Synchronous lifting device of H-shaped steel assembling machine

A technology of synchronizing lifting and assembling machines, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of affecting production efficiency and processing quality, and cannot guarantee the level of the assembling machine roller table and conveying roller table. , Affect clamping and positioning and other issues to achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

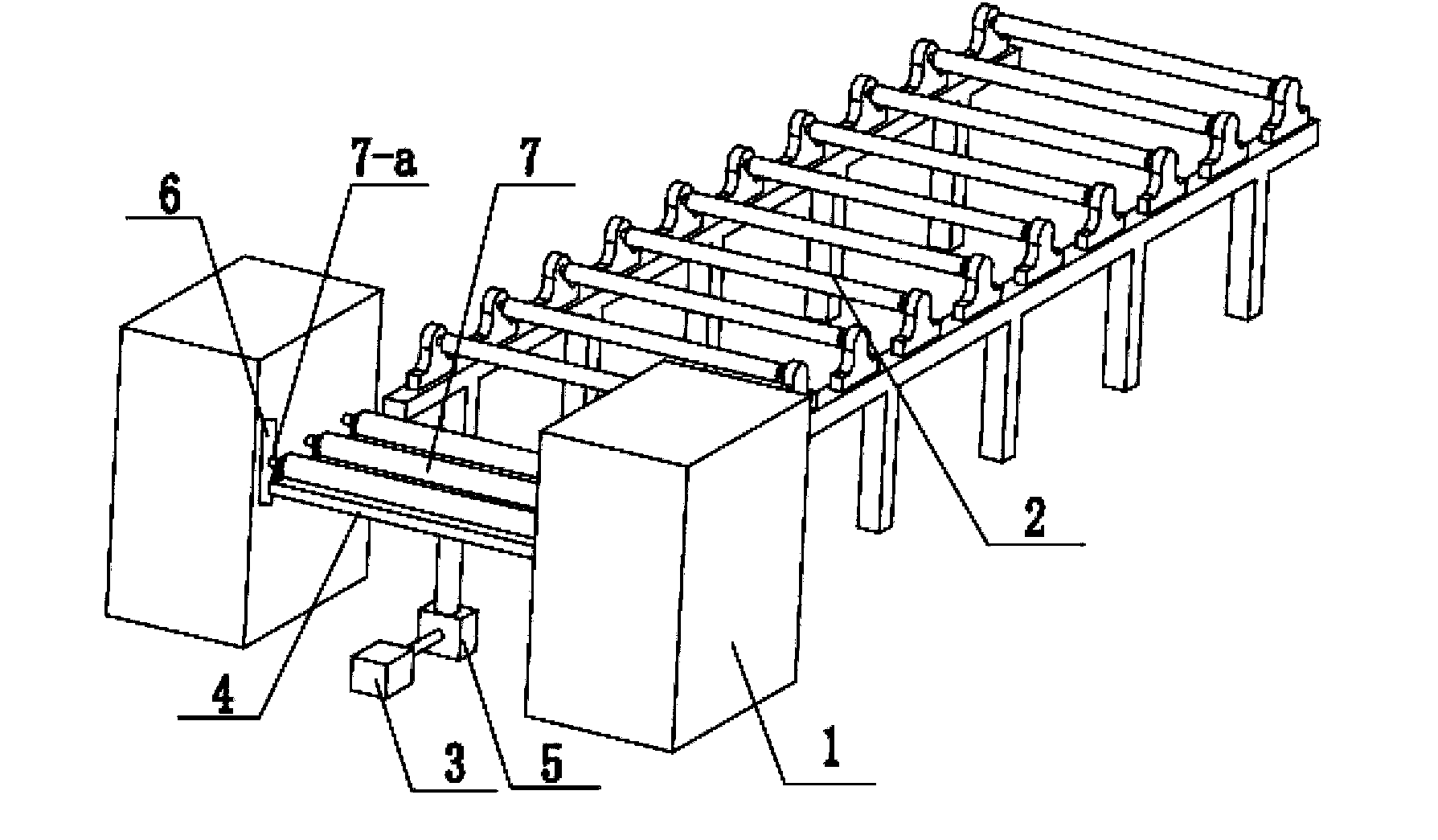

