Patents

Literature

182 results about "Hammer mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hammer mill, hammer forge or hammer works was a workshop in the pre-industrial era that was typically used to manufacture semi-finished, wrought iron products or, sometimes, finished agricultural or mining tools, or military weapons. The feature that gave its name to these workshops was the water-driven trip hammer, or set of hammers, used in the process. The shaft, or 'helve', of the hammer was pivoted in the middle and the hammer head was lifted by the action of cams set on a rotating camshaft that periodically depressed the end of the shaft. As it rose and fell, the head of the hammer described an arc. The face of the hammer was made of iron for durability.

Compactor Feeder

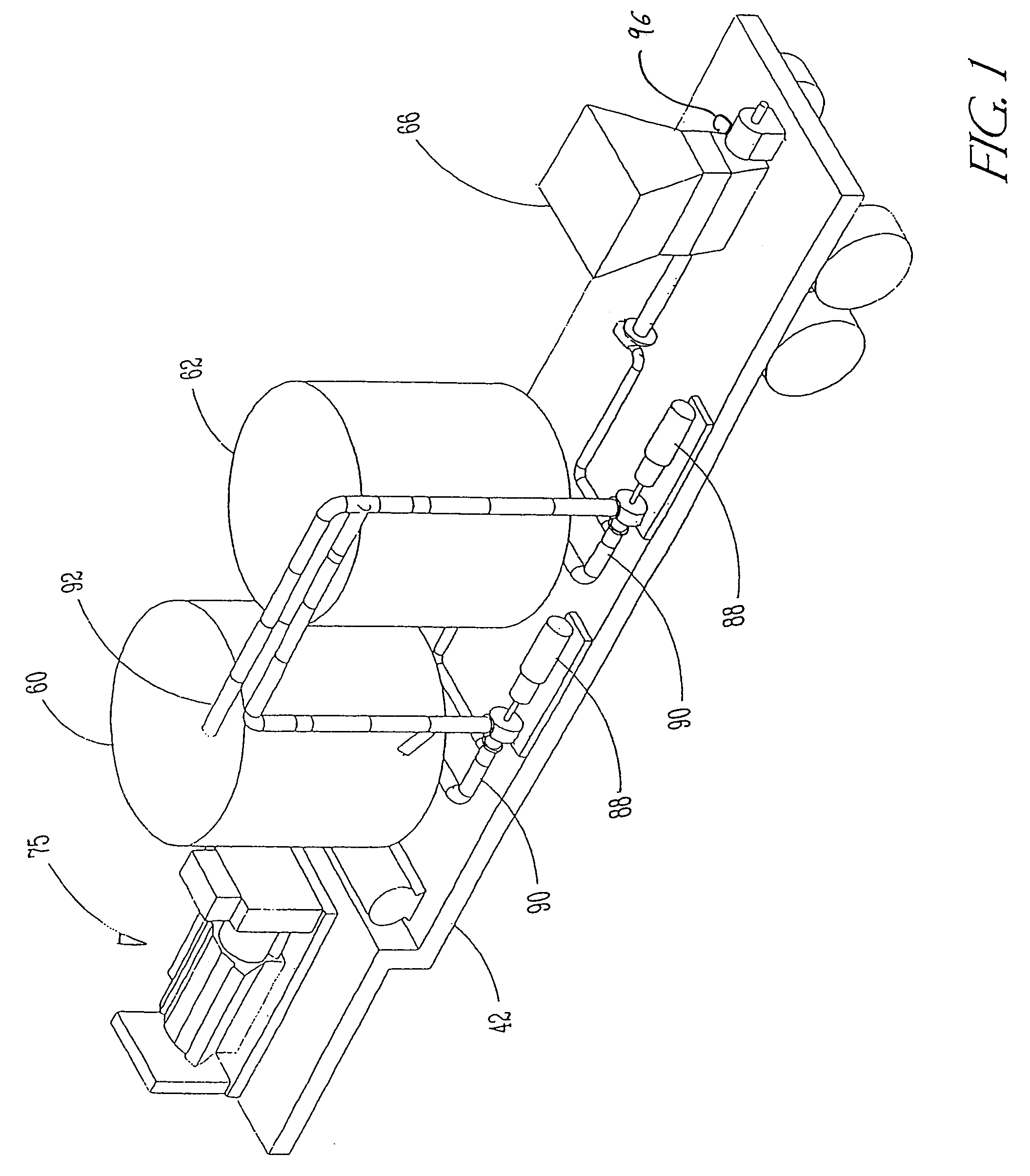

A compactor feeder and methods for feeding relatively low-density biomass materials into a grinding device (such as a hammer mill) is described. The compactor feeder increases the density of the relatively low-density biomass materials in order to fill the grinding device with the biomass materials at a rate that is sufficient to substantially equal the design capacity of the grinding device.

Owner:SURE CHAMPION INVESTMENT LTD

Method and apparatus for the manufacture of meat

InactiveUS6635301B1Proteins working-up by texturisingAnimal feeding stuffMineral bindingTemperature control

A method of manufacturing a texturised proteinaceous meat analogue product, including: subjecting, in a food extruder a mixture containing: about 40 to 95% by weight edible proteinaceous materials selected from the group of predetermined mixtures of defatted soy flour, soy meal, soy concentrate, cereal gluten in vital or starch-containing form and egg white, and up to about 7% by weight of edible mineral binding and cross-linking compounds; to mechanical pressure and added heat sufficient to convert the mixture into a hot, viscous protein lava; extruding the protein lava through and from a temperature controlled cooling die which cools and reduces the viscosity of the protein lava to obtain a cohesive, texturised, extrudate slab or ribbon in which vapour-flashing is substantially inhibited; and subjecting the solidified extrudate slab or ribbon to mechanical shredding in a hammer mill having a cage plate with a plurality of elongate discharge openings and a plurality of hammer bars hinged to discs attached to a rotating shaft, so as to obtain a plurality of extrudate shred that resemble in consistency and texture flaked or shredded meat.

Owner:MARS INC

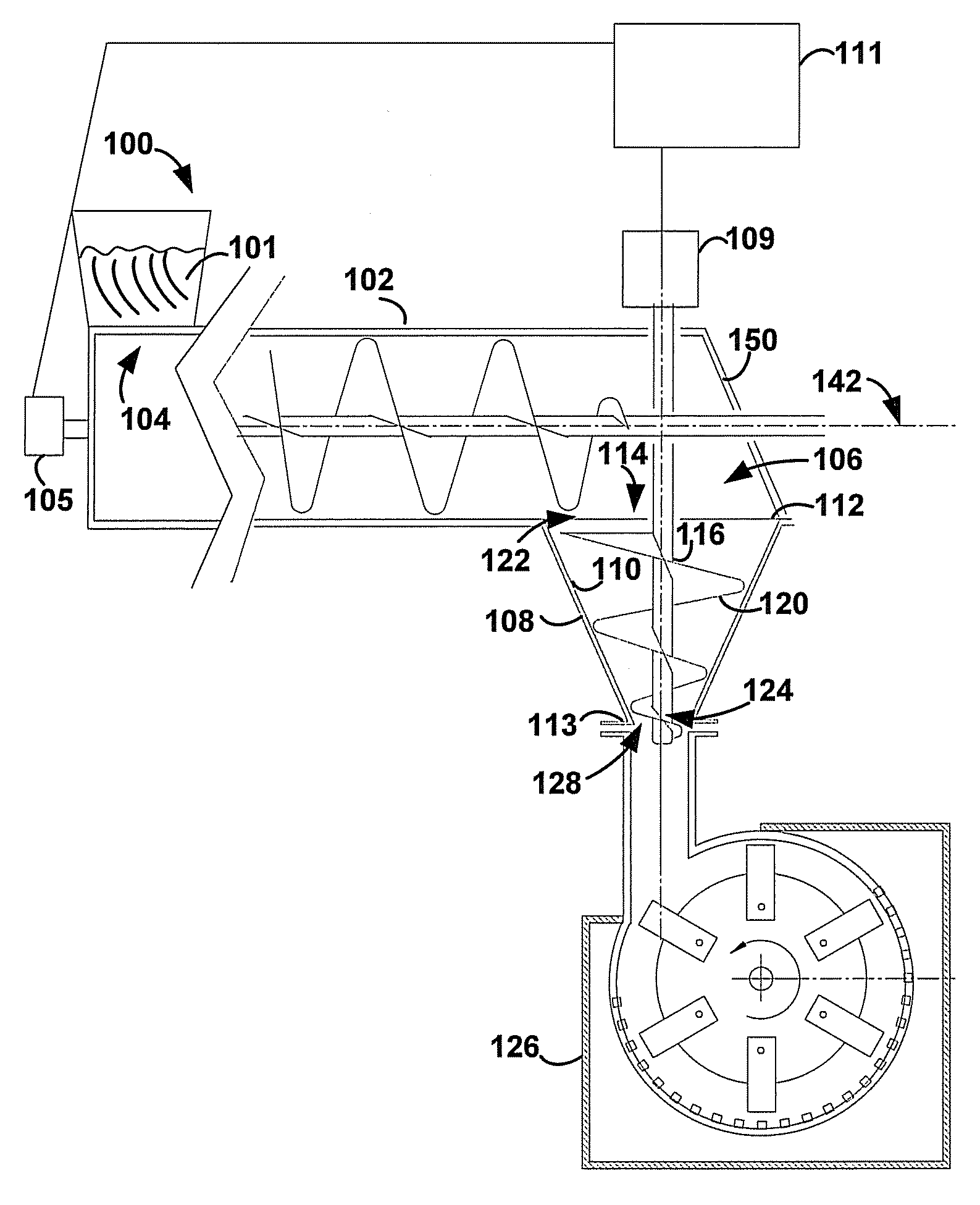

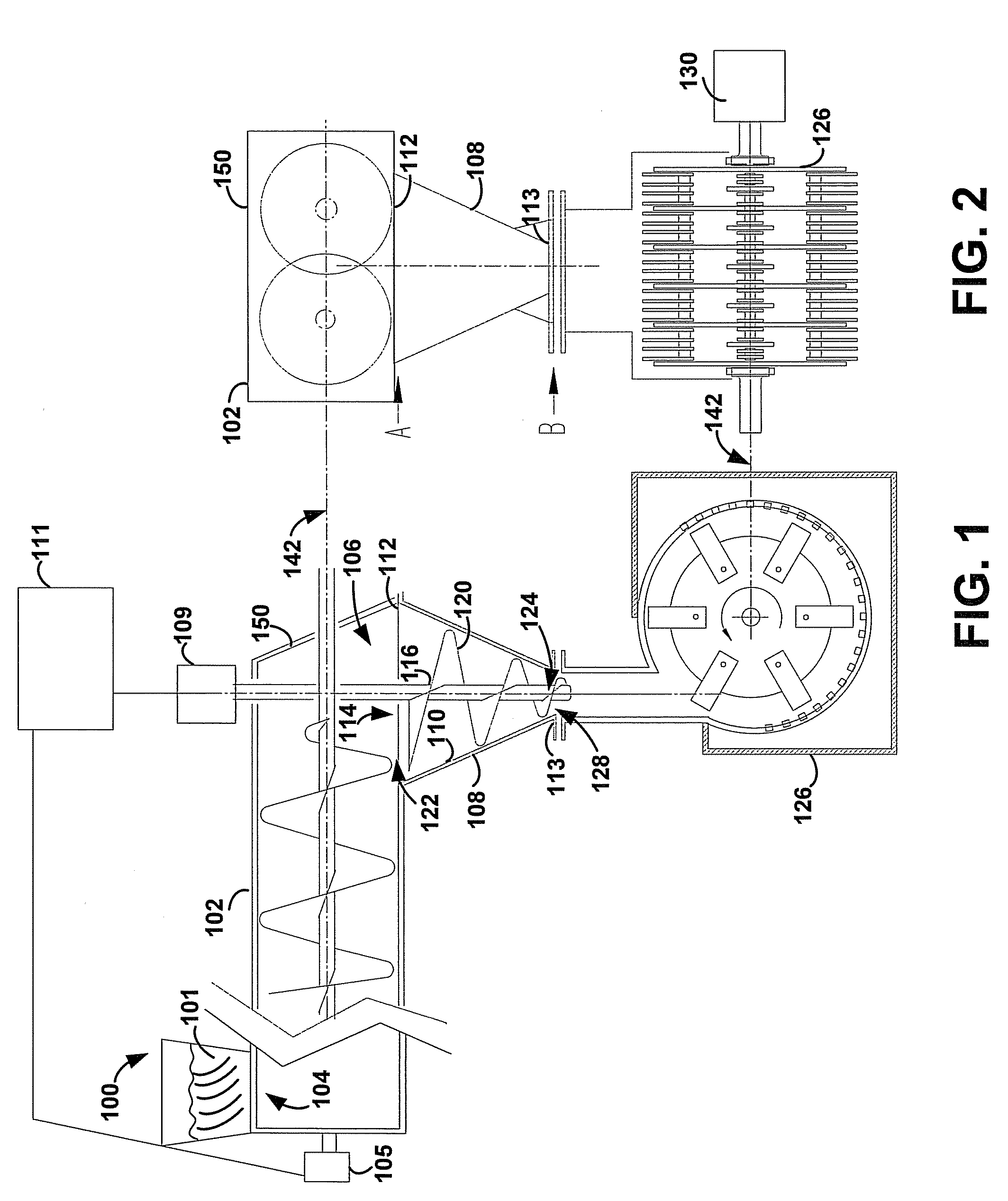

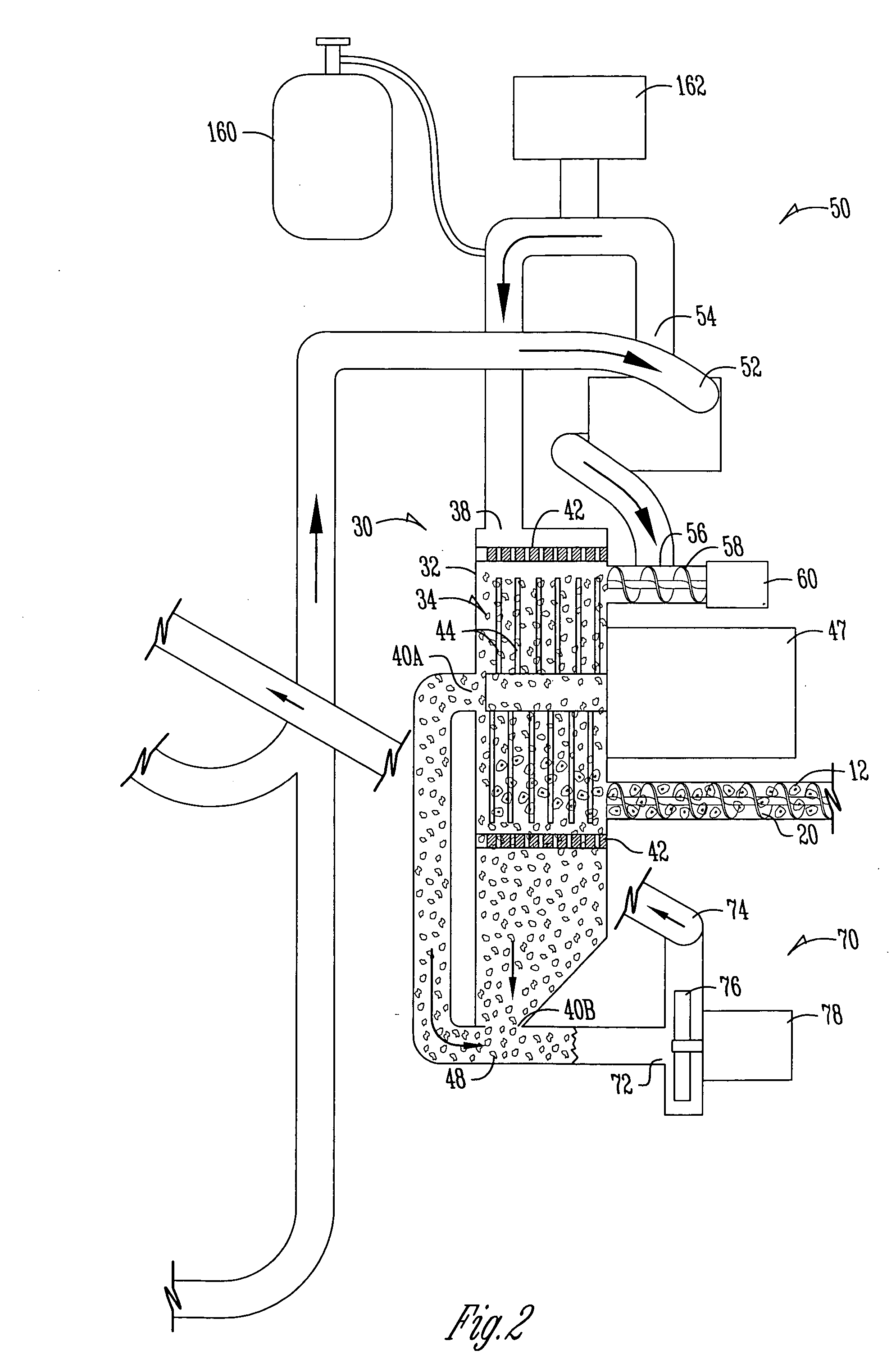

Compactor feeder

A compactor feeder and methods for feeding relatively low-density biomass materials into a grinding device (such as a hammer mill) is described. The compactor feeder increases the density of the relatively low-density biomass materials in order to fill the grinding device with the biomass materials at a rate that is sufficient to substantially equal the design capacity of the grinding device.

Owner:SURE CHAMPION INVESTMENT LTD

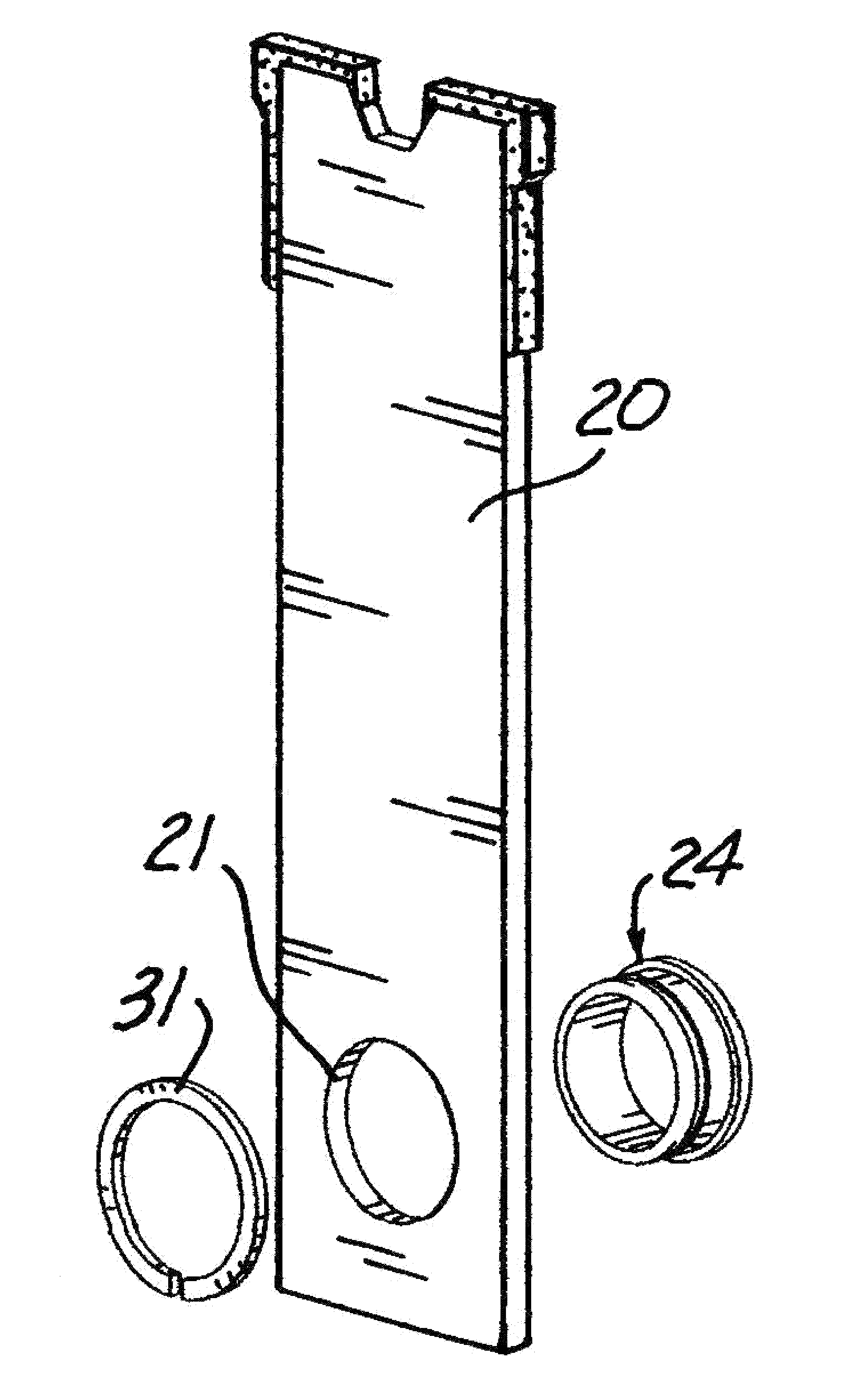

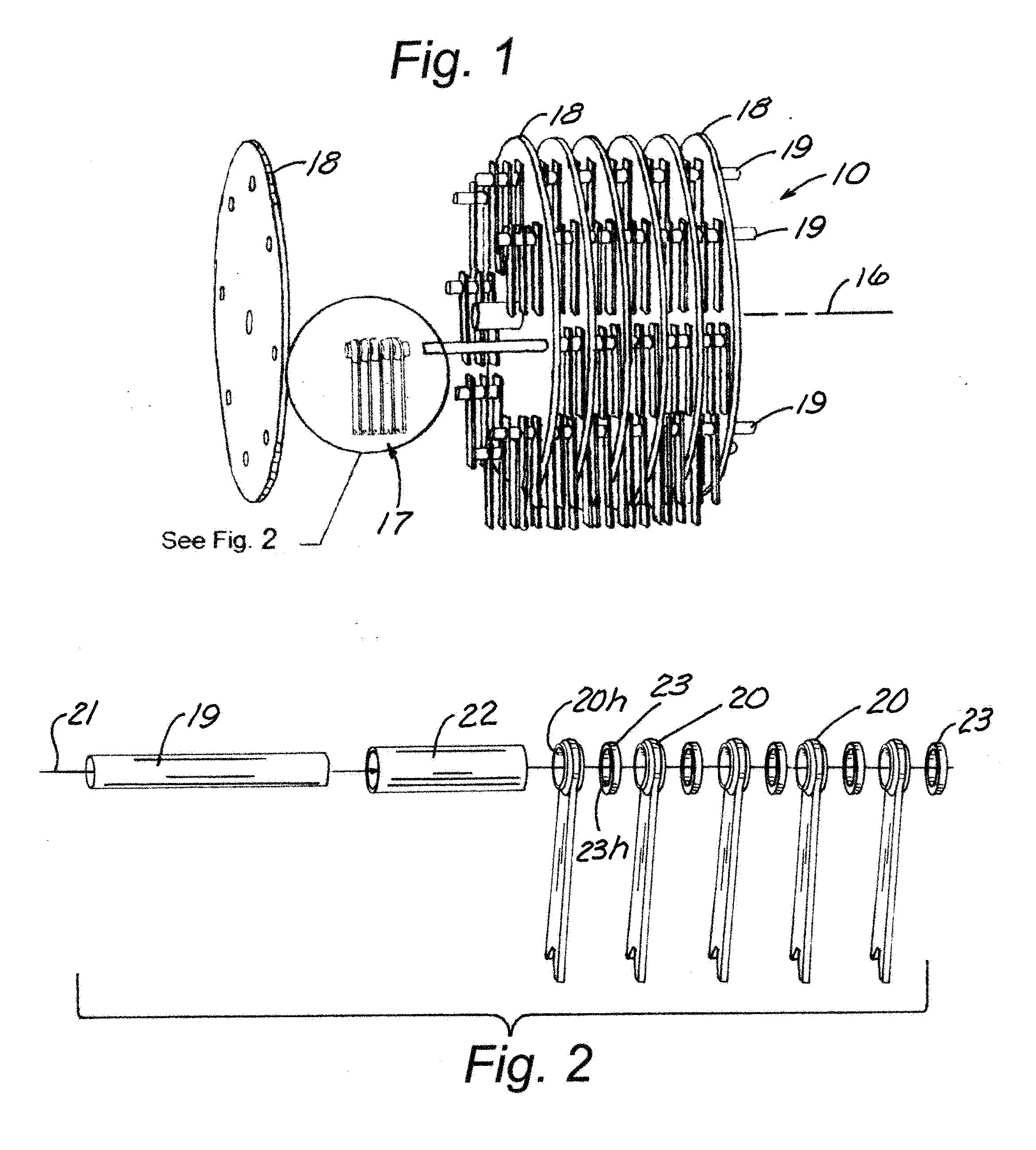

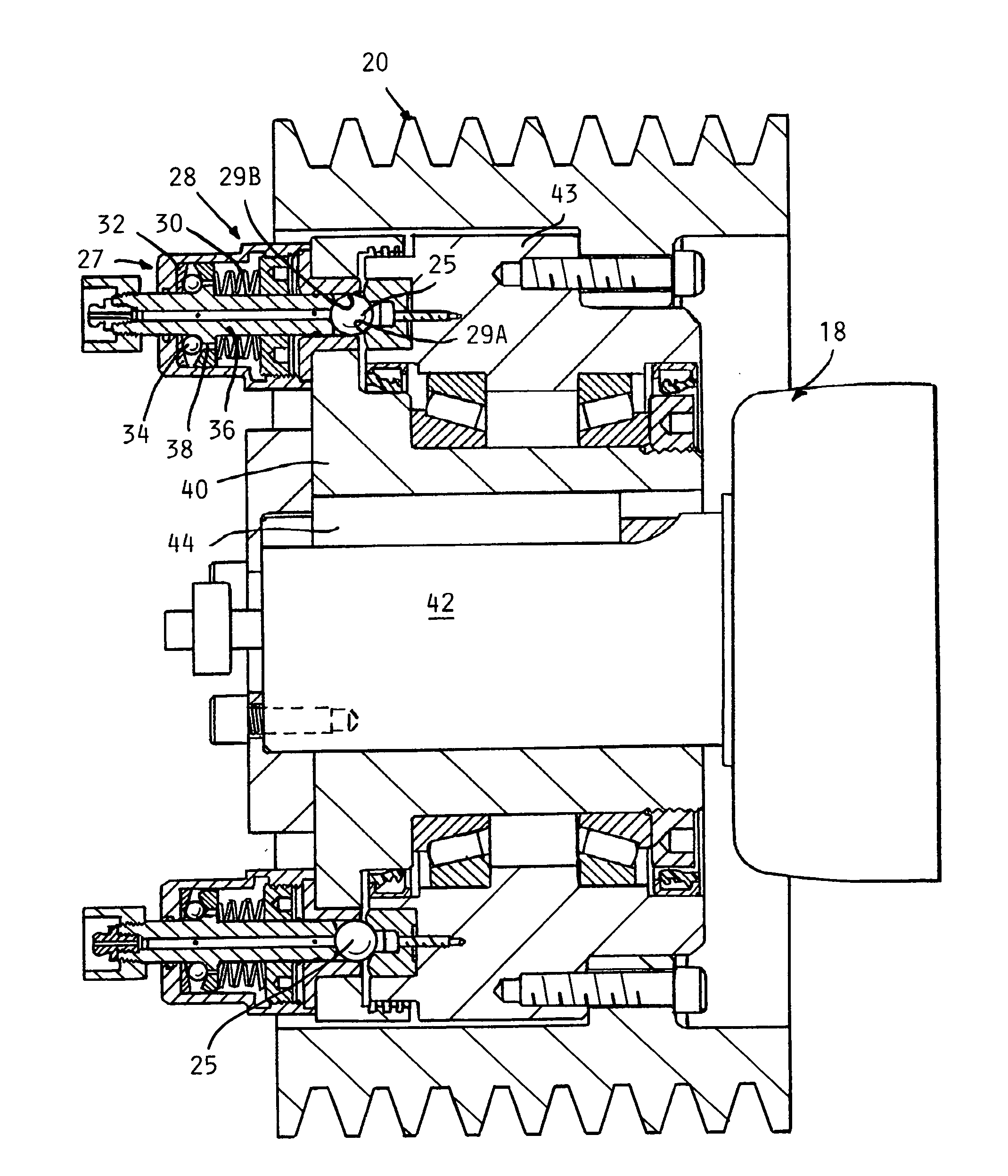

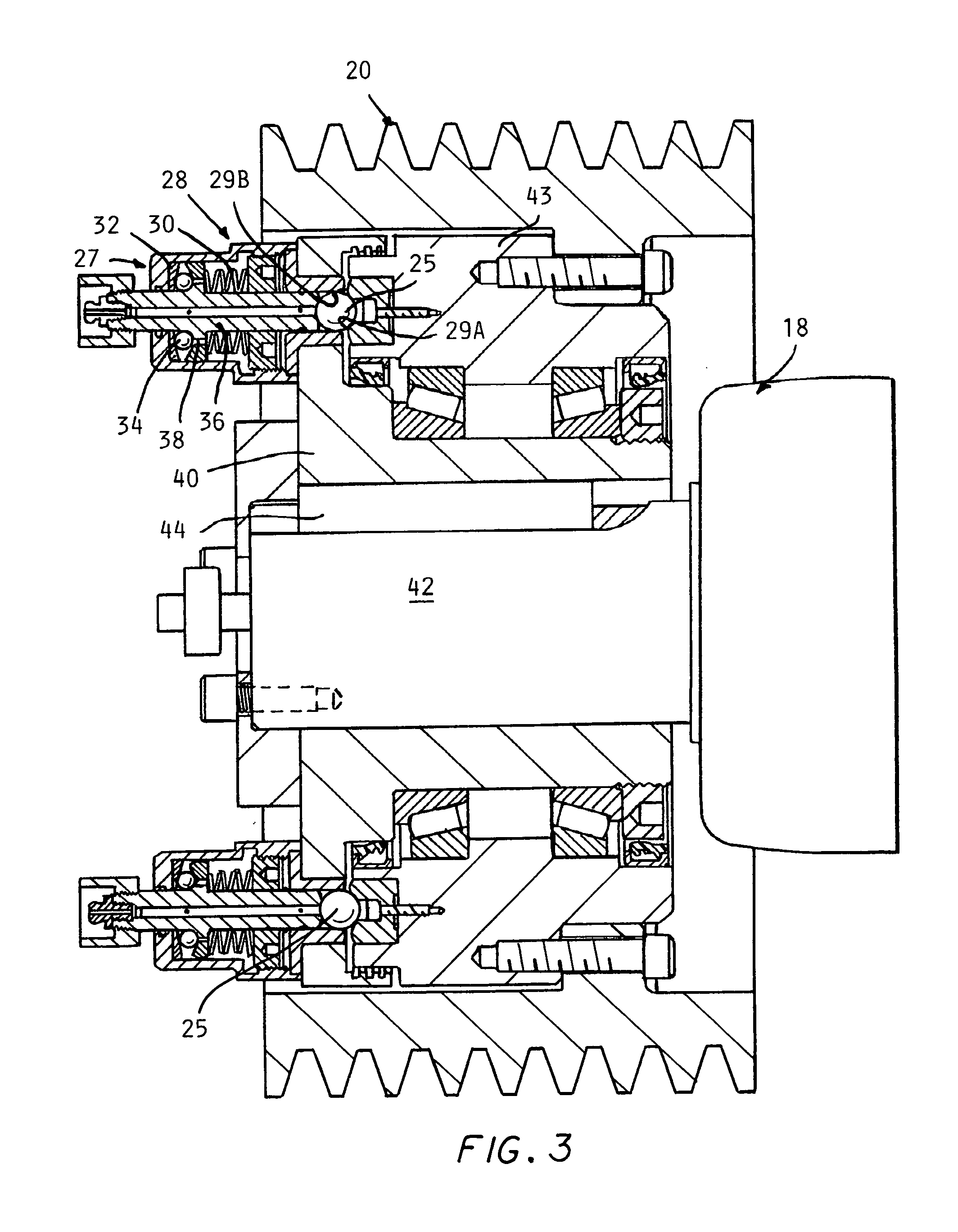

Apparatus for attaching hammers to a hammer mill

ActiveUS7419109B1More quickly and more securely attachingGrain treatmentsMechanical engineeringHammer mill

An apparatus for mounting hammers to a hammer mill having at least one hammer provided for attachment to a hammer mill, the at least one hammer having an opening disposed in one end thereof corresponding to a pivot axis, the opening being of a first diameter. A sleeve having a central opening therein is operatively attached to the hammer mill, the sleeve being disposed in the opening in the one end of the at least one hammer. The sleeve has a first cylindrical outer surface with a second diameter, the second diameter being only slightly smaller than the first diameter of the opening in one end of the at least one hammer. The sleeve has a second cylindrical outer surface with a third diameter, the third diameter being larger than said second diameter. A shoulder on the sleeve extends from the second cylindrical outer surface to the third cylindrical outer surface. An annular groove is disposed in the first cylindrical outer surface. A snap ring is selectively disposed in the annular groove, the snap ring having an outer diameter which is larger than the second diameter, whereby the at least one hammer will be disposed between the shoulder and the snap ring. A second embodiment uses a compression ring with a groove in it, instead of using a snap ring.

