Patents

Literature

338results about How to "Solving Recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

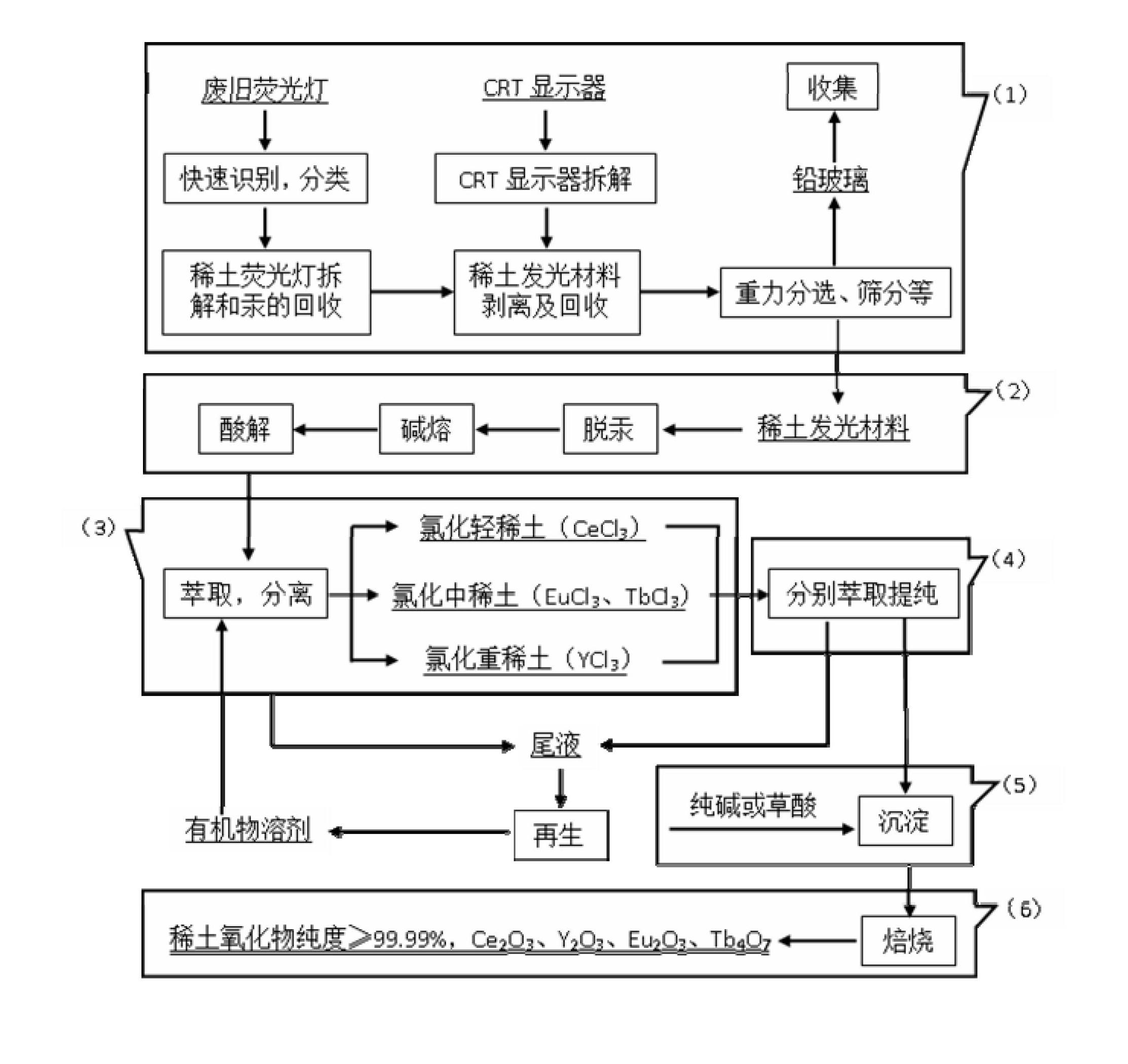

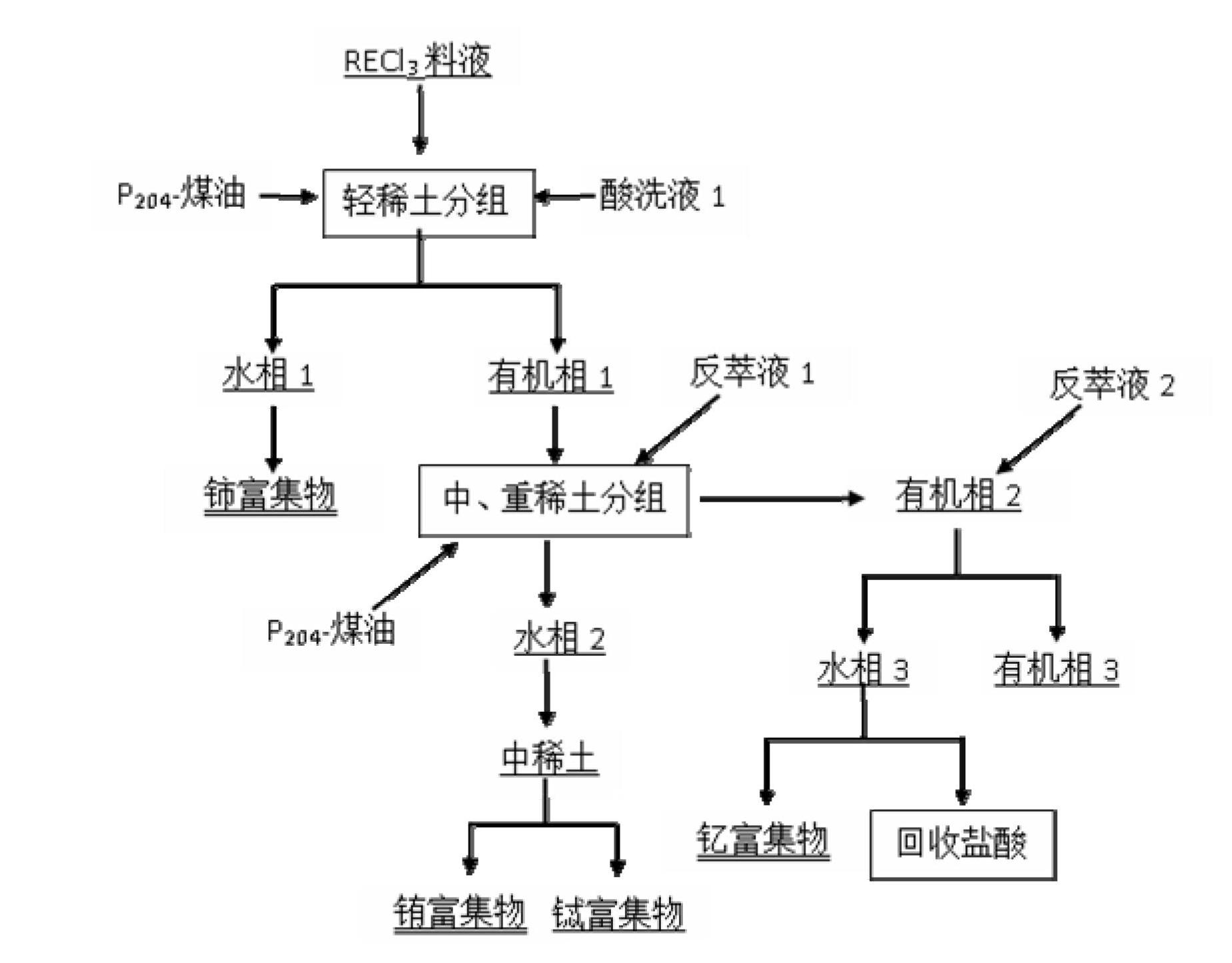

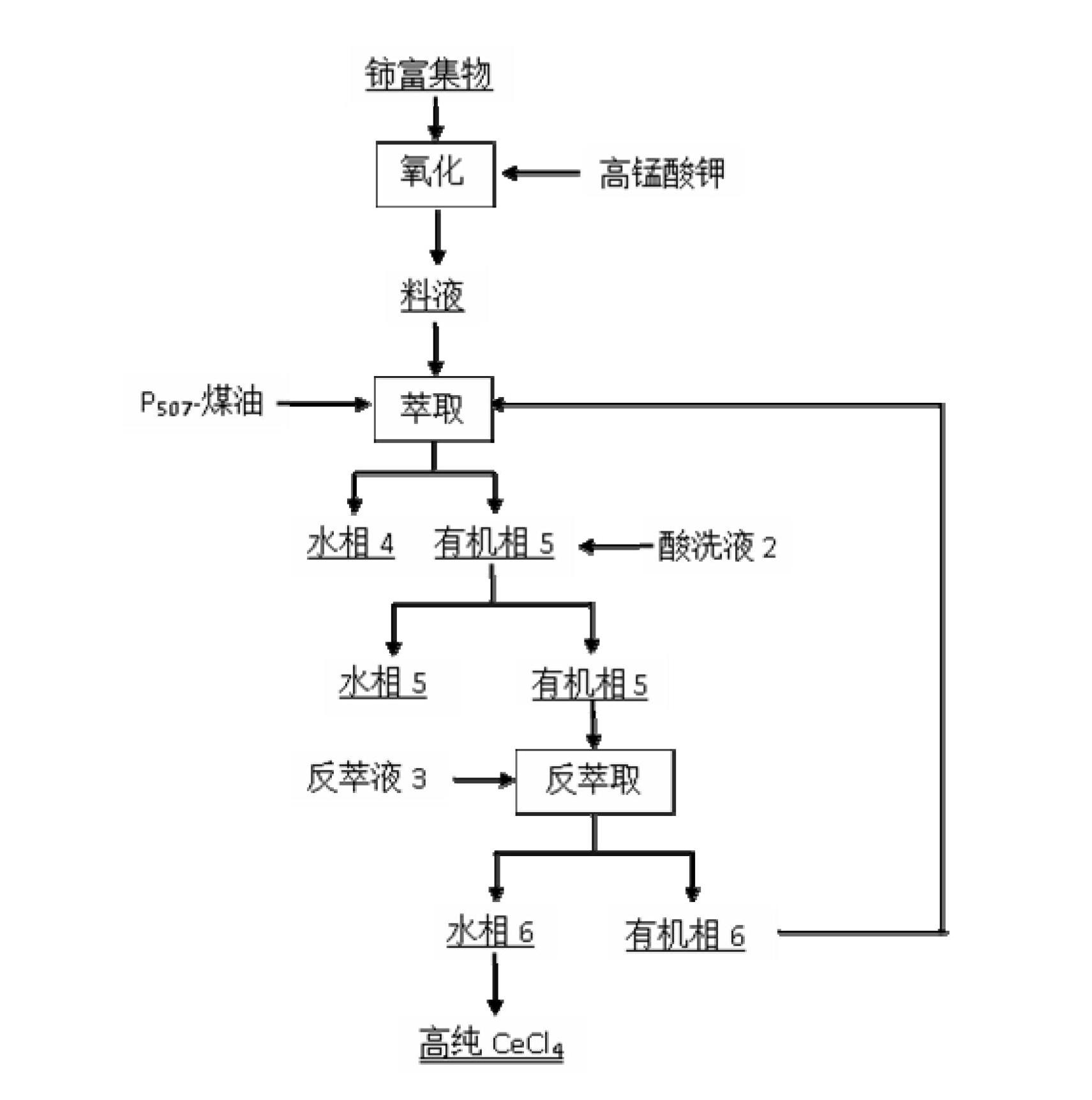

Method for recovering rare earth from waste rare earth luminescent material

InactiveCN102660688AHigh recovery rateProtect environmentGlass recyclingCerium oxides/hydroxidesRare-earth elementGlass matrix

The invention relates to a method for recovering rare earth from waste rare earth luminescent material, comprising the following steps: collection of waste rare earth luminescent material, including quick identification on rare earth fluorescent lamp and dismantling and breaking of the rare earth fluorescent lamp, breaking of a CRT display, and peeling and collection of the waste rare earth luminescent material and a glass matrix; pretreatment on the waste rare earth luminescent material, including demercuration oxidation precipitation, alkali fusion and acidolysis; extraction separation of rare earth elements to obtain rare earth chloride enrichment; extraction purification of the rare earth elements to obtain high-purity rare earth chloride; precipitation separation of the rare earth elements to obtain oxalate rare earth or carbonic acid rare earth precipitates; and sintering of the oxalate rare earth or carbonic acid rare earth precipitates to obtain high-purity-level rare earth oxide. The method realizes separation of rare earth elements including Ce, Eu, Tb and Y from impurity elements including Mg, Ba, Ca and the like and complete separation and recovery of light, mediate and heavy rare earth elements, and purification is carried out to obtain the high-purity rare earth oxide, so that the resources are comprehensively recycled, the process flow is reasonable, economic and practical, the rare earth recovery rate is high and the added value of the product is high.

Owner:UNIV OF SCI & TECH BEIJING

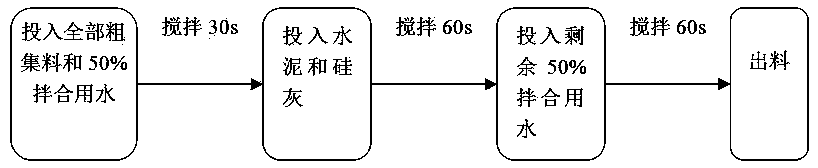

Pervious concrete of recycled aggregate and preparation method thereof

The invention discloses pervious concrete of recycled aggregate and a preparation method thereof, and belongs to the technical field of pervious concrete of recycled aggregate. The pervious concrete of the recycled aggregate comprises the following components by mass percent: 71.77-73.16% of coarse aggregate, 18.88-19.04% of cement, 6.58-8.14% of water and 1.21-1.22% of silica fume, wherein the recycled aggregate and the natural aggregate accord with the stone utilization standard II, the mixing amount of the recycled aggregate can be customized according to the actual performance index, the cement is 42.5-level ordinary portland cement, and the mixing amount of the silica fume is 6% of the dosage of a binding material. The preparation method comprises the following steps: agitating, vibrating, molding and floating. The mix proportion is designed by adopting a volume process, and the concrete is prepared according to the scheduled preparation process. By adopting the pervious concrete of the recycled aggregate, on the one hand, the problem of recycling of the waste concrete can be solved, on the other hand, underground water can be effectively supplied, collected and purified, and water resources are repeatedly utilized, so as to relieve the 'heat island effect'.

