Jig for case sand blasting of electronic product

An electronic product, sandblasting technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of easy displacement or deviation, incomplete adhesion, difficult positioning, etc., to achieve accurate positioning, Reduce the amount of deformation and avoid the effect of residual glue on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

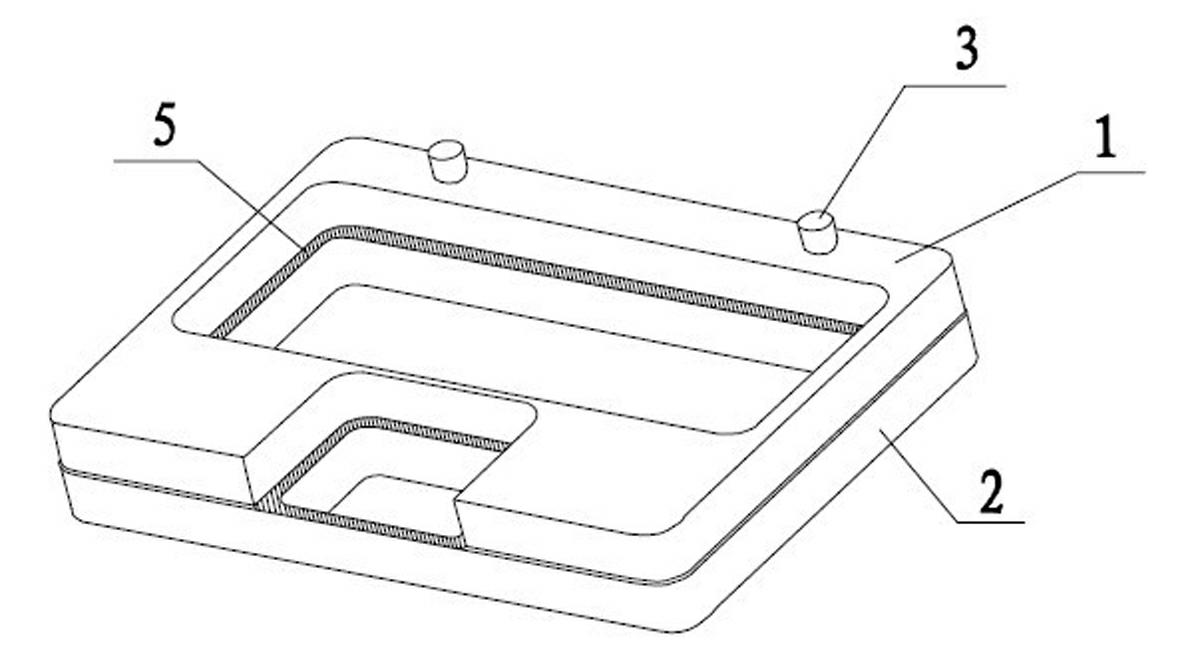

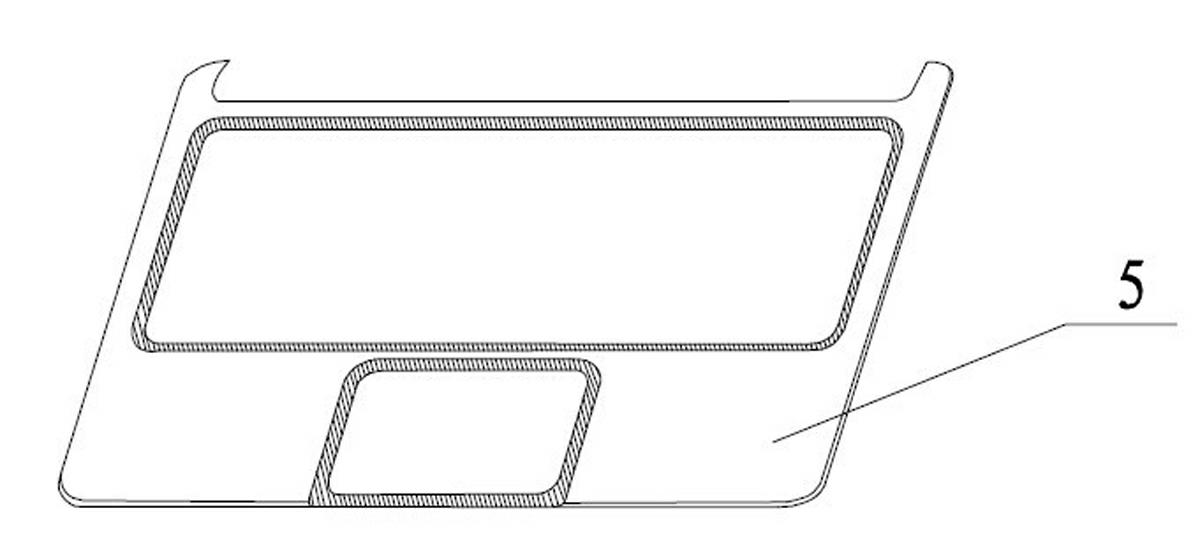

[0017] This embodiment provides a jig for sandblasting a notebook computer case. Such as image 3 As shown, the casing of the notebook computer in this embodiment is set on the computer keyboard, the shaded part in the figure is the sandblasting area of the casing, and the rest is the non-sandblasting area.

