Patents

Literature

158 results about "Silicone membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dermal substitute consisting of amnion and biodegradable polymer, the preparation method and the use thereof

InactiveUS20050107876A1Less inflammatory responseMaintain formSkin implantsTissue cultureSecond-Degree BurnBiocompatibility Testing

The present invention relates to a dermal substitute comprising the biodegradable polymer such as collagen and the biomaterial such as amnion, the preparation method and the use thereof. Specifically, the present invention provides with an amnion-collagen sponge complex structure prepared by attaching, inserting or incorporating an amnion obtained from placenta to / in collagen. Inventive dermal substitute can be applied to surgery and wound requiring skin graft, for example, severe burns such as second-degree burn, without rejection by immune system. Further, inventive dermal substitute with amnion instead of silicone membrane has several advantages, such as better biocompatibility, anti-inflammatory activity and promoting activity of wound healing and commercial utilization as basement membrane. Also, inventive complex structure can be used as the basic matrix of bio-artificial skin for culturing cells and the biodegradable basic matrix for preparing artificial organs.

Owner:SK BIOLAND CO LTD

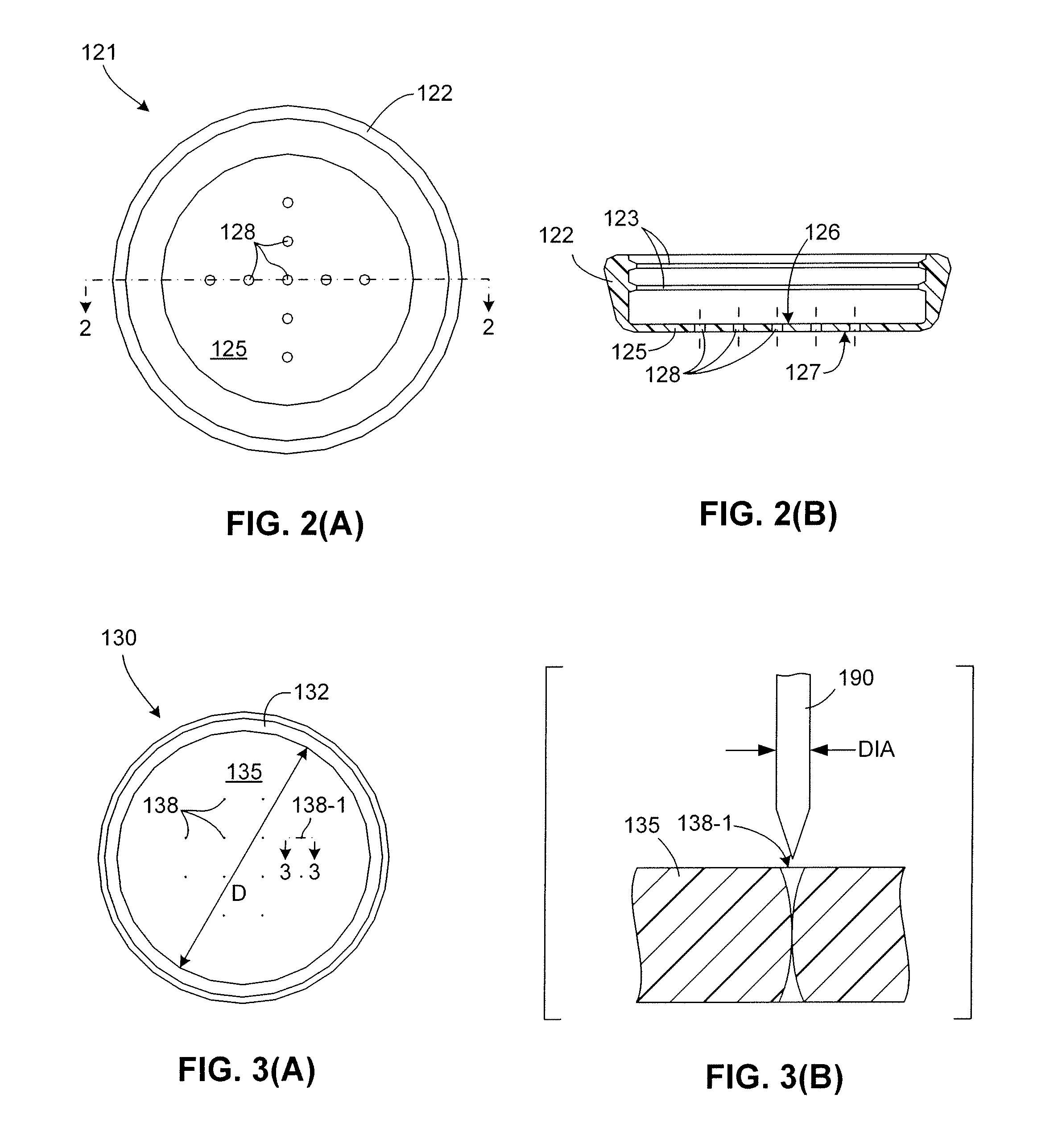

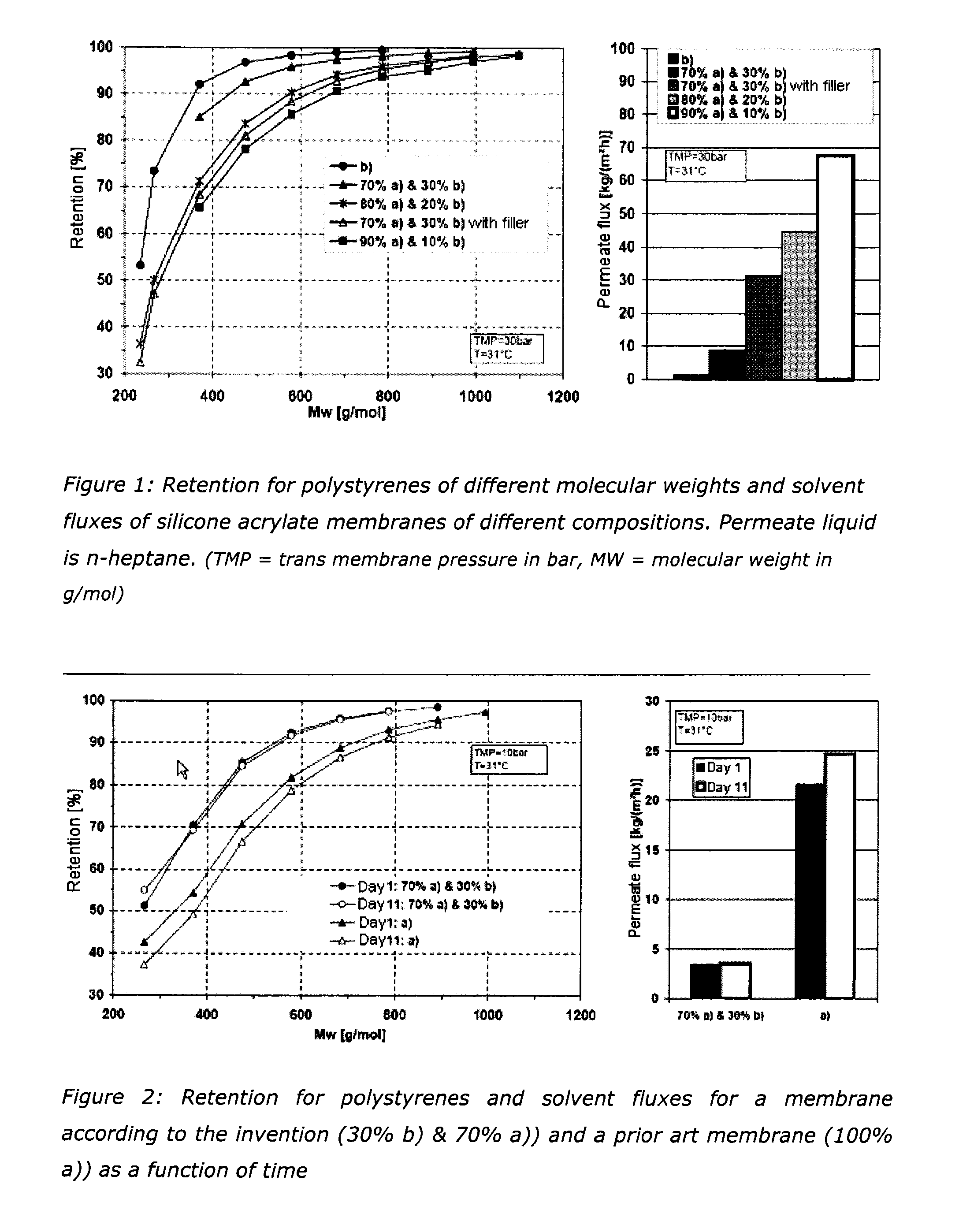

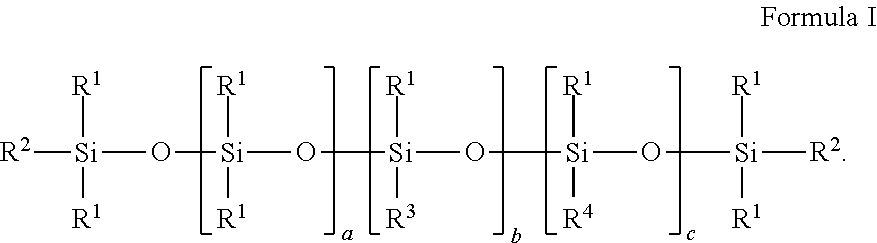

Composite silicone membranes of high separation efficiency

ActiveUS20120279922A1Reduce high tendency to swellingSuitable crosslinkingGas treatmentUltrafiltrationSilicone membraneMembrane layer

