Patents

Literature

195results about "High pressure gas fuel injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

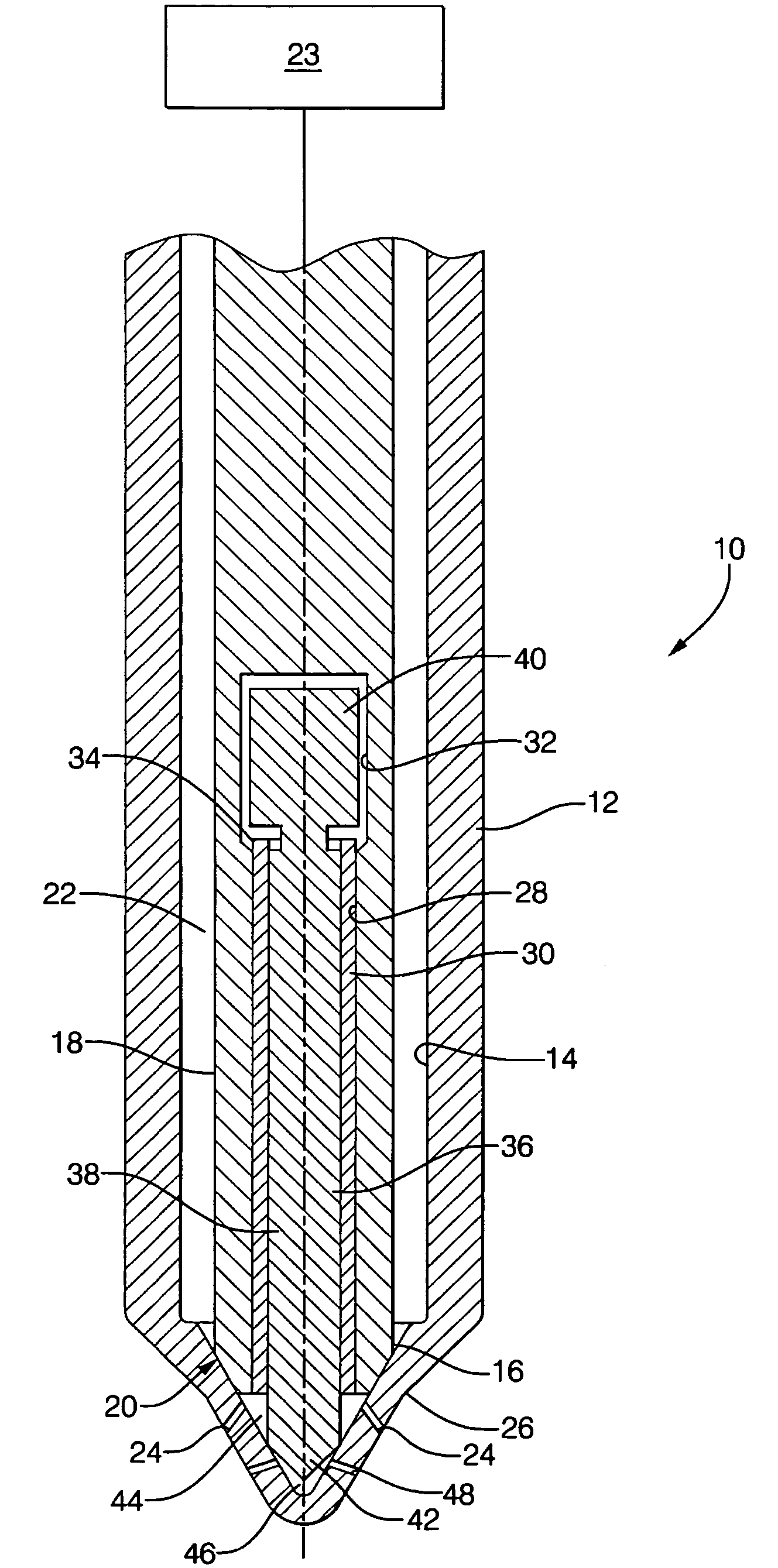

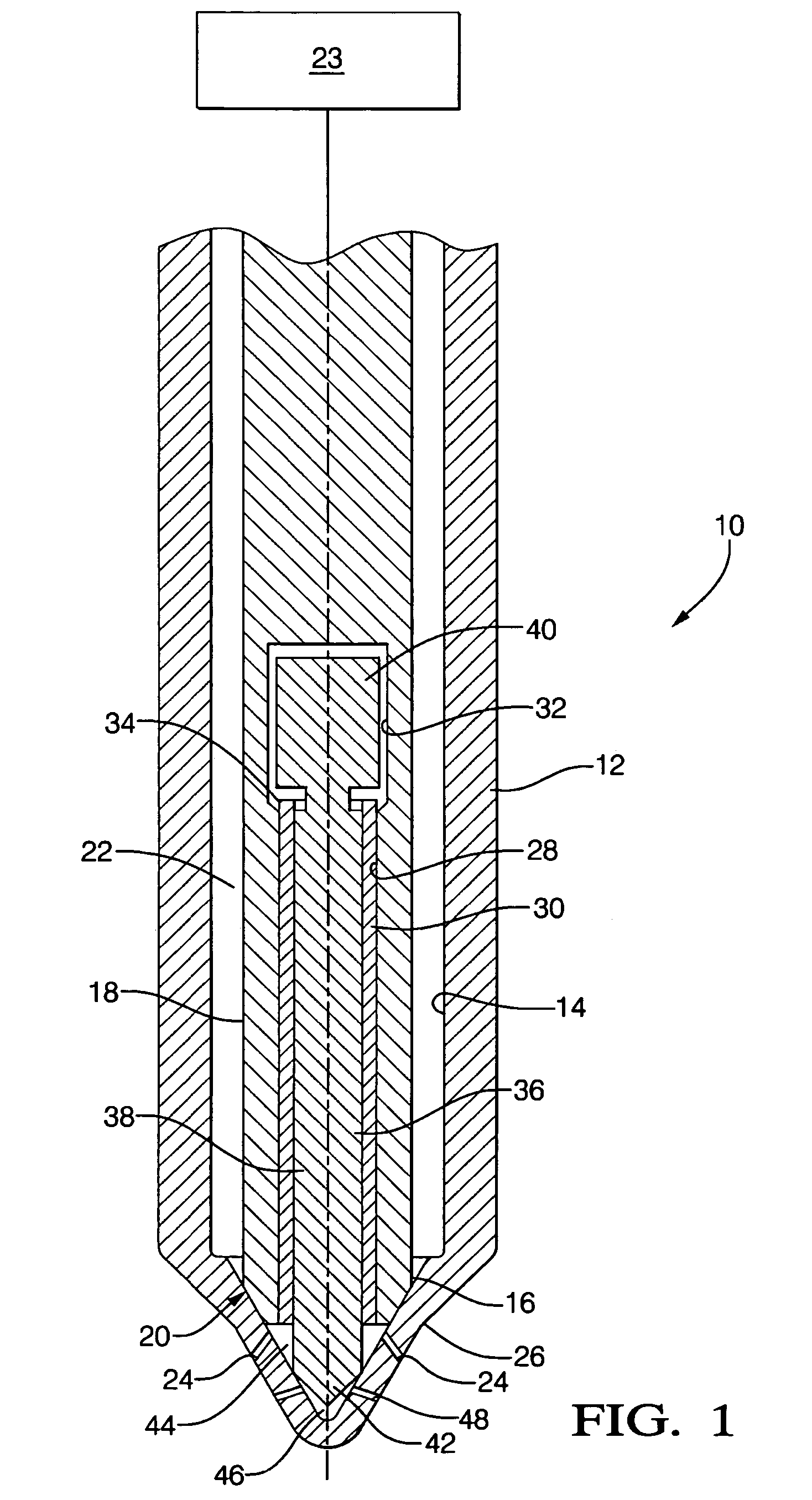

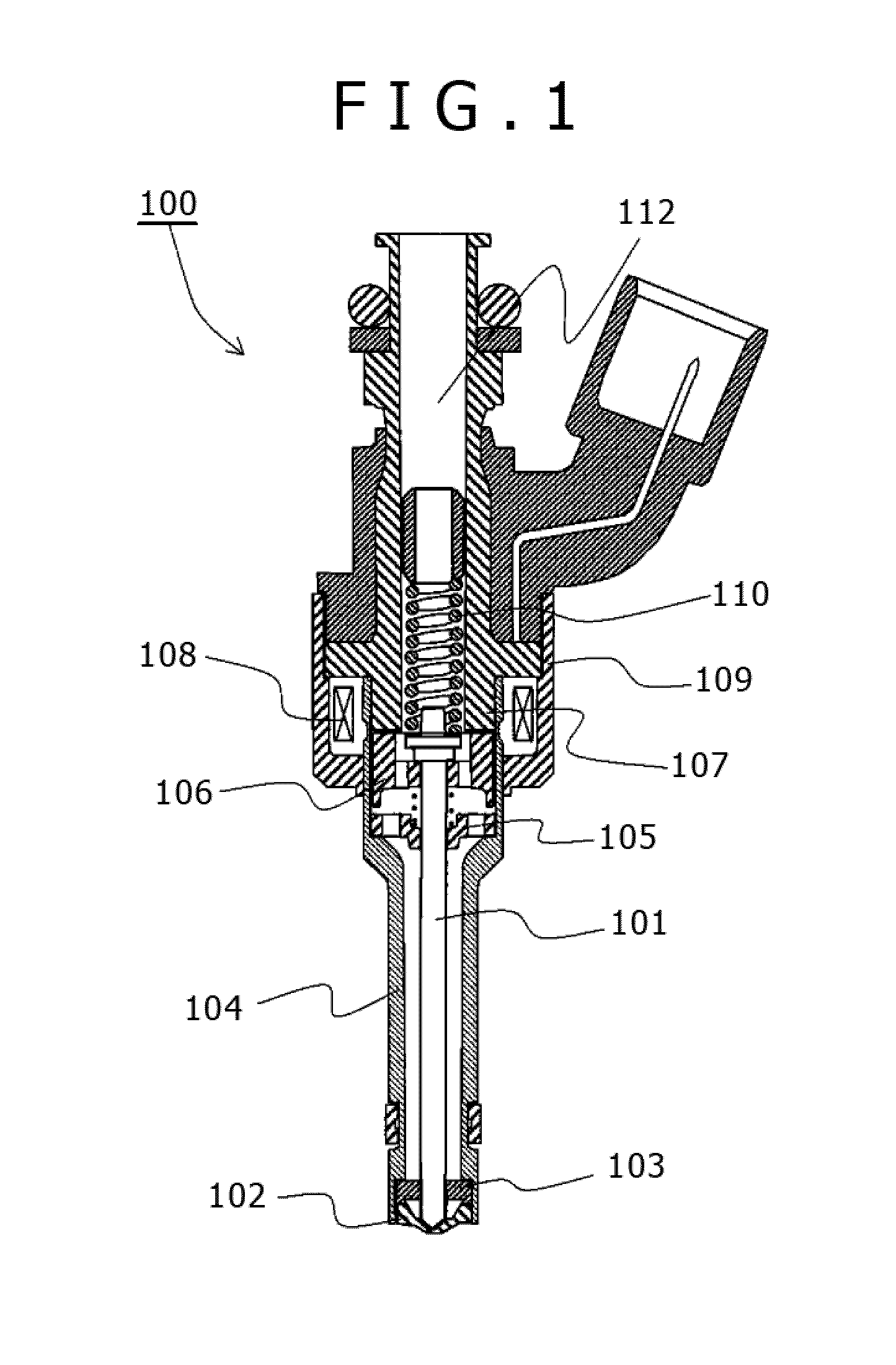

Combined fuel injection and ignition means

InactiveUS7086376B2Reduce capacityConstruction is difficultHigh pressure gas fuel injectionMachines/enginesEngineeringInternal combustion engine