Owner:JACOBS CORP

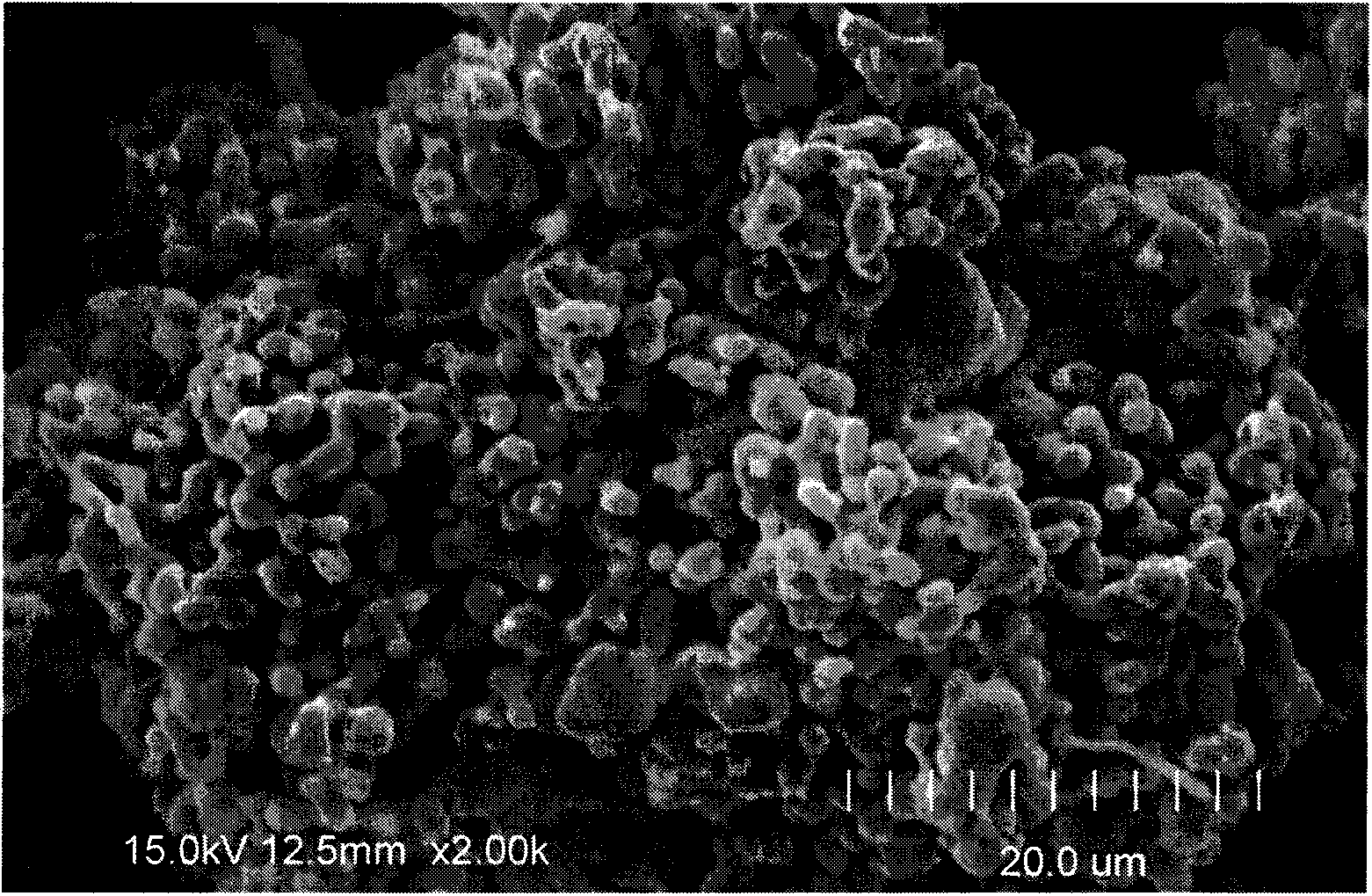

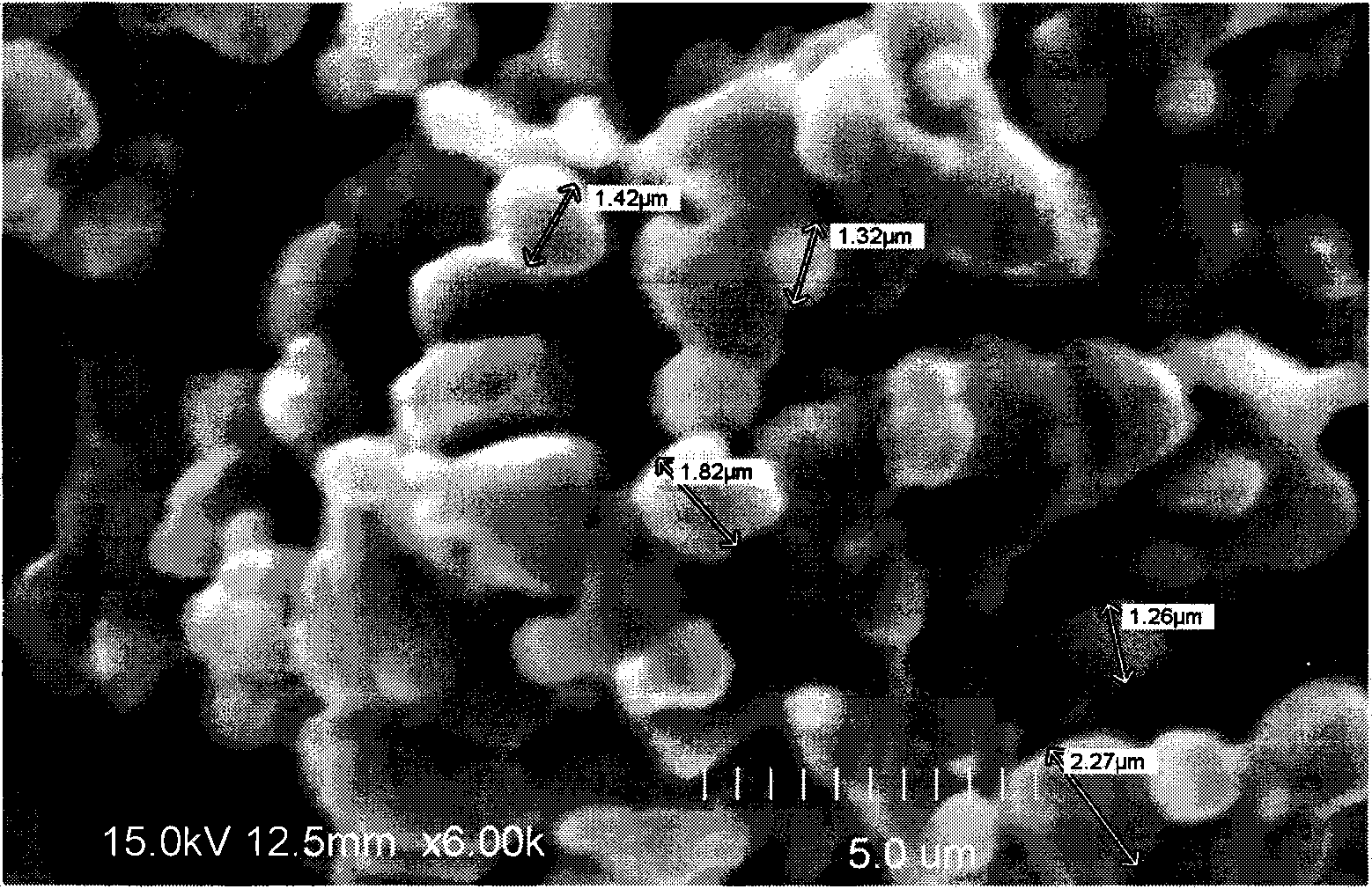

Novel martensitic wear resistant steel and production technology for steel casting thereof

The invention particularly relates to novel martensitic wear resistant steel and a production technology for steel casting thereof, belonging to the technical field of wear resistant steel in iron and metal metallurgy and foundry industry. Chemical components in the novel martensitic wear resistant steel comprise, by weight, C 0.3% to 0.5%, Si 0.8% to 1.5%, Cr 2.1% to 2.5%, Mn 0.8% to 1.5%, Ni 0.7% to 1.2%, Mo, 0.6% to 1.0%, Nb 0.1% to 0.3%, Ti 0.1% to 0.5%, Re 0.04% to 0.05%, and P and S no more than 0.04, with the balance being Fe. The production technology for steel casting comprises a smelting process, a casting process, a heat treatment process and quality inspection. The novel martensitic wear resistant steel provided in the invention can be used for liner plates of ball mills, hammerheads of hammer mills or the like used in metallurgic mines under the condition of low impact, is applicable to wear resistant products used in various mines like gold mines, iron mines and cement quarries, and is a novel wear resistant material capable of substituting conventional high manganese steel. According to results of utilization in ore dressing factories for iron ore and cement, the novel martensitic wear resistant steel has an improved service life 2 to 2.3 times longer than the high manganese steel.

Owner:ANSTEEL GRP MINING CO LTD

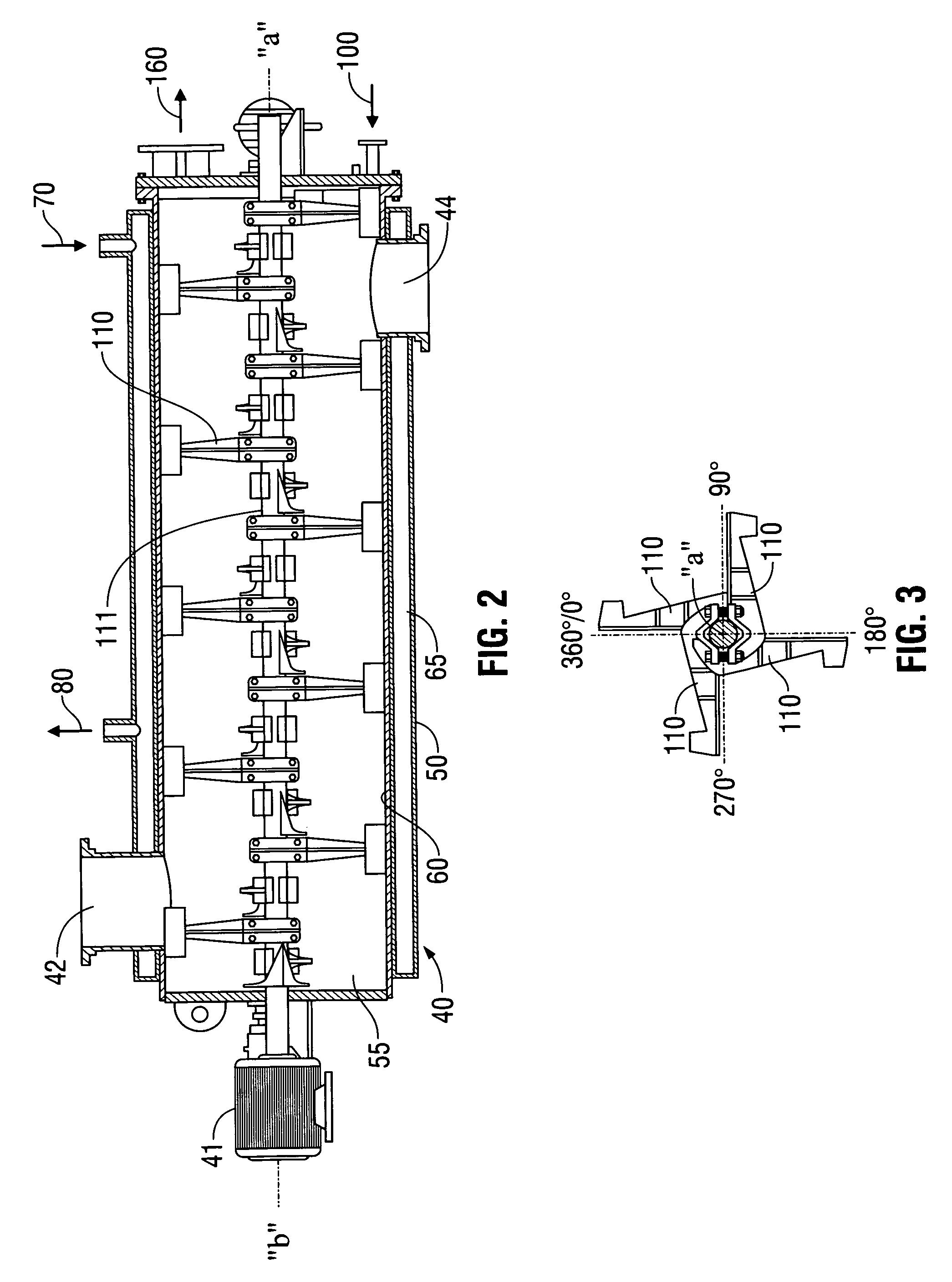

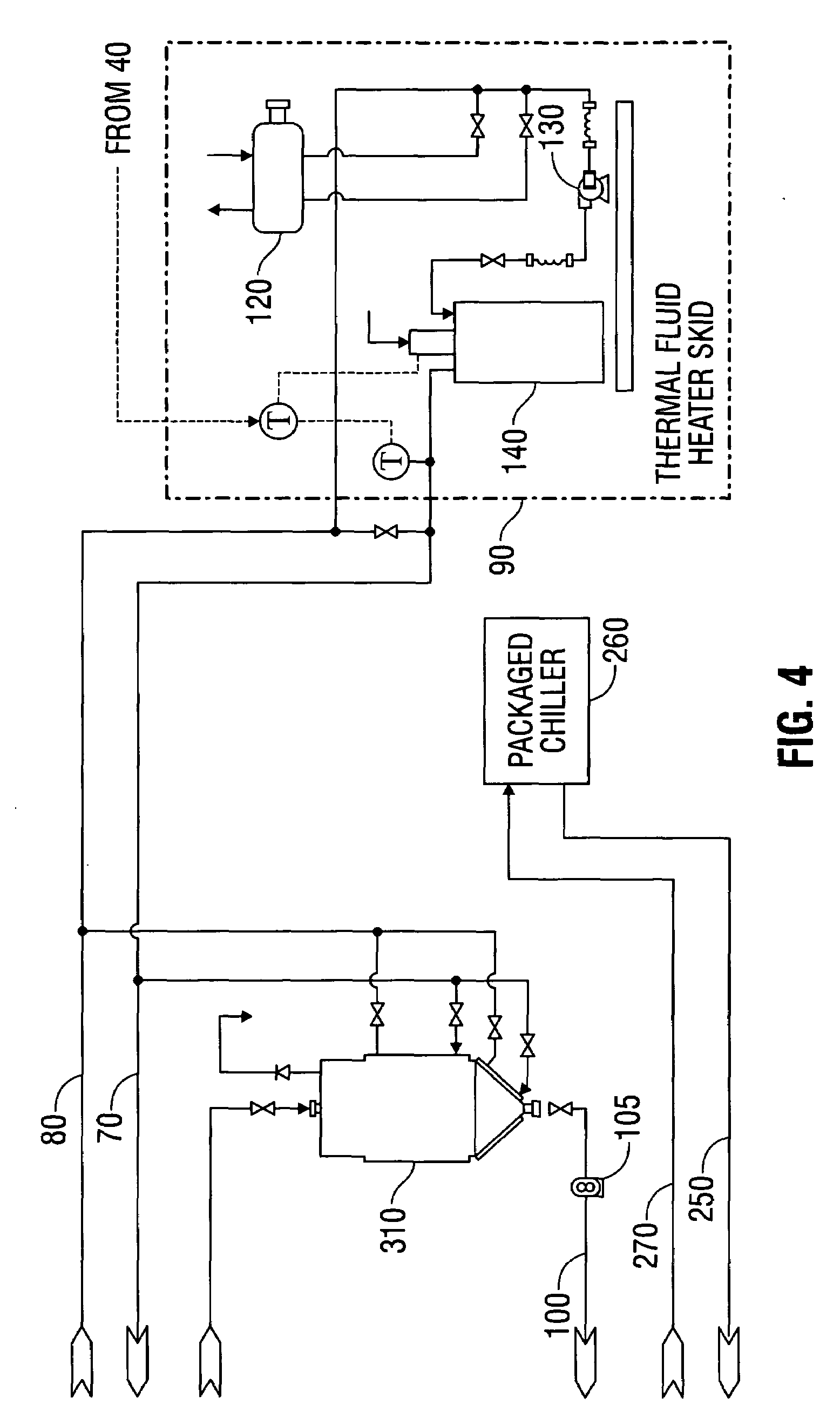

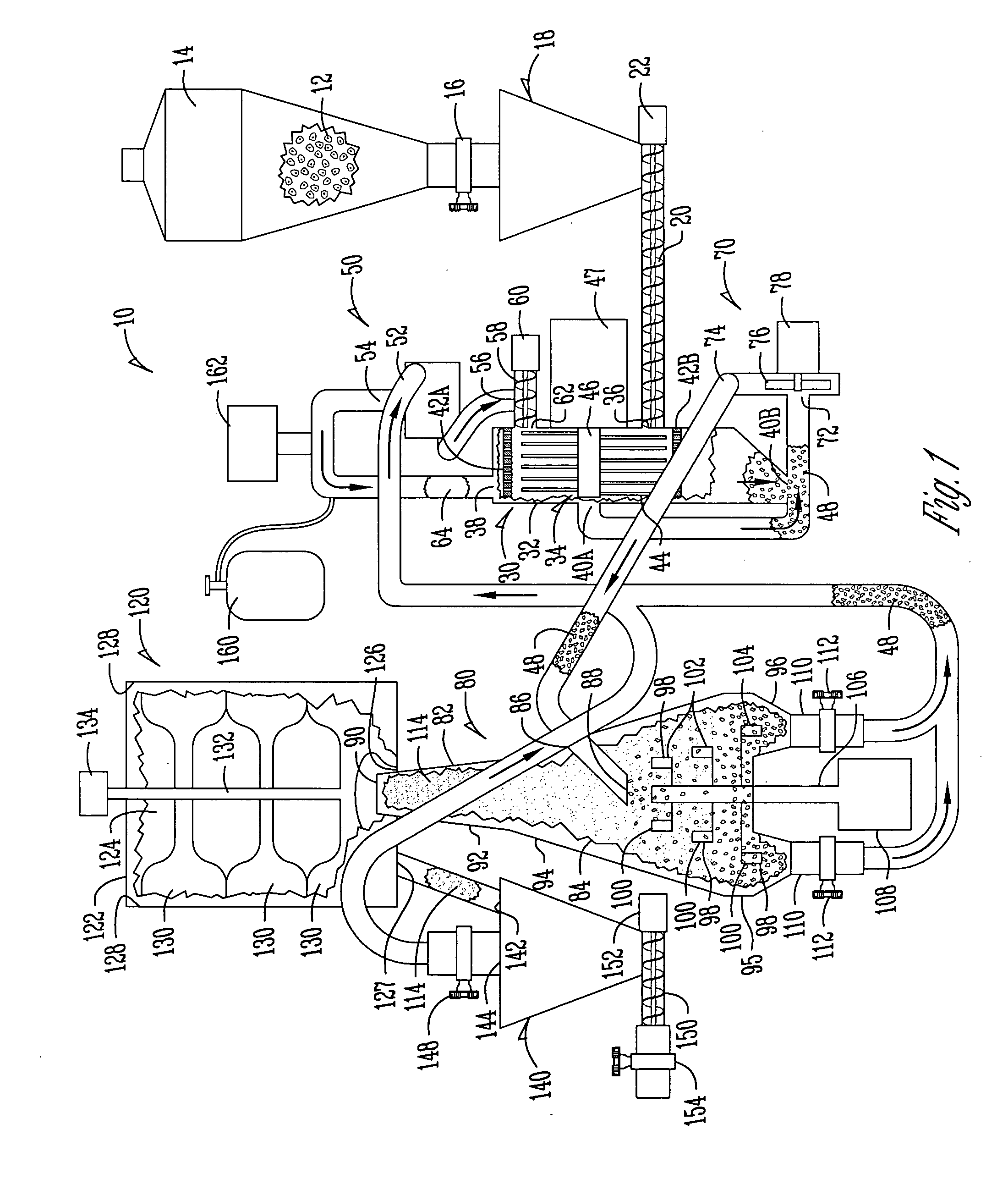

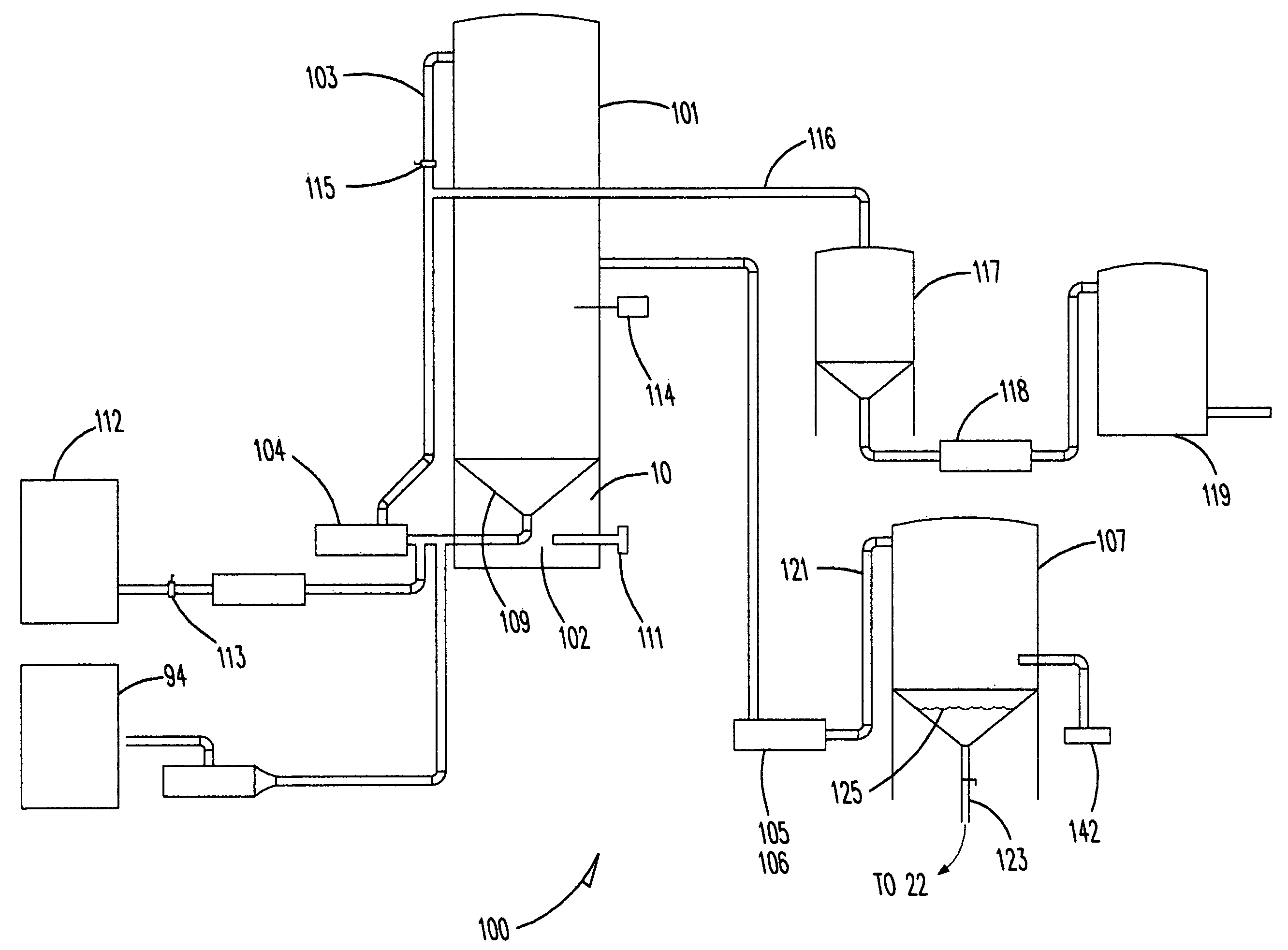

Asphalt shingle recycling system and method

ActiveUS20090229491A1Small particle sizeImprove consistencySolid waste disposalPlastic recyclingAsphalt shingleSolid particle

The asphalt roofing material is delivered into a treatment chamber of a processor. Hot oil is passed through a jacket surrounding the treatment chamber. Heated asphalt forms a hot solid and / or a liquefied slurry. The hot solid and / or the liquefied slurry is then removed from the treatment chamber. The asphalt roofing material in the treatment chamber can be agitated to promote mixing. The asphalt is heated to a temperature in the range from 200 degrees Fahrenheit to 650 degrees Fahrenheit within the treatment chamber. The solid and / or liquefied slurry is milled after it has been removed from the treatment chamber. The solid and / or the liquefied slurry is cooled after it exits the treatment chamber, preferably to a temperature in the range of approximately 90 degrees Fahrenheit to 110 degrees Fahrenheit. The hot solid and / or the liquefied slurry is passed through a hammer mill after the hot solid and / or the liquefied slurry exits the treatment chamber to reduce the particle size of the solid particles.

Owner:DUPPS

Process for isolation of hepatoprotective agent silymarin from the seeds of the plant Silybum marianum

The invention relates to a novel process for the isolation of a hepatoprotective agent Silymarin from the seeds of the plant Silybum marianum comprising (i) Precooling the seeds to (-) 20° C. for 24 hours in a deep freezer / cold room. (ii) Powdering the cooled seeds in a hammer mill, fitted with about 40 mesh discharge screen. (iii) Defatting the seeds by extracting with hexane in a soxhlet type extractor to remove the total quantity of fatty oil without using a scrain. (iv) Extracting the defatted seeds with acetonitrile at 20-30° C. to extract silymarin fraction. (v) Concentration of the sensitive silymarin fraction under vacuum in a agitated wiped thin film evaporator (vi) stirring the silymarin such dry powder with cold dichloromethane at 5° C. followed by filtration and drying with a slow purge of nitrogen gas. (vii) Further purification of silymarin by suspending in 5 times its weight of acetonitrile and precipitating by 8-12 times its weight of water at 20° C. (viii) Filtering the precipitated silymarin in a closed vacuum filter and having 1-2 mum screen washing the cake three times with distilled water (ix) Drying of Silymarin cake in vacuum oven to obtain substantially pure silymarin.