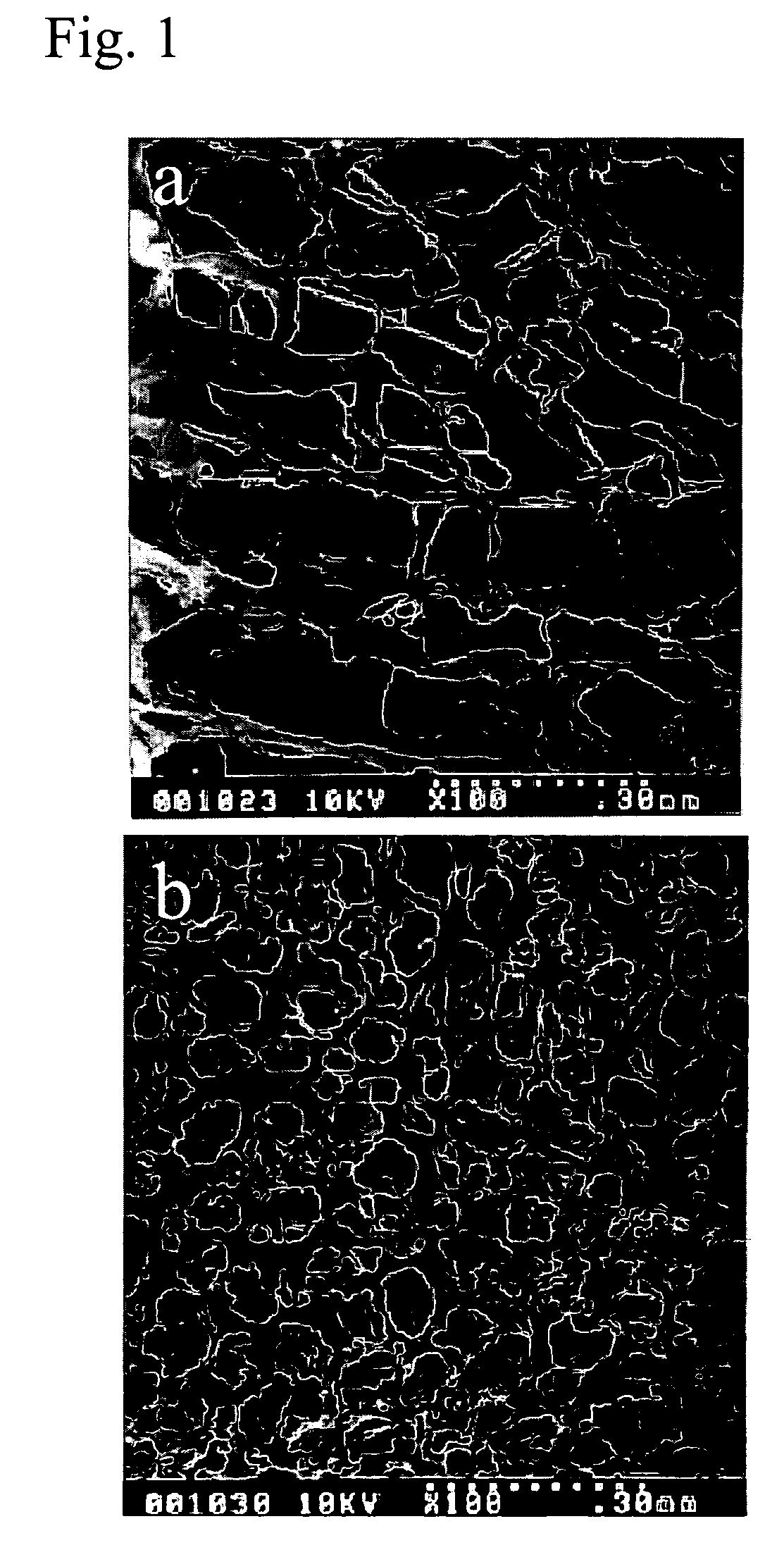

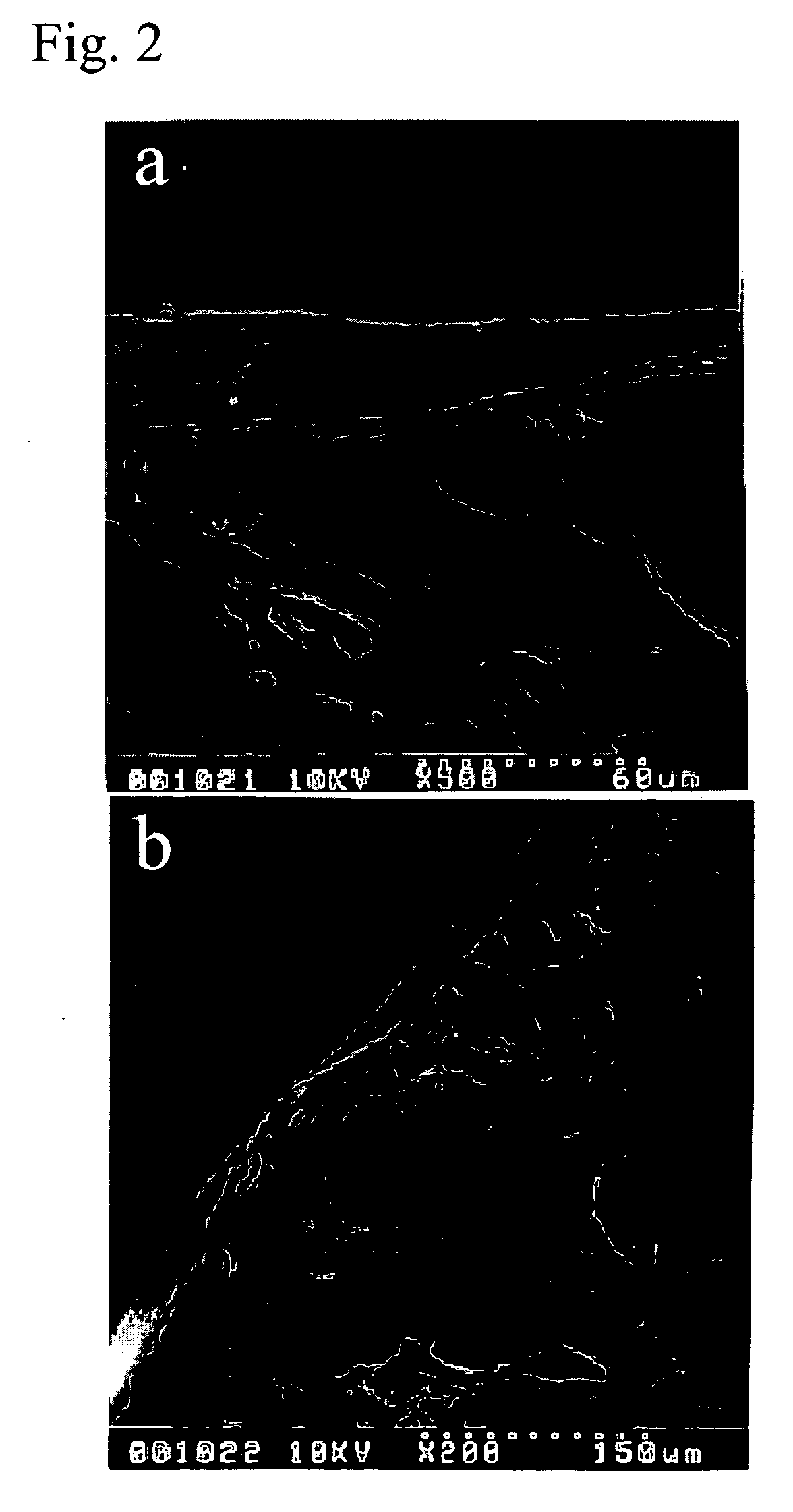

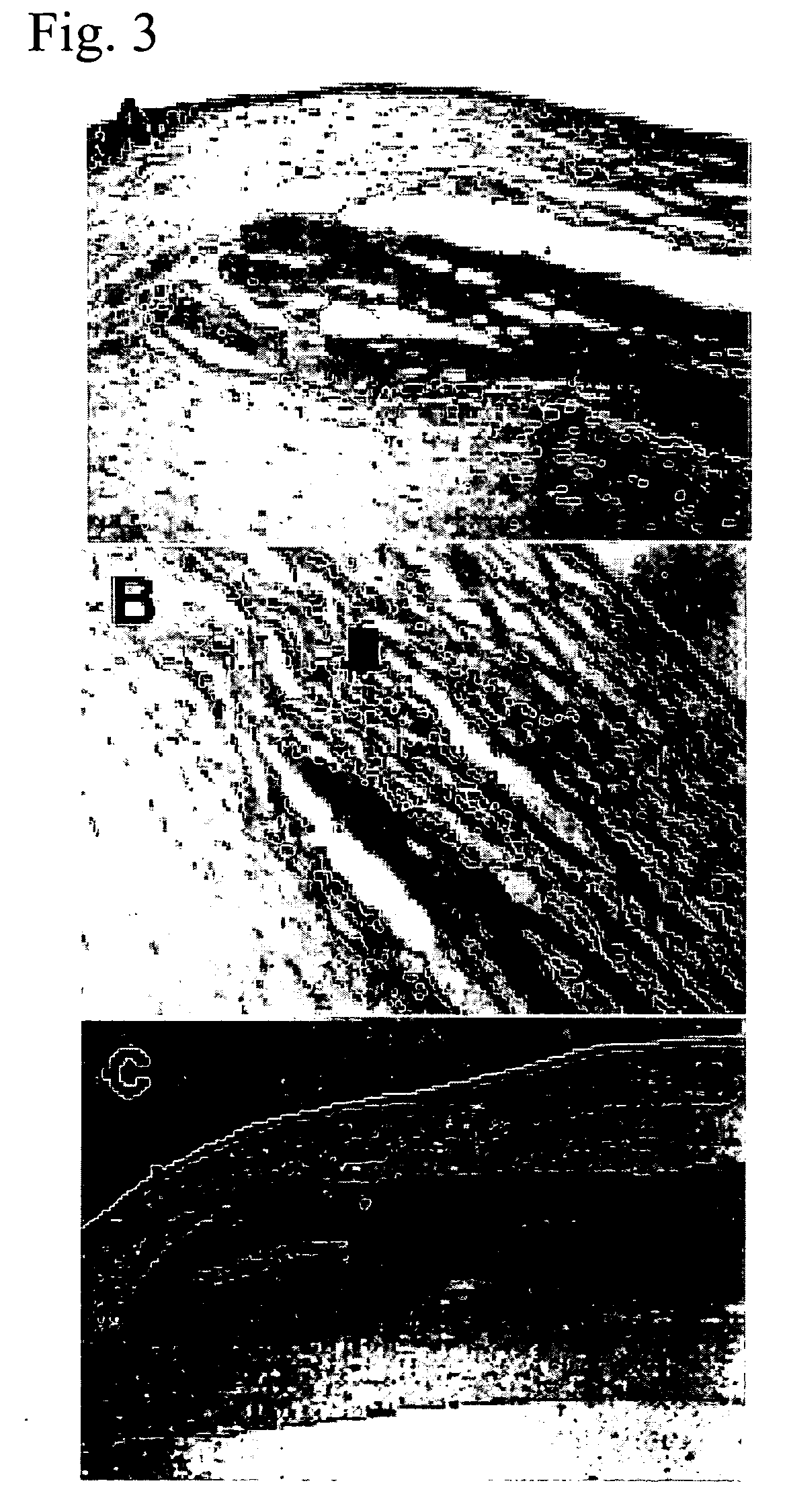

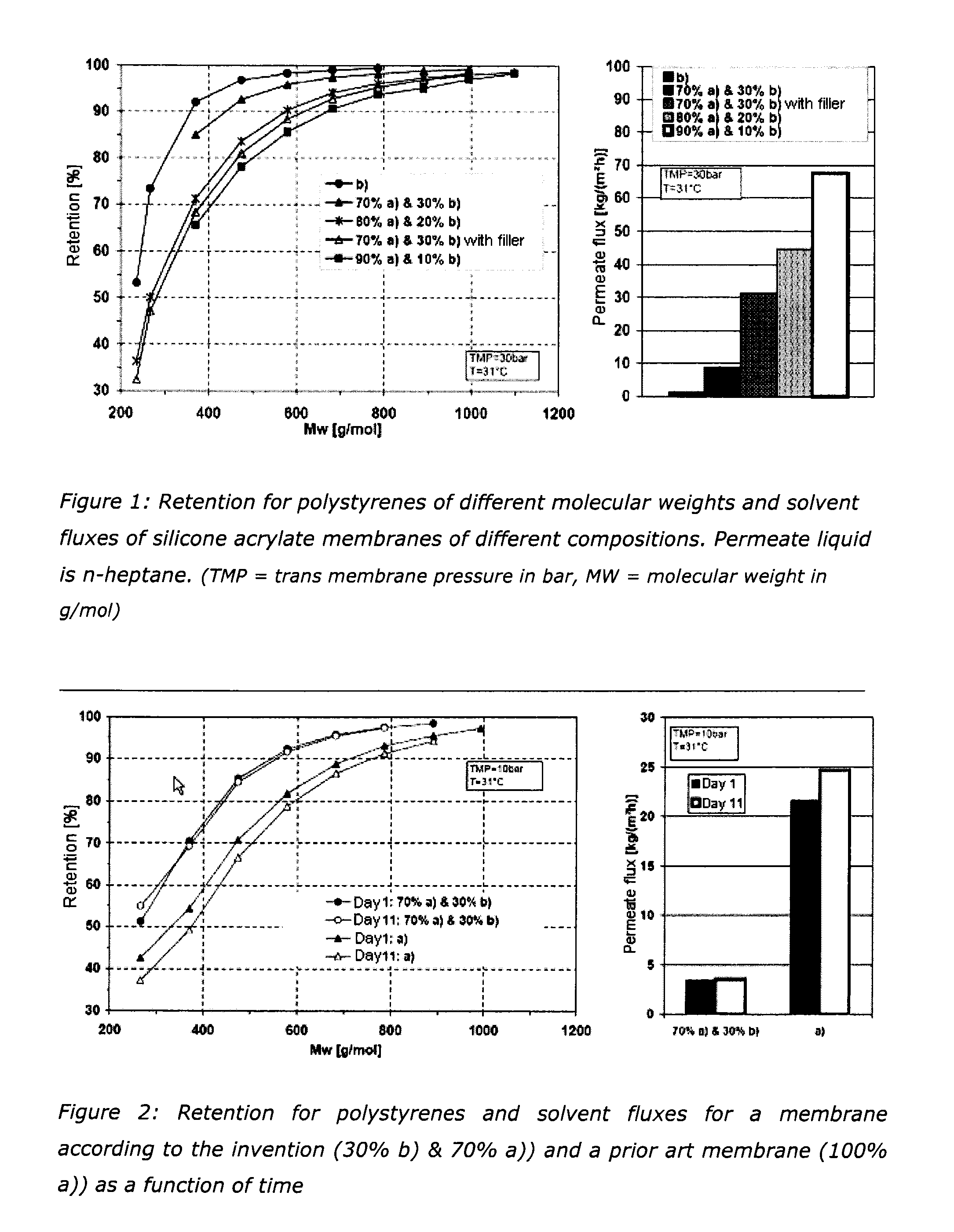

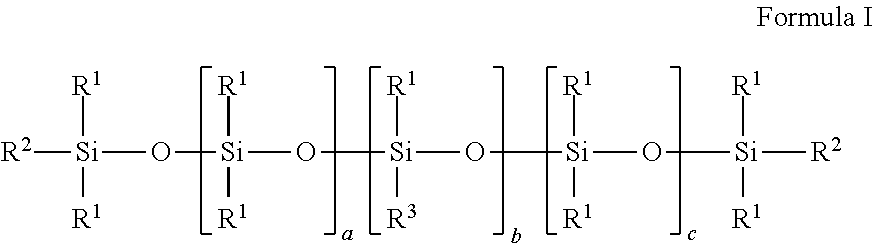

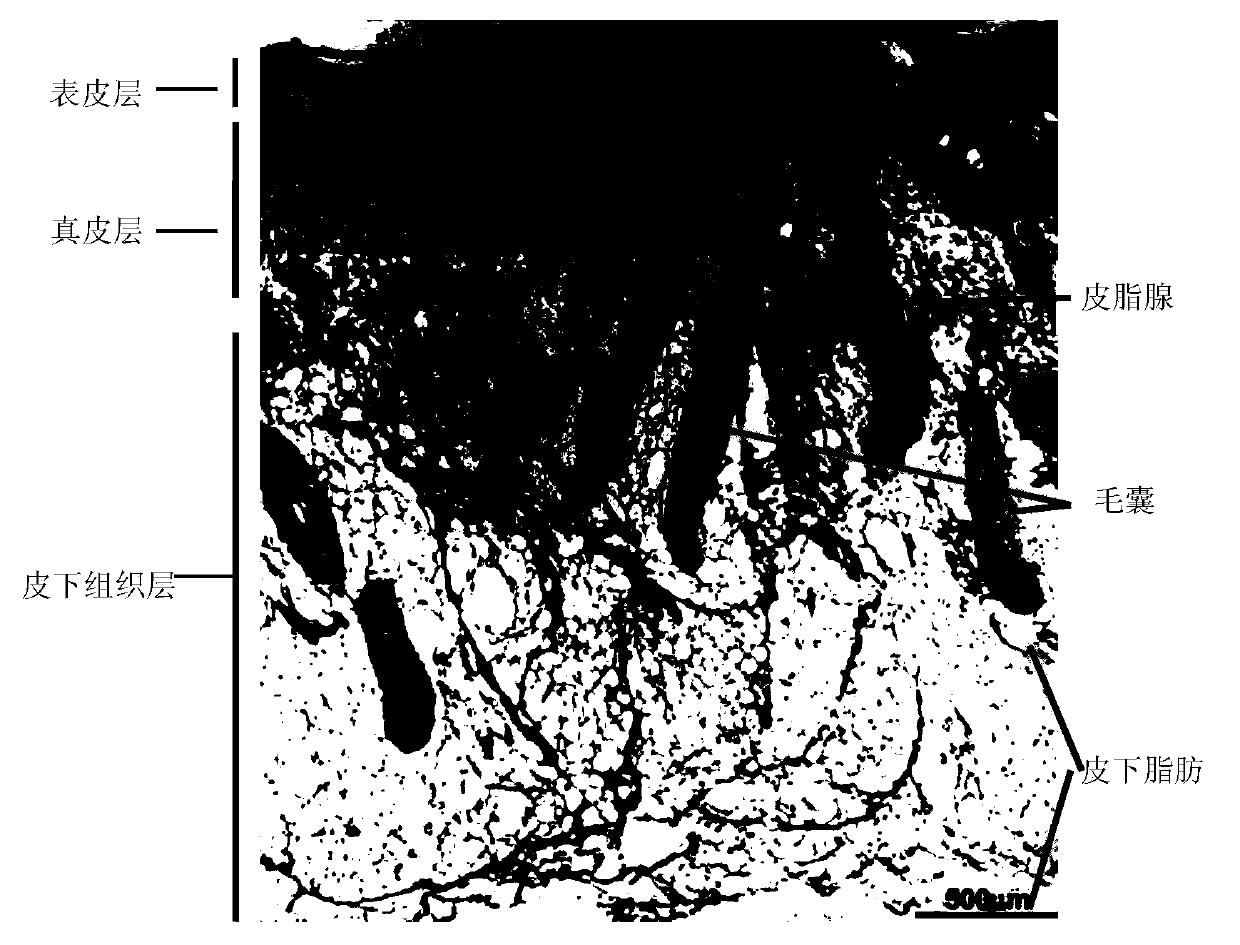

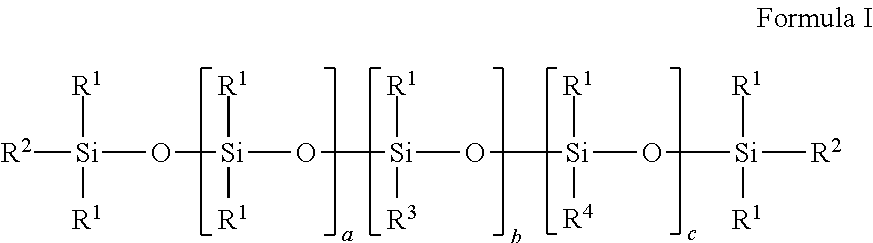

Composite membrane having a separating membrane layer characterized in that a separating membrane layer is produced by curing laterally modified silicone acrylates of the general Formula I

Owner:EVONIK OPERATIONS GMBH

Method for regenerating human intact skin tissue by use of in vitro cultured cells

ActiveCN103785064APromote wound healingTreat aging skinIn-vivo testing preparationsProsthesisDiseaseCuticle

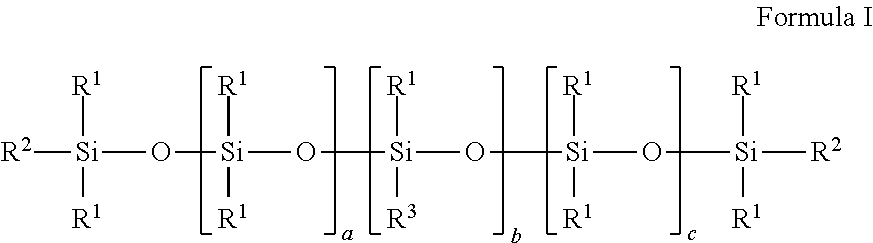

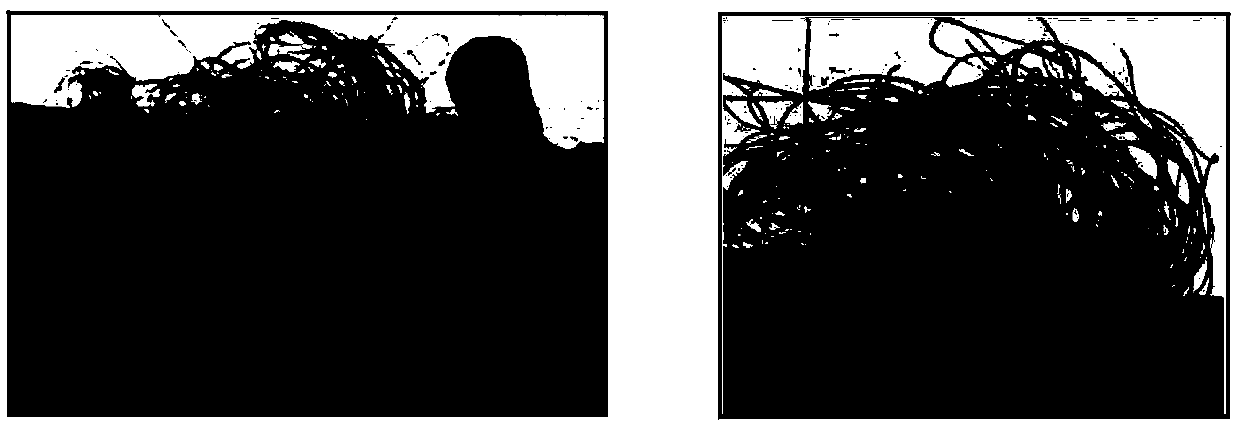

The invention discloses a skin model and application. The method comprises separately culturing epidermal cells and dermal cells derived from fetus scalp, newborn prepuce or adult scalp, and subculturing, wherein the used culture medium and culture method can maintain multiple functions of skin cells; separately digesting the cultured and proliferated multifunctional epidermal cells and dermal cells into single cells, and mixing to obtain suspension; transferring onto a semipermeable polymer or silica gel membrane substrate for incubation; transplanting cells on adhesive film to a receptor. The method can regenerate human intact functional skin and hair, the regenerated skin contains an epidermal layer, a dermal layer and a subcutaneous tissue as well as skin appendant organs. The skin model regenerated by the method disclosed by the invention can be used for study of human skin diseases, screening of skin drugs, and development of cell products for treating wound and other skin diseases.

Owner:JINAN PANSHENG BIOTECH

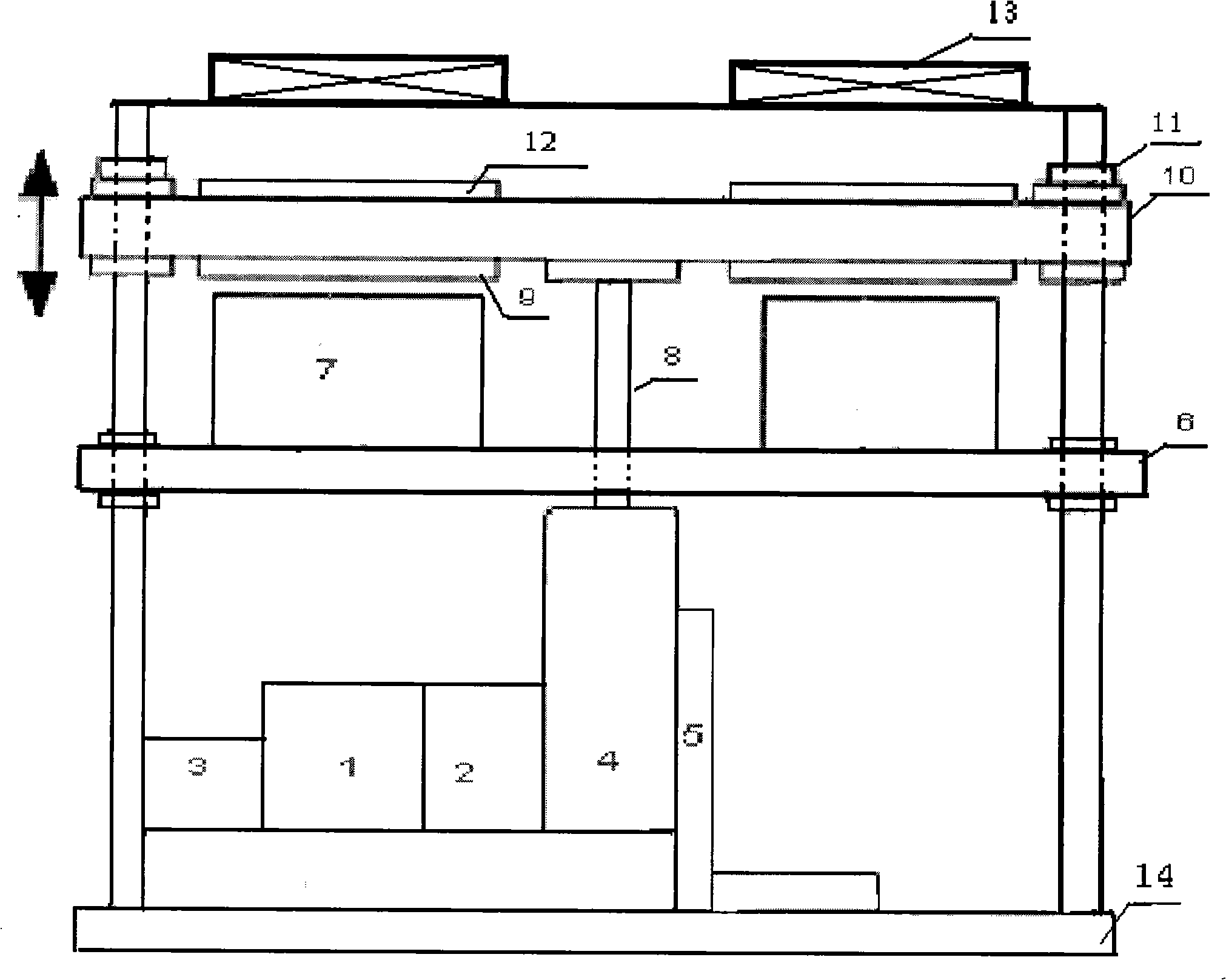

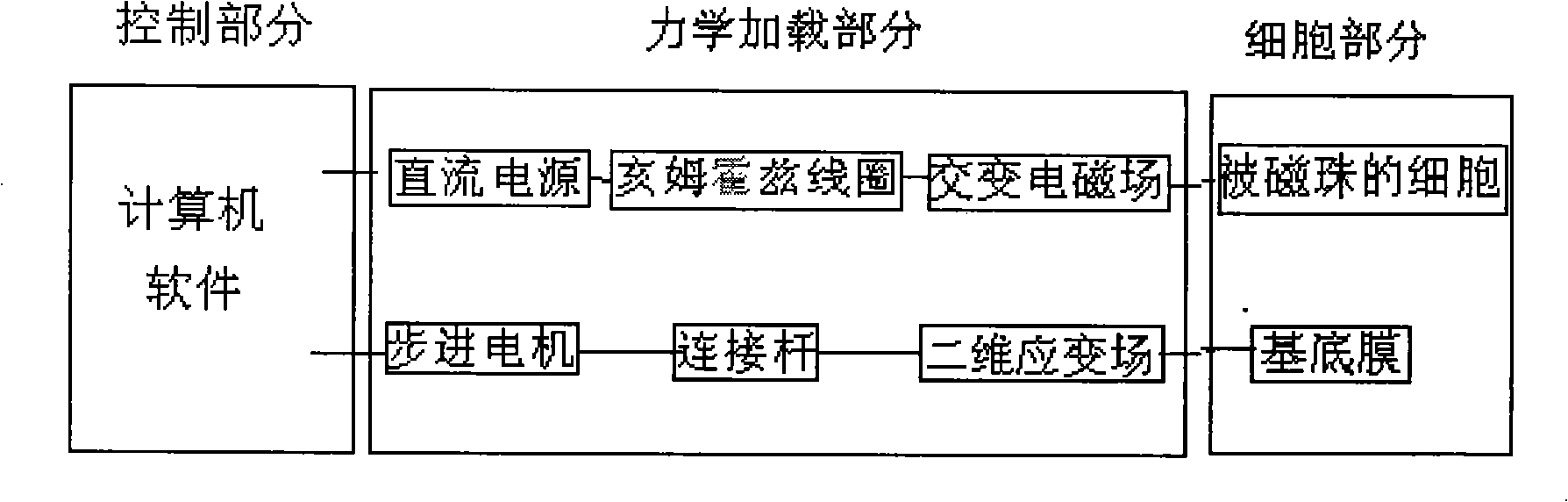

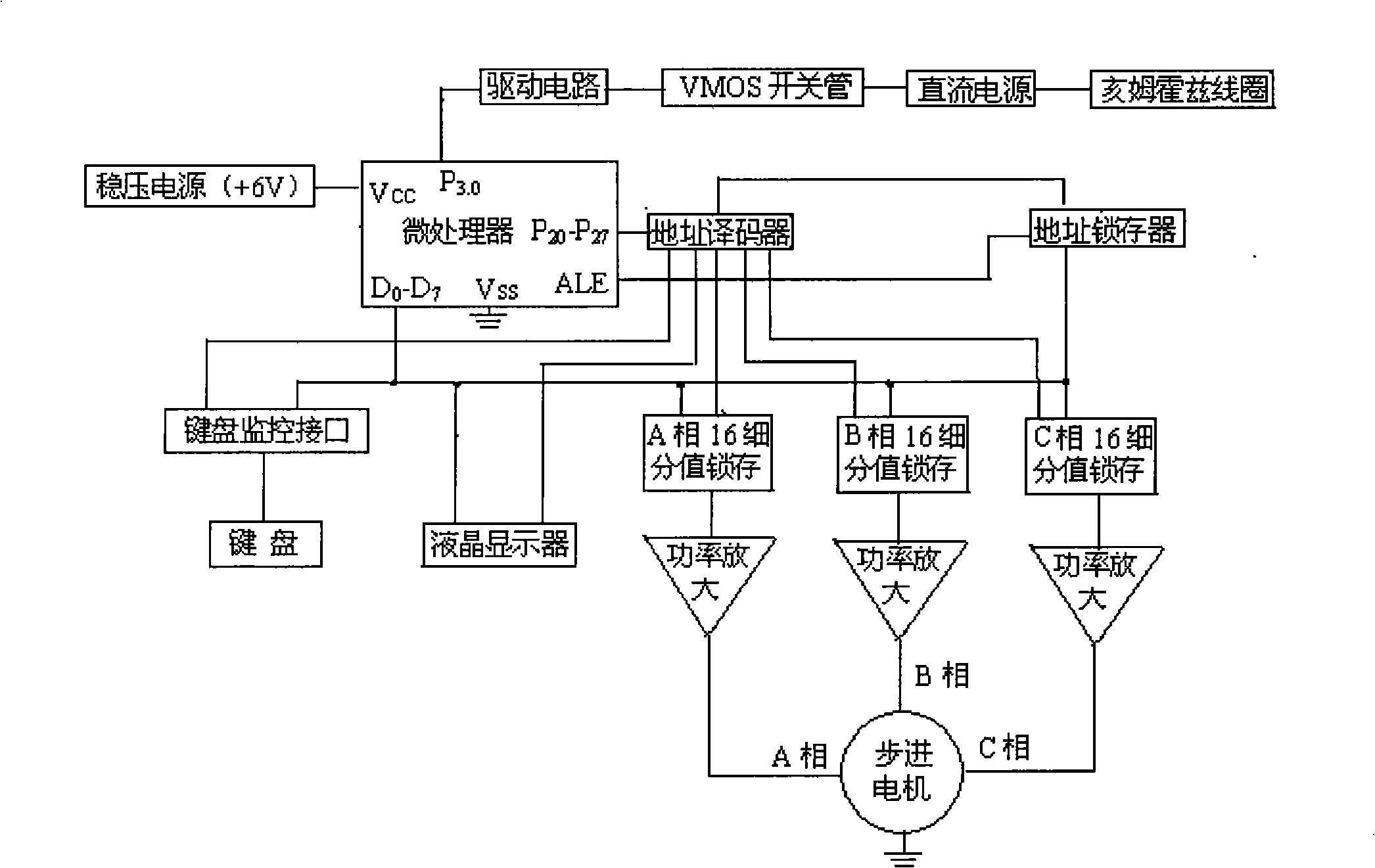

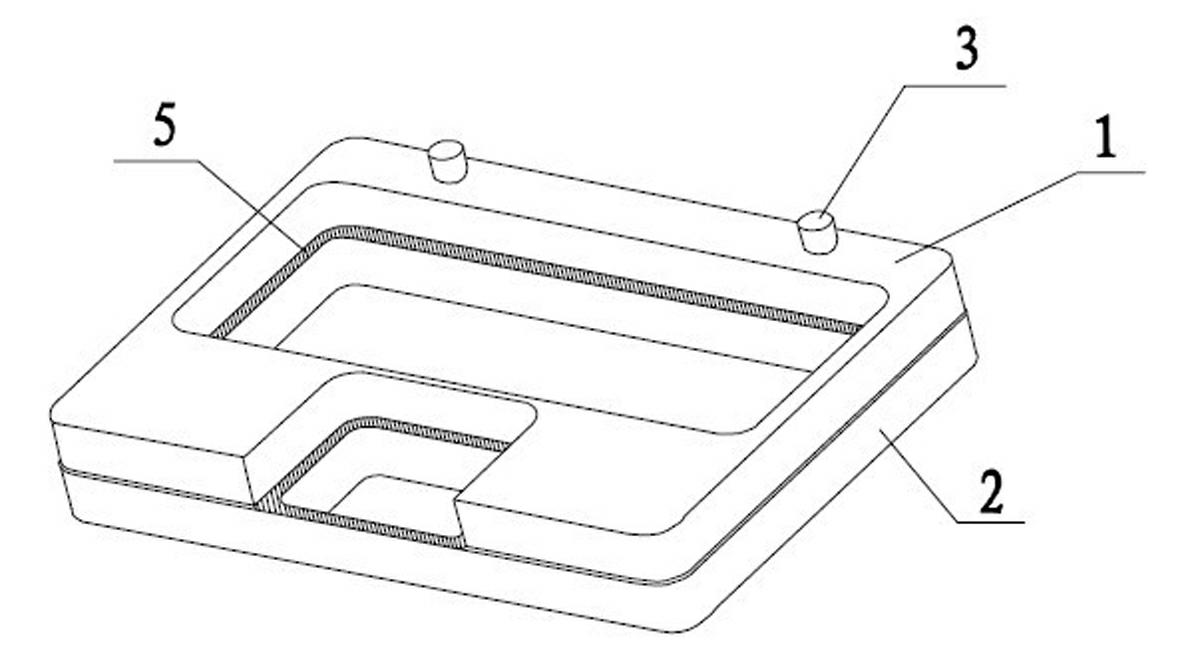

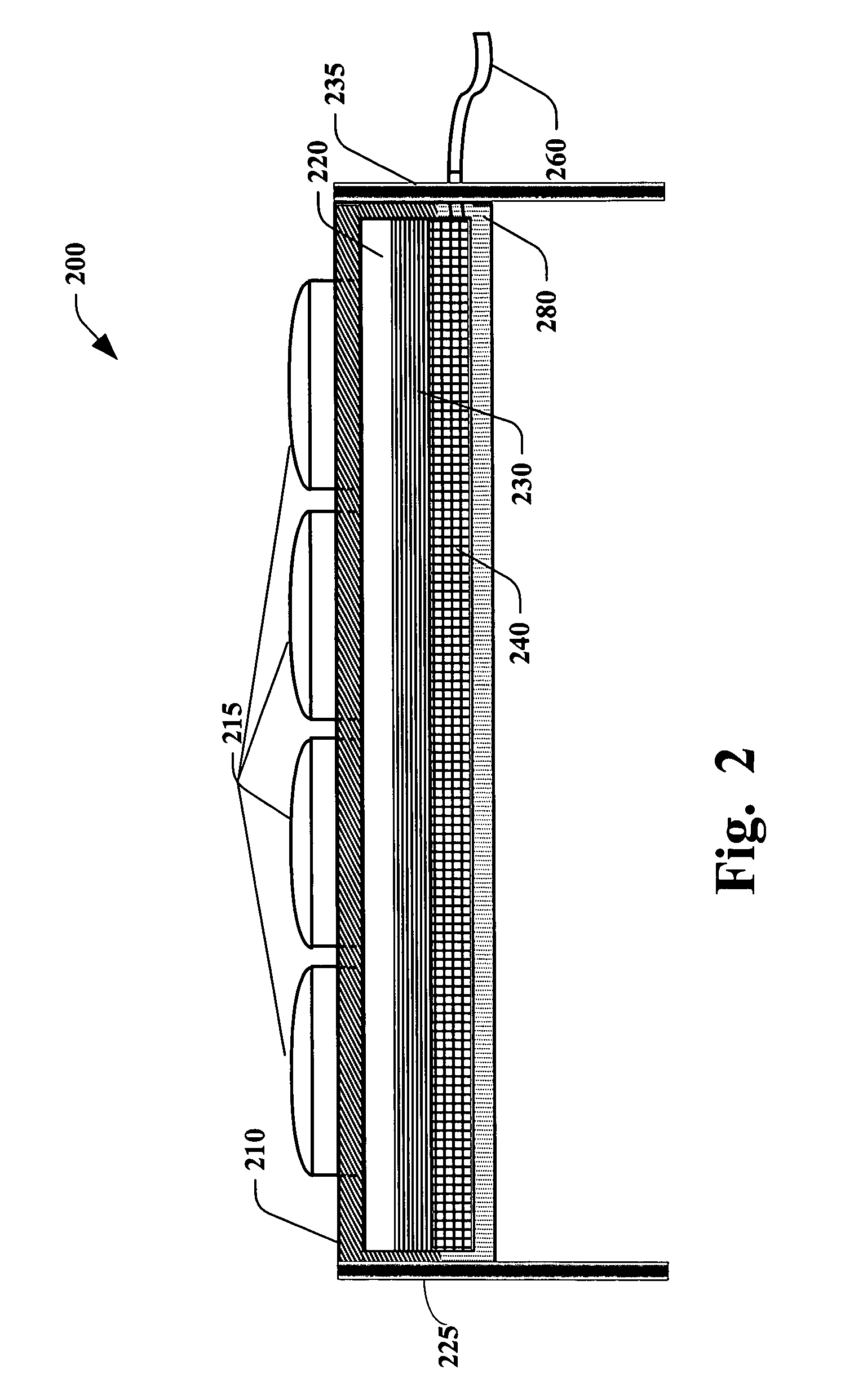

Cell three-dimensional mechanical loading unit

InactiveCN101298592AIncrease stretch areaIncreased adhesion areaTissue cultureElectrical/wave energy microorganism treatmentSilicone membraneMagnetic bead

The invention discloses a drawing and loading device for cells, which relates to a cellular mechanics loading device that belongs to the medical instrument. The drawing and loading device for cells consists of a control part, a mechanical part and an electromagnetic part, which is characterized in that: the cells are cultivated on an elastic silicon membrane, and circumferential-direction drawing and compressive loading are carried out for the cells through a dynamic system, meanwhile, magnetic bead collagen with ferroferric oxide enveloped is attached to the surfaces of the cells through integrin family, then alternating magnetic field is respectively loaded at an upper and a lower bottoms of a cell cultivating box, rendering the cells to be drawn under the magnetic force while being under the circumferential stress in a base strain field, so as to control the transformation of the cells along the axis Z and control the cell morphology. By simulating the borne mechanical stress of cells under physiological conditions, the drawing and loading device for cells can realize mechanical loading with different dimensions under different mechanical forces, and has the advantages of simple structure, convenient use, wide application and excellent reproducibility, etc.

