Patents

Literature

41results about How to "Improve ignition stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

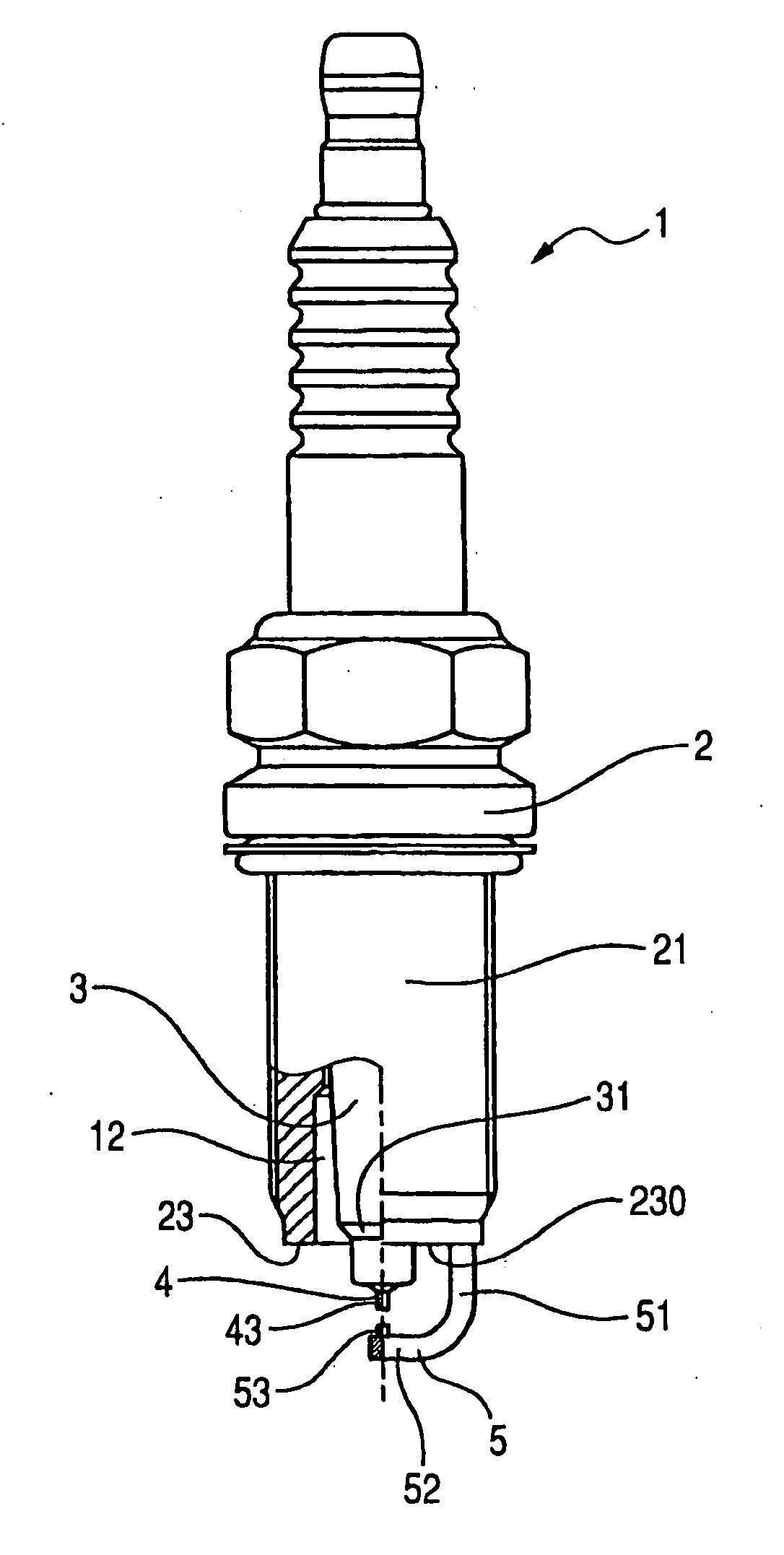

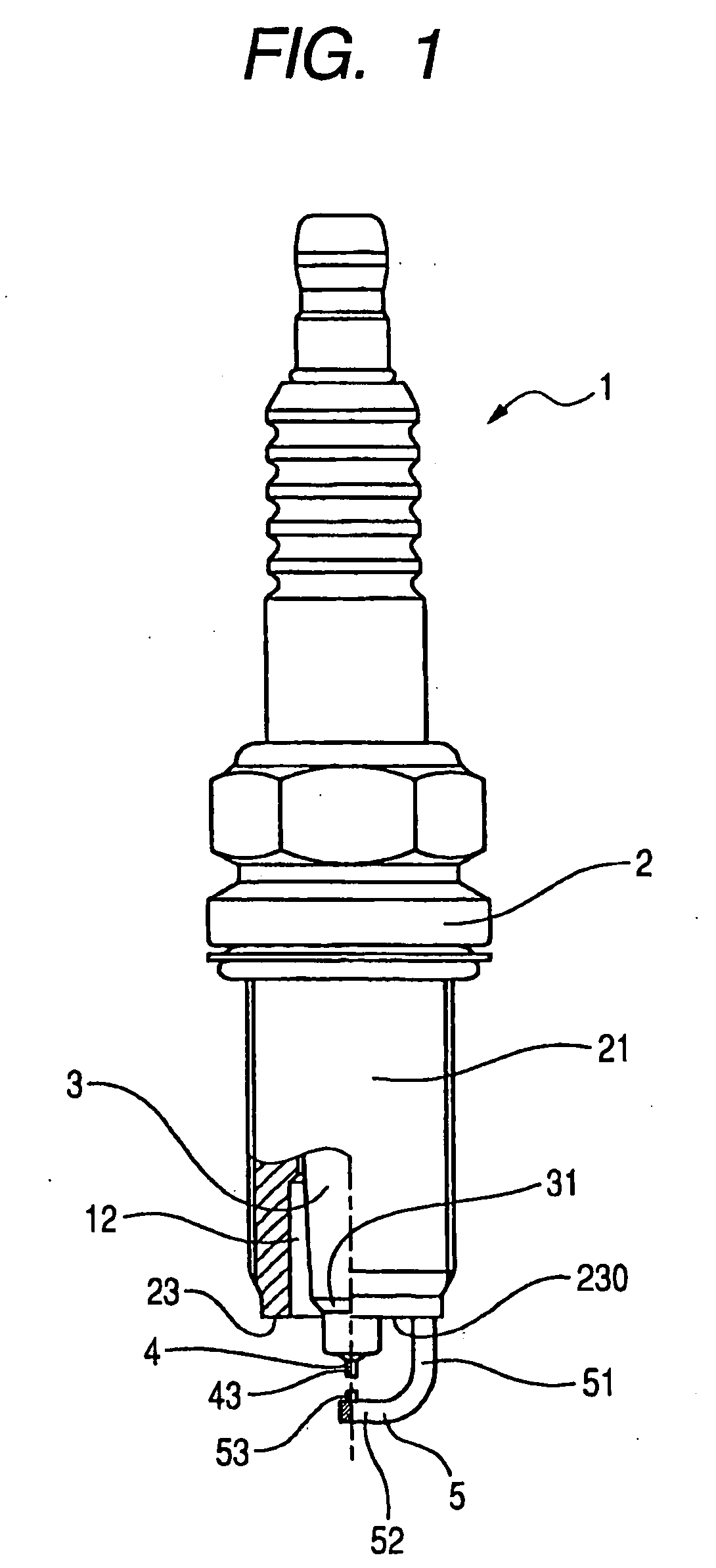

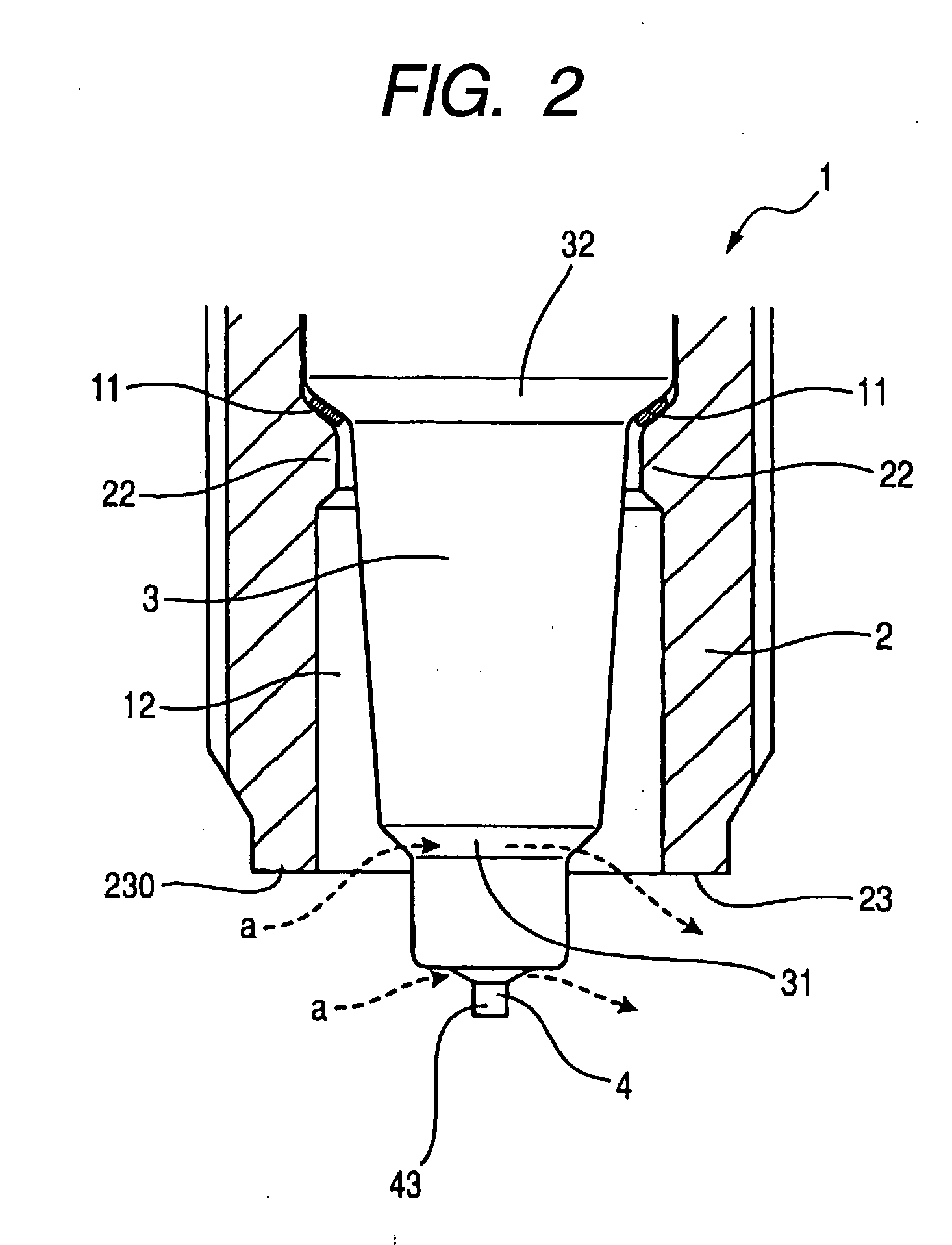

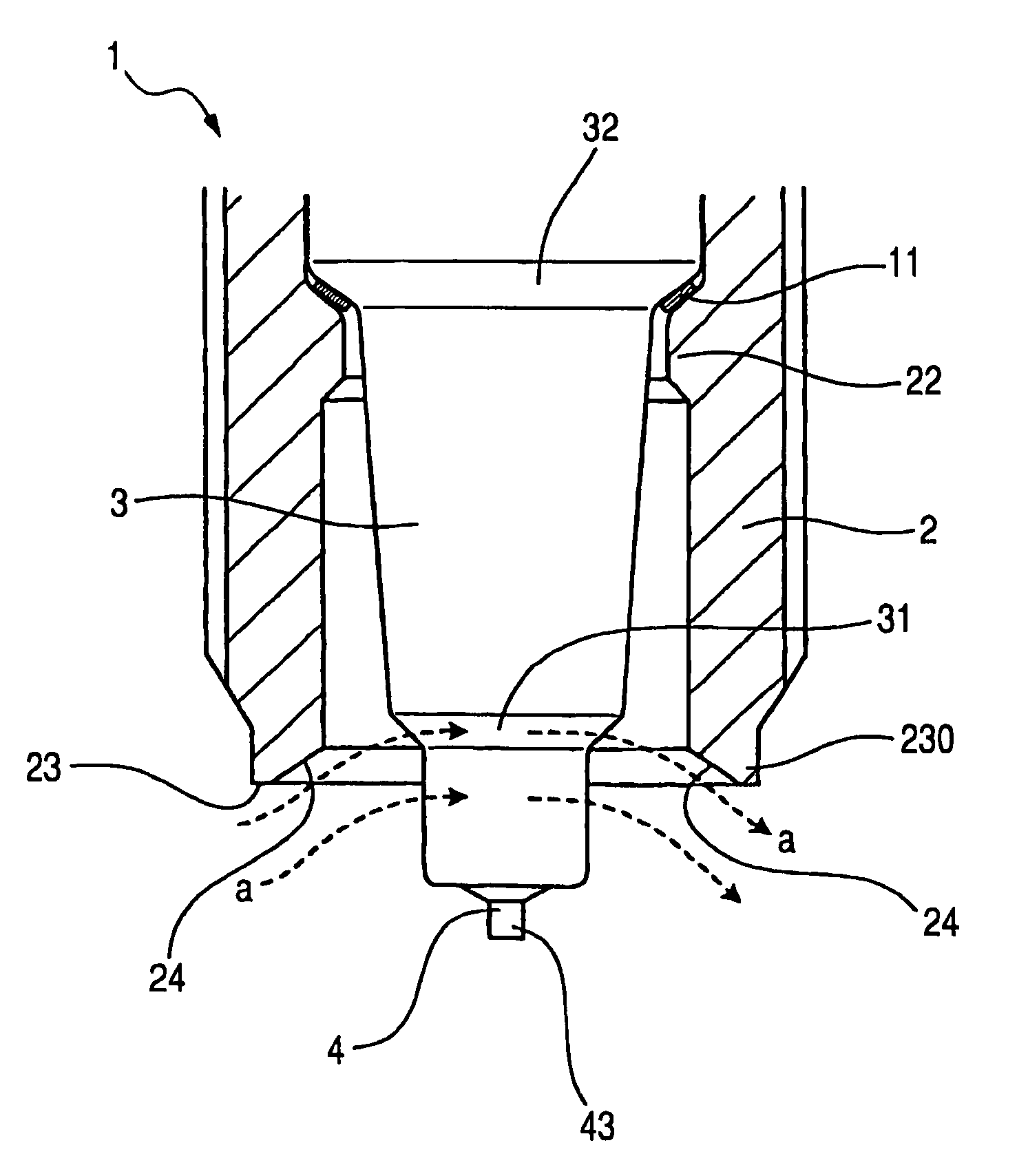

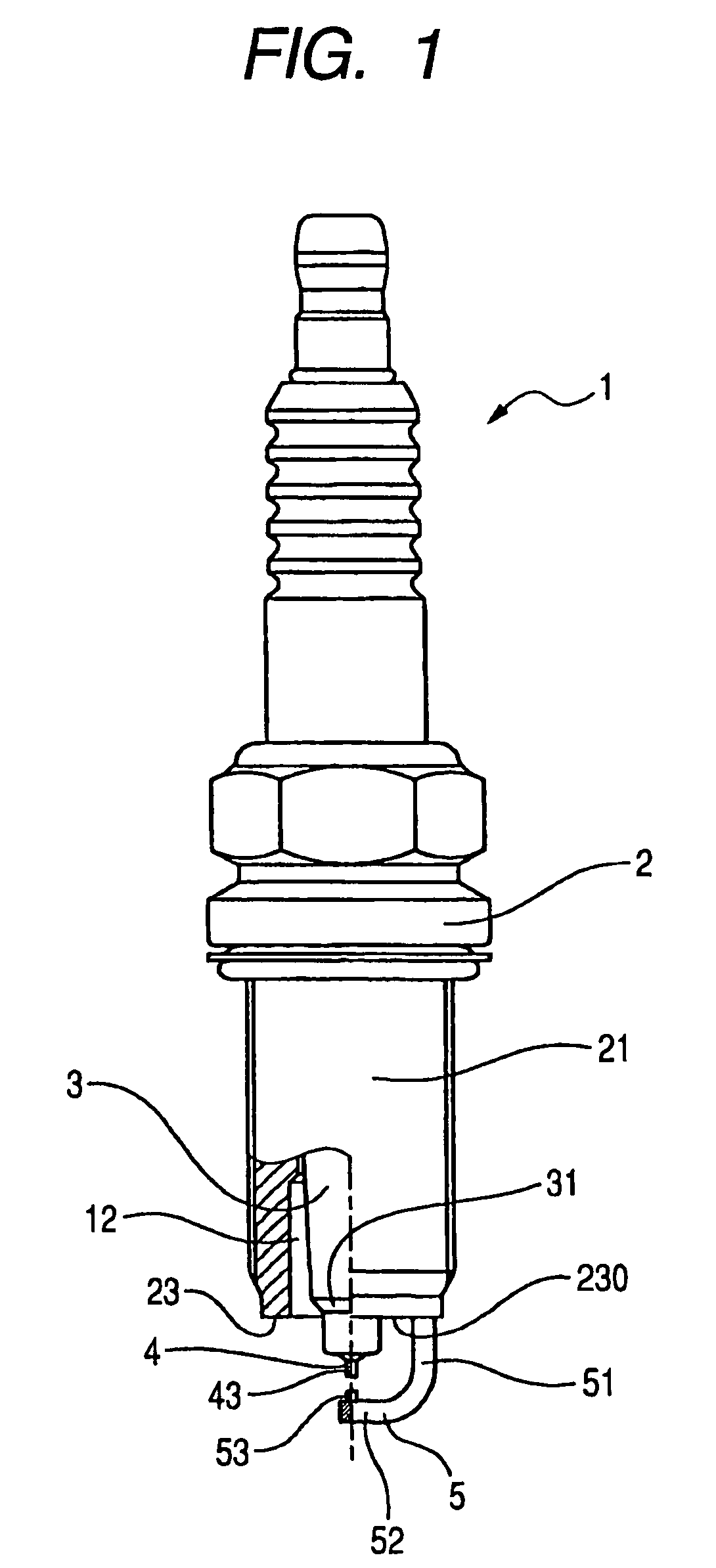

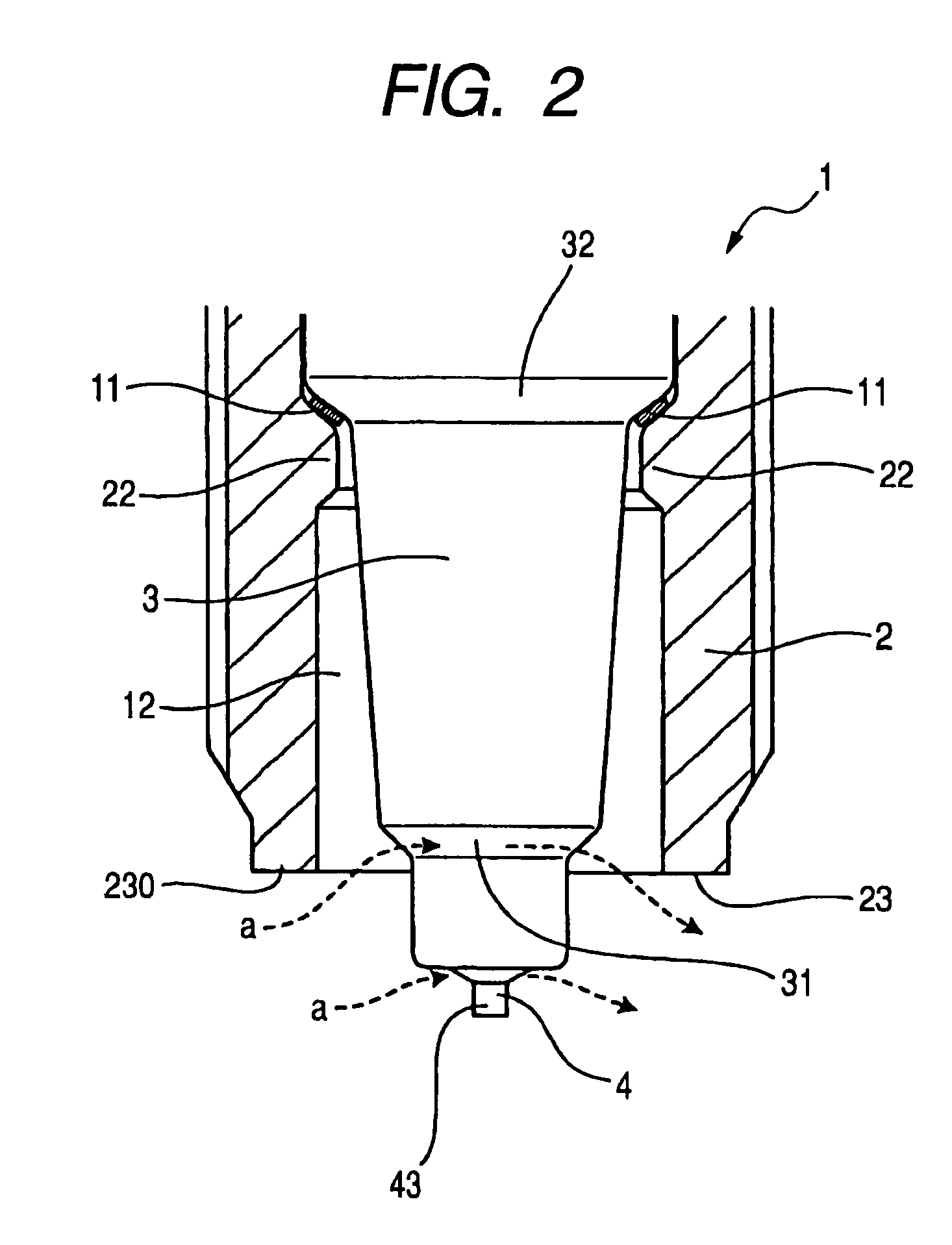

Spark plug designed to ensure stability of ignition of air-fuel mixture

InactiveUS20080093965A1Minimize the possibilityEasy to shapeSparking plugsCombustion chamberEngineering

A spark plug for an internal combustion engine is provided which includes a hollow cylindrical metal shell with an open end portion to be exposed to a combustion chamber of the engine, a ground electrode joined to the metal shell, a center electrode disposed in the metal housing to define a spark gap between itself and the ground electrode. The spark plug also includes a stream shaper or a stream reflector geometrically formed on the metal shell and / or the porcelain insulator to shape a vortex steam of air-fuel mixture into a stream thereof which is oriented outside the spark plug or serves to decrease the amount of the air-fuel mixture into a pocket between the metal shell and the porcelain insulator. This ensures the stability of ignition of the air-fuel mixture.