Owner:YANGZHOU UNIV

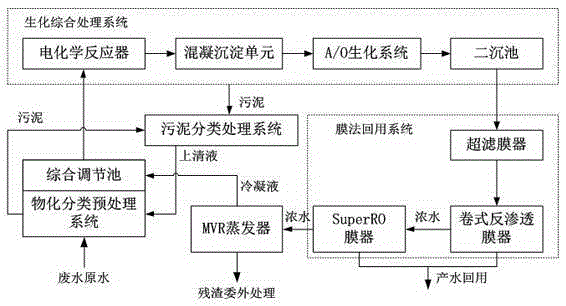

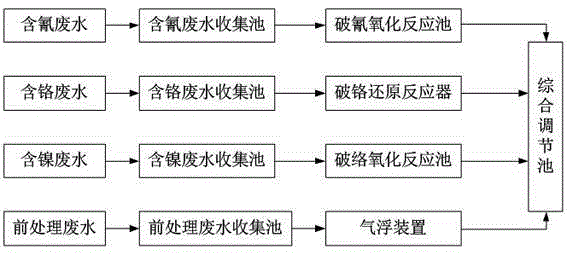

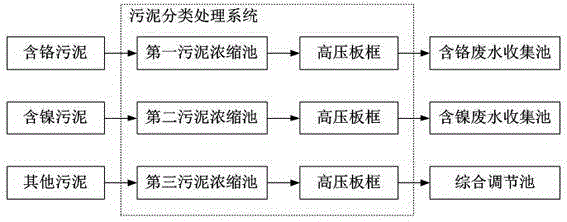

Technique and system for zero discharging treatment of electroplating effluent

ActiveCN105271622AReduce processing costsAvoid wastingSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processSludgeWastewater

The invention discloses a technique and a system for zero discharging treatment of electroplating effluent. The system comprises a material classifying pre-treatment system, a biochemical comprehensive treatment system, a membrane method system, a membrane concentrated liquor vaporization system and a sludge classifying treatment system which are connected with each other in turn, wherein the sludge classifying treatment system is connected with the material classifying pre-treatment system and the biochemical comprehensive treatment system; the raw wastewater enters into the material classifying pre-treatment system; water generated by the membrane method system is recycled; the condensed liquid from the membrane concentrated liquor vaporization system is re-injected into the material classifying pre-treatment system. According to the technique provided by the invention, the wastewater is firstly treated in classifying form, so that the heavy pollution ions, such as, chromium, cyanogen, nickel, and the like, and the oily matters in the wastewater are effectively removed, and then the biochemical comprehensive treatment system is used for further treating, and lastly, the RO+SuperRo two-level combination mode is utilized to achieve the gross recovery at 94%, and meanwhile, the liquid amount for evaporation treatment is less than 6% of the gross wastewater quantity, the cost of the evaporation treatment is saved, the sludge is recycled, the waste of resources is avoided and the sludge treating cost is saved.

Owner:CHENGDU MEIFUTE MEMBRANE TECHNOLOGY CO LTD

Treatment method for solidifying sludge of sewage plant in city

This invention relates to a method for solidification treatment of sludge discharged from urban sewage treatment plant. The method utilizes solidification and stabilization techniques to treat sludge discharged from urban sewage treatment plant, and improve its landfill physicochemical properties, thus can solve the problems related to sludge landfill. The method adopts cement as the solidification agent, and one or more of lime, aluminum salt, aluminum oxide and cinder as the coagulant aid. The method comprises: adding 3-8% solidification agent and 1-8% coagulant aid into sludge, mechanically stirring uniformly, spreading onto a landfill site, covering with a waterproof film, dry-maintaining for 3-15 days, and performing following landfill. The method has such advantages as low cost, easy operation and good effect. The treated sludge has such advantages as high compressive strength, high soaking resistance and low leaching toxicity.

Owner:GUOZHONG AIHUA TIANJIN MUNICIPAL ENCIRONMENT ENG

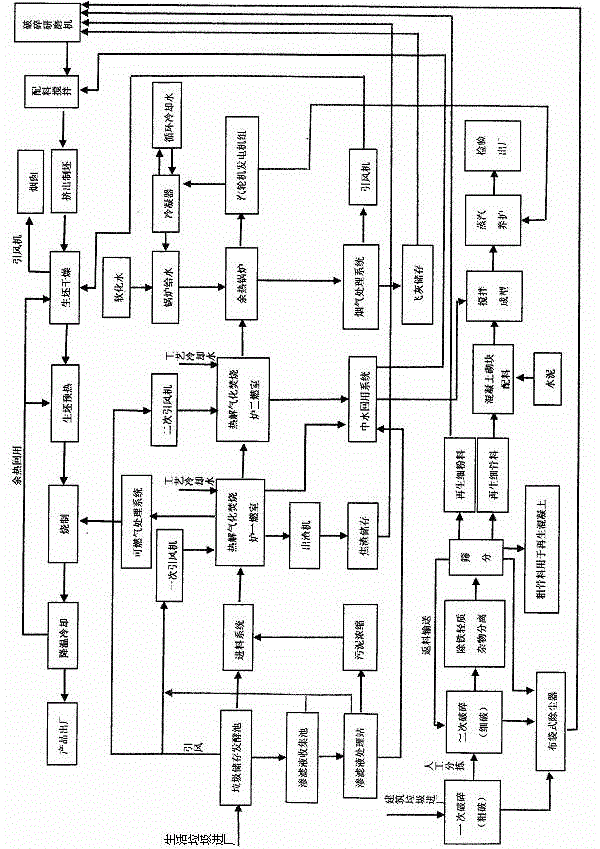

Resourceful cyclic utilization technology for household and building rubbish

InactiveCN105983567AAvoid secondary pollutionSolving RecyclingConstruction waste recoverySolid waste disposalTunnel kilnBrick

The invention discloses a resourceful cyclic utilization technology for household and building rubbish. The technology comprises the steps that firstly, the rubbish is fermented, percolate treatment is conducted, the rubbish is conveyed into a pyrolysis gasifier, and methane is used for supporting combustion; secondly, the rubbish is combusted, and coke residues are stored and left for use; thirdly, high-temperature smoke is subjected to heat absorbing and recycled to be guided into a tunnel kiln for air drying of sintered green bricks; fourthly, the coke residues and fly ash are conveyed to the tunnel kiln for brick sintering; fifthly, recycled water and process cooling water are used for green brick manufacturing and stirring, and high-temperature steam is used for power generation; sixthly, the building rubbish is roughly broken, impurity removing is conducted, secondary fine breaking is conducted, impurity removing is conducted, and recycled aggregate is screened and used; seventhly, the recycled aggregate with the particle size being 3 mm-10 mm is used for manufacturing hollow blocks; and eighthly, recycled fine powder with the particle size being smaller than 3 mm is used for brick sintering. The resourceful cyclic utilization technology has the beneficial effects that the household rubbish, the building rubbish and the brick sintering technology are organically combined, waste water reaching the standard, the coke residues, the fly ash, the high-temperature smoke, steam and generated electricity are utilized in rubbish treatment and brick sintering, the rubbish is thoroughly utilized, secondary pollution is eliminated, the household rubbish and the building rubbish are cyclically utilized, and waste is turned into wealth.

Owner:于继林

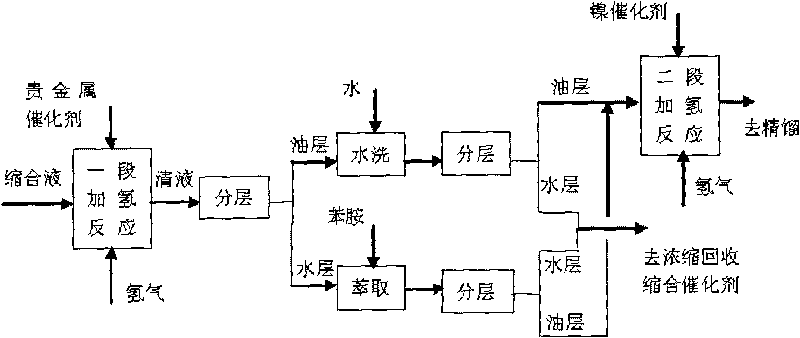

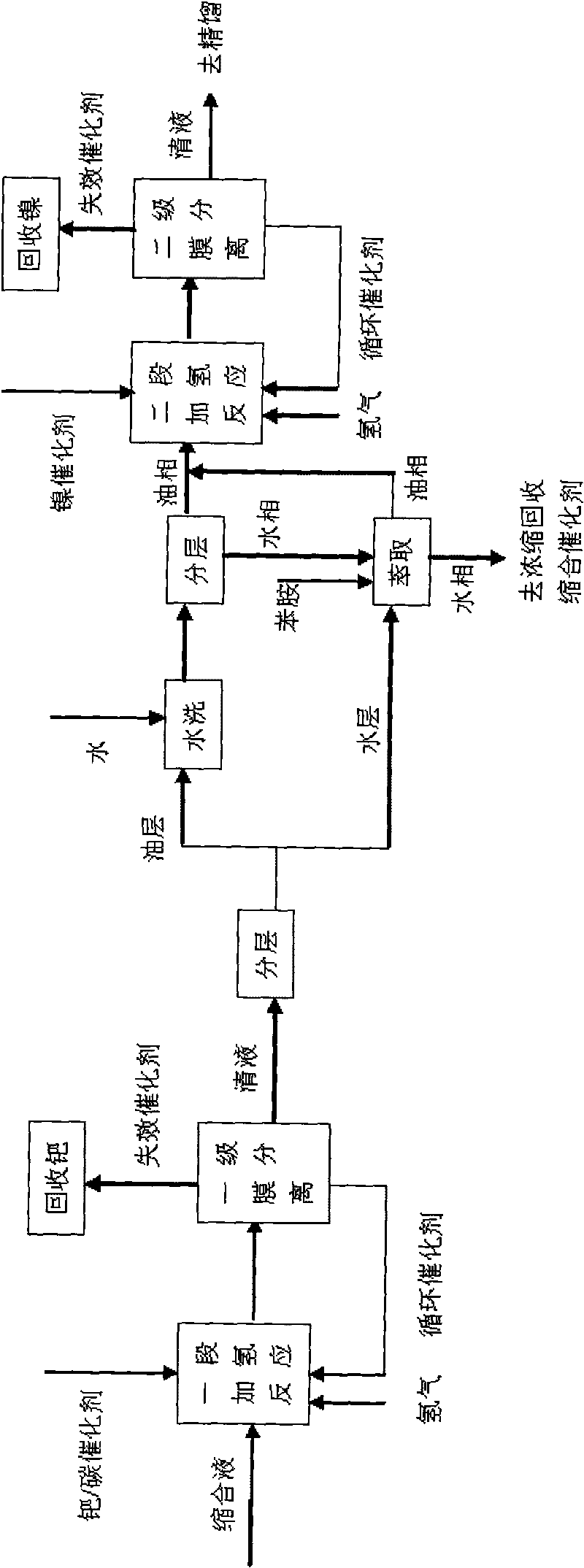

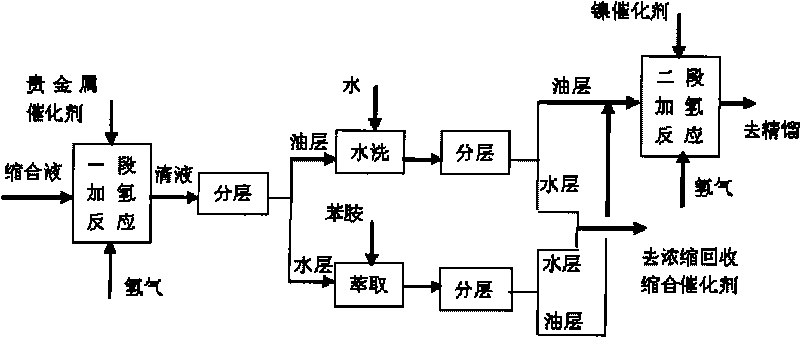

Method for preparing 4-amino diphenylamine by catalytic hydrogenation

ActiveCN101691332AEasy to cleanImprove regenerative abilitySemi-permeable membranesAmino compound purification/separationNitrosoNitrobenzene

The invention provides a method for preparing 4-amino diphenylamine by catalytic hydrogenation. The method adopts two sections of hydrogenation reaction processes, and comprises the following steps: performing the condensation reaction of condensation solution formed by the condensation reaction of nitrobenzene and aniline which serve as raw materials under an alkaline condition by using using a noble metal hydrogenation catalyst and a nickel catalyst sequentially so as to make the conversion rate of 4-nitroso diphenylamine, 4-nitro diphenylamine and azoxybenzene achieve 100 percent; and separating the noble metal hydrogenation catalyst and the nickel catalyst by using a two-stage membrane separation component system to avoid the loss of small particles of catalyst. At the same time, the method has high degree of automation and can easily realize the continuous hydrogenation process.

Owner:JIANGSU YANGNONG CHEM GROUP +1

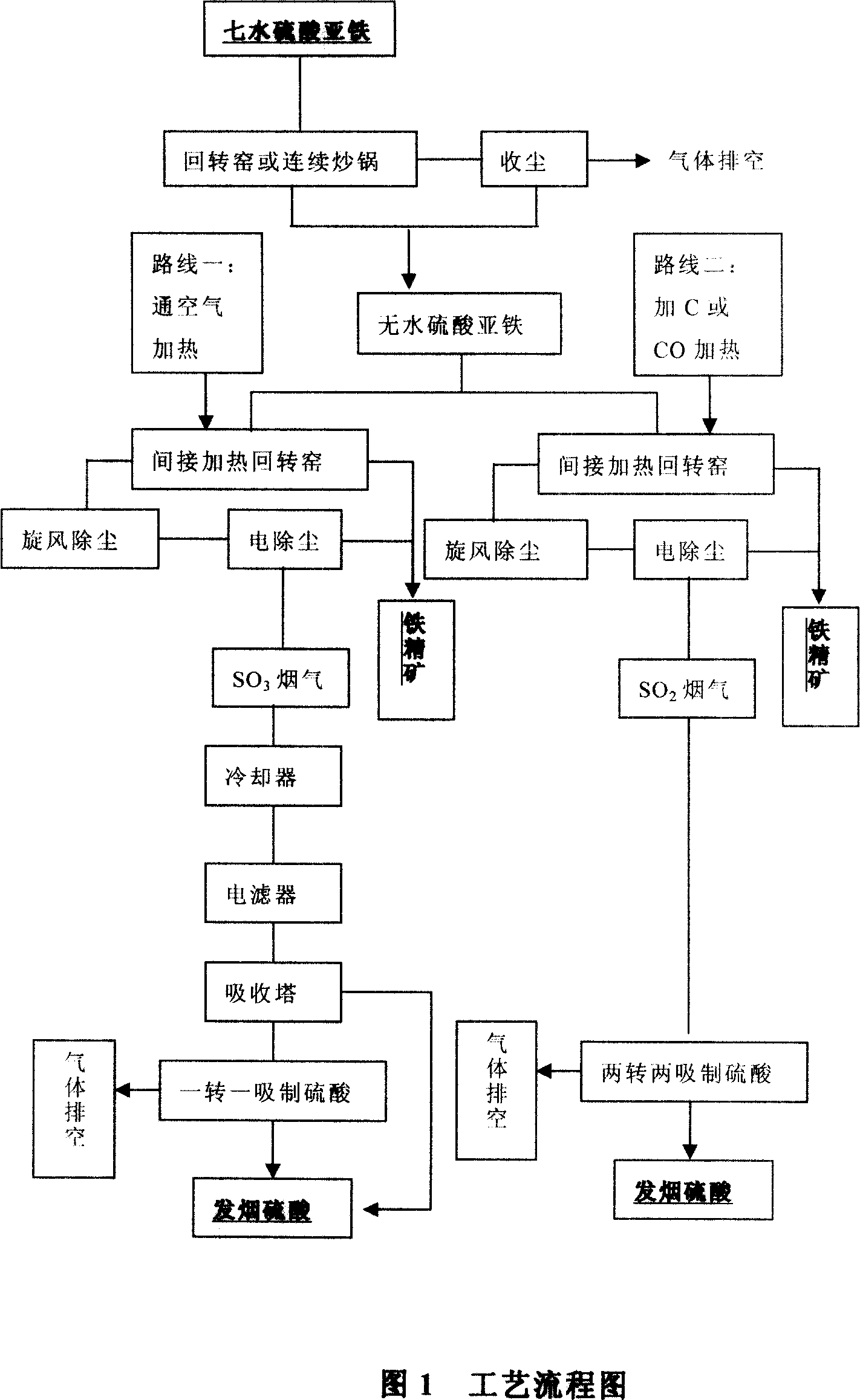

Method for producing vitriol and iron ore concentrate using ferrous sulfate

InactiveCN1994868AReduce adverse effectsAchieve mass productionSulfur-trioxide/sulfuric-acidFerric oxidesTitanium oxideMaterials science

