Patents

Literature

108results about How to "Improve production efficiency and product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

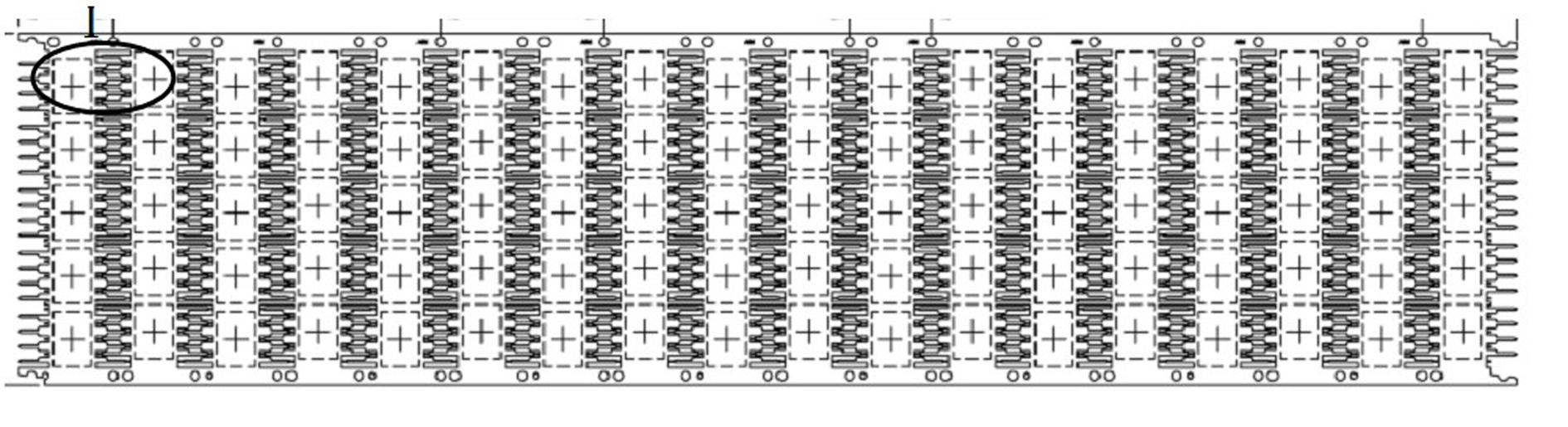

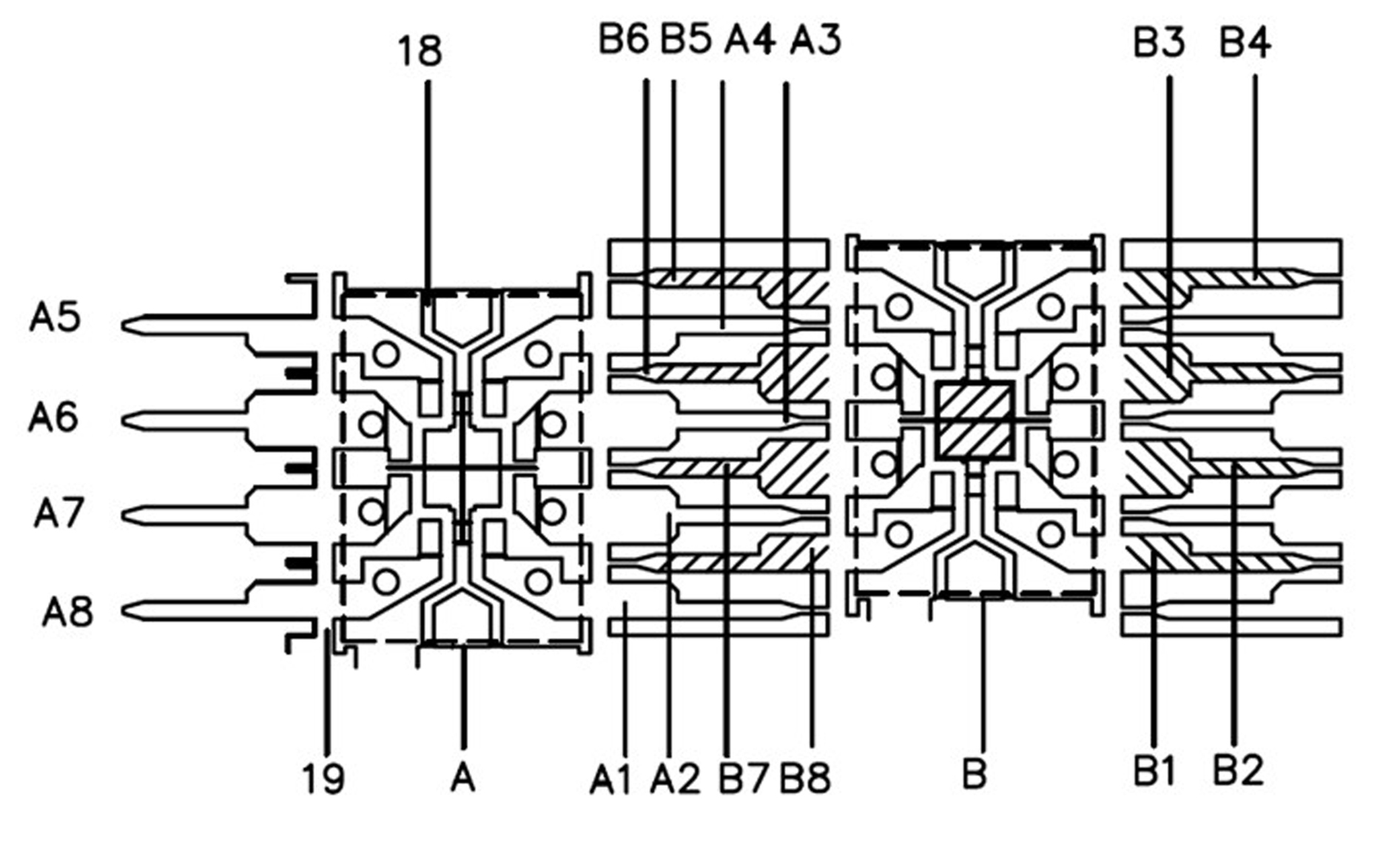

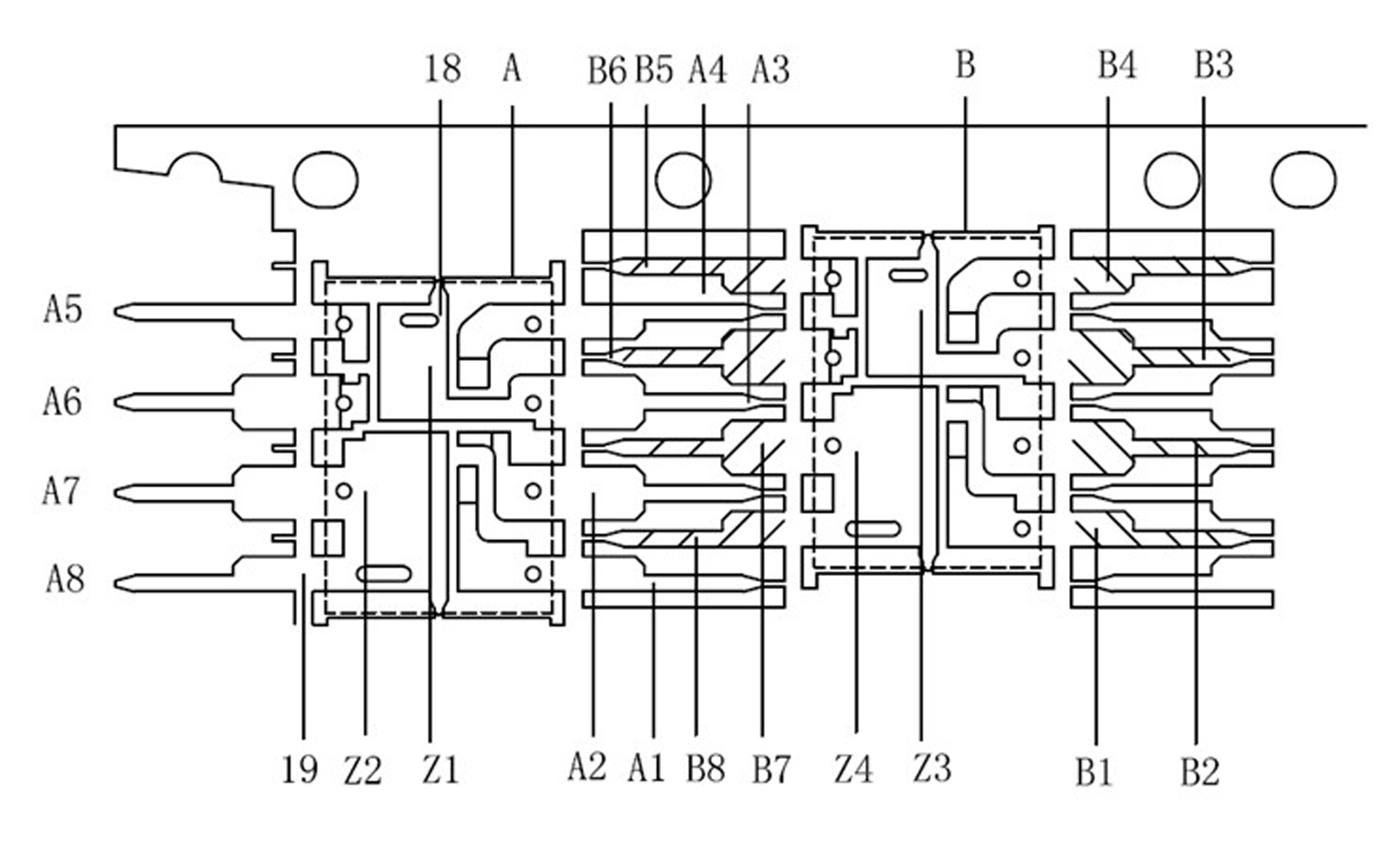

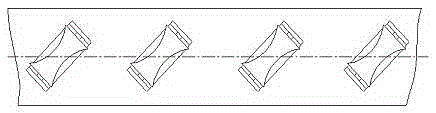

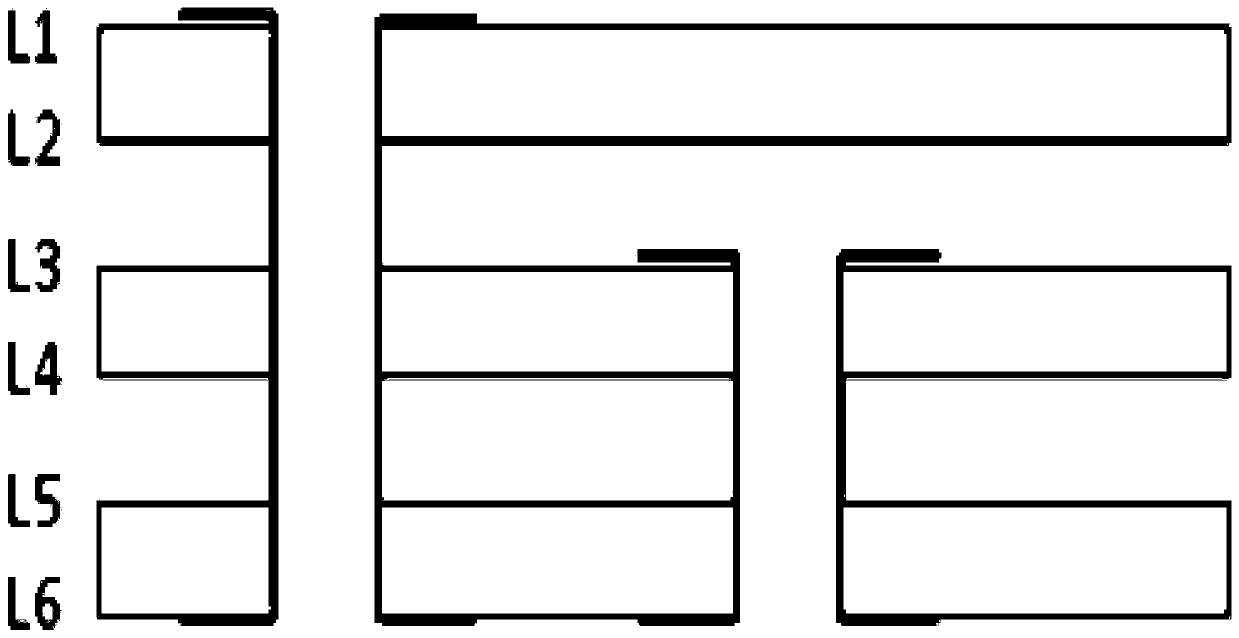

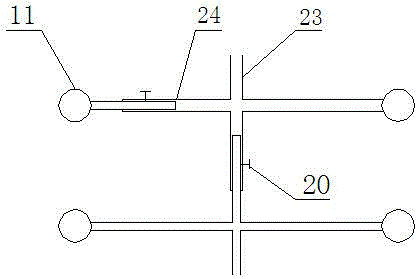

Matrix dual in-line package (DIP) lead frame, integrated circuit (IC) packages based on frame and production method of IC packages

ActiveCN102074540AImprove production efficiency and product qualityReduce error rateSemiconductor/solid-state device detailsSolid-state devicesPrinted circuit boardDIP switch

The invention provides a matrix dual in-line package (DIP) lead frame, integrated circuit (IC) packages based on the frame and a production method of the IC packages. The matrix DIP lead frame comprises a frame and a plurality of unit frames in the frame, wherein the unit frames are distributed on the frame in a matrix manner and are in odd-numbered lines; the base islands of the adjacent unit frames in the 2n-1 line and the 2n line are connected with the borders of the frame via connecting bars; and the outer lead pins of the adjacent unit frames in the 2n-1 line and the 2n line are arranged in a staggered manner and are connected with the borders of the frame via grids. The invention improves the use ratio of the frame materials, has simple and reasonable structure, has the advantages of low cost, energy conservation and emission reduction and the like, can be widely applied in the fields such as LED tubes, computer interface types, power supply modules, network transformers, DIP switches, pressure sensors, standard logic ICs, large-scale integration (LSI) of memories and the like and is convenient for implementing printed circuit board (PCB) perforating and welding.

Owner:TIANSHUI HUATIAN TECH

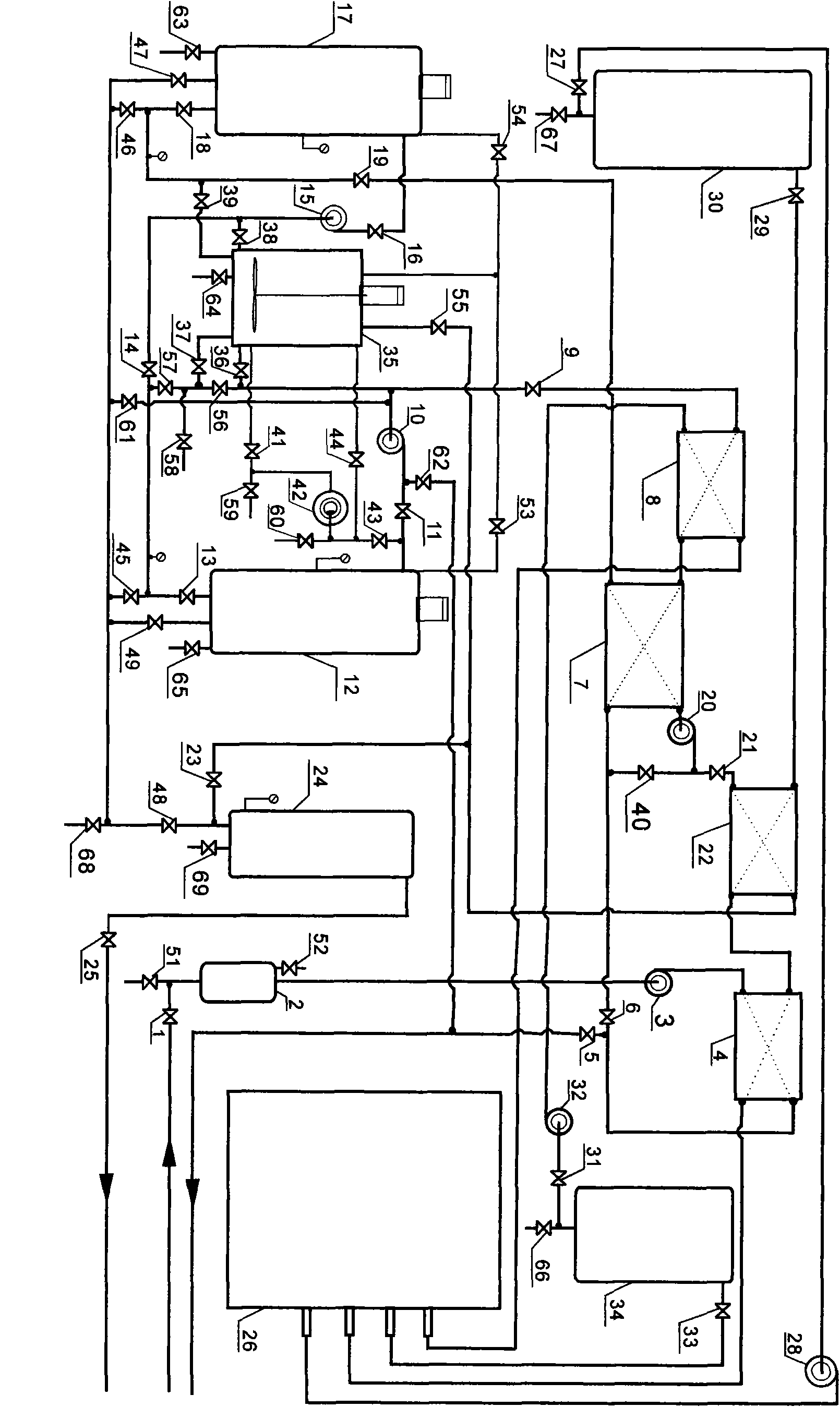

Liquid environment protection energy-saving low-temperature filter and process thereof

ActiveCN101797455AReduce manufacturing costImprove production efficiency and product qualityAlcoholic beverage preparationFiltration separationEngineeringGreenhouse effect

The invention provides a liquid environment protection energy-saving low-temperature filter and a process thereof, which relate to a low-temperature filter for separating other impurities from mild wine and a process thereof. The invention aims at solving the problem of filtration at the non-constant temperature of the exiting ordinary refrigerating filter and overcoming the defects of great operation difficulty, water resource waste and room temperature effect caused by the factor of the filtration at the non-constant temperature. The invention uses the normal temperature of the original liquid to carry out exchange with condensed liquid through an energy-saving exchanger, twice cold energy exchange and recovery of the cold energy of clean liquid after the filtration can be realized through the energy-saving exchanger, and the temperature of the condensed liquid really reaches the temperature reduction standard requirement of a refrigerating machine, so the goal that the refrigerating filter set works in the constant temperature filtering work requirement range is reached. The defects of a water cooling tower are avoided, and the goals of full utilization of energy sources, high efficiency, energy saving, environment protection and practicability are realized.

Owner:高云芝

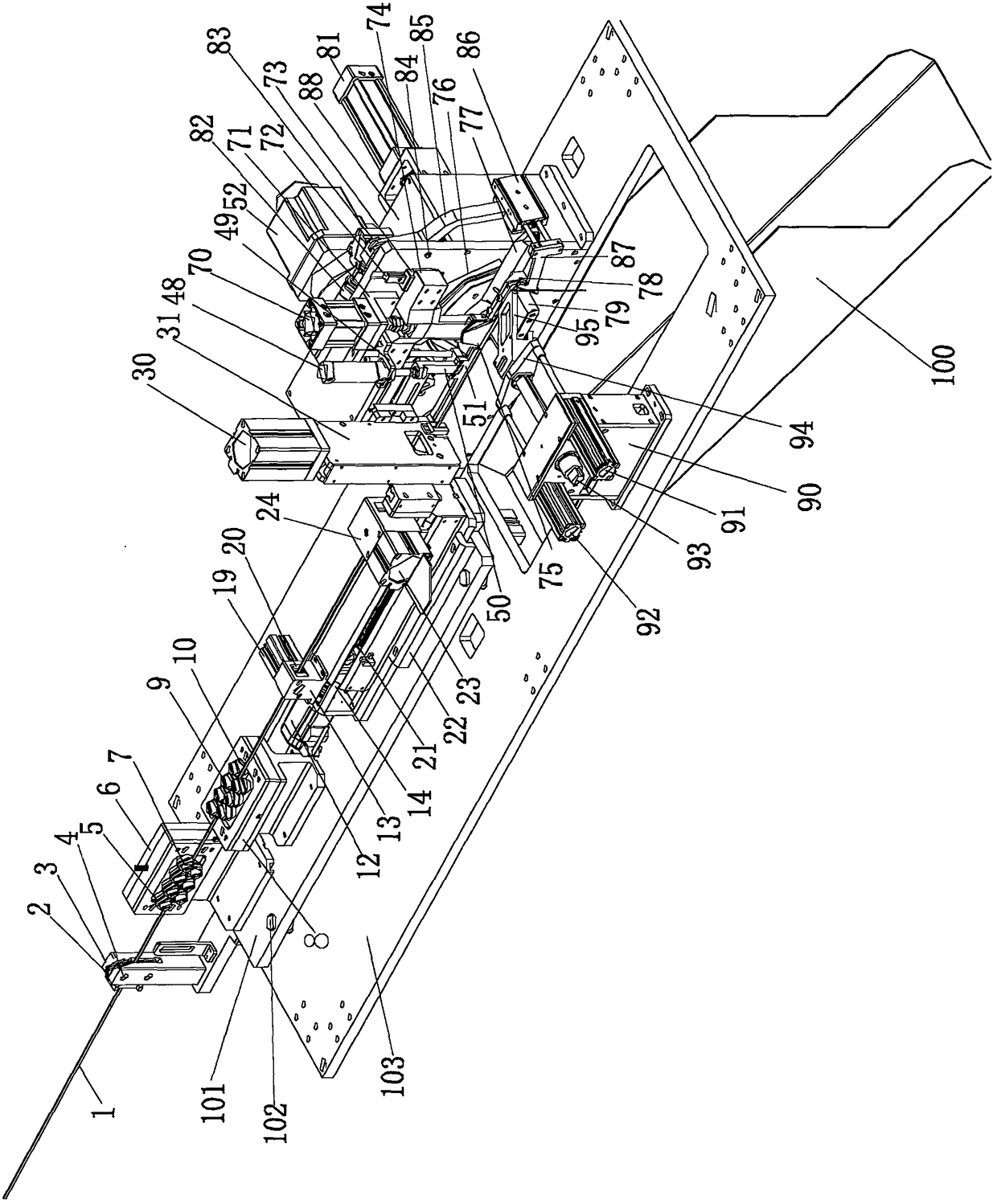

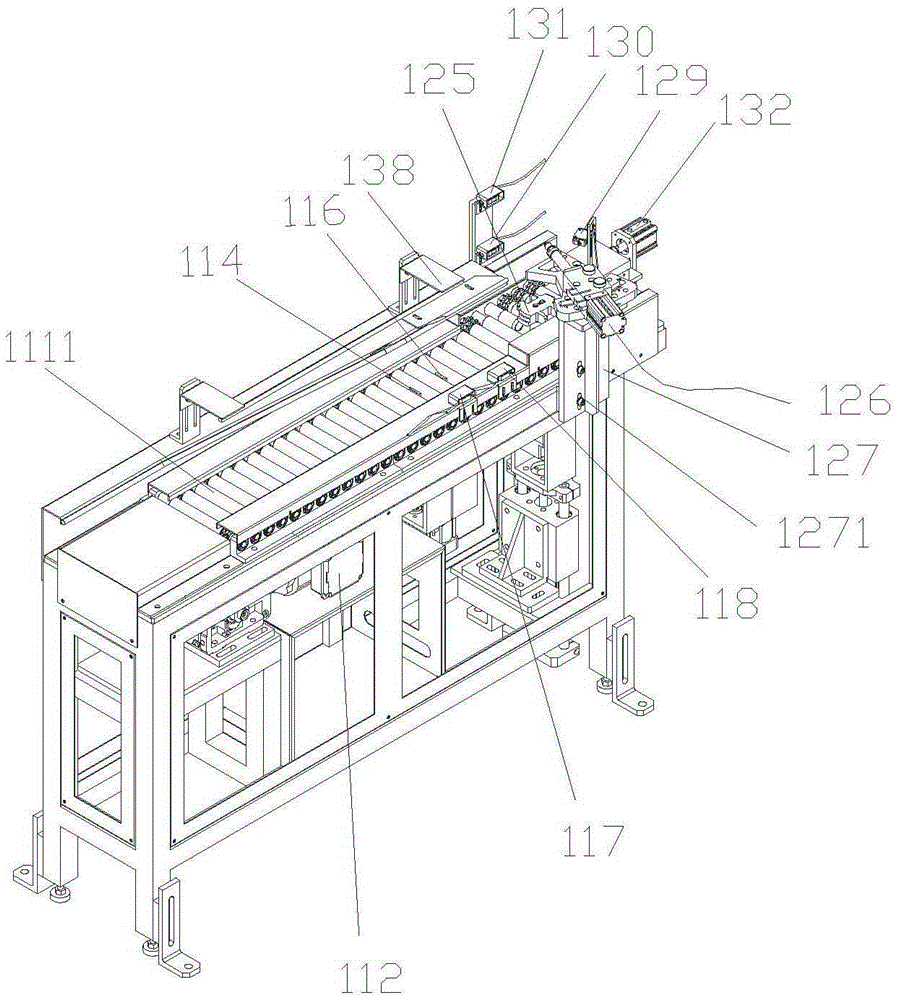

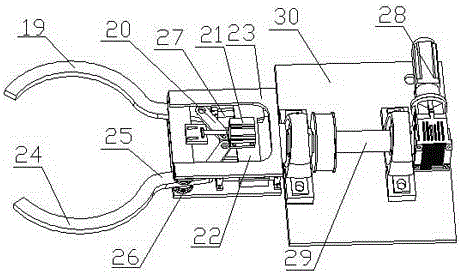

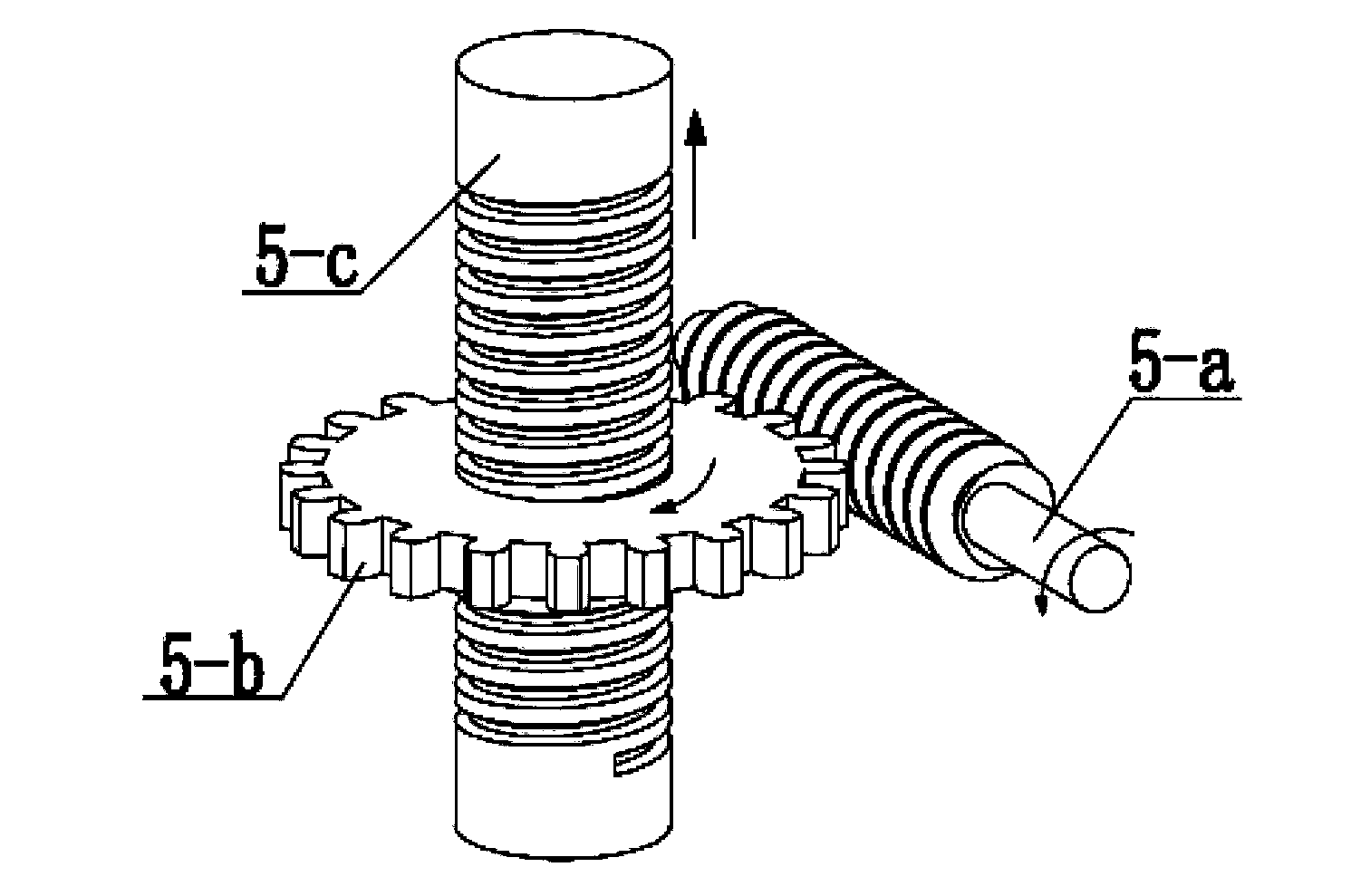

Automatic bristle filling mechanism for paint brush head

InactiveCN103181679AHigh degree of automationImprove production efficiency and product qualityBrush bodiesProcess engineeringProgrammable logic controller

The invention discloses an automatic bristle filling mechanism for a paint brush head, which comprises a steel casing conveying and positioning mechanism, a bristle dividing and taking mechanism, a uniform pressing and dabbing mechanism, a filling and stuff-up mechanism, a shaving and roughening carding mechanism and a control system. The automatic bristle filling mechanism adopts the PLC (Programmable Logic Controller) control system to control a servo motor and a plurality of cylinders, so that a plurality of processes can synchronously work; a filling manner of the automatic bristle filling mechanism adopts a vertical filling manner; the automatic bristle filling mechanism adopts the process of uniformly pressing for at least once, dabbling for at least twice and filling for at least once; the filling and stuff-up mechanism of the automatic bristle filling mechanism adopts a movable rack; and each mechanism of the automatic bristle filling mechanism can be regulated by a handwheel to adapt to the paint brush heads with different specifications. The automatic bristle filling mechanism has high automation degree, can effectively improve product quality, has high production efficiency, can effectively reduce use of labor, saves cost and has a wide market prospect.