Owner:CHONGQING UNIV

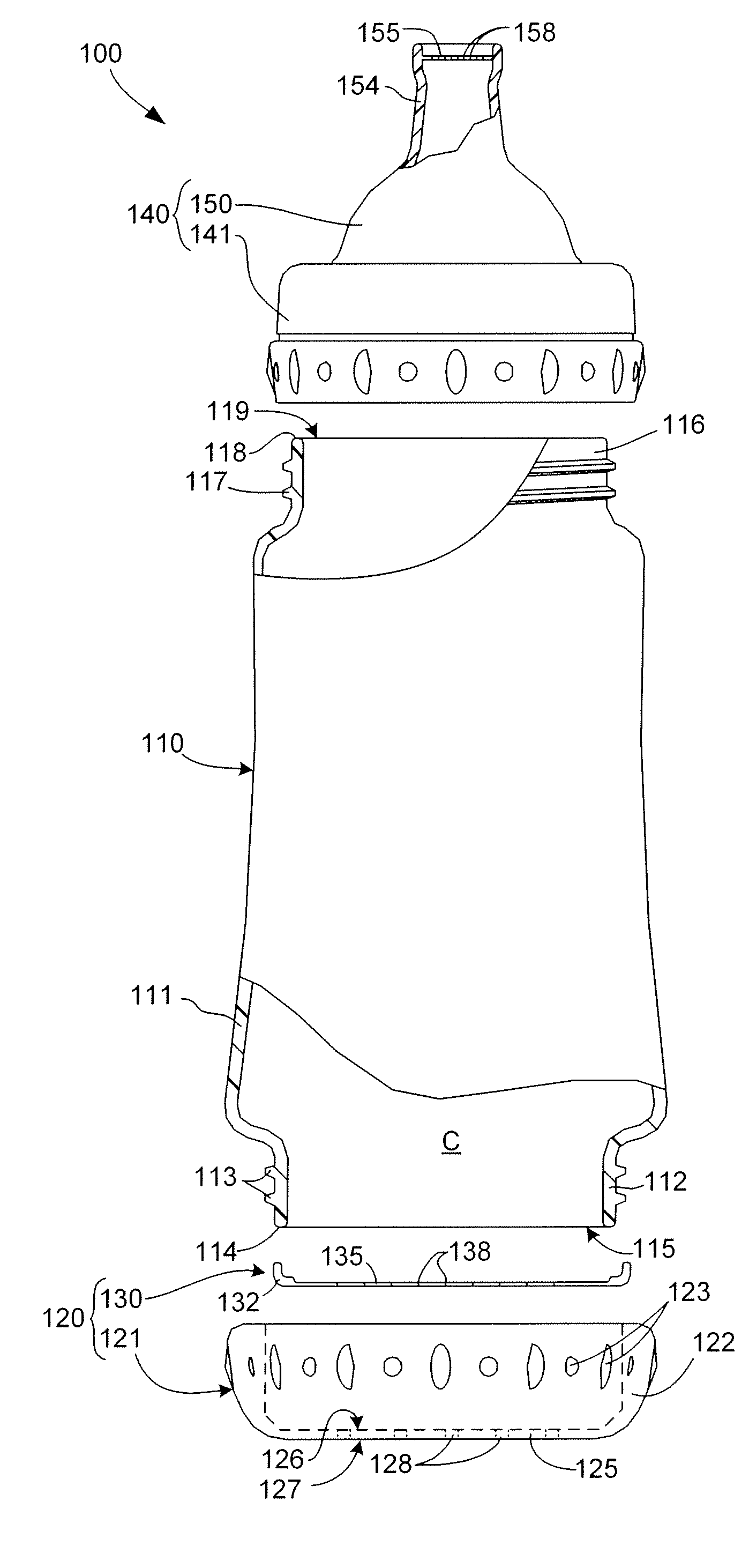

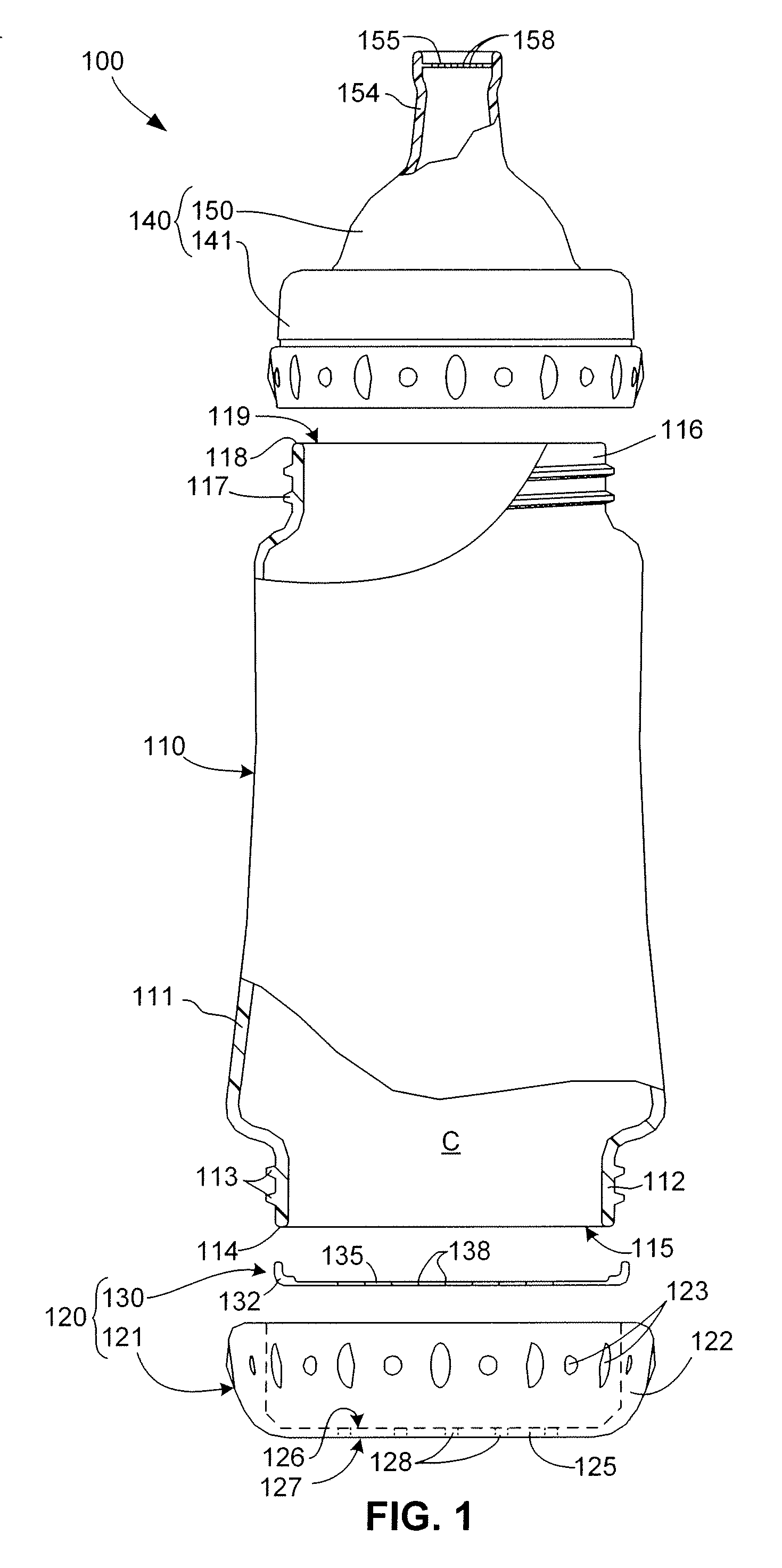

Beverage Container Vent Mechanism Including Perforated Elastic Membrane And Support Plate

InactiveUS20070181520A1Easy to manufactureEasy to operateFeeding-bottlesTeatsSilicone membraneEngineering

A beverage container assembly includes a thin, silicone membrane that is perforated with multiple pinholes and is mounted on a rigid support plate defining multiple vent holes. The silicone membrane rests against an inside surface of the support plate when the pressure inside the container is equal to or greater than the surrounding environment, and the pinholes remain closed to prevent beverage leakage. When beverage is drawn from the container, the resulting pressure differential causes the membrane to bend inward, which opens the pinholes to allow venting of air into the container. The membrane is formed at the end of an elongated silicone fluid containment member that forms a liner inside a container body.

Owner:MEDELA HLDG AG +1

Composite silicone membranes of high separation efficiency

ActiveUS9539549B2Reduce high tendency to swellingSuitable crosslinkingSemi-permeable membranesGas treatmentSilicone membranePolymer science

Owner:EVONIK OPERATIONS GMBH

Method Of Separating A Gas Using at Least One Membrane In Contact With An Organosilicon Fluid

ActiveUS20150190747A1Improve throughputReduce leakageMembranesSemi-permeable membranesSilicone membraneOrganosilicon

The present invention relates to a method of removing a gas from a mixture. The method includes contacting a silicone membrane with a feed mixture including at least a first gas component and contacting a second side of the membrane with an organosilicon sweep liquid, producing a retentate mixture depleted in the first gas component and an organosilicon sweep liquid enriched in the first gas component. The invention also provides methods of removing a gas from a liquid, and methods of regenerating and recycling an organosilicon sweep liquid.

Owner:DOW SILICONES CORP

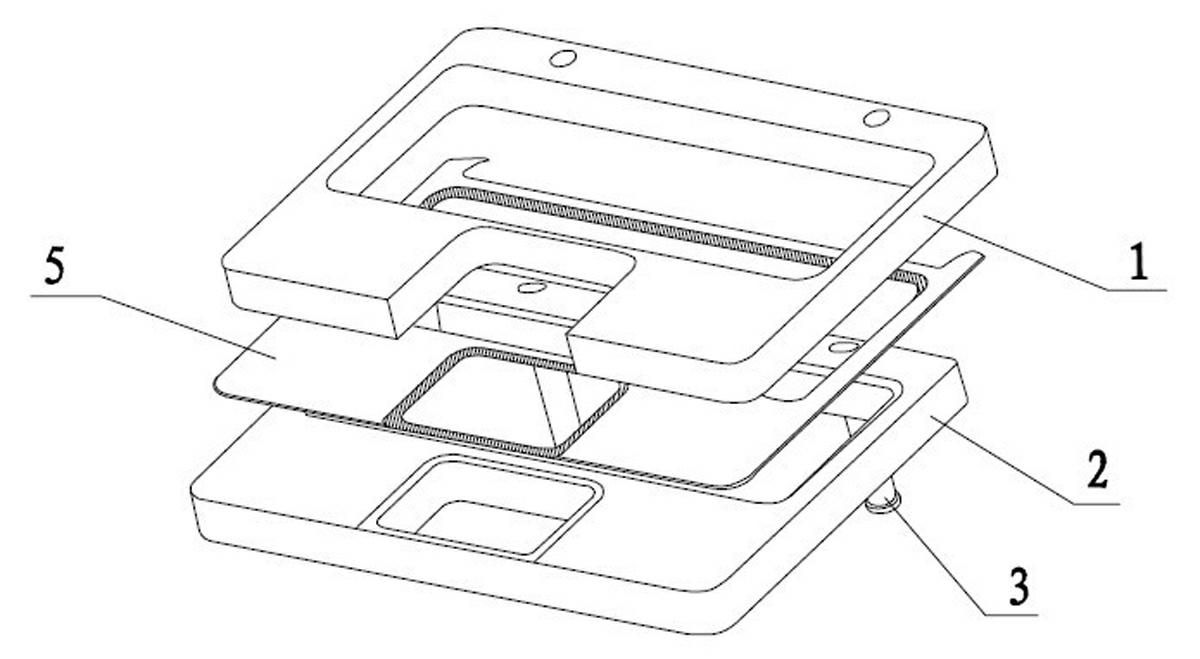

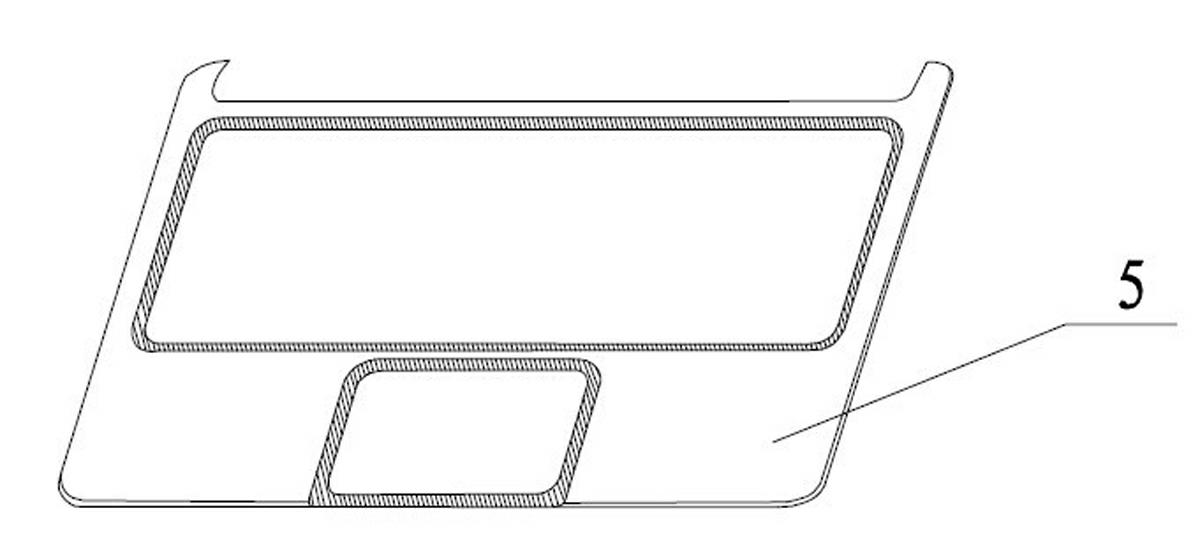

Flow Chamber for Disturbed Flow Loading of Co-Cultivated Cells

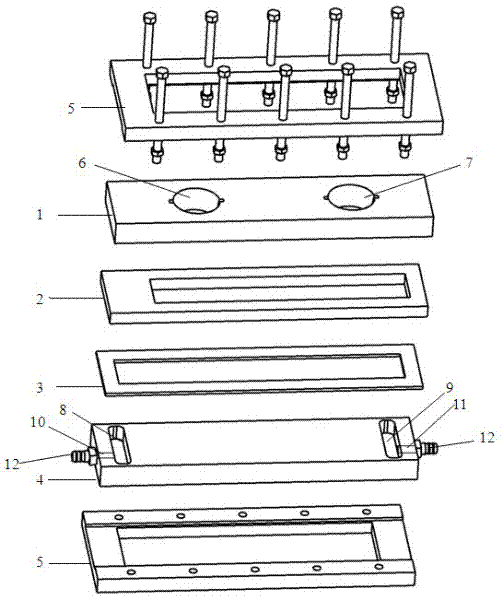

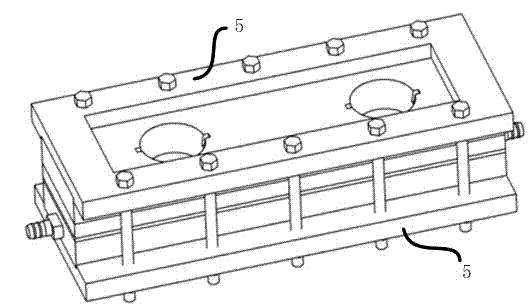

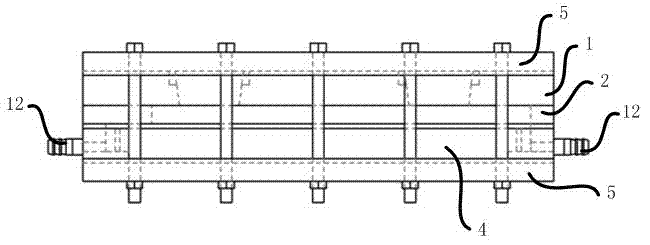

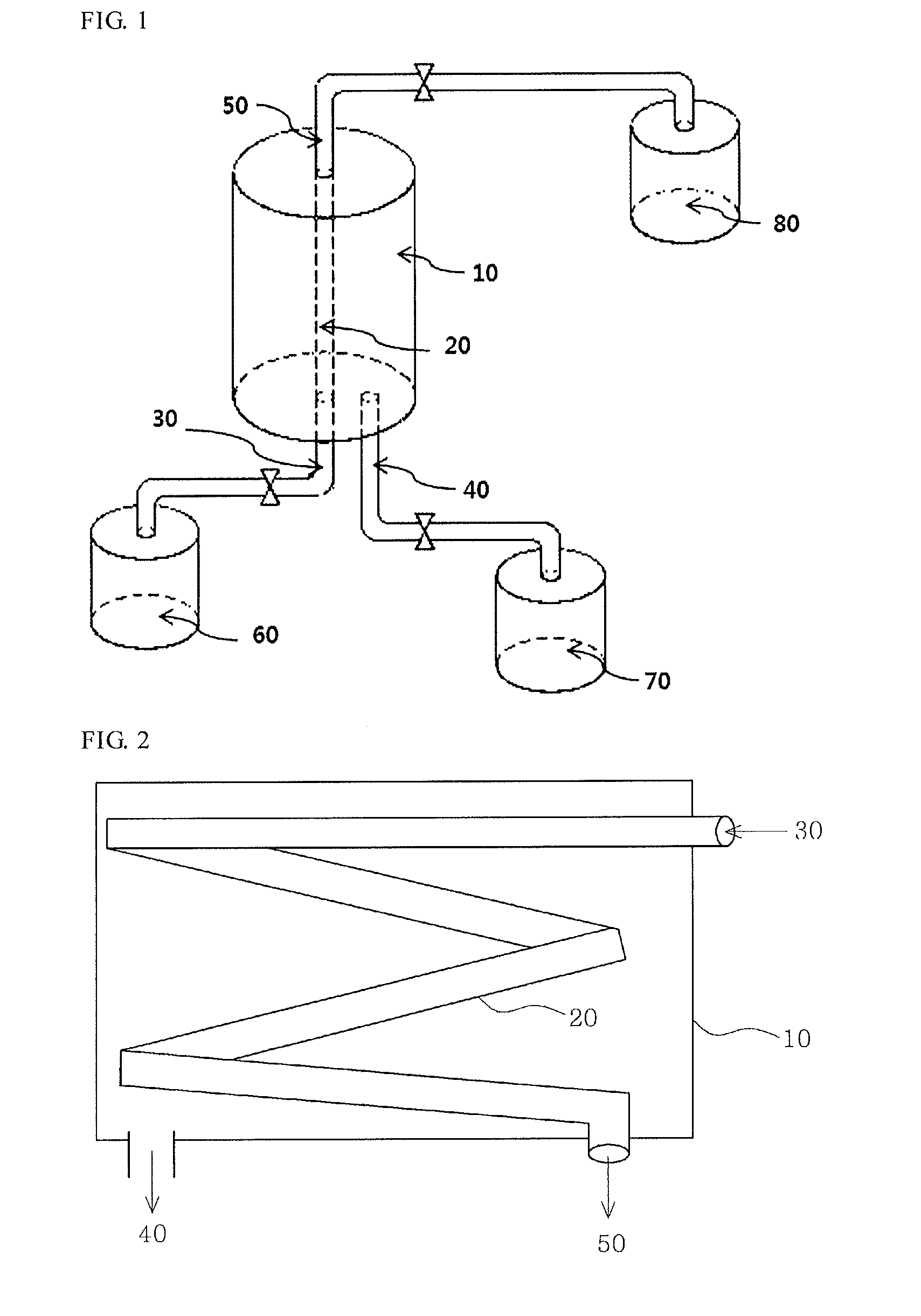

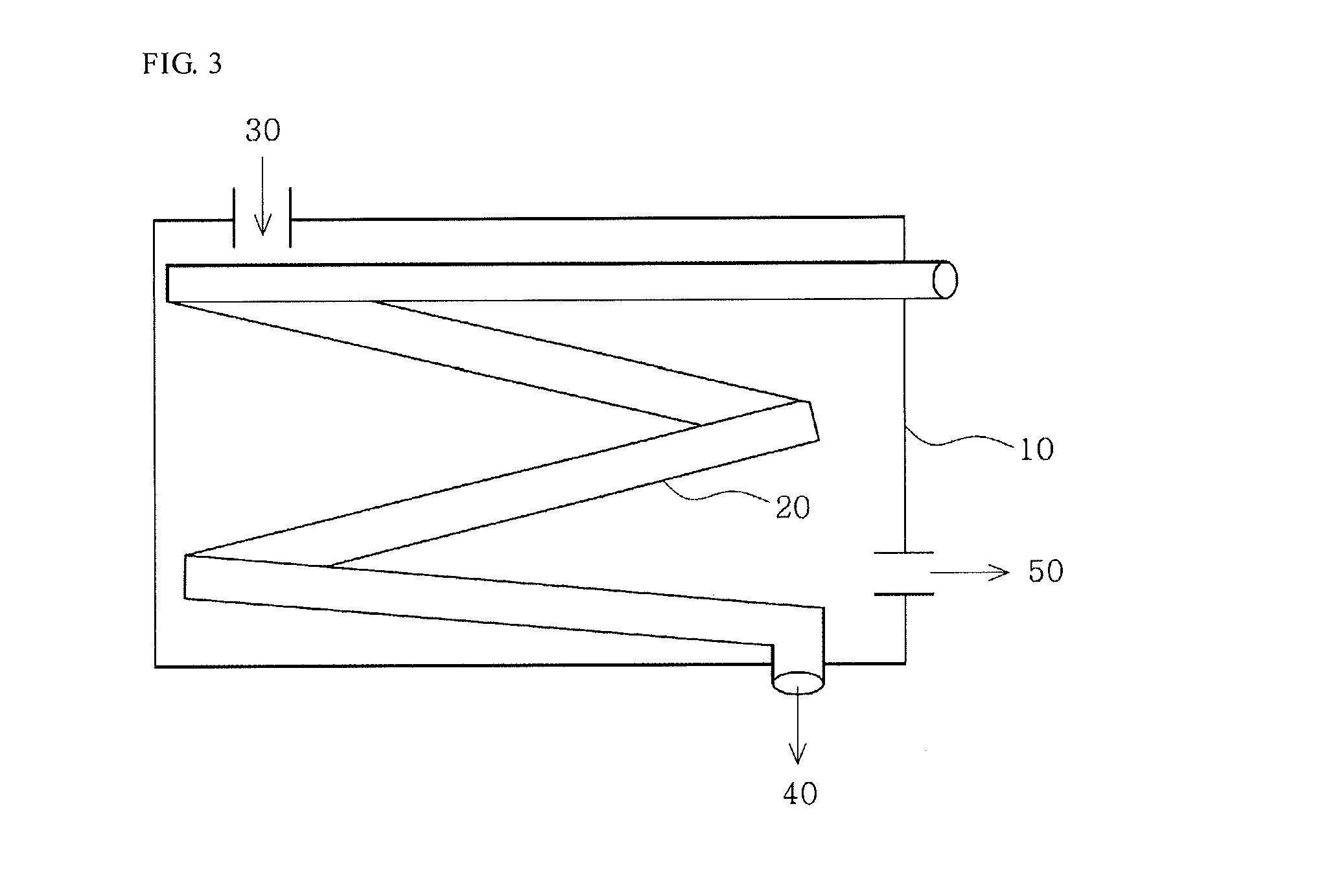

InactiveCN102296030AEasy to assembleEasy to useTissue/virus culture apparatusSilicone membraneSilicon membrane

The invention provides a flow chamber for loading disturbance flow on co-cultured cells, which comprises a polycarbonate upper plate, a polycarbonate middle plate, a medical silicon membrane, a polycarbonate lower plate and a stainless steel fastener. The polycarbonate upper plate is provided with two co-cultured placement holes; the polycarbonate lower plate comprises an inlet, an inlet fluid buffer slot, an outlet, an outlet fluid buffer slot and a metal joint; the middle of the polycarbonate middle plate is provided with one first rectangular cavity; the middle of the medical silicon membrane is provided with a second rectangular cavity; the inlet fluid buffer slot is communicated with the first rectangular cavity through the second rectangular cavity; and the inlet fluid buffer slot is positioned below the front end of the polycarbonate middle plate and is far away from the first rectangular cavity. In the invention, not only can the influence between two types of relative cells be considered, but also the disturbance and laminar flow can be simultaneously and respectively loaded on the co-cultured cells. The flow chamber is convenient to use, is very easy to disassemble and assemble and is easy to obtain the cells acted on by different flow fields for carrying out subsequent control study.

