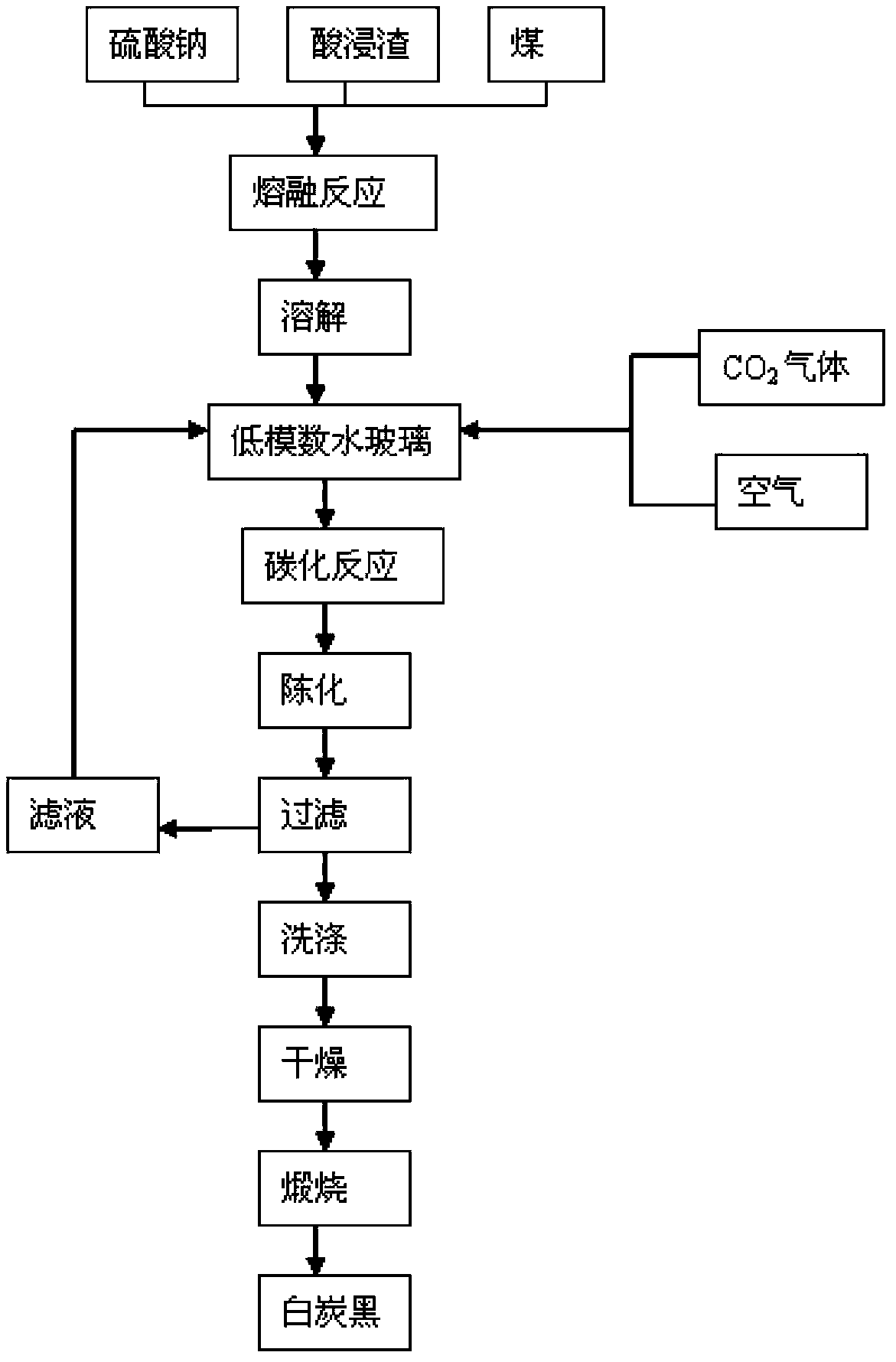

Method for preparing white carbon black by utilizing water glass with low modulus through carbonizing method of precipitation

A water glass and silica technology, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the application bottleneck of low modulus water glass market, and achieve the effect of stable product quality, convenient operation and no harsh process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 500ml of water glass with a modulus of 1.0, dilute the water glass with carbonized filtrate to a mass concentration of 15wt%, take 500g of the diluted solution, add 2.5g of sodium sulfate, 1g of finished white carbon black, transfer it to a 1000ml three-necked bottle, and use The digital display water bath is heated, the thermometer is placed in the three-necked flask, and the temperature is controlled at 95°C. When the temperature rises to the required temperature, start stirring, set the speed at 350rpm, and feed in a gas volume of 10L / min with a carbon dioxide content of 50%. Mixed gas, the pH value at the end of the reaction is 8.5, after the reaction is completed, heat preservation and aging for 2 hours, after filtration, washing, drying, and calcination, the white carbon black product is obtained. After analysis, the product meets the requirements of the HG / T3062-3072-2008 rubber compounding agent standard .

Embodiment 2

[0036] Take 500ml of water glass with a modulus of 1.2, dilute the water glass with carbonized filtrate to a mass concentration of 12wt%, take 500g of the diluted solution, add 2.0g of sodium sulfate, 1.2g of finished white carbon black, and transfer it to a 1000ml three-necked bottle. Heat with a digital display water bath, place a thermometer in a three-necked flask, and control the temperature at 85°C. When the temperature rises to the required temperature, start stirring, set the speed at 350rpm, and feed in a gas volume of 9L / min with a carbon dioxide content of 45 % mixed gas, the pH value at the end of the reaction is 8.5, after the reaction is completed, heat preservation and aging for 2 hours, filter, wash, dry, and calcinate to obtain a white carbon black product. After analysis, the product meets the requirements of the HG / T3062-3072-2008 rubber compounding agent standard .

Embodiment 3

[0038] Take 500ml of water glass with a modulus of 1.5, dilute the water glass with carbonized filtrate to a mass concentration of 10wt%, take 500g of the diluted solution, add 1.5g of sodium sulfate, 1.0g of finished white carbon black, and transfer it to a 1000ml three-necked bottle. Heat with a digital display water bath, place a thermometer in a three-necked flask, and control the temperature at 75°C. When the temperature rises to the required temperature, start stirring, set the speed at 350rpm, and feed in a gas volume of 8L / min with a carbon dioxide content of 40 % mixed gas, the pH value at the end of the reaction is 8.5, after the reaction is completed, keep it warm for 2 hours, filter, wash, dry, and calcinate to obtain a white carbon black product. After analysis, the product meets the rubber compounding agent standard of HG / T3062-3072-2008 Require.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com