Owner:COUNCIL OF SCI & IND RES

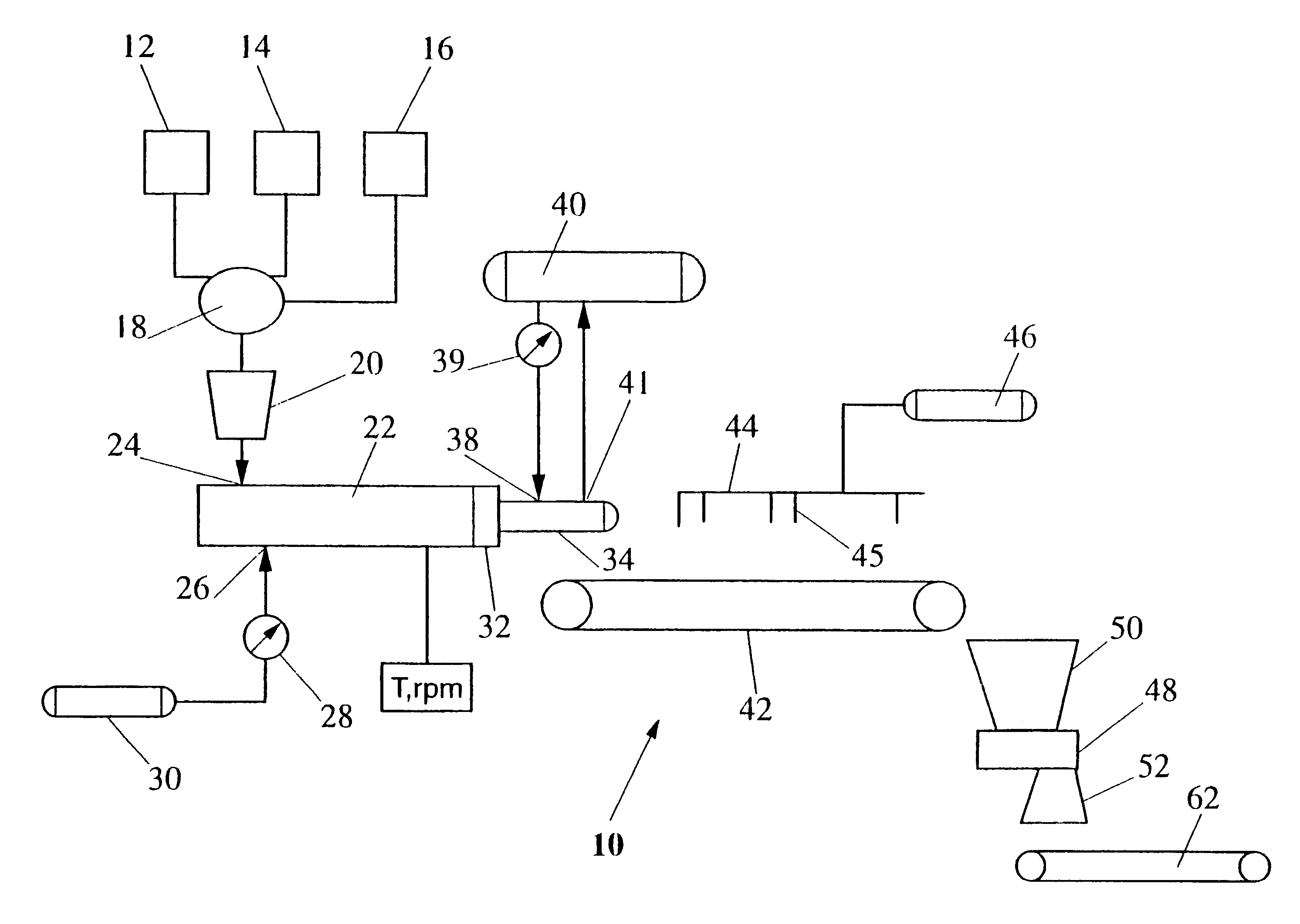

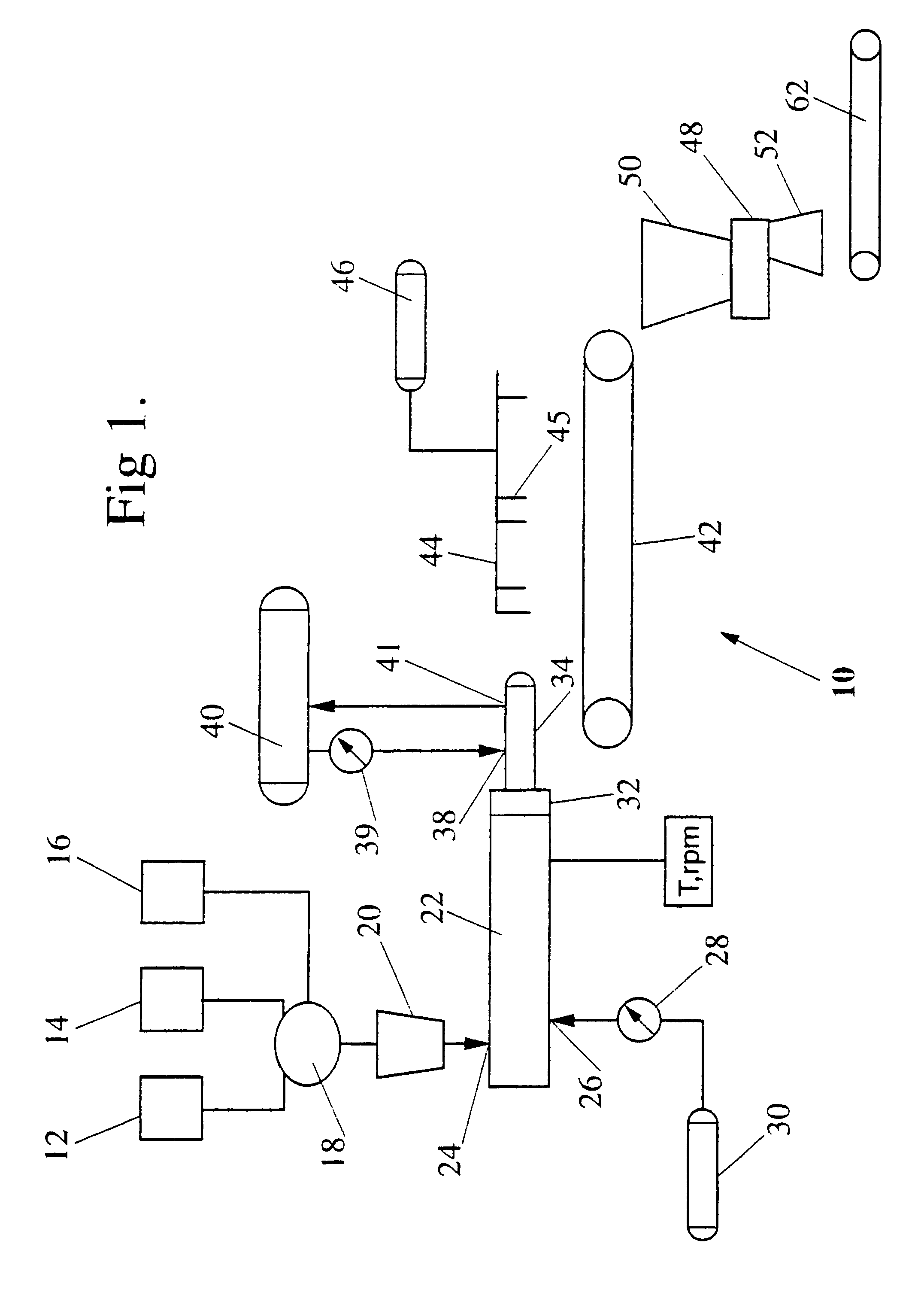

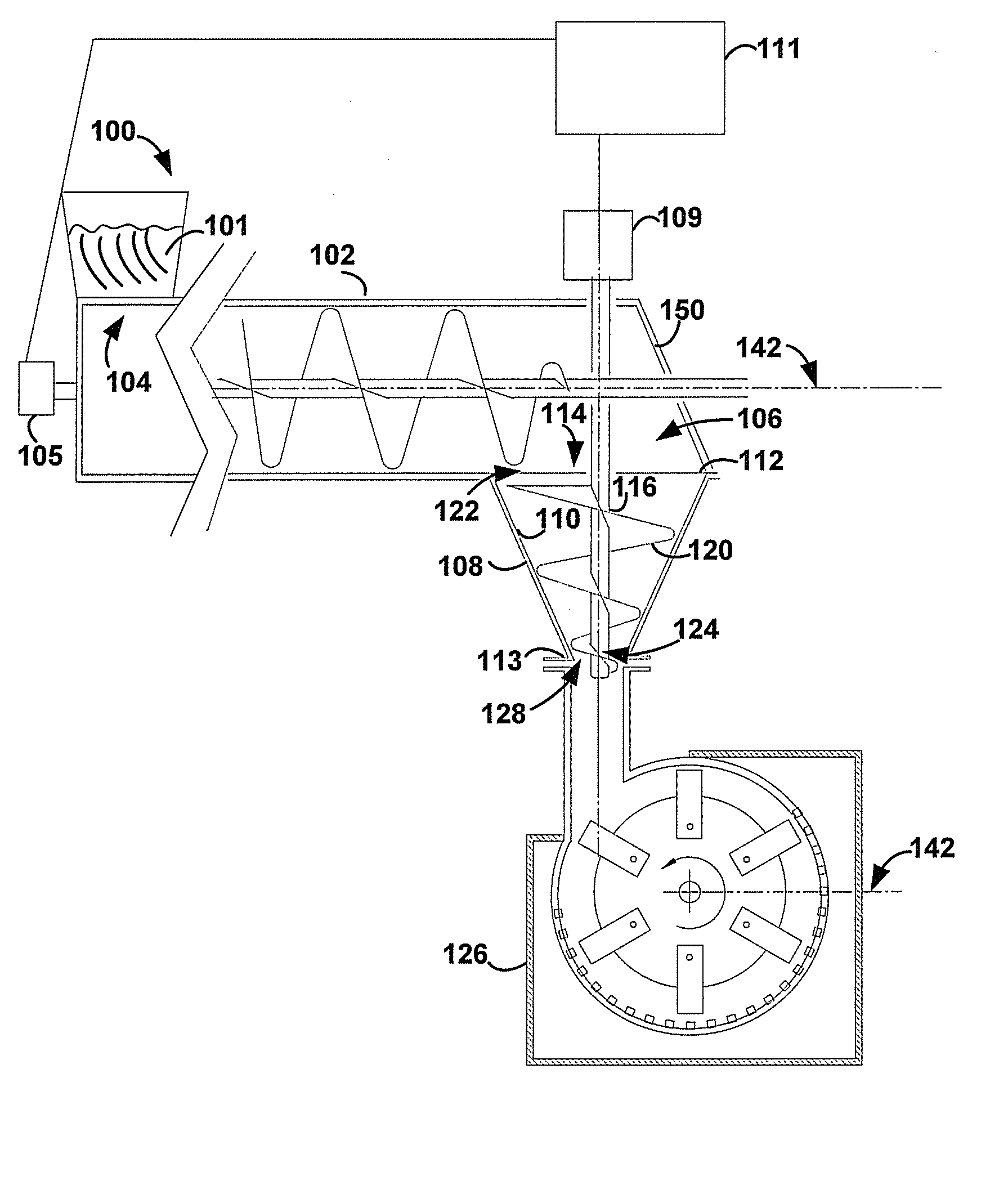

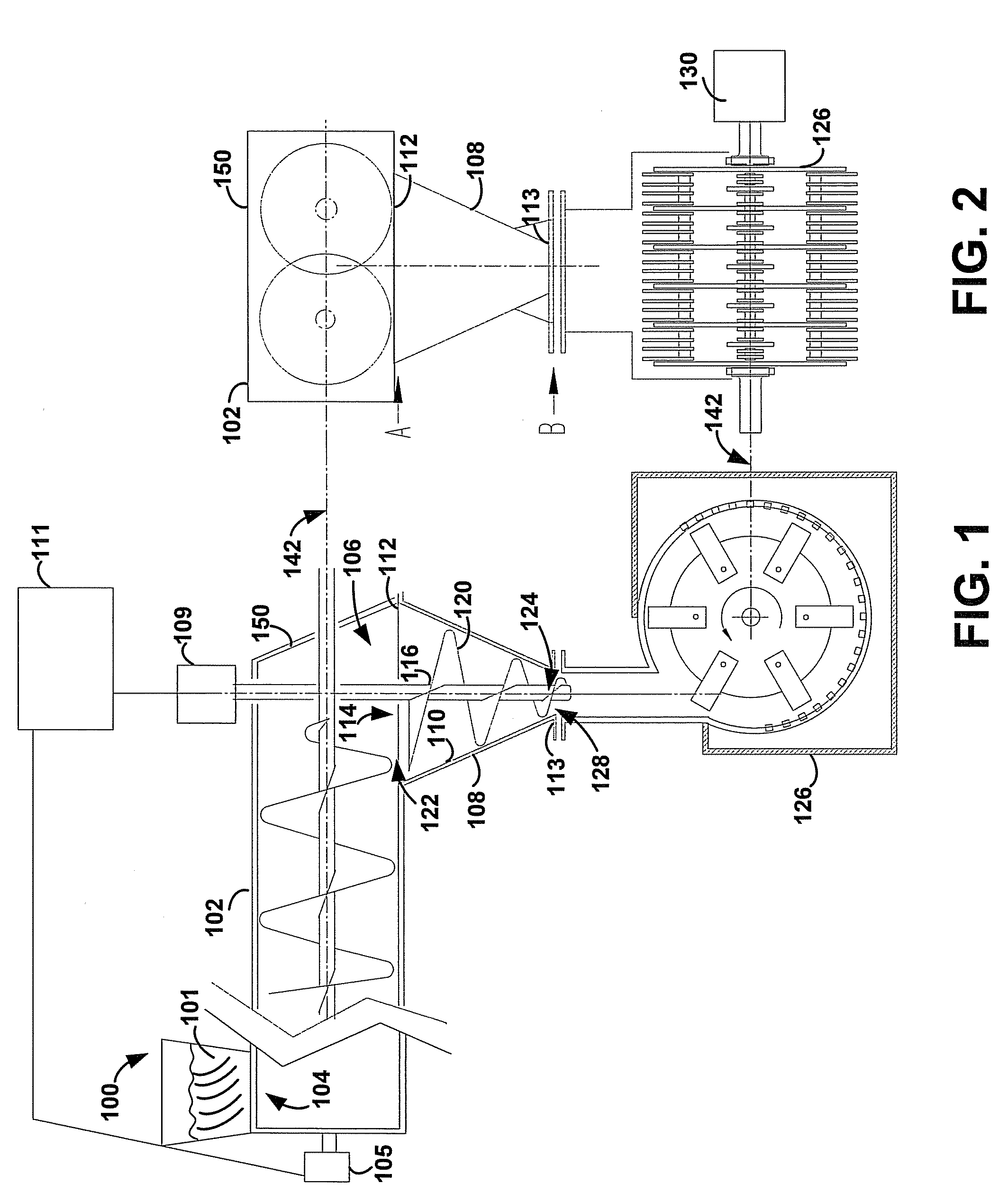

Method and apparatus for the manufacture of meat analogue product

A method of manufacturing a texturised proteinaceous meat analogue product, including: subjecting, in a food extruder, a mixture containing: about 40 to 95 % by weight edible proteinaceous materials selected from the group consisting of predetermined mixtures of defatted soy flour, soy meal, soy concentrate, cereal gluten in vital or starch-containing form and egg white, and up to about 7 % by weight of edible mineral binding and cross-linking compounds; to mechanical pressure and added heat sufficient to convert the mixture into a hot, viscous protein lava; extruding the protein lava through and from a temperature controlled cooling die which cools and reduces the viscosity of the protein lava to obtain a cohesive, texturised, extrudate slab or ribbon in which vapour-flashing is substantially inhibited; and subjecting the solidified extrudate slab or ribbon to mechanical shredding in a hammer mill having a cage plate with a plurality of elongate discharge openings and a plurality of hammer bars hinged to discs attached to a rotating shaft, so as to obtain a plurality of extrudate shreds that resemble in consistency and texture flaked or shredded meat.

Owner:EFFEM FOODS

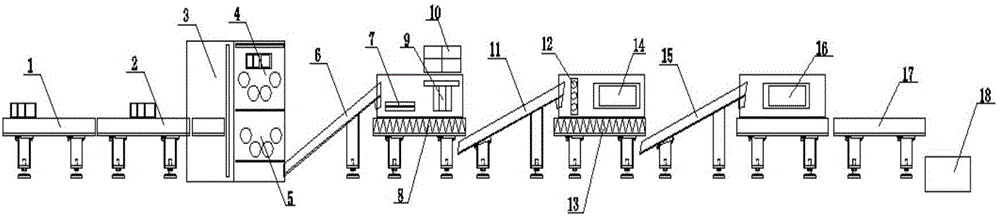

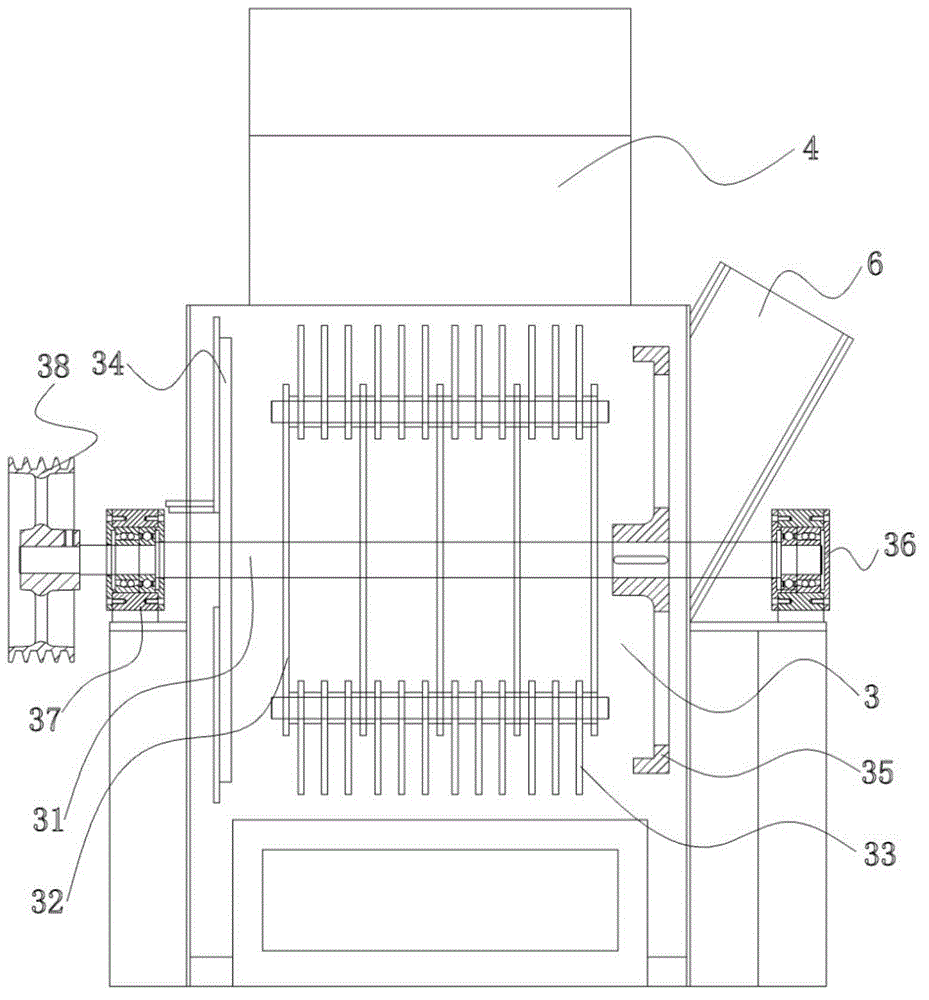

Automatic crushnig and sorting equipment of garbage and method for sorting out foreign substance in the garbage

Disclosed are an automatic crushing and sorting equipment of garbage and a method for sorting foreign substances in the garbage. The equipment includes a case having a perforated base plate and a discharge outlet for sorting out and discharging organic matters and foreign substances in garbage charged through a hopper; a striking cover plate for letting the garbage carried from the case being collided and crushed; a vertical partition for isolating the perforated base plate from the discharge outlet; a drive shaft passing through the case in a longitudinal direction of the case such that both end parts thereof projecting from both sides of the case are rotated; and a plurality of hammer mill assemblies successively and fixedly installed on the drive shaft, and being sequentially titled while maintaining a predetermined deviation in angle between unit members so that the garbage is crushed into a micro-sized particles and carried by maintaining a minute gap between end parts of the hammer mill assemblies and the inner surface of the striking cover plate to collide the garbage with the striking cover plate. The present invention has an advantage of recreating available resources and minimizing environmental pollution since a huge volume of garbage dispensed from households, restaurants, etc. are crushed into a wanted size and at the same time foreign substances in the garbage are automatically sorted out and completely separated.

Owner:DREAMBIOS CO LTD +1

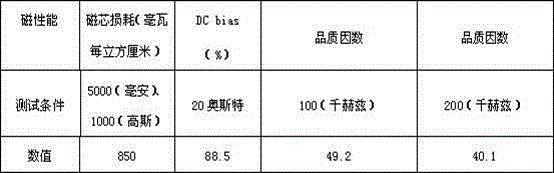

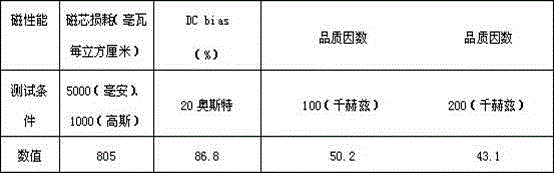

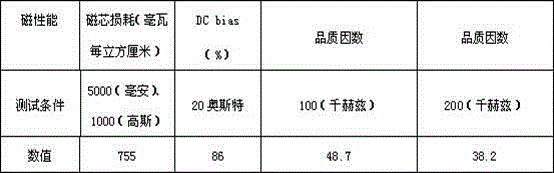

Method for preparing iron silicon soft magnetic alloy powder core

InactiveCN102974821AImprove magnetic propertiesMeet performance requirementsInorganic material magnetismEpoxySilicon alloy

The invention discloses a method for preparing an iron silicon soft magnetic alloy powder core. The method for preparing the iron silicon soft magnetic alloy powder core comprises the steps of 1, melting an iron silicon alloy by adopting a rapid solidification strip casting furnace, and preparing the alloy into powder by using a ring hammer mill after rapid quenching; 2, mixing the powder with atomized iron silicon alloy powder, and sieving the resultant powder; 3, performing surface treatment on the powder in a protective atmosphere furnace; 4, adding phosphoric acid, deionizer water, isopropanol and normal silicate ester, mixing, stirring and drying in a frying way; 5, pressing the powder into the powder core by using a hydraulic press; 6, performing protective atmosphere heat treatment on the powder core; and 7, performing protective treatment on the surface of the powder core through the reinforcement of epoxy resin and the spray painting. The iron silicon soft magnetic alloy powder core prepared by the method is high in cost performance and has the advantages of direct current overlapping characteristic, high-frequency low-loss and good characteristic; and in addition, the better magnetic performance still can be kept under a high temperature.

Owner:GUANGDONG IRON & STEEL INST

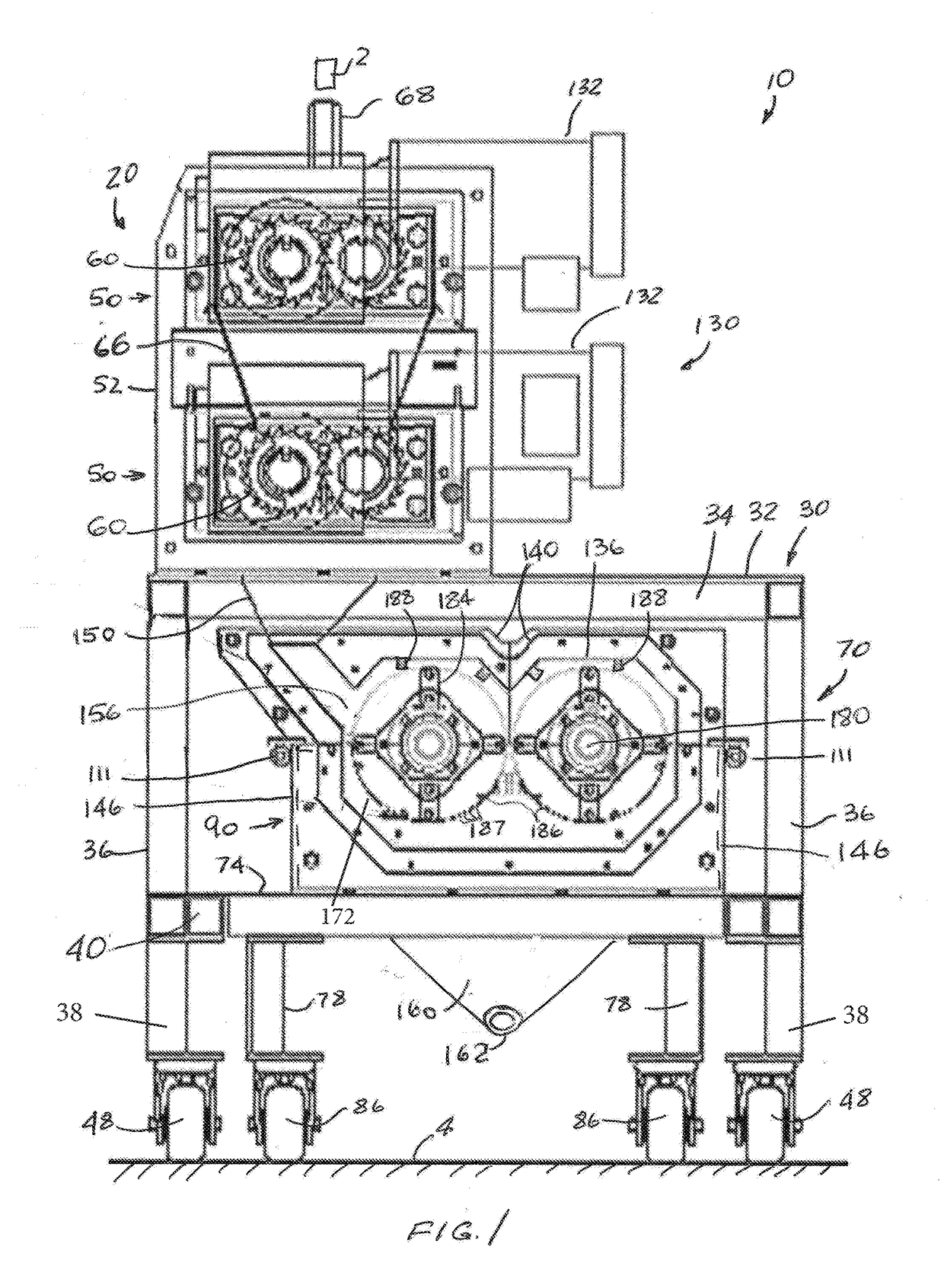

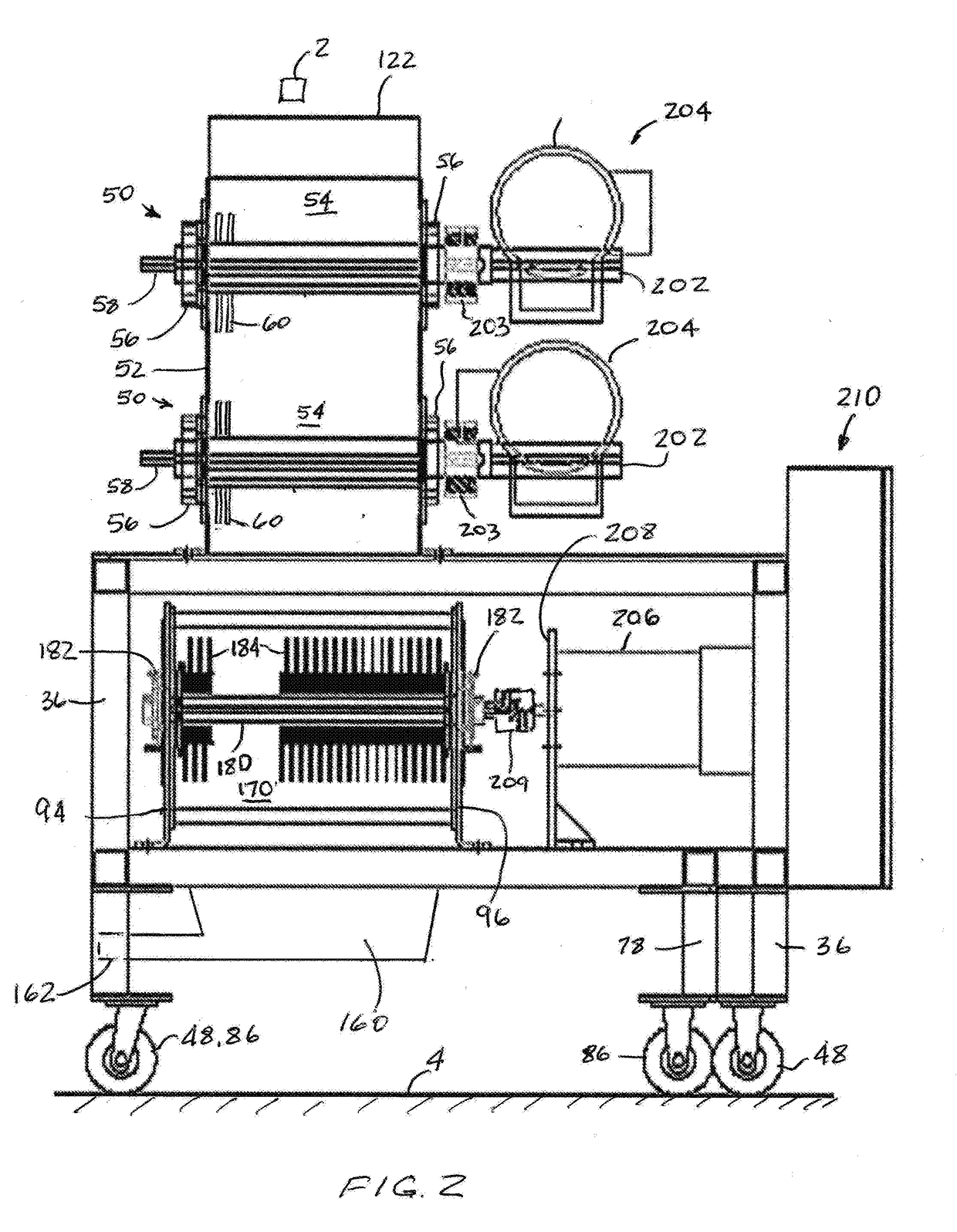

Apparatus for destroying digital media storage devices

An apparatus for destroying data storage devices comprises a shredder assembly, a hammer mill assembly, a chute mounted in an open communication with an interior of the shredder assembly and with an interior of the hammer mill assembly, the chute sized and shaped to transfer shredded remnants from the shredder assembly into the hammer mill assembly, a power drive assembly coupled to each of the shredder assembly and the hammer mill assembly, and a control assembly configured to operate the shredder assembly and the hammer mill assembly.

Owner:ALLEGHENY PAPER SHREDDERS

Ferment method of producing fuel ethanol using stalk material

The invention relates to a method for preparing fuel ethanol by taking straw as raw material. It comprises following steps: (1) selecting crop straw as raw material; (2) disintegrating: disintegrating straw by using hammer mill, sifting and getting straw powder of 20- 40 order; (3) pre- treating: lignin degrading raw material by way of culturing white-rot fungi in solid culture medium and liquid enzyme; (4) saccharifying two enzymes, saccharifying straw by using cellulase and xylanase at 45 Deg. C, pH 4.5, 150 rmp and ratio between liquid and solid 15, getting reduced sugar; (5) fermenting; (6) distilling. The fuel ethanol productivity is 16.7% in this invention, that is 16.7 ton waterless ethanol with every 100 ton straw, the production efficiency is high and economic benefit and social benefit is pretty good. Compared with current process, this invention is characterized in that the fermentation is thorough and the fuel ethanol production cost is low.

