Energy-saving heat retaining rectangular-hole porous brick

A technology of porous bricks and rectangular holes, applied in the field of bricks, can solve the problems of insufficient light weight, insufficient strength, and inability to fully meet the requirements of brick making, and achieve the effect of small drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

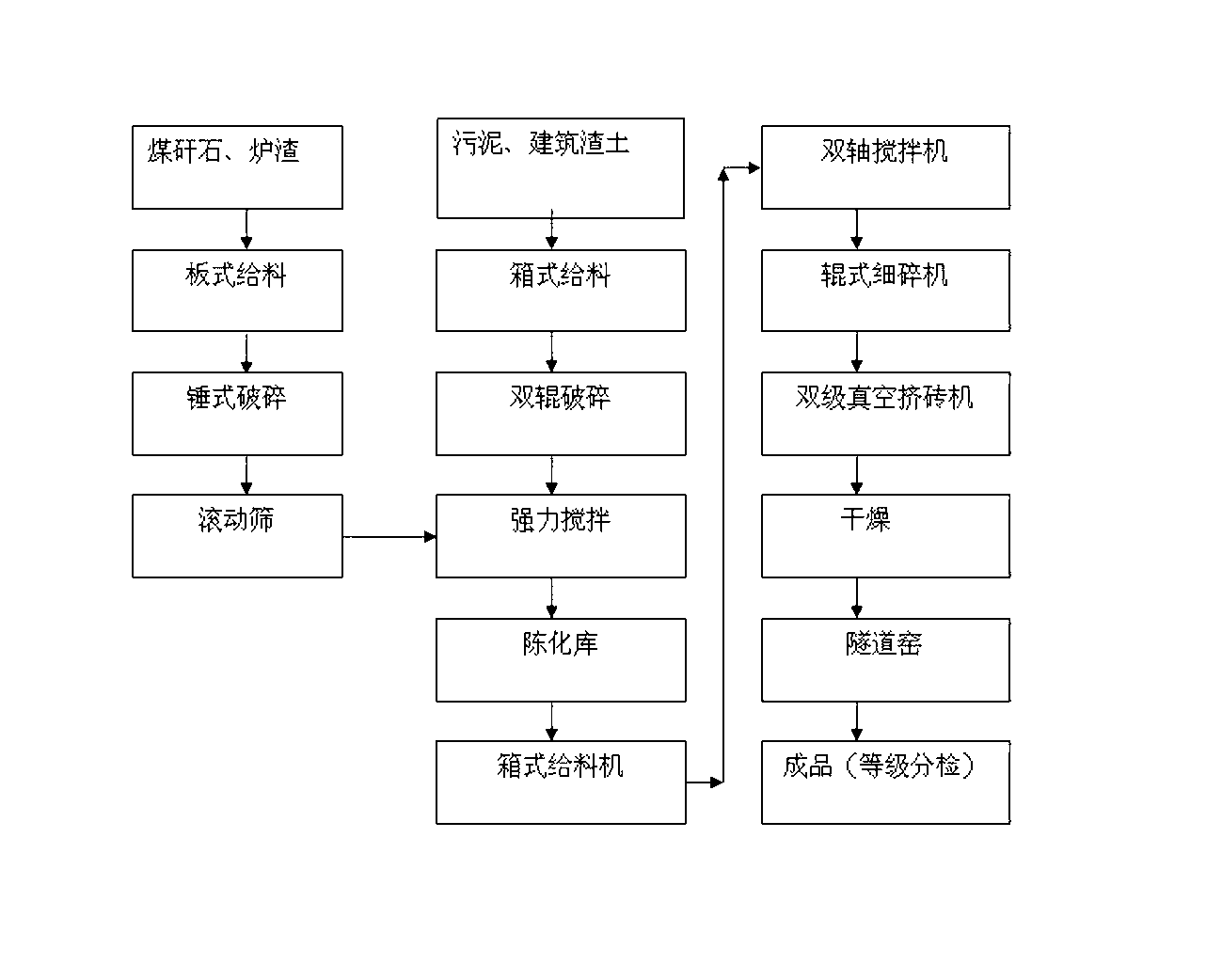

[0029] An energy-saving and heat-retaining rectangular-hole porous brick, the preparation steps of which are as follows:

[0030] 1) Put the coal gangue into the hopper and send it to the raw material processing plant through a belt conveyor, and then it is crushed by a hammer mill, screened by a drum screen or a vibrating screen and processed into coal gangue powder;

[0031] 2) Then the coal gangue powder plus construction slag, slag, sludge and water are sent to the first stage of mixing and then sent to the aging warehouse for aging;

[0032] 3) Send the aged material to the secondary mixing and vacuum brick making machine with a belt conveyor to make bricks;

[0033] 4) Then use the hydraulic automatic stacking machine to stack the bricks on the kiln car and send them into the drying hole for drying;

[0034] 5) Send the dried bricks to the entrance of the tunnel kiln with a ferry car, and push them into the kiln for sintering to become finished bricks.

[0035] The wei...

Embodiment 2

[0040] An energy-saving and heat-retaining rectangular-hole porous brick, the preparation steps of which are as follows:

[0041] 1) Put the coal gangue into the hopper and send it to the raw material processing plant through a belt conveyor, and then it is crushed by a hammer mill, screened by a drum screen or a vibrating screen and processed into coal gangue powder;

[0042] 2) Then the coal gangue powder plus construction slag, slag, sludge and water are sent to the first stage of mixing and then sent to the aging warehouse for aging;

[0043] 3) Send the aged material to the secondary mixing and vacuum brick making machine with a belt conveyor to make bricks;

[0044] 4) Then use the hydraulic automatic stacking machine to stack the bricks on the kiln car and send them into the drying hole for drying;

[0045] 5) Send the dried bricks to the entrance of the tunnel kiln with a ferry car, and push them into the kiln for sintering to become finished bricks.

[0046] The wei...

Embodiment 3

[0051] An energy-saving and heat-retaining rectangular-hole porous brick, the preparation steps of which are as follows:

[0052] 1) Put the coal gangue into the hopper and send it to the raw material processing plant through a belt conveyor, and then crush it with a hammer mill, screen it with a drum screen or a vibrating screen and process it into coal gangue powder;

[0053] 2) Then the coal gangue powder plus construction slag, slag, sludge and water are sent to the first stage of mixing and then sent to the aging warehouse for aging;

[0054] 3) Send the aged material to the secondary mixing and vacuum brick making machine with a belt conveyor to make bricks;

[0055] 4) Then use the hydraulic automatic stacking machine to stack the bricks on the kiln car and send them into the drying hole for drying;

[0056] 5) Send the dried bricks to the entrance of the tunnel kiln with a ferry car, and push them into the kiln for sintering to become finished bricks.

[0057] The we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com