The invention discloses a manufacturing method of sulfuric acid and fine ferric ore based on ferrous sulfate heptahydrate as by-product of titanium oxide, which is characterized by the following: heating anhydrous ferrous sulfate in the rotary kiln at 700-1000 deg. c; decomposing to obtain fine ferric ore and sulfur oxide gas under reducing atmosphere; using normal two-rotation two-adsorption technique to make sulfuric acid; purifying flue gas for sulfur trioxide and little of sulfur dioxide; adsorbing sulfur trioxide through concentrated sulfuric acid to produce fuming nitric acid; making residual sulfur dioxide gas into normal one-rotation one-adsorption technique to make sulfuric acid.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing urea phosphoric acid with wet-process phosphoric acid

ActiveCN101318914AImprove conversion rateSimple processUrea derivatives preparationOrganic compound preparationPhosphoric acidReaction temperature

The invention discloses a method for producing urea phosphate by using wet-process phosphoric acid, belonging to the chemical engineering field. The method comprises the following steps of: taking the wet-process phosphoric acid with a concentration of between 25 and 50 percent of P2O5 as measured weight, and adding the wet-process phosphoric acid in a reaction kettle which is provided with a stirring device and a heating device; starting the stirring device to heat the wet-process phosphoric acid to a temperature of between 60 and 95 DEG C; adjusting a rotational speed of a stirrer to between 60 and 300 revolutions / min, and adding a reaction activating agent and a suspending agent in the reaction kettle, with a dosage of the activating agent being 0.1 to 1.2 per thousand of phosphoric acid in a reaction system, and a dosage of the suspending agent being 0.2 to 1.0 per thousand of the phosphoric acid in the reaction system; keeping stirring for 5 to 10 minutes, and adding urea, in which a mol ratio of the urea to the phosphoric acid is between 1.0 and 1.4, in the reaction kettle, and maintaining the reaction temperature for 0.5 to 1.5 hours; closing the heating device, cooling and crystallizing to room temperature, and separating a dried product; and using a separated mother solution to produce wood fire retardant or fertilizer. The method has the characteristics of simple process, high coefficient of recovery, high product purity, low manufacturing cost, cleanness without pollution and so on.

Owner:WENGFU (GRP) CO LTD

Medium for seedling raising and cultivation and preparation method of medium

ActiveCN102838415AWide variety of sourcesNo pollution in the processFertilizer mixturesPlant growthPollution

The invention relates to a medium for seedling raising and cultivation and a preparation method of the medium, belonging to the technical field of agricultural production. In order to solve the problems that the existing cultivation medium uses non-renewable resources such as plant ash and vermiculite as raw materials, and environmental damages are caused because vermiculite and perlite cannot bedecomposed easily, the invention provides the medium for seedling raising and cultivation and the preparation method of the medium. The sources of raw materials are wide, the raw materials are degradable materials and pollution is not caused to the environment; and since chemical fertilizers are not used, the soil structure is not damaged. By using recycled aggregate, the problem of recycling building wastes is solved; and since kieselguhr and seaweed fertilizers take an effect of improving the soil and contain rich elements, the needs of growth of different plants can be met. By using the medium for seedling raising and cultivation provided by the invention, the survival rate of cultivated seedlings is high, the cultivated seedlings grow well and the situation that weeds grow is avoided.

Owner:山东天酵源生物科技有限公司

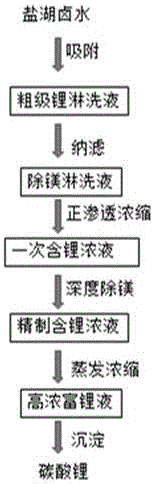

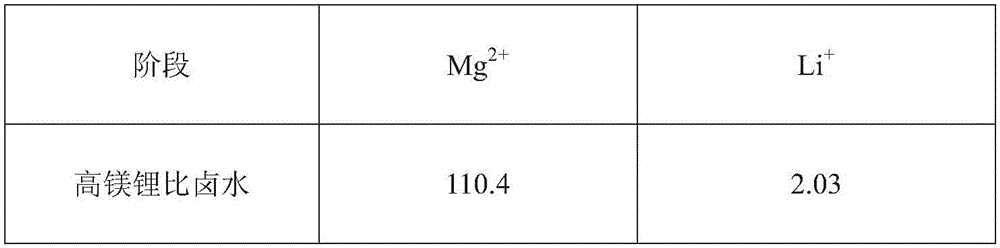

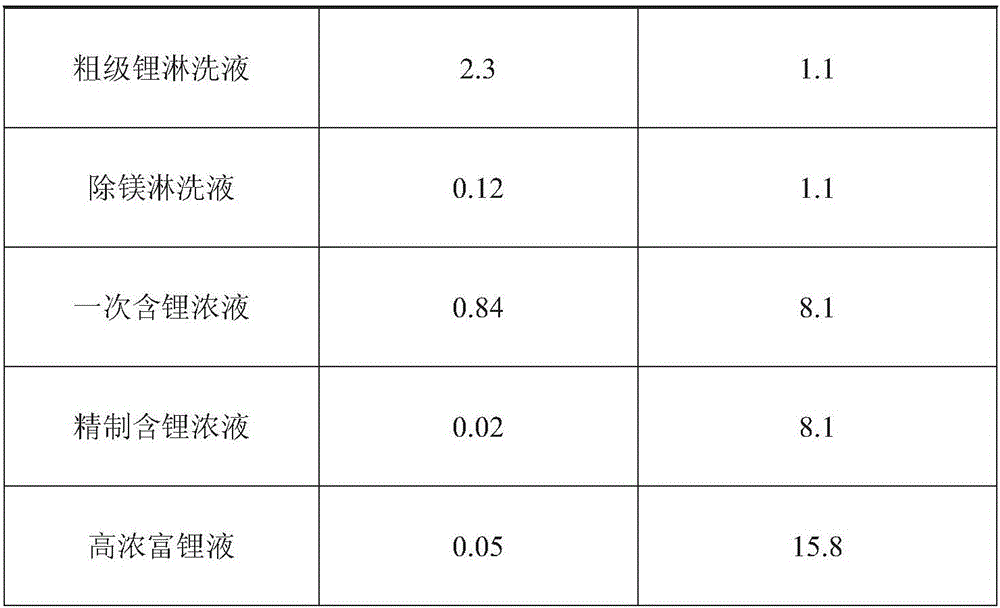

Method for preparing lithium carbonate through salt lake brine

ActiveCN106241841AHigh purityEasy to separateLithium carbonates/bicarbonatesMembrane methodLithium carbonate

The invention discloses a method for preparing lithium carbonate through salt lake brine. The method comprises the following steps of firstly adsorbing the salt lake brine through a high-property lithium extraction adsorbent, then performing nanofiltration for removing magnesium, performing forward osmosis and preliminary concentration, performing deep magnesium removal, performing multiple-effect evaporation, and performing sedimentation so as to obtain the battery-grade lithium carbonate. According to the method disclosed by the invention, an adsorption method, a membrane method and an evaporation method are organically combined together, so that the energy consumption is greatly reduced, and the cost is reduced; and besides, the lithium carbonate prepared by the method disclosed by the invention is high in purity and stable in quality. The method disclosed by the invention has the advantages of being simple and convenient to operate, low in energy consumption, stable in effects and the like.

Owner:JIANGSU HELPER FUNCTIONAL MATERIALS

Magnesium oxychloride fiber light wallboard

InactiveCN103979921AAvoid the phenomenon of moisture absorption and return to halogenHigh strengthSolid waste managementCompressive resistanceSlag

The invention provides a magnesium oxychloride fiber light wallboard, and relates to the wallboard field in the construction materials. The wallboard is composed of the following components in parts by weight: 40 to 60 parts of magnesium chloride water solution, 20 to 30 parts of magnesium oxide, 0.1 part of fly ash, 0.2 part of slag, 0.5 part of construction waste, 0.1 part of waste ceramic, 2 parts of short glass fiber, 2 parts of straw, 2 parts of saw dust, 3 parts of perlite, and 0 to 2 parts of modifier. The formula of the wallboard comprises industrial and agricultural wastes such as fly ash, slag, mineral slag, construction wastes, broken ceramics, straws, and saw dust, thus the wastes are fully recycled and reutilized, and moreover the using amount of sands and stones is reduced, so the destroy on mountain and river bed is avoided, resources are saved, and environment is protected. The prepared magnesium oxychloride fiber light wallboard has the advantages of good water resisting property, high compressive strength, good freeze resisting performance, good acid / alkali resistant property, no halogen appearance, no scumming, and no deformation.

Owner:四川省元程中博能源开发有限公司

Fermented asparagus puer tea and preparation method thereof

ActiveCN101623040AStorage availableSolve the use problemPre-extraction tea treatmentFood preparationYeastRaw material

The invention belongs to the technical field of tea preparation, in particular to a fermented asparagus puer tea and a preparation method thereof, taking branches and leaves of the asparagus as raw materials. The invention is characterized in that the branches and the leaves of the asparagus match with sunlight-dried hairy tea, and the mixed tea is fermented in a piling way by tea yeast and asparagus yeast. The invention solves the problem of using the branches and the leaves of the asparagus, solves the problems of environment pollution and recycling, and fills a gap in the field of tea drinking in the international and the domestic.

Owner:山东巨鑫源农业科技有限公司

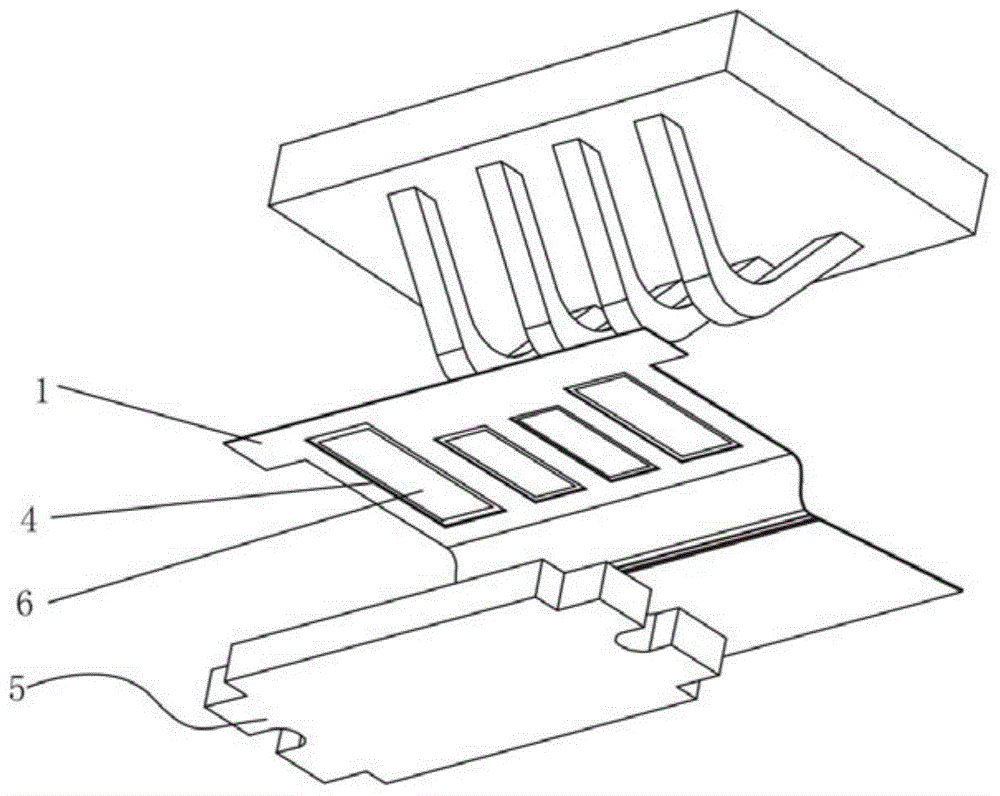

Common chip for regenerative printing supplies and communication verification method

InactiveCN104441982AAchieve regenerationSolving RecyclingDigital data authenticationElectrographic process apparatusMicrocontrollerControl set

The invention provides a common chip for regenerative printing supplies. A circuit combination of the common chip and an old chip is adopted, a command judgment unit is arranged on a microcontroller of the common chip to judge whether a command sent out by a printer contains a password check command signal, a password check command is stored through the microcontroller and forwarded to the old chip, a check result value is worked out through the old chip and sent to the microcontroller, the common chip then responds to a verification command, and the verification command is sent to the printer; alternatively, the microcontroller controls setting of an on-off control unit, a power supply line or a data bus line of the old chip is controlled by the on-off control unit to be switched on or switched off, and the old chip directly receives the password check command and responds to the verification command. Response processing is indirectly or directly verified through the old chip, regeneration of old printing supplies is achieved through verification of the printer, the old printing supplies are reused, and low carbon and environmental protection are achieved.

Owner:中山铭祺电子科技有限公司

Selenium-rich agaricus bisporus production method using selenium-rich crop straws

InactiveCN104604519ASolving RecyclingImprove protectionCalcareous fertilisersExcrement fertilisersAgaricusBiotechnology

The present invention discloses a selenium-rich agaricus bisporus production method using selenium-rich crop straws. Selenium-rich crop straws with 50%-70% of the total weight of cultivation dry materials are mixed into the cultivation dry materials. The selenium-rich agaricus bisporus production method uses natural selenium-rich crop straws as raw materials, has a high selenium utilization and no pollution problems, and can solve the crop straw recycling problem, is environmentally friendly, is simple and easy to operate, and improves the selenium content of agaricus bisporus to 0.2-1.5 mg / kg.