Owner:SHANGHAI JIAO TONG UNIV

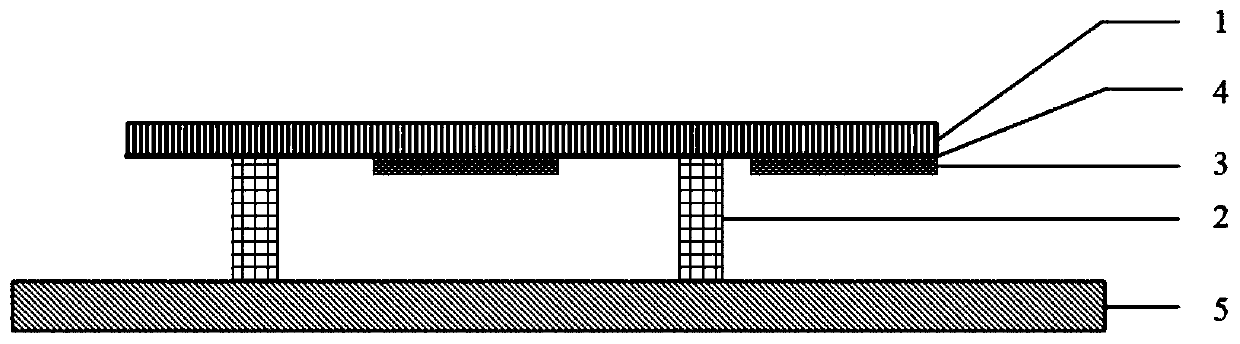

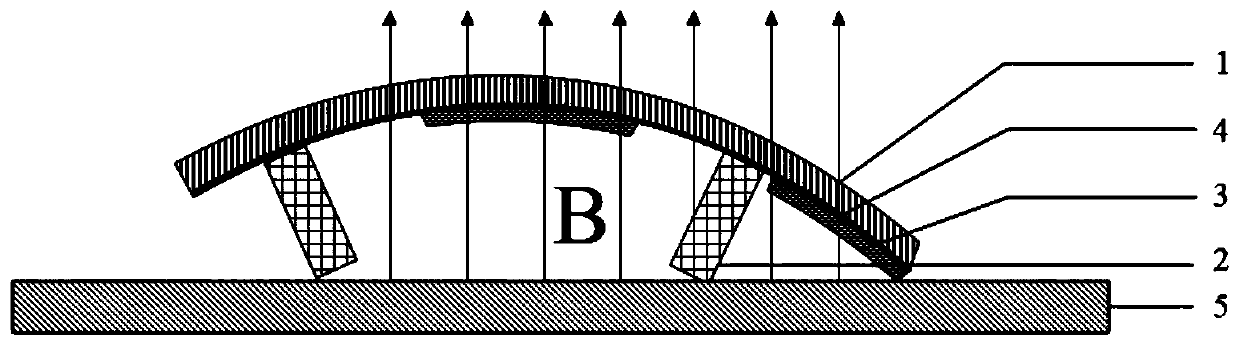

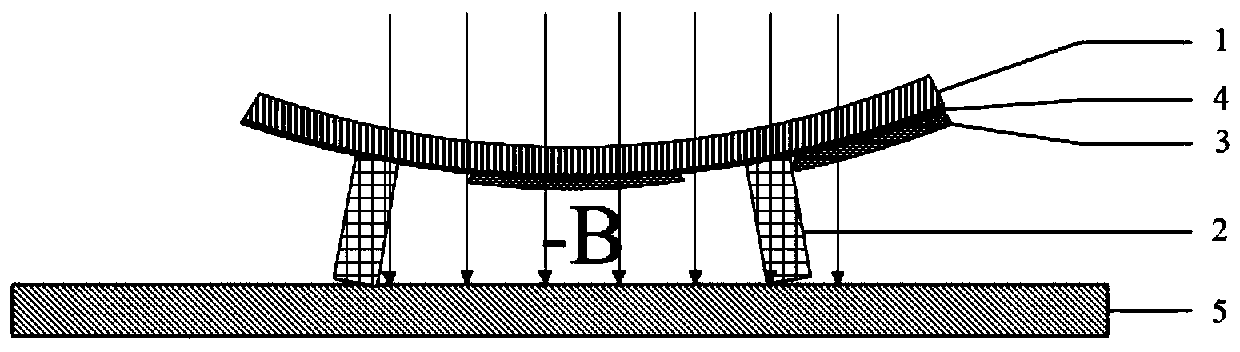

Inchworm bionic structure based on magnetic drive flexible film drivers and manufacturing process

ActiveCN111531528ARealize controllable driveAccurate and controllable manufacturingProgramme-controlled manipulatorSilicone membraneThin membrane

The invention relates to an inchworm bionic structure based on magnetic drive flexible film drivers and a manufacturing process. The structure comprises a silica gel film at the top layer, a foot structure is arranged below the silica gel film, the magnetic drive flexible film drivers are arranged below the head and abdomen of the silica gel film, the magnetic drive flexible film drivers and the foot structure are bonded with the silica gel film through an adhesive material, and the magnetic poles of the magnetic drive flexible film drivers at the head and the abdomen are opposite. The manufacturing process comprises the following steps of firstly preparing the silica gel film, then preparing the foot structure, then preparing the magnetic drive flexible thin film drivers, and finally preparing the inchworm bionic structure. According to the structure and the method, through the magnetic drive characteristic of the magnetic drive flexible thin film drivers, controllable driving of theinchworm bionic structure under adjustment and control of a magnetic field is achieved; and the manufacturing process of the structure adopts technological means based on photoetching, molding and spin coating, so that accurate and controllable manufacturing of part of structures is achieved, and the organic unification among simple driving conditions, rapid response and large deformation is achieved.

Owner:XI AN JIAOTONG UNIV

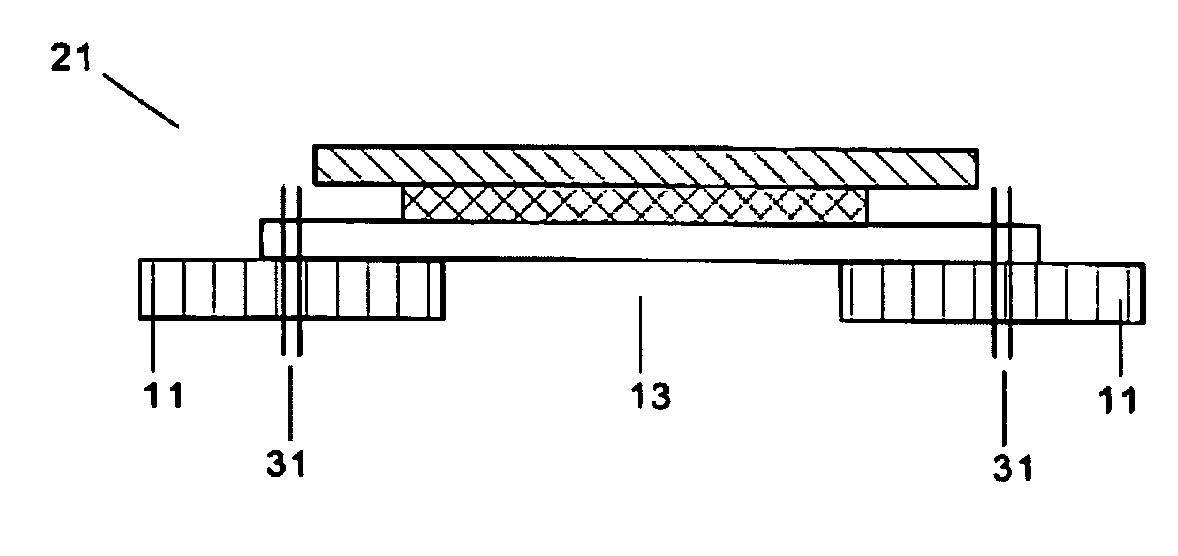

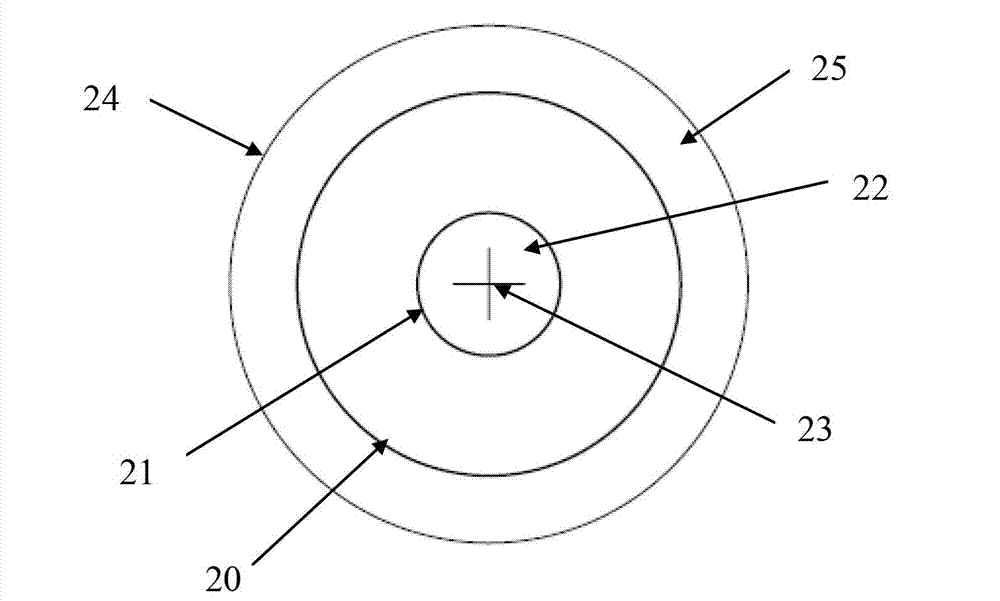

Sealing patch for the ventilation hole of a non-siliconized cushion of an airbag module

ActiveUS20090001697A1Convenience to mergePedestrian/occupant safety arrangementBuilding constructionsInternal pressureSilicone membrane

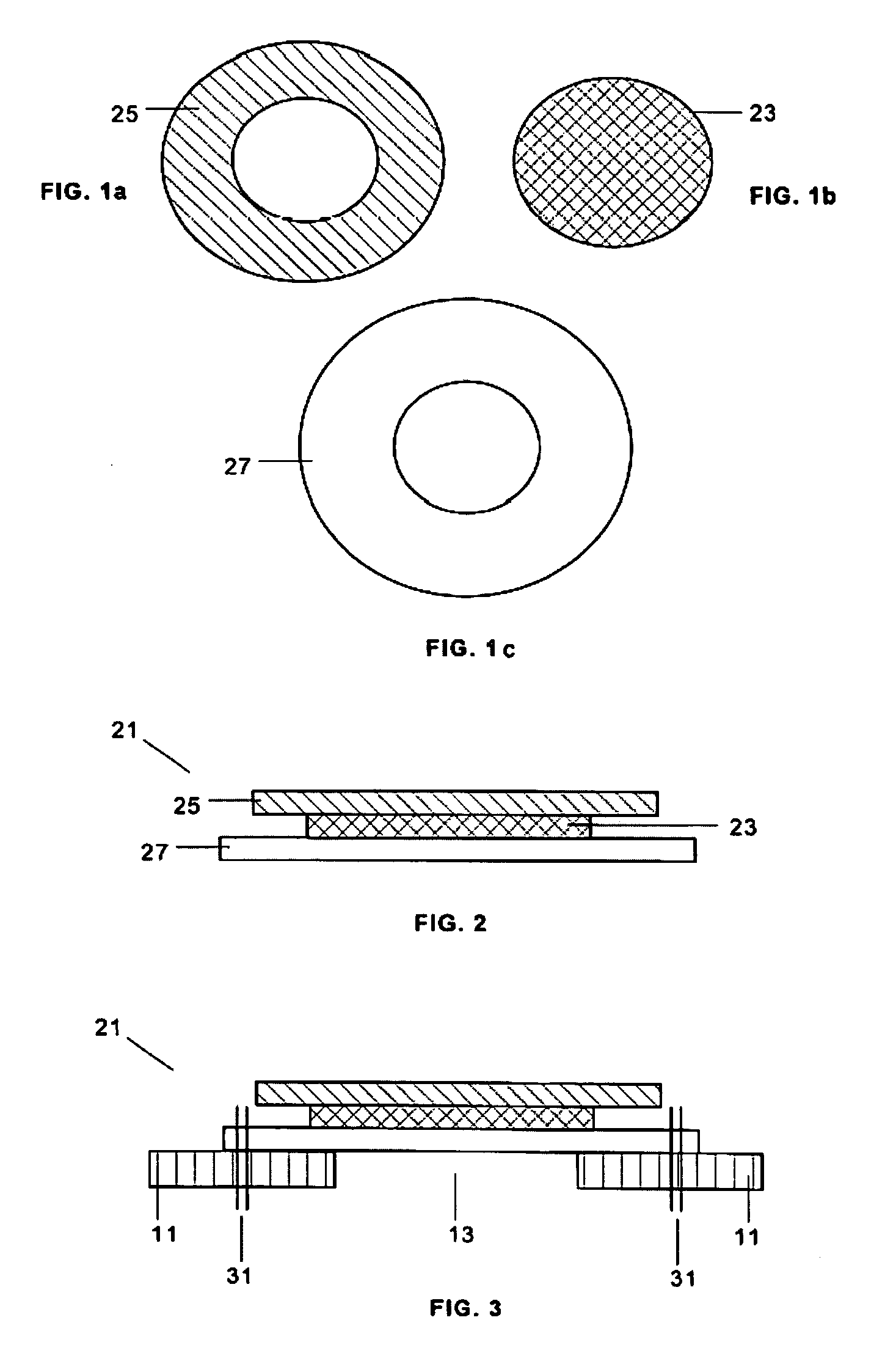

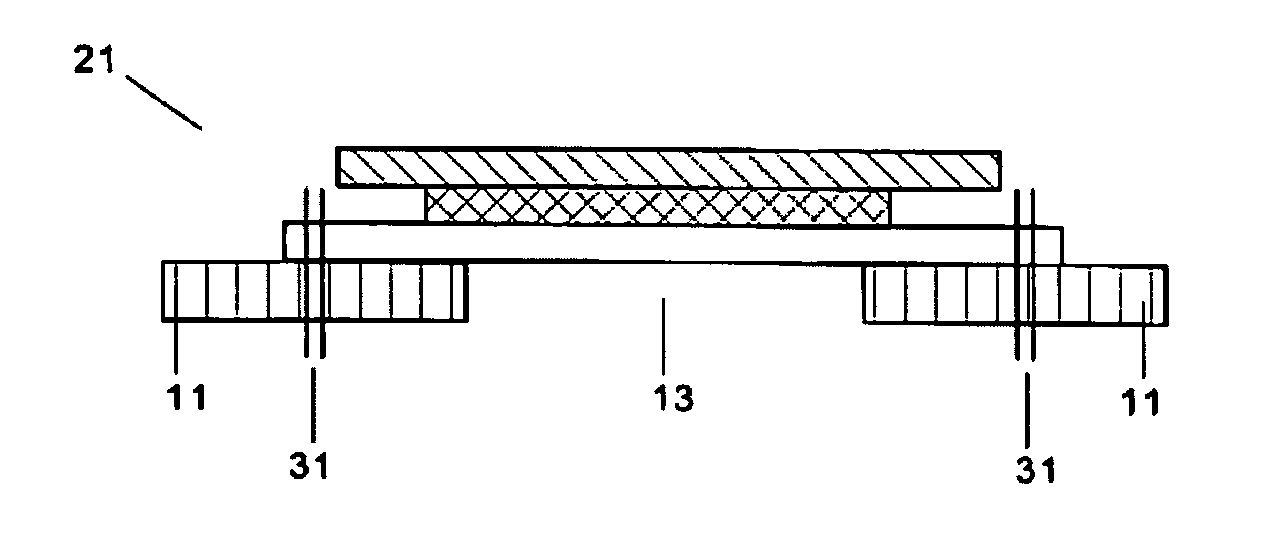

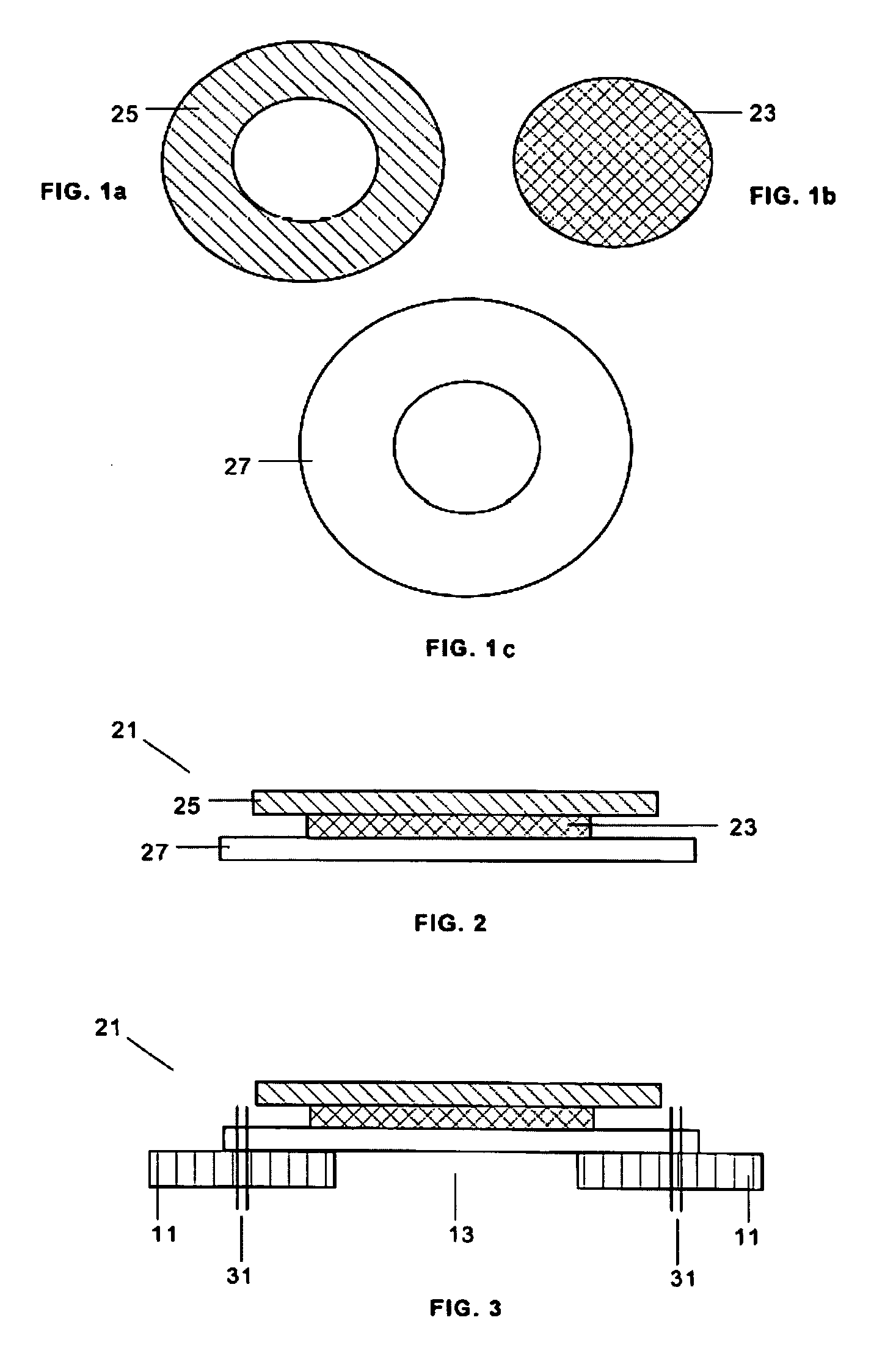

The invention relates to an airbag module for protecting an occupant of a vehicle in the event of a collision, comprising a cushion (11) that can expand with the gas provided by a generator with at least one ventilation hole (13) sealed with a patch (21) including a silicone membrane (23) intended to break due to the effect of the internal pressure in the cushion (11) so as to allow gas discharge, in which the fabric of the cushion (11) does not have a silicone coating, the patch (21) is formed by said membrane (23) joined at its edges to two pieces (25, 27) of fabric and fixed to the cushion (11) by means of a seam (31). The invention also comprises a process for manufacturing the cushion (11).

Owner:DALPHI METAL ESPANA

Device for separating carbon dioxide using silicone separation film and method for manufacturing same

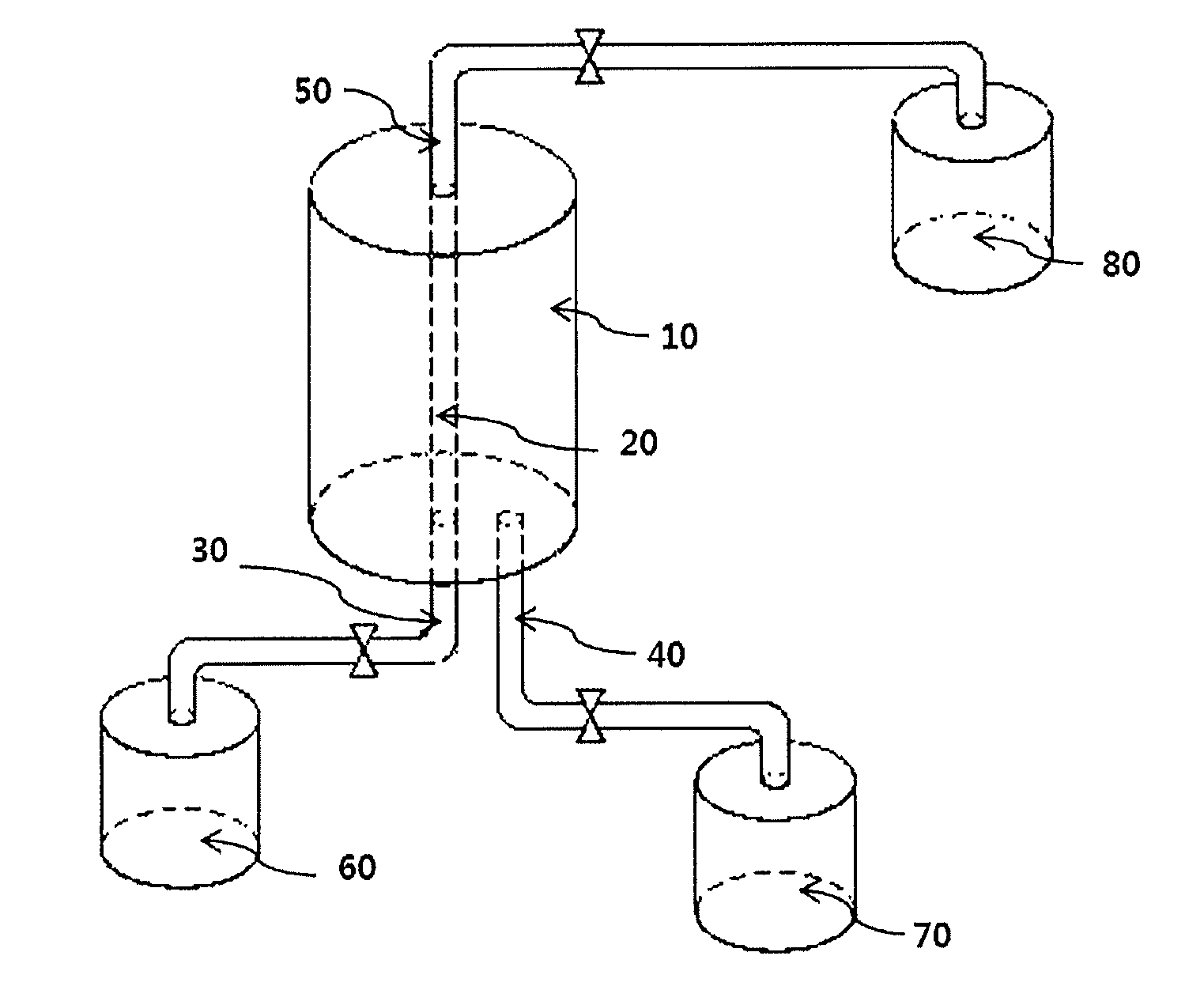

ActiveUS20160059181A1Avoid large pressure differencesSimple methodSemi-permeable membranesGas treatmentSilicone membraneProduct gas

Provided are an apparatus for separating and collecting carbon dioxide and a method of separating carbon dioxide, and more particularly, an apparatus and method of selectively separating carbon dioxide from a byproduct gas using a difference in negative pressure and a difference in carbon dioxide concentration between the inside of a separator, which is made of a ceramic-coated porous silicone membrane and in which the byproduct gas flows, and the outside of the separator in which carbon dioxide is collected.

Owner:ARSTROMA CO LTD

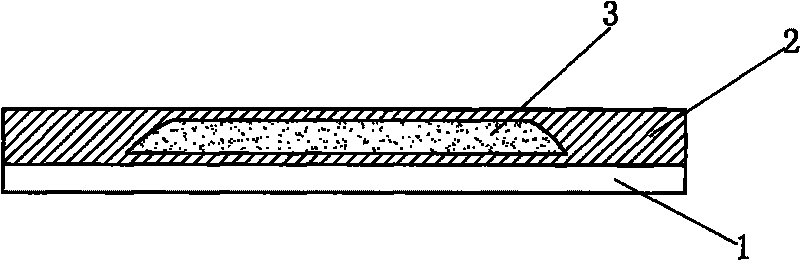

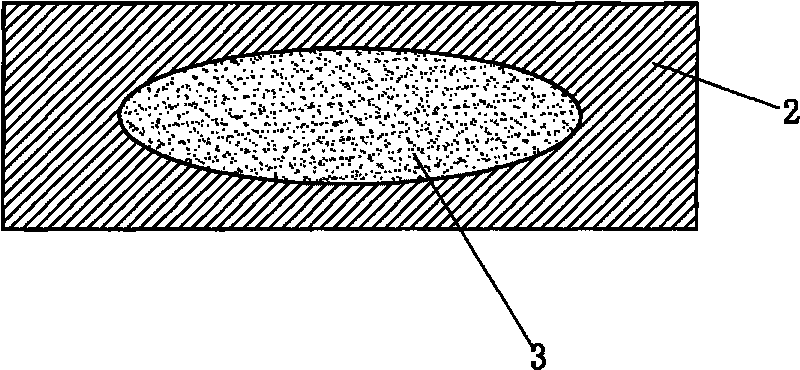

Drug-reservoir type scar-removing silicone gel paster and preparation method thereof

InactiveCN101756941AEasy to prepareEasy to operatePharmaceutical non-active ingredientsDermatological disorderSilicone membraneSilicone Gels

The invention relates to a drug-reservoir type scar-removing silicone gel paster and a preparation method thereof. The drug-reservoir type scar-removing silicone gel paster is characterized by comprising a silicone membrane and a silicone gel layer, wherein a drug reservoir is arranged in the silicone gel layer, and the inner part of the drug reservoir contains drugs and organic silicon polymer mixed liquid. The drug reservoir is directly arranged in the silicone gel layer, so the drug-reservoir type scar-removing silicone gel paster solves the problem that active ingredients in the drugs are isolated by the silicone membrane to cause macromolecular drugs to difficultly penetrate. The drugs in the drug-reservoir can better penetrate the silicone gel layer and play a role of treatment for scars, so that the paster shortens the treatment cycle and increases the treatment effect for the scars. In addition, the drug-reservoir type scar-removing silicone gel paster has simple preparation method, does not need complex molding equipment and is easy to produce and operate.