Owner:HENAN AGRICULTURAL UNIVERSITY

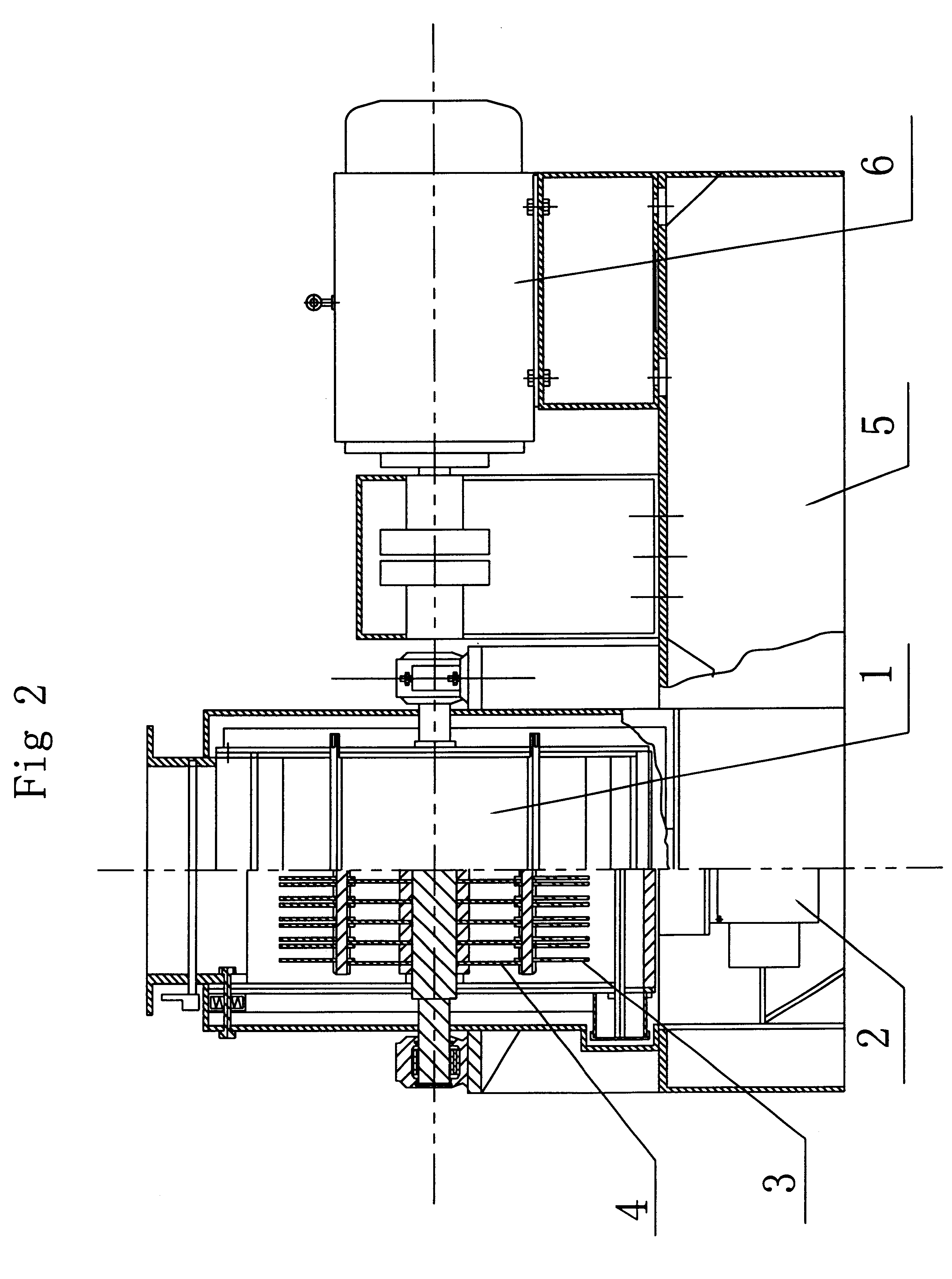

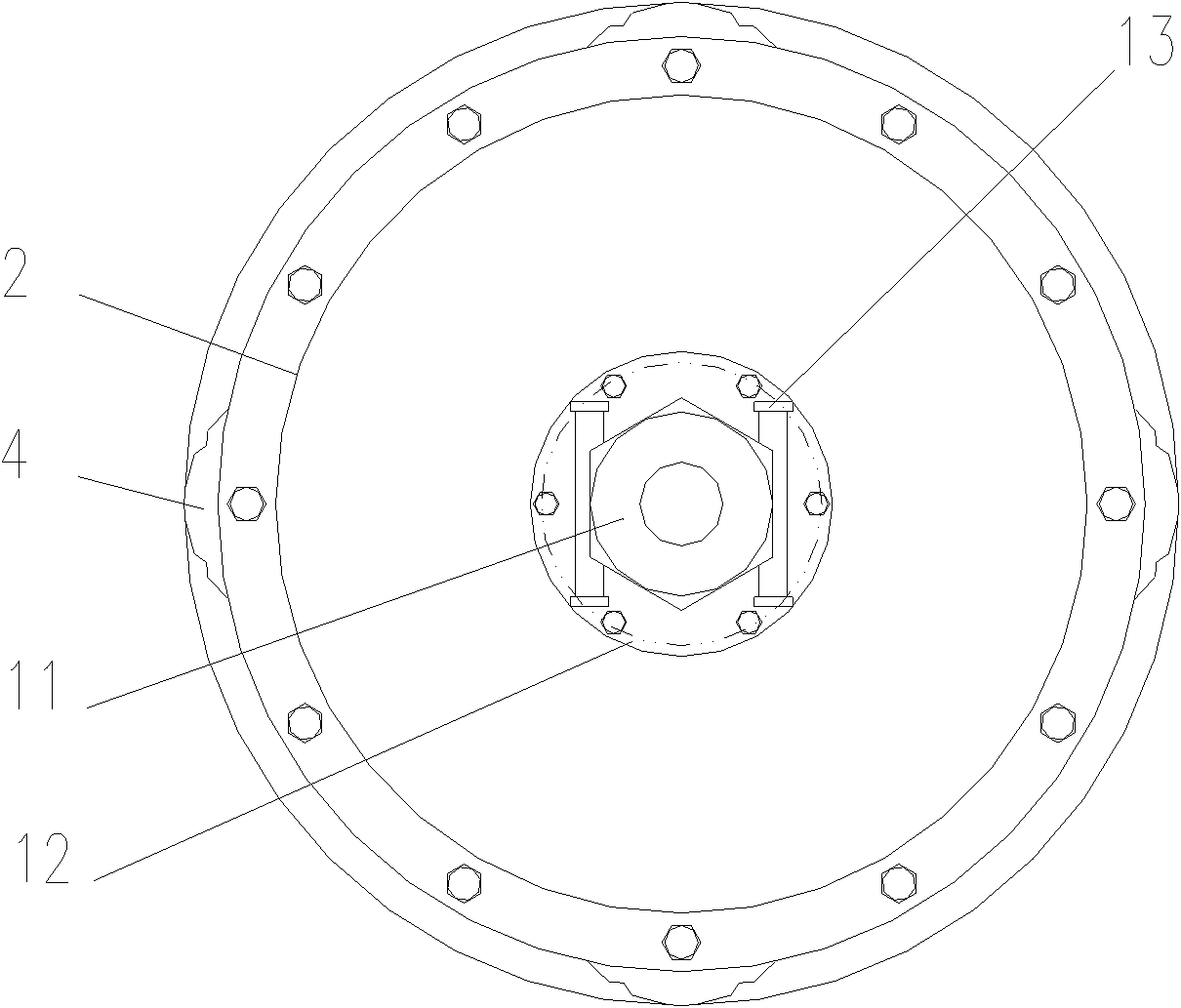

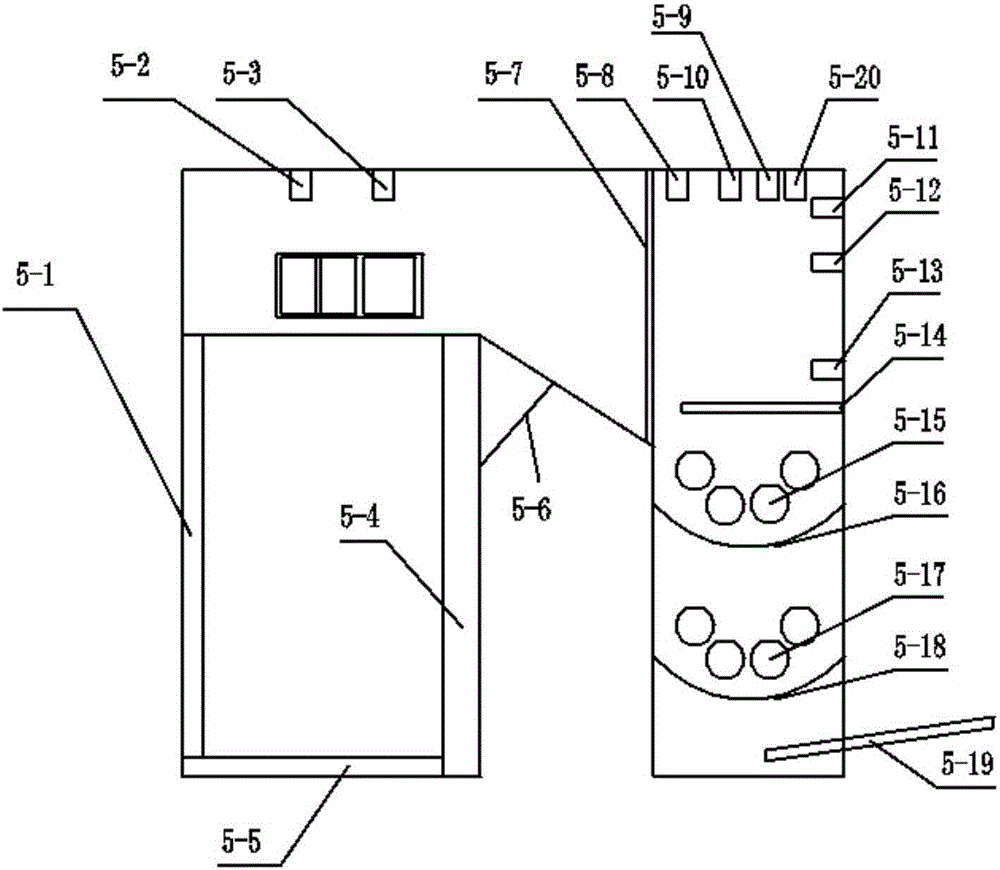

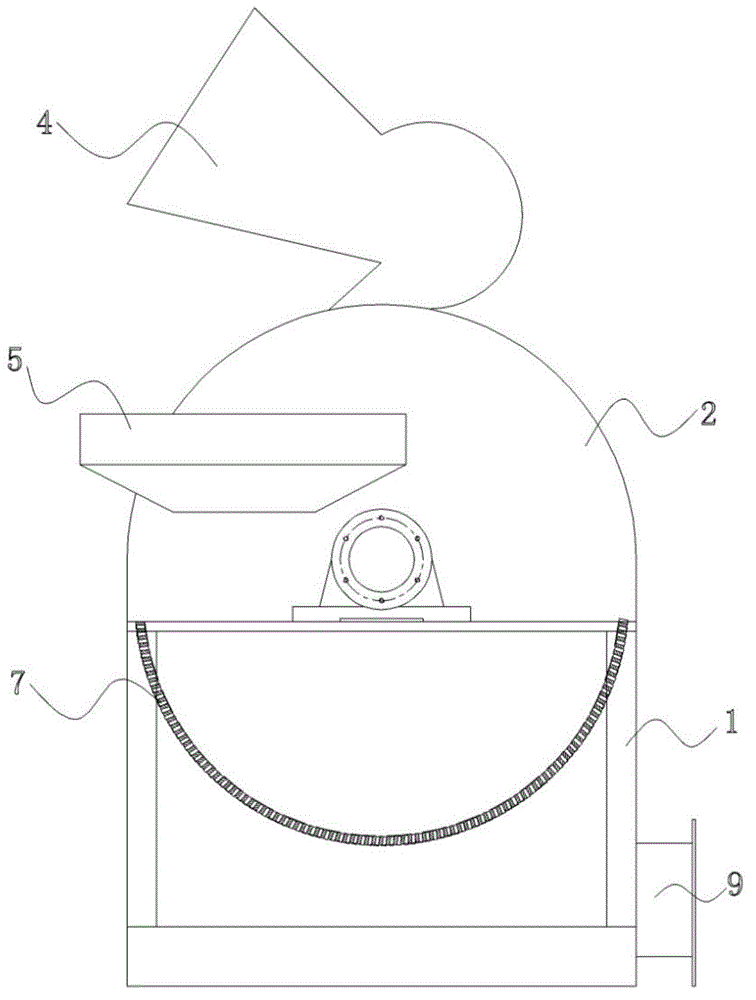

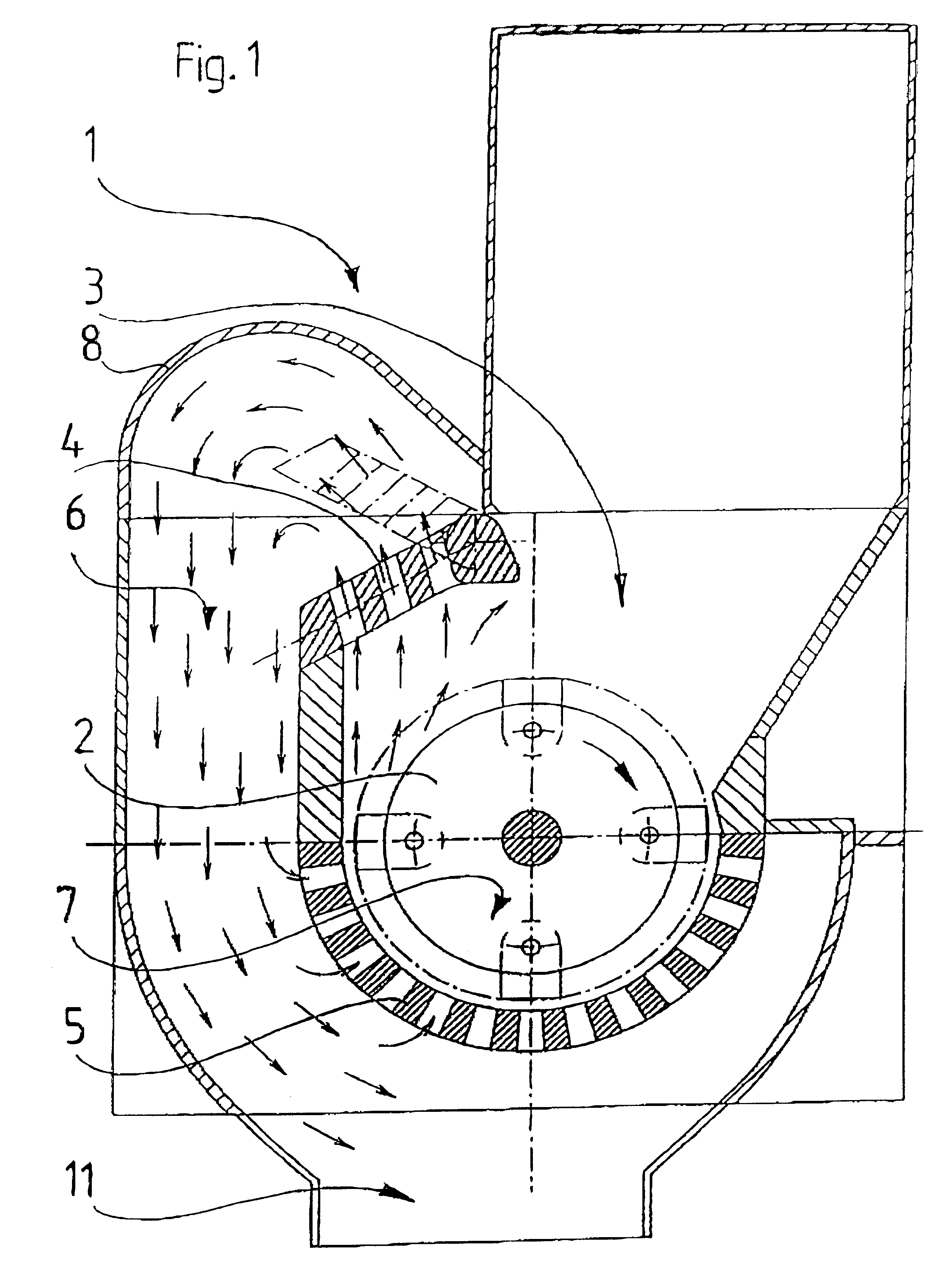

Hammer mill

This invention relates to a hammer mill used for feed processing, food processing or chemical industries. The said hammer mill has a casing, a rotor arranged in the casing and is provided with several hammers, and a vibrating screen with an active power source located around the rotor. The vibrating parameters can be set for control. In the cross section of the rotor, the width of the screen in the horizontal direction is more than that in the vertical height and it is symmetrical at the left and the right.

Owner:YU XIN GUO +1

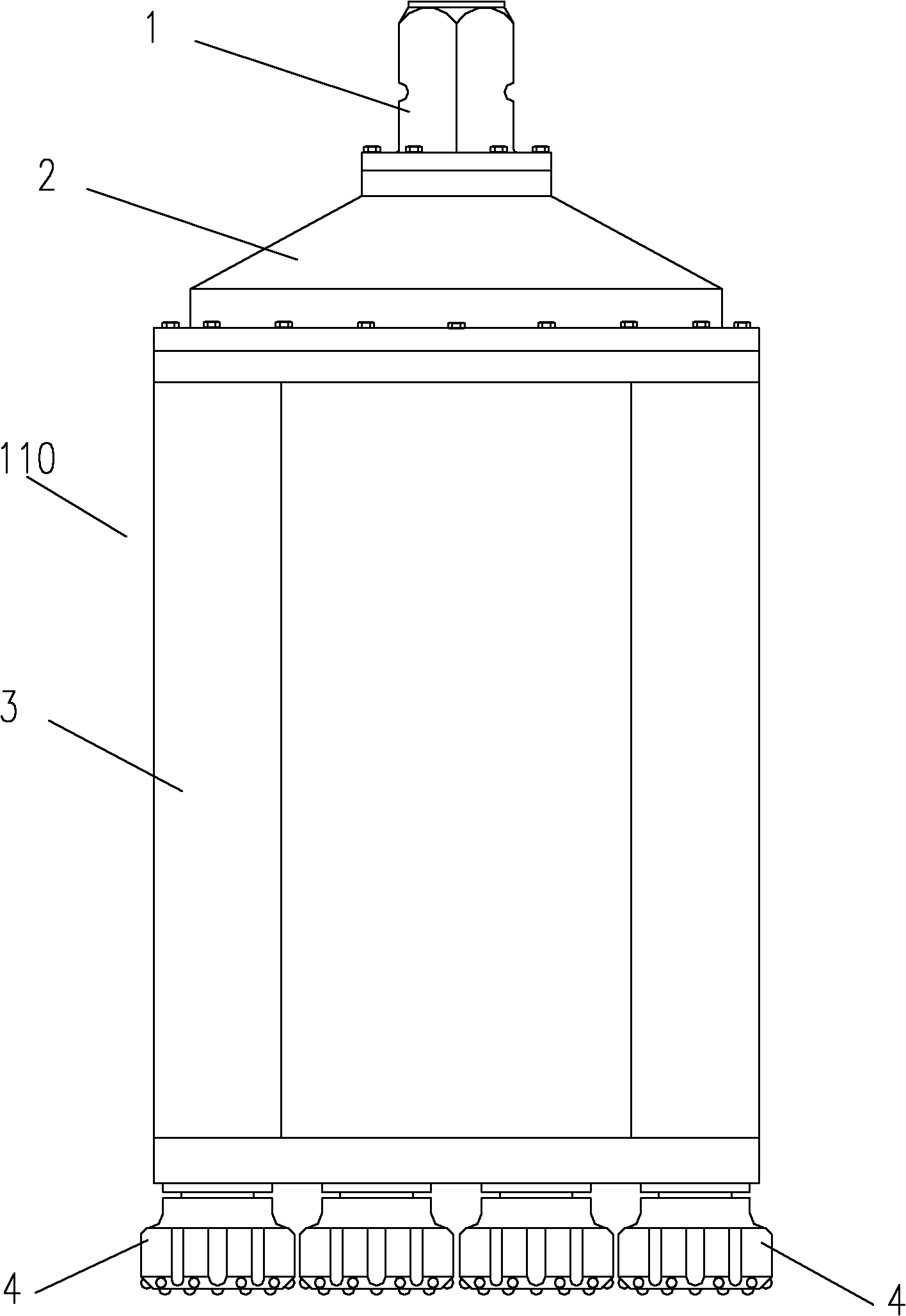

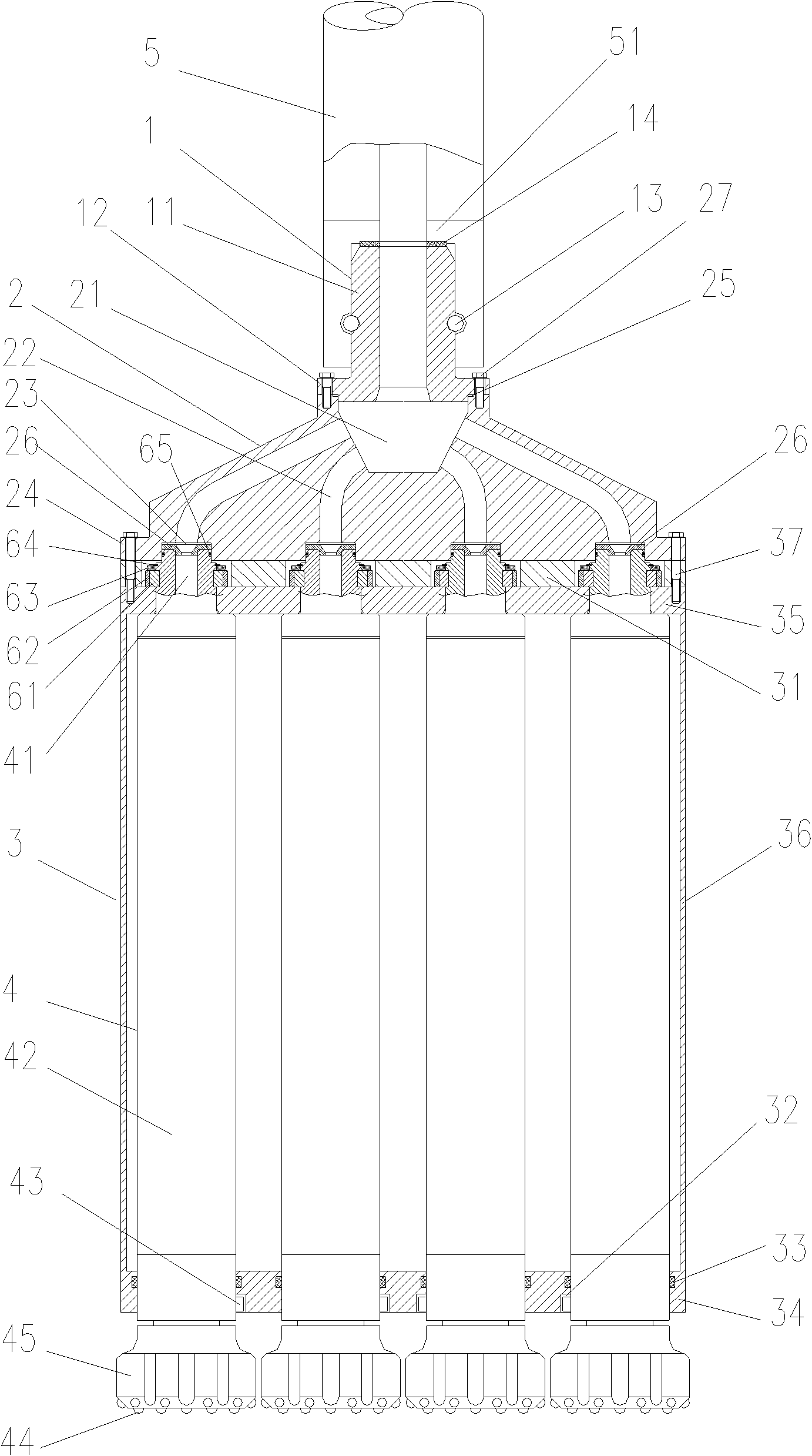

Rotation-revolution combined down-hole hammer and construction method thereof

ActiveCN101967955AEfficient use ofImprove drilling efficiencyConstructionsReciprocating drilling machinesPunchingArchitectural engineering

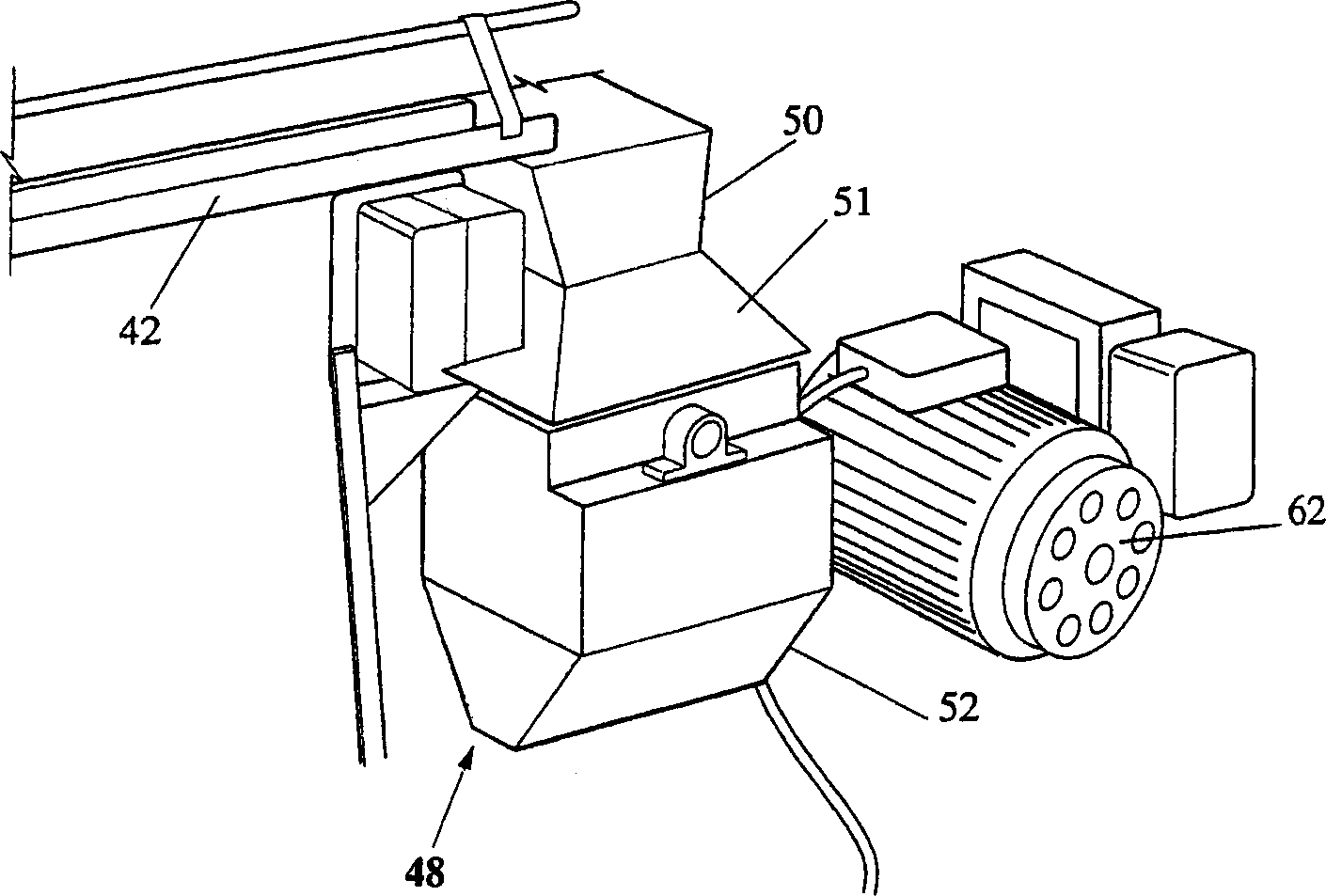

The invention discloses a rotation-revolution combined down-hole hammer. A front end of a hammer body (42) of a hammer (4) is provided with a cylindrical guide sleeve (47); the neck part of a hammer bit (45) is provided with a cylindrical guide shaft (49); the cylindrical guide shaft (49) of the hammer bit (45) is inserted into the cylindrical guide sleeve (47) at the front end of the hammer body(42) and positioned through a split limiting ring (48), so that the hammer bit (45) can axially move and be coaxially and rotatably arranged on the hammer body (42); the hammer bit of the hammer can relatively rotate; when the combined down-hole hammer punches rotatably, the hammer bits of a plurality of small-diameter hammers can also rotate while the hammer bits revolute; and a damping adjustment ring is arranged in an air dividing device. The invention provides the combined down-hole hammer and a construction method thereof; and a hard alloy head on the hammer drill is worn towards equilibrium, so that the working efficiency can be improved and the service life can be prolonged, and the combined down-hole hammer has low cost, a rational structure, high punching efficiency and long service life, is easy to maintain, convenient to disassemble and reliable to seal and can save energy.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

Harmless disassembling and resource classified recycling equipment and method of waste refrigerator

ActiveCN106269803AImprove recycling ratesNo secondary pollutionSolid waste disposalGrain treatmentsRubidiumEngineering

The invention relates to the technical field of environment protection aiming to recycling treatment of substances in a waste refrigerator. Manual pre-treatment is carried out on a disassembling station; the treated refrigerator is crushed and harmful gas is treated to obtain material grains; rough iron is sorted through suspension magnetic selection, and polyurethane foam is selected through wind selection; the rough iron and the polyurethane foam are subjected to dust removal and block pressing treatment; fine iron is selected through a rubidium-iron roller and a separator; copper and aluminum are selected through non-ferrous metal sorting and are treated into copper and aluminum grains with a hammer mill, and the copper and aluminum grains are subjected to dust removal treatment; the copper and the aluminum are sorted through proportion sorting; and ABS (Acrylonitrile Butadiene Styrene) and other plastic are sorted through light spectrum sorting. The invention provides harmless disassembling and resource classified recycling equipment and method of a waste refrigerator and a scientific, reasonable and standard recycling flow is established.

Owner:BEIJING AREOSTANARD NEW TECH

Granular material grinder and method of use

A granular material grinder and method of use includes a hammer mill for reducing incoming granular material into particulate material, a microgrinder for reducing the particulate matter into microground powder by particulate matter to particulate matter collisions, and a product collector to collect the microground powder portion. The granular material grinder having the feature of being operated in a closed system to facilitate efficient recovery of grain into microground powder and operable in a cooled inert gas to prevent any compound degradation due to temperature or oxygen.