Owner:福建新金誉自动化科技有限公司

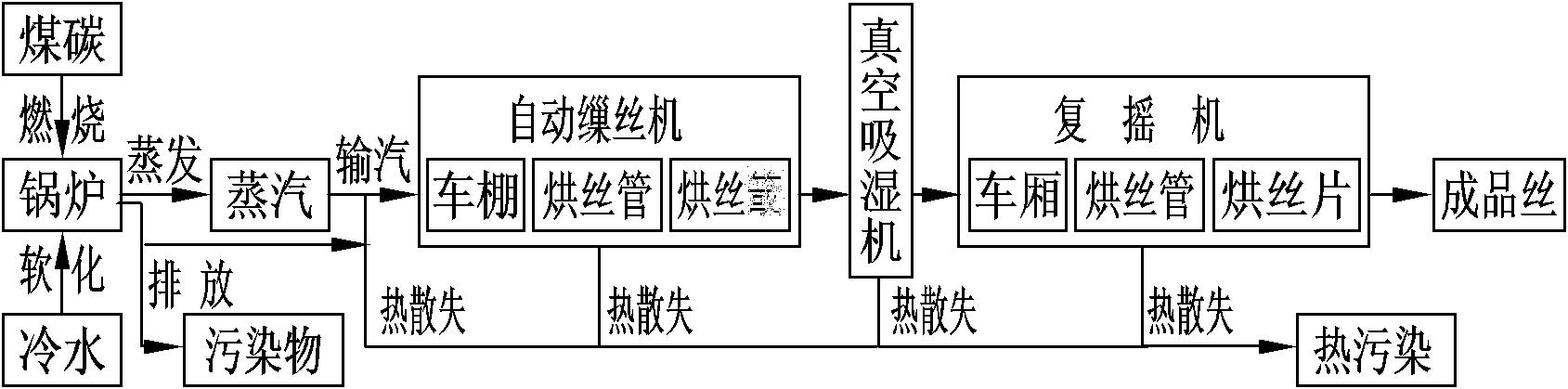

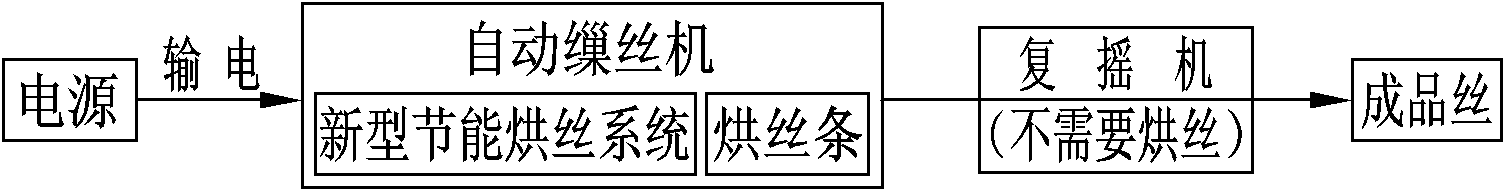

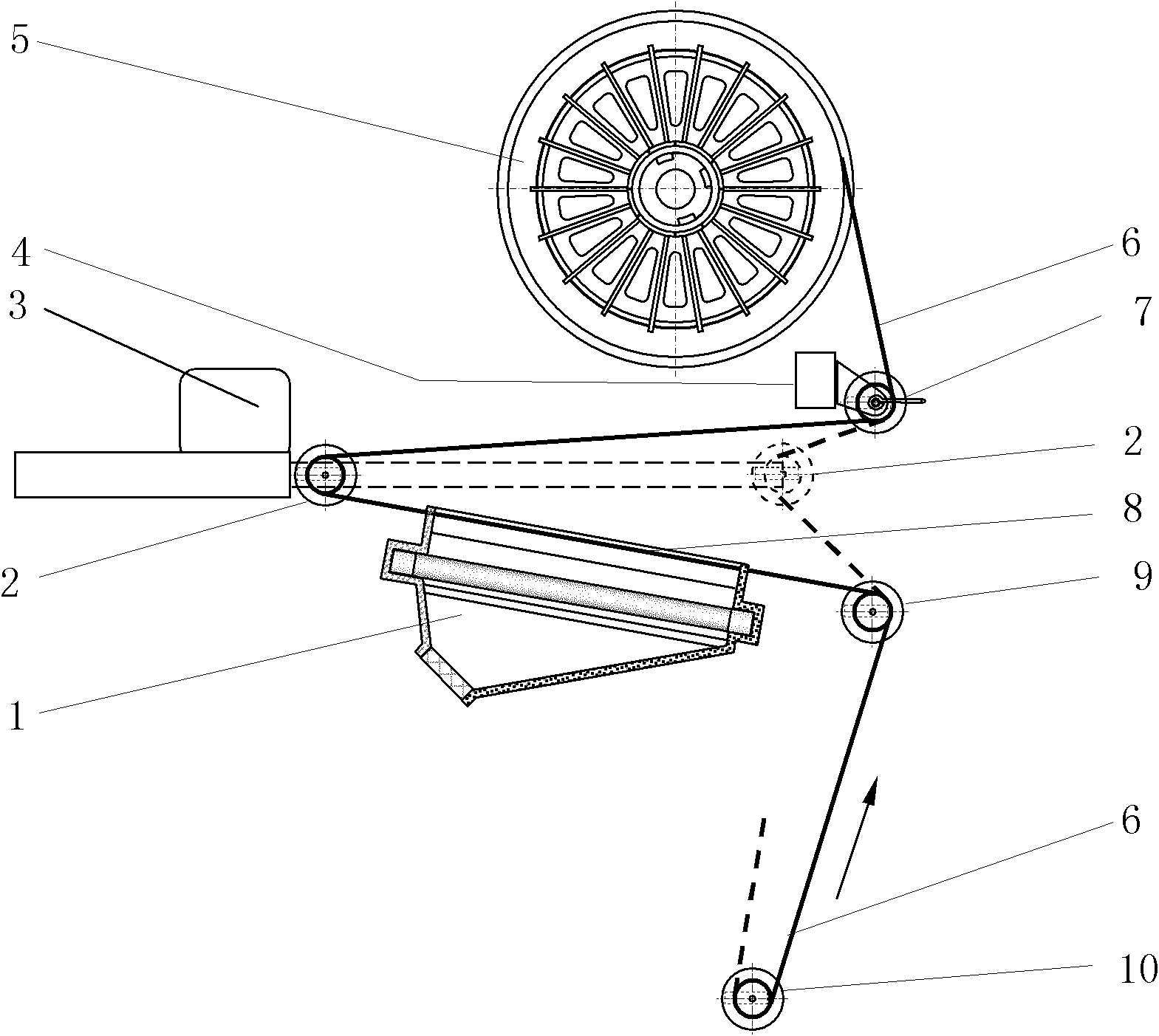

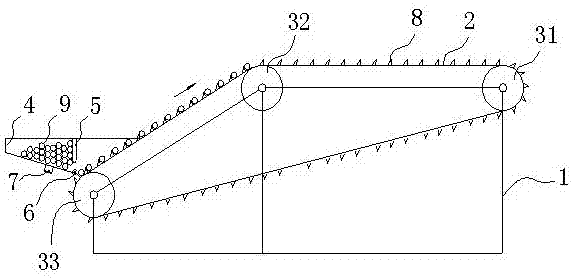

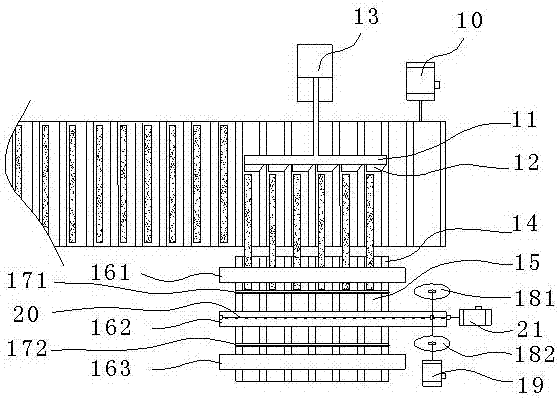

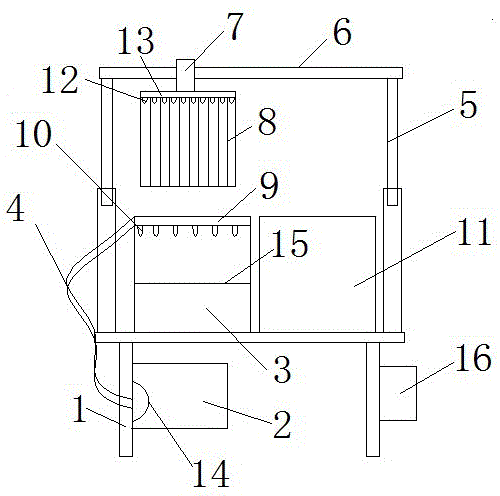

Novel energy-conservation silk drying system of automatic silk reeling machine

ActiveCN101984156AImprove production efficiency and product qualityReduce manufacturing costArtificial filament washing/dryingSilk reelingProcess engineeringEnergy loss

The invention relates to an automatic silk reeling machine in the technical field of raw silk production in the silk reeling industry, in particular to a novel energy-conservation silk drying system of an automatic silk reeling machine. The novel energy-conservation silk drying system comprises a compensation drum wheel, a traverse rod, a silk arranging drum wheel and a small silk-collecting tool. The technical scheme of the invention is as follows: a silk drier inlet drum wheel is arranged at the silk outlet of the compensation drum wheel, a far infrared silk drier is arranged adjacent to the silk drier inlet drum wheel, a photoelectric automatic silk moving mechanism is arranged at the silk outlet of the far infrared silk drier, and the silk outlet of the photoelectric automatic silk moving mechanism is provided with the silk arranging drum wheel. In the invention, less air is heated to heat wet raw silks, the raw silks are evenly dried at a high speed, and silk drying can be finished in the silk reeling machine once, thus the novel energy-conservation silk drying system not only saves energy, but also is favorable for lowering the workshop temperature, the silk reeling operation environment is improved, the problems of multiple working procedures, large energy loss and high workshop temperature of the traditional silk steam drying system for silk reeling production can be thoroughly solved, and according to incomplete statistics, the silk reeling energy consumption is greatly reduced compared with the silk coal-fired steam drying process.

Owner:SICHUAN RES INST OF SILK SCI

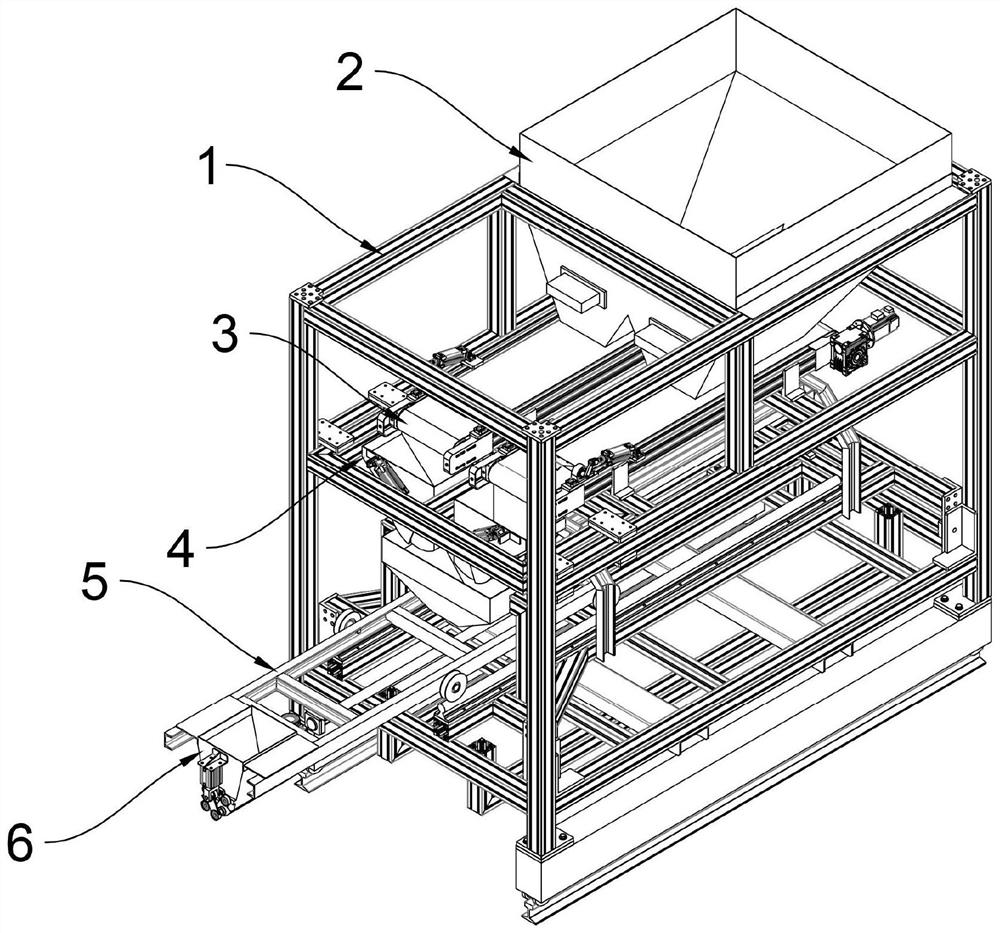

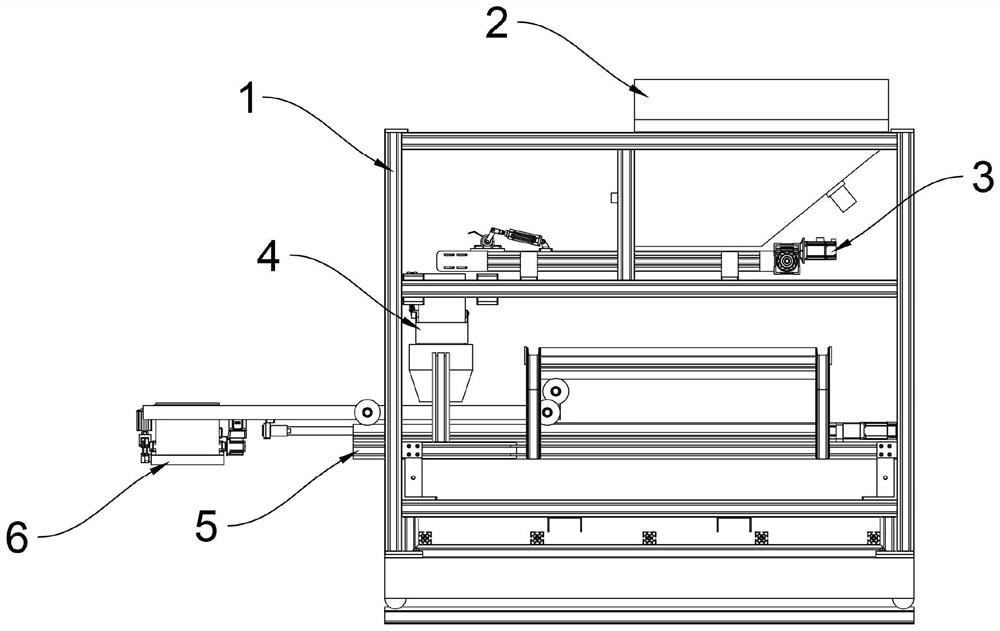

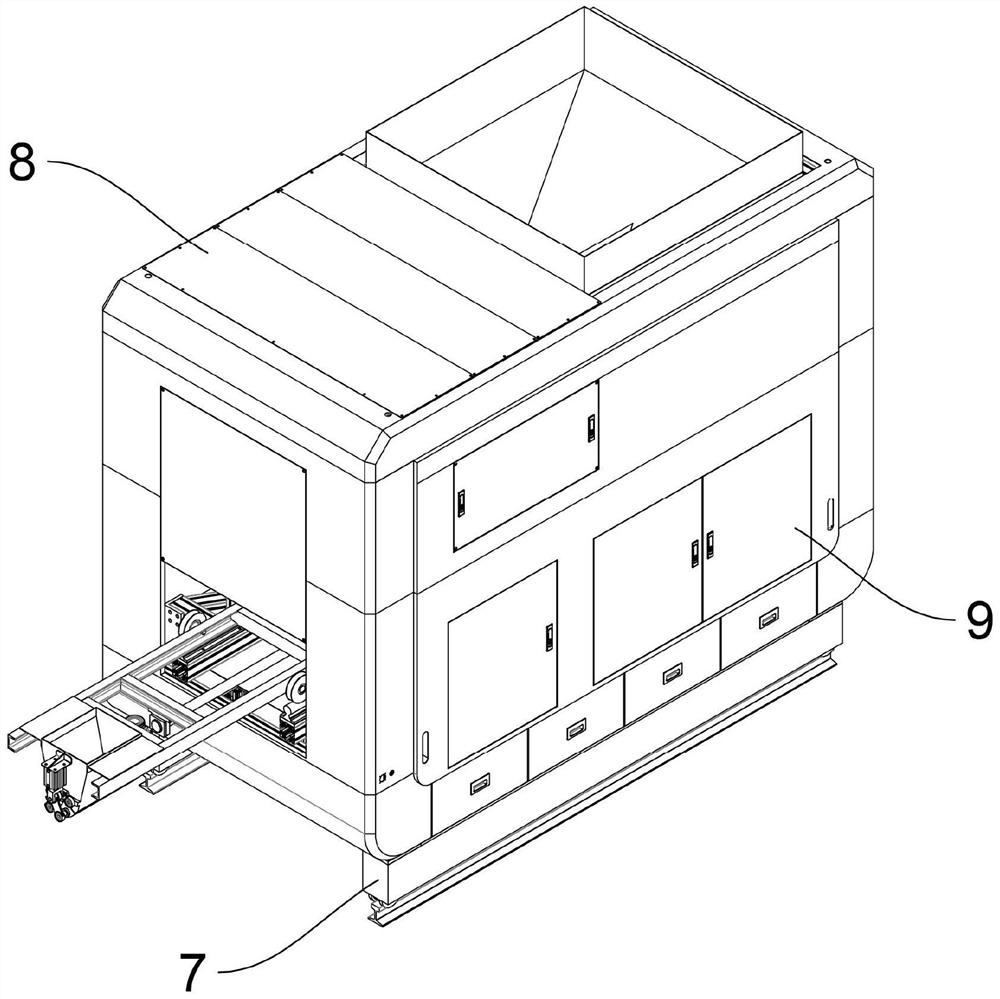

Automatic feeding and cutting device of glass rod material

ActiveCN107117806AImprove production efficiency and product qualityMeet the requirements of fast section cuttingGlass severing apparatusGlass productionBatch productionEngineering

The invention discloses an automatic feeding and cutting device of a glass rod material, belongs to the technical field of secondary drawing and mating of glass preformed rods and mainly solves the problems of large labor intensity, high risks, low production efficiency, unreliable product quality and the like of the prior art. The automatic feeding and cutting device is mainly characterized by comprising a rack, a feeding system and a cutting system, wherein the feeding system comprises a material collection box, a conveyor belt, a driving wheel, a driven wheel, a tensioning wheel, a servo motor, a material pushing plate and a material pushing cylinder; sawtooth-shaped raised strips are arranged on the conveyor belt at intervals; the material pushing plate and the material pushing cylinder are arranged on the rack which is arranged at the side part of the other end of the conveyor belt; the cutting system comprises a working platform, a material pressing plate, a cutting blade, a blade rotation driving motor, a blade feeding screw rod and a bladed feeding driving motor; the cutting blade, the blade feeding screw rod and the blade feeding driving motor are arranged on the material pressing plate. The automatic feeding and cutting device disclosed by the invention has the characteristics of high production efficiency, good product quality, simpleness and convenience in operation and safety and reliability, and is suitable for batch production of the glass rod material.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Environment-friendly stirring equipment for internal wall putty powder production and processing

InactiveCN108609209AImprove production efficiency and product qualityImprove quality and efficiencyRotary stirring mixersSolid materialEngineeringUltimate tensile strength

The invention discloses environment-friendly stirring equipment for internal wall putty powder production and processing. The environment-friendly stirring equipment comprises a shell; the upper surface of the shell is fixedly connected with a U-shaped plate; the upper surface of the U-shaped plate is fixedly connected with a rotating motor; an output shaft of the rotating motor is fixedly connected with the U-shaped plate through a first rolling bearing; the output end of the rotating motor penetrates through the U-shaped plate, downwards extends and is fixedly connected with a first gear; two circular through holes are formed in the upper surface of the shell, and the hole walls of the circular through holes are fixedly connected with second rolling bearings; the inner walls of the two second rolling bearings are fixedly connected with stirring rods; the top ends of the two stirring rods are fixedly connected with second gears correspondingly, and the two second gears are engaged with the first gear jointly; and a first hopper is fixedly connected to the bottom end of the shell. The product quality and production efficiency of putty powder are improved, the putty powder subpackage process is quick and convenient, the time and labor are saved, and the labor intensity of workers is reduced.

Owner:贵州省漆彩金州涂料有限公司

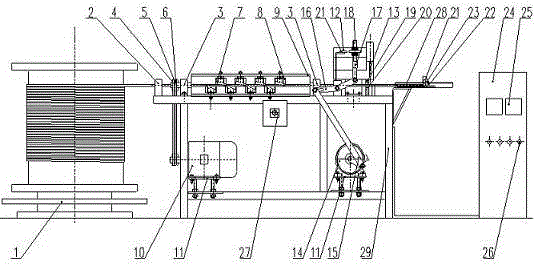

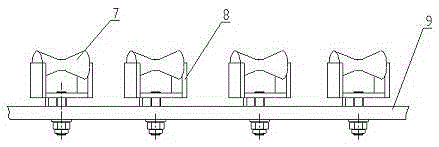

Winding forming machine for flat type copper wire

PendingCN109378952AImprove production efficiency and product qualityReduce manual labor intensityManufacturing dynamo-electric machinesWire cuttingPush out

A winding forming machine for a flat type copper wire includes a table plate, and a wire fixing seat, a vertical alignment mechanism used for vertically aligning the flat type copper wire, a horizontal alignment mechanism used for horizontally aligning the flat type copper wire, a wire feeding mechanism used for conveying the flat type copper wire, a wire cutting mechanism, a wire guiding mechanism, a wire press mechanism, a wire lead mechanism, a wire folding mechanism, a wire winding mechanism, a wire pushing mechanism for pushing out formed coils, and a material channel which are installedon the table plate. The wire fixing seat, the vertical alignment mechanism, the horizontal alignment mechanism, the wire feeding mechanism, the wire cutting mechanism, the wire guiding mechanism, thewire press mechanism, the wire winding mechanism, and the wire folding mechanism are arranged in order from back to front; and a discharging opening used for discharging the coils is disposed on a front side of the table plate, and the material channel is located below the table plate and is installed on the discharging opening. The invention provides the winding forming machine for the flat typecopper wire, which is capable of automatically setting the length of a lead wire and automatically winding forming, thereby improving the production efficiency and the product quality, and the labor intensity of workers is reduced.