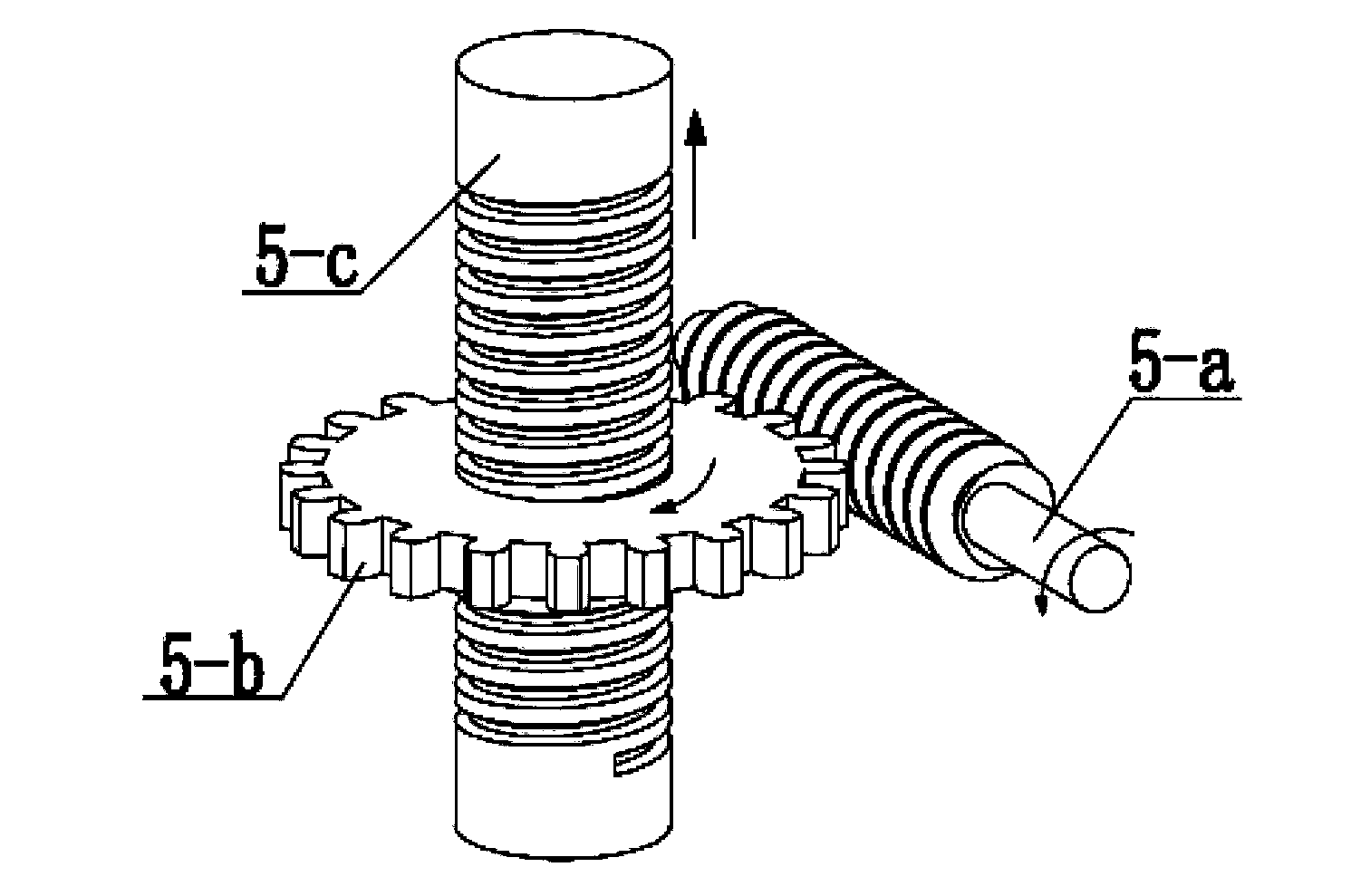

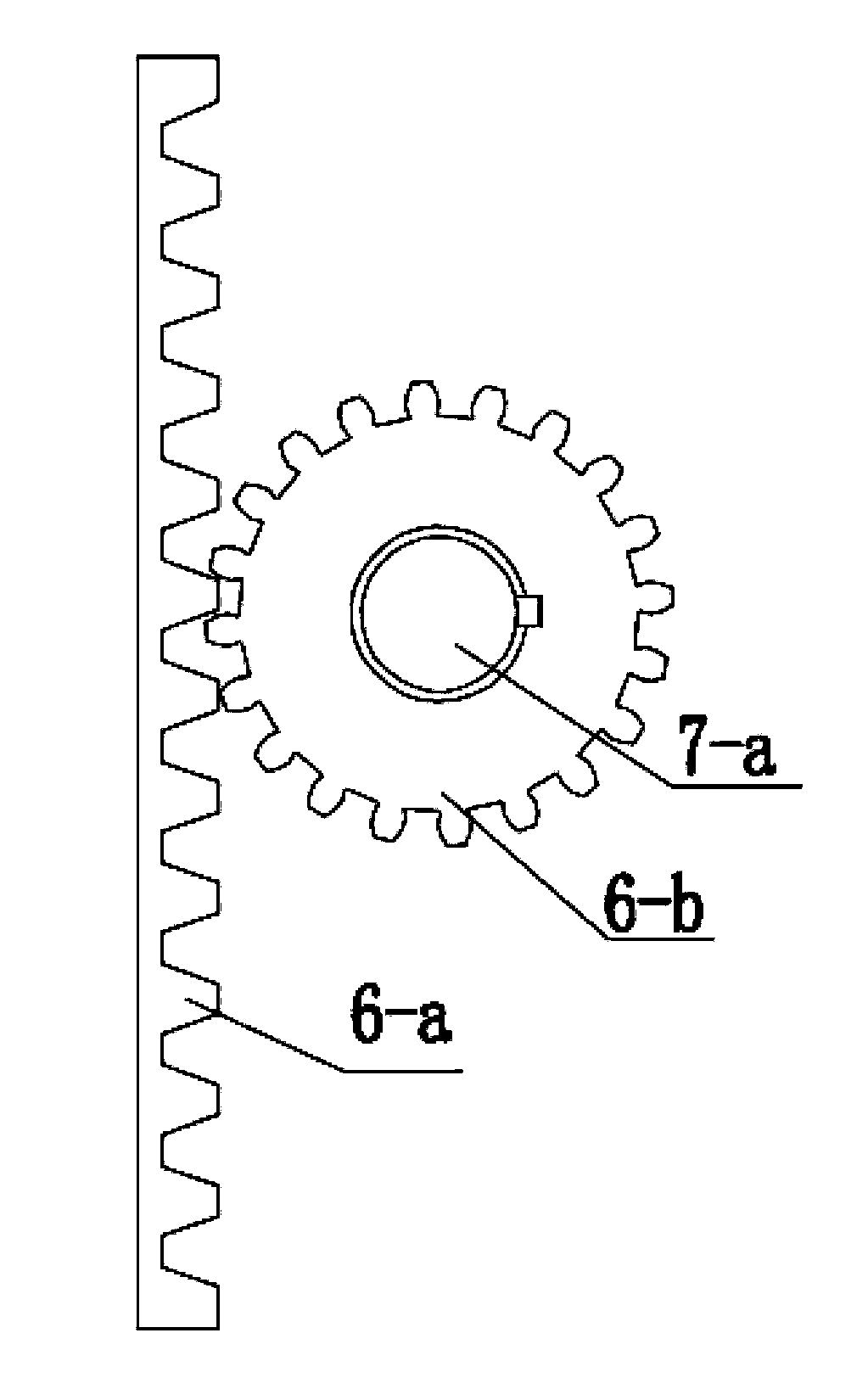

[0012] The synchronous lifting device of the H-shaped steel vertical machine of the present invention is composed of a lifting platform 4, a lifting roller table 7, a lifting driving device and a lifting guide mechanism 6, the top of the lifting driving device is connected with the bottom of the lifting platform 4, and the lifting roller table 7 passes through the bearing. The supports are fixed on the lifting platform 4 in parallel and at intervals, and the two ends of the mandrel 7-a of the lifting roller table 7 are respectively connected to the lifting guide mechanism 6 installed in the assembly machine 1, and the lifting platform 4 is driven by the lifting drive device to move up and down , the lifting roller table 7 installed on the lifting platform 4, through the two ends of the mandrel 7-a and the lifting guide mechanism 6 on both sides, it is lifted along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com