Owner:云南白药集团无锡药业有限公司

Graphite sheet material preparation method

InactiveCN104827591AReduce processing stepsImprove competitive advantageFine working devicesColloidal silicaSilicone membrane

The invention relates to a graphite sheet material preparation method comprising the following steps that the traces of a graphite shape are formed by S50021-50 material through punching so that graphite alignment and fitting are facilitated; graphite material is adhered on a weak adhesive silica membrane by a manual rotary adhering mode so as to be changed into the coiled material state; a graphite mould is cut into fixed shapes by using plane blade hole sleeving lines, and then double-sided adhesive tape fitting motion is performed; hole positioning transferring is performed; a single-sided adhesive tape and a bearing membrane and an underlying membrane are fit; ear and tearing hand mould cutting is performed; internal holes are formed via punching through a 420 mould cutting machine, the cutter faces S7502L-25B, the holes are wholly cut, and waste material of the internal holes is punched to the internal part of the machine to be discharged via a hardware punching mould; peripheral formation is performed, the cutter faces S7502L-25B in mould cutting, cutting is performed at the upper half of 50T004 by all the cutter lines, and a large coil is retreated; waste of the machine is discharged, contour waste material of the product is removed to a material collecting shaft in a compound machine through a scraper; and independent cut sheets are formed through cutting. The preparation method is high in productivity and qualification rate.

Owner:SUZHOU SHIYOUJIA ELECTRONICS TECH

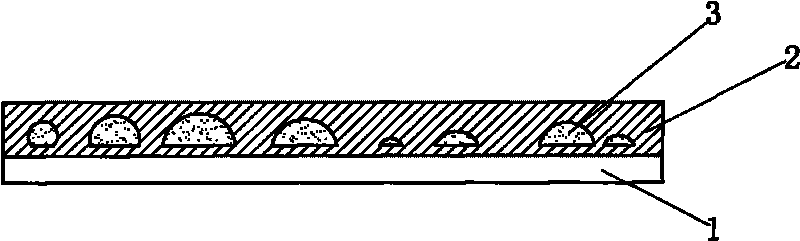

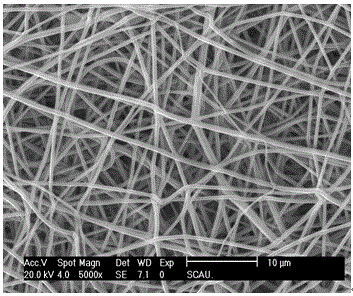

Wound dressing and preparation method thereof

InactiveCN105769442AImprove breathabilitySmall sizeNon-adhesive dressingsPlastersFiberWound dressing

Provided are a wound dressing and a preparation method thereof.The wound dressing is composed of a silicone membrane layer and an electrospun nanofiber layer.The preparation method comprises the steps that silicone, liquid paraffin, normal hexane and span-80 are mixed to be uniform, the mixed solution is cast in a polytetrafluoroethylene mold through a membrane casting method, after a membrane is formed through drying, a silicone membrane is soaked in ethyl alcohol, the composition of paraffin is removed, and the silicone membrane with a pore structure is obtained; eletrospinning is conducted on the silicone membrane to form a layer of biodegradable polymer nanofibers through an eletrospinning method, after drying is conducted, radiation sterilization is conducted, and a finished product is obtained.The wound dressing prepared through the method has good moisture retention and air permeability, the wound can be kept moist, hypertrophic scars are prevented, body tissue generation can be promoted by means of the unique support function of the nanofiber layer, and wound healing is accelerated.

Owner:GUANGZHOU DIANFANG BIOTECH CO LTD

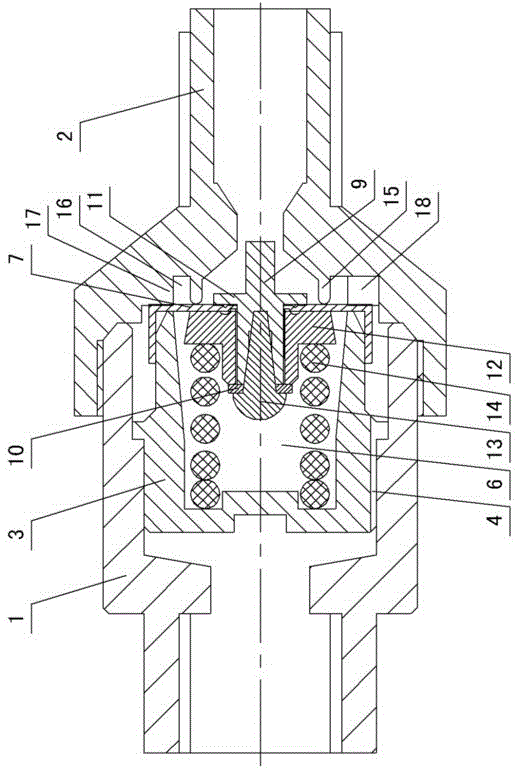

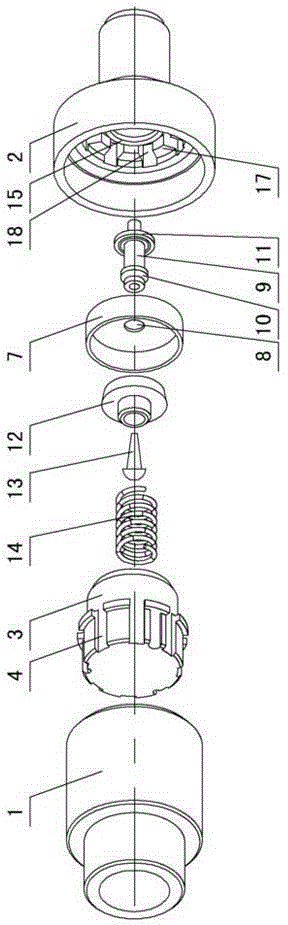

Anti-siphoning-pressure one-way valve

An anti-siphoning-pressure one-way valve is characterized by comprising a nozzle connector and a spray rod connector. One end of the nozzle connector is connected with a nozzle, and the other end of the nozzle connector is internally provided with a water outflow base which is provided with an outflow duct and an exhaust hole. The water outflow base is provided with a cavity, and the exhaust hole is communicated with the cavity. One end of the cavity of the water outflow base is provided with an opening which is sleeved with a silicone membrane. The silicone membrane is provided with a through hole. A membrane holder disposed in the through hole is provided with a spring holder baffle and a membrane baffle. The membrane baffle contacts with one side of the silicone membrane. The silicone membrane is provided with a spring holder on one side of the cavity. The spring holder baffle contacts with the spring holder. A screw penetrates the spring holder baffle and is fixed to the membrane holder. Springs are disposed between the spring holder and the inner wall of the cavity of the water outflow base. The spray rod connector is provided with an internal seal ring which contacts with the silicone membrane. The spray rod connector is also provided with an internal ring groove outside the seal ring. The spray rod connector is also provided with an internal stopper and an internal flow groove outside the ring groove, the stopper and the flow groove are separated, and the flow groove is communicated with an outflow groove of the outflow block.

Owner:SEESA HLDG

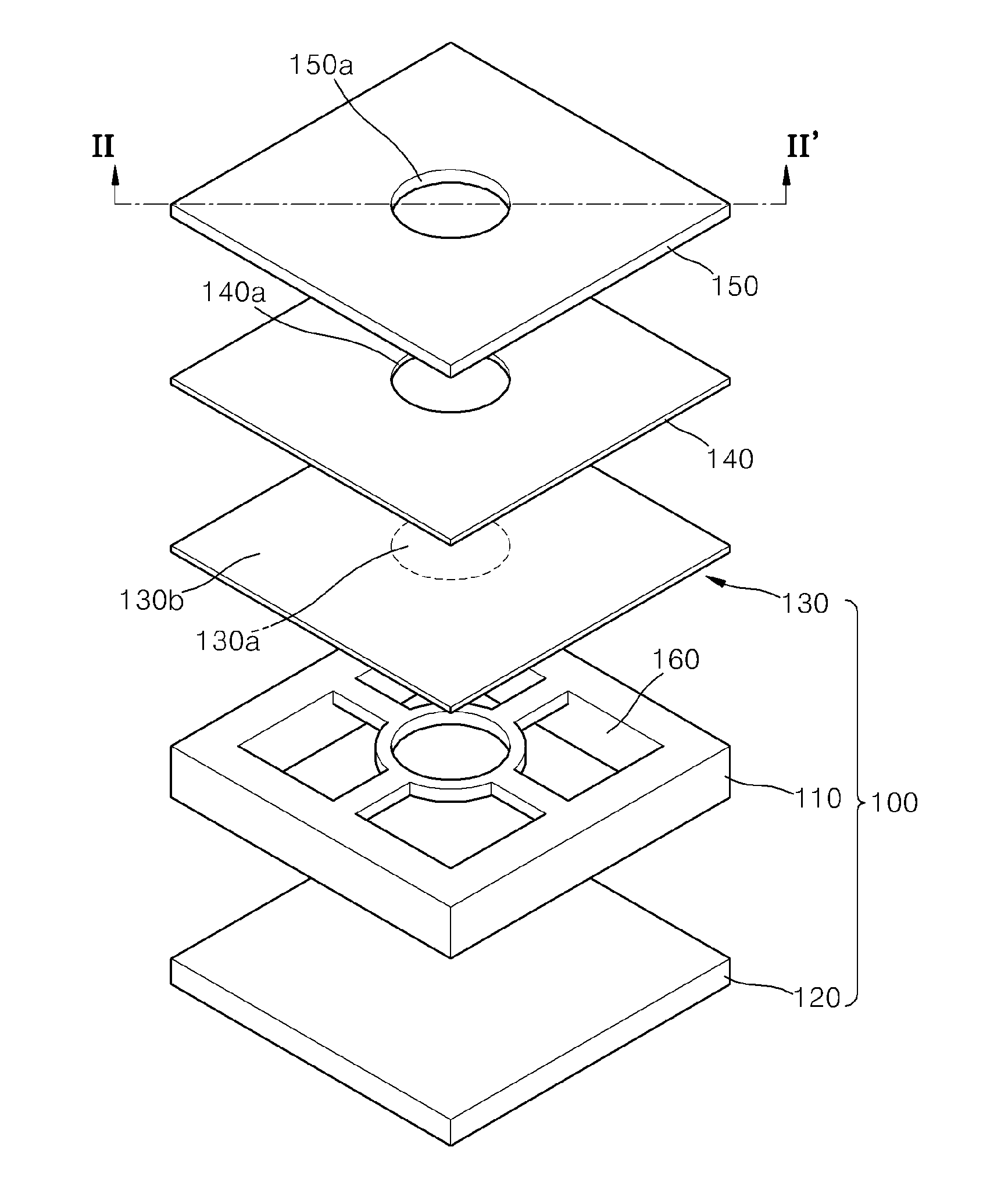

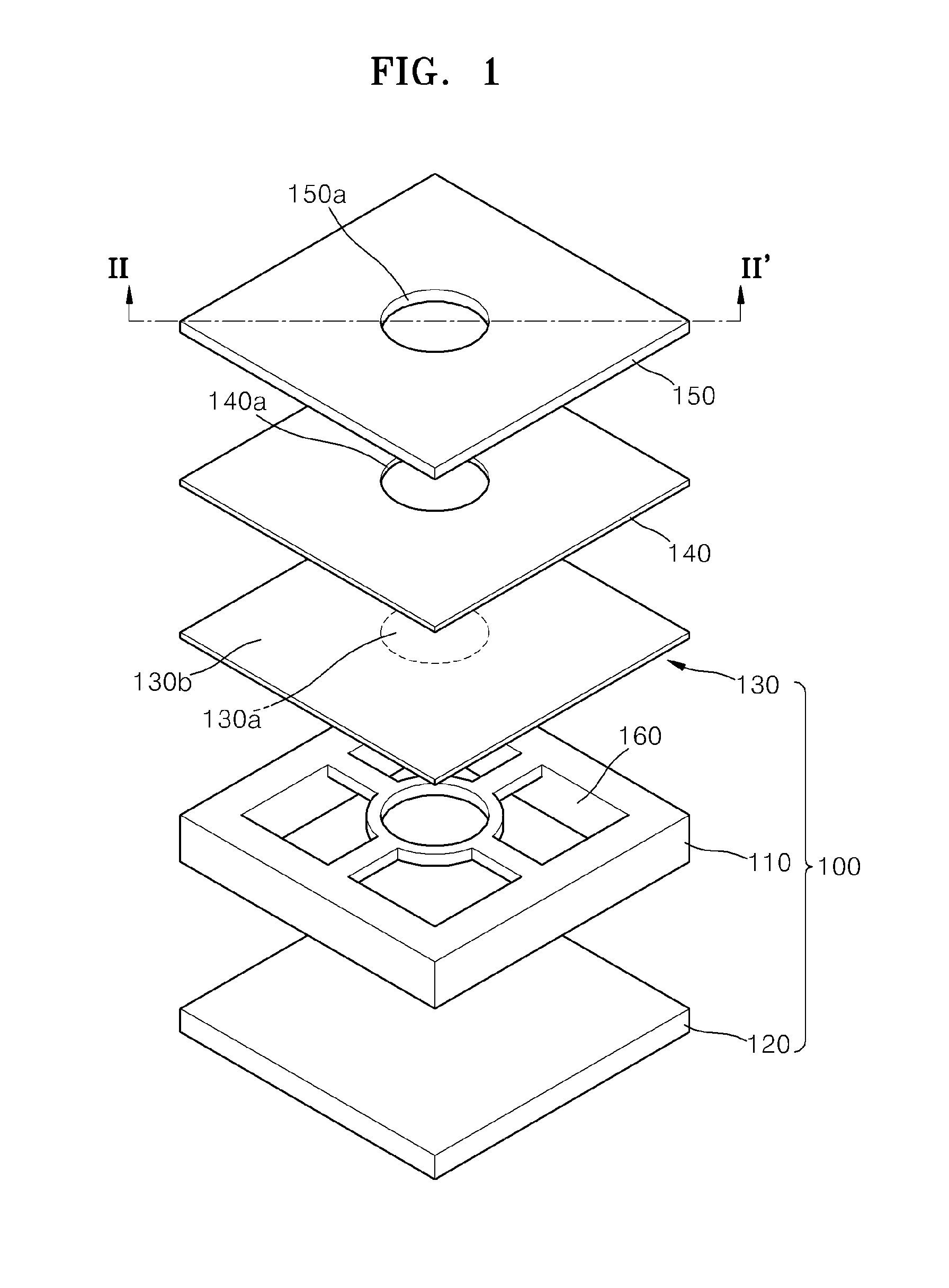

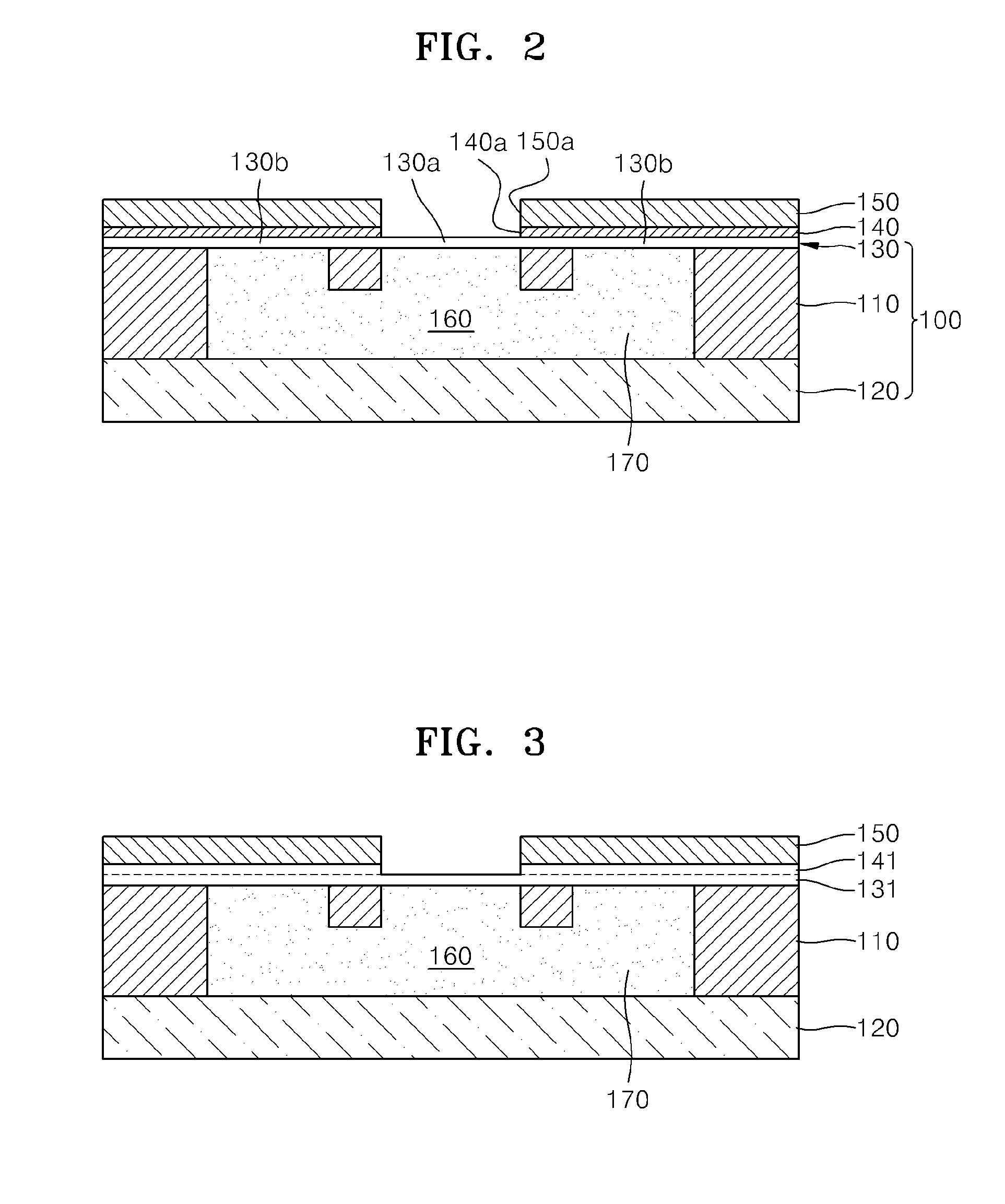

Varifocal lens structure, method of manufacturing the varifocal lens structure, optical lens module including the varifocal lens structure, and method of manufacturing the optical lens module

ActiveUS20120147478A1Lamination ancillary operationsFilm/foil adhesivesSilicone membraneOptoelectronics

A varifocal lens structure, a method of manufacturing the varifocal lens structure, an optical lens module, and a method of manufacturing the optical lens module. The varifocal lens structure includes a liquid lens unit including a silicone membrane that includes a first silicone elastomer, a polymer actuator disposed on an upper surface of the silicone membrane, and an adhesive silicone layer that is disposed between the silicone membrane and the polymer actuator and includes a second silicone elastomer.

Owner:SAMSUNG ELECTRONICS CO LTD

Jig for case sand blasting of electronic product

ActiveCN102615029AAvoid surface residuePrecise positioningLiquid surface applicatorsCoatingsSilicone membraneSand blasting

The invention relates to a jig for case sand blasting of an electronic product and is used for shielding the sand-blasting-free region of a case casing of the electronic product during the sand blasting. The jig comprises an upper plate, a lower plate and a positioning bolt, wherein the positioning bolt can be arranged on the upper plate and the lower plate in a penetrating way and can fix the upper plate and the lower plate, the shape of the upper plate is designed according to the sand-blasting-free region of the casing surface, the upper plate is used for shielding the sand-blasting-free region of the casing surface, when the casing is positioned between the upper plate and the lower plate, the upper plate can be attached to the surface of the casing, and in addition, on the surface with a layer of silica gel surface of the upper plate attached to the casing. The jig has the advantages that the jig with the silica gel surface is used for replacing a silica gel membrane for shielding the sand-blasting-free region of the case of the electronic product, so the sand-blasting region positioning is more accurate, the deformation of the case of the electronic product during the sand blasting is reduced, the casing surface gel residue problem when the silica gel membrane is torn off is avoided, and meanwhile, the problem that sand overflows to the sand-blasting-free region during the sand blasting is also avoided.

Owner:沪华五金电子(吴江)有限公司

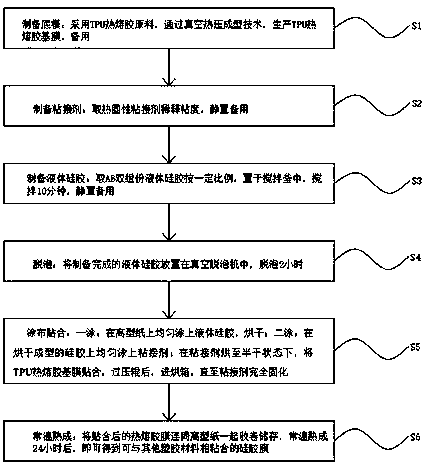

Preparation method and application of heat-transfer printing silicone film and heat-transfer printing silicone membrane

InactiveCN106543727ASolve the problem of poor printing firmnessTransfer printingCoatingsPolymer scienceSilanes

The invention discloses a preparation method of a heat-transfer printing silicone film; the preparation method comprises the steps of (1) selecting hot-melt film, and melting the hot-melt film at 120 DEG C to 150 DEG C; (2) blending coating silicone that is made by mixing, by weight, 90 parts of bicomponent additional liquid silicone, 0.01 part of aluminate coupler, 2-5 parts of hydroxyalkyl modified silane, 0.5 part of linear methyl hydrogen silicone oil, 0.005 part of metal platinum catalyst, 2-5 parts of epoxy modified silicon resin, and 2.5 parts of toluene; (3) applying coating silicone to the hot-melt film to 5-10 si in thickness, and the heat-transfer printing silicone film is prepared by drying. Heat-transfer printing silicone film and application thereof are also disclosed. The problem that efficiency is low since hot-melt silicone used in current heat-transfer printing ins only suitable for single-sheet printing is solved, the problem that print durability is poor due to silicone being directly on common hot-melt silicone film is also solved, and silicone printing is suitable for batched heat-transfer printing.

