as to other systems that use a charged particle beam as an observation tool.

Owner:ASML NETHERLANDS BV

Electron beam apparatus

An electron beam apparatus has an optical axis, an electron beam source for generating an electron beam directed along the optical axis, and a magnetic field lens having an axis coincident with the optical axis for focusing the electron beam onto a sample which is subjected to a negative voltage so that secondary electrons are emitted from the sample. The magnetic field lens has a conductive cylinder surrounding a part of the optical axis to permit the passage therethrough of an electron beam from the electron beam source. A first detector detects secondary electrons emitted by the sample in a direction away from the optical axis and is disposed at a position generally confronting the conductive cylinder. A second detector is disposed over the conductive cylinder. A Wien filter deflector deflects secondary electrons emitted by the sample toward and for detection by the second detector. The Wien filter deflector is disposed on the optical axis and between the conductive cylinder and the second detector.

Owner:HITACHI HIGH TECH SCI CORP

Wien filter

ActiveUS20130112889A1Minimize aberrationReduced structureStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsHarmonicWien filter

This invention provides a multi-pole type Wien filter, which acts more purely approaching its fundamentally expected performance. A 12-electrode electric device acts as an electric deflector,or acts as an electric deflector and an electric stigmator together. A cylindrical 4-coil magnetic device with a magnetic core acts as a magnetic deflector. Both can produce a dipole field while only incurring a negligibly-small 3rd order field harmonic. The magnetic core enhances the strength and more preciously regulates the distribution of the magnetic field originally generated by the coils. Then two ways to construct a Wien filter are proposed. One way is based on both of the foregoing electric and magnetic devices, and the other way is based on the foregoing electric device and a conventional magnetic deflector. The astigmatism in each of such Wien filters can be compensated by the electric stigmator of the electric device.