Owner:DENSO CORP +1

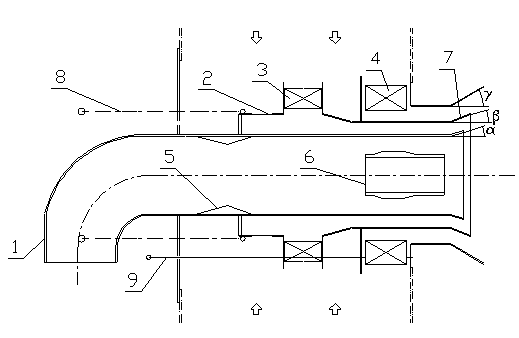

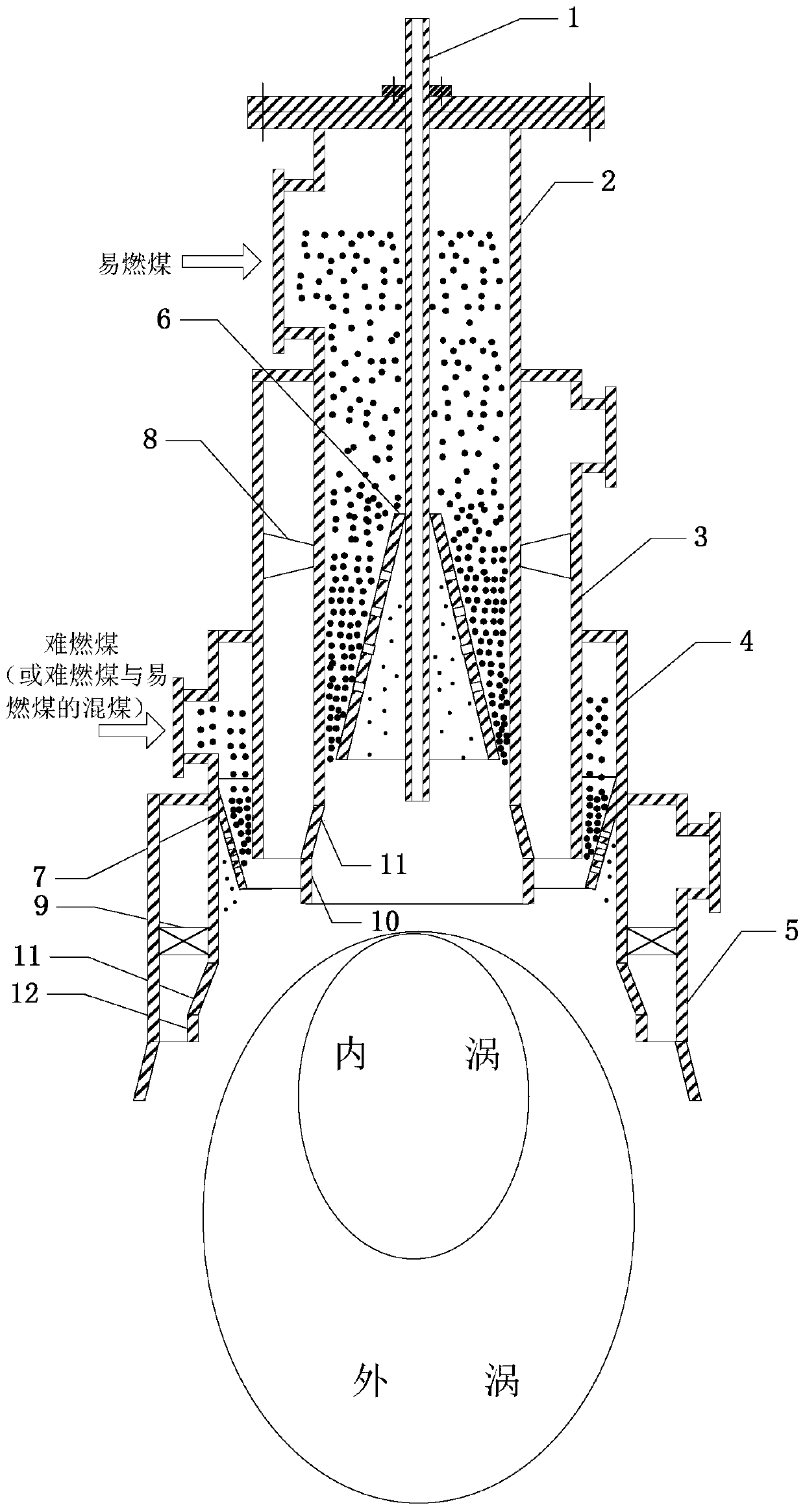

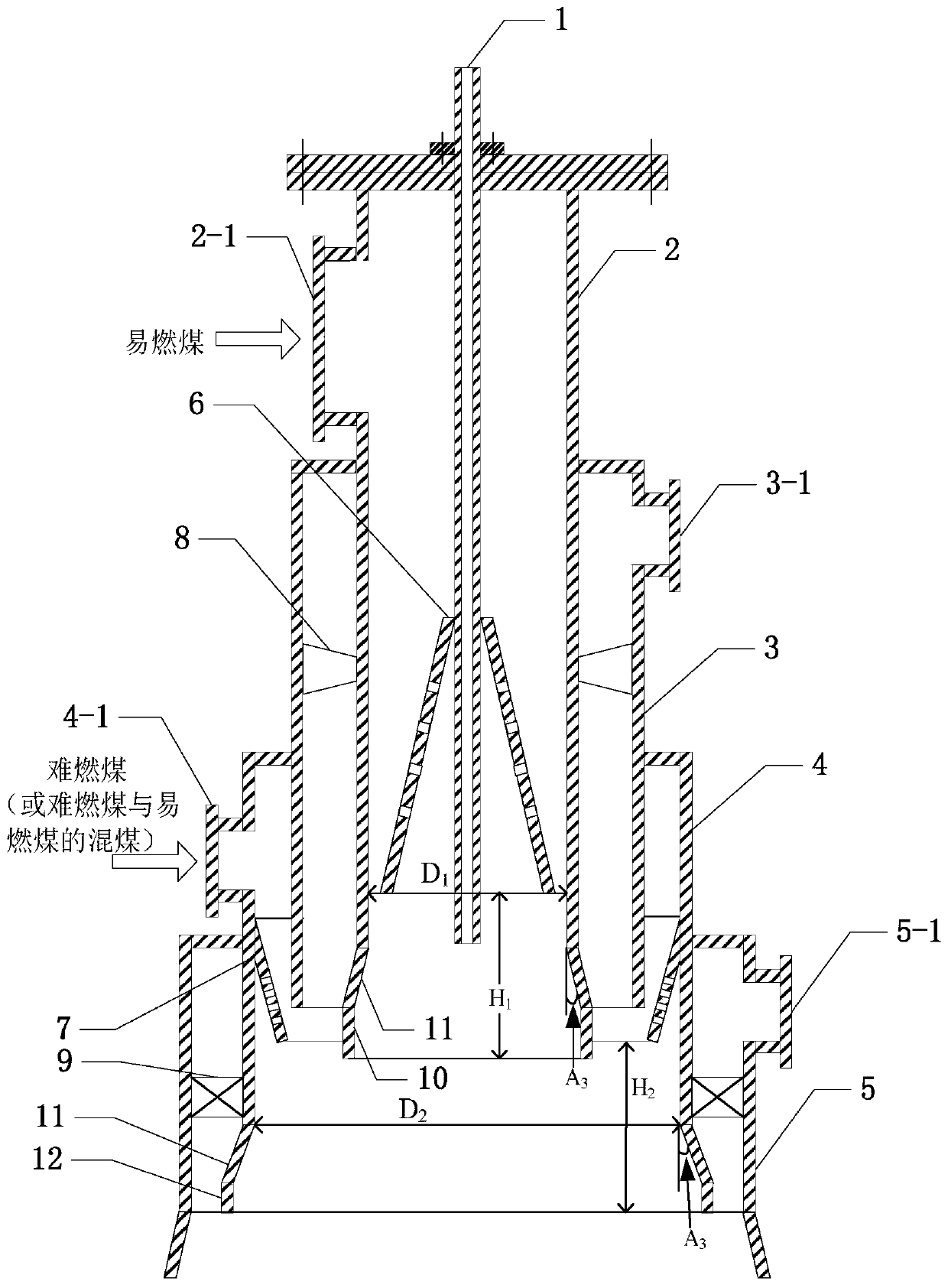

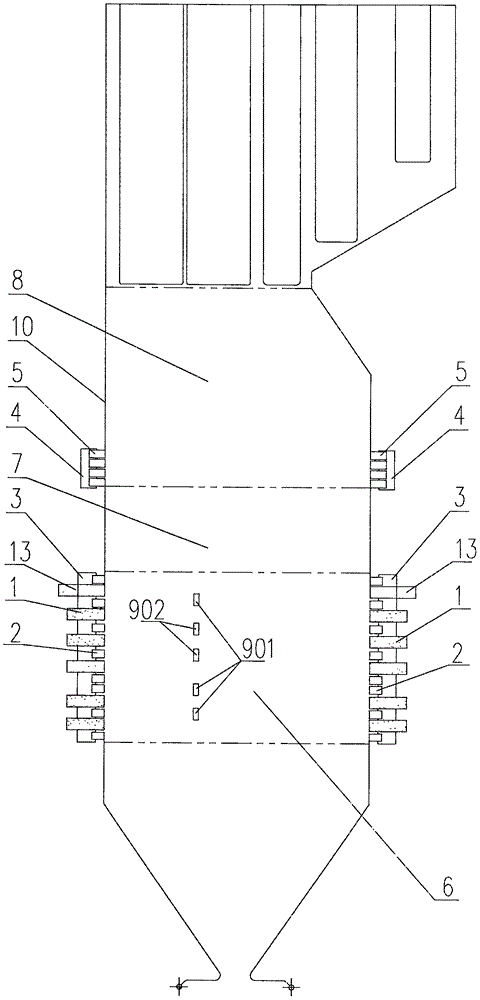

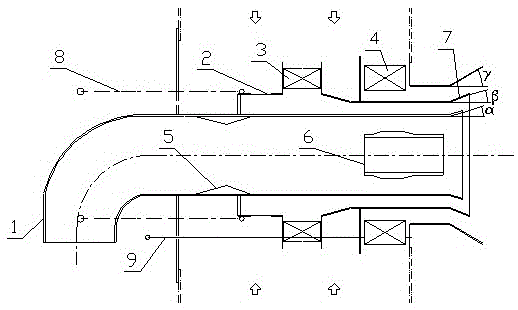

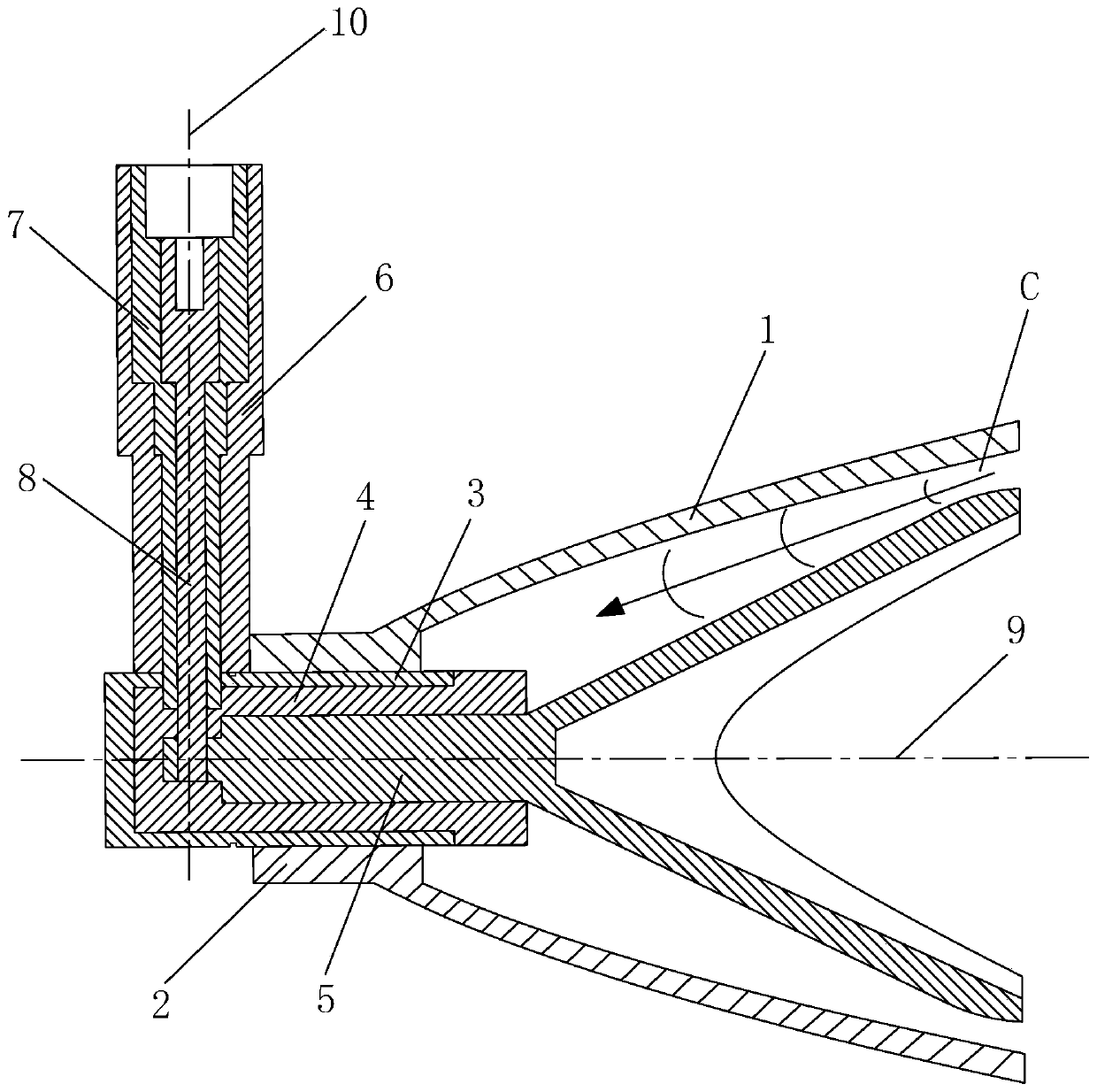

Fuel-saving/gas-ignition stable-combustion low-nitrogen swirling pulverized coal combustor

ActiveCN103759258ASolve severe wear and slagging at the nozzleSolve corrosivePulverulent fuel combustion burnersCombustion apparatusCombustion chamberCombustor

A fuel-saving / gas-ignition stable-combustion low-nitrogen swirling pulverized coal combustor comprises a primary air channel, a multi-channel secondary air intake tube and a fuel / gas combustor. A circle of rectifying vanes are evenly distributed on the inner wall of an entryway of a strengthening combustion chamber in the primary air channel, a circle of swirling vanes are evenly distributed on the front outer wall of the fuel / gas combustor, the length from front the end of each swirling vane to the front end of the fuel / gas combustor is larger then or equal to the length of each overall rectifying vane, and the outer diameter of each swirling vane is smaller than the inner diameter of each rectifying vane; the fuel / gas combustor is back-front adjustable and capable of driving relative positions between the swirling vanes and the rectifying vanes to change; swirling intensity of secondary air of the combustor can be adjusted online, a reasonable high-temperature flue gas recirculation zone is formed in a nozzle center of the combustor through adjustment of the swirling intensity of the secondary air, and stable heat sources are provided for ignition and stable combustion of pulverized coal; timely mixing of the secondary air and the pulverized coal is effectively controlled, and a water-cooled wall area at the position of a nozzle is enabled to be in the oxidizing atmosphere, so that scorification and high-temperature corrosion of a water-cooled wall in the area of the combustor can be effectively prevented.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD +1

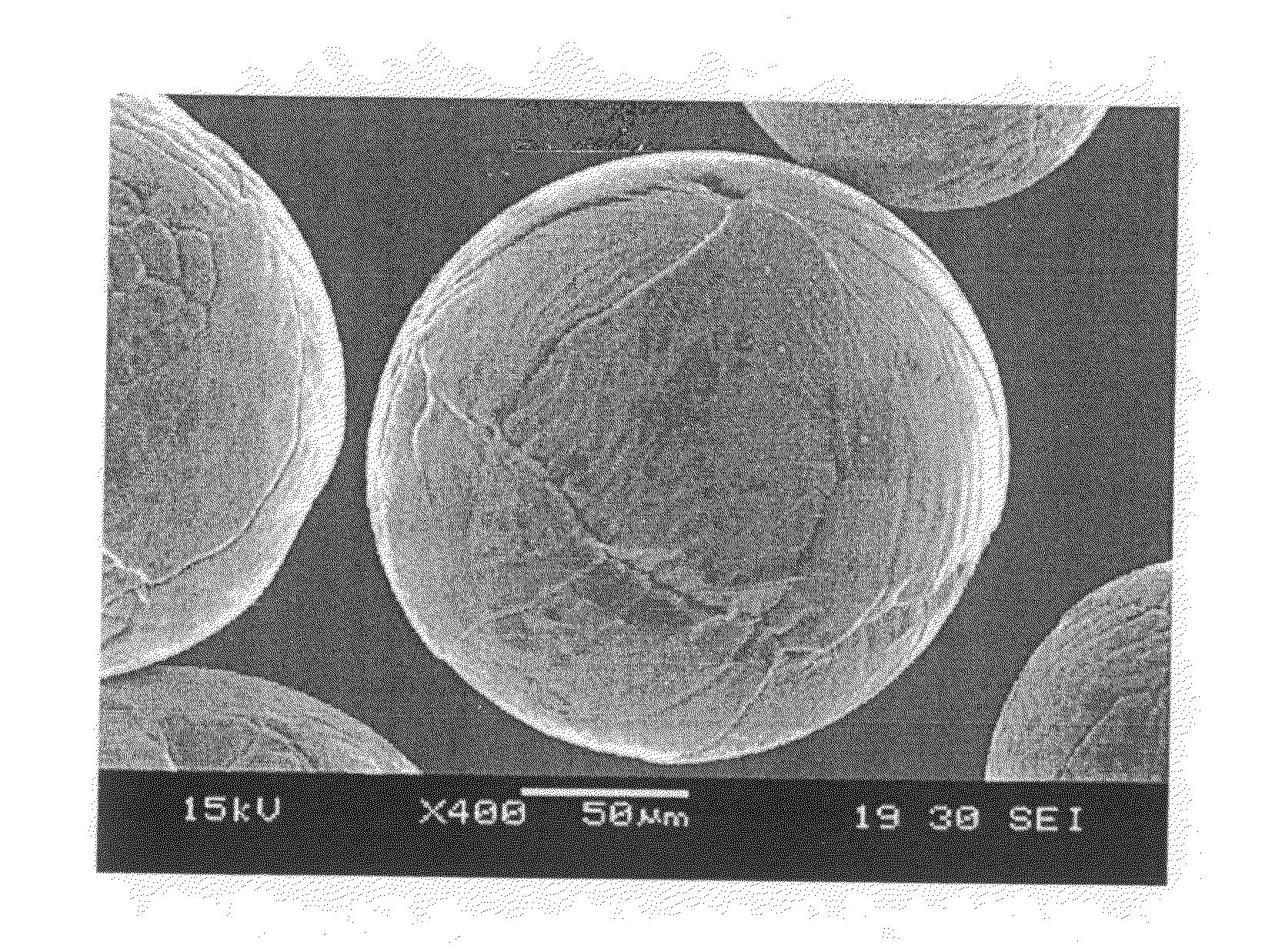

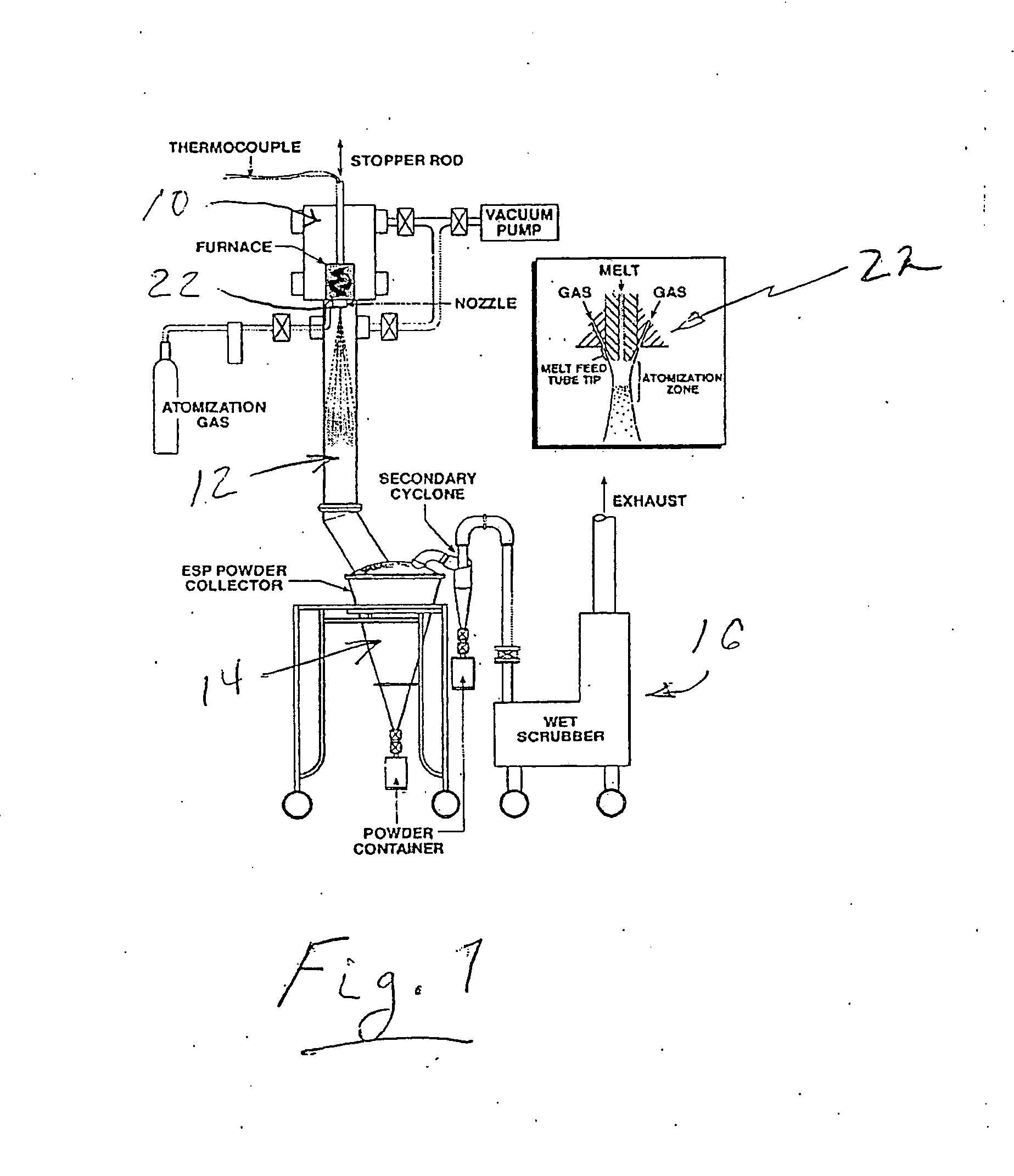

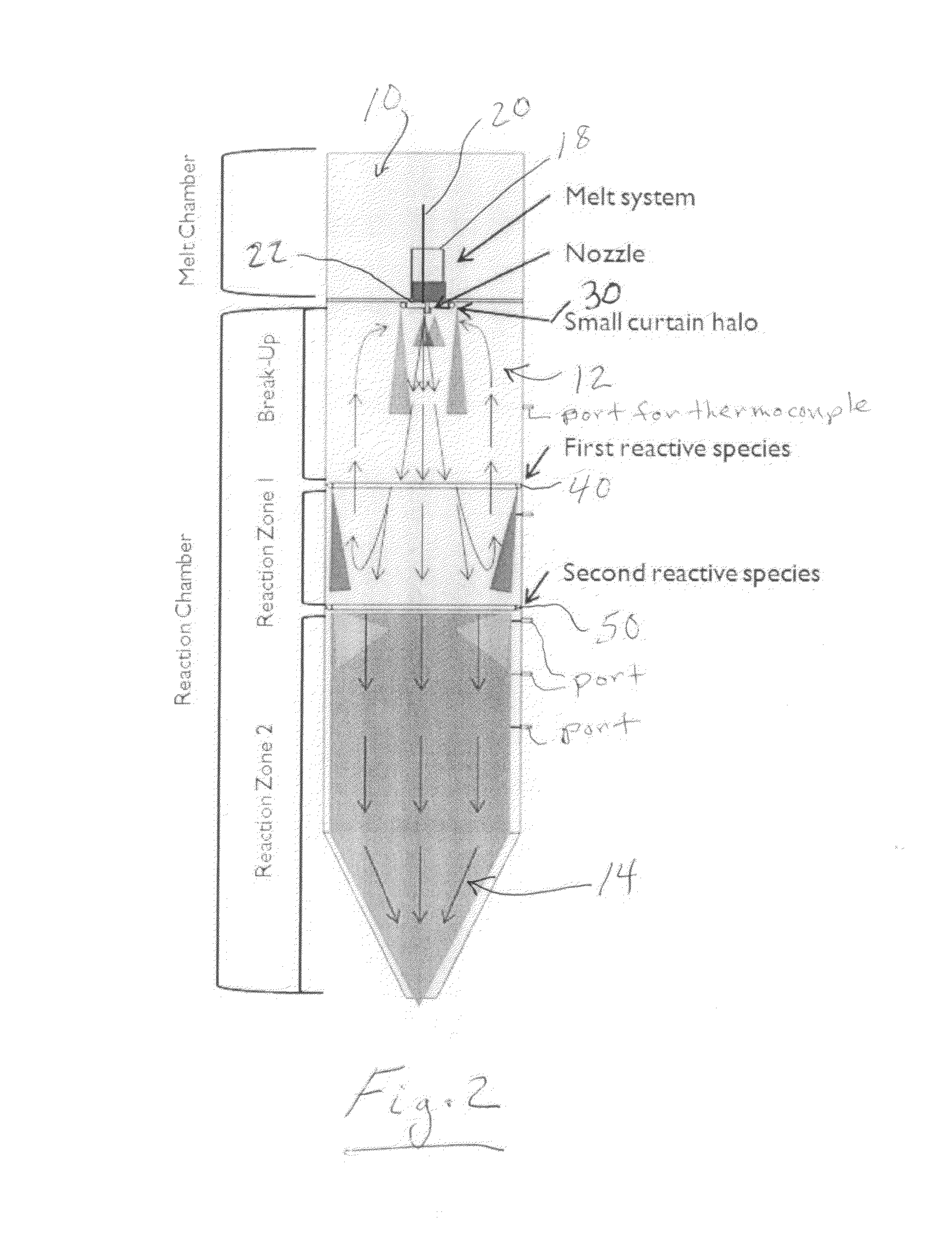

Stability of gas atomized reactive powders through multiple step in-situ passivation

ActiveUS20130306205A1Increases thermal ignition temperatureIncreases ignition spark resistanceTransportation and packagingMetal-working apparatusOxygenReactive agent

A method for gas atomization of oxygen-reactive reactive metals and alloys wherein the atomized particles are exposed as they solidify and cool in a very short time to multiple gaseous reactive agents for the in-situ formation of a protective reaction film on the atomized particles. The present invention is especially useful for making highly pyrophoric reactive metal or alloy atomized powders, such as atomized magnesium and magnesium alloy powders. The gaseous reactive species (agents) are introduced into the atomization spray chamber at locations downstream of a gas atomizing nozzle as determined by the desired powder or particle temperature for the reactions and the desired thickness of the reaction film.