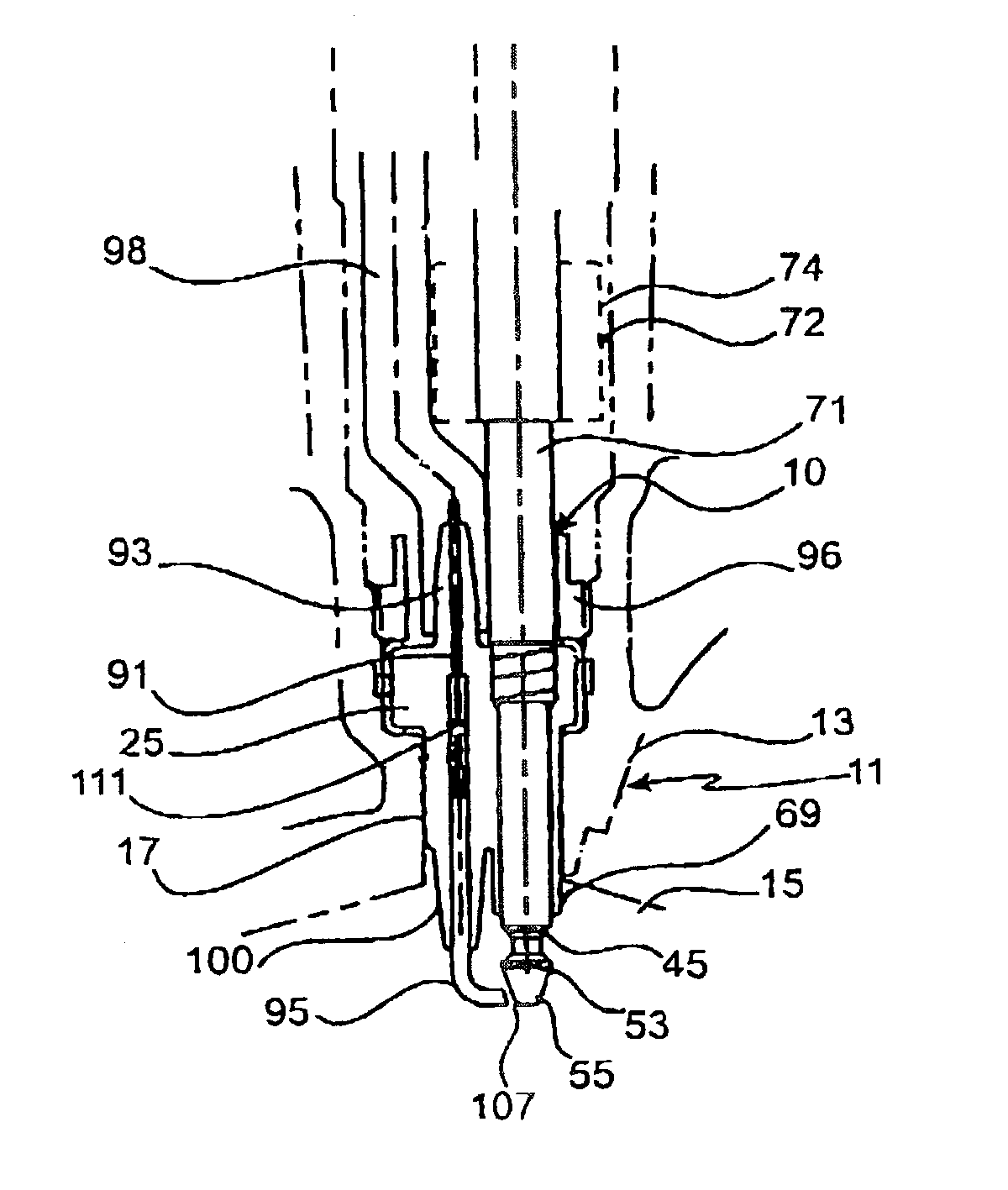

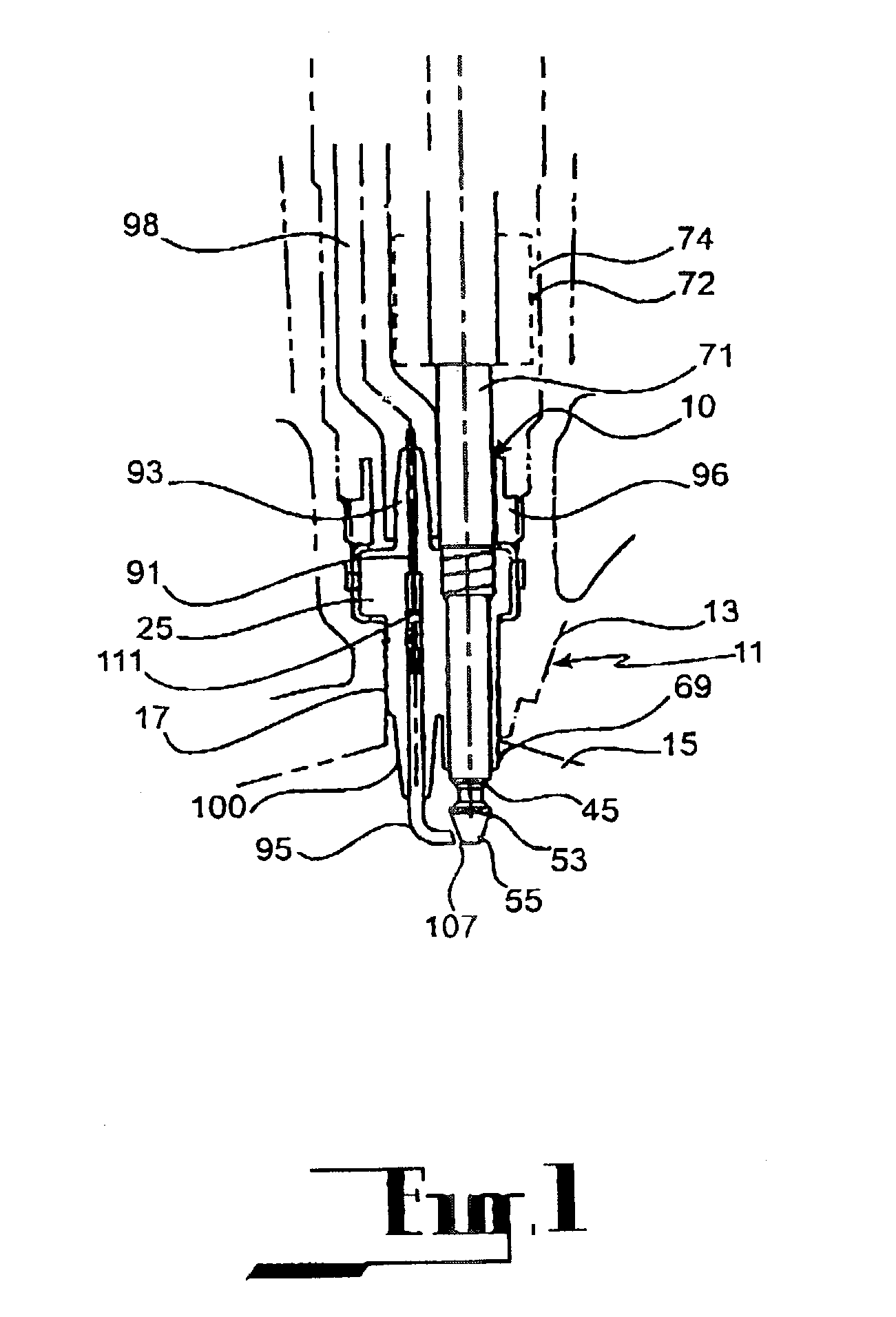

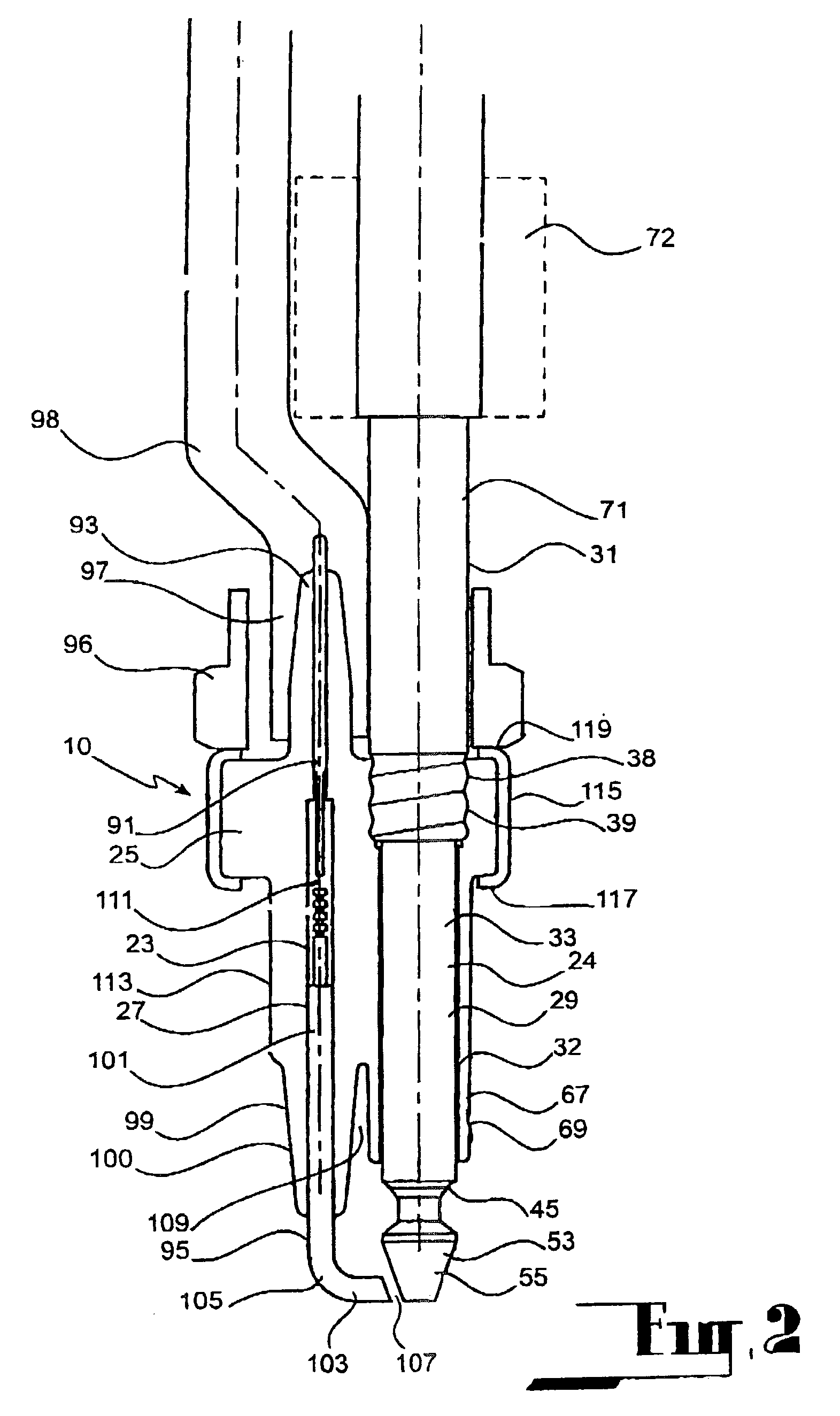

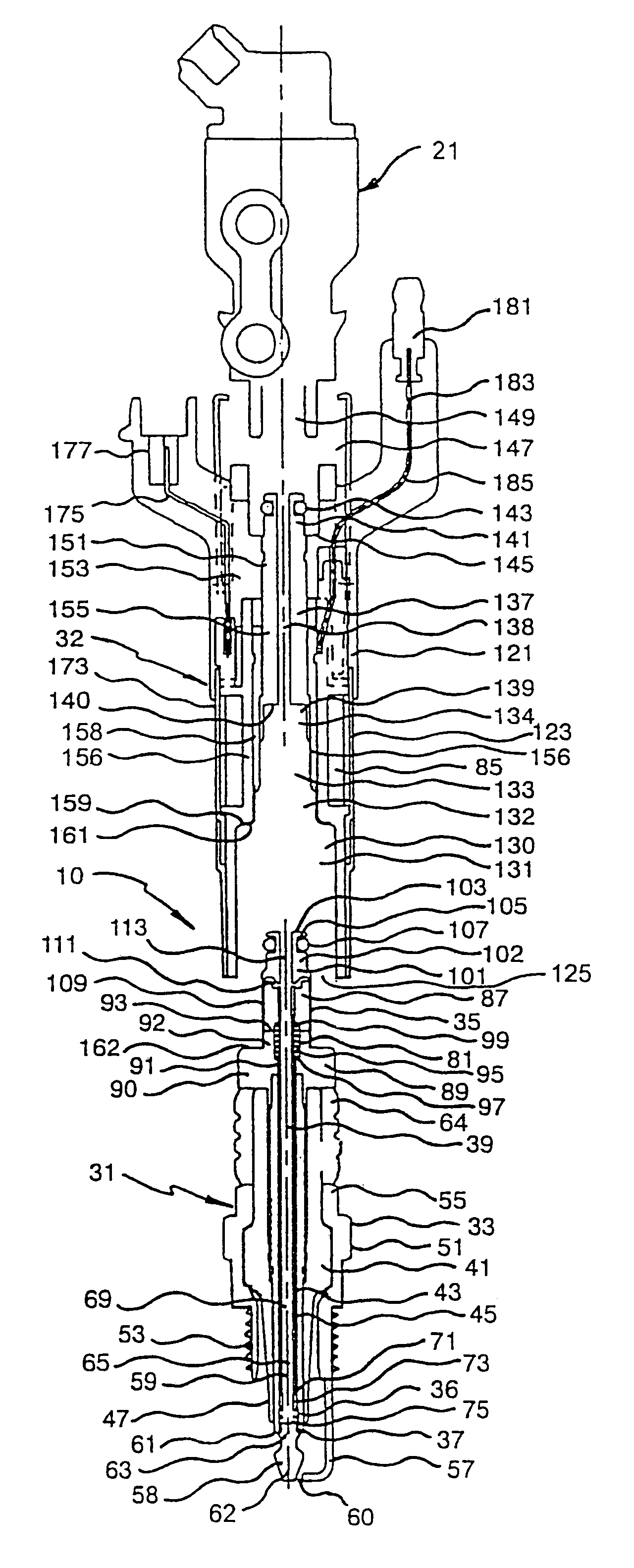

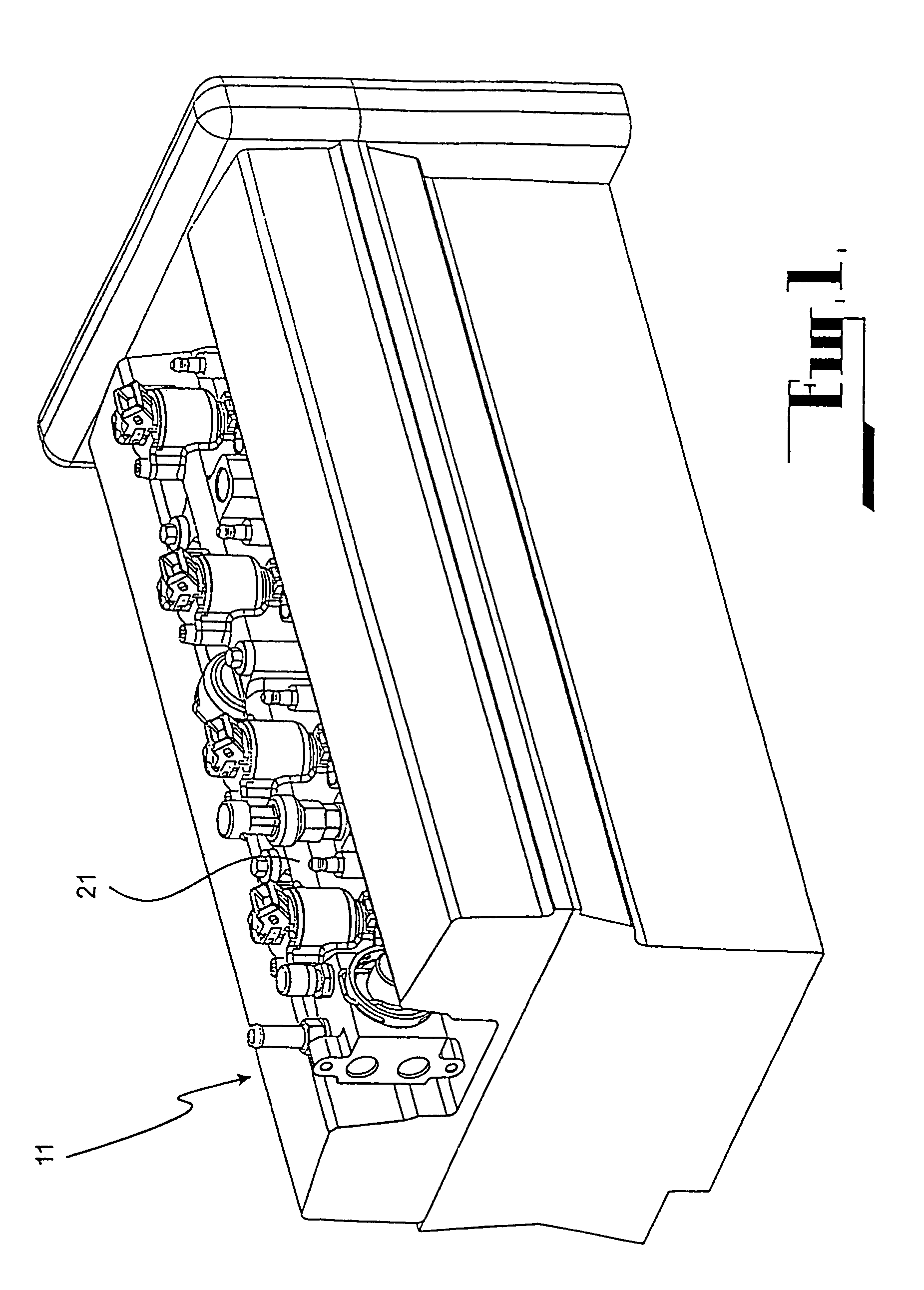

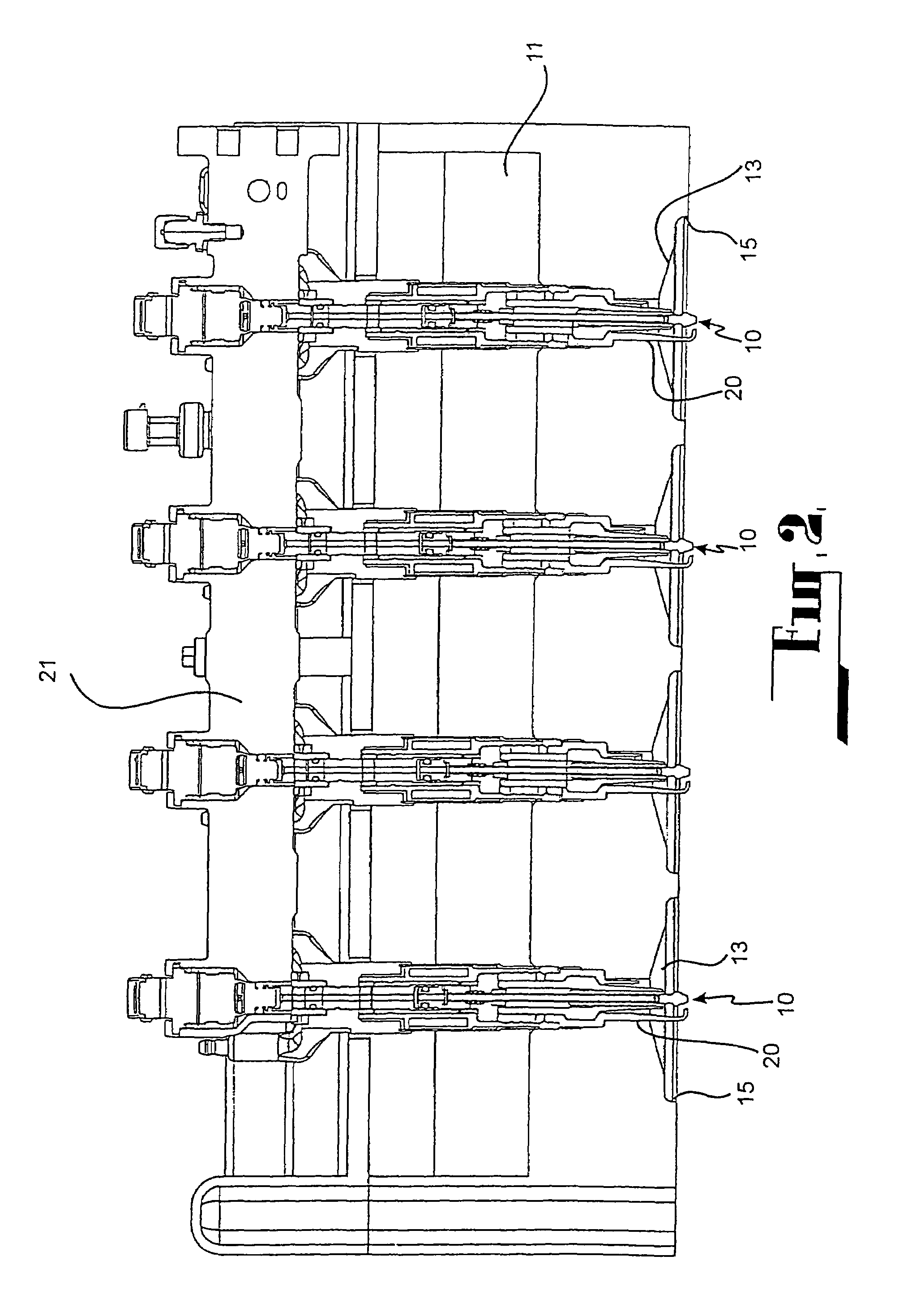

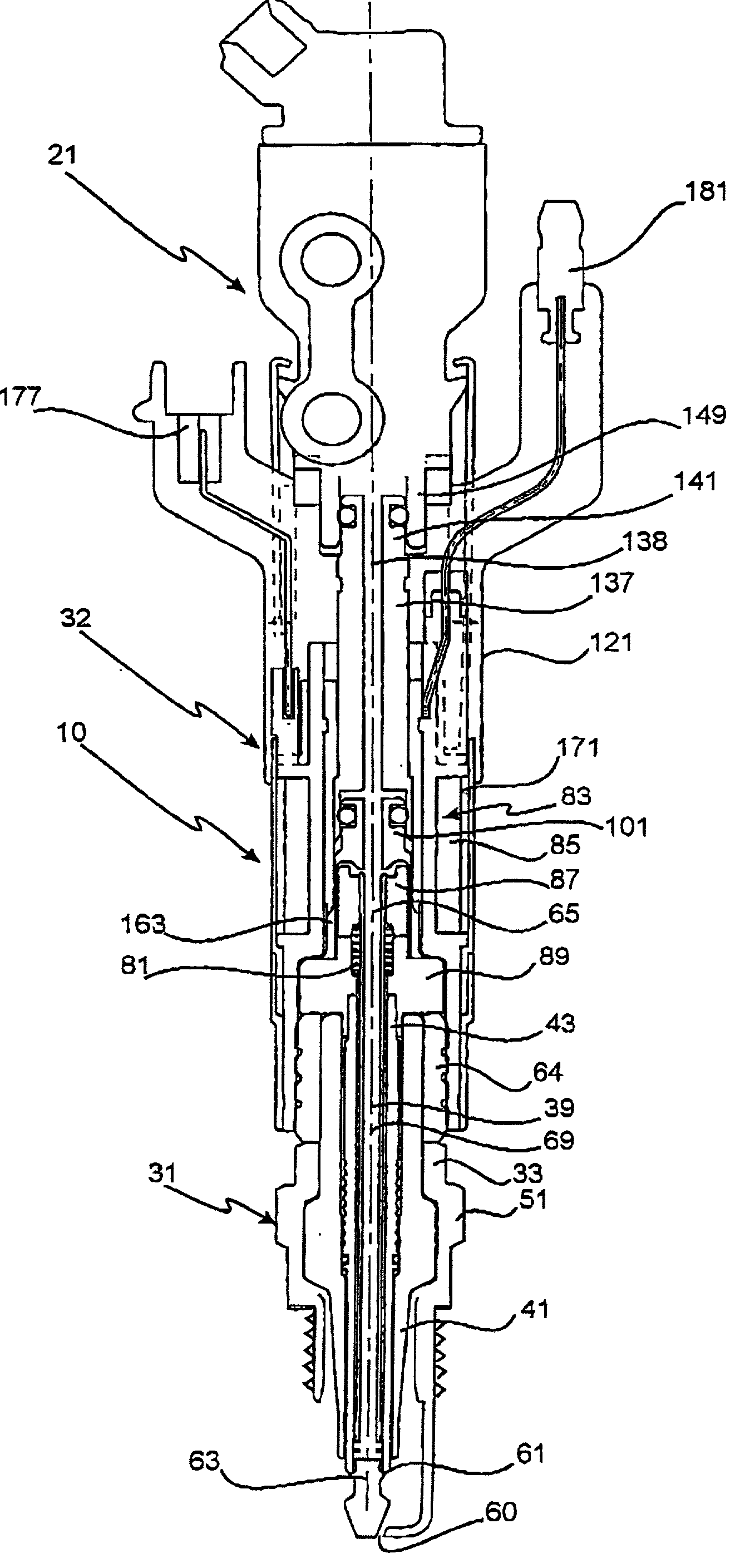

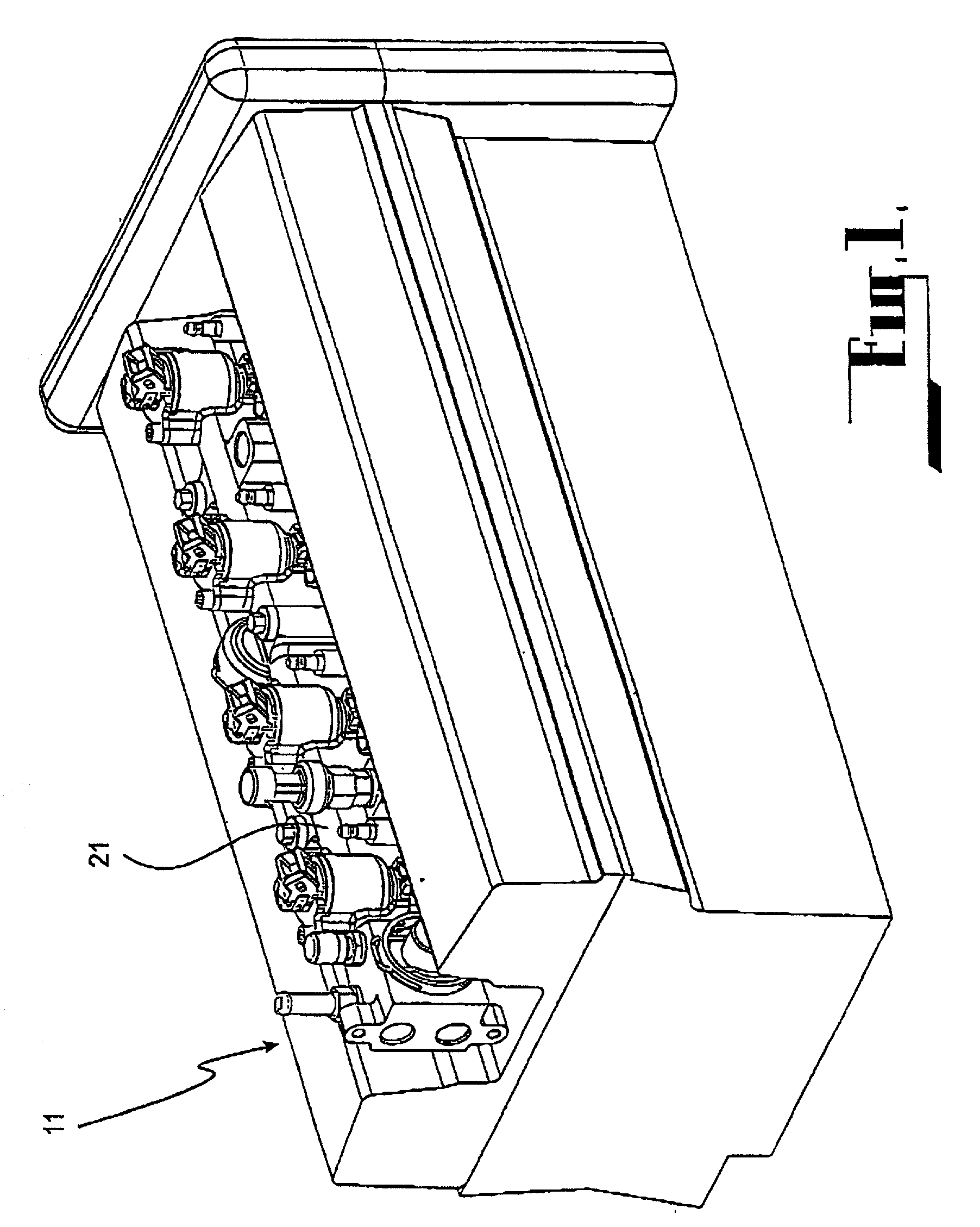

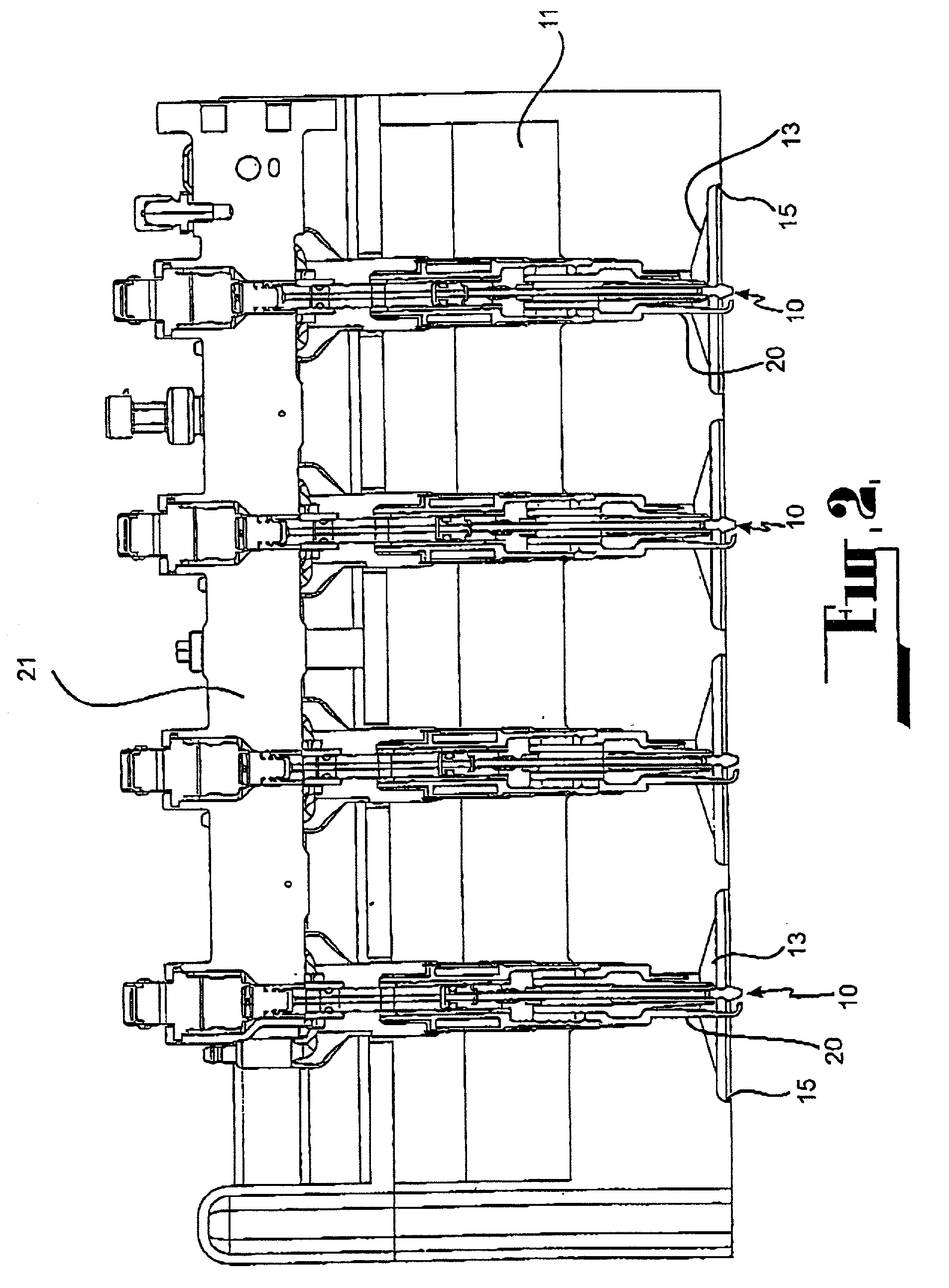

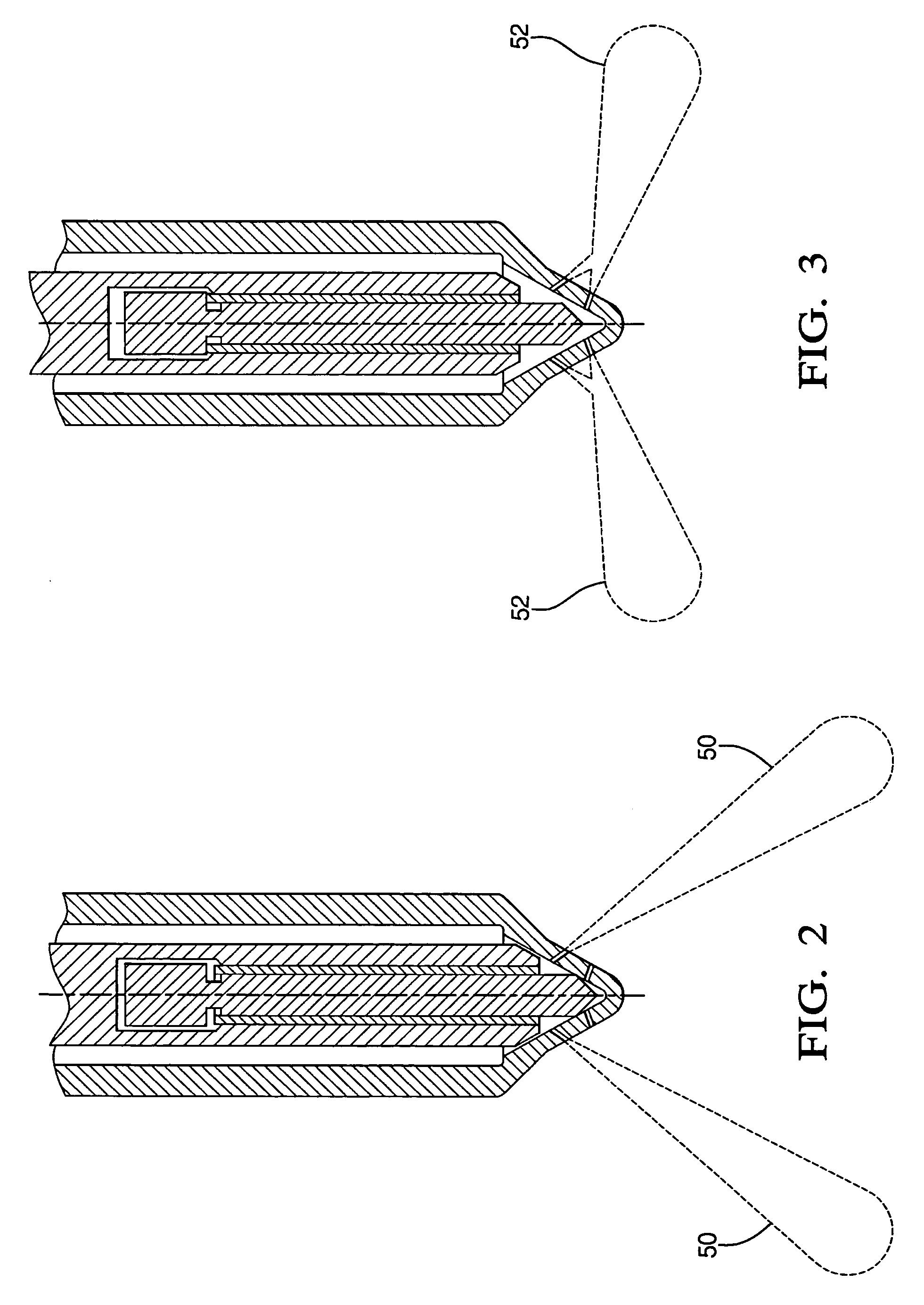

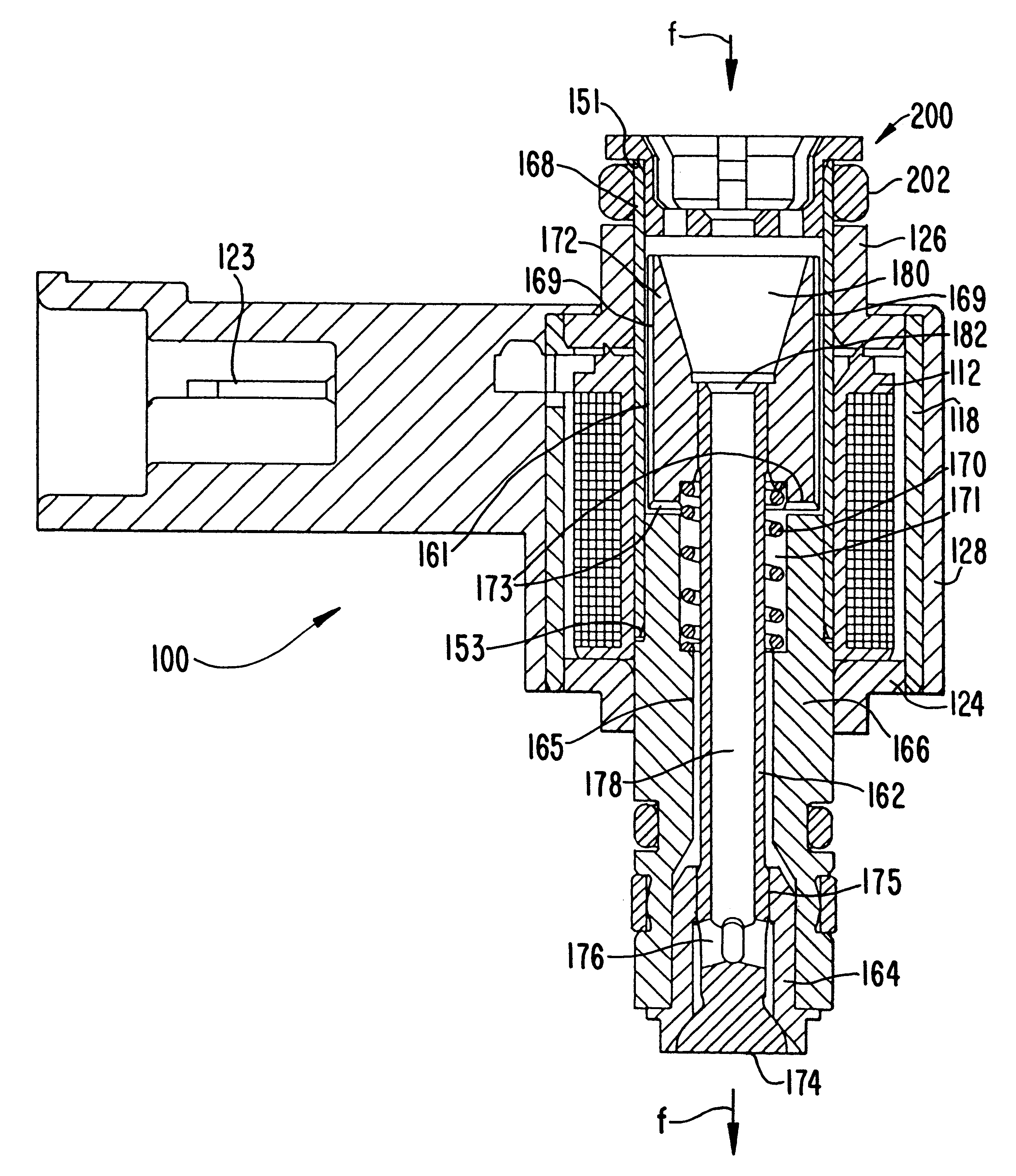

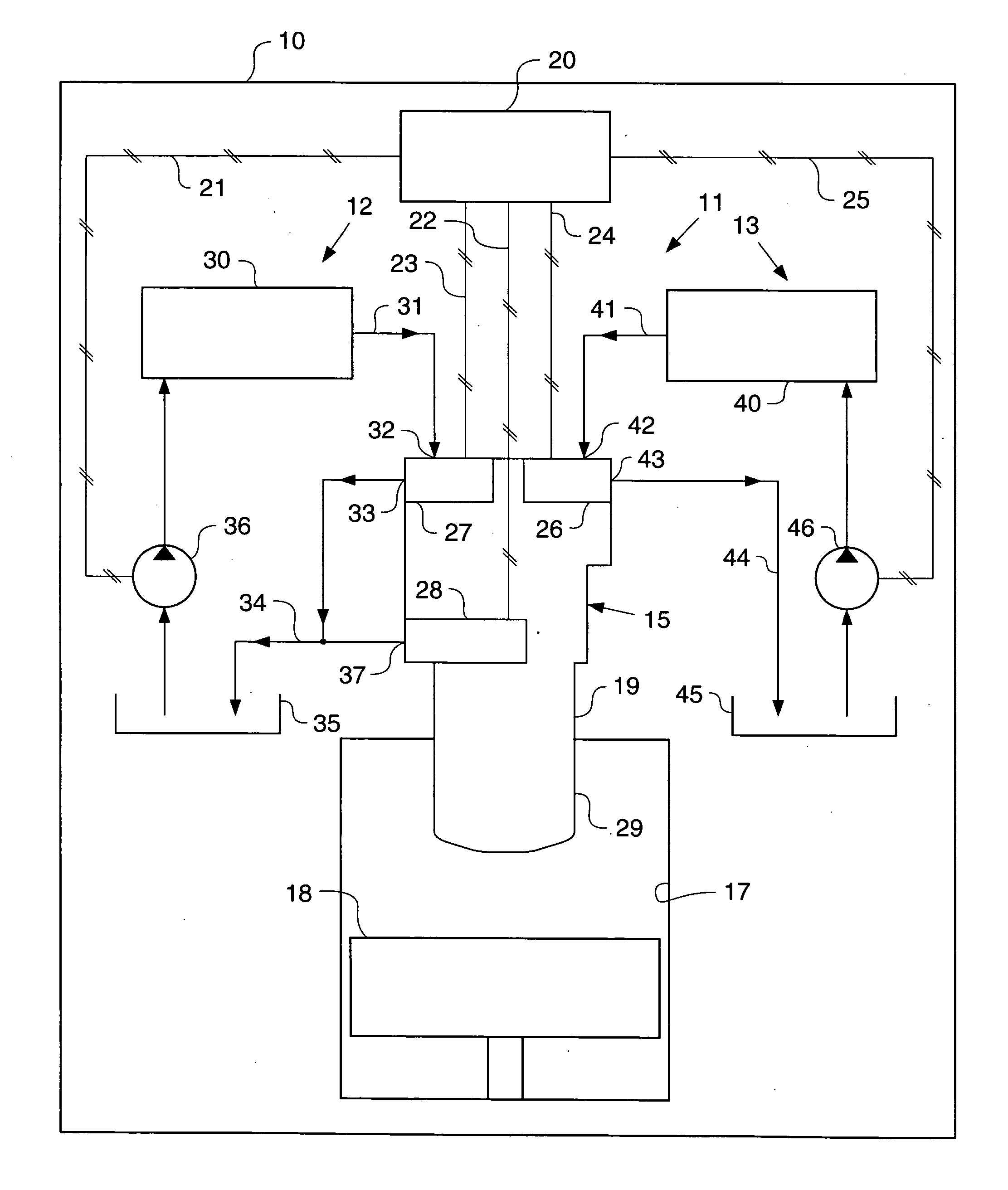

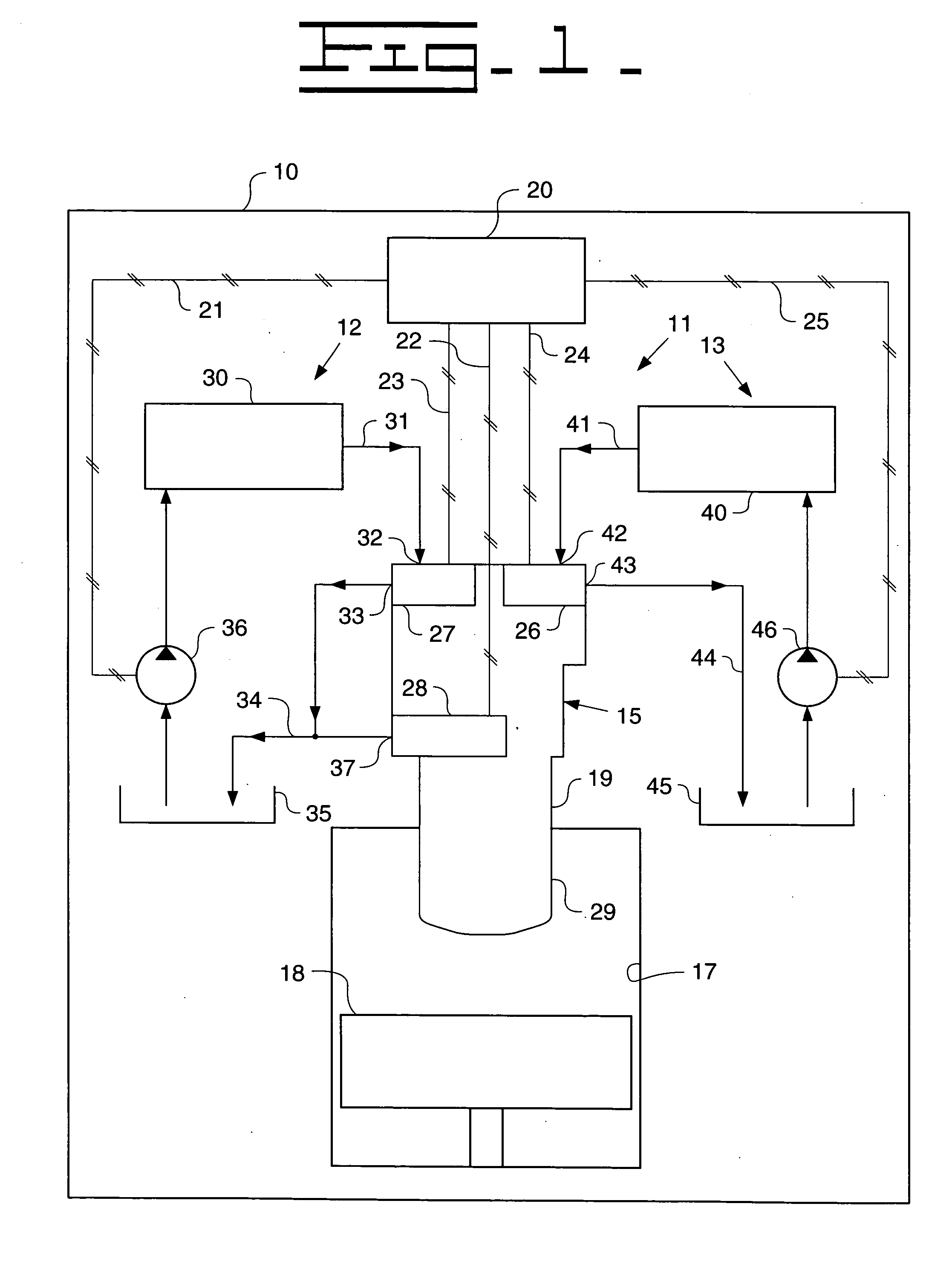

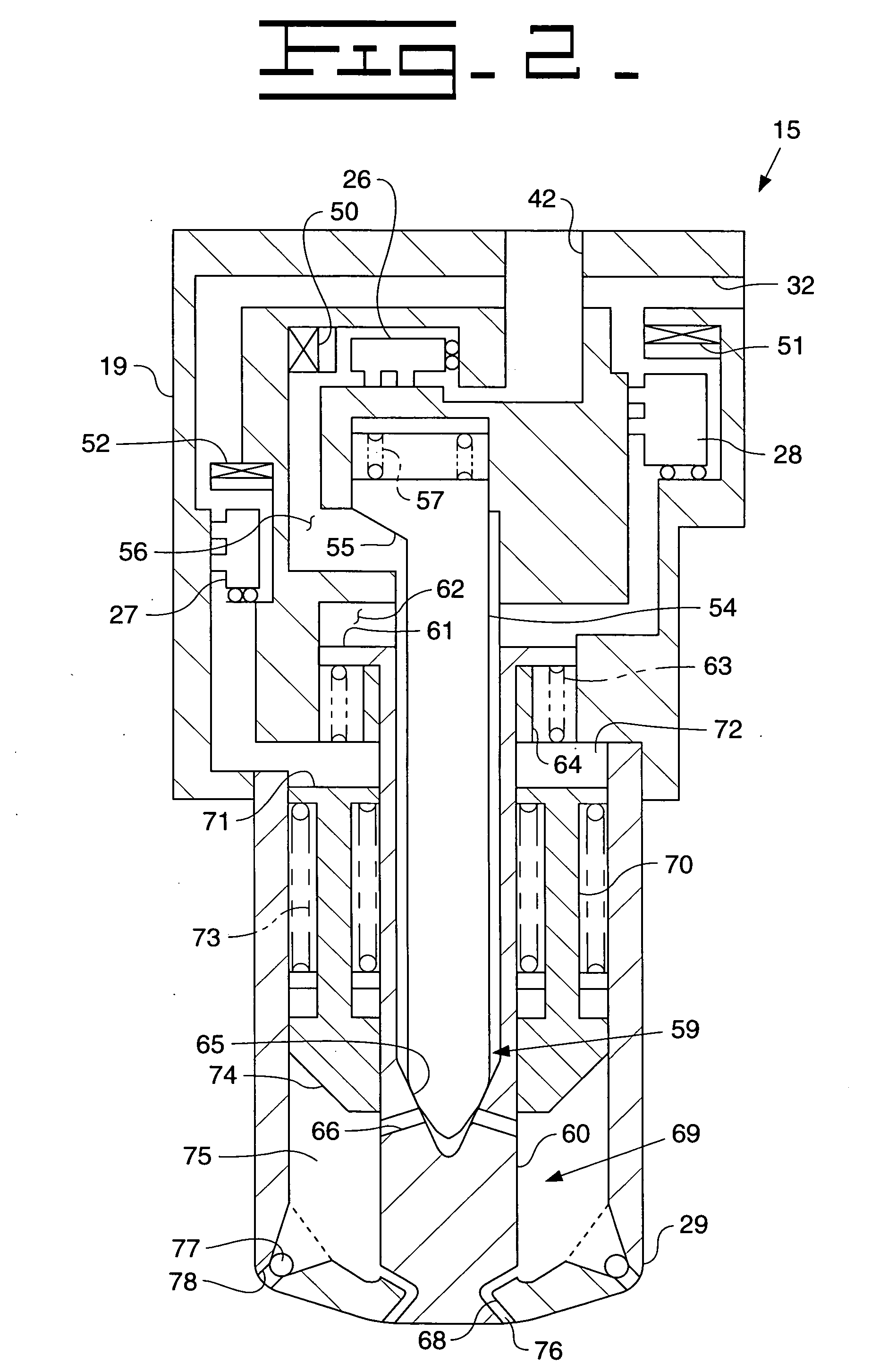

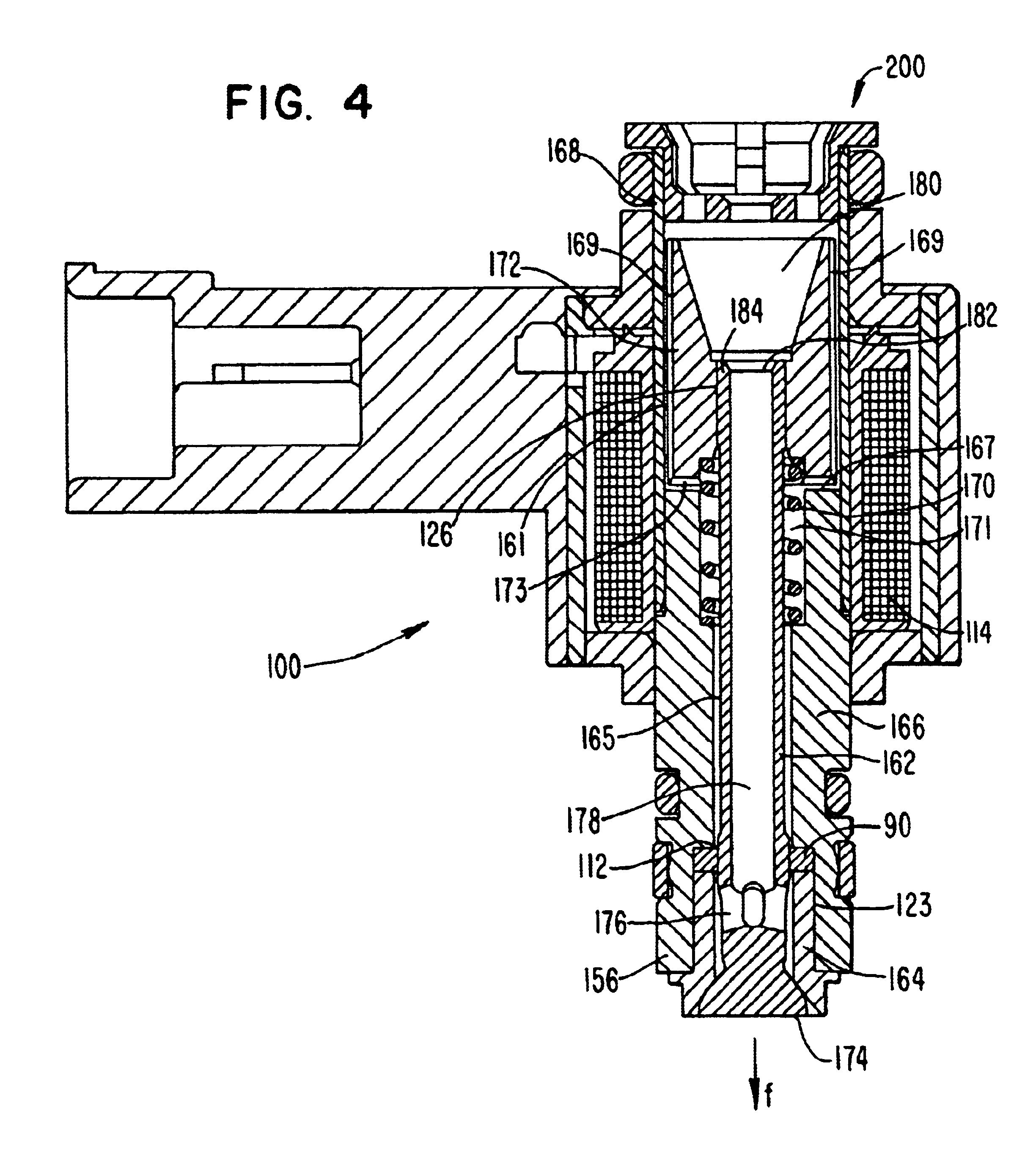

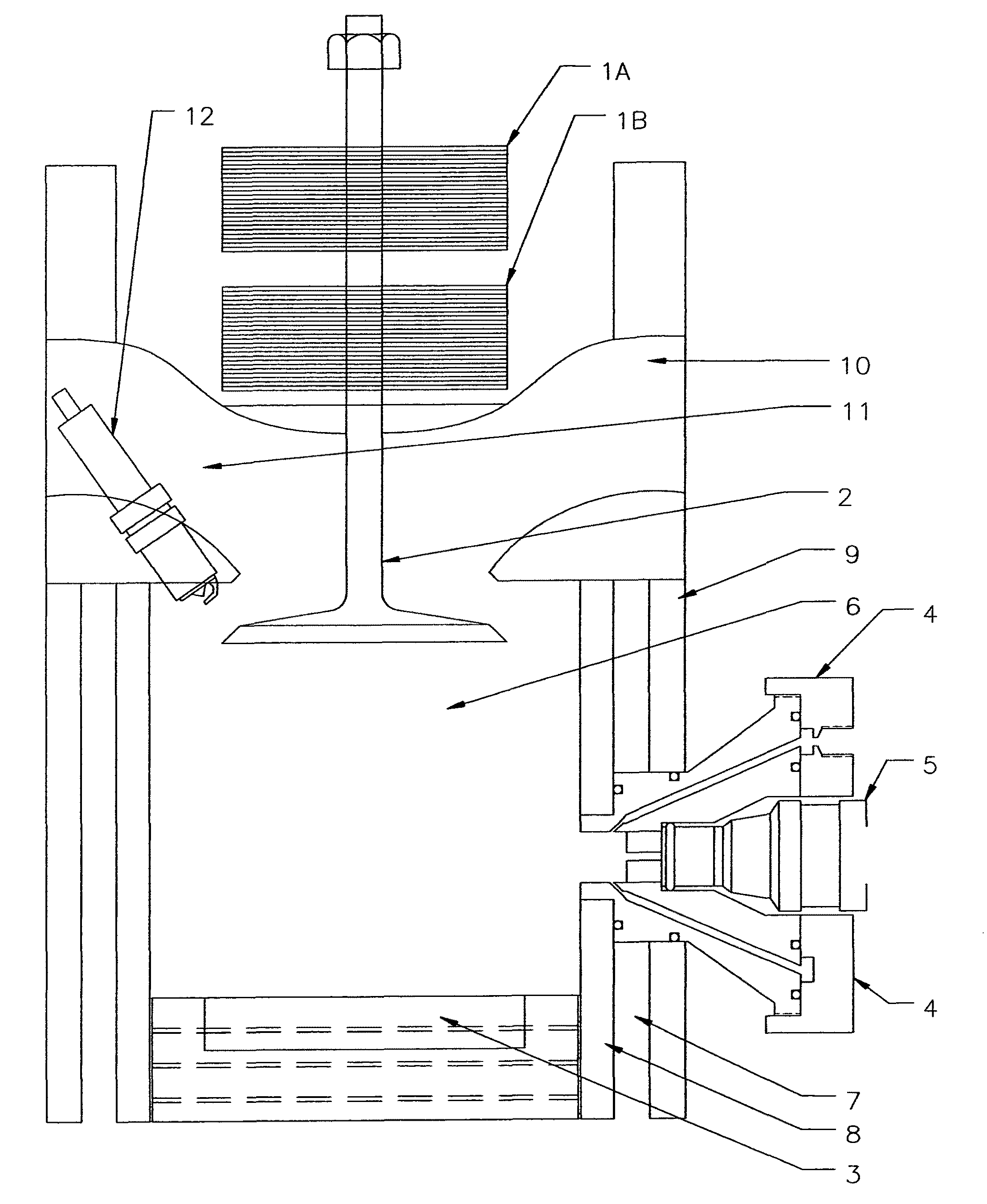

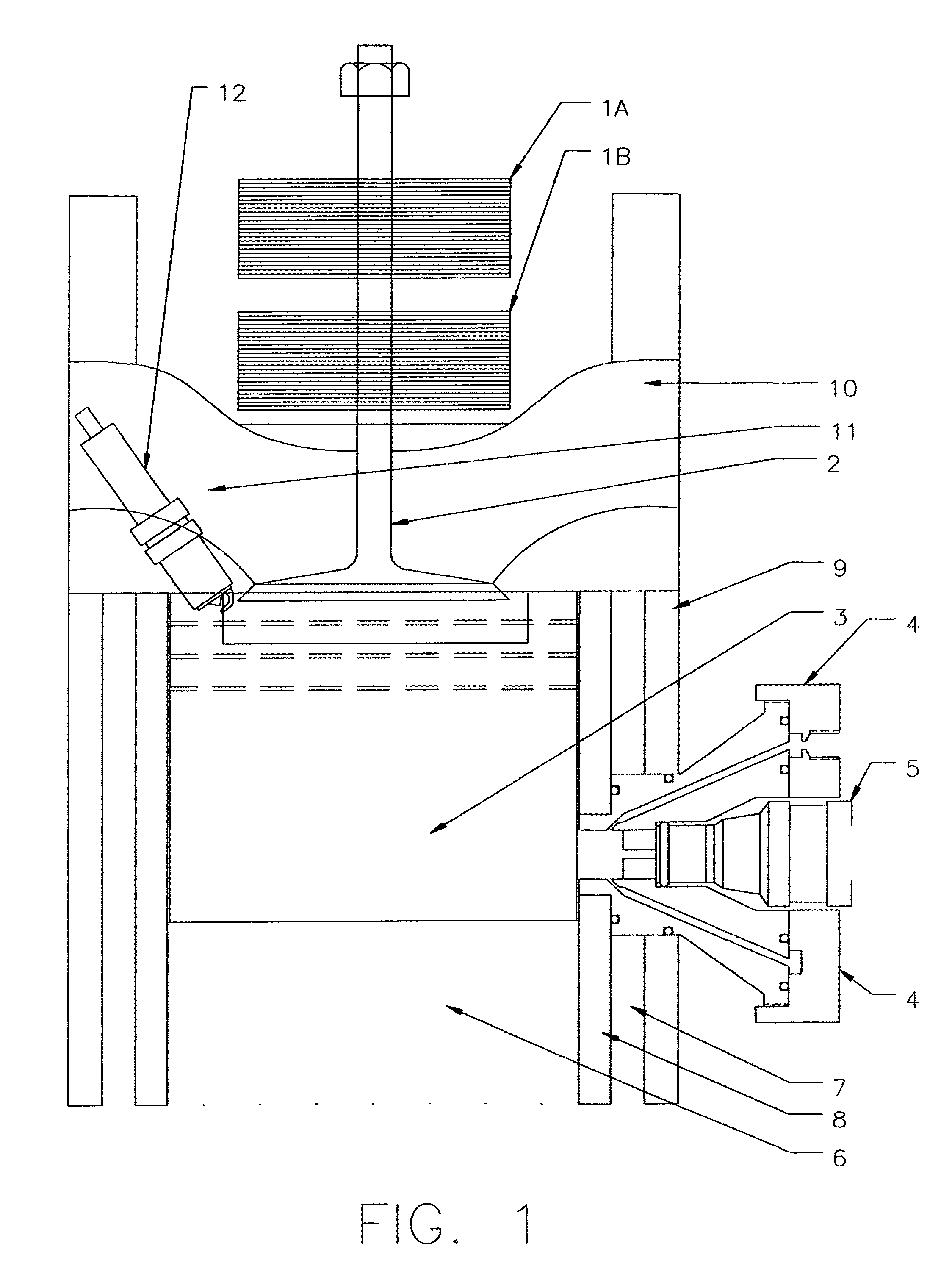

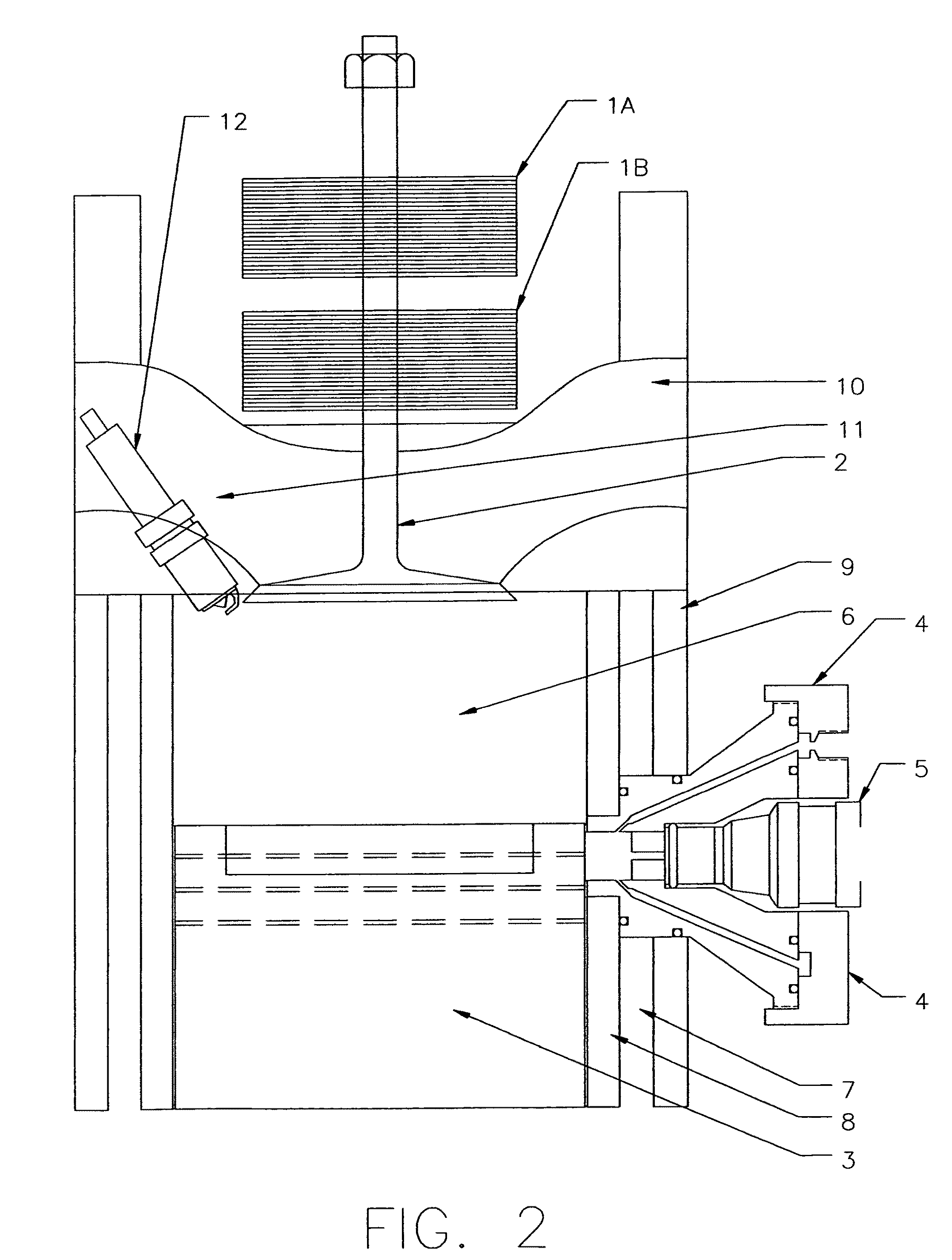

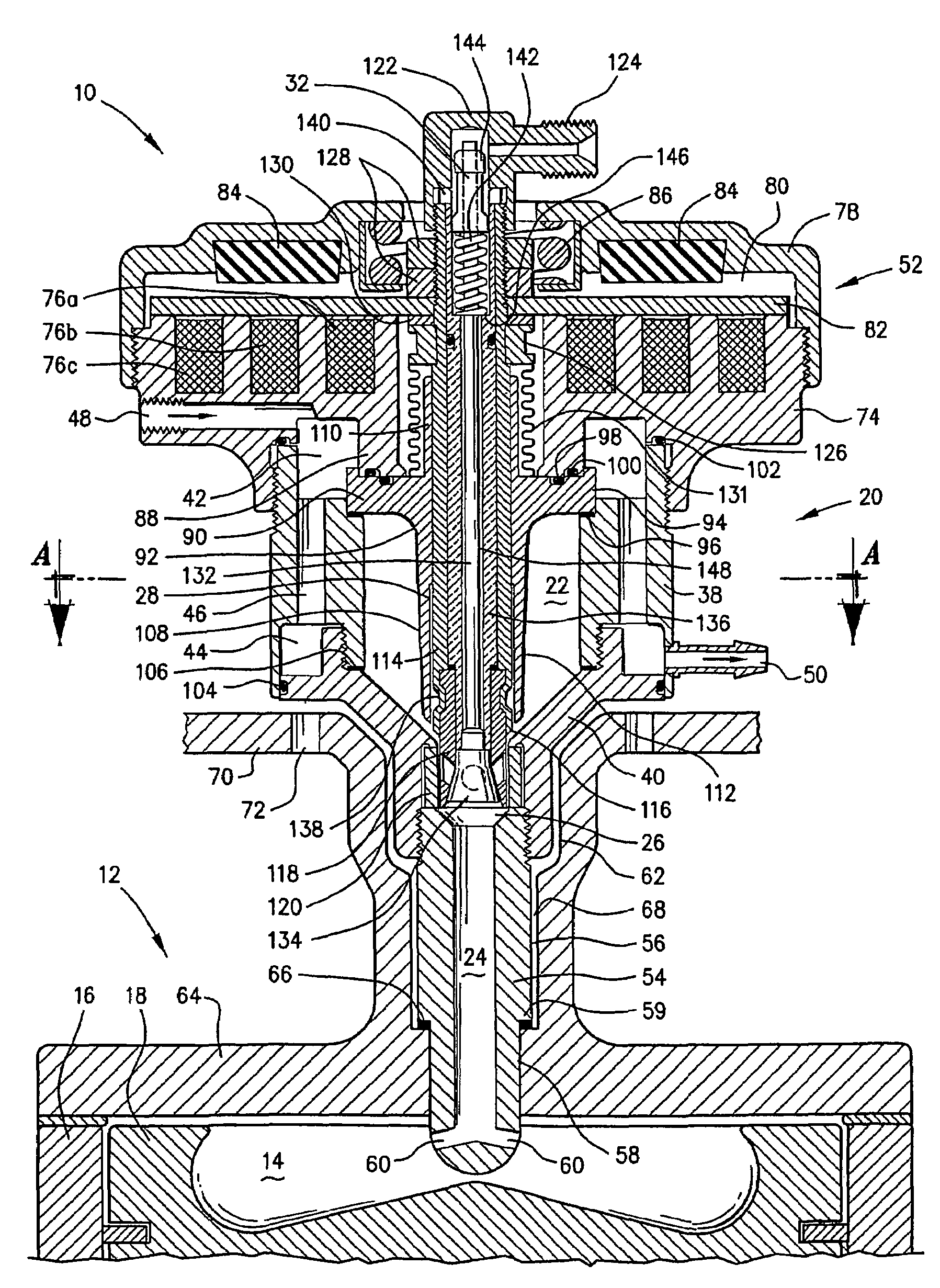

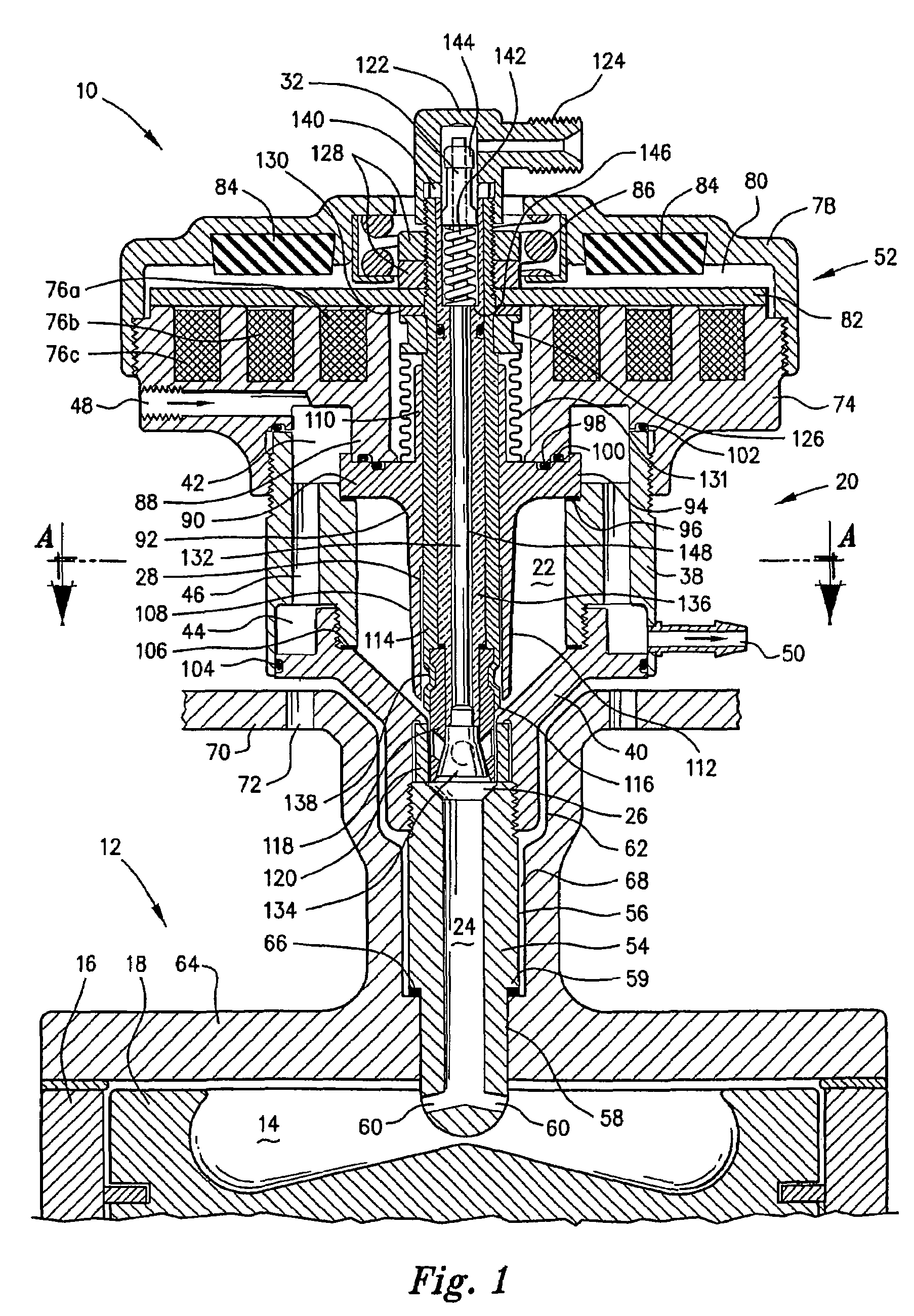

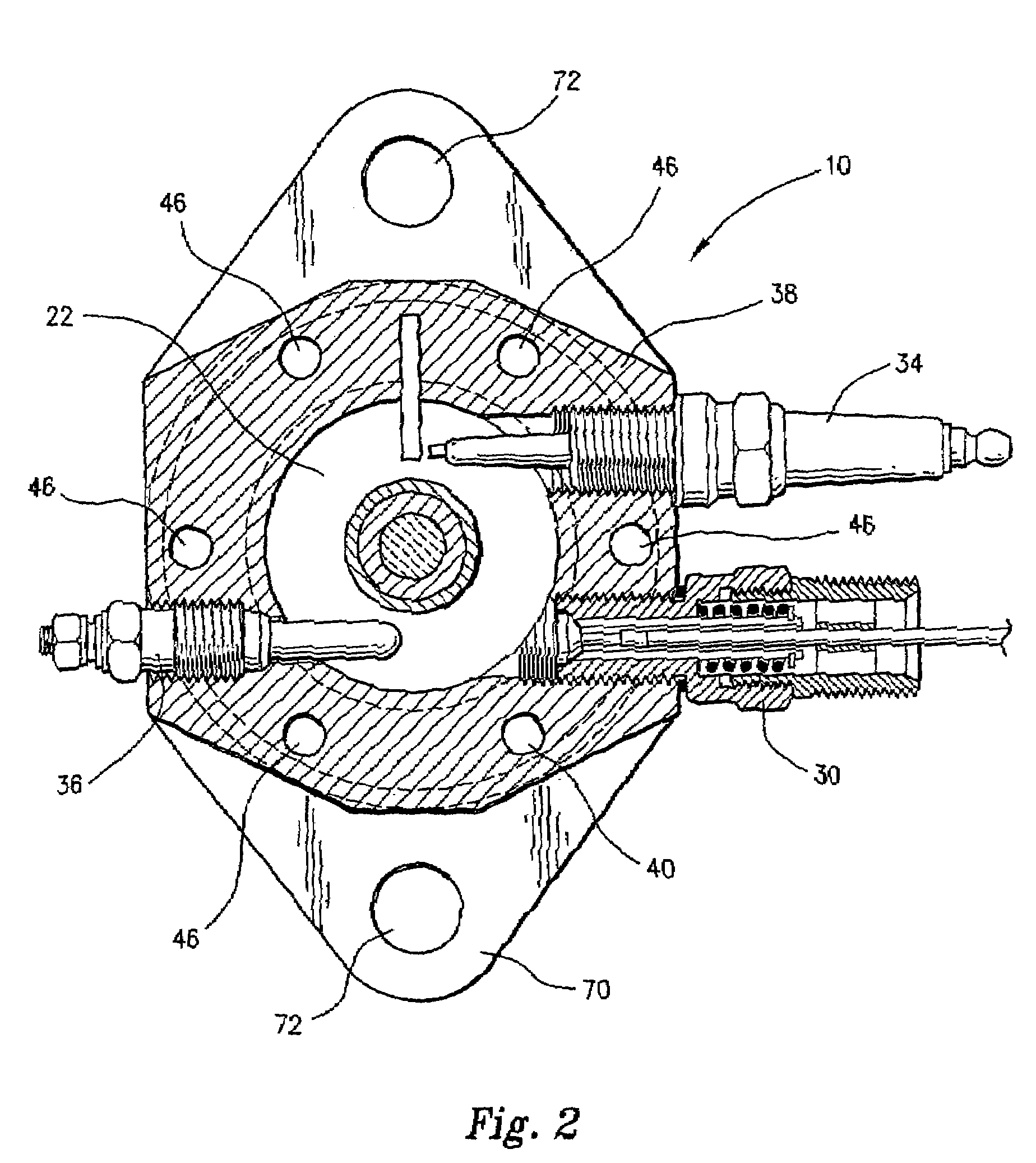

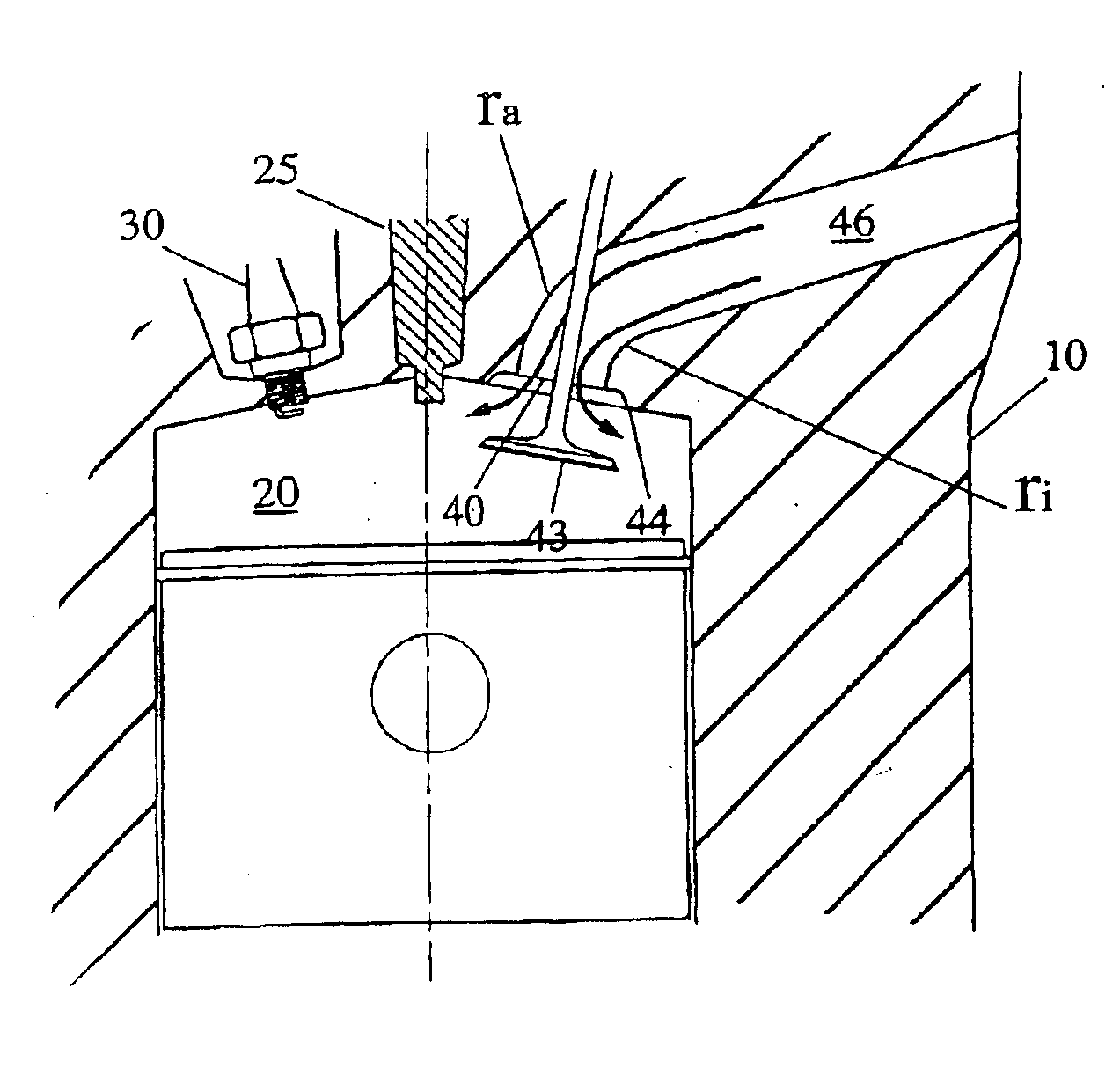

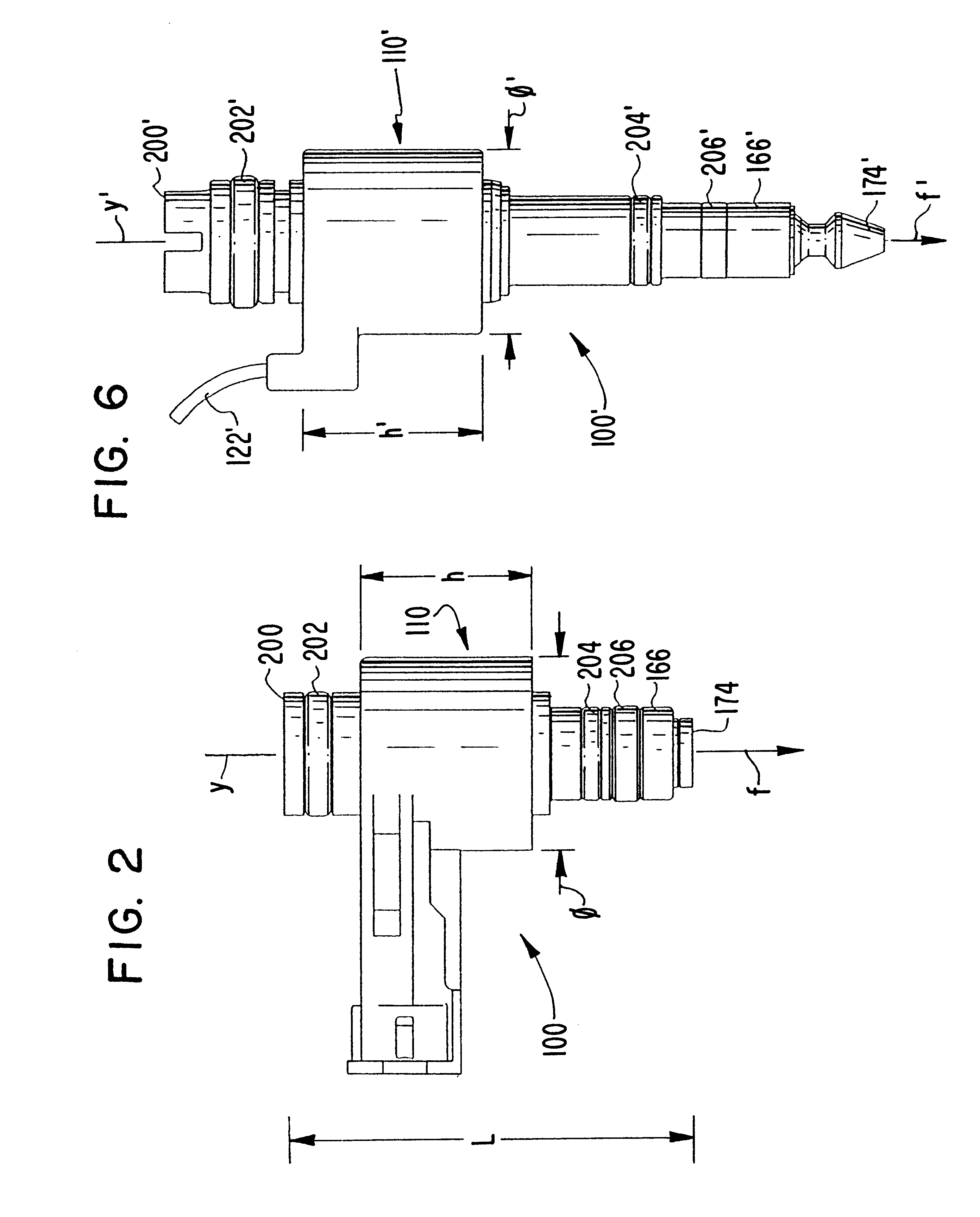

A device (10) providing a combined fuel injection and ignition means for a spark-ignition internal combustion engine. The device (10) comprises a insulator body (25) of ceramic material, a fuel flow path (24) having a section thereof encased in the insulator body (25) and terminating at a delivery port (45) disposed outwardly of the insulator body (25), and, an ignition path (23) having a section encased in the insulator body (25) in a spaced apart relationship with respect to the section of the fuel path (24). The fuel path (24) is defined within a valve structure (33) detachably secured to the insulator body (25) so as to be selectively removable therefrom. The ignition path (23) terminates at an electrode (95) disposed outwardly of the insulator body (25). The insulator body has a nose portion (100) and a skirt portion (69) beyond the delivery port (45). The nose (100) and the delivery port (45) are positioned relative to each other such that all or at least part of the fuel spray issuing from the delivery port (45) avoids impingement on the nose (100).

Owner:ORBITAL ENGINE CO PTY LTD

