Patents

Literature

72results about How to "Overcome the hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

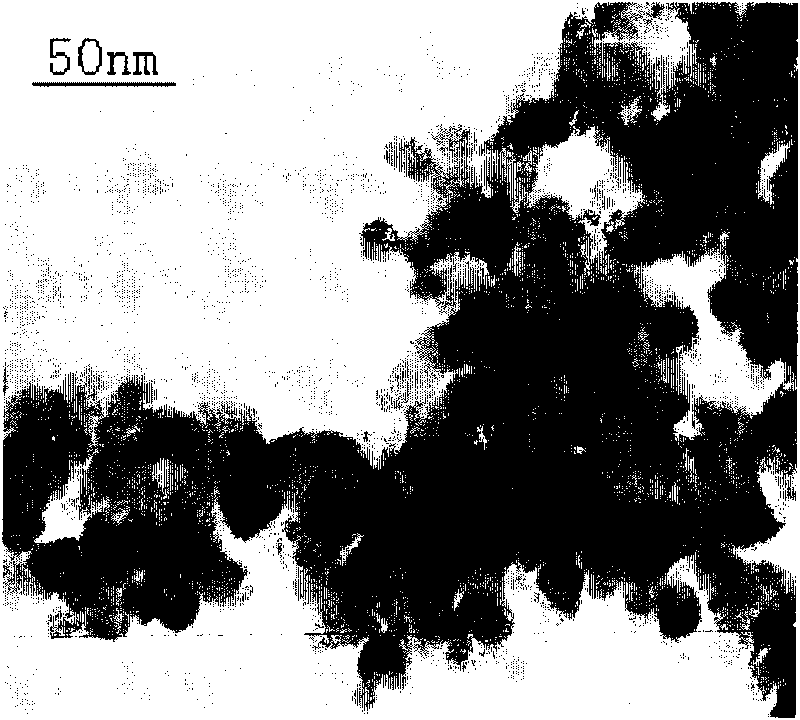

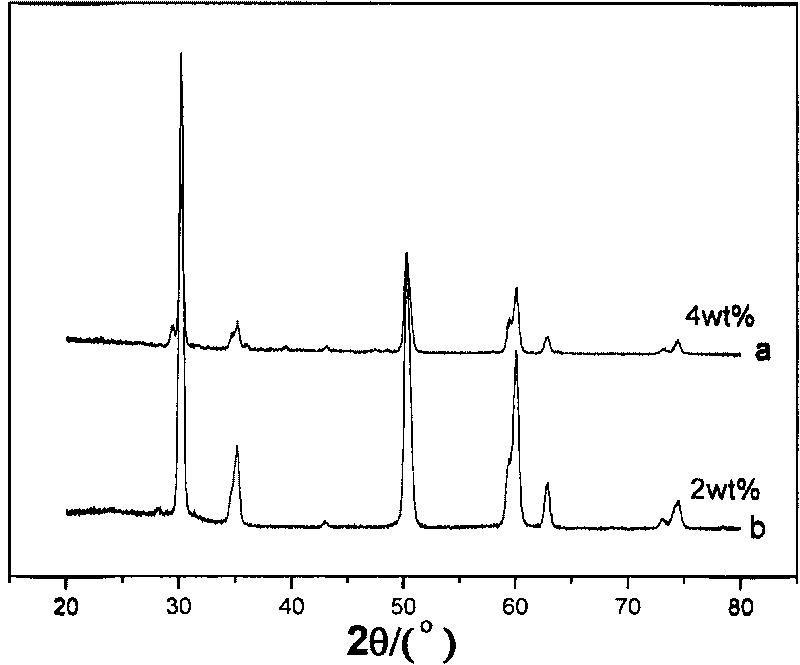

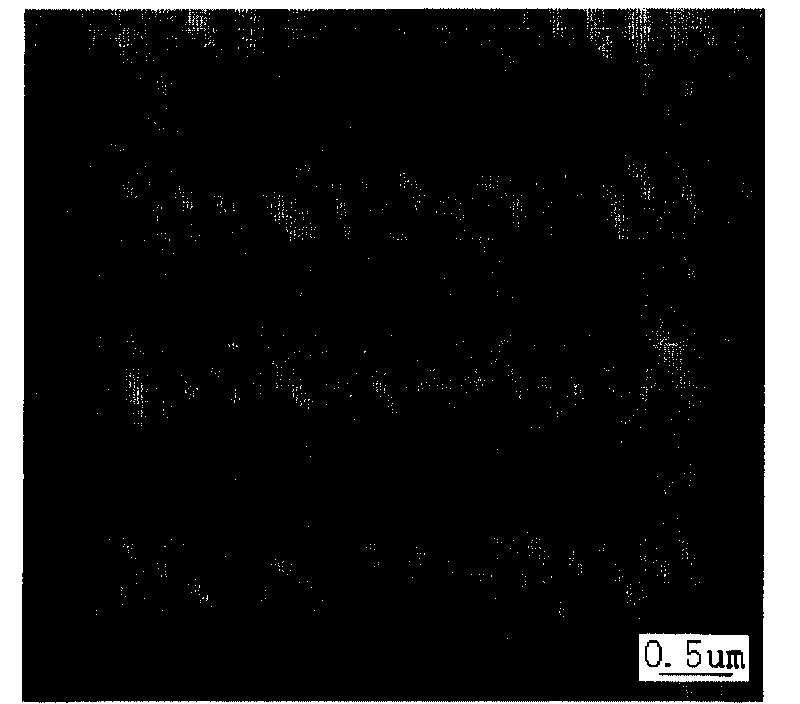

Method for preparing black zirconia ceramics at low temperature

The invention relates to a method for preparing black zirconia ceramics at the low temperature and belongs to the technical field of the preparation of high-temperature structural material. The method respectively uses a homogeneous precipitation method for synthesizing a nanometer coloring agent, and a coprecipitation method for synthesizing nanometer zirconia powder, and adopts Fe-Co-Ni-Mn as a coloring agent. The zirconia powder is not added with any sintering additive, only added with small amount of coloring agent and sintered at the temperature of 1150-1350 DEG C, thus obtaining the black zirconia ceramics with excellent performance and bright color. As the homogeneous precipitation method is adopted for synthesizing coloring agent powder, the monodisperse nanometer particles with uniform powder granules, narrow size distribution and high purity are obtained so that the coloring agent easily colors the particles. As the coprecipitation method is used for synthesizing zirconia powder, nanometer particles with small granularity, big superficial area and high activity are obtained, and can reduce the temperature of the solid-phase reaction, greatly reduce the sintering temperature and solve the problem that the black coloring agent oxide decomposes and volatiles at the high temperature. Simultaneously the method adopts the Fe-Co-Ni-Mn as the coloring agent, thus avoiding the poisonous function of Cr on the human body.

Owner:TSINGHUA UNIV

Halogen-free intumescent flame-retardant polypropylene/ethylene vinyl acetate cable material

ActiveCN101649088AImprove insulation performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesExtensibilityUv absorber

The invention relates to a halogen-free intumescent flame-retardant polypropylene / ethylene vinyl acetate cable material which is characterized by comprising the following components by weight part: 20-40 parts of polypropylene, 60-80 parts of ethylene vinyl acetate, 45-65 parts of compound flame retardant, 5-15 parts of grafting agent, 1.0-2.0 parts of antioxidizer, 1.0-2.0 parts of ultraviolet absorbent and 1.0-3.0 of processing aid. With the advantages of favorable flexibility, high breakage extensibility, favorable tensile strength, excellent electrical insulating property and good flame retardant, the material favorably meets the requirements on the burning property, the mechanical property and the heat property of the cable material and is mainly used as the outer coating material ofcables.

Owner:应急管理部四川消防研究所

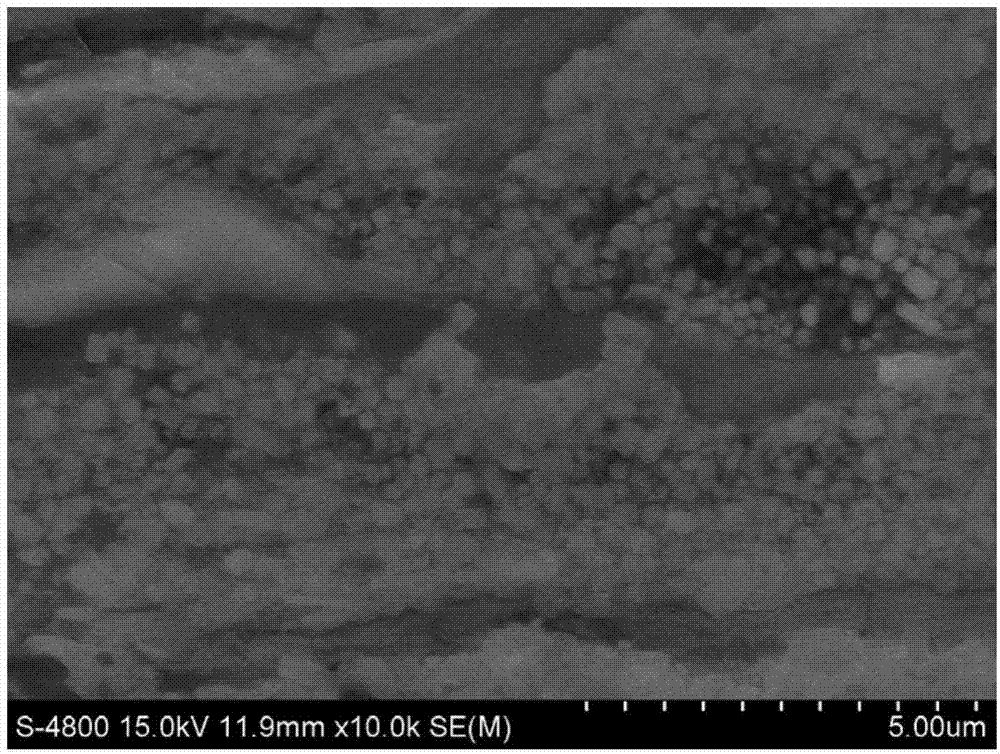

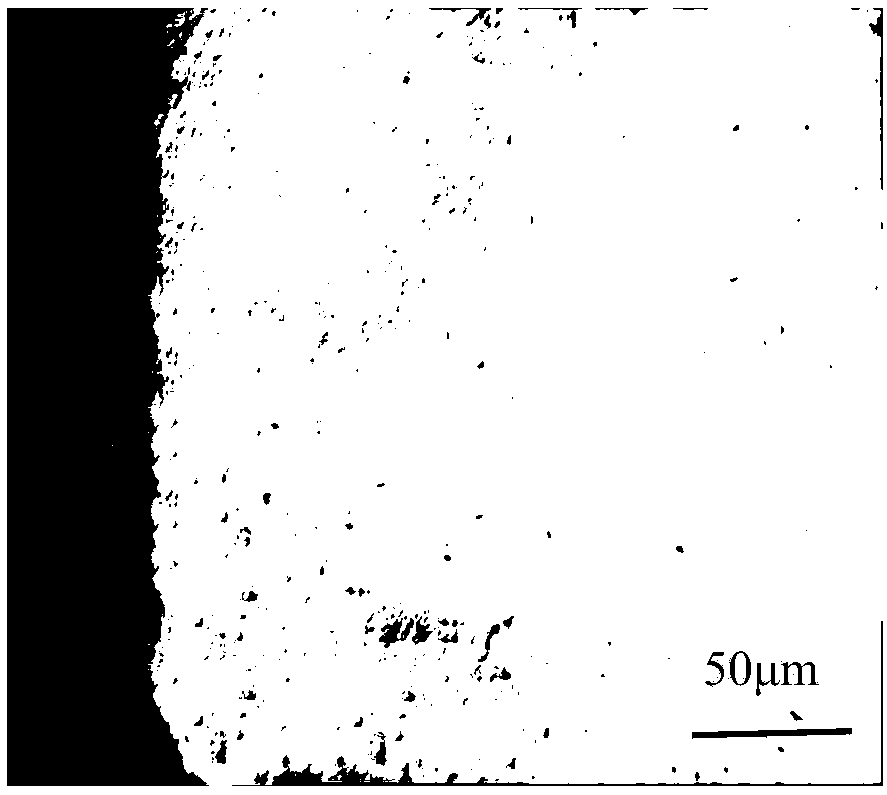

Polyaniline modified metal-ceramic nano coating and preparation method thereof

ActiveCN101643607AOvercoming the easy formation of hard precipitatesOvercome the hardnessEpoxy resin coatingsEpoxyPhytic acid

The invention relates to coating technology, in particular to a polyaniline modified metal-ceramic nano coating and a preparation method thereof to solve the problems that compositions of a base stockof the coating existing in the prior art are easy to form hard precipitation, and the coating has low hardness. The polyaniline modified metal-ceramic nano coating mainly comprises nano-whisker, polyaniline and phytic acid modified zinc powder, epoxy resin and a curing agent. The preparation method takes the epoxy resin as a binder and organically combines the metal zinc and the nono ceramic whisker, so that the coating has ductility. The nano-whisker ceramic material reinforces the epoxy coating, strengthens the ductility and the permeability resistance of the epoxy coating; and the polyaniline modified zinc powder improves the corrosion resistance of the coating. The coating is widely used for heavy-duty anticorrosion of petrochemical equipment, maritime facilities and traffic facilities.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

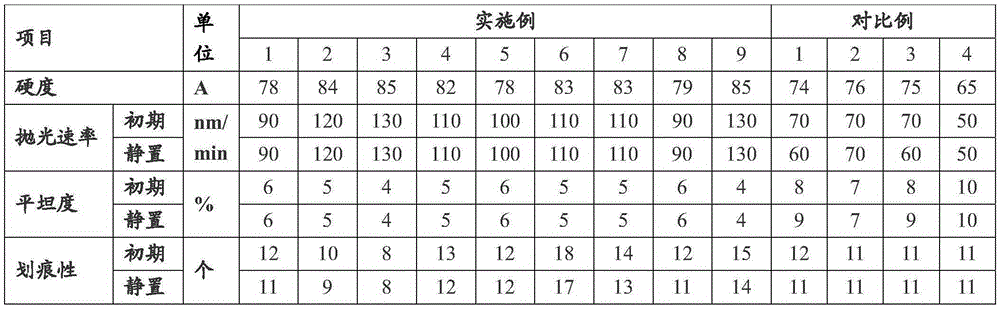

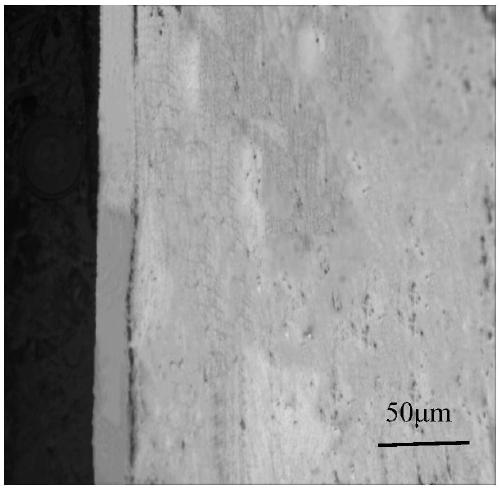

Composite polishing pad and preparation method thereof

ActiveCN105415168AReduce hair sheddingGood surface smoothnessGrinding devicesLapping toolsElastomerPolymer science

The invention discloses a preparation method of a composite polishing pad. The preparation method comprises the following steps that (1) non-woven fabric is preprocessed, specifically, (a) the non-woven fabric is put into a drying oven for flattening, (b) the flattened non-woven fabric is immersed into a glue solution and then is taken out after being infiltrated sufficiently, and a non-woven fabric substrate material is obtained; (2) a polymer solution is prepared, specifically, (I) a macromolecular elastomer is dissolved into a solvent, and a macromolecular elastomer solution is prepared; (II) polymer particles are added into the macromolecular elastomer solution, and the polymer solution is obtained; (3) the non-woven fabric is made into a pad, specifically, the non-woven fabric substrate material is infiltrated into the polymer solution and then is taken out after being infiltrated sufficiently, and unnecessary solutions on the surface of the non-woven fabric substrate material are scraped off; the non-woven fabric substrate material is immersed into coagulating bath for consolidation forming and then put into pure water for rinsing and finally dried to the constant weight, and an original polishing pad is obtained; and (4) the polishing pad is formed, specifically, after the surface of the original polishing pad is polished, cut and rubberized, and the finished polishing pad is obtained. By means of the preparation method, the composite polishing pad has a large polishing rate, and moreover the flatness of a polished object is good.