Owner:IOWA STATE UNIV RES FOUND

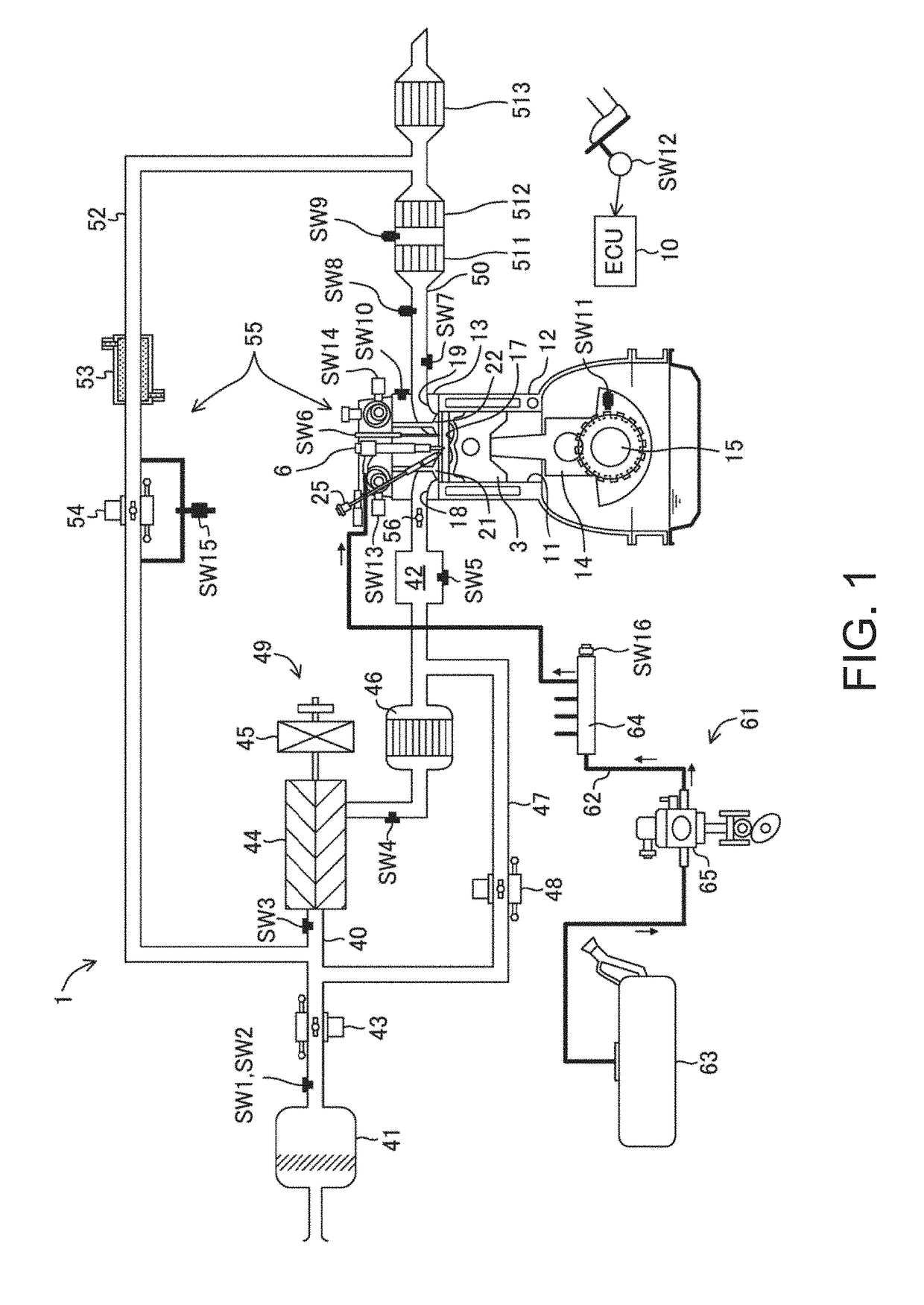

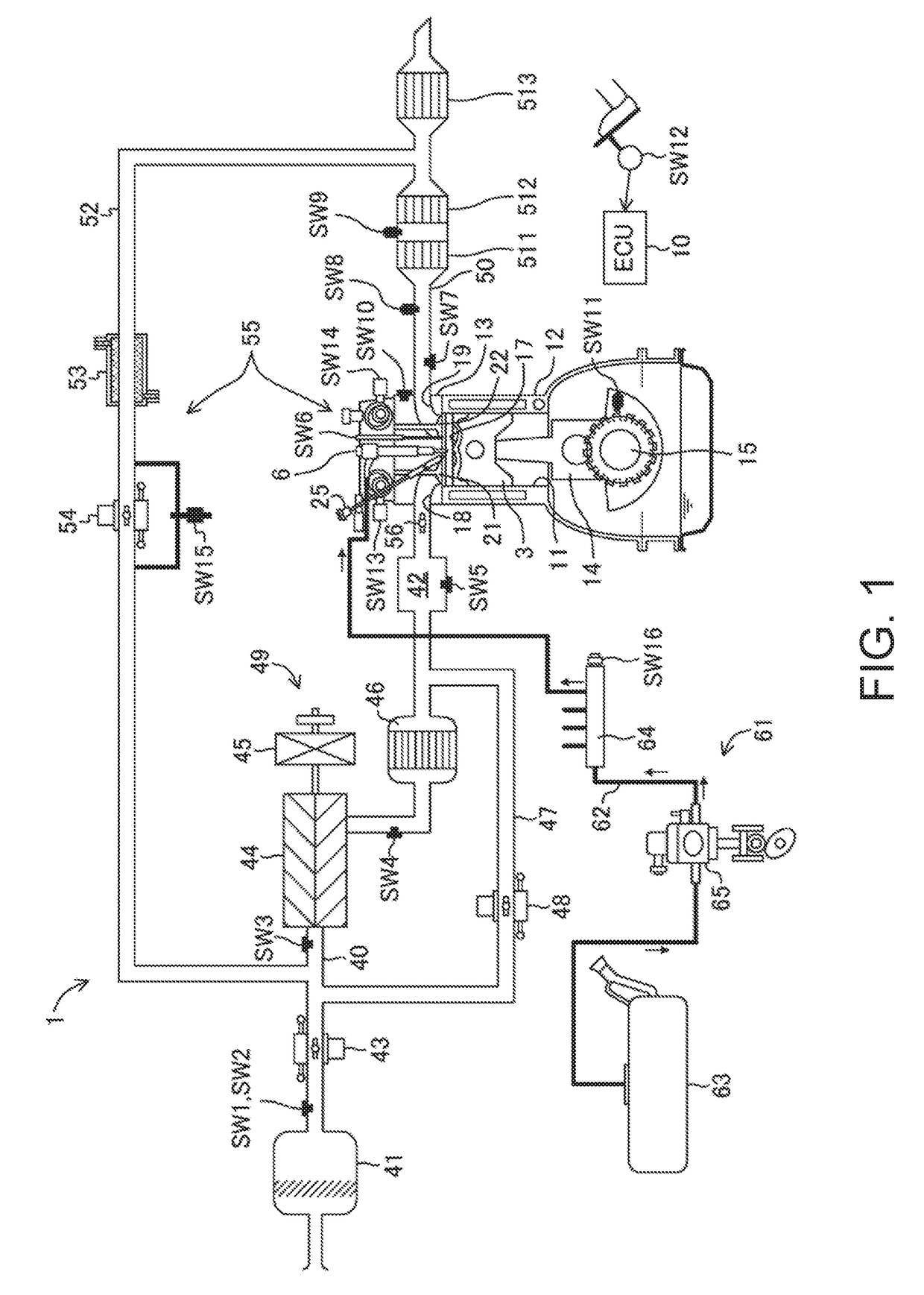

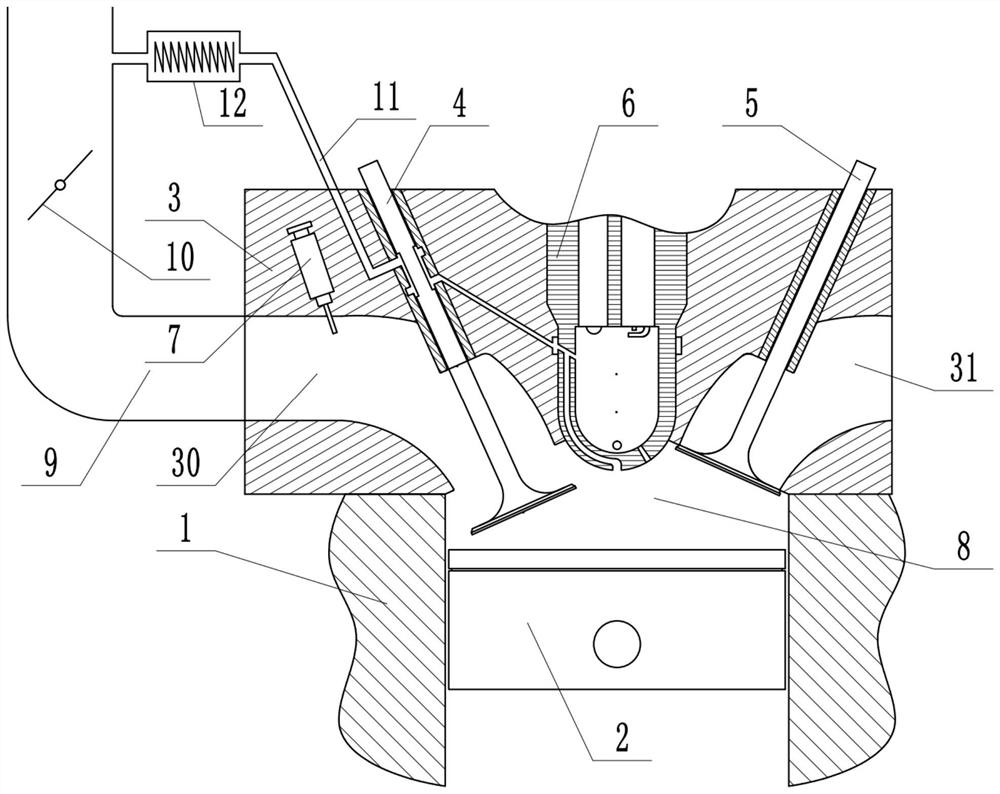

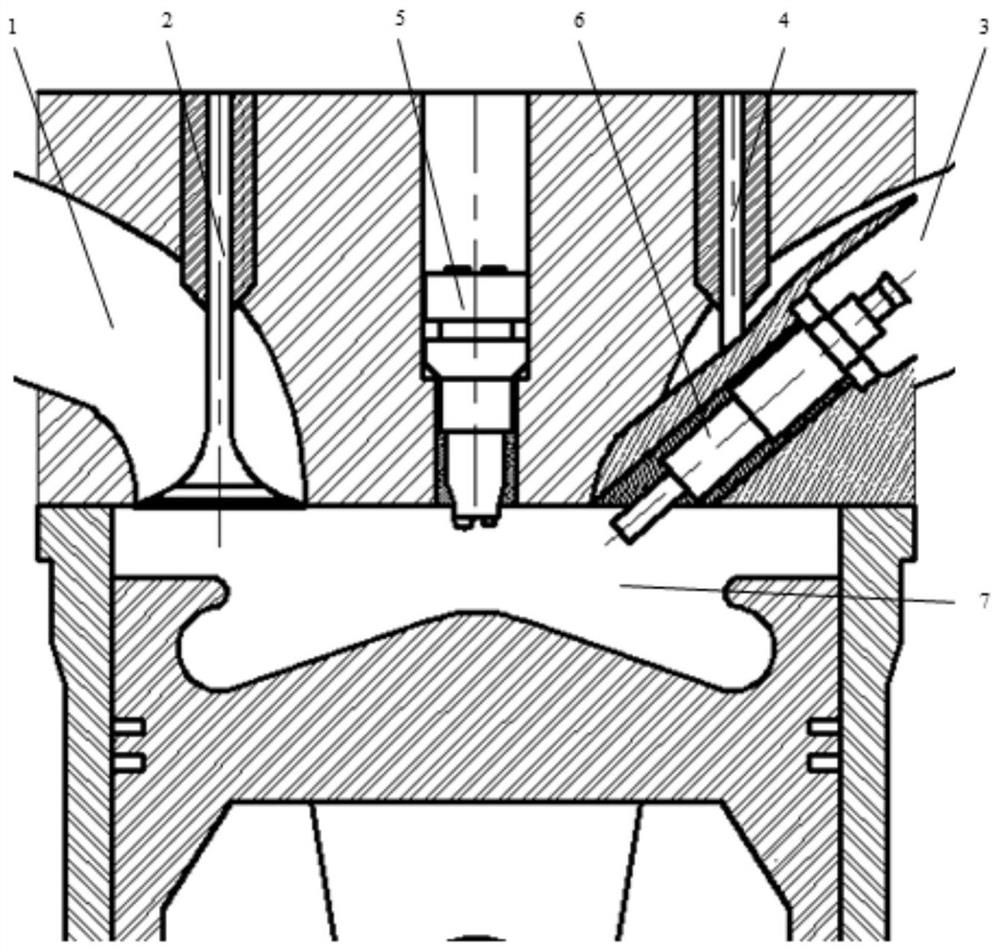

Combustion system of gasoline direct injection engine and control method thereof

InactiveCN102182608AChanges are easy to implementImprove ignition stabilityElectrical controlInternal combustion piston enginesCombustion systemExhaust valve

The invention provides a combustion system of a gasoline direct injection engine and a control method thereof, for improving the combustion and discharge status of a cold starting stage. The combustion system of the gasoline direct injection engine comprises a cylinder cover, a piston, a cylinder sleeve, a spark plug and an oil injector; the cylinder cover is provided with an intake valve, an exhaust valve, an intake passage connected with the intake valve, and an exhaust passage connected with the exhaust valve; the top surface of the piston is provided with an intake valve evading pit corresponding to the position of the intake valve and an exhaust valve evading pit corresponding to the position of the exhaust valve; the spark plug is mounted on one side of the cylinder cover between the intake valve and the exhaust valve and is close to the exhaust valve, the top surface of the piston rod between the downside of the spark plug and the oil sprayer is hollowed to form a concave pit, and the oil injector is arranged under the intake valve and faces towards the concave pit. The control method of the combustion system comprises the steps: A, a twice-injection layered combustion manner is adopted under a cold starting condition; and B, and a single-injection homogeneous equivalence-ratio combustion manner in which gasoline is injected one time in a gas inlet stroke is adopted under the other conditions.