Owner:ASML NETHERLANDS BV

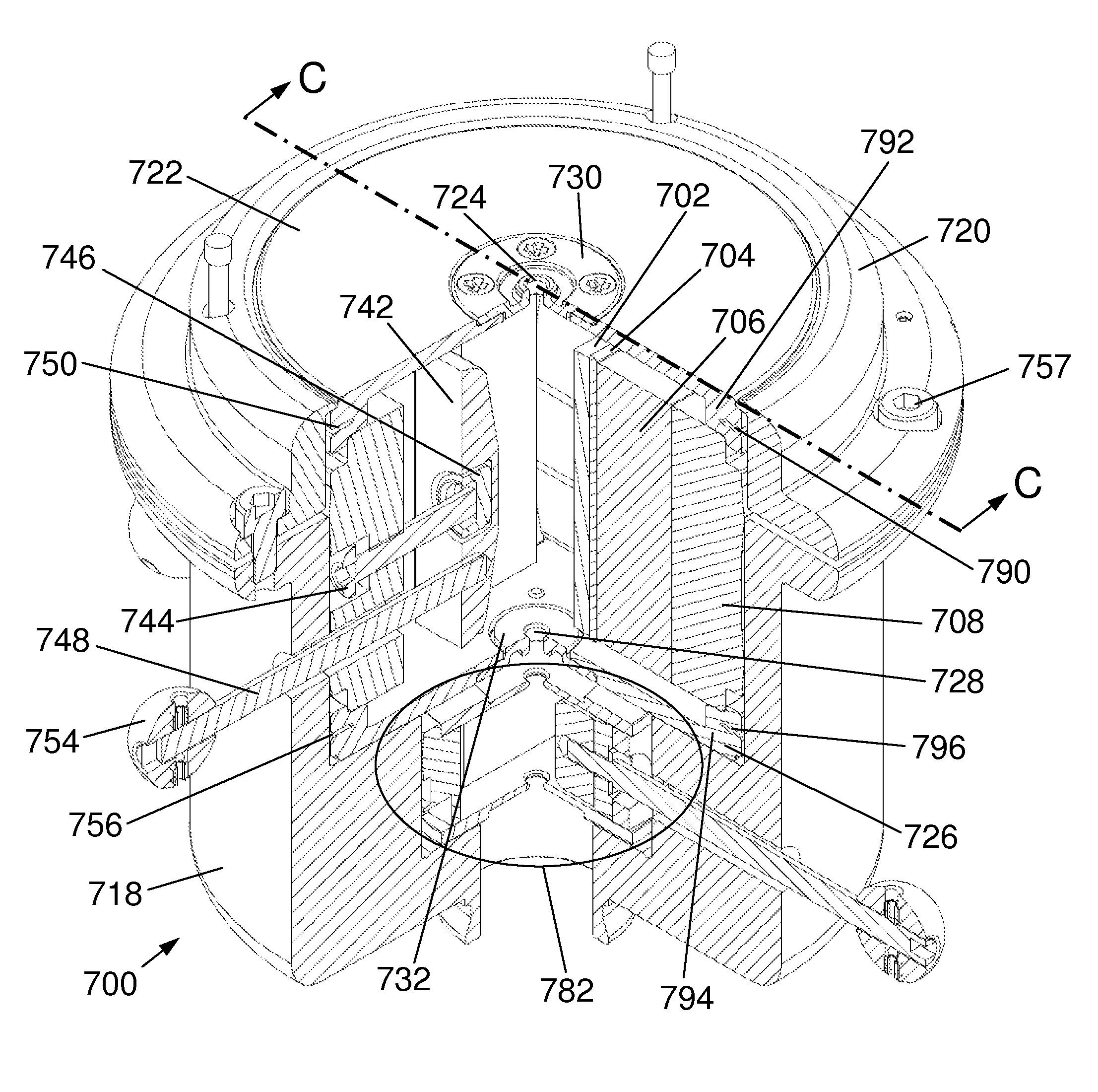

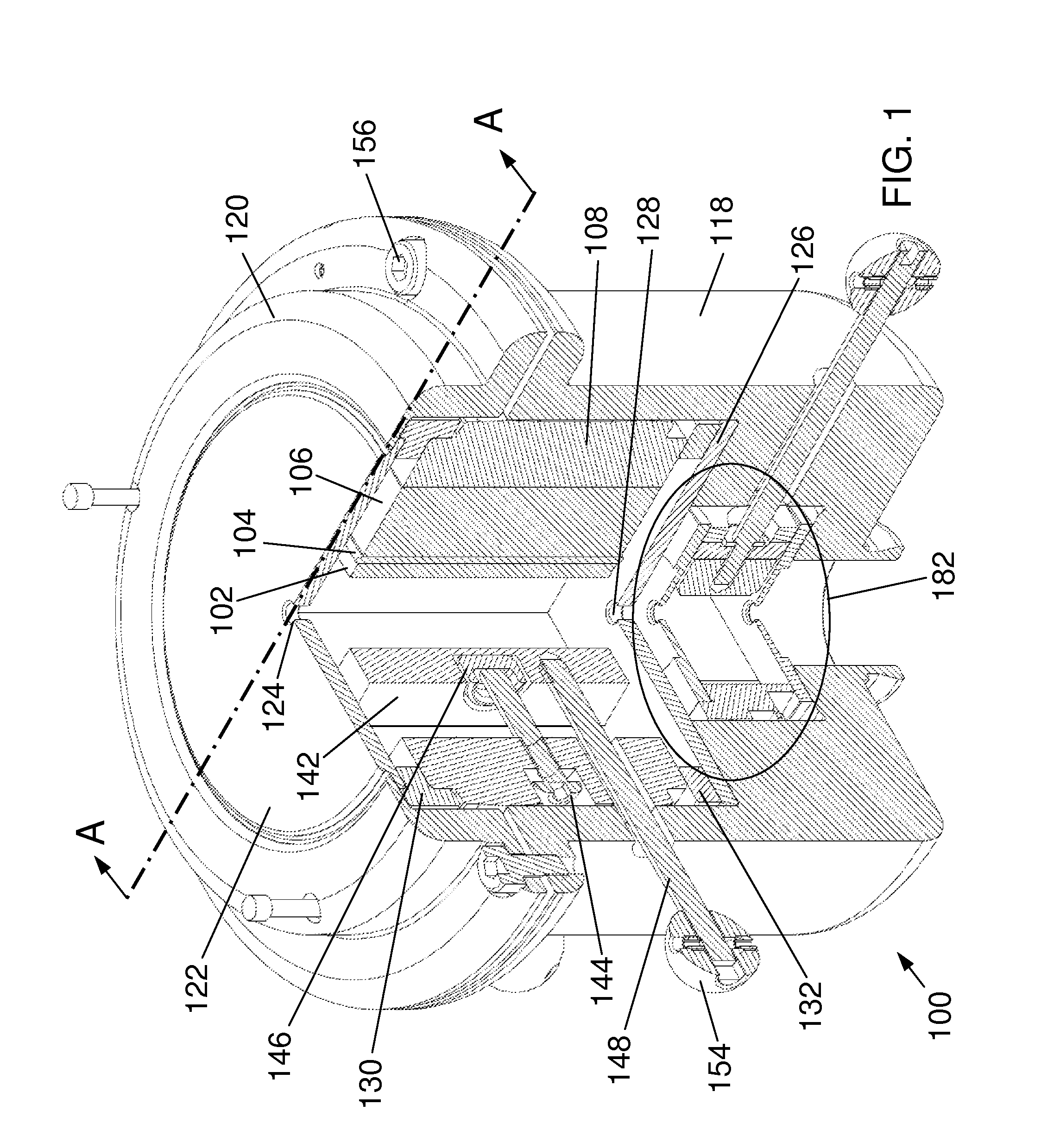

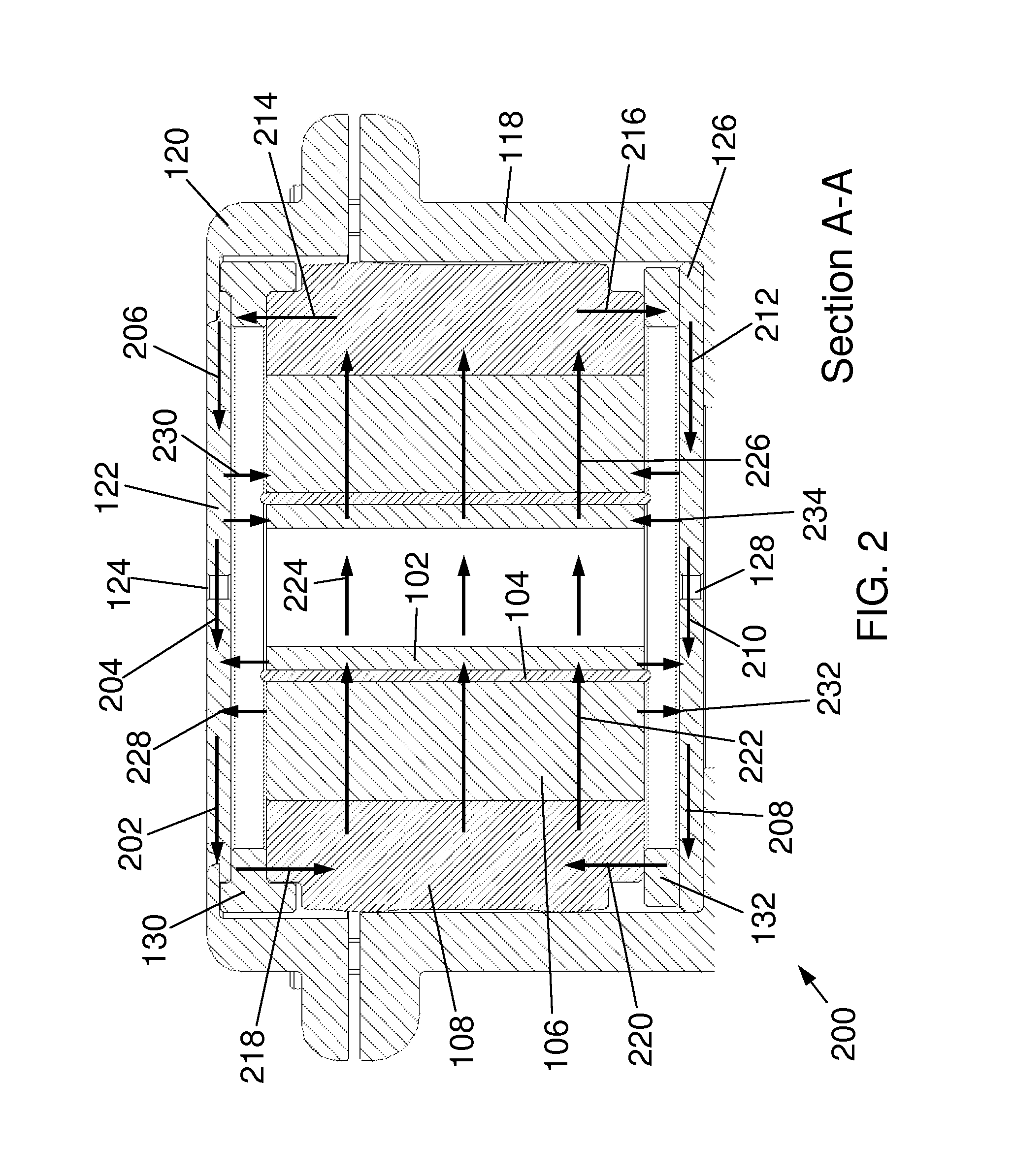

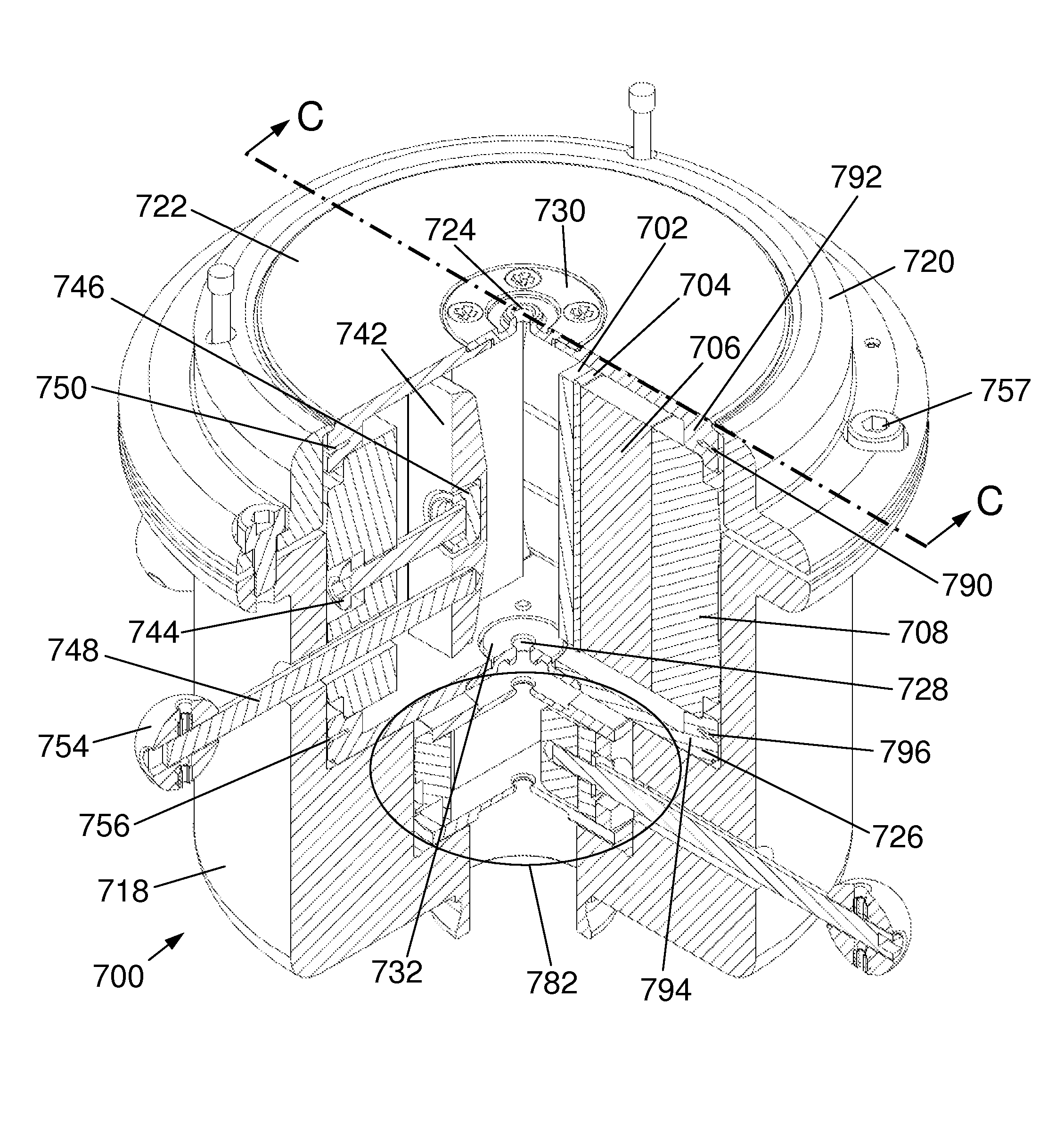

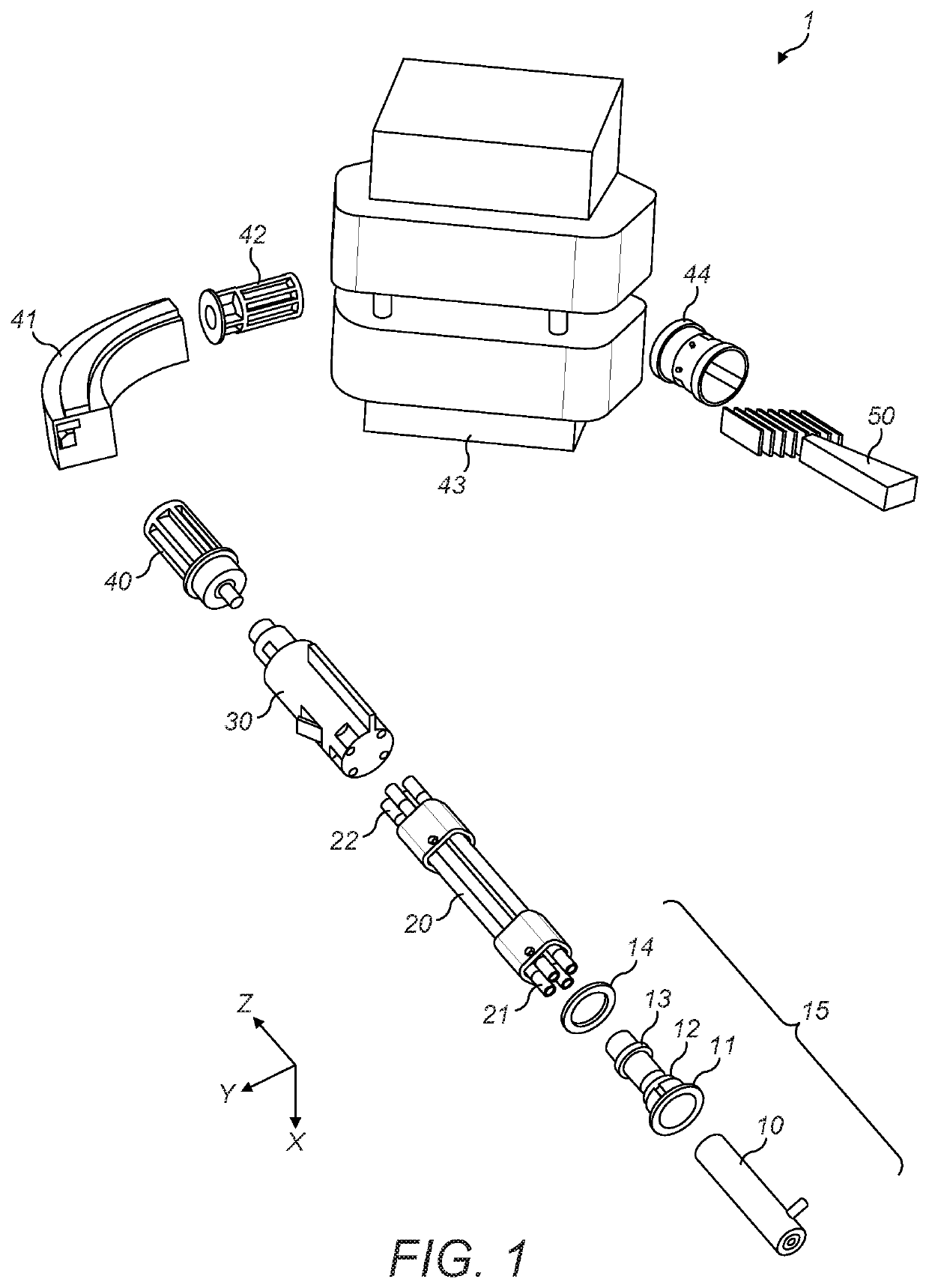

Method and Structure for Controlling Magnetic Field Distributions in an ExB Wien Filter

ActiveUS20120292497A1Improve matchShorten the lengthIsotope separationStatic spectrometersWien filterEarth's magnetic field

An ExB Wien mass filter providing a method and structure for mechanically adjusting the magnetic field distributions at the mass filter entrance and exit end caps. The reluctance of the flux return path may be modified by configuring pluralities of magnetic shims within slots at the outer diameters of the entrance and exit end caps, and also by configuring pluralities of magnetic plug shims within circular flux dams surrounding the entrance and exit apertures. Advantages of purely mechanical adjustment for the magnetic fields of the present invention, compared with prior art electromagnet adjustment methods include greater reliability, simplicity, lower cost, and lack of power dissipation. The invention may employ either permanent magnets or electromagnets for generation of the mass-separation magnetic field.