Owner:河南惠强新能源材料科技股份有限公司

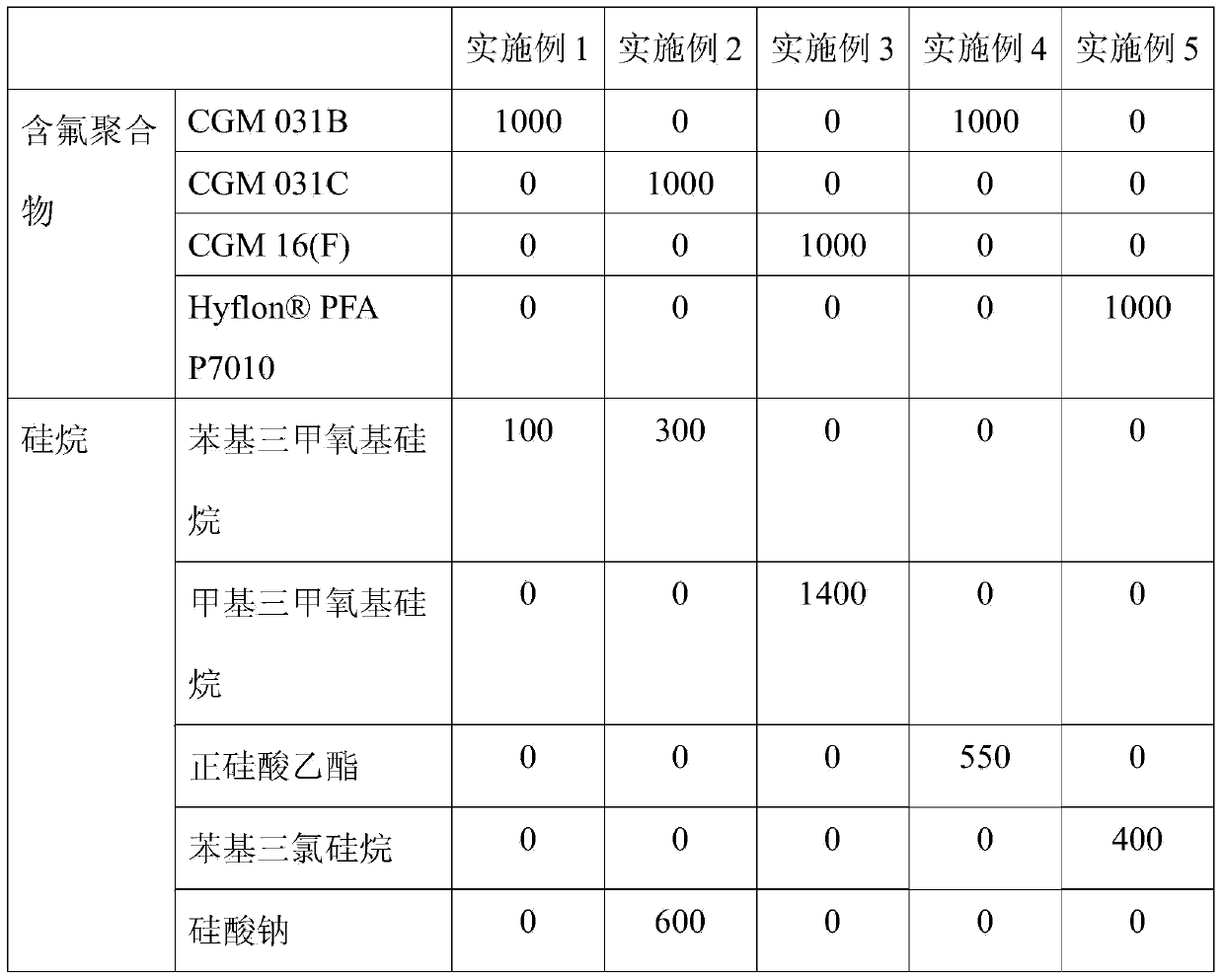

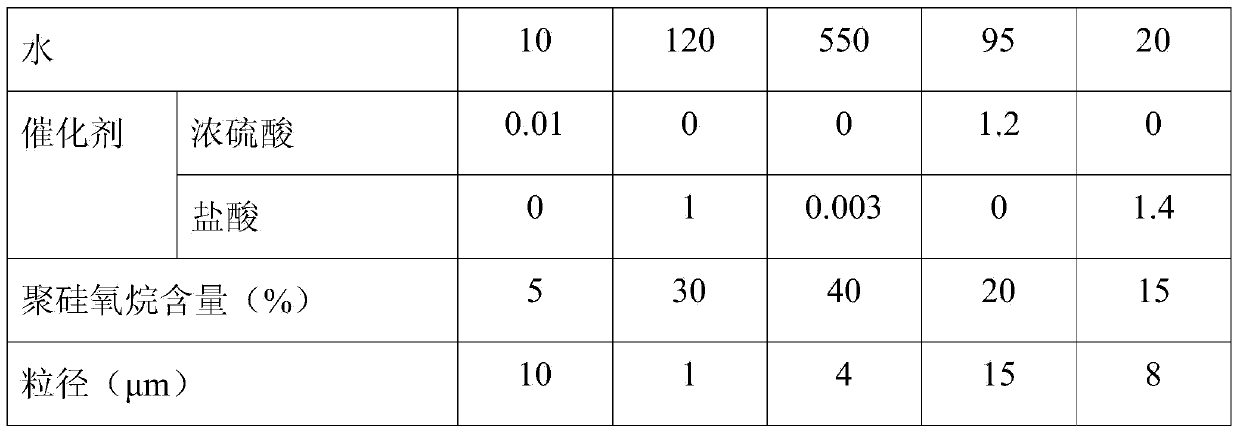

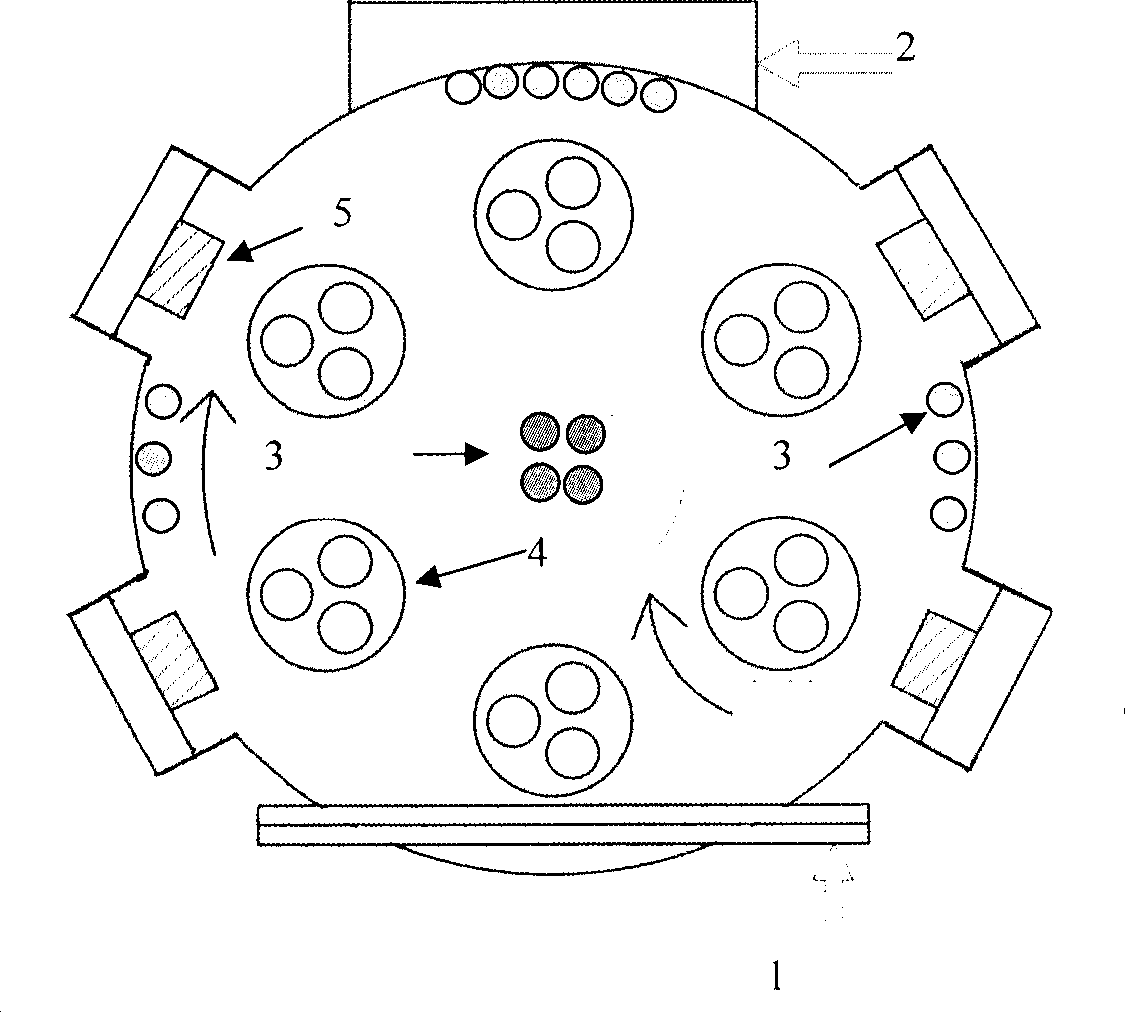

Composite micropowder and method for manufacturing the same, ceramic paint, and protection coating

ActiveCN103849092ANot stickySimple stepsPaints with free metalsThin material handlingSilanesFluoropolymer

Disclosed is a method of forming a composite micropowder, including mixing 100 parts by weight of fluorine-containing polymer, 10 to 140 parts by weight of silane, catalyst, and water, such that the silane is in-situ polymerized in the fluorine-containing polymer to form a polysiloxane, and the fluorine-containing polymer and the polysiloxane form a composite. The composite is dried, and then physically crushed to form composite micropowder. The total weight of the fluorine-containing polymer and the silane and the weight of the catalyst have a ratio of 100:0.1 to 100:0.0001. The silane and the water have a molar ratio of 1:0.5 to 1:3. The composite micropowder has a diameter of 0.1 [mu]m to 15 [mu]m. The fluorine-containing polymer and the polysiloxane in the composite micropowder have a weight ratio of 95:5 to 60:40. The composite micropowder has excellent non-sticky property, manufactured in a simple way, safe, environmentally-friendly and low in cost.

Owner:GRAND TEK ADVANCE MATERIAL SCI

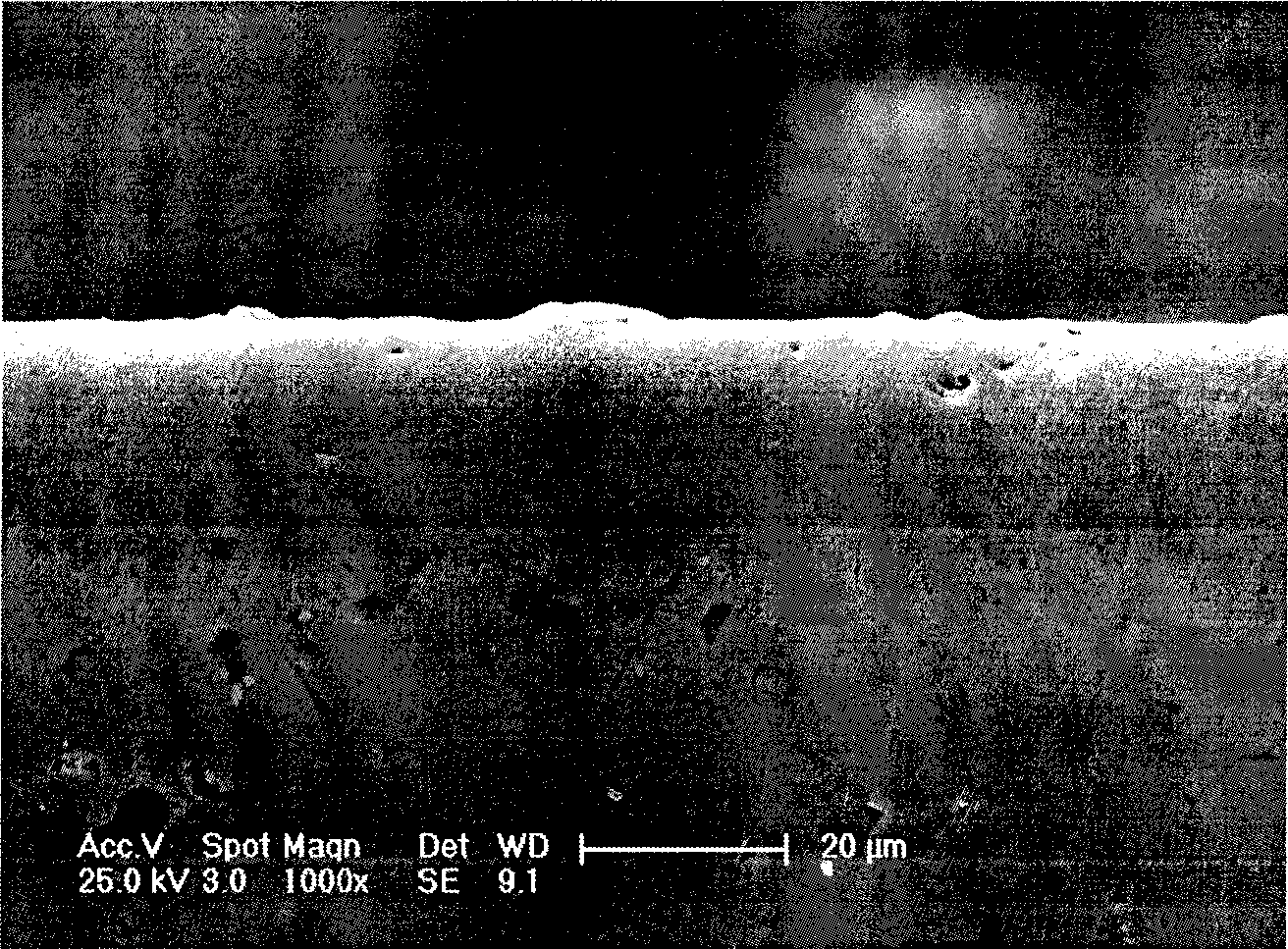

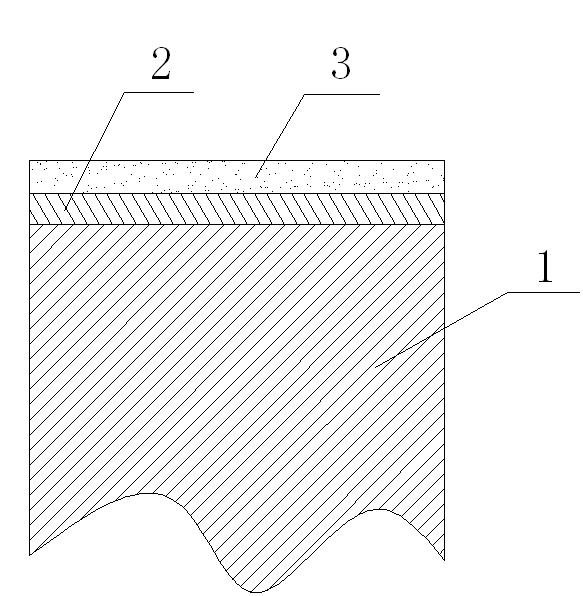

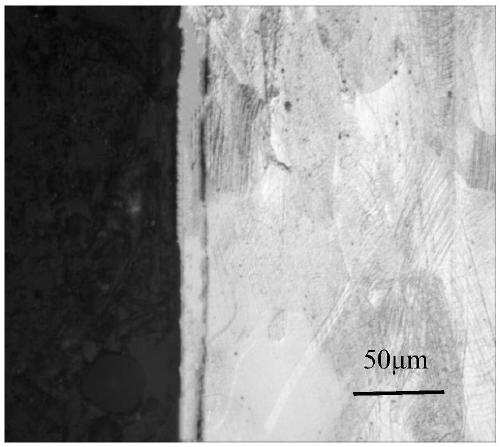

PVD chromium based ceramic composite coating piston ring and method for producing the same

InactiveCN101430004AOvercome the hardnessOvercome uniformity issuesPiston ringsVacuum evaporation coatingCeramic compositePiston ring

The invention discloses a PVD chromium base ceramic composite coating piston ring and a preparation method thereof, and the piston ring is manufactured by plating a chromium base ceramic composite coating on a basal body of the piston ring which is treated by nitriding by adopting high power electric arc discharge method; the chromium base ceramic composite coating is composed of a bonding layer, a main wearing layer and an anti-attrition layer, wherein, the bonding layer is binded with the basal body of the piston ring in a metallurgical way, the main wearing layer is arranged on the bonding layer, and the anti-attrition layer is positioned on the surface of the main wearing layer; the bonding layer is Cr, the main wearing layer is a Cr / CrN multilayer coating formed by the Cr and the CrN which are alternately arranged, and the anti-attrition layer is a Cr / Cr2O3 multilayer coating formed by the Cr and the Cr2O3 that are alternately arranged. The coating structure has reasonable design, and the manufactured coating has good cementing property, high hardness and good lubricating property. Furthermore, the method used for manufacturing the piston ring has no pollution in the preparation process, and overcomes the serious problem of environmental pollution of the conventional electrodeposited chromium; as the manufactured coating has better abrasion resistant and corrosion resistant performance compared with the electrodeposited chromium, the service life of the piston ring is greatly prolonged.