Owner:ANHUI YULONG NEW MATERIALS TECH

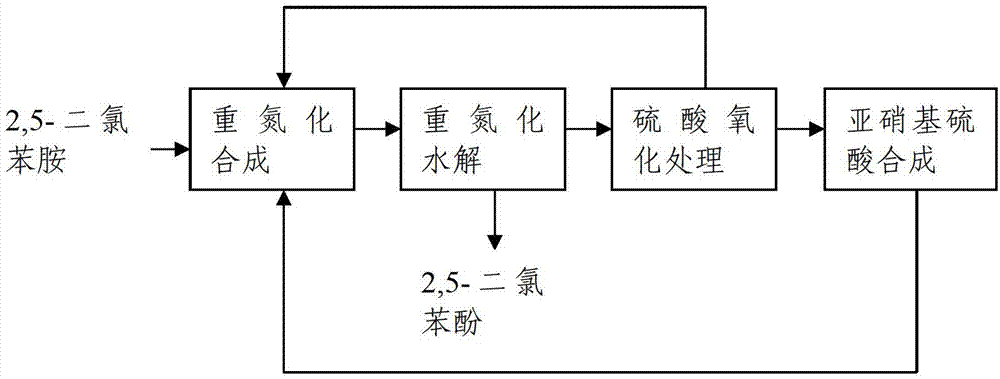

Clean production process of dicamba synthesis midbody

ActiveCN102964221AHigh reaction yieldEasy to recycleOrganic chemistryOrganic compound preparationNitrosylsulfuric acidNitroso

The invention relates to a clean production process of a dicamba synthesis midbody, and provides a clean production method of 2,5-dichlorophenol. The clean production process comprises the following steps: stirring 30-70% of dilute sulfuric acid and 2,5-dichloroaniline in a backflow state for 1-2hours, wherein the weight ratio of the dilute sulfuric acid to the 2,5-dichloroaniline is (6:1)-(9:1); after the reaction, cooling the reaction liquid to 0-5 DEG C, and dropping 10-60% nitroso-sulfuric acid and stirring for 2 hours to obtain diazonium liquid, wherein the molar ratio of the 2,5-dichloroaniline to the nitroso-sulfuric acid is 1:(1.0-1.5); carrying out pyrohydrolysis on the synthesized diazonium liquid at 140-170 DEG C to obtain 2,5-dichlorophenol; and carrying out diazotization synthesis on part of the hydrolyzed dilute sulfuric acid subjected to recovery processing as batch charging of dilute sulfuric acid, and synthesizing the other part of the dilute sulfuric with SO2 to be 10-60% nitroso-sulfuric acid, and then applying to diazotization synthesis. According to the synthesis process, no waste salt or phenolic wastewater are generated during diazotization reaction, the reaction yield is as high as 95%, and diazonium liquid is subjected to pyrohydrolysis and the dilute sulfuric acid can be recycled, so that the cycle use of the two can be achieved. The clean production process belongs to a clean and environment-friendly production process.

Owner:JIANGSU YOUJIA CHEM +2

Recovery treatment method for Mn containing waste batteries

ActiveCN104789778AEasy to operateImprove processing efficiencyWaste accumulators reclaimingProcess efficiency improvementSlagFe content

The invention discloses a recovery treatment method for Mn containing waste batteries. The method includes the steps of: (1) preparing Mn containing waste batteries, additionally preparing a slag former, which at least contains 10wt.% of Si; and (2) putting the prepared various materials into a smelting furnace to conduct smelting to produce alloy containing Co and / or Ni, Mn containing slag and flue dust. By controlling the oxygen partial pressure in the smelting furnace, the smelting temperature and smelting time, the smelting produced Mn containing slag has an Mn content of greater than or equal to 15wt.%, the Fe content is smaller than or equal to 5wt.%, the Al2O3 content is less than or equal to 30wt.%, and Mn / SiO2 is greater than or equal to 0.2 and smaller than or equal to 3.0. The recovery treatment method provided by the invention has better comprehensive economic benefits and environmental benefits.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

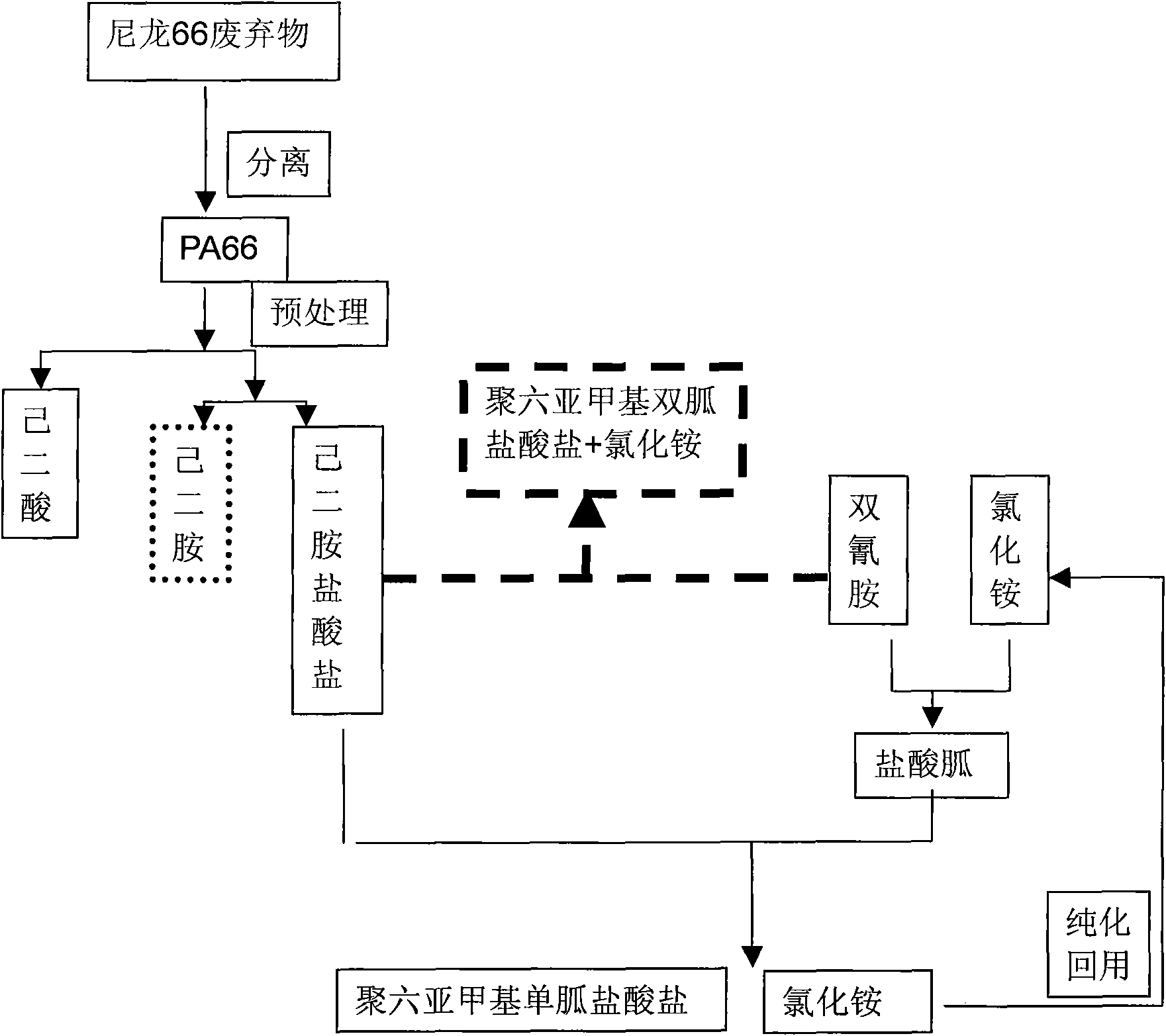

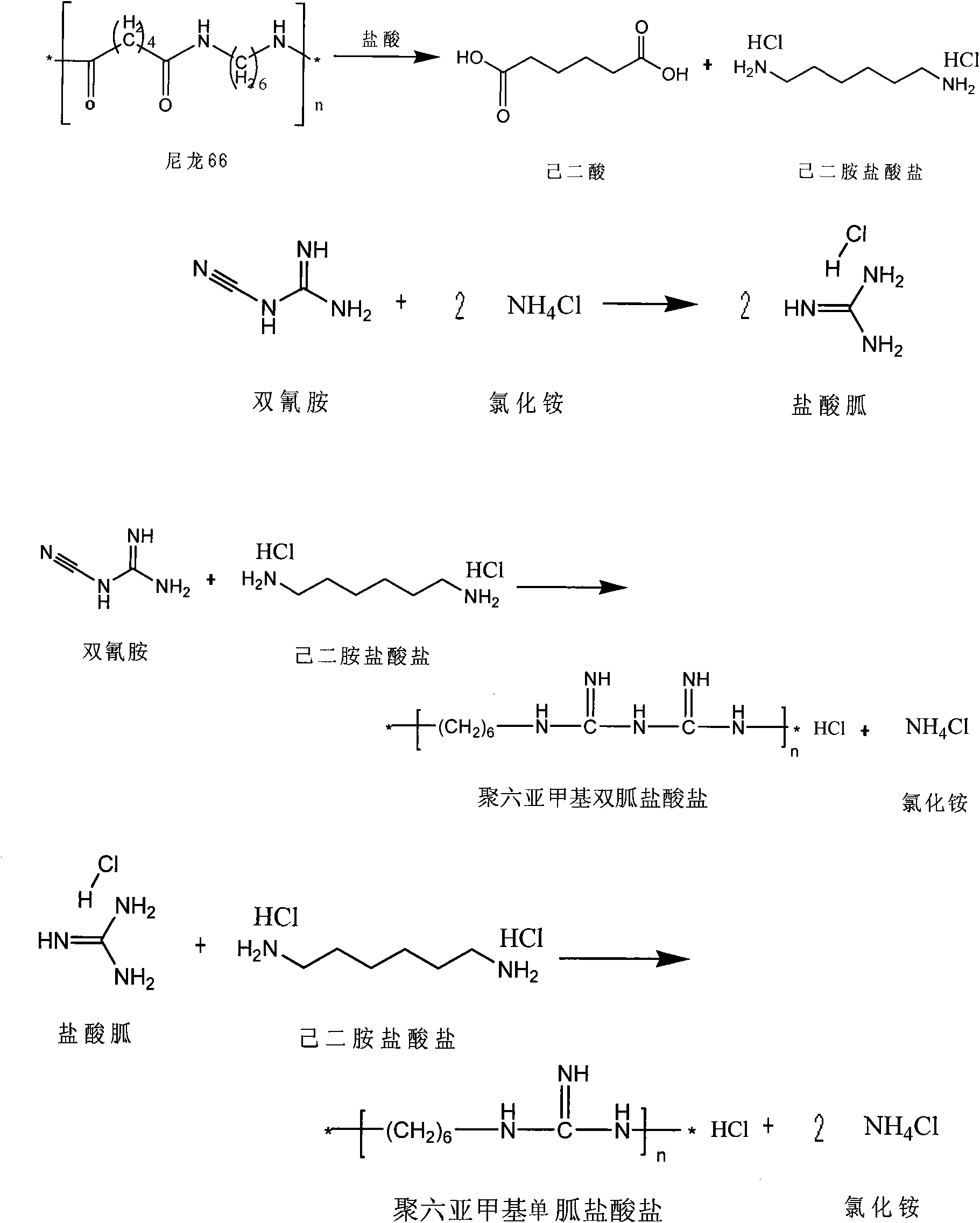

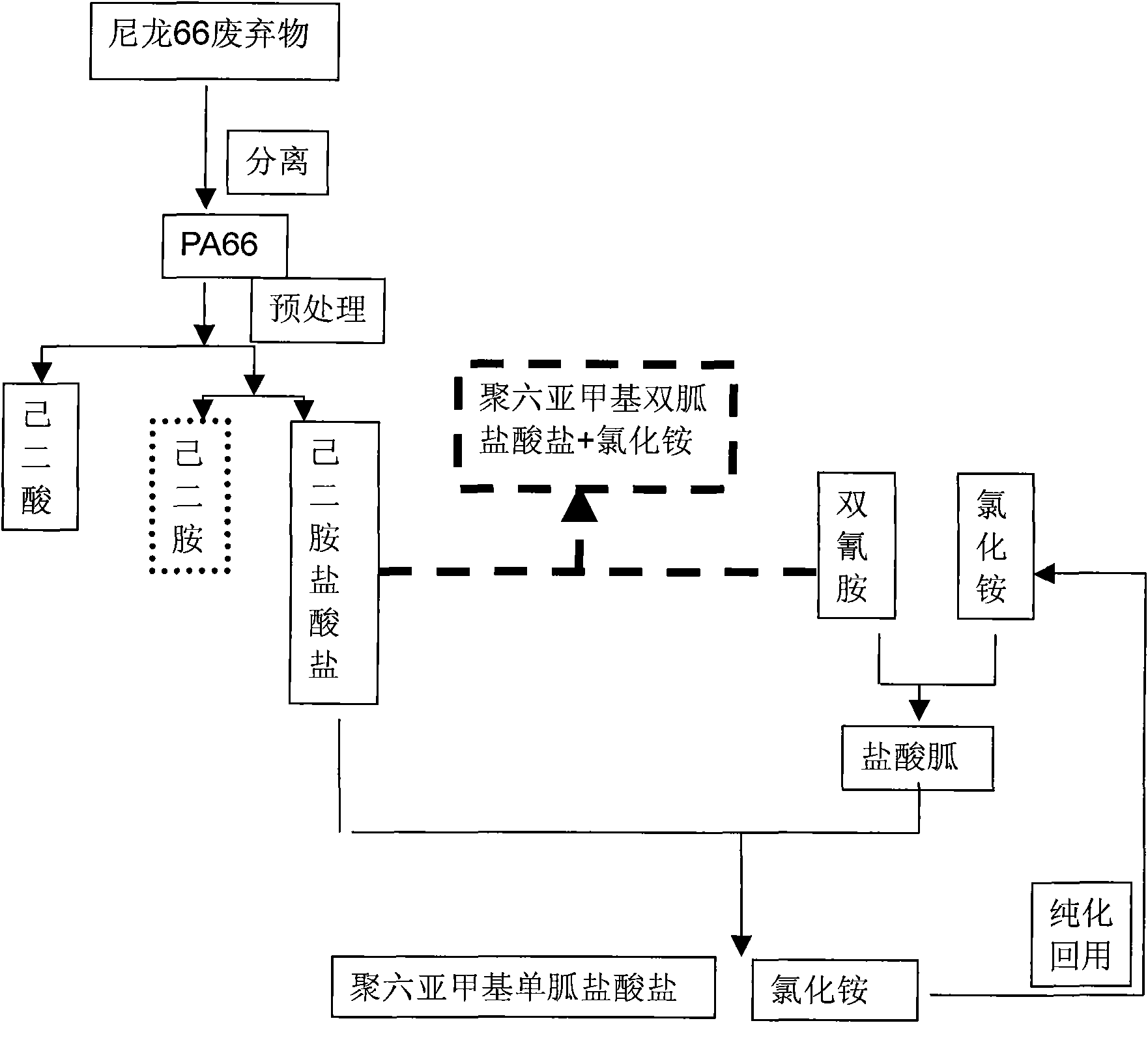

Method for producing adipic acid, hexamethylenediamine hydrochloride and polyhexamethylene (di)guanidine chloride from nylon-66 through depolymerization