Owner:R A MONTAG

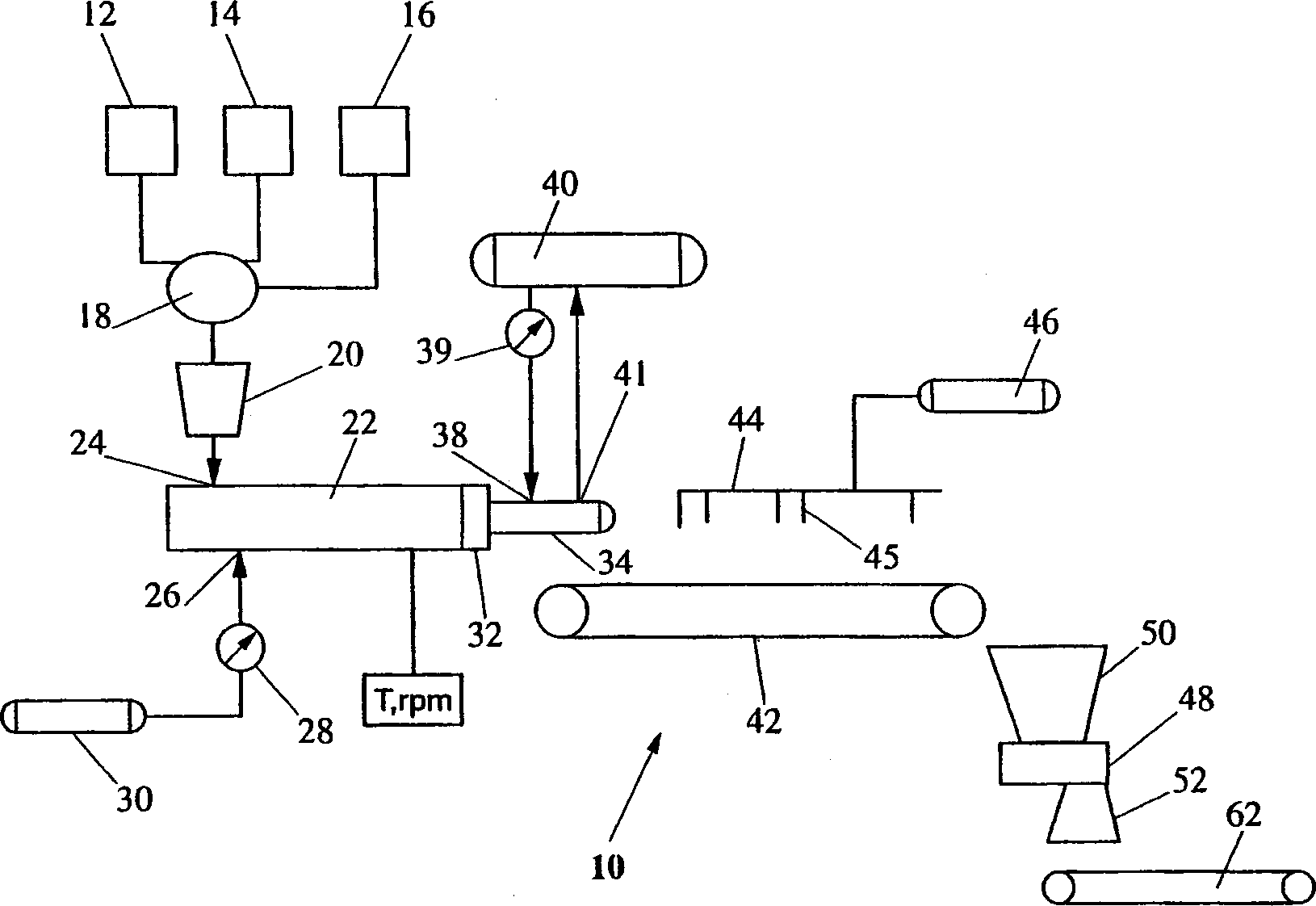

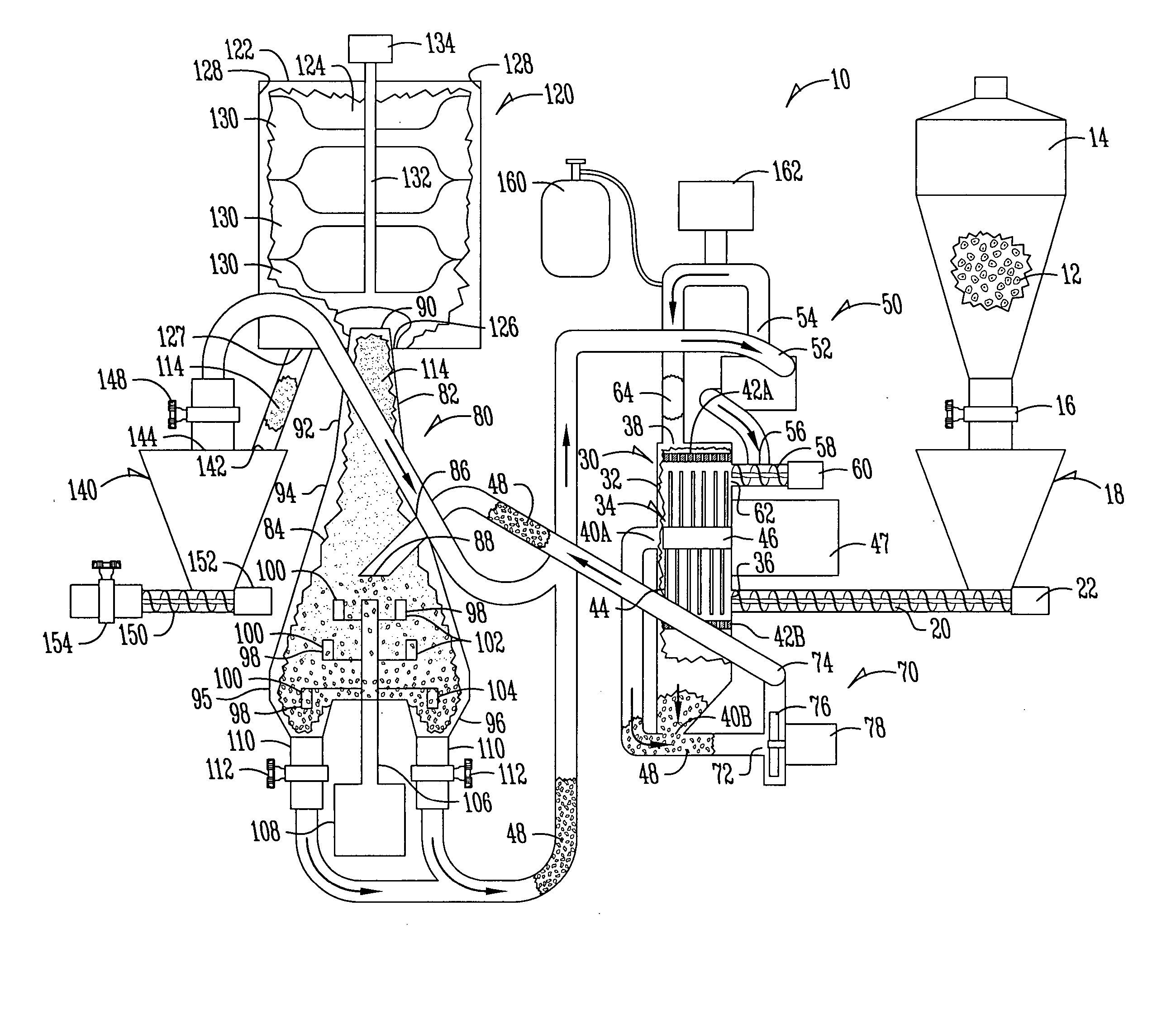

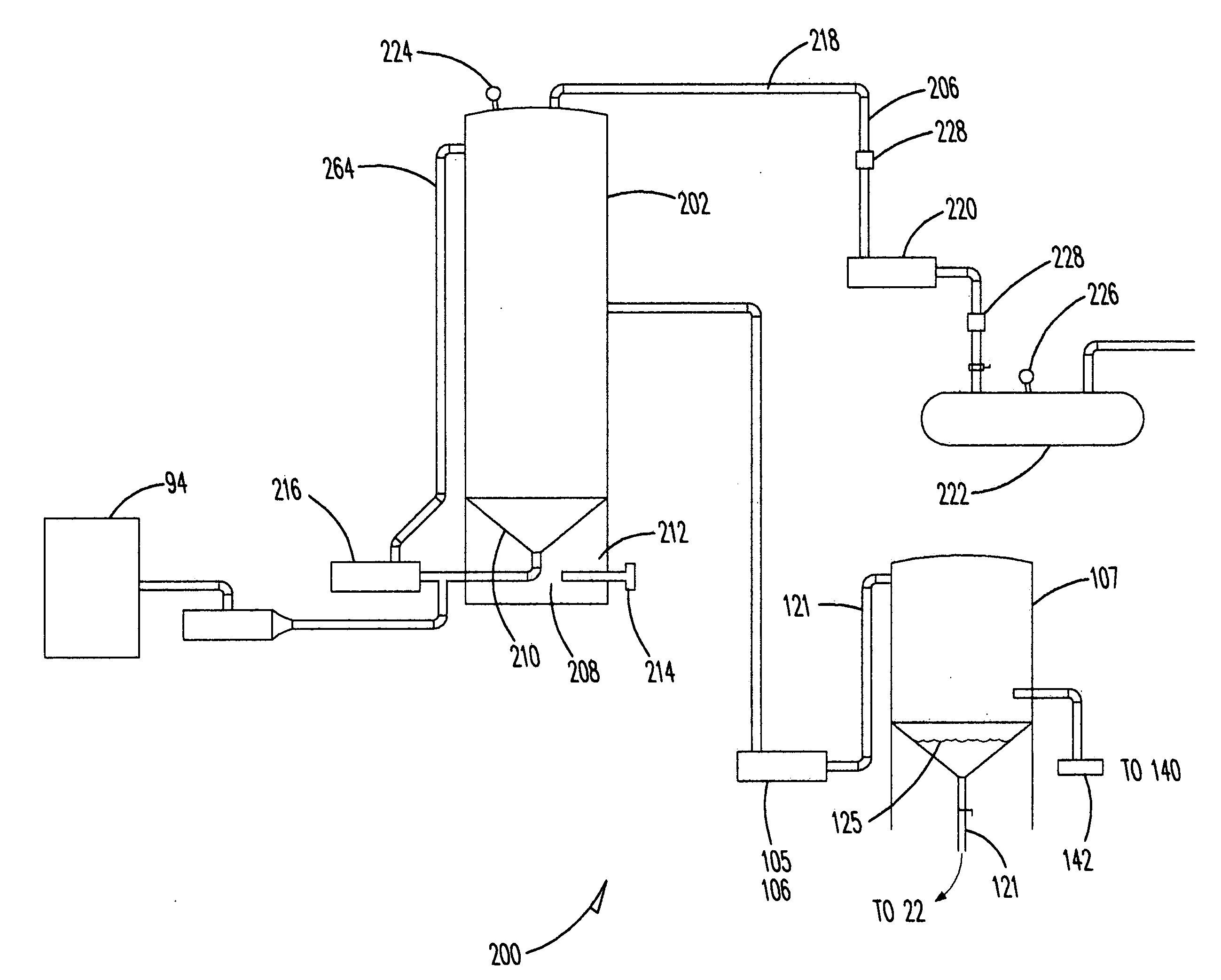

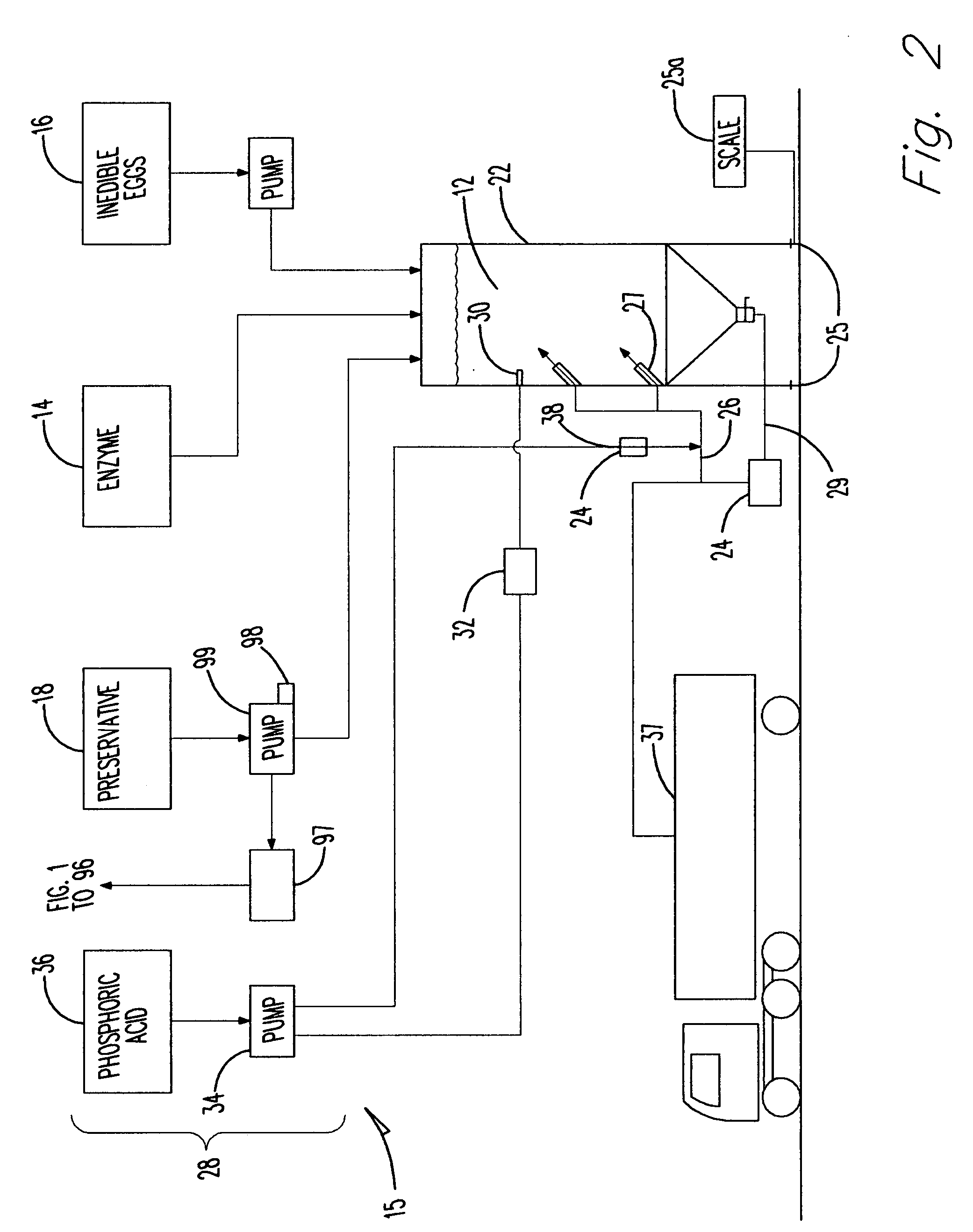

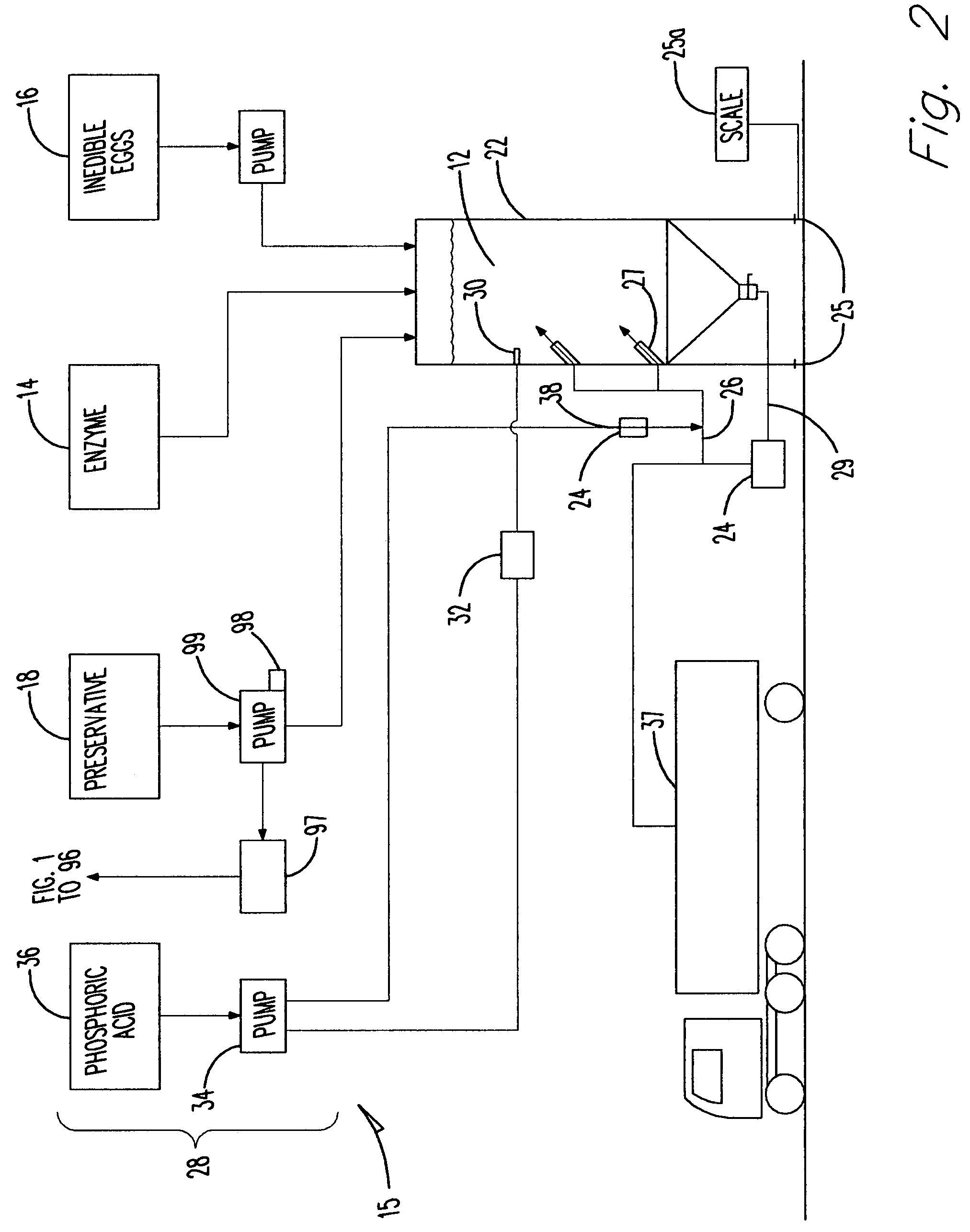

Apparatus for recycling of protein waste and fuel production

ActiveUS20070212776A1Small particle sizeWell mixedBioreactor/fermenter combinationsBiochemistry cleaning apparatusPreservativeEngineering

The apparatus of the present invention is useful for recycling protein waste and producing fuel from protein waste. Waste is ground by a grinding means and digested by a enzyme digest medium composed of enzymes, preservatives, and inedible egg. The ground proteins are digested with the enzyme in recirculated digest tanks. Fat can be collected from the tank by addition of acid and separation of fat from water with a centrifuge. Alternatively the ground protein and enzyme can be fermented and gas collected from the digest tank in a pressure tank with a compressor. The protein solubles are emulsified, separated from water, and extruded before drying. Either fat or gas can be used to fuel a dryer. The dried proteins are then milled in a hammer mill and screened for uniform size.