Owner:金华市捷欣智能科技有限公司

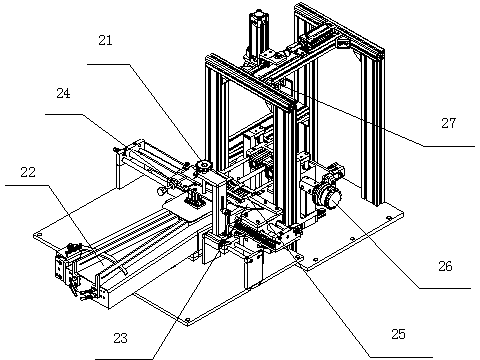

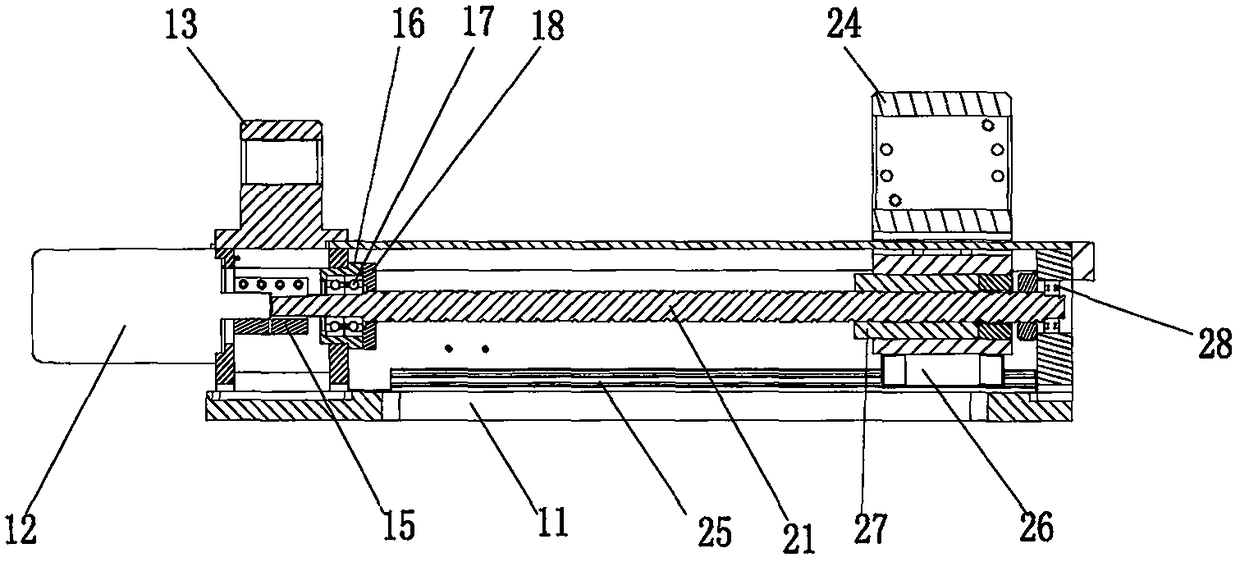

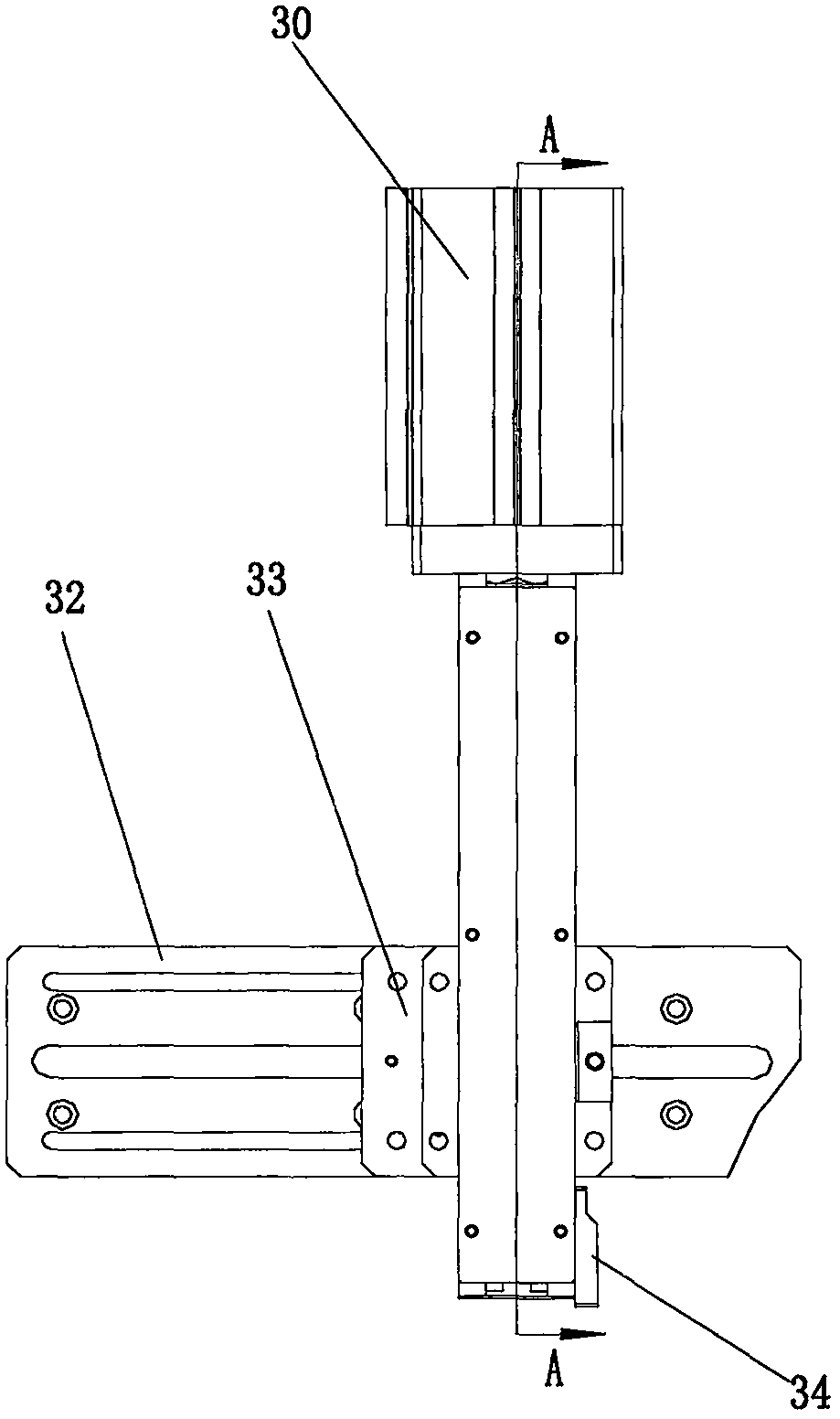

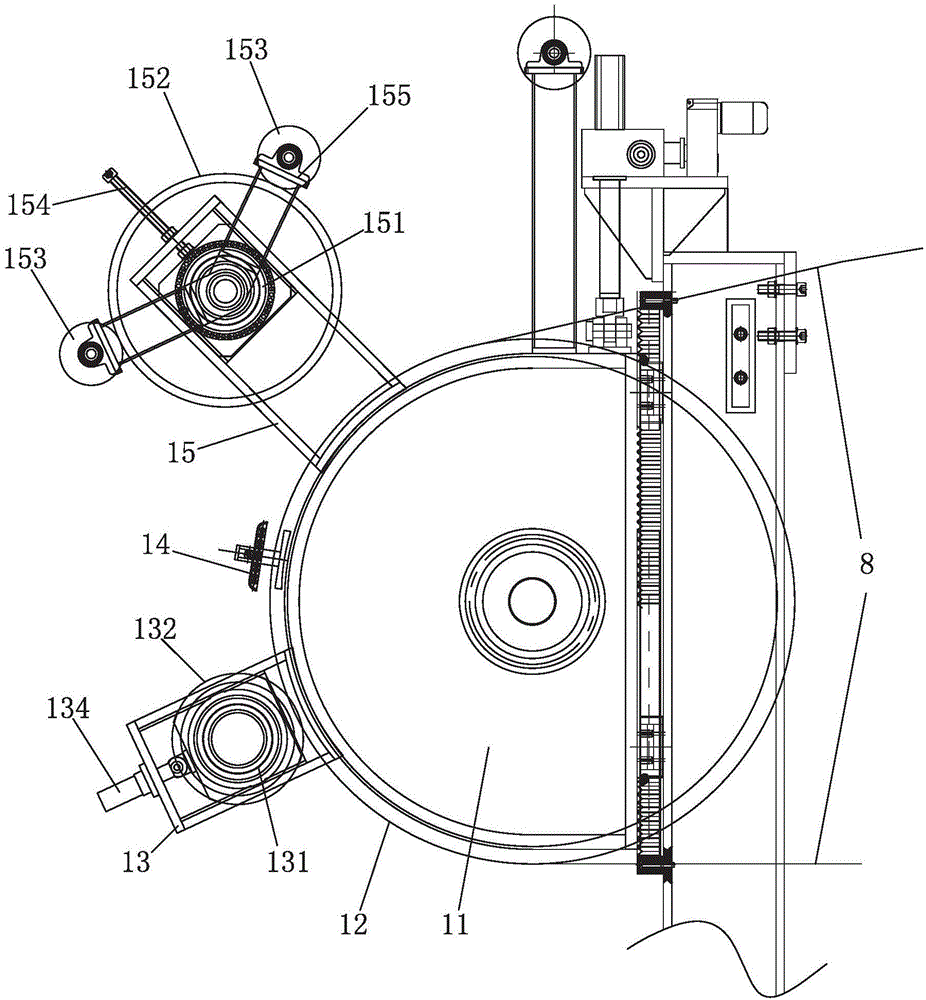

Processing equipment for straightening and cutting steel stranded wire

ActiveCN105290265AImprove production efficiency and product qualityAchieve alignmentWire segmentEngineering

The invention provides processing equipment for straightening and cutting a steel stranded wire. The processing equipment comprises a conveying tray, wherein a rack is arranged on one side of the conveying tray, a guide wheel is arranged on the rack, a conveying and straightening mechanism is arranged on one side of the guide wheel, the conveying and straightening mechanism comprises a conveying frame, a toothless saw is arranged on one side of a discharging opening of the conveying frame, one side of the toothless saw is movably connected with the rack through a connecting shaft, the other side of the toothless saw is connected with a second power part through a driving rod, and a fixed-length regulating bracket is arranged on one side of the toothless saw. The processing equipment for straightening and cutting the steel stranded wire, provided by the invention, realizes production full automation on conveying, straightening and cutting the steel stranded wire, can control the length error of the steel stranded wire section within 1mm, and greatly improves production efficiency and product quality.