Owner:CHERY AUTOMOBILE CO LTD

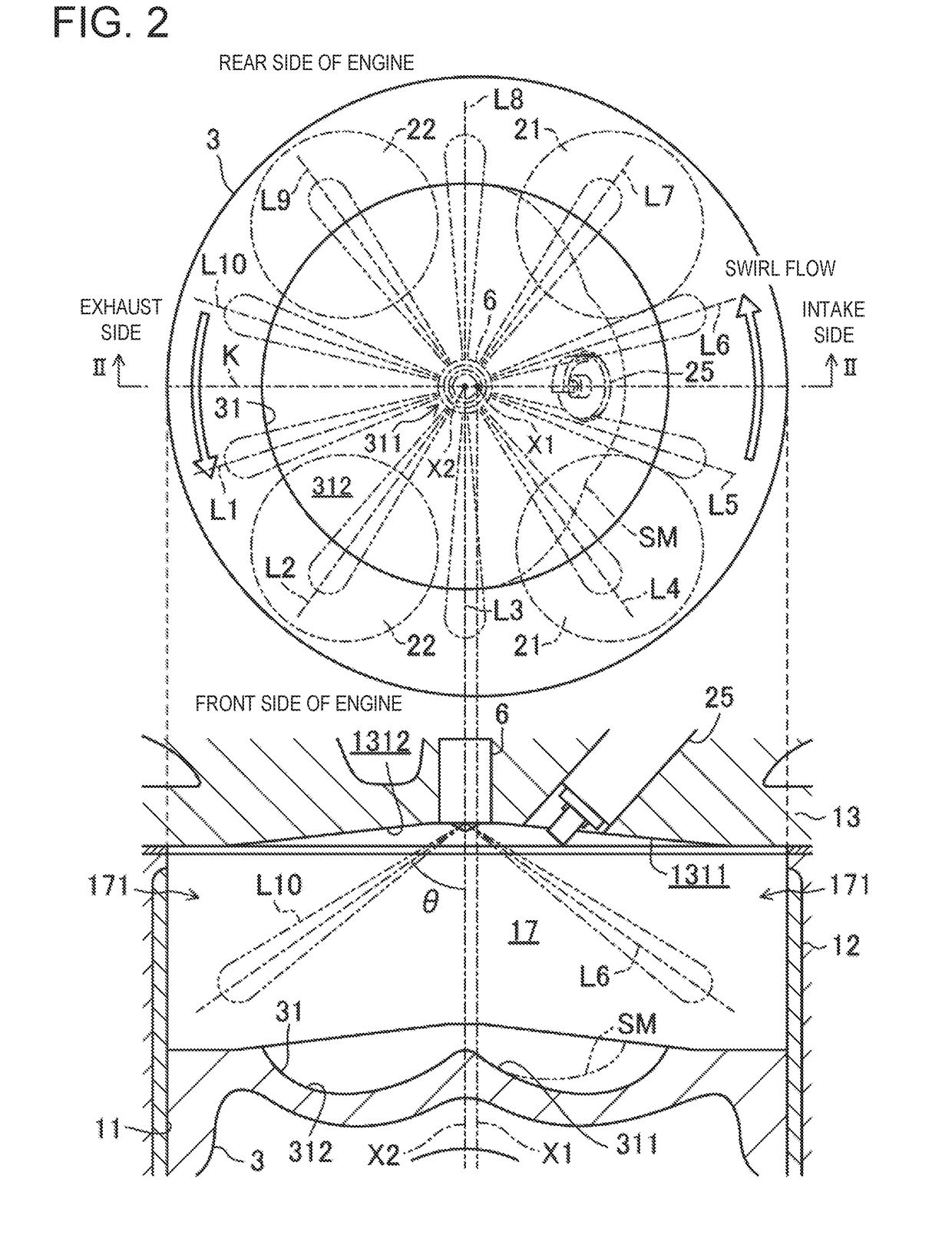

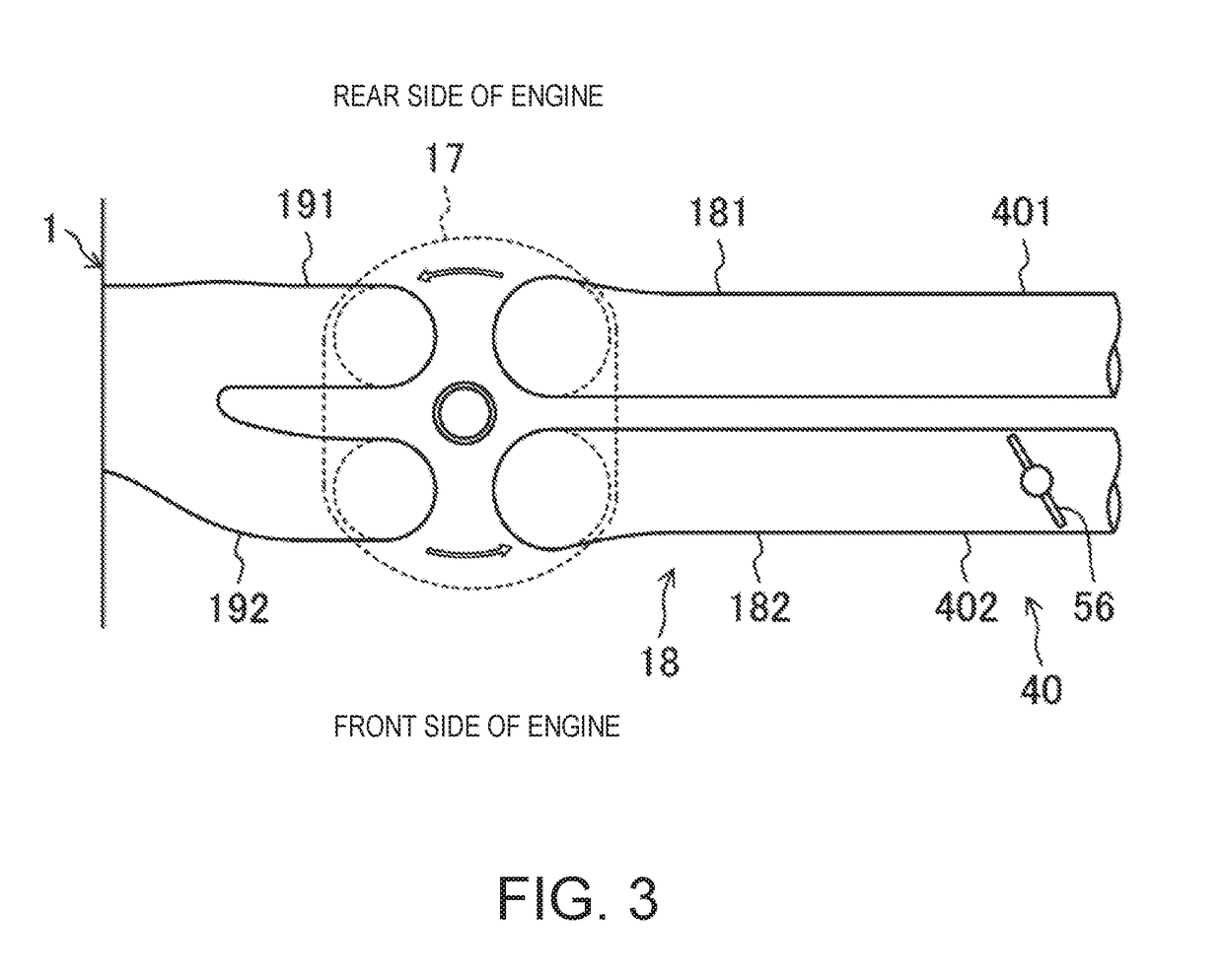

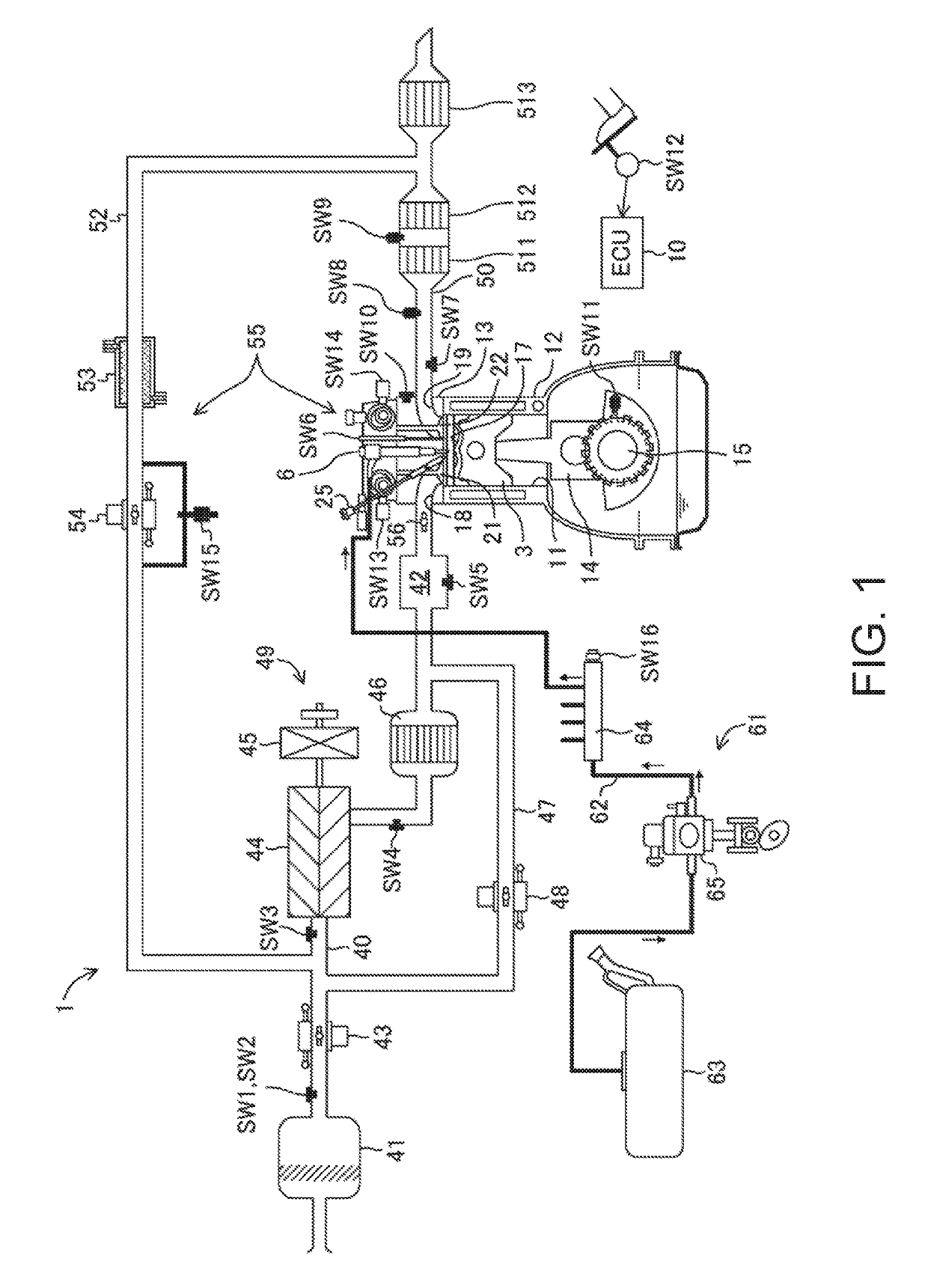

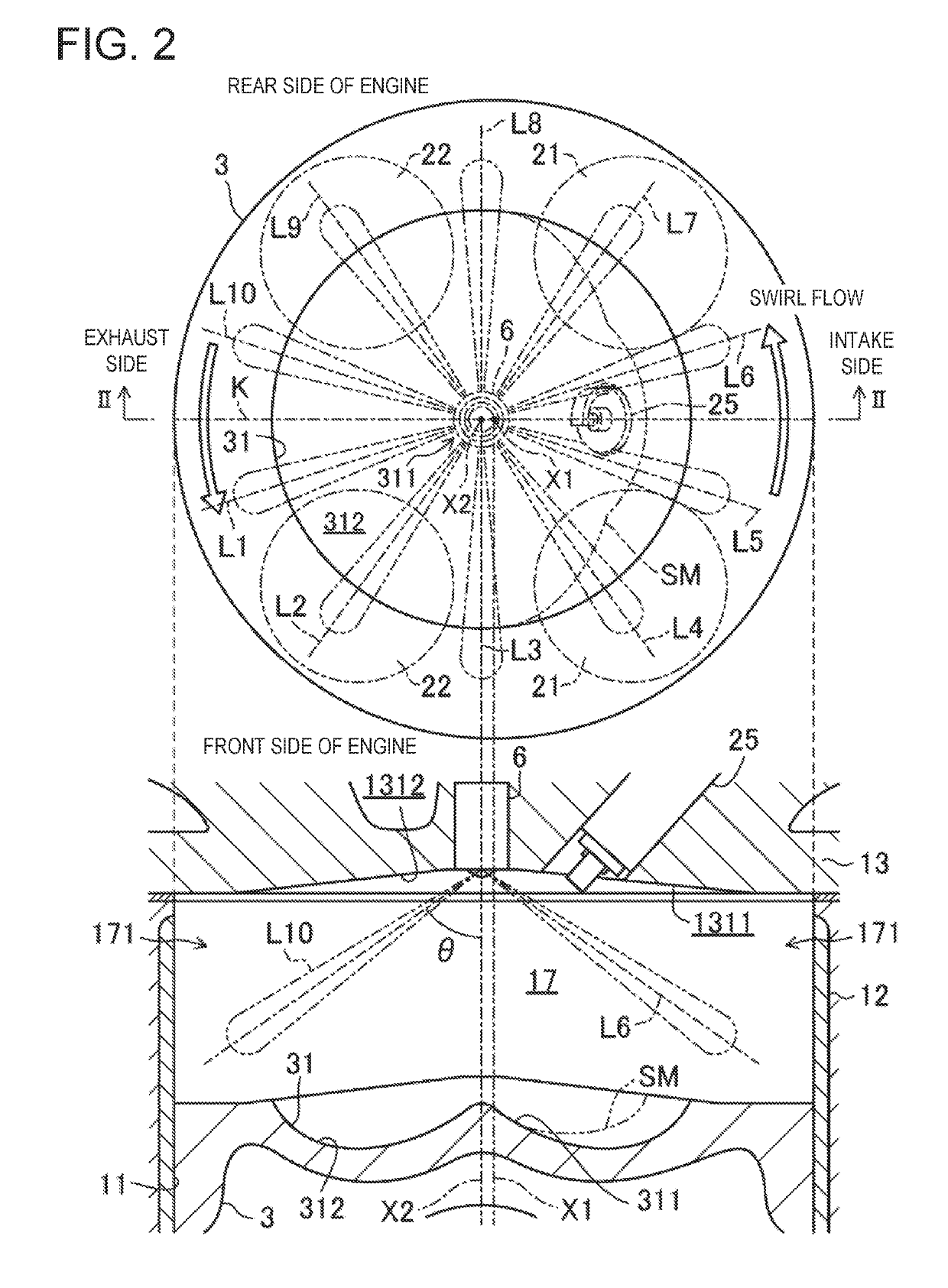

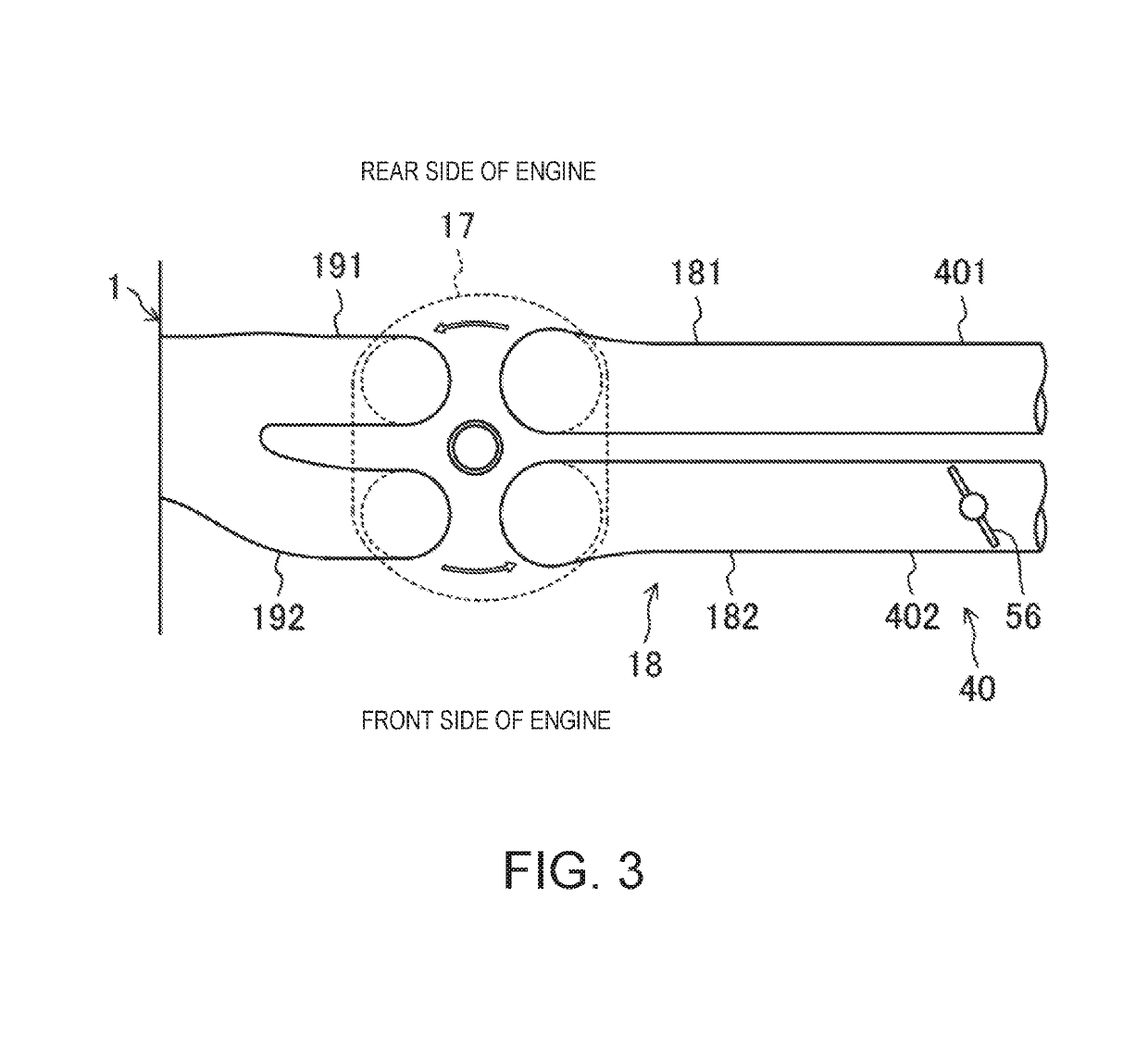

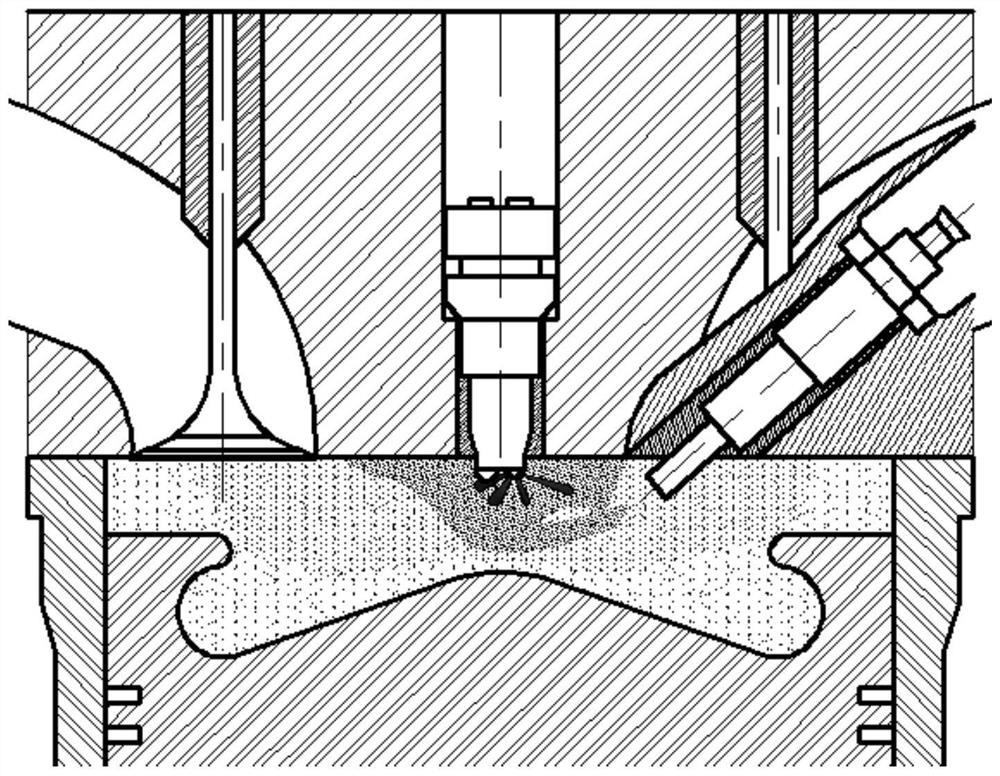

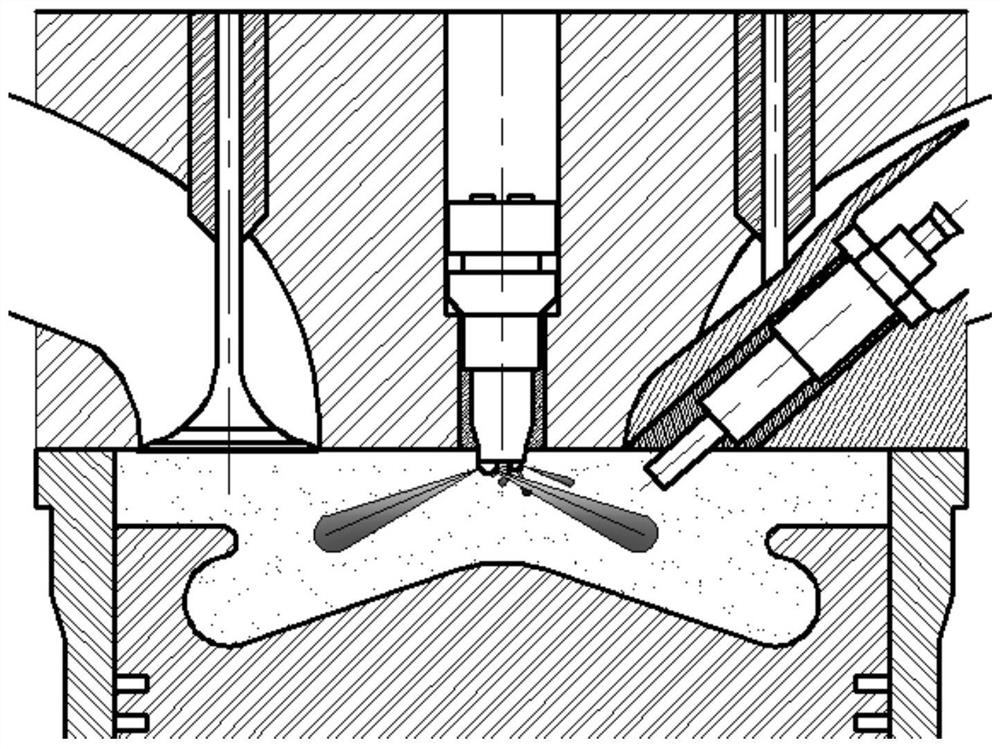

Fuel injection device of engine

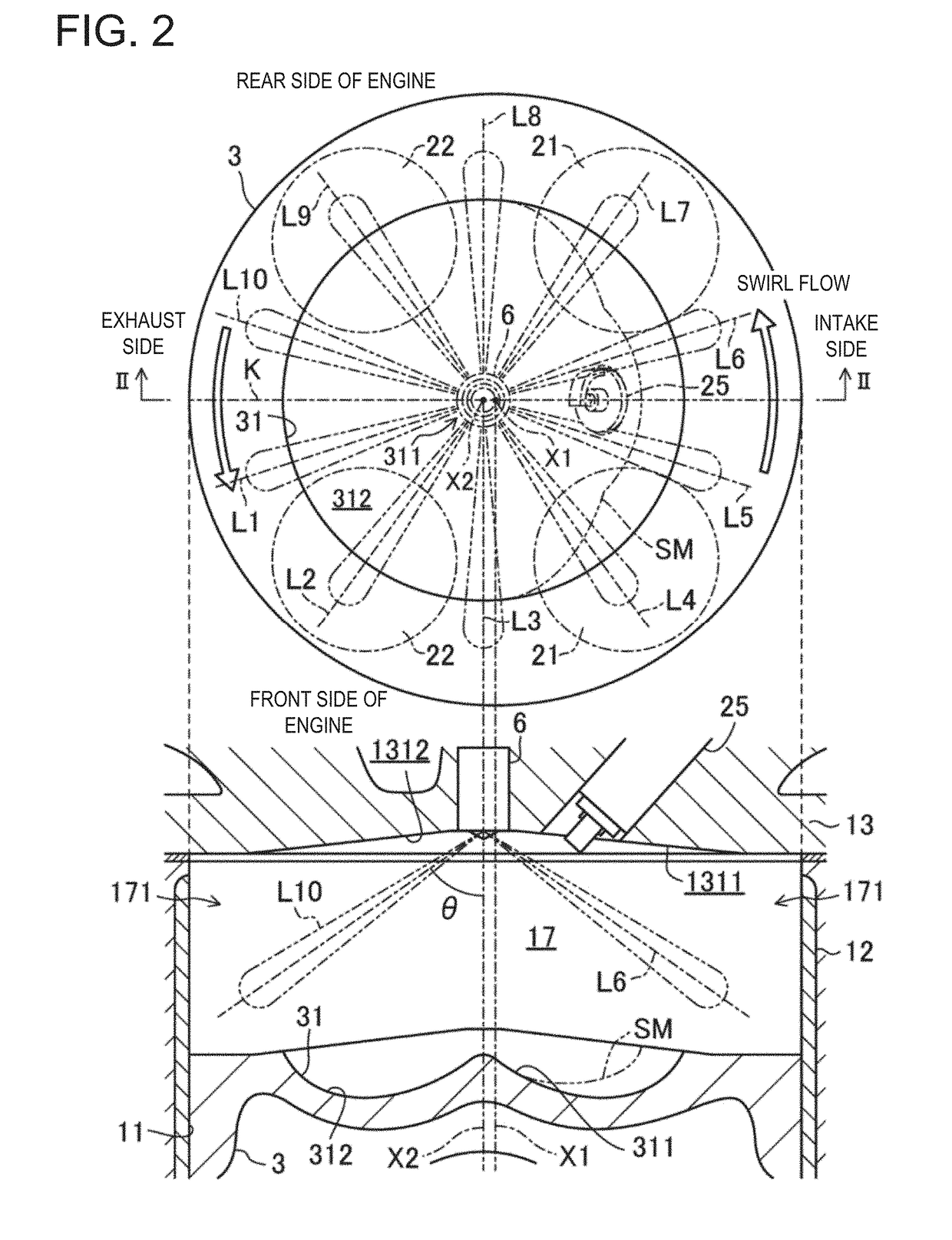

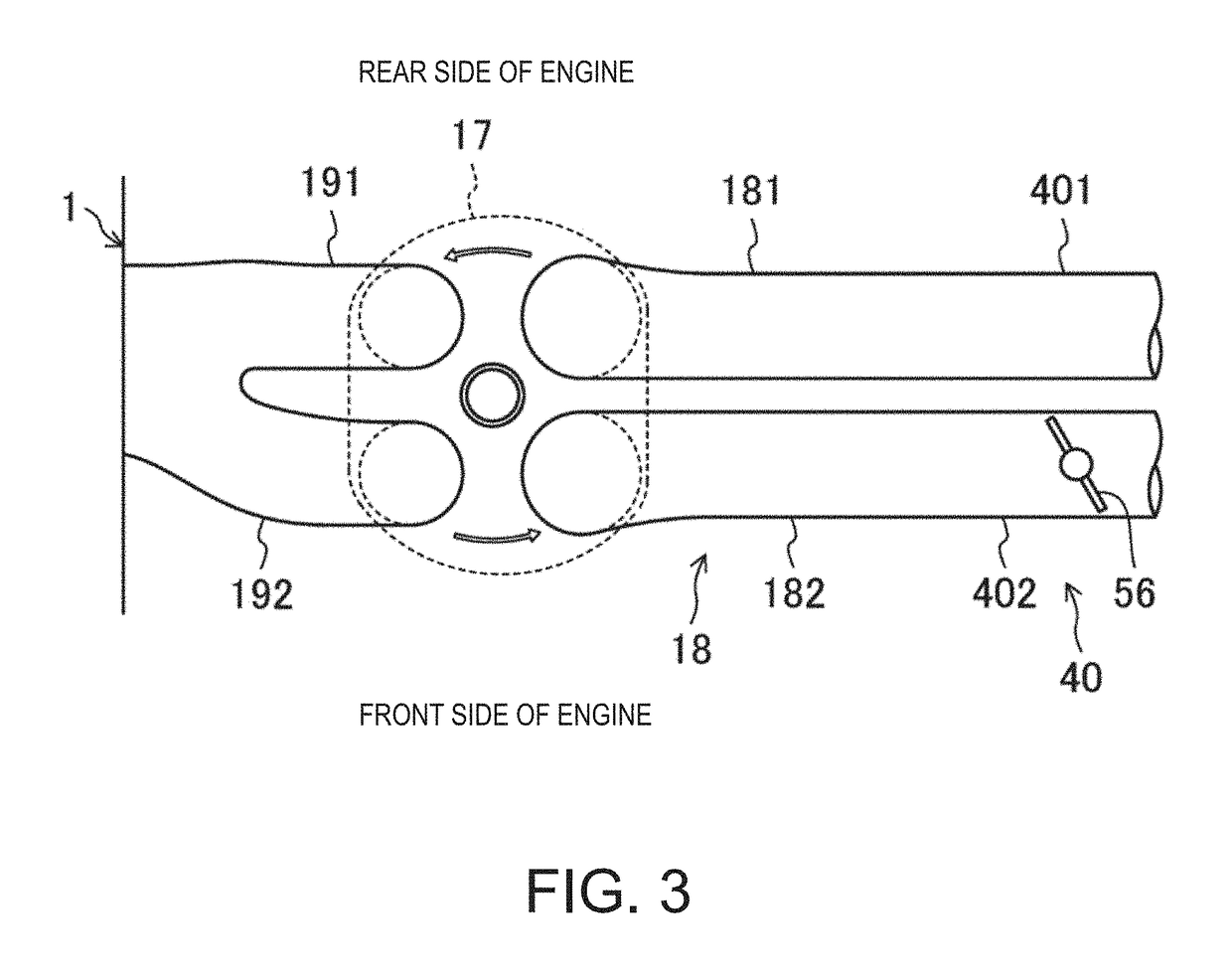

ActiveUS20190063338A1Stable flowImprove ignition stabilityElectrical controlInternal combustion piston enginesCombustion chamberControl signal

A control device of an engine including a cylinder, a piston, a cylinder head, and a combustion chamber is provided, which includes intake and exhaust ports, a swirl control valve provided in an intake passage connected to the intake port, a fuel injection valve attached to the cylinder head to be oriented into the center of the combustion chamber in a plan view thereof, and having first and second nozzle ports, and a control unit. The control unit includes a processor configured to execute a swirl opening controlling module to output the control signal to the swirl control valve to have a given opening at which a swirl ratio inside the combustion chamber becomes 2 or above, and a fuel injection timing controlling module to output the control signal to the fuel injector to inject fuel at a given timing at which the swirl ratio becomes 2 or above.

Owner:MAZDA MOTOR CORP

Spark plug with slant peripheral surface

A spark plug for an internal combustion engine is provided which includes a hollow cylindrical metal shell with an open end portion to be exposed to a combustion chamber of the engine, a ground electrode joined to the metal shell, a center electrode disposed in the metal housing to define a spark gap between itself and the ground electrode. The spark plug also includes a stream shaper or a stream reflector geometrically formed on the metal shell and / or the porcelain insulator to shape a vortex steam of air-fuel mixture into a stream thereof which is oriented outside the spark plug or serves to decrease the amount of the air-fuel mixture into a pocket between the metal shell and the porcelain insulator. This ensures the stability of ignition of the air-fuel mixture.

Owner:DENSO CORP +1

Fuel injection device of engine

ActiveUS20190063303A1Stable flowImprove ignition stabilityElectrical controlInternal combustion piston enginesCombustion chamberCylinder head

A control device of an engine including a cylinder, a piston, a cylinder head, and a combustion chamber, is provided. The device includes intake and exhaust ports, a swirl control valve, a fuel injection valve attached to the cylinder head to be oriented into the combustion chamber and having first and second nozzle ports, and a control unit. The control unit includes a processor configured to execute a swirl opening controlling module to control the swirl control valve to have a given opening at which a swirl ratio inside the combustion chamber becomes 2 or above, and a fuel injection timing controlling module to control the fuel injection valve to inject fuel at a given timing at which the swirl ratio becomes 2 or above and a swirl flow from a lower portion to a higher portion of the combustion chamber in a side view occurs.

Owner:MAZDA MOTOR CORP

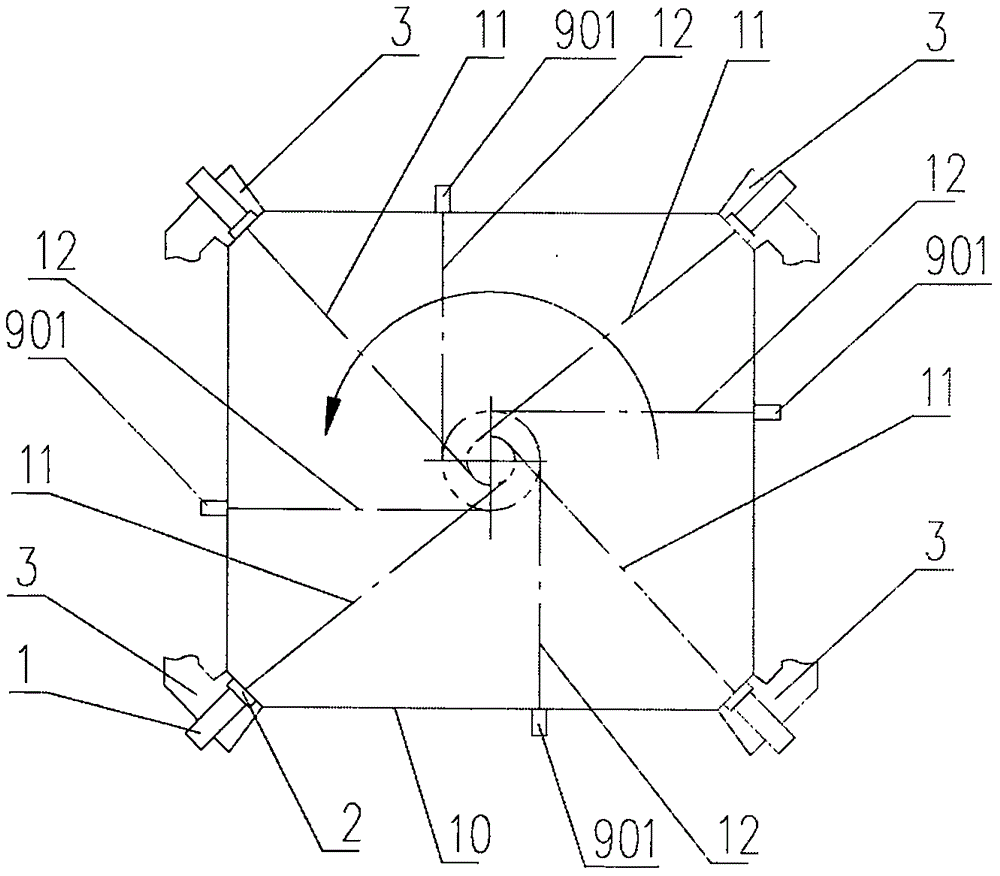

Intensive-classification low-NOx pulverized coal burner

ActiveCN103759259AIncrease swirl intensityIncrease combustionPulverulent fuel combustion burnersCombustion apparatusSlagNitric oxide

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD

Fuel injection device of engine

ActiveUS10480395B2Stable flowImprove ignition stabilityElectrical controlInternal combustion piston enginesCombustion chamberCylinder head

A control device of an engine including a cylinder, a piston, a cylinder head, and a combustion chamber, is provided. The device includes intake and exhaust ports, a swirl control valve, a fuel injection valve attached to the cylinder head to be oriented into the combustion chamber and having first and second nozzle ports, and a control unit. The control unit includes a processor configured to execute a swirl opening controlling module to control the swirl control valve to have a given opening at which a swirl ratio inside the combustion chamber becomes 2 or above, and a fuel injection timing controlling module to control the fuel injection valve to inject fuel at a given timing at which the swirl ratio becomes 2 or above and a swirl flow from a lower portion to a higher portion of the combustion chamber in a side view occurs.

Owner:MAZDA MOTOR CORP

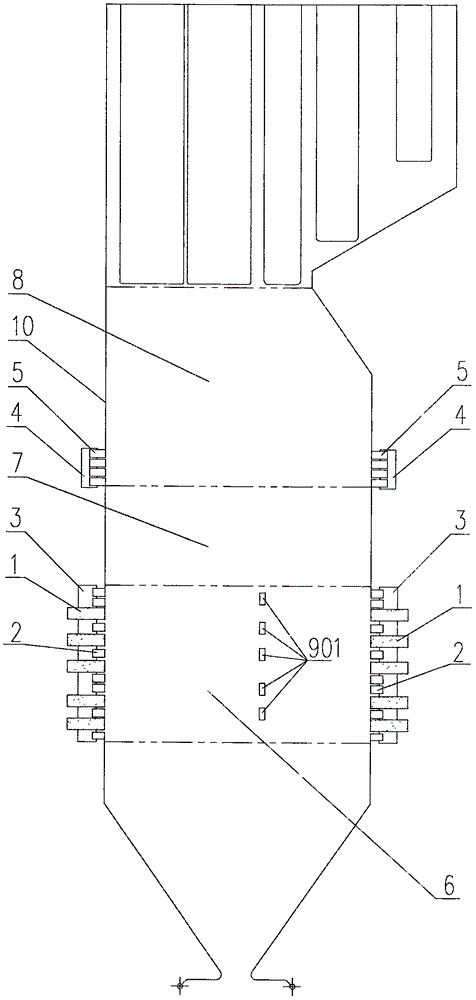

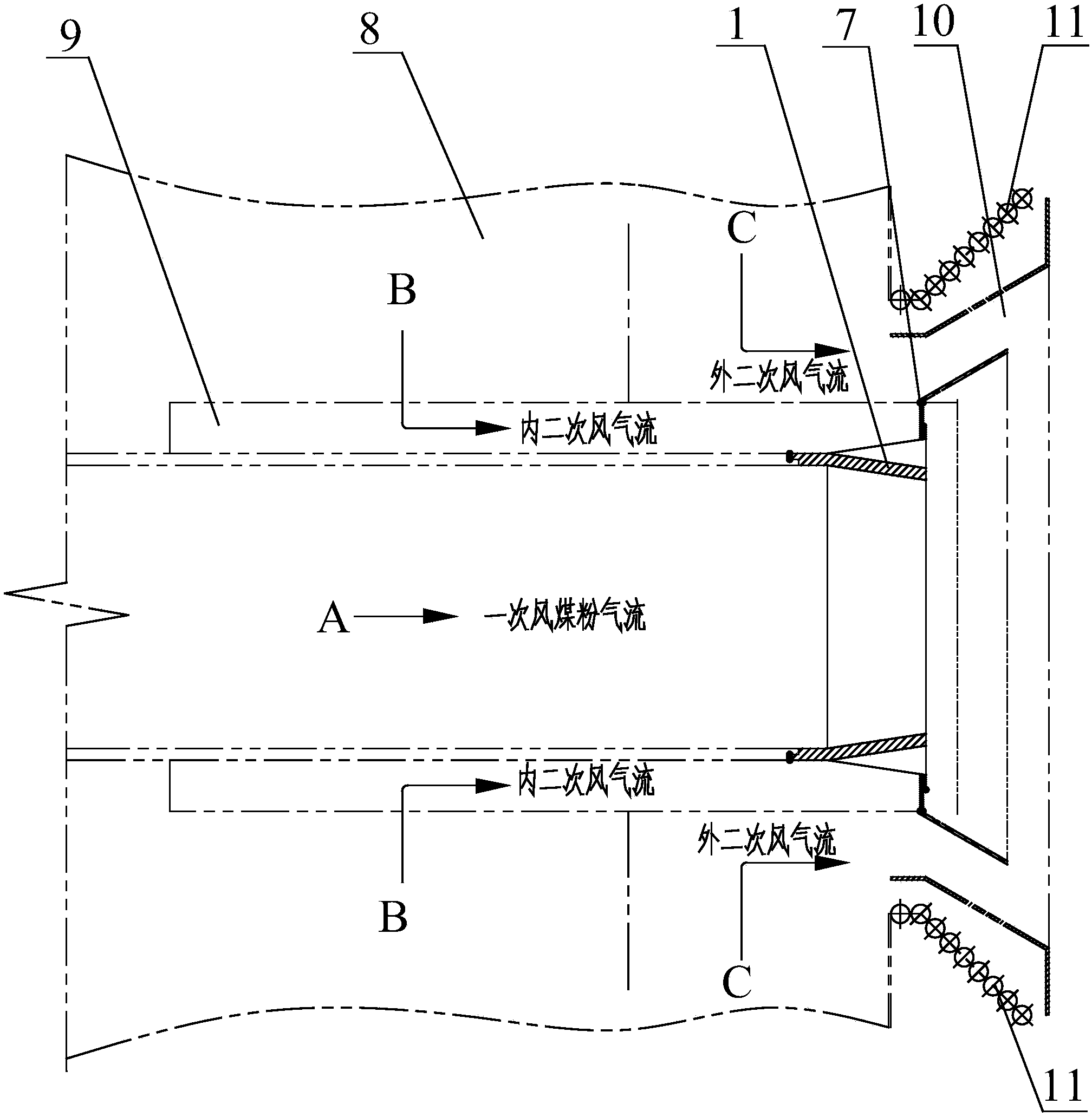

High-efficiency NOx double-vortex rotational flow pulverized coal burner

PendingCN111594830AAchieve combustionEliminate concentrated flamesPulverulent fuel combustion burnersNon-combustible gases/liquids supplyThermodynamicsCombustor

The invention discloses a high-efficiency NOx double-vortex rotational flow pulverized coal burner and relates to the technical field of clean energy combustion. The problems that an existing rotational flow pulverized coal burner is poor in coal type adaptation, the NOx discharging inhibiting technology is not complete, and high-efficiency low NOx pulverized coal combustion is hardly achieved aresolved. By means of the high-efficiency NOx double-vortex rotational flow pulverized coal burner, combustion classification is conducted, traditional primary air pulverized coal air flow is divided into an inner strand and an outer strand with the same coal quality or the different coal quality; thick air flow and thin air flow are separate, in other words, an inner conical concentrator and an outer conical concentrator are used for conducting thick and thin separation on inner and outer primary air pulverized coal air flow; classification air distribution is conducted, wherein inner secondary air and outer secondary air which are independently controlled respectively are matched and cooperated with the inner and outer primary air pulverized coal air flow to be sprayed into a furnace, anda center pipe provides center air; and absolute ignition combustion stabilization based on inner vortex rotational flow pulverized coal air flow ignites outer vortex rotational flow pulverized coal air flow constantly, and generation of various kinds of NOx is effectively reduced. The high-efficiency NOx double-vortex rotational flow pulverized coal burner is mainly used for achieving pulverizedcoal ignition combustion stabilization and efficient low NOx combustion.

Owner:HARBIN INST OF TECH

Pulverized coal jet flow midstream and downstream combustion organization method in tangent circle pulverized coal combustion boiler

InactiveCN106287678AIncrease oxygen concentrationIncrease burn rateCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBurning tissueCombustor

The invention discloses a pulverized coal jet flow midstream and downstream combustion organization method in a tangent circle pulverized coal combustion boiler. Corresponding wall air nozzles are distributed in a hearth main combustion area of the pulverized coal combustion boiler in a manner of corresponding to primary air pulverized coal combustors, and are formed in the positions, close to the pulverized coal jet flow midstream and downstream positions of outlets, of a hearth water cooling wall, part of hot air is introduced into the wall air nozzles, and is directly sprayed into the corresponding primary air pulverized coal jet flow midstream and downstream interval in a jet flow manner, pulverized coal jet flow midstream and downstream combustion organization is carried out, the oxygen concentration and the pulverized coal combustion rate of the pulverized coal jet flow midstream and downstream interval are improved, and wall attaching happening of the pulverized coal jet flow midstream and downstream interval is directly obstructed. According to the method, pulverized coal jet flow midstream and downstream interval combustion organization and control can be achieved, happening of water cooling wall coking and high-temperature corrosion is prevented, the pulverized coal combustion efficiency is further improved, NOx generation and emissions are reduced, the proper combustion capacity of the pulverized coal combustion boiler for combustion low-volatile lower-ash-melting-point coal is expanded, and the fuel procurement cost is reduced.

