Tension bracing mechanism and tension bracing method thereof of template clamp tool

A template clamp and fixture technology, applied in clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of reducing production quality, increasing processing costs, processing failure, etc., to reduce processing failure rate, improve product quality and Production efficiency, the effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] The preferred embodiments of the present invention will be described below with reference to the drawings.

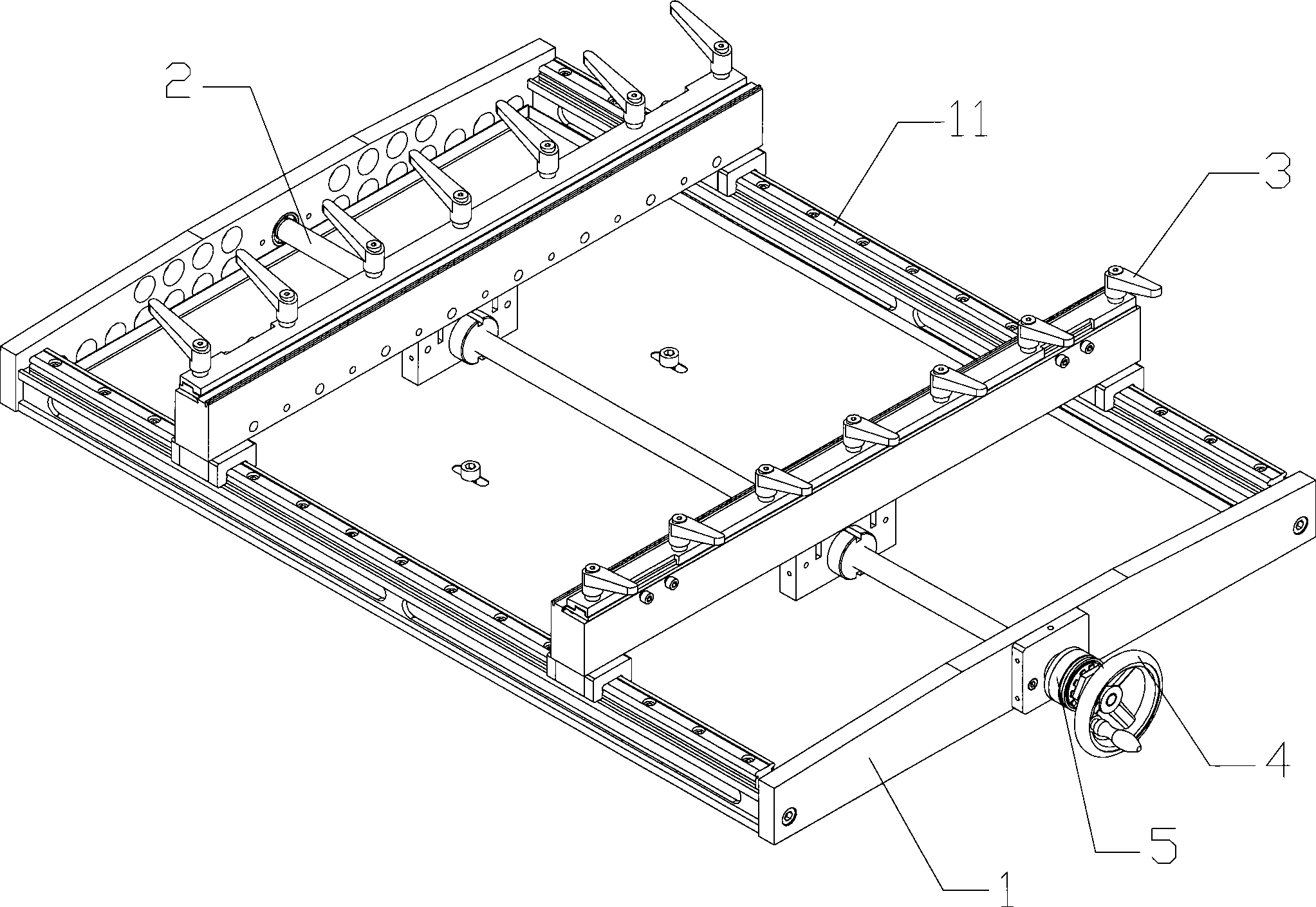

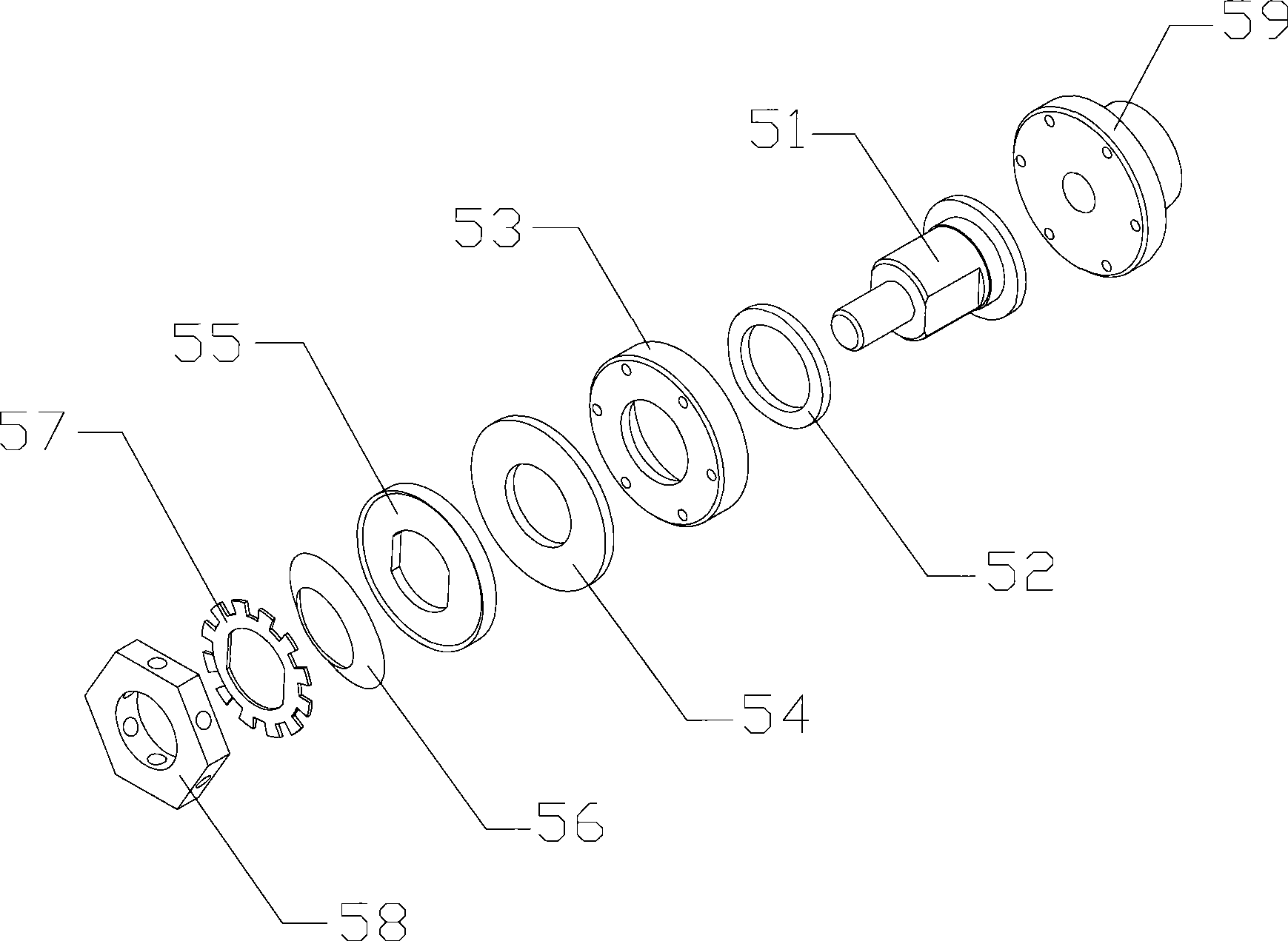

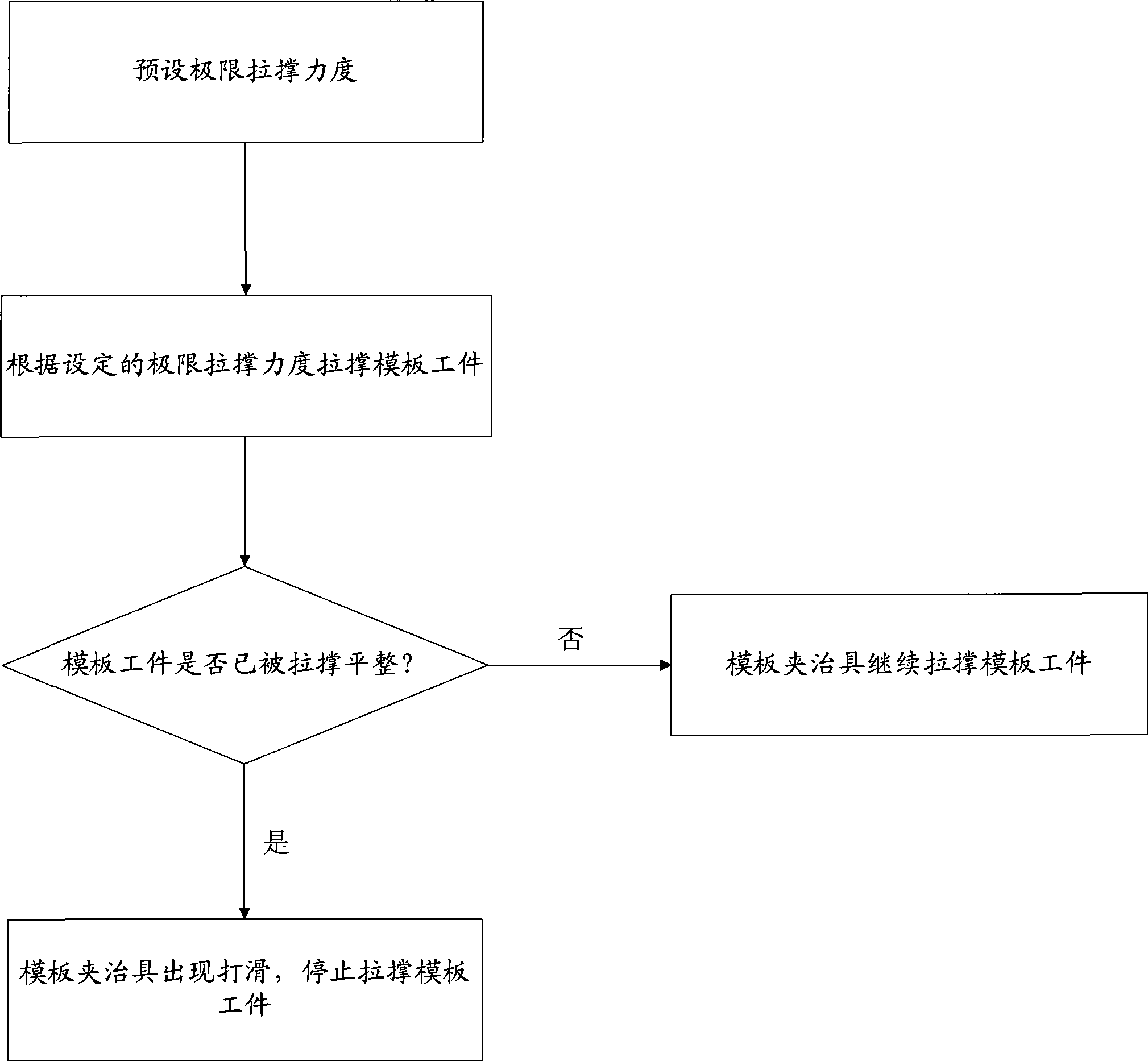

[0015] Refer to figure 1 As shown, the template clamping fixture stretching mechanism of the embodiment of the present invention includes a base 1 provided with a guide rail 11. A screw rod 2 with a drive nut is installed on the base 1, and a clamping jaw clamp 3 and a clamping jaw clamp 3 are fixed on the transmission nut. It is also fixedly connected to the sliding block installed on the guide rail 11. The screw rod 2 is bounded by the center, and the two ends are respectively provided with transmission threads with opposite spiral directions. It also includes a power device and a tension control device 5. In the embodiment of the present invention, the power The device adopts a rocking handle 4, which is fixed to one end of the tension control device 5 through a threaded connection, and the other end of the tension control device 5 and the screw rod 2 are fixed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com