Owner:广东省良展有机硅科技有限公司

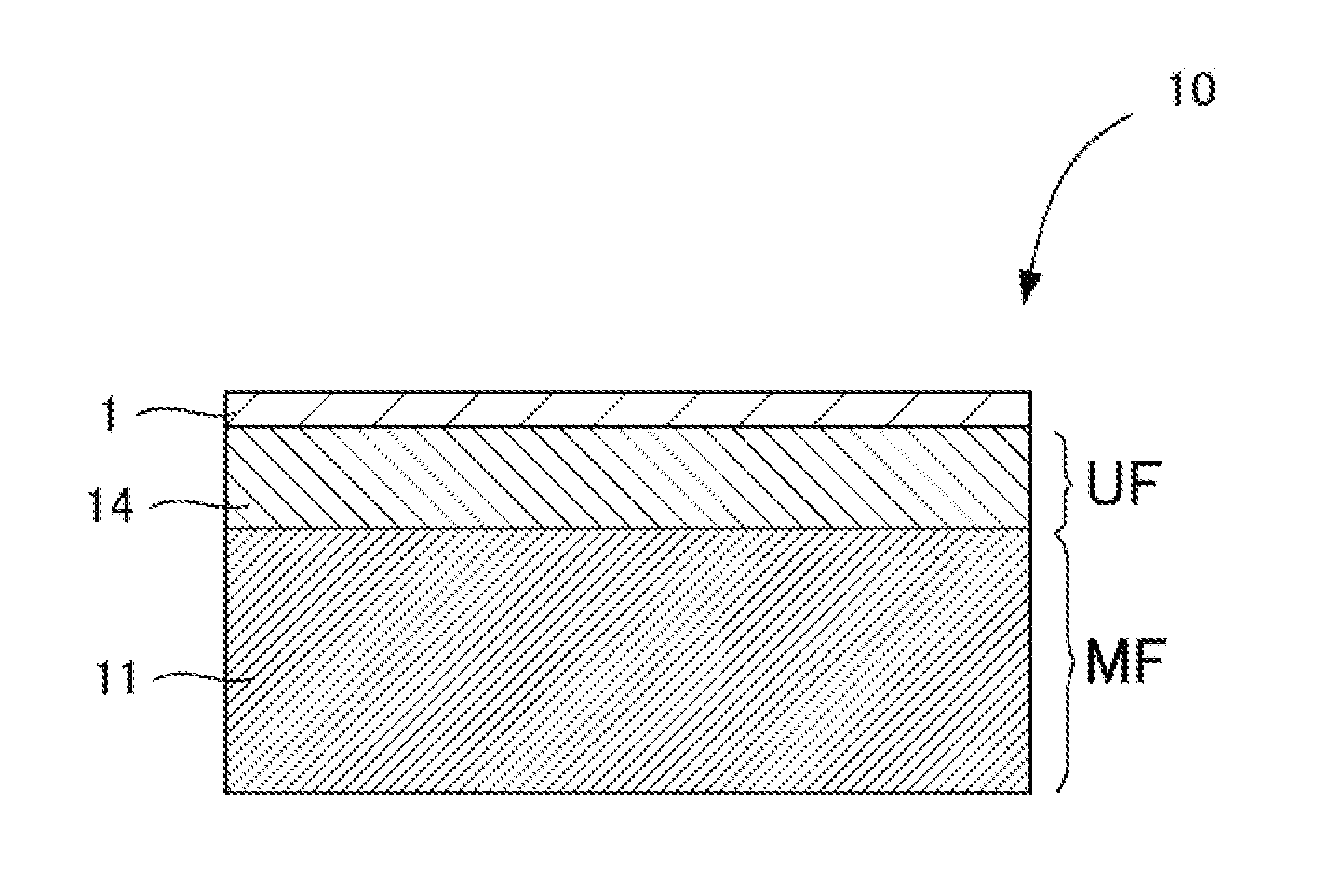

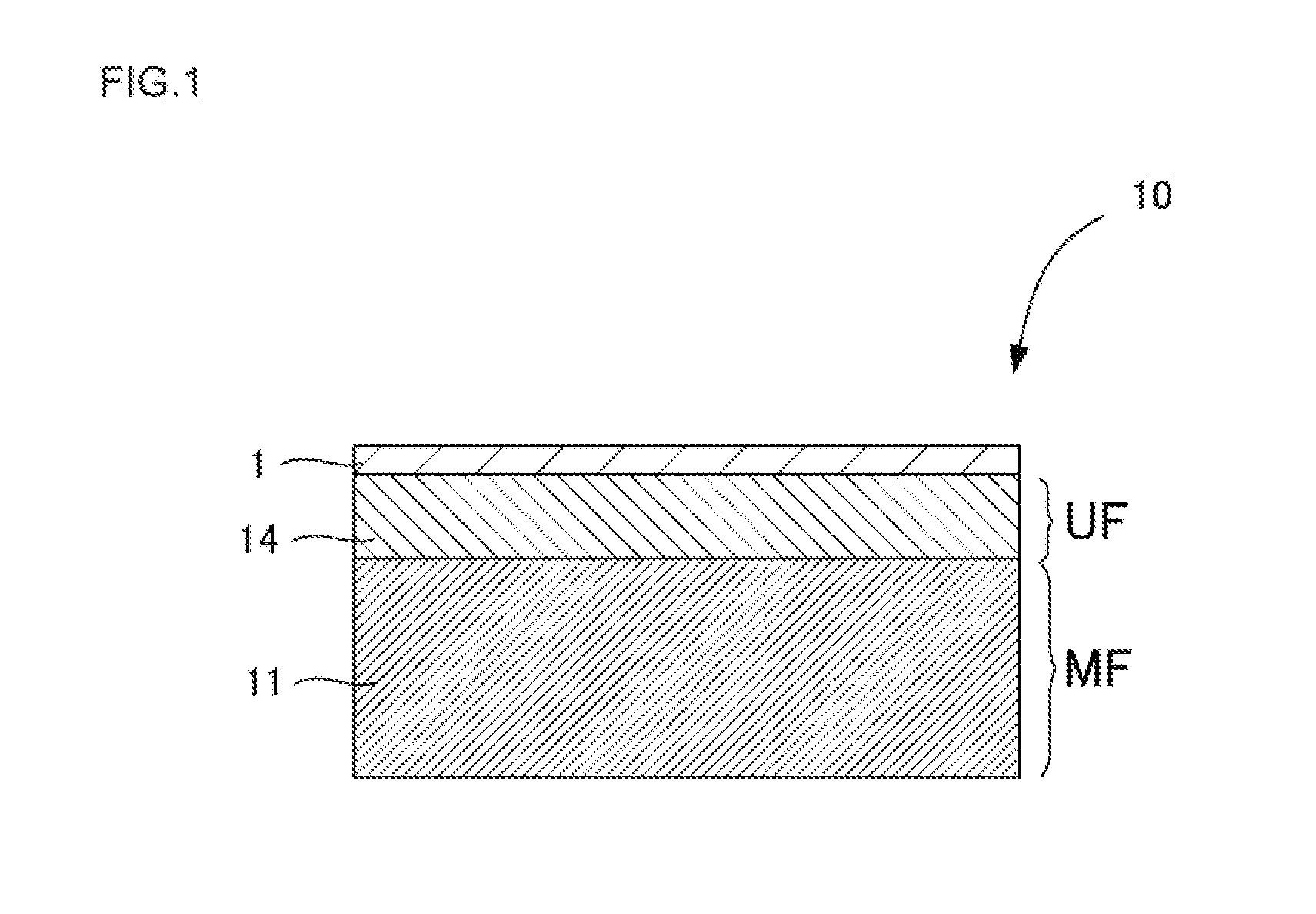

Silica membrane and method for manufacturing the same

ActiveUS20120018370A1Water permeation amount increaseIncrease ionic strengthMembranesSemi-permeable membranesPorous substrateDesorption

There is provided a silica membrane 1 formed on a porous substrate. A desorbed ionic strength of water having a temperature of 500° C. in a temperature-programmed desorption analysis of water of the silica membrane is 2,000,000 / g. The silica membrane 1 is manufactured by allowing a silica sol having a water concentration of 0.03 to 3 mass % to adhere to a porous substrate by an ethanol solvent, drying the silica sol by sending air having a dew point of −70 to 0° C., and firing the dried silica sol at 200 to 400° C.

Owner:NGK INSULATORS LTD

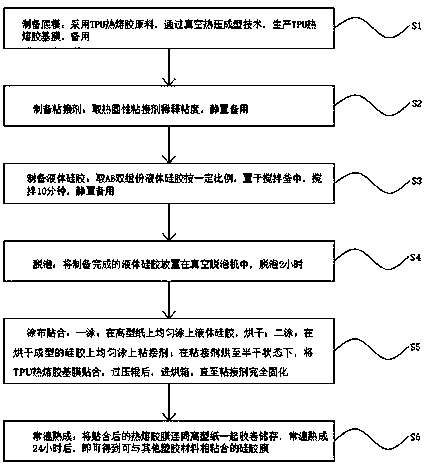

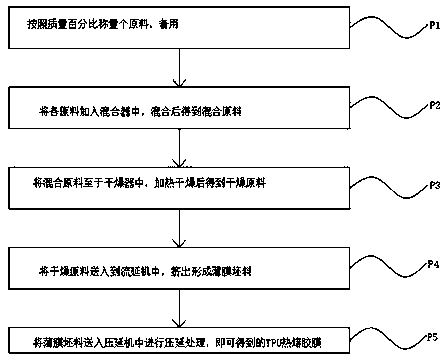

Silica gel film capable of being bonded with other plastic materials and preparation method thereof

InactiveCN111171749AScientific and reasonable structureEasy to useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSilicone membranePolymer science

The invention discloses a preparation method of a silica gel film capable of being bonded with other plastic materials, which comprises the following steps: S1, preparing a bottom film: producing a TPU (Thermoplastic Polyurethane) hot melt adhesive base film for later use by adopting a TPU hot melt adhesive raw material through a vacuum hot press molding technology; S2, preparing an adhesive: taking a thermosetting adhesive to dilute the viscosity, and standing for later use; S3, preparing liquid silica gel: taking AB double-component liquid silica gel according to a certain ratio, putting theAB double-component liquid silica gel into a stirring kettle, stirring for 10 minutes, and standing for later use; S4, defoaming: putting the prepared liquid silica gel into a vacuum defoaming machine, and defoaming the liquid silica gel for 2 hours; and S5, coating and laminating. The silica gel film is scientific and reasonable in structure and safe and convenient to use. The base film is prepared, the liquid silica gel is applied to form a film, and the base film and the film forming silica gel are adhered, such that the whole stability of the product can be ensured, the peeling due to insufficient adhesion fastness is avoided, the adhesion fastness stability is improved, the process is simplified, the process control is easily achieved, the processing convenience can be substantiallyimproved, and promotion and application are facilitated.

Owner:晋江市诺特新材料科技有限公司

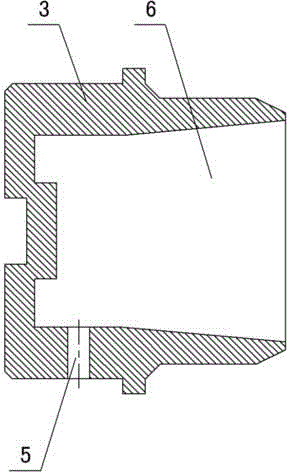

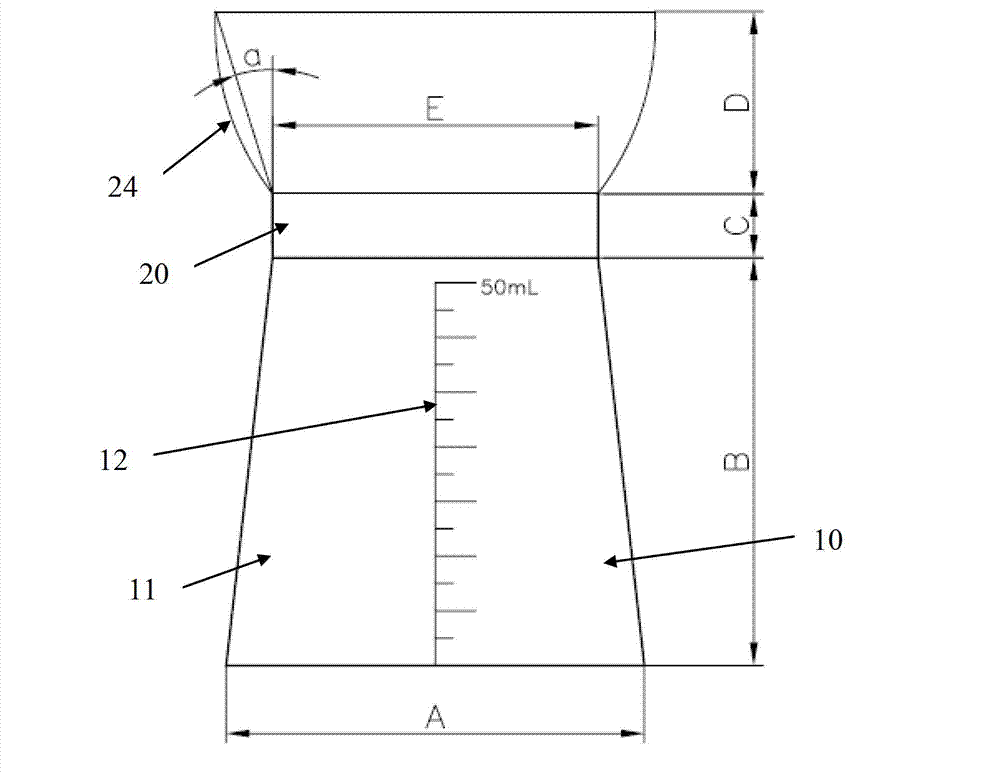

Device for sterilizing medical pipe joint

ActiveCN103285413AStop pollutionEliminate other influencesChemicalsPeritoneal dialysisSilicone membrane

The invention particularly relates to a device for sterilizing a medical pipe joint, and particularly relates to a device, which is suitable for being applied to peritoneal dialysis treatment and used for sterilizing a titanium joint of a peritoneal dialysis tube. The medical pipe joint is connected with a medical pipe. The device comprises a bottle body and a bottle cap, wherein the bottle body is used for loading a disinfectant; the bottle cap is tightly arranged at and connected to the upper end part of the bottle body; a hole for inserting and extracting the medical pipe joint is formed in the bottle cap; the diameter of the hole is correspondingly matched with that of the medical pipe joint; the area of the hole covers an elastic silicone membrane; the device is a sterilization space for providing external relative seal to the medical pipe joint. By adopting the device, the whole aseptic and safe sterilization process is effectively ensured; the operation is facilitated.

