Resourceful cyclic utilization technology for household and building rubbish

A technology for construction waste and domestic waste, applied in recycling technology, construction waste recycling, solid waste removal, etc., to achieve the effect of eliminating secondary pollution, enriching profits, and eradicating secondary pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

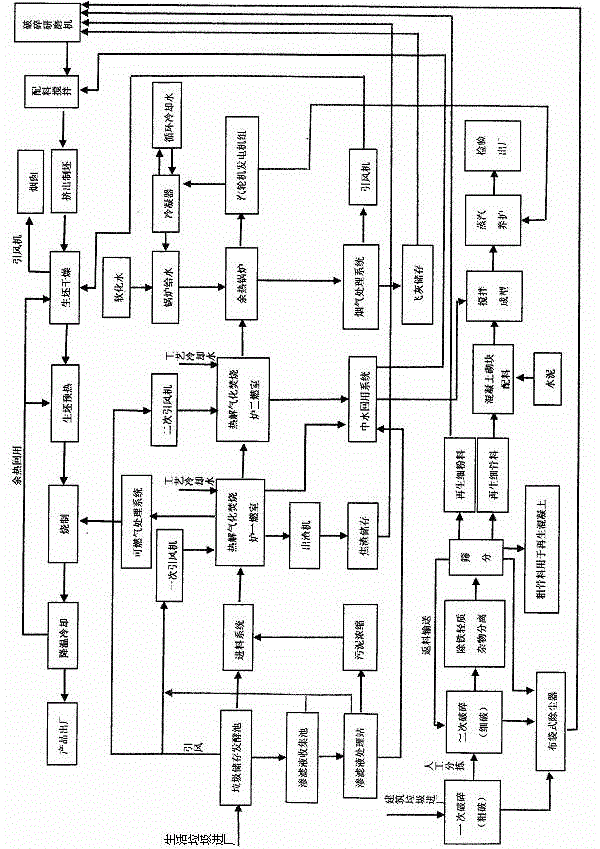

[0008] Example 1, such as figure 1As shown, this domestic and construction waste resource recycling process includes the following steps: (1) The domestic waste is transported into the treatment plant area by a special transport vehicle, and unloaded into a closed garbage storage fermentation tank. The storage fermentation tank is surrounded by 40- 50cm thick reinforced concrete maintenance wall, the bottom of the storage fermentation tank is funnel-shaped, and the bottom of the storage fermentation tank is installed with a landfill leachate filtration device produced by garbage storage and fermentation. The filtered landfill leachate is collected in the collection tank and sent to the leachate treatment Station, using coagulation sedimentation + UASB + MBR + NF treatment process for leachate treatment, and the treated reclaimed water that meets the discharge standard is discharged into the reclaimed water reuse system to be used as a blank for sintered porous bricks and recycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com