Owner:张泽

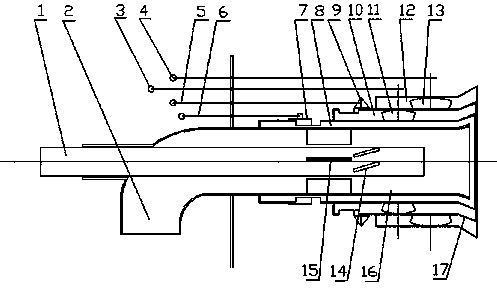

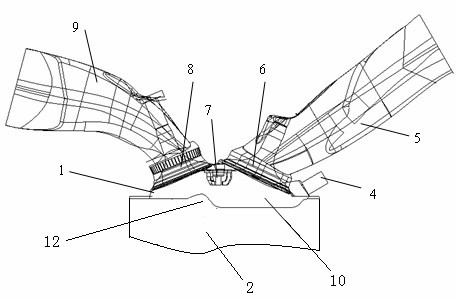

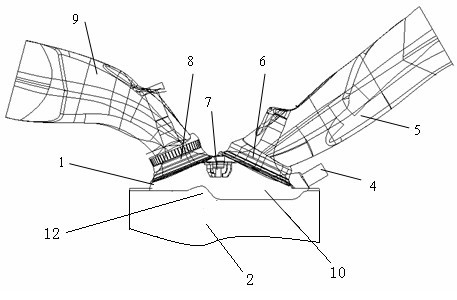

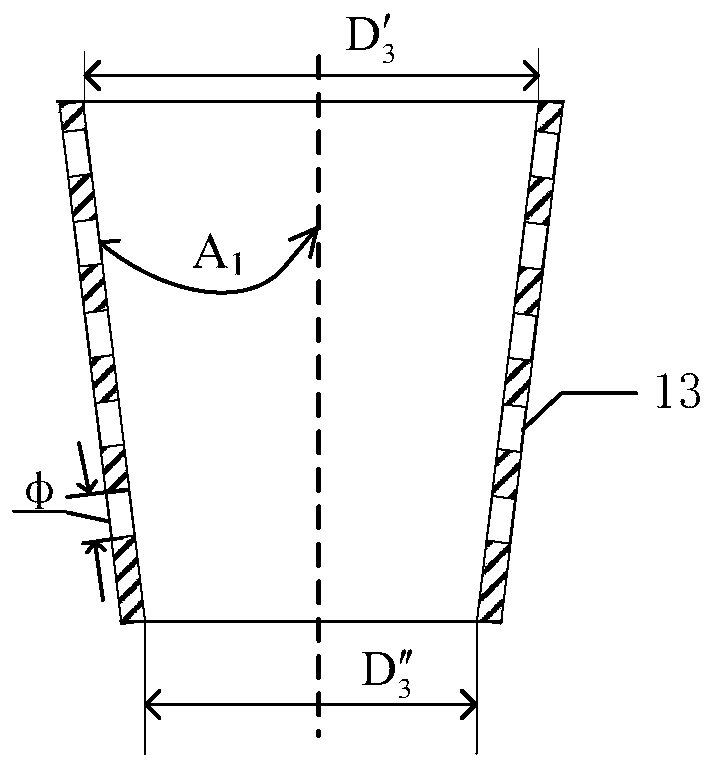

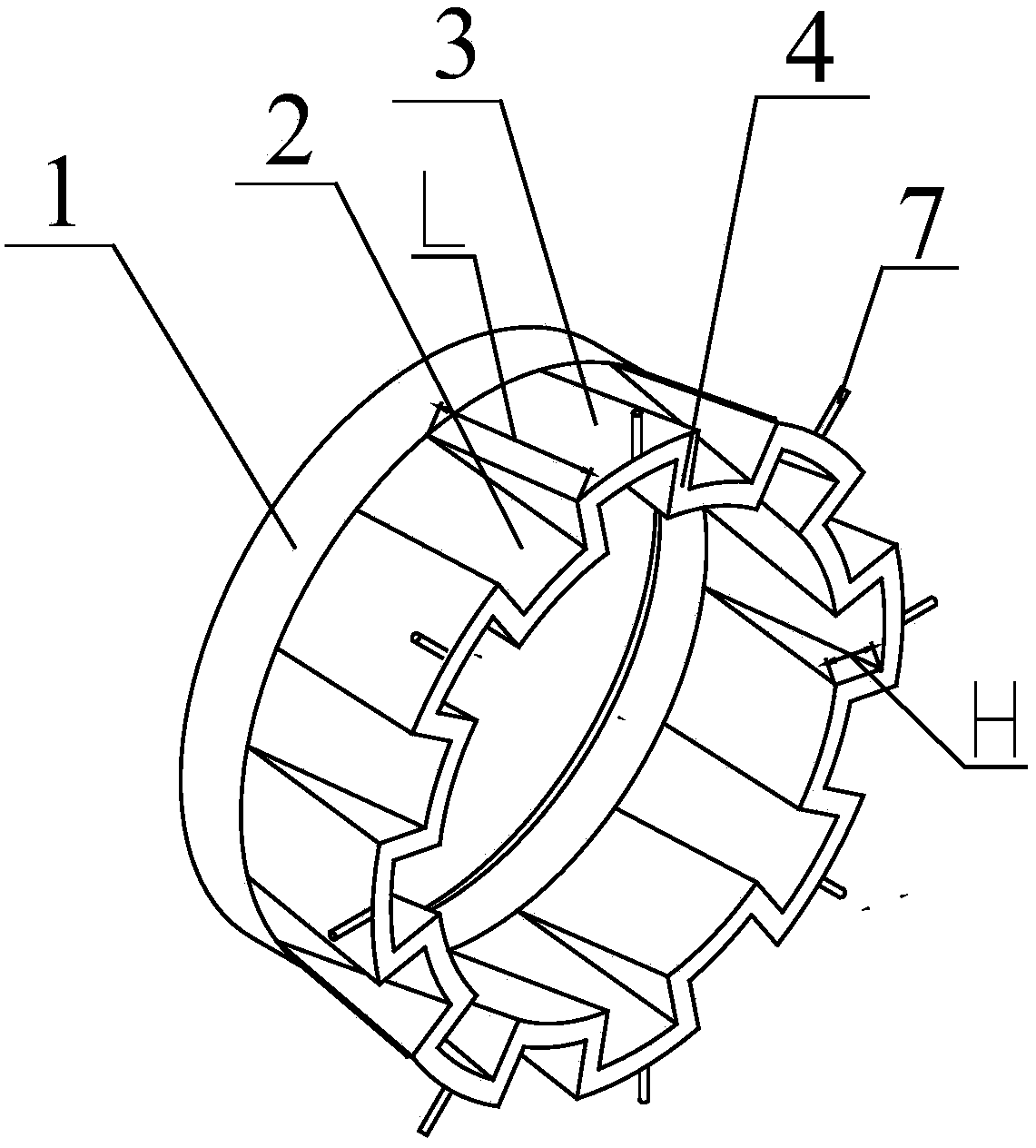

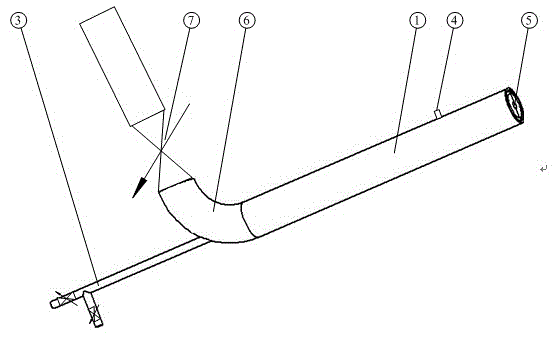

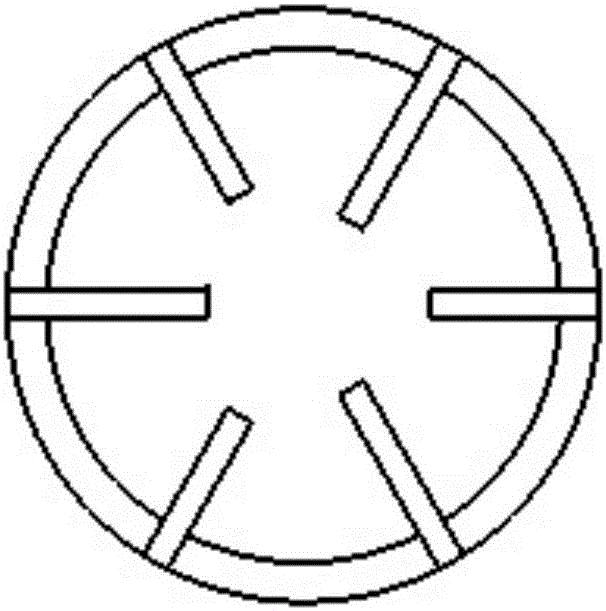

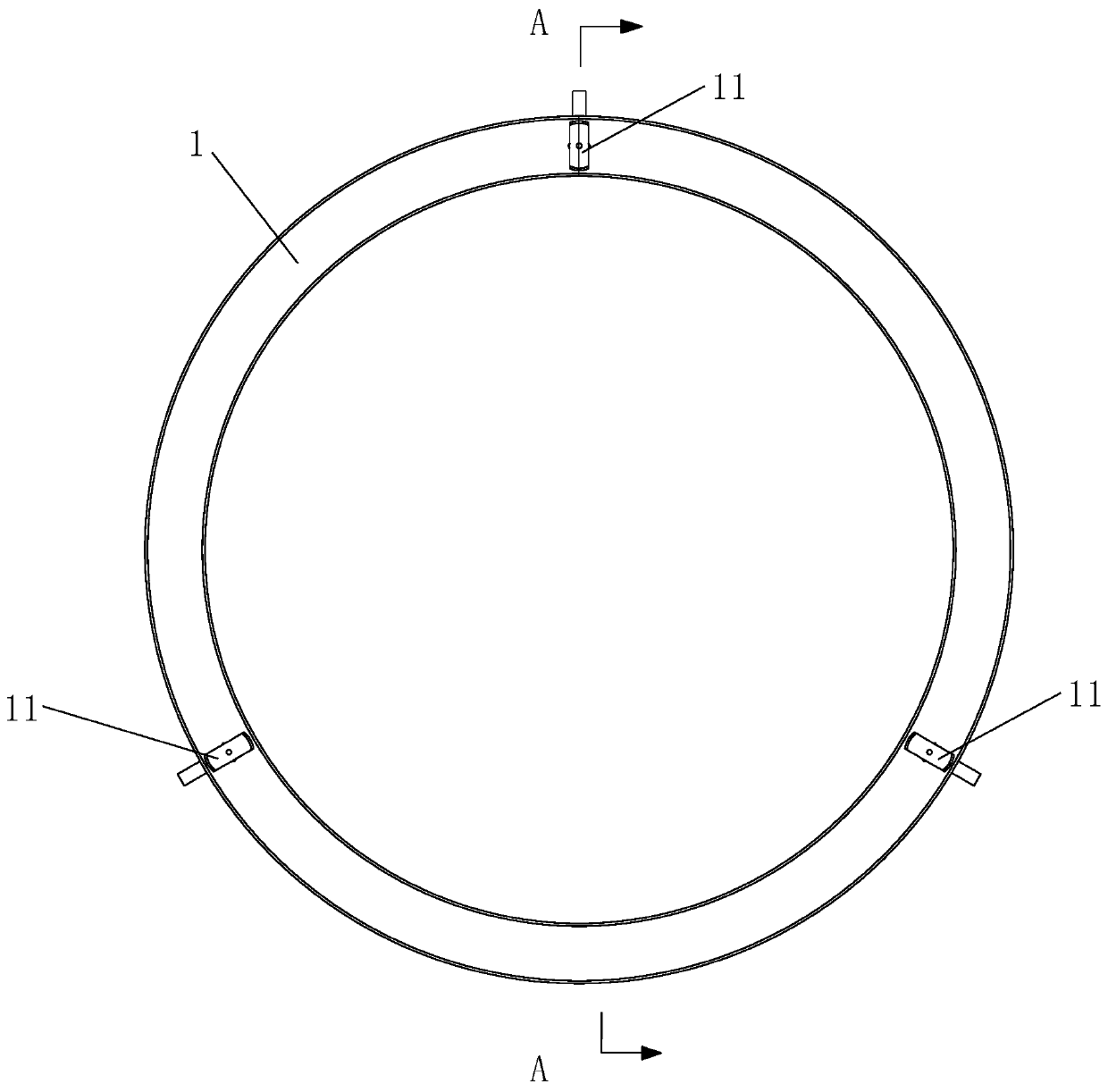

Internal contraction and external expansion type nozzle for swirl pulverized coal burner

ActiveCN103411214AReduce the impact of a direct collisionGuaranteed strong ignition and stable combustion performancePulverulent fuel combustion burnersCoal particleCoal fired

The invention discloses an internal contraction and external expansion type nozzle for a swirl pulverized coal burner. The opening section of a nozzle body is in a two-sided battlement guide structure and comprises internal contraction type flow deflectors and external expansion type flow deflectors which are arranged circumferentially in a staggered mode, radiuses of sections of the internal contraction type flow deflectors from the root to the end decrease gradually with the diameter D of the inner cavity of the opening section of the nozzle body serving as the reference, radiuses of sections of the external expansion type flow deflectors from the root to the end increase gradually with the diameter D of the inner cavity of the opening section of the nozzle body serving as the reference, and adjacent internal contraction type flow deflectors and external expansion type flow deflectors are connected through radial transition plates. The internal contraction and external expansion type nozzle has a good guide effect on pulverized coal airflow, direct impact of pulverized coal particles on the nozzle is reduced, the pulverized coal airflow is mixed with external hot smoke intensely for heat exchange when sprayed from the nozzle, strong ignition and stable combustion performances of the pulverized coal are guaranteed, the pulverized coal airflow resistance can be effectively reduced, abrasion to the nozzle is small, and the service life of the nozzle is long. The internal contraction and external expansion type nozzle is particularly suitable for coal-fired boilers of swirl pulverized coal burners with front and back walls in cross arrangement.

Owner:中节环立为(武汉)能源技术有限公司

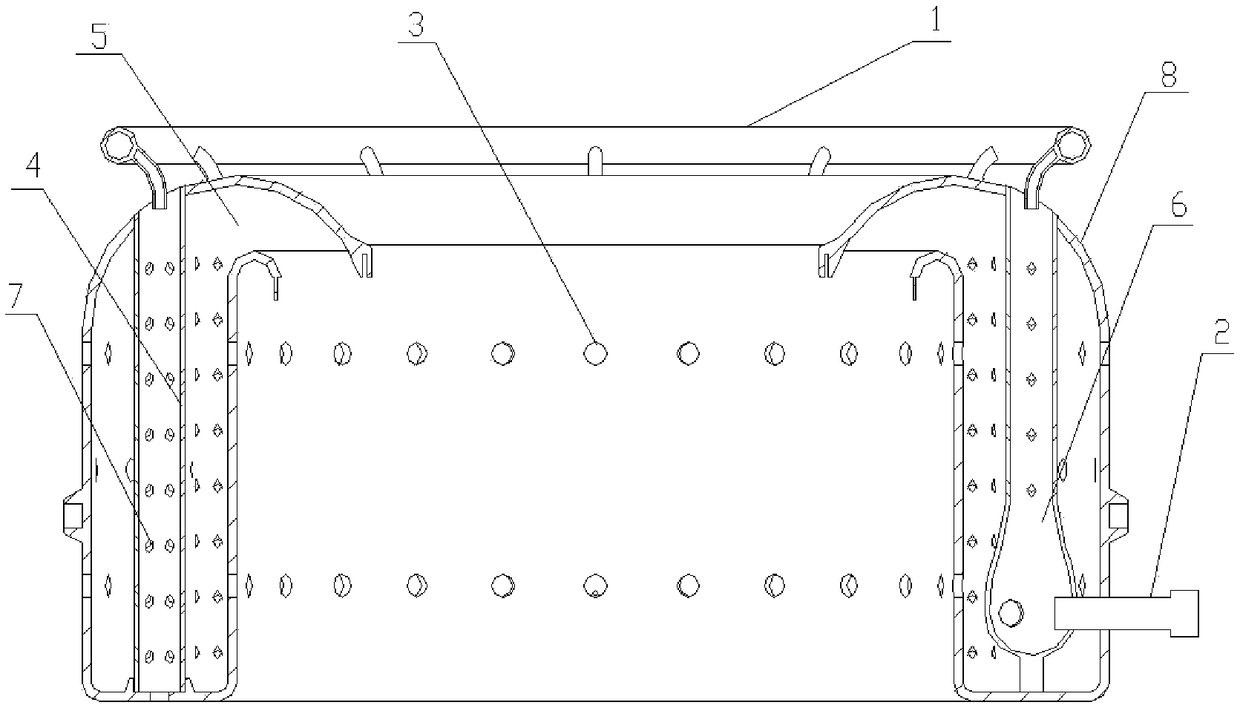

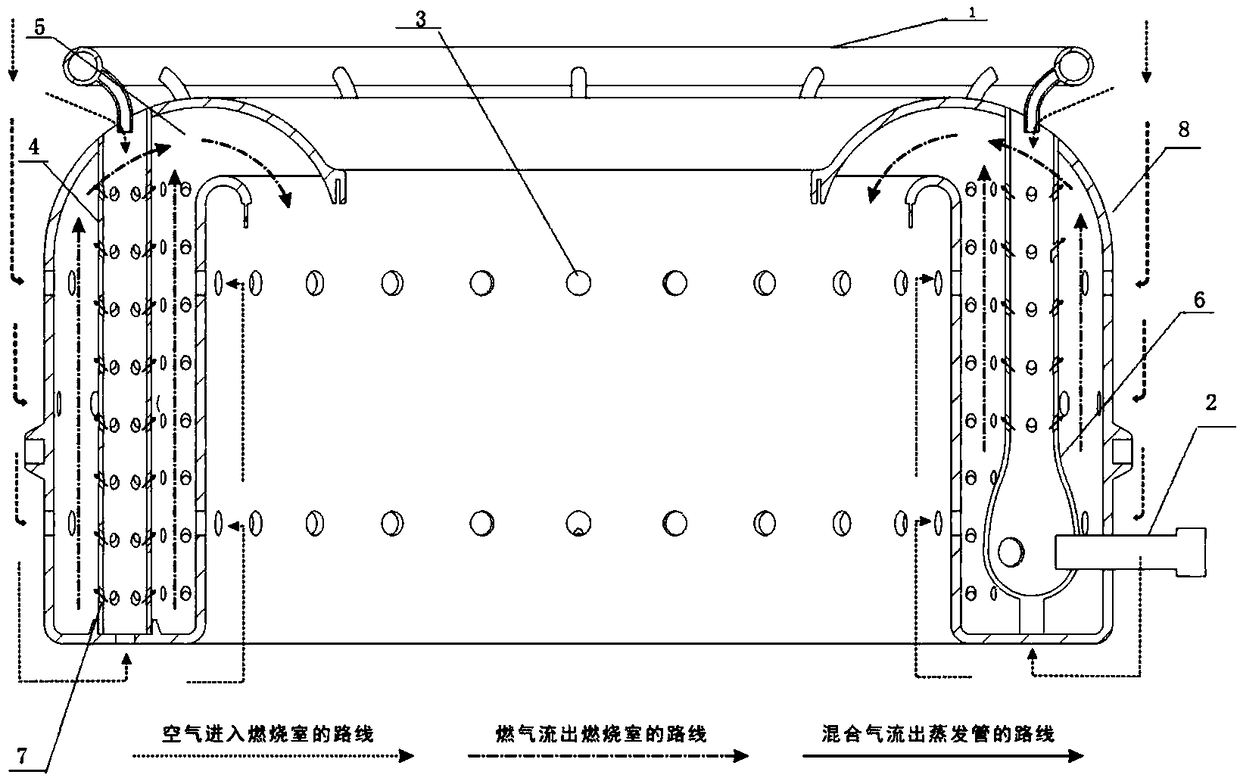

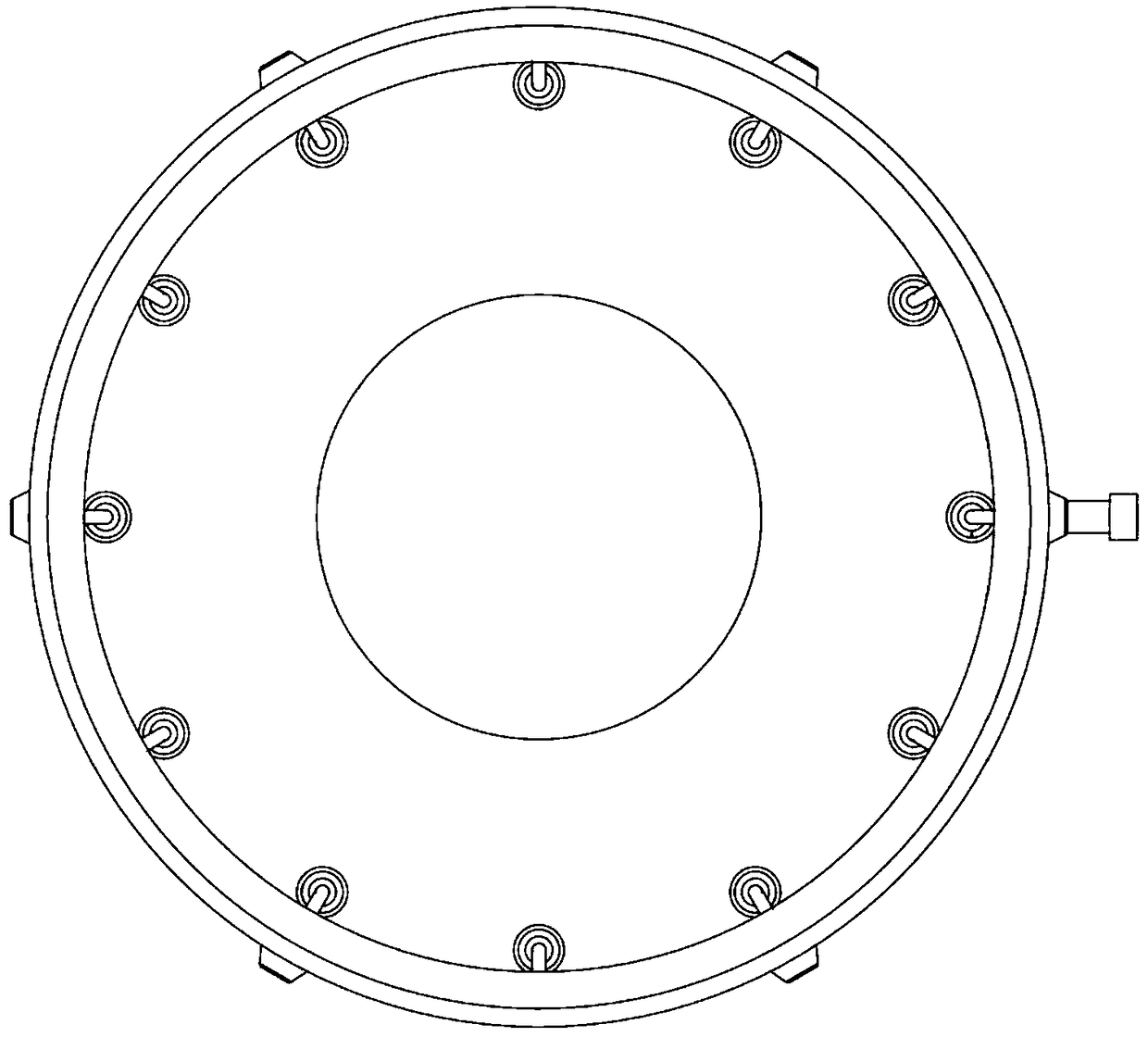

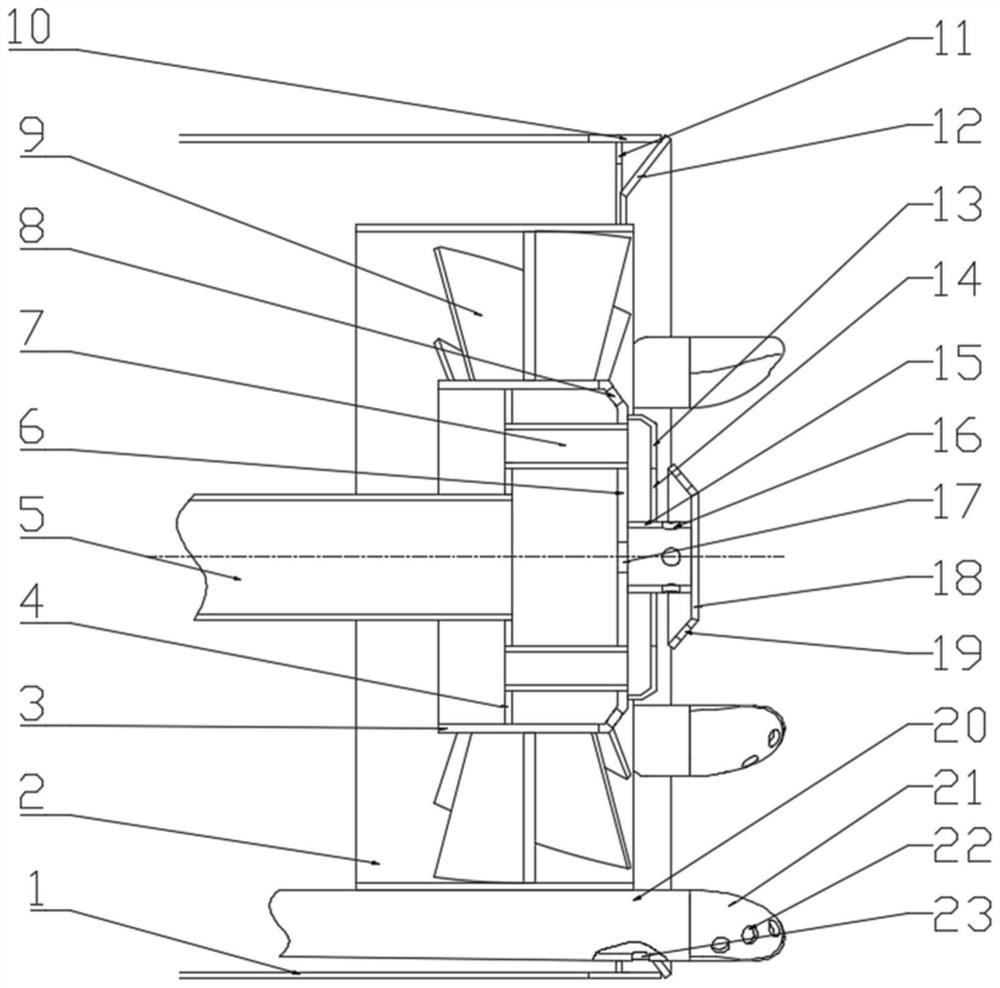

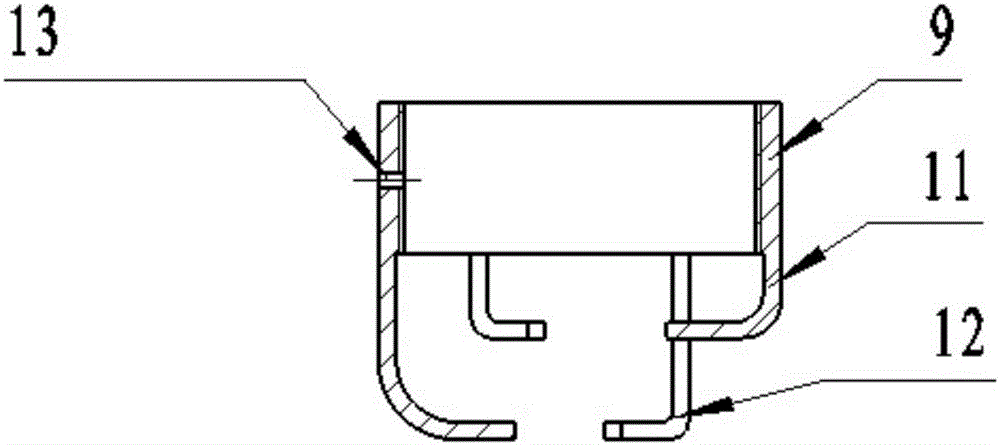

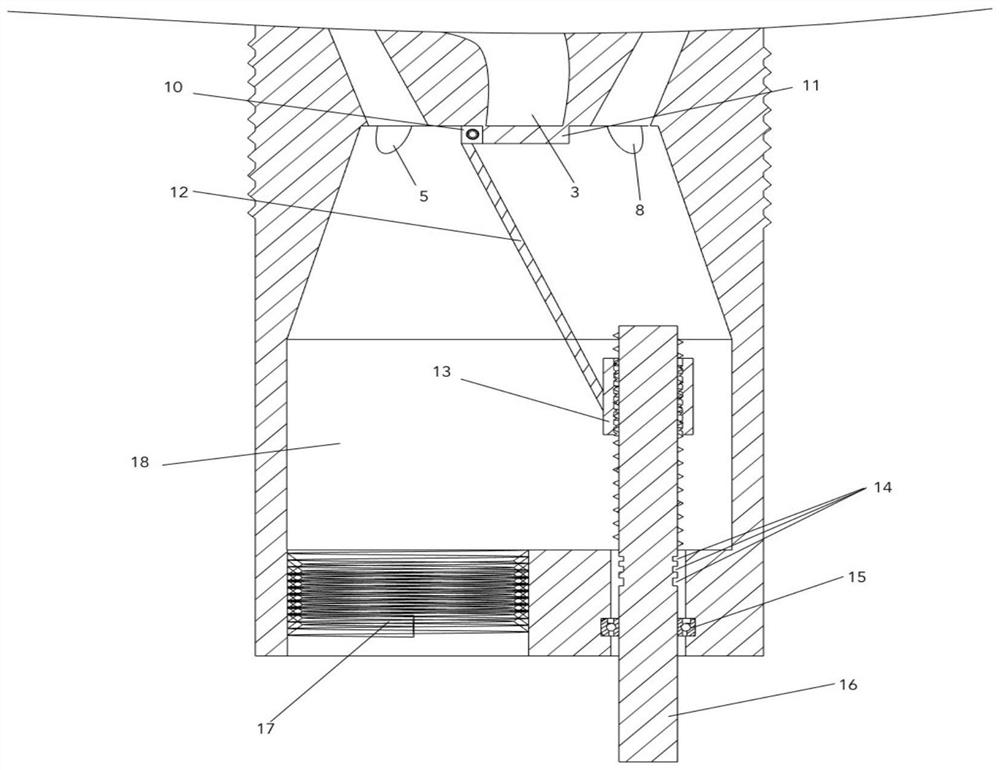

Mini type turbine engine combustion chamber

PendingCN108758689AImprove ignition stabilitySlow airflowContinuous combustion chamberCombustion chamberEvaporation

The invention provides a mini type turbine engine combustion chamber. The mini type turbine engine combustion chamber comprises an oil conveying ring, an igniter, evaporation pipes, a combustion chamber shell and a combustion chamber ignition cavity. Combustion chamber air inlet holes are formed in the outer wall of the combustion chamber shell. After the lower area of the outer wall of the combustion chamber shell extends into the body and is bent, an inner wall is formed, and an annular U-shaped cavity is formed by the outer wall and the inner wall and is a combustion chamber cavity. The oilconveying ring is fixedly connected to the upper end of the combustion chamber shell, the tail end of an oil conveying pipe is arranged in each evaporation pipe, and the igniter is arranged on the side wall of the combustion chamber shell. The multiple evaporation pipes are fixedly connected in the combustion chamber cavity. The injection action of high-temperature and high-pressure airflow in the combustion chamber is utilized for bringing out fuel oil and air mixed gas in the evaporation pipes, and combustion in the combustion chamber is more uniform; and meanwhile, the independent ignitioncavity is used in the combustion chamber, and ignition stability is improved.

Owner:西安空天能源动力智能制造研究院有限公司

Pre-combustion chamber device for improving combustion and reducing thermal loads and engine

PendingCN113153515AAvoid reverse flowPrevent reverse flow backInternal combustion piston enginesAir coolingThermodynamicsCombustion chamber

The invention relates to a pre-combustion chamber device capable of improving combustion and reducing thermal loads and an engine. The pre-combustion chamber device comprises a cylinder cover, an intake valve, an intake valve guide pipe, an intake pipe, a pre-combustion chamber body, a gas connecting pipe and a heater. A pre-combustion chamber inner cavity is formed in the pre-combustion chamber body, and the cylinder cover is provided with an intake channel, a cylinder cover air entraining channel and a cylinder cover gas channel. The outer end of the intake channel is communicated with the intake pipe, the gas connecting pipe is connected between the intake pipe and an inlet of the cylinder cover air entraining channel, the heater is connected to the middle of the gas connecting pipe, and the pre-combustion chamber body is provided with a pre-combustion chamber scavenging channel communicated with an outlet of the cylinder cover gas channel and the pre-combustion chamber inner cavity. A pre-combustion chamber cooling channel with the upper end being communicated with the middle of the pre-combustion chamber scavenging channel, and the lower end being communicated with a main combustion chamber of the engine is further formed in the pre-combustion chamber body. According to the pre-combustion chamber device for improving combustion and reducing the thermal loads, the combustion stability of the main combustion chamber of the engine can be improved, and meanwhile the thermal loads of the pre-combustion chamber body can be reduced.

