Unloading and dismantling construction method for heavy-duty floor type steel pipe support

A steel pipe support and construction method technology, which is applied in the processing of formwork, erecting/assembling bridges, and processing building materials, etc., can solve the problems of cumbersome construction, high safety risks, and difficult realization, and achieves low cost, rapid drop, The effect of strengthening economic value and promoting application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

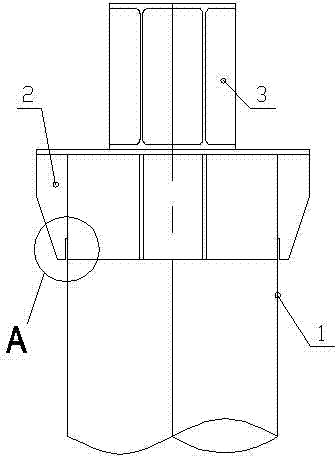

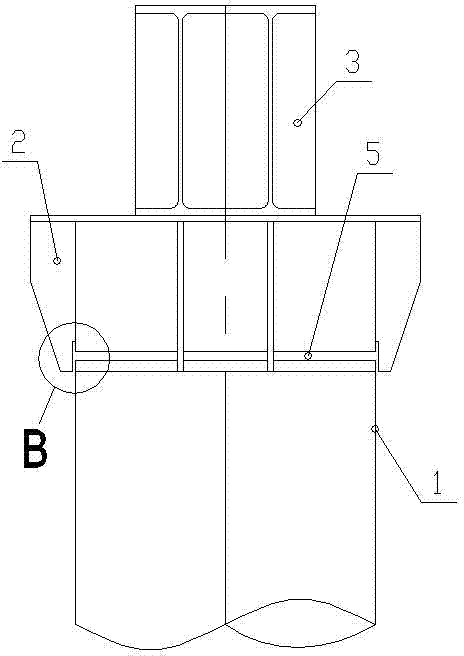

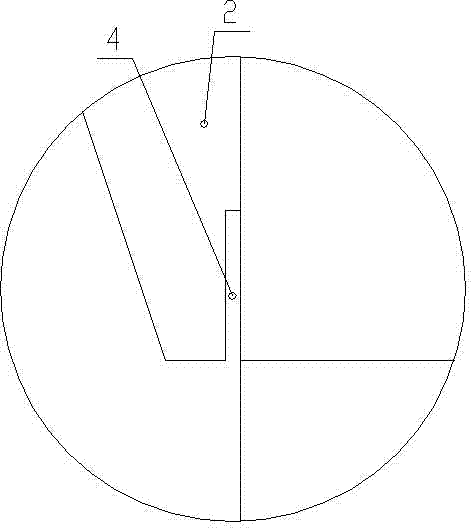

[0014] Such as figure 1 with figure 2 As shown, the steel pipe column support in the present invention is an existing structure, including a steel pipe column 1, and a number of stiffening plates 2 (generally 4-6 pieces) are uniformly arranged on the top column head part of the steel pipe column 1 along the circumferential direction, and each stiffening plate 2 All are arranged along the radial direction of the steel pipe column 1. The top ends of the steel pipe column 1 and the stiffening plate 2 are connected to the distribution beam 3, and the distribution beam 3 carries a bottom formwork system upwards (the bottom formwork is a conventional structure, which has different shapes according to different construction structures, and the bottom formwork is not shown in the figure). During construction, it is used to support the building structure to be constructed. The bottom opening of the steel pipe column 1 is supported on a rigid foundation such as a cap.

[0015] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com