Combustion system of gasoline direct injection engine and control method thereof

A combustion system and in-cylinder direct injection technology, applied in engine control, charging system, electrical control, etc., can solve the problems of high unburned hydrocarbons, high NOx emissions, and difficulty in controlling stratified lean-burn mixture, etc. To achieve the effect of improving combustion conditions and improving ignition stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

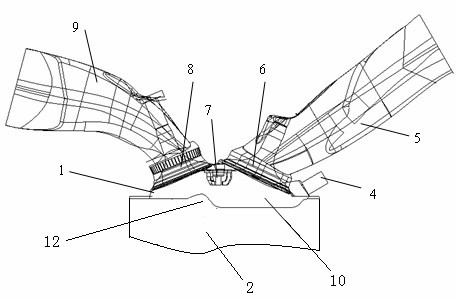

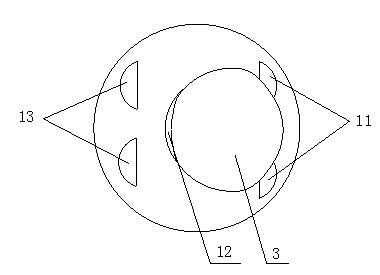

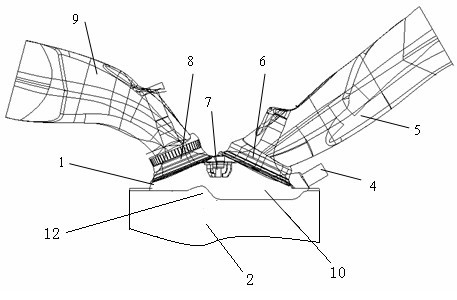

[0022] Such as figure 1 , 2 As shown, the combustion system of the in-cylinder direct injection gasoline engine of the present embodiment includes a cylinder head 1, a piston 2, a spark plug 7 and a fuel injector 4, and the cylinder head 1 is equipped with an intake valve 6, an exhaust valve 8 and an intake valve. The high tumble intake port 5 connected with 6, and the exhaust port 9 connected with the exhaust valve 8; the top surface of the piston 2 corresponds to the position of the intake valve 6, and an intake valve avoidance pit 11 is provided, corresponding to the position of the exhaust valve 8 is provided with an exhaust valve avoidance pit 13. The cylinder head 1 is dome-shaped and is located on the upper end of the piston 2 , and the space between it and the piston 2 forms a combustion chamber 3 . The spark plug 7 is installed vertically on the cylinder head 1 between the intake valve 6 and the exhaust valve 8, and is biased to the side of the exhaust valve 8; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com