Owner:东莞市晨兴智能精密装备有限公司

Fuel gas decoupling combustor and using method thereof

The invention relates to a fuel gas decoupling combustor and a using method thereof. The fuel gas decoupling combustor adopts a partition staged combustion mode of central and peripheral oxygen deficit and central area lean combustion, diffusion type oxygen-deficient combustion with high combustion stabilizing capacity and low heat intensity is adopted in the central combustion area, reliable ignition and low-load stable combustion of the oxygen-deficient combustion area are ensured, the peripheral oxygen-deficient combustion area controls temperature distribution of a combustion chamber by accurately controlling partition mixing of fuel gas and air, the radiation heat transfer capacity is improved, and mixed burnout of the peripheral fuel gas and the main combustion area is promoted. In aword, the problem that the combustion temperature of a diffusion combustion mode is too high in the central stage is effectively solved by the fuel gas decoupling combustor and the using method thereof, the combustion chamber is more uniform in heat intensity, high in flame fullness, high in heat transfer capacity and long in smoke retention time, the combustion efficiency is guaranteed under thecondition of low fan power consumption, meanwhile, generation of thermal NOX is reduced, and decoupling combustion of the fuel gas is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

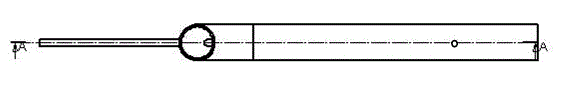

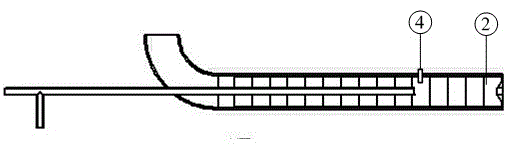

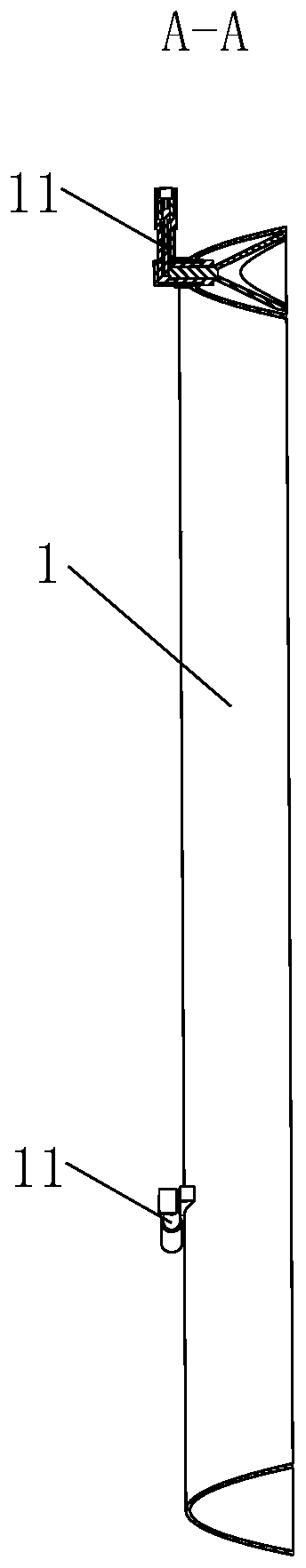

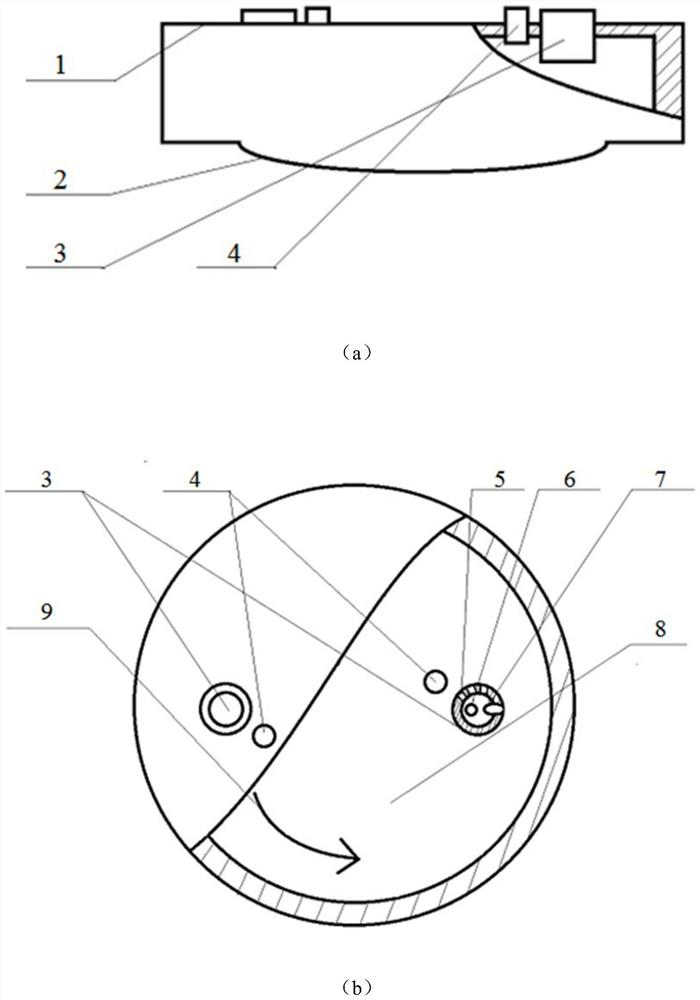

Tiny-oil ignition device of pulverized coal burner

InactiveCN102913949ASave ignition fuel consumptionLow costPilot flame ignitersPulverulent fuel combustion burnersCombustorIgnition coil

The invention discloses a tiny-oil ignition device of a pulverized coal burner, and belongs to the field of burners. The tiny-oil ignition device of the pulverized coal burner is formed by mounting and connecting a round igniter channel pipe 1 which is provided with an adjusting valve 7 and is internally lined with a high-temperature fire-resistant ceramic chip 2, an igniter 4 extending the inside of the igniter channel pipe, a stretchable ignition oil gun 3 coaxial with the igniter channel pipe, a high-temperature fire-resistant ceramic bluff body 5 arranged at an outlet end of the igniter channel pipe, and the like. One end of the ignition oil gun is arranged in the igniter channel pipe in an extending way; the igniter is arranged on a pipe wall of the igniter channel pipe and is arranged in the igniter channel pipe in the extending way; the igniter is arranged near the outlet end of the ignition oil gun inside the igniter channel pipe; and the high-temperature fire-resistant ceramic bluff body is arranged at the outlet end of the igniter channel pipe. The tiny-oil ignition device provided by the invention has the advantages of reasonable science, simple structure, easiness for production and manufacture, convenience for use and good effect; the ignition oil consumption of the pulverized coal burner can be saved; and the fuel cost of an enterprise is reduced.

Owner:YANGZHOU UNIV

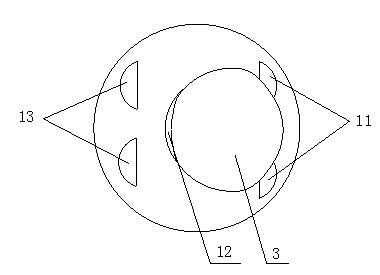

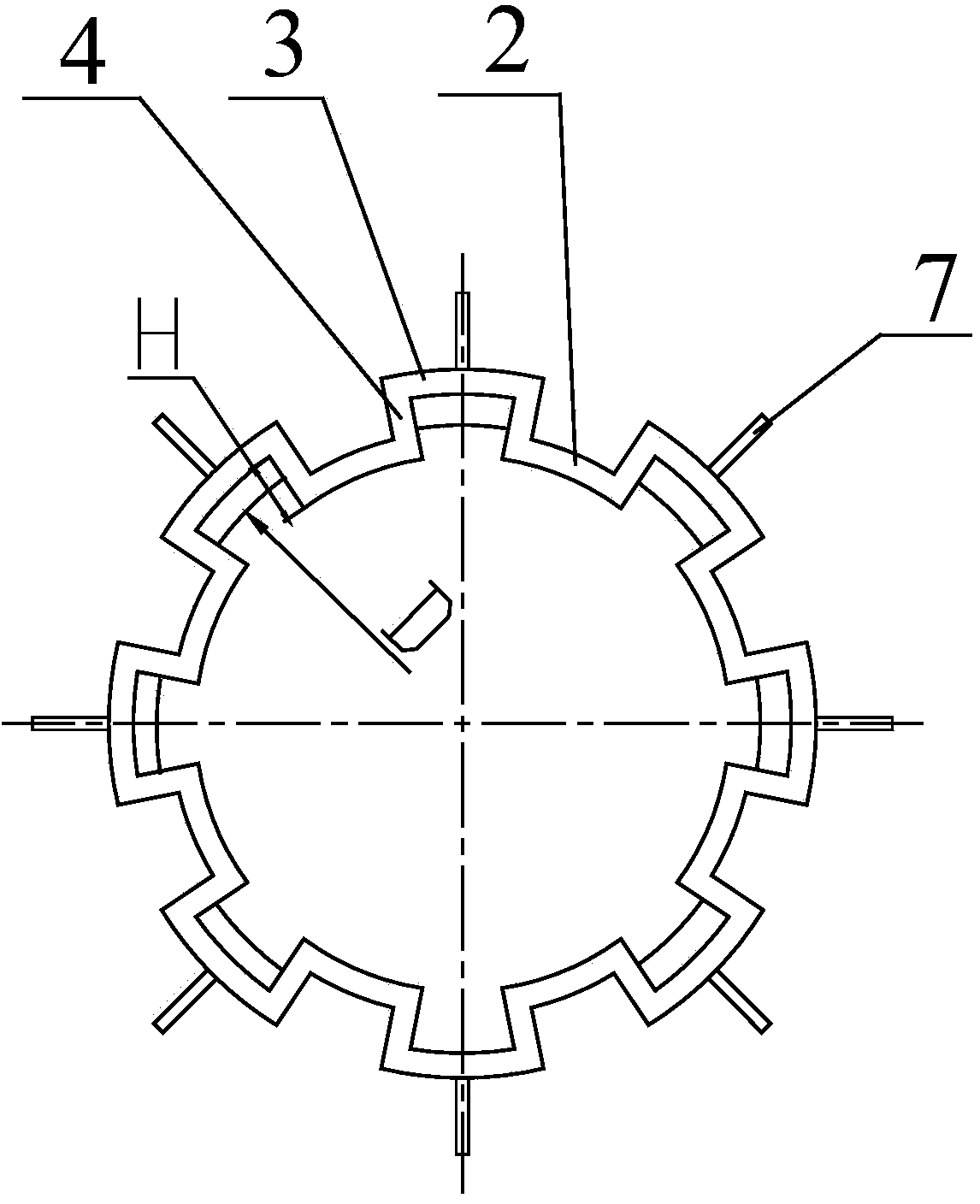

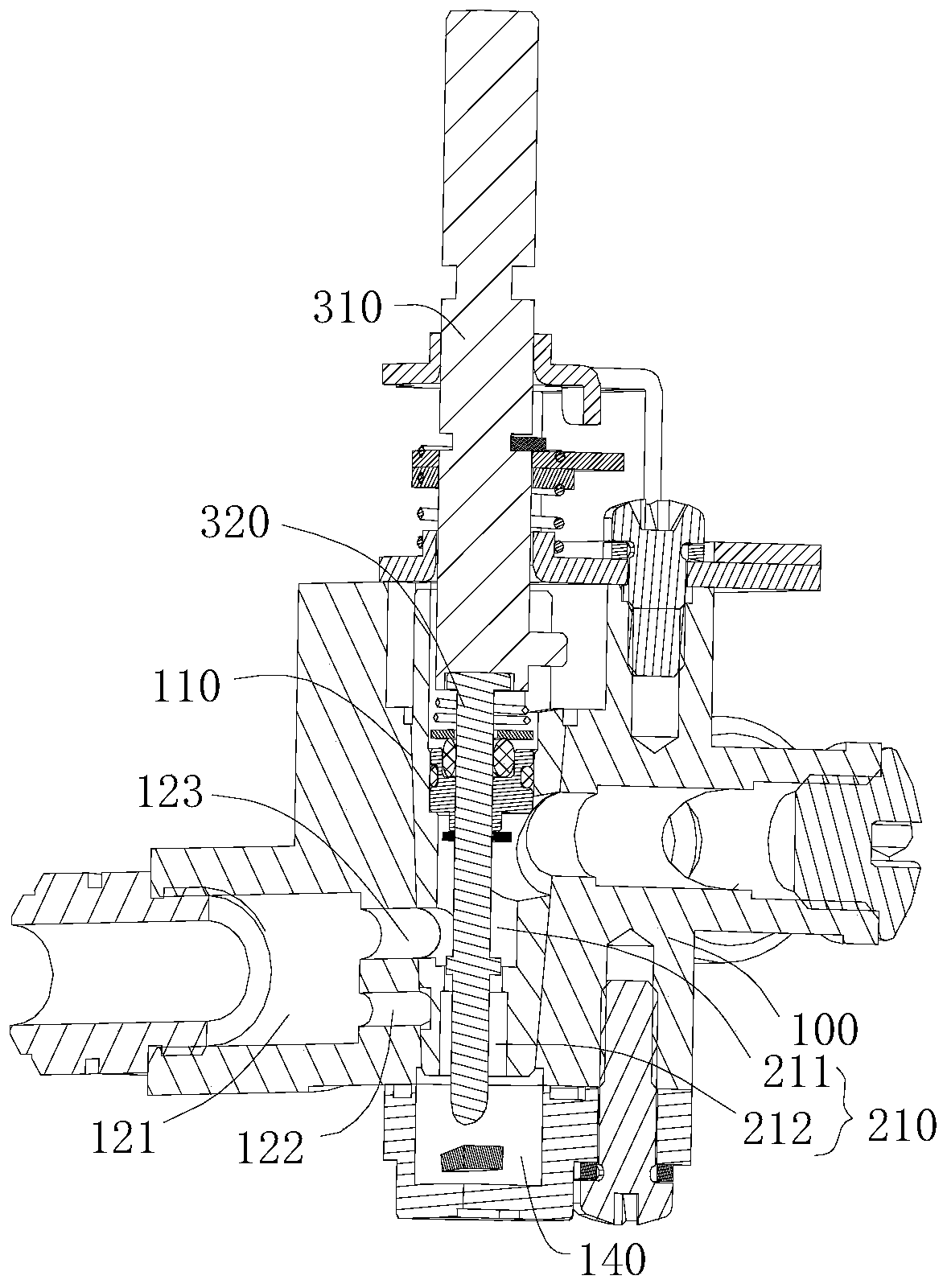

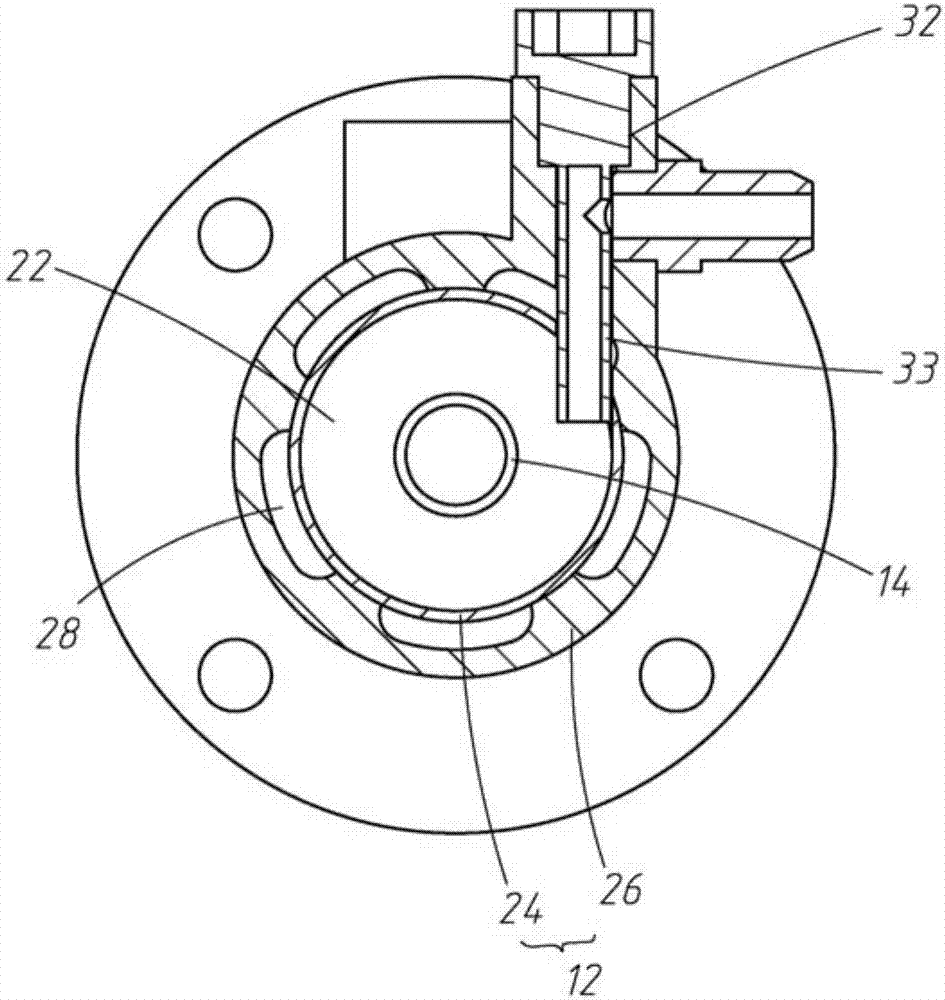

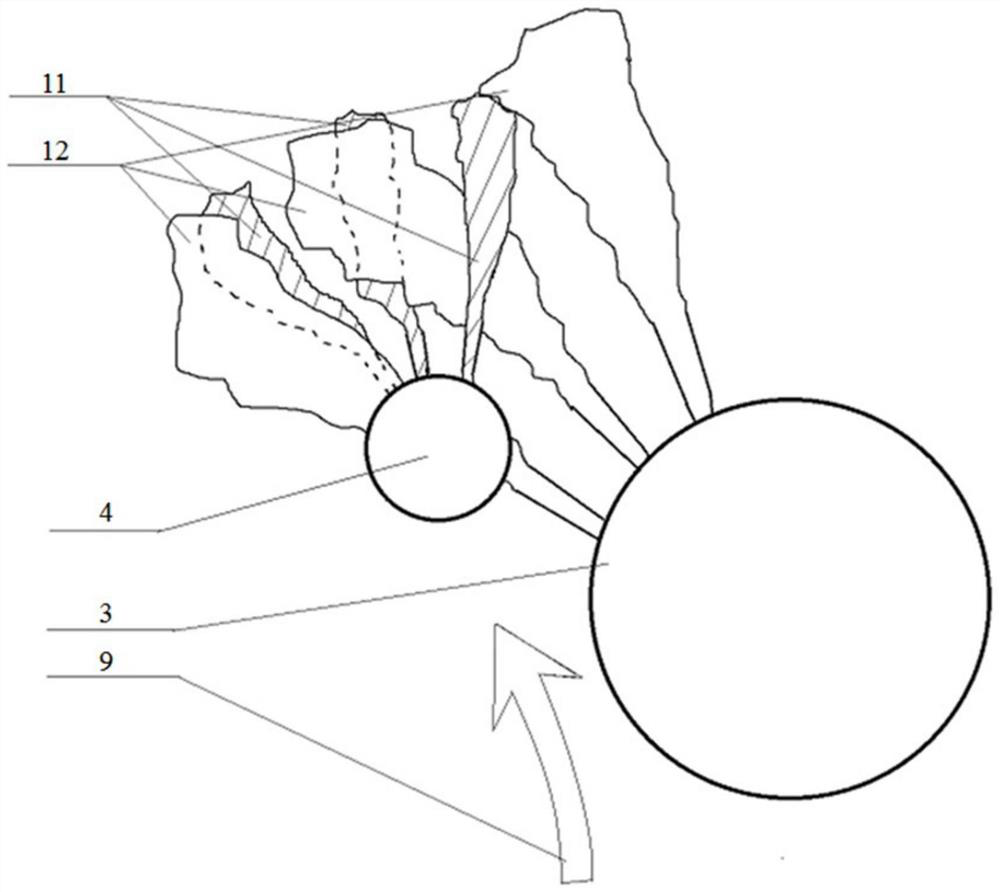

Fire leading channel of rotor engine

InactiveCN107013321AImprove combustion efficiencyAvoid getting lostInternal combustion piston enginesCycloneEngineering

The invention provides a fire leading channel of a rotor engine. The fire leading channel comprises a fire leading channel body. The fire leading channel body is arranged in a sparking plug installation hole in a cylinder body of the rotor engine and penetrates through the sparking plug installation hole. The fire leading channel body comprises two perpendicular grooves in the profile of the cylinder body, wherein one groove is parallel to the movement direction of airflow in the cylinder body of the rotor engine. The perpendicular grooves each comprise a rear wall face and a front wall face, wherein the rear wall face is an end face opposite to the airflow direction, the front wall face is an end face facing the airflow direction, the rear wall face and the front wall face are circular arc faces, and the circular arc diameter of the rear wall face is larger than that of the front wall face. According to the fire leading channel, a cyclone can be formed in the channel, flame is stabilized, fuel is sufficiently combusted, a heating piece achieves a heating effect to increase the temperature in the channel, liquid fuel is rapidly evaporated, and combustible mixed gas is rapidly formed.

Owner:JIANGSU UNIV

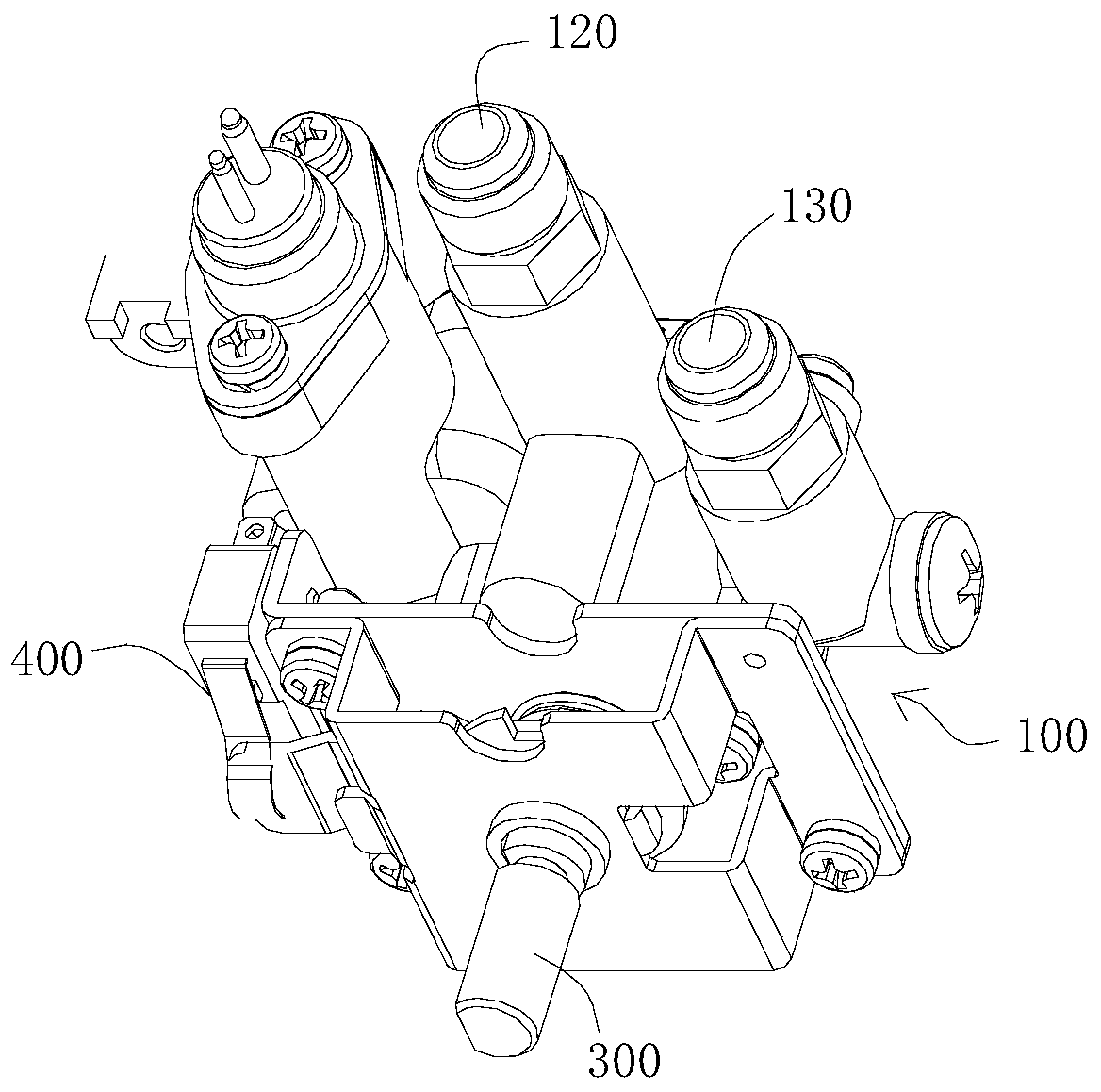

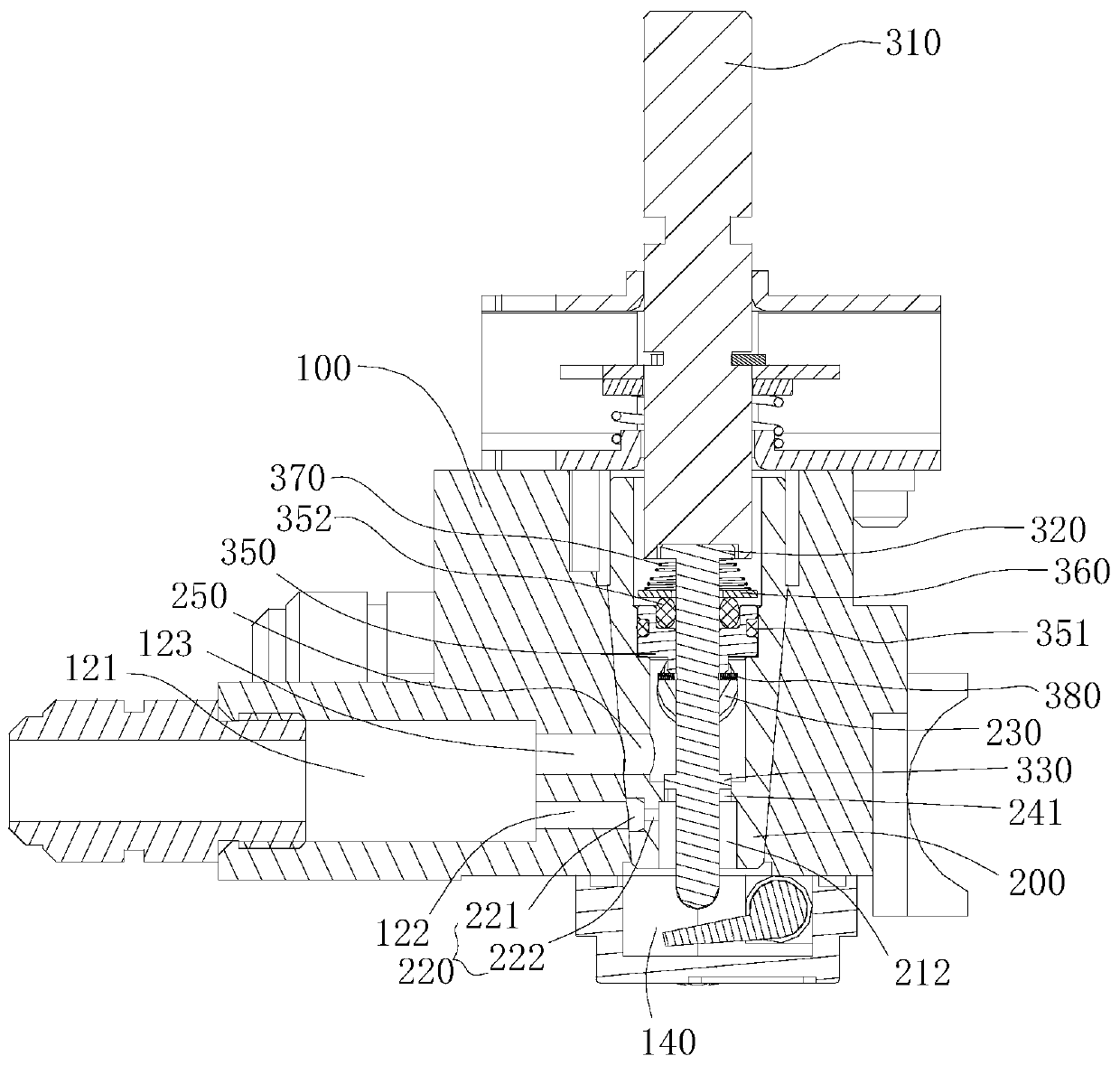

Gas plug valve and gas stove

PendingCN111425627AReduce misfireImprove ignition stabilityOperating means/releasing devices for valvesMultiple way valvesEngineeringMechanical engineering

