Reverse-installation posture assembling positioning tool for side beam welding

A technology for positioning tooling and side beams, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the axle hinge seat welding posture and position are prone to deviation, the positioning of the axle hinge seat and the welding process are time-consuming and laborious, Welding quality is difficult to be effectively controlled and other problems, to achieve the effect of improving production efficiency and product quality, simple and practical structure, and easy to popularize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

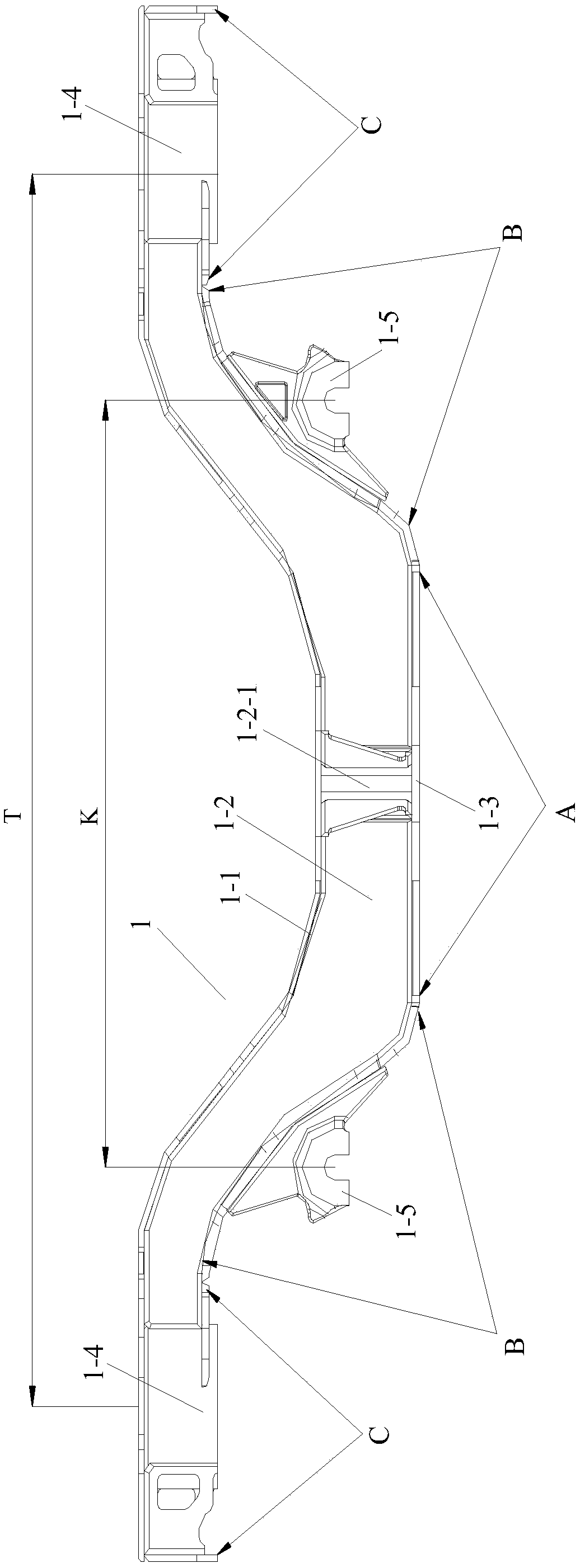

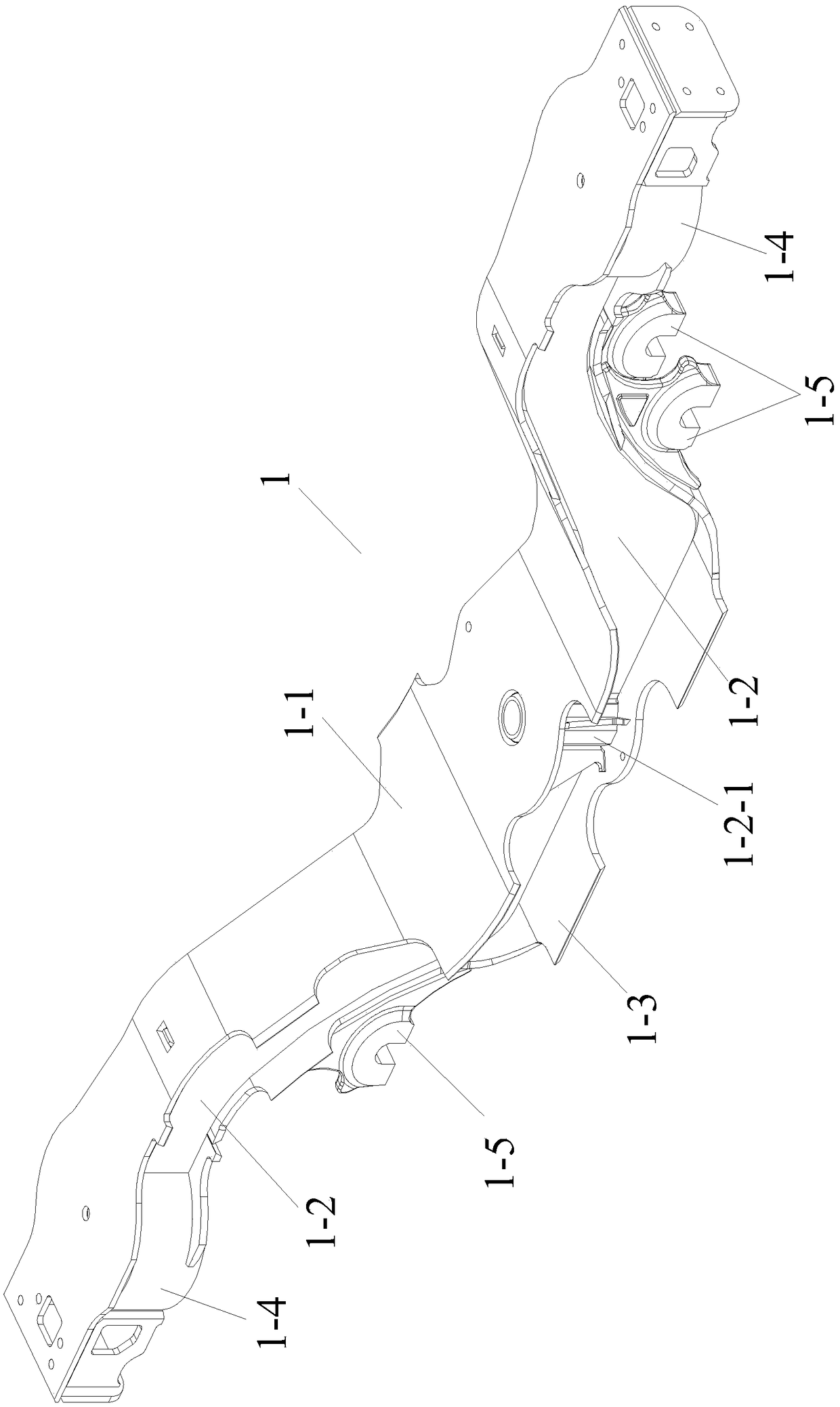

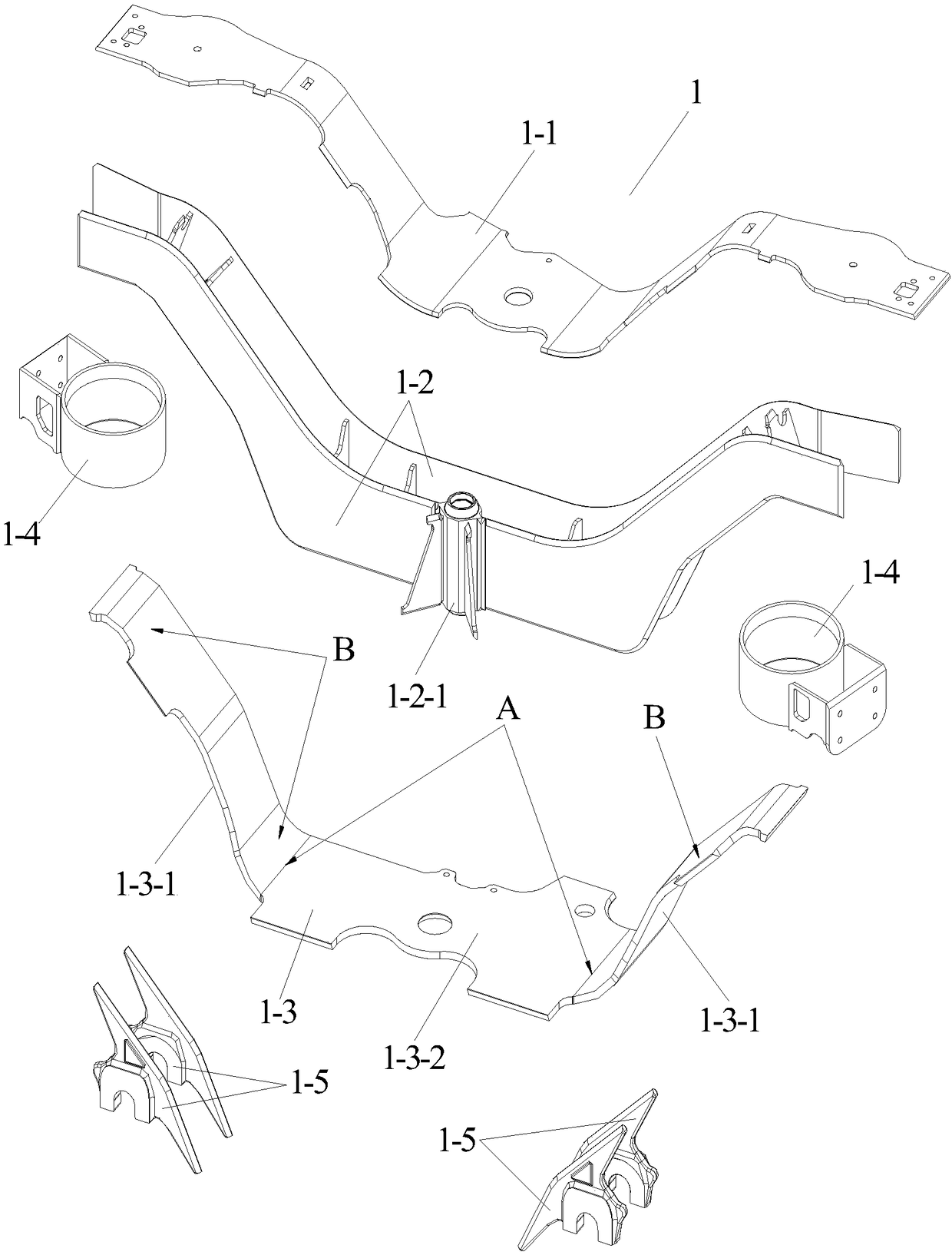

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0051] Such as Figure 9 with Figure 10 As shown, the anti-installation posture assembly positioning tool for side beam welding of the present invention includes a foundation platform 2, a positioning seat 3 for the middle section of the side beam, two spring seat pressing mechanisms 4 and two axle hinge seat door arch positioners 5 , the lower ends of the positioning seat 3 of the middle section of the side beam, the two spring seat pressing mechanisms 4 and the lower ends of the two axle hinge seat door arch positioners 5 are all fixedly connected to the end surface of the foundation platform 2, and the positioning seat 3 of the middle section of the side beam is located on the foundation platform 2 In the center of the center, two spring seat pressing mechanisms 4 are symmetrically arranged on the left and right sides of the positioning seat 3 in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com