Owner:NATURALLY RECYCLED PROTEINS

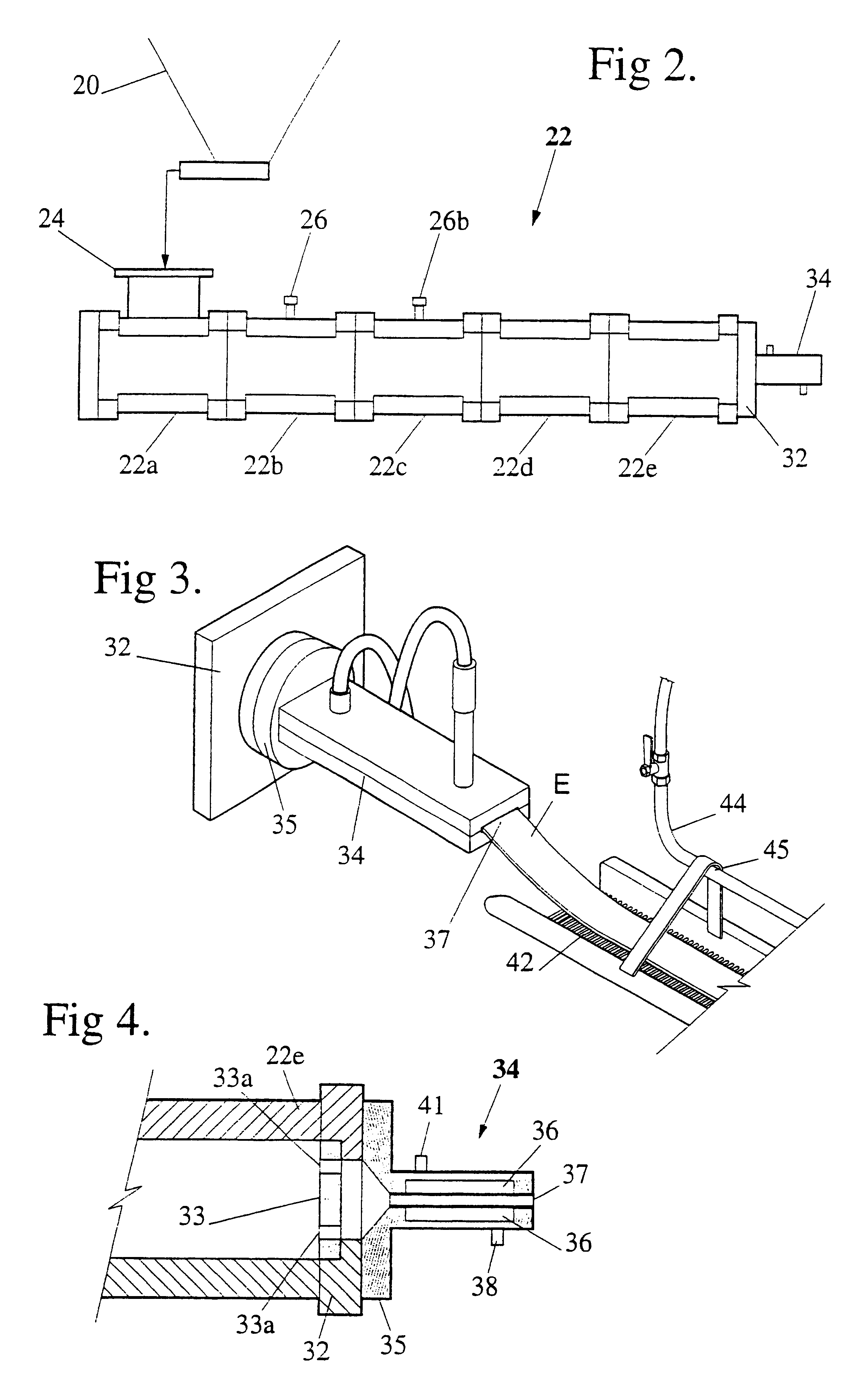

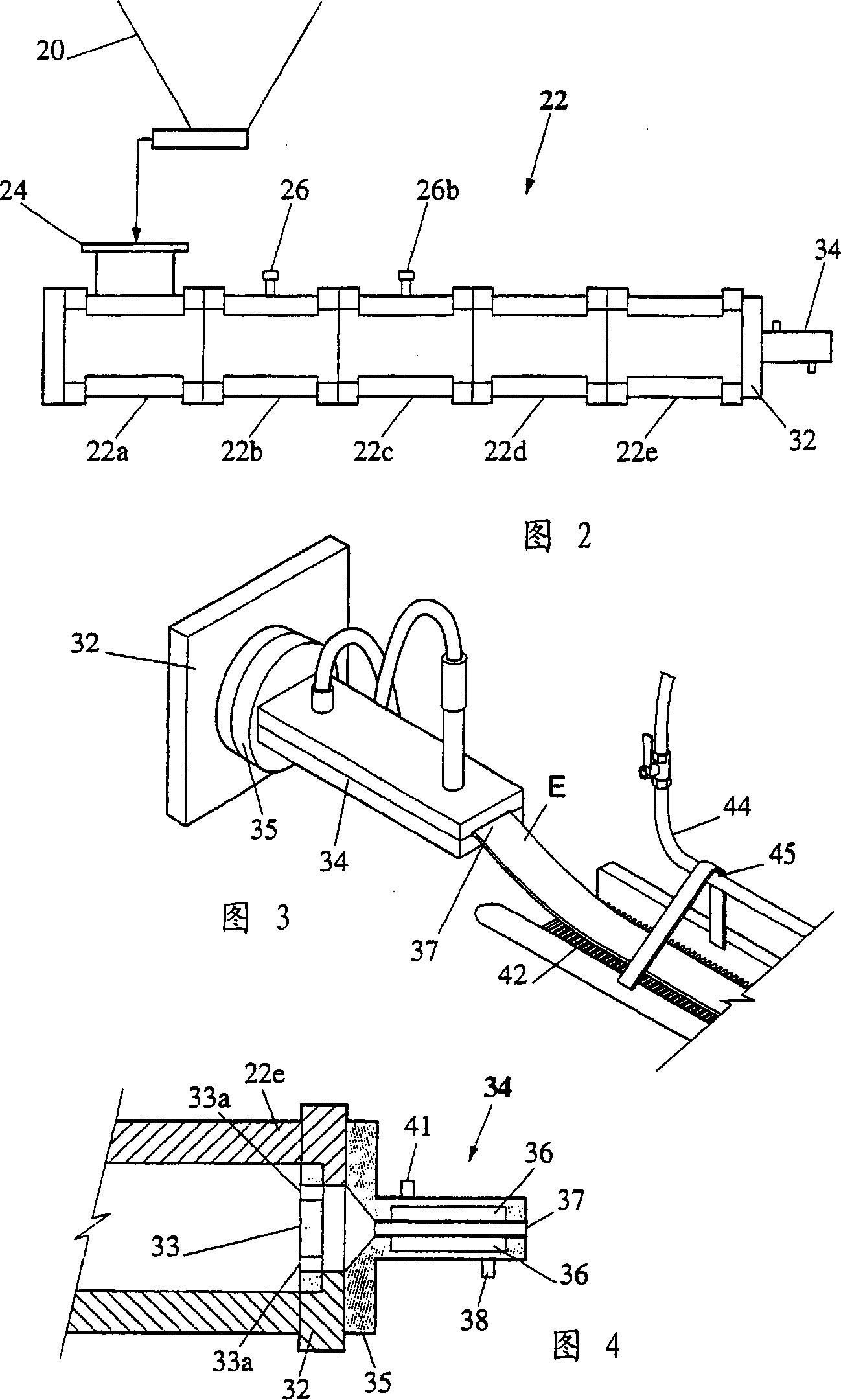

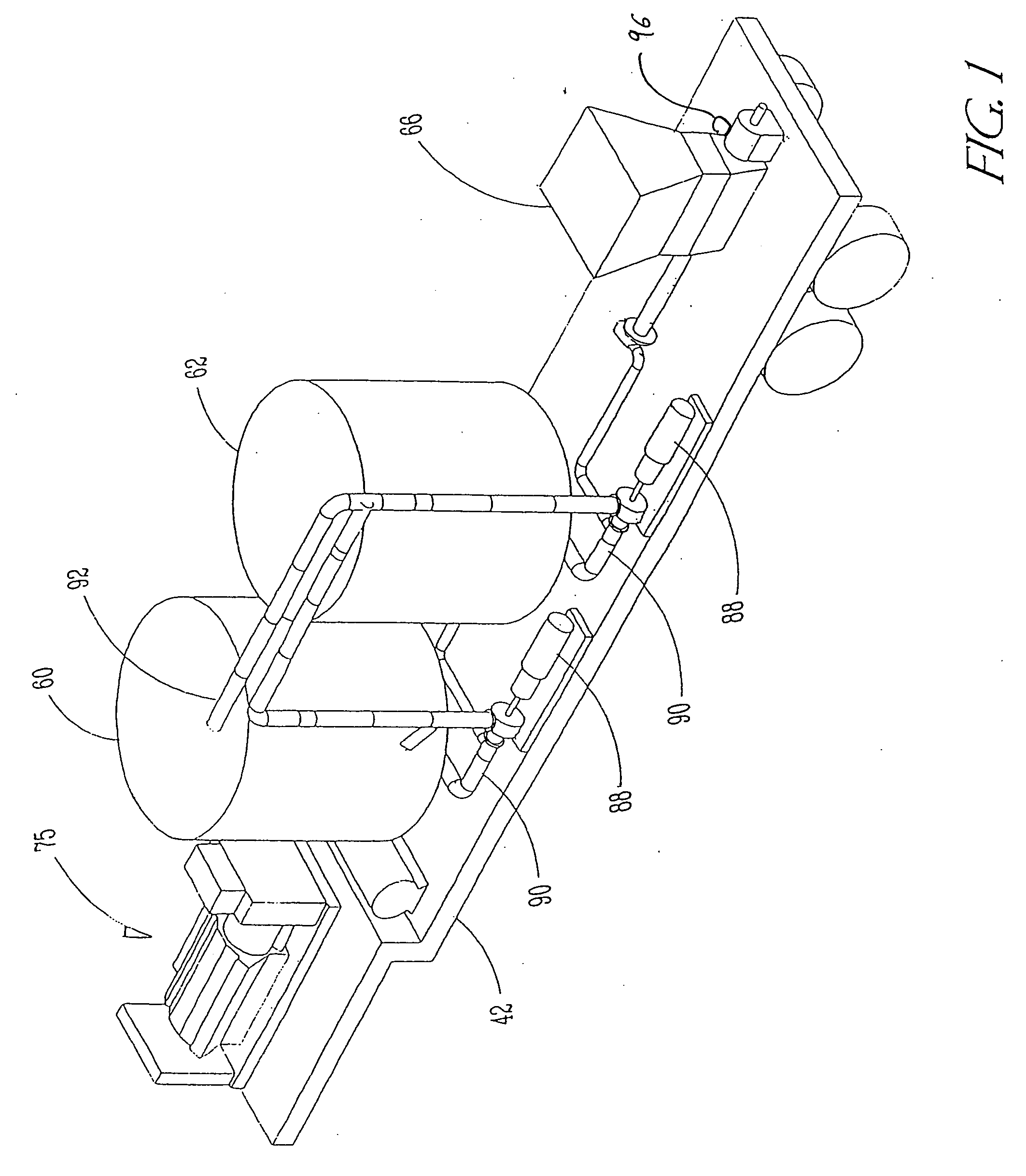

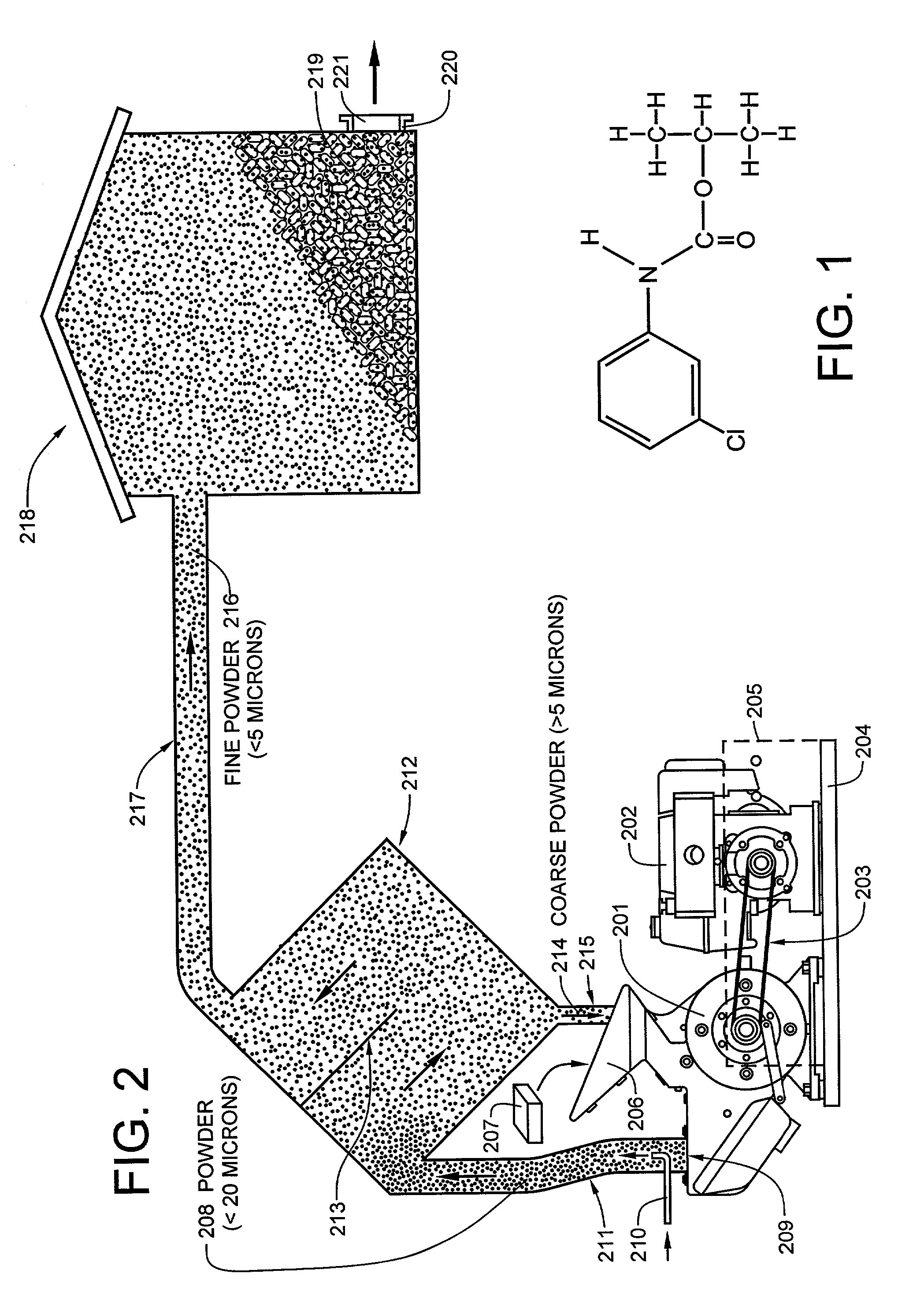

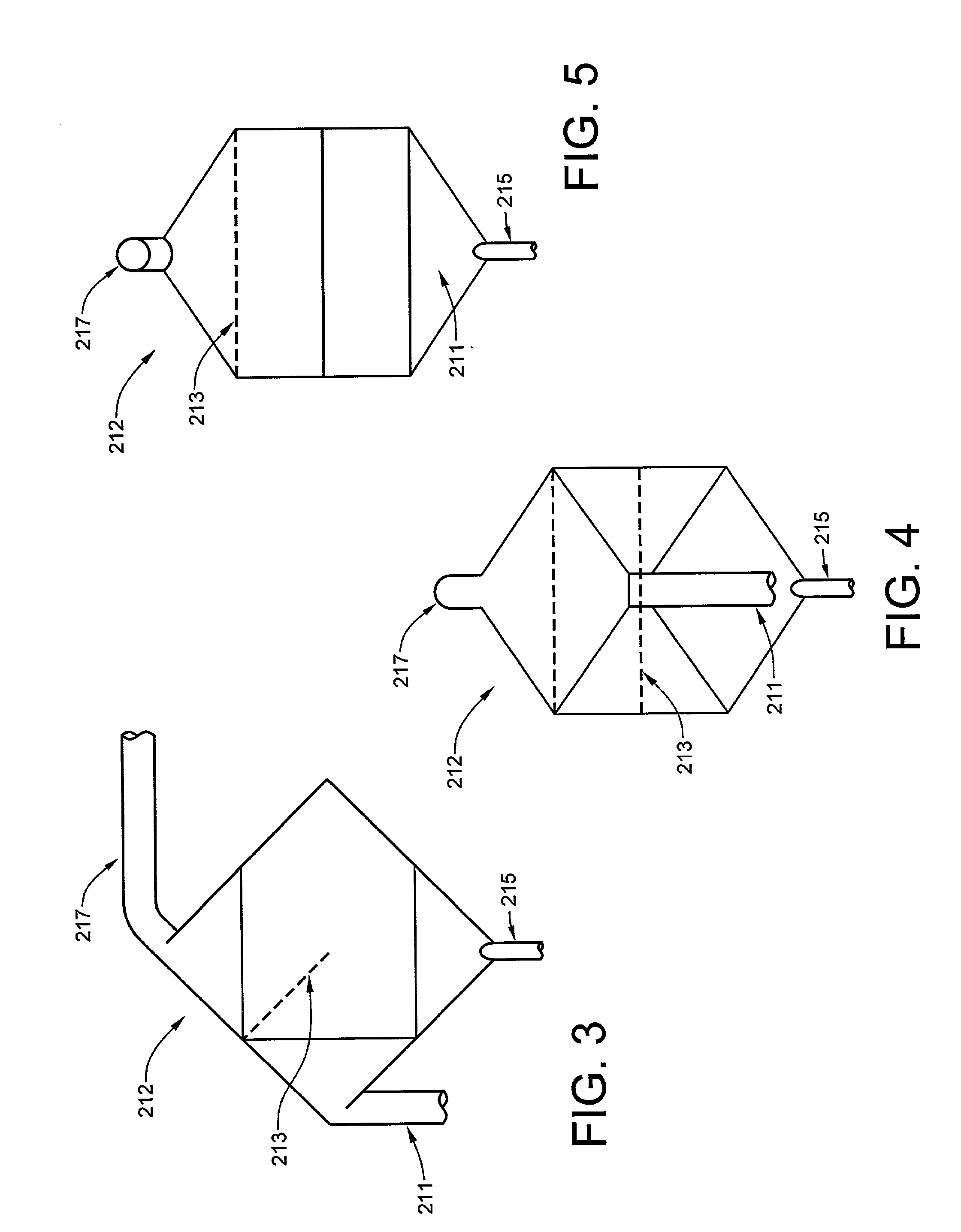

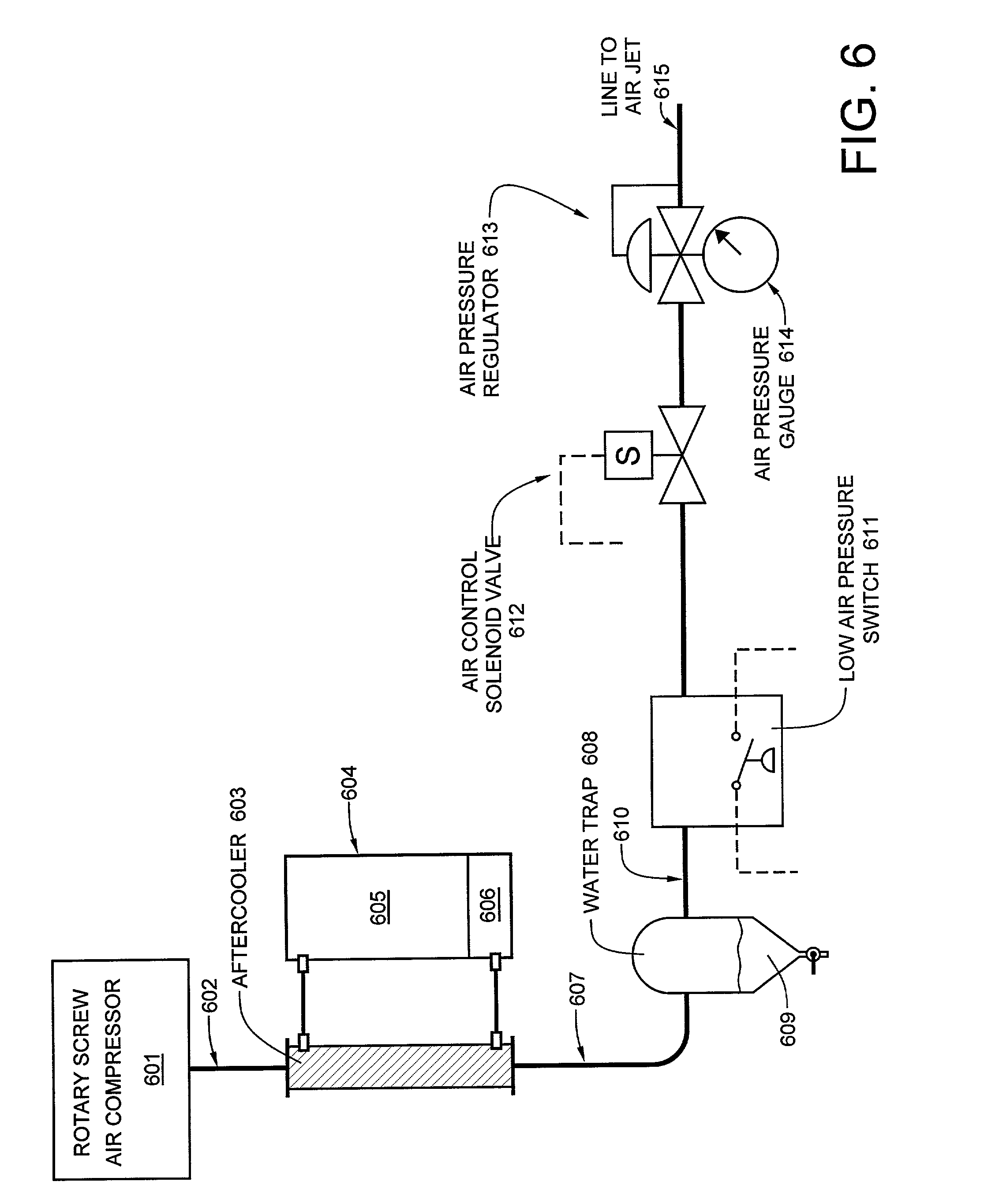

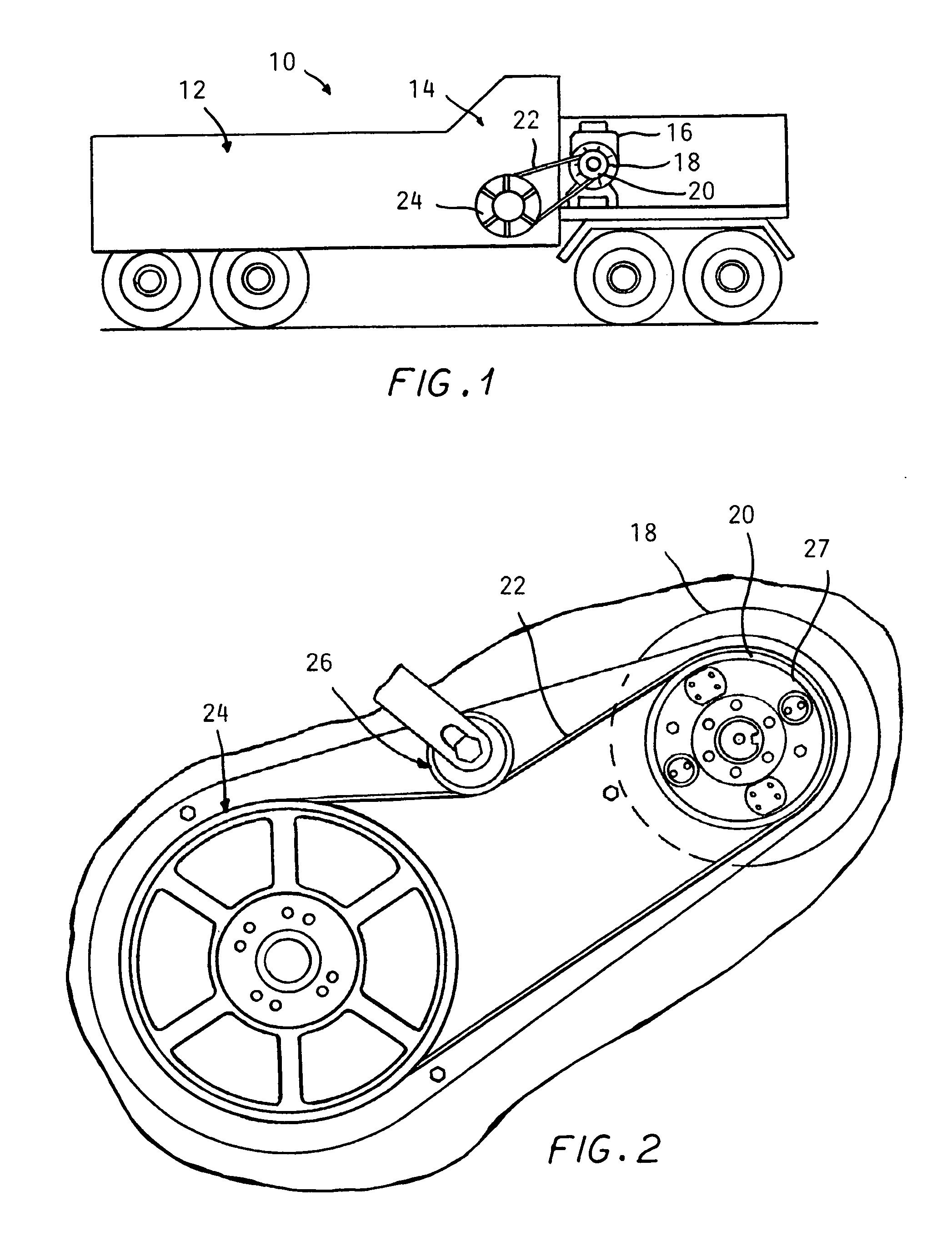

Method and apparatus for treating tubers with a powdered organic compound

The present invention provides both a process and apparatus for treating tubers in storage with chlorpropham (CIPC) dust or the dust of any other similar organic compound. The process includes the steps of forming minute particles of solid CIPC particles from a larger block or chunks of solid CIPC, and inducting the particles into an airstream which transports the particles to a tuber storage shed. For a preferred embodiment of the invention, the blocks or chunks of solid CIPC are fed into a hammer mill or like apparatus, which pulverizes the solid CIPC. Insufficiently fine particles are returned to the mill for further pulverization. Fine powder consisting of particles, each of which has a major dimension of less than about 5 micrometers, is transported by the ducted airstream from the separator to a storage shed containing a pile of tubers. The powder filters through the pile and coats exposed surfaces of the exposed tubers.

Owner:INDAL VENTILATION

Activating acid leaching method for extracting vanadium from bone coal

InactiveCN102392126ALower manufacturing requirementsHigh activityProcess efficiency improvementChemical reactionSlag

The invention discloses an activating acid leaching method for extracting vanadium from bone coal. The method is innovative that a bone coal grinding step employs mechanical force for activation; clay minerals containing vanadium like illite in the bone coal bone coal are treated with mechanical force chemical reaction and activated through controlling rotating speed and vibration frequency of a planet mill or a vibromill of a jaw breaker and a hammer mill, ball milling time and particle size in each operation, but carbonaceous structure is not destroyed, so as to lay foundation for increasing yield of vanadium and obtain carbon rich acid leaching slag. The invention also has innovation that a normal pressure acid leaching method is employed to realize an extraction rate of 90-98%.

Owner:森松(江苏)海油工程装备有限公司

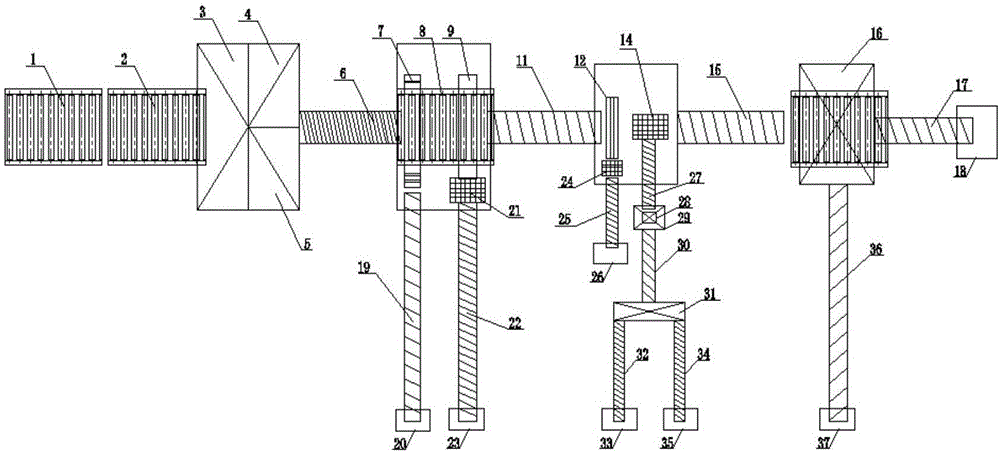

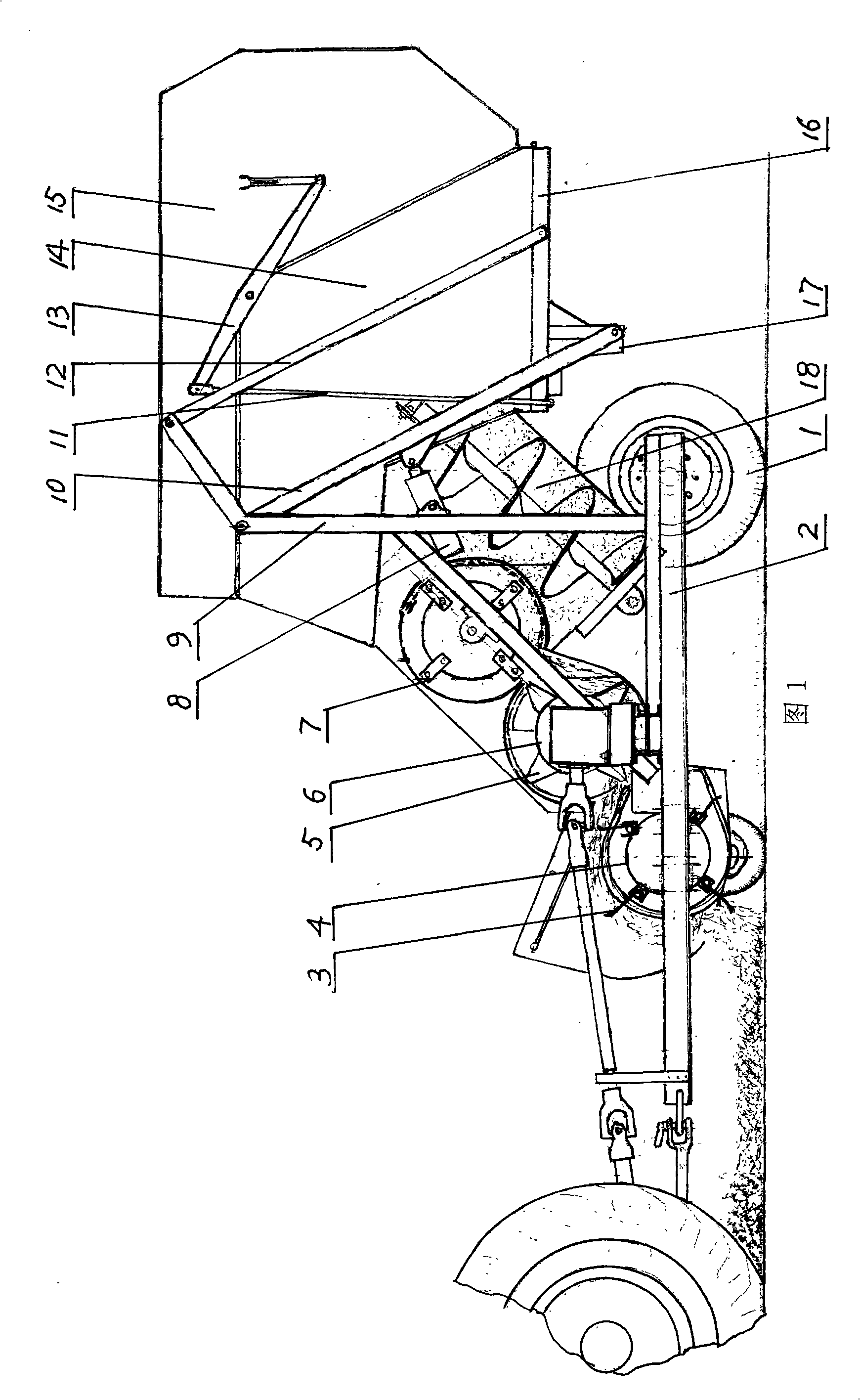

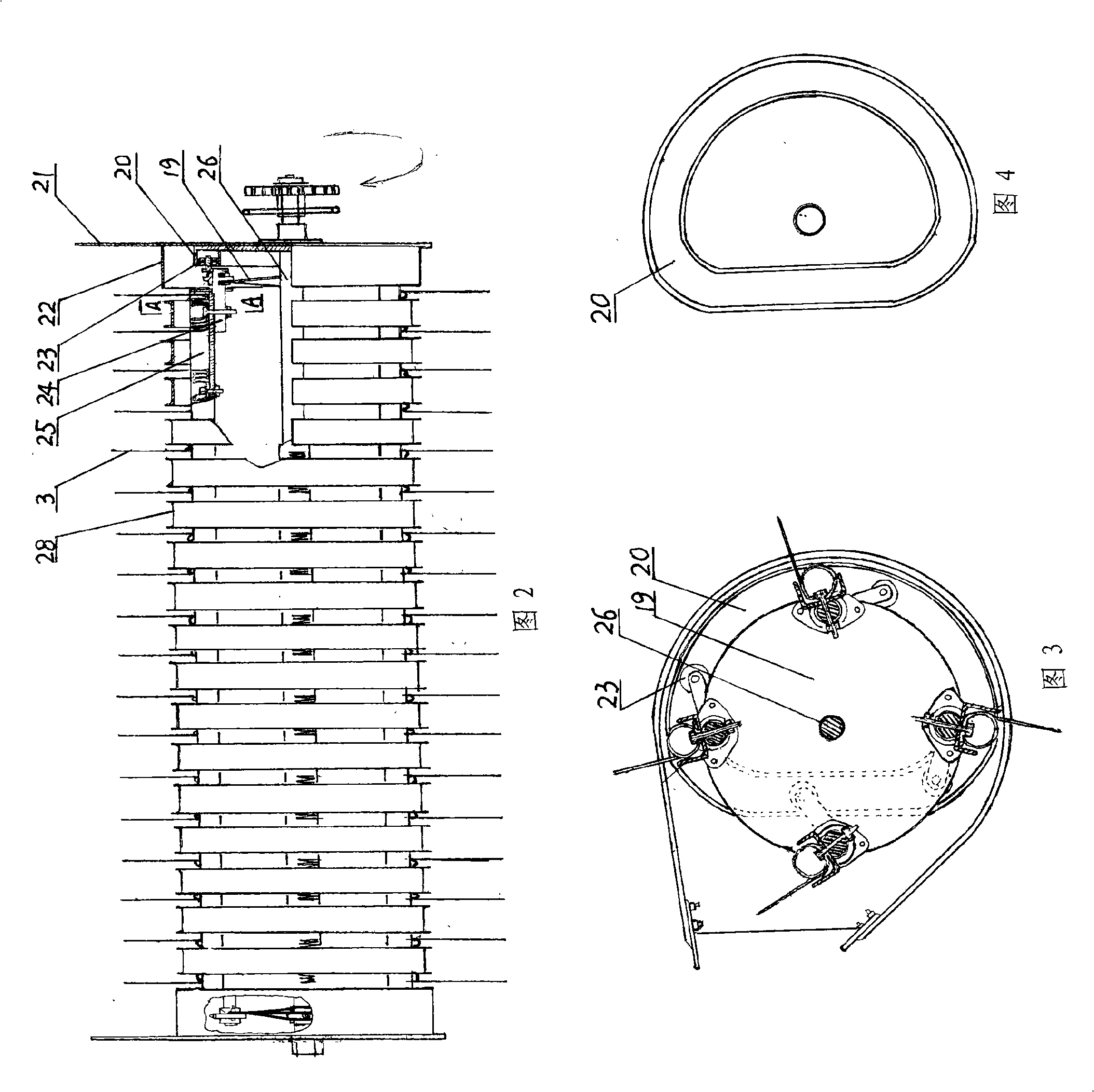

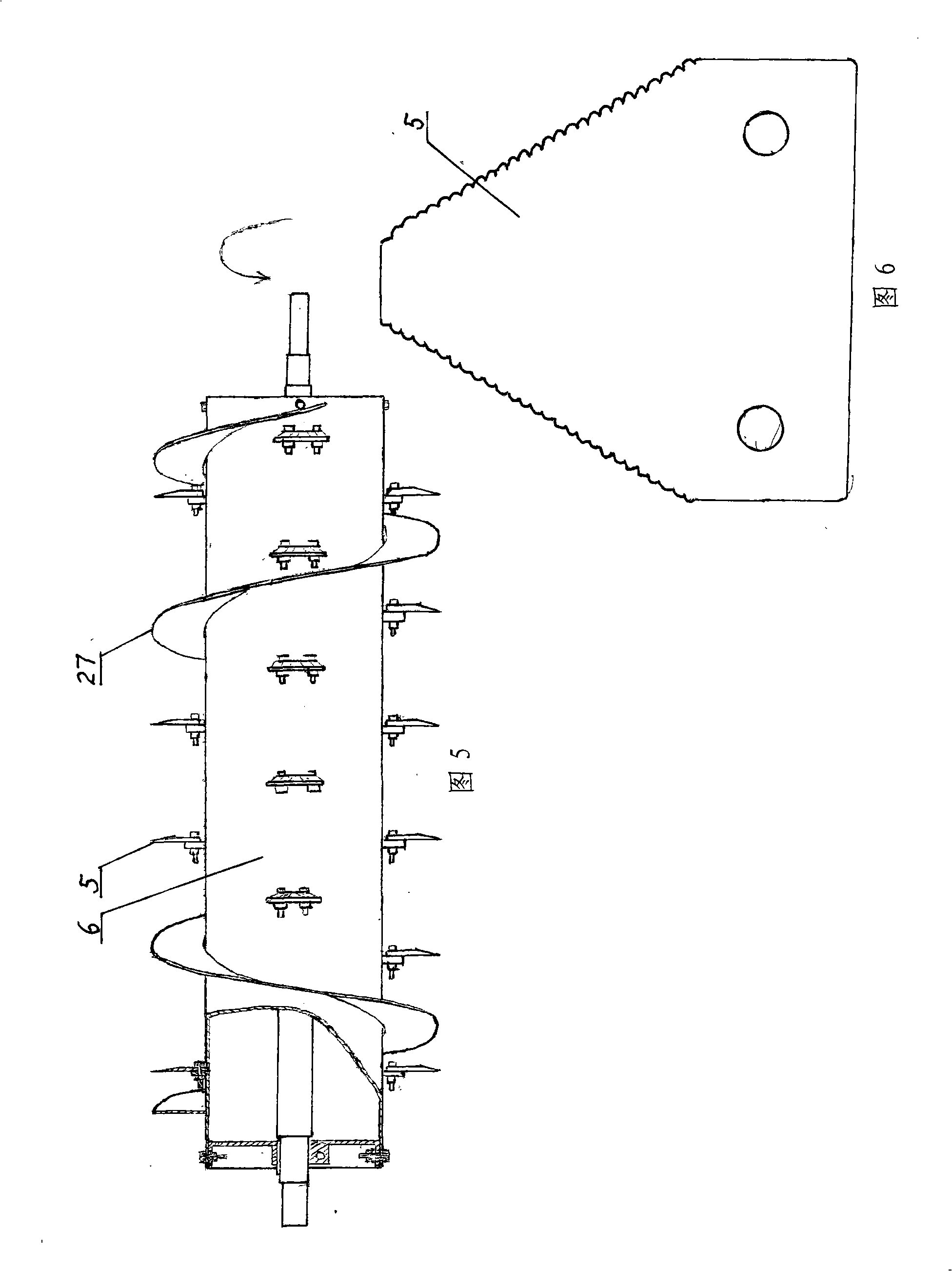

Pasturage combine harvesting disintergrator

InactiveCN101253831AQuality improvementReduce configurationLoadersCrop conditionersEngineeringKnife blades

The invention belongs to a forage combine harvesting and grinding machine that integrates picking, grinding, collecting and loading of main-field forage or straw-type crops after the forage or the crops are harvested. The machine comprises a hammer mill mounted on a chassis, which is provided with wheels and towed by a tractor; a pickup device provided with elastic claws which are evenly distributed on the roller surface is mounted in the front of the chassis; an antithetic spiral conveyor roller provided with cutters which are evenly distributed on the roller surfaces is mounted in back of the pickup device; the discharge hole of the conveyor roller is connected with the feeding hole of the hammer mill. The discharge hole of the hammer mill is connected with the feeding hole of the spiral conveyor which inclines upwards; the feeding hole of the spiral conveyor communicates with a hydraulically controlled grass storage device which can automatically unload the grass. The machine can complete the processes such as picking up the forage or straws from the field, feeding, grinding, conveying and loading on a one-off basis, thus reducing labor intensity, saving manpower, curtailing agricultural equipment, raising production efficiency, ensuring safe production, facilitating operation and maintenance, as well as improving the forage quality.

Owner:杨学仁

Apparatus for recycling of protein waste and fuel production

ActiveUS7851210B2Small particle sizeWell mixedBioreactor/fermenter combinationsAnimal corpse fertilisersPreservativeEngineering

Owner:NATURALLY RECYCLED PROTEINS

Multi-function crusher

InactiveCN102974423ARealize the effect of one machine with multiple functionsGrain treatmentsEngineeringCrusher

The invention discloses a multi-function crusher. The multi- function crusher comprises a base seat and a crusher shell, wherein the crusher shell is arranged on the base seat. A crushing room is arranged inside the crusher shell. An upper feeding inlet is arranged at the top end of the crushing room. A left feeding inlet and a right feeding inlet are respectively arranged on the left side of the crushing room and the right side of the crushing room. A main shaft is arranged inside the crushing room. A hammer carrier which corresponds to the upper feeding inlet is arranged in the middle portion of the main shaft. The hammer carrier is provided with multiple hammer sheets. A blade set which corresponds to the left feeding inlet is arranged on the left side of the main shaft, and a right blade set which corresponds to the right feeding inlet is arranged on the right side of the right feeding inlet. The lower portion of the crushing room is provided with a plurality of filter screens which are provided with multiple sieve pores. Section of each the sieve pore is of a trumpet shape with the upper portion small and the lower portion big. A discharging port is arranged at the right end of the bottom portion of the crushing room. The multi- function crusher combines the advantages of a hammer mill, a slicing machine and a hay cutter and the like. Further, the multi- function crusher is provided with the upper feeding inlet, the left feeding inlet, and a right feeding inlet, and according to different materials, different blades are arranged, and therefore, the effect of multi-purposes of a crusher is achieved.