Owner:FEI CO

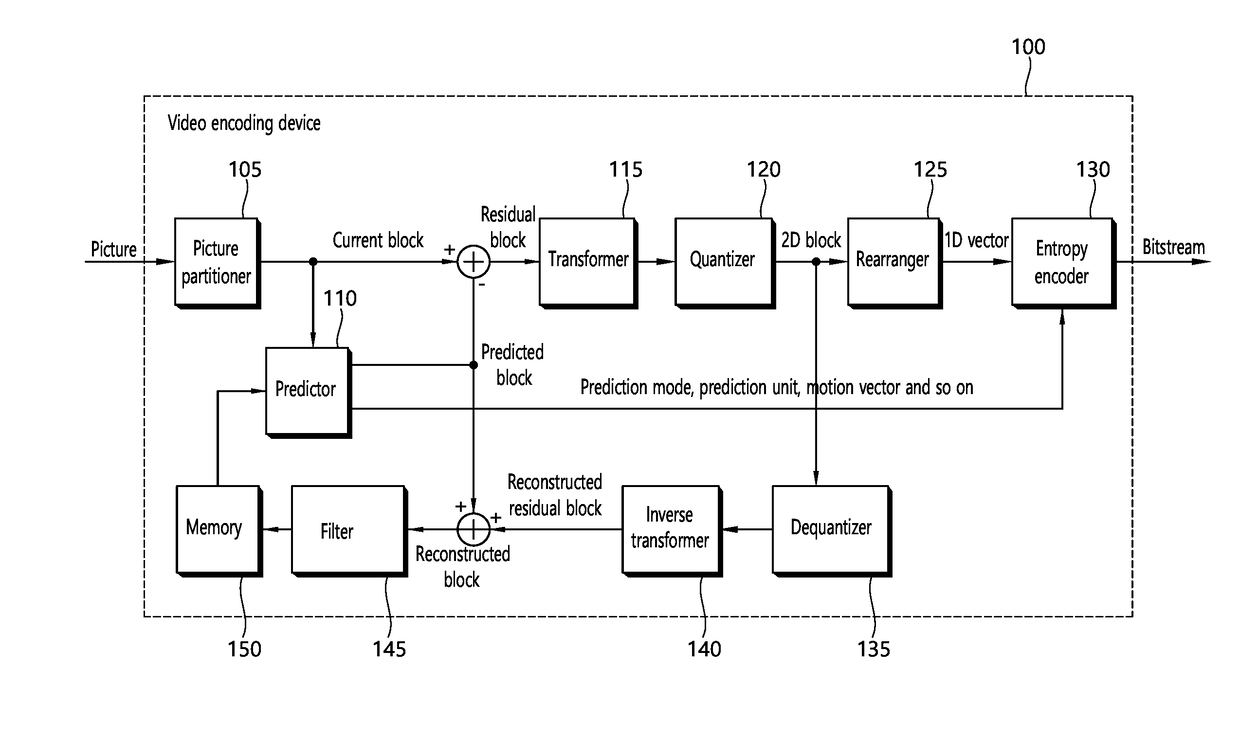

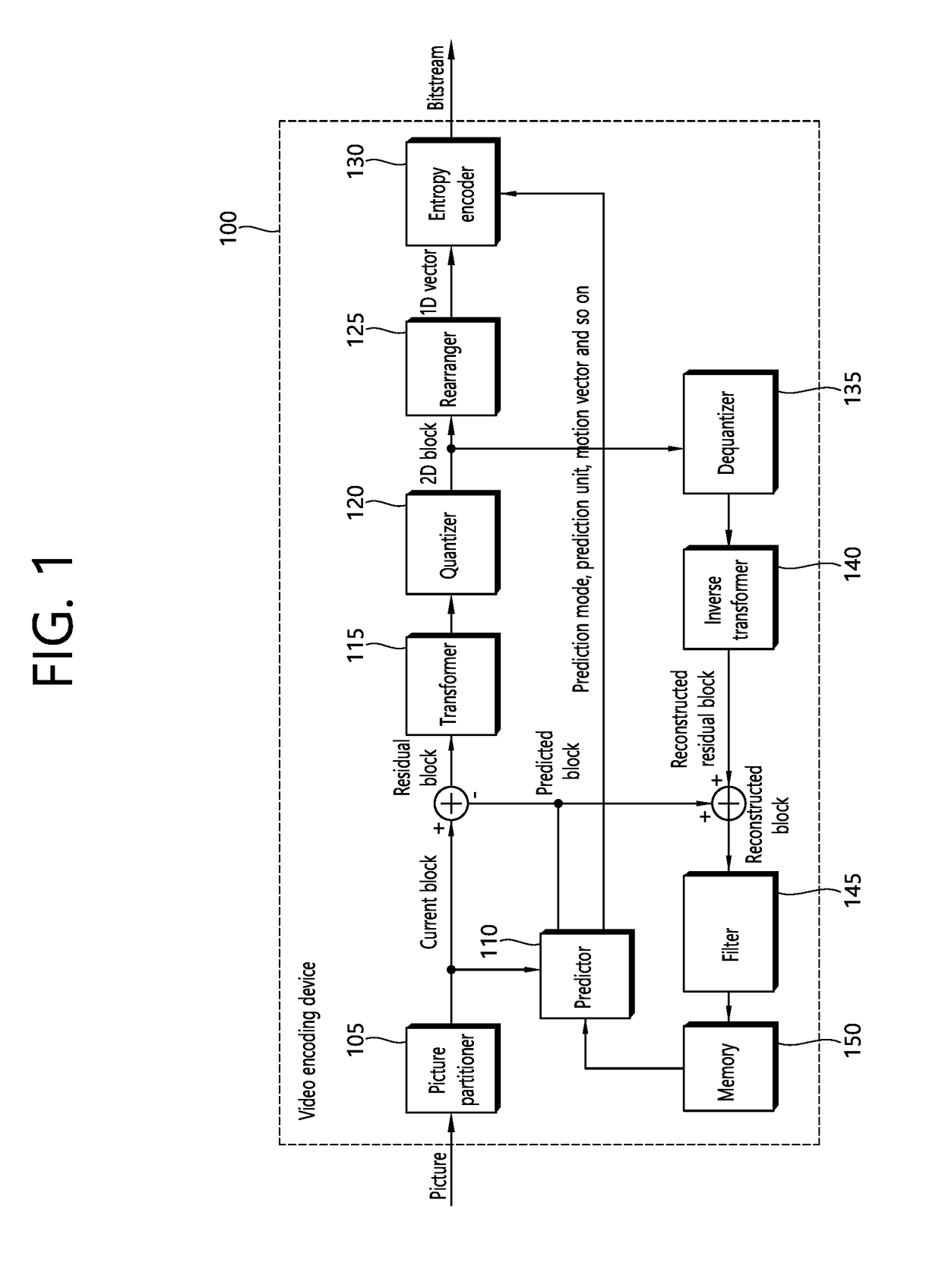

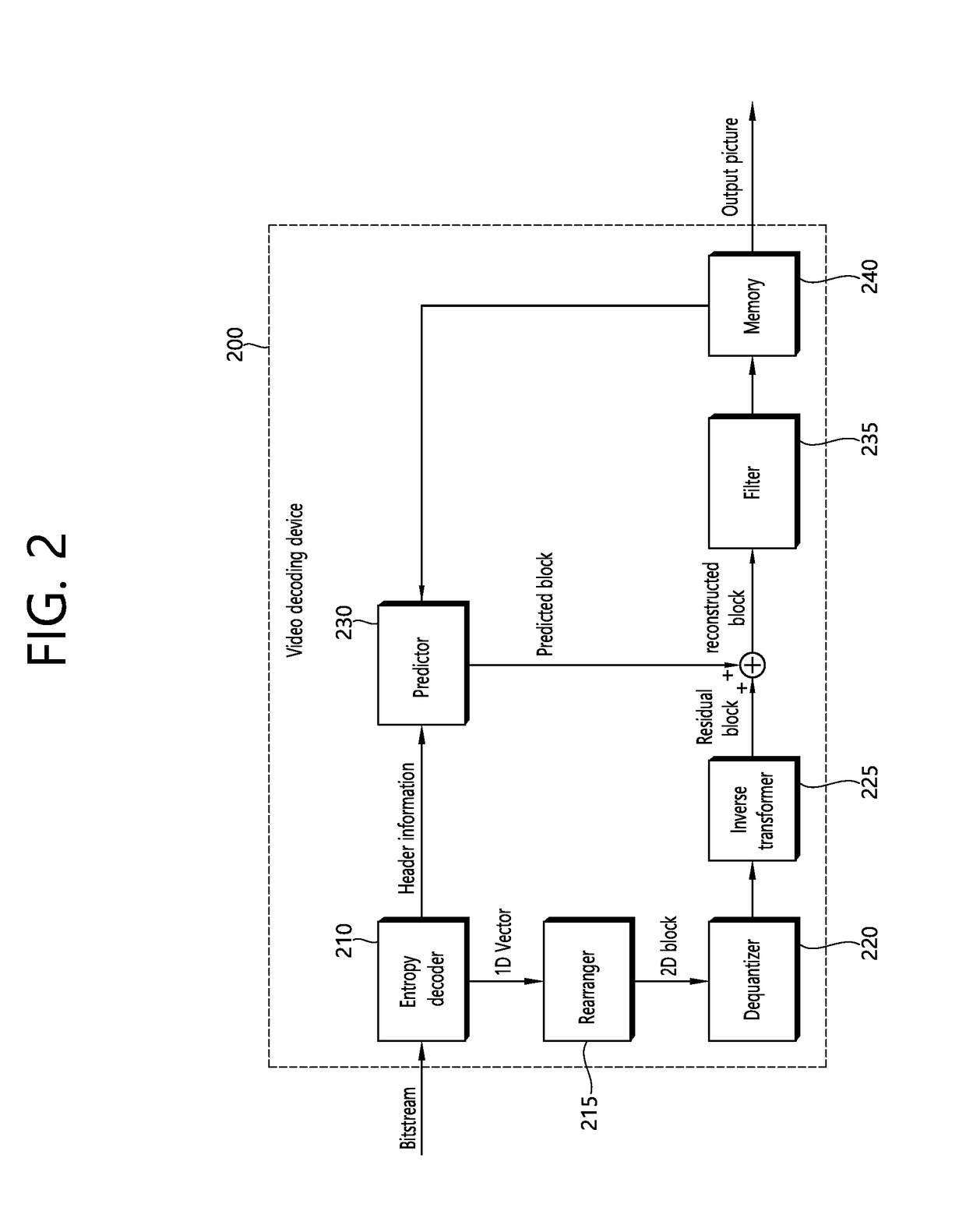

Filtering method and apparatus for improving prediction in image coding system

ActiveUS20180309987A1Efficiently derivedImprove coding efficiencyDigital video signal modificationRelevant informationWien filter

An inter prediction method according to the present invention, which is performed by a decoding apparatus, comprises the steps of: acquiring prediction-related information and residual information from a received bitstream; performing inter prediction on a current block on the basis of the prediction-related information so as to generate prediction samples; generating a list of Wiener filter candidates on the basis of spatially neighboring blocks of the current block, and deriving Wiener filter coefficients for the current block on the basis of candidate blocks in the list of the Wiener filter candidates; filtering the prediction samples on the basis of the derived Wiener filter coefficients; deriving residual samples for the current block on the basis of the residual information; and generating a reconstructed picture on the basis of the filtered prediction samples and the residual samples. The present invention can reduce the amount of data for a residual signal and improve coding efficiency.

