Pressure sensing pickup principle based comb-type roller pick-up machine

A comb type and picker technology, which is applied in the agricultural field, can solve the problems of damage to fruit skin, lack of protective function, and too much soil, so as to avoid residues, ensure protection, and improve yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

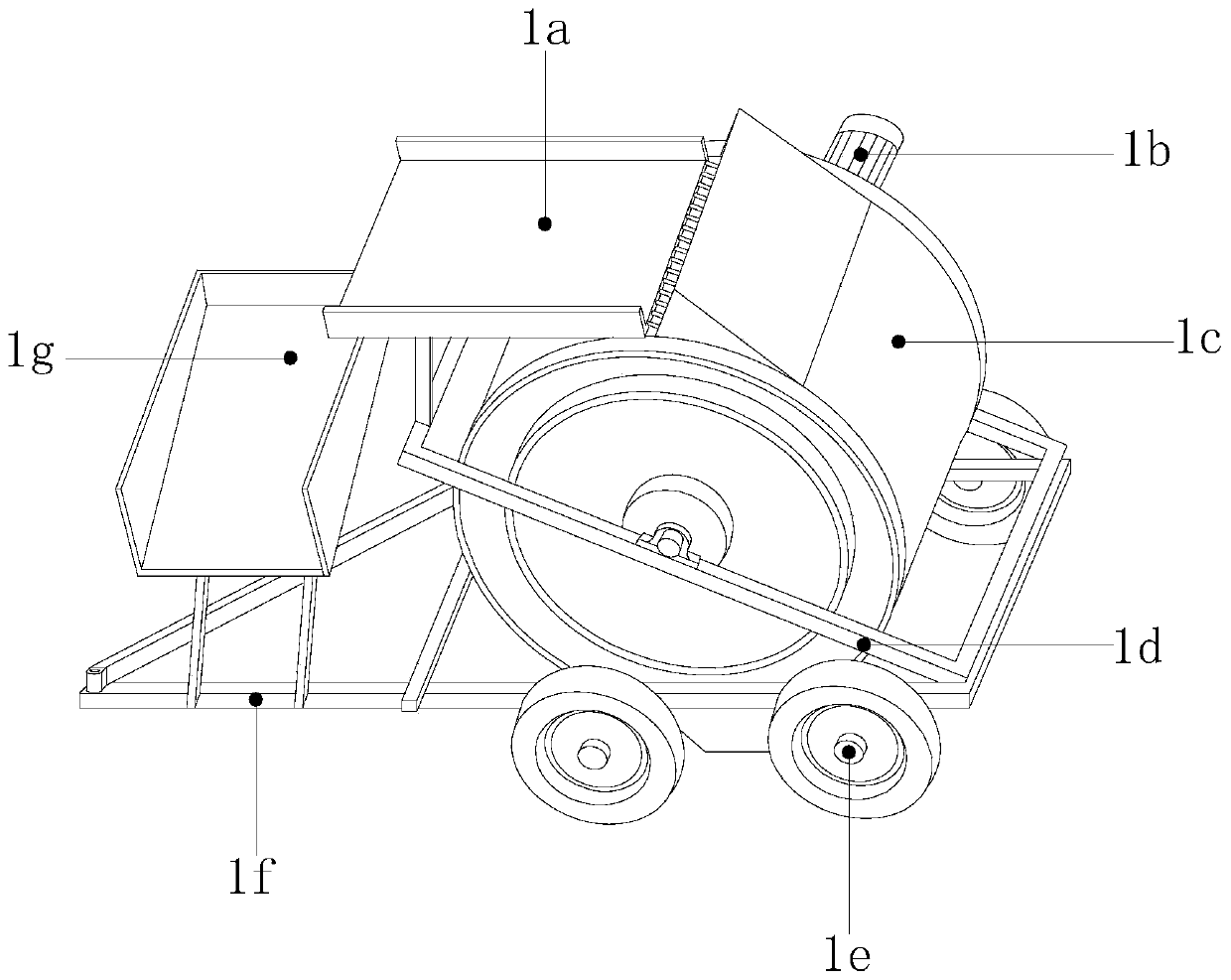

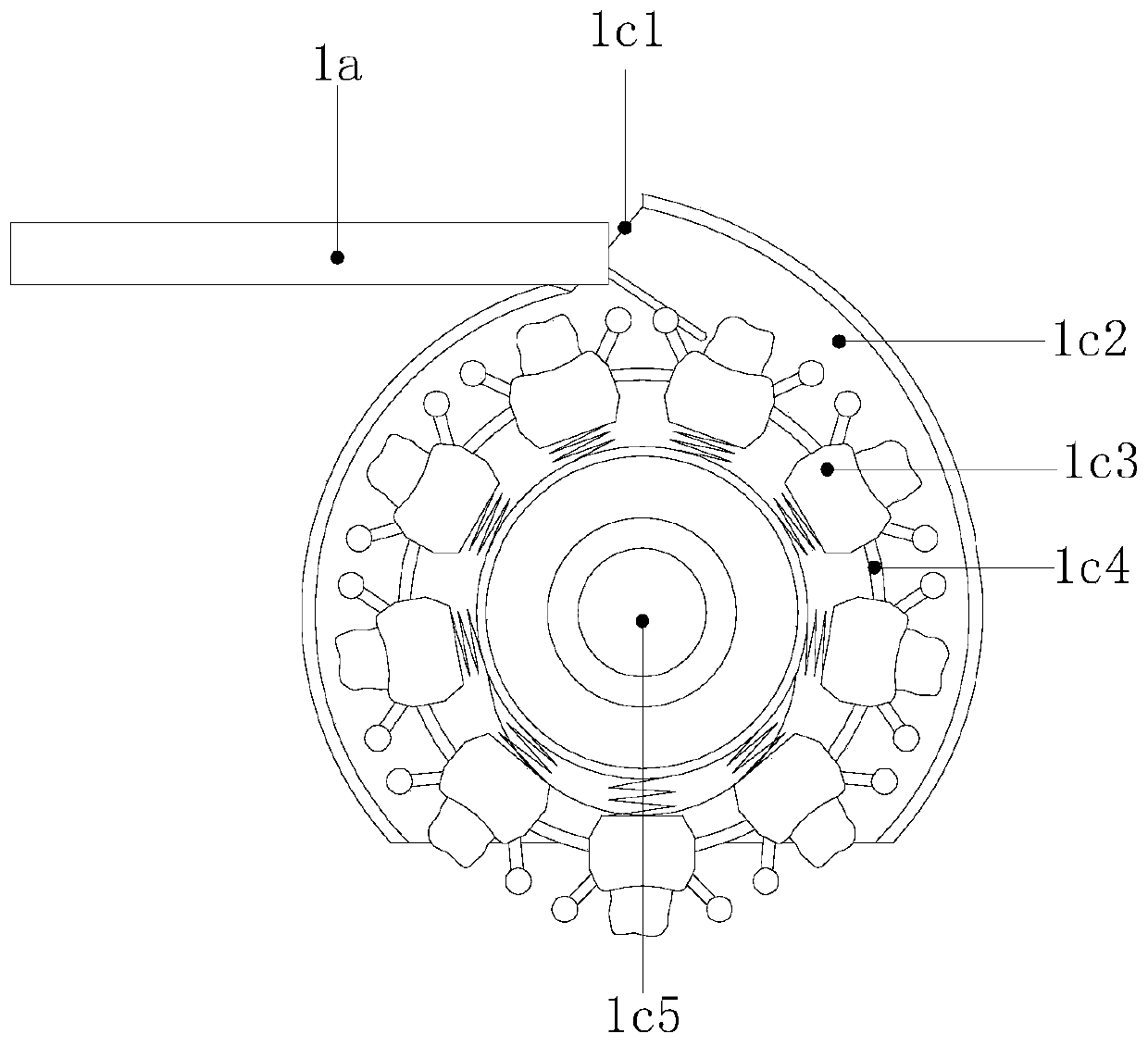

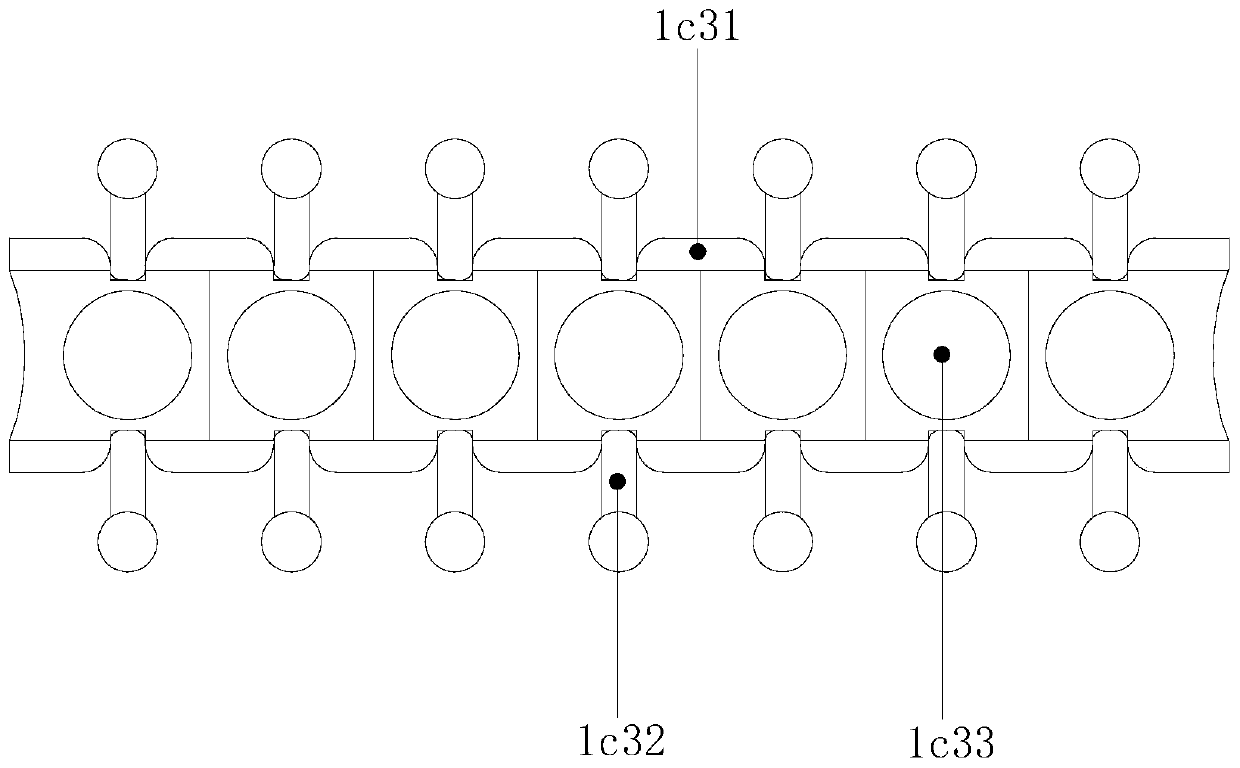

[0030] see Figure 1-Figure 6 , the present invention provides a comb-toothed roller pick-up machine adopting the principle of pressure-sensing pick-up, its structure includes a comb-tooth disc 1a, a drive motor 1b, a pick-up bin 1c, a positioning bracket 1d, a moving wheel 1e, a moving frame 1f, and a discharge tray 1g, the positioning bracket 1d is installed on the right end of the top of the moving frame 1f by welding, four moving wheels 1e are evenly and equidistantly arranged on both sides of the right end of the moving frame 1f, and the two sides of the picking bin 1c are installed on the The middle part of the positioning bracket 1d, the comb plate 1a is installed on the left end of the top of the pick-up bin 1c by welding, the bottom of the discharge plate 1g is connected to the left end side of the moving frame 1f, and the drive motor 1b is installed on the pick-up bin by embedding. The rear end of the bin 1c is driven by the drive motor 1b to rotate the picking bin 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com