Owner:石家庄开发区华能电气有限公司

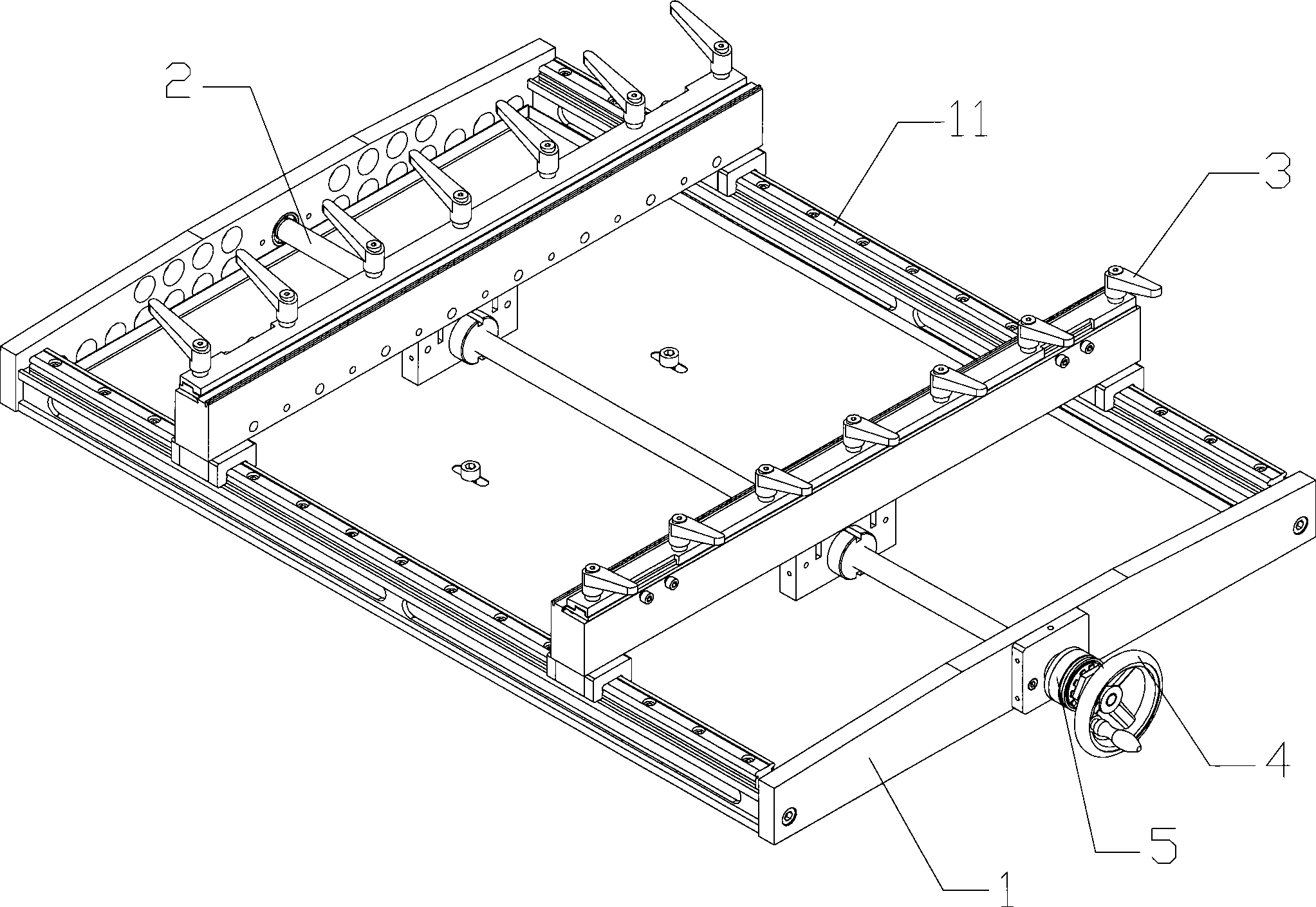

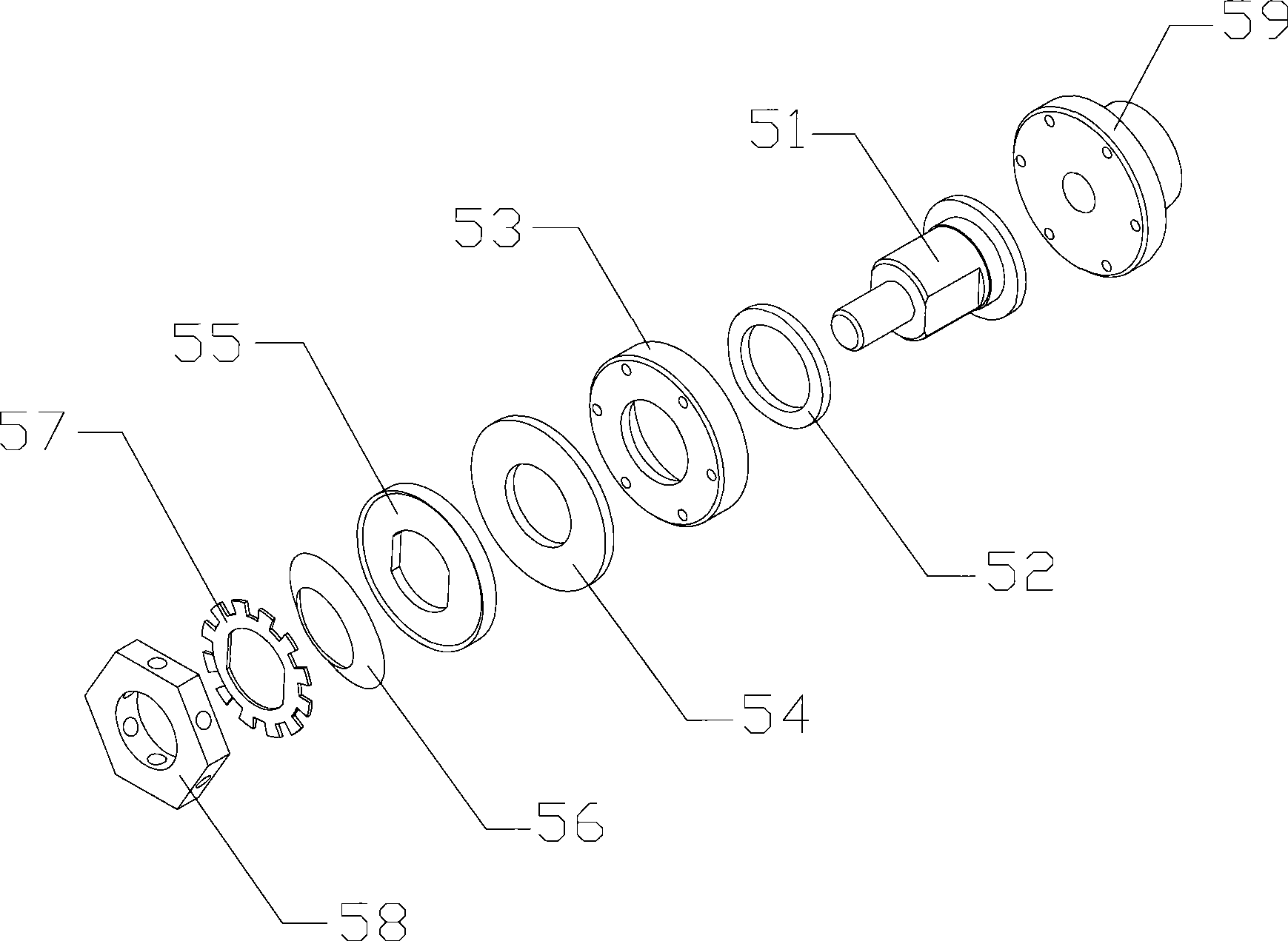

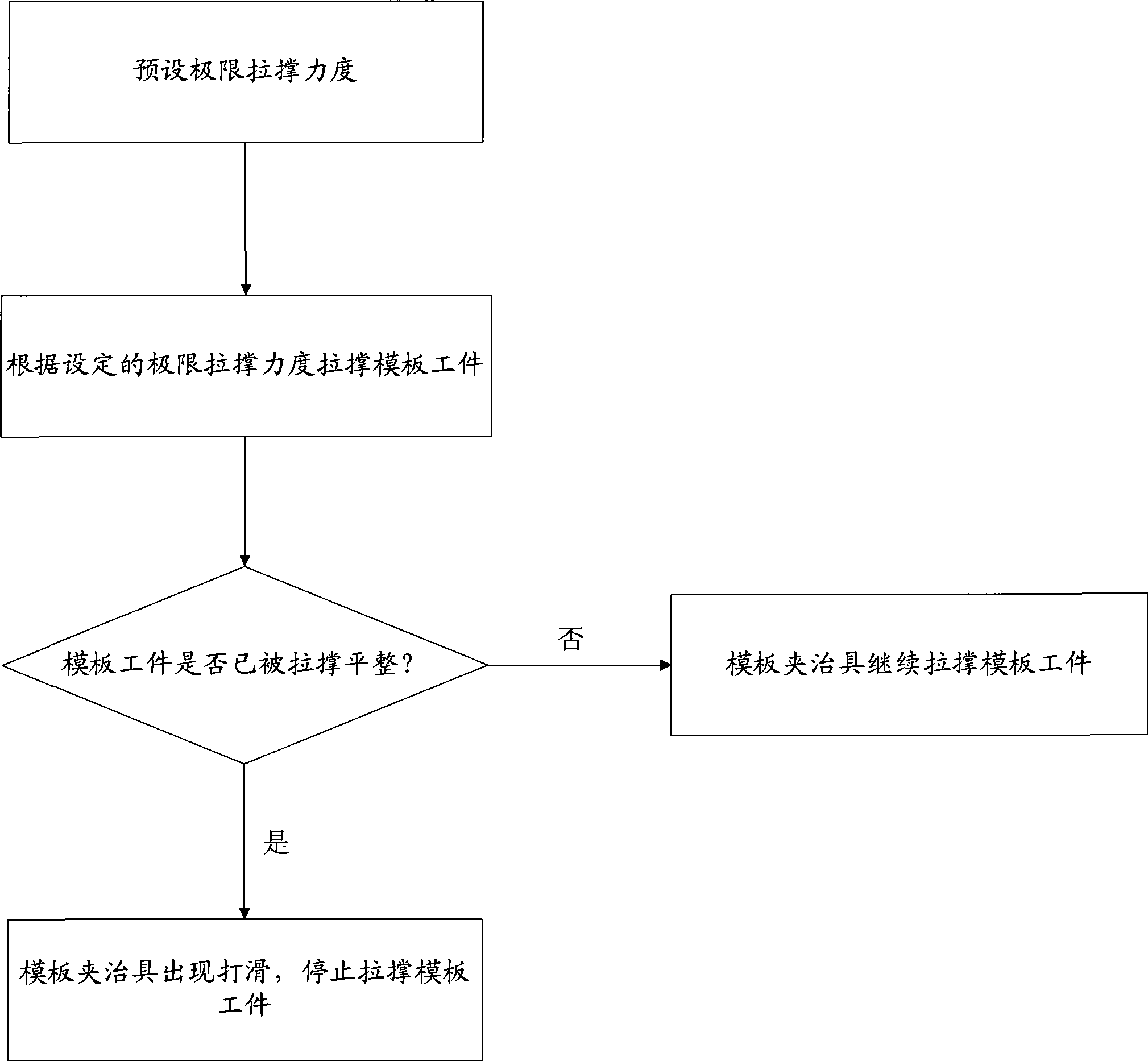

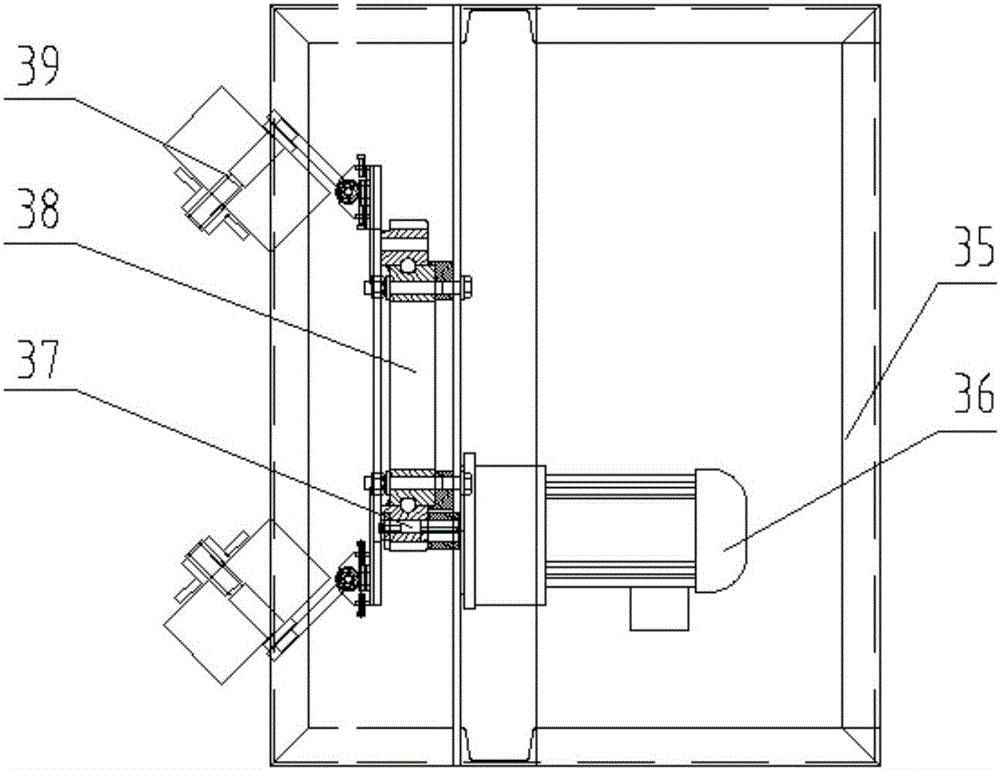

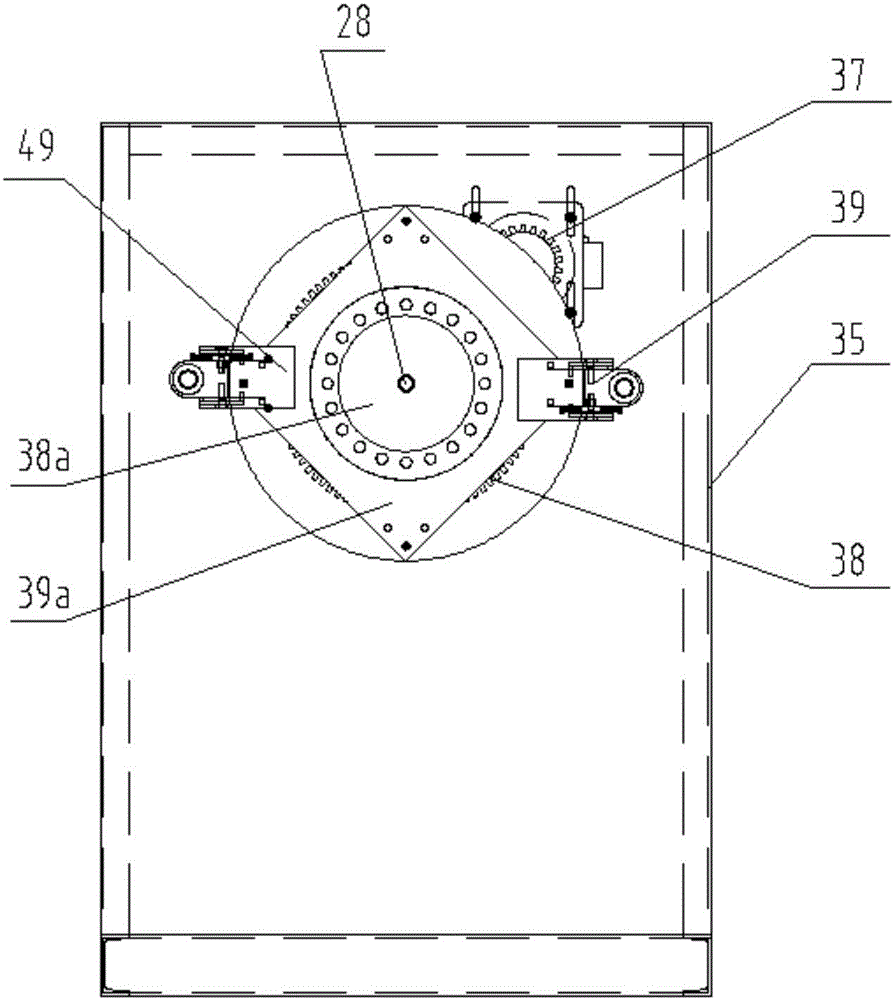

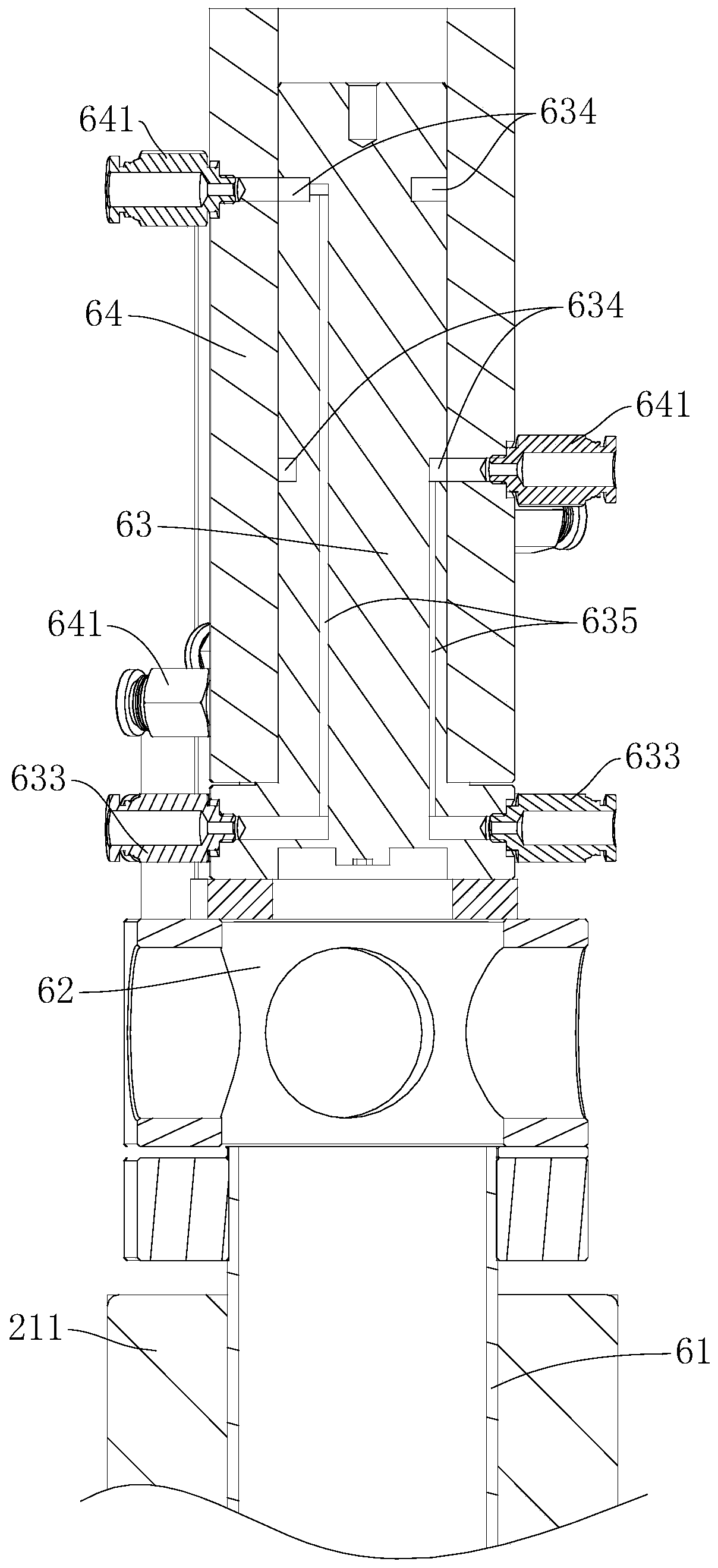

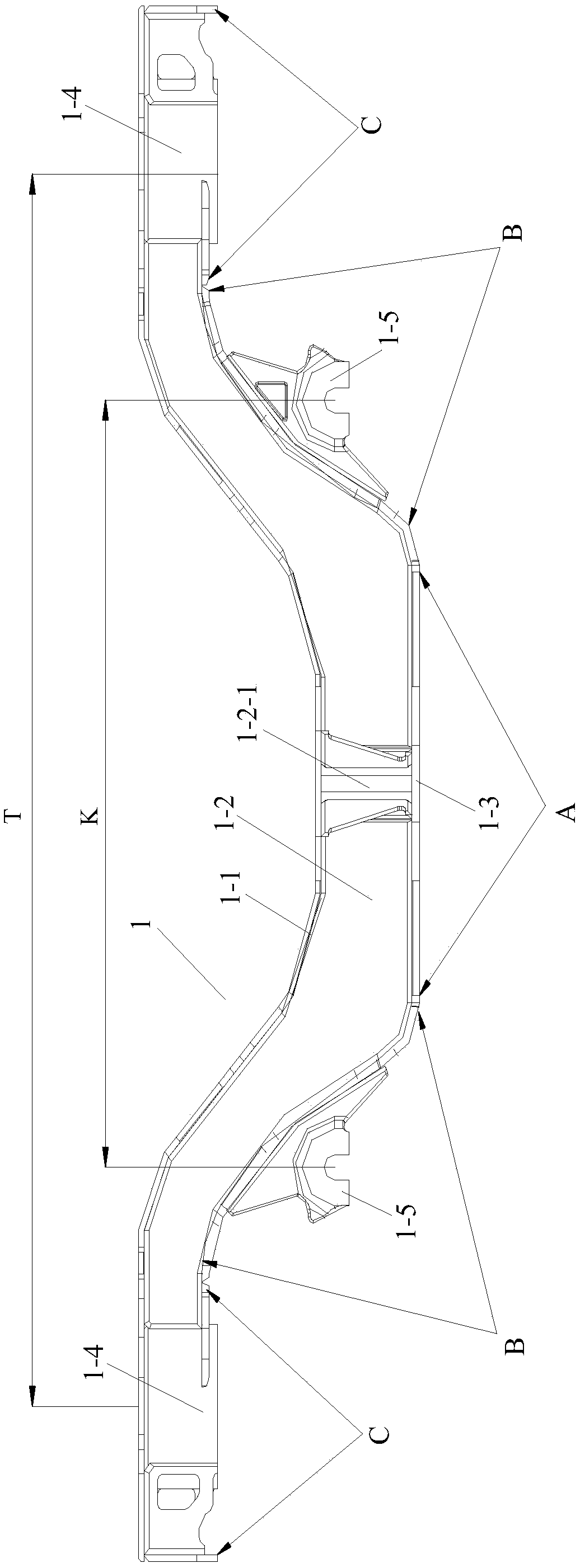

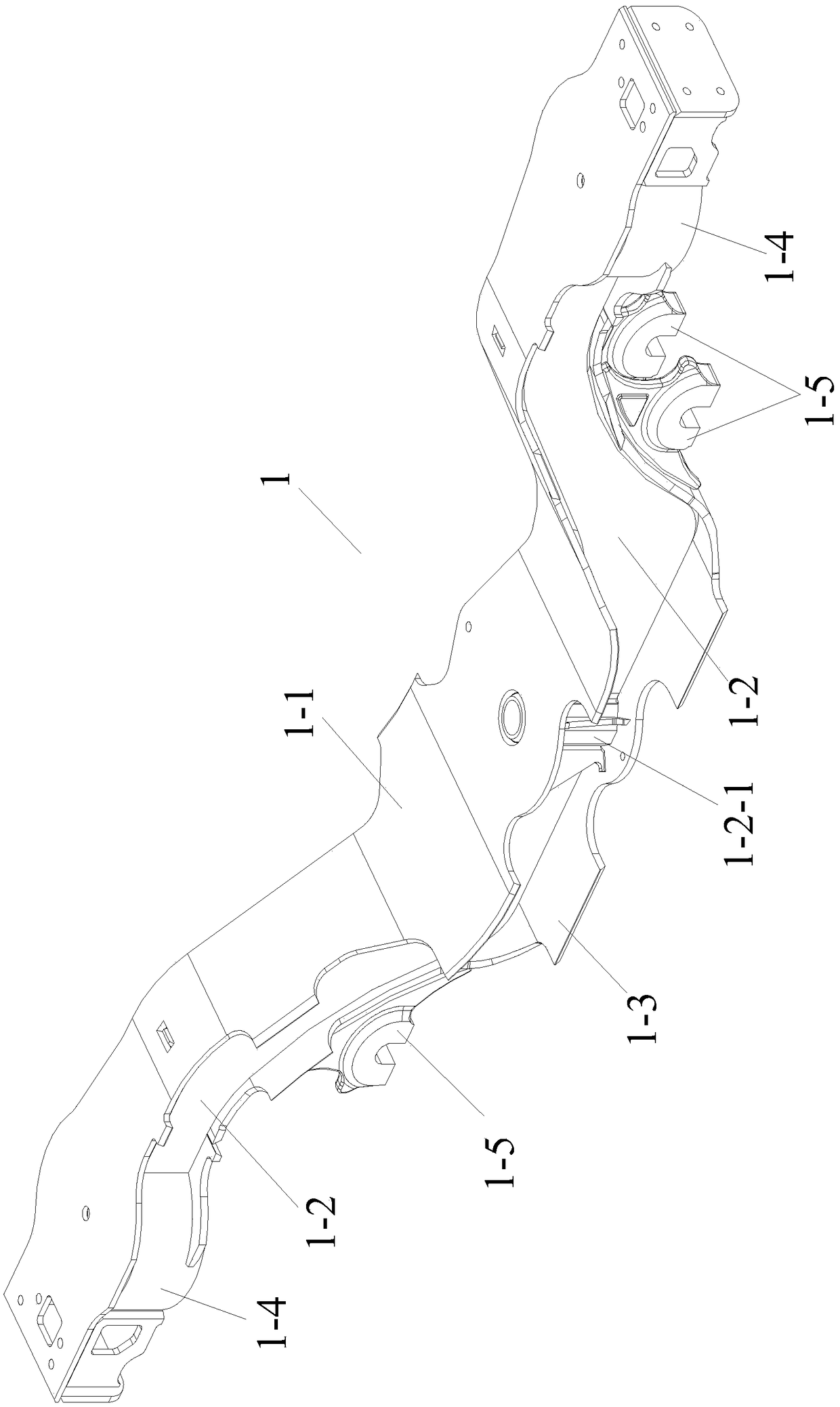

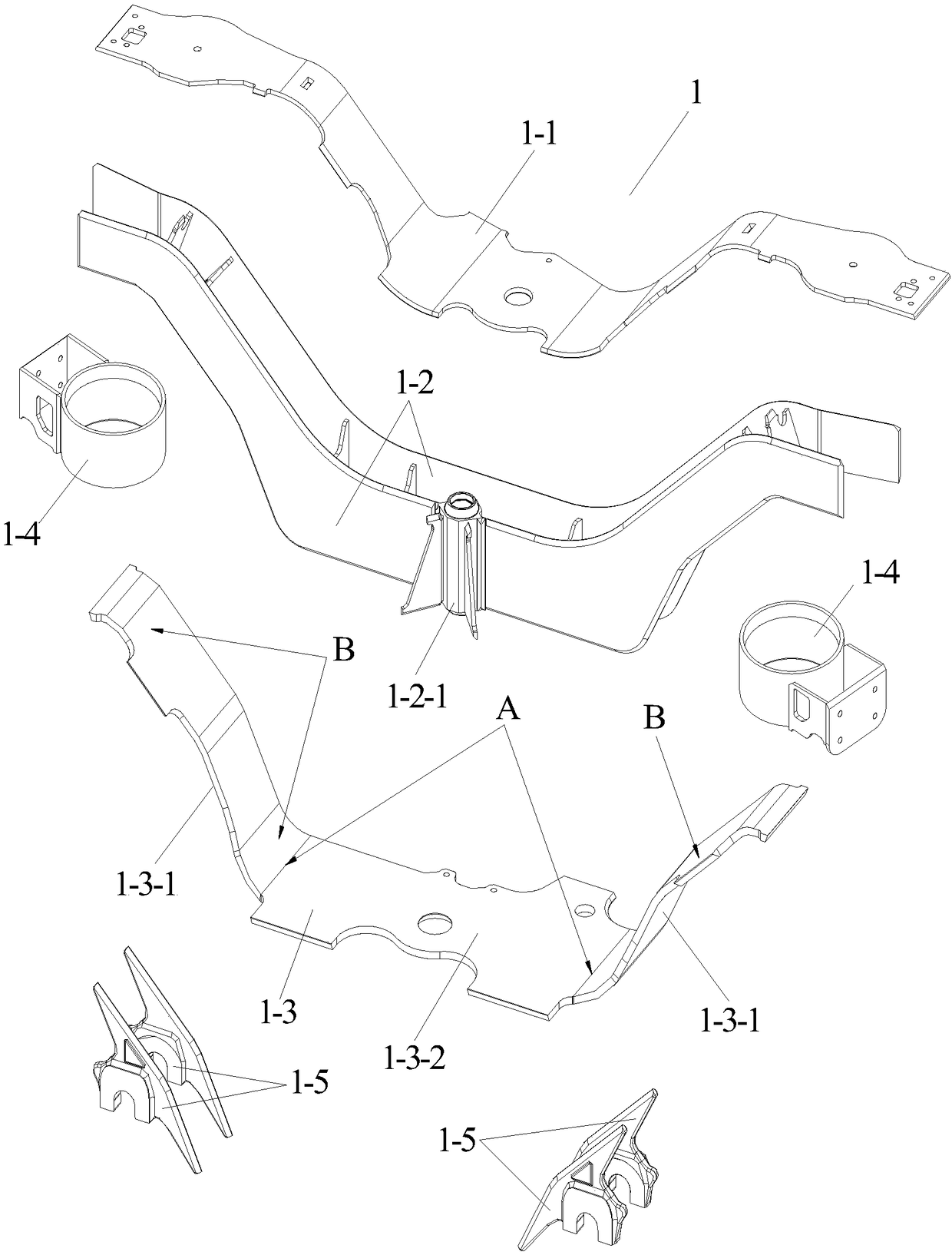

Tension bracing mechanism and tension bracing method thereof of template clamp tool

InactiveCN101497159AImprove production efficiency and product qualityReduce processing failure rateWelding/cutting auxillary devicesAuxillary welding devicesPower unitEngineering

Owner:SHENZHEN MUSEN TECH

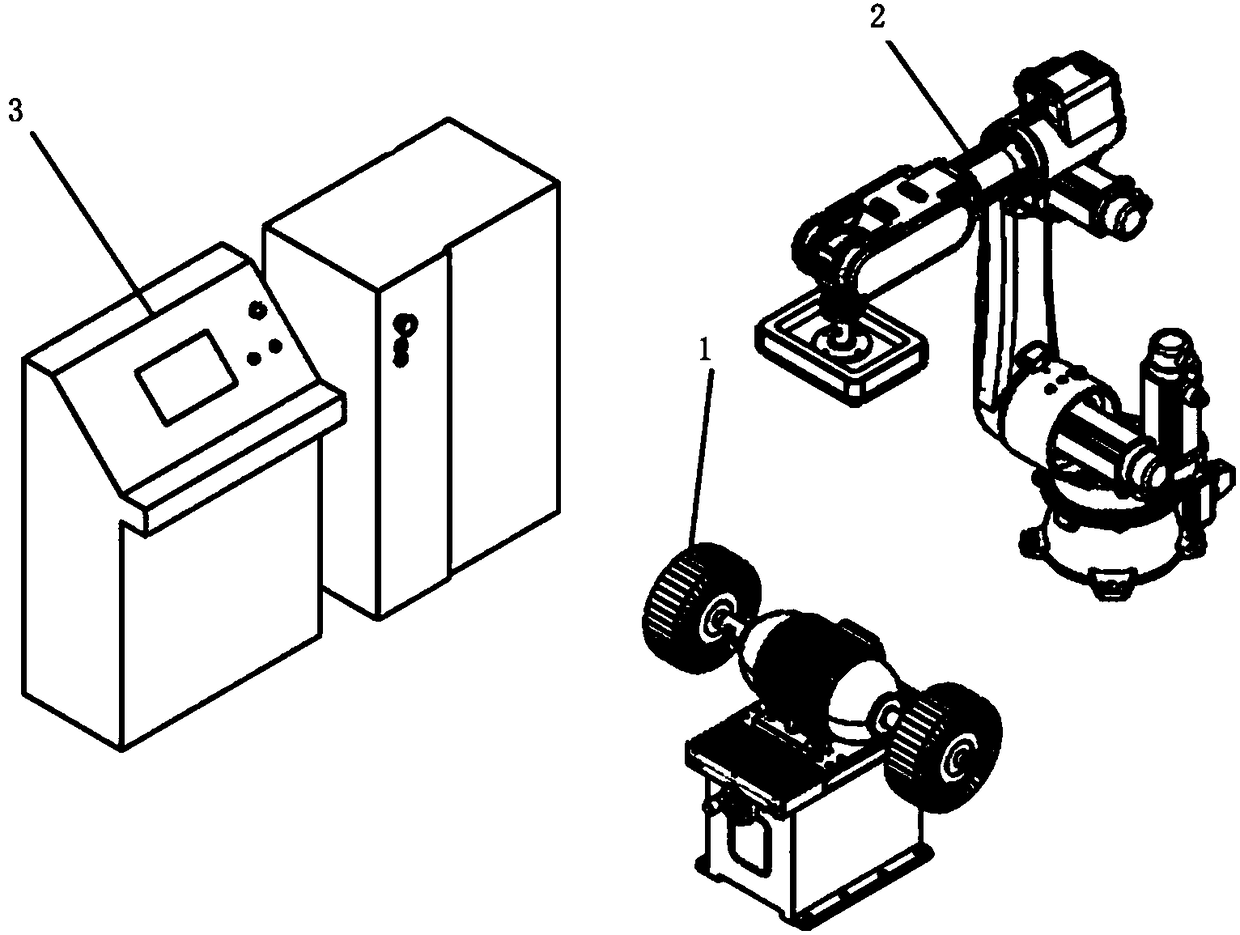

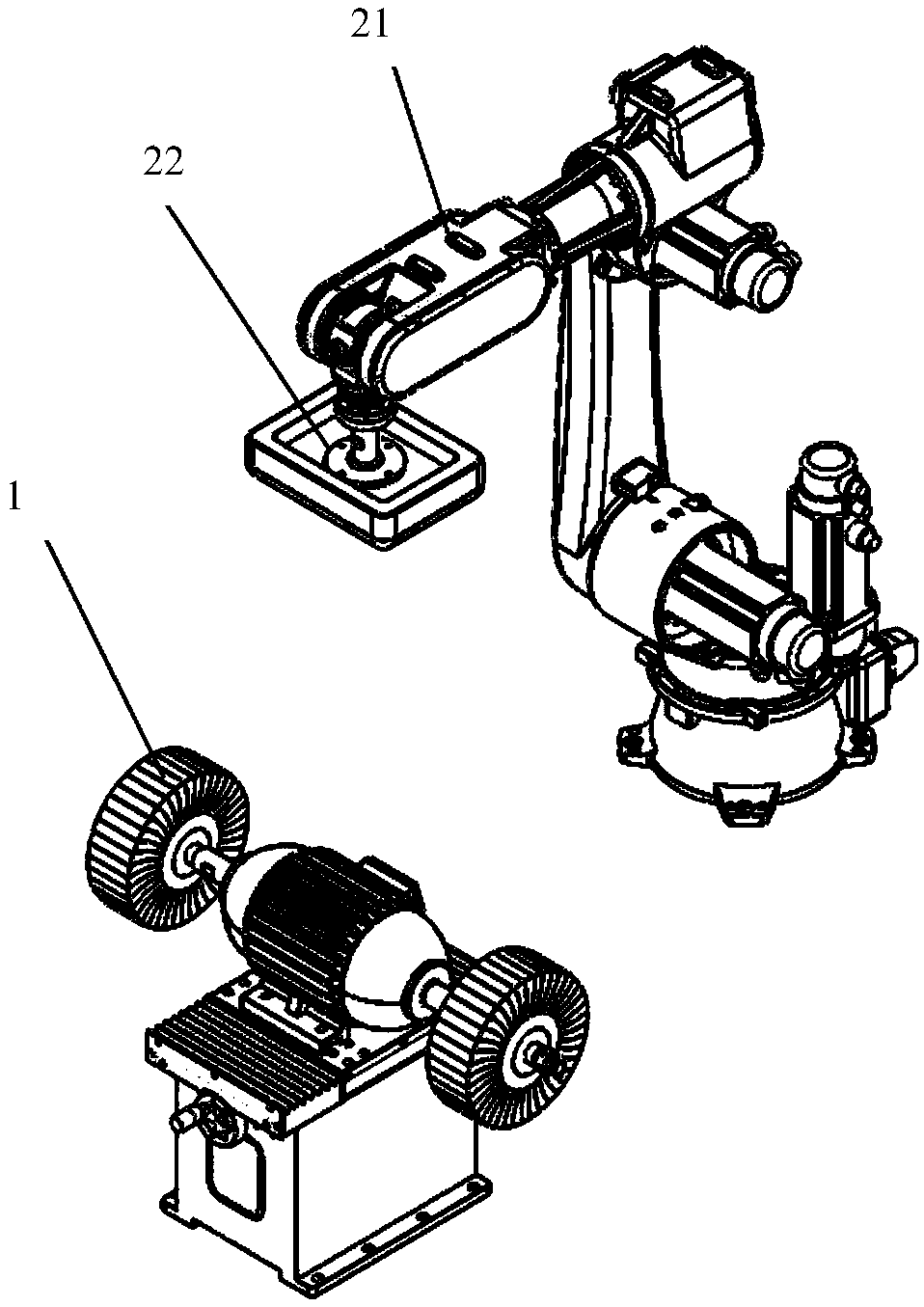

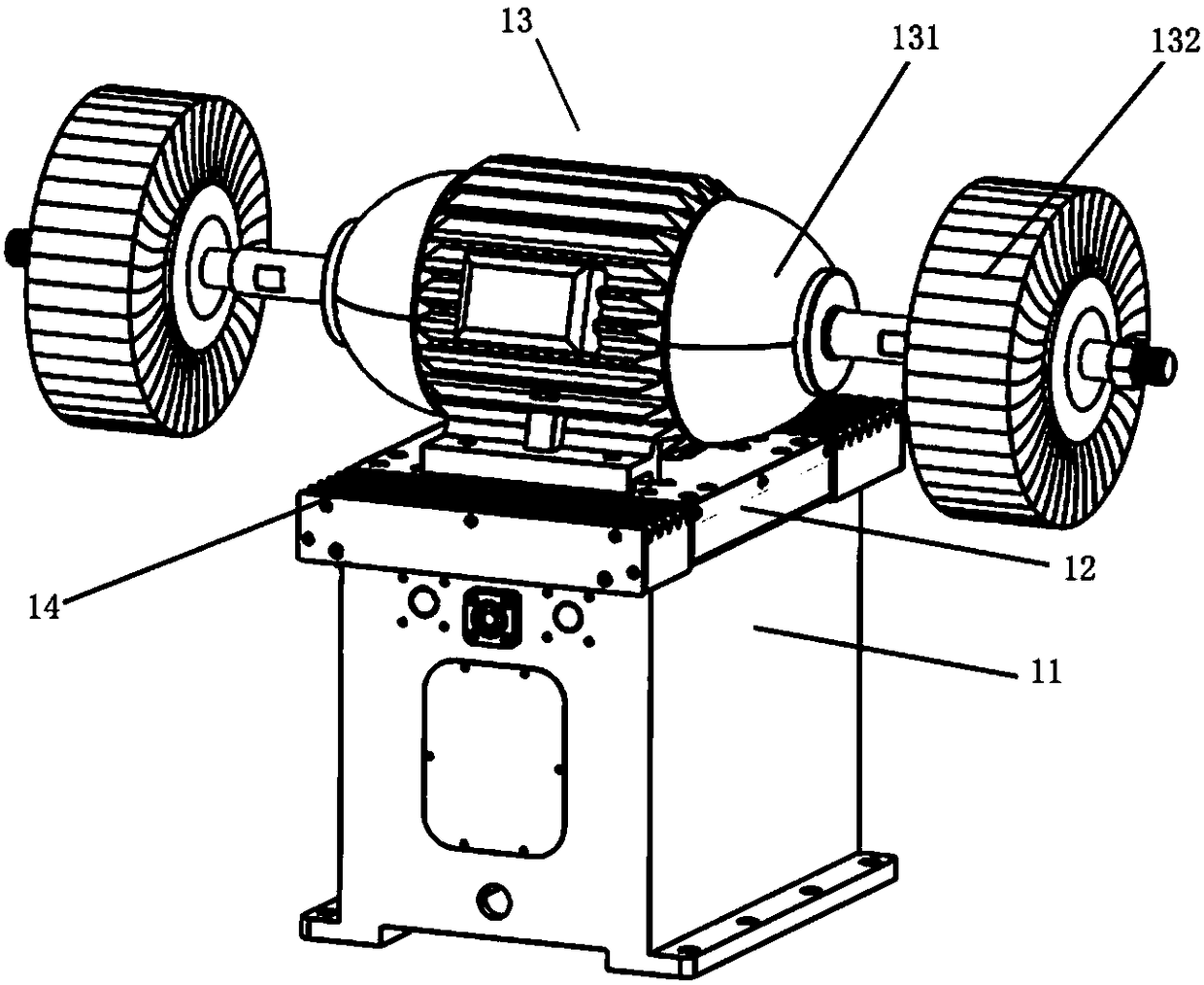

Pressure-controllable industrial robot grinding and polishing system and grinding and polishing method

PendingCN108296962AImprove grinding and polishing effectImprove production efficiency and product qualityPolishing machinesGrinding drivesPulp and paper industryIndustrial robot

The invention provides a pressure-controllable industrial robot grinding and polishing system. The pressure-controllable industrial robot grinding and polishing system is characterized by comprising apolishing device, a feeding device and a controller, and the polishing device comprises a fixed base, a mounting seat, a polishing mechanism, first slide rails, a position adjusting mechanism and a cylinder. The cylinder is connected with the mounting seat, and the mounting seat is slidably connected with the first slide rails to realize that the cylinder pushes the mounting seat to move in the length direction of the first slide rails to drive the polishing mechanism to move. The cylinder is connected with the controller to enable the controller to control the cylinder to control grinding pressure between the polishing mechanism and a workpiece. The cylinder is disposed on the fixed base through the position adjusting mechanism. The pressure-controllable industrial robot grinding and polishing system can improve grinding and polishing effects and improve production efficiency and product quality. The invention further provides an industrial robot grinding and polishing method which is capable of realizing constant grinding pressure between the polishing mechanism and the workpiece, effectively improving the grinding and polishing effects and improving the production efficiency and the product quality.

