Granularity-adjustable laying hen feed and preparation method thereof

A layer and particle size technology, which is applied in animal feed, animal feed, additional food elements, etc., can solve the problems of uneven material particle size, low energy utilization rate, poor uniformity, etc., achieve small particle size difference, strengthen nutritional value, The effect of low excretion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

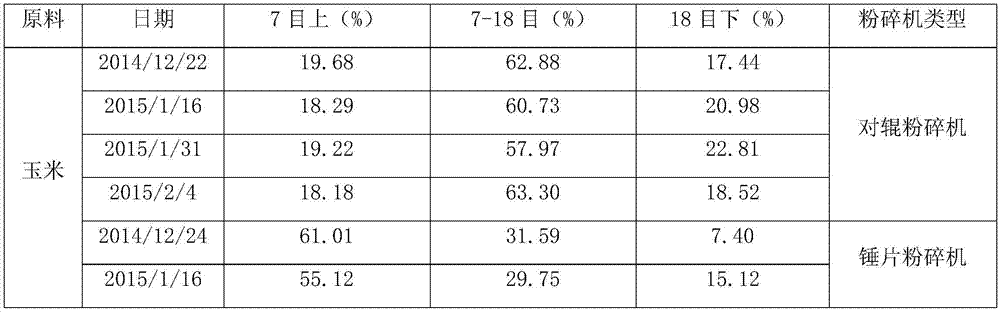

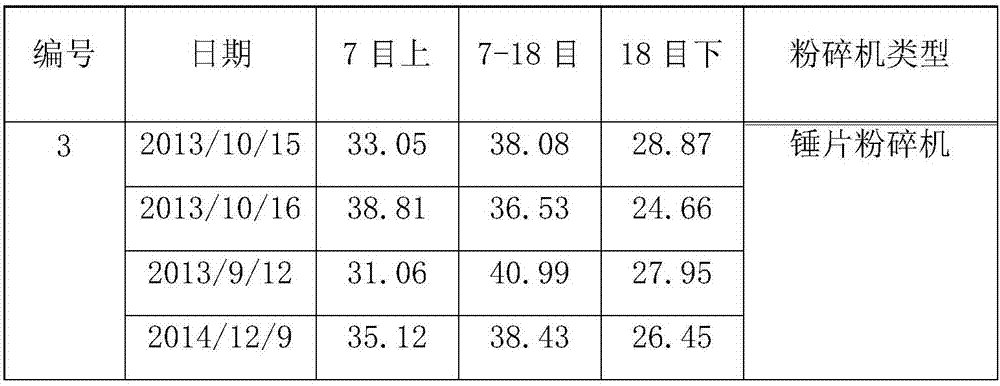

[0053] A method for preparing laying hen feed with particle size control, comprising the following steps: corn, the main raw material of laying hen feed, is pulverized by a roller mill, sieved by a vibrating sieve, and the under-sieve is used for standby; the over-sieve is then pulverized by a hammer mill , and mix with the undersieve evenly to obtain the main raw materials after crushing. Prepare laying hen feed according to a conventional method.

[0054] The laying hen feed with regulated granularity is made of the following raw materials in parts by weight: 50 corn, 12 soybean meal, 8.30 DDGS, 8.5 stone powder, 5 corn bran, 2.2 canola meal, 1.5 monosodium glutamate protein, 1.4 rice bran oil, Calcium hydrogen phosphate 0.55, palm meal 9.20, 70% lysine sulfate 0.2, salt 0.24, DL-methionine 0.168, baking soda 0.1, choline chloride 0.04, threonine 0.134, arginine 0.2, valine 0.174 , betaine 0.03, compound enzyme 0.03, phytase 0.01, compound vitamin 0.05, compound trace eleme...

Embodiment 2

[0071] A method for preparing laying hen feed with particle size control, comprising the following steps: corn, the main raw material of laying hen feed, is pulverized by a roller mill, sieved by a vibrating sieve, and the under-sieve is used for standby; the over-sieve is then pulverized by a hammer mill , and mix with the undersieve evenly to obtain the main raw materials after crushing. Prepare laying hen feed according to a conventional method. The main raw material is: corn.

[0072] The laying hen feed with particle size control is made of the following raw materials in parts by weight: 40 corn, 14 soybean meal, 8.50 DDGS, 9.0 stone powder, 4 corn bran, 2.4 canola meal, 2.0 monosodium glutamate protein, 1.6 rice bran oil, Calcium hydrogen phosphate 0.6, palm meal 8, 70% lysine sulfate 0.5, salt 0.1, DL-methionine 0.3, baking soda 0.1, choline chloride 0.06, threonine 0.4, arginine 0.6, valine 0.1 , betaine 0.05, compound enzyme 0.05, phytase 0.01, compound vitamin 0.02...

Embodiment 3

[0084] A method for preparing laying hen feed with particle size control, comprising the following steps: corn, the main raw material of laying hen feed, is pulverized by a roller mill, sieved by a vibrating sieve, and the under-sieve is used for standby; the over-sieve is then pulverized by a hammer mill , and mix with the undersieve evenly to obtain the main raw materials after crushing. Prepare laying hen feed according to a conventional method. The main raw material is: corn.

[0085] The laying hen feed with particle size control is made of the following raw materials in parts by weight: 60 corn, 14 soybean meal, 8.10 DDGS, 8.0 stone powder, 6 corn bran, 2.0 canola meal, 1.0 monosodium glutamate protein, 1.2 rice bran oil, Calcium hydrogen phosphate 0.6, palm meal 8, 70% lysine sulfate 0.1, salt 0.4, DL-methionine 0.3, baking soda 0.3, choline chloride 0.06, threonine 0.4, arginine 0.2, valine 0.5, betaine 0.05, compound enzyme 0.05, phytase 0.02, compound vitamin 0.08,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com