Automatic bristle filling mechanism for paint brush head

An automatic and paint technology, applied in the direction of brushes, brush bodies, household utensils, etc., can solve the problems of low production efficiency, non-conformity, and uneven thickness, so as to improve product quality and production efficiency, reduce labor use, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

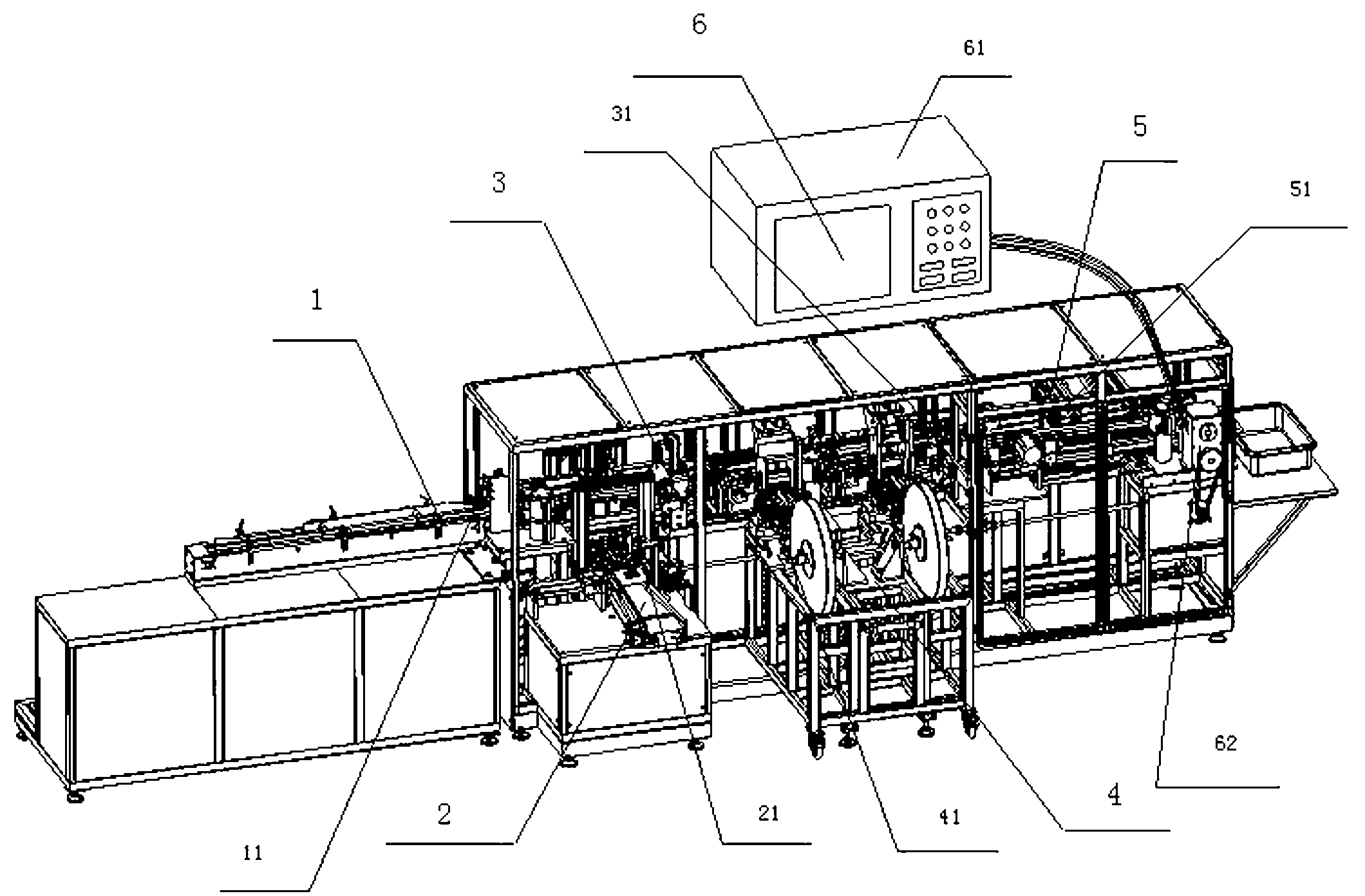

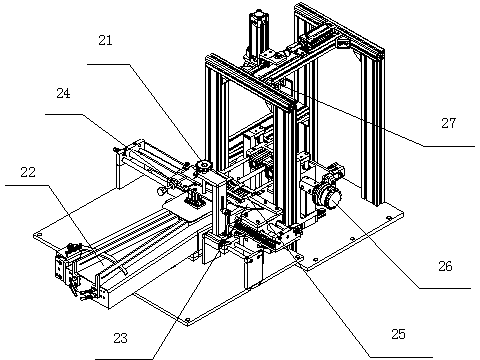

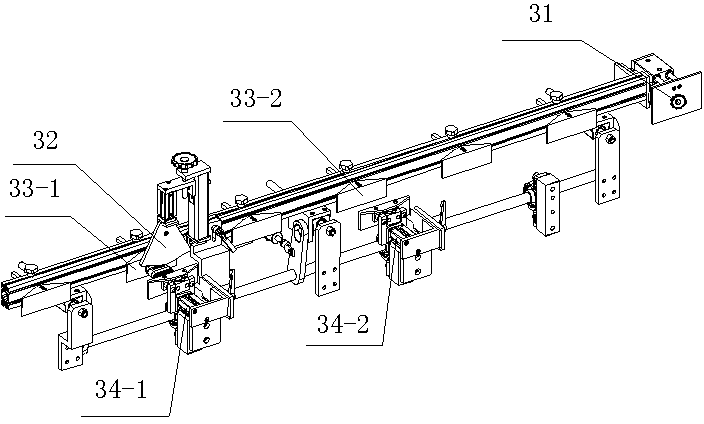

[0020] Such as figure 1 As shown, an automatic hair loading mechanism for a paint brush head includes an iron shell conveying and positioning mechanism 1, a hair separating and picking mechanism 2, a pressing and patting mechanism 3, a filling and plugging mechanism 4, a shaving and combing mechanism 5 and a control The system is composed of 6; the control system is composed of PLC controller 61 and servo motor 62, and controls the working status of each cylinder and components of the automatic wool loading mechanism through a pre-programmed program; the iron shell hand of the iron shell conveying and positioning mechanism 1 The wheel 11 can be adjusted according to the size of the required iron shell; the hair-splitting handwheel 21 of the hair-splittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com