Owner:FOSHAN INST OF INTELLIGENT EQUIP TECH +1

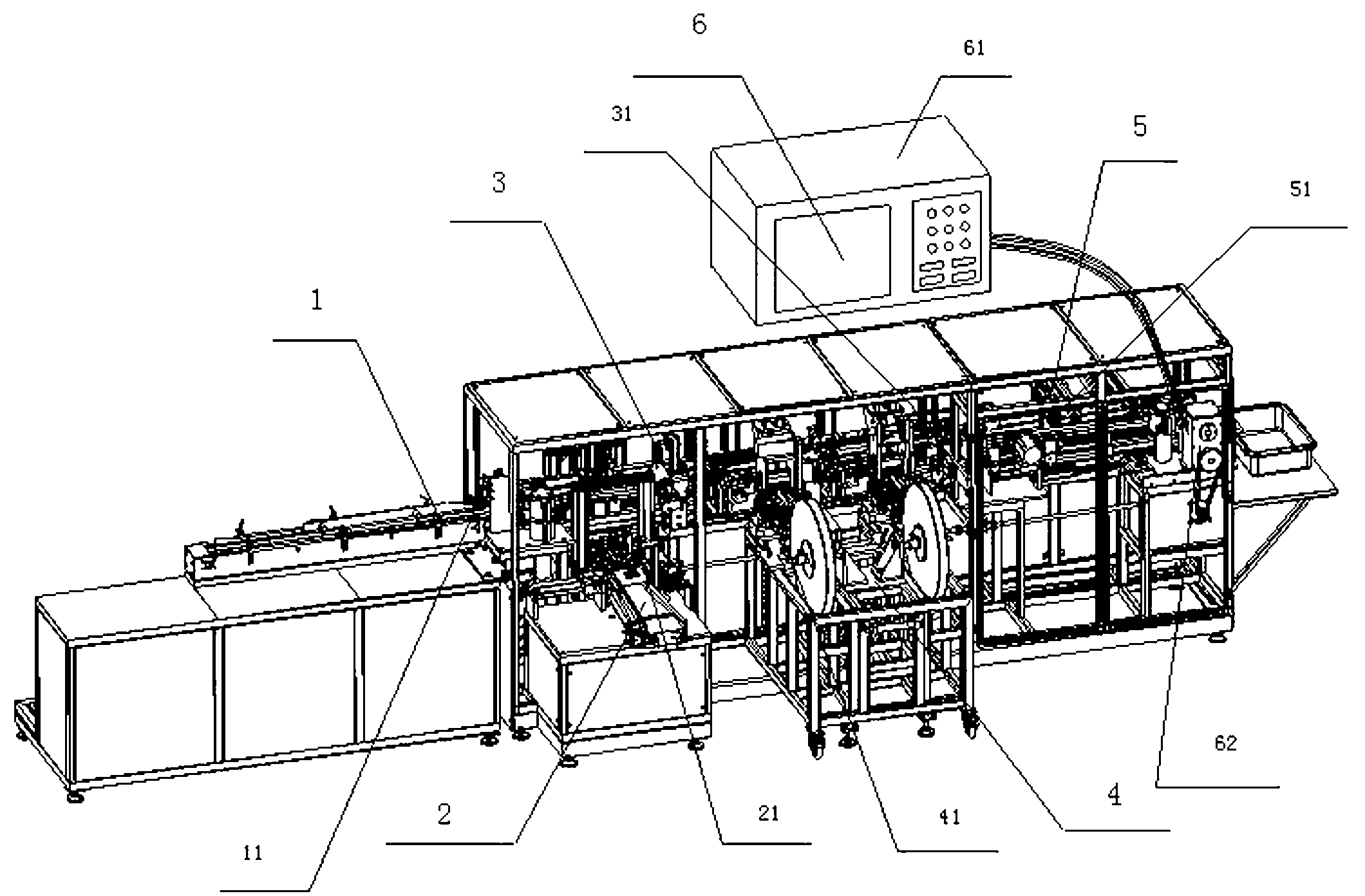

Automatic welding device for barrel

ActiveCN105269134AReduce labor costsImprove production efficiency and product qualityResistance electrode holdersWelding monitoring devicesTransfer mechanismEngineering

The invention discloses an automatic welding device for a barrel. The automatic welding device comprises a rack, an industrial personal computer arranged on the rack, a transfer mechanism arranged on the rack, and a feeding frame assembly. Three welding assemblies and three feeding assemblies are arranged on the portion, below the transfer mechanism, of the rack. Under control of the industrial personal computer, the to-be-welded barrel is firstly fed through the feeding frame assembly and transferred to a welding point defined by the three welding assemblies through the transfer mechanism after being positioned through a positioning mechanism, at the moment, L-shaped stand bars are fed through the three feeding assemblies synchronously, a controller is started, and then the L-shaped stand bars and the barrel are welded. According to the automatic welding device for the barrel, automatic equipment is adopted, automation of the feeding, welding and detection overall process is achieved, labor cost is reduced, and production efficiency and product quality are improved.

Owner:SHENZHEN PREVAIL TECH

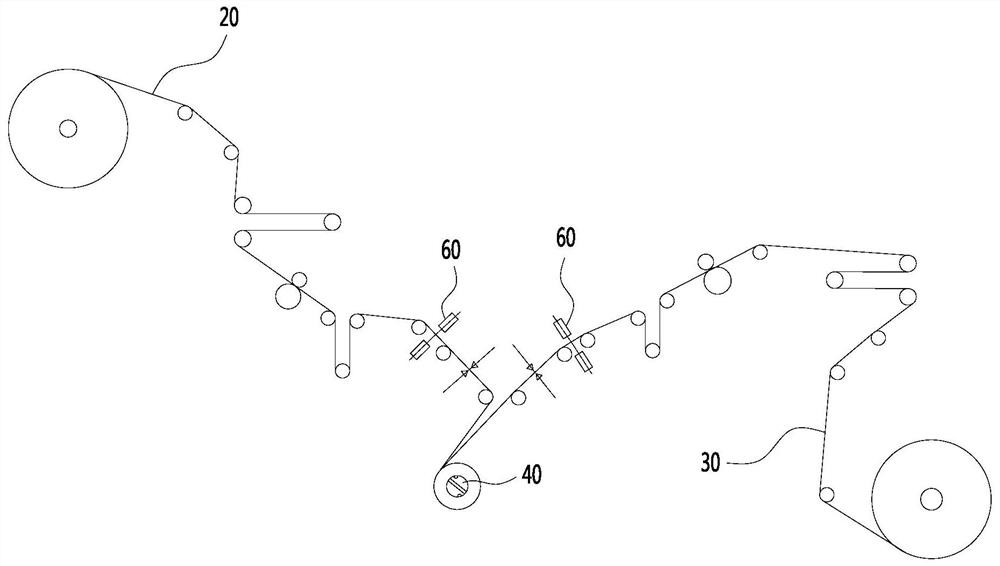

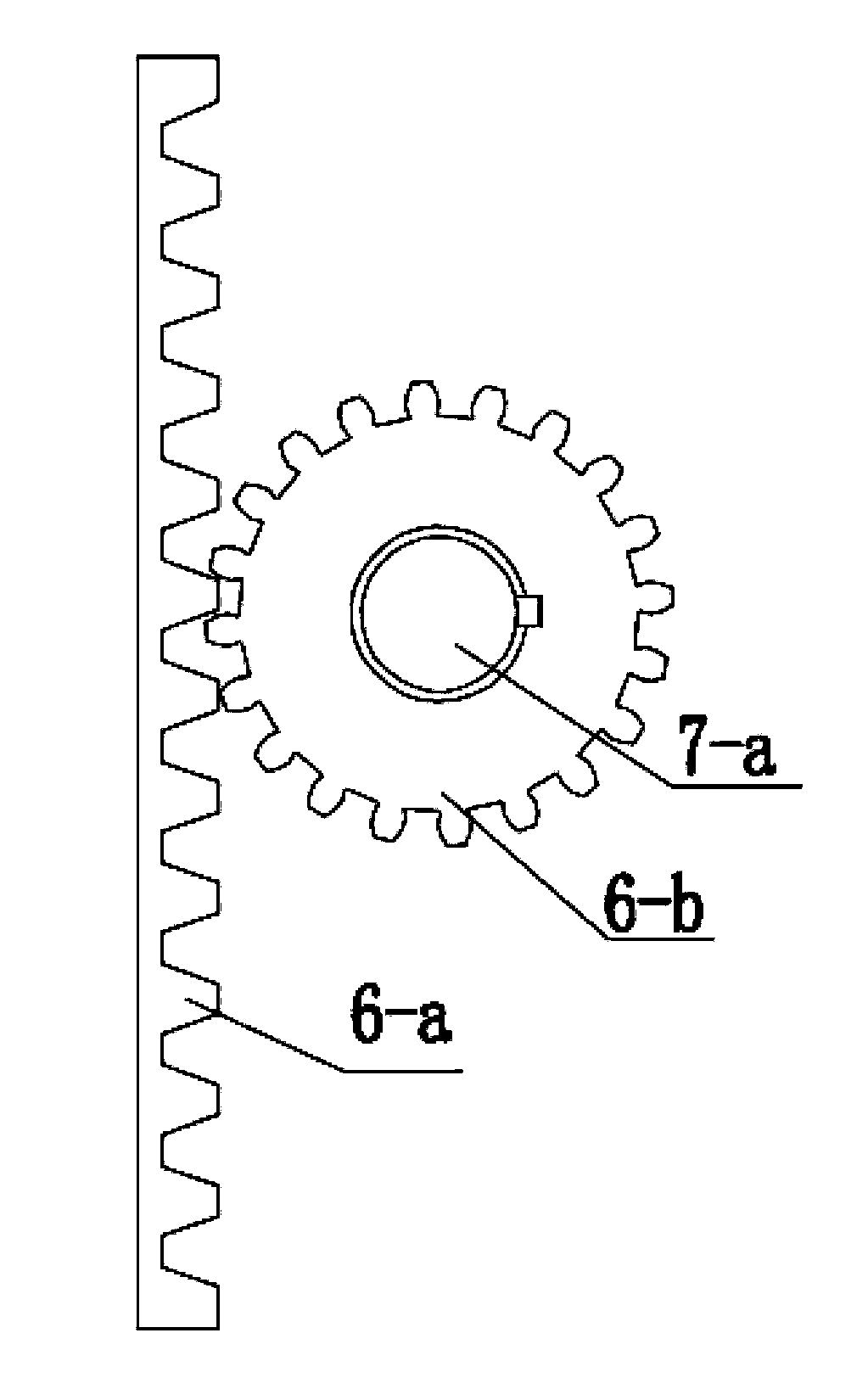

Deviation rectifying device of gypsum board production line

ActiveCN102785288AImprove control accuracy and automationImprove production efficiency and product qualityCeramic shaping plantsAuxillary shaping apparatusGypsumAutomation

The invention provides a deviation rectifying device of a gypsum board production line. The deviation rectifying device comprises a sensor, a deviation rectifying controller and a driving mechanism. The sensor detects edge positions of coiled materials and sends detected position information to the deviation rectifying controller, the deviation rectifying controller receives the position information sent by the sensor to conduct calculation and judgment to generate control instructions and sends the control instructions to the driving mechanism, and the driving mechanism receives the control instructions sent by the deviation rectifying controller and moves according to the control instructions. The deviation rectifying device uses the sensor to measure position situations of the coiled materials on line, the deviation rectifying controller timely generates deviation rectifying instructions, a deviation rectifying framework is driven by the driving mechanism to enable the coiled materials to be placed in the middle, skewing is basically avoided, control accuracy and automation degree are high, and production efficiency and product quality are greatly improved.

Owner:HUAINAN BEIXIN BUILDING MATERIAL

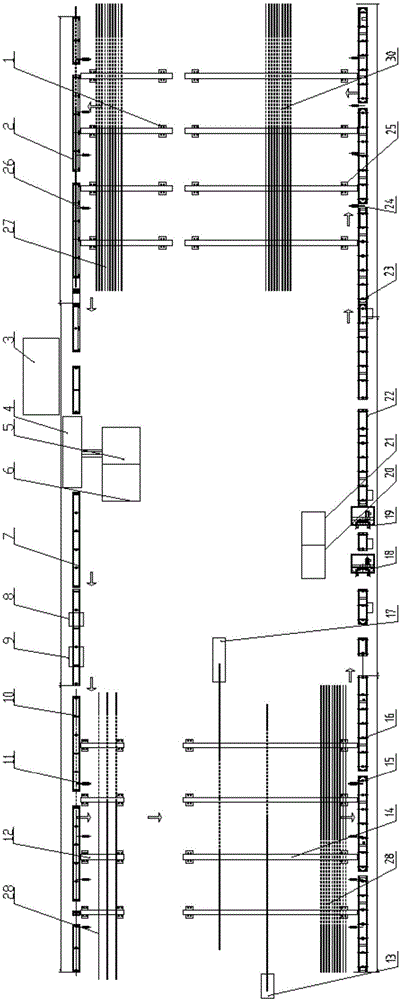

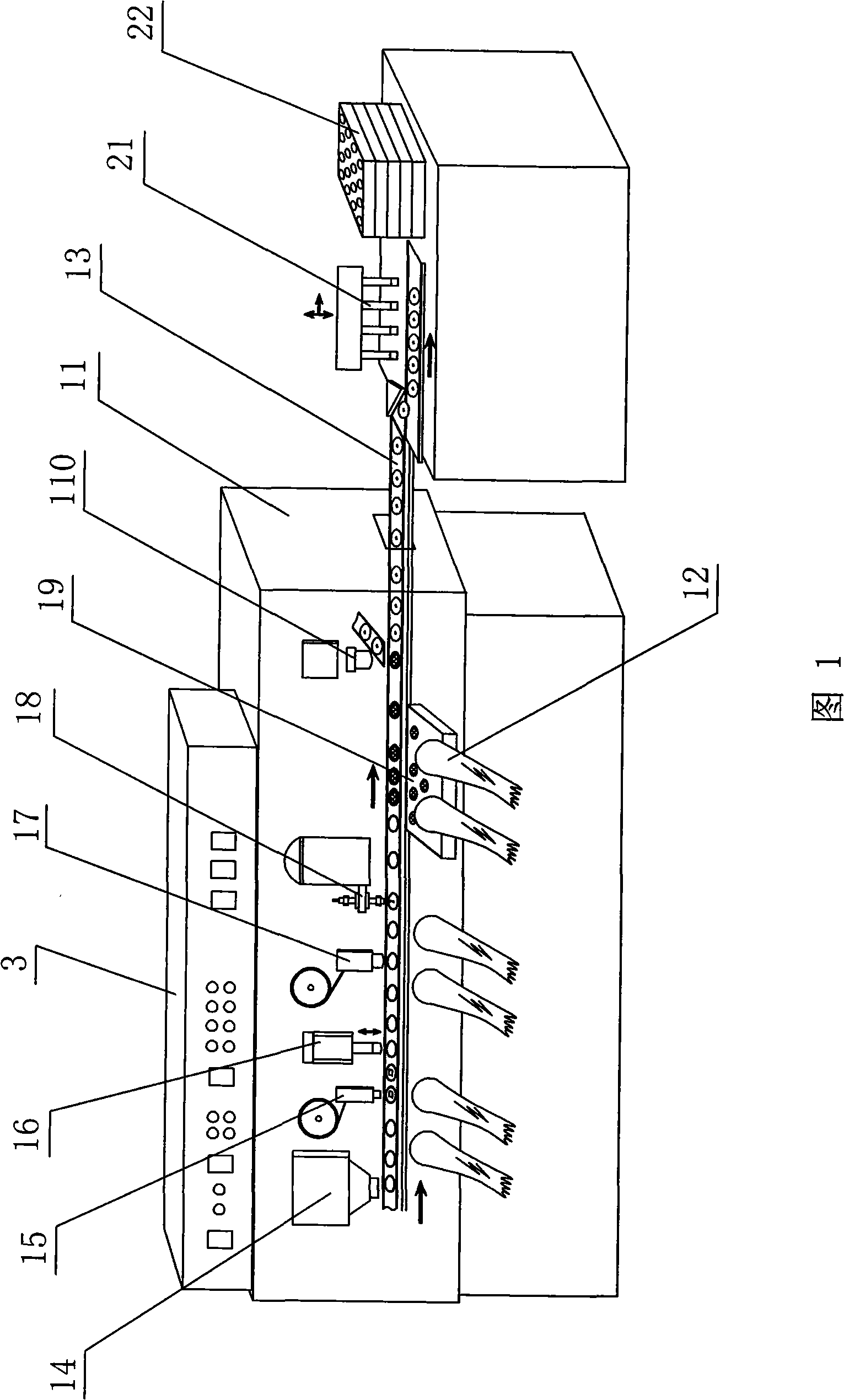

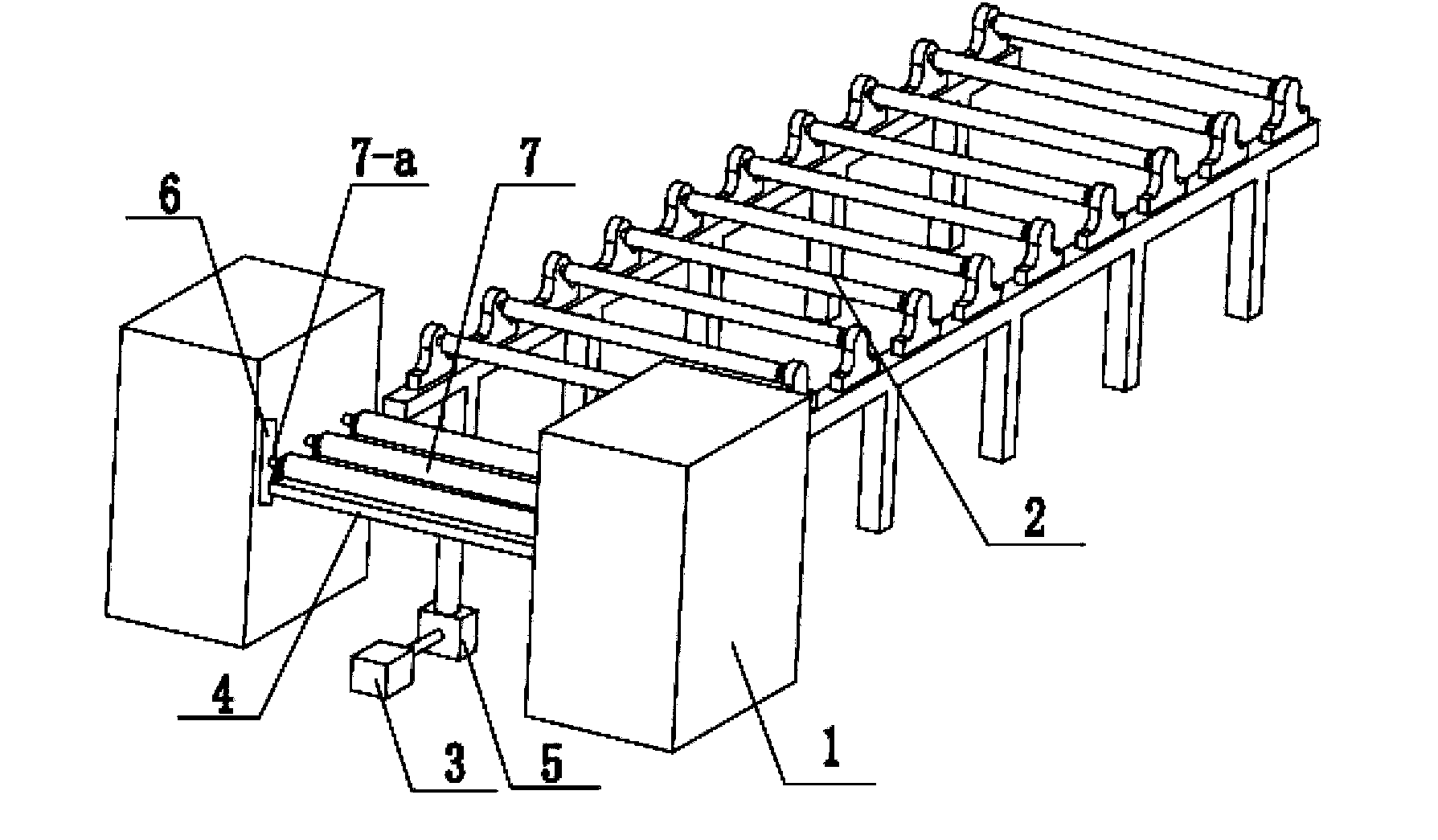

Automatic production line and production method for anti-corrosion steel tubes

PendingCN106345662AReduce labor intensityImprove production efficiency and product qualityPretreated surfacesCoatingsSteel tubeEngineering

The invention discloses an automatic production line and a production method for anti-corrosion steel tubes. The production method for anti-corrosion steel tubes includes the steps that steel tubes are turned into the front section of a derusting conveying line, and tube-tracking conveying is carried out towards the middle section of the derusting conveying line; the steel tubes are subjected to derusting in the middle section of the derusting conveying line; when the steel tubes obtained after derusting are conveyed to the rear section of the derusting conveying line, tube-separating conveying is carried out; the steel tubes are turned into the front section of a winding conveying line, tube-tracking conveying is carried out towards the middle section of the winding conveying line, and connection is carried out through tube connectors; the steel tubes are subjected to strip winding in the middle section of the winding conveying line; the steel tubes obtained after strip winding are conveyed to the rear section of the winding conveying line for tube-separating conveying. By using the speed-adjustable automatic conveying lines in coordination and cooperation with automatic derusting treatment equipment and automatic strip winding treatment equipment, the purpose of automatic flow production is achieved, the labor intensity is relieved, and the product quality and production efficiency are improved.

Owner:中油管道防腐工程有限责任公司 +1

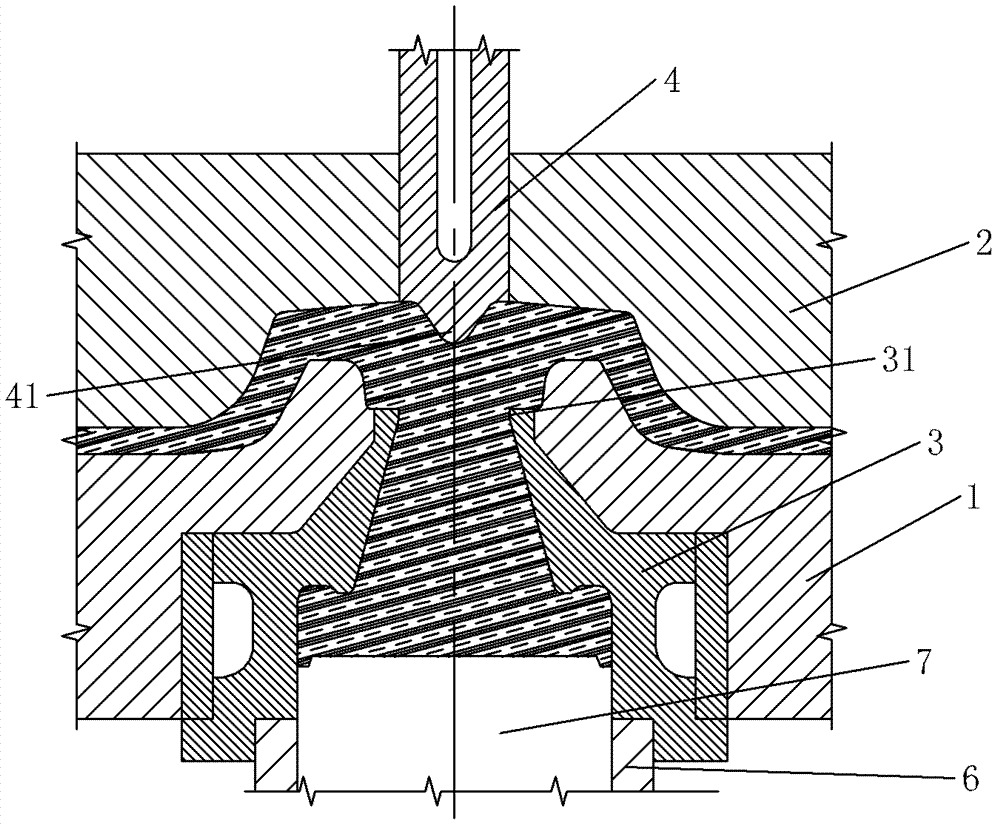

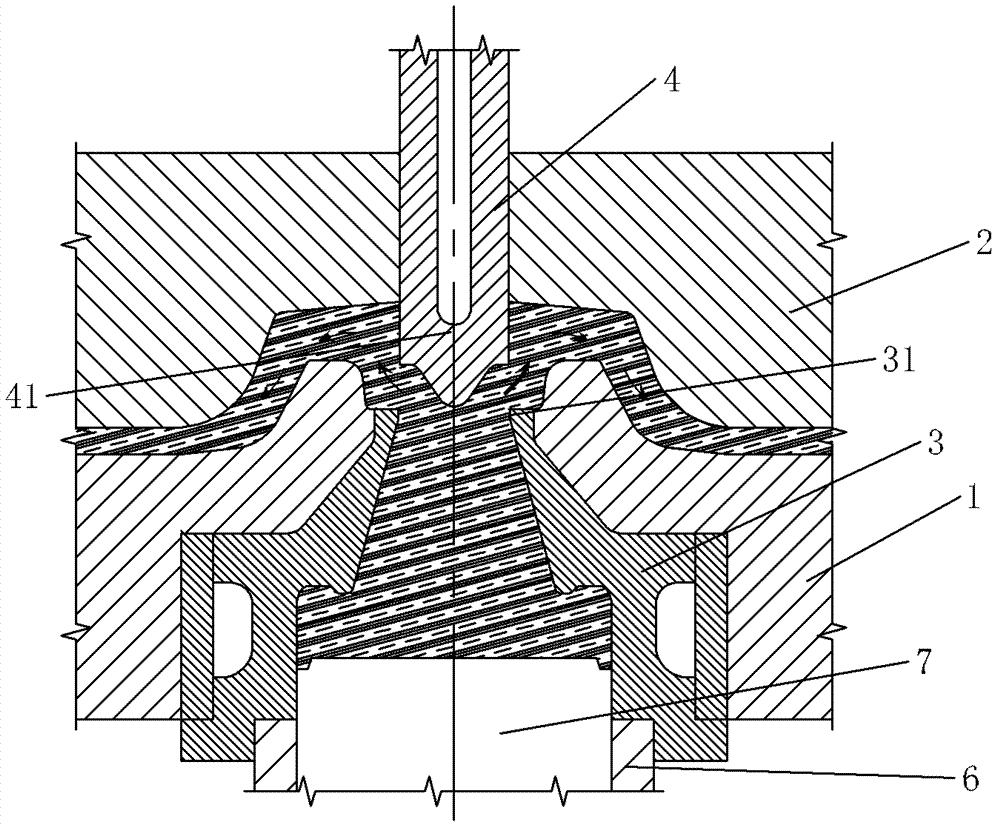

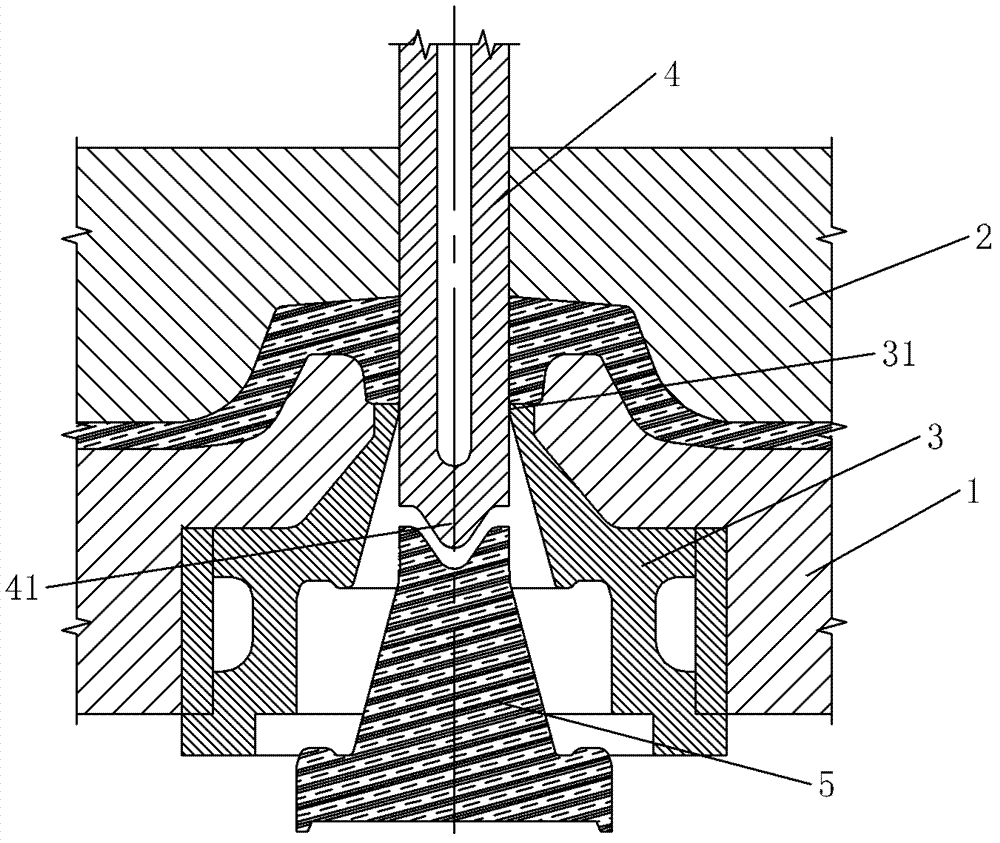

Mould structure for centering molding process of rotating shaft symmetrical part

InactiveCN103192056AImprove production efficiency and product qualityIncrease productivityFoundry mouldsFoundry coresPower equipmentEngineering