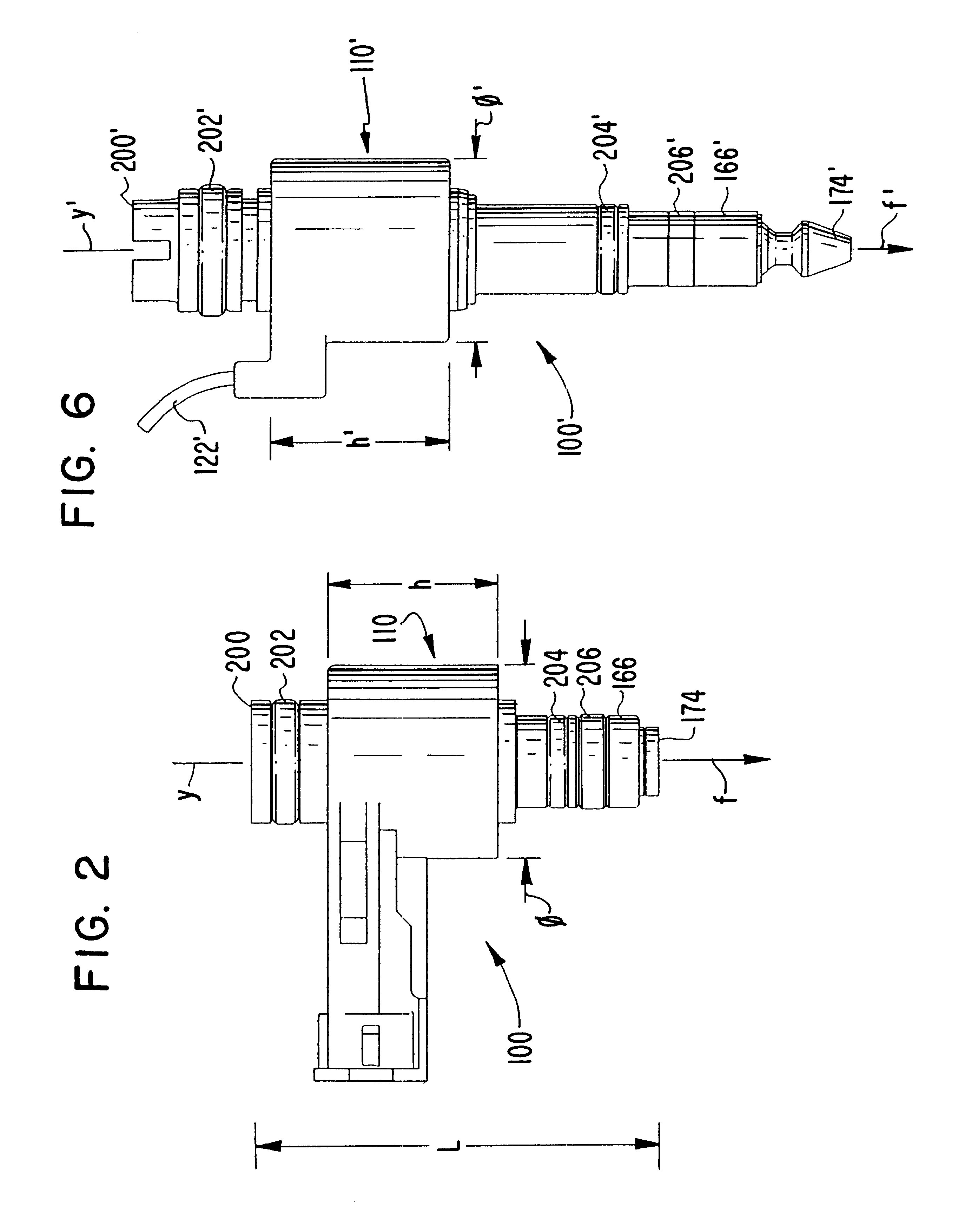

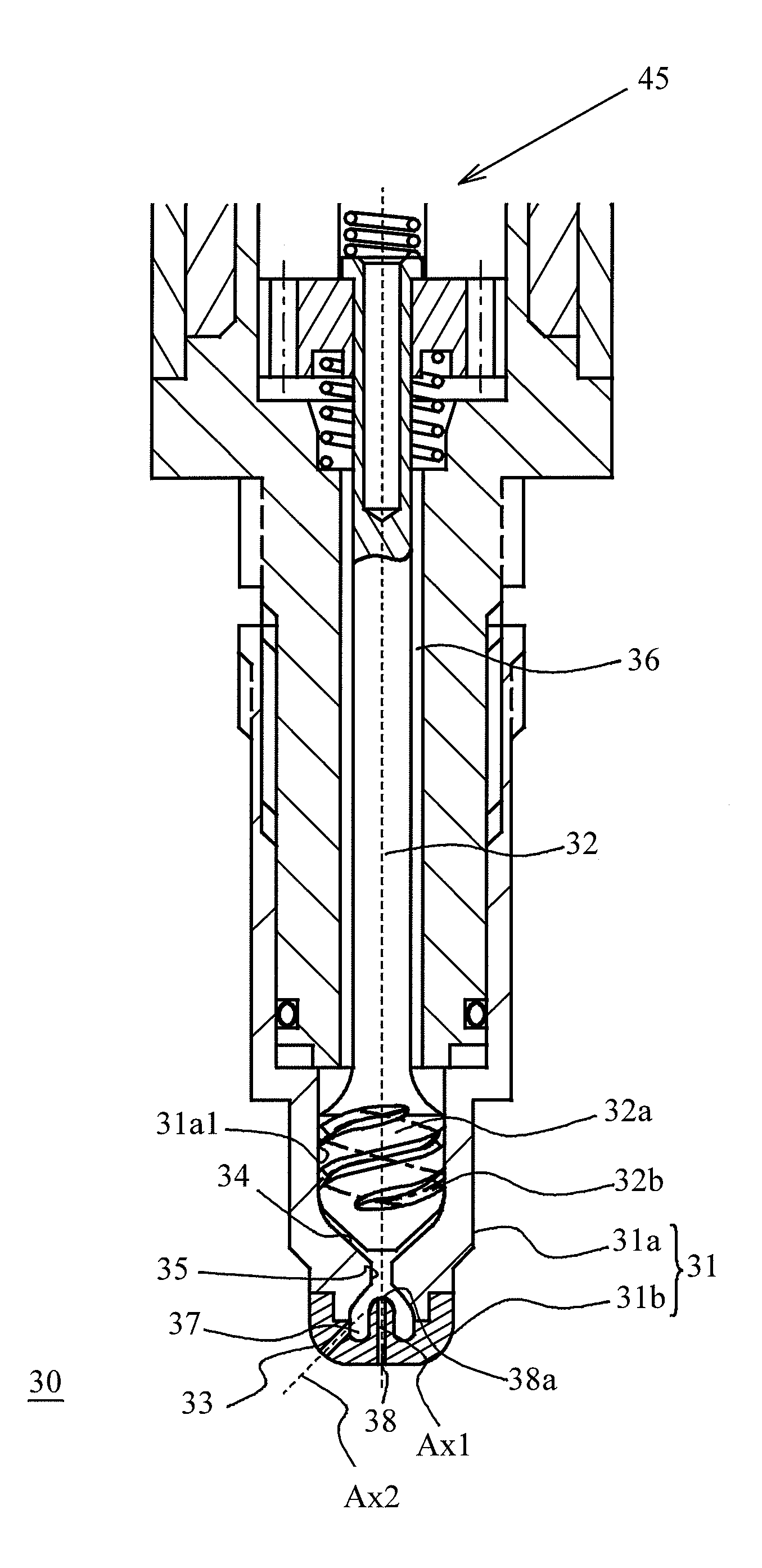

Direct injection of fuels in internal combustion engines

A fuel delivery injector for an internal combustion engine is provided. A fuel injector forms part of a device which provides a combined injection and ignition. The fuel delivery injector comprises first and second portions adapted to be detachably connected together. The first portion incorporates a valve structure having a valve member movable with respect to a valve seat for opening and closing a delivery port, and an actuating member operatively connected to the valve member. An actuator is provided in the second portion. When the first and second portions are connected together, the actuator is operably associated with the actuating member to provide an actuating assembly. Typically, the actuating assembly comprises an electromagnetic device in which the actuating member comprises a solenoid armature and the actuator comprises a solenoid coil, whereby connection of the first and second portions together completes assembly of the electromagnetic device.

Owner:ORBITAL ENGINE CO PTY LTD

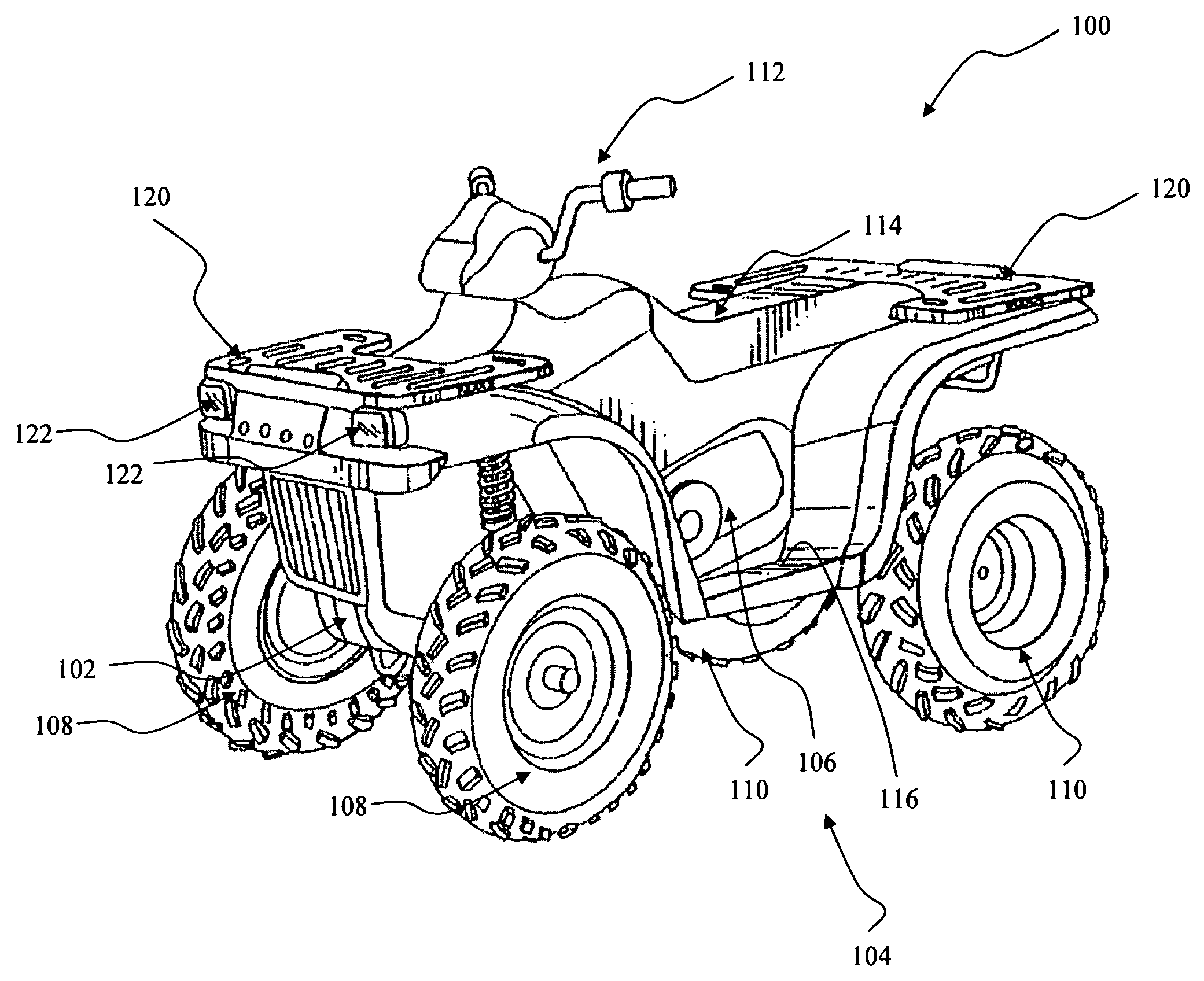

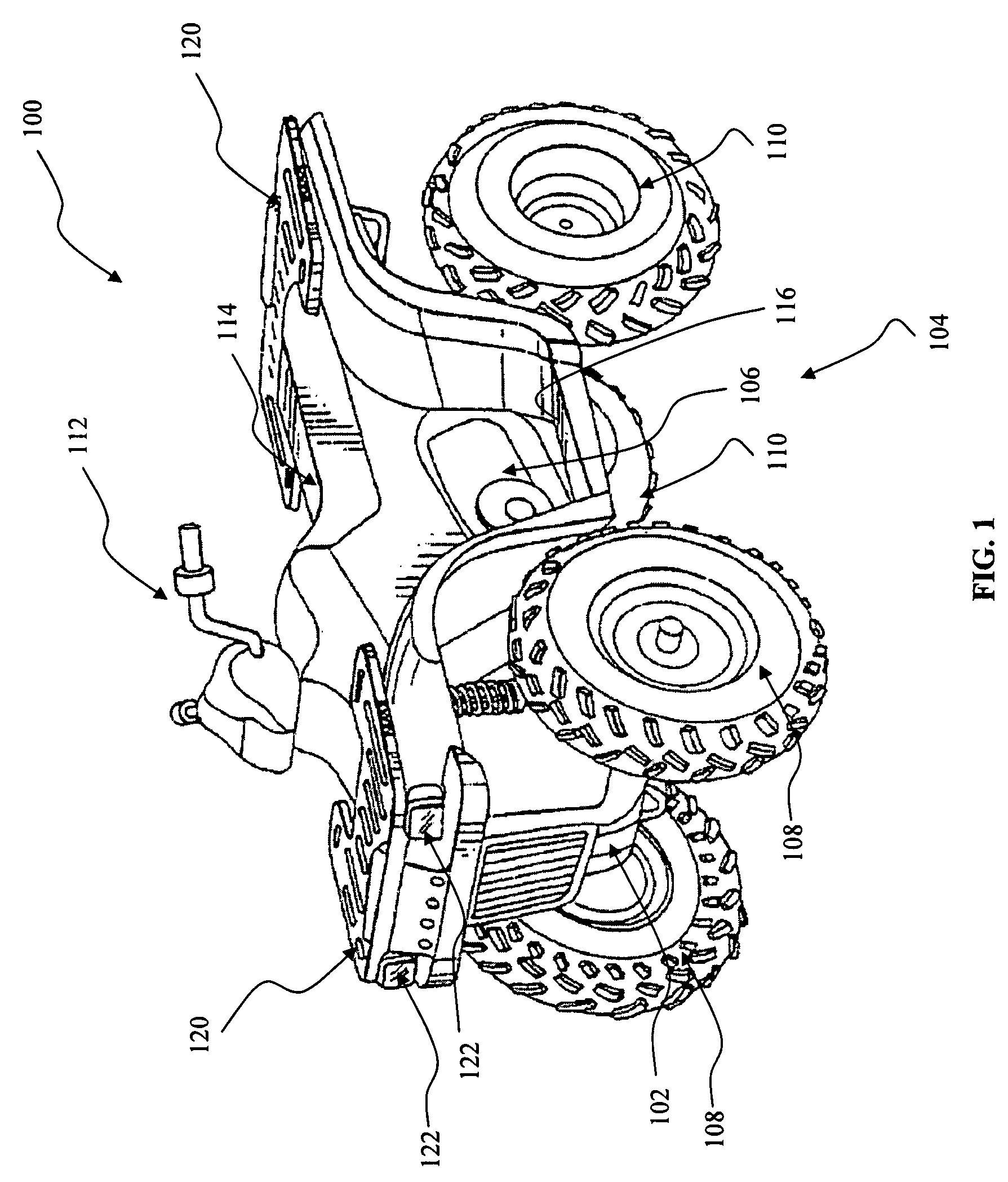

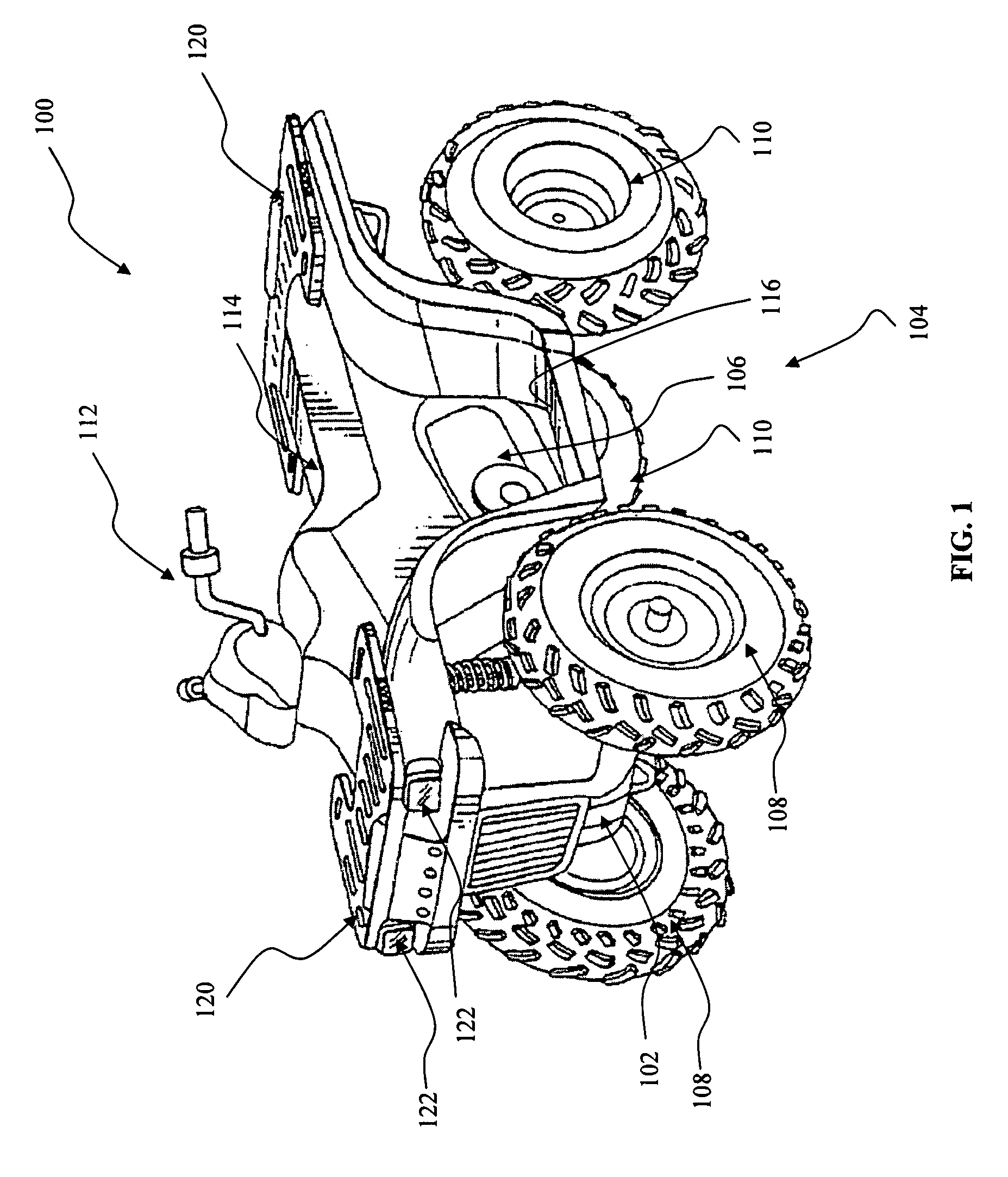

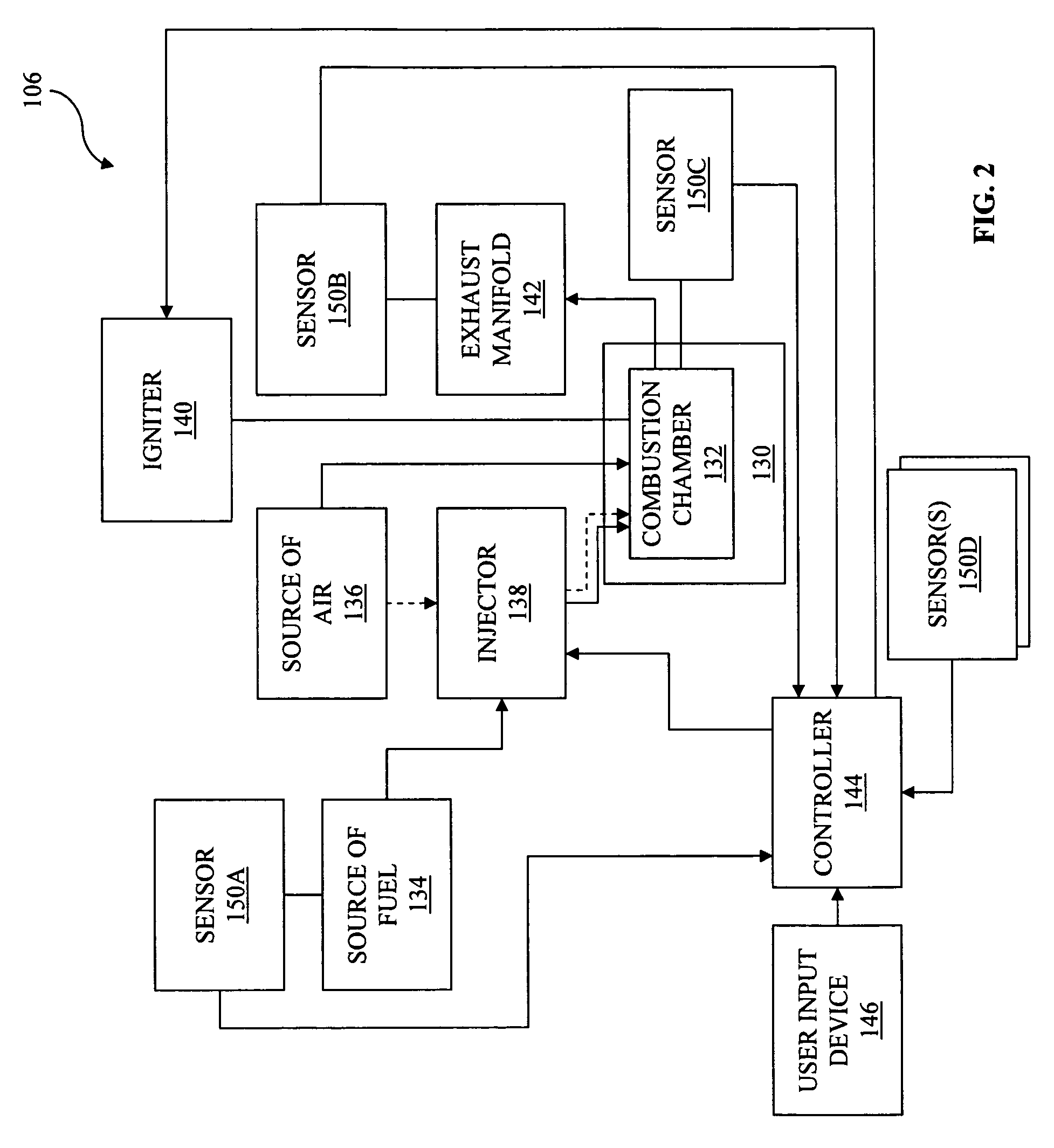

Method and operation of an engine

An engine is disclosed which may operate in a first operating state wherein a spark ignited fuel is ignited in a combustion chamber with an igniter and a second operating state wherein a compression ignited fuel is ignited in a combustion chamber with an igniter. A compression ratio in the combustion chamber being up to about eight to one. The engine may be a four-stroke engine. The engine may include a piston having a top portion with a recessed central portion.

Owner:POLARIS IND INC

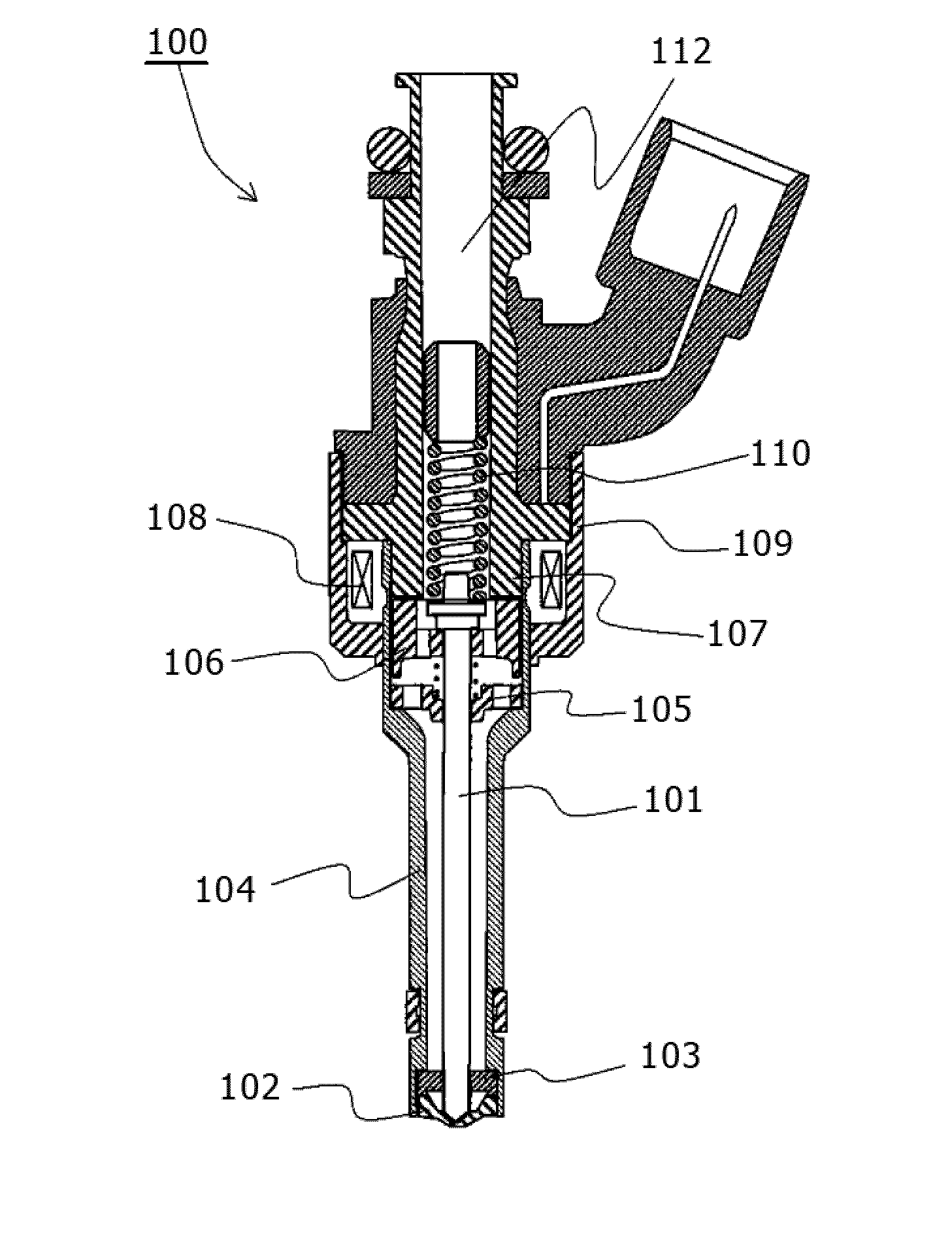

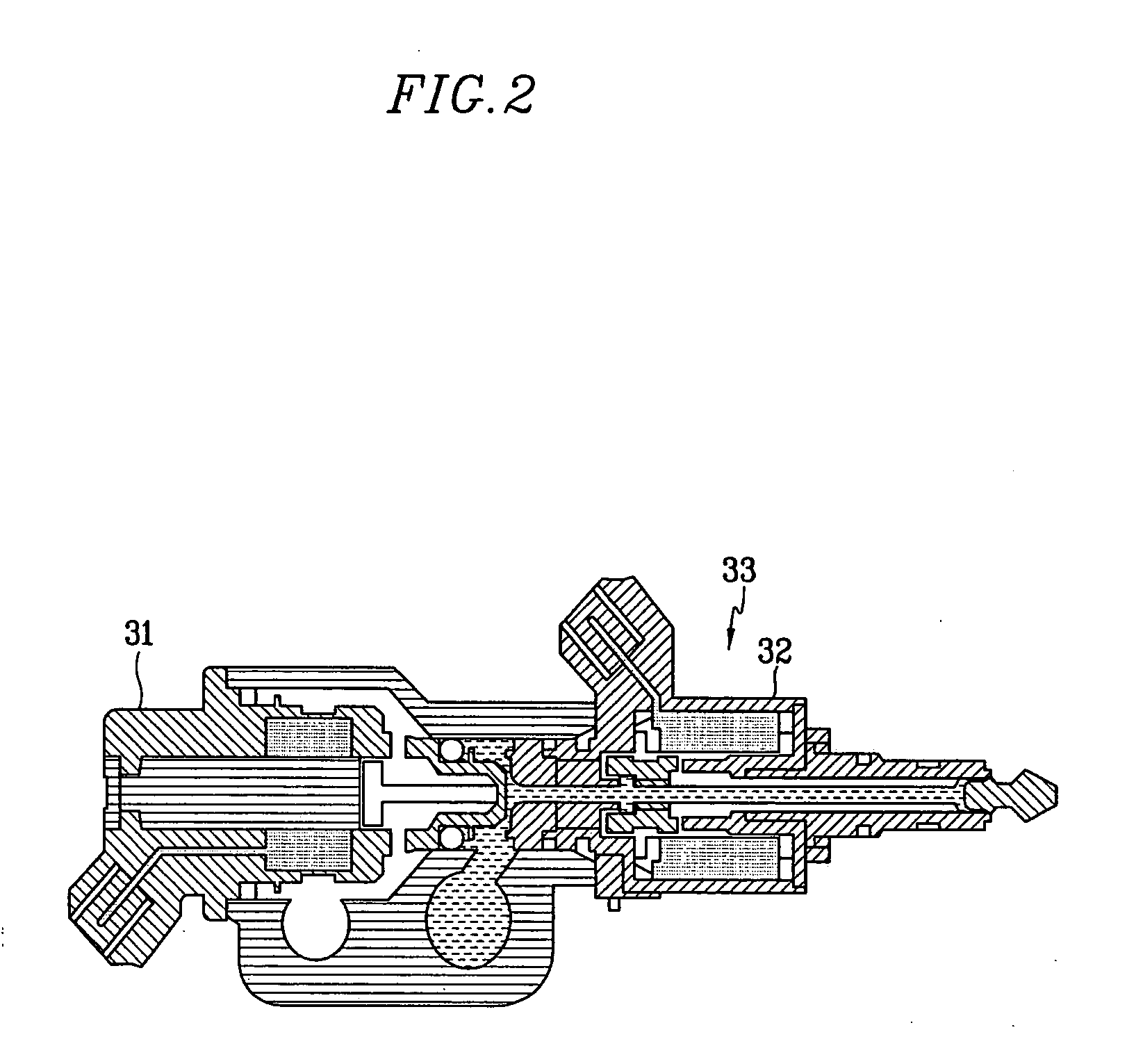

Direct injection of fuels in internal combustion engines

InactiveUS20050045146A1Maintain integritySparking plugsHigh pressure gas fuel injectionCombustionEngineering