Owner:WUHAN UNIV

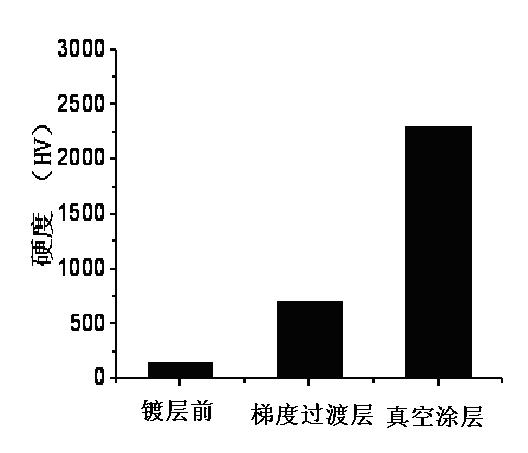

Surface compound strengthening process for aluminum alloy material

ActiveCN102115883AHigh bonding strengthHigh hardnessSuperimposed coating processDlc coatingChemical plating

The invention discloses a surface compound strengthening process for an aluminum alloy material, aiming to solve the problems that chemical plating of Ni, Ni-P and Ni-W-P or electroplating of Ni and Cr for aluminum and aluminum alloy has good bonding strength but low rigidity and poorer wear resistance, and vacuum coatings of CrN, TiN, TiAlN, TiCN or DLC for an aluminum alloy material have high rigidity and good wear resistance but poorer bonding strength with a substrate. The surface compound strengthening process disclosed by the invention comprises the following steps: firstly, plating a 2-10mu m thick gradient transition layer on the surface of an aluminum alloy substrate, then baking for 1-2 hours at constant temperature of 75-85 DEG C in a dry environment, and finally depositing oneor multiple coatings of CrN, TiN, TiAlN, TiCN or DLC on the aluminum alloy substrate by a vacuum coating technology. The surface compound strengthening process can improve the bonding strength between the vacuum coating and the aluminum alloy substrate, and simultaneously the surface of the aluminum alloy substrate has higher rigidity and wear resistance.

Owner:NAXAU NEW MATERIALS CORP

Method for manufacturing compressed carbonized poplar board

InactiveCN101733805AReduce stressGood dimensional stabilityWood compressionWood charring/burningCarbonizationHardness

The invention relates to a method for manufacturing fast-growing wood sheet, in particular to a manufacturing method for modifying a fast-growing poplar board, belonging to the technical field of sheet manufacture. The invention has the advantages of small internal stress of a compressed carbonized poplar board manufactured by the method and good stability of the size of the board, thereby ensuring the quality of a compressed carbonized wood. The invention overcomes the defects of a fast-growing poplar sheet, such as low density, low hardness, low strength, easy corrosion, difficult direct use and the like, improves the density of the sheet by carrying out compression and densification for the poplar sheet, carries out carbonization on the compressed poplar sheet on the condition of pressurization, and eliminates the compression stress inside the sheet so as to prevent springback of the sheet and improve the size stability, density and strength. The poplar board manufactured by the method can be directly used as a sheet. The compressed carbonized poplar board can be partially or entirely used to replace high-quality precious wood, thereby relieving the contradiction between continuously reduced precious wood resources and increasing demand for wood.

Owner:NANJING FORESTRY UNIV

Processable aluminium oxide base composite ceramic material and preparation method thereof

The invention discloses a processable aluminium oxide base composite ceramic material, which comprises the following raw materials in parts by mass: 60-88 parts of Al203, 5-15 parts of MgO, 5-15 parts of TiO2, 1-5 parts of SiO2 and 1-5 parts of CaO. The preparation method thereof comprises the following steps: mixing Cao powder and SiO powder in a proportion of 1:1 to prepare a sintering assistant; premixing MgO powder and TiO2 powder, then mixing with Al203 powder and the sintering assistant, ball-milling, drying the powder by ball-milling, and hot pressed sintering and molding at vacuum atmosphere. The invention overcomes the shortages that the aluminium oxide ceramic has higher hardness, and is difficult to process, produces a compound ceramic material with certain processability, and is especially applicable to a full ceramic reparation material in dentistry.

Owner:SHIJIAZHUANG TIEDAO UNIV

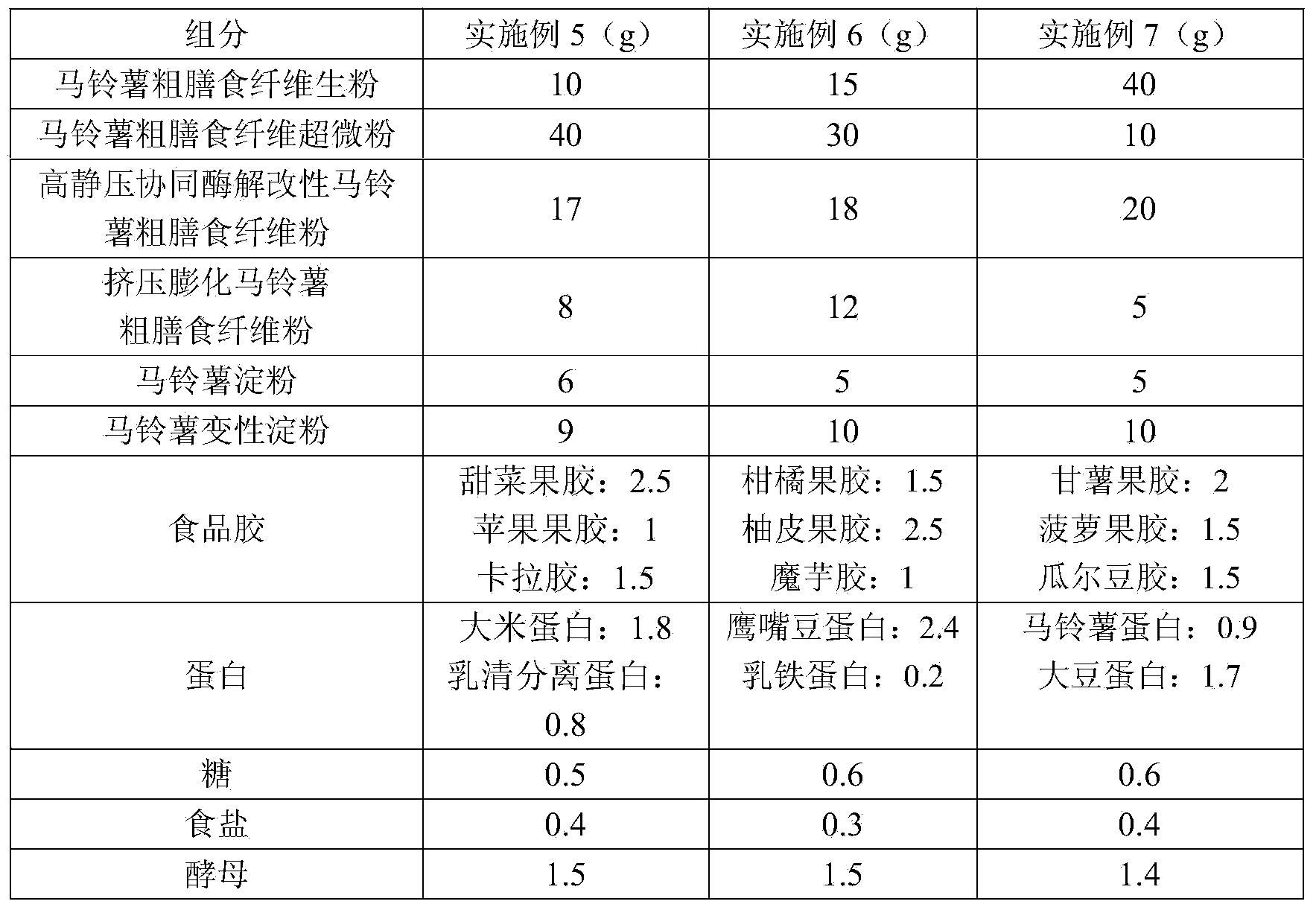

Potato dietary fiber bread and making method of potato dietary fiber bread

ActiveCN104365733AOvercoming the low proportion of ingredientsOvercoming low nutritional valueDough treatmentModified nutritive productsPotato starchAntioxidant

The invention relates to the field of foods, in particular to potato dietary fiber bread and a making method of the potato dietary fiber bread. The potato dietary fiber bread comprises, by mass, 10 parts to 40 parts of potato coarse dietary fiber starch, 10 parts to 40 parts of potato coarse dietary fiber submicron powder, 10 parts to 20 parts of high-hydrostatic-pressure synergetic enzymatic hydrolysis modified potato coarse dietary fiber powder, 4 parts to 12 parts of extrusion potato coarse dietary fiber powder, 5 parts to 12 parts of potato starch, 5 parts to 13 parts of potato modified starch, 2 parts to 6 parts of food gum, 1 part to 3 parts of egg white, 0.5 part to 3 parts of sugar, 0 part to 1 part of salt and 1 part to 3 parts of yeast. The potato dietary fiber bread does not contain gluten, the contents of protein, mineral substances, dietary fibers, vitamins and antioxidants are obviously higher than the contents of protein, mineral substances, dietary fibers, vitamins and antioxidants in existing wheat bread, and the potato dietary fiber bread is suitable for being eaten by the crowd allergic to wheat or celiac disease patients.

Owner:北京中农探味科技有限公司

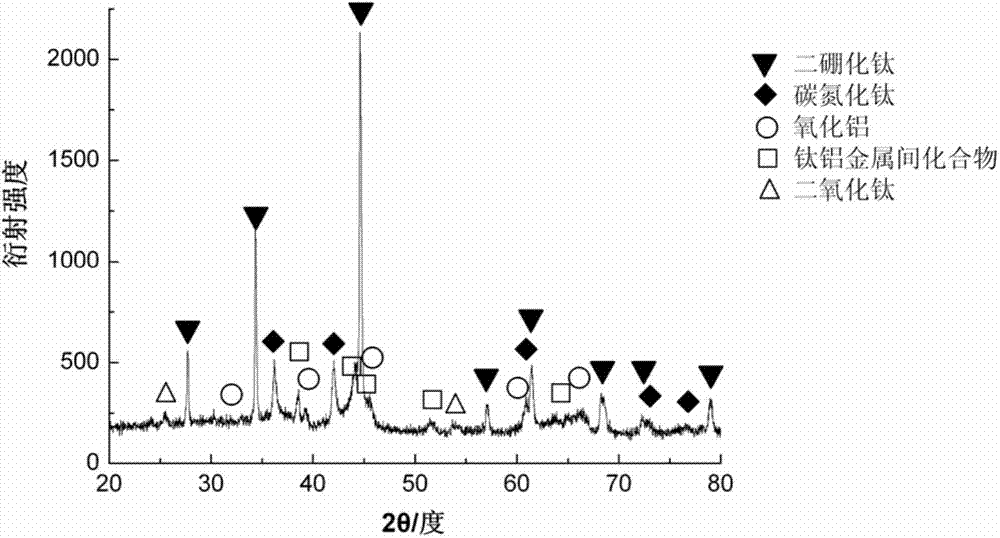

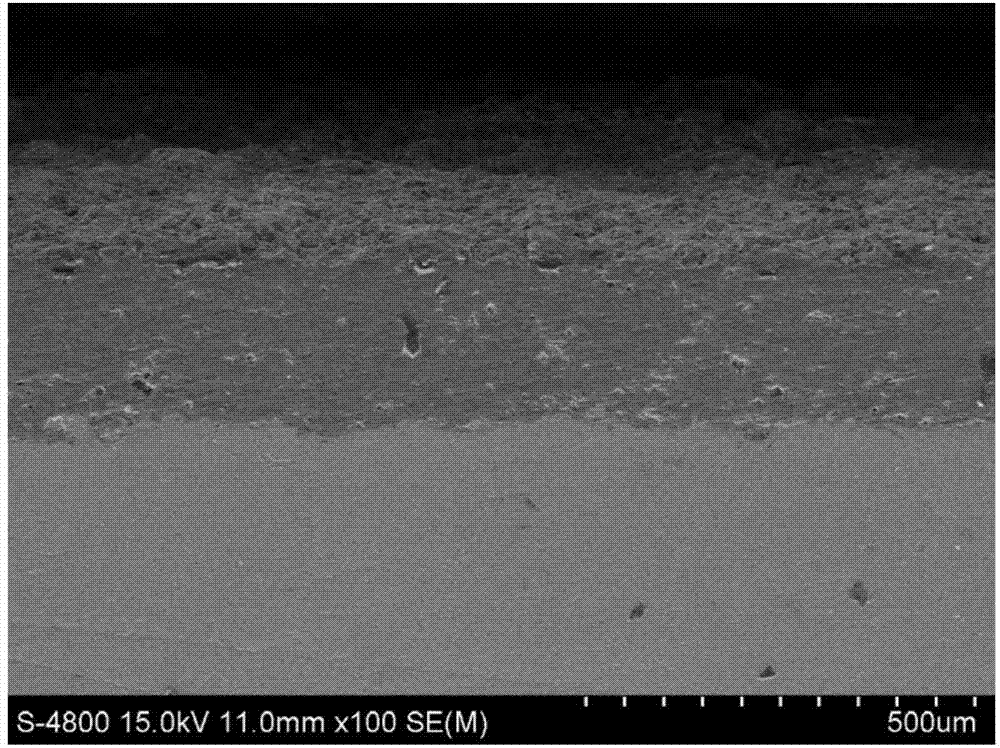

Preparation method of titanium boride based inorganic composite coating

Relating to plating of metal materials, the invention provides a preparation method of a titanium boride based inorganic composite coating. The mixed powder of micron-sized metal Al powder, micron-sized, submicron-sized or nano-sized TiO2 powder, and micron-sized, submicron-sized or nano-sized B4C powder is taken as a raw material, the mixed powder is sprayed on the alloy underlayer surface of a metal or alloy workpiece surface by thermal spraying. During thermal spraying, the Al, TiO2 and B4C in the mixed powder react with nitrogen in a powder feeding gas to synthesize the titanium boride based inorganic composite coating in situ. The method provided in the invention overcomes the defects of high raw material cost, complicated preparation process, high energy consumption, low efficiency, difficult control of coating processing precision, low coating density, poor coating uniformity, weak binding force between the coating and a substrate, low coating toughness, easy coating cracking, and unsuitability for application in large-scale industrial production existing in the prior art for preparation of titanium boride based composite coatings.