The invention discloses a mould structure for the centering molding process of a rotating shaft symmetrical part. The mould structure comprises a fixed mould and a movable mould, wherein a cavity is formed between the fixed mould and the movable mould; the fixed mould is positioned in the center position of the cavity and is provided with a sprue bushing communicated with the cavity; the movable mould is positioned in the center position of the cavity and is provided with a secondary squeezing bar interspersed in the fixed mould and connected with external power equipment; the secondary squeezing bar and the sprue bushing are coaxially arranged; and the head part of the secondary squeezing bar is matched with an inner orifice of the sprue bushing to form an internally-tangent pouring gate structure. According to the invention, the innovative mould structure is adopted, and the secondary squeezing bar arranged on the fixed mould is matched with the sprue bushing, so that both the centering squeezing and the interior contact of an pouring gate can be realized, coherent actions of secondary squeezing and material handle shearing can be formed; and accordingly, the production efficiency of molding is improved, and the product quality is improved.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Method for efficiently purifying artemisinin

ActiveCN109320523AReduced recrystallization stepsImprove production efficiency and product qualityOrganic chemistrySolventWax

The invention relates to a method for efficiently purifying artemisinin. The method is characterized in that artemisinin leaching liquor is extracted from leaves of artemisia annua by a leaching solvent and is concentrated to obtain extract; the extract is dissolved by an extracting agent to obtain extraction liquid, and a wax oil inhibitor is added into the extraction liquid to inhibit co-crystallization between wax oil and the artemisinin in the crystallization process, so that the purity of the crude artemisinin is improved; the number of times of recrystallization is reduced, and the production process is simplified. The method has the advantages of simplicity in operation, high purification efficiency, high product purity, recyclability of the inhibitor and the like, and efficient purification and separation of the artemisinin can be realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Frosted glass reaction tank

InactiveCN104591548AReduce investmentImprove production efficiency and product qualityFrosted glassEngineering

A disclosed frosted glass reaction tank comprises a frame, a frosting liquid box, a reaction pool and a flexible pipe; the frosting liquid box and the reaction pool are both installed on the frame; the frame is provided with a telescopic support rod; the telescopic support rod is provided with a cross bar; the cross bar is flexibly provided with a movable block; the movable block is connected with a glass placing rack; the reaction pool is inside provided with a liquid spraying pipe; the liquid spraying pipe is provided with a high-pressure nozzle, and is connected with the frosting liquid box via the flexible pipe; and the right side of the reaction pool is provided with a cleaning pool. Through the up-down moving of the telescopic support rod and the left-right moving of the movable block, glass on the glass placing rack can enter the reaction pool for processing, can be cleaned after processing is finished, and can be drying after cleaning is finished. Production is fully automatically controlled, thus manual investment is reduced, production efficiency and product quality are improved, and also human body is prevented from being damaged caused by contacting with a frosting liquid.

Owner:DENGFENG CITY YUKE GLASS TECH

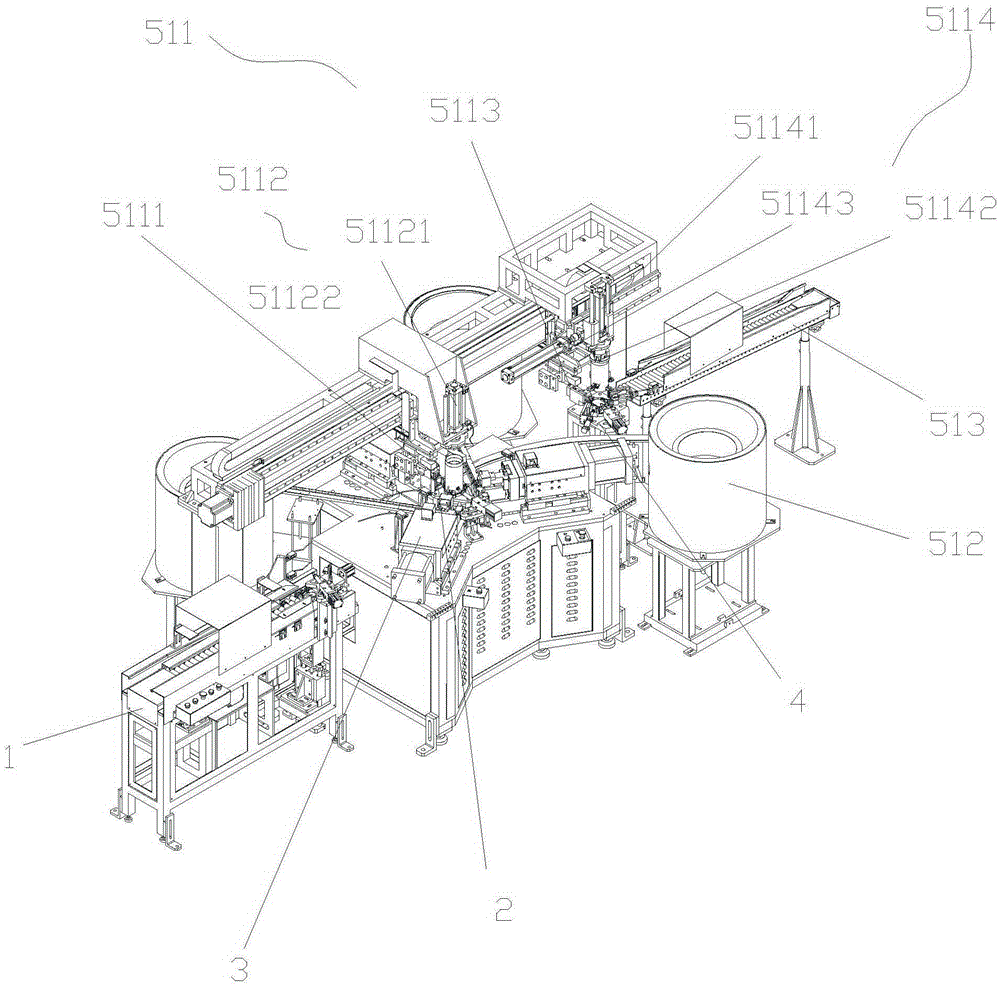

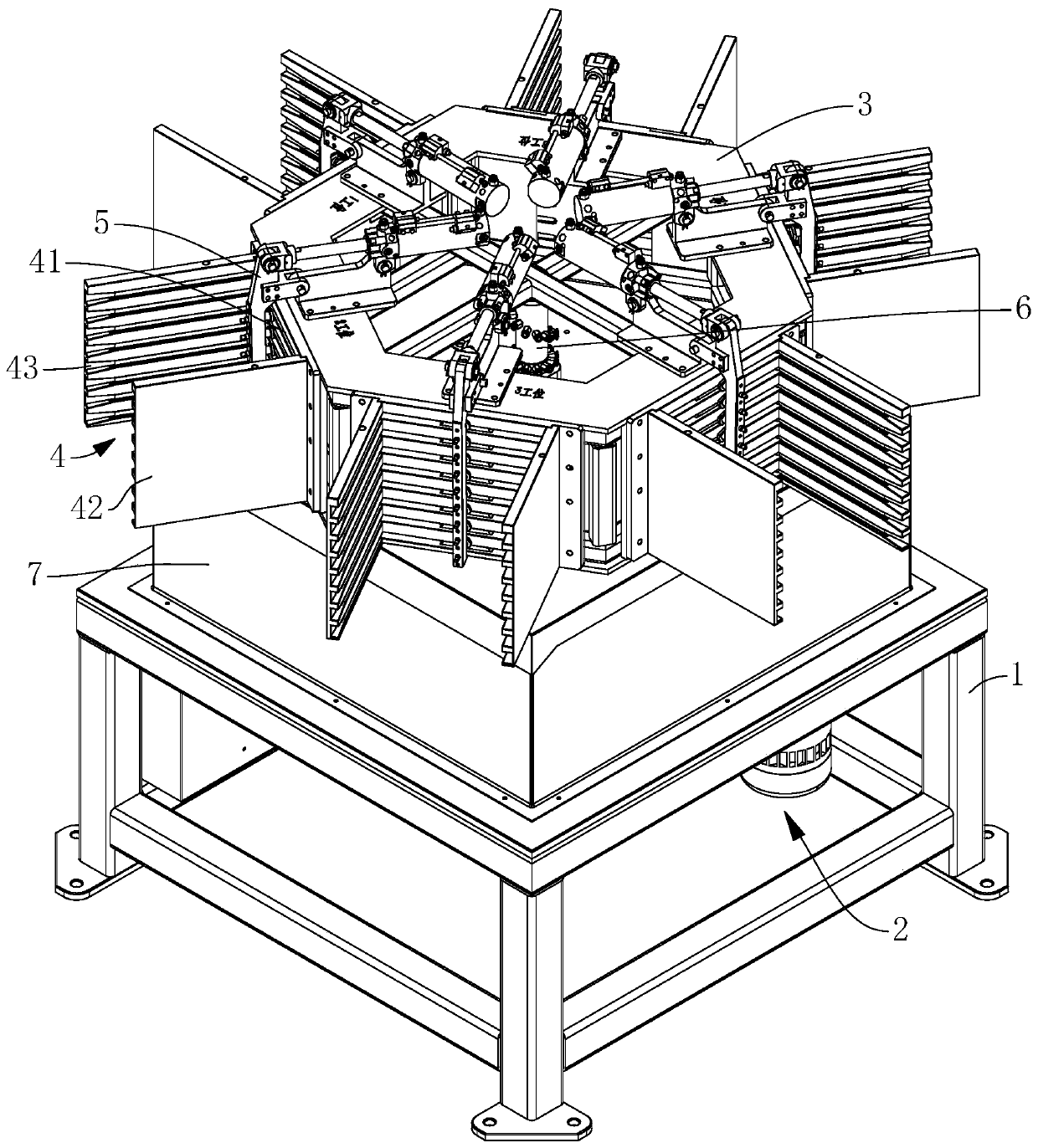

Multi-station rotary welding equipment and welding method thereof

PendingCN110076489AReduce labor intensityImprove production efficiency and product qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention provides multi-station rotary welding equipment and a welding method thereof. The equipment comprises a frame, a driving device, a rotating frame, multiple stations and a pressing mechanism; the driving device is mounted on the frame; the rotating frame is arranged above the driving device; an output shaft of the driving device is connected with the center of the rotating frame for driving the rotating frame to intermittently rotate; the multiple stations are arranged at the outer periphery of the rotating frame at equal intervals; each station comprises a baffle plate and two side plates; the baffle plate is fixed at the outer periphery of the rotating frame; the two side plates are relatively fixed on two sides of the baffle plate to form station space with an outward opening; multiple positioning grooves are vertically arranged on the inner side surfaces of the baffle plate and the two side plates; workpieces are positioned in the positioning grooves from the opening ends for positioning; and the pressing mechanism is arranged on the rotating frame, and is used for pressing the workpieces in the positioning grooves. The multi-station rotary welding equipment facilitates reduction of the labor intensity of workers, and improves the production efficiency and the product quality.

Owner:HONORFAITH FURNITURE

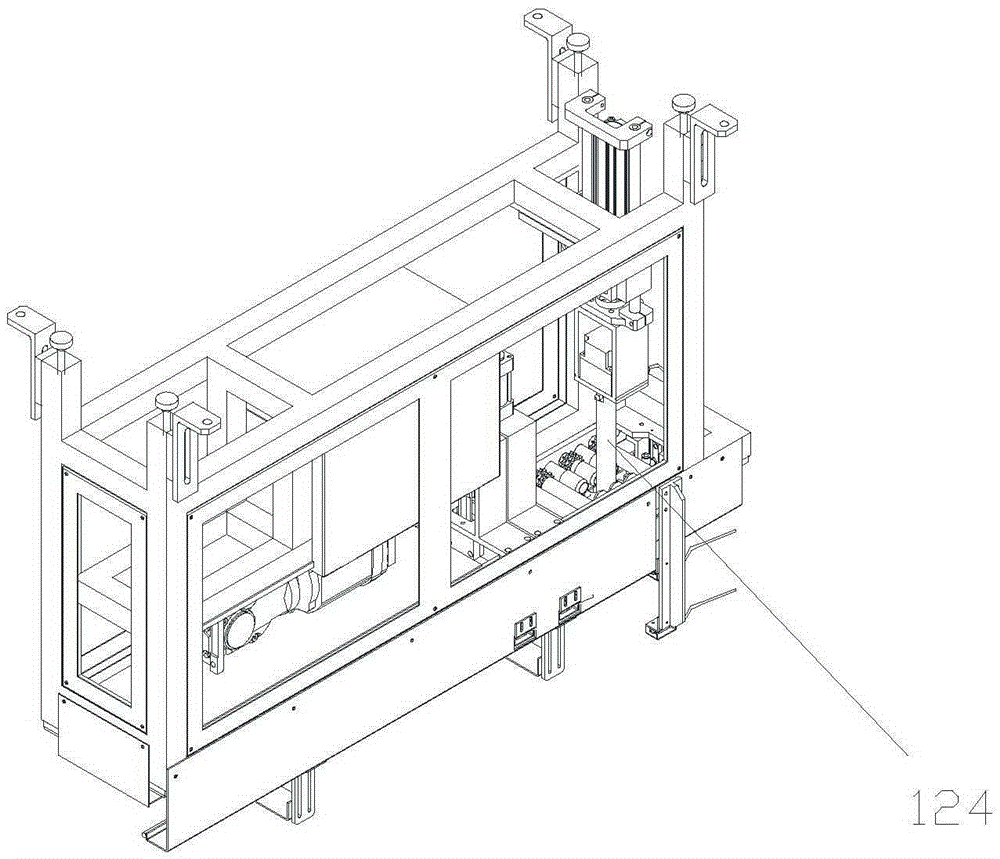

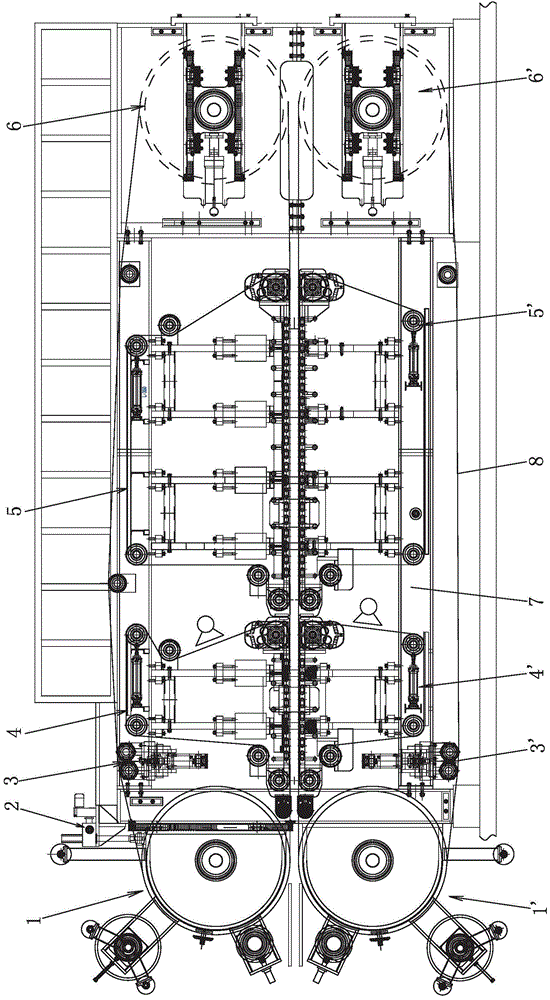

Production line for Li-Mn button battery

InactiveCN101267039AImprove production efficiency and product qualityIncrease productivityNon-aqueous electrolyte cellsEngineeringManufacturing line

The present invention provides a production assembly line of a Li / MnO_2 button battery, including an assembly line, a battery box packing platform and an electric equipment, the whole assembly line is located in a transparent sealing cover, two sides of the isolating cover are provided with operation hand hole which covering with the rubber gloves, the assembly line includes a conveyor belt which circularly operates, and an assembly equipment provided on two sides of the conveyor belt, the assembly equipment along the transferring direction of the conveyor belt in turns are an vibratory feeder, a lithium plate implantation device, a lithium plate punch, a membrane implantation device, a drop liquid device, a cathode plate implantation device and a cathode case sealing device, the conveyor belt extends to the battery box packing platform by penetrating the exit which is provided by the isolating cover end. The production line of the Li / MnO_2 button battery markedly improves the production efficiency and the production quality.

Owner:徐剑锋

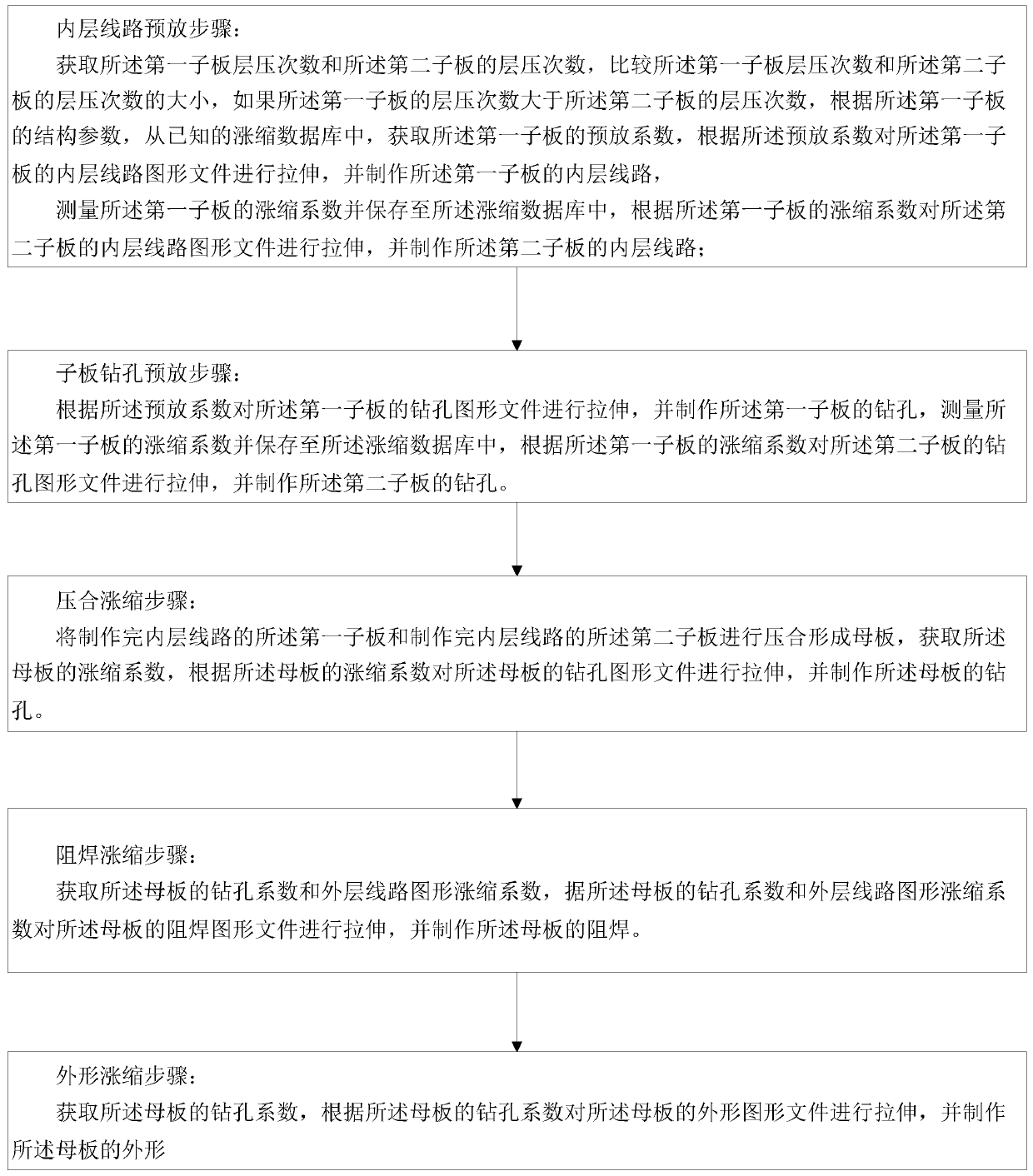

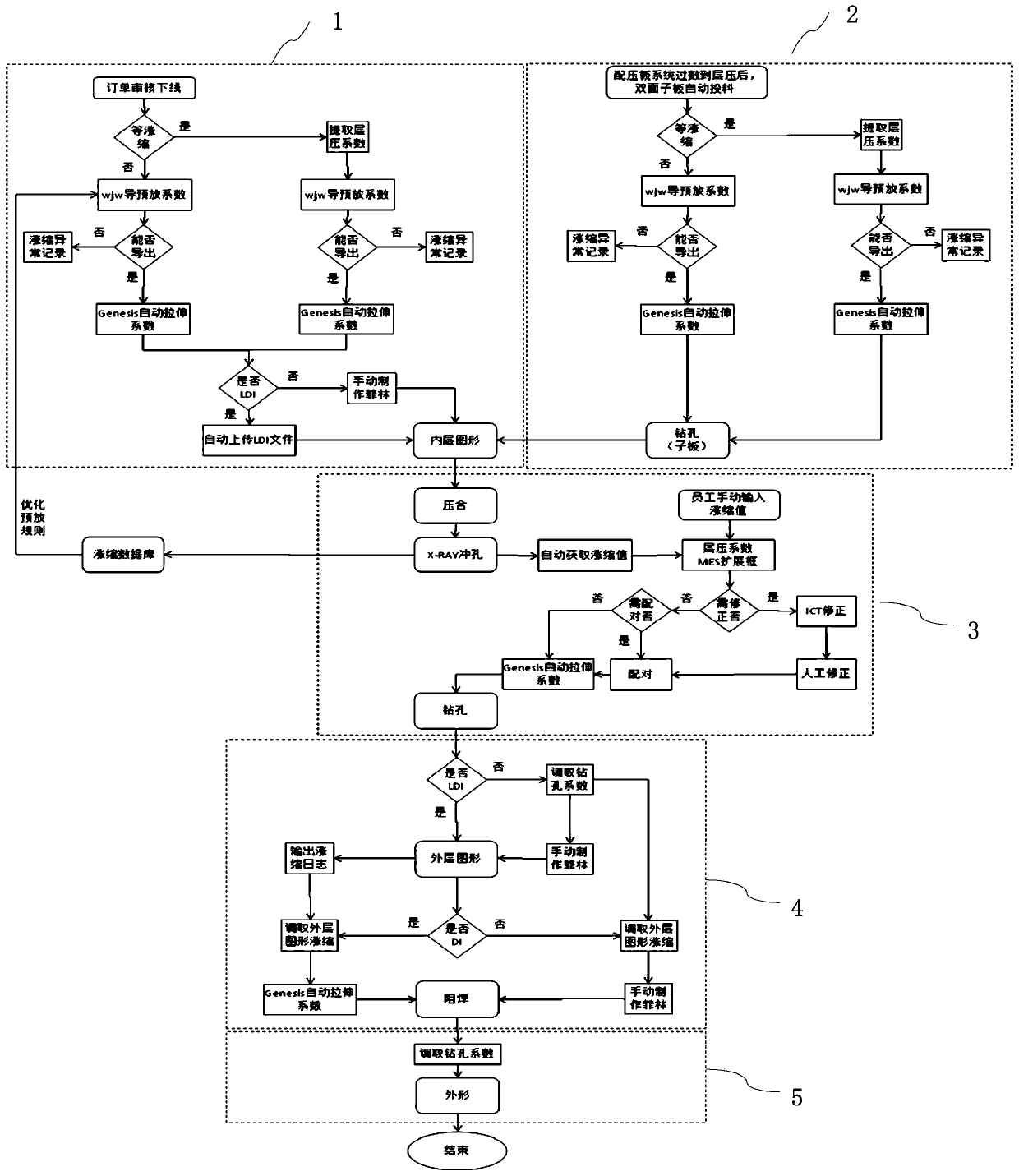

Method and device for controlling expansion and contraction of printed circuit board

ActiveCN110267437ANot easy to make mistakesImprove production efficiency and product qualityComputer designed circuitsDrill holePrinted circuit board

The invention discloses a method and device for controlling the expansion and contraction of a printed circuit board. The method comprises the following steps: pre-laying of an inner-layer circuit; pre-laying of drill holes in daughter boards; press-fitting expansion-contraction; resistance welding expansion-contraction; and shape expansion-contraction. The method of the invention controls pre-laying of the inner-layer circuit, pre-laying of the drill holes in the daughter boards, press-fitting expansion-contraction, resistance welding expansion-contraction and shape expansion-contraction to overally control expansion-contraction procedures involved in the processing of the printed circuit board by means of controlling interlayer expansion-contraction and integral expansion-contraction; the linking of procedures before and after expansion-contraction is logical and systematic, so mistakes hardly occurs in the expansion-contraction procedures; and factors affecting efficiency can be traced, which helps to correct errors and improve product quality and production efficiency. The method and device for controlling the expansion and contraction of the printed circuit board in the invention are widely applicable to the technical field of printing of inner-layer circuit boards.