InactiveCN101857540ASolving RecyclingSolve the problem of the sourceBiocideOrganic active ingredientsDepolymerizationHexamethylenediamine

The invention discloses a method for producing adipic acid, hexamethylenediamine hydrochloride and polyhexamethylene (di)guanidine chloride from waste nylon-66 serving as a raw amerial through depolymerization, which is characterized by comprising the following steps of: depolymerizing the waste nylon-66 by using hydrochloric acid to obtain refined adipic acid and hexamethylenediamine hydrochloride; polymerizing the hexamethylenediamine hydrochloride and dicyandiamide (in a molar ratio of 1:1) at the temperature of between 170 and 190DEG C for 1 to 3 hours to obtain a white or pale yellow solid polyhexamethylene diguanidine chloride; and adding dicyandiamide and ammonium chloride powder in a molar ratio of 1:2 into a reactor, performing reaction at high temperature for 1 to 3 hours, slowly adding hexamethylenediamine hydrochloride powder, continuously reacting for 3 to 7 hours to obtain a white or pale yellow solid polyhexamethylene guanidine chloride. The method improves production efficiency, reduces production cost, and solves the problems of difficult separation of the product hexamethylenediamine due to depolymerization, low yield and poor benefit; and the technological process is environment-friendly, simple and convenient, and is suitable for industrial production.

Owner:NINGBO UNIV

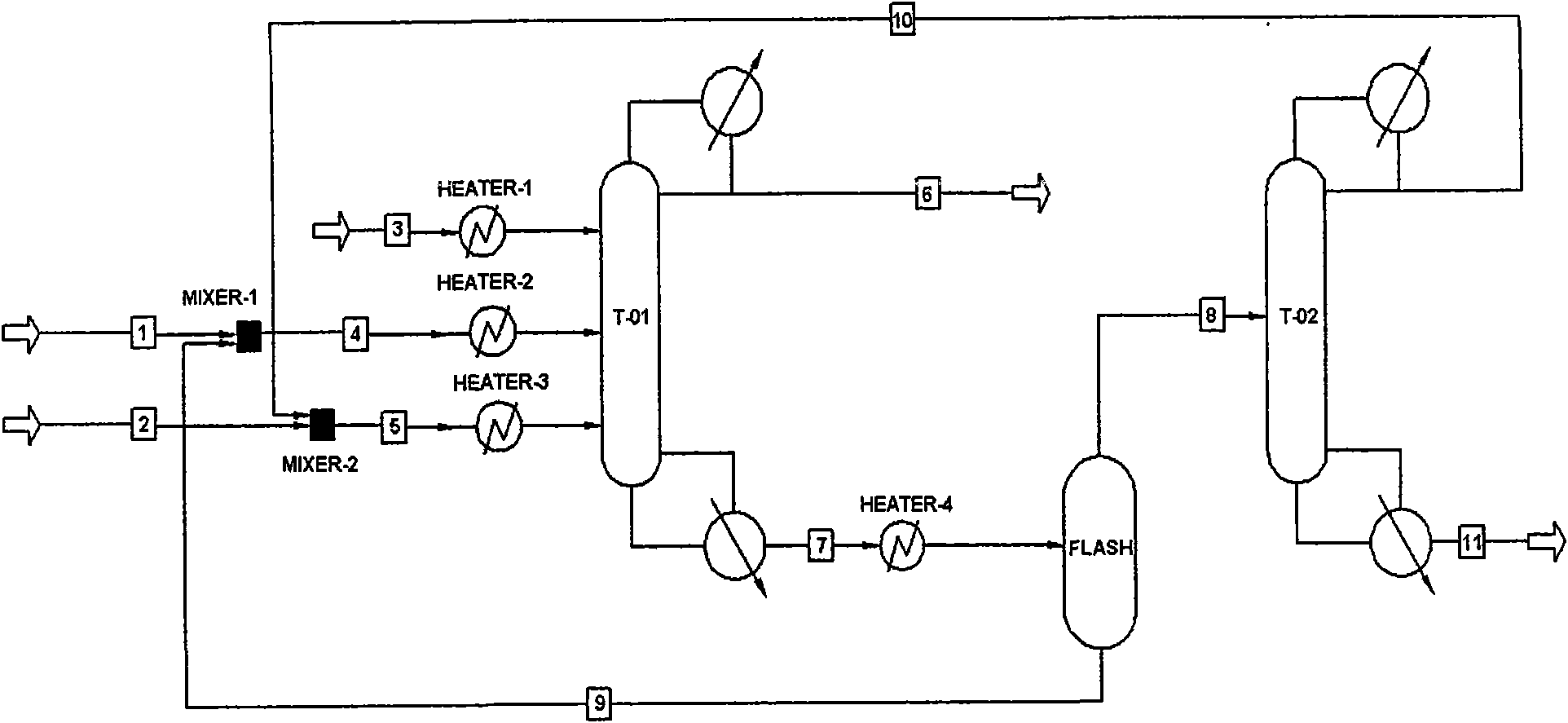

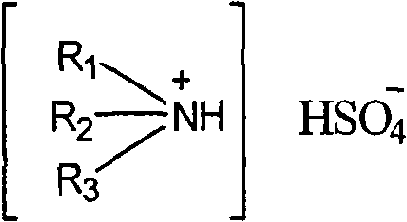

Process for continuously generating methyl acetate by reactive distillation taking ionic liquid as catalyst

ActiveCN101560151AGuaranteed purityReduce loadOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIonChemistry

A process for continuously generating methyl acetate by reactive distillation taking ionic liquid as a catalyst is as follows: raw materials are preheated, acetic acid is input from the upper segment of a reactive distillation tower, ionic liquid is input from the central segment of the tower and methanol is input from the lower segment of the tower simultaneously, the central segment of the reactive distillation tower is a reaction zone, the product of methyl acetate is extracted from the top of the tower, the catalyst of ionic liquid is extracted from the bottom of the tower and enters a flash drum for flash evaporation, the liquid extracted from the bottom of the flash drum is the catalyst of ionic liquid which returns to the reactive distillation tower, gas phase evaporated from the flash drum is mixed vapour of water and methanol, which is input to a methanol recovery tower, raw material of methanol is extracted from the top of the methanol recovery tower after being separated, and returns to the reactive distillation tower to be raw material, water is extracted from the bottom of the methanol recovery tower and is discharged. The process of the invention discharges no waste acid water, the material of devices of the required towers is only 316L stainless steel and can reduce the corrosion for the devices and one-time investment remarkably, energy consumption decreases by more than 15% simultaneously, therefore the production cost of final product reduces by more than 30%.

Owner:NANJING UNIV

Preparation method for conjugated oil, conjugated oil and application thereof

InactiveCN103074161AImprove conversion rateReduce dosageFatty acid chemical modificationFertilizer mixturesOil and greasePtru catalyst

The invention relates to the technical fields of oil deep processing and oil comprehensive utilization, and particularly discloses a preparation method for conjugated oil and application of the conjugated oil. The preparation method comprises the following steps: adding iodine into oil, reacting at the temperature of between 80 and 200DEG C for 0.5 to 5 hours under stirring in the nitrogen environment, and removing the iodine to obtain the conjugated oil. The preparation method is simple, the using amount of a catalyst is small, the conversion rate is high and solvents are not required to be added. Illegal cooking oil also can be taken as a raw material which is low in cost. The conjugated oil prepared can serve as a raw material for preparing fine chemicals, slow release fertilizers or controlled-release fertilizers.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Waste concrete regeneration method

InactiveCN105884308ASolving RecyclingShorten the production cycleSolid waste managementEnvironmental engineeringConstruction waste

The invention discloses a waste concrete regeneration method. By means of the provided concrete preparation method, the problem about recycling of building waste can be effectively solved, the production cycle of regenerated concrete prepared with the method is short, the porosity of recycled aggregate is effectively reduced through microorganism deposition treatment, the crushing value of the aggregate is reduced, the water absorption of the aggregate is reduced, the strength of the produced regenerated concrete can reach C50, and the performance of the concrete in all aspects is stable.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

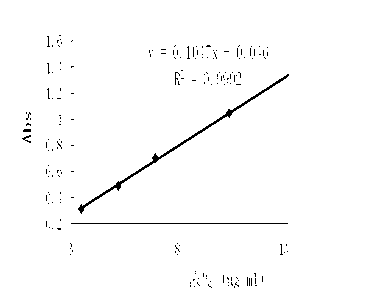

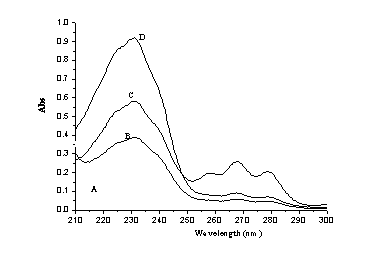

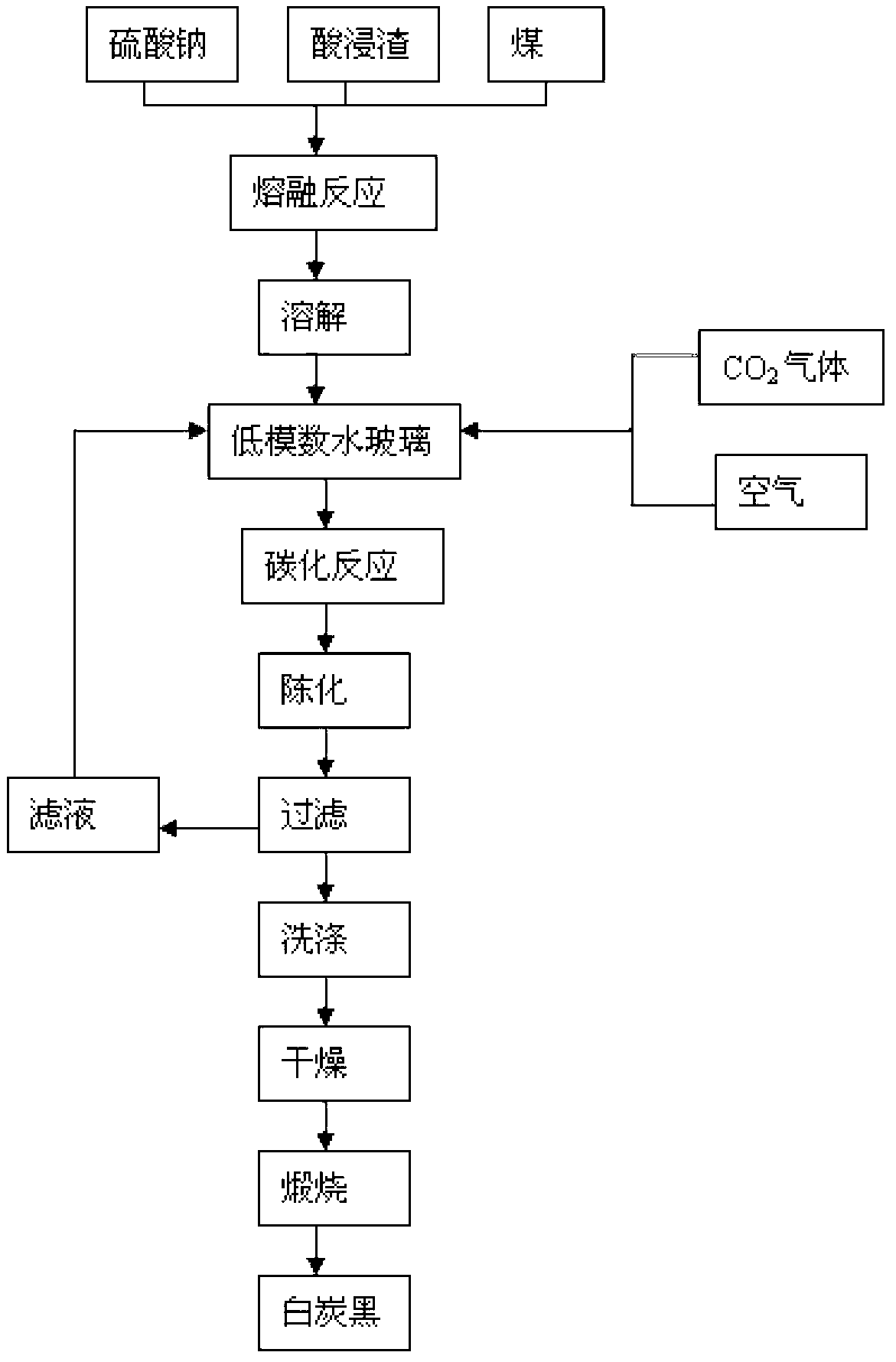

Method for preparing white carbon black by utilizing water glass with low modulus through carbonizing method of precipitation

InactiveCN103288091ASolve market application problemsInnovative production methodsSilicaSodium sulfateMixed gas

The invention relates to a method for preparing white carbon black by utilizing water glass with low modulus through a carbonizing method of precipitation. The method comprises the following steps: by using water glass as a raw material with the modulus of 1.0-1.5, diluting the raw material by a carbonizing filtrate to a liquor with 10-15wt% of water glass and adding 3.0-3.5wt% of sodium sulfate and 2-3wt% of product white carbon black as a precursor; introducing a mixed gas with content of carbon dioxide of 40-50v% at a flow of 8-10L / min at the carbonizing temperature of 65-95 DEG C, wherein the PH of the carbonizing endpoint is equal to 8.5; insulating and aging the carbonizing liquor for 2 hours and filtering; adequately washing, and drying and calcining to prepare white carbon black. The product is in accordance with the standard request of rubber compound ingredient (HG / T3062-3072-2008). According to the invention, the production path of white carbon black is innovated, the market application problem of water glass with low modulus is solved, and a technical support for comprehensive utilization of industrial wastes such as coal gangue and coal ash is provided, so that the method is beneficial to the development of related industries.