Owner:HEBEI UNIV OF TECH

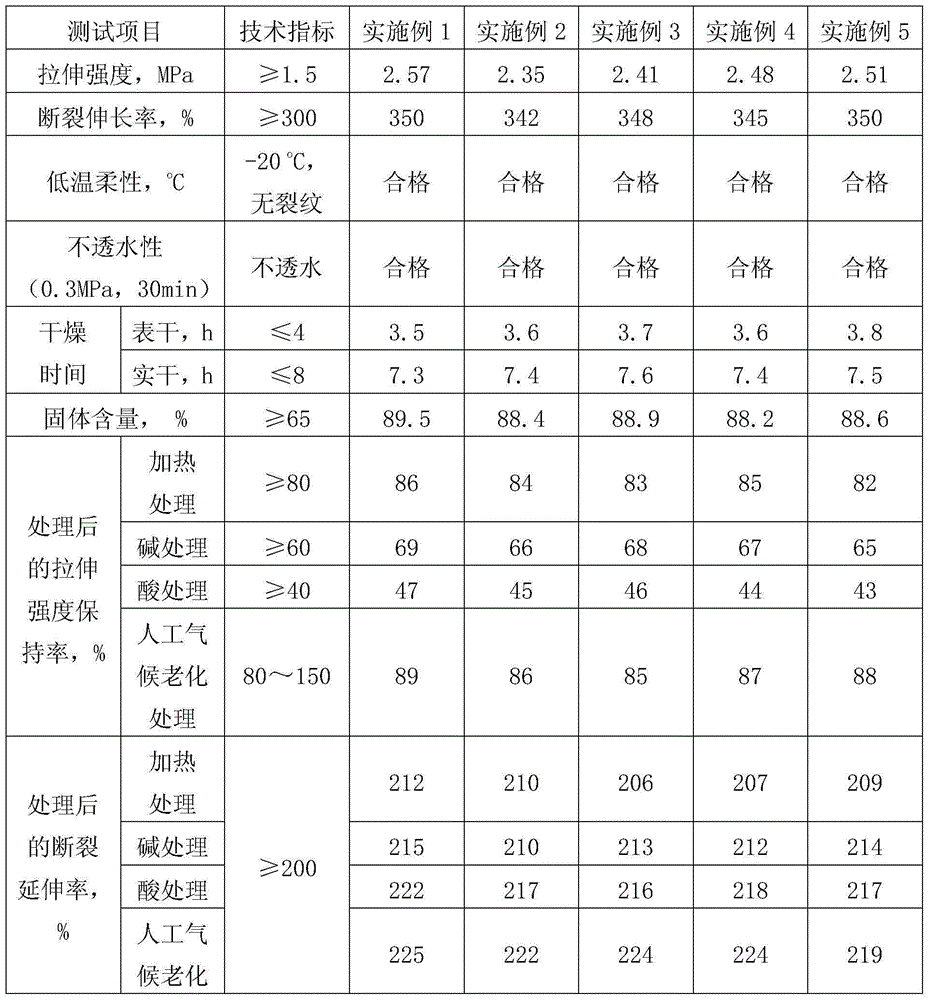

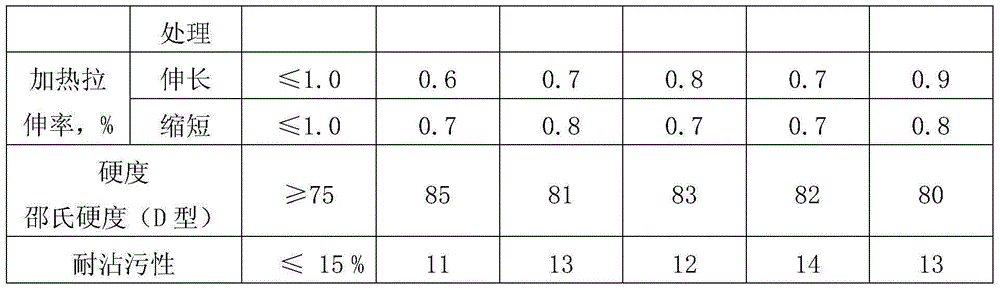

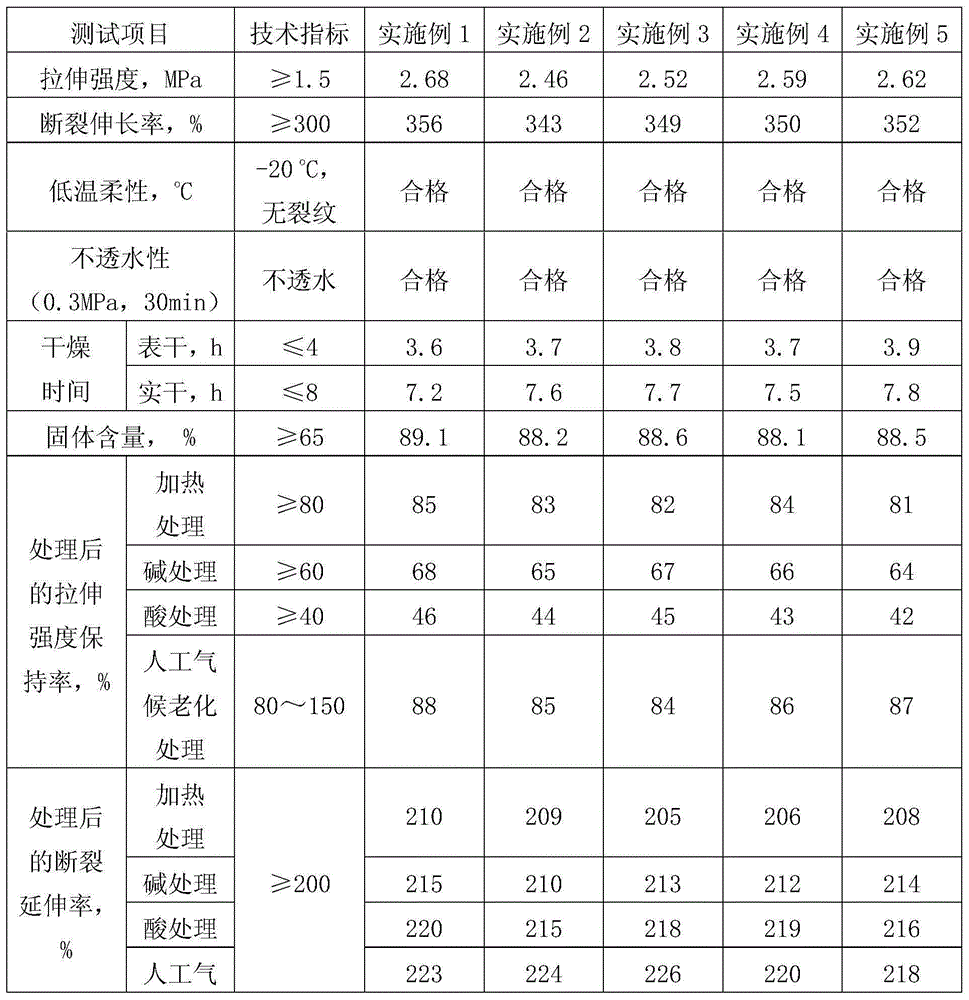

Modified acrylic ester waterproof coating

InactiveCN105199529AOvercome the hardnessOvercome the technical problems of poor stain resistanceAntifouling/underwater paintsPaints with biocidesGlass fiberEmulsion

The invention discloses a modified acrylic ester waterproof coating. The waterproof coating is prepared from components in parts by weight as follows: 35-55 parts of an acrylic ester modified compound emulsion, 2-6 parts of a fluorocarbon surfactant, 2-8 parts of nano-modified materials, 20-30 parts of pigment filler, 0.1-0.3 parts of a humidity controlling agent, 0.3-0.7 parts of a dispersing agent, 0.2-0.4 parts of a defoaming agent, 1-2 parts of a coalescing agent, 0.5-0.7 parts of a thickening agent, 0.2-0.6 parts of an antioxidant, 0.4-0.8 parts of glass fiber, 0.1-0.3 parts of a preservative sterilizing agent, 0.4-0.6 parts of emulsified paraffin and 25-35 parts of water. The waterproof coating adopts a reasonable formula, has good stain resistance, high hardness and excellent overall performance and can be applied to waterproofing work of a roof, a basement, a toilet and the like.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

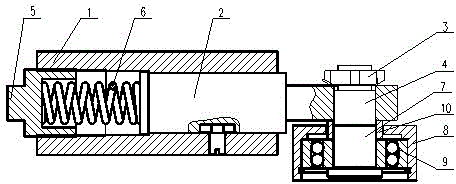

Rolling cutter bit

InactiveCN104097022ASimple structureOvercoming uneven surface hardnessEngineeringMechanical engineering

The invention discloses a rolling cutter bit, comprising a cutter shell and a cutter body; the cutter body is arranged in the cutter shell; one end of the cutter body extends out of the cutter shell; the rolling cutter bit is fixed by the end port of the cutter body by a fastening bolt; the other end of the cutter body is provided with a regulating bolt; a spring is arranged between regulating bolt and the cutter body. The rolling cutter bit disclosed by the invention is simple in structure and capable of effectively overcoming cutter aligning errors and inconsistent workpiece surface hardness, and the machining precision is improved.

Owner:NANJING HAOWEI MACHINERY

Gold-silver-palladium alloy single-crystal bonding wire and manufacturing method thereof

InactiveCN103779308ALow priceReduce performanceSemiconductor/solid-state device detailsSolid-state devicesMinor metalsMetallic materials

Provided are a gold-silver-palladium alloy single-crystal bonding wire and a manufacturing method thereof. The main material of the gold-silver-palladium alloy single-crystal bonding wire is high-purity silver, and the gold-silver-palladium alloy single-crystal bonding wire further comprises gold, palladium, europium, lanthanum and other trace metal materials. The gold-silver-palladium alloy single-crystal bonding wire comprises, by weight, 98.713%-99.157% of the silver, 0.8%-1.2% of the gold, 0.04%-0.08% of the palladium, 0.002%-0.004% of the europium and 0.001%-0.003% of the lanthanum. The manufacturing method comprises the steps that the high-purity silver with the purity higher than 99.9999% is extracted and manufactured into silver alloy ingots, as-cast gold-silver-palladium alloy single-crystal main wires are manufactured, the single-crystal main wires are manufactured into single-crystal wires of around 1mm through a drawing mode, heat treatment is carried out on the single-crystal wires, and then gold-silver-palladium alloy single-crystal bonding wires of different specifications are manufactured through precise drawing, heat treatment and cleaning.

Owner:江西蓝微电子科技有限公司

Novel waterproof acrylate coating

InactiveCN105219204AOvercome the hardnessOvercome the technical problems of poor stain resistanceAntifouling/underwater paintsPaints with biocidesGlass fiberEmulsion

The invention discloses a novel waterproof acrylate coating. The novel waterproof acrylate coating is prepared from the following components in parts by weight: 30 to 50 parts of an acrylate modified composite emulsion, 2 to 4 parts of a fluorocarbon surfactant, 2 to 6 parts of a nano modified material, 20 to 30 parts of pigment and filler, 0.1 to 0.5 part of a humidity-controlling agent, 0.5 to 0.7 part of a dispersing agent, 0.3 to 0.5 part of an antifoaming agent, 1 to 2 parts of a coalescing agent, 0.6 to 0.8 part of a thickening agent, 0.2 to 0.8 part of an antioxidant, 0.3 to 0.7 part of glass fiber, 0.2 to 0.4 part of an anticorrosion and bactericidal agent, 0.2 to 0.6 part of emulsified paraffin and 20 to 30 parts of water. The novel waterproof acrylate coating disclosed by the invention is reasonable in formula, good in stain resistance, high in hardness and good in overall performance, and can be applied to waterproof treatment of roofs, basements, bathrooms and the like.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

