Self-lubricating angle contact ball bearing

An angular contact ball bearing and self-lubricating technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of corrosion resistance and high temperature resistance, high temperature resistance and corrosion resistance, and failure to pass the bearing salt spray test. Solve the problem of dust prevention, the friction coefficient is small, and it is beneficial to the effect of heavy load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

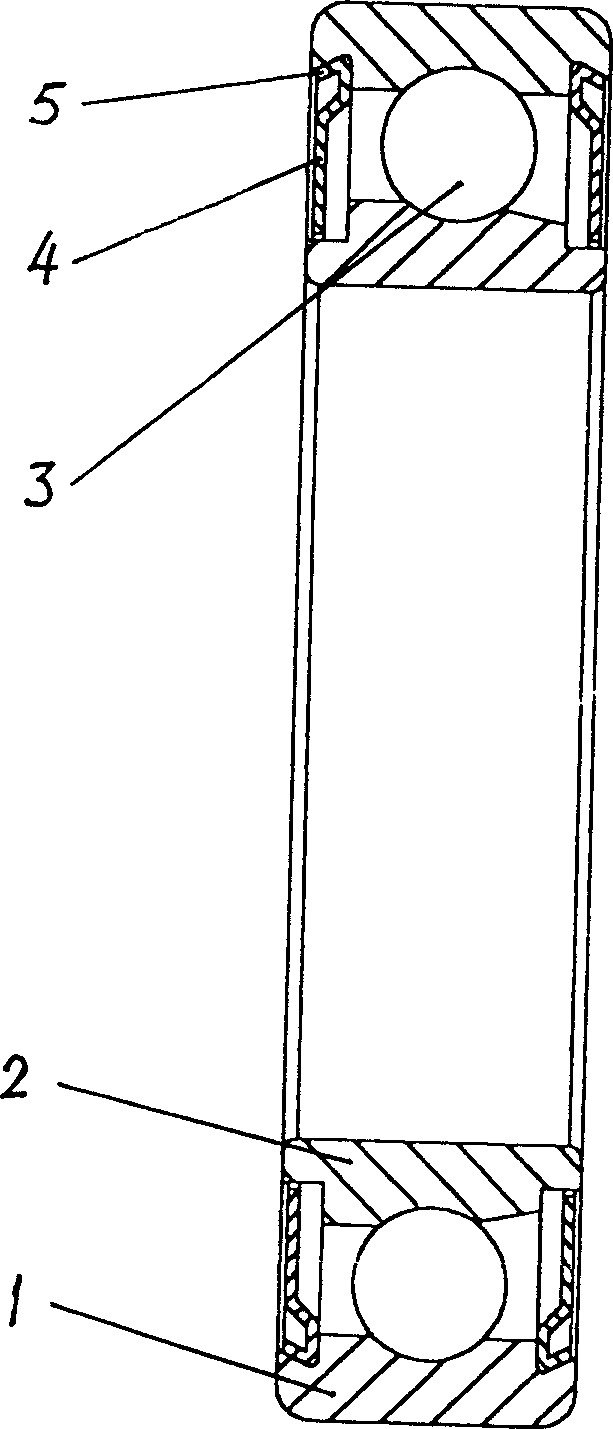

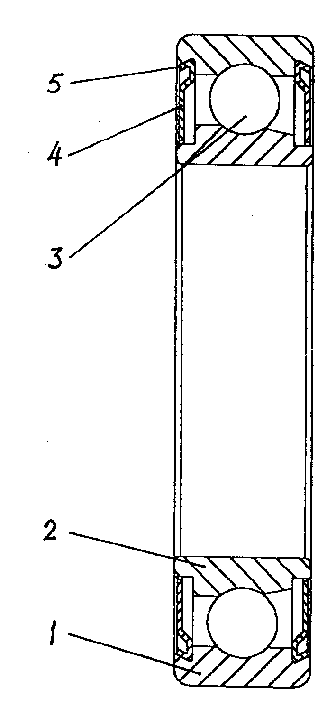

[0011] see figure 1 , a self-lubricating angular contact ball bearing, comprising a rolling body 3, a bearing inner ring 2, and a bearing outer ring 1. The rolling element 3 is a silicon nitride (Si3N4) ceramic ball, and the silicon nitride (Si3N4) ceramic ball is subjected to high temperature and high pressure (2000°C, 2000kg / cm 2 ) post-treatment to improve the easily corroded grain boundary phase and improve the stability of the ceramic ball. Bearing inner ring 2 and bearing outer ring 1 are made of 940 stainless steel. The 940 steel has undergone special heat treatment, and its hardness can reach HRC50, which meets flight requirements and meets the life index of nearly 10,000 swings under heavy load conditions, and reaches temperature shock (-70 ℃450℃) test and salt spray test. The silicon nitride (Si3N4) rolling element 3 cooperates with the 940 stainless steel bearing inner ring 2 and the bearing outer ring 1, the friction coefficient is small, self-lubrication is real...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com