Owner:GUIZHOU PROVINCE PAN COUNTY ZISENYUAN GRP IND DEV INVESTMENT +1

Preparation method of regenerated concrete

InactiveCN105924053ASolve the recycling problemShort production cycleSolid waste managementEnvironmental geologyArchitectural engineering

The invention discloses a preparation method of regenerated concrete. The provided method can effectively solve the problem of construction waste recovery and reutilization. Moreover, the concrete production period is short, the microbial treatment can effectively reduce the porosity of regenerated aggregate, thus the crushing value and water absorption of aggregate are reduced, the strength of produced regenerated concrete can reach C50, and the properties of regenerated concrete become more stable.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

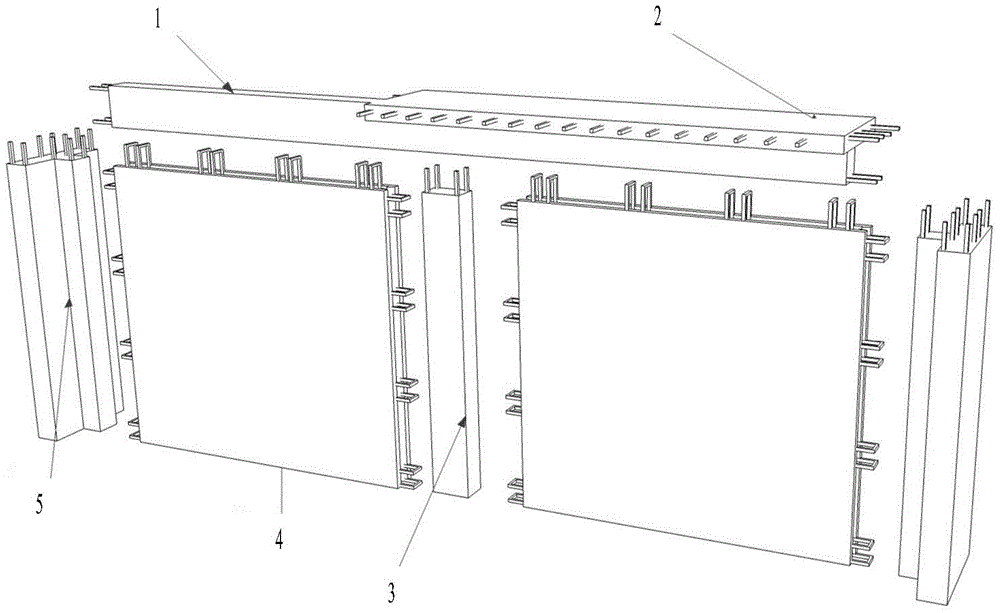

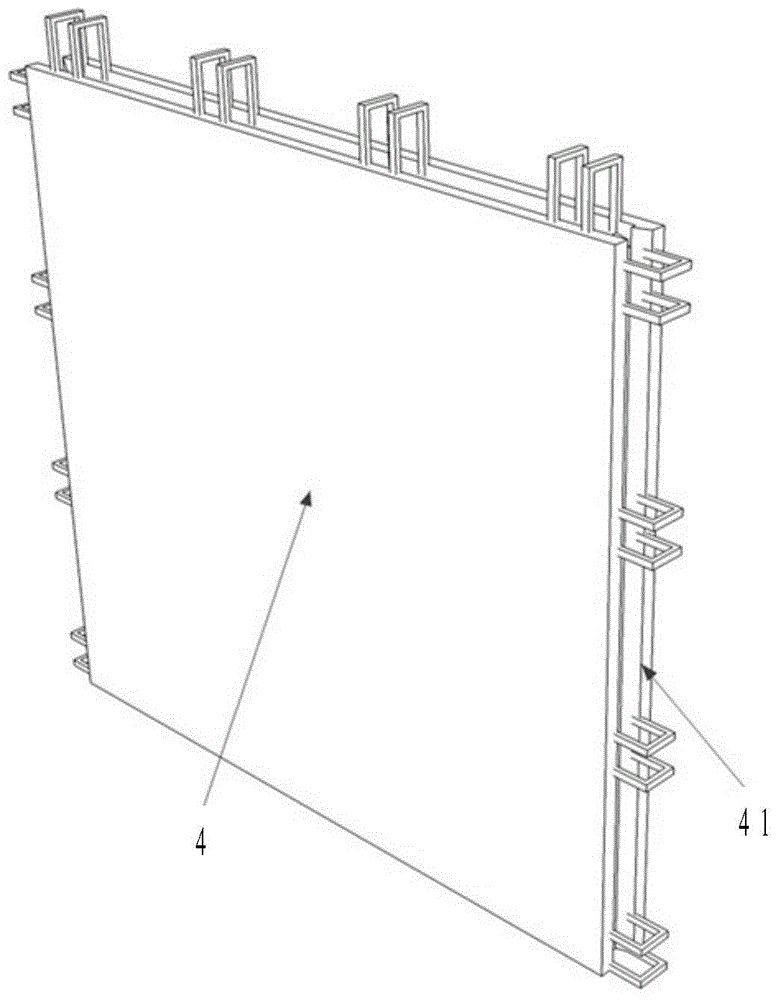

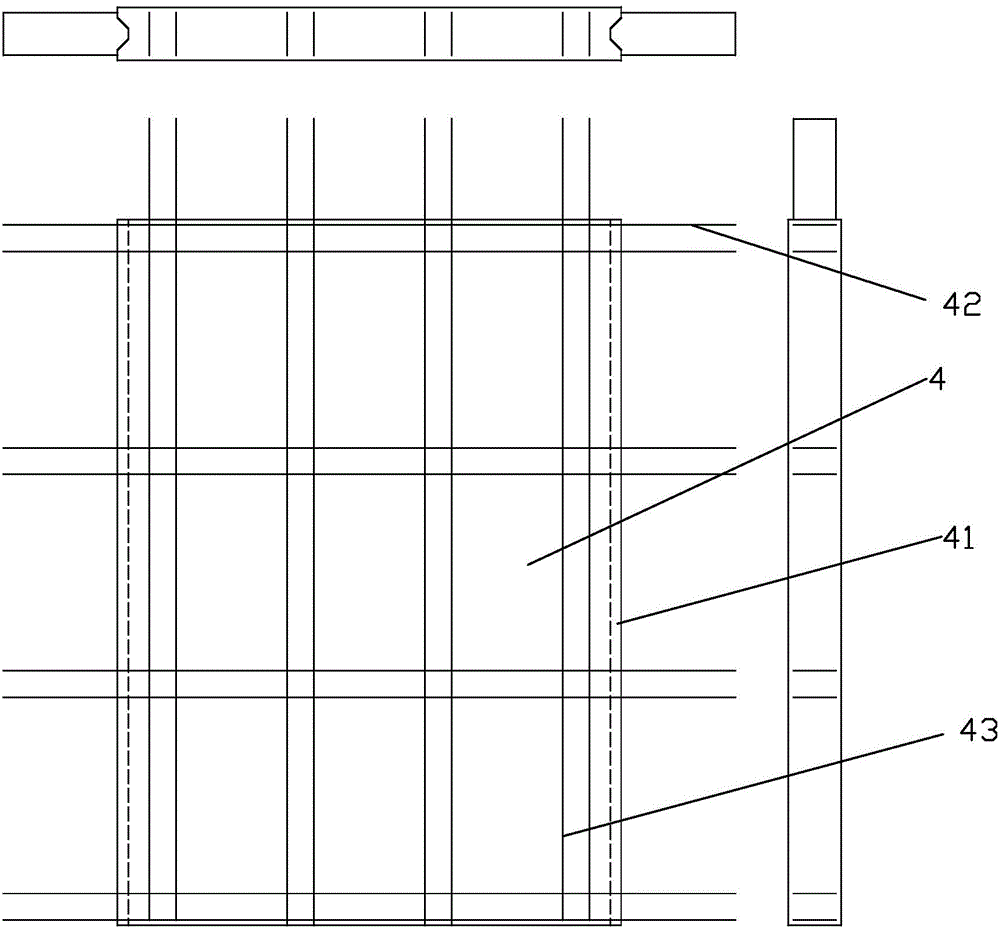

Prefabricated steel fiber sludge-made ceramisite concrete wall based on T-shaped groove connection and construction method of prefabricated steel fiber sludge-made ceramisite concrete wall

A prefabricated steel fiber sludge-made ceramisite concrete wall based on T-shaped groove connection comprises prefabricated wall plates, cast-in-place connection columns and cast-in-place vertical edge components, wherein the two lateral sides of each prefabricated wall plate are each of a T-shaped groove structure, horizontal and vertical reinforcing steel bars are arranged in the prefabricated wall plates, each cast-in-place column is embedded in the T-shaped groove structures of the corresponding adjacent prefabricated wall plates to connect the prefabricated wall plates, each cast-in-place vertical edge component is provided with a longitudinal protrusion structure matched with the corresponding T-shaped groove structure, the longitudinal protrusion structures are embedded in the T-shaped groove structures on the outer sides of the edge prefabricated wall plates, longitudinal ribs are arranged in the cast-in-place vertical edge components, and reliable anchoring is achieved when the longitudinal ribs and the horizontal reinforcing steel bars in the edge prefabricated wall plates are embedded and spot welding is conducted on the joints one by one. The invention further provides a construction method of the prefabricated steel fiber sludge-made ceramisite concrete wall, and by means of the innovation of materials, the connection mode and the rib matching mode, the wall structure can have the advantages of being capable of lowing energy consumption and reducing vibration, ecological, environmentally friendly, capable of being rapidly constructed, economical and practical.