Owner:SHENZHEN FASTPRINT CIRCUIT TECH +1

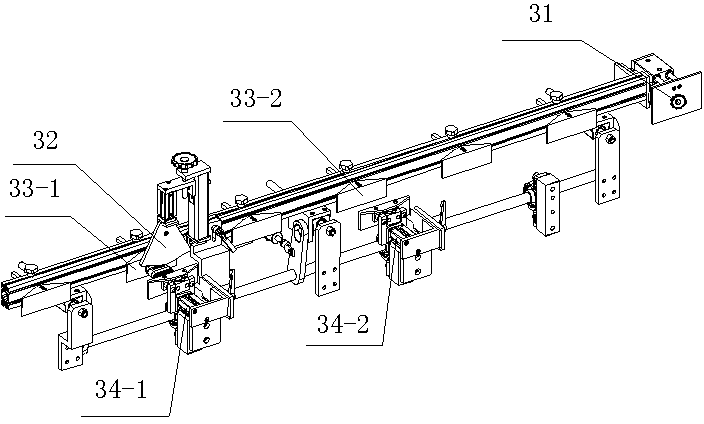

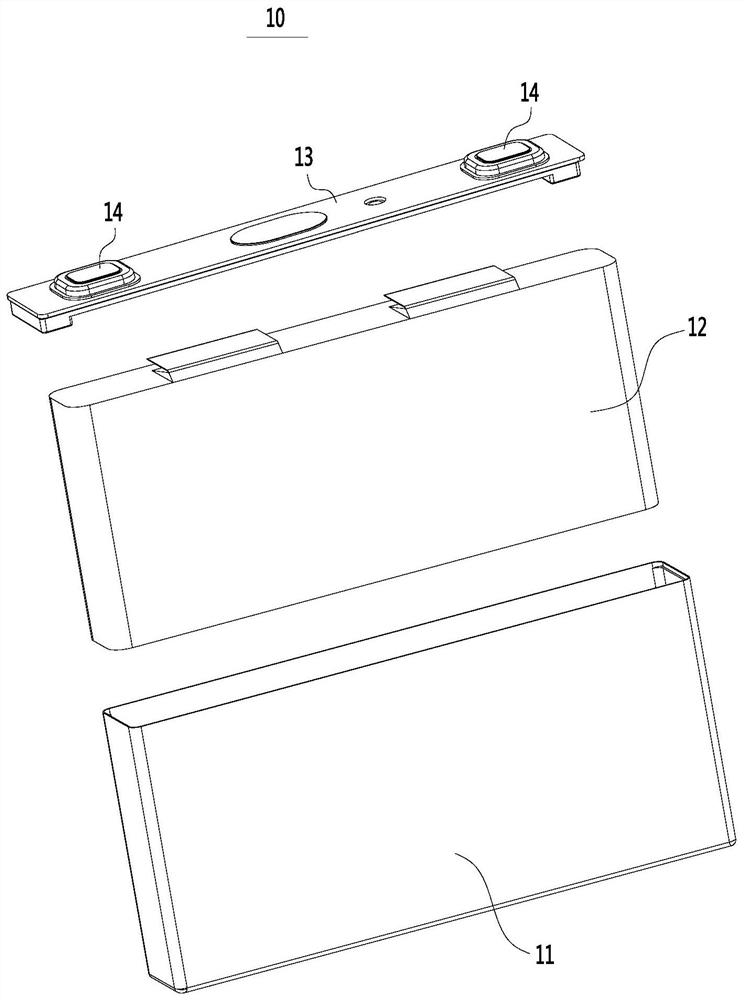

Tab dislocation adjusting method and device

ActiveCN112310568AReduce the likelihood of failureImprove production efficiency and product qualityFinal product manufactureSecondary cellsPhysicsEngineering

The invention relates to a tab dislocation adjusting method and device. The tab dislocation adjustment method comprises the following steps of: winding a pole piece on a winding needle, selecting a predetermined number of tabs on the pole piece as test tabs, obtaining an actual angle value of the winding needle corresponding to each test tab, the actual angle value being an angle value of the winding needle rotating when the winding needle detects that the corresponding test tab is about to be wound on the winding needle from a timing zero point; comparing the actual angle value of each test tab with a corresponding standard angle value to obtain an angle difference value of each test tab; obtaining a dislocation arc length corresponding to each test tab according to the angle difference value corresponding to each test tab; determining an average dislocation arc length according to the dislocation arc length of each test tab; and under the condition that the average dislocation arc length exceeds an allowable dislocation value, enabling the winding needle to rotate to compensate the angle value. According to the tab dislocation adjusting method disclosed by the invention, dislocated tab clusters can be adjusted towards preset positions, so that the possibility of disqualification of a battery cell caused by deviation of the tab clusters is reduced.

Owner:CONTEMPORARY AMPEREX TECH CO

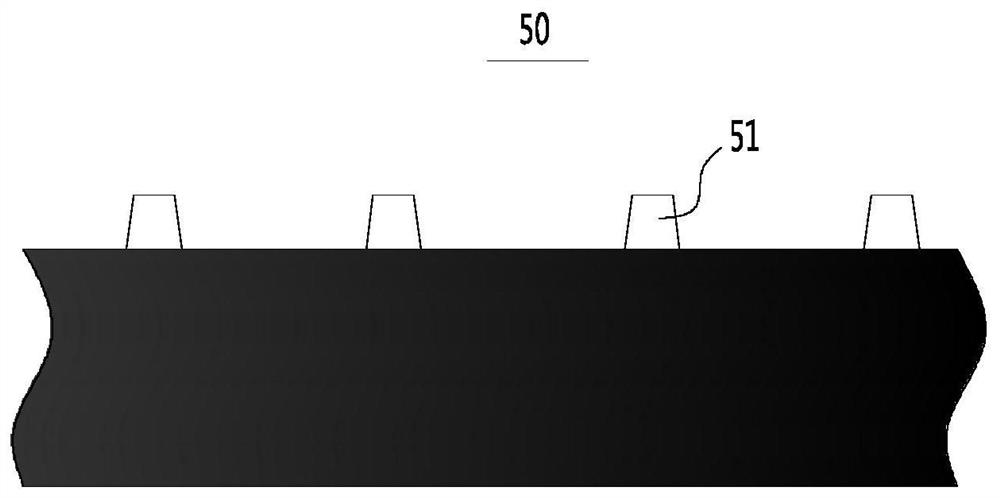

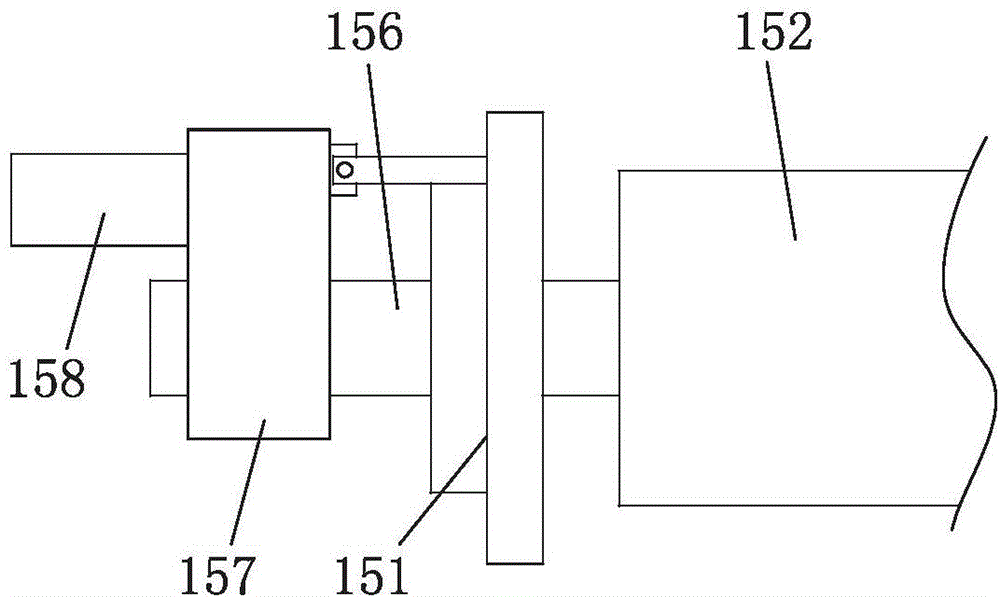

Thermoplastic cellular board and production method thereof, and double-steel-strip continuous press

ActiveCN103950264AImprove production efficiency and product qualityThe honeycomb structure is stableLamination ancillary operationsLaminationThermoplasticHoneycomb structure

The invention discloses a thermoplastic cellular board and a production method thereof, and a double-steel-strip continuous press. The double-steel-strip continuous press comprises preheating mechanisms, steel strip mechanisms, roller blanket mechanisms and cooling and forming mechanisms, wherein the two roller blanket mechanisms are respectively arranged in respective annular spaces formed by the upper and lower steel strips; and the two roller blanket mechanisms in the annular space of each steel strip is arranged front and back. By adopting the upper and lower roller blanket mechanisms and the cooling and forming mechanisms inside, the cooling and forming process of the cellular board is divided into a first cooling section and a second cooling section, so that the sectional cooling and forming of the cellular board can be implemented according to the technical design demands, thereby effectively controlling the technical temperatures of the two cooling sections and enhancing the product quality and production efficiency. The thermoplastic cellular board produced by the production method and press has the advantages of stable cellular structure, favorable surface quality, high strength and large area.

Owner:HANGZHOU HOLYCORE COMPOSITE MATERIAL

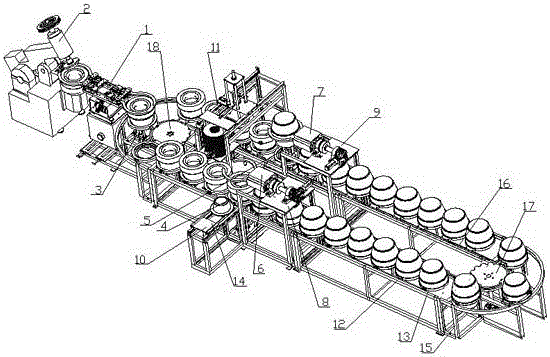

Automatic ceramic body forming production line

ActiveCN106113248AImprove production efficiency and product qualityRealize automated productionCeramic shaping plantsAuxillary shaping apparatusEngineeringAutomation

The invention relates to an automatic ceramic body forming production line which comprises a clamping transposition device, a green body forming machine, a lifting device I, a lifting device II, a lifting device III, a clamping device I, a clamping device II, a turnover device I, a turnover device II, a green body taking device, a base plate placing device, a circulatory transport mechanism and a hot air pipeline drying system, wherein a plurality of brackets are arranged on the circulatory transport mechanism; the lifting device I, the lifting device II and the lifting device III are arranged below the brackets at the middle section, the front section and the back section of the circulatory transport mechanism; the clamping transposition device is arranged beside the lifting device I; the green body forming machine is arranged on the other side of the clamping transposition device; the green body taking device is arranged at the lifting device II; and the base plate placing device is arranged at the lifting device III. The automatic ceramic body forming production line improves the production efficiency and product quality while realizing mechanization and automation of ceramic production.

Owner:GUANGXI BEILIU ZHIYU CERAMIC AUTOMATION EQUIPCO

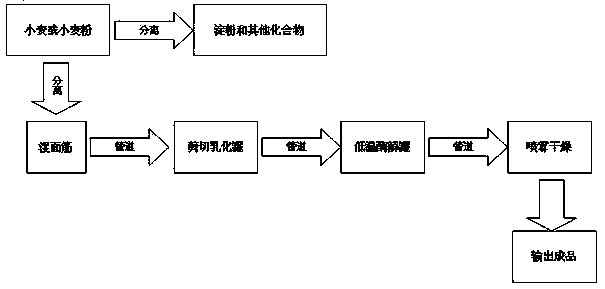

Production process for producing wheat hydrolyzed protein by wet gluten

InactiveCN103875886AImprove production efficiency and product qualityEnergy savingProtein proteinViscose

The invention discloses a production process for producing wheat hydrolyzed protein by wet gluten. The production process for producing wheat hydrolyzed protein by wet gluten comprises the following steps: (1) removing starch and other carbohydrate in a separator by taking wheat or wheat flour as a raw material so as to obtain a protein ingredient and then obtain wet gluten; (2) conveying wet gluten into a shearing and emulsifying tank by a pipeline to perform viscose-removing, shearing and enzymolysis liquidation treatment, and meanwhile, sampling the determination quality and dry basis content; (3) reducing the viscose of the wet gluten after viscose-removing and shearing treatment, conveying the wet gluten into a low-temperature enzymolysis tank, and carrying out enzymolysis treatment at the temperature of 45 DEG C-65 DEG C under the condition of pH value of 6.0-8.0; (4) degrading a great number of protein in wheat protein in the wet gluten into small peptide after full enzymolysis liquidation, conveying the small peptide into a spraying system from the low-temperature enzymolysis tank by a pipeline, and drying; (5) outputting finished products directly from a material receiving tower after spraying and drying. According to the invention, the production efficiency and the product quality are improved, and energy sources are saved.

Owner:JIANGSU ZHIHUI BIOTECH +1

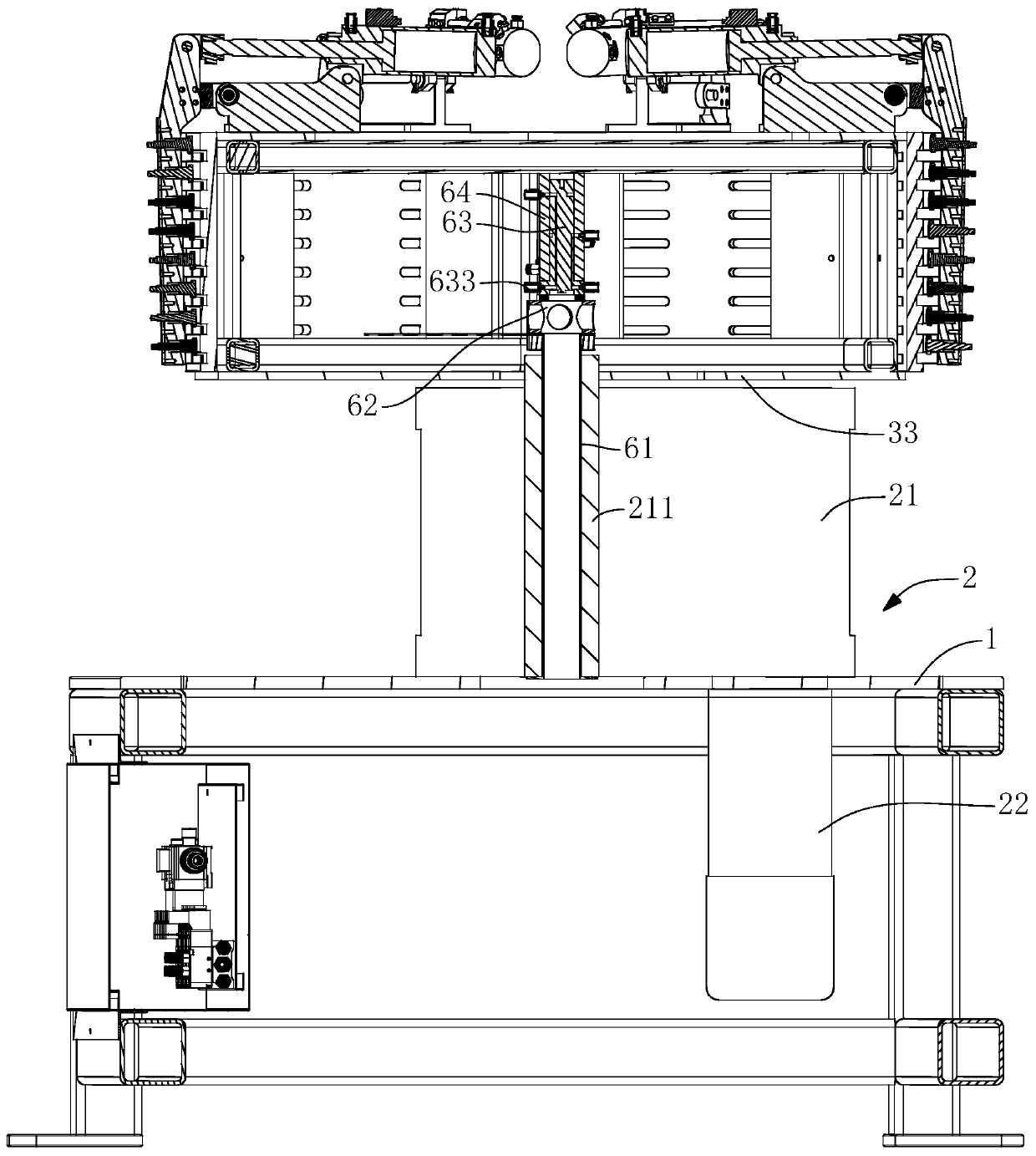

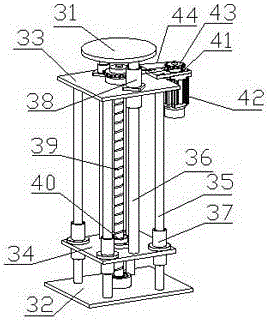

Synchronous lifting device of H-shaped steel assembling machine

InactiveCN103846586AImprove production efficiency and product qualityImprove production efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringIndustrial engineering

The invention relates to a synchronous lifting device of an H-shaped steel assembling machine, and belongs to the field of mechanical processing equipment. The device consists of a lifting platform, a lifting roller way, a lifting driving device and lifting guiding mechanisms, wherein the lifting platform is installed on the assembling machine; the lifting roller way is fixed on the lifting platform through a bearing support; the top end of the lifting driving device is connected with the bottom of the lifting platform; the lifting guiding mechanisms are symmetrically and fixedly installed on the two sides of the assembling machine; the two ends of a mandrel of the lifting roller way are in transmission connection with the lifting guiding mechanisms symmetrically arranged on the two sides of the assembling machine respectively; the lifting platform goes up and down under the driving of the lifting driving device, and the lifting roller way on the lifting platform goes up and down along the lifting guiding mechanisms, so that the lifting roller way on the lifting platform of the assembling machine is as high as a conveying roller way, an H-shaped steel workpiece at an assembling workstation can stably run along the conveying roller way, and thus the production efficiency of the assembling workstation and the product quality are improved.

