Fluidizing and spray-drying granulator

A fluidized spray and granulator technology, applied in the direction of powder suspension granulation, etc., can solve the problems of product quality impact, low adaptability, production efficiency discount, etc., to increase the atomization range, reduce drying energy consumption, The effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

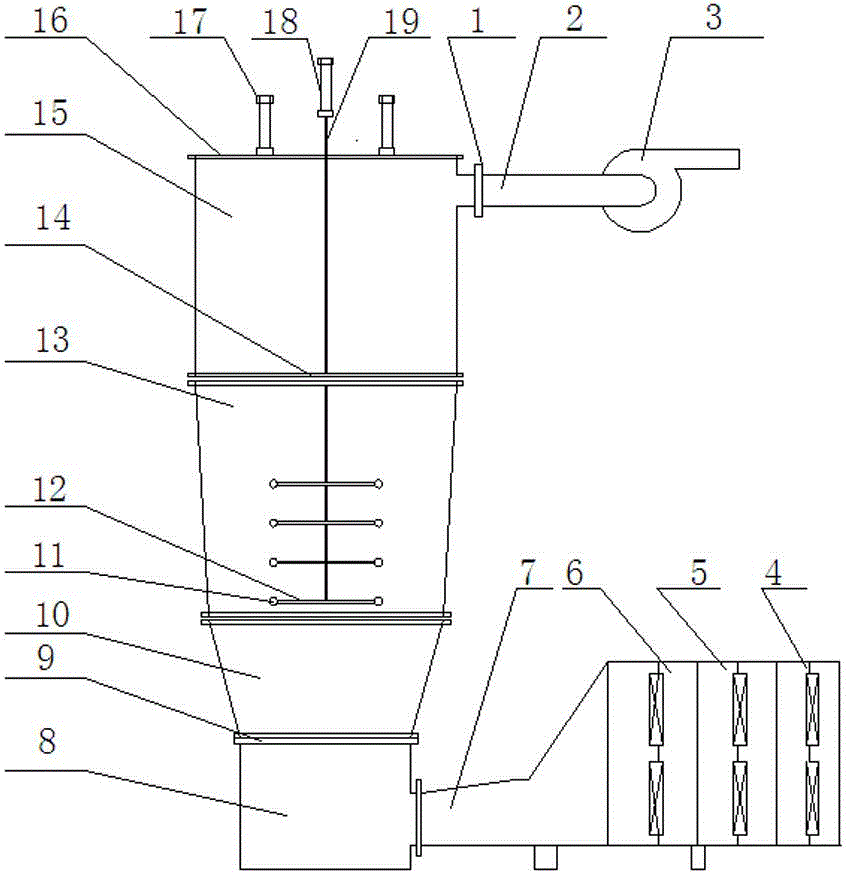

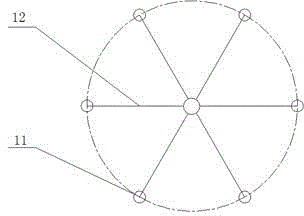

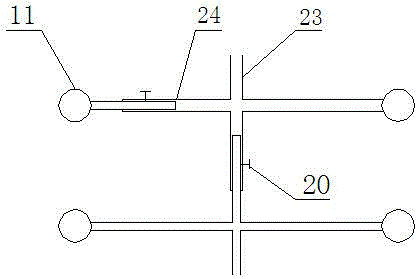

[0019] Such as figure 1 As shown, the present invention includes a collection chamber 15, a spray chamber 13, a fluidization chamber 10 and an air inlet chamber 8 arranged sequentially from top to bottom, and the top cover 16 of the collection chamber 15 is provided with a filter bag vibrator 17, The upper side wall of the trapping chamber 15 is provided with an air induction pipe 2, and the air induction pipe 2 is provided with an exhaust valve 1. The air induction pipe 2 is connected with the induced draft fan 3. A cloth bag filter 14 is provided at the junction, a position-adjustable injection device is provided in the spray chamber 13, and a fluidized perforated plate 9 is provided at the junction of the bottom of the fluidization chamber 10 and the top of the air inlet chamber 8, An air inlet pipe 7 is arranged on the lower side wall of the air in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com