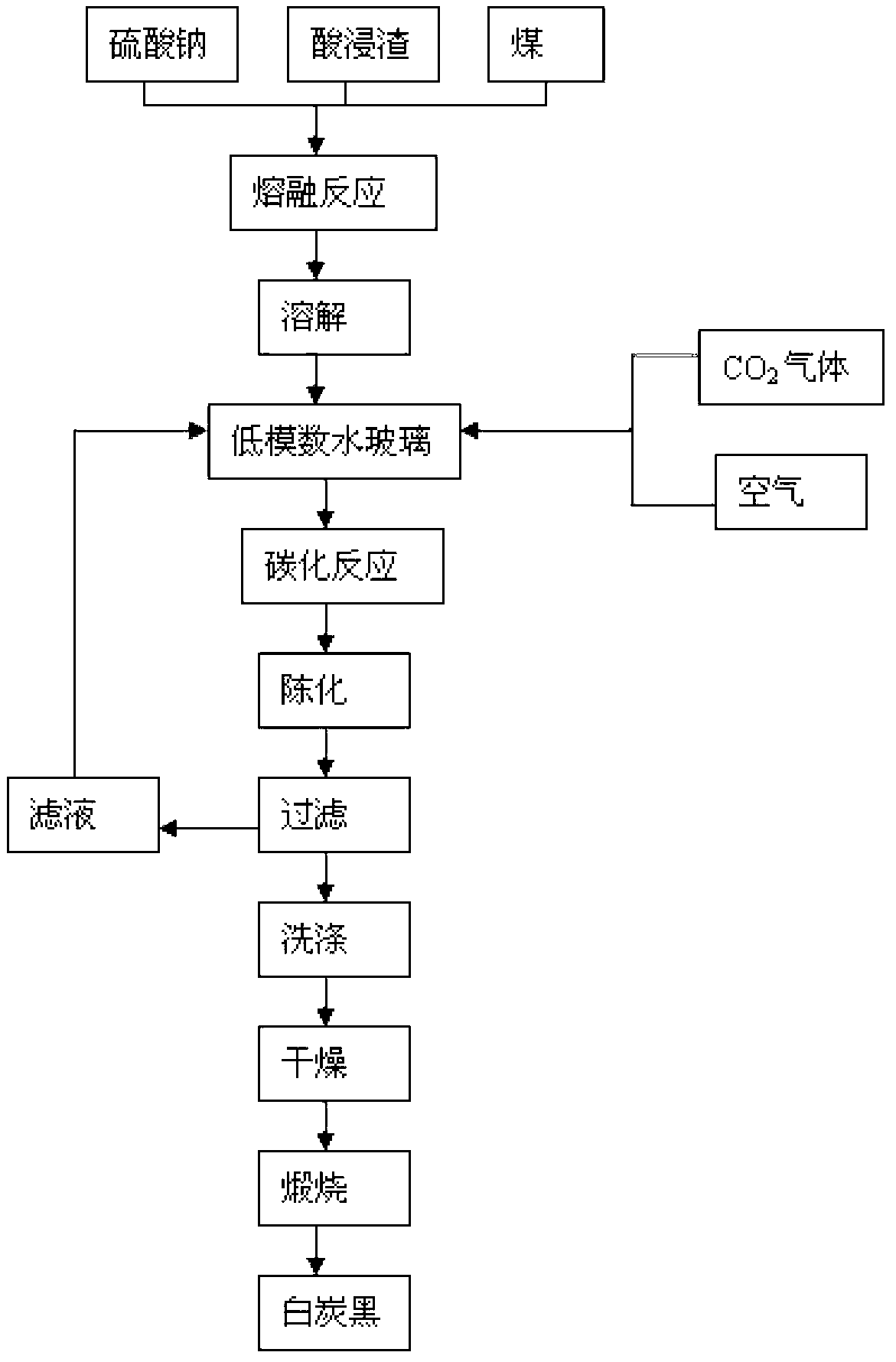

Method for preparing white carbon black by utilizing water glass with low modulus through carbonizing method of precipitation

A technology of water glass and white carbon black, which is applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of low-modulus water glass market application bottlenecks, etc., and achieve the effects of stable product quality, simple equipment, and no harsh process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 500ml of water glass with a modulus of 1.0, dilute the water glass with carbonized filtrate to a mass concentration of 15wt%, take 500g of the diluted solution, add 2.5g of sodium sulfate, 1g of finished white carbon black, transfer it to a 1000ml three-necked bottle, and use The digital display water bath is heated, the thermometer is placed in the three-necked flask, and the temperature is controlled at 95°C. When the temperature rises to the required temperature, start stirring, set the speed at 350rpm, and feed in a gas volume of 10L / min with a carbon dioxide content of 50%. Mixed gas, the pH value at the end of the reaction is 8.5, after the reaction is completed, heat preservation and aging for 2 hours, after filtration, washing, drying, and calcination, the white carbon black product is obtained. After analysis, the product meets the requirements of the HG / T3062-3072-2008 rubber compounding agent standard .

Embodiment 2

[0036] Take 500ml of water glass with a modulus of 1.2, dilute the water glass with carbonized filtrate to a mass concentration of 12wt%, take 500g of the diluted solution, add 2.0g of sodium sulfate, 1.2g of finished white carbon black, and transfer it to a 1000ml three-necked bottle. Heat with a digital display water bath, place a thermometer in a three-necked flask, and control the temperature at 85°C. When the temperature rises to the required temperature, start stirring, set the speed at 350rpm, and feed in a gas volume of 9L / min with a carbon dioxide content of 45 % mixed gas, the pH value at the end of the reaction is 8.5, after the reaction is completed, heat preservation and aging for 2 hours, filter, wash, dry, and calcinate to obtain a white carbon black product. After analysis, the product meets the requirements of the HG / T3062-3072-2008 rubber compounding agent standard .

Embodiment 3

[0038] Take 500ml of water glass with a modulus of 1.5, dilute the water glass with carbonized filtrate to a mass concentration of 10wt%, take 500g of the diluted solution, add 1.5g of sodium sulfate, 1.0g of finished white carbon black, and transfer it to a 1000ml three-necked bottle. Heat with a digital display water bath, place a thermometer in a three-necked flask, and control the temperature at 75°C. When the temperature rises to the required temperature, start stirring, set the speed at 350rpm, and feed in a gas volume of 8L / min with a carbon dioxide content of 40 % mixed gas, the pH value at the end of the reaction is 8.5, after the reaction is completed, keep it warm for 2 hours, filter, wash, dry, and calcinate to obtain a white carbon black product. After analysis, the product meets the rubber compounding agent standard of HG / T3062-3072-2008 Require.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com