Fire leading channel of rotor engine

A rotary engine and fire channel technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of aggravated rotary engine ignition, unfavorable ignition, and increased engine cost, so as to improve ignition stability and reduce unburned Hydrocarbon content, the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

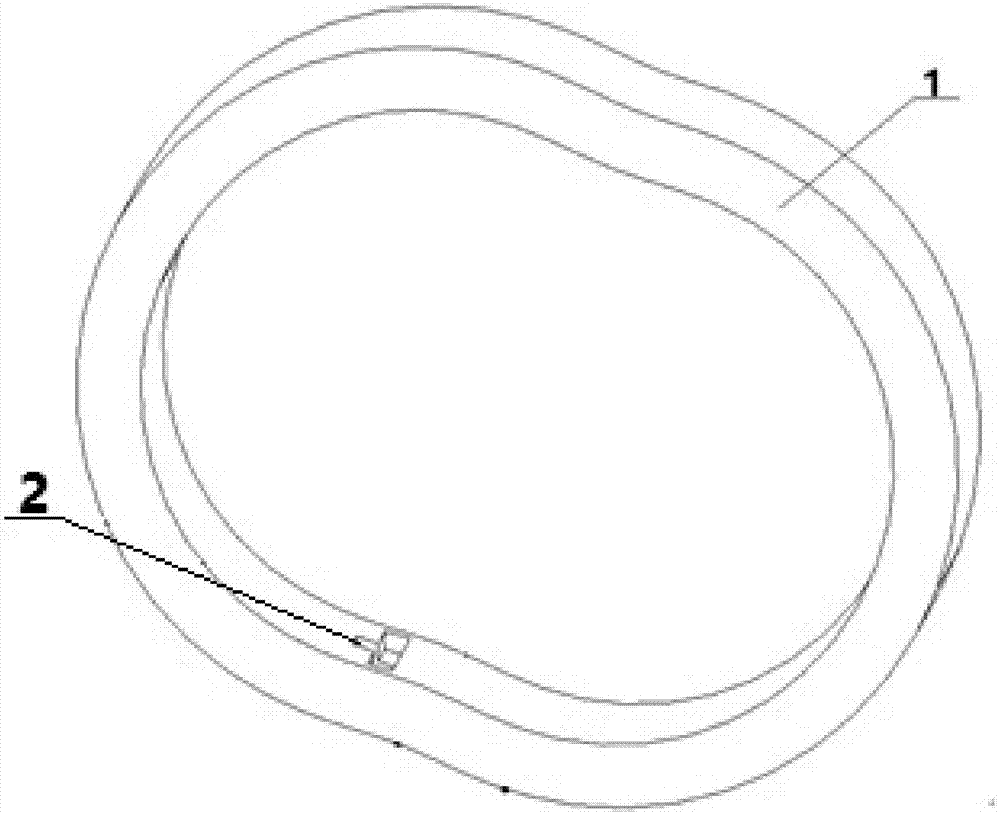

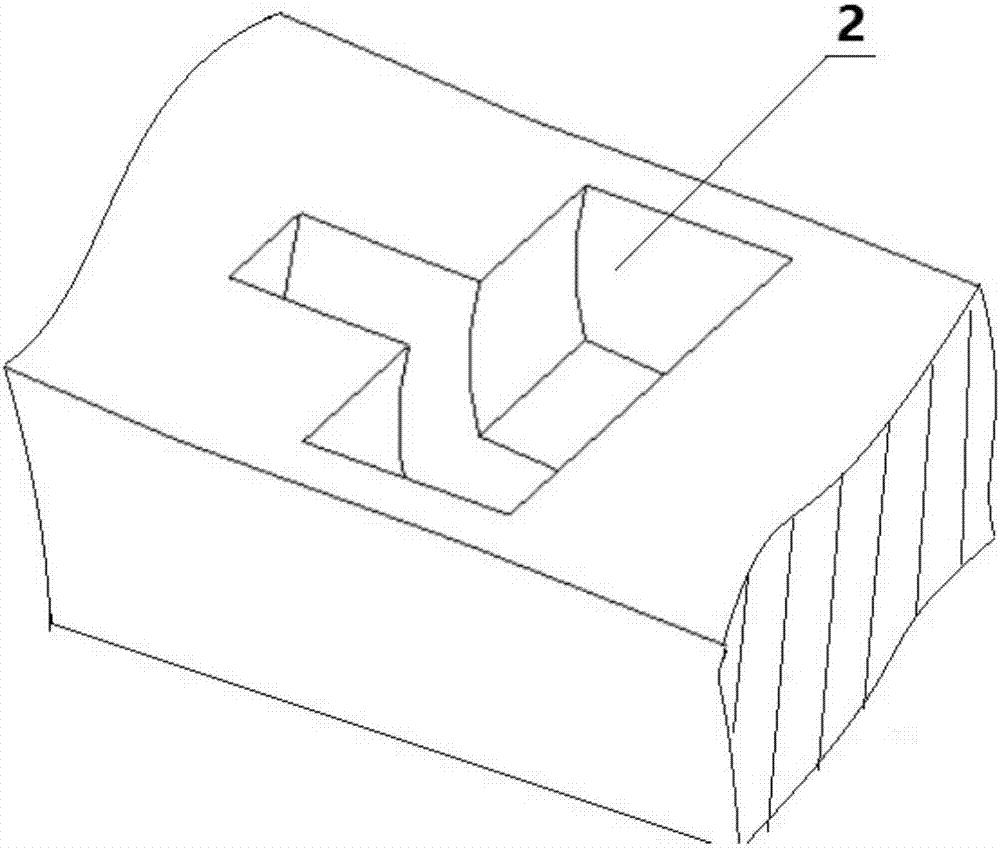

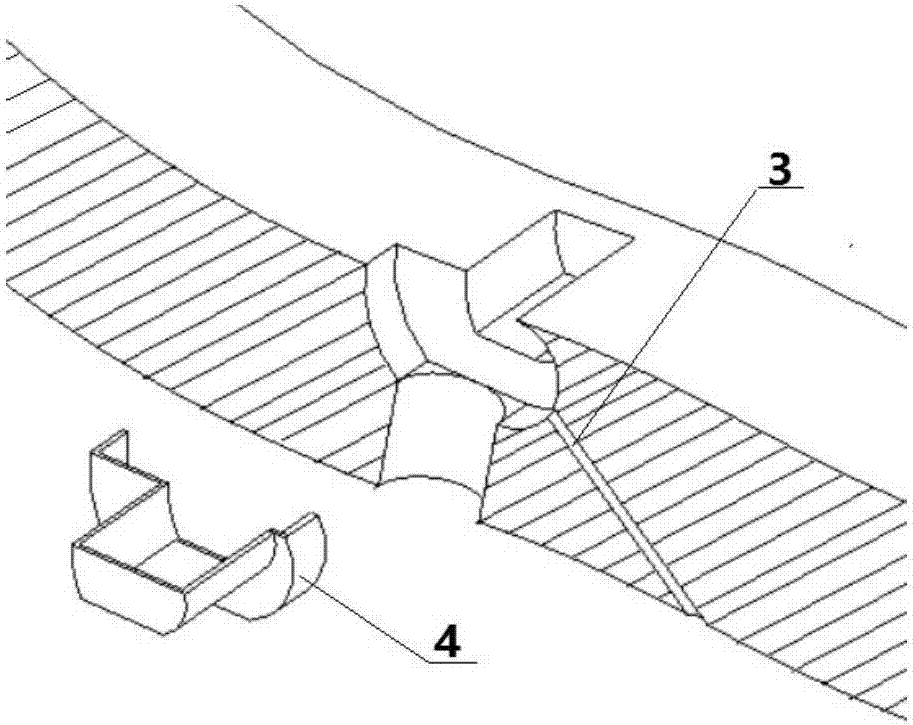

[0027] Such as figure 1 with figure 2 As shown, a fire channel of a rotary engine includes a fire channel 2. The spark plug mounting hole in the rotor engine cylinder 1 is provided with a fire channel 2, and the fire channel 2 is connected with the spark plug mounting hole; the fire channel 2 is in the cylinder There are grooves perpendicular to each other on the body surface, one of which is parallel to the direction of air flow in the cylinder block 1 of the rotary engine. Since the rotary engine rotates in one direction, the airflow in the combustion chamber flows in one direction with the rotor, and the groove parallel to the direction of the airflow enables the rapid formation of the air swirl, prevents the energy loss generated by the spark plug, and ignites the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com