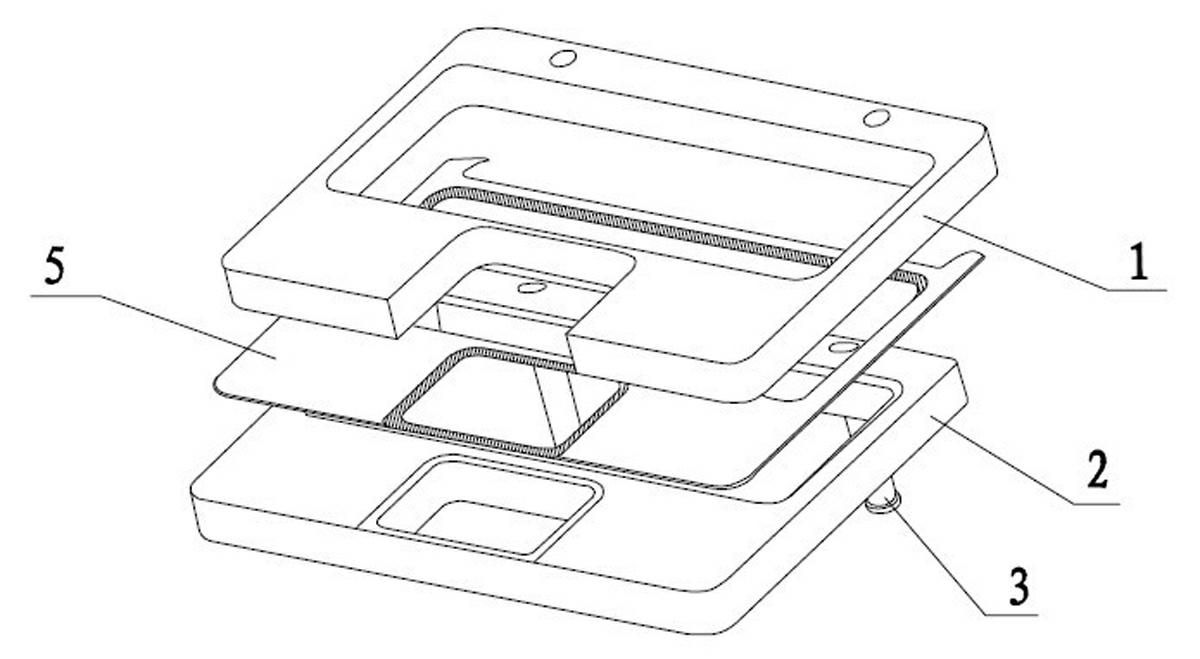

[0018] see figure 1 , 2 and 4, the jig of this embodiment is used to cover the non-sandblasting area of the notebook shell shell 5 during sandblasting, including the upper plate 1, the lower plate 2 and the upper plate 1 and the lower plate 2, and the two The positioning bolt 3 is fixed; the shape of the upper plate 1 is opened according to the non-blasting area on the surface of the shell 5, and is used to cover the non-blasting area on the surface of the shell 5; when the shell 5 is located on the upper plate 1 and the lower plate 2, the upper plate 1 can stick to the surface of the shell 5, and the upper plate 1 has a layer of silica gel layer 4 on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com