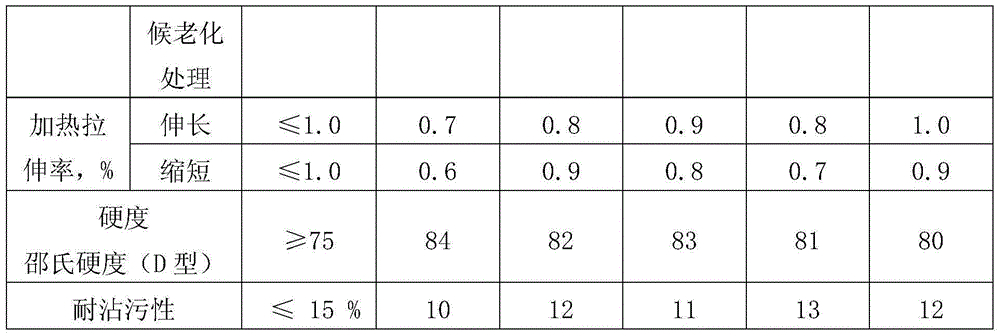

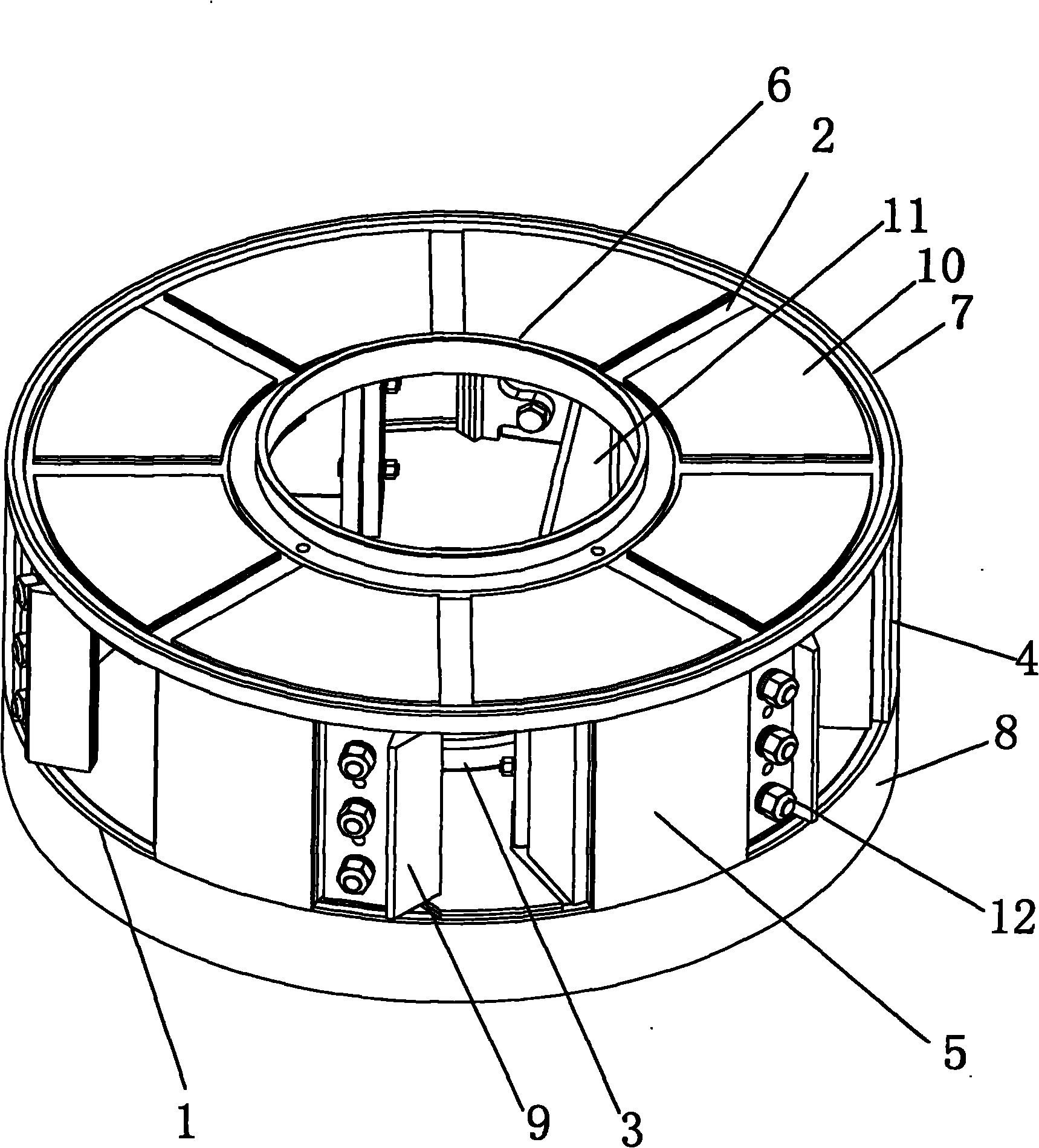

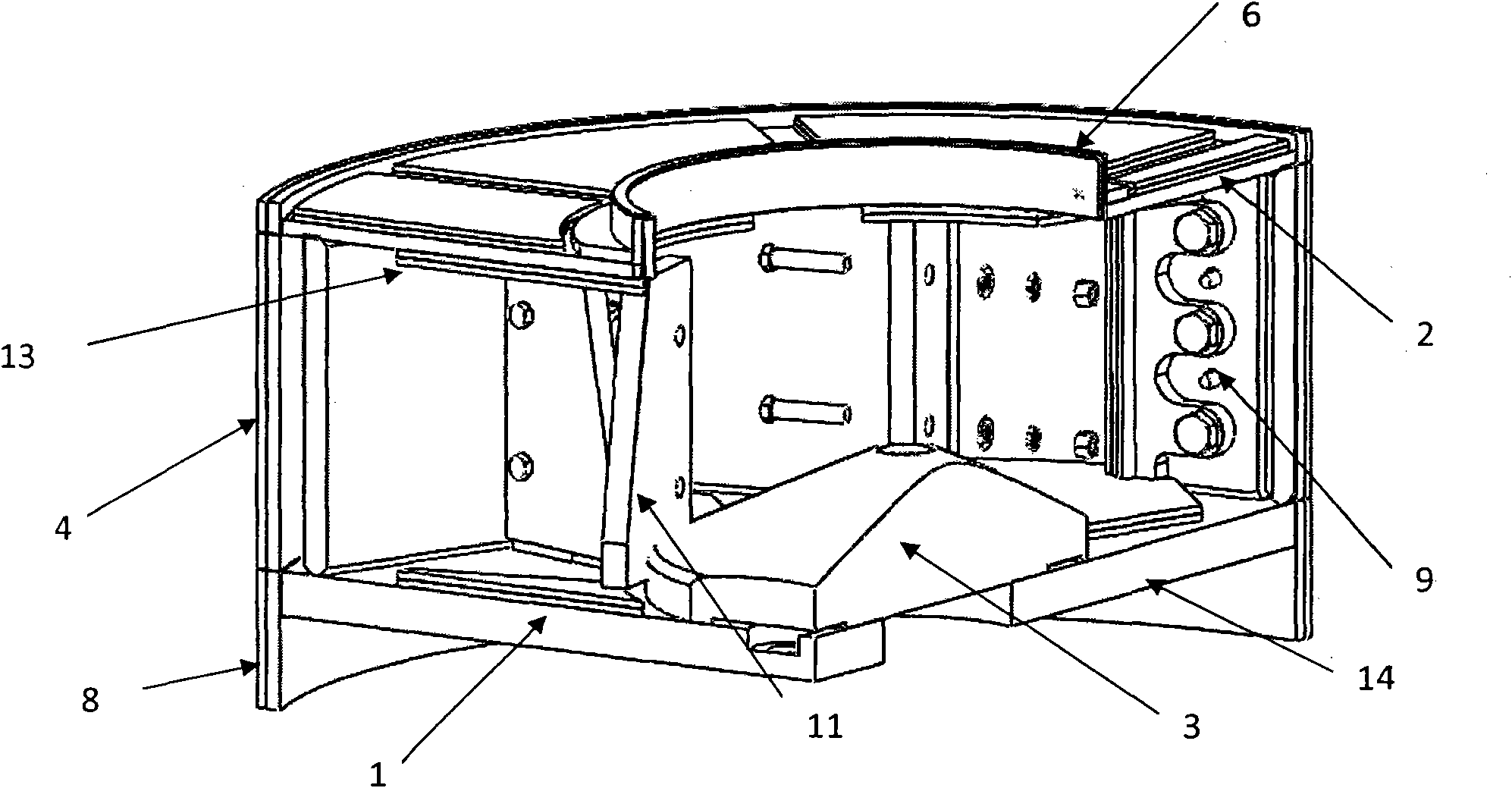

Structure type impeller breaker

The invention relates to a structure type impeller breaker, comprising a rotor; the structure type impeller breaker is characterized in that: the rotor comprises a bottom plate (1), a ring-shaped top plate (2), a material dividing cone (3) and a plurality of connection plates (4); the material dividing cone (3) is fixed on the bottom plate (1) by a fastening piece, the connection plates (4) are arranged between the bottom plate (1) and the ring-shaped top plate (2), and a material blowing opening (5) is formed between the adjacent connection plates (4); a discharging outlet protecting ring (6) is arranged at the center of the ring-shaped top plate (2), an upper protecting ring (7) is welded at the outer ring of the ring-shaped top plate (2), a lower protecting ring (8) is welded at the outer ring of the bottom plate (1), and a wear resistant material layer is arranged on the outer surface of the connection plate (4); a replaceable injection orifice lining plate (9) is arranged at the same sides of all material blowing openings (5), and an upper padding plate (13) and a lower padding plate (14) are respectively welded on the upper and lower surfaces of the material blowing opening (5). The structure type impeller breaker radically solves the difficult problem that a rotor wear-out part is hard to be used repeatedly after being worn out, a great amount of raw material can be saved and the cost is reduced.

Owner:NANJING ZHONGDA BUILDING MATERIAL EQUIP MFG

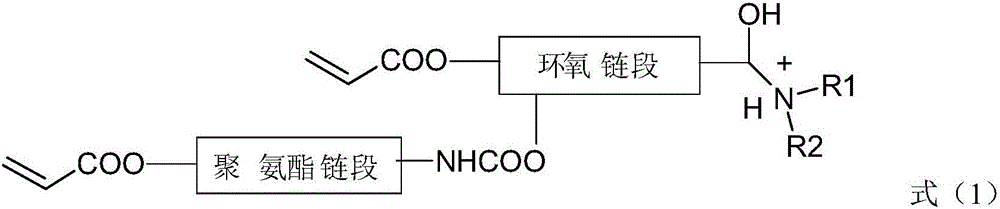

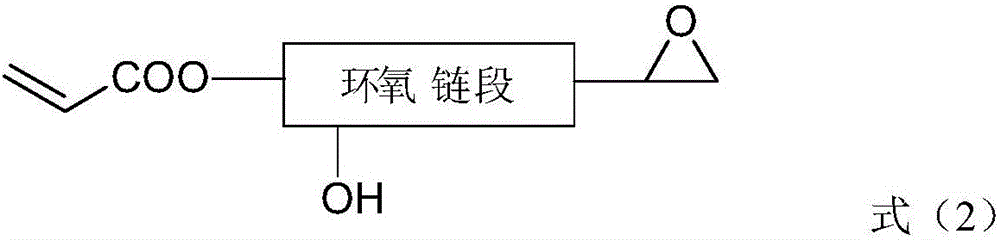

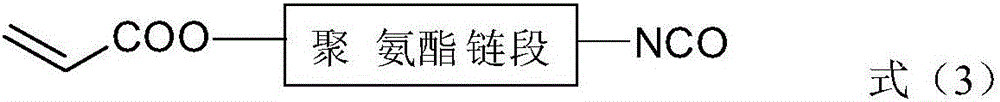

Polyurethane acrylate modified ultraviolet light cured water-dilutable resin and preparation method thereof

The invention provides polyurethane acrylate modified ultraviolet light cured water-dilutable resin and a preparation method thereof.The structure of the polyurethane acrylate modified ultraviolet light cured water-dilutable resin is shown in the formula (1), wherein R1 represents CH3 or CH2CH3 or CH2CH2OH or CH2CH2CH3 or CH2CH2CH2CH3, and R2 represents CH3 or CH2CH3 or CH2CH2OH or CH2CH2CH3 or CH2CH2CH2CH3.According to the technical scheme, the resin structure is provided with a polyurethane flexible chain segment and an epoxy rigid chain segment, a cured film has good abrasion resistance and hardness, and the after-curing hardness is H or above; meanwhile, curing can be conducted by means of ultraviolet light, and use is more convenient; water can serve as a diluent, and the toxicity and irritation of a system are reduced.

Owner:SHENZHEN POLYTECHNIC

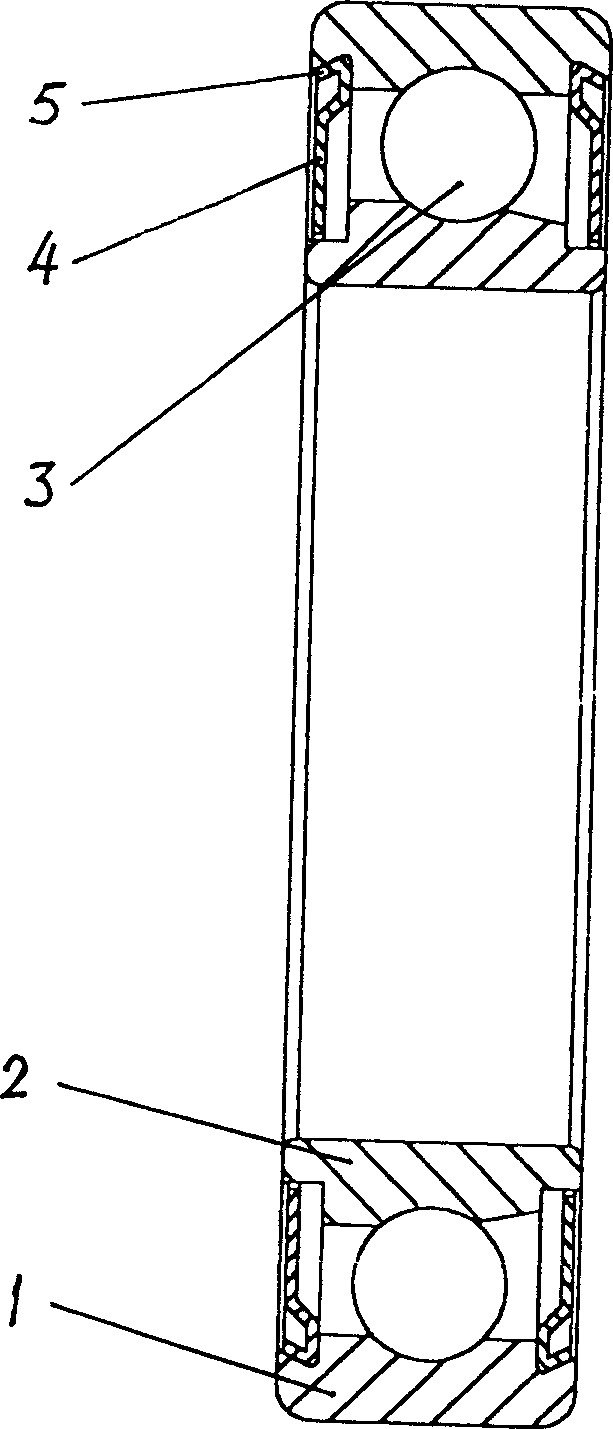

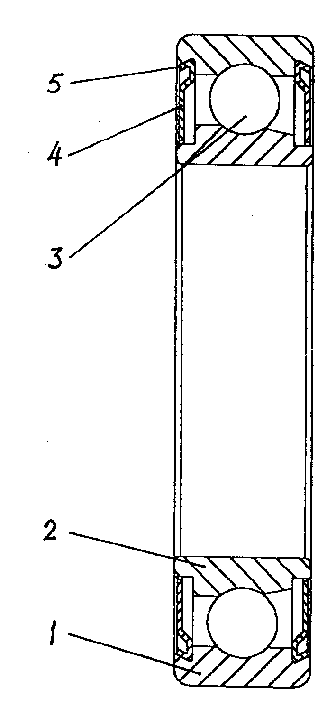

Self-lubricating angle contact ball bearing

InactiveCN1548783ASolve the problem of dustOvercoming Corrosion ResistanceBearing componentsChemical industryBall bearing

The present invention relates to angular contact bearing, and is one self-lubricating angular contact ball bearing for application in high temperature, heavy load and corrosive condition. The bearing includes rolling body, inner bearing ring and outer bearing ring, the rolling body is made of silicon nitride ceramic balls, and the inner bearing ring and the outer bearing ring are made of stainless steel. The rolling body is fully filled with balls with contact angle greater than 36 deg, and double-side dust cap is mounted between the inner bearing ring and the outer bearing ring. The present invention is self-lubricated, has high hardness, no holder and good dust preventing performance. The present invention is used mainly in butterfly valve of absolute pressure regulator in aeronautic and astronautic fields, and may be also used in field with corrosive medium, such as in chemical industry, navigation, etc.

Owner:上海市轴承技术研究所有限公司

Wooden article shading process

InactiveCN102553792AImprove adhesionImprove mechanical propertiesPretreated surfacesCoatingsAir velocityEngineering

The invention relates to a processing method for wood working of furniture industry. A wooden article shading process sequentially comprises the following steps of: a, sanding primer; b, checking whether a spray gun has an air leakage phenomenon; c, adjusting the amount of a paint; d, controlling air velocity in a spray room; e, preparing before spraying; f, spraying base color; g, shading and polishing; and h, performing secondary shading according to the step g. According to the wooden article shading process, the main means of increasing air pressure of an air gun, spraying air pressure, air velocity in the spray room, spraying pressure and distance of a spray gunpoint is adopted; and a paint film on the surface of a wooden article is rich, smooth and attractive by adopting the secondary shading method.