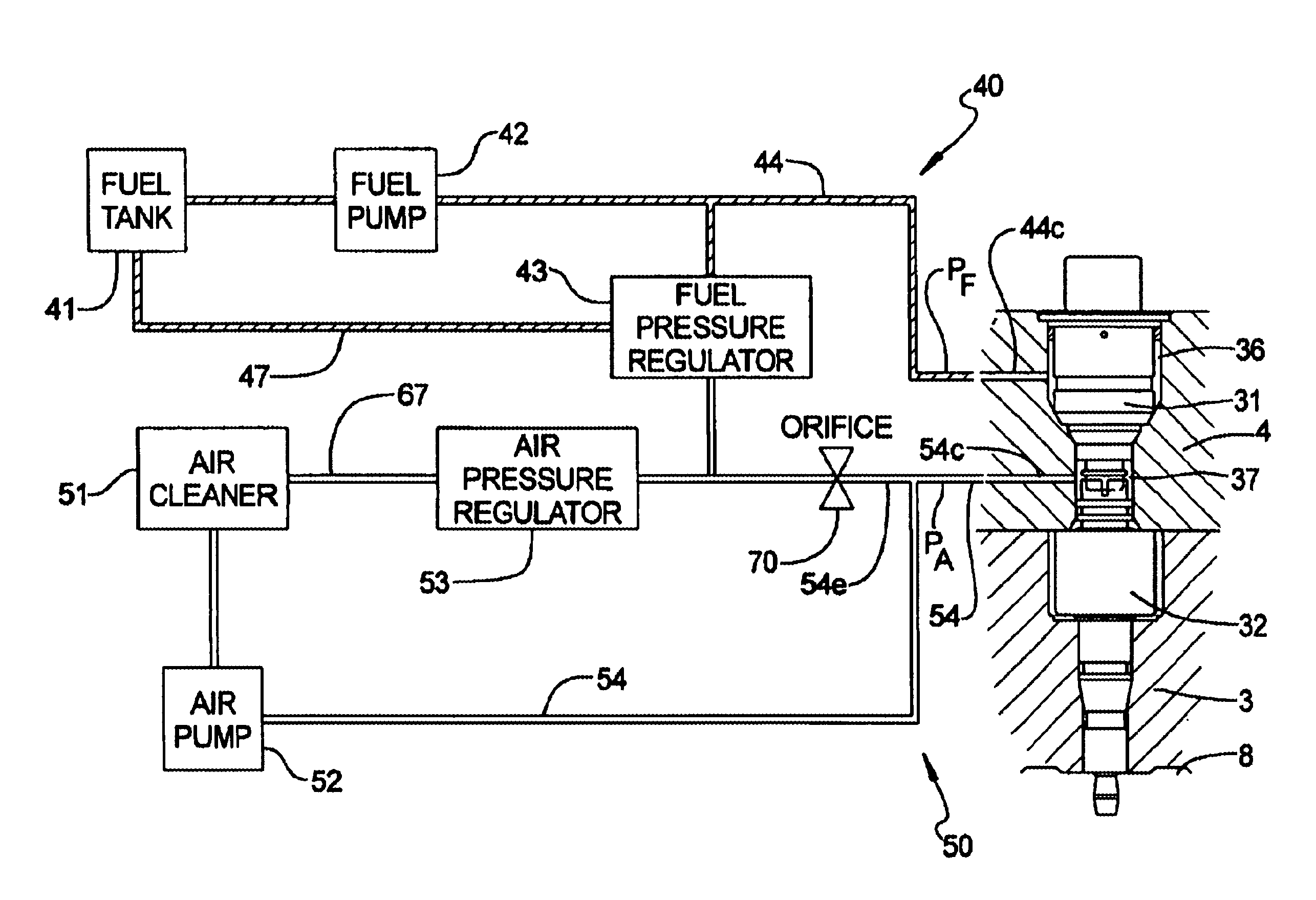

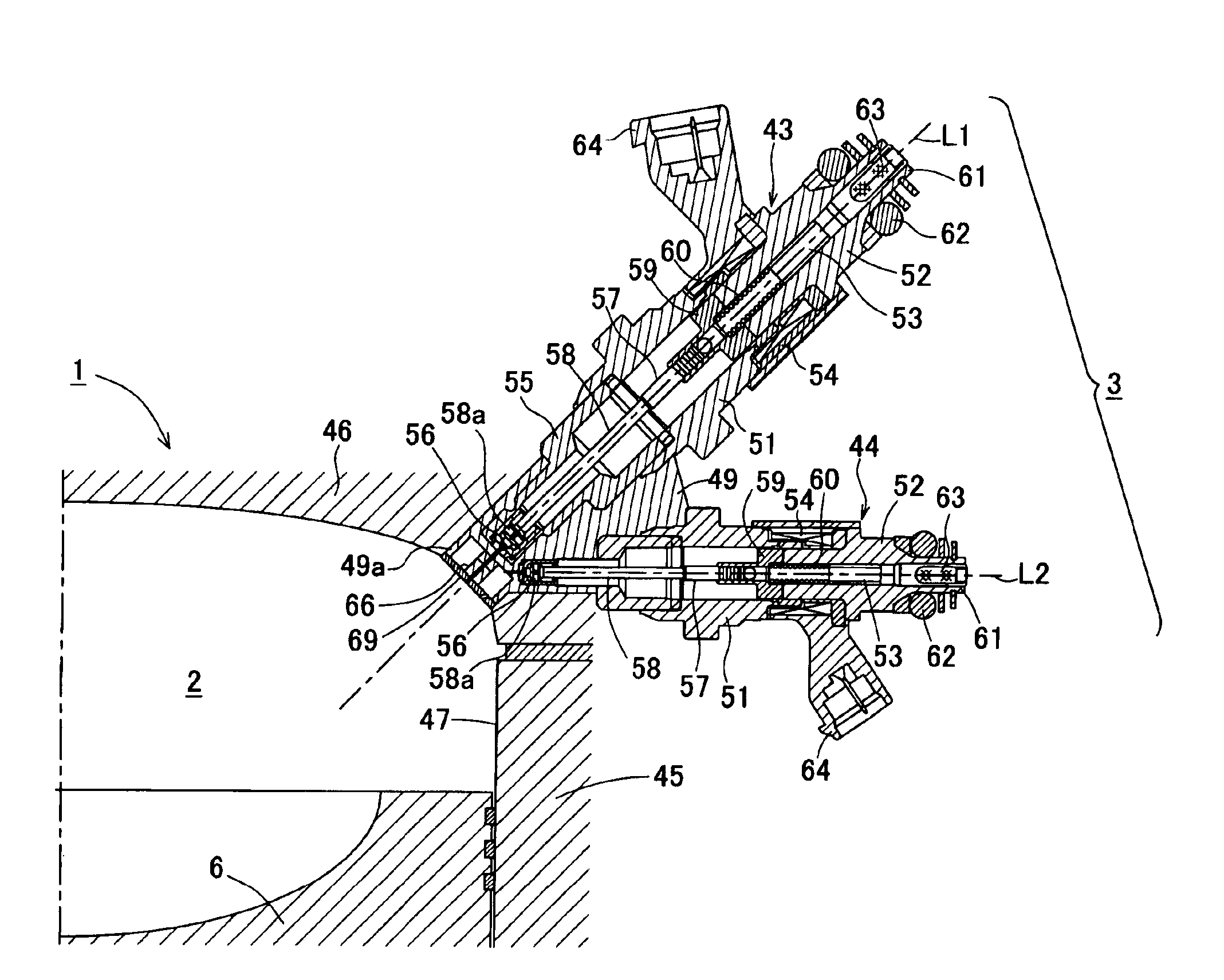

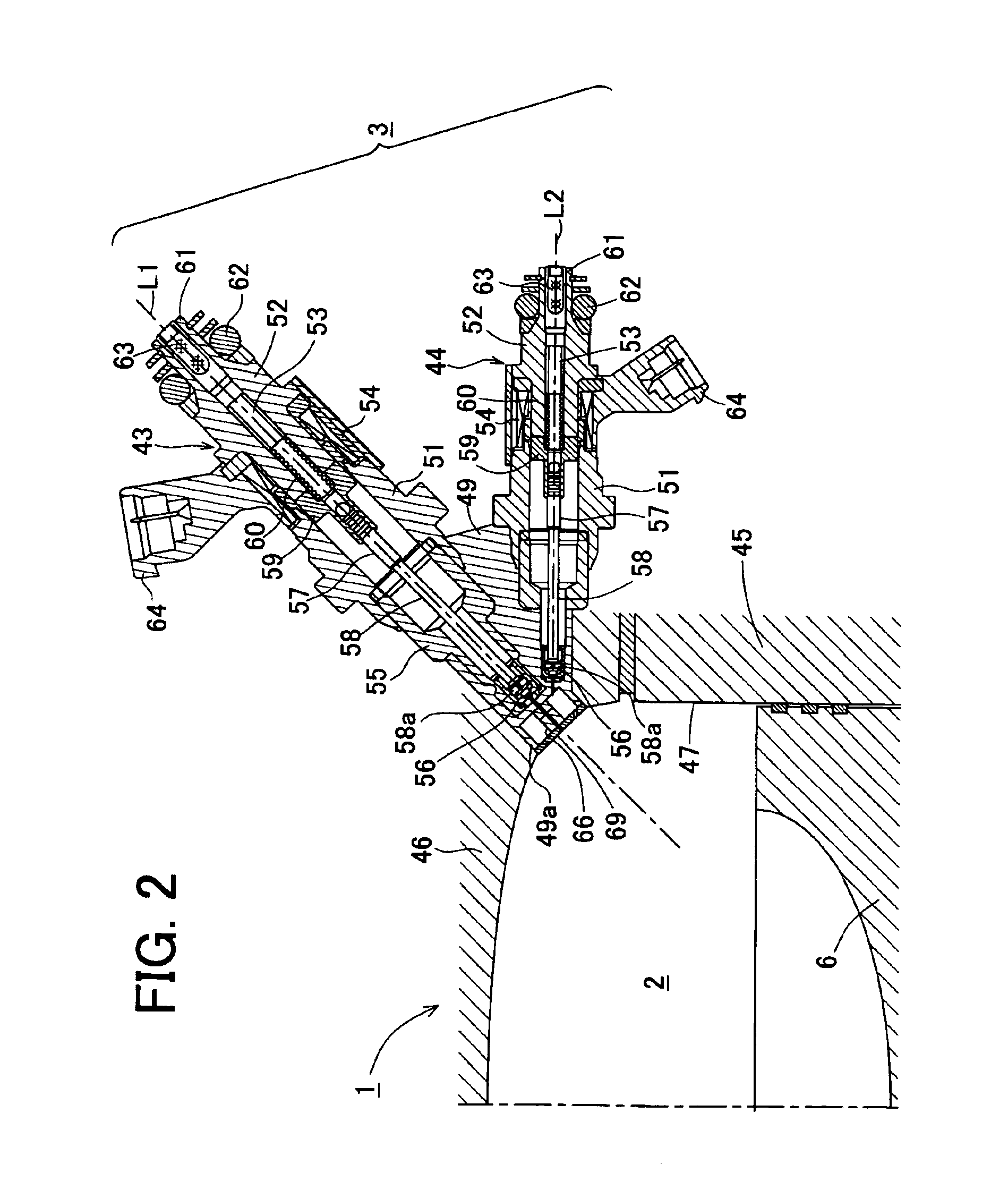

A fuel delivery injector for an internal combustion engine. The fuel injector forms pan of a device (10) which provides a combined injection and ignition means for the engine. The fuel delivery injector comprises a first portion (31) and a second portion (32) adapted to be detachably connected together. The first portion has a delivery port (37) defined between a valve seat (61) and a valve member (63) movable with respect to the valve seat (61) for opening and closing the delivery port (37). An actuating member (87) is provided in the first portion (31) and is operatively connected to the valve member (63). An actuating means (85) is provided in the second portion (32). When the first and second portions (31, 32) are connected together, the actuating mean (85) is operably associated with the actuating member (87) to provide an actuating assembly (83). Typically, the actuating assembly (83) comprises an electromagnetic means in which the actuating member (87) comprises a solenoid armature and the actuating means (85) comprises a solenoid oil, whereby connection of the first and second portions (31, 32) together completes assembly of the electromagnetic means. Where the device (10) provides a combined fuel injector and ignition me the device (10) is provided with a primary electrode (58) which cooperates with a secondary electrode (57) to define a spark gap (60). A popper projection (62) provided on the valve member (63) is utilized to define the primary electrode (58), as well as to provide spray guidance effects on the fuel spray issuing from the delivery port (37). The device (10) providing the combined fuel injection and ignition means is also described and claimed.

Owner:ORBITAL ENGINE CO PTY LTD

Method and operation of an engine

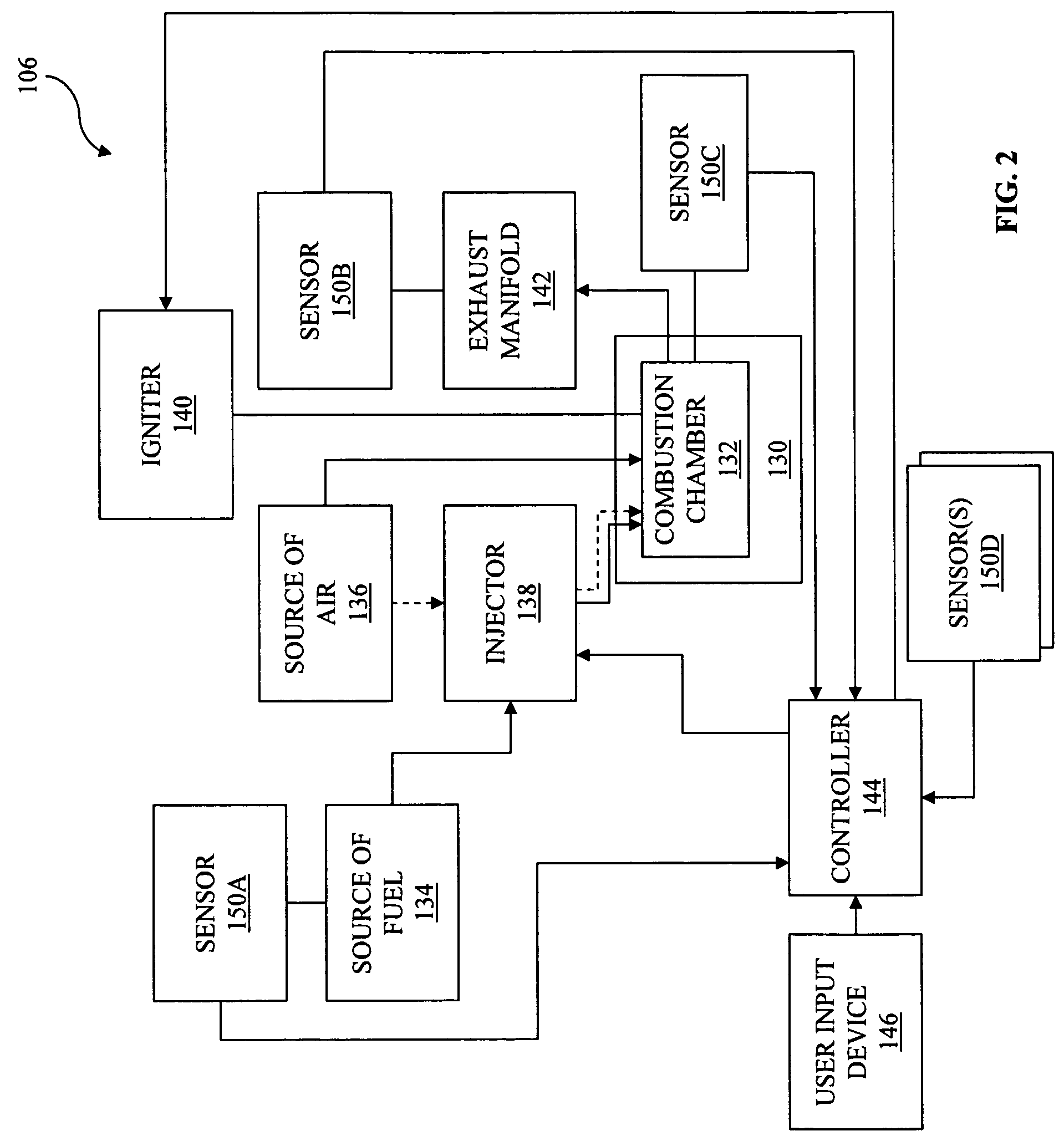

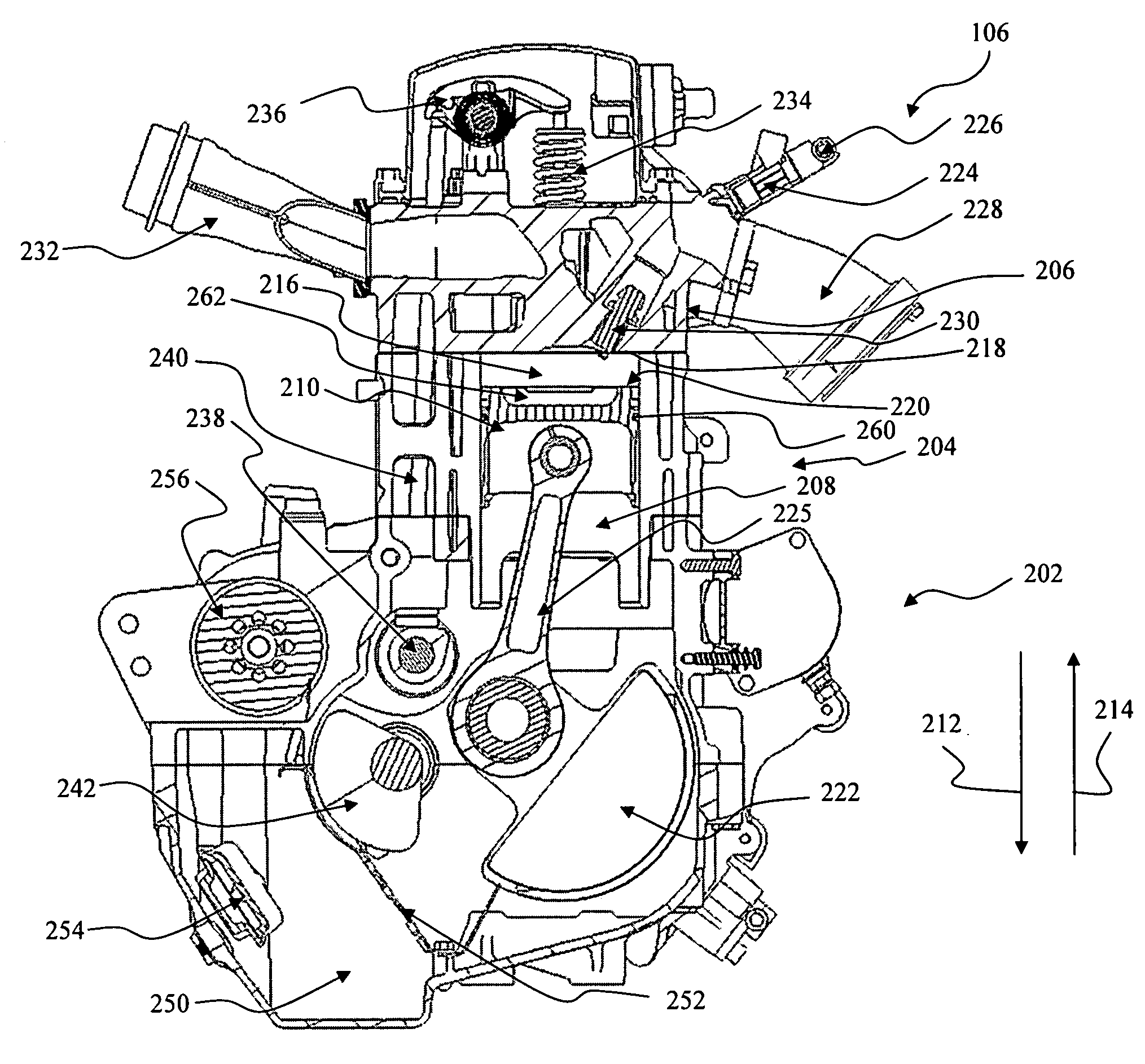

ActiveUS20080041335A1Electrical controlInternal combustion piston enginesFour-stroke engineCompression ratio

An engine is disclosed which may operate in a first operating state wherein a spark ignited fuel is ignited in a combustion chamber with an igniter and a second operating state wherein a compression ignited fuel is ignited in a combustion chamber with an igniter. A compression ratio in the combustion chamber being up to about eight to one. The engine may be a four-stroke engine. The engine may include a piston having a top portion with a recessed central portion.

Owner:POLARIS IND INC

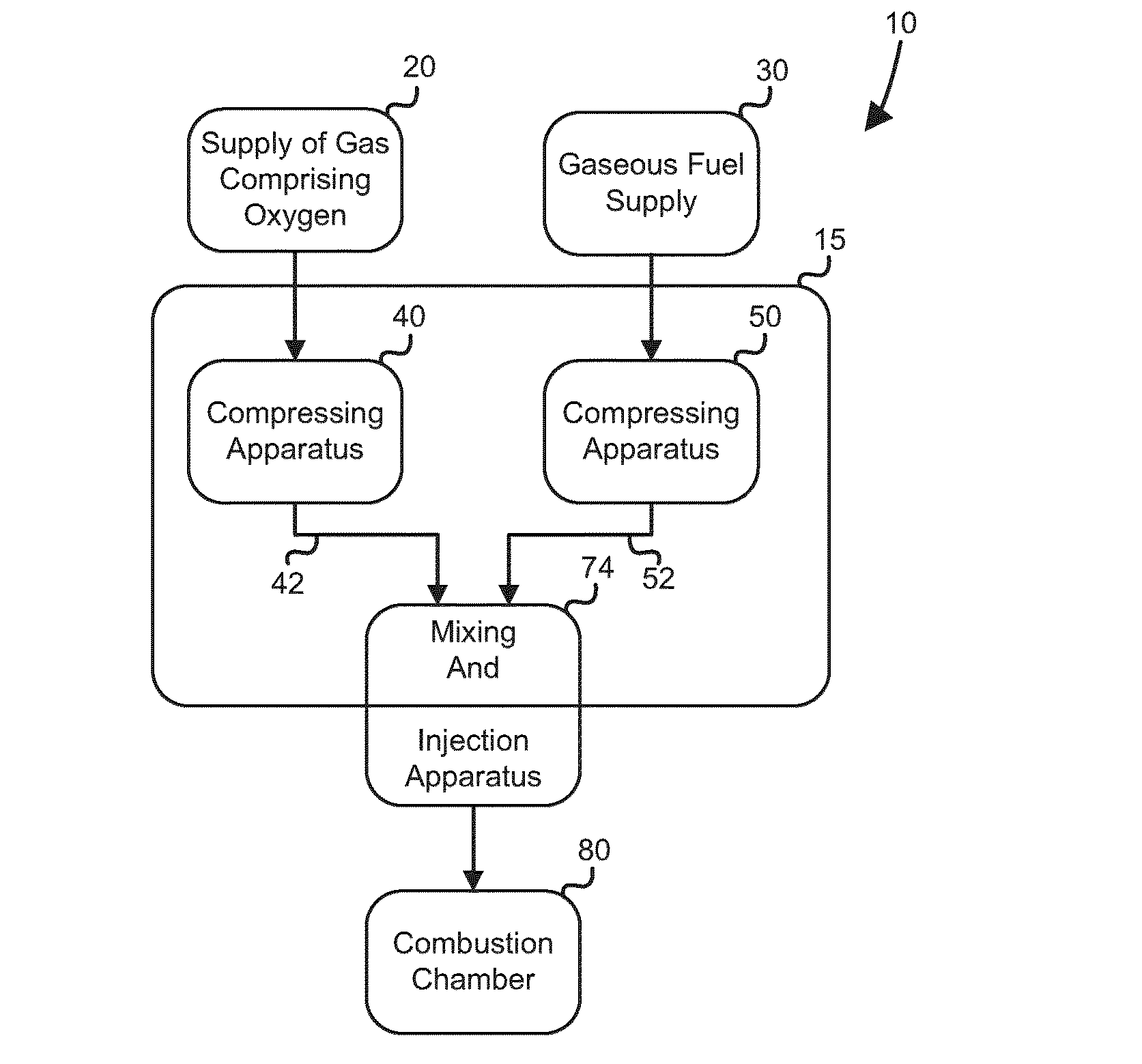

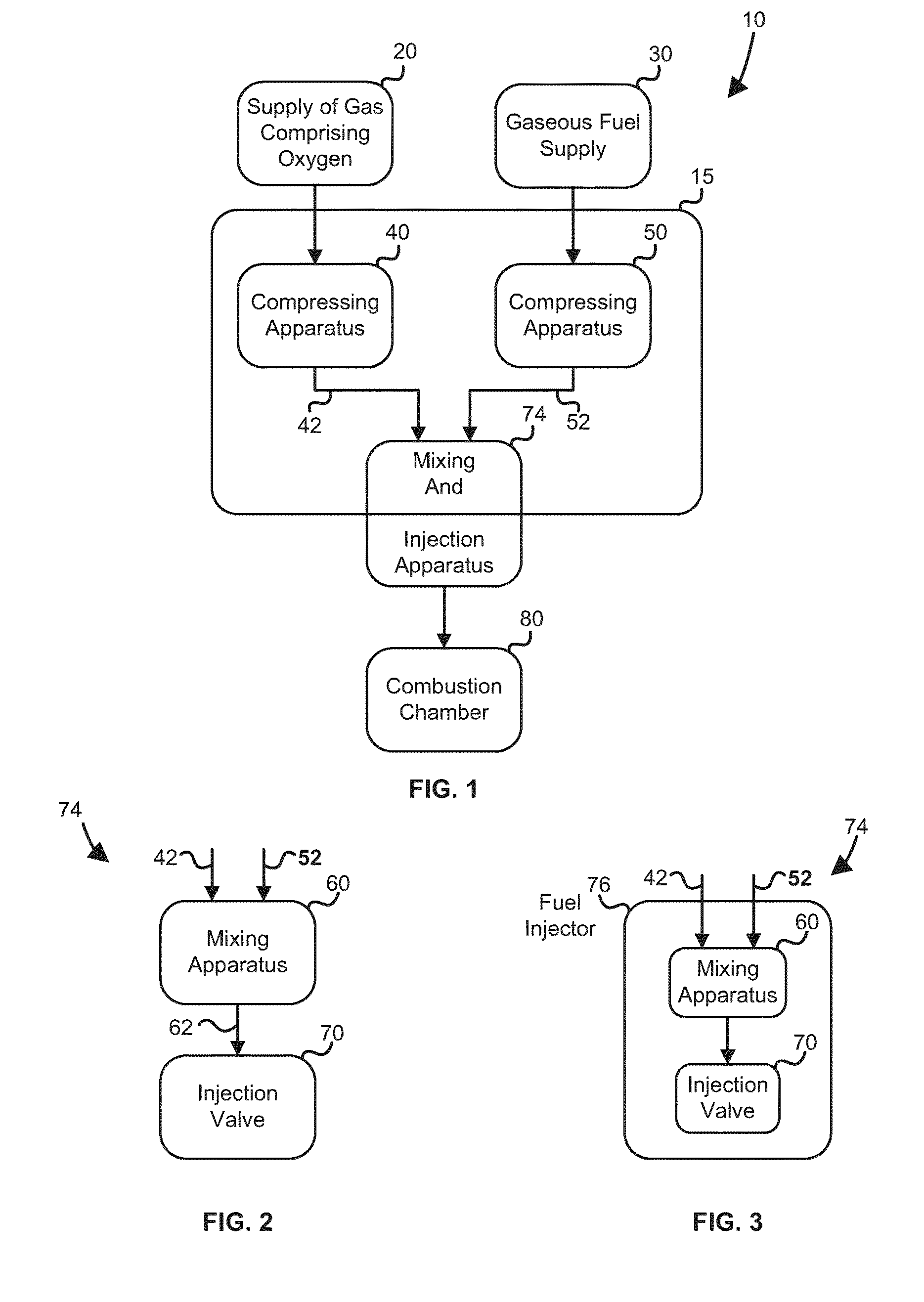

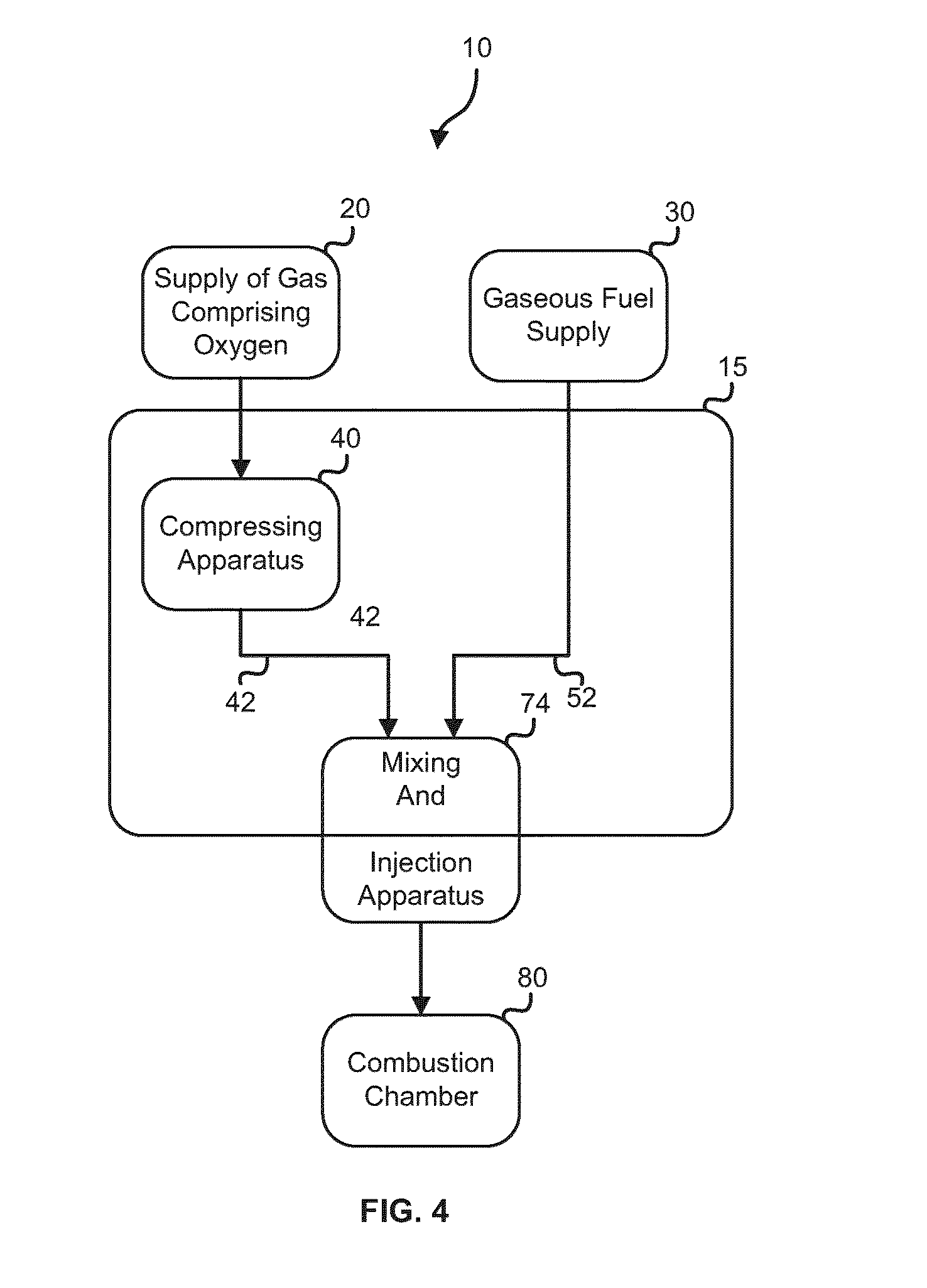

Air-Enriched Gaseous Fuel Direct Injection For An Internal Combustion Engine

ActiveUS20160017845A1Electrical controlInternal combustion piston enginesExternal combustion engineInternal combustion engine

A method for introducing a gaseous fuel into a combustion chamber of an internal combustion engine includes forming a non-ignitable mixture of the gaseous fuel and a gas including oxygen in a predefined mixture mass ratio within a predetermined range of tolerance having a pressure suitable for directly introducing the non-ignitable mixture into the combustion chamber during at least the compression stroke; and introducing the non-ignitable mixture directly into the combustion chamber.

Owner:WESTPORT FUEL SYST CANADA INC

Apparatus and method for mode-switching fuel injector nozzle

A fuel injector nozzle and method for dispersing fuel during a normal combustion operation and a supplemental combustion operation, the fuel injector nozzle comprising: a plurality of first outlet openings configured to disperse fuel in a first arrangement; and a plurality of second outlet openings configured to collide with the fuel passing through the plurality of first openings to disperse fuel in a second arrangement, wherein either the first or second arrangement is selected by the position of the piston.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

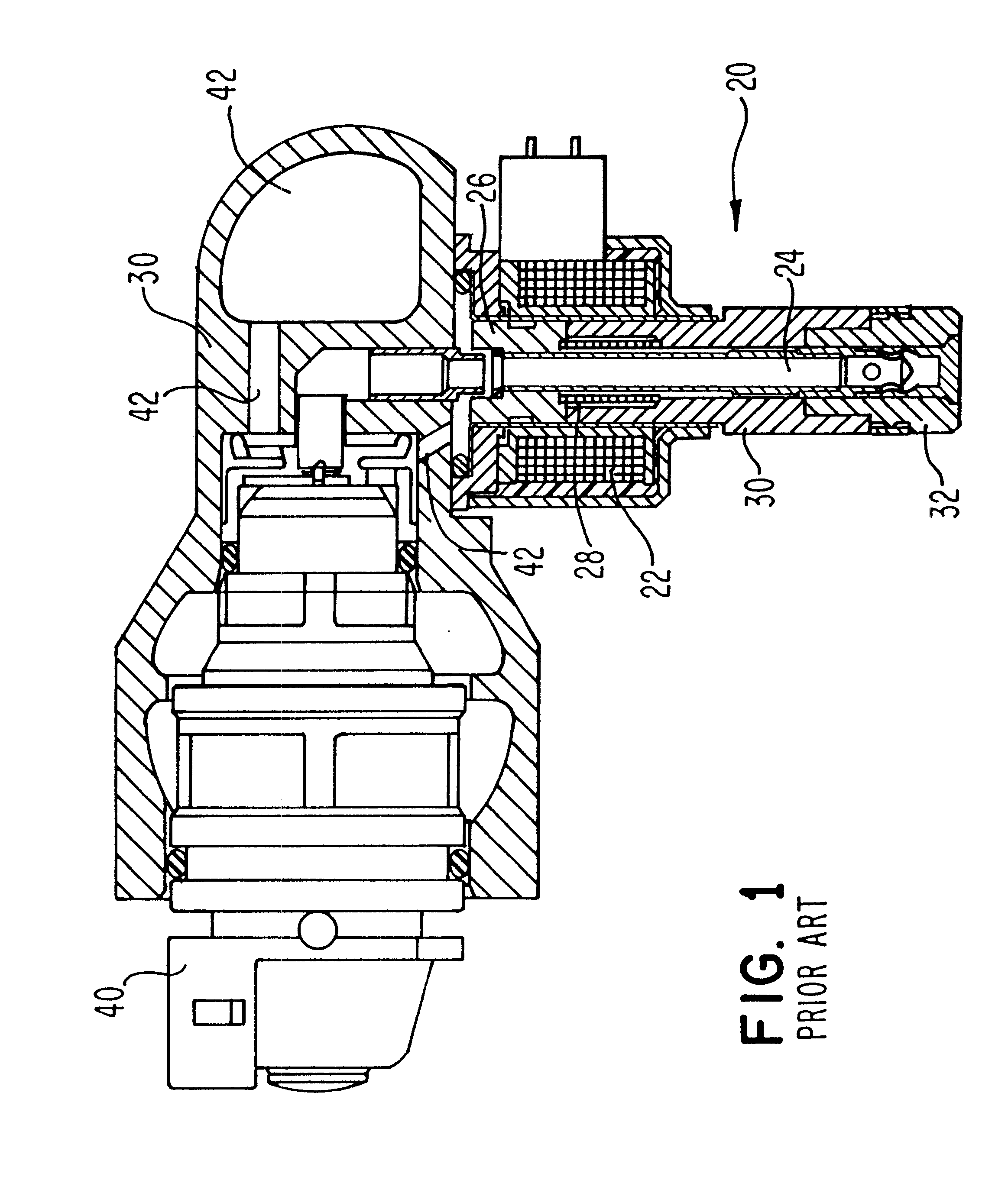

Sealing arrangement for air assist fuel injectors

A sealing arrangement for an air assist fuel injector having an interface cap. The sealing arrangement includes a sleeve sealingly attached to a leg of the air assist fuel injector and that receives at least a portion of the interface cap. A seal member abuts the sleeve to seal a solenoid from liquid fuel and gas and to seal an interface between the air assist fuel injector and a rail when the air assist fuel injector is received by the rail.

Owner:SYNERJECT

Injection of fuel vapor and air mixture into an engine cylinder

One strategy for reducing undesirable emissions from internal combustion engines relates to finding ways to better mix fuel and air prior to combustion. One such method is commonly referred to as homogenous charge compression ignition (HCCI); however, that strategy is problematic in both controlling ignition timing and avoiding overstressing the engine at higher speeds and loads. The present invention addresses these issues by mixing air and fuel vapor within an injector instead of within the engine cylinder. The air / fuel mixture is then injected into the engine cylinder at some desired timing and over some desired duration. Such a strategy permits for lower emissions due to better mixing of air and fuel, while also permitting control over some aspects of combustion timing and duration not apparently possible with a conventional HCCI strategy. The present invention is generally applicable to all internal combustion engines, but especially applicable to diesel engines.

Owner:CATERPILLAR INC

Charge-injected internal combustion engine, and method of operating same

ActiveUS6955161B2Improve startupImprove fuel efficiencyElectrical controlInternal combustion piston enginesCharge injectionExternal combustion engine

A charge-injected internal combustion engine exhibits improved starting performance with charge-injection timing control. A charge-injected internal combustion engine has an air-fuel injection valve for directly injecting a compressed air-fuel mixture into a combustion chamber. The engine is also provided with an air pump, driven by the crankshaft for discharging compressed air, and a timing controller for setting injection timing of the air-fuel injection valve. When initial startup of the engine is detected, the controller sets the injection timing to the intake stroke. When the engine reaches a predetermined engine speed, or when the pressure of the injection air reaches a threshold pressure where injection of the air-fuel mixture is possible on the compression stroke, the timing controller switches the injection timing from the intake stroke to the compression stroke.