Owner:临沂高新区人才职业培训学校有限公司

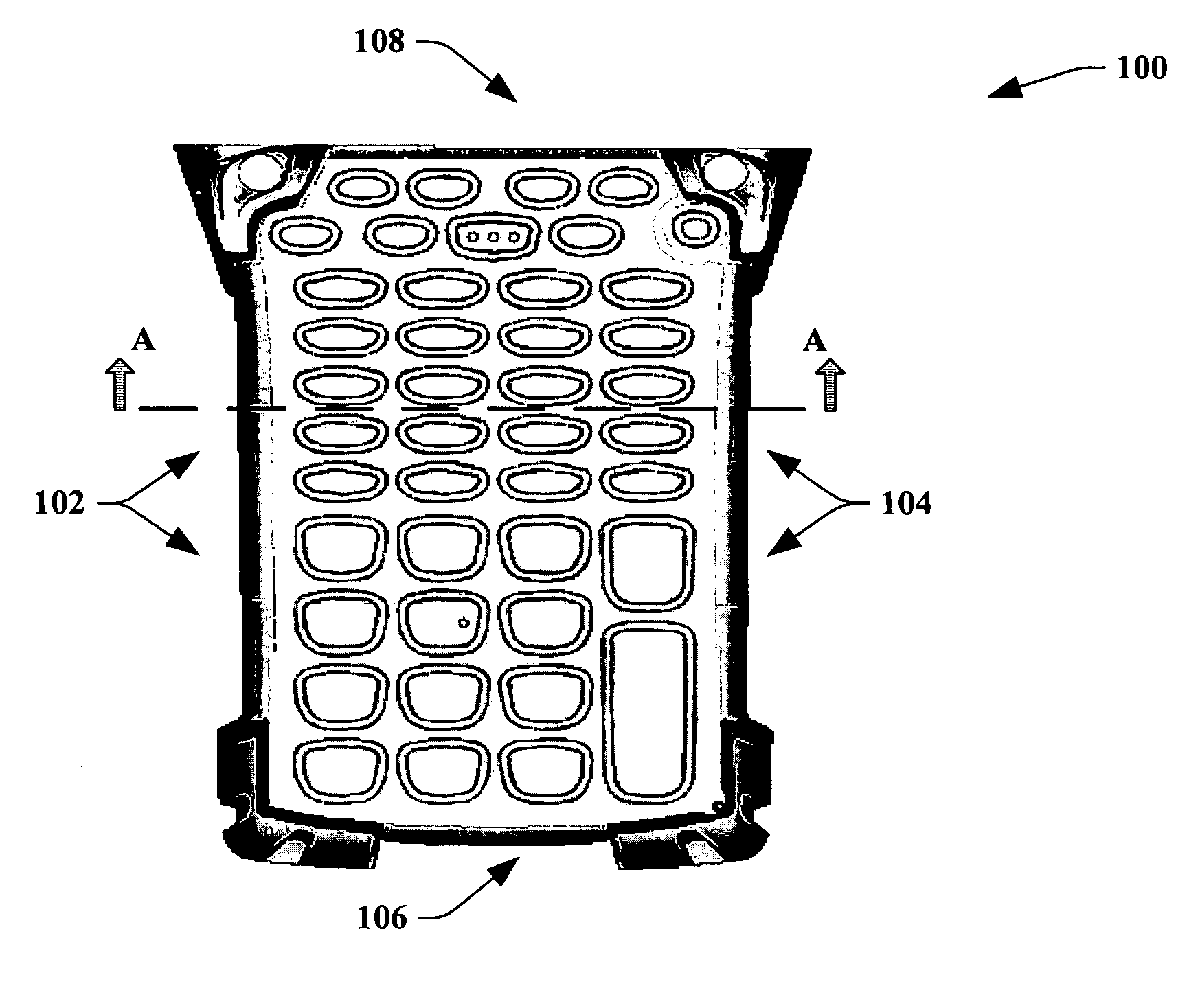

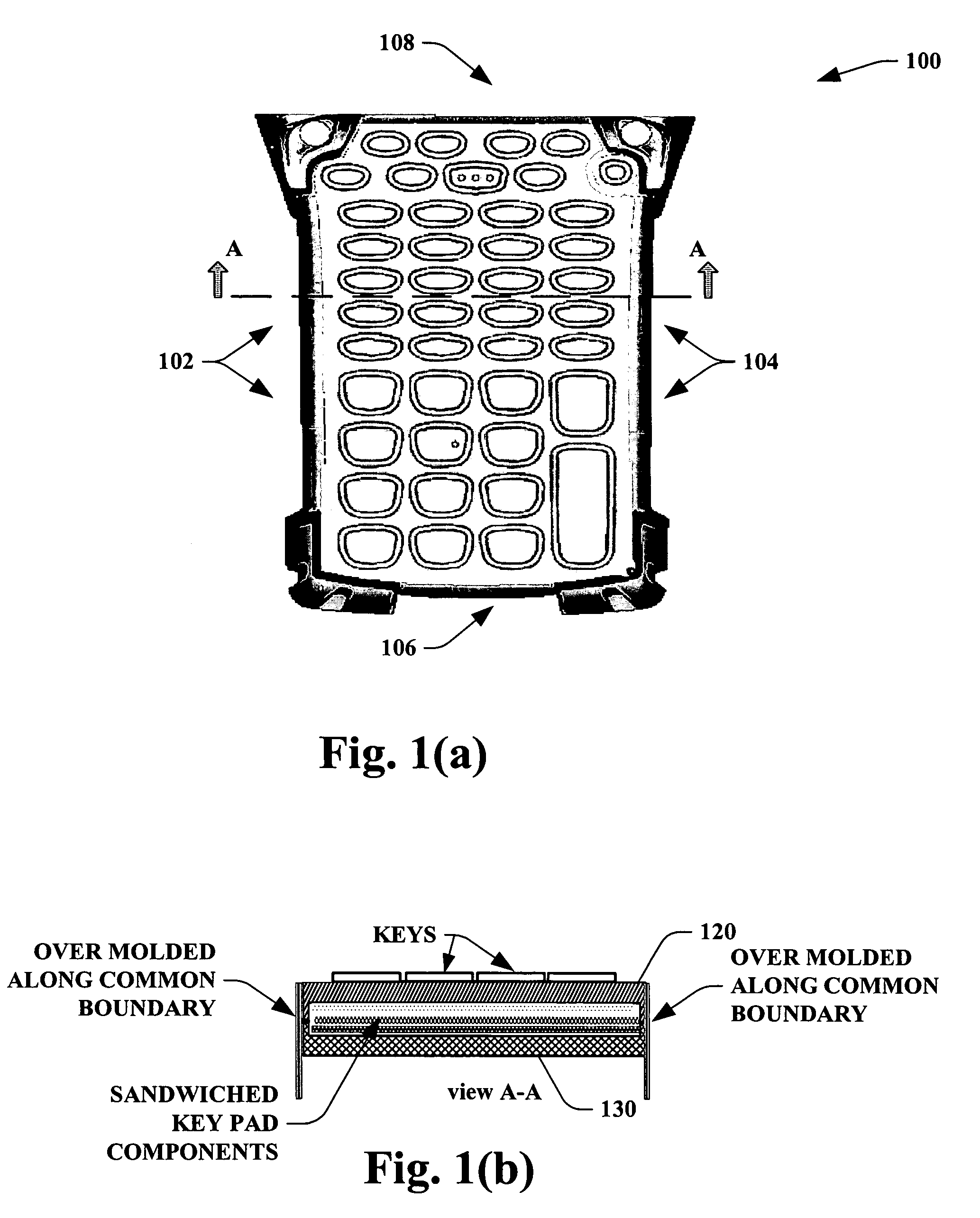

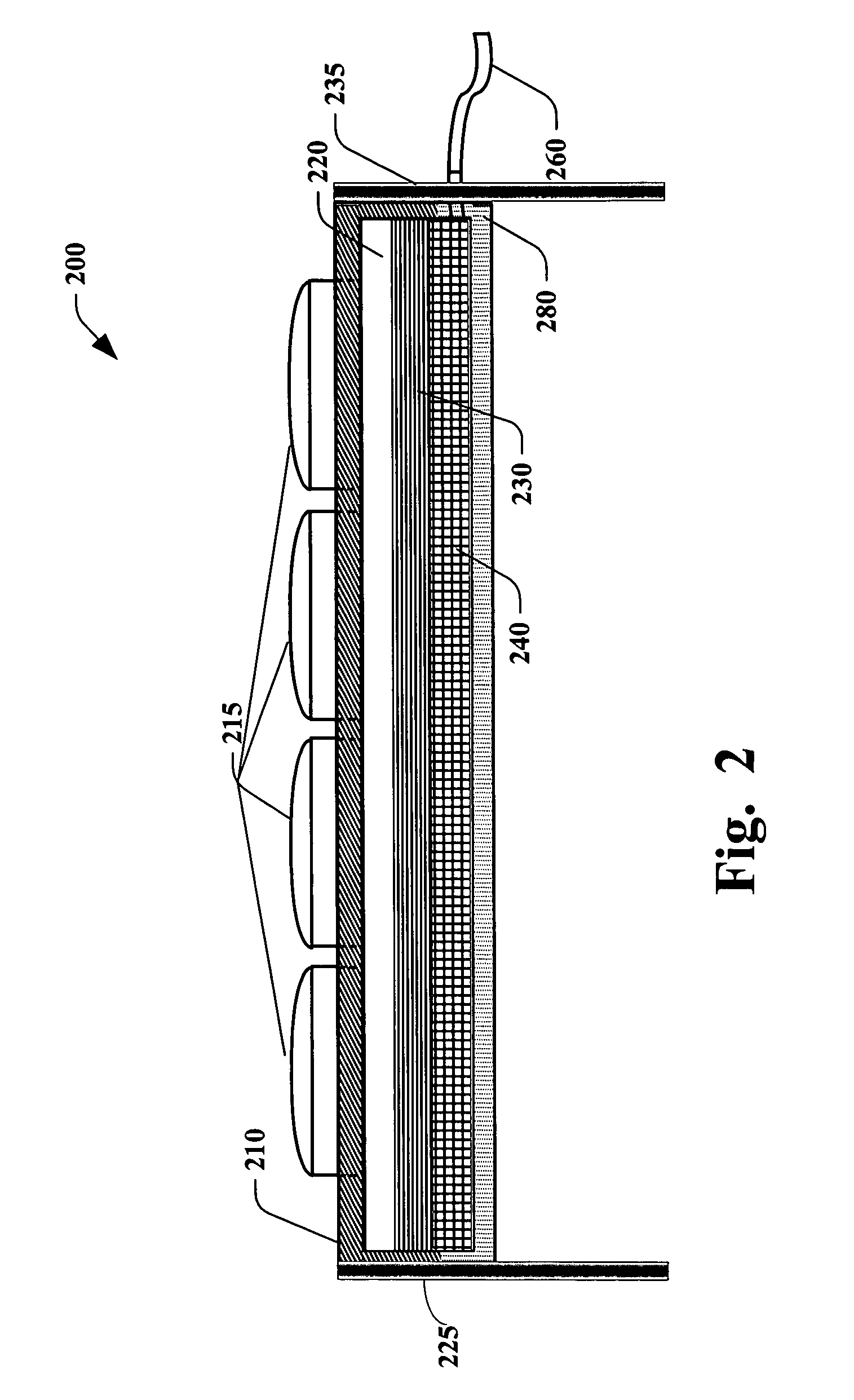

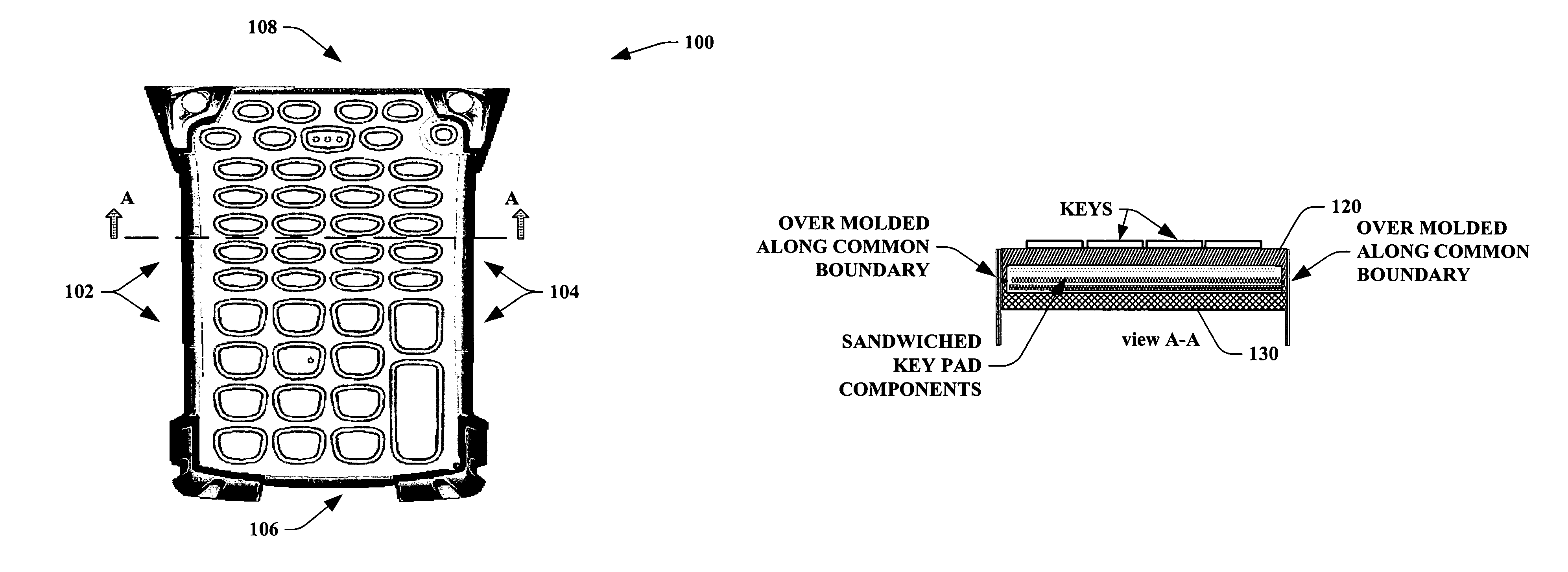

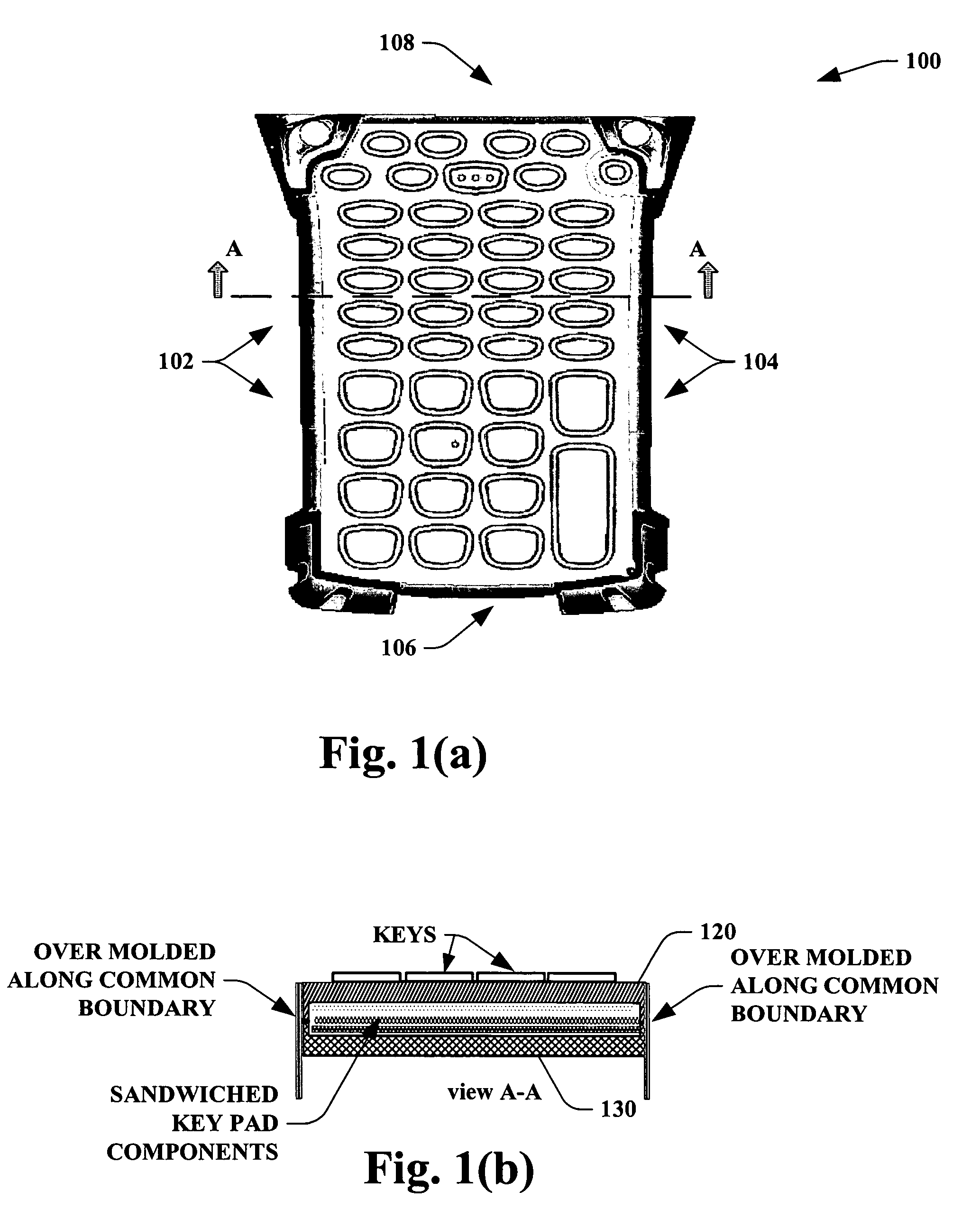

Self contained keypad assembly

ActiveUS20050237229A1Avoid damageLow costInput/output for user-computer interactionEmergency casingsSilicone membraneElectroluminescence

Systems and methodologies are provided for fabrication of a self contained key pad module having a top cover and a bottom cover. The top cover and the bottom cover encapsulate and / or sandwich a stack of keypad components via an over mold procedure that is performed around the stack. The packed stack between the top cover and the bottom cover can include a flex member, an electro luminous panel, and a silicone membrane with a plurality of keys thereupon.

Owner:SYMBOL TECH LLC

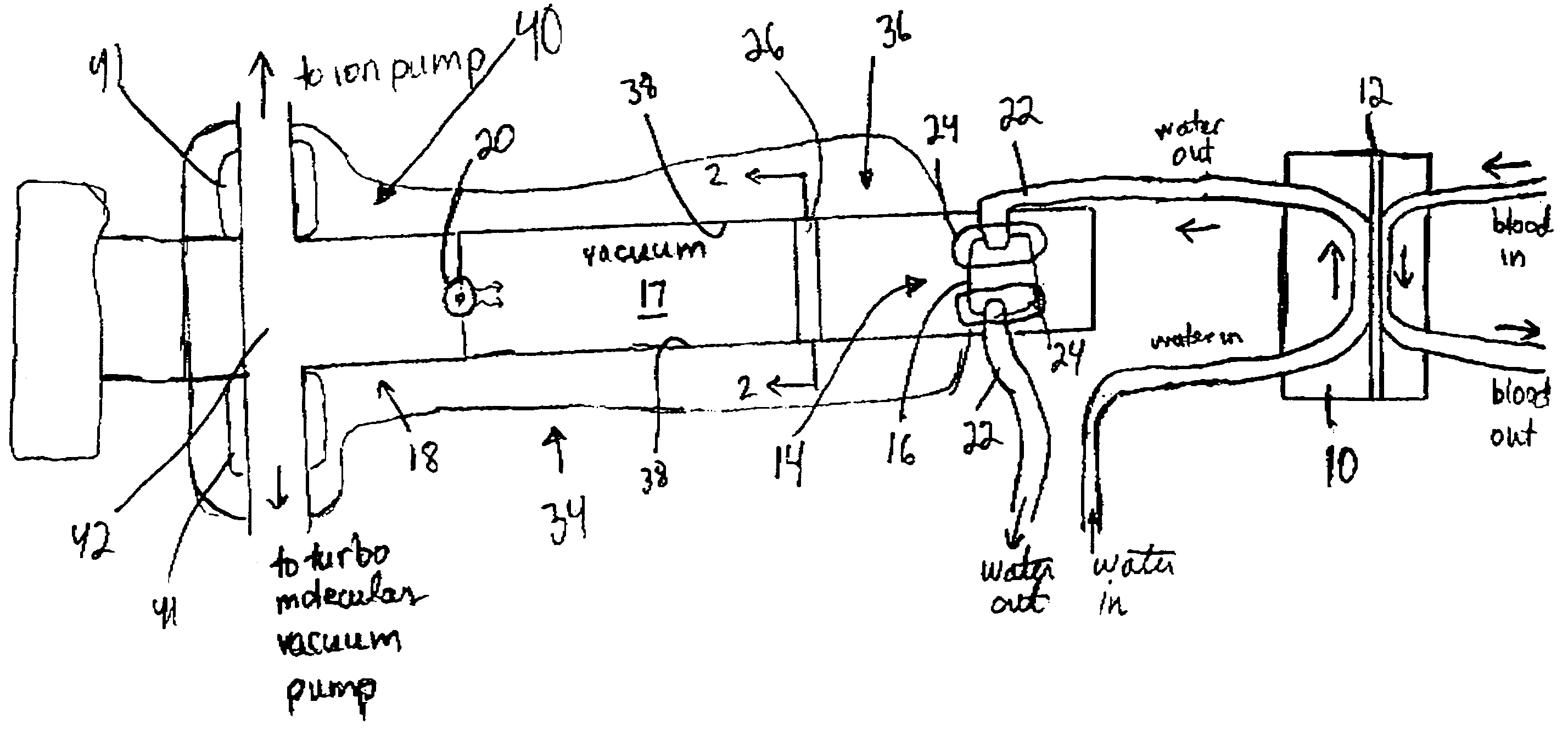

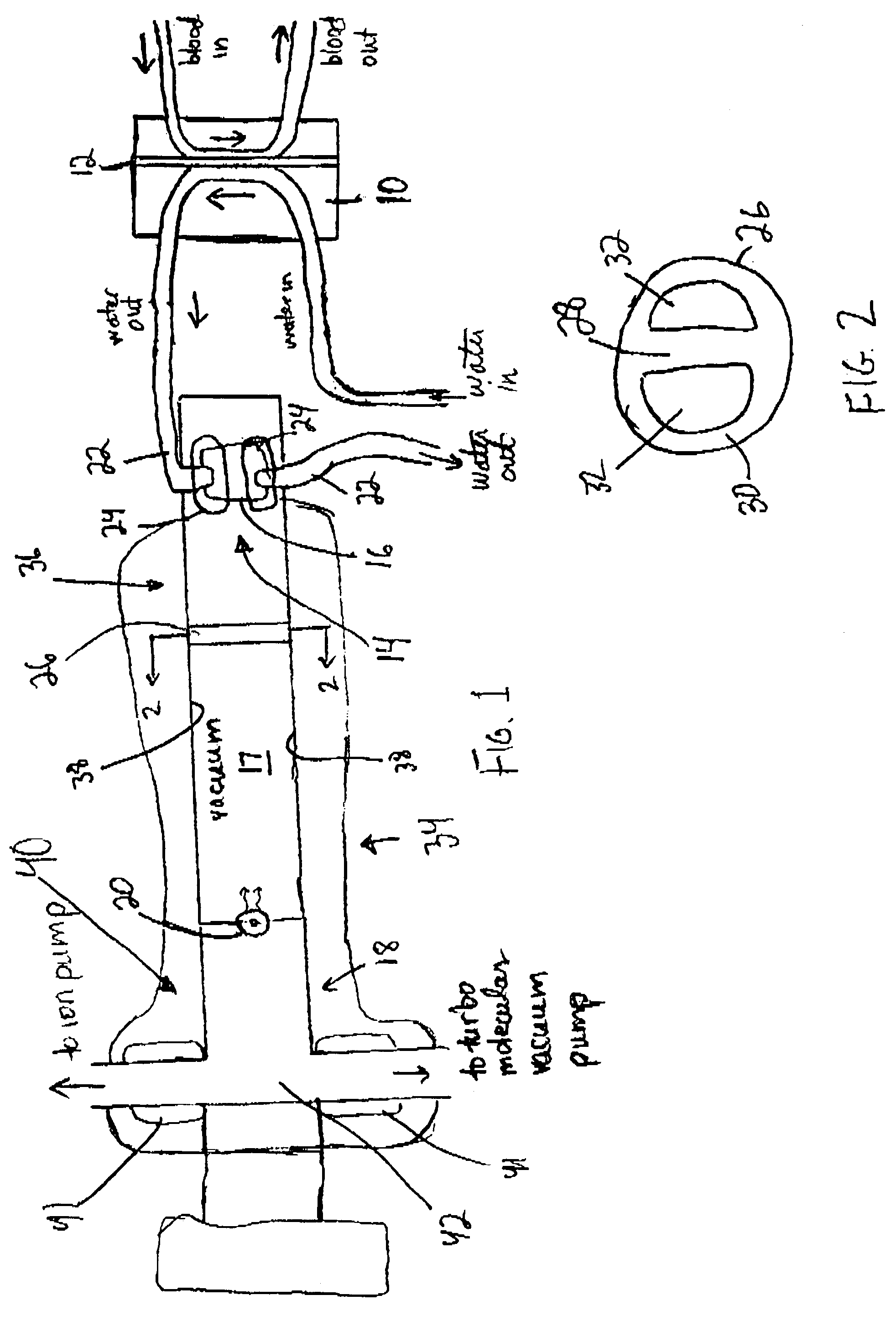

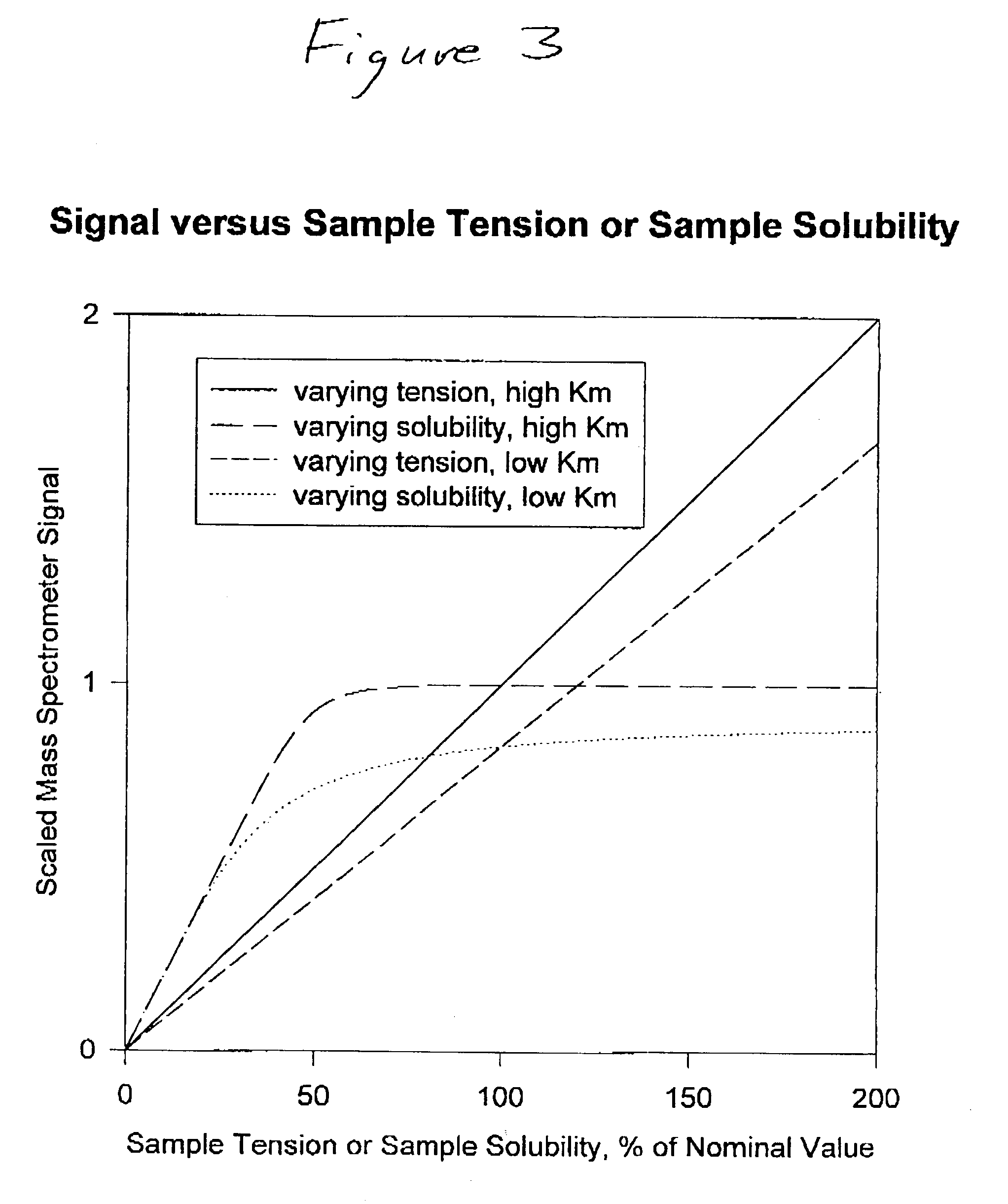

Membrane countercurrent exchanger and membrane inlet mass spectrometer for the analysis of gas partial pressure in liquid samples

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

Disposable package molding method of electric heating film unit product

InactiveCN104441707AUnitization of inventionInventing ModularityOhmic-resistance heatingFlat articlesSilicone membranePolymer science

The invention relates to a disposable package molding method of an electric heating film unit product. With a naked film, a pre-coated plastic film, silicon rubber, plastics, plastic-wood, resin and the like as materials, the electric heating film unit product is fabricated by a molding machine mold, and the disposable package molding method comprises the steps of: firstly cutting the naked film, connecting a conducting wire, then taking the plastic film, pre-coating an adhesive layer or refined silica gel on a single surface of the plastic film, and calendering a film; cutting the pre-coated film or silica gel film to form a cut film; wrapping the cut film provided with the pre-coated film or the silica gel film with the naked film from upper and lower surfaces, and finally putting multiple layers of films in the molding machine mold for forming under certain conditions. The electric heating film product provided by the invention is unitized and modular. In the electric heating film unit product provided by the invention is subjected to package molding at one time, and nearly all insulating and sealing materials can be used as the package naked film in the invention. The electric heating film unit product provided by the invention can be made into electric heating film products with various shapes.

Owner:青岛四机宏达工贸有限公司

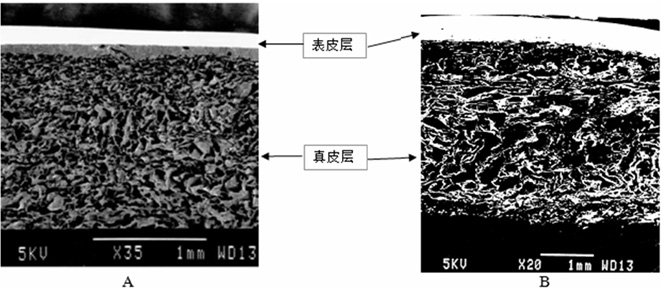

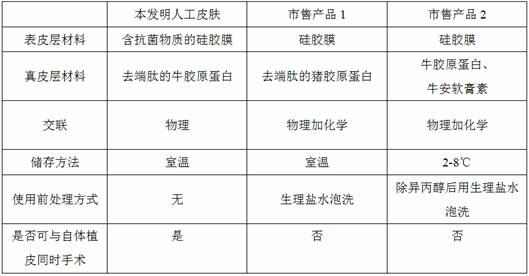

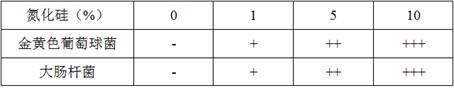

Artificial skin

PendingCN111700713AReduce infectionImprove life-saving rateSkin implantsSkin graftingSilicone membrane

The invention discloses novel artificial skin. The artificial skin is composed of an epidermal layer and a corium layer, wherein the epidermal layer is a strength-reinforced antibacterial silica gel film, and the corium layer is of a three-dimensional porous structure composed of denatured collagen and fibrosis collagen. The artificial skin provided by the invention has a good antibacterial effect, can be used together with autologous reticular skin grafting to realize one-step treatment transplantation, so that the operation time is greatly shortened, secondary operation treatment is avoided,and the skin repair time can also be shortened, and therefore, the artificial skin has high application value and market popularization prospect.

Owner:福建华民生物科技有限公司

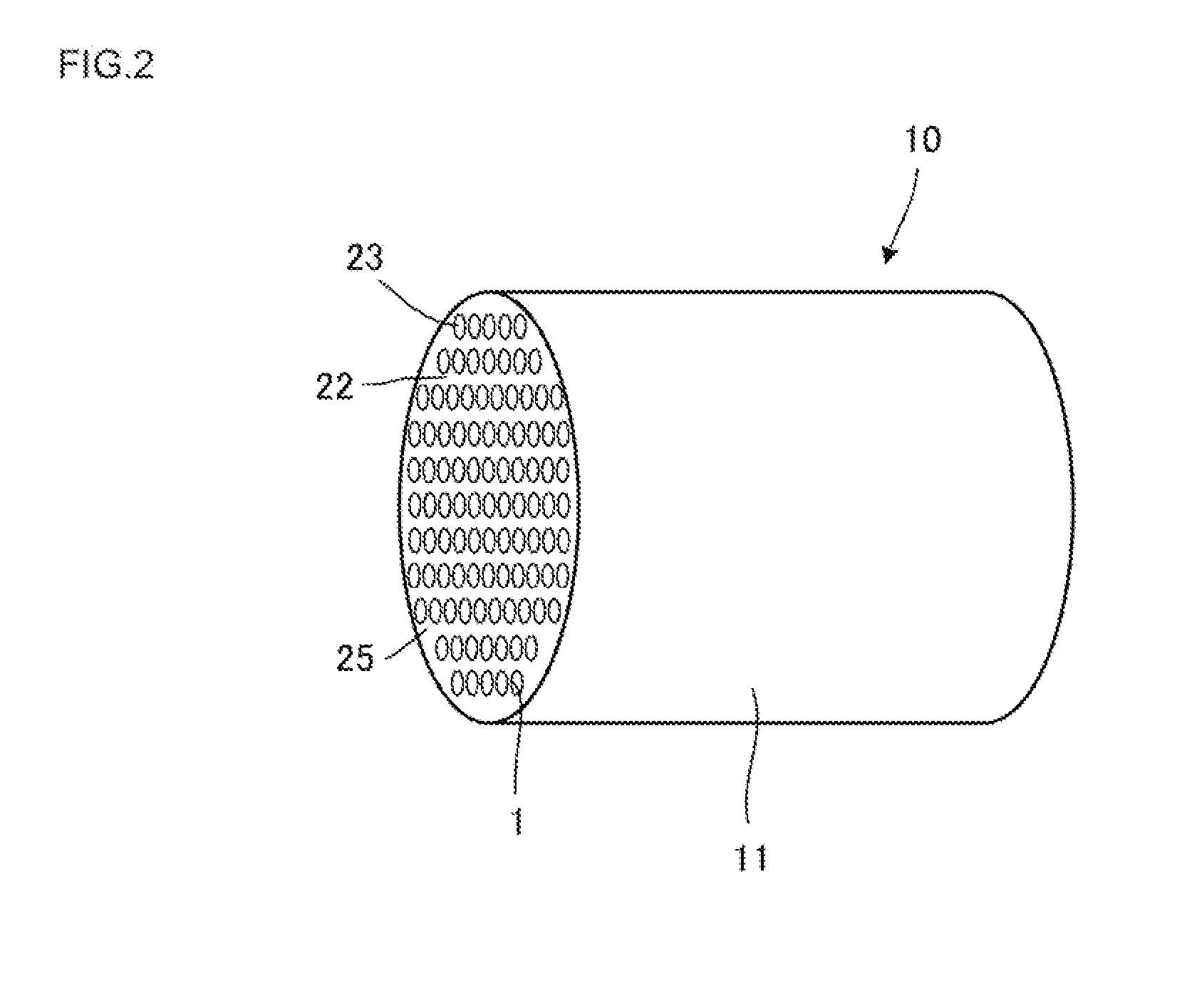

Sealing patch for the ventilation hole of a non-siliconized cushion of an airbag module

ActiveUS7874584B2Convenience to mergePedestrian/occupant safety arrangementBuilding constructionsSilicone membraneSilicone coating

The invention relates to an airbag module for protecting an occupant of a vehicle in the event of a collision, comprising a cushion (11) that can expand with the gas provided by a generator with at least one ventilation hole (13) sealed with a patch (21) including a silicone membrane (23) intended to break due to the effect of the internal pressure in the cushion (11) so as to allow gas discharge, in which the fabric of the cushion (11) does not have a silicone coating, the patch (21) is formed by said membrane (23) joined at its edges to two pieces (25, 27) of fabric and fixed to the cushion (11) by means of a seam (31). The invention also comprises a process for manufacturing the cushion (11).

