Automatic welding device for barrel

An automatic welding and barrel technology, applied in welding monitoring devices, welding power sources, welding equipment, etc., can solve the problems of high labor intensity, low production efficiency, poor product quality, etc., to reduce labor costs, improve production efficiency and product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below with reference to the accompanying drawings.

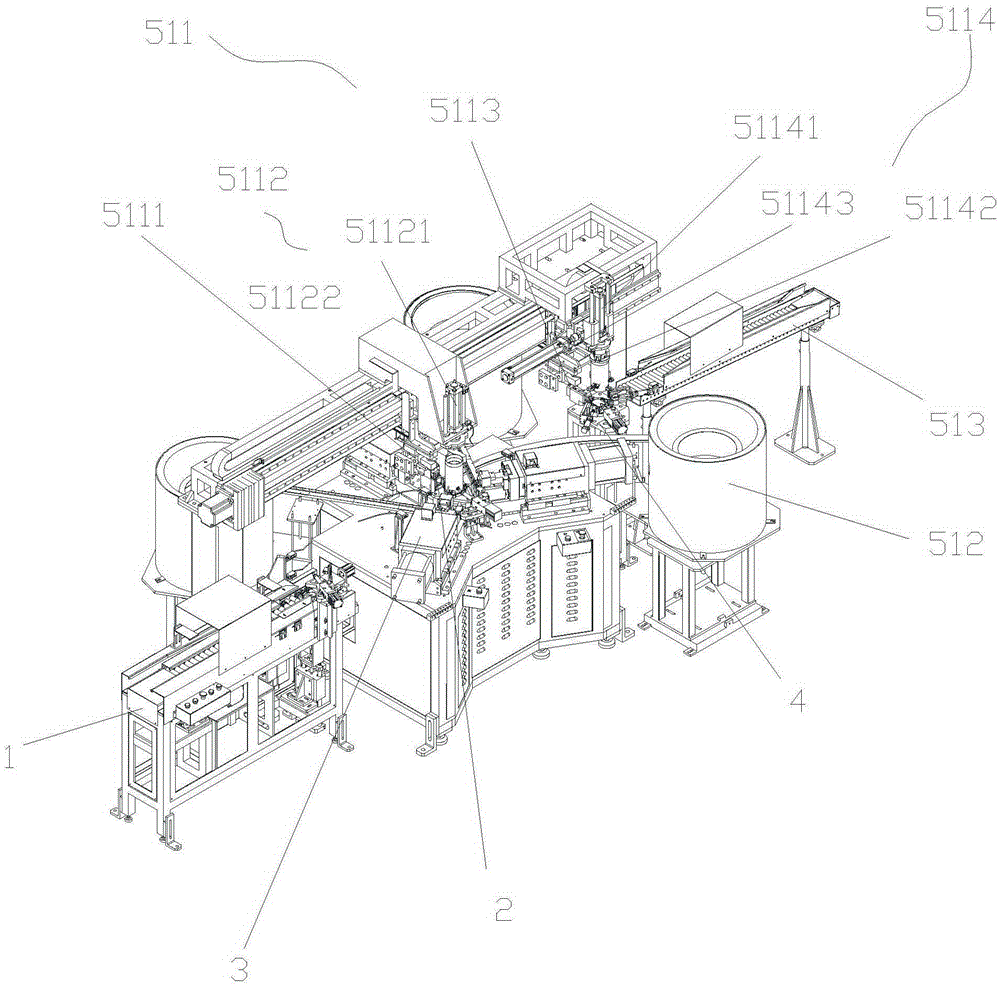

[0021] Please refer to the attached figure 1 to attach Figure 15 , the cylinder automatic welding device, which includes: a machine frame, an industrial computer, a feeding frame assembly 1, a feeding assembly 2, a welding assembly 3 and a detection assembly 4.

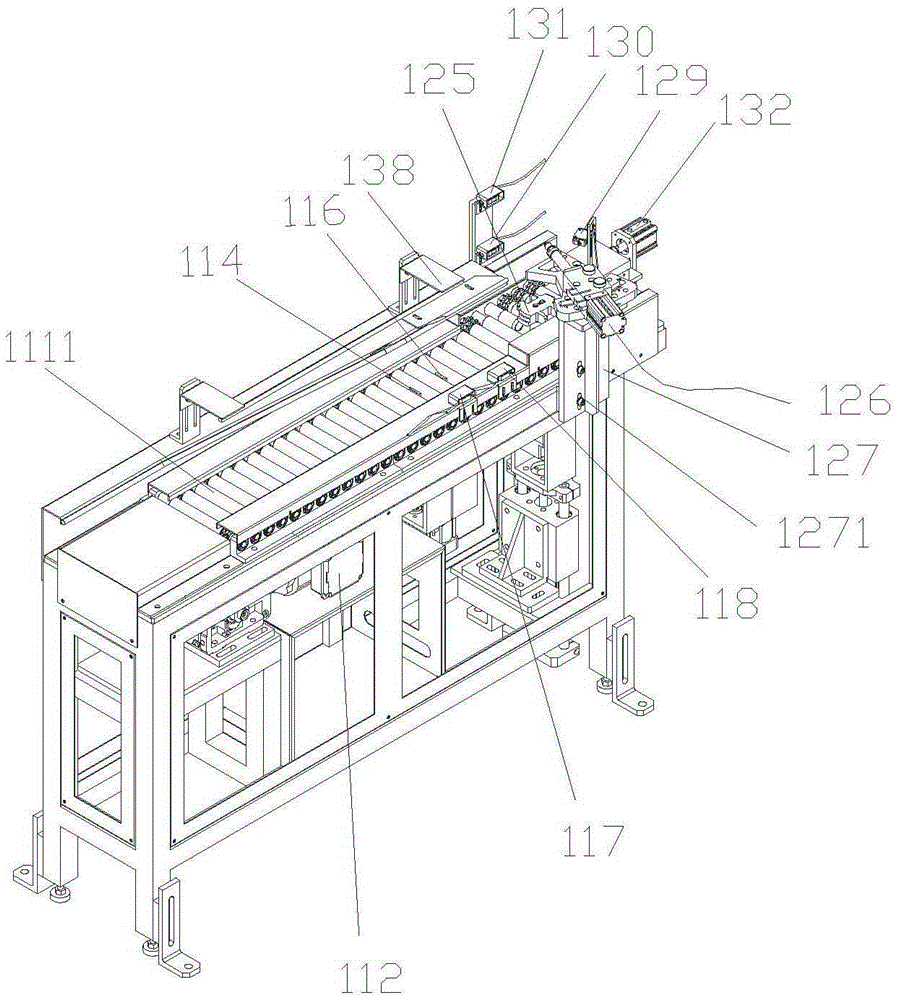

[0022] Please refer to the attached figure 1 to attach Figure 5 , The feeding frame assembly 1 includes the following structure: the conveyor frame 111 is provided with a roller assembly 1111, and the motor 112 is installed under the conveyor frame 111 to drive the roller assembly 1111 to move. One end of the conveyor frame 111 is the feeding end, and the other end is provided with three stations, which are successively from the feeding end: the blocking station, the releasing station, and the feeding preparation station. The stop material station is provided with the first stop material cylinder 113 belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com