Owner:LG ELECTRONICS INC

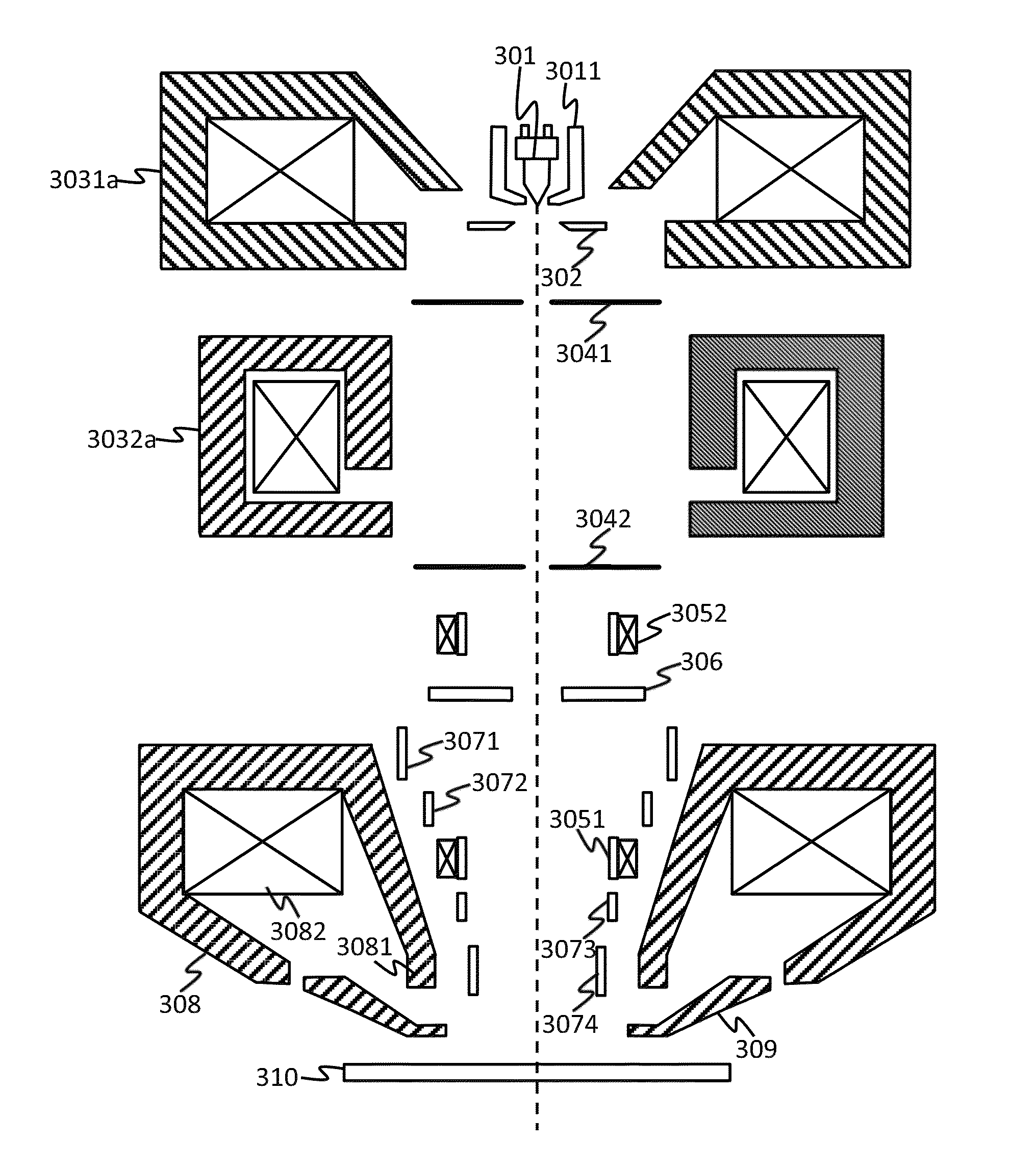

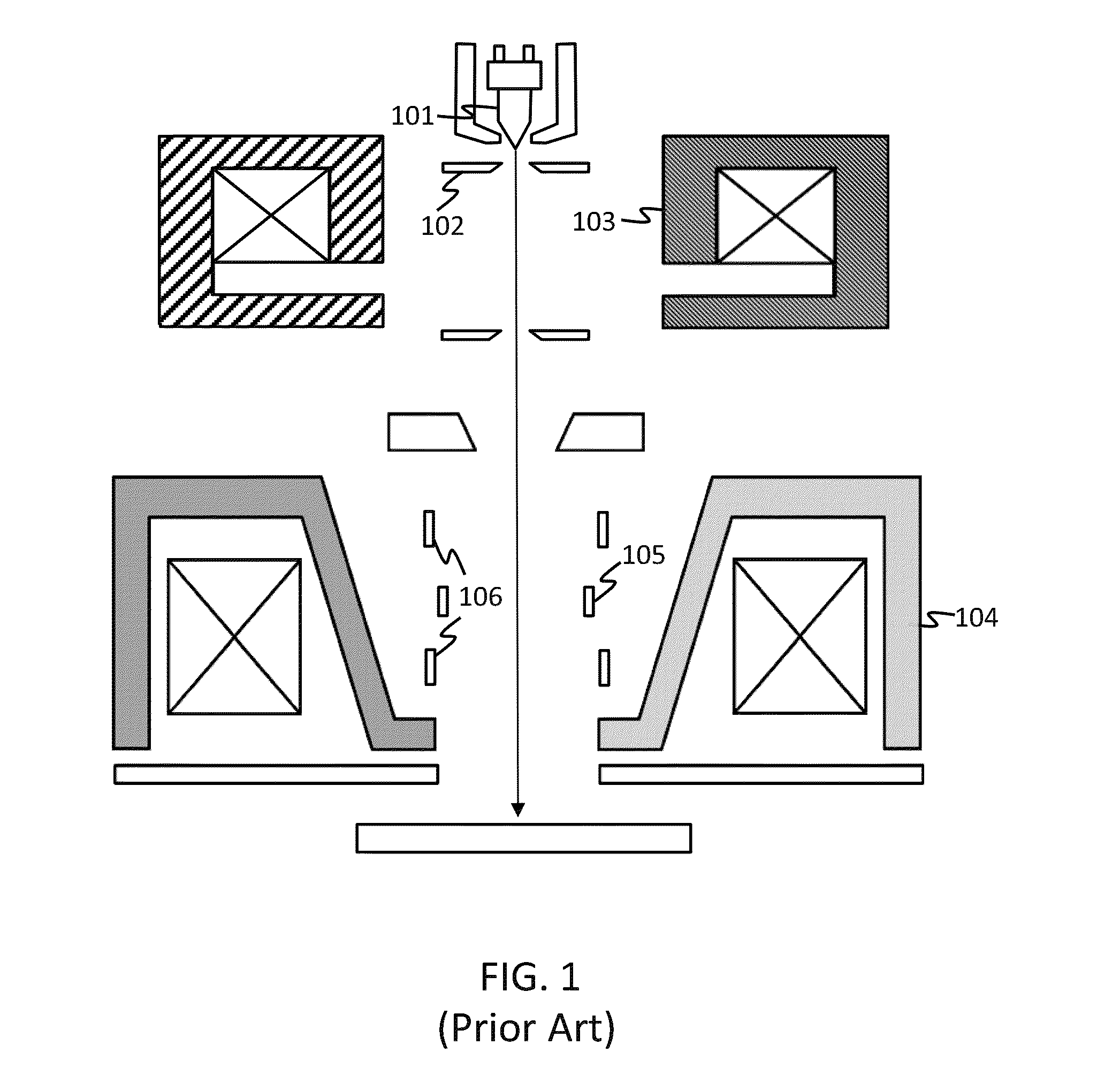

Method and compound system for inspecting and reviewing defects

The present invention provides an improved electron-optical apparatus for the inspection and review of the specimen, and for the defect inspection, an inspection mode of operation is performed to generate inspection data, wherein the large beam current is formed by a magnetic immersion lens to scan the specimen, and preferably the objective lens system, a swing objective retarding immersion lens, focuses the beam current and generates the large scanning field, and for the defect review, the review mode of operation is performed to analyze the defects, wherein the large beam current is abandoned and the small beam current is adopted to examine the specimen without a large scanning field, and in order to properly select and detect signal charged particles excited from the specimen, a first Wien filter is utilized to select the acquired signal particles and a second Wien filter is used to compensate the aberrations induced when the signal particles pass through the first Wien filter.

Owner:ASML NETHERLANDS BV

Monochromator for charged particle beam apparatus

ActiveUS8592761B2Weaken energyImprove imaging resolutionStability-of-path spectrometersMaterial analysis using wave/particle radiationElectron sourceWien filter

The monochromator for reducing energy spread of a primary charged particle beam in charged particle apparatus comprises a beam adjustment element, two Wien-filter type dispersion units and an energy-limit aperture. In the monochromator, a dual proportional-symmetry in deflection dispersion and fundamental trajectory along a straight optical axis is formed, which not only fundamentally avoids incurring off-axis aberrations that actually can not be compensated but also ensures the exit beam have a virtual crossover which is stigmatic, dispersion-free and inside the monochromator. The present invention also provides two ways to build a monochromator into a SEM, in which one is to locate a monochromator between the electron source and the condenser, and another is to locate a monochromator between the beam-limit aperture and the objective. The former provides an additional energy-angle depending filtering, and obtains a smaller effective energy spread.

Owner:ASML NETHERLANDS BV

Method and structure for controlling magnetic field distributions in an ExB Wien filter

ActiveUS8835866B2Improve matchShorten the lengthMaterial analysis by optical meansIsotope separationWien filterElectromagnet

An ExB Wien mass filter providing a method and structure for mechanically adjusting the magnetic field distributions at the mass filter entrance and exit end caps. The reluctance of the flux return path may be modified by configuring pluralities of magnetic shims within slots at the outer diameters of the entrance and exit end caps, and also by configuring pluralities of magnetic plug shims within circular flux dams surrounding the entrance and exit apertures. Advantages of purely mechanical adjustment for the magnetic fields of the present invention, compared with prior art electromagnet adjustment methods include greater reliability, simplicity, lower cost, and lack of power dissipation. The invention may employ either permanent magnets or electromagnets for generation of the mass-separation magnetic field.