Owner:涂佳永

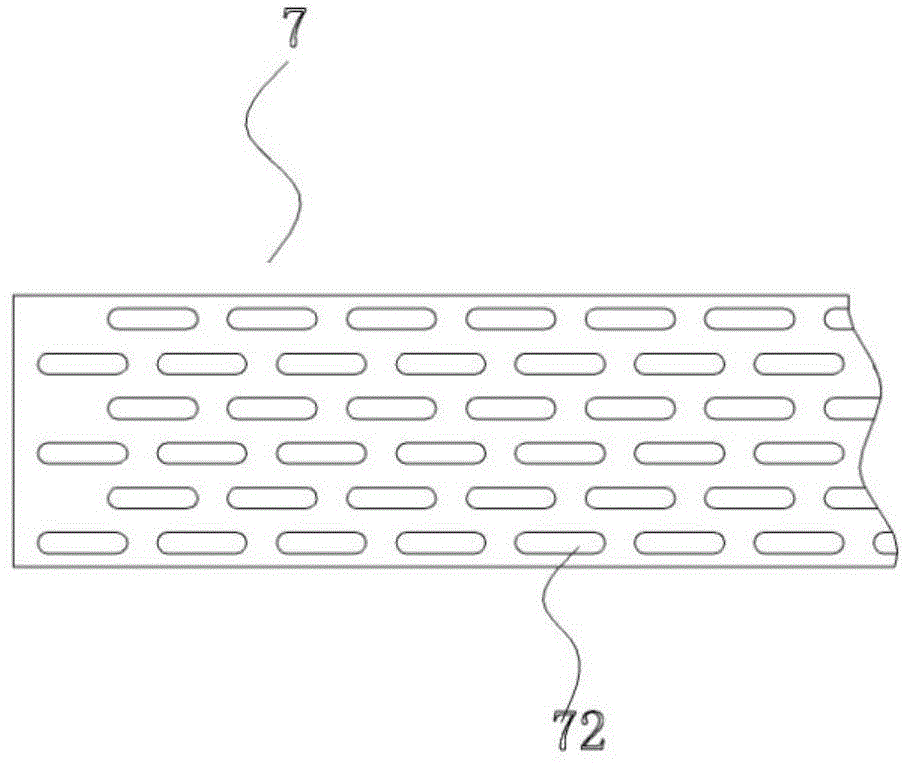

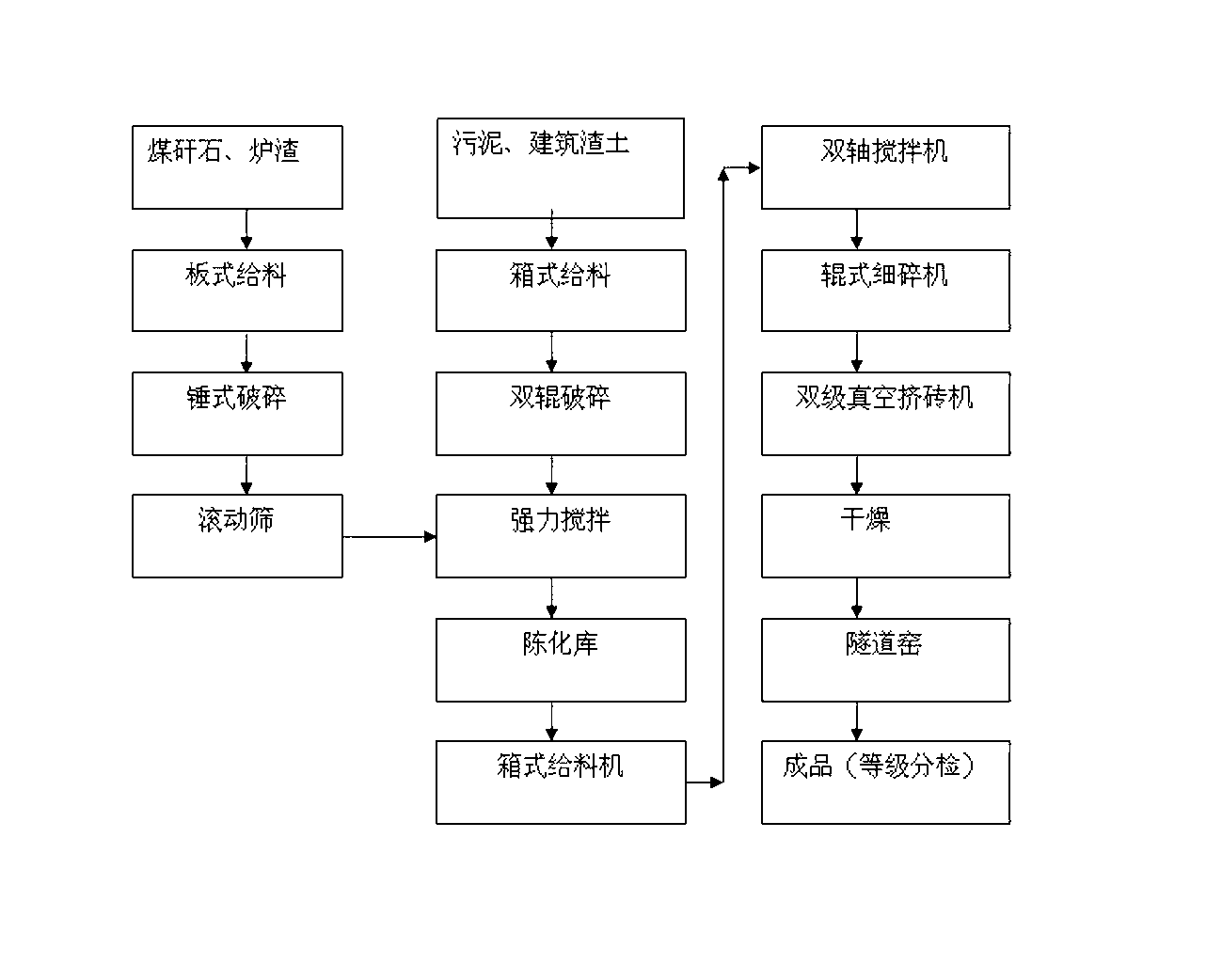

Energy-saving heat retaining rectangular-hole porous brick

InactiveCN102795877AMeet the requirements for the production of porous bricksCeramicwareTunnel kilnBrick

The invention discloses an energy-saving heat retaining rectangular-hole porous brick, prepared through the following steps of: 1) charging coal gangue into a hopper and conveying the same to a raw material processing workshop through a belt conveyor, and then crashing the coal gangue by a hammer mill and screening the same by a rotary screen or a vibrating screen to form coal gangue powder; 2) feeding the coal gangue powder together with building wastes, slags, sludge and water to perform primary stirring and then feeding the mixture to an aging chamber for aging; 3) conveying the aged material to perform secondary stirring and producing green bricks in a vacuum brickmaking machine by the belt conveyor; 4) stacking the green bricks on a kiln car by a hydraulic automatic setting machine and then feeding the green bricks into a drying cavity for drying; and 5) conveying the dried green bricks to the opening of a tunnel kiln by a ferry vehicle and then lifting the green bricks in the kiln for sintering, thereby obtaining finished products of bricks, wherein the bricks comprise the following raw materials by weight percent: coal gangue powder 70-80%, building wastes 5-10%, slags 8-13%, sludge 2-6%, and the balance of water. The energy-saving heat retaining rectangular-hole porous brick is high in strength, high in voidage, low in dead load, good in sound isolation and excellent in heat retaining performance.

Owner:浙江嘉荣新型材料有限公司

Manufacturing method of high-green-strength atomized copper powder

The invention discloses a manufacturing method of high-green-strength atomized copper powder. The manufacturing method includes steps of smelting, specifically, placing solid-state pure-copper materials into a smelter and smelting to obtain liquid-state copper, and oxygenating during smelting; atomizing, ejecting atomized copper powder by a closed type V-shaped nozzle under the condition of high pressure when the liquid-state copper flows out of the smelter; drying, to be specifically, drying the copper powder subjected to atomization; reduction, reducing the dried copper powder by reducing gas; after-treatment, more specifically, coarsely crushing the reduced copper powder by a hammer mill, then finely crushing by a turbo type mill, finally screening by an ultrasonic screening machine with copper granularity of 150-600 meshes to obtain high-green-strength atomized copper powder. The manufacturing method of the high-green-strength atomized copper powder can manufacture copper powder in various and complicated shape, green strength of the copper powder is effectively improved, and loose-packed density of the copper powder is reduced.