Owner:LANGFANG HUARI FURNITURE CO LTD

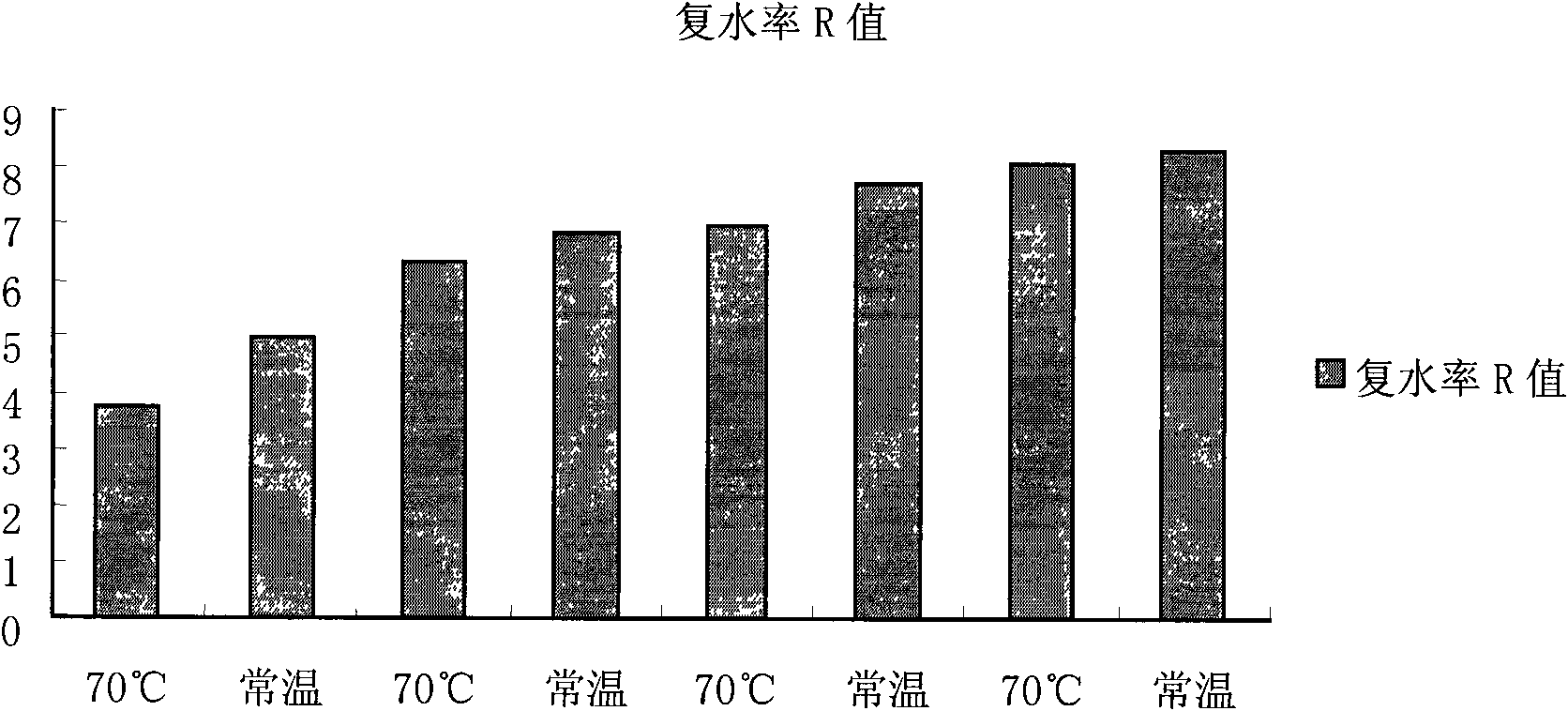

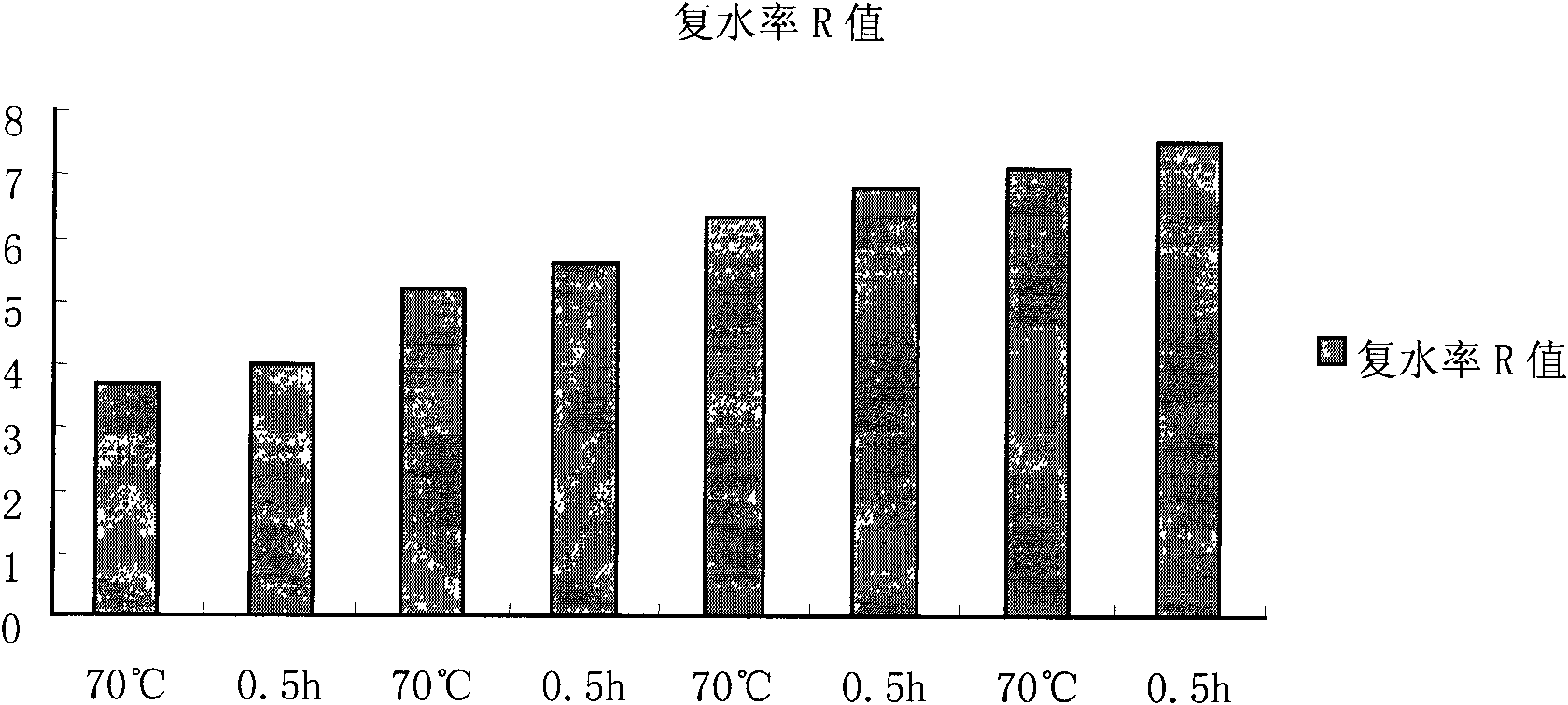

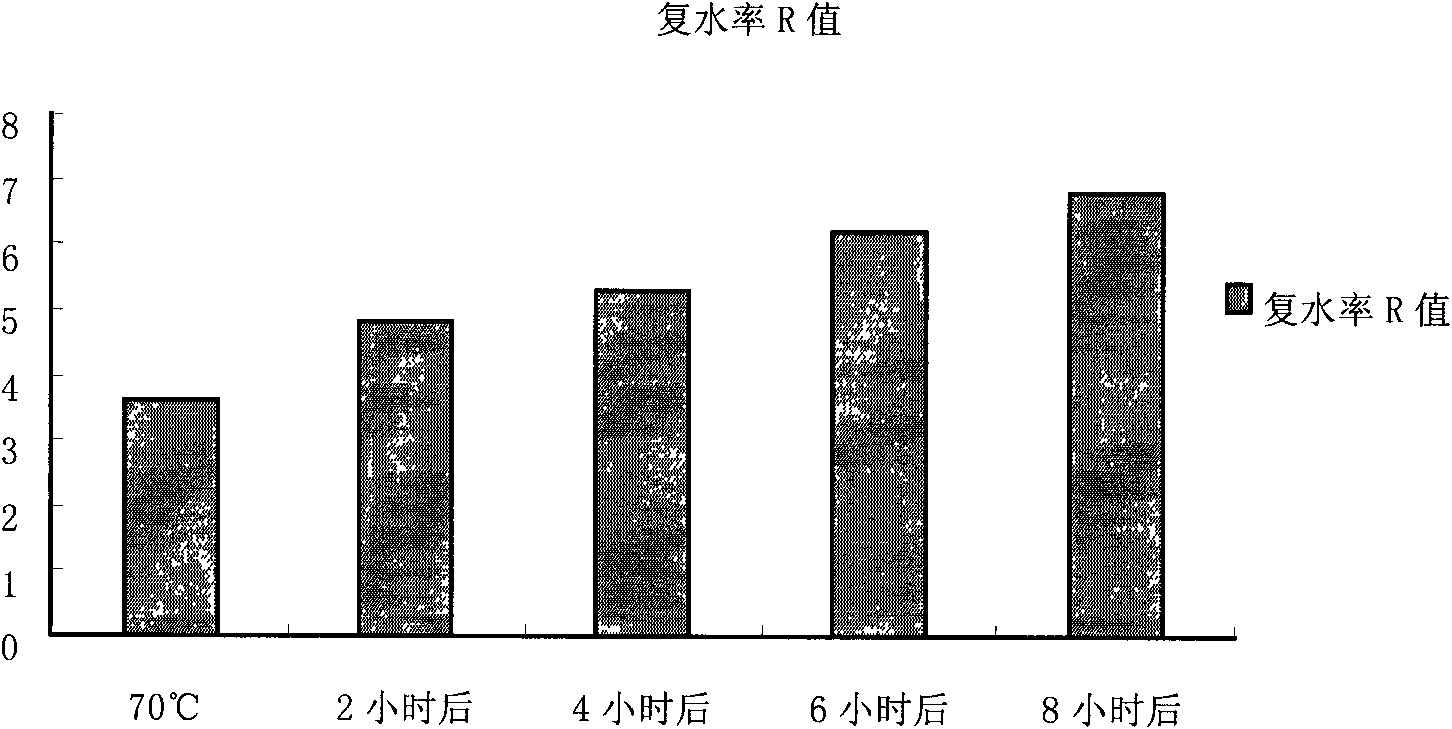

Processing method for rapidly rehydrating dried osmunds

The invention relates to a processing method for rapidly rehydrating dried osmunds, which is characterized by comprising a step of circularly immersing the dried osmunds in a heat soak solution and a normal temperature soak solution, wherein the dried osmunds are immersed for 1 h respectively in the heat soak solution and the cold soak solution each time, the temperature of the heat soak solution is 50-90 DEG C, preferably 70 DEG C, both weight ratios of the dried osmunds to the heat soak solution and the normal temperature soak solution are 1: (20-40), preferably 1: 30, and the total immersing time is 6-10h, preferably 8h. The rehydrating method adopted by the invention is short in immersing time, the rehydrated product has good quality, and the purpose of rapidly rehydrating is achieved so as to be beneficial for post-processing of the dried osmunds; meanwhile, the method optimizes rehydrating parameters and mode, thereby effectively enhancing the rehydrating effect and being beneficial for helping a producer shorten production duration better, save production cost and control quality and commercial performance of the product.

Owner:ZHEJIANG WANLI UNIV

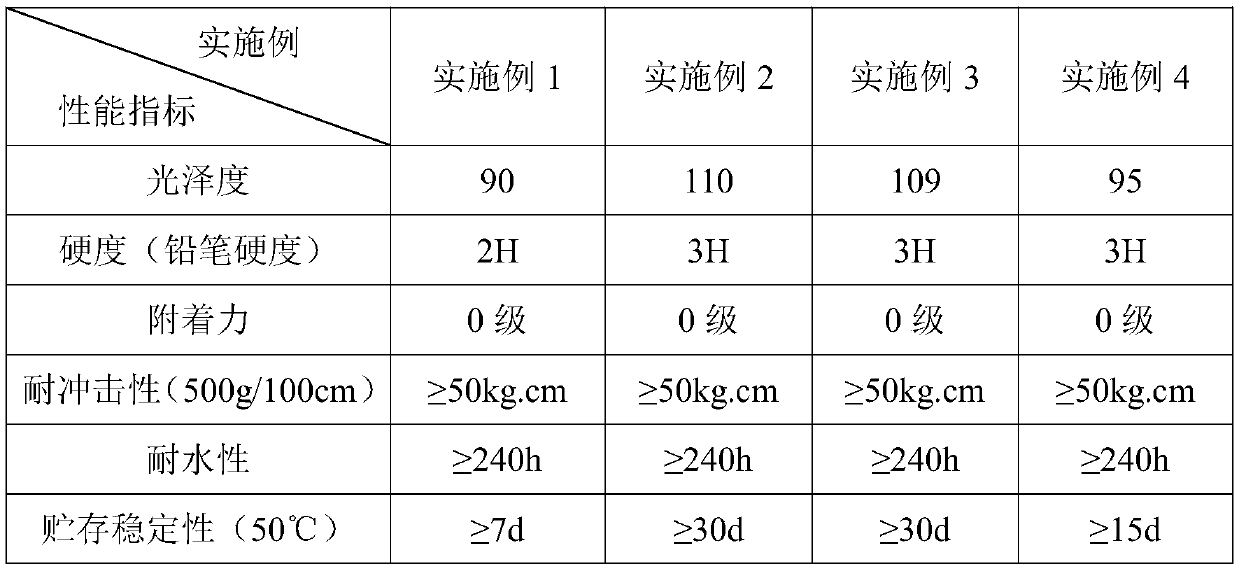

Aqueous polyester-acrylic resin hybrid body and preparation method

The invention discloses an aqueous polyester-acrylic resin hybrid body and a preparation method. The hybrid body is characterized in that a hybrid body copolymer has an acid value of 40-50mgKOH / g, andcomprises the following raw materials in parts by weight: 100 parts of a polyester prepolymer, 50-150 parts of acrylic resin, 50-100 parts of a hybridization cosolvent, 8-16 parts of a neutralizing agent and 150-250 parts of deionized water, wherein the polyester prepolymer has an acid value of 45-65mgKOH / g, and the acrylic resin has an acid value of 15-45mgKOH / g. The aqueous polyester-acrylic resin hybrid body disclosed by the invention can be adopted to prepare an amino stoving varnish together with excellent performance when being baked with amino resin (AR) at 150 DEG C. A stoving varnishmembrane has excellent mechanical properties such as wearing resistance, impact resistance, hardness, adhesiveness and the like, and excellent chemical properties such as water resistance, solvent resistance, corrosion resistance and the like, and the stoving varnish membrane is uniform and flat and good in glossiness. The hybrid body can be widely applied to the field of high-end automotive topcoats.

Owner:江西高信前沿科技有限公司

Environmentally-friendly white flat lacquer for furniture and preparation method thereof

ActiveCN104130650AOvercome the hardnessOvercome the bad anti-back stickinessPolyurea/polyurethane coatingsLacquerDrying time

The invention discloses environmentally-friendly white flat lacquer for furniture and a preparation method thereof. The environmentally-friendly white flat lacquer comprises, by weight, 40-60% of a fluorocarbon-modified acrylic acid emulsion, 10-20% of a polyurethane emulsion, 15-20% of titanium dioxide, 4-9% of a film forming assistant and 4-16% of water. The environmentally-friendly white flat lacquer improves the traditional formula, improves hardness of a film of the existing aqueous furniture paint, improves after-tackiness resistance, greatly shorts drying time, is nontoxic and environmentally friendly, can be directly constructed, is beautiful, reduces labor intensity of a worker, does not influence health of the worker, has advantages of the furniture paint, utilizes water as a main solvent, avoids non-renewable resource wasting and belongs to an energy-saving environmentally-friendly product.

Owner:FOSHAN GAOMING FULONGSI NEW MATERIAL TECH

Large-deformation enhanced rapid ion nitriding method

ActiveCN109371212AImproves strength and hardnessHigh chemical activitySolid state diffusion coatingDislocationIon

The invention belongs to the technical field of metal surface treatment, and relates to a large-deformation enhanced rapid ion nitriding method. The large-deformation enhanced rapid ion nitriding method comprises the specific steps that original steel is machined and cut into a plate shape; plate-shaped to-be-nitrided steel is subjected to solution treatment; solid-solution-state to-be-nitrided steel is placed in a cold rolling machine to be subjected to cold rolling treatment; and the large-plastic-deformation to-be-nitrided steel obtained after cold rolling treatment is machined and cut intoa sample, and then ion nitriding treatment is conducted. According to the method, the large plastic deformation treatment is conducted before ion nitriding, the dislocation density in a microstructure is obviously increased, grains are obviously refined, in the nitriding process, a rapid diffusion channel is provided for nitrogen atoms through high-density dislocation and other defects, the ion nitriding efficiency is obviously improved, and the thickness of a nitriding layer is improved; and under the situation that the same nitriding layer depth is obtained, the nitriding time can be greatly shortened, accordingly, the energy is saved, and the production cost is reduced.

