Harmless disassembling and resource classified recycling equipment and method of waste refrigerator

A resource classification and recycling equipment technology, applied in the direction of electronic waste recycling, recycling technology, solid waste removal, etc., can solve the problems of large broken particles, low efficiency, and plastics that have not been further differentiated and separated. The effect of secondary pollution and high resource recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The following describes the patent of the present invention in further detail with reference to the drawings and embodiments, but the protection scope of the present invention is not limited to the embodiments.

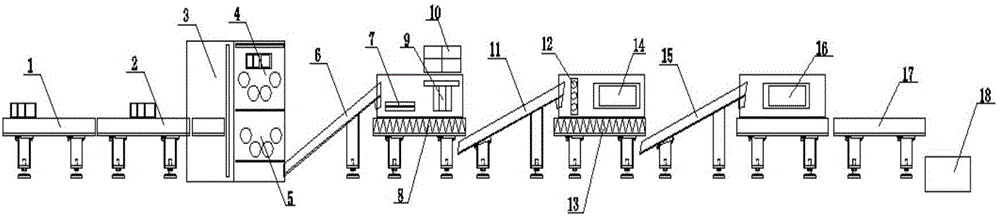

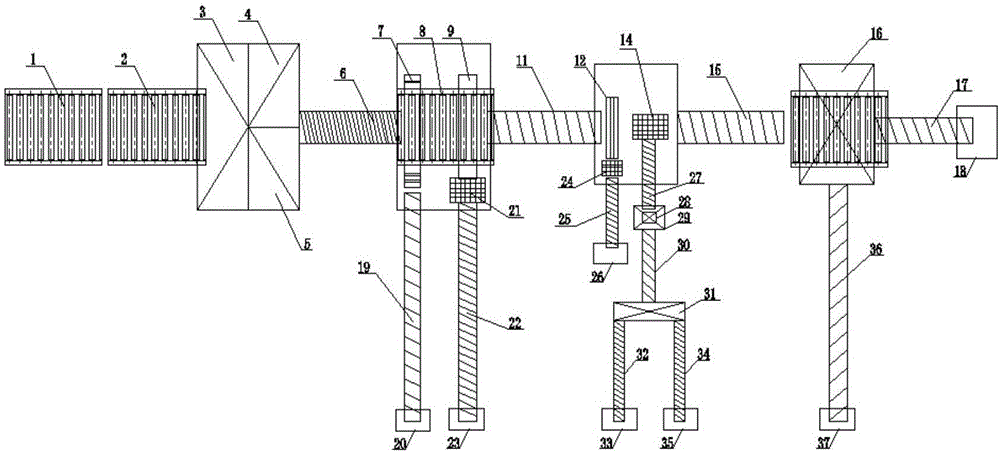

[0067] Such as figure 1 with 2 As shown, a kind of harmless dismantling and resource sorting and recycling equipment for waste refrigerators includes manual dismantling station 1, which is connected to weighing station 2, lifting and conveying station 3, crusher 4, and first conveyor belt 6 in sequence. , The first vibrating trough 8, the second conveyor belt 11, the second vibrating trough 13, the rubidium ferromagnetic roller 12, the separator 24, the non-ferrous metal sorting machine 14, the third conveyor belt 15;

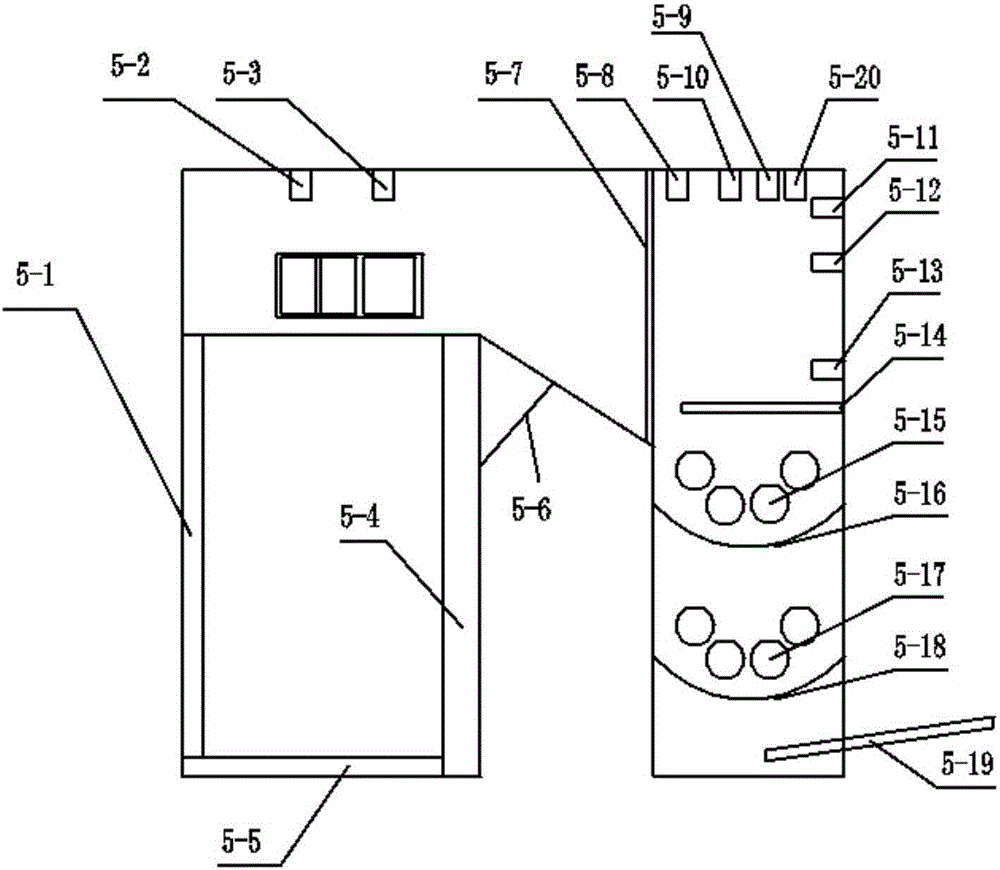

[0068] The lifting and conveying station 3 and the crusher 4 are installed in a closed working warehouse, and the first dust removal filter device 5-12 is installed in the warehouse; the crusher 5 is installed with a screen door 5-7 and a refrigeratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com