Owner:FEI CO

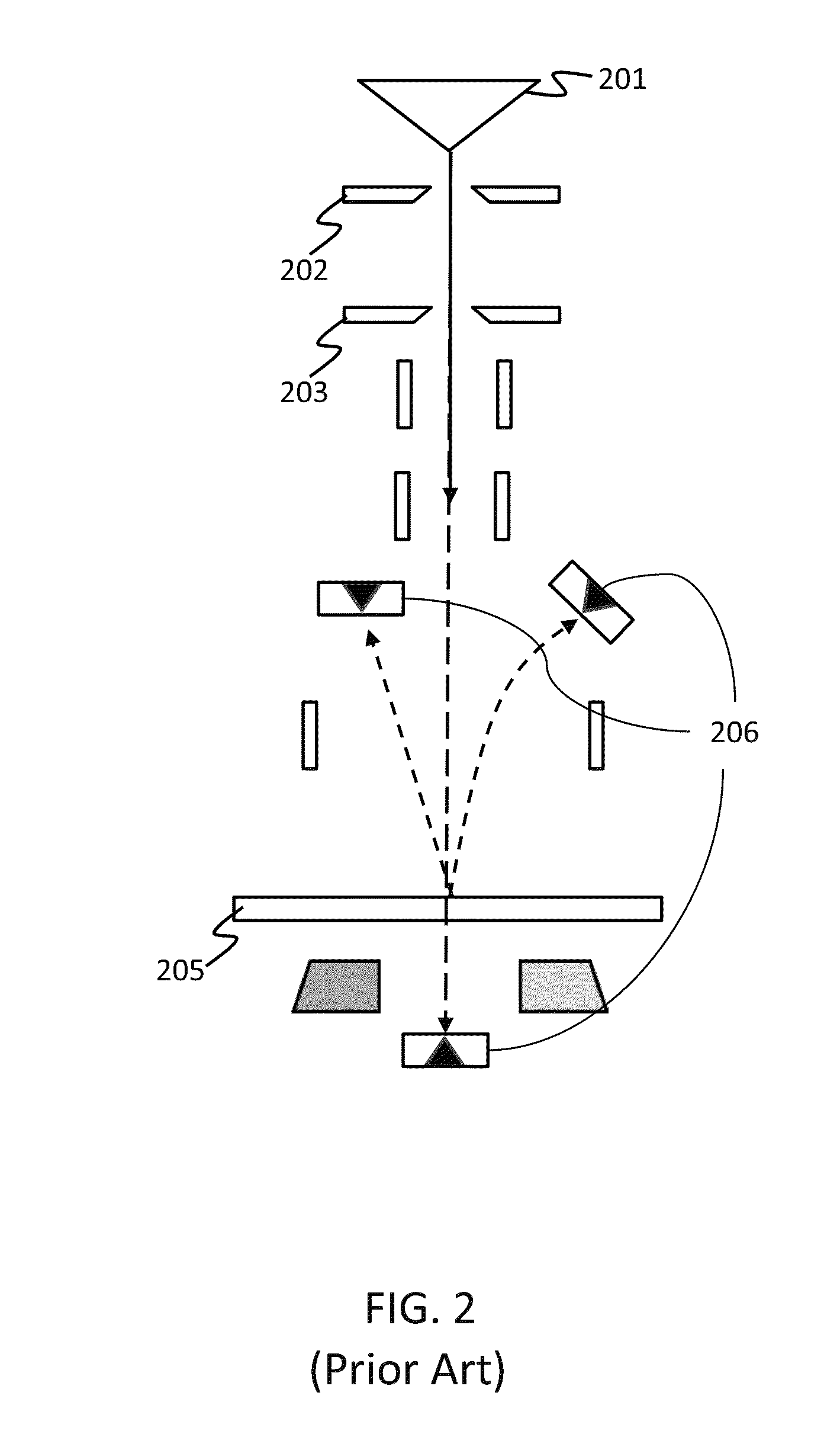

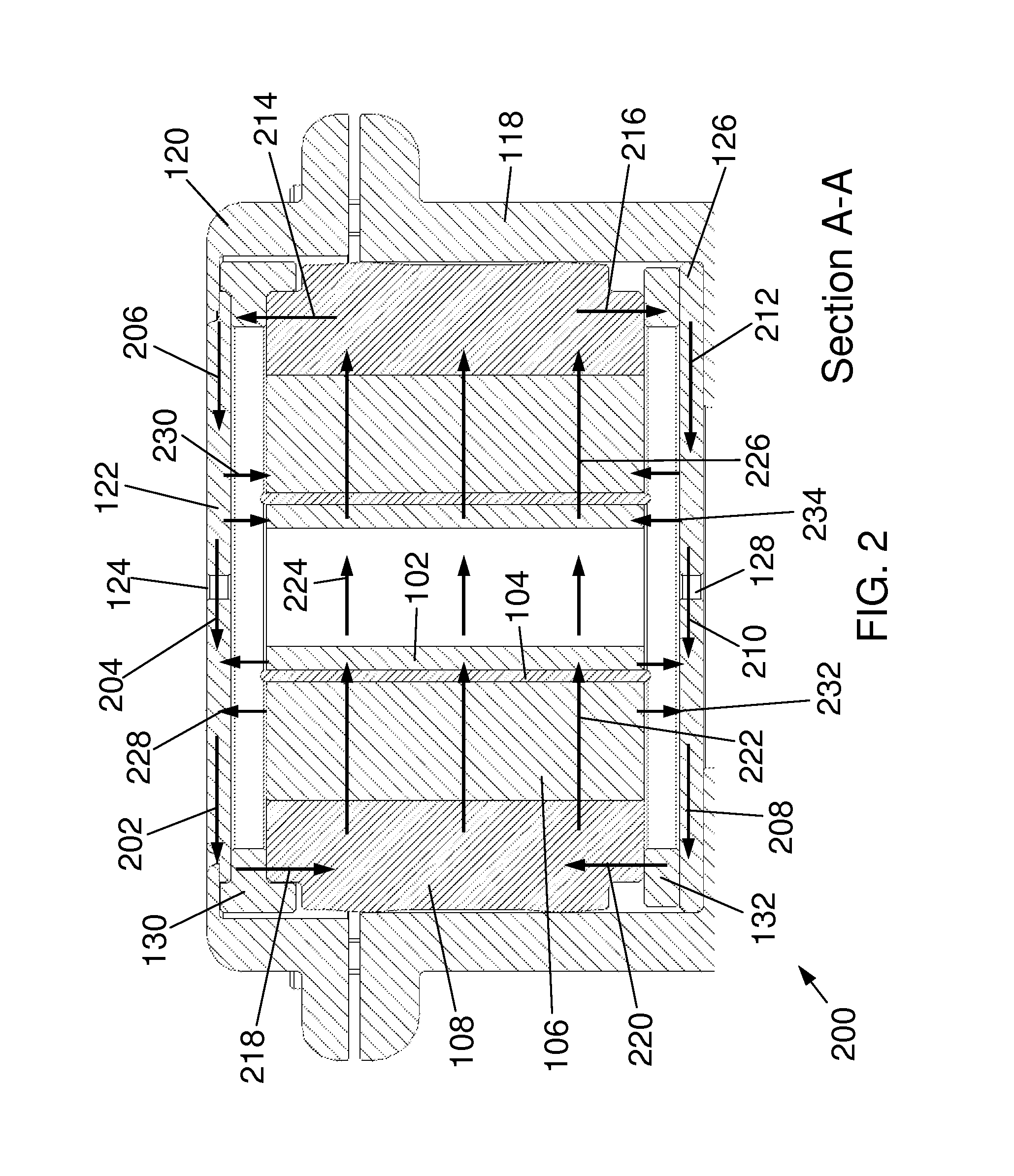

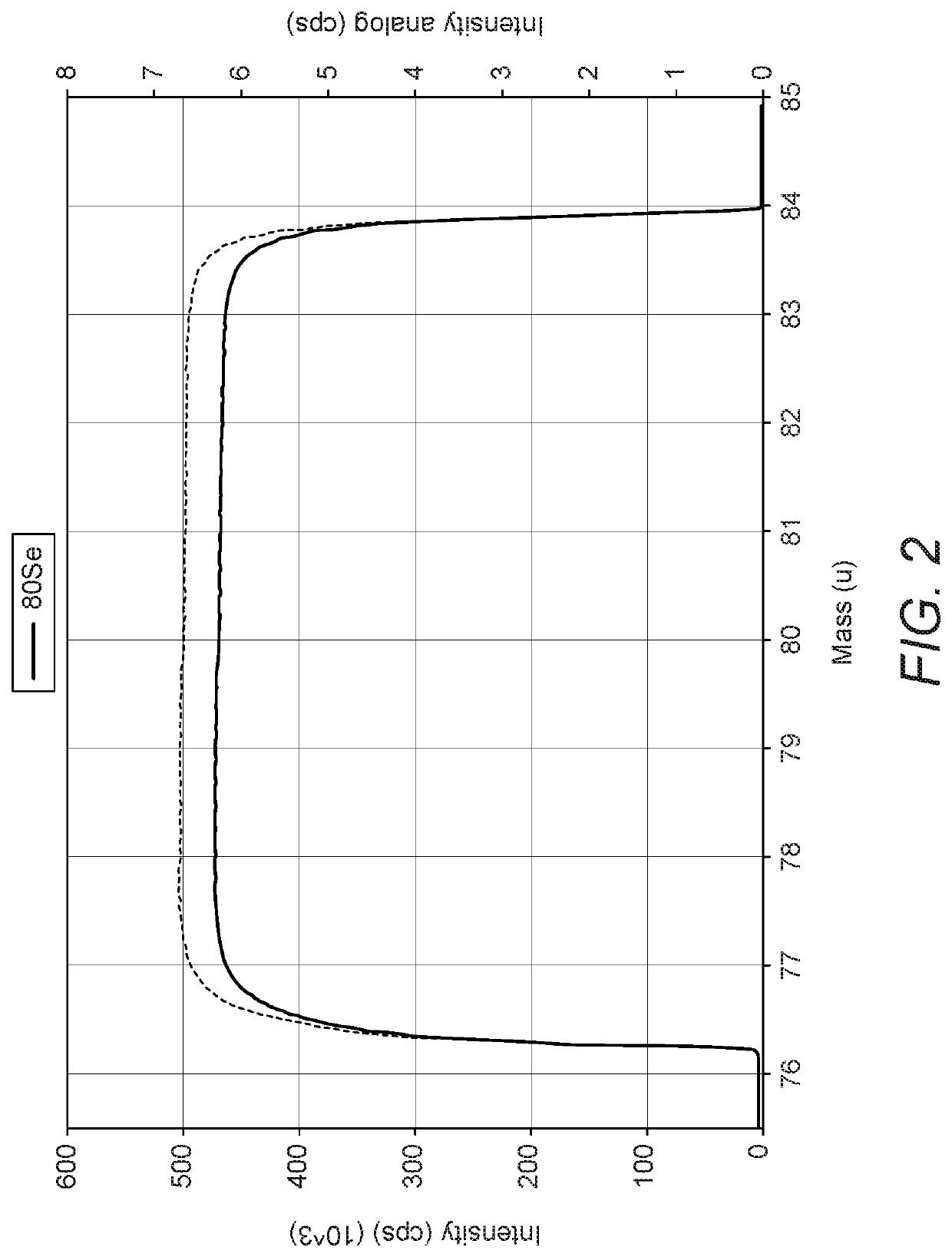

Mass Spectrometer

InactiveUS20210013017A1Improve transmittanceHigh sensitivityElectron/ion optical arrangementsIon sources/gunsWien filterOptical spectrometer

An isotope ratio mass spectrometer has an ion source, a static field mass filter, a reaction cell to induce a mass shift reaction, and a sector field mass analyser for spatially separating ions from the reaction cell according to their m / z. A detector platform detects a plurality of different ion species separated by the sector field mass analyser. The static field mass filter has a first Wien filter that deflects ions away from a longitudinal symmetry axis of the spectrometer in accordance with the ions' m / z, and a second Wien filter that deflects ions back towards the longitudinal symmetry axis in accordance with the ions' m / z. An inverting lens is positioned along the longitudinal axis between the Wien filters to invert the direction of deflection of the ions from the first Wien filter. The static field mass filter provides high transmission and improved spectrometer sensitivity. The first and second Wien filters permit simple tuning.

Owner:THERMO FISHER SCI BREMEN

Noise cancellation system and method

InactiveUS8296135B2Improve speech recognition performanceReduce noiseSpeech recognitionTransmission noise suppressionWien filterEngineering

A noise cancellation apparatus includes a noise estimation module for receiving a noise-containing input speech, and estimating a noise therefrom to output the estimated noise; a first Wiener filter module for receiving the input speech, and applying a first Wiener filter thereto to output a first estimation of clean speech; a database for storing data of a Gaussian mixture model for modeling clean speech; and an MMSE estimation module for receiving the first estimation of clean speech and the data of the Gaussian mixture model to output a second estimation of clean speech. The apparatus further includes a final clean speech estimation module for receiving the second estimation of clean speech from the MMSE estimation module and the estimated noise from the noise estimation module, and obtaining a final Wiener filter gain therefrom to output a final estimation of clean speech by applying the final Wiener filter gain.