Owner:铜陵国传电子材料科技有限公司

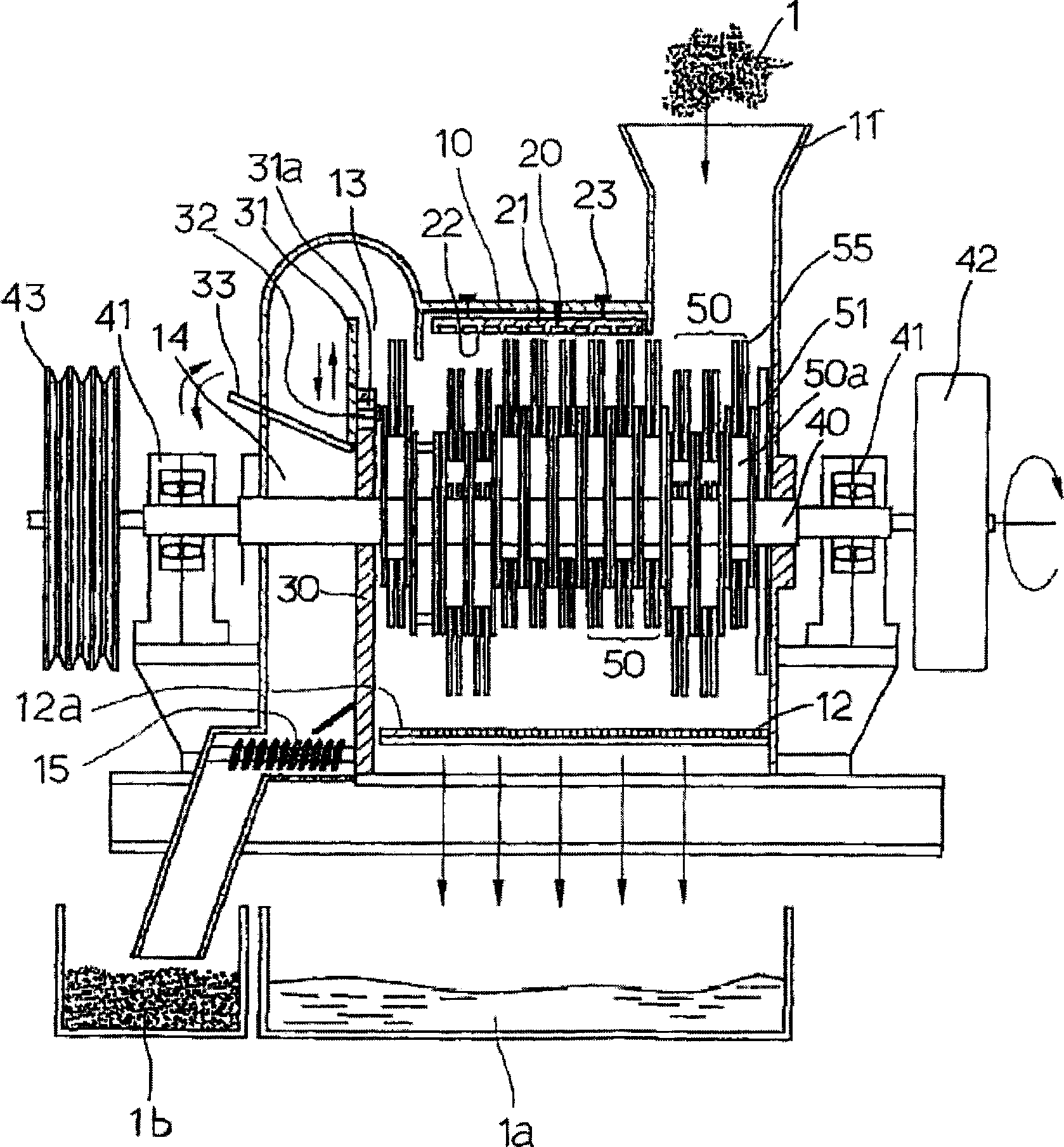

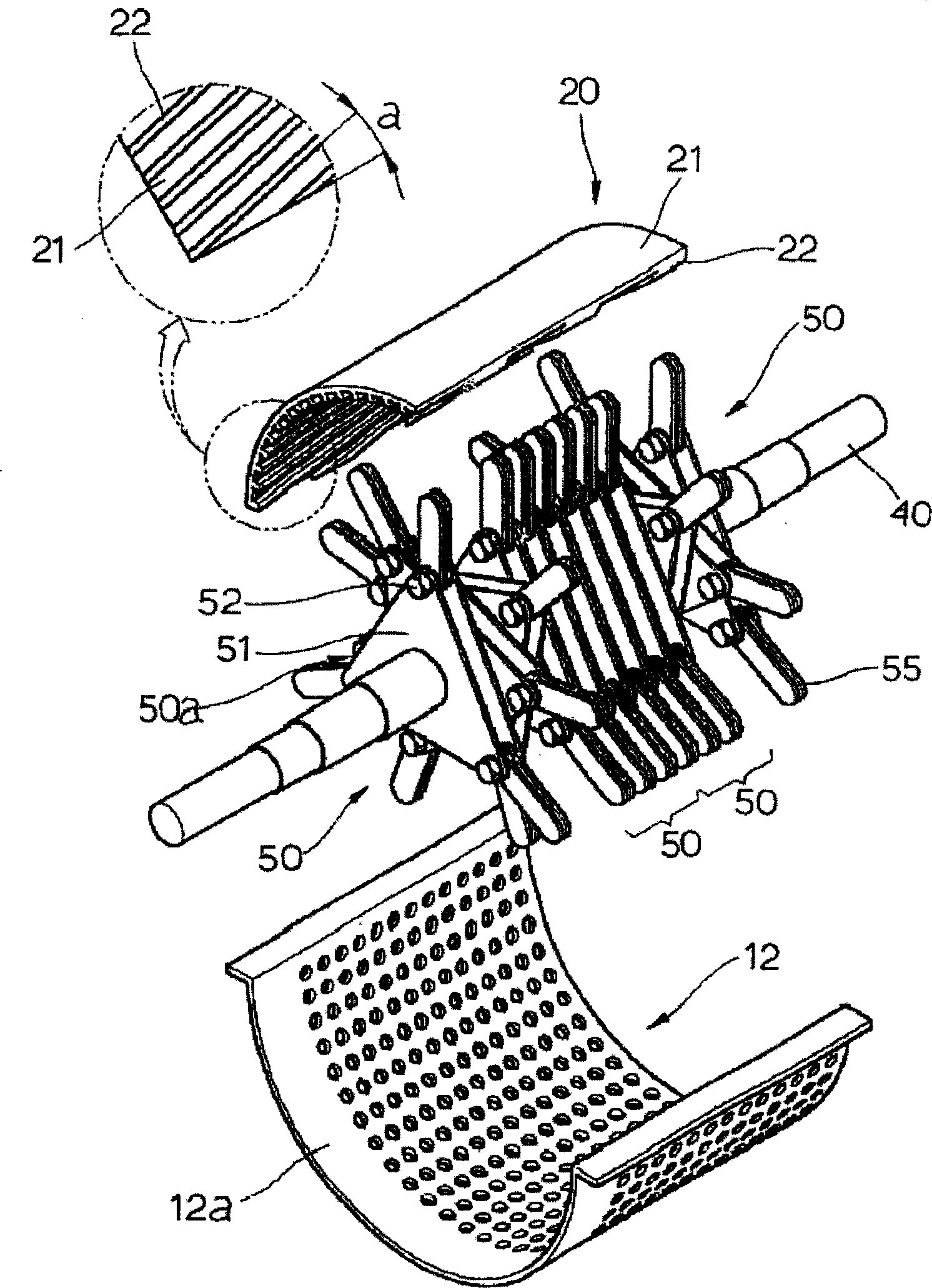

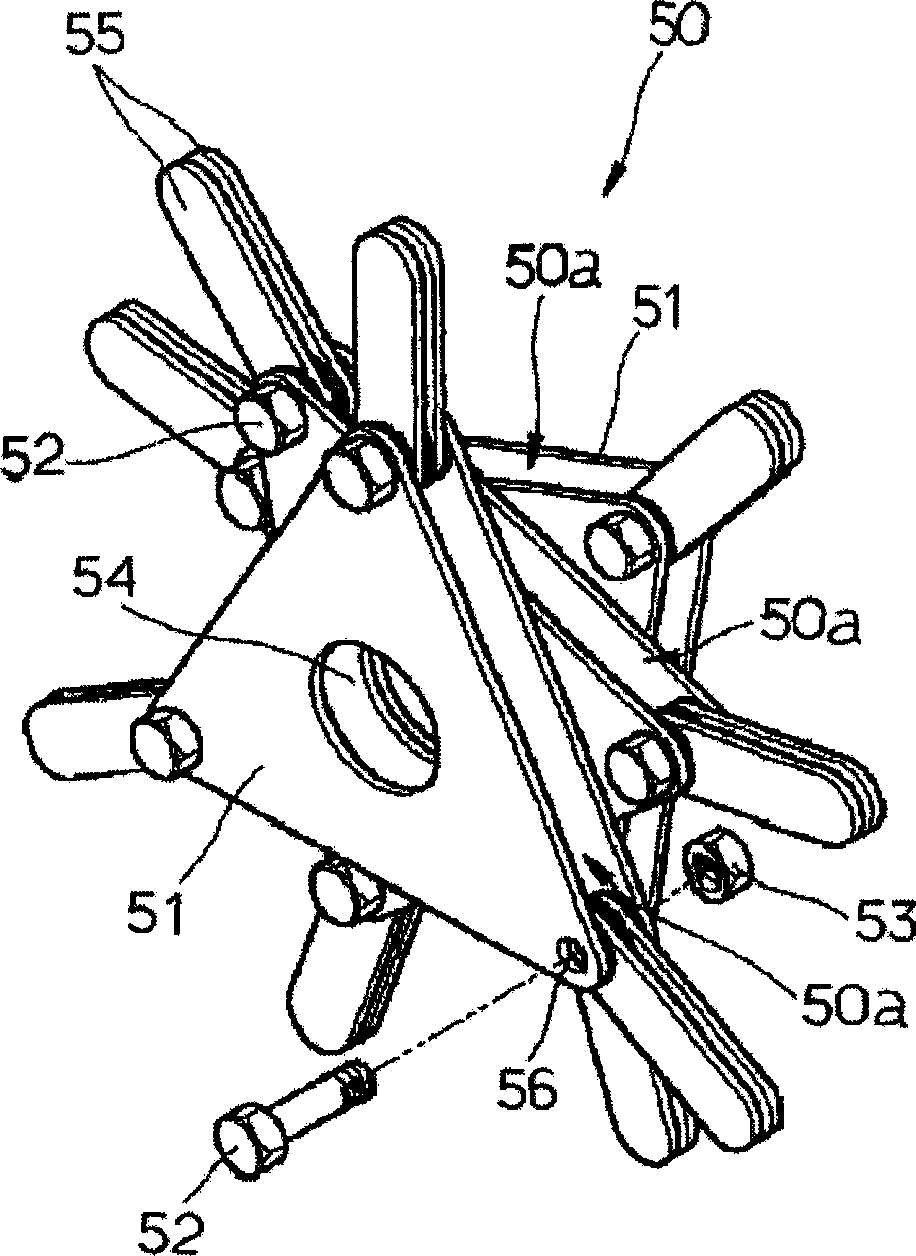

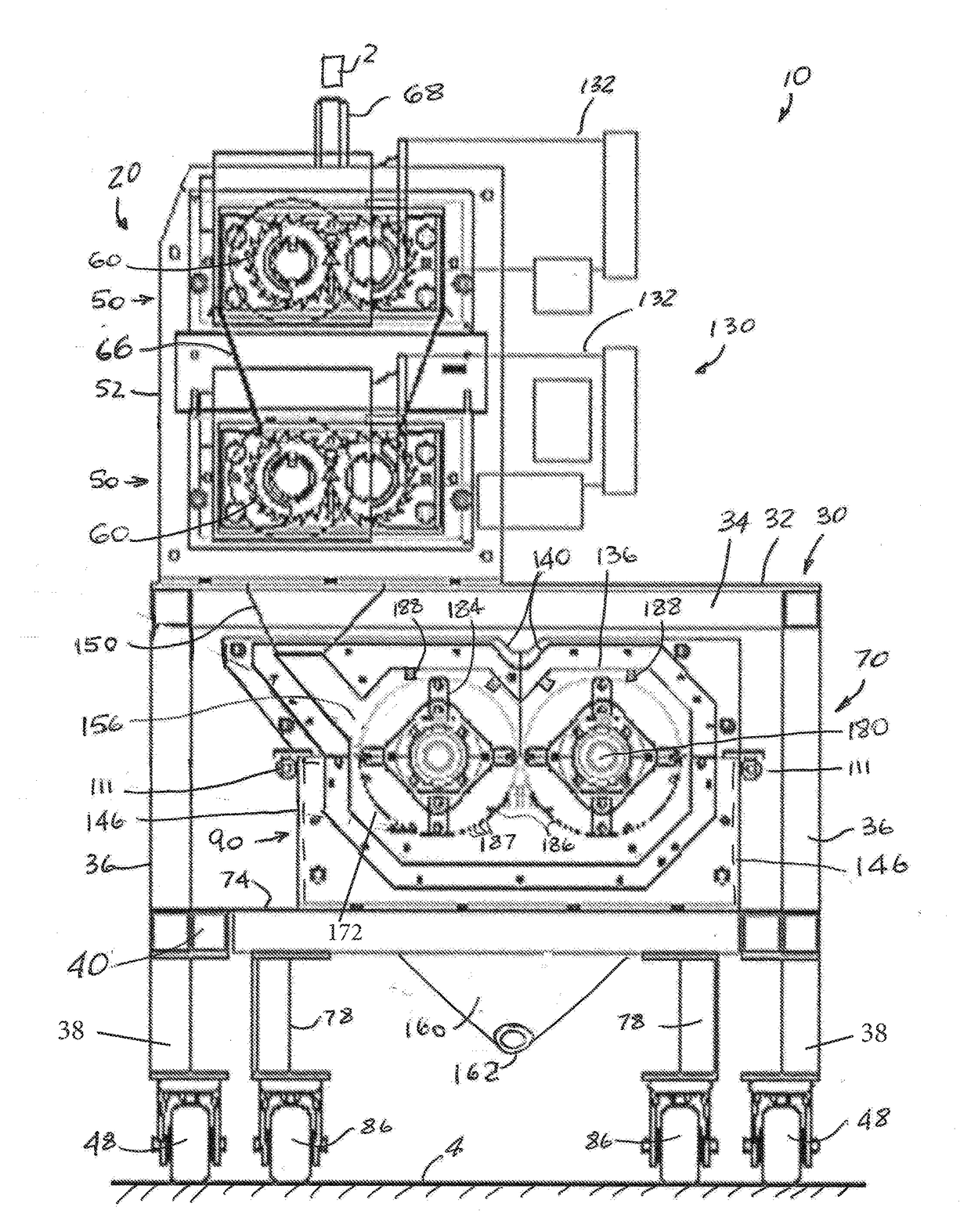

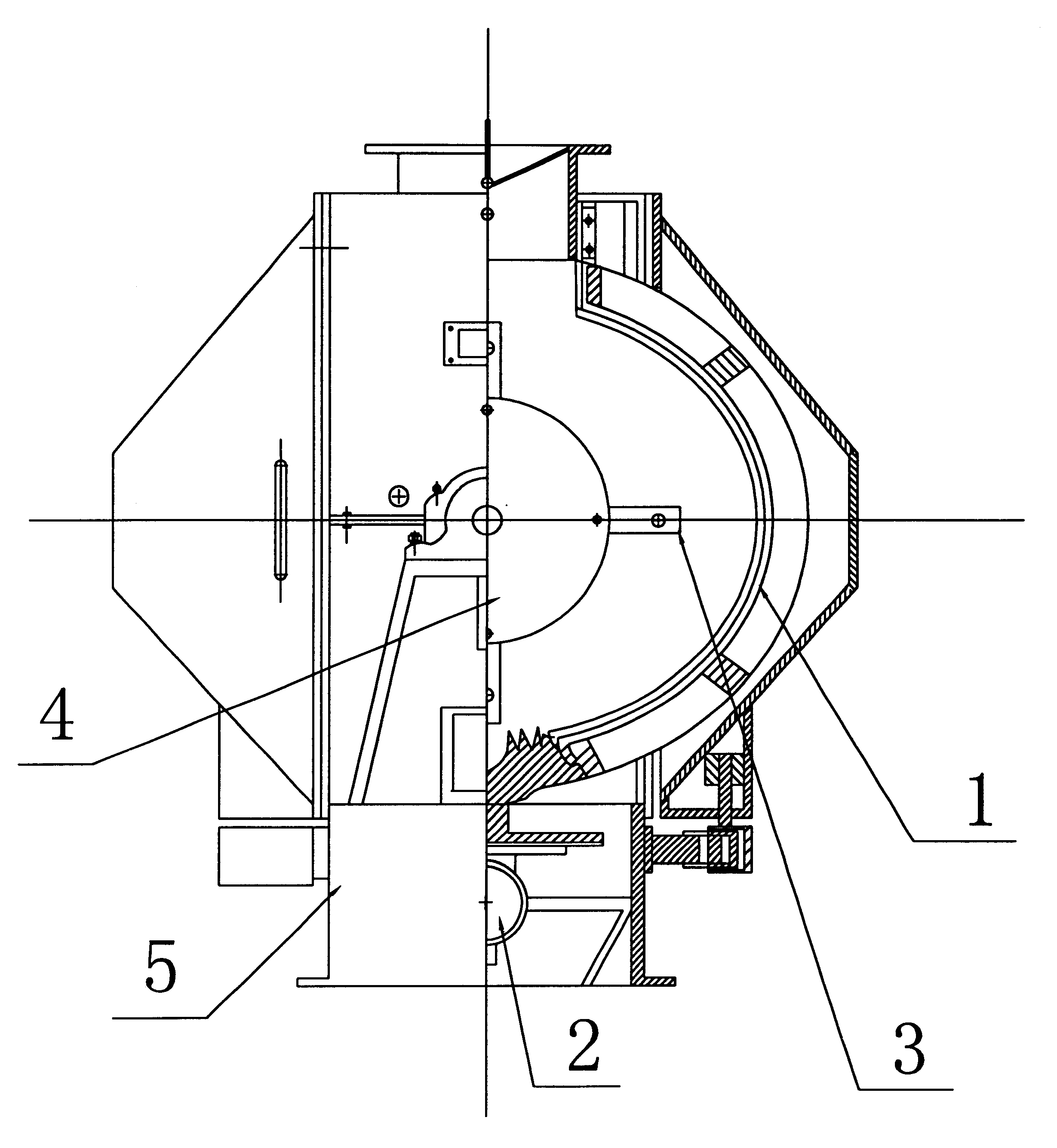

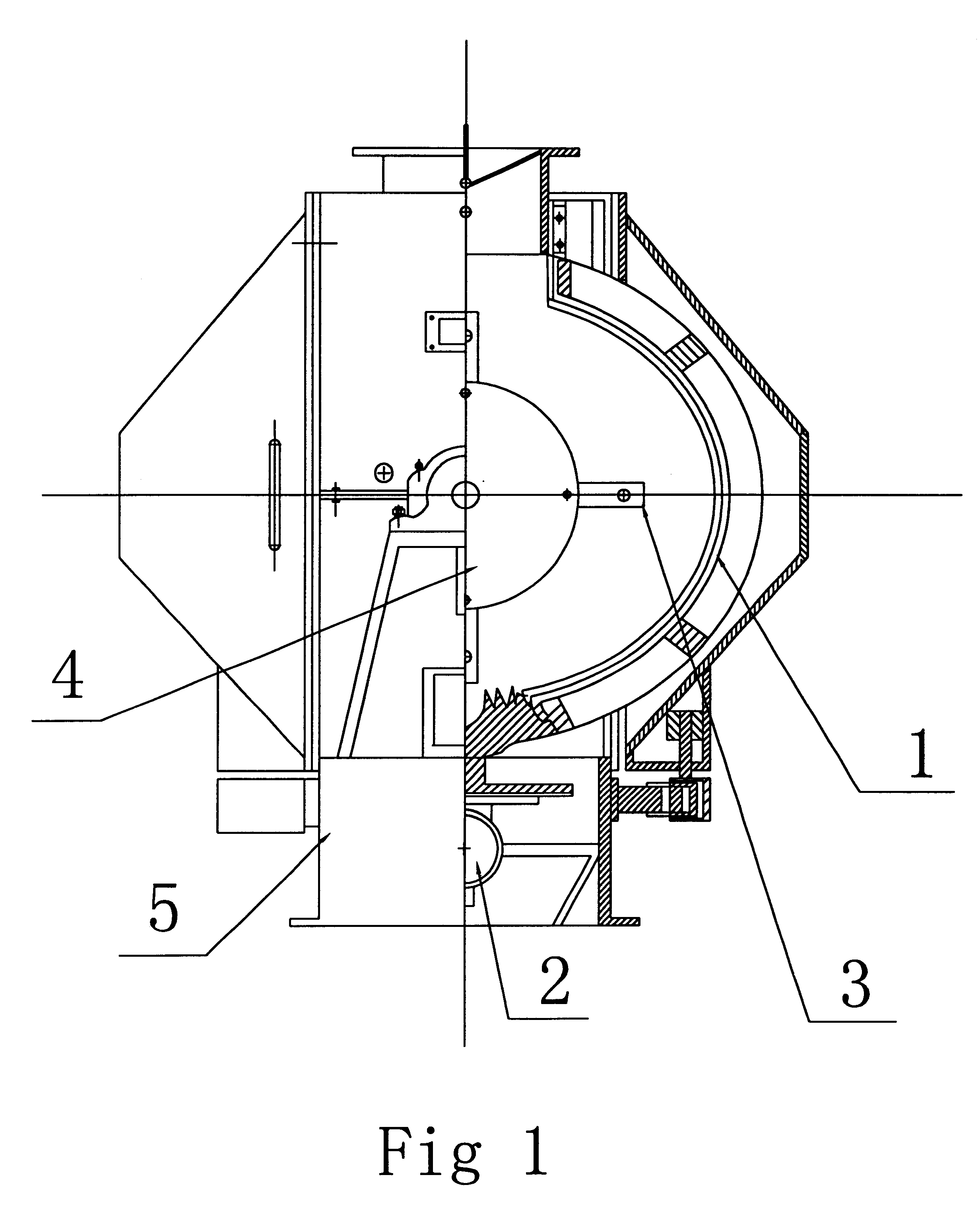

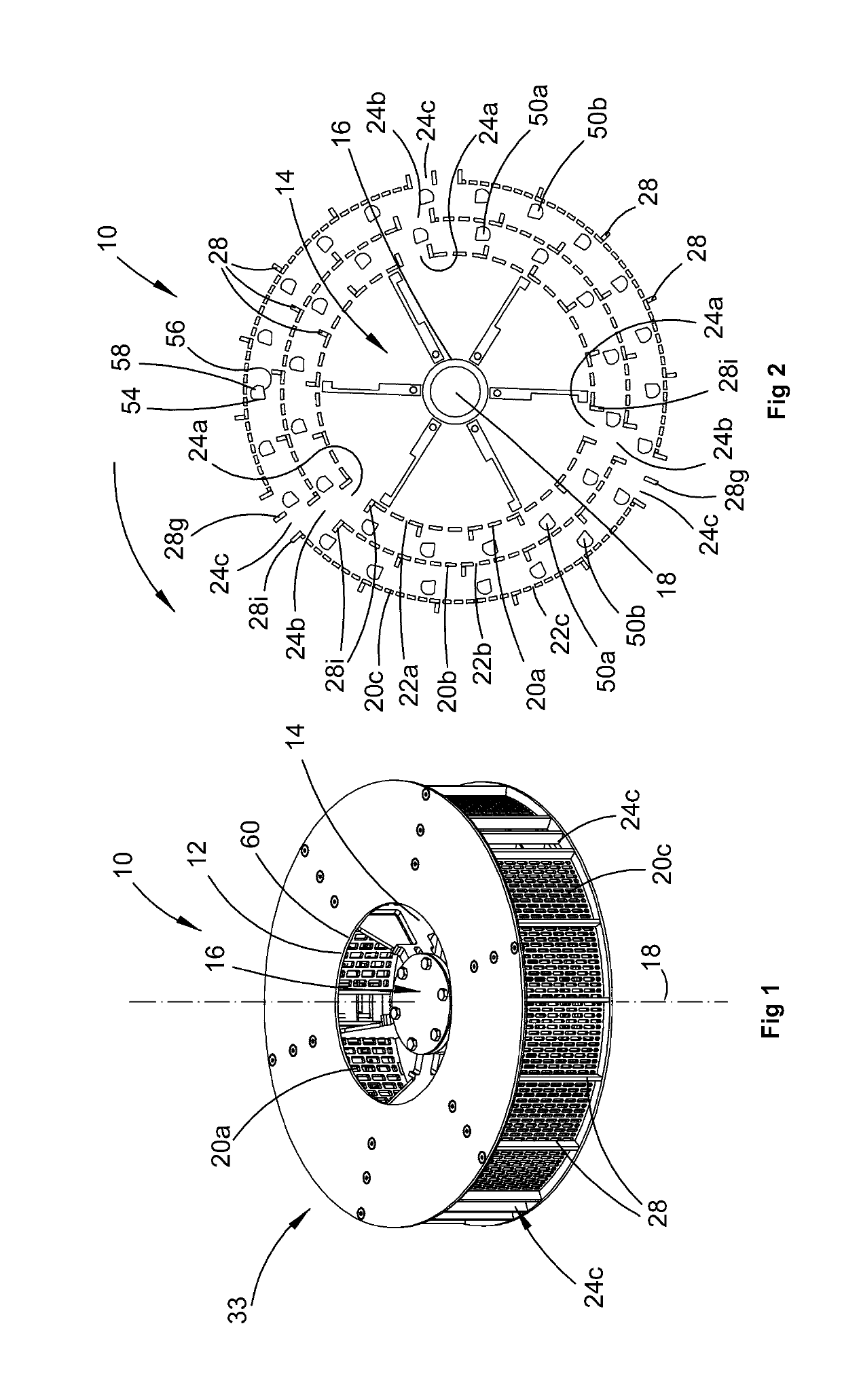

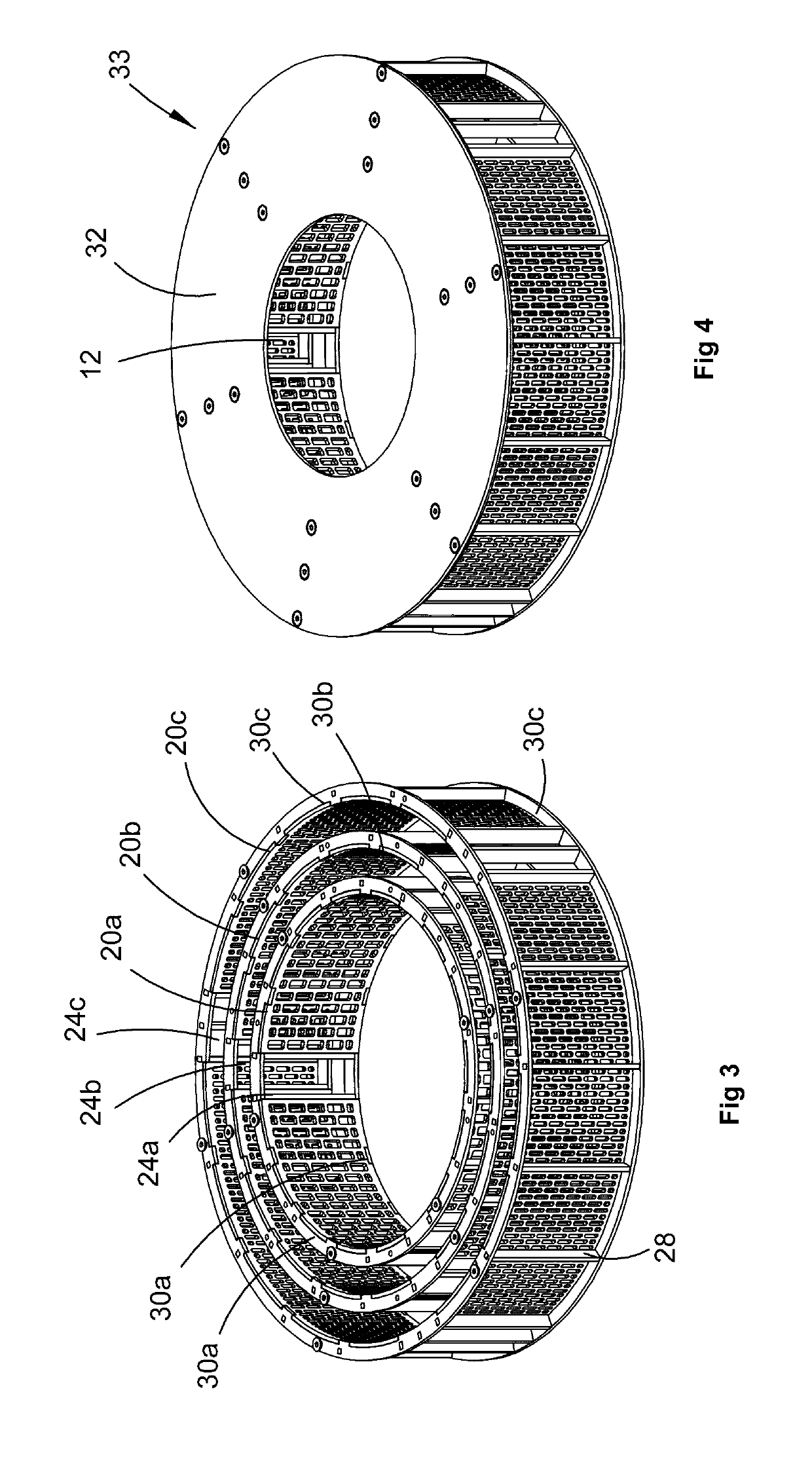

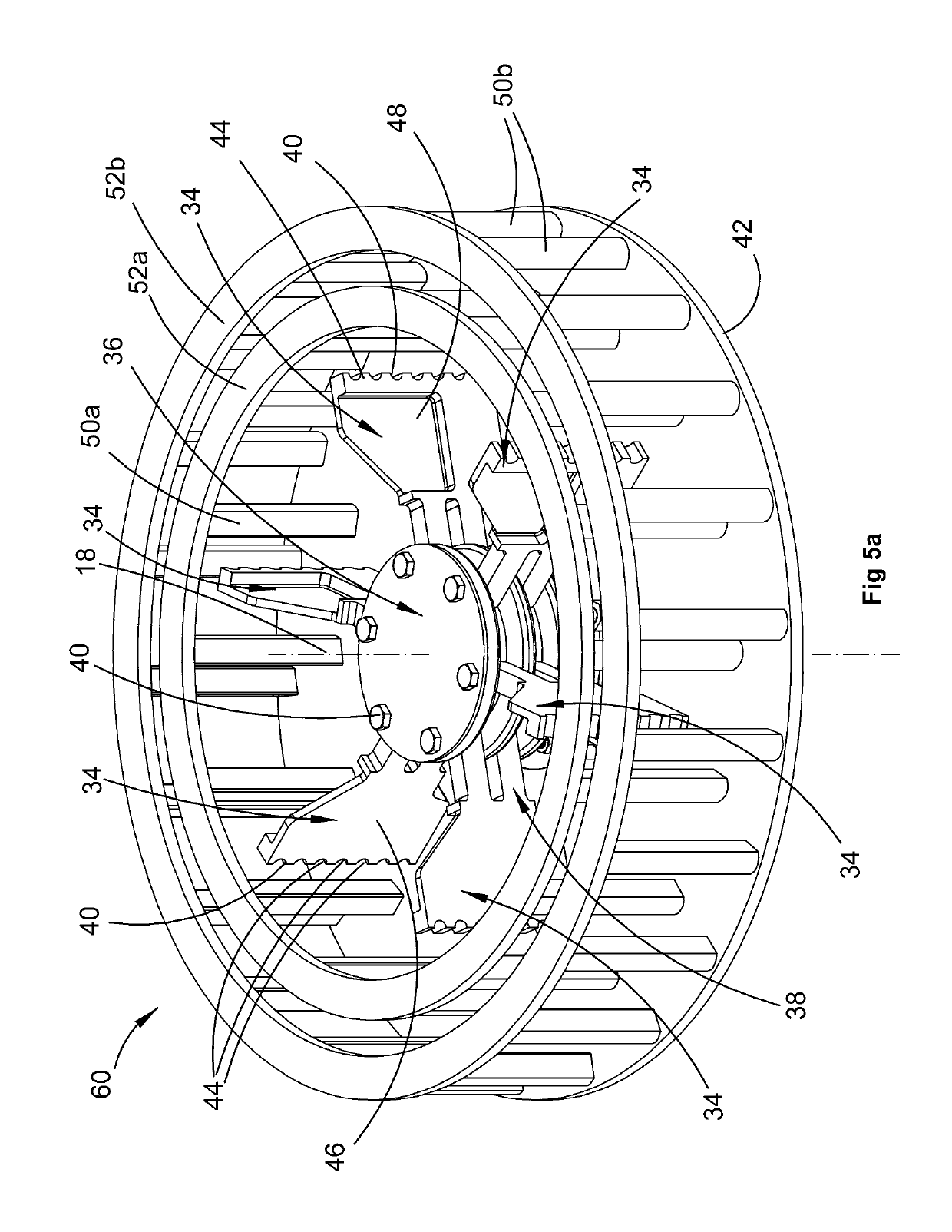

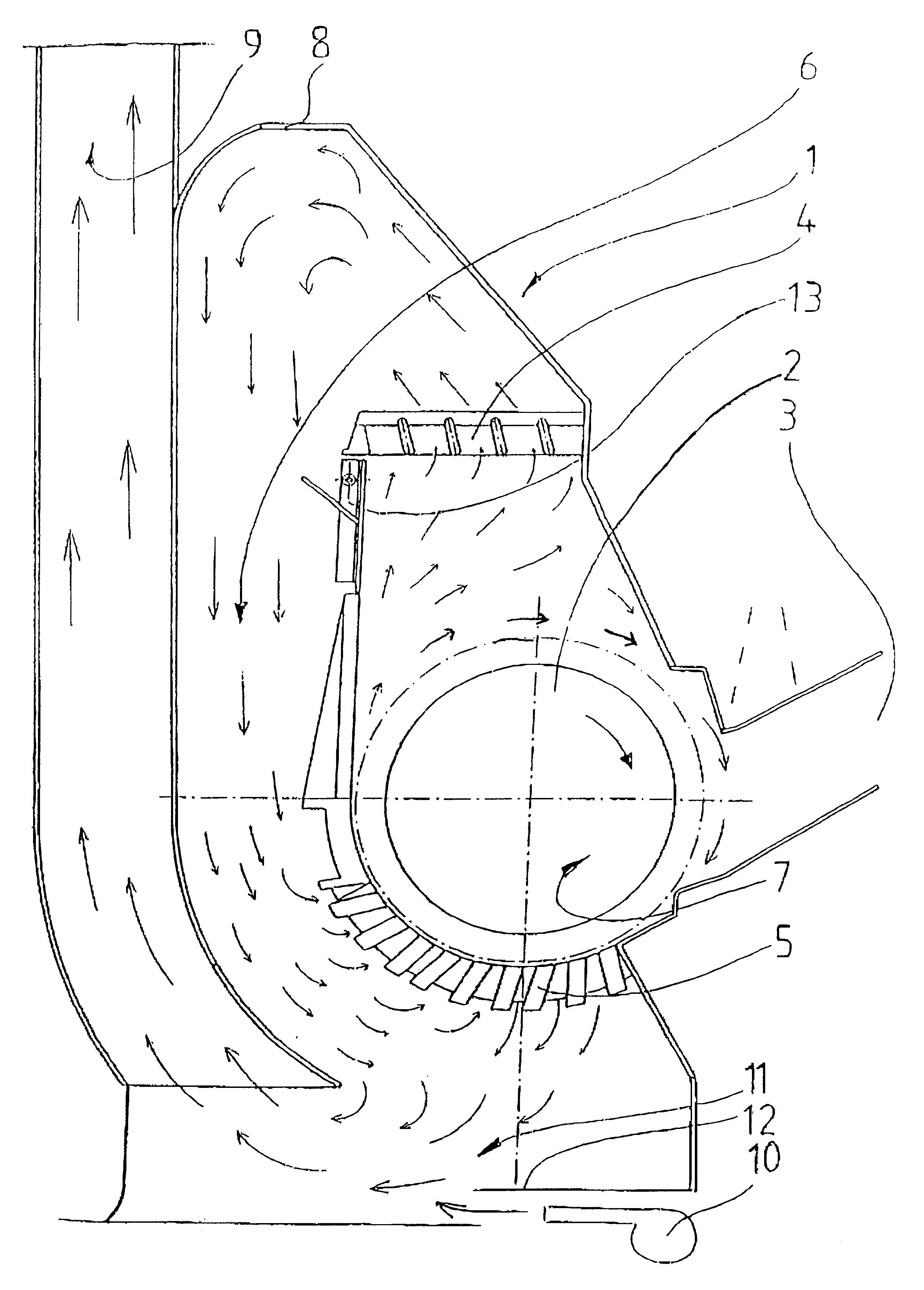

A multistage hammer mill and a residue processing system incorporating same

A multistage hammer mill (10) has a plurality of milling stages arranged concentrically about each other. The plurality of milling stages arranged so that substantially all material in a first inner most of the milling stages passes through all subsequent adjacent milling stages. The milling stages include a first milling stage and a second milling stage. A central feed opening (12) enables material flow into a primary impact zone (14) of the first milling stage. The first milling stage has an impact mechanism (16) and a first screen arrangement (20a). The impact mechanism (16) rotates about a rotation axis (18). The first screen arrangement (20a) is disposed circumferentially about and radially spaced from the impact mechanism (16) and is provided with a plurality of apertures (22) through which impacted material of a first size range can pass. The second milling stage has a second arrangement (20b) disposed circumferentially about and radially spaced from the first screen arrangement (20a) and a circular array of impact elements (50a) disposed between the first screen arrangement (20a) and the second screen arrangement (20b).

Owner:SEED TERMINATOR HLDG PTY LTD

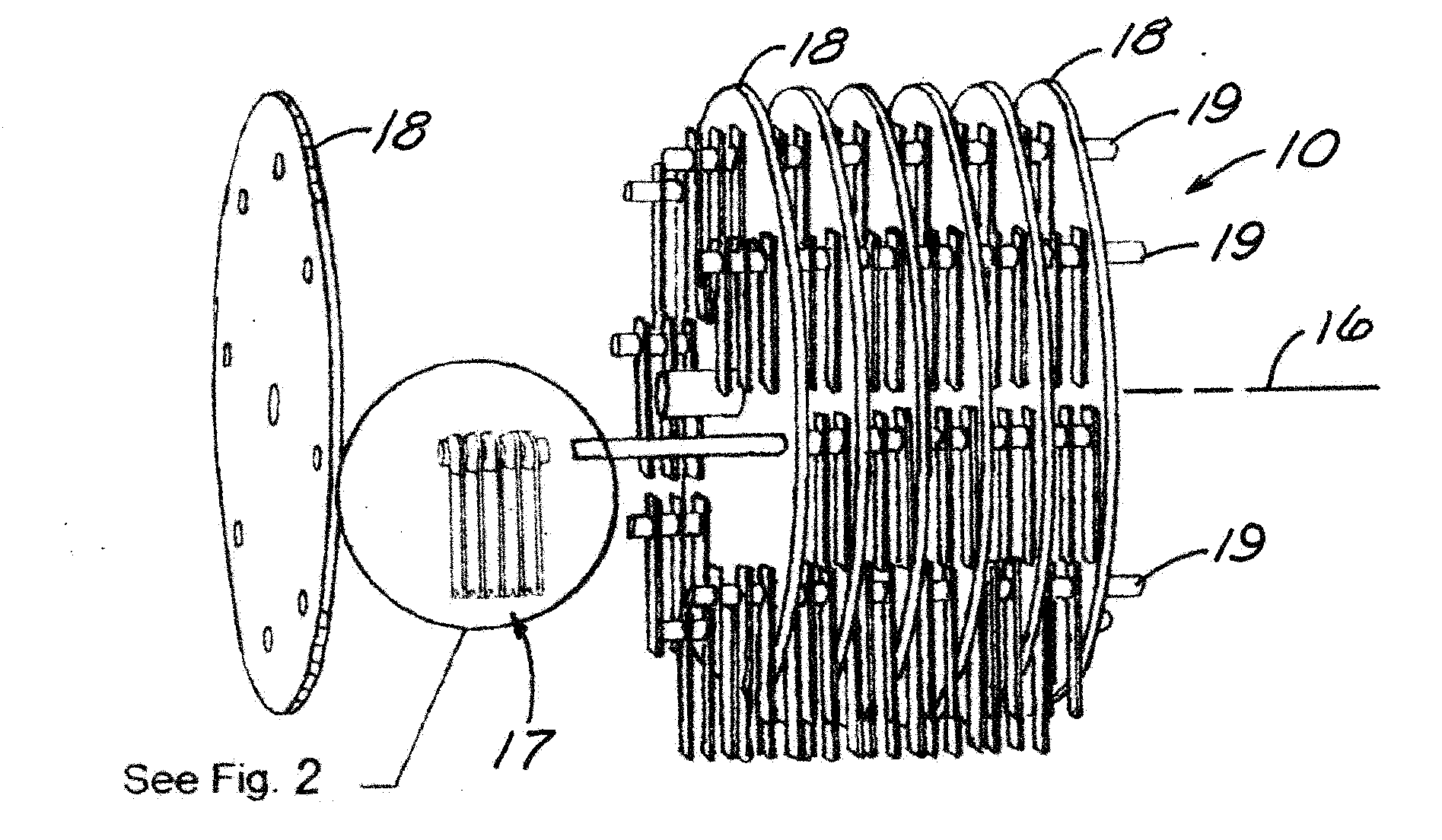

Multipiece hammer for hammer mills

Hammers, including hammer blades, for hammer mills are shown which have an insert bushing press fit into a hole in each hammer blade so that the hammer blades rotate with the bushing around rods being rotated in a circle around a central rotary axis of the rotor of a hammer mill.

Owner:JACOBS CORP

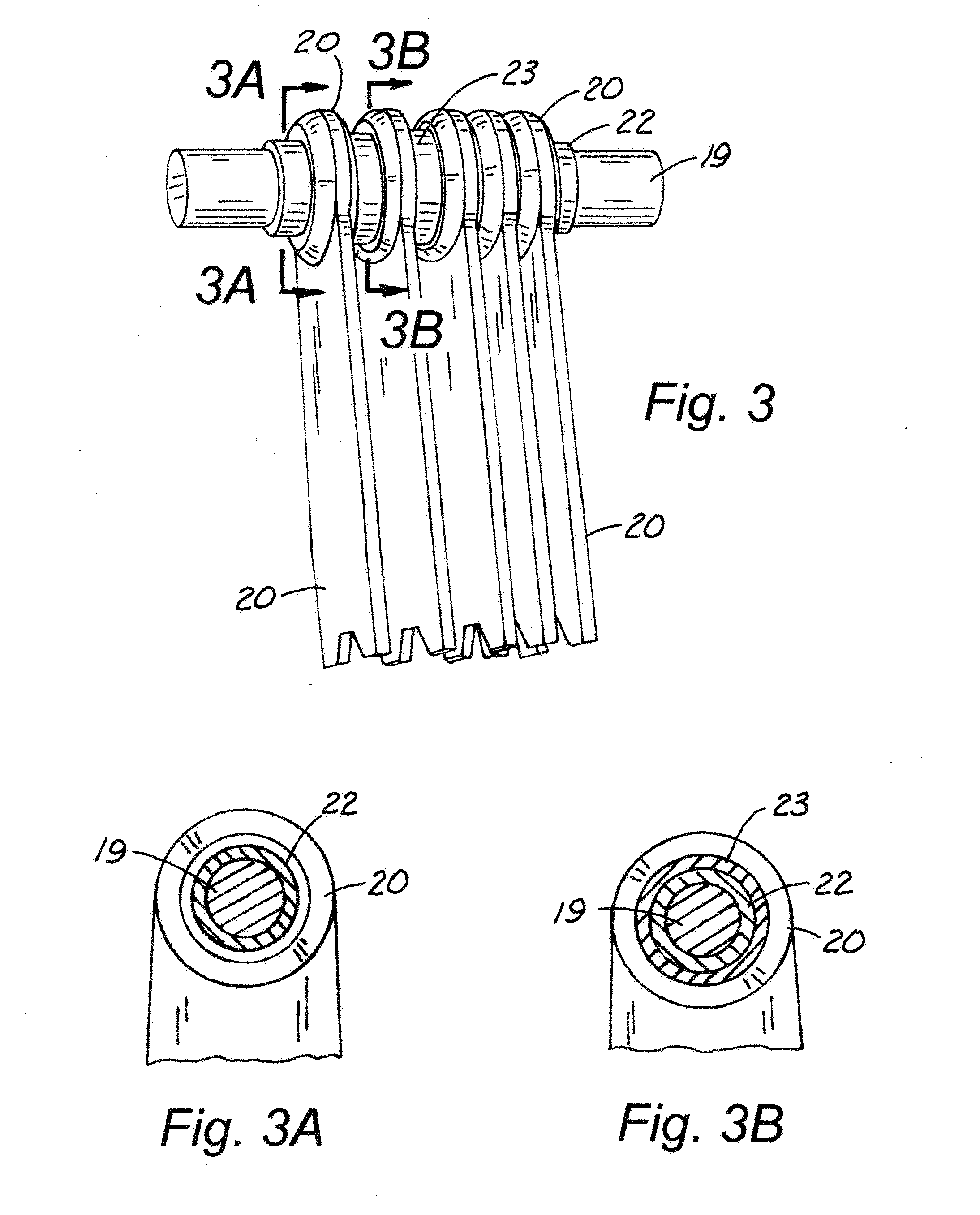

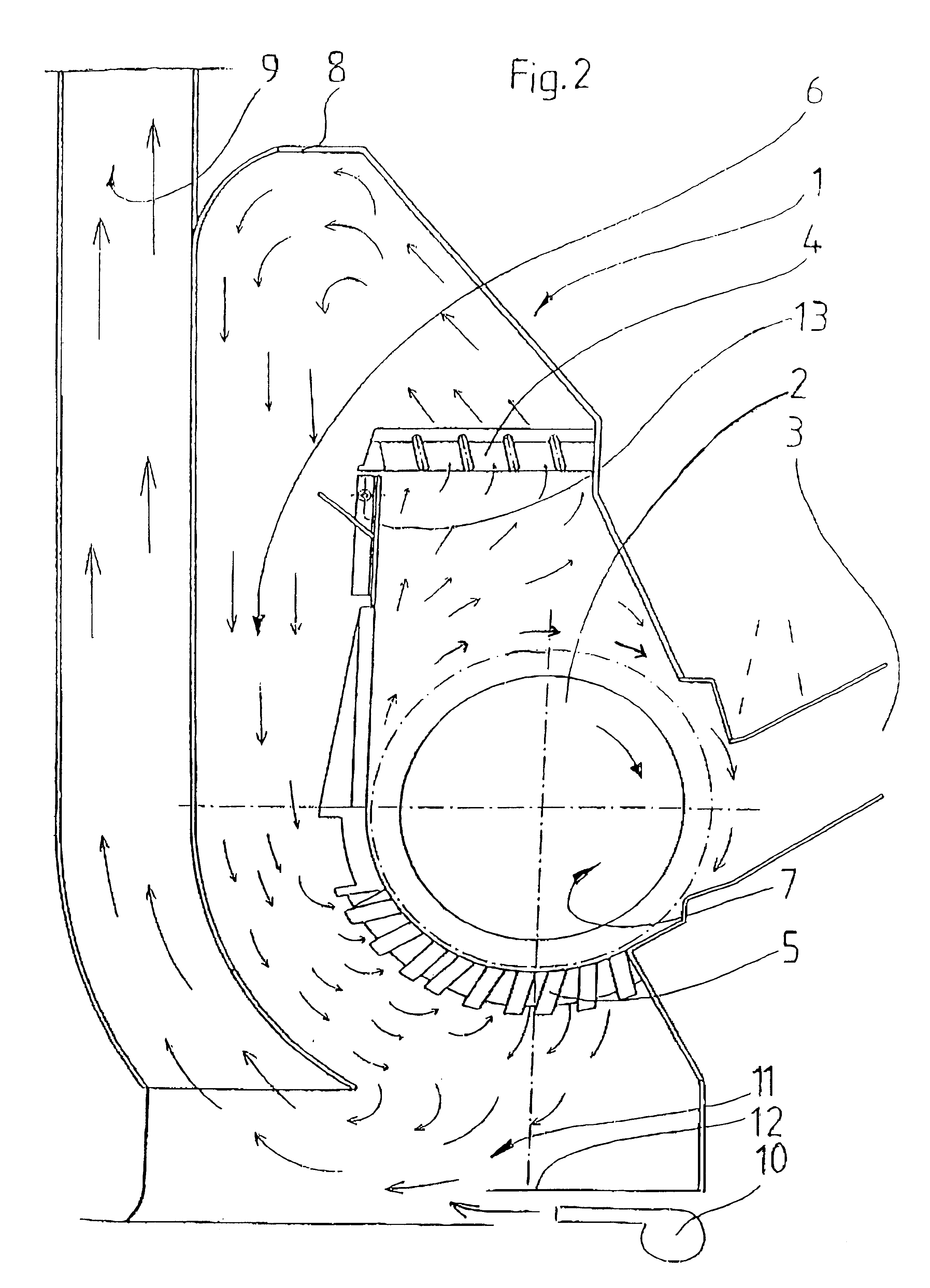

Method for operating the air circuit and conveying stock flow in the casing of a hammer mill

InactiveUS6648253B1Constant air volumeAir capacity of the dust exhaust device can be reducedGas current separationSolid waste disposalAir cycleEngineering

To operate the air circulation and convey the stock flow of scrap material comminuted in the housing (1) of a hammer mill, the airflow generated by the blower effect of a rotor (2) and the stock flow passing through an upper classifying grate (4) are diverted by a deflector hood (8) and guided vertically downwards into a duct (6) that is separate from the housing (1). The stock flow is combined with the stock flow classified in the area of a lower classifying grate (5). The air flow is then guided in the circulating air and the combined stock flow is conveyed to a device (11) for further processing, sorting and / or conveyance.

Owner:METABO LINDEMANN GMBH

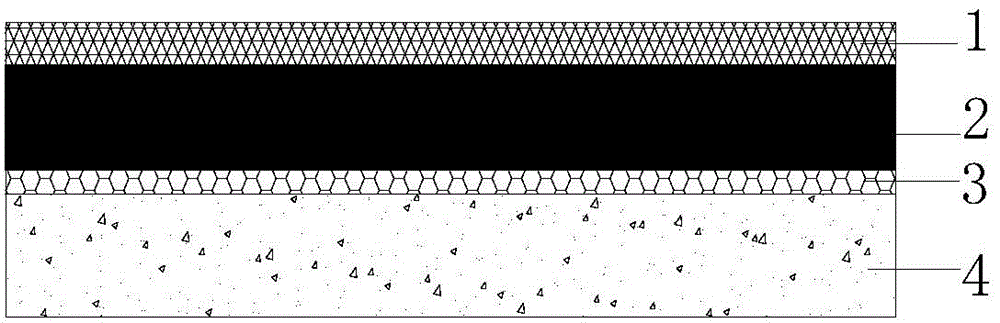

Composite anti-seepage structure for red mud tailing ponds

ActiveCN104805872AReduce peeling damagePrevent subsidenceProtective foundationGasketsRed mudUltraviolet lights

The invention discloses a composite anti-seepage structure for red mud tailing ponds, which comprises an anti-seepage layer, a flexible protective layer and a rigid protective layer, wherein the anti-seepage layer is arranged on a side slope, the flexible protective layer is arranged on the anti-seepage layer, the rigid protective layer is arranged under the anti-seepage layer, an isolating layer is also arranged between the rigid protective layer and the anti-seepage layer, wheat straws or rice straws and clay are mixed to form the isolating layer, and the materials of the anti-seepage layer include polycarbonate, polytetrafluoroethylene, polybutylene terephthalate, fly ash, hammer-milled glass fibers, graft copolymerization acrylic acid derivative, antioxidant, ultraviolet light absorber and anti-aging agent. The physical and chemical properties of the adopted anti-seepage materials are stable, the low-temperature properties and the ageing resistance are excellent, the right-angled tear resistance is high, the reliability of joints is high, the strength of the whole anti-seepage layer structure is high, and the composite anti-seepage structure has extremely high tensile strength and elongation in order to adapt to local anti-piercing strength on sand and stones in a large-area tailing stack, thus ensuring that wastewater from red mud cannot seep into the ground during the usage of the stack.

Owner:乐陵市建兴装饰工程有限公司

Production process for steel casting of martensitic wear-resistant steel

InactiveCN103436810AExtended service lifeFoundry mouldsProcess efficiency improvementWear resistantFerrochrome

The invention discloses a production process for a steel casting of martensitic wear-resistant steel. The martensitic wear-resistant steel comprises the chemical components by the weight percentage: 0.3%-0.5% of C, 0.4%-0.9% of Si, 1.1%-1.8% of Cr, 0.8%-1.5% of Mn, 0.7%-1.2% of Ni, 0.6%-0.8% of Mo, 0.2%-0.5% of V, 0.1%-0.5% of Ti, 0.07%-0.09% of Re, not more than 0.04% of P and S, and the balance being Fe. The production process comprises the following steps: 1) scrap steel, pig iron, ferrochrome, sponge iron and a smelting additive with an amount of 1-1.5% based on the total mass of the above raw materials are added to an induction furnace for mixing and heating to melt, wherein the smelting additive is prepared from 10-15 parts of sodium oxide, 3.5-4.5 parts of aluminum oxide, 3-5 parts of potassium oxide, 6-8 parts of sodium carbonate, 4-6 parts of silicon dioxide, 11-15 parts of iron oxide, 0.5-2 parts of titanium dioxide, and 5-10 parts of anhydrous borax, and the contents of the chemical components are adjusted according to requirements. Under a condition of relatively low shock, the martensitic wear-resistant steel is applied in ball mill lining plates of metallurgical mines, hammerheads of hammer mills and the like, is applicable to wear-resistant products of gold mines, iron mines, cement and other types of mines, and is a new wear-resistant material instead of conventional high manganese steel.

Owner:湖北洪伯车辆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com