Owner:CHANGZHOU UNIV

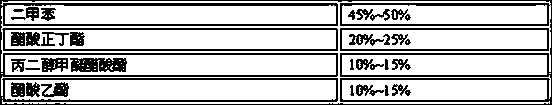

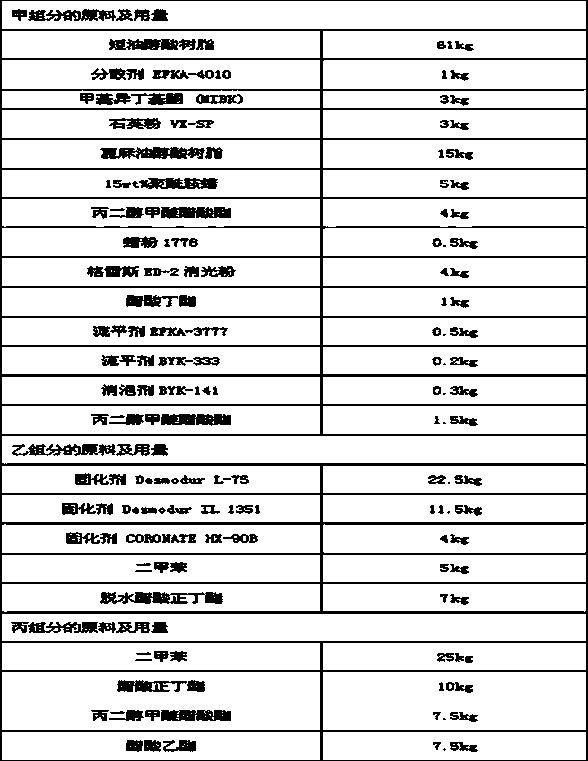

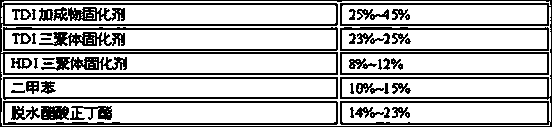

Wear-resistant anti-cracking PU matt floor paint

ActiveCN103555190AHigh hardnessImprove wear resistancePolyurea/polyurethane coatingsPolymer sciencePolymer chemistry

The invention relates to wear-resistant anti-cracking PU matt floor paint, belonging to the wooden floor paint manufacturing industry. In the wear-resistant anti-cracking PU matt floor paint provided by the invention, the short-oil alkyd resin, castor oil alkyd resin, TDI addition product curing agent, TDI trimer curing agent and HDI trimer curing agent are used as the main paint film forming matters, and the crosslinking degree is remarkably improved; under the effect of a dispersant EFKA-4010, the film forming matters interact with quartz powder; after film formation, the floor paint can be uniformly and neatly arranged on the surface of the pain film so that the paint film has relatively high hardness. The HDI hexamethylene diisocyanate in the trimer curing agent (HX-90B) interacts with the components such as short-oil alkyd resin and castor oil alkyd resin, and the flexibility of the paint film is remarkably improved. Therefore, by adopting the wear-resistant anti-cracking PU matt floor paint provided by the invention, the hardness of the paint film is improved while the flexibility of the paint film can be remarkably improved so as to overcome the contradictory relation between hardness and flexibility.

Owner:山东巴德士新材料有限公司

Precision casting technology of hard and wear-resistant automotive pump

InactiveCN108034882AOvercome the hardnessHigh hardnessFoundry mouldsFurnace typesConventional castingWear resistant

The invention discloses a precision casting technology of a hard and wear-resistant automotive pump. The precision casting technology of the hard and wear-resistant automotive pump comprises the following steps: making a casting mould and casting a pump body, wherein a casting mould is formed by combing a cast mould and an inner mould which are connected by a high-temperature-resistant adhesive, and is filled with mixed quartz sand; the pump body casting step comprises the following steps: (1), selecting a casting raw material; (2), smelting the casting raw material; (3), rapidly casting; (4),annealing, quenching and tempering; (5), roughing, deburring, polishing and performing flaw detection; and (6), performing quality inspection. By the precision casting technology, the problem of lowhardness and wear resistance of a pump body cast by the conventional casting technology is solved, so that the hardness and the wear resistance of the pump body are improved; and in addition, throughoverall reformation of the casting mould, the possibility of impurity introduction in the casting process can be effectively reduced, so that the intrinsic quality of the pump body is also guaranteedand the service life of the pump body is prolonged.

Owner:TAIZHOU BOSHITE PRECISION CASTING CO LTD

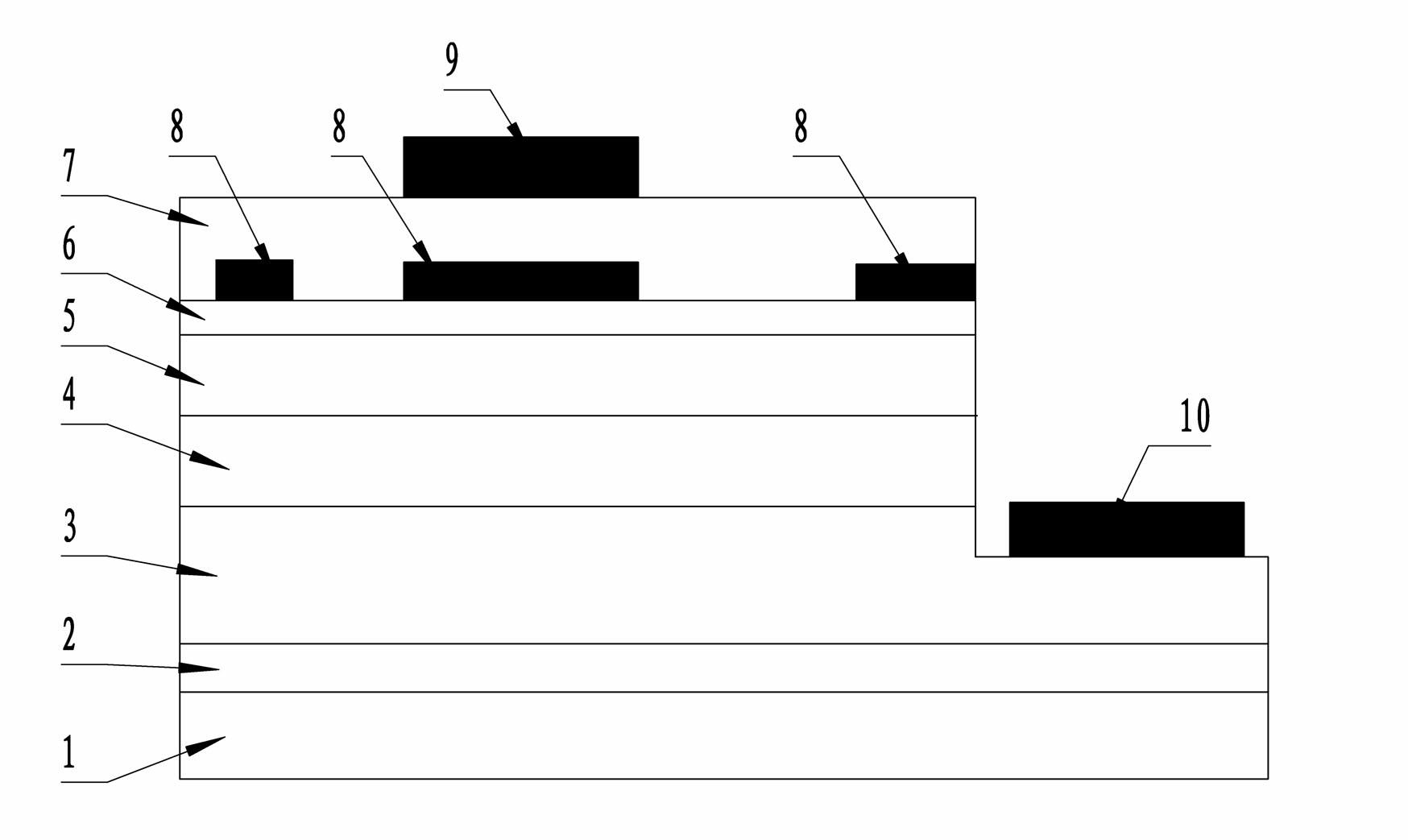

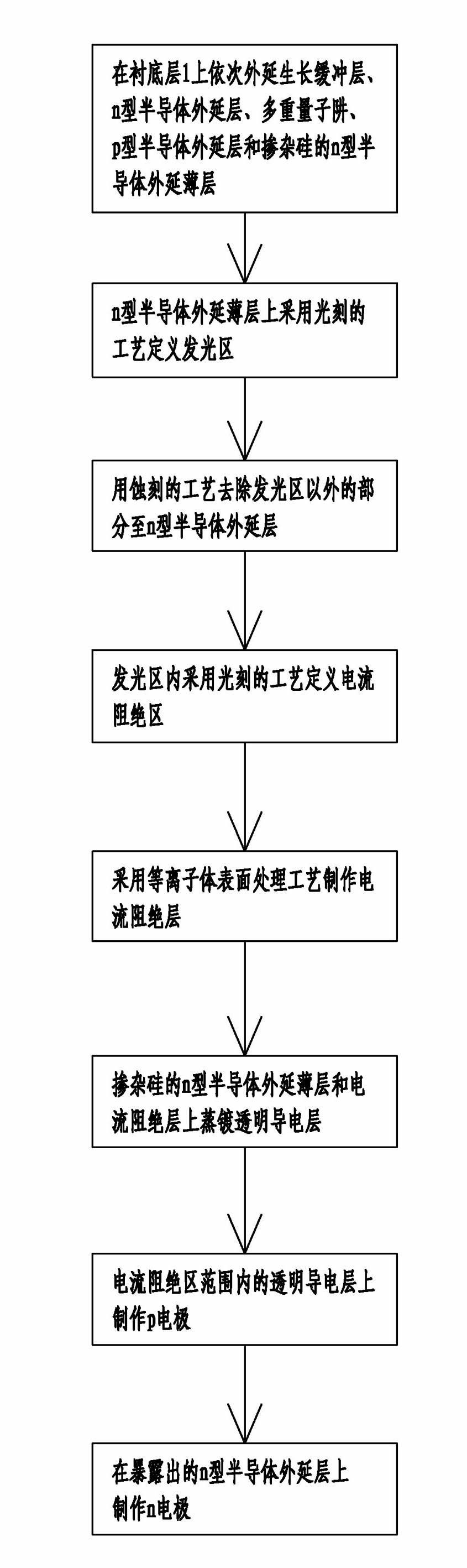

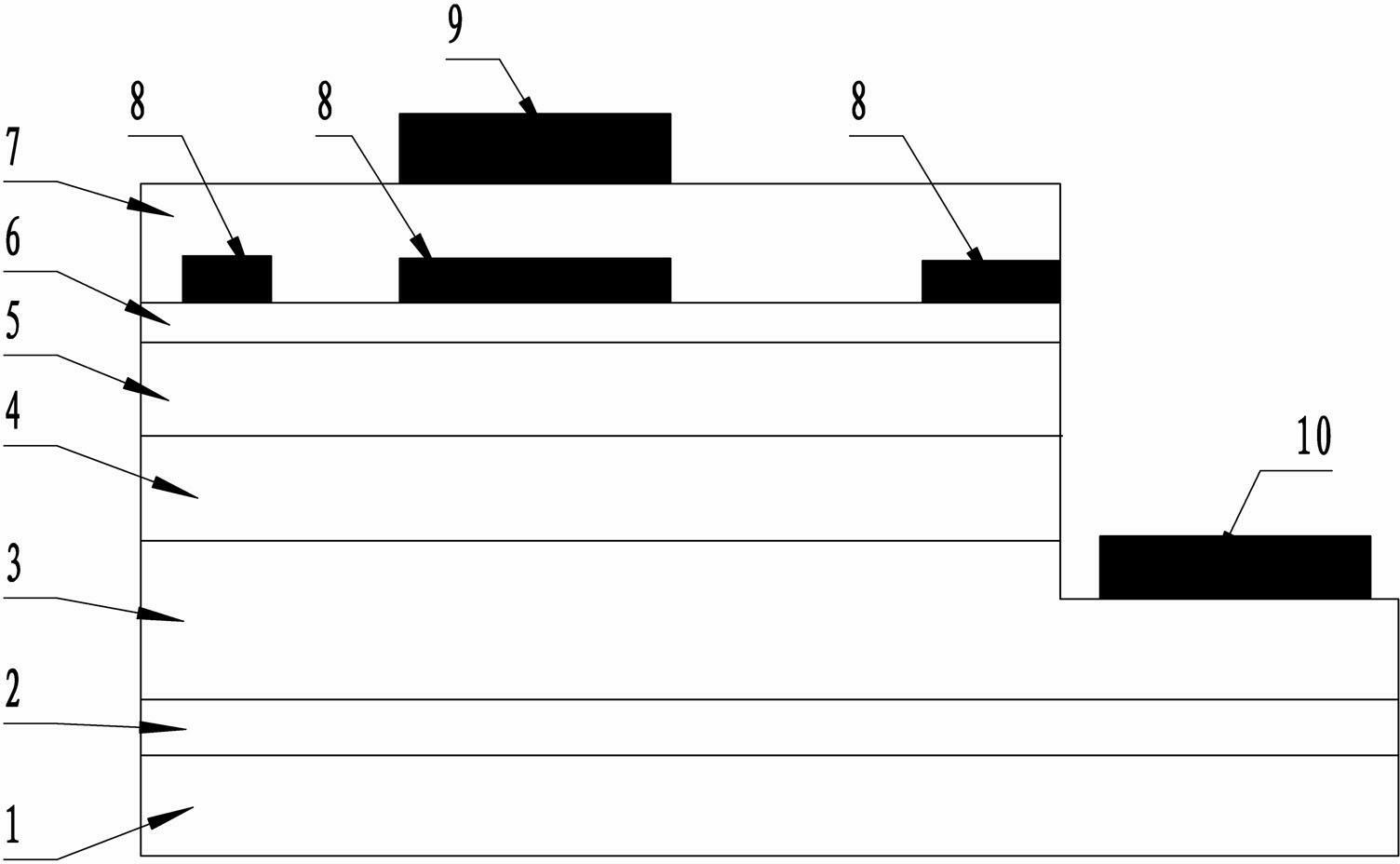

Light-emitting diode with current blocking layer and manufacturing method thereof

InactiveCN102290512AGood current blocking effectLow costSemiconductor devicesMultiple quantumElectrically conductive

The invention provides a light-emitting diode with a current blocking layer, comprising an n-type semiconductor epitaxial layer, a multiple quantum well, and a p-type semiconductor epitaxial layer arranged in sequence from bottom to top, and the p-type semiconductor epitaxial layer is further provided with A silicon-doped n-type semiconductor epitaxial thin layer, a current blocking layer is arranged in the light-emitting region defined on the silicon-doped n-type semiconductor epitaxial thin layer, and the silicon-doped n-type semiconductor epitaxial thin layer and The current blocking layer is provided with a transparent conductive layer, the transparent conductive layer is provided with a p-electrode, the p-electrode is arranged above the range of the current blocking layer, and the n-type semiconductor epitaxial layer is provided with an n-electrode ; According to the above light-emitting diodes, the present invention provides its manufacturing method. The light-emitting diode provided with the current blocking layer of the present invention has the advantages of ideal compactness and hardness of the current blocking layer, simple manufacturing process and low cost.