Owner:ELECTRONICS & TELECOMM RES INST

Speech enhancement method applied to deaf-aid

The invention provides a speech enhancement method that can restrain noise component in noisy voice and improve voice quality and intelligibility in noise environment. According to the method of the present invention, it specifically includes the following steps: 1) first, estimating the noise spectrum of the speech using endpoint detection technology; 2) removing noise using two-step Wiener filter technology; 3) meanwhile, adjusting the filter parameters according to auditory masking curve. The de-noising method in the invention has undertaken a thorough study and consideration on the signal level and perceptual level. For the estimation of noise, it uses the endpoint detection method, which has good robustness, to accurate estimate the noise spectrum as far as possible. Furthermore, it uses a two-step Wiener filter to solve this problem. Meanwhile, taking into account people's ears, by using auditory masking curve, it decreases the signal distortion. Thus, the eventually enhanced signal has a big increase on the voice quality and intelligibility.

Owner:北京大学科技开发有限公司

Wien filter and electron-optics apparatus

ActiveUS20190250361A1Improve the magnetic shielding effectParticle separator tubesOptical filtersWien filterMagnetic shield

A Wien filter to be disposed inside a lens barrel made of a magnetic material includes: a plurality of electromagnetic poles disposed at equal angular intervals about a center axis of the lens barrel; a first magnetic shield disposed so as to cover the area around the plurality of electromagnetic poles; and a second magnetic shield disposed so as to cover the area around the first magnetic shield. The first magnetic shield is supported by a first support member made of a non-magnetic material provided at an inner surface of the second magnetic shield. The second magnetic shield is supported by a second support member made of a magnetic material provided at an inner surface of the lens barrel.

Owner:EBARA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com