Owner:西咸新区矩阵住宅工业有限公司

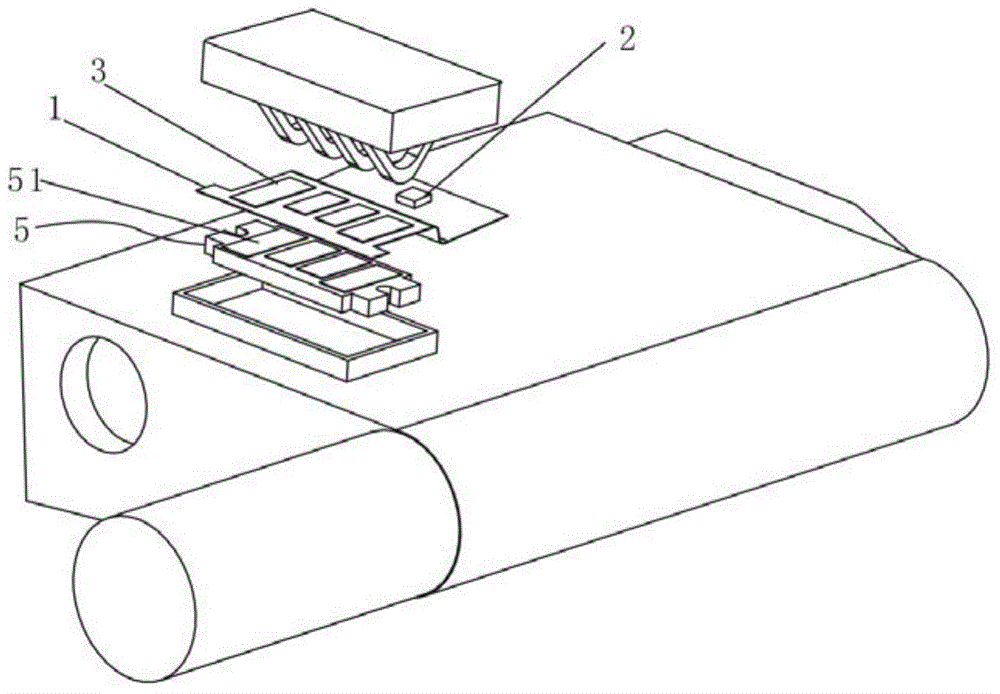

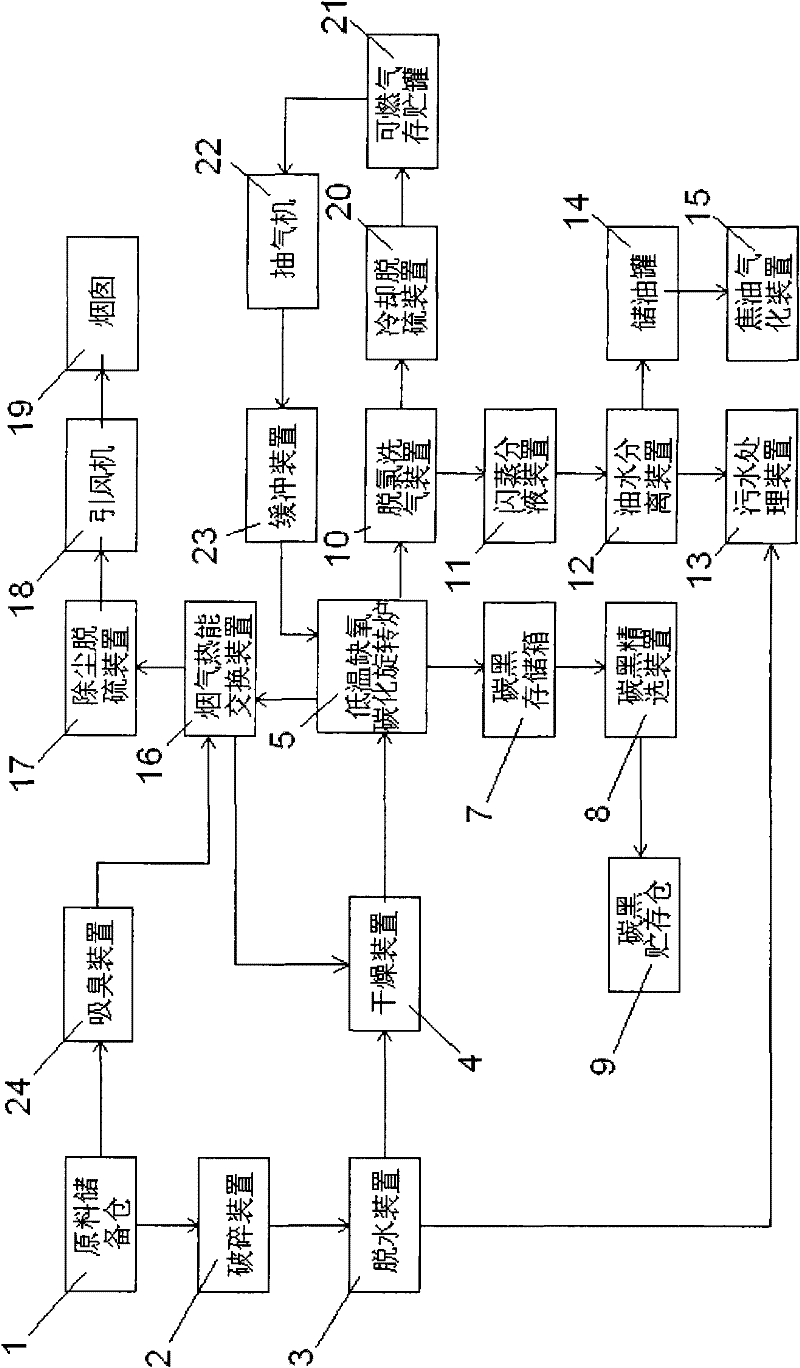

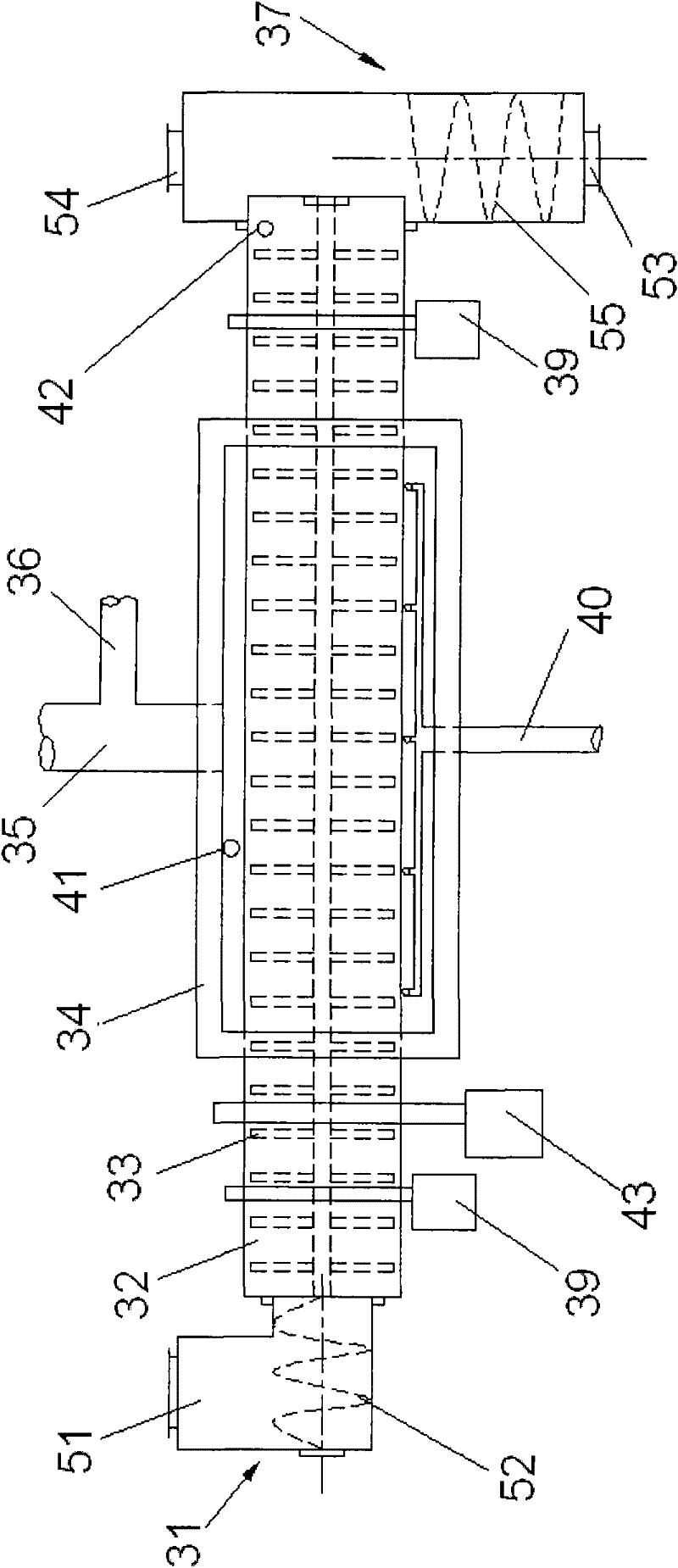

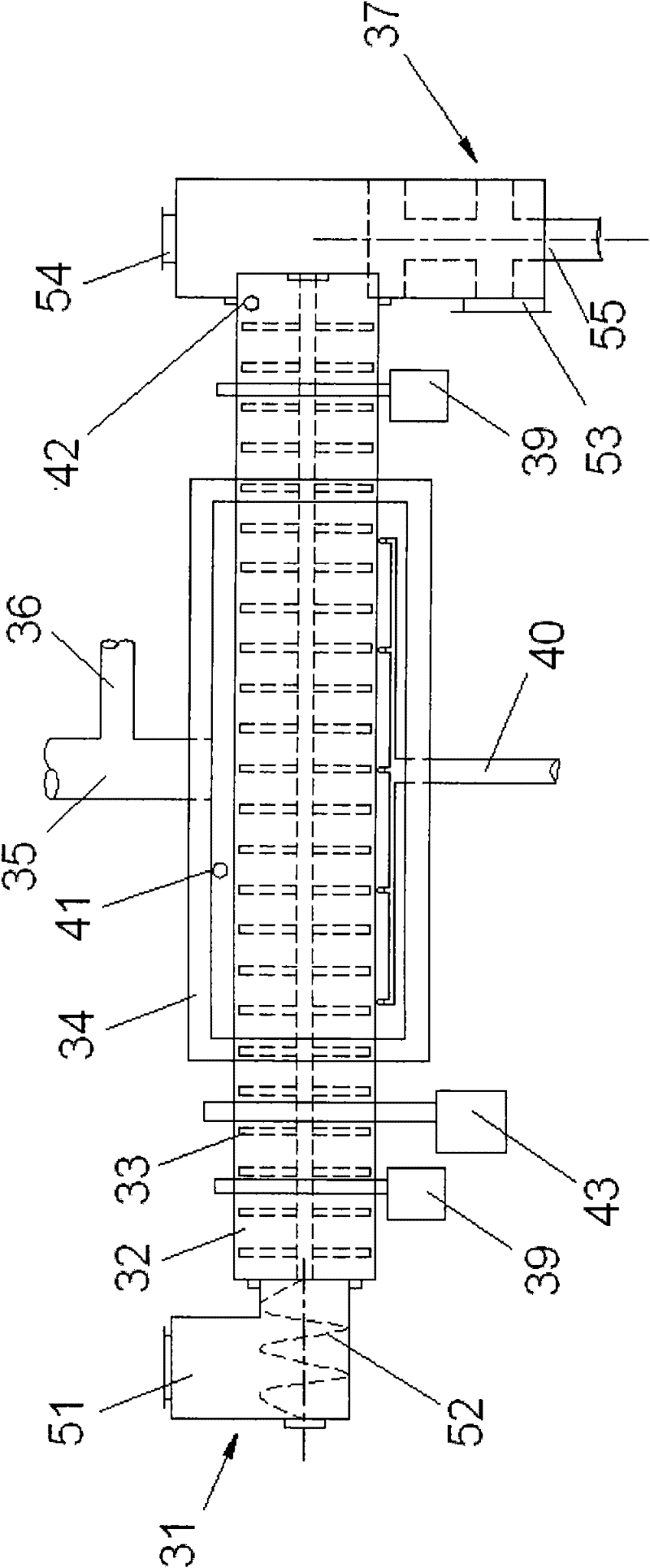

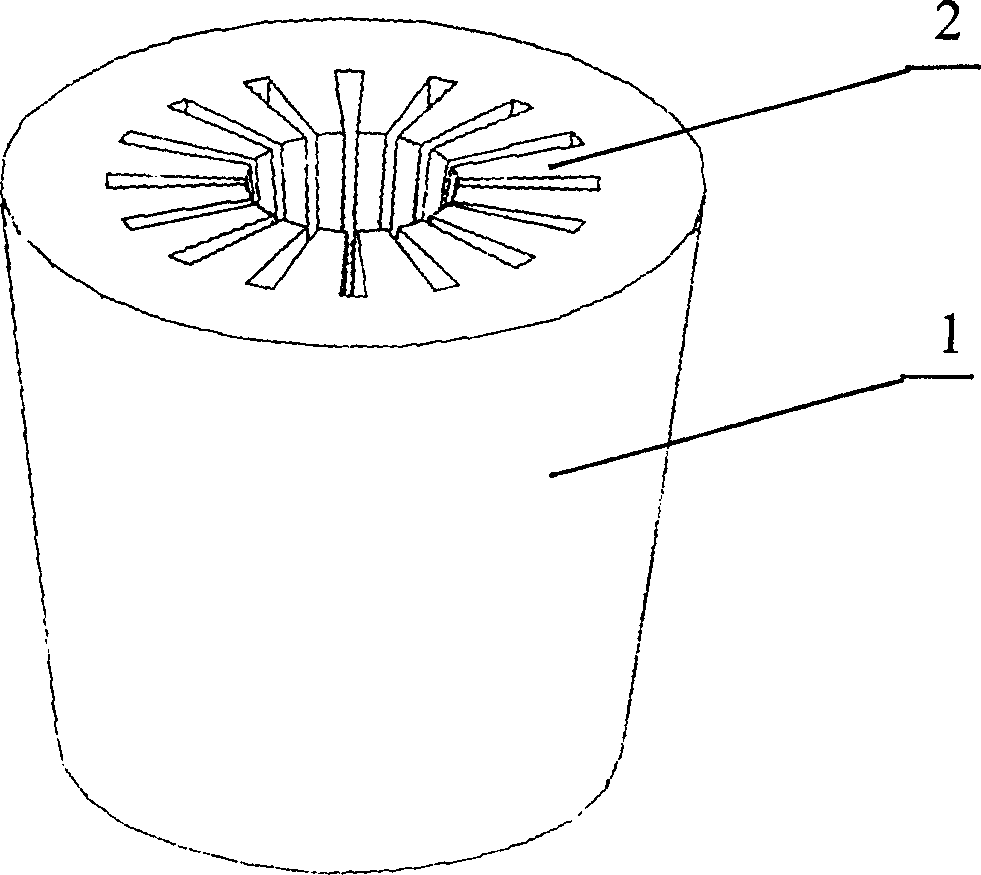

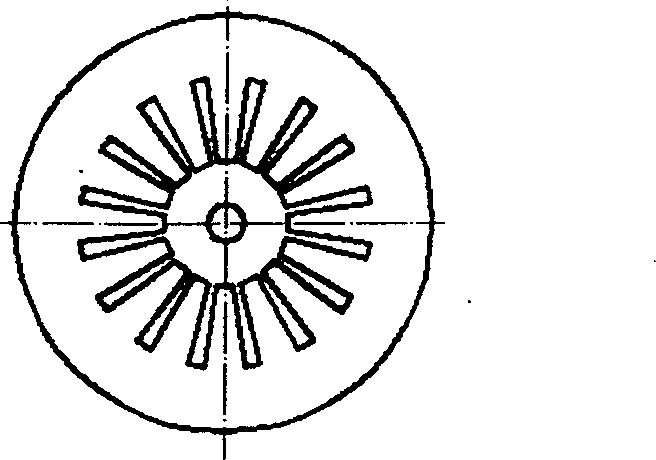

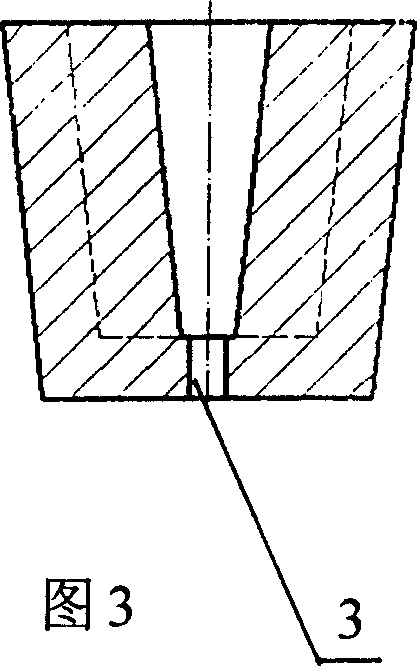

Municipal waste low-temperature anoxic carbonization system equipment and low-temperature anoxic carbonization rotary furnace for it

InactiveCN102274845ASuppress generationSolving RecyclingPigmenting treatmentSolid waste disposalTemperature controlFlue gas

The invention brings forward municipal refuse low-temperature oxygen-free carbonization system equipment. The municipal refuse low-temperature oxygen-free carbonization system equipment comprises a raw material preparation part, a low-temperature oxygen-free carbonization part, a resultant treatment part and a heat energy exchange part. The invention also provides a low-temperature oxygen-free carbonization revolving furnace for the municipal refuse low-temperature oxygen-free carbonization system equipment. The low-temperature oxygen-free carbonization revolving furnace comprises a feed part, a kettle body, a transmission mixer, an insulation tank, a flue gas outlet, a circulating heat conduction pipe, a discharging part, a supporting seat, a heating device, a temperature control device of the insulation tank, a temperature control device of the kettle body, and a transmission device. Through the municipal refuse low-temperature oxygen-free carbonization system equipment and the low-temperature oxygen-free carbonization revolving furnace therefor, it is prevented effectively that dioxin substances are produced in carbonization of refuse raw materials; authigenic energy sources can be recycled in carbonization of refuse; and a purpose of energy saving is realized effectively.