Owner:ORBITAL ENGINE CO PTY LTD

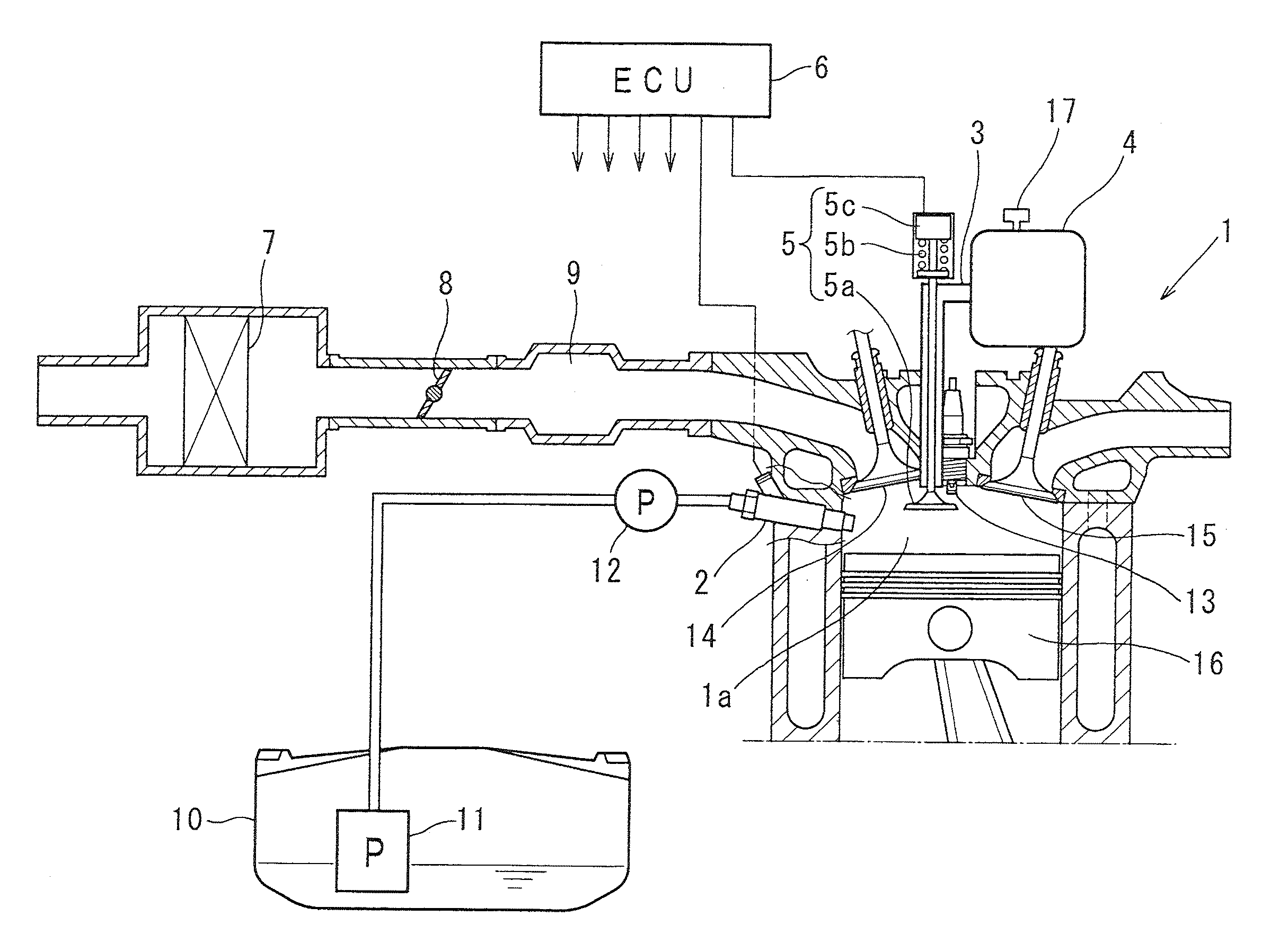

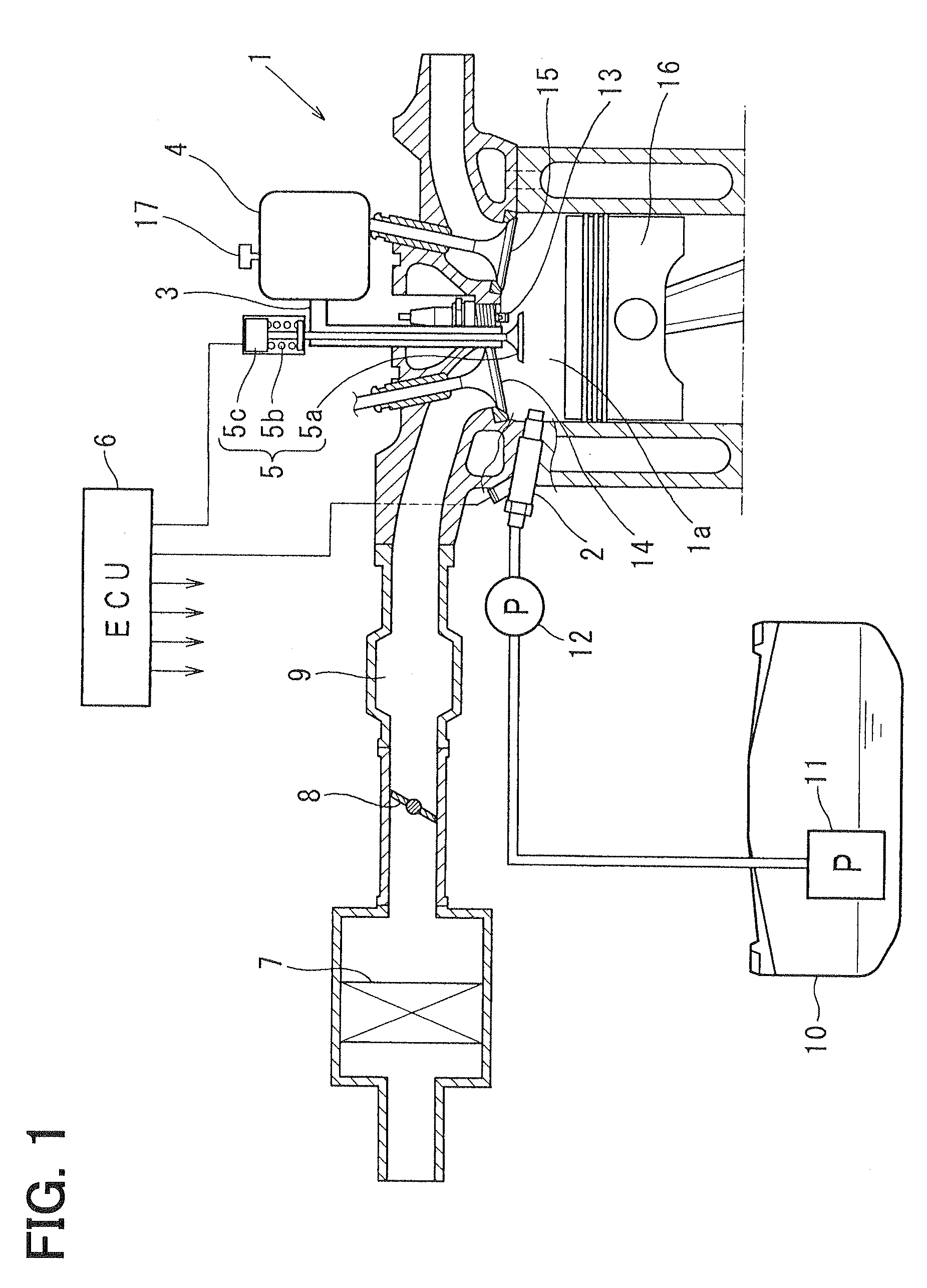

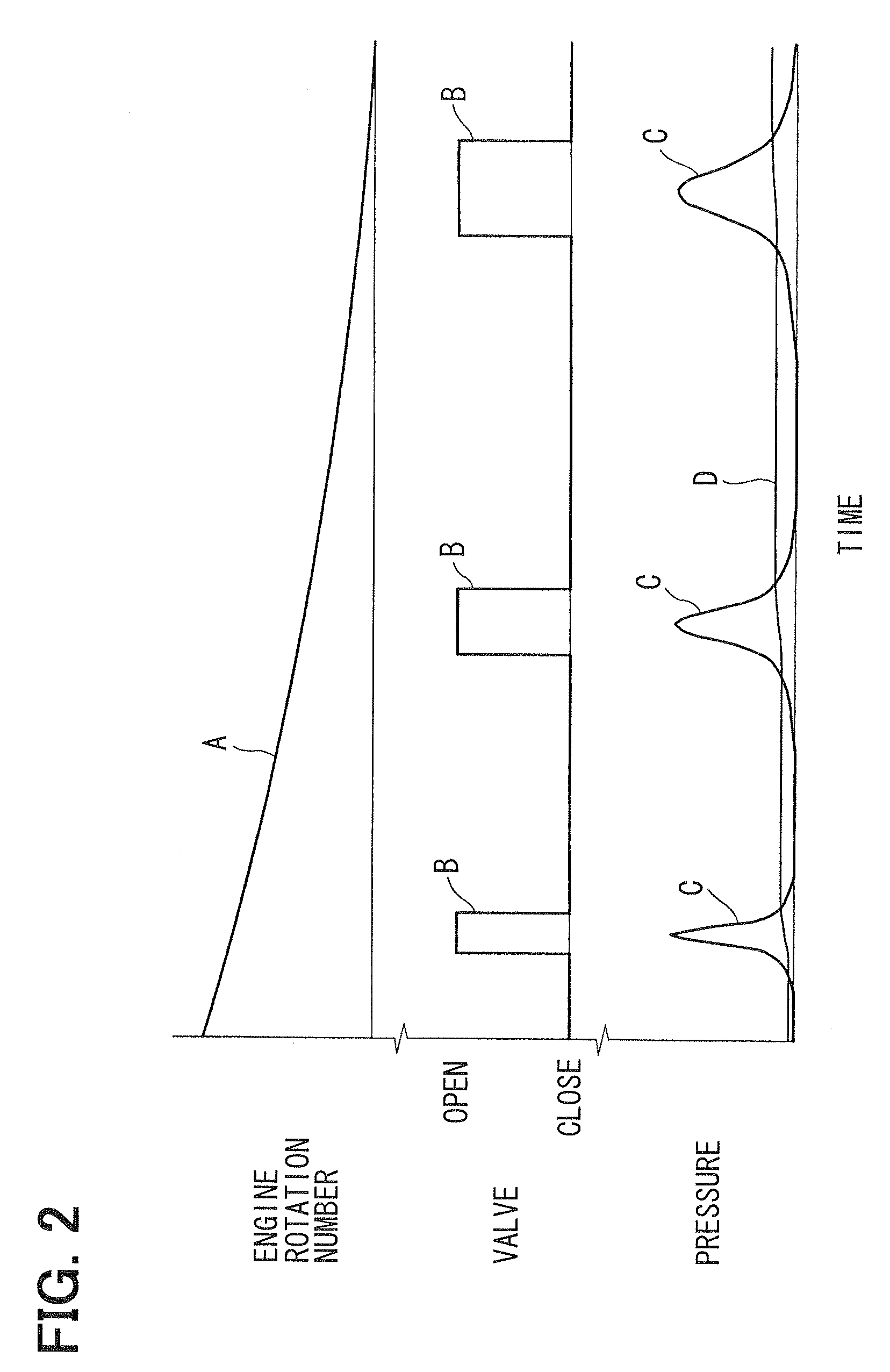

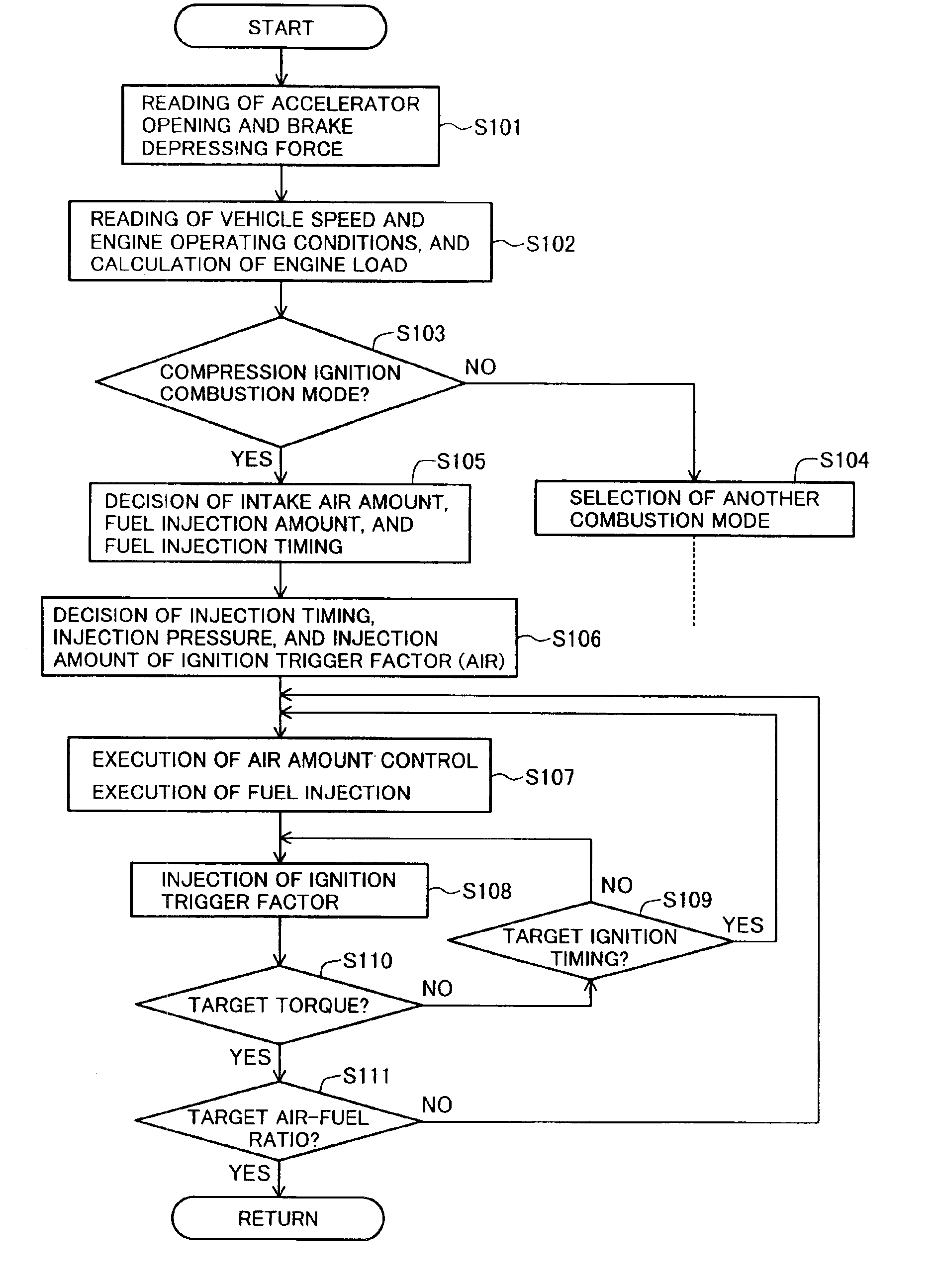

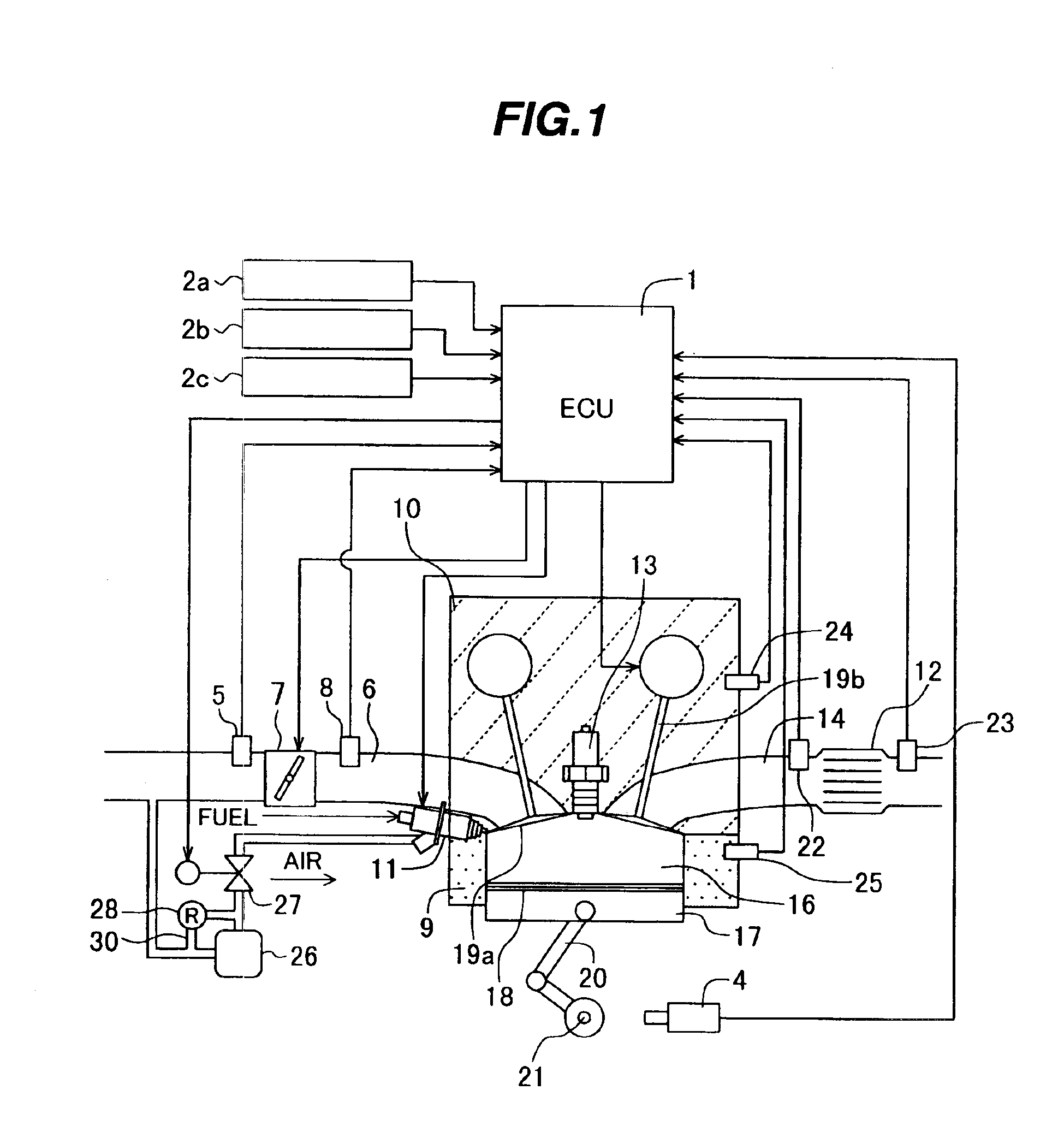

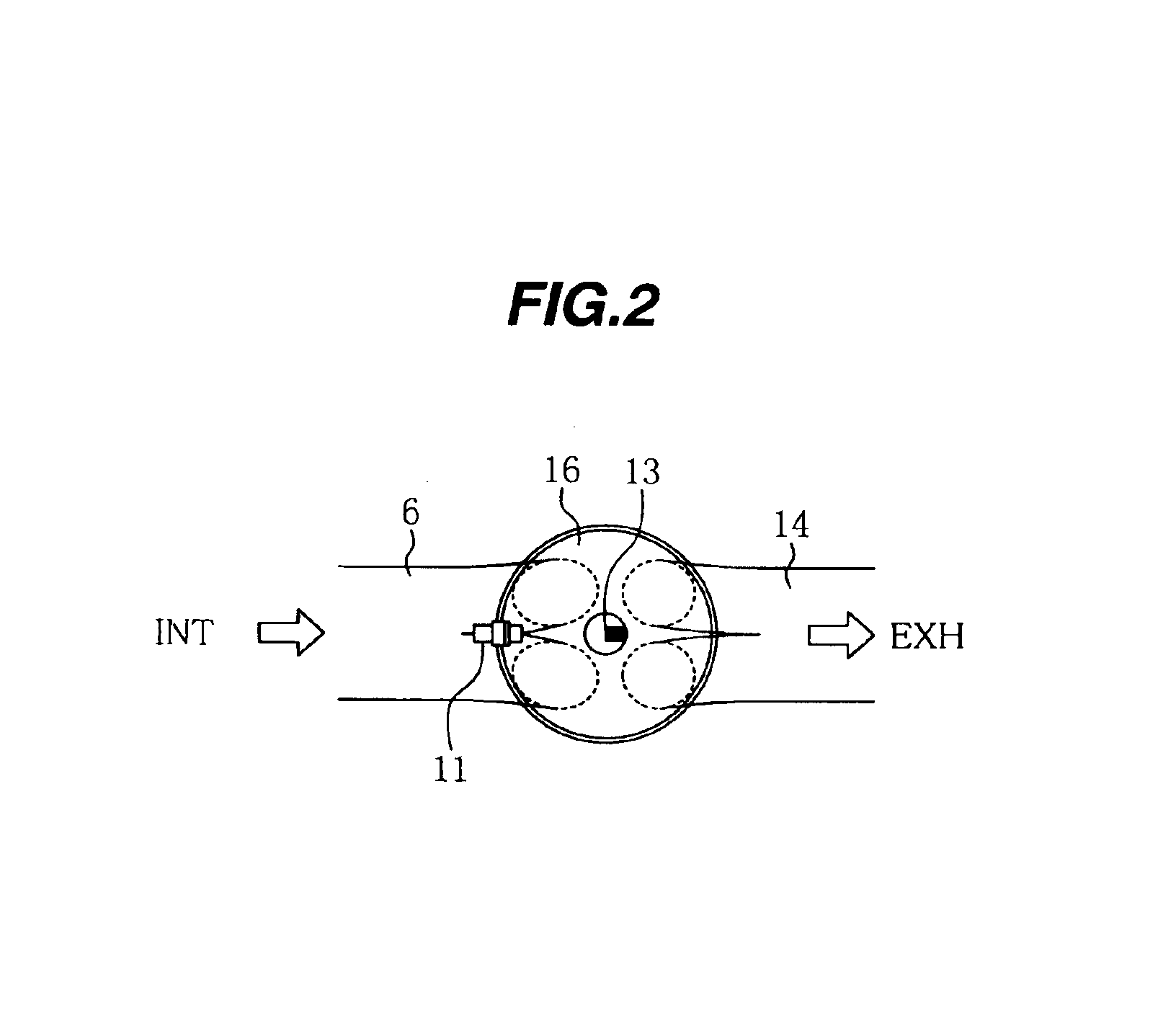

Compression ignition internal combustion engine

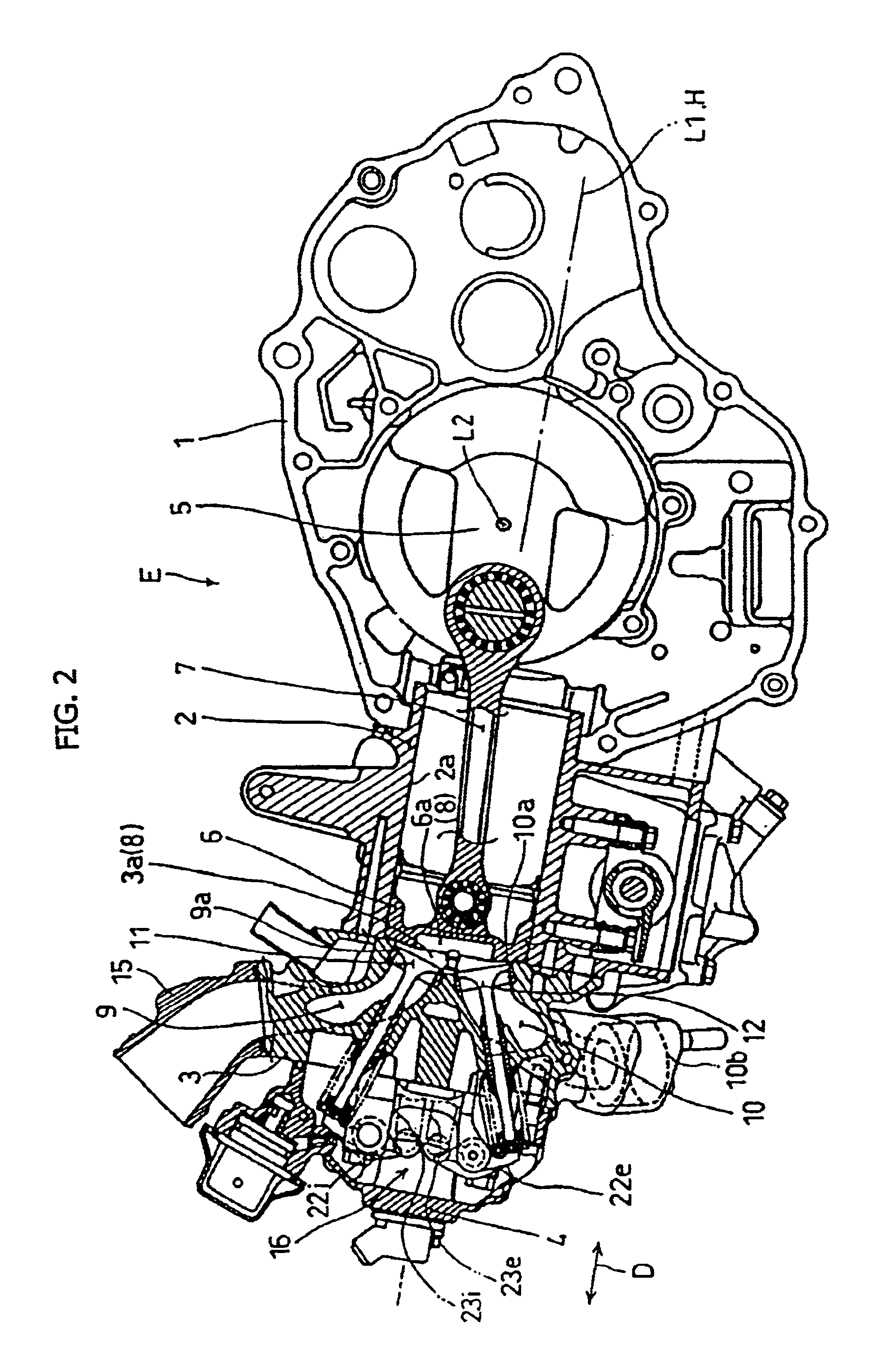

InactiveUS7055495B2Accurate timingWide range of operationsElectrical controlInternal combustion piston enginesExhaust valveCombustion chamber

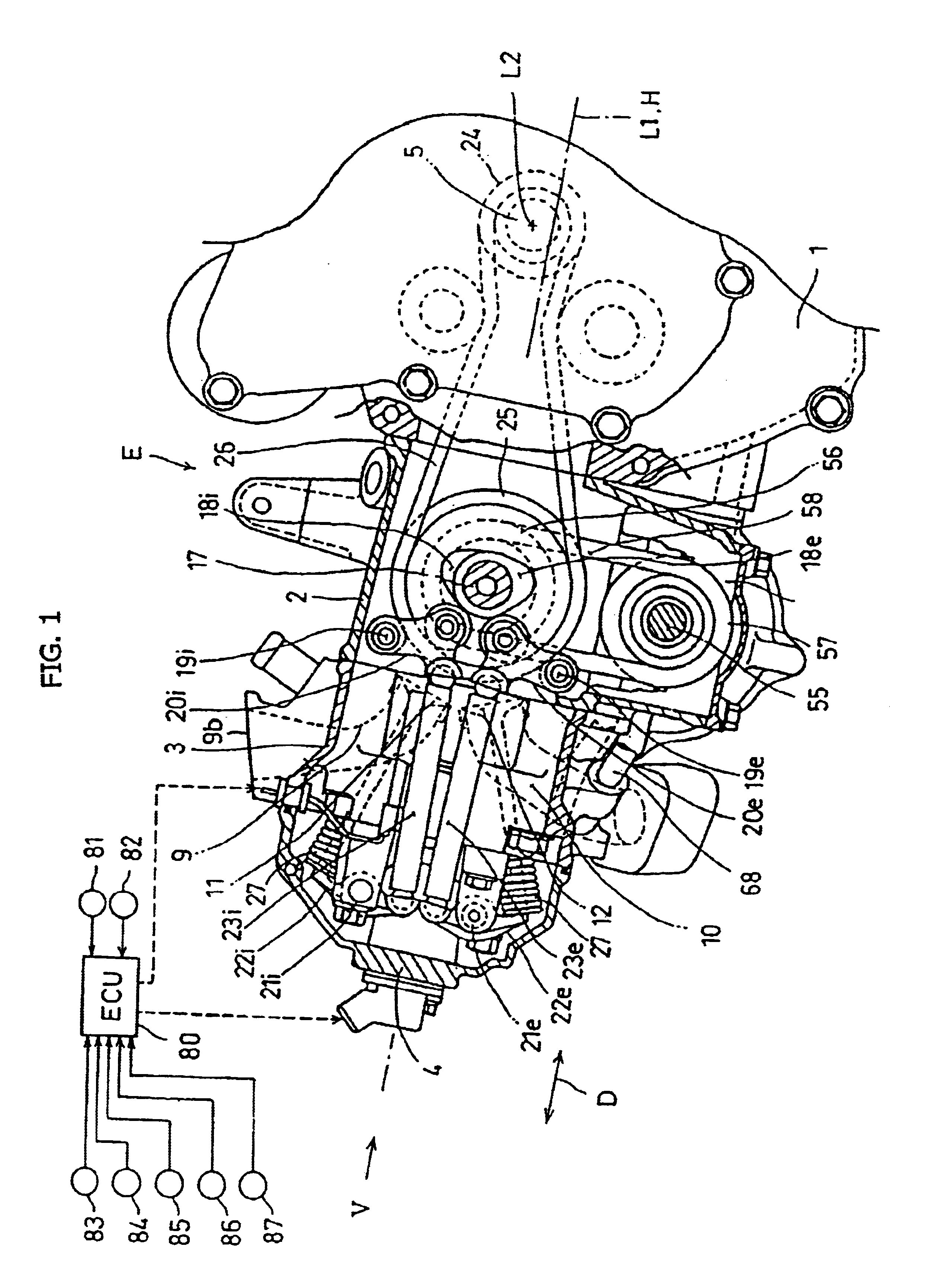

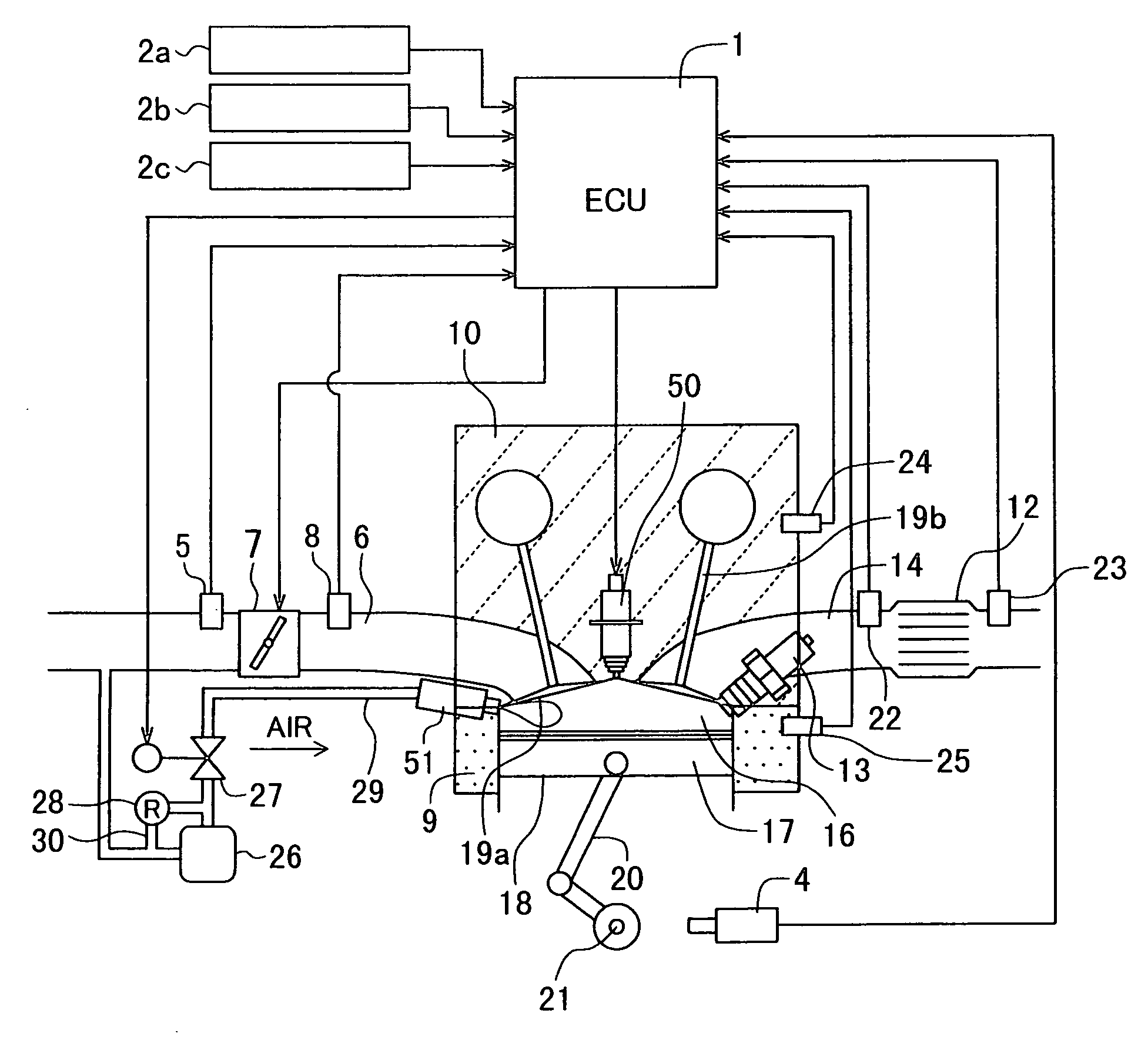

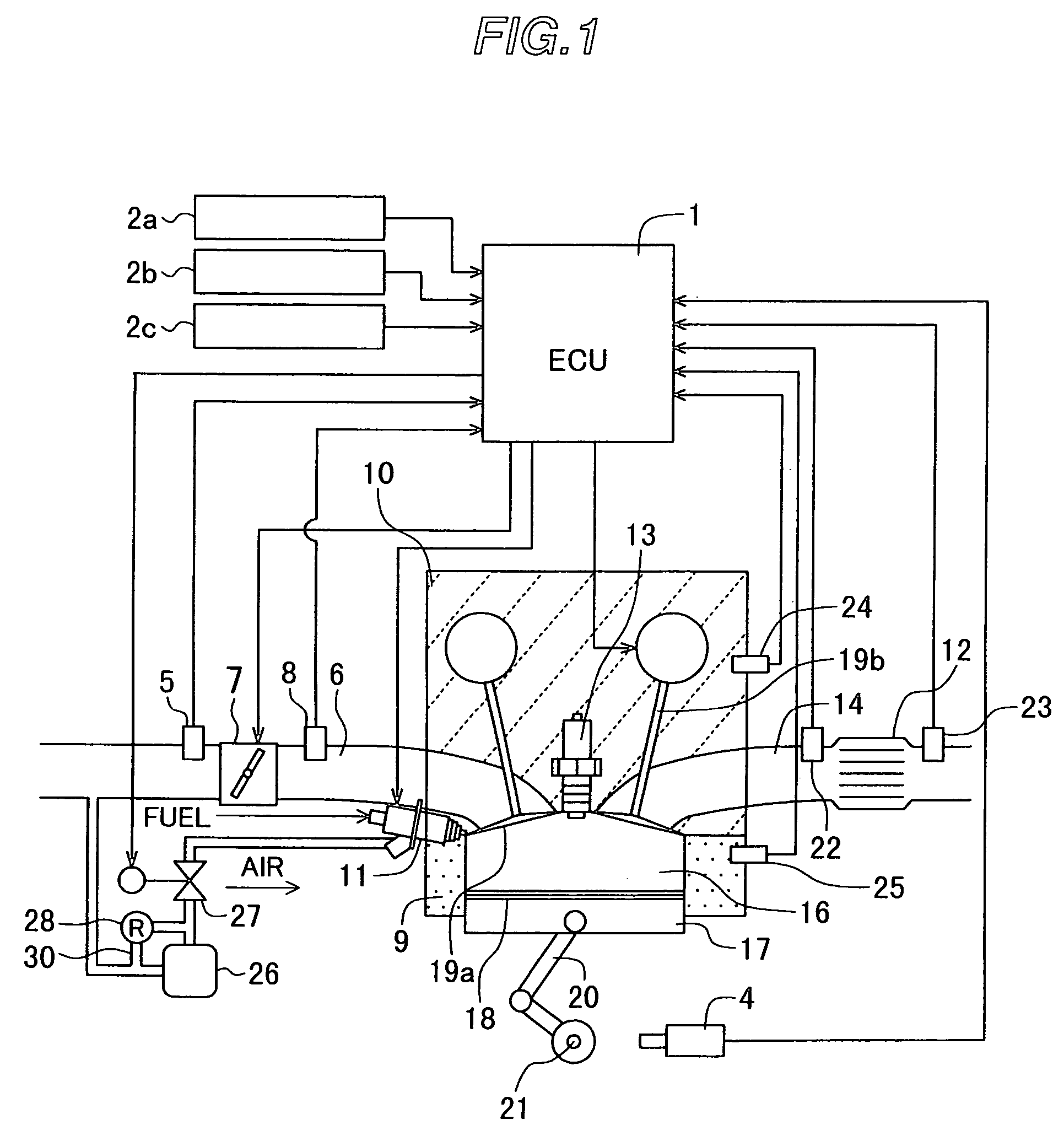

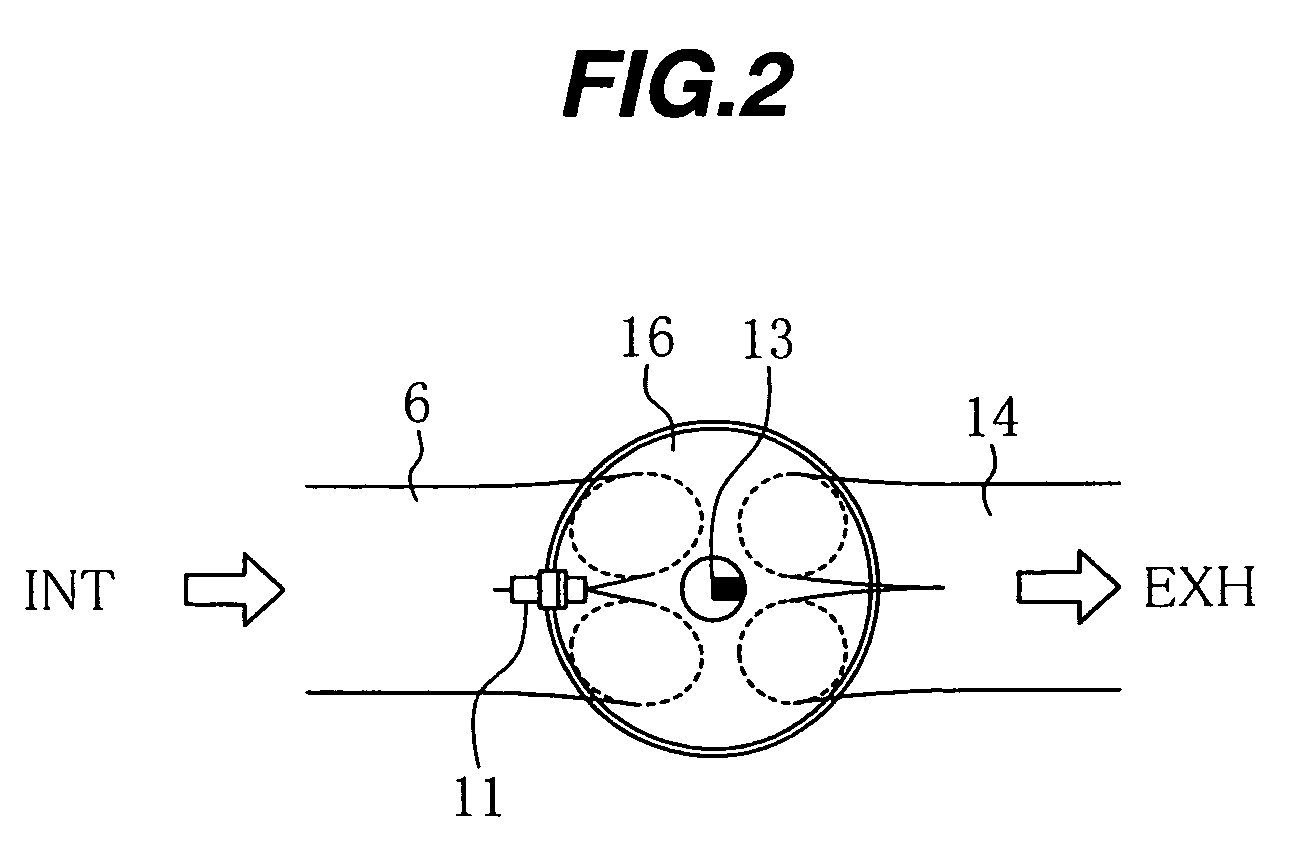

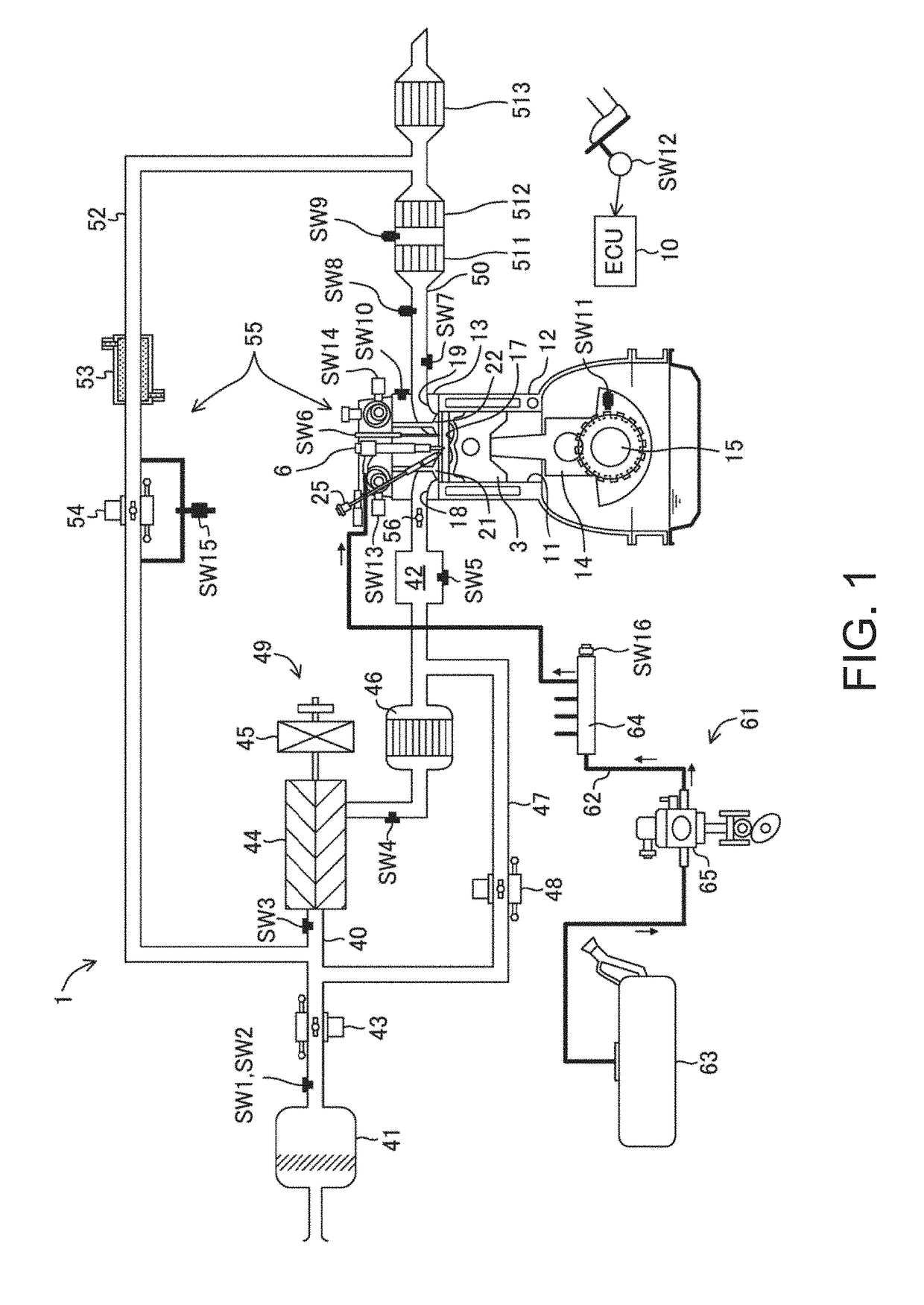

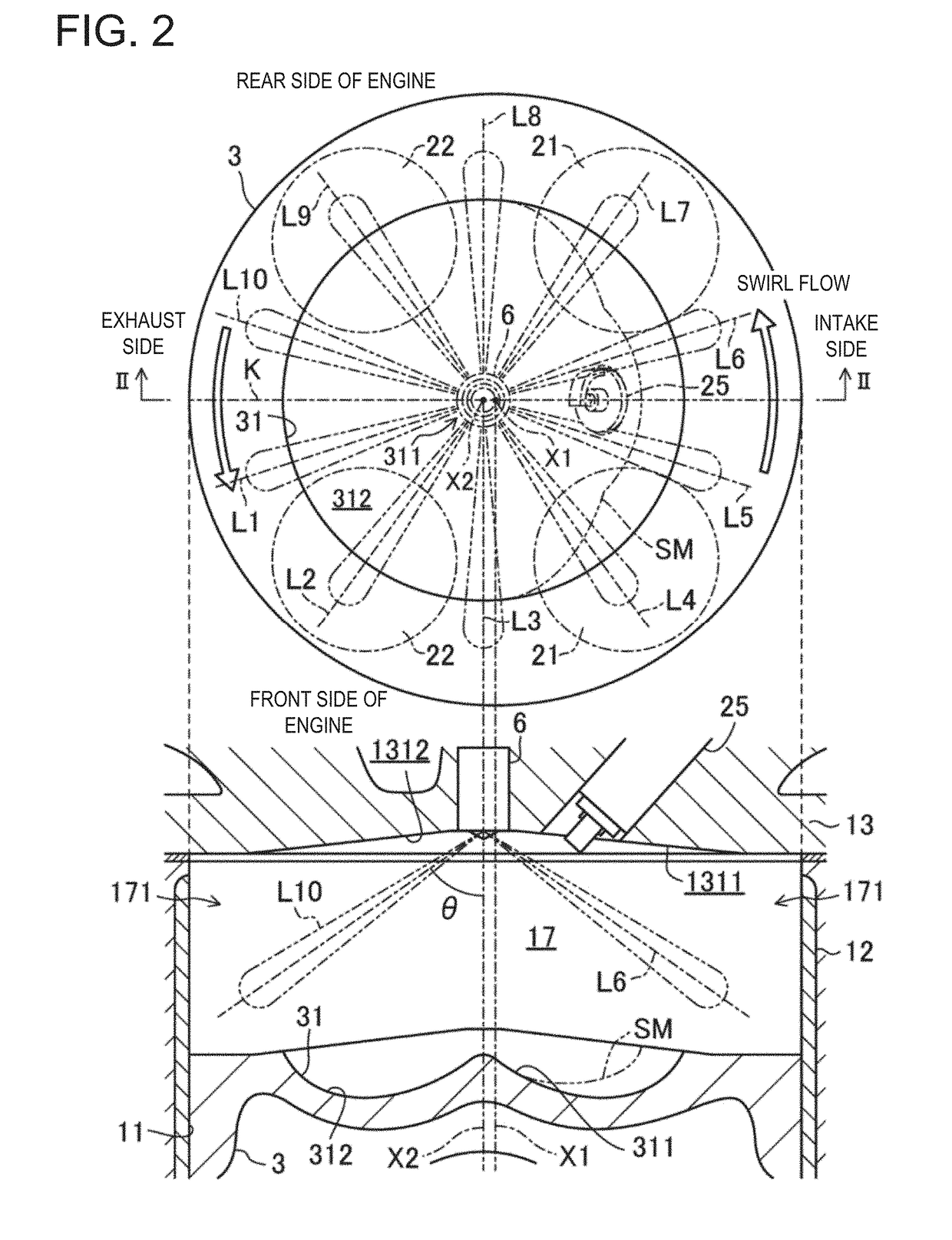

A compression ignition internal combustion engine includes a combustion chamber, an intake valve 19a, intake port 6, and an exhaust valve 19b. The temperature and pressure in the combustion chamber are increased to self-ignite an air-fuel mixture with the compressive operation of a piston after closing of the intake valve 19a. A fuel injection valve 11 injects pressurized air, serving as an ignition trigger factor, directly into the combustion chamber so that the air-fuel mixture under the expansion stroke of the piston is brought into an ignitable state. An ECU 1 controls the injection timing of the pressurized air depending on the ignition timing. The self-ignition timing can be controlled to a proper timing in a wide engine operating range with respect to a load and a revolution speed without changing the shape of the combustion chamber to a large extent.

Owner:HITACHI LTD

Internal combustion engine having an electric solenoid poppet valve and air/fuel injector

InactiveUS8056541B1Increase in sizeInternal combustion piston enginesHigh pressure gas fuel injectionForced-airEngineering

The invention presents new and useful improvements in the mechanical design of control elements of a reciprocating piston engine. The camshaft is replaced by electric magnetic solenoids that operate a single poppet valve for each cylinder. The invention also includes an air injector combined with a fuel injector, mounted through the engine block and into the cylinder. The injectors are located in the lower ⅓ of the piston stroke area of said cylinder. The ability of the air injector to force air into the cylinder while the poppet valve is open will clean the cylinder of all exhaust gases. With the poppet valve closed the air and fuel injectors can inject any amount of air fuel mixture that is desired into the cylinder, resulting in the possibility of a power boost equal to that of a supercharged engine.

Owner:DONICK ENGINES

Split phase fuel conditioner

InactiveUS7367307B2Internal combustion piston enginesHigh pressure gas fuel injectionCombustion chamberControl manner

A split phase fuel conditioner 10 includes a main body 20 defining an ignition chamber 22. A transfer passage 24 is in fluid communication between the ignition chamber 22 and chamber 14. A valve 28 selectively opens and closes a throat 26 of the transfer passage 24 to control fluid communication between chamber 22 and chamber 14. A first injector 30 injects a first fuel volume into ignition chamber 22. A second fuel injector 32 injects a second volume of fuel directly into transfer passage 24 through the first valve 28. The first fuel volume is ignited in the chamber 22 to form an ignition plasma. Valve 28 is opened allowing the ignition plasma to condition the second fuel volume by vaporising the second fuel volume. The ignition plasma then sweeps the conditioned second fuel volume into the combustion chamber where it combusts in a controlled manner.

Owner:BARRACK COMBUSTION PROCESS

High pressure common rail fuel system with gas injection

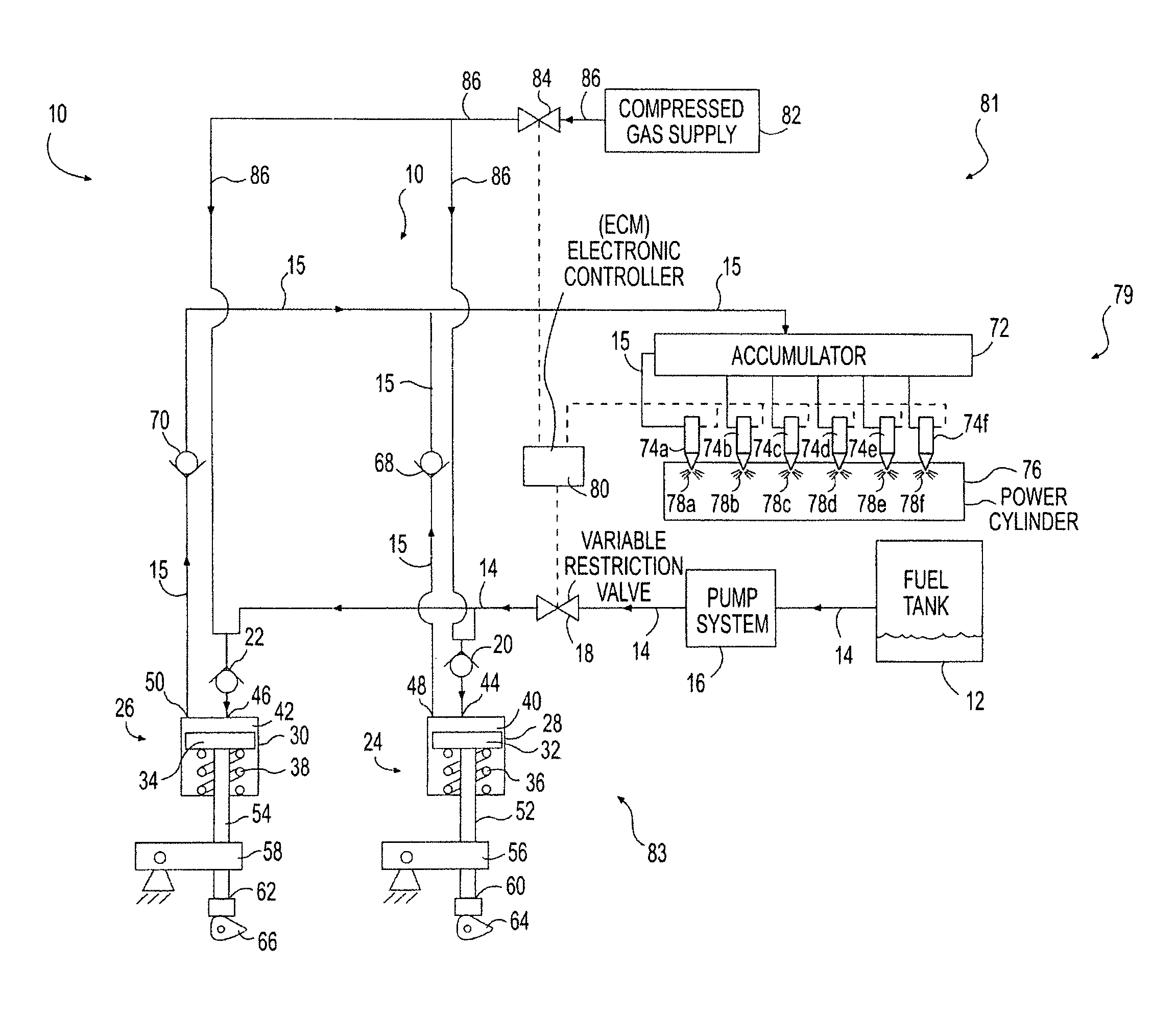

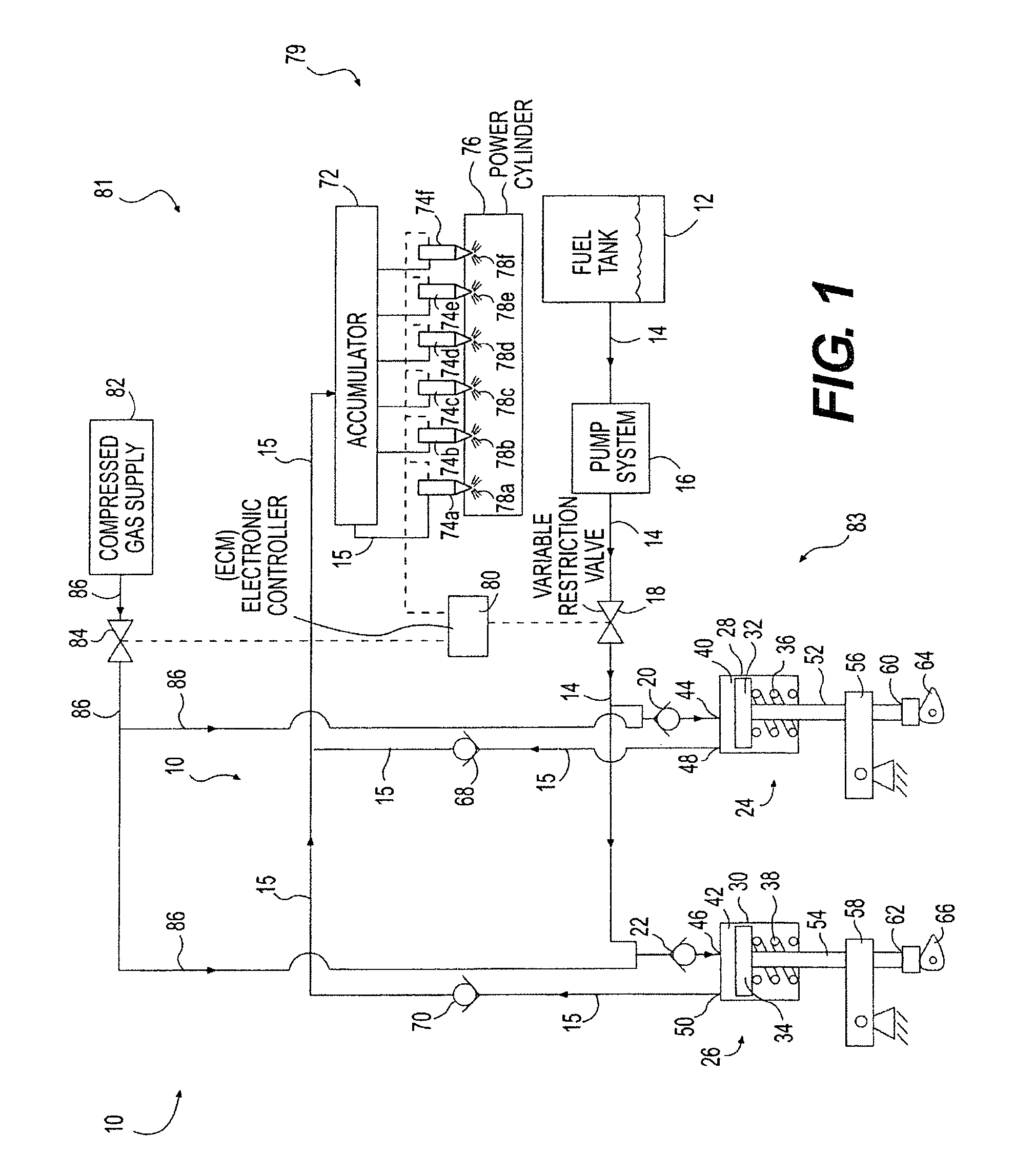

ActiveUS7950370B2Reduce cavitationInternal combustion piston enginesFuel supply apparatusCommon railGas supply

A high pressure common rail fuel system is provided including a fuel supply, a high pressure pump assembly fluidly connected to receive fuel from the fuel supply, and a gas supply system fluidly connected to provide gas to the high pressure pump assembly to create a high pressure gas fuel mixture. A common rail fuel system is fluidly connected to the high pressure pump assembly to receive the high pressure gas fuel mixture.

