Patents

Literature

100 results about "Diffusion flame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In combustion, a diffusion flame is a flame in which the oxidizer combines with the fuel by diffusion. As a result, the flame speed is limited by the rate of diffusion. Diffusion flames tend to burn slower and to produce more soot than premixed flames because there may not be sufficient oxidizer for the reaction to go to completion, although there are some exceptions to the rule. The soot typically produced in a diffusion flame becomes incandescent from the heat of the flame and lends the flame its readily identifiable orange-yellow color. Diffusion flames tend to have a less-localized flame front than premixed flames.

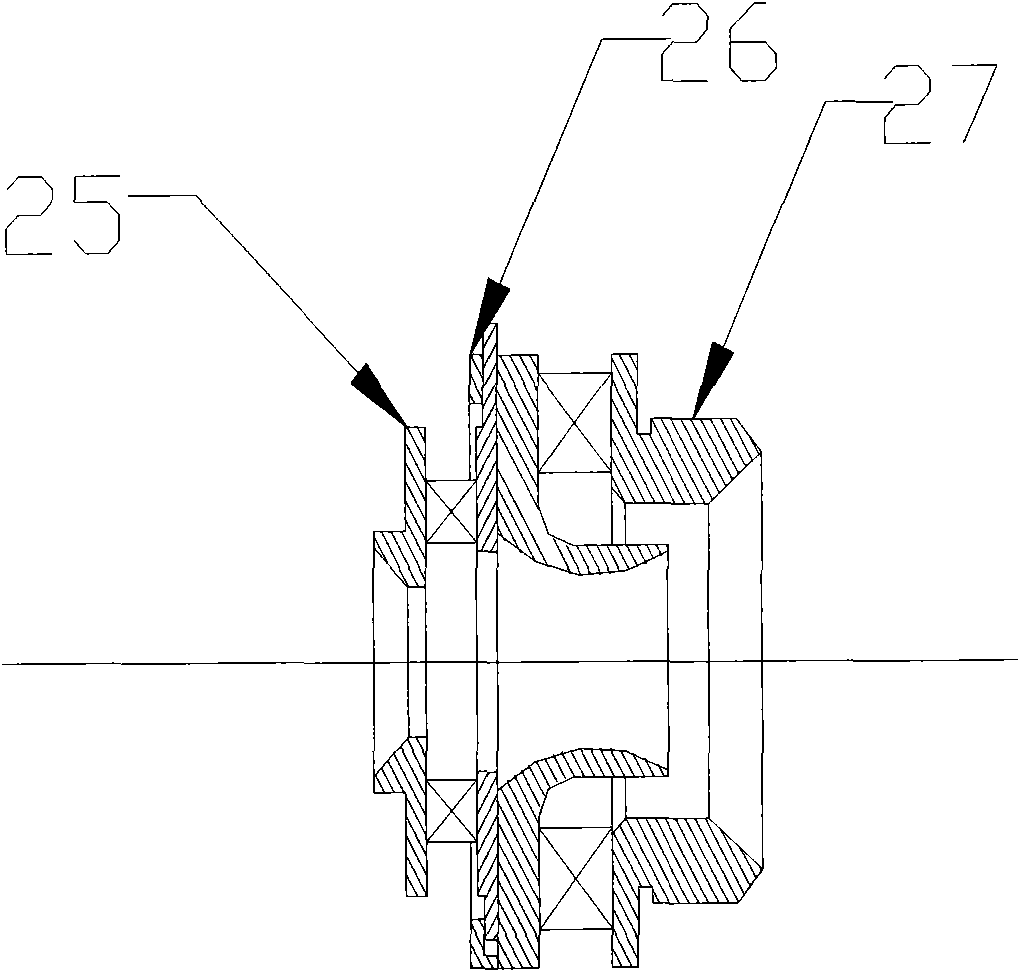