Owner:冠铨(山东)光电科技有限公司

Silver-lanthanum-calcium alloy bonding wire and manufacturing method thereof

InactiveCN103996668ALow priceReduce performanceSemiconductor/solid-state device detailsSolid-state devicesSterling silverBusbar

The invention discloses a silver-lanthanum-calcium alloy bonding wire and a manufacturing method thereof. According to the bonding wire, high sterling silver is used as a main part material, and a lanthanum metal material, a calcium metal material and a gold metal material are included. The bonding wire comprises, by weight, 95-97% of silver, 2-3% of lanthanum, 0.5-1% of calcium and 0.5-1% of gold. The manufacturing method includes the steps that the high sterling silver with the purity being larger than 99.9999% is extracted to be prepared into silver alloy ingots and then to be prepared into cast condition silver-lanthanum-calcium alloy busbars, the alloy busbars are pulled to be wires of about 1 mm, heat treatment is completed, and then precision drawing, heat treatment and washing are conducted so that silver-lanthanum-calcium alloy bonding wires of different specifications can be manufactured.

Owner:江西蓝微电子科技有限公司

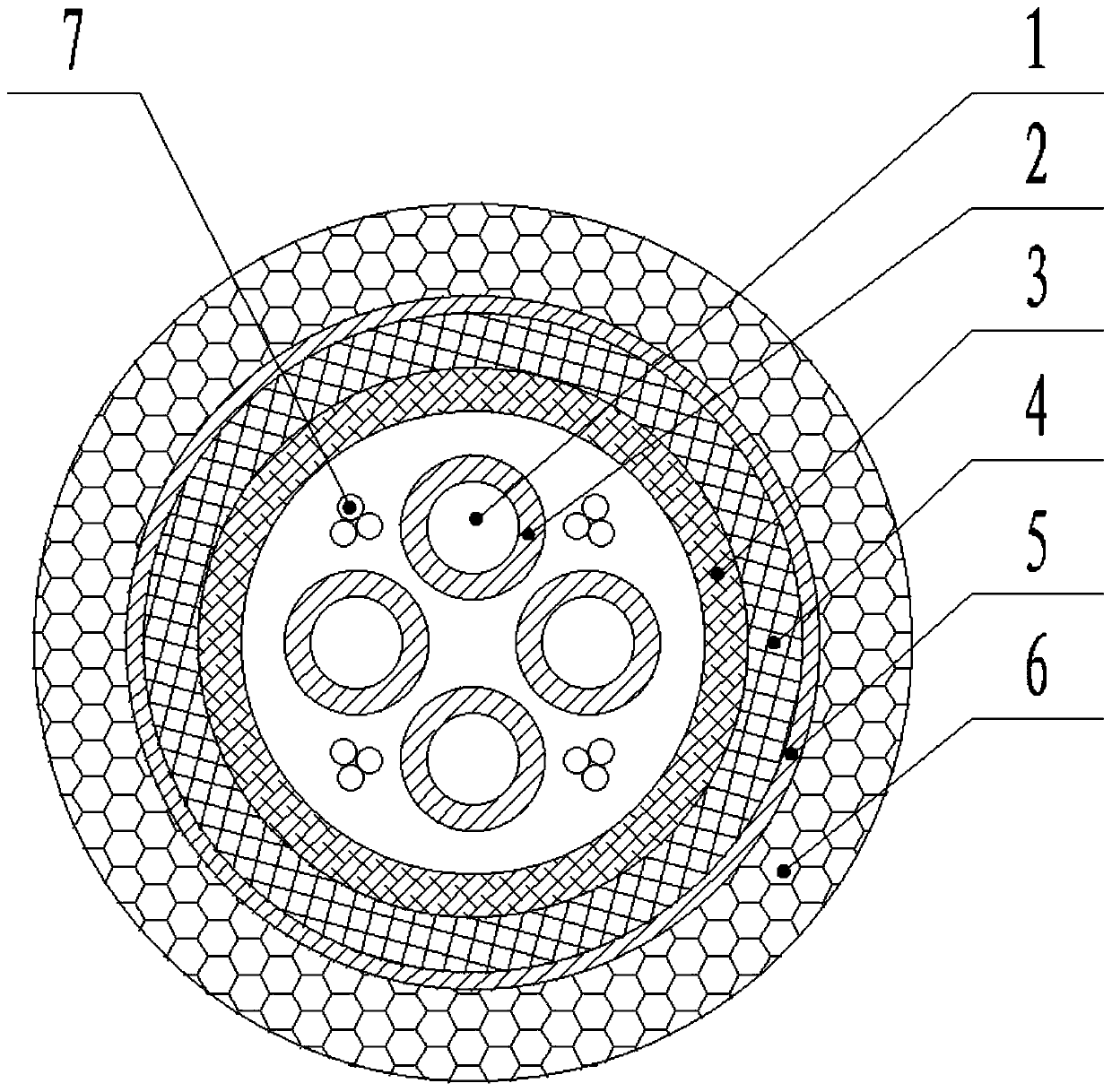

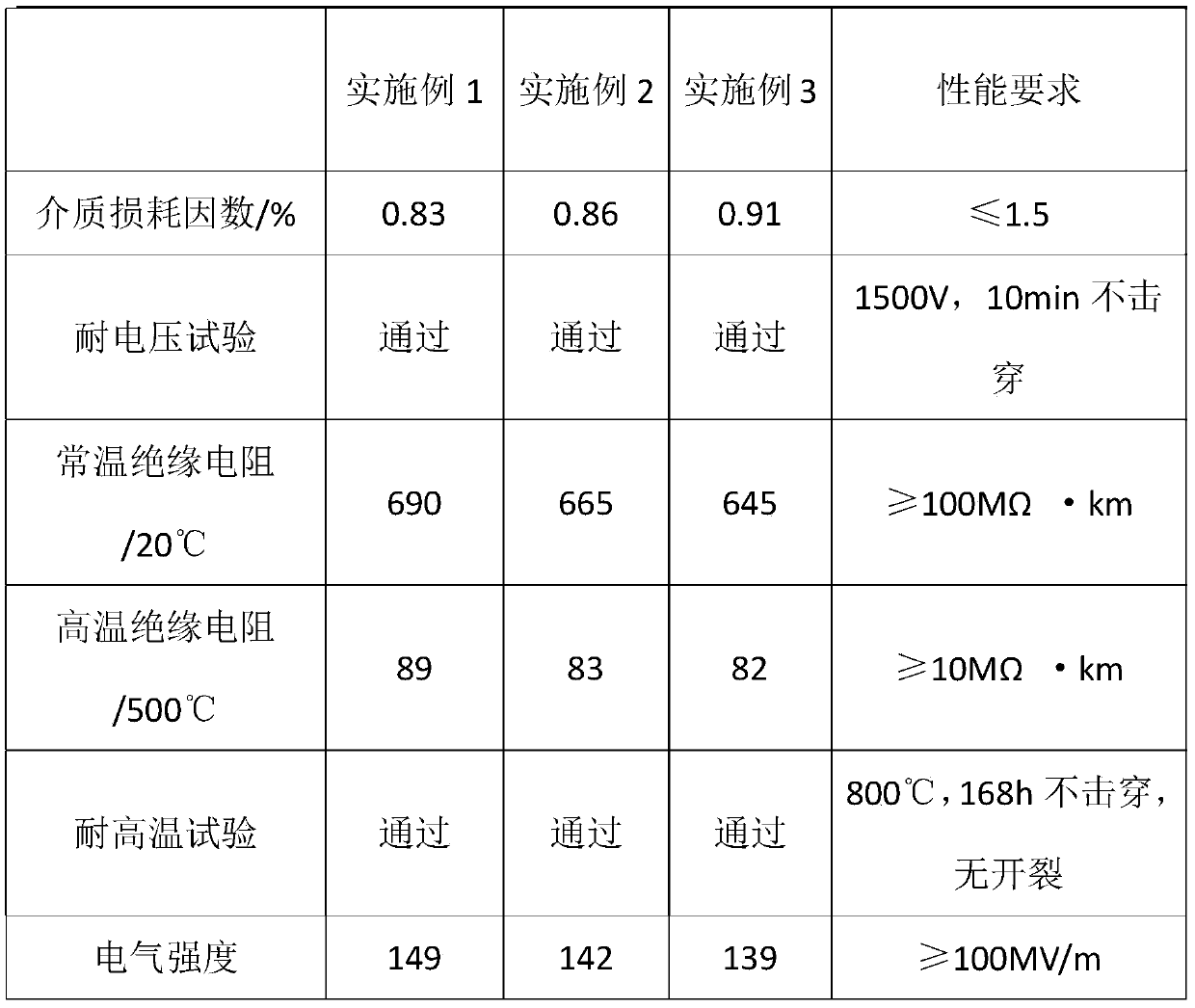

Stretching-resistant high-temperature-resistant aerospace cable and preparation method thereof

ActiveCN111276287AMeet performance requirementsOvercoming weightInsulated cablesInsulated conductorsInsulation layerAdhesive

The invention discloses a stretching-resistant and high-temperature-resistant aerospace cable and a preparation method thereof. The stretching-resistant and high-temperature-resistant aerospace cablecomprises a high-temperature-resistant sheath layer, a flame-retardant semi-conductive cloth tape layer wrapping layer, a glass fiber woven layer, a composite heat insulation layer wrapping layer anda cable core from outside to inside, wherein the cable core is formed by twisting a plurality of wires, aramid fibers are filled among the wires, each wire comprises a core material and a polyimide wrapping layer wrapping the core material, and nano inorganic particles are added into the polyimide wrapping layer; the composite heat insulation layer wrapping comprises a synthetic mica paper base material, iron oxide red silica gel belts are adhered to the two faces of the synthetic mica paper base material through high-temperature-resistant inorganic adhesives, and glass paper is adhered to theouter sides of the iron oxide red silica gel belts through high-temperature-resistant inorganic adhesives. The aerospace cable disclosed by the invention is excellent in various performances, not only meets the performance requirements of all aerospace cables, but also considers various environmental conditions possibly existing in the application process, and has extremely high technological content and application prospect.

Owner:济南今日复兴电气集团有限公司

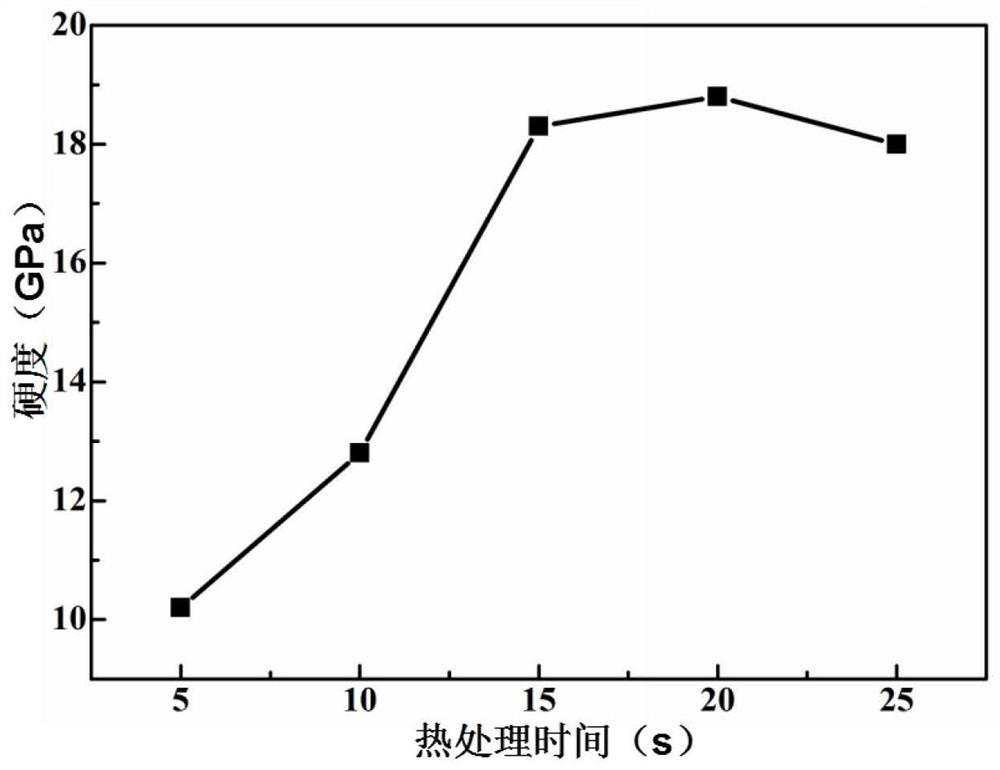

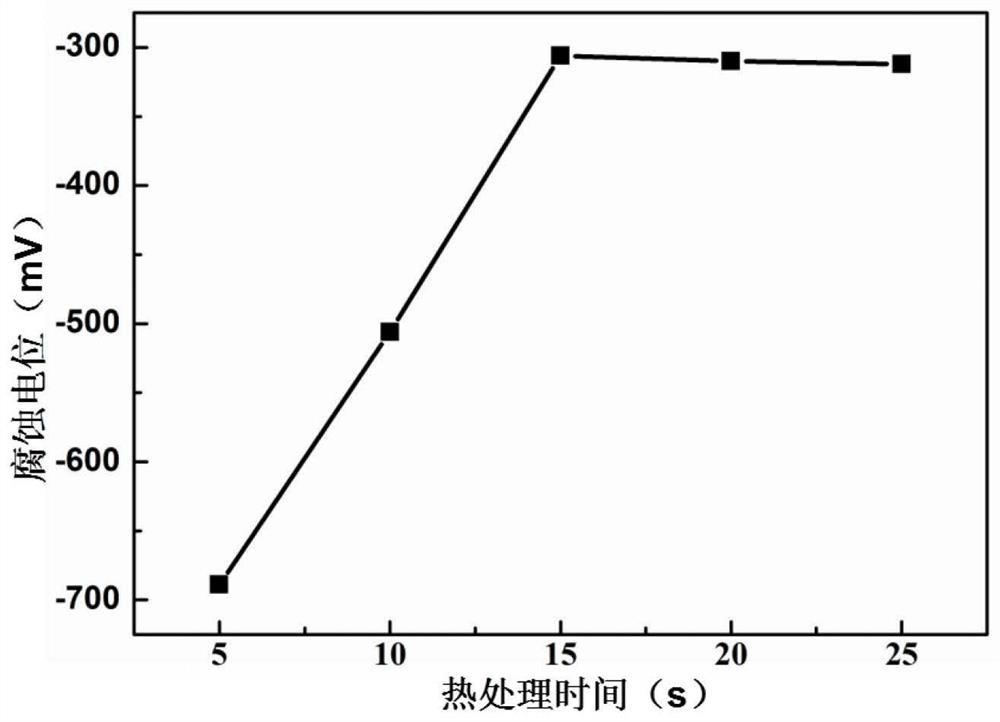

Porous high-entropy alloy oxide film and preparation method thereof

ActiveCN112553576AUniform porosityHigh hardnessVacuum evaporation coatingSputtering coatingHigh entropy alloysThin membrane

The invention belongs to the technical field of high-entropy alloys, and particularly relates to a porous high-entropy alloy oxide film and a preparation method thereof. The preparation method comprises the following steps of: co-sputtering a CoCrFeMnNi target material and an Al target material, then soaking in a dealloying solution for dealloying treatment to obtain a porous high-entropy alloy film, and finally performing heat treatment by using a sealing tube to obtain the porous high-entropy alloy oxide film on the surface. The prepared porous high-entropy alloy oxide film is uniform in pore, high in hardness and resistant to corrosion, the pore density can be adjusted by controlling an Al component, the preparation process is simple, large-area operation can be achieved, and the production efficiency is high.

Owner:JIANGSU UNIV OF TECH

Heat treatment process of 7A33 aluminum alloy sheet

The invention discloses a heat treatment process of a 7A33 aluminum alloy sheet; tests research the influence of annealing, quenching and double aging process parameters on the mechanical performance and the structure of the 7A33 aluminum alloy sheet, measure the intergranular corrosion performance, the stress corrosion performance and the electrical conductivity of alloy samples, and determine an O-state annealing process system capable of enabling the alloy sheet to obtain better comprehensive performance to preserve the temperature of 390-410 DEG C for 2 h; a T62-state heat treatment process system is 460 DEG C of quenching temperature and water quenching; and the double aging system is 75 DEG C for 1 h and 150 DEG C for 20 h. The 7A33 aluminum alloy sheet accordant with the requirement is industrially produced.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com