Internal combustion engine combustion system for direct injection of methanol fuel in cylinder

A methanol fuel and combustion system technology, applied in combustion engines, mechanical equipment, machines/engines, etc., can solve problems such as difficult application, difficult methanol evaporation, high octane number, etc., to achieve improved ignition stability and high ignition energy , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further illustrate the functions of the present invention, the present invention will be described in detail below, but it should be understood that the protection scope of the present invention is not limited by specific embodiments.

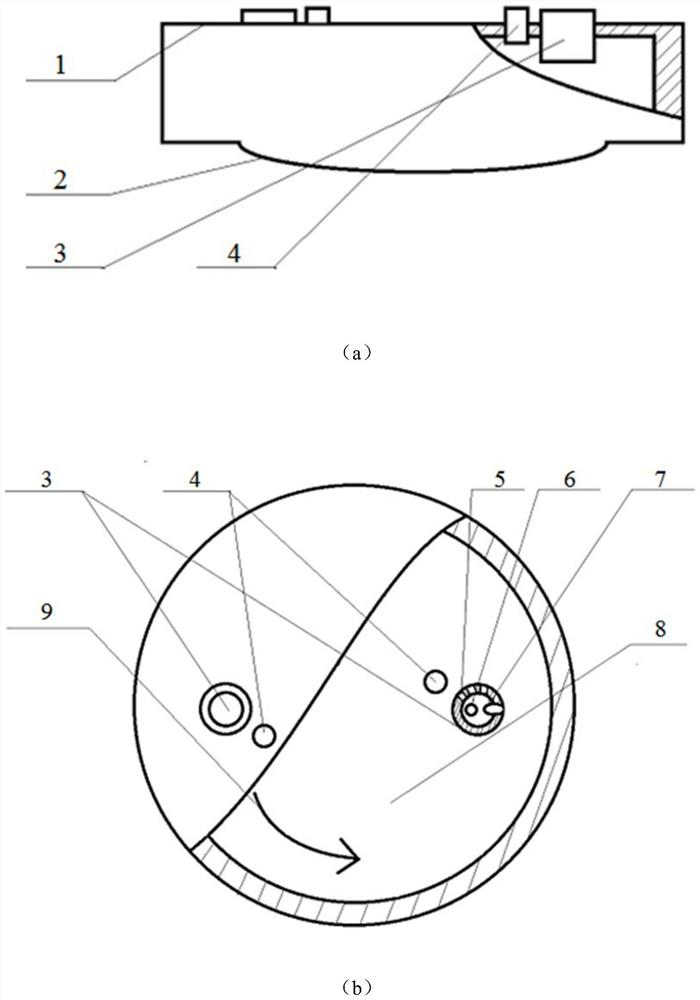

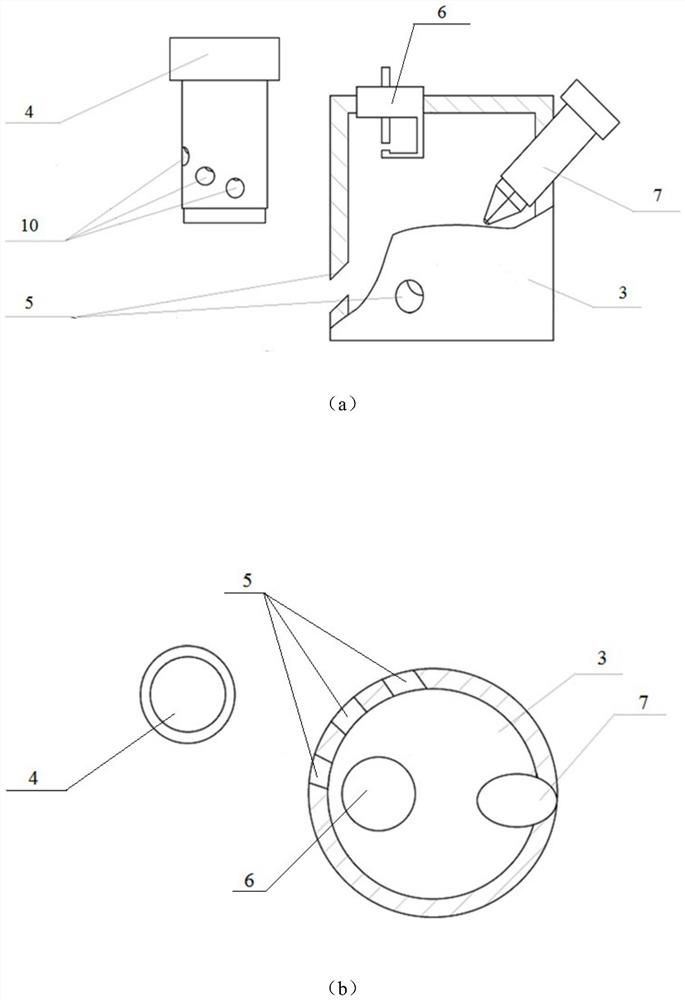

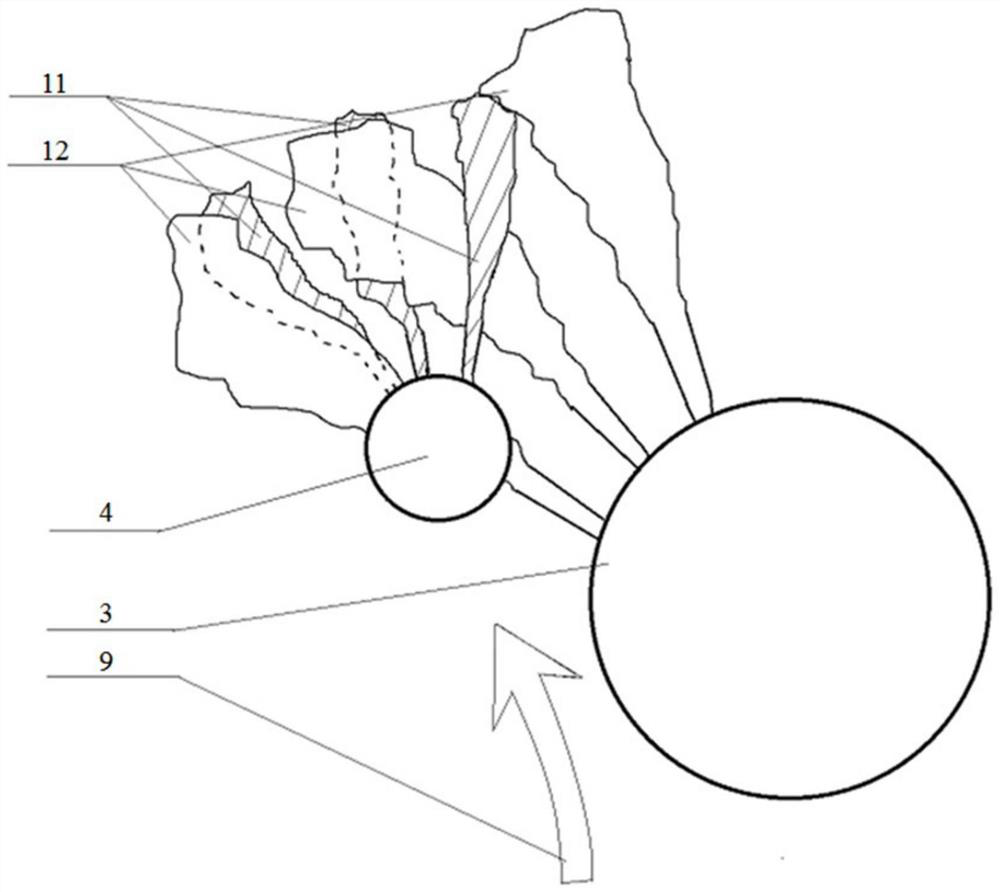

[0020] Such as Figures 1 to 3 As shown, the combustion system of an internal combustion engine with direct injection of methanol fuel in the cylinder of the present invention mainly includes a combustion chamber between the cylinder head 1 and the top surface of the piston 2, and the combustion chamber is composed of a main combustion chamber 8 and several pre-combustion chambers 3 .

[0021] The main combustion chamber 8 is the main combustion area of the internal combustion engine, and several methanol injectors II4 are embedded on its top, and each of the methanol injectors II4 is provided with a number of nozzle holes 10 in different directions and different levels, which can realize Inject methanol spray 11 with a rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com