Owner:CUMMINS INC

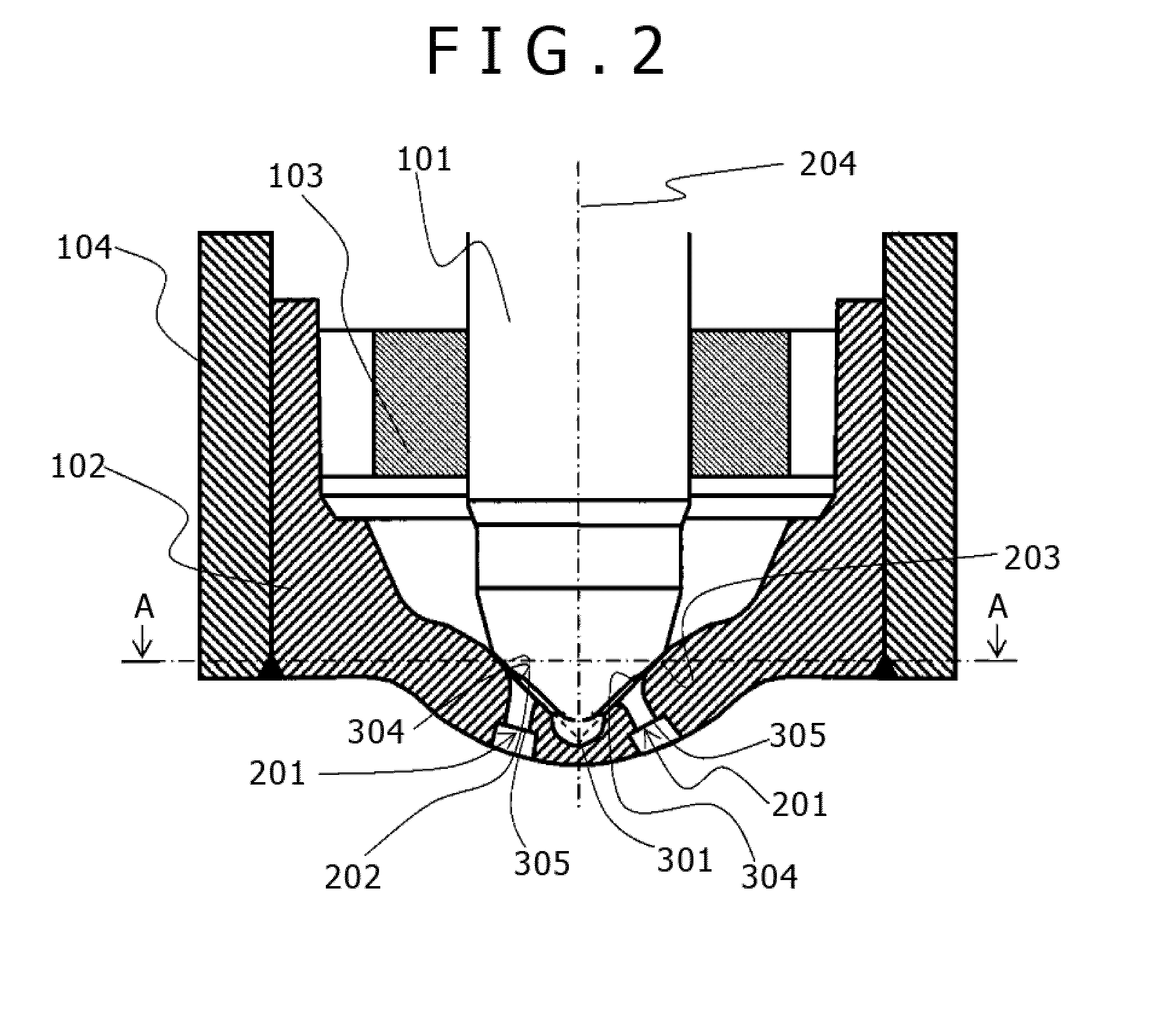

Spark-ignition direct fuel injection valve

ActiveUS20150047611A1High pressure gas fuel injectionLow pressure fuel injectionEngineeringVALVE PORT

A spark-ignition direct fuel injection valve includes, at least, a seat member provided with a fuel injection hole and a valve seat and a valve body which controls fuel injection from the injection hole by contacting and separating from the valve seat. In the spark-ignition direct fuel injection valve: the injection hole has an injection hole inlet which is open inwardly of the seat member and an injection hole outlet which is open outwardly of the seat member; an opening edge of the injection hole inlet has a first round-chamfered portion formed on an upstream side with respect to a fuel flow toward the injection hole inlet; and an extending length (L) of the injection hole does not exceed three times a hole diameter (D) of the injection hole.

Owner:HITACHI ASTEMO LTD

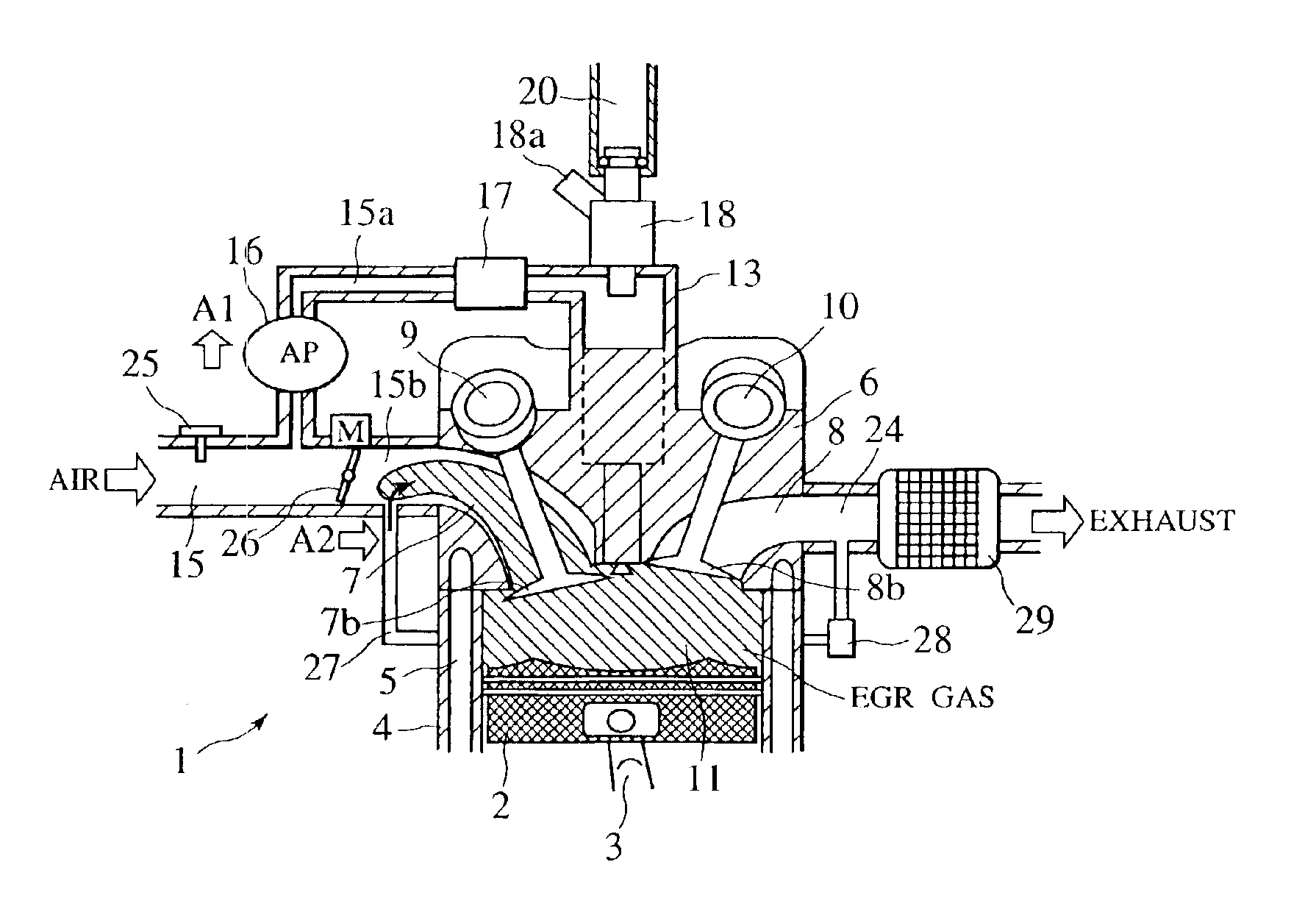

Internal combustion engines and control

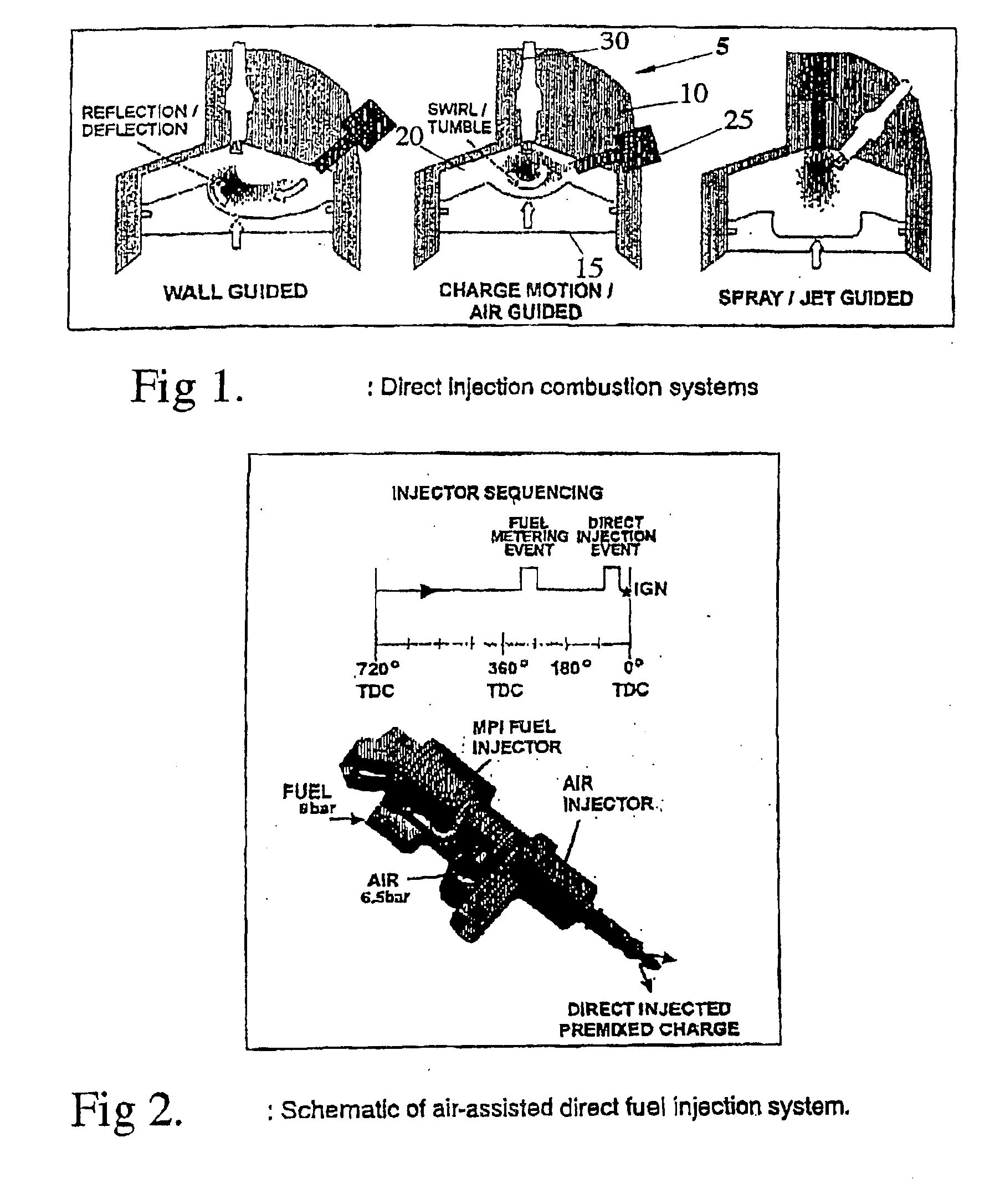

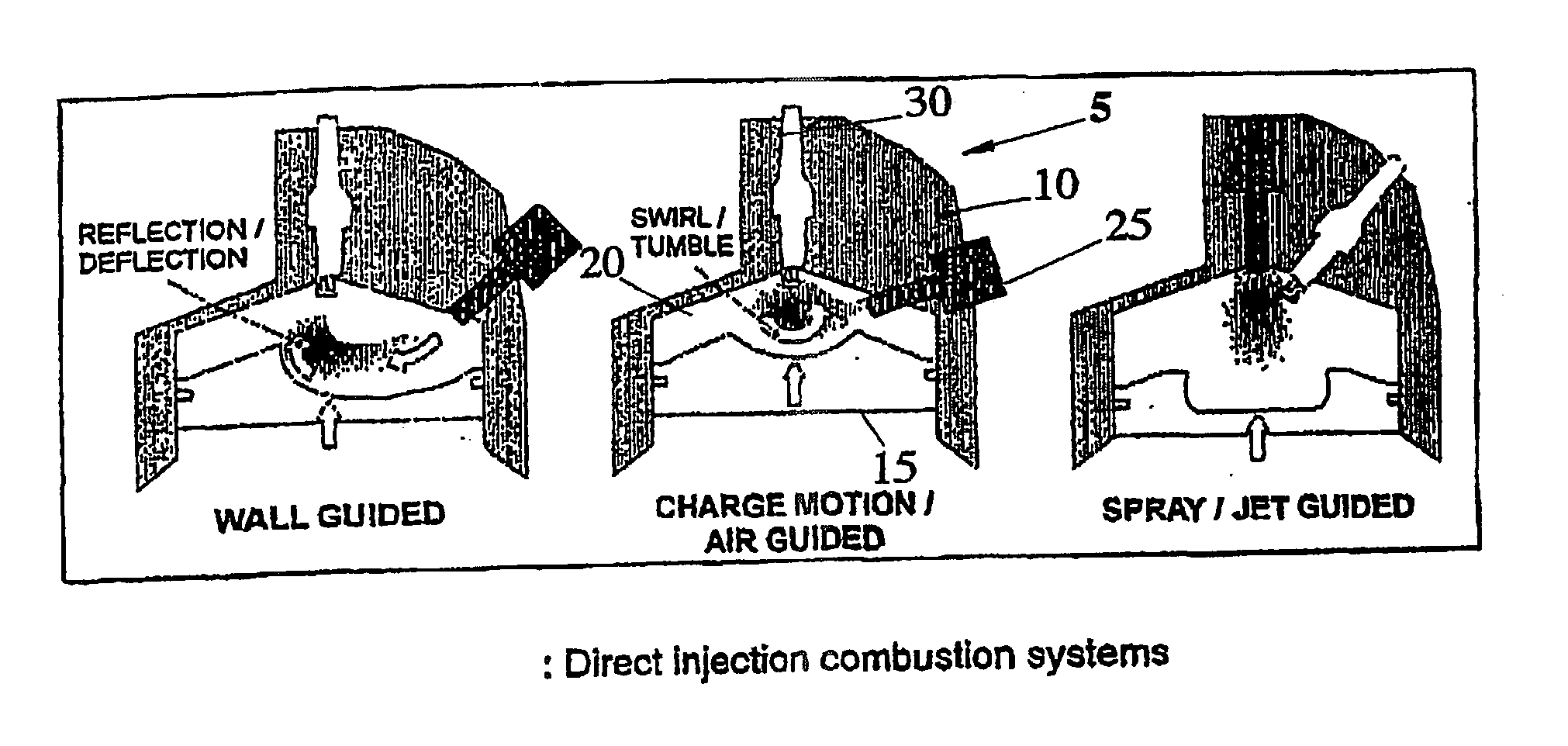

InactiveUS6854440B2Reduce decreaseReduce over-enleanmentInternal combustion piston enginesHigh pressure gas fuel injectionExternal combustion engineInternal combustion engine

Disclosed is an internal combustion engine comprising at least one cylinder with a reciprocating piston to provide said engine with at least one combustion chamber, said combustion chamber further comprising a delivery injector for injecting fuel directly into said combustion chamber, said engine further comprising at least one valved inlet air duct for delivering combustion air into said combustion chamber, wherein at least said inlet air duct and / or its valve is arranged to provide a low tumble inlet port to said at least one combustion chamber, said combustion chamber, in use, having low in-cylinder tumble gas motion of said combustion air and wherein said low in-cylinder tumble gas motion of said combustion air reduces over-enleanment of fuel in end gas regions of said combustion chamber.

Owner:ORBITAL ENGINE CO PTY LTD

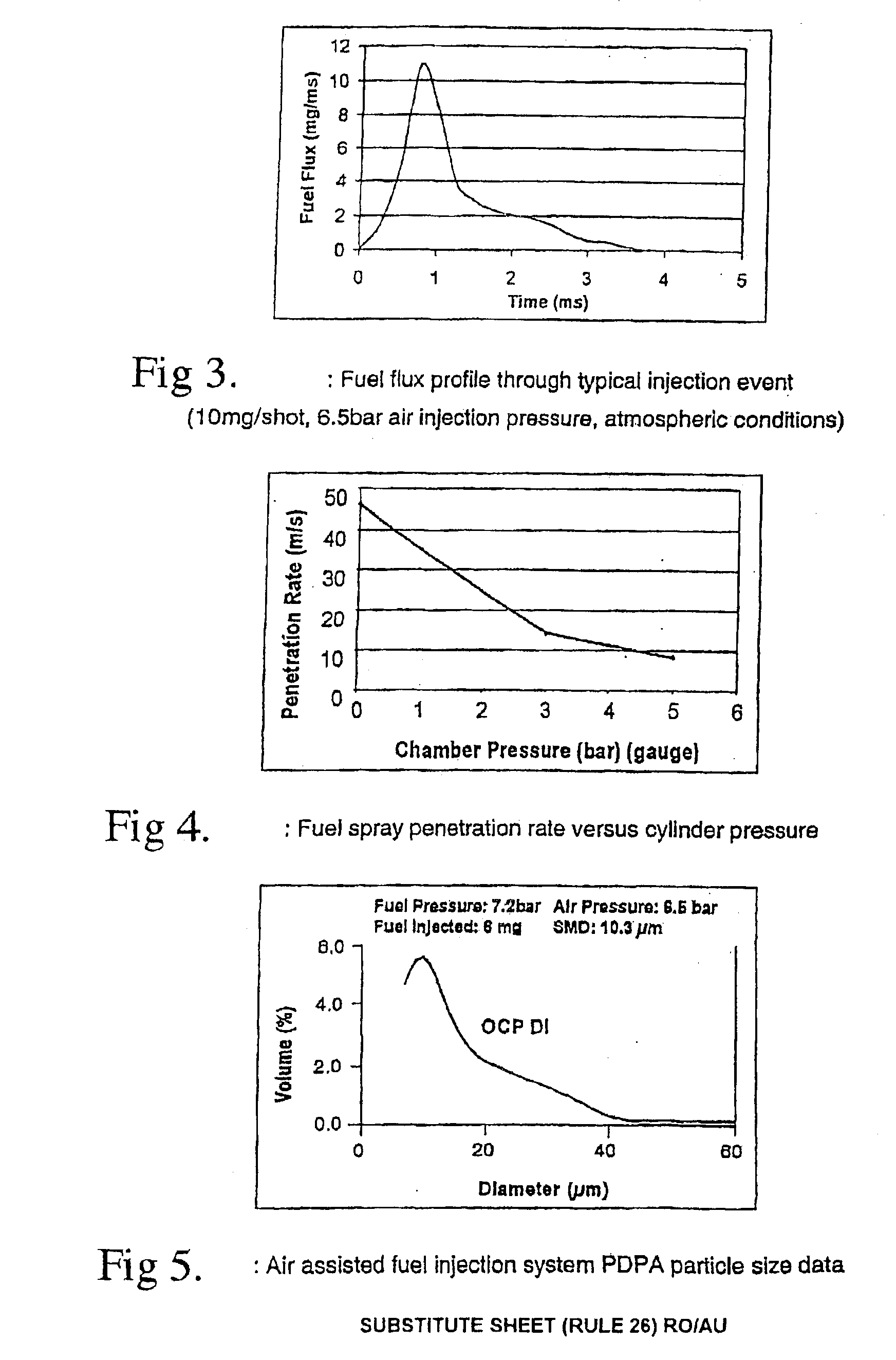

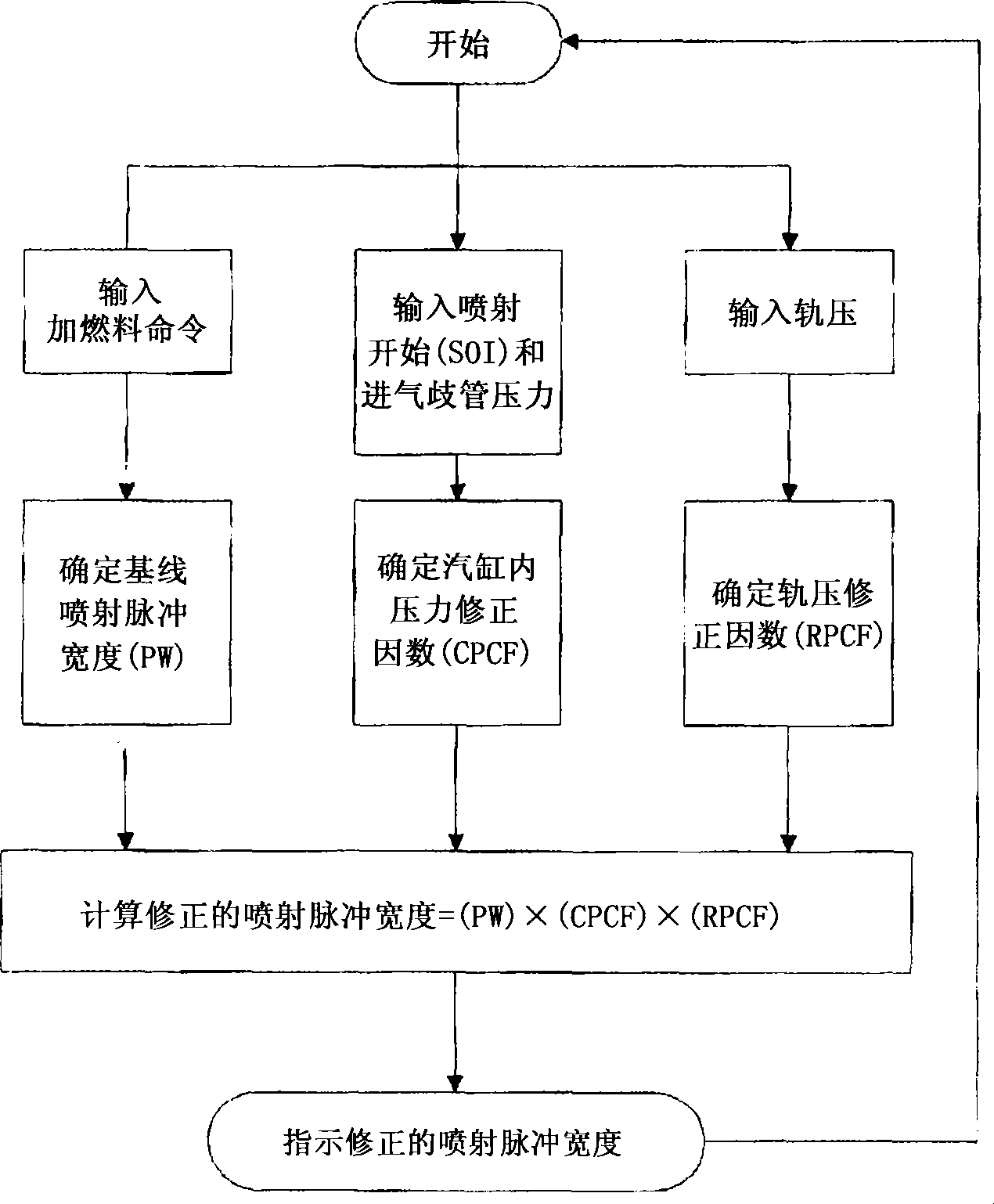

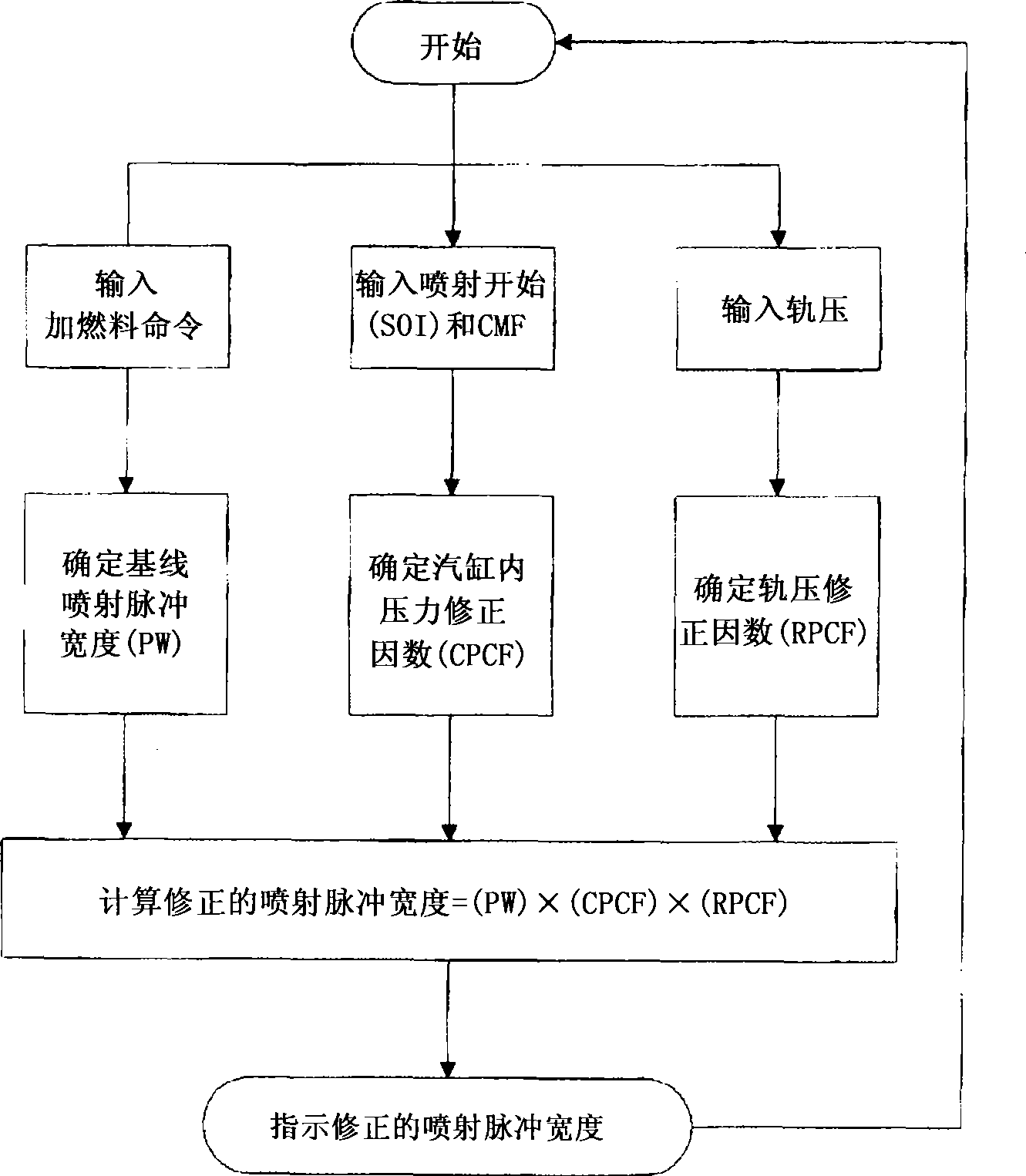

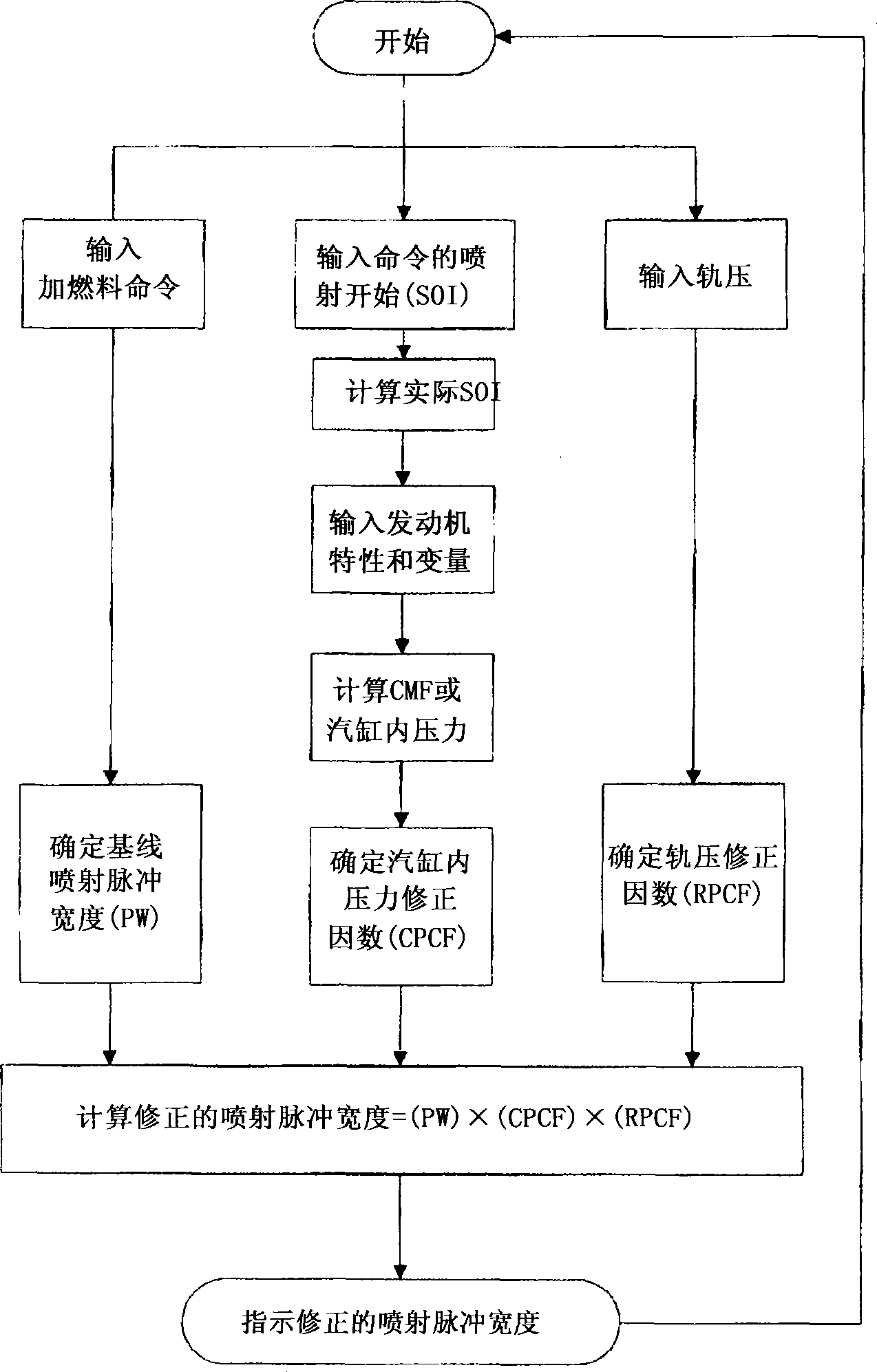

Method of accurately metering a gaseous fuel that is injected directly into a combustion chamber of an internal combustion engine

InactiveCN101400887AElectrical controlInternal combustion piston enginesCombustion chamberProduct gas

For gaseous fuels that are injected directly into a combustion chamber the mass flow rate through an injection valve can be influenced by changes in the in-cylinder pressure. A method and apparatus are provided for accurately metering a gaseous into a combustion chamber of an internal combustion engine. The method comprises inputting a fueling command; determining from said fueling command a baseline pulse width of an injection event, based upon a baseline pressure differential across a fuel injection valve; estimating the difference between said baseline pressure differential and an actual pressure differential; calculating a corrected pulse width by applying at least one correction factor to said baseline pulse width, wherein said correction factor is a function of the estimated difference between said baseline pressure differential and said actual pressure differential.

Owner:WESTPORT POWER

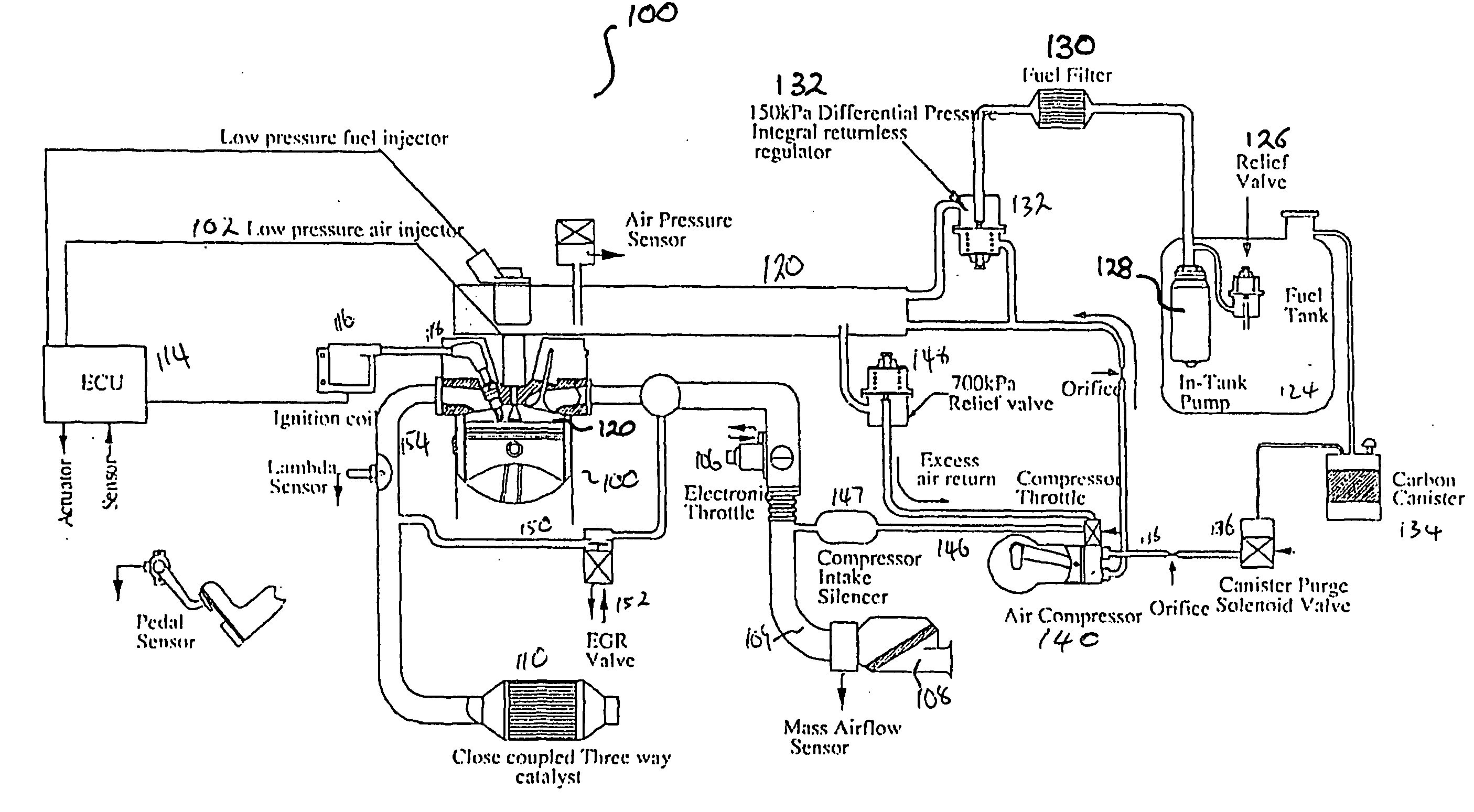

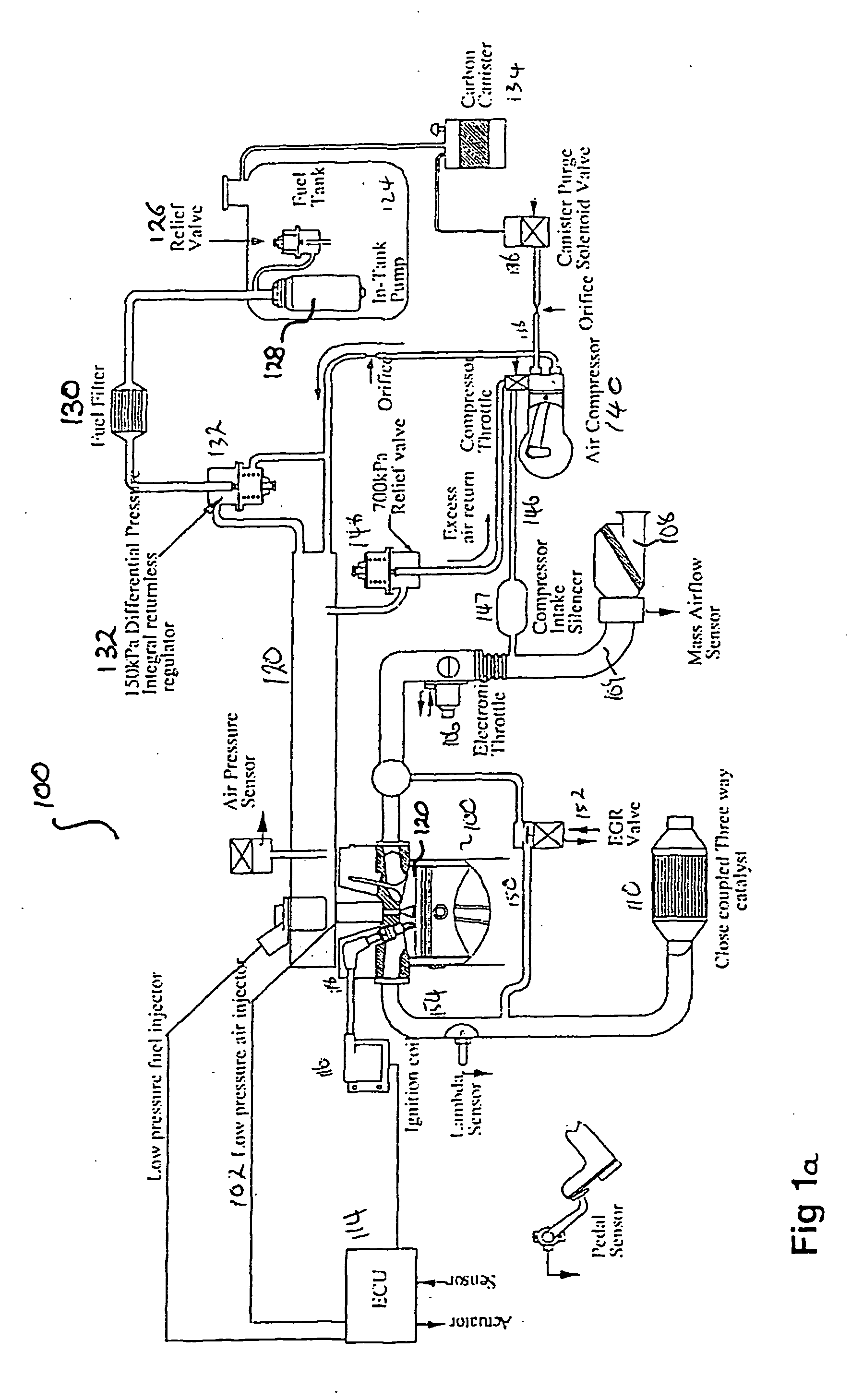

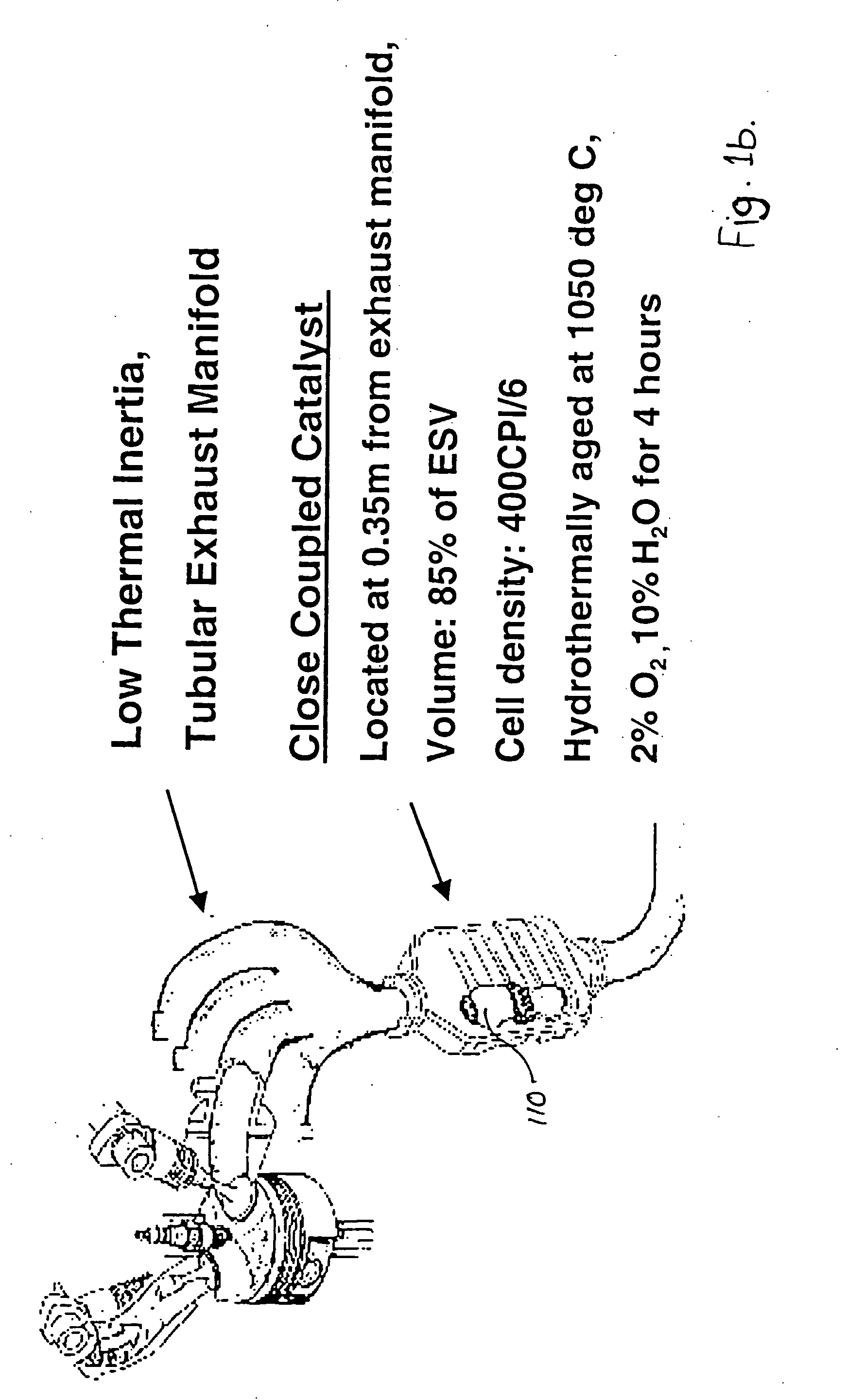

Low emission vehicle

InactiveUS20040244368A1Satisfies requirementElectrical controlInternal combustion piston enginesAfter treatmentExternal combustion engine

A low emission vehicle operates an internal combustion engine with lean air fuel ratios over at least a portion of its operating load range. The vehicle satisfies EURO IV emission requirements with just a three way catalyst and without any NOX storage capability in the exhaust after treatment system. An electronic control unit is programmed to operate the engine such that 80% or less of any tail pipe NOX mass emitted by the vehicle is generated during lean operation of the engine whereby the vehicle satisfies the EURO IV emission requirements.