Owner:SHANGHAI ZHONGKE ANDA ENERGY SAVING PROD TECH

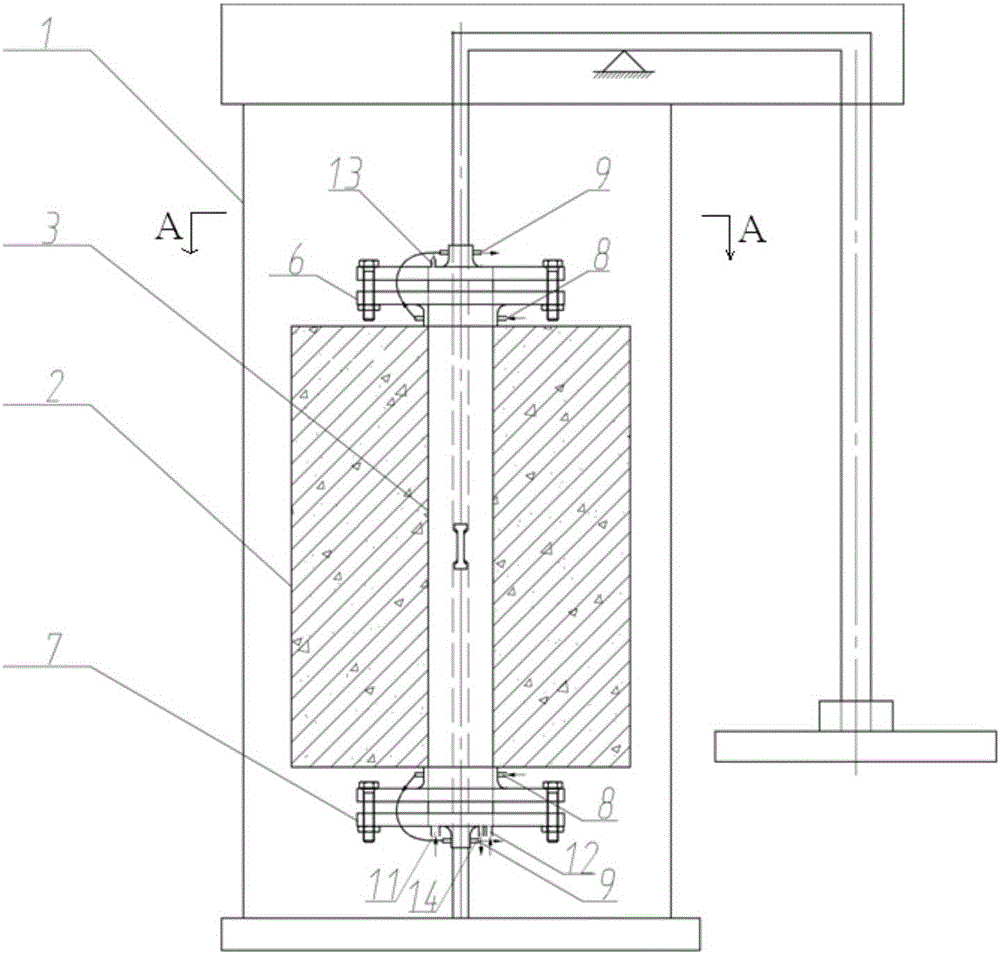

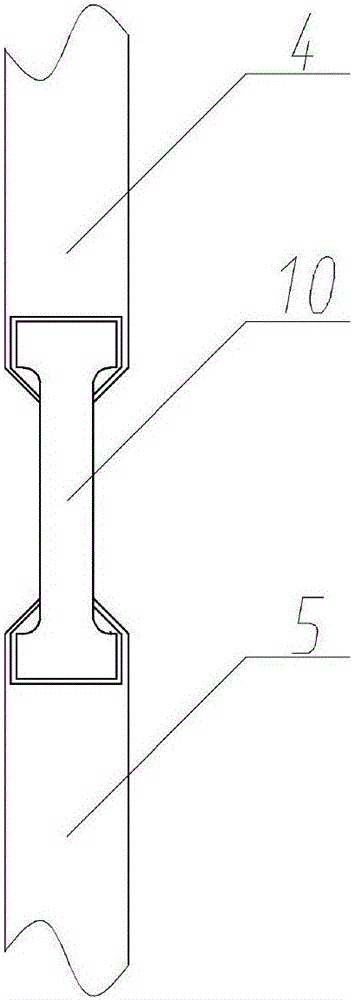

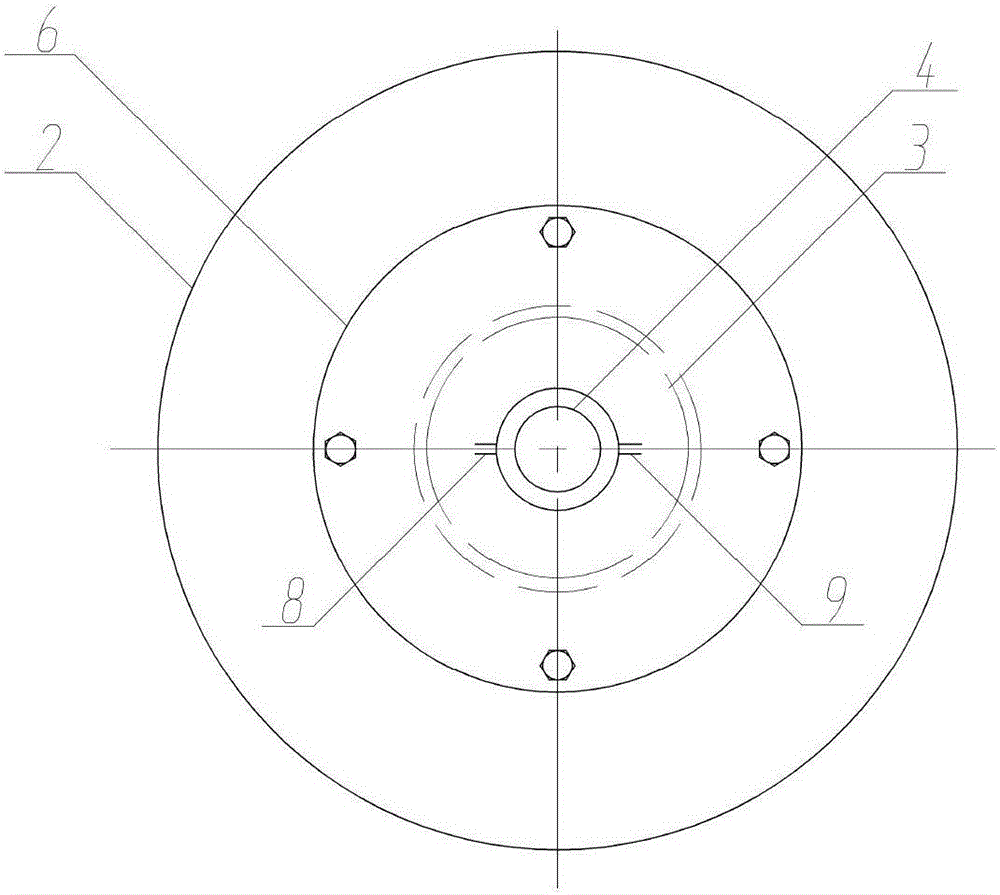

High-temperature lasting test device and method for environment corrosion

InactiveCN105842081ASimple structureEasy to operateWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesDistribution systemCorrosion

The invention relates to a high-temperature lasting test device and method for environment corrosion. The test device comprises a quartz sealing system arranged in a high-temperature lasting test machine, and a gas distribution system which is communicated with the quartz sealing system and can provide corrosive gas or water vapor. The quartz sealing system comprises a quartz tube used for carrying a metal sample, an upper end flange used for sealing the upper end of the quartz tube is arranged at the upper end of the quartz tube, a lower end flange used for sealing the lower end of the quartz tube is arranged at the lower end of the quartz tube, the upper end flange is provided with gas outlet holes communicated with the quartz tube, and the lower end flange is provided with corrosive gas inlet holes and water vapor inlet holes, wherein the corrosive gas inlet holes and the water vapor inlet holes are communicated with the quartz tube. The high-temperature lasting test device and method for environment corrosion are especially suitable for testing the high-temperature lasting performance of metal materials in harsh serving environments, the problem that in the prior art, tests can only be carried out under high-temperature dry air is solved, the device can carry out high-temperature lasting tests for special environment atmospheres, and the lasting performance in certain special atmospheres such as smoke and water vapor can be truly reflected.

Owner:HUANENG POWER INTERNATIONAL +1

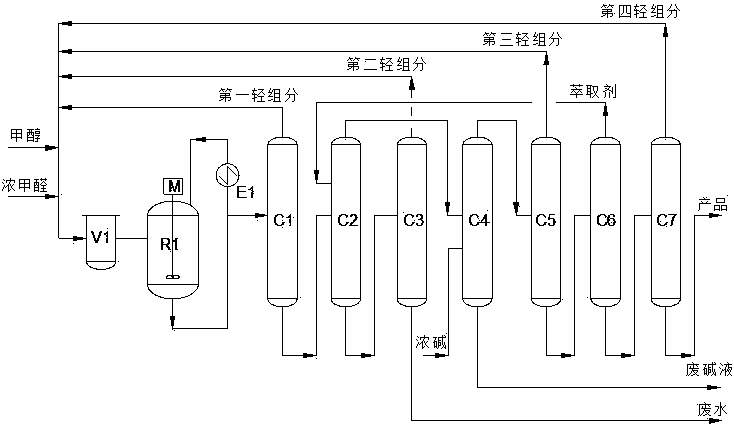

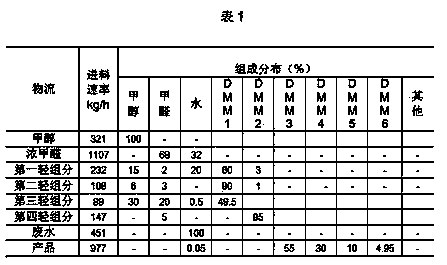

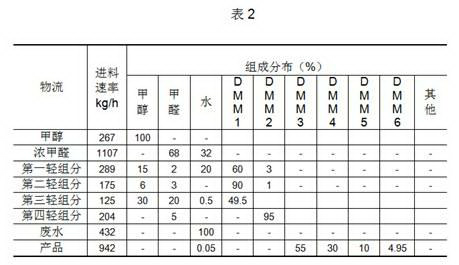

System using supported ionic liquid catalyst for continuous preparation of polyoxymethylene dimethyl ether

InactiveCN104045530ASimple processReduce energy consumptionOrganic chemistryOrganic compound preparationPtru catalystExtractive distillation

The invention discloses a reaction system and process using methanol and concentrated formaldehyde as initial reaction raw materials and a supported ionic liquid for catalyzed acetalation for preparation of polyoxymethylene dimethyl ether. The reaction system mainly comprises a reaction zone and a refining zone, the reaction zone includes a raw material pre mixing tank, a tank reactor, a reactor circulating pump, a circulating heat exchanger and the like, and the refining zone includes a reaction liquid distillation system, an extraction system, a catalyst concentration circulation system, an alkali washing system, a rectification separation system and the like. The reaction system uses the methanol and concentrated formaldehyde as the initial reaction raw materials for continuous acetalation for preparation of the polyoxymethylene dimethyl ether. The process is simple, the energy consumption is low, an extractive distillation separation mode is used, the ionic liquid catalyst is in no need of separation, and is supported on a carrier, the catalyst loss is reduced, the energy consumption is reduced, the product purity is high, the new tank reactor is used, and the reaction system and the process are suitable for large-scale industrialized production.

Owner:SHANGHAI PAN MA CHEM ENG TECH

Easily-cutting brass and processing method of strips thereof

The invention discloses an easily-cutting brass and a processing method of strips thereof, wherein the brass comprises the following ingredients in percentage by weight: 57-60 percent of Cu, less thanor equal to 0.05 percent of Pb, less than or equal to 0.7 percent of Sn, 0.5-0.6 percent of Ni, less than or equal to 0.2 percent of impurity elements, and the balance of Zn. The processing method ofstrips of the brass comprises the working procedures of smelting and continuous casting, hot rolling, rough rolling, annealing, first acid-washing, fine rolling and second acid-washing. Compared withthe prior art, the copper alloy of the invention can substitute the prior Hpb59-1 lead brass, achieves the environmental protection of a key strip and takes white-plated materials as raw materials for producing, thereby the recycling problem of the white-plated materials is solved, and the processing ratio is increased by utilizing the characteristics of hard and crisp (Alpha plus Beta) two-phaseorganization in the alloy and the solution strengthening of Sn and Ni elements so as to improve the hardness and the strength of copper alloy products.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

Comprehensive utilization method for phosphate flame retardant wastewater

ActiveCN104692571AGive full play to the energy-saving featuresAvoid structurePhosphatesMultistage water/sewage treatmentLiquid wasteHigh concentration

The invention relates to a method for treating phosphate flame retardant wastewater and particularly relates to a comprehensive phosphate flame retardant wastewater utilization method integrating energy-saving rectification-evaporation, oriented conversion and other technologies. The method specifically comprises the following steps: (1) effectively separating wastewater components by adopting a rectification-evaporation technology; (2) converting high-concentration phosphate waste liquor into polyphosphates by adopting an oriented conversion technology, and purifying to obtain the industrial grade polyphosphate product, so that the harmless problem of the phosphate waste liquor is solved; (3) using the water obtained by rectification to produce phosphate flame retardant products, and recycling the water; (4) converting inorganic salt solid wastes into recyclable industrial products by virtue of a fractionation and purification method, so that the discharge problem of the inorganic salt solid wastes is solved; and (5) taking the product as fuel in an oriented conversion process in the basis of the characteristic that the rectified low-boiling-point compound is high in heating value. Therefore, the discharge problem is solved, the energy can be saved, and the wastewater treatment cost is reduced.

Owner:ZHENJIANG JIANGNAN CHEM

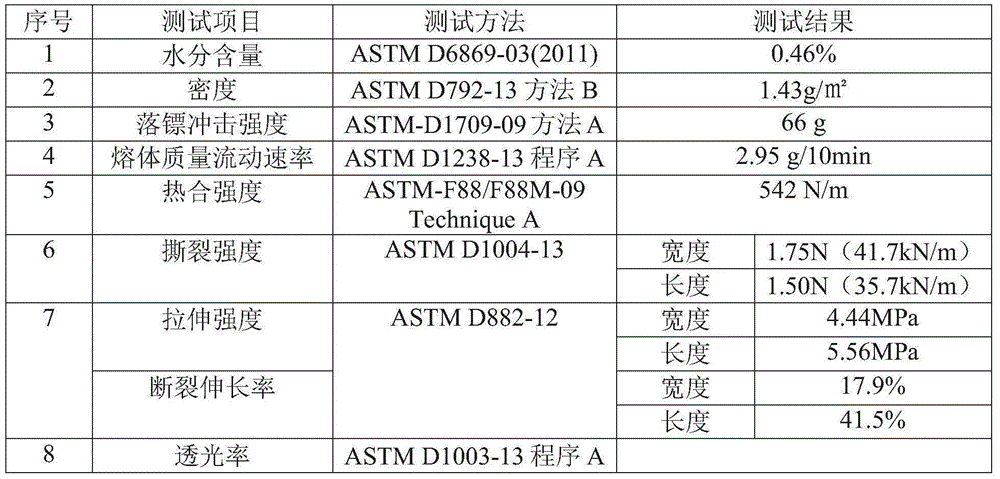

Biodegradable material and preparation method and use thereof

The present invention belongs to the field of polymer materials, and in particular relates to a biodegradable material, a preparation method and use thereof in preparation of a film container. The biodegradable material is prepared from the following components in parts by weight: 5 to 40 parts of polylactic acid, 5-40 parts of inorganic powder, 10-60 parts of PBAT, and 0.2-12.6 parts of an aid. The biodegradable material is prepared from good biodegradable polylactic acid and PBAT recycled materials and second line materials as main components with a large amount of inorganic powder and a plurality of finely-selected additives, physical and chemical modification are performed by mixing, molecular structure modification and self-combination and compounding are performed, and application performance is improved to achieve the characteristics of water resistance, oil resistance, leakage resistance, high impact resistance, strong rigidity, and good flexibility and achieve the performance of traditional plastics, cost is greatly reduced, and the biodegradable material is an ideal alternative of the traditional plastics.

Owner:邓铁军 +1

Manufacturing method of degradable pot for growing seedlings

A method for preparing the degradable seedling-culturing bowl includes such steps as providing the mud or the mud compost as basic raw material, mixing it with adhesive, and die pressing. It can decrease the pollution of mud to environment.

Owner:侯芸 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com