The invention provides a gas plug valve and a gas stove, and relates to the technical field of stoves. The gas plug valve comprises a valve body, a valve element and a valve rod. A valve cavity is formed in the valve body, and the side portion of the valve cavity communicates with an inner ring passageway and an outer ring passageway. The valve element is rotationally embedded into the valve cavity, a vent cavity is formed in the valve element, and an inner ring vent hole and an outer ring vent hole are formed in the side wall of the vent cavity. An annular boss is arranged on the inner wall of the vent cavity in the circumferential direction of the vent cavity. The valve rod is inserted into the vent cavity from top to bottom, the valve rod is provided with a partition part, when the valve rod is pressed down, the vent cavity can be partitioned into an upper chamber and a lower chamber through the partition part and the annular boss, and the upper chamber and the lower chamber can communicate with each other through a pressure relief passageway. The gas stove comprises a burner and the gas plug valve. The outer ring passageway communicates with an outer ring nozzle of the burner,and the inner ring passageway communicates with an inner ring nozzle. During ignition of the gas plug valve, inner ring fire of the burner is stably ignited, the ignition time is also short when outerring fire needs to be used, and the use experience of a user is good.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

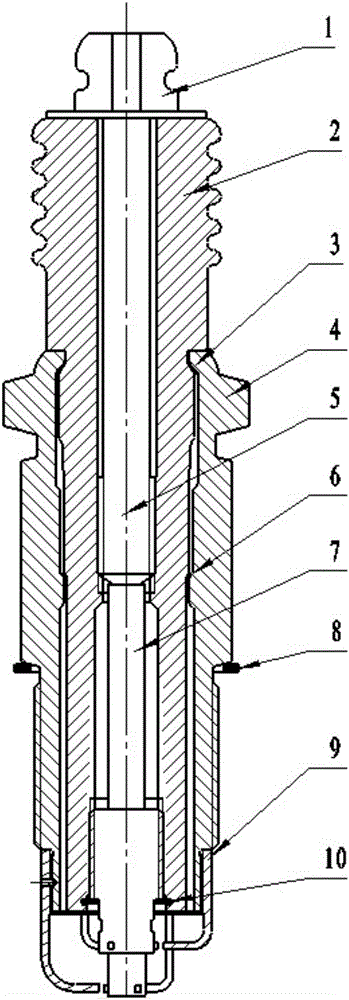

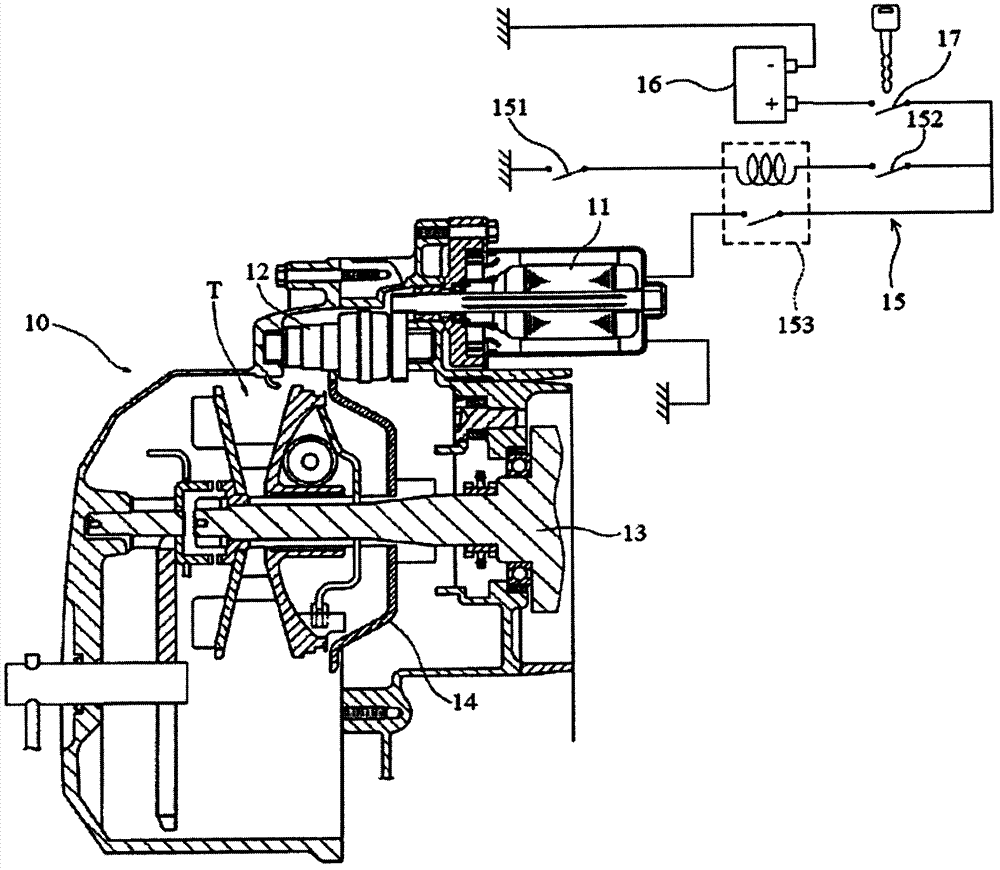

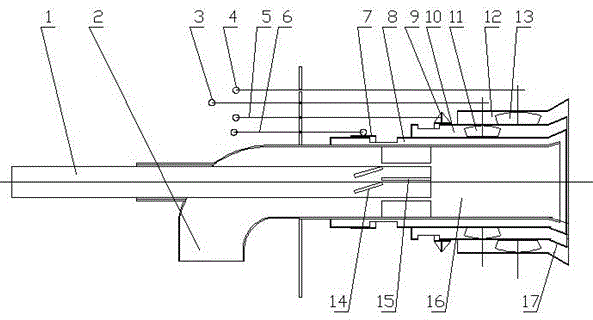

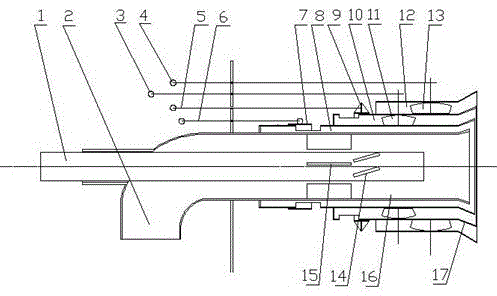

Enhanced discharge igniter for marine large-bore gas engine

ActiveCN106451081AImprove discharge capacityImprove ignition stabilitySparking plugsElectric ignition installationEngineeringMetal

The invention aims to provide an enhanced discharge igniter for a marine large-bore gas engine. The enhanced discharge igniter comprises a wiring nut, an insulator, a metal casing, a wiring screw, a central electrode and a side electrode, wherein the metal casing is isolated from the central electrode by the insulator; the central electrode is arranged in a central hole of the insulator through threads and is in tight contact with the wiring screw; the side electrode and the metal casing are independent of each other; the side electrode is arranged on the metal casing through threads; each of the side electrode and the central electrode is provided with a first-order discharge electrode and a second-order discharge electrode; in addition, each of the first-order discharge side electrode and the second-order discharge side electrode of the side electrode is provided with a plurality of secondary electrodes; the plurality of secondary electrodes respectively form discharge circuits with secondary electrodes of the first-order discharge central electrode and the second-stage discharge central electrode of the central electrode. According to the enhanced discharge igniter provided by the invention, the ignition stability of the marine gas engine is improved under lean burn conditions, cyclical variation is reduced, and fuel economy and emission performance of the engine are improved.

Owner:HARBIN ENG UNIV

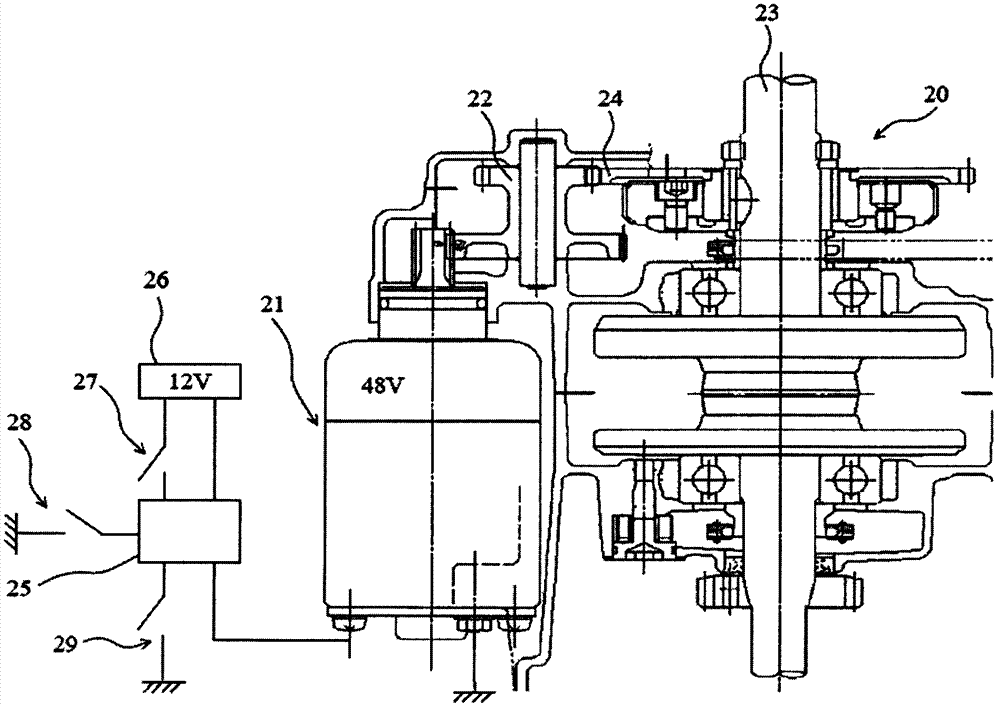

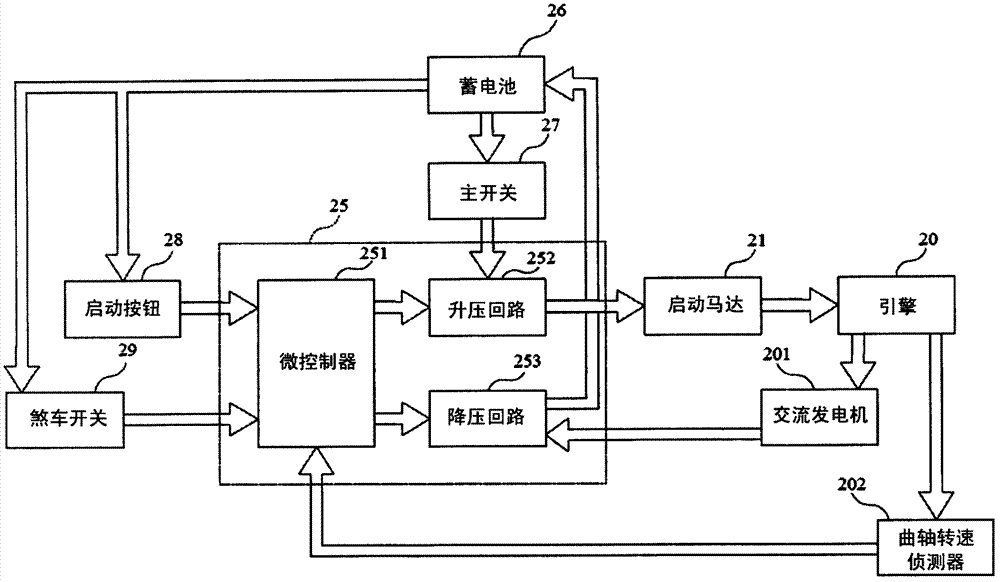

Boost control device of motorcycle starting motor

InactiveCN102820778AImprove startup smoothnessImprove stabilityBatteries circuit arrangementsAc-dc conversion without reversalMicrocontrollerPower flow

Disclosed is a boost control device of a motorcycle starting motor. A microcontroller is used for controlling a boost loop, original voltage of a storage battery is boosted by the boost loop and is supplied to a starting motor with high voltage specifications, and flexible starting control is conducted to the starting motor. The starting motor with high voltage specifications can provide sufficient stable torque force for an engine, so that the starting motor cannot require high current for the storage battery at the moment of starting, the starting smoothness of the starting engine and stability of a motorcycle electric power system and engine starting are improved, and starting noise and abrasiveness of a starting gear set are reduced relatively.

Owner:KYMCO

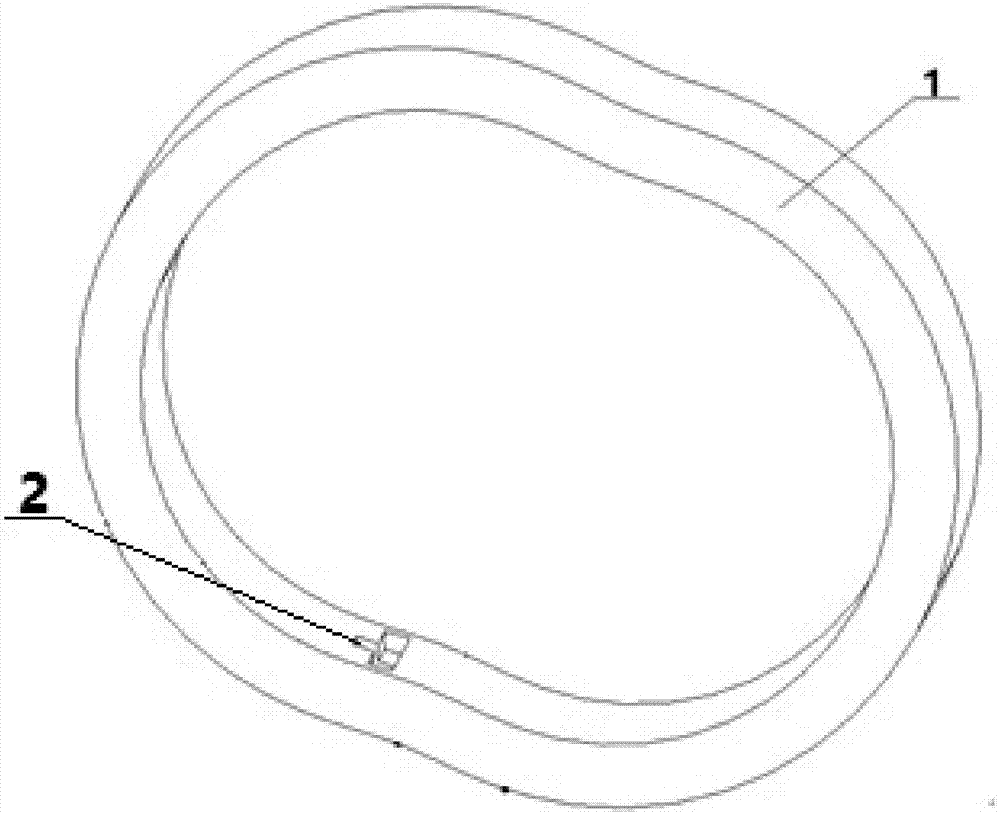

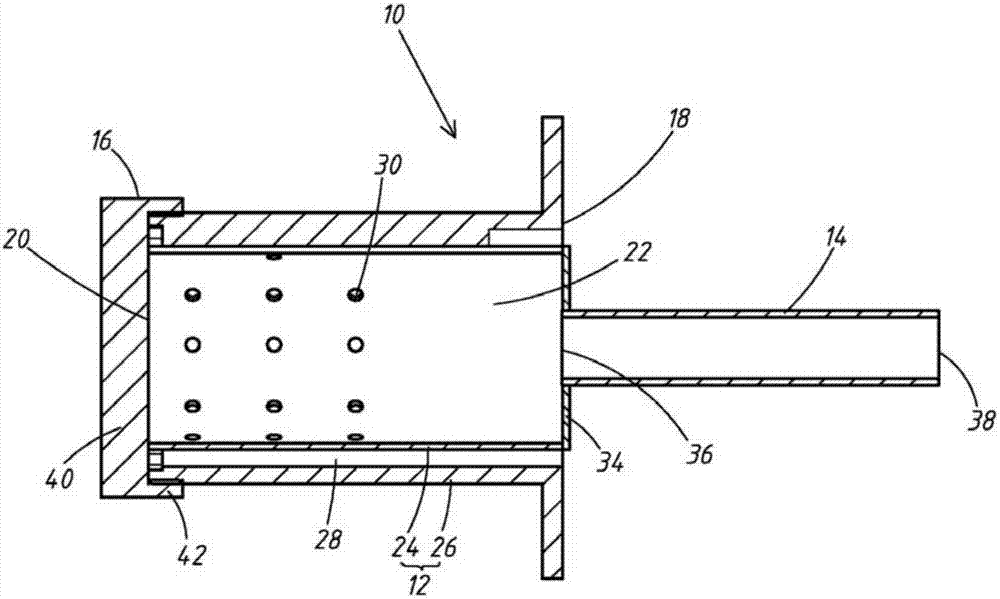

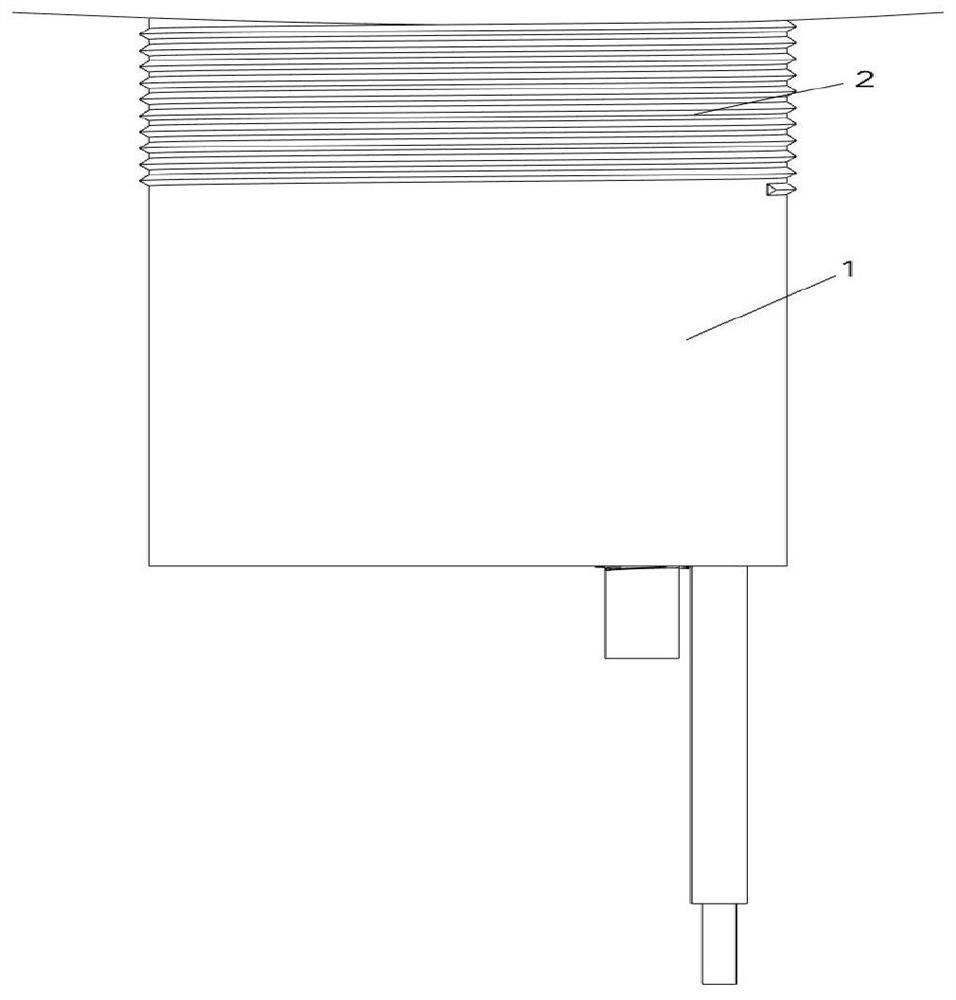

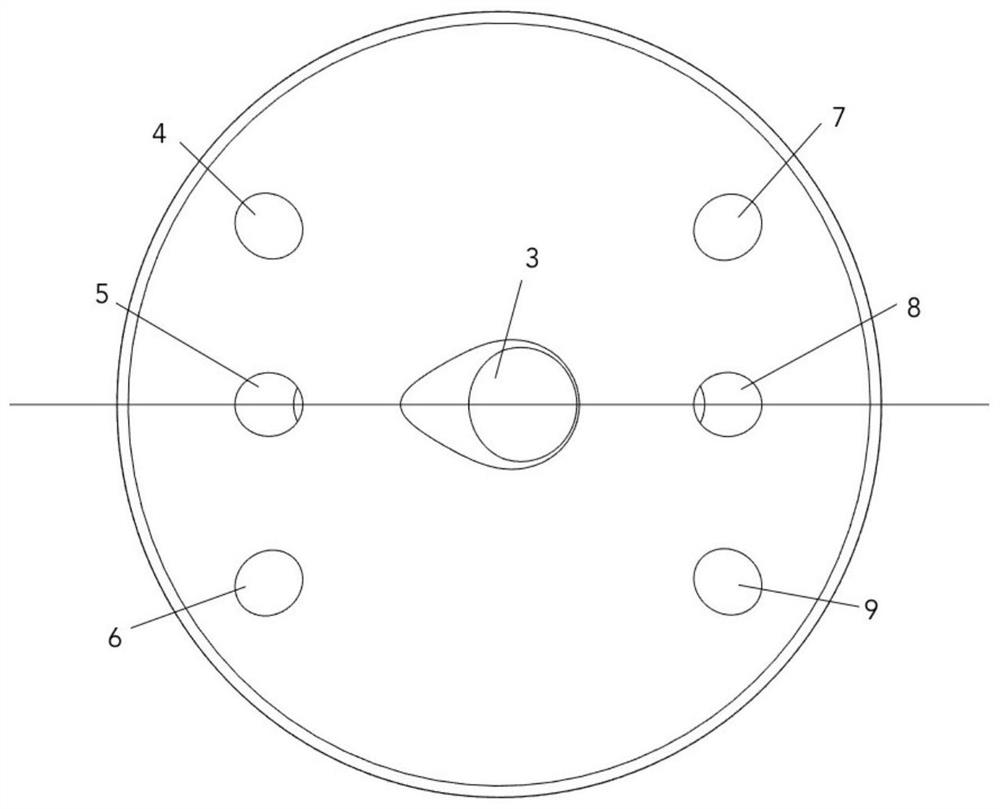

Ignition nozzle device capable of improving ignition stability

The invention provides an ignition nozzle device capable of improving the ignition stability. The ignition nozzle device comprises a nozzle wall cylinder and a nozzle pipe, wherein a combustion chamber is formed in the nozzle wall cylinder; the nozzle wall cylinder comprises a front end and a rear end which are oppositely arranged along the axial direction; the nozzle pipe is mounted at the front end of the nozzle wall cylinder, communicates with the combustion chamber, and is used for igniting a to-be-ignited device; a fuel gas nozzle used for injecting fuel gas into the combustion chamber is arranged on the nozzle wall cylinder; the mounting position of the fuel gas nozzle is close to the rear end; and the injection direction of the fuel gas nozzle is deviated from the diameter direction of the nozzle wall cylinder at the mounting position of the fuel gas nozzle, so that a rotating fuel gas flow field can be formed by the fuel gas injected by the fuel gas nozzle in the combustion chamber. The ignition nozzle device provided by the invention is simple in structure, ingenious in design, convenient to mount, high in practicability, and suitable for popularization and application.

Owner:SHENZHEN WISDOM ENERGY TECH CO

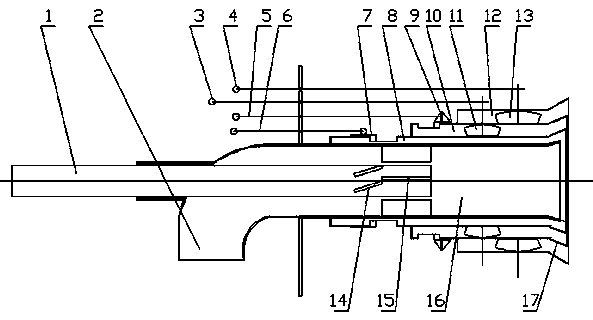

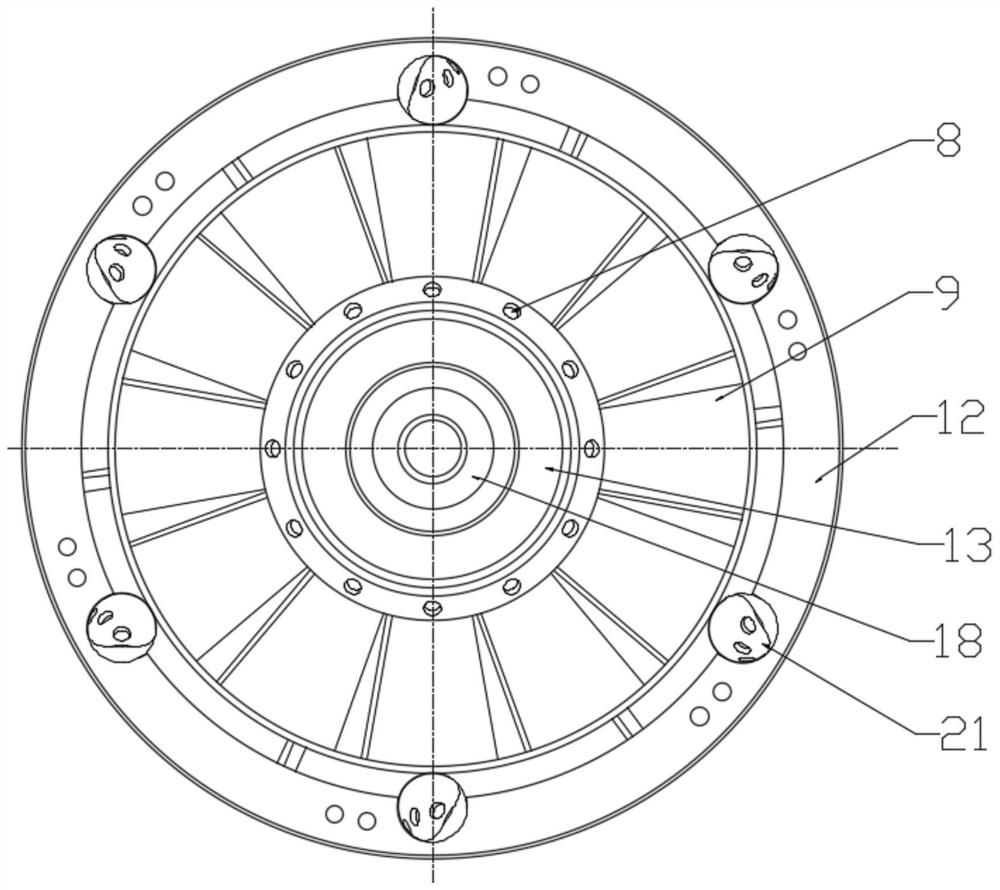

A Jet-Controlled Ignition Plug for a Rotary Engine

ActiveCN110145395BSmooth entryEasy accessInternal combustion piston enginesCombustion chamberRotary engine