Owner:ORBITAL ENGINE CO PTY LTD

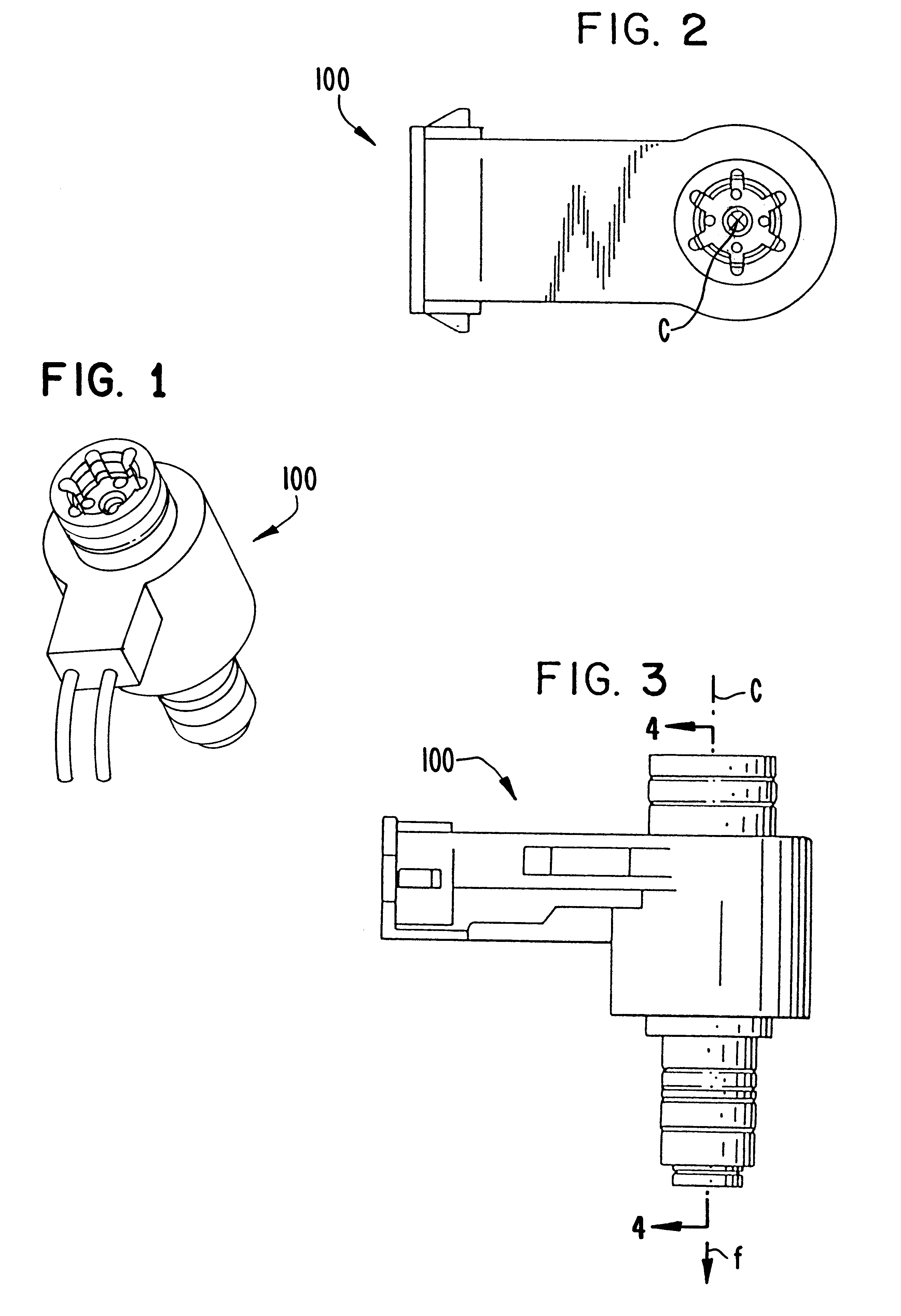

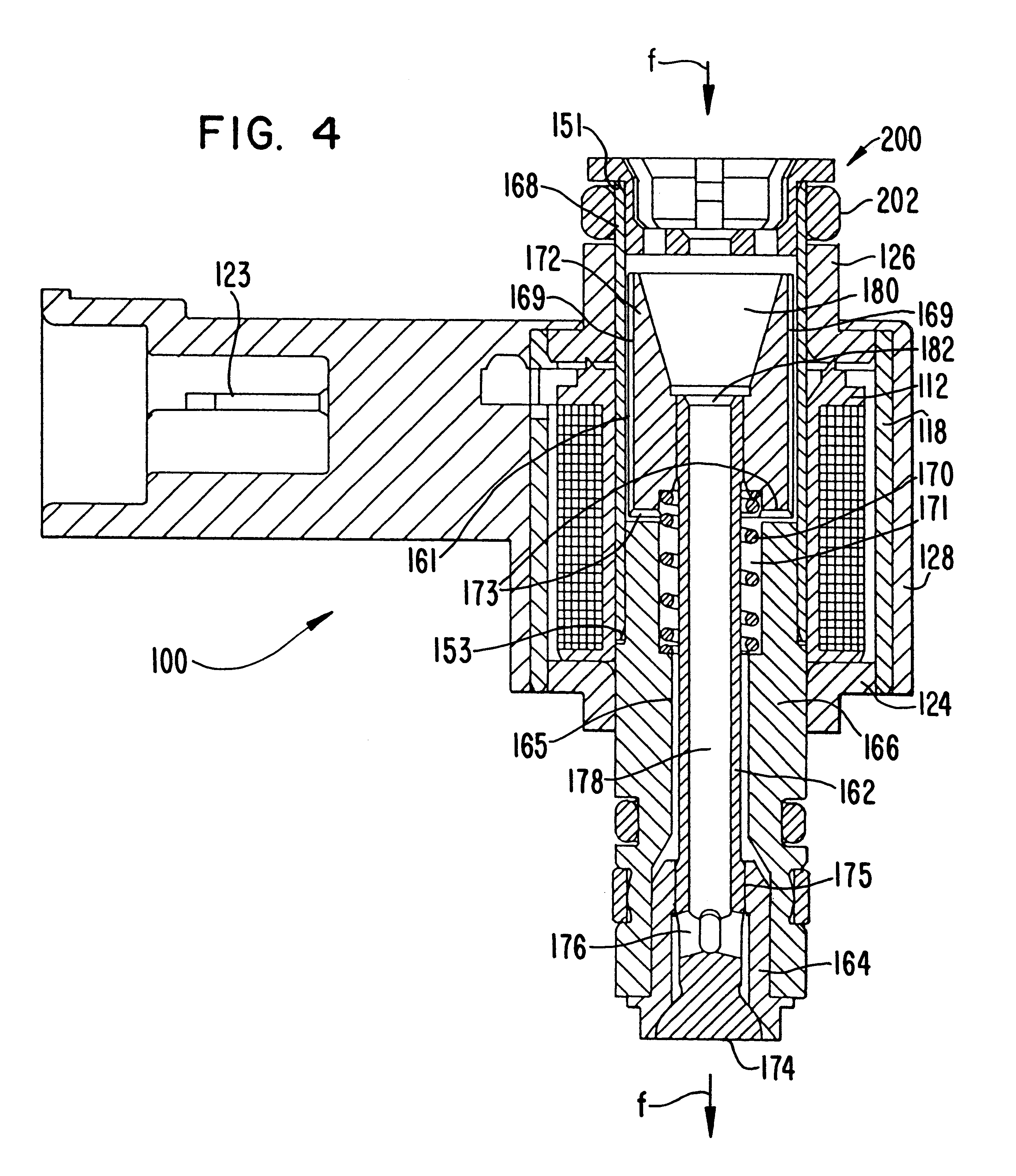

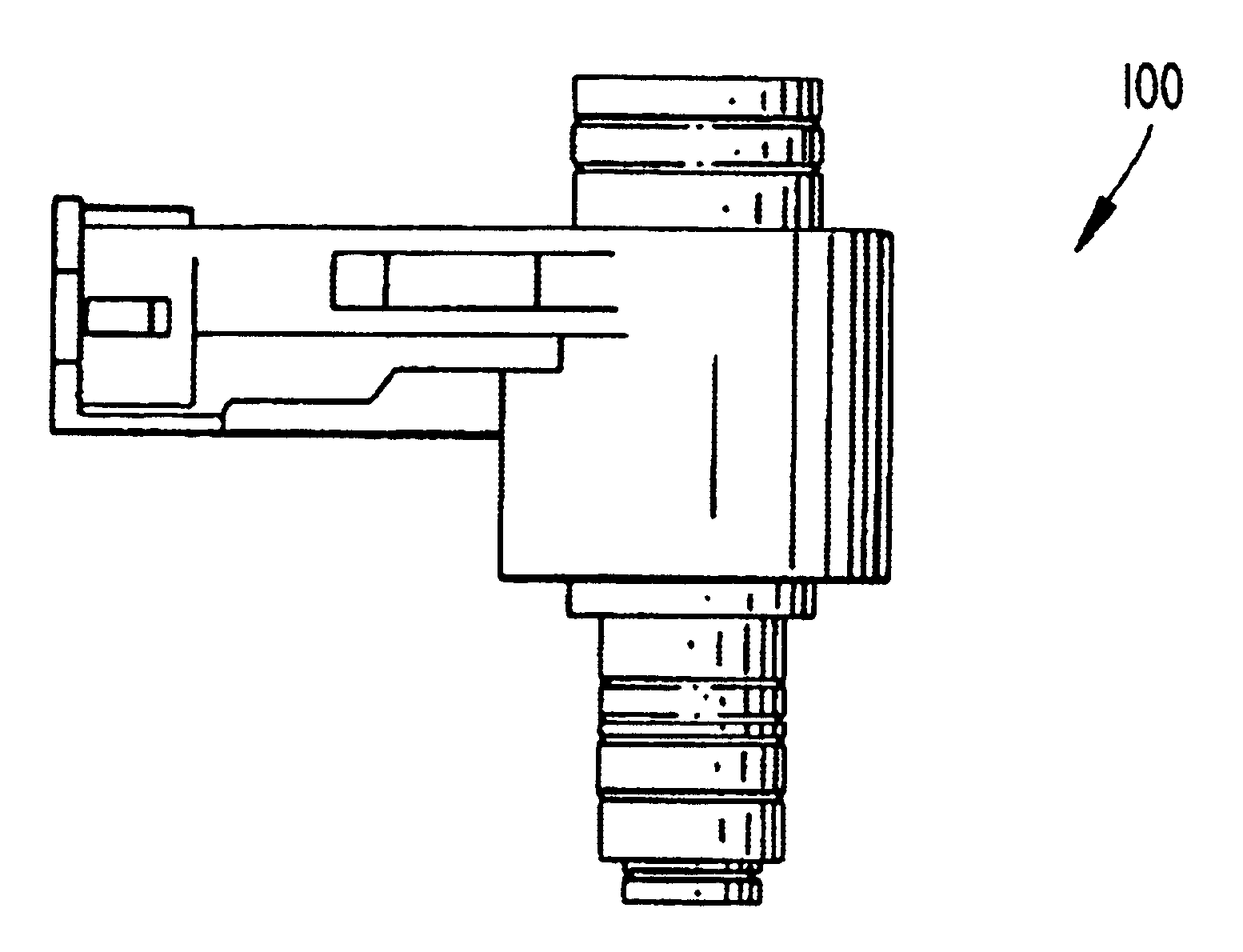

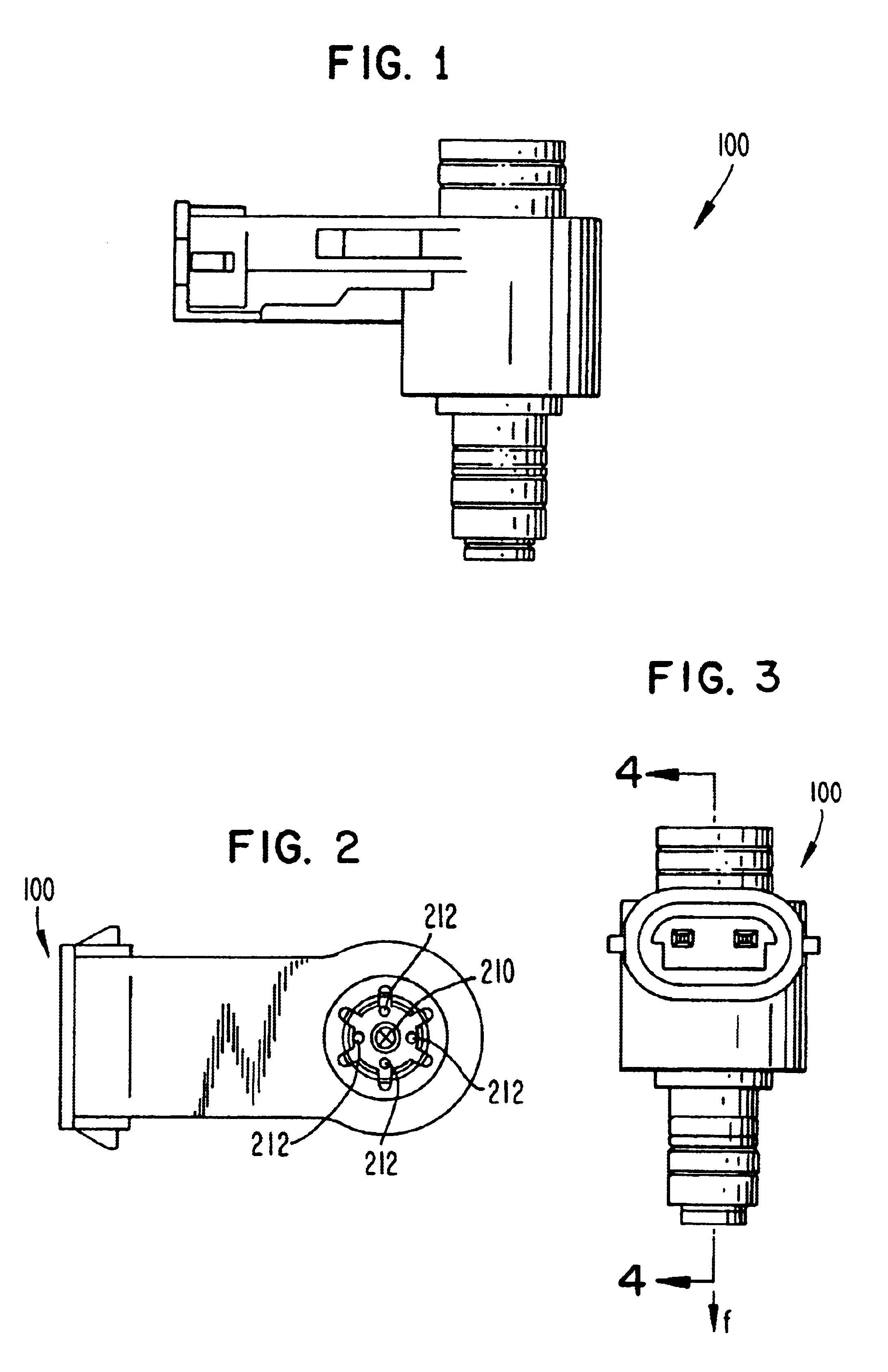

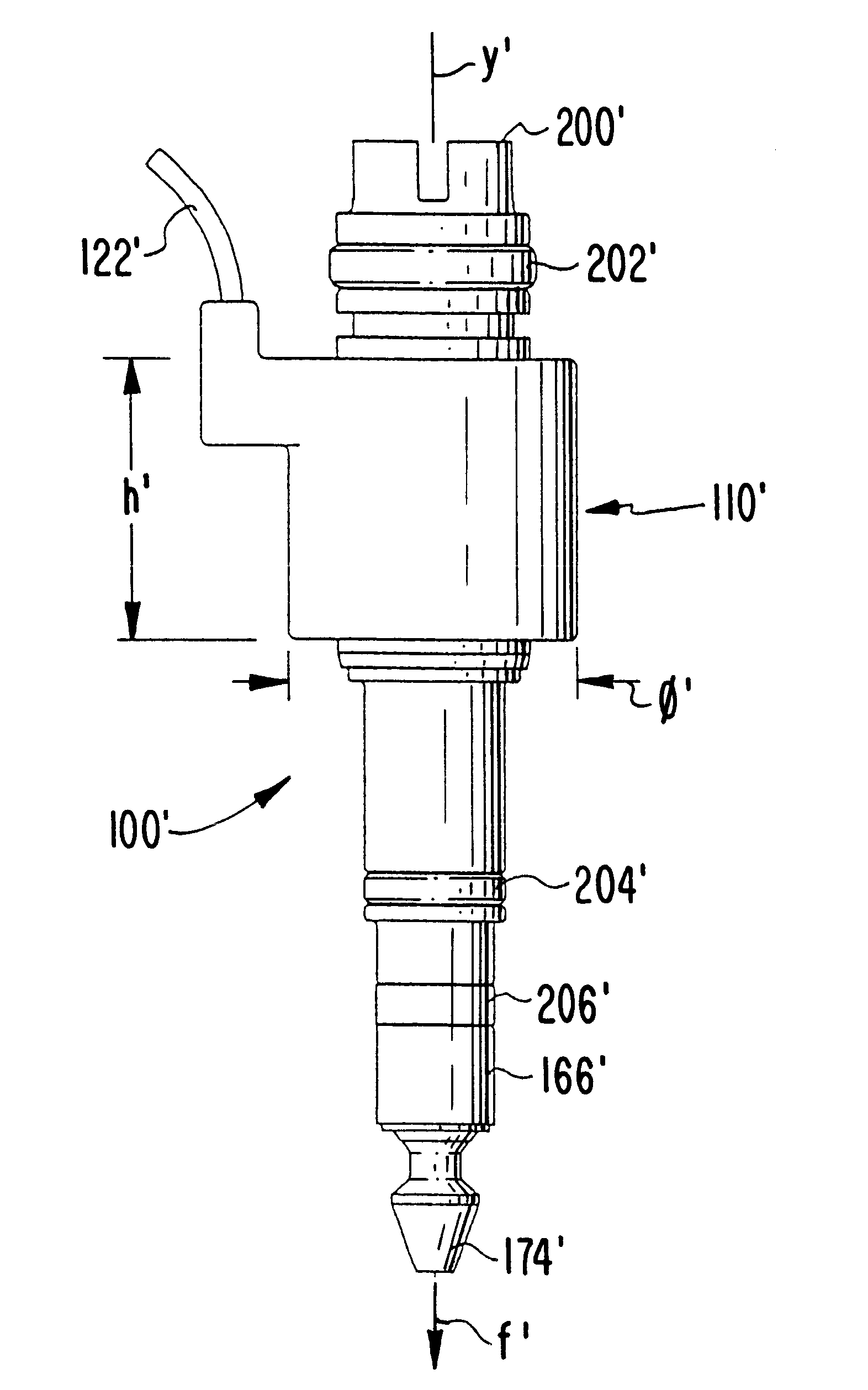

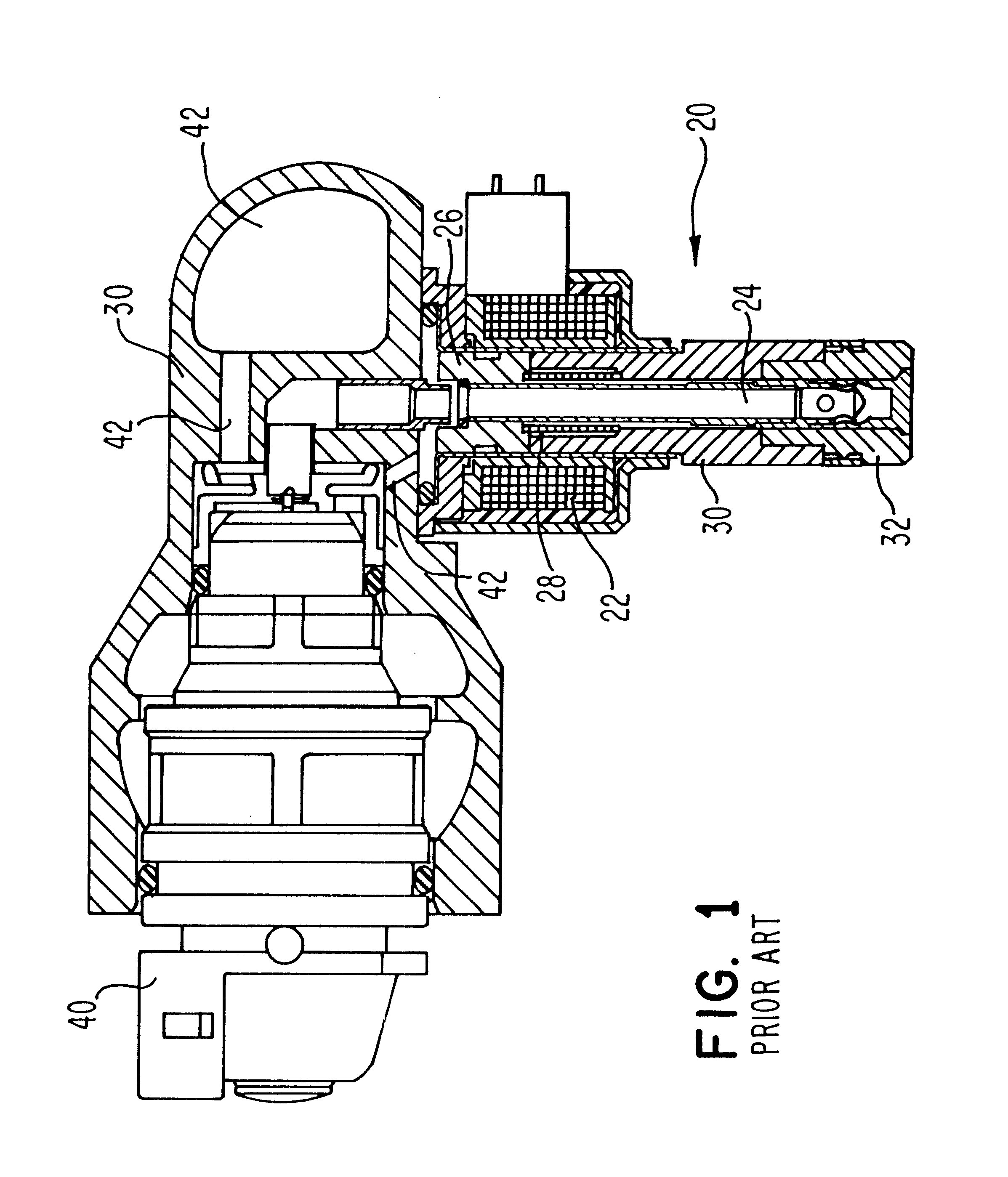

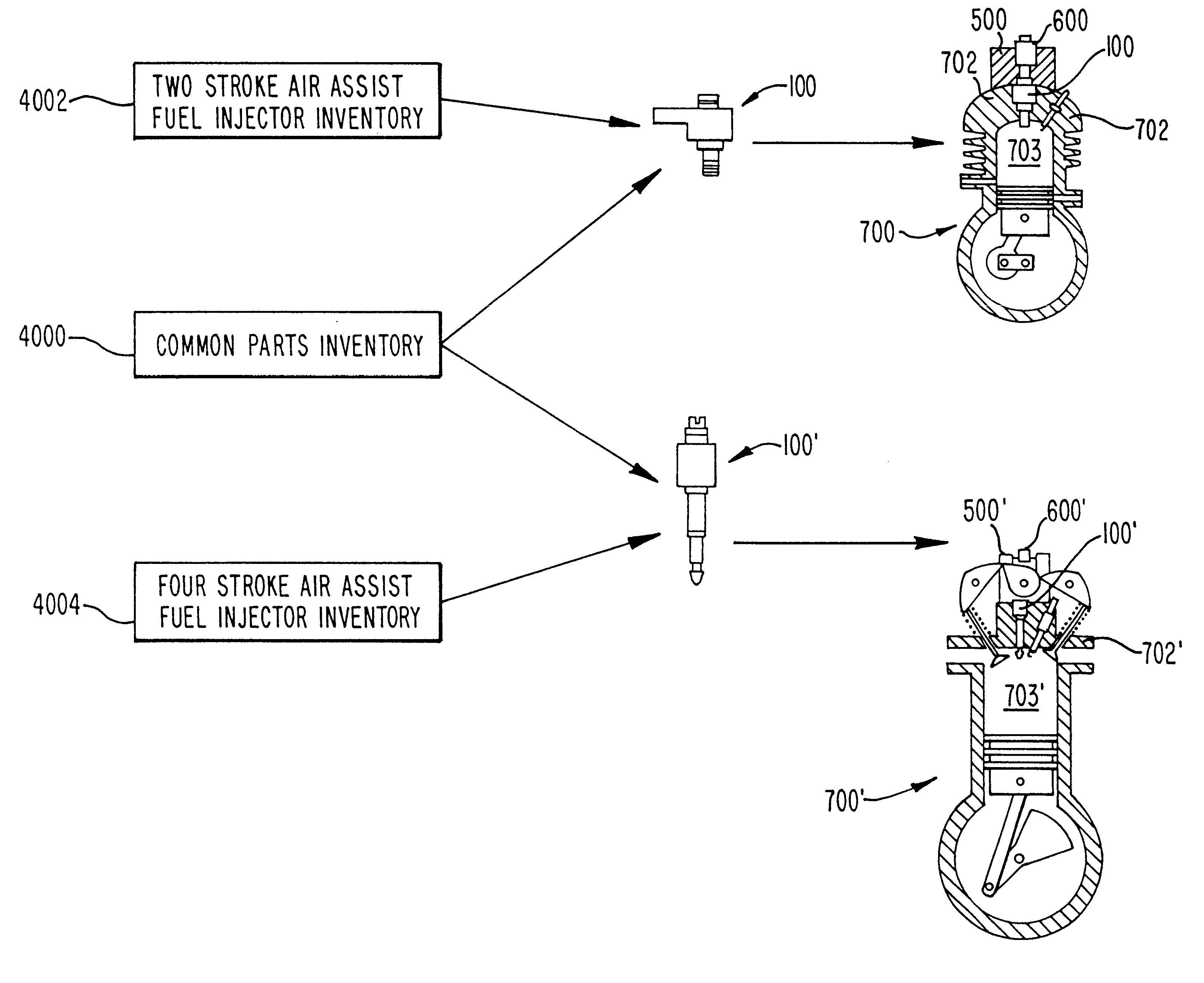

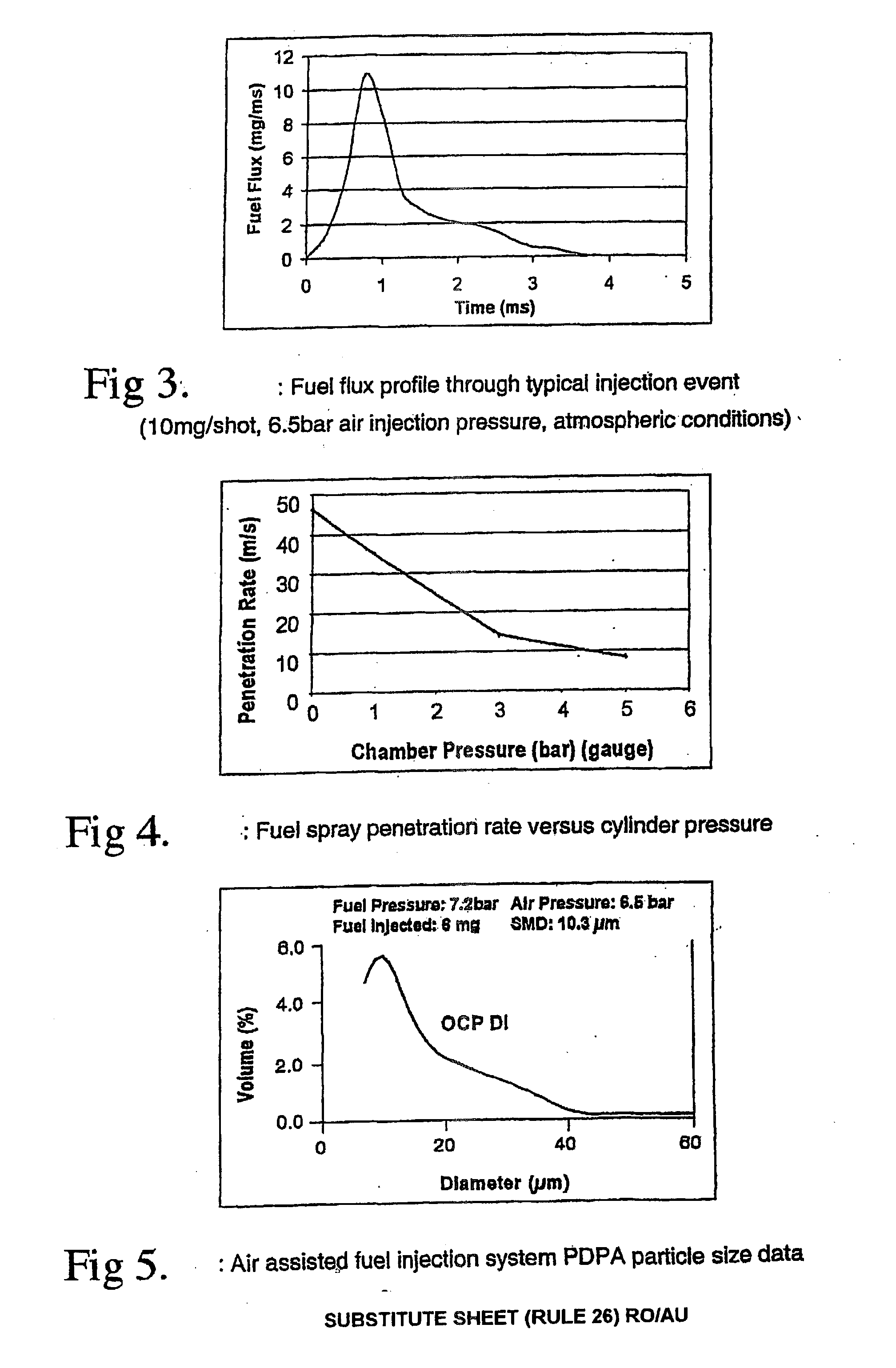

Air assist fuel injectors and method of assembling air assist fuel injectors

InactiveUS6402057B1High pressure gas fuel injectionSpray nozzlesFour-stroke engineElectromagnetic coil

A first air assist fuel injector configured for operation with a two stroke engine and a second air assist fuel injector configured for operation with a four stroke engine. The first air assist fuel injector and the second air assist fuel injector share one or more common items, such as a solenoid coil assembly and / or an armature, even though the air assist fuel injectors are configured for different applications.

Owner:SYNERJECT

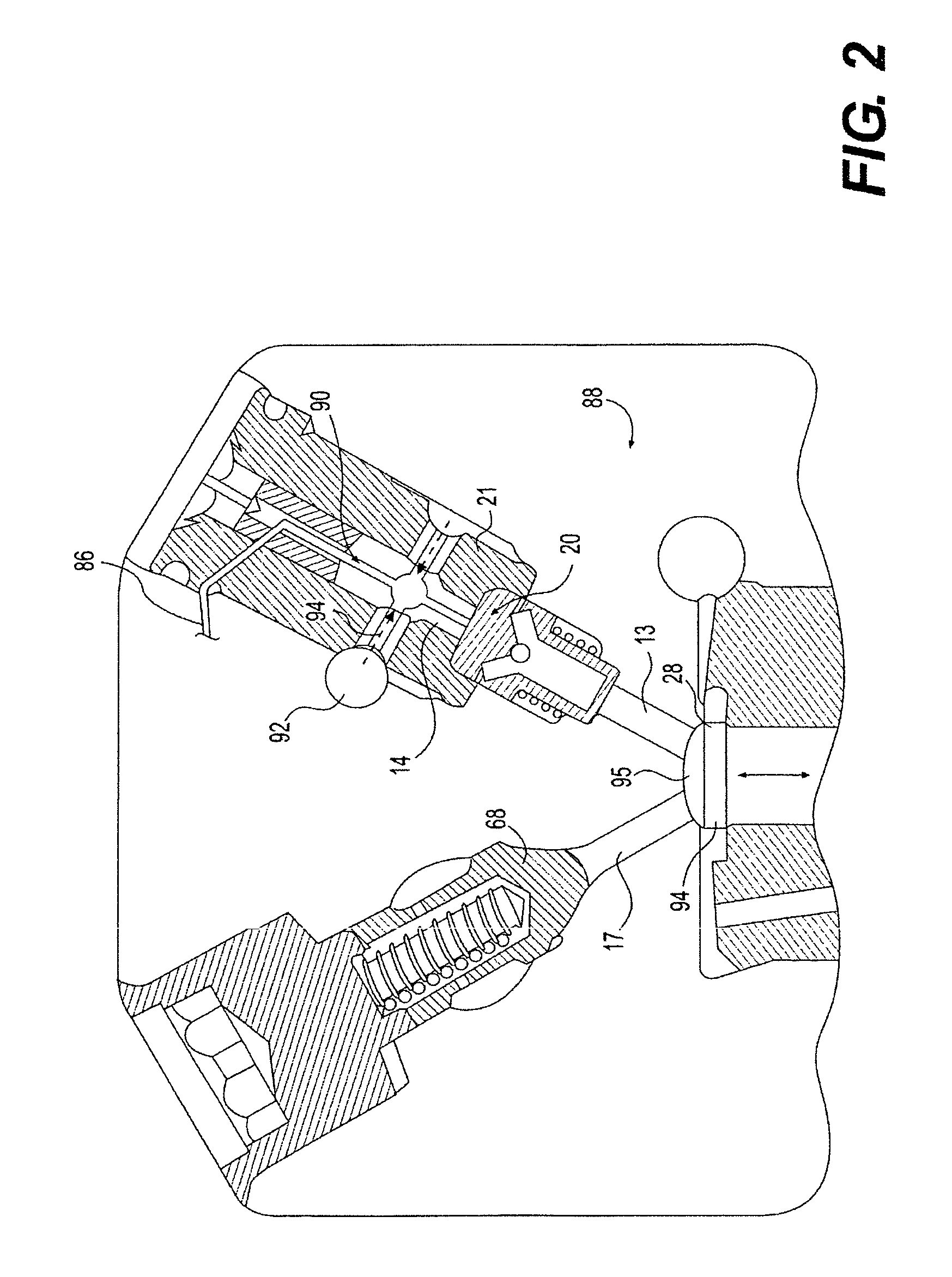

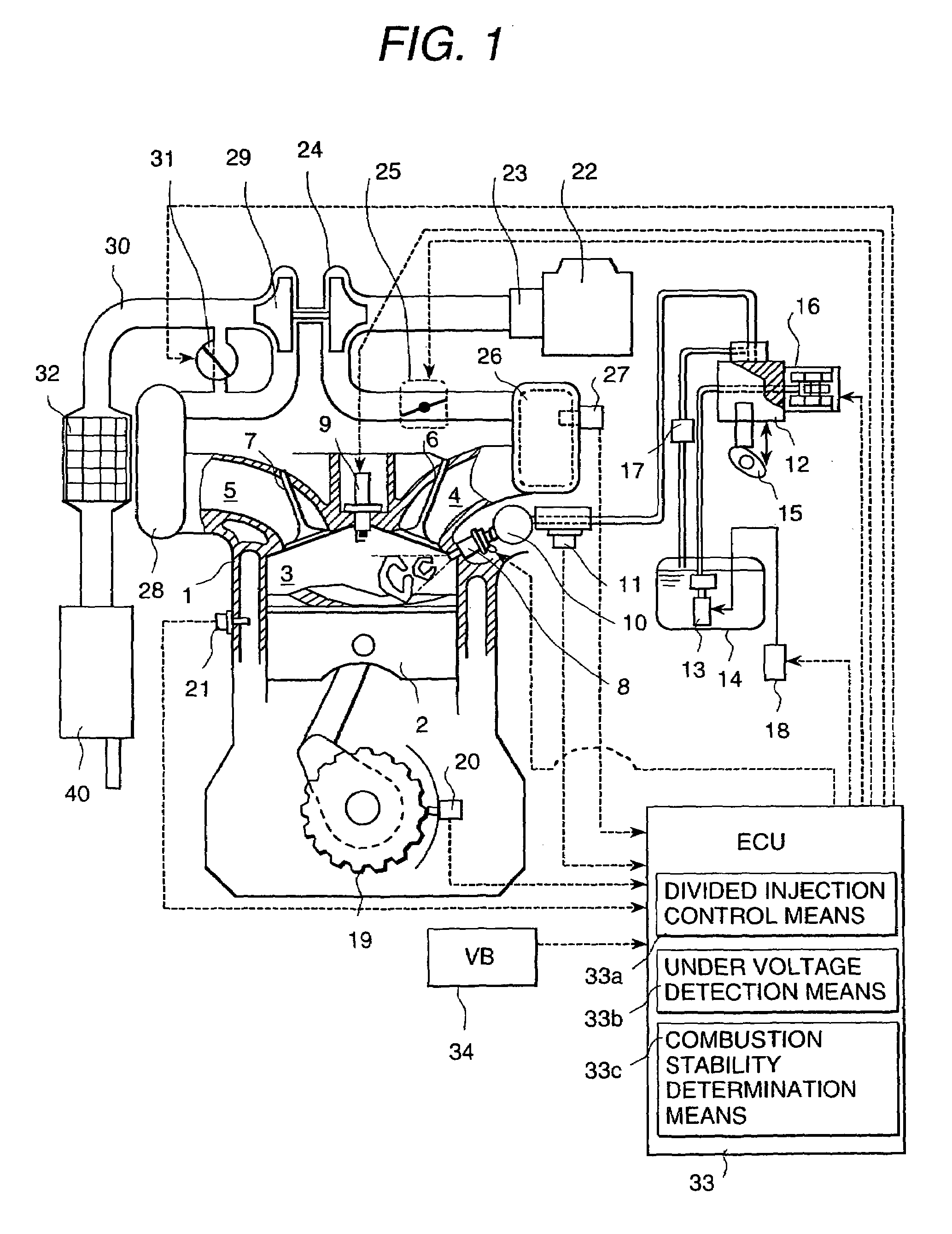

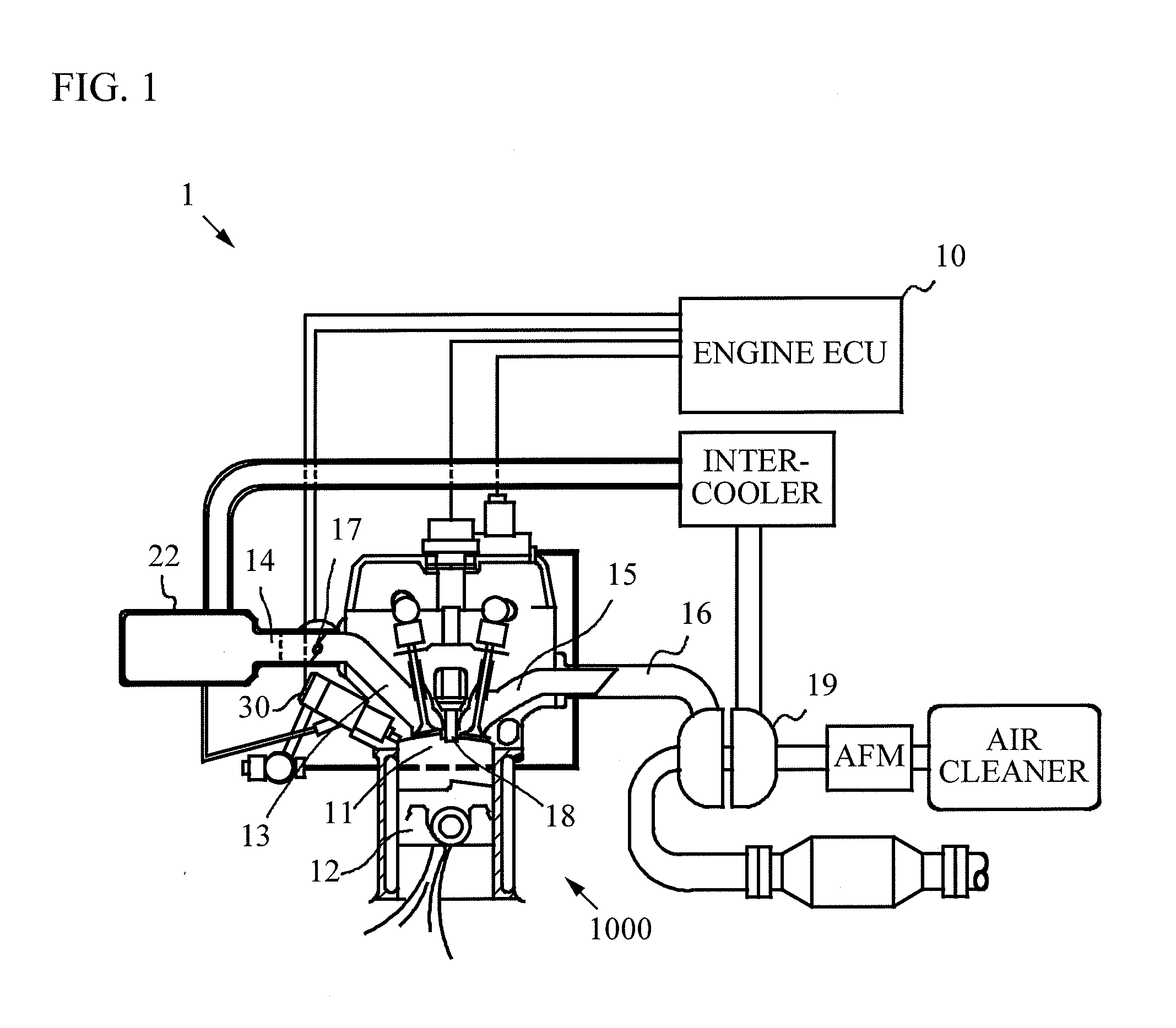

Fuel injection control devices for internal combustion engines

InactiveUS6920861B2Improve engine performanceElectrical controlHigh pressure gas fuel injectionExternal combustion engineInternal combustion engine