Owner:DALPHI METAL ESPANA

Self contained keypad assembly

ActiveUS7873394B2Avoid damageLow costInput/output for user-computer interactionEmergency casingsSilicone membraneComputer module

Owner:SYMBOL TECH LLC

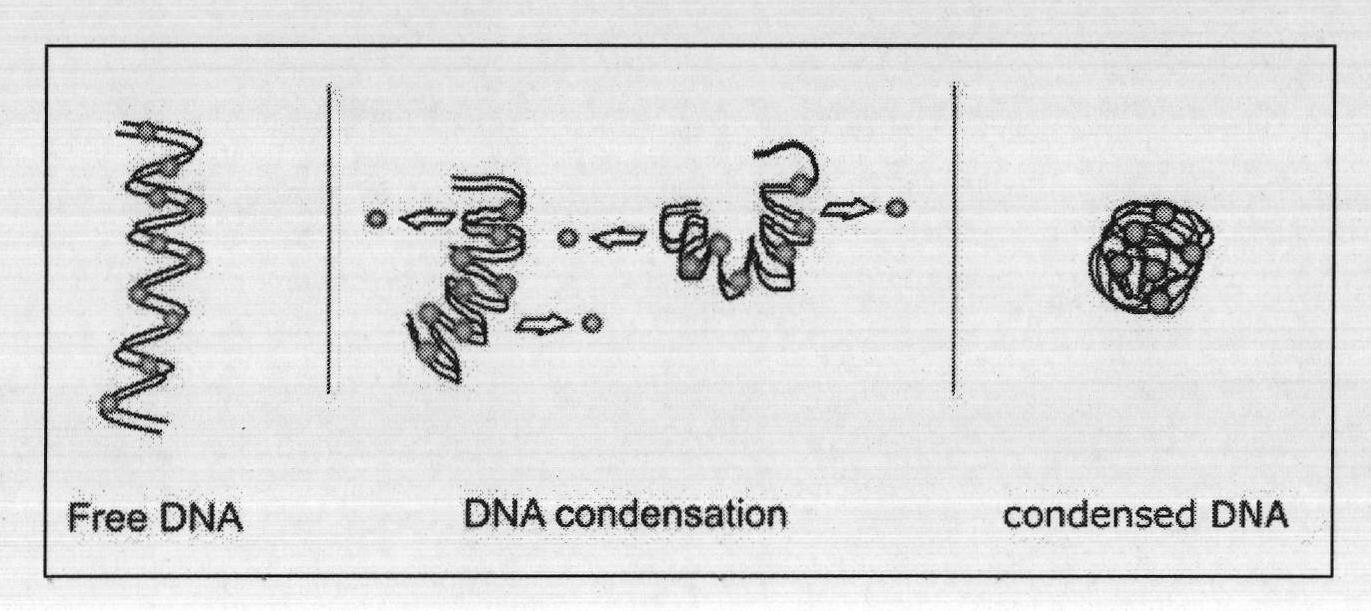

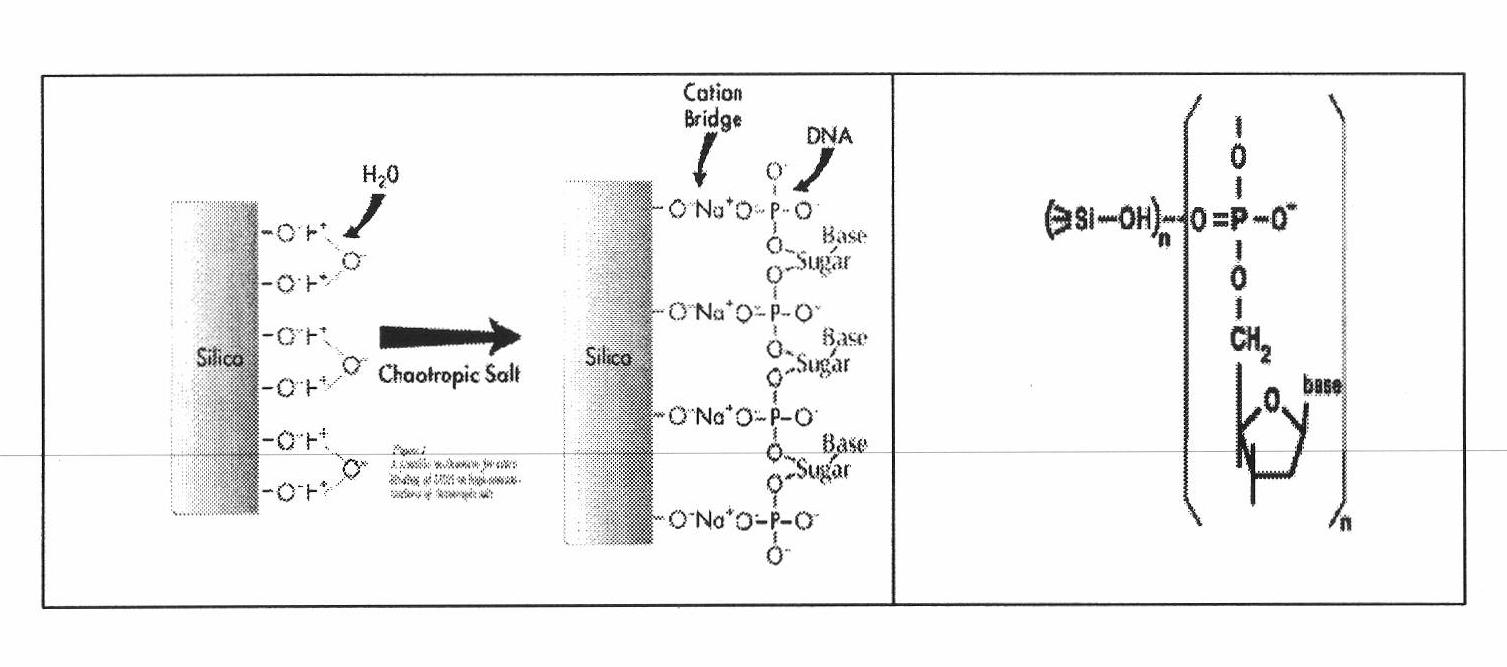

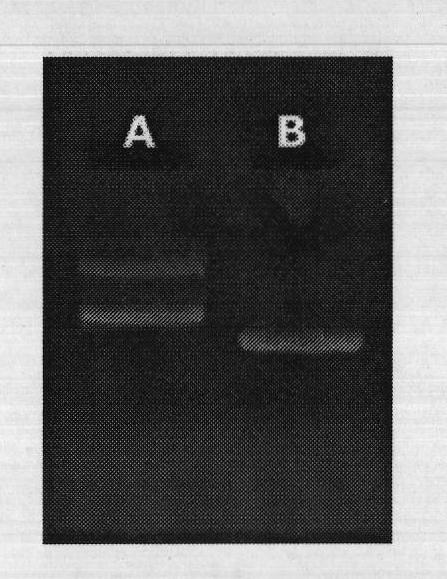

Rapid covalently closed circular DNA purification kit

The invention relates to a rapid covalently closed circular DNA purification kit. The kit is finished by a method which comprises the following steps of: bacterial precipitation, non-alkaline cracking, combining circular DNA by a silicone membrane, column elution, and elution; on the basis of the method, components such as hexamminecobalt chloride and spermine are added; bacteria are cracked by adopting improved non-alkaline cracking liquid; linear genome DNA and RNA are highly concentrated by using polyamine to lose the capability of combining the silicone membrane selectively, so that the genome DNA and RNA can still combine the silicone membrane; and a rapid covalently closed circular DNA purification kit can be achieved by washing and eluting. The DNA purification technology of the invention replaces two-step DNA purification technology, completely saves a plasmid crude extraction step, does not depend on the insensitivity of the species of escherichia coli to the acuteness degree of an operation, has less steps, shortens the time of the purification operation of plasmid DNA, saves manpower and material resources, and is suitable to be used in high-flux plasmid DNA purification and industrial large-scale plasmid DNA purification technology.

Owner:徐堤

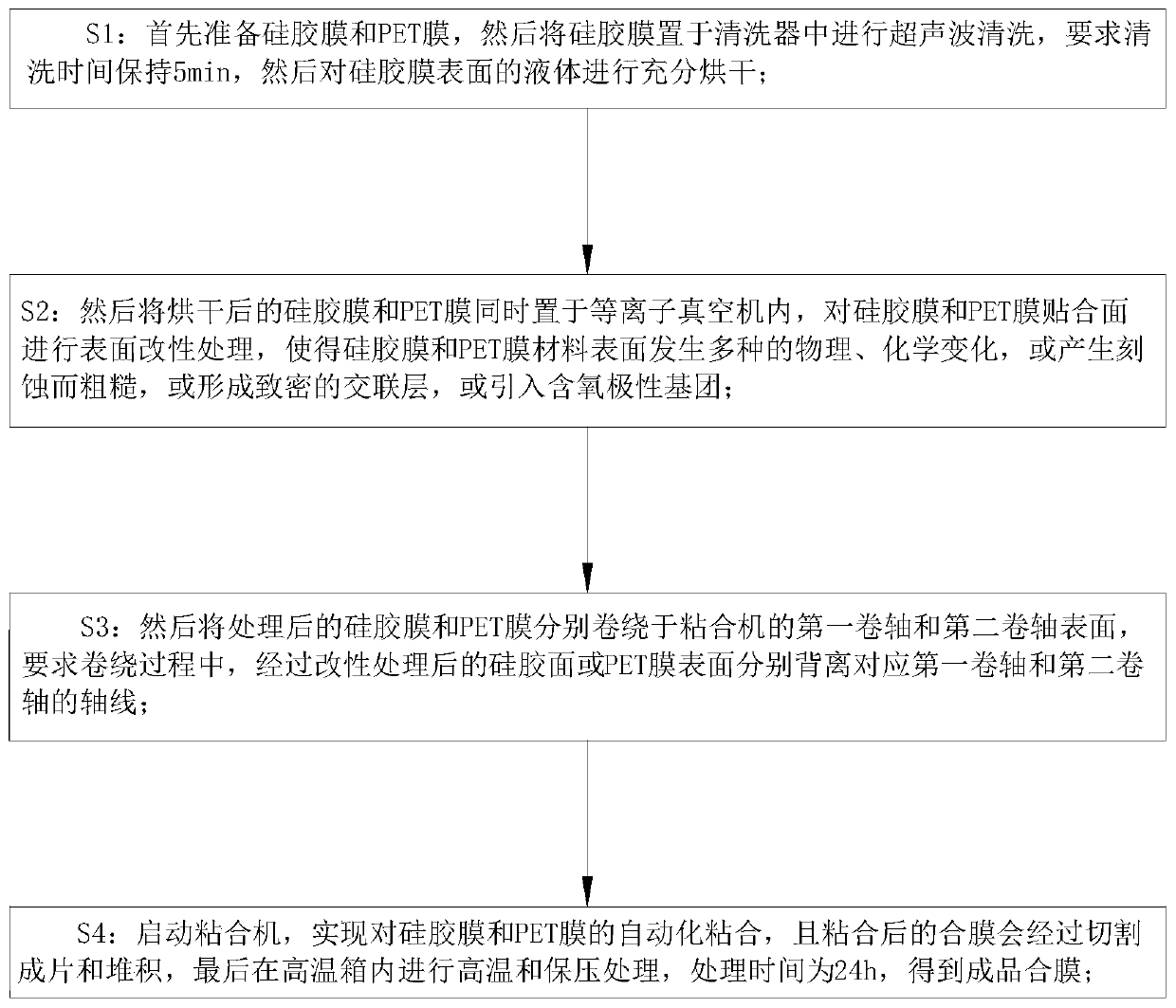

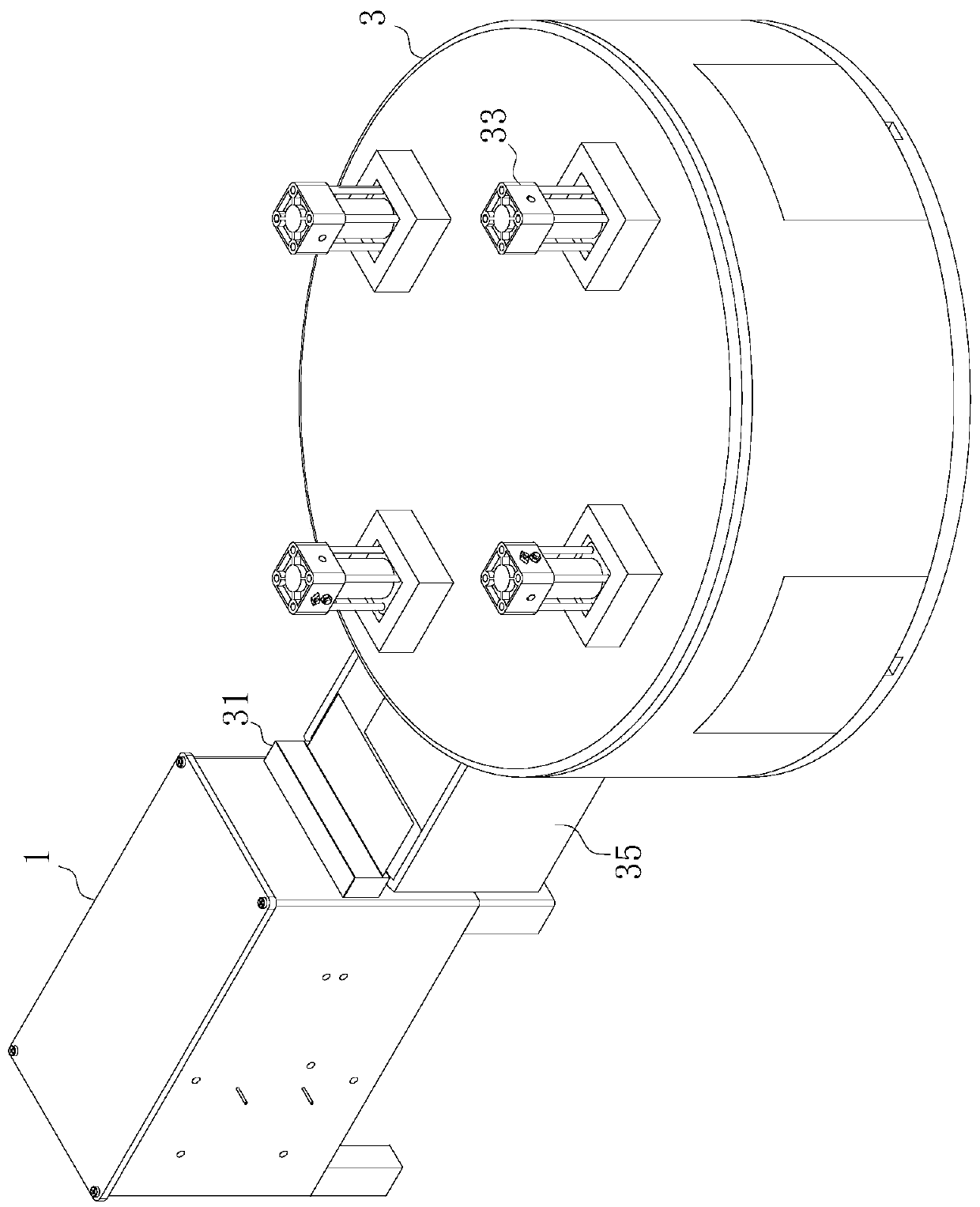

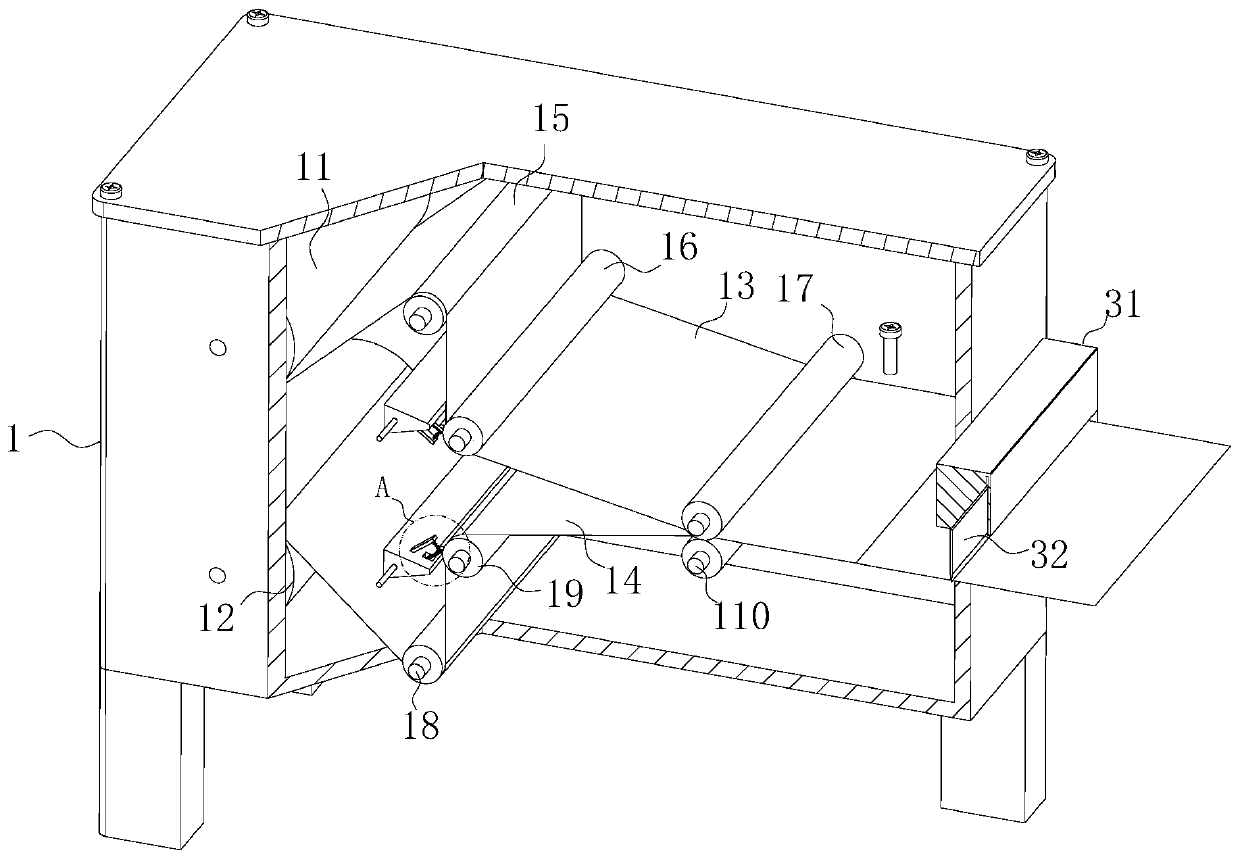

Silica gel and PET bonding process

The invention belongs to the technical field of bonding, in particular to a silica gel and PET bonding process. A first reel and a second reel are commonly connected between the front and back side walls of a bonding box, and the surfaces of the first reel and the second reel are respectively connected to a silica gel film and a PET film in a wound manner; a first transmission shaft, a second transmission shaft and a first bonding shaft are commonly connected between the front and back side walls of the bonding box; a third transmission shaft, a fourth transmission shaft and a second bonding shaft are commonly connected between the front and back side walls of the bonding box; two glue spraying pipes are commonly connected with the front and back side walls of the bonding box to the rightside positions of the second transmission shaft and the fourth transmission shaft; and a high-temperature box is disposed at the right side position of the bonding box. The silica gel and PET bondingprocess effectively implements automatic bonding of the silica gel film and the PET film, achieves higher efficiency and more stable quality, reduces the labor cost, and can effectively perform high-temperature pressure maintenance processing, so that a finished combined film is more excellent in quality and higher in bonding firmness, and the rejection rate of the product is reduced.

Owner:宿州德源服装有限公司

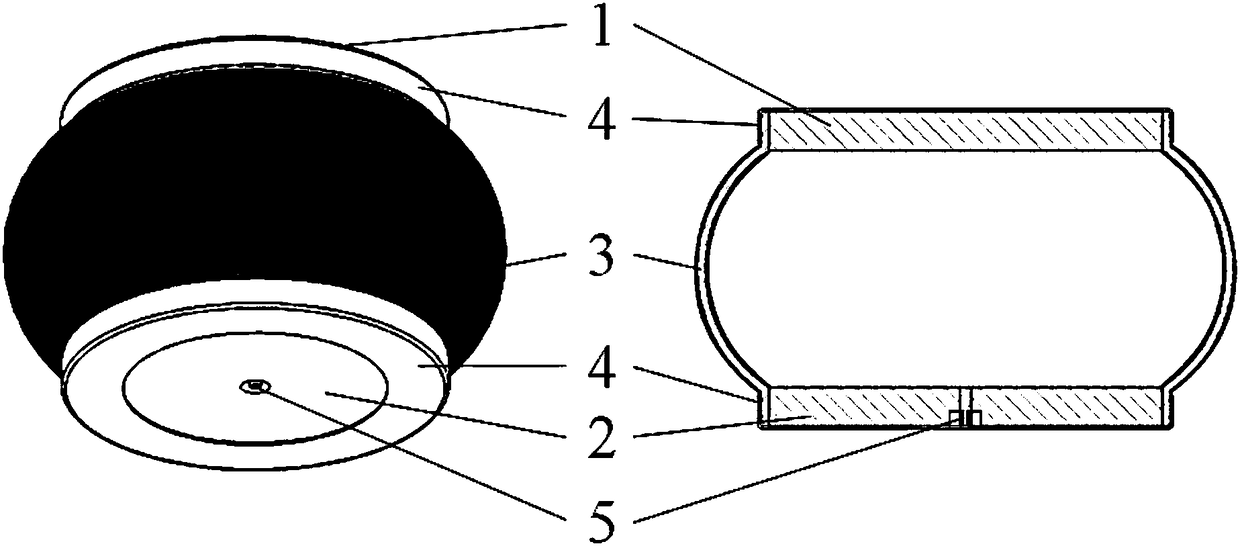

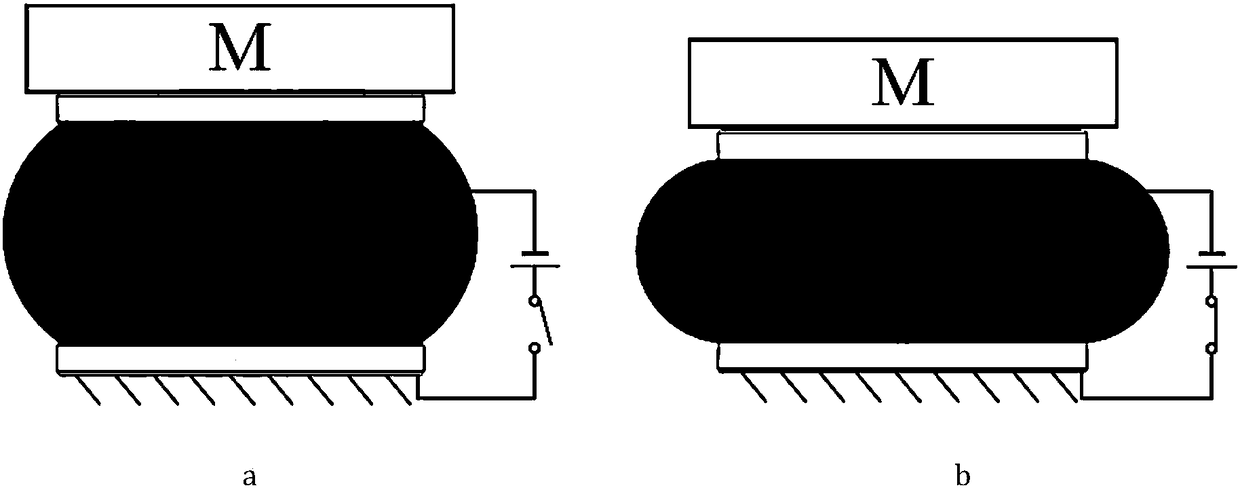

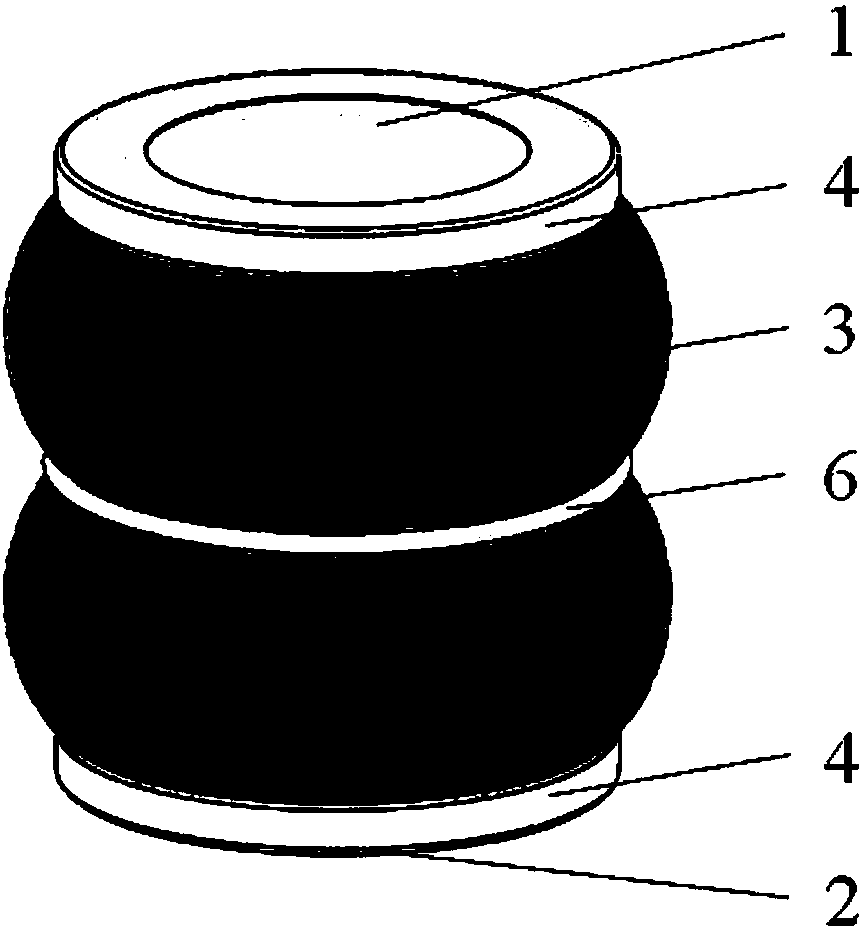

Dielectric elastomer active vibration isolation air spring

InactiveCN108488291ARealize the effect of active vibration isolationReduce volumeSpringsGas based dampersInternal pressureSilicone membrane

The invention provides a dielectric elastomer active vibration isolation air spring comprising a dielectric elastomer air bag with an upper end cover and a lower end cover. The inner portion of the dielectric elastomer air bag is hollow and forms an air bag structure. The dielectric elastomer air bag is composed of silicone membrane or rubber membrane, wherein the two sides of the silicone membrane or rubber membrane are coated with flexible electrodes. When voltage is applied to the dielectric elastomer air bag, induced maxwellian stress enables the area of the air bag to be increased and thethickness of the air bag to be reduced, under the action of the internal pressure and the borne load, the dielectric elastomer air bag expands outwards, and different descent displacements can be generated by changing the amplitude of the applied voltage. When the voltage is removed, the air spring rapidly recovers, and the borne load can be jacked to the original position. In this way, active vibration isolation can be achieved through control over voltage application. The dielectric elastomer active vibration isolation air spring is compact in structure, light in mass, silent in operation,convenient to control and rapid in response, the stiffness and damping of the air spring can be controlled through voltage application, and then active vibration isolation is achieved.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com