Atomization structure and ejector

A deflector and nozzle seat technology, which is applied in the field of atomization structure and injector, can solve the problems that the urea spray cannot be guaranteed or penetrate the exhaust flow, the engine is complicated, etc., and achieve the effect of expanding the atomization range and good reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

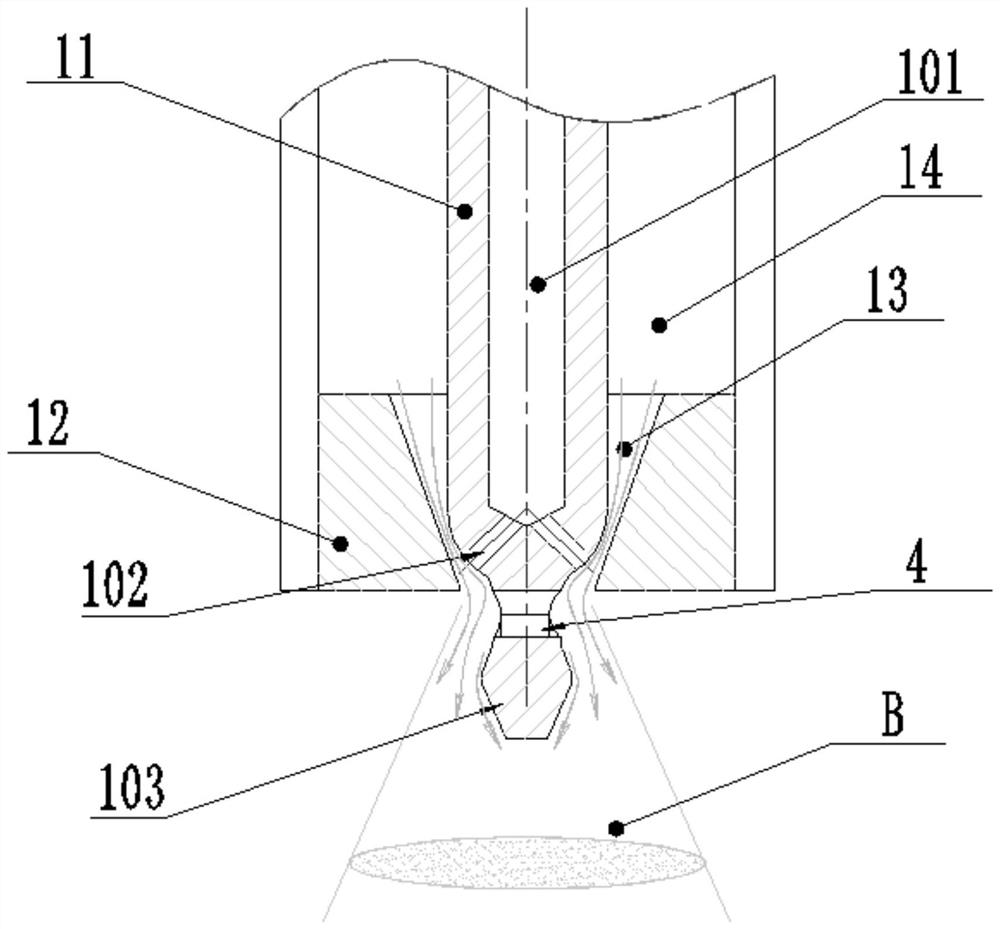

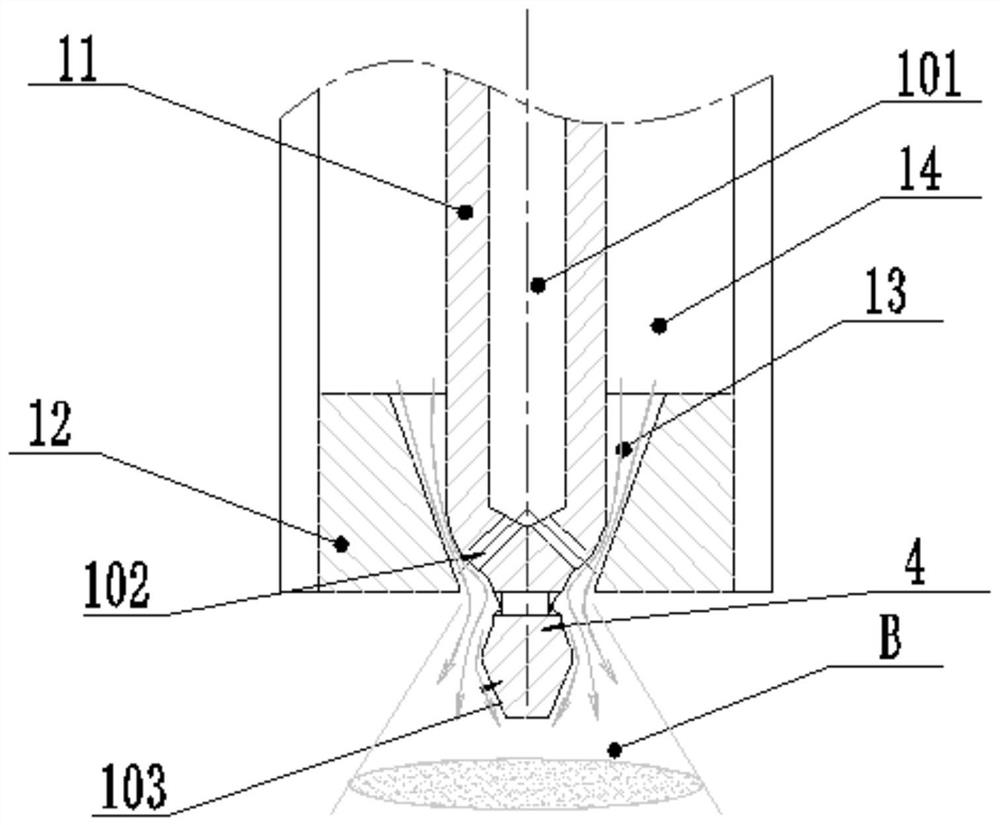

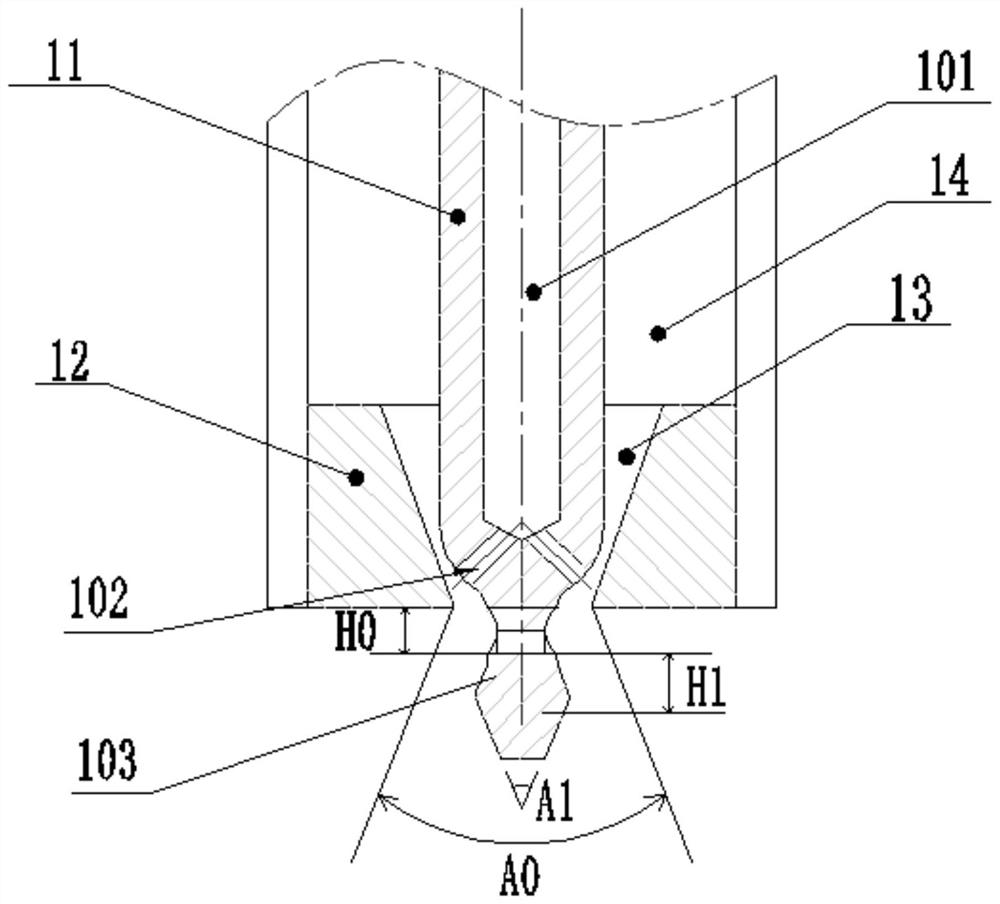

[0047] Figures 1 to 2 An embodiment of the atomization structure of the present invention is shown, including: a liquid guide 11 , a nozzle seat 12 surrounding the liquid guide 11 , and a connection between the nozzle seat 12 and the liquid guide 11 . A throat structure 13 is formed and a gas channel 14 connected to the throat structure 13 is constructed.

[0048] The liquid guide 11 is provided with a liquid channel 101 for introducing fluid and a liquid injection hole 102 for ejecting the fluid.

[0049] The nozzle seat 12 surrounds the outside of the liquid deflector 11 , and forms a throat structure 13 with the liquid deflector 11 that shrinks first and then expands.

[0050] The gas channel 14 is connected to the throat structure 13 and passes into the gas. The gas is accelerated by the throat structure 13 and ejected along the extending direction of the liquid guide 11 .

[0051] The liquid injection hole 102 is arranged on the throat structure 13, so that the injecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com