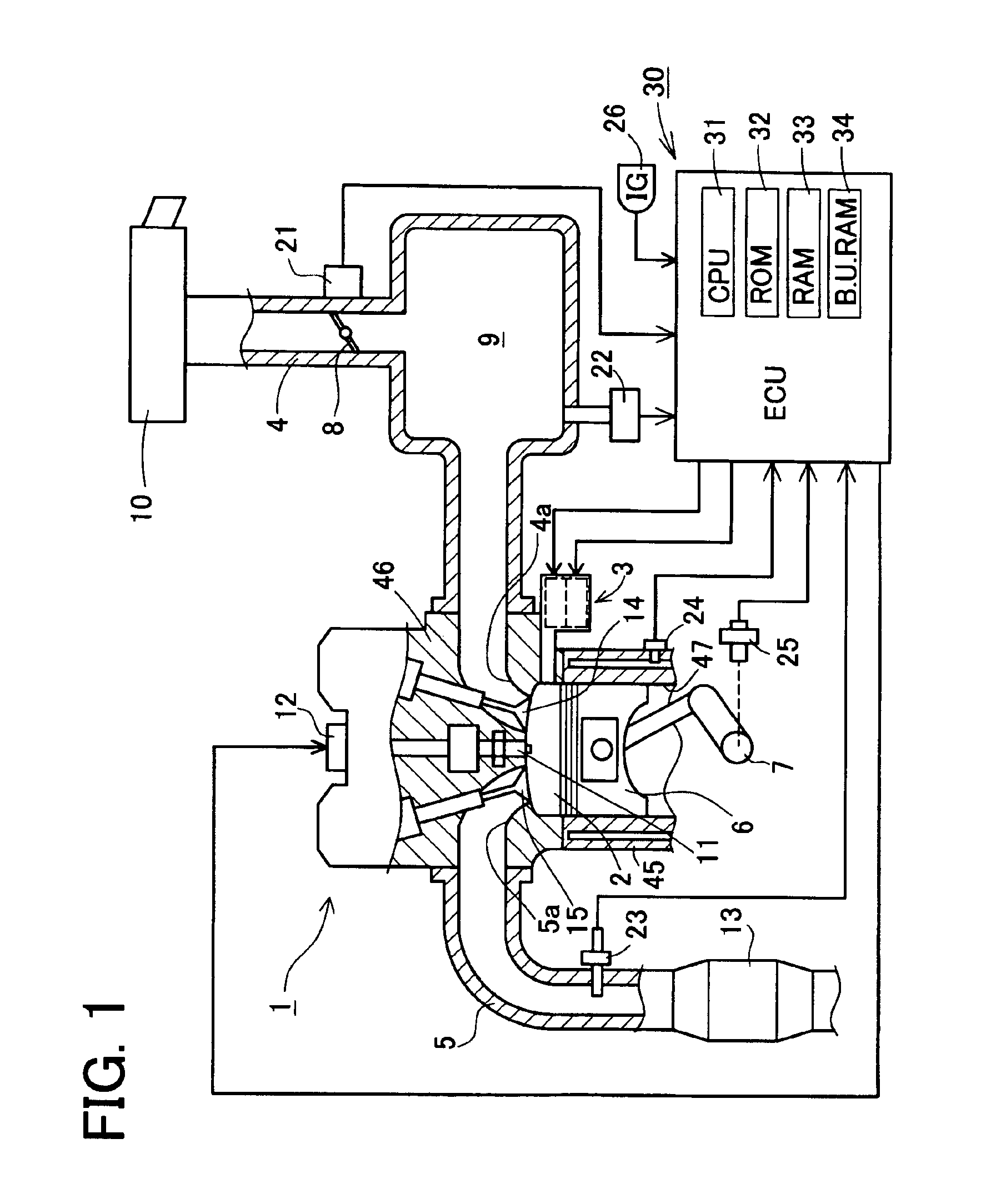

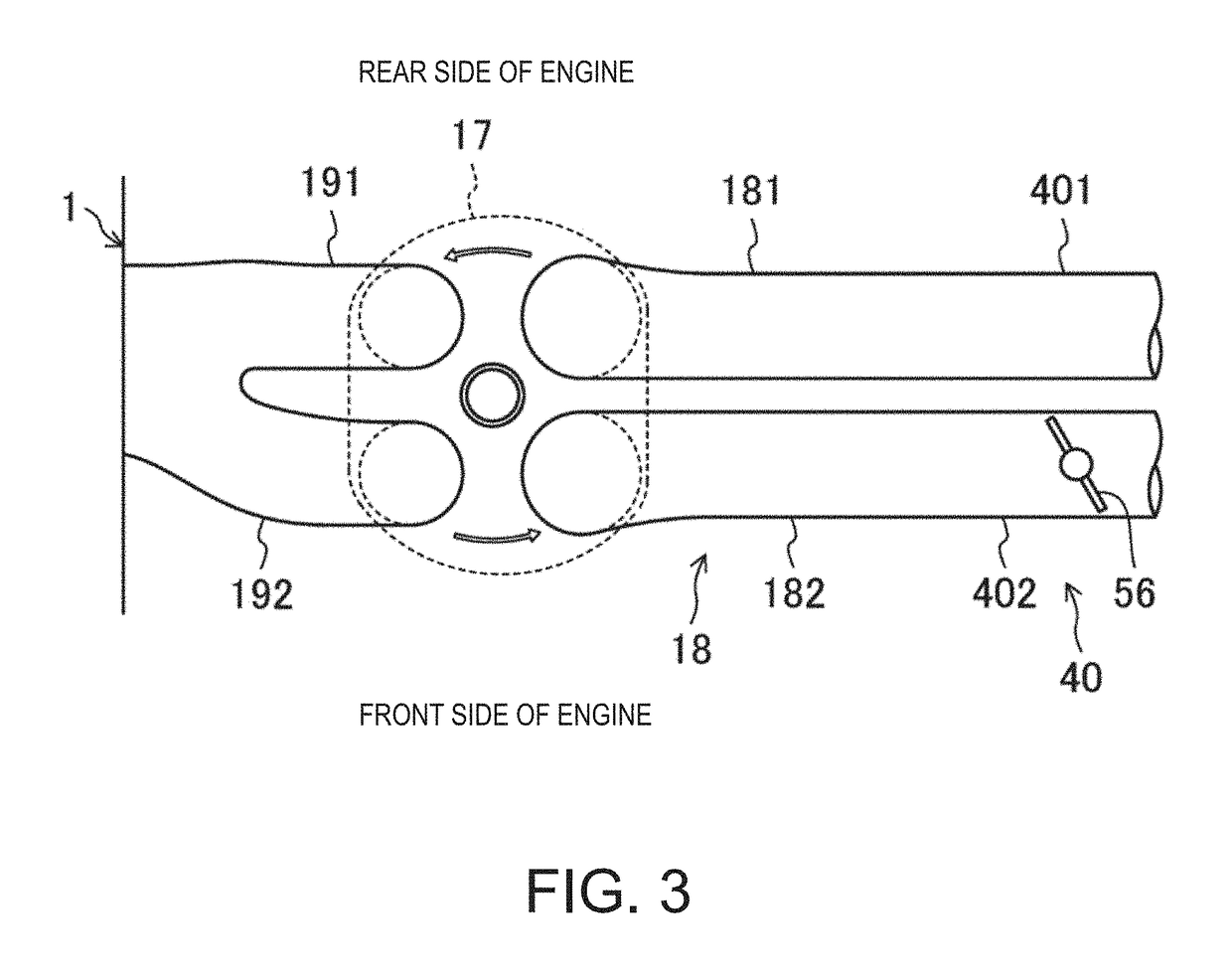

A fuel injection device includes a fuel injection valve for injecting fuel through a fuel injection orifice opening into a combustion chamber, an air injection valve for injecting air through an air injection orifice opening into the combustion chamber, sensors for detecting an operating condition of an engine, and an electronic control unit (ECU) for controlling the fuel injection valve and the air injection valve. Orientations of the air injection orifice and the fuel injection orifice are determined to make an air jet collide with a fuel spray. The ECU controls the fuel injection valve based on the operating condition detected by the sensors to control spray velocity, spray particle diameter, spray angle, etc. of the fuel to be injected through the fuel injection orifice, and at least one of an air injection timing and an air injection period of air injection to be performed by the air injection valve.

Owner:AISAN IND CO LTD

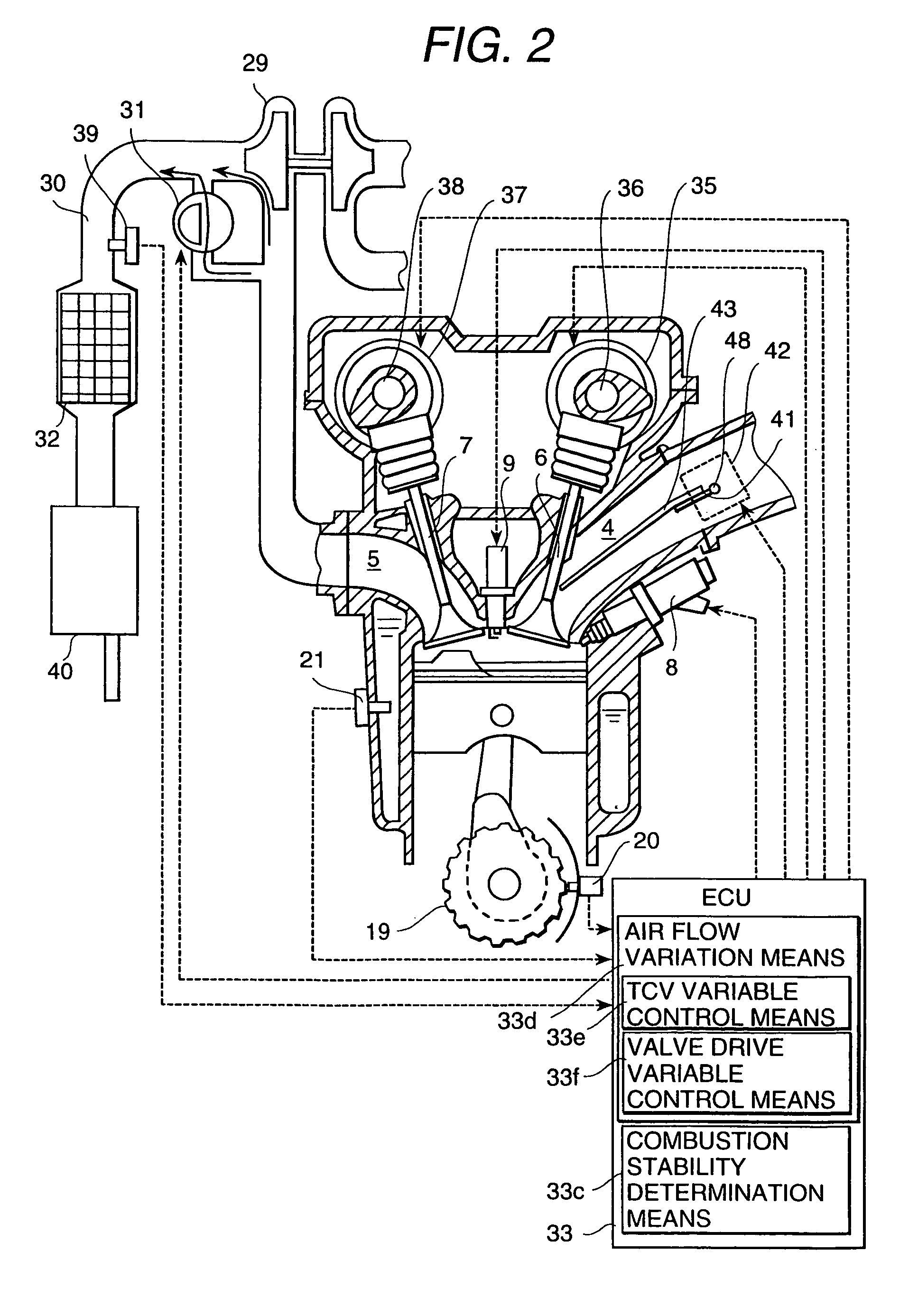

Internal combustion engine and fuel injection control device therefor

InactiveUS7089916B2Effective installationReduce rateElectrical controlInternal combustion piston enginesExhaust valveExternal combustion engine

In the fuel cylinder injection engine with the supercharging machine, the ignitability deteriorates because the density of the fuel at the spray center becomes excessive due to the shrinkage of the fuel spray under the supercharging. As a result, the density of the smoke and the hydrocarbon exhaust rate increase. The mixture of the fuel and the air under the supercharging is promoted by the control by TCV installed in the suction port which is a divided spray and air flow generation mechanism and the valve timing control of the suction and exhaust valve, etc.

Owner:HITACHI LTD

Fuel supply device

A fuel supply device includes: an injector that injects and supplies fuel to an engine; a pressure accumulator communicating with a cylinder of the engine through a communication passage; a valve that opens or closes the communication passage; and a controller that controls the injector and the valve. When the engine is rotated, an air-fuel mixture is compressed in the cylinder, and an accumulating portion of the controller accumulates the air-fuel mixture in the pressure accumulator. When the engine is restarted, a supplying portion of the controller supplies the air-fuel mixture accumulated in the pressure accumulator to the cylinder.

Owner:DENSO CORP +1

Compression ignition internal combustion engine

InactiveUS6966295B2Timely controlAccurate timingValve arrangementsElectrical controlCombustion chamberInlet valve

A compression ignition internal combustion engine in which the temperature and pressure in the combustion chamber are increased to self-ignite an air-fuel mixture with the compressive operation of a piston after closing of the intake valve. An ECU [1] controls injection timing of the pressurized air depending on the ignition timing. Self-ignition timing can be controlled to a proper timing in a wide engine operating range with respect to a load and a revolution speed without substantially changing the shape of the combustion chamber.

Owner:HITACHI LTD

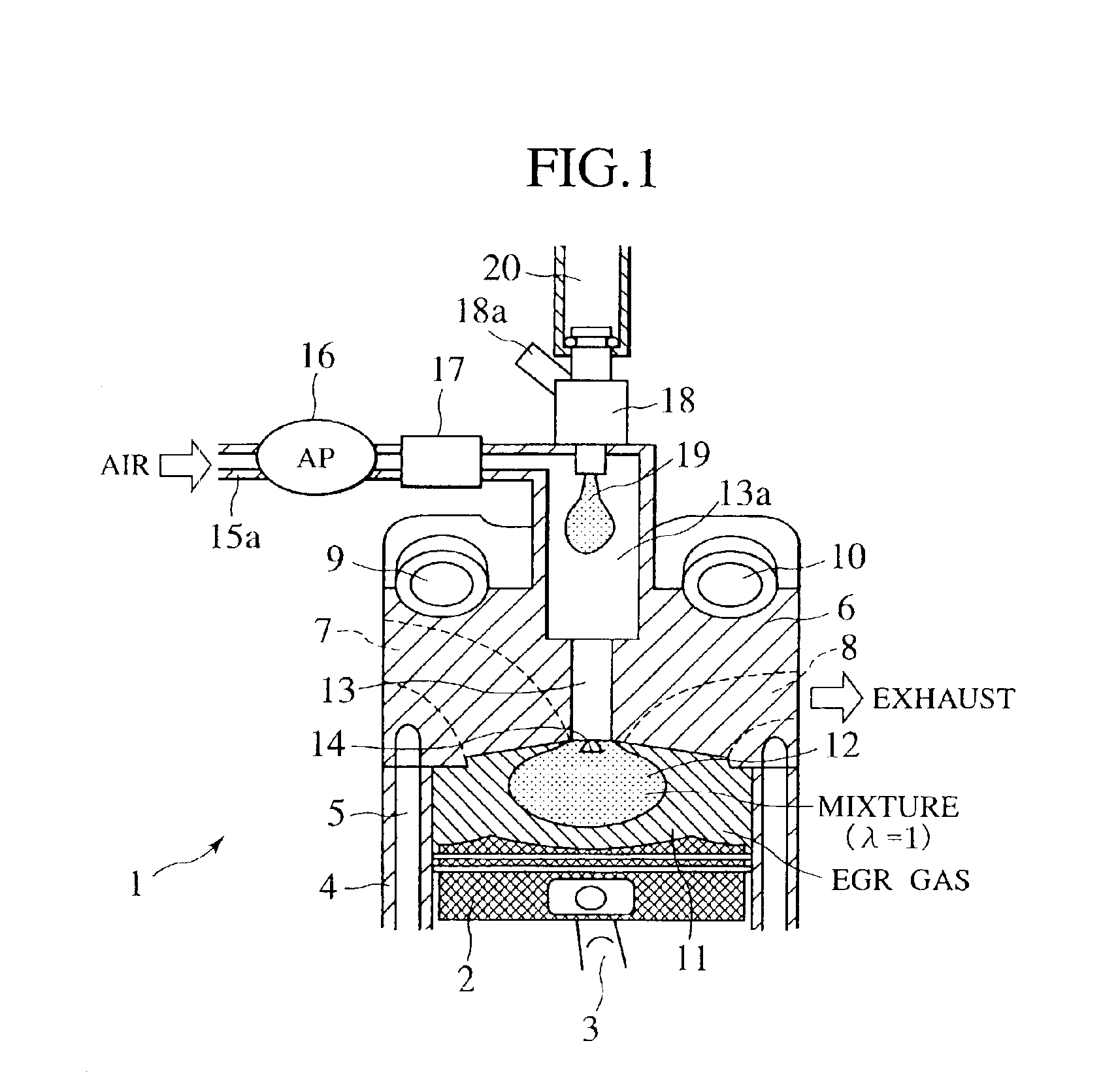

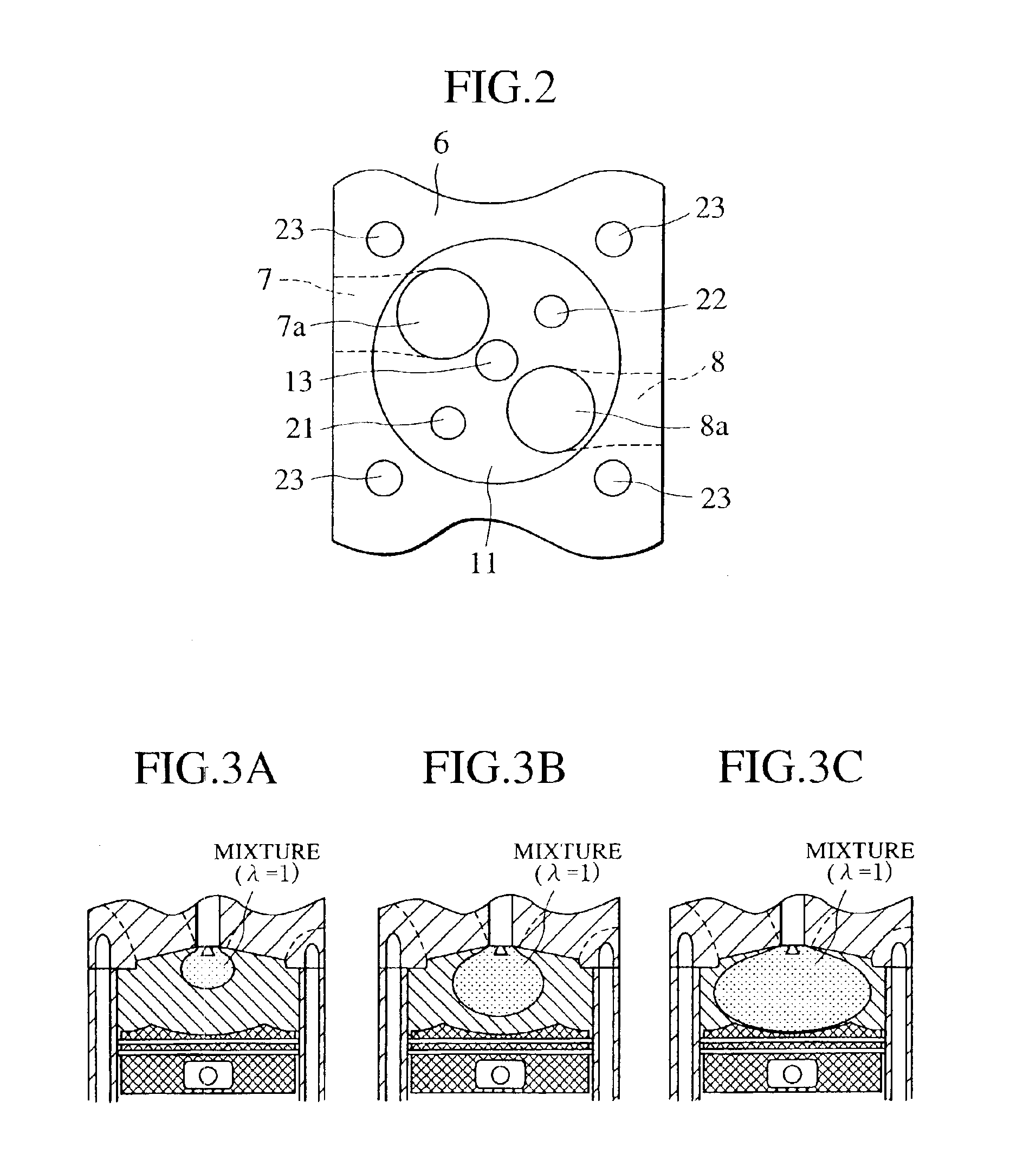

Control apparatus for internal combustion engine and control method for internal combustion engine combustion method for internal combustion engine and direct injection engine

InactiveUS6899089B2Stable combustionValve arrangementsElectrical controlExternal combustion engineGasoline

A gasoline engine is provided which is capable of introducing a large amount of EGR gas for performing homogeneous combustion and thus offering a good fuel economy. An external EGR mechanism or an internal EGR mechanism is used to introduce an EGR gas into a combustion chamber (a cylinder). A mixture of fresh air and fuel is thereafter directly injected from a mixture injection valve into the combustion chamber, thereby forming a region of said mixture in an area near an ignition plug. In addition, engine operating parameters are controlled in accordance with the amount of fresh air supplied into the combustion chamber (cylinder) after an intake valve has been closed. This makes possible homogeneous combustion using a large amount of EGR, which eventually increases fuel economy.

Owner:HITACHI LTD

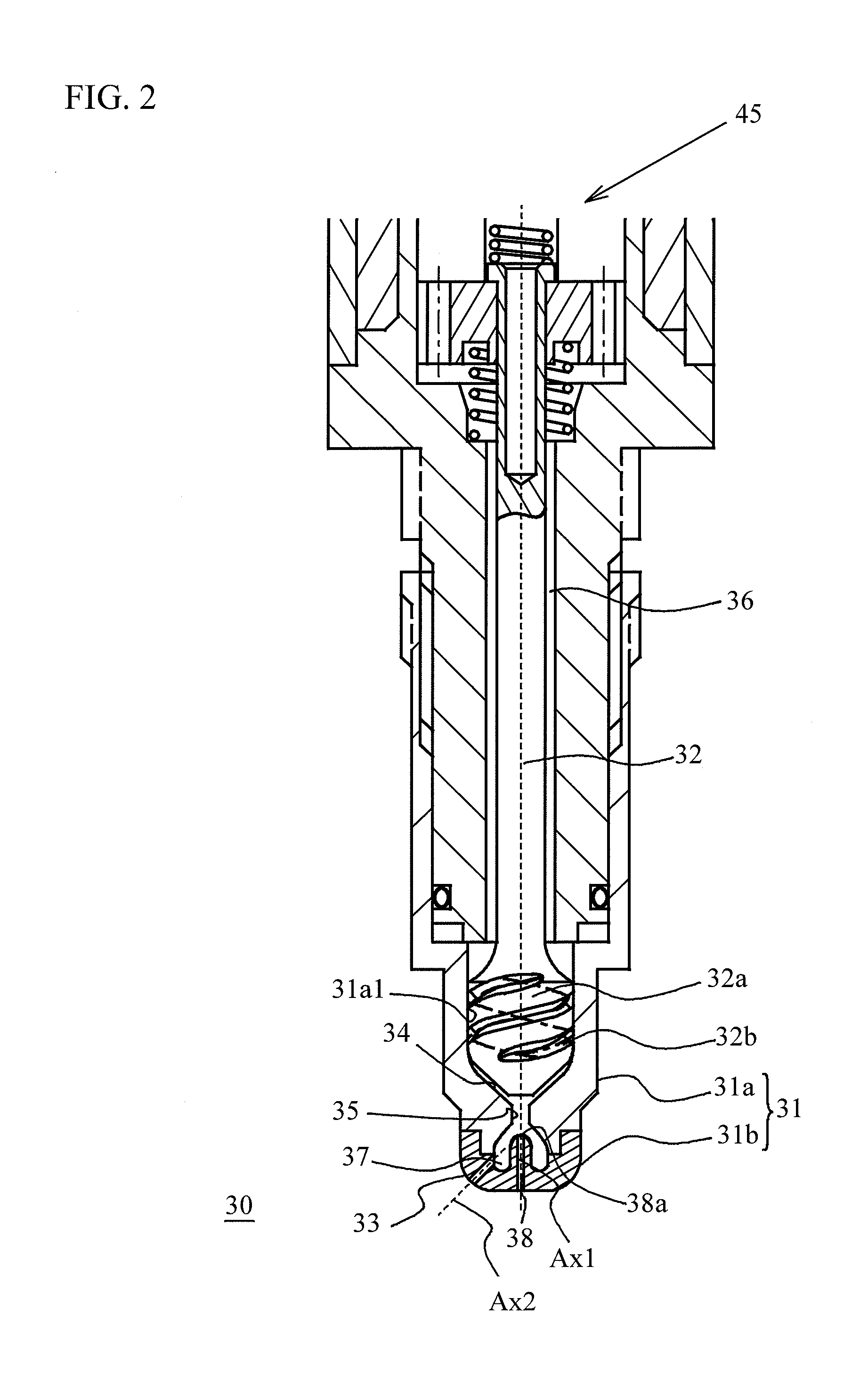

Fuel injection valve

ActiveUS20130233946A1Increase freedomHigh pressure gas fuel injectionSpray nozzlesEngineeringVALVE PORT

A fuel injection valve includes a nozzle body including an injection aperture; a needle that is slidably located in the nozzle body, forms a fuel introduction path between the needle and the nozzle body, and is seated on a seat portion in the nozzle body; a swirling flow generating portion that is located more upstream than the seat portion, and imparts a swirl with respect to a sliding direction of the needle to fuel introduced from the fuel introduction path; a swirl velocity increasing portion that is located more downstream than the seat portion, and increases a swirl velocity of a swirling flow generated in the swirling flow generating portion; and an air bubble reserving portion that is located more downstream than the swirl velocity increasing portion, and reserves air bubbles generated by passage through the swirl velocity increasing portion. The injection aperture opens in the air bubble reserving portion.

Owner:TOYOTA JIDOSHA KK

Air assist fuel injectors and method of assembling air assist fuel injectors

InactiveUS6568080B2Valve arrangementsHigh pressure gas fuel injectionFour-stroke engineElectromagnetic coil

A first air assist fuel injector configured for operation with a two stroke engine and a second air assist fuel injector configured for operation with a four stroke engine. The first air assist fuel injector and the second air assist fuel injector share one or more common items, such as a solenoid coil assembly and / or an armature, even though the air assist fuel injectors are configured for different applications.

Owner:SYNERJECT

Fuel injection device of engine

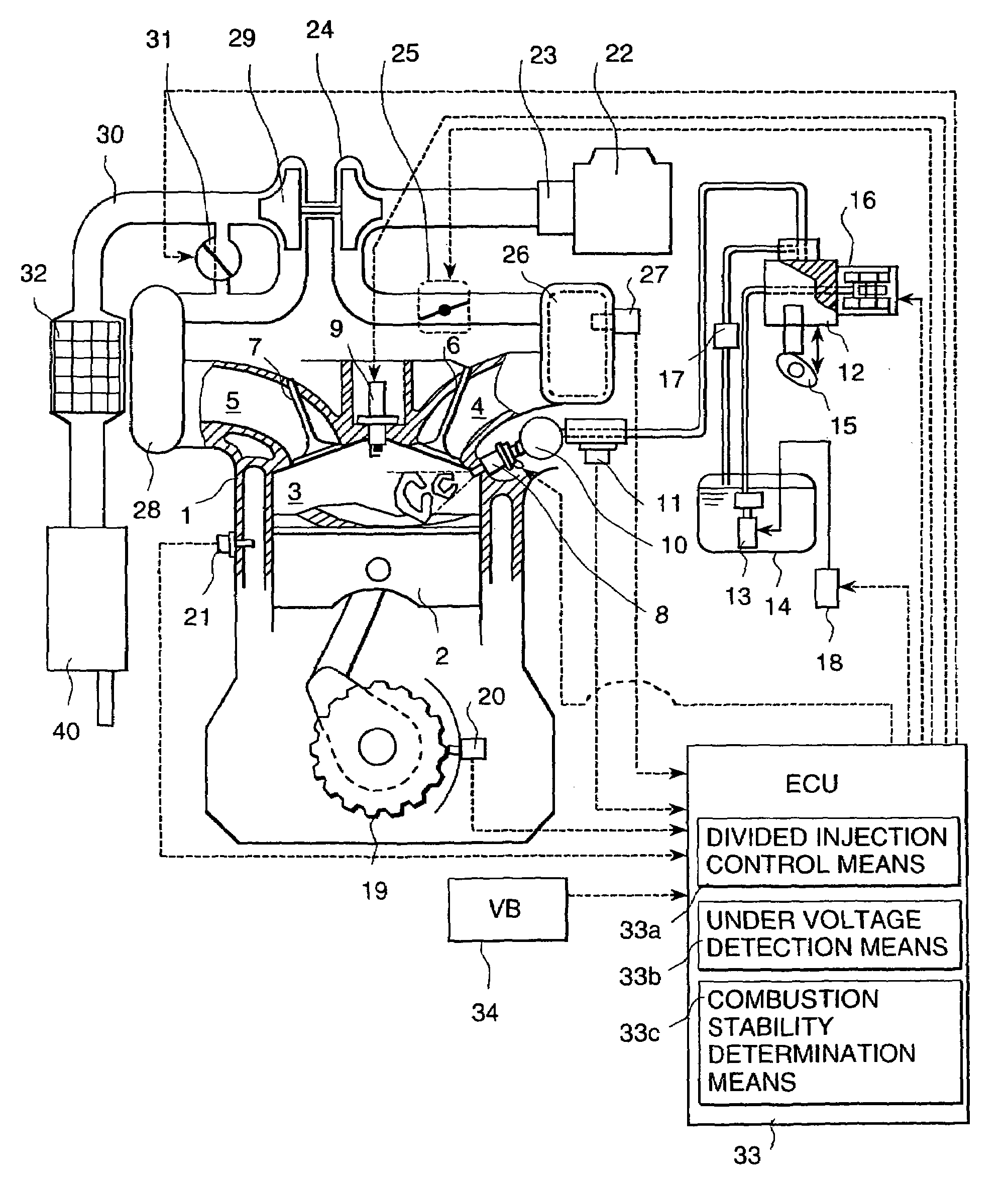

ActiveUS20190063338A1Stable flowImprove ignition stabilityElectrical controlInternal combustion piston enginesCombustion chamberControl signal

A control device of an engine including a cylinder, a piston, a cylinder head, and a combustion chamber is provided, which includes intake and exhaust ports, a swirl control valve provided in an intake passage connected to the intake port, a fuel injection valve attached to the cylinder head to be oriented into the center of the combustion chamber in a plan view thereof, and having first and second nozzle ports, and a control unit. The control unit includes a processor configured to execute a swirl opening controlling module to output the control signal to the swirl control valve to have a given opening at which a swirl ratio inside the combustion chamber becomes 2 or above, and a fuel injection timing controlling module to output the control signal to the fuel injector to inject fuel at a given timing at which the swirl ratio becomes 2 or above.

Owner:MAZDA MOTOR CORP

Internal combustion engines and control

InactiveUS20030140891A1Internal combustion piston enginesHigh pressure gas fuel injectionExternal combustion engineProduct gas

Disclosed is an Internal combustion engine comprising at least one cylinder with a reciprocating piston to provide said engine with at least one combustion chamber, said combustion chamber further comprising a delivery injector for injecting fuel directly into said combustion chamber, said engine further comprising at least one valved inlet air duct for delivering combustion air into said combustion chamber, wherein at least said inlet air duct and / or its valve is arranged to provide a low tumble inlet port to said at least one combustion chamber, said combustion chamber, in use, having low in-cylinder tumble gas motion of said combustion air and wherein said low in-cylinder tumble gas motion of said combustion air reduces over-enleanment of fuel in end gas regions of said combustion chamber.

Owner:ORBITAL ENGINE CO PTY LTD

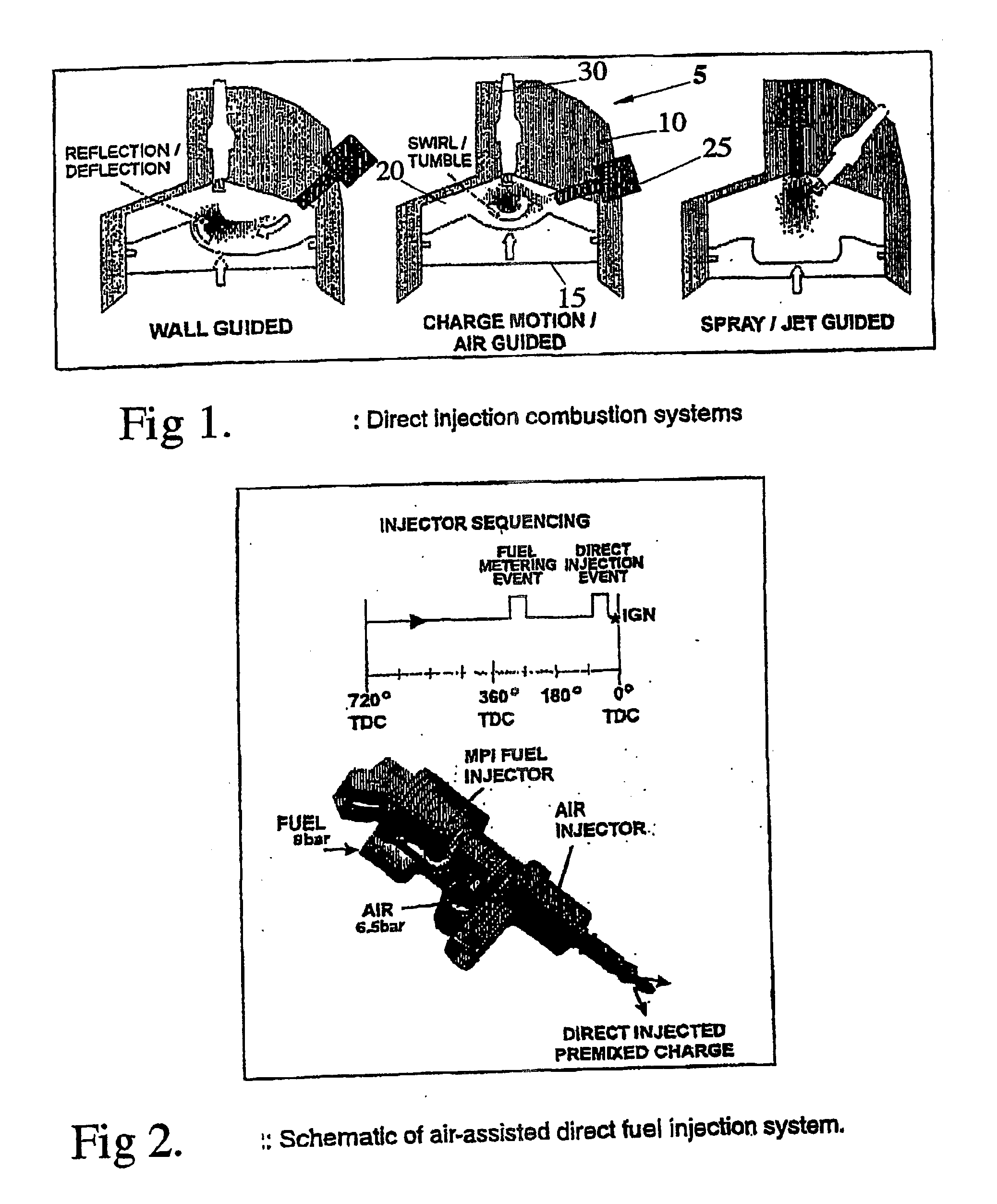

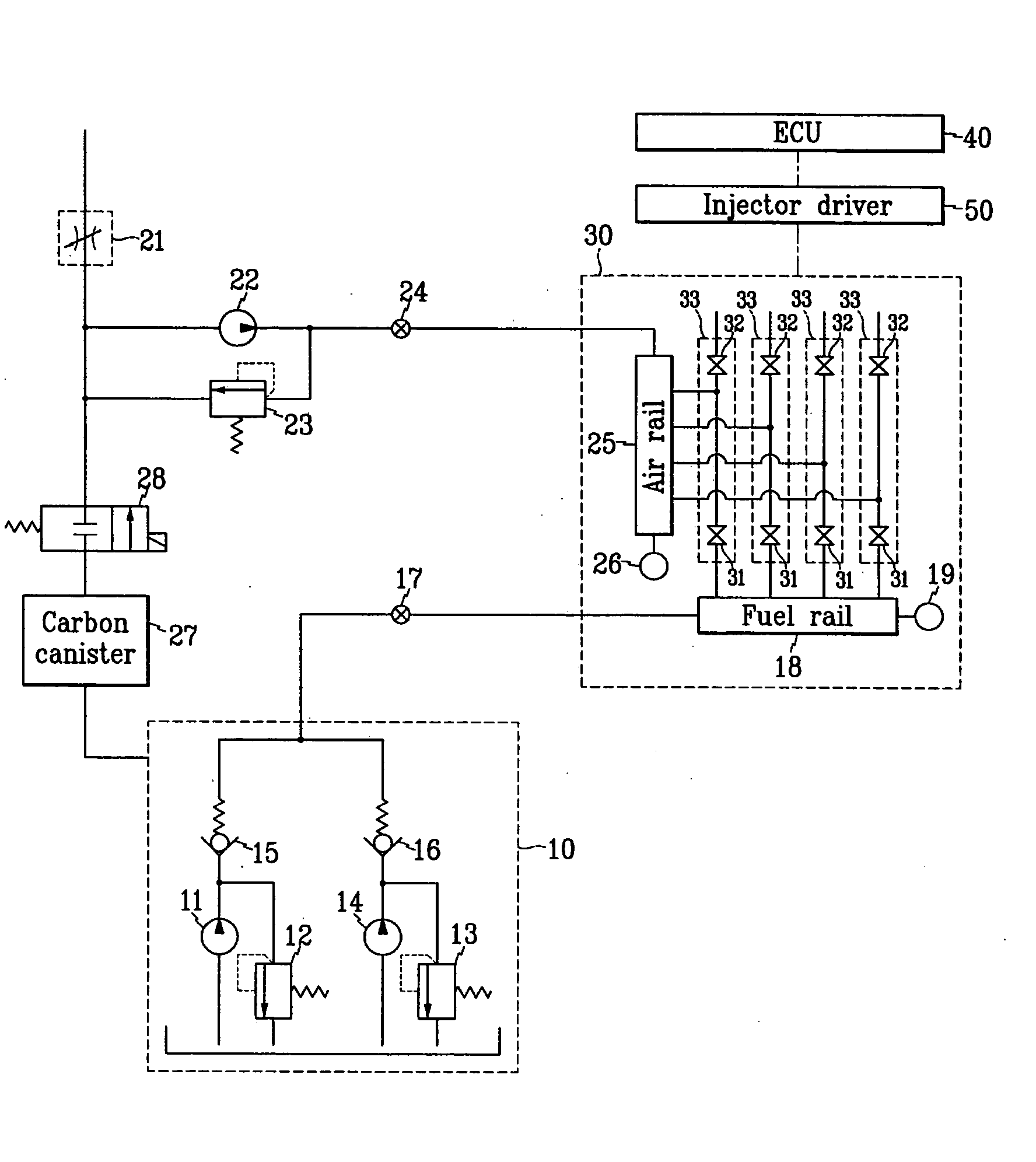

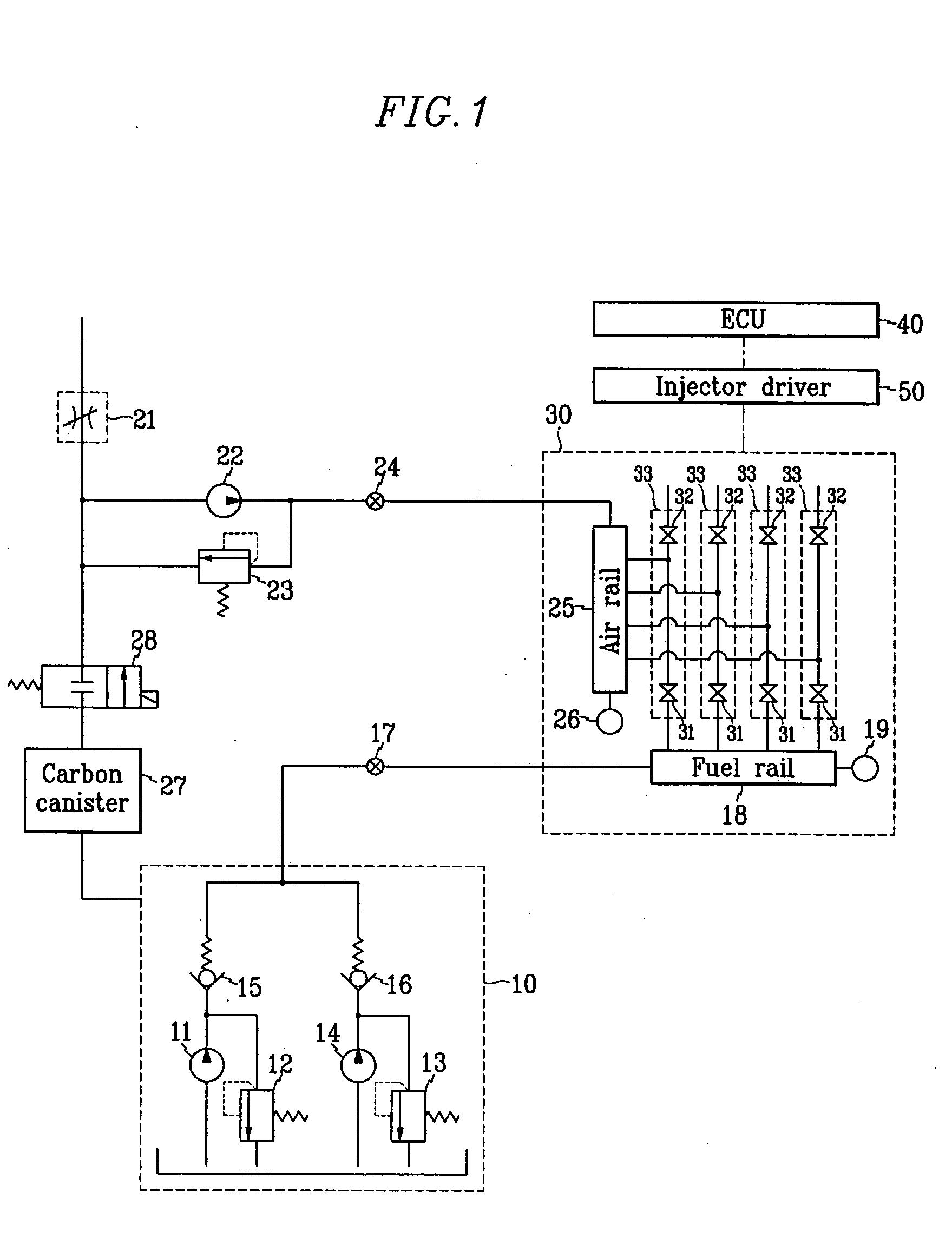

Gasoline direct injection system

InactiveUS20050072407A1Internal combustion piston enginesHigh pressure gas fuel injectionGasoline direct injectionFuel tank

A gasoline direct injection engine system provided with an air rail for supplying air and a fuel rail for supplying fuel comprises an air supply for adjusting the flow rate of intake air, pressurizing the intake air, and supplying the pressurized air to the air rail. A fuel supply pressurizes the fuel from a fuel tank and supplying the pressurized fuel to the fuel rail. At least one injector assembly is connected to both the air rail and the fuel rail, forming an air-fuel mixture and injecting the air-fuel mixture into a cylinder of an engine.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com