Owner:HUBEI HONGYI BUILDING DECORATION ENG

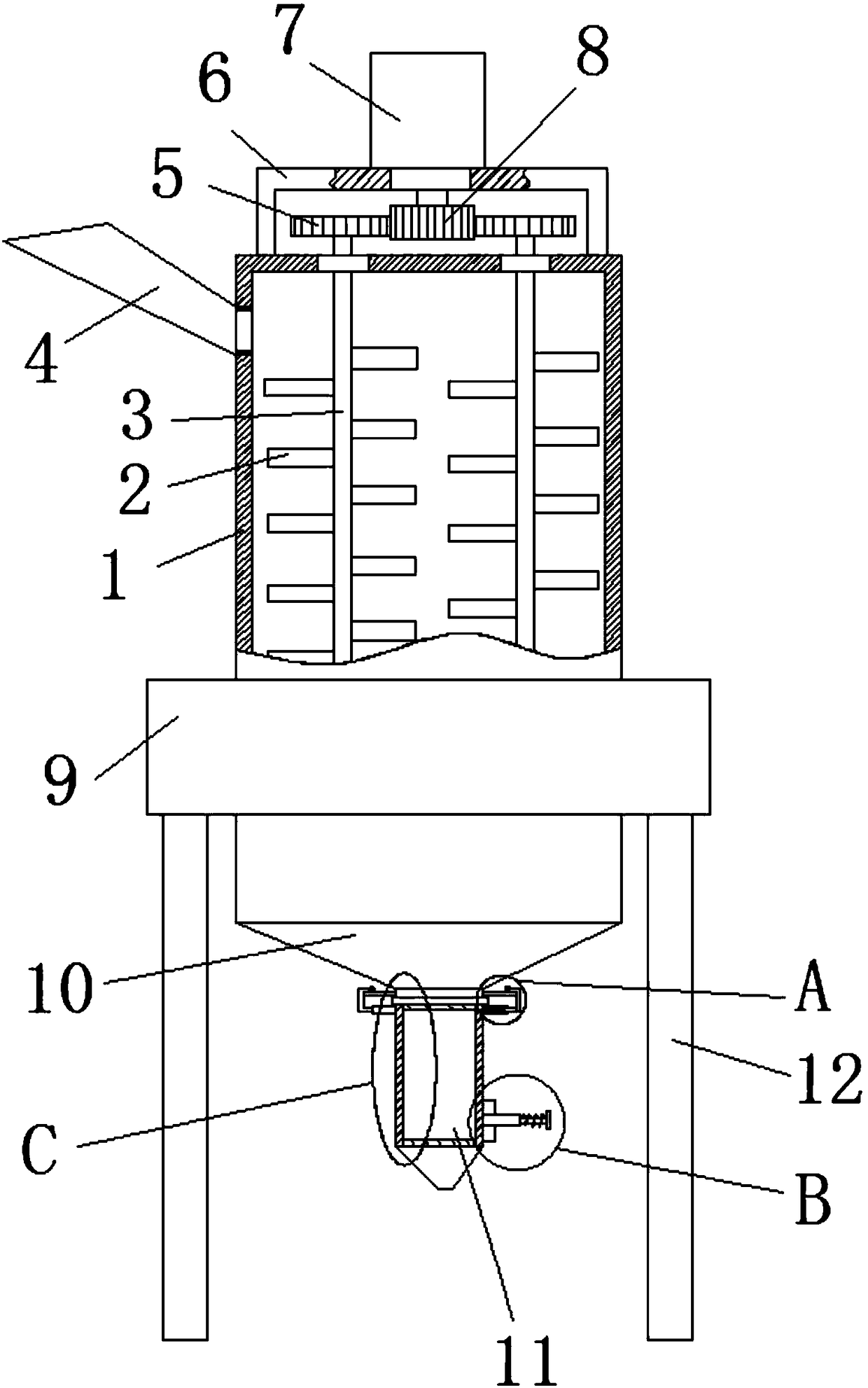

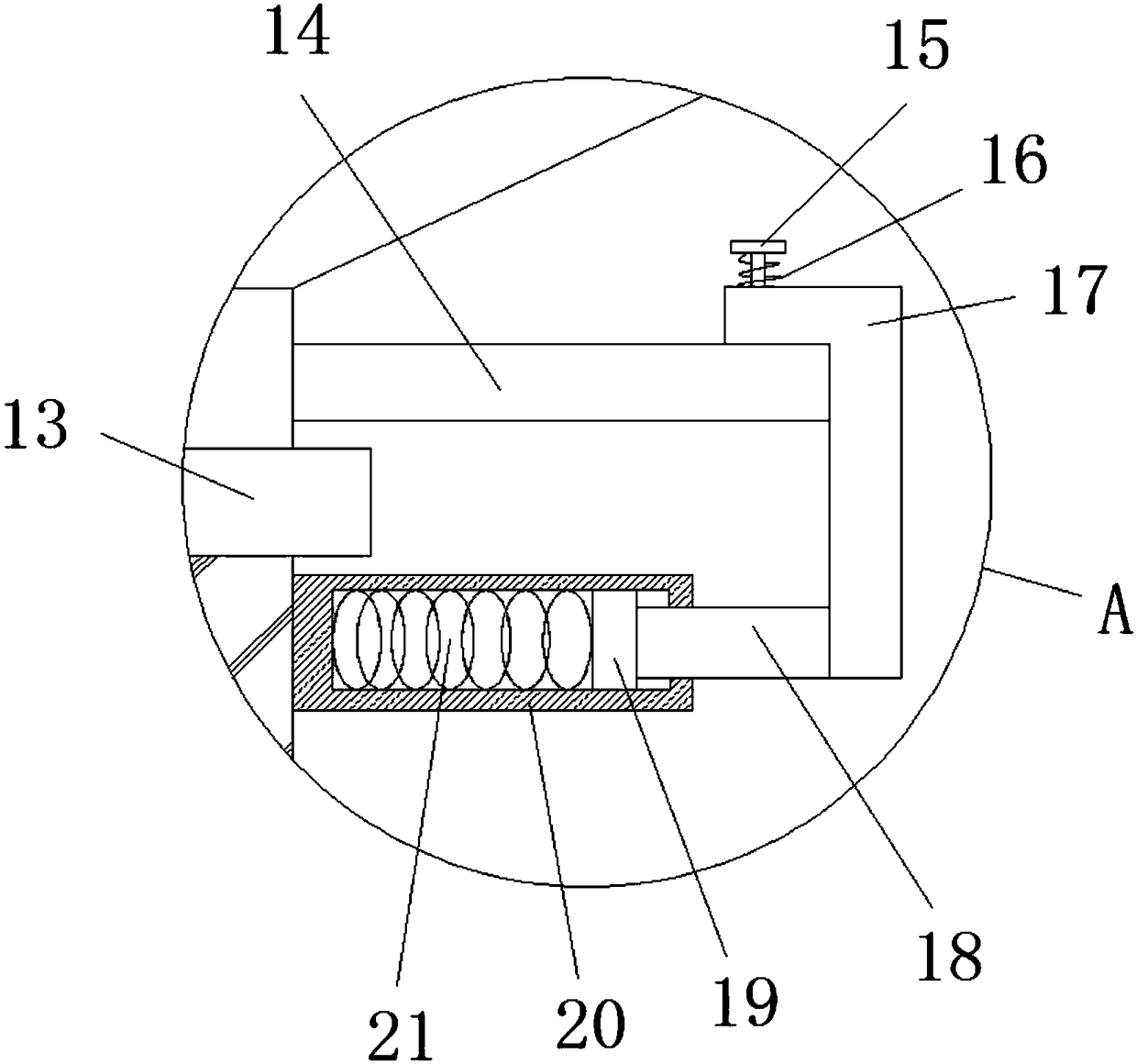

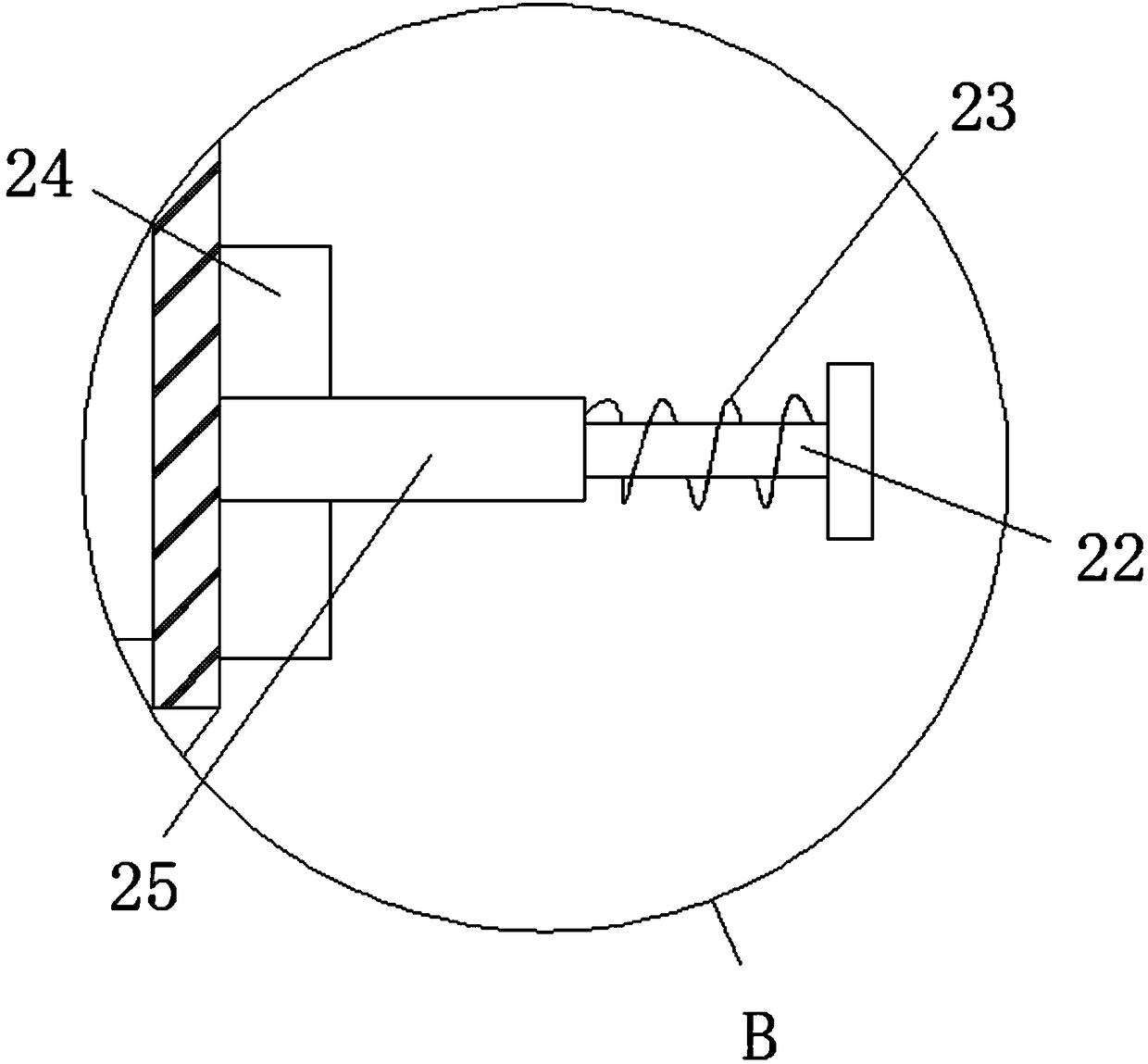

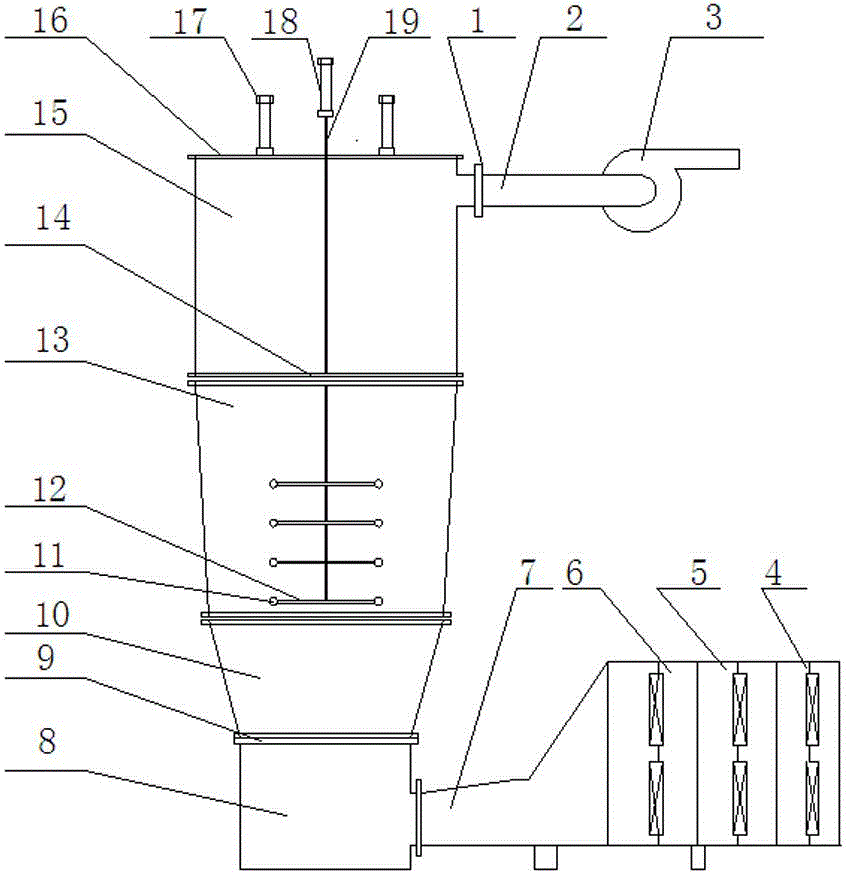

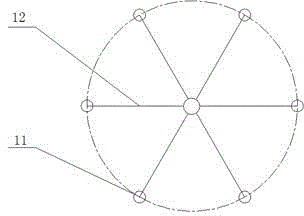

Fluidizing and spray-drying granulator

InactiveCN104549044AExpand the atomization rangeImprove production efficiency and product qualityGranulation by powder suspensionEngineeringEnergy consumption

The invention discloses a fluidizing and spray-drying granulator. The granulator comprises a trapping chamber, a spraying chamber, a fluidizing chamber and an air inlet chamber which are sequentially arranged from top to bottom, wherein an air inducing pipe is arranged on the side wall of the upper part of the trapping chamber and connected with an induced draft fan, a bag filter is arranged in a position where the bottom of the trapping chamber and the top of the spraying chamber are connected, a position-adjustable spraying device is arranged in the spraying chamber, a perforated fluidizing plate is arranged in a position where the bottom of the fluidizing chamber and the top of the air inlet chamber are connected, an air inlet pipe is arranged on the side wall of the lower part of the air inlet chamber, and a filter, a dehumidifier and a heater are arranged on the air inlet pipe. The spraying device and the perforated fluidizing plate are movably connected, relative positions of all spraying guns, the spraying amount, the auxiliary material amount and the aperture ratio of the perforated fluidizing plate can be adjusted according to granulation requirements, and enlargement of the liquid atomization range and stable fluidization of seed powder are realized, so that the production efficiency and the product quality are improved, and the drying energy consumption is reduced.

Owner:XIANGTAN UNIV

Reverse-installation posture assembling positioning tool for side beam welding

ActiveCN109048158AQuick coincidence positioningPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesBogieEngineering

The invention discloses a reverse-installation posture assembling positioning tool for side beam welding, and belongs to the field of auxiliary clamping devices for welding assembling positioning of railway vehicle bogie side beam devices. The reverse-installation posture assembling positioning tool comprises a foundation platform, a side beam middle section positioning seat, two spring seat pressing mechanisms and two axle hinge seat door arch positioners, the lower end of the side beam middle section positioning seat, the lower ends of the two spring seat pressing mechanisms and the lower ends of the two axle hinge seat door arch positioners are fixedly connected to the end surface of the foundation platform, the side beam middle section positioning seat is located in the center of the foundation platform, the two spring seat pressing mechanisms are symmetrically arranged on the left side and the right side of the side beam middle section positioning seat, and the two axle hinge seatdoor arch positioners are symmetrically and fixedly connected to the two ends of the foundation platform. According to the reverse-installation posture assembling positioning tool, the mapping and marking operation performed during side beam assembling can be completely avoided, the mode of the reverse-installation posture assembling positioning tool for positioning components is simple, convenient, fast, accurate and reliable, moreover, welding deformation of all portions on a pinion-shaped side beam can be effectively inhibited, the adjusting and repairing work after welding is reduced, andtherefore, the production efficiency and the product quality can be greatly improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Double-weighing automatic feeder used for refractory brick processing

PendingCN113043445AReduce manual labor intensityImprove production efficiency and product qualityFeeding arrangmentsAuxillary shaping apparatusMachine pressProcess engineering

The invention discloses a double-weighing automatic feeder used for refractory brick processing. The double-weighing automatic feeder used for refractory brick processing comprises a machine frame, a material bin device, a discharging device, a weighing device, a moving device and a feeding device, the material bin device, the discharging device, the weighing device and the moving device are mounted on the machine frame, the feeding device is mounted on the moving device, the material bin device is used for loading raw materials, the discharging device is used for conveying the raw materials in the material bin device to the weighing device, the weighing device is used for quantitatively weighing the raw materials, the moving device is used for pushing the feeding device to a position above a mold from a position below the weighing device, and the feeding device is used for feeding the raw materials. According to the double-weighing automatic feeder used for refractory brick processing, the discharging device which comprises a double-belt conveying mechanism and the weighing device which comprises a double-weighing hopper are adopted to cooperate to form the two weighing operation lines, the two weighing operation lines alternately work to feed the raw materials into the feeding device, the feeding device is pushed to the position above the mold in a press machine through the moving device to carry out the feeding procedure, and therefore the labor intensity of workers is reduced, and the production efficiency and the product quality are improved.

Owner:武汉吉森智能技术有限公司

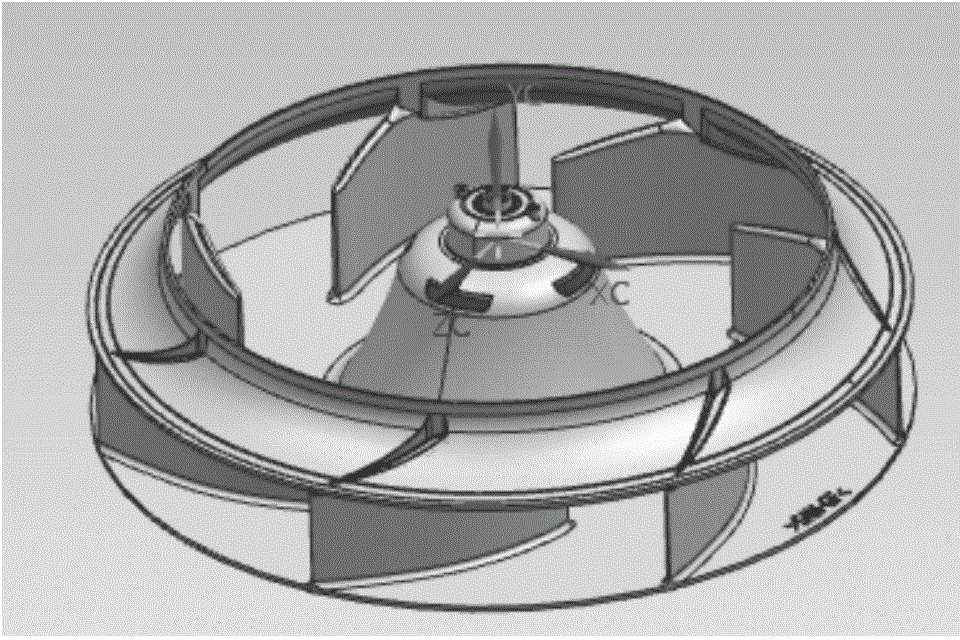

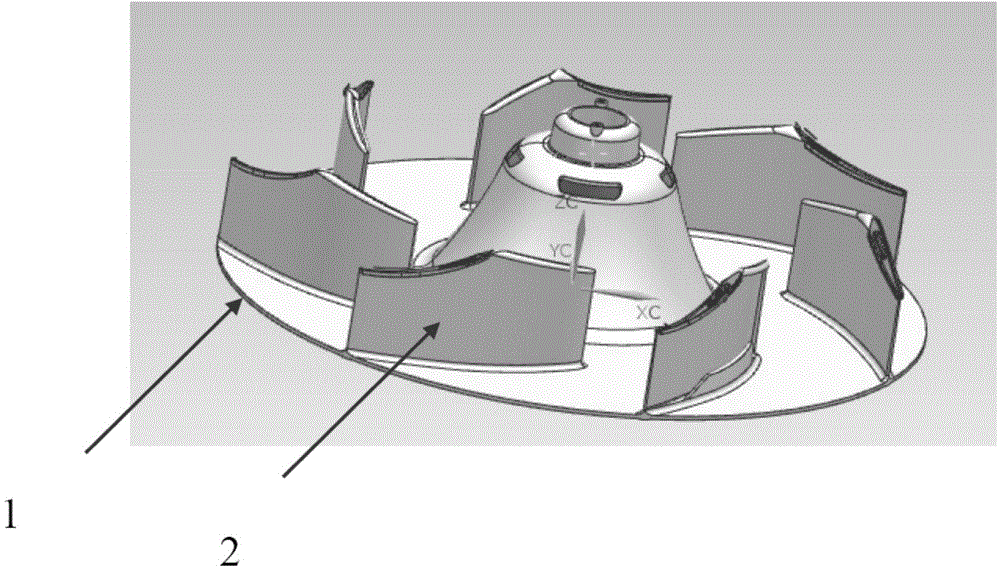

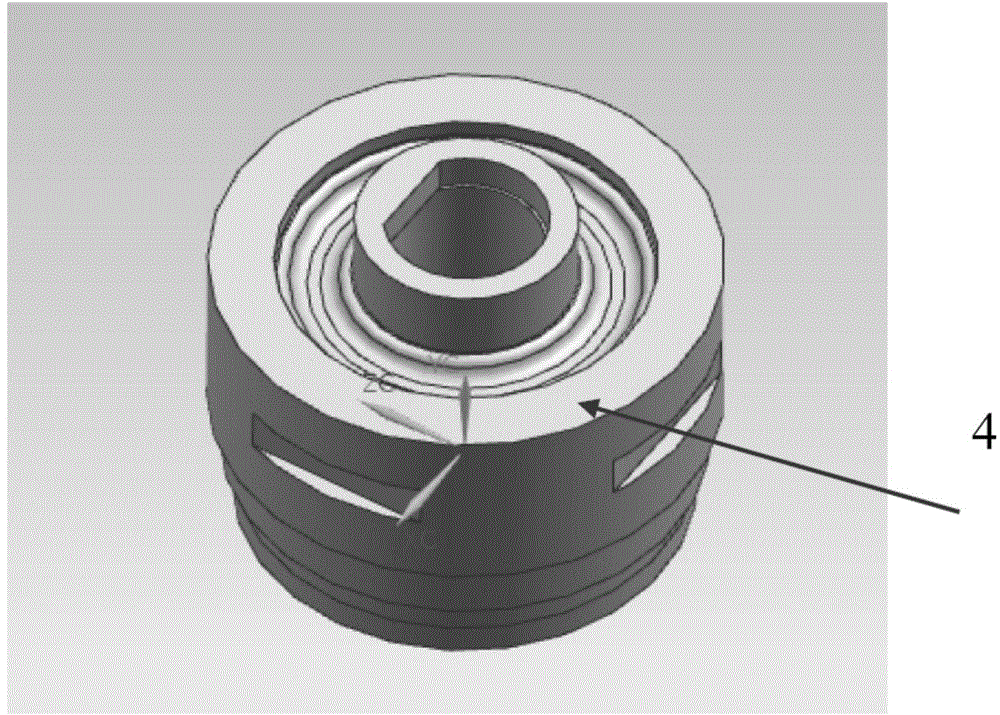

Ultrasonic welding equipment for fans, as well as usage method and application thereof

InactiveCN104690412AImprove production efficiency and product qualityLow costPump componentsPumpsElectrical controlEngineering

The invention discloses ultrasonic welding equipment for fans, as well as a usage method and application thereof. The ultrasonic welding equipment comprises a frame, an electrical control box, a workbench with positioning molds, and an ultrasonic welding device mounted in the frame. The ultrasonic welding equipment is characterized in that the ultrasonic welding device is provided with a plurality of adjustable ultrasonic welding heads; during the welding process, the ultrasonic welding heads carry out one-time welding forming at the same time. The ultrasonic welding equipment provided by the invention is used for welding fans, such as turbine fans and tubular fans of air conditioners and air coolers.

Owner:ZHEJIANG GOLDENSEA ENVIRONMENT TECH

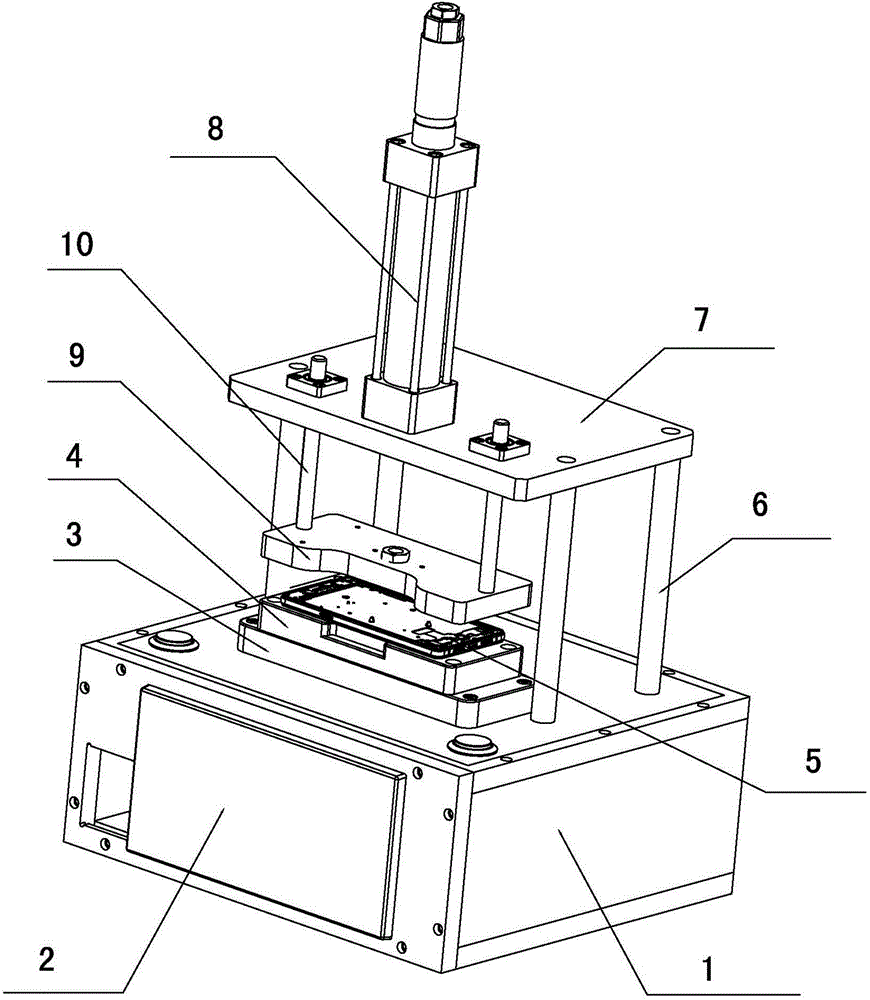

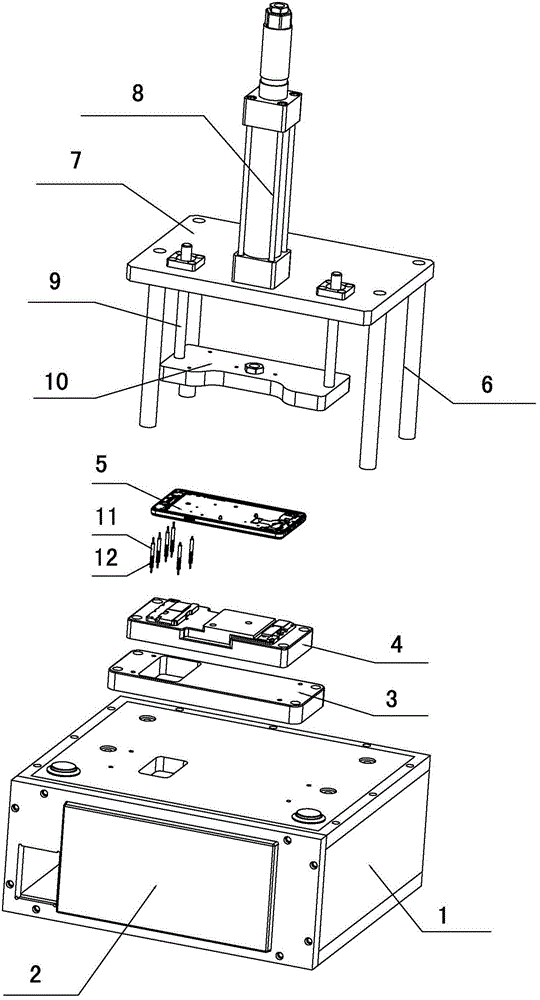

Equipment for automatically detecting ground resistance of mobile phone housings

InactiveCN104808068AReduce labor costsImprove production efficiency and product qualityEarth resistance measurementsAgricultural engineeringDisplay device

The invention discloses equipment for automatically detecting ground resistance of mobile phone housings. The equipment comprises a rack, a fixing plate, a mobile phone fixture and a display device, wherein the display device is fixedly mounted on the rack; the fixing plate is fixedly mounted at the top of the rack; the mobile phone fixture is fixedly mounted on the fixing plate; more than one detection probe is mounted in the mobile phone fixture. The device servers as a self-developed device for automatically detecting resistance and is capable of automatically detecting the ground resistance of the mobile phone housing; the labor cost is effectively reduced; the production efficiency and the quality of products can be improved.

Owner:SHENZHEN DONGFANG LIANGCAI PRECISION TECH

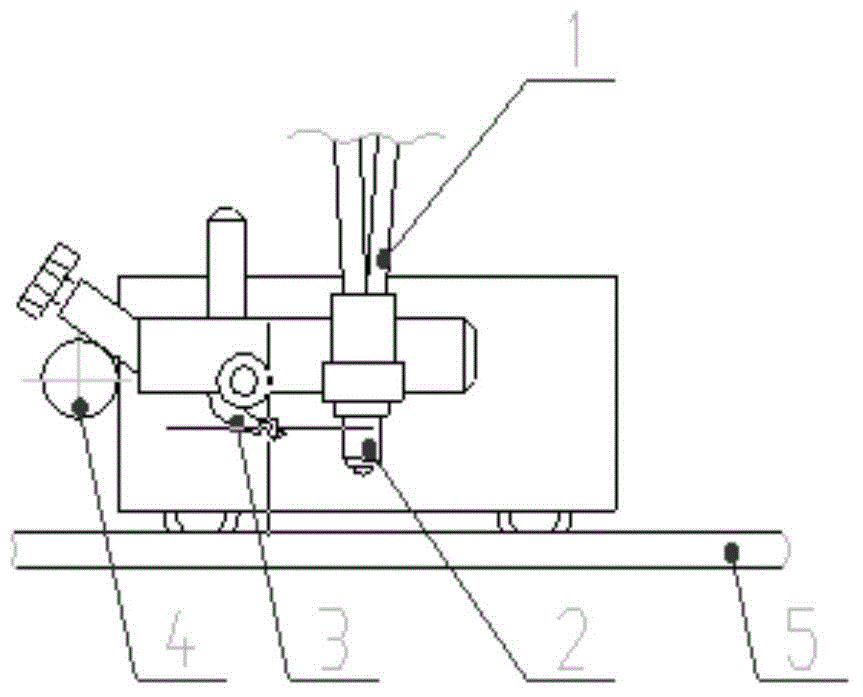

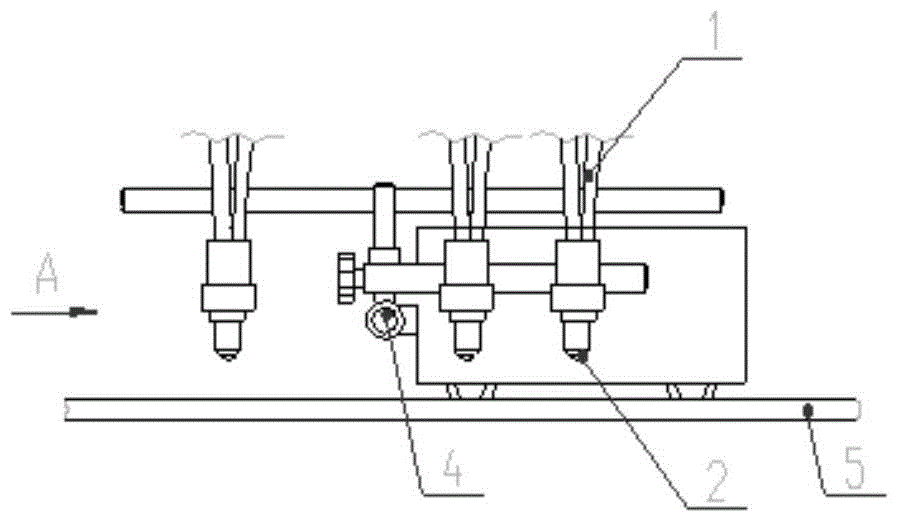

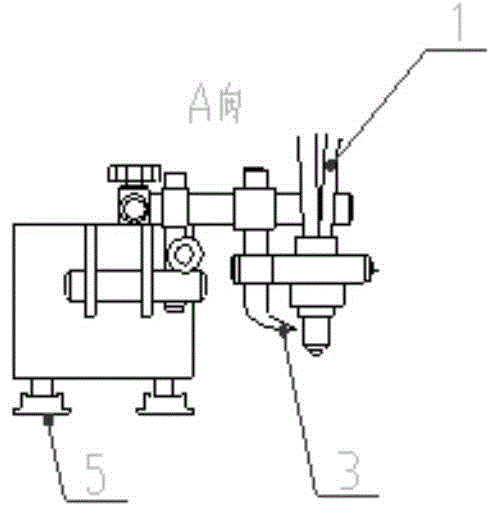

A flame cutting device

InactiveCN104985278AImprove production efficiency and product qualityRealize intermittent cuttingGas flame welding apparatusSteel platesFlame cutting

The invention provides a three-gun flame cutting device at least comprising a first flame cutting gun head, a second flame cutting gun head and a third flame cutting gun head. The first flame cutting gun head is arranged on the next working position of the second flame cutting gun head; the third flame cutting gun head is located on the previous working position of the second flame cutting gun head. The cutter enables the preheating flame area and the cutting speed to be adjusted according to the material and the thickness of steel plates, thereby realizing portable multifunctional intermittent cutting. The risk of cutting crack of the steel is controlled and the technology and equipment guarantee is provided for stable production of high quality products.

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com