Owner:JIANGSU UNIV

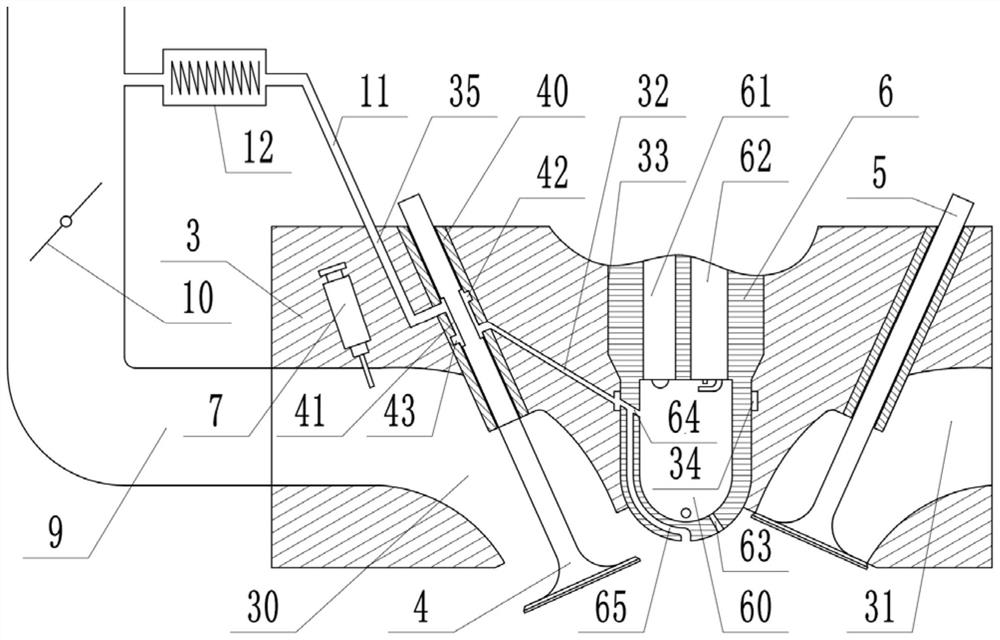

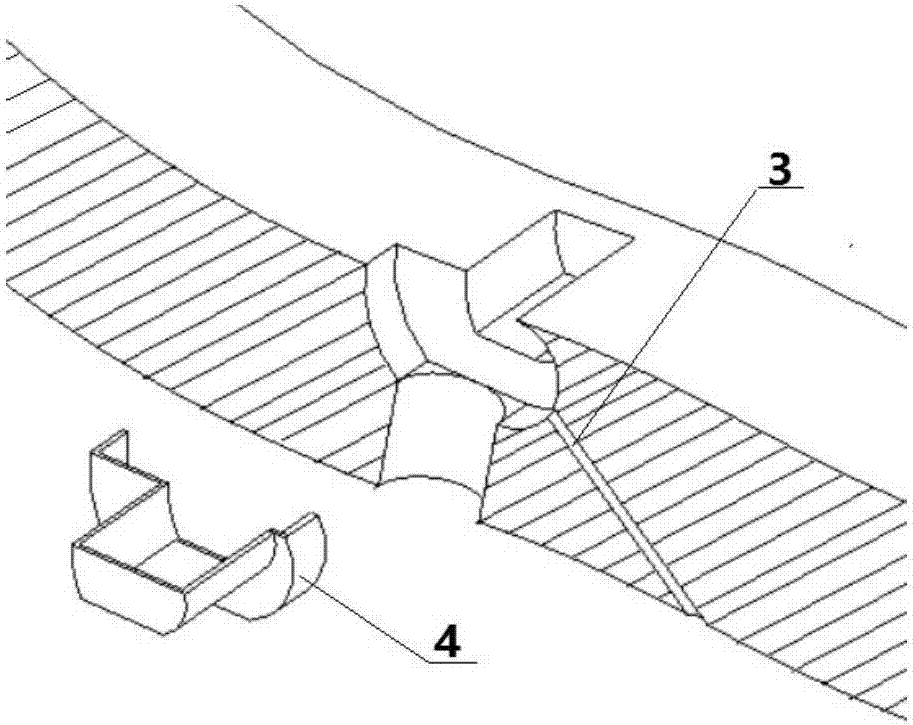

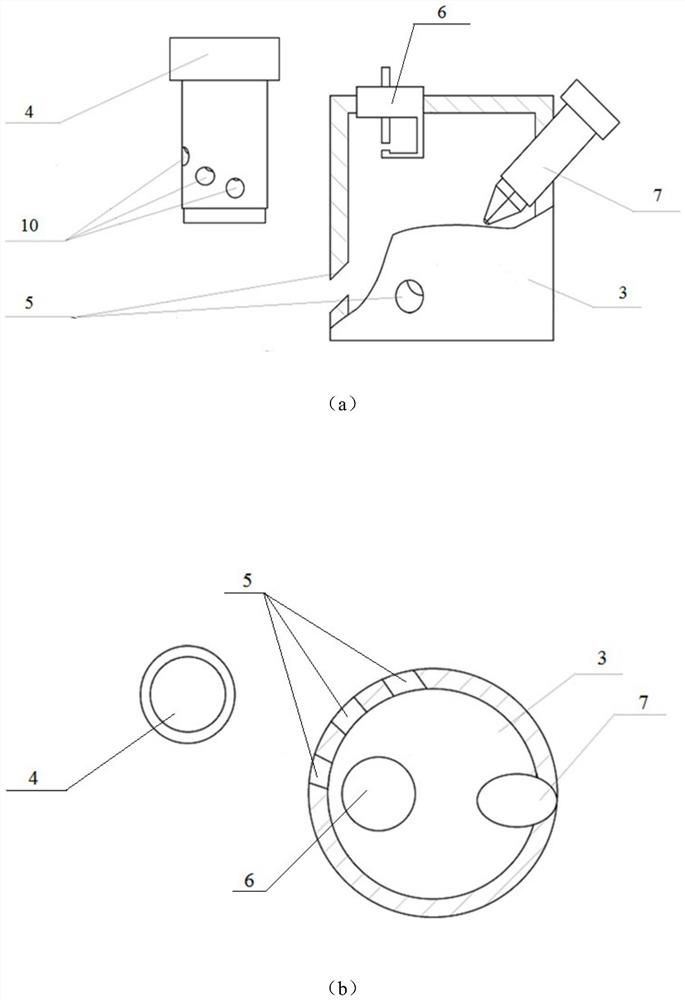

Enhanced graded low NOx pulverized coal burner

ActiveCN103759259BIncrease swirl intensityAdaptablePulverulent fuel combustion burnersCombustion apparatusCombustorSlag

A classification strengthened low NOX pulverized coal burner comprises a primary air passage (1), a straight flow inner secondary air passage (2) and a rotating flow inner secondary air passage (3). The pulverized coal is separated at a spray nozzle into an inside-concentration and outside-dilution structure and is sprayed into a hearth through a pulverized coal equalizer (5) and a pulverized coal separator (6), which are arranged inside the primary air passage (1). Inner secondary air is provided with a straight flow air inlet and a rotating flow air inlet and then sprayed into the hearth after being mixed in the air passage. The volume of the straight flow air is controlled through a pull rod (8), so that the rotating flow strength of the inner secondary air can be controlled. Both of primary air outlet and secondary air outlet are provided with a structure of spray nozzle expanded-cone (7) with a certain angle, so that the timely mixing of secondary air and the pulverized coal is effectively controlled. Meanwhile, the water cooling wall of the spray nozzle is maintained in oxidization atmosphere for a long time. The slag formation and high-temperature corrosion on the water-cooling wall in the burner area can be effectively avoided.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD

Combustion device and method for a dual-fuel engine based on a dual-needle valve injector

ActiveCN109184926BFlexible switchingReduce the temperatureInternal combustion piston enginesFuel supply apparatusCombustion chamberFuel oil

The invention relates to the field of dual-fuel engines, in particular to a dual-fuel engine combustion device and method based on a double-needle-valve oil atomizer. The dual-fuel engine combustion device based on the double-needle-valve oil atomizer comprises an air distribution system, a fuel supply system and a combustion chamber system. The air distribution system is located on an air cylinder cover. An air inlet part and an exhaust part are symmetrically distributed at the two ends of the air cylinder cover. The fuel supply system is located on the air cylinder cover and is right opposite to the lower combustion chamber system. The combustion chamber system is formed by connecting the air cylinder cover and an air cylinder through bolts. The dual-fuel engine combustion method based on the double-needle-valve oil atomizer comprises the steps that firstly, the dual-fuel engine is in a gas mode; and secondly, the diesel oil mode is switched when the dual-fuel engine is in starting and idling work conditions. Dual-fuel engine gas and fuel oil dual modes are rapidly and flexibly switched, mixed gas concentration layering in the dual-fuel engine gas mode is achieved, and accordingly power performance, economic efficiency and discharging performance of the fuel are improved.

Owner:HARBIN ENG UNIV

Plasma Duty Flame Igniter Based on Aeroengine Afterburner

ActiveCN110439691BImprove reliabilitySimple structureGas turbine plantsJet propulsion plantsCombustion chamberEngineering

Owner:AIR FORCE UNIV PLA

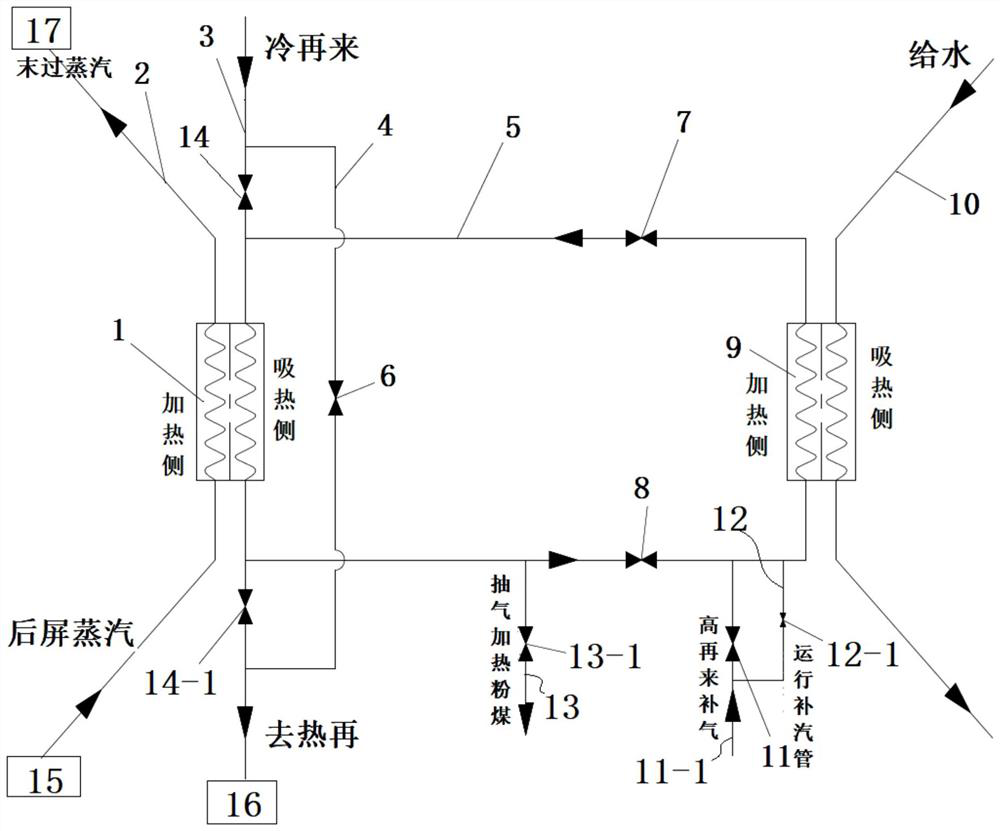

System and method for heating feed water through reheated steam to achieve deep peak regulation

ActiveCN114576605AReduce water spray to reduce temperatureHigh load pointBoiler water tubesBoiler controlCombustionCoal pipeline

The invention discloses a system and method for heating feed water through reheat steam to achieve deep peak regulation. According to the system and method, a steam-steam heat exchanger serves as a full-load-section operation system, steam behind a rear screen is used for heating cold reheat steam, the reheat steam is used for heating the feed water, and low-pressure steam heated through the rear screen is extracted for heating a primary air pulverized coal pipeline. When the system runs, reheated steam is pumped to heat feed water through the steam-water heat exchanger, the temperature of the feed water and the wall temperature of the water cooling wall are increased, and the combustion condition of the boiler is improved; after the cooled steam absorbs heat in the steam-steam heater, part of the cooled steam is pumped out to heat primary air pulverized coal airflow, the initial temperature of the pulverized coal airflow is increased, and the ignition and stable combustion performance of the boiler is improved; heat of the superheater is guided out through the steam-steam-water heat exchanger, part of heat of superheated steam and reheated steam is used for increasing the feed water temperature and the primary air pulverized coal airflow temperature, and the effects that the low-load ignition stability is improved, the load point for converting the boiler into the wet state is increased, the deep adjustment load of the boiler is reduced, and the unit operation flexibility is improved are achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

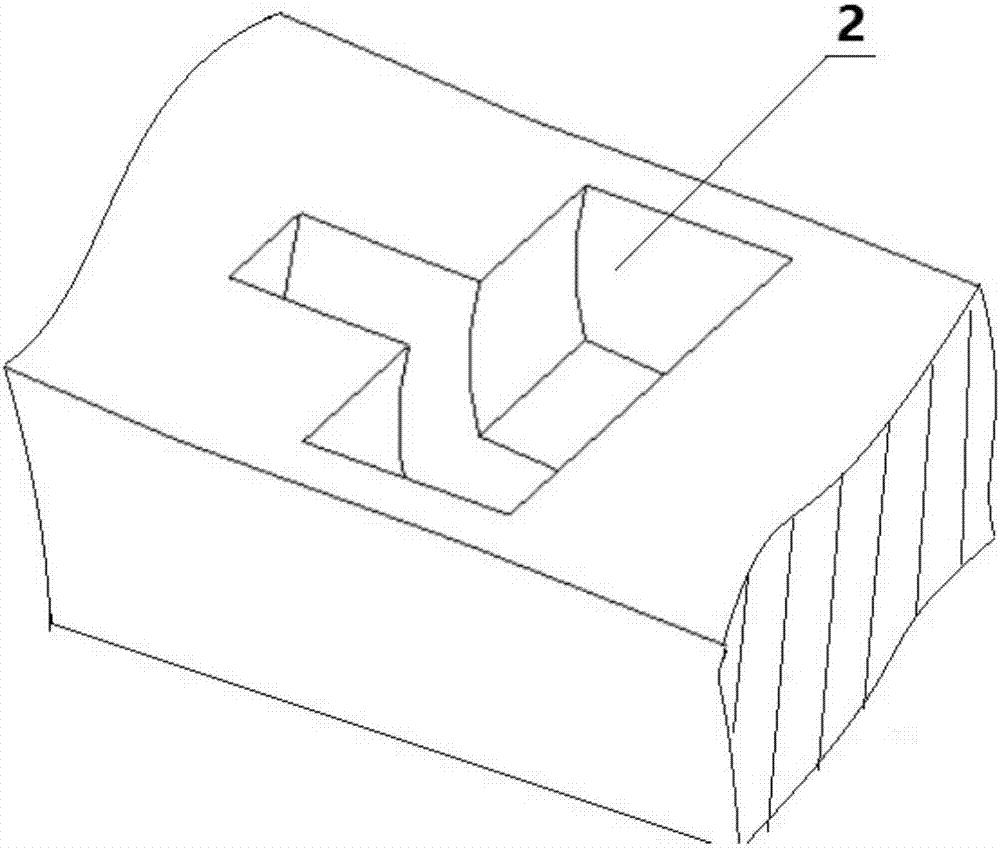

A low-nitrogen swirl pulverized coal burner with fuel-saving/gas ignition and stable combustion

ActiveCN103759258BAdaptableImprove adaptabilityPulverulent fuel combustion burnersCombustion apparatusEntrywayCombustion chamber

A fuel / gas-saving ignition stable-combustion low-nitrogen swirling pulverized coal combustor, comprising a primary air channel (2), a multi-channel secondary air intake pipe and a fuel / gas combustor (1). A circle of straightening vanes (15) are evenly distributed on the inner wall of an entryway of a strengthened combustion chamber (16) in the primary air channel (2). A circle of swirling vanes (14) are evenly distributed on the front outer wall of the fuel / gas combustor (1). The length from the front end of the swirling vane (14) to the front end of the fuel / gas combustor (1) is larger than or equal to the length of the straightening vane (15), and the outer diameter of the swirling vane (14) is smaller than the inner diameter of the straightening vane (15). The fuel / gas combustor (1) is adjustable front and back, causing relative positions of the swirling vanes (14) and the straightening vanes (15) to change. The swirling intensity of secondary air of the combustor can be adjusted online, a proper high-temperature flue gas recirculation zone is formed in the center of a nozzle of the combustor through adjustment of the swirling intensity of the secondary air, and a stable heat source is provided for ignition and stable combustion of pulverized coal.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD +1

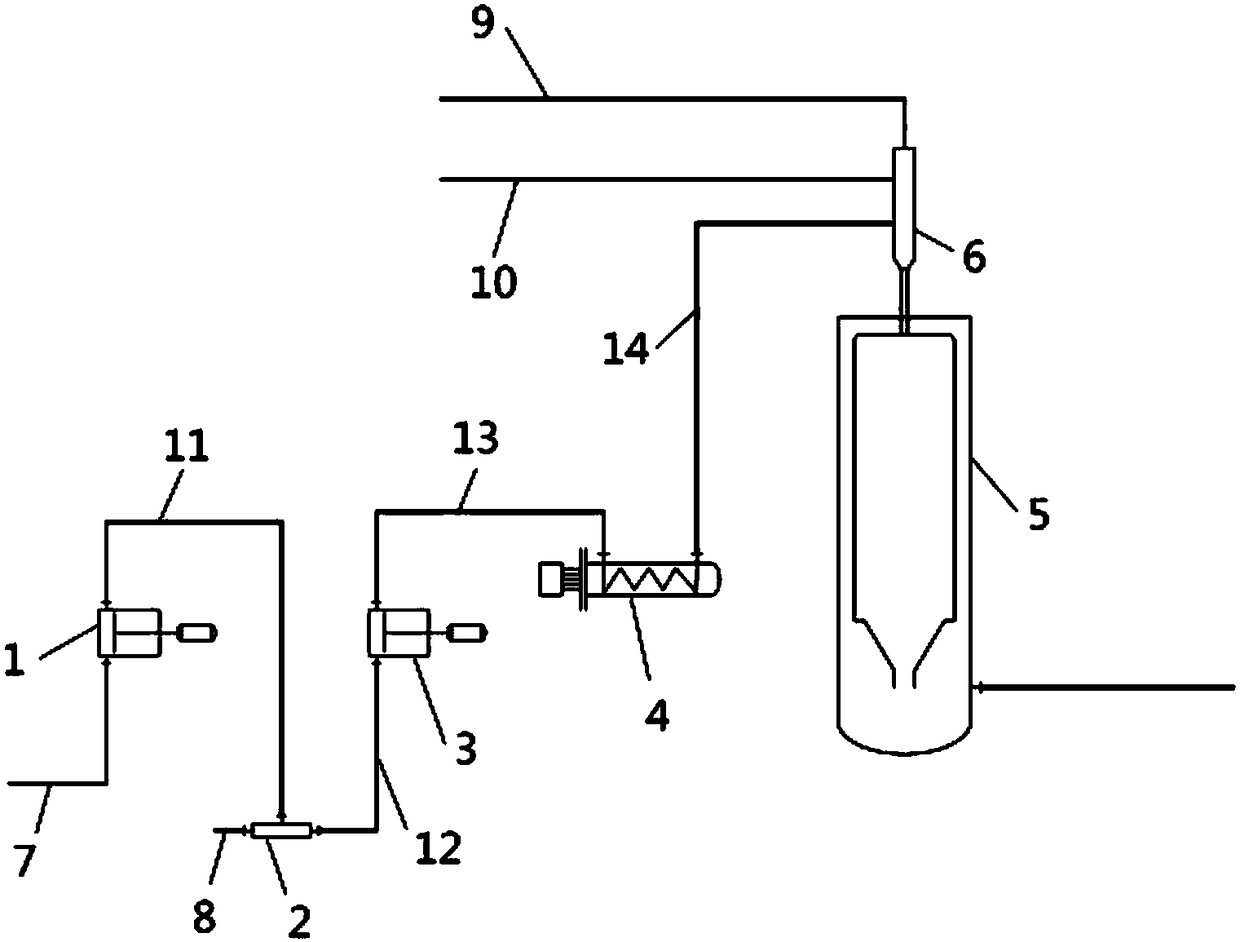

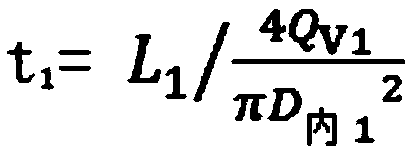

Supercritical water oxidation ignition system and ignition process

ActiveCN108317540ASmall output flowReduce concentrationPilot flame ignitersNuclear engineeringHigh pressure oxygen

The invention provides a supercritical water oxidation ignition system. The supercritical water oxidation ignition system comprises a fuel metering pump, a mixer, a high-pressure fuel pump, a heatingfurnace and a reactor, and the fuel metering pump, the mixer, the high-pressure fuel pump, the heating furnace and the reactor are connected in sequence through pipelines; the fuel metering pump is connected with a feeding pipeline; the mixer is connected with a water charging pipeline; and a nozzle of the reactor is connected with a high-pressure oxygen pipeline. The invention further provides asupercritical water oxidation ignition method which comprises the following steps: heating and pressurizing the reactor, mixing a water-soluble fuel with water and afterwards feeding the mixture to the reactor; making the mixture react with oxygen; heating the reactor again; and regulating the flow rate of the water-soluble fuel output by the fuel metering pump to continuously increase the temperature of the reactor. According to the method provided by the invention, the temperature of the reactor can be increased continuously and finally reaches 600-700 DEG C to finish ignition, thus the problems about reactor temperature runaway and drastic pressure fluctuation caused by sudden change of the thermal value of the fuel in a supercritical water oxidation process are solved, the ignition stability is improved, the ignition time is shortened, and the workload is reduced.

Owner:ENN ENVIROTECH CO LTD

Internal combustion engine combustion system for direct injection of methanol fuel in cylinder

PendingCN114233463AIncrease costDirect injection combustionCombustion enginesCombustion systemDiffusion flame

The internal combustion engine combustion system comprises a combustion chamber, the combustion chamber is composed of a main combustion chamber and pre-combustion chambers, and each pre-combustion chamber is embedded into the top of the main combustion chamber; methanol ejectors II are embedded in the top of the main combustion chamber, and each methanol ejector II is provided with spraying holes in different directions and at different horizontal heights, so that high-pressure methanol spray is sprayed into the main combustion chamber; each pre-combustion chamber is provided with a spark plug and a methanol ejector I, each pre-combustion chamber is provided with through holes with different directions and different horizontal heights, the pre-combustion chambers are communicated with the main combustion chamber through the through holes, jet flame is jetted into the main combustion chamber through the through holes, methanol spray is ignited through the jet flame, and methanol spray combustion is achieved. Methanol spray in the main combustion chamber is ignited through jet flame generated by ignition combustion in the pre-combustion chamber, methanol spray combustion in the main combustion chamber is achieved, and engine combustion is controlled by diffusion flame of methanol.

Owner:TIANJIN UNIV

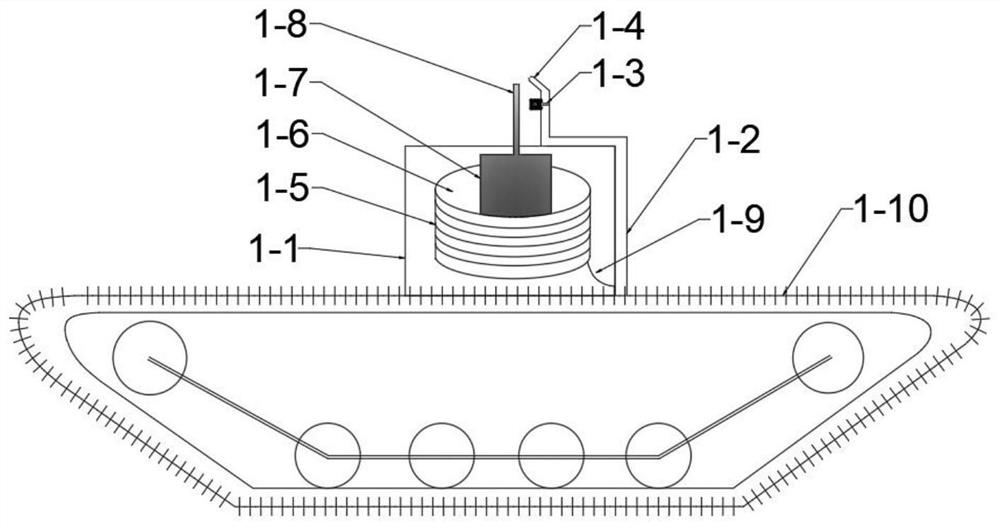

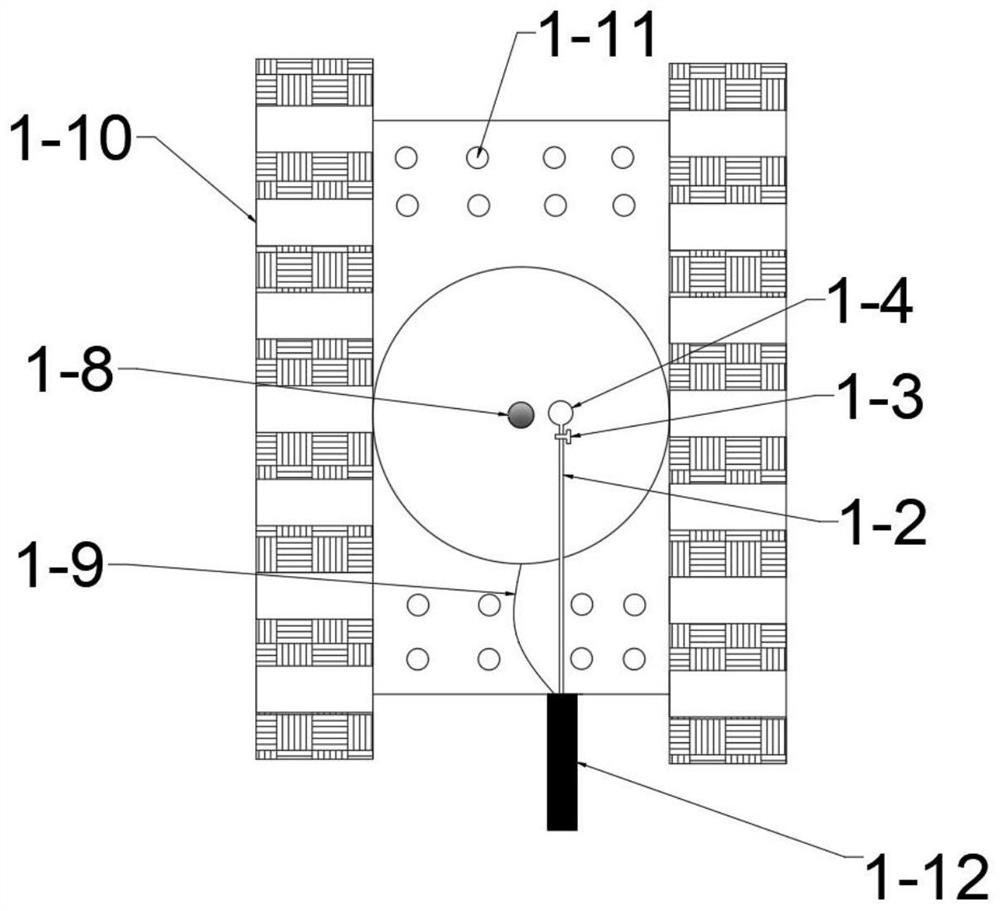

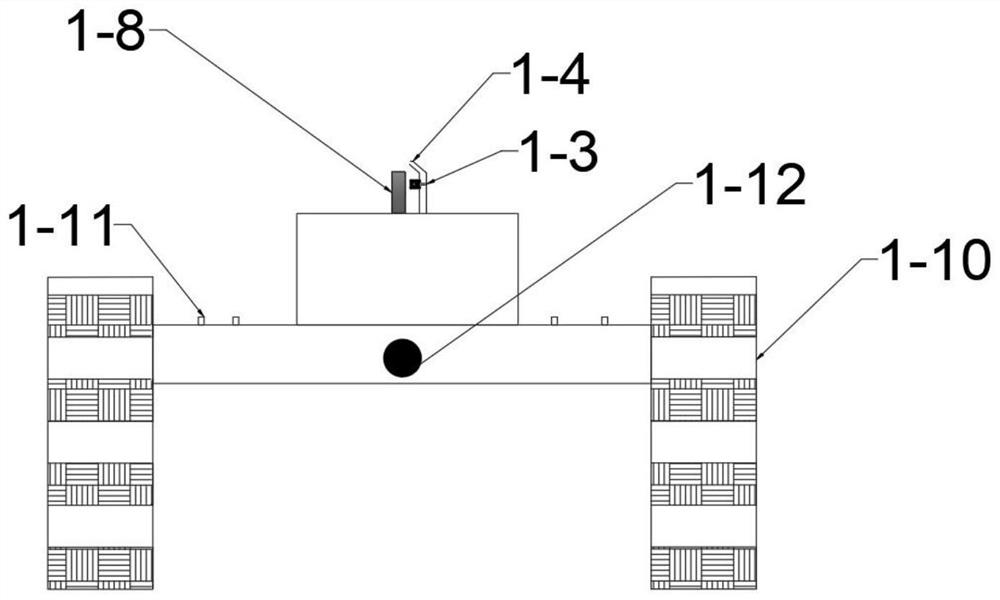

Movable ignition system, device and method for underground coal gasification

ActiveCN112627791AAccurate arrivalImprove adaptabilityElectric spark ignitersFluid removalTemperature controlProcess engineering

The invention belongs to the technical field of underground coal gasification, and discloses a movable ignition system, device and method for underground coal gasification. The movable ignition system comprises a movable ignition device control module, a high-pressure combustible agent pipeline module, a temperature sensor module, a ventilation module, a power supply module, an electromagnetic heating igniter and a crawler belt moving module. According to the movable ignition system, device and method for underground coal gasification, ignition can be carried out in a movable mode as required under the condition that a large amount of underground water exists at the designed ignition position, and the problem that secondary ignition cannot be rapidly conducted after primary ignition fails in the traditional ignition technology is solved; an electromagnetic induction heating system can well protect an igniter structure and is stable in ignition, the ignition defect existing in electric ignition and other methods is effectively avoided, and the movable ignition device can be used repeatedly; under the dual action of a temperature control switch and a temperature sensor, fuel gas conveying is controlled, stable flames are formed, and the burning explosion phenomenon is eradicated; and a crawler-type moving system can pass through a complex structure in a drill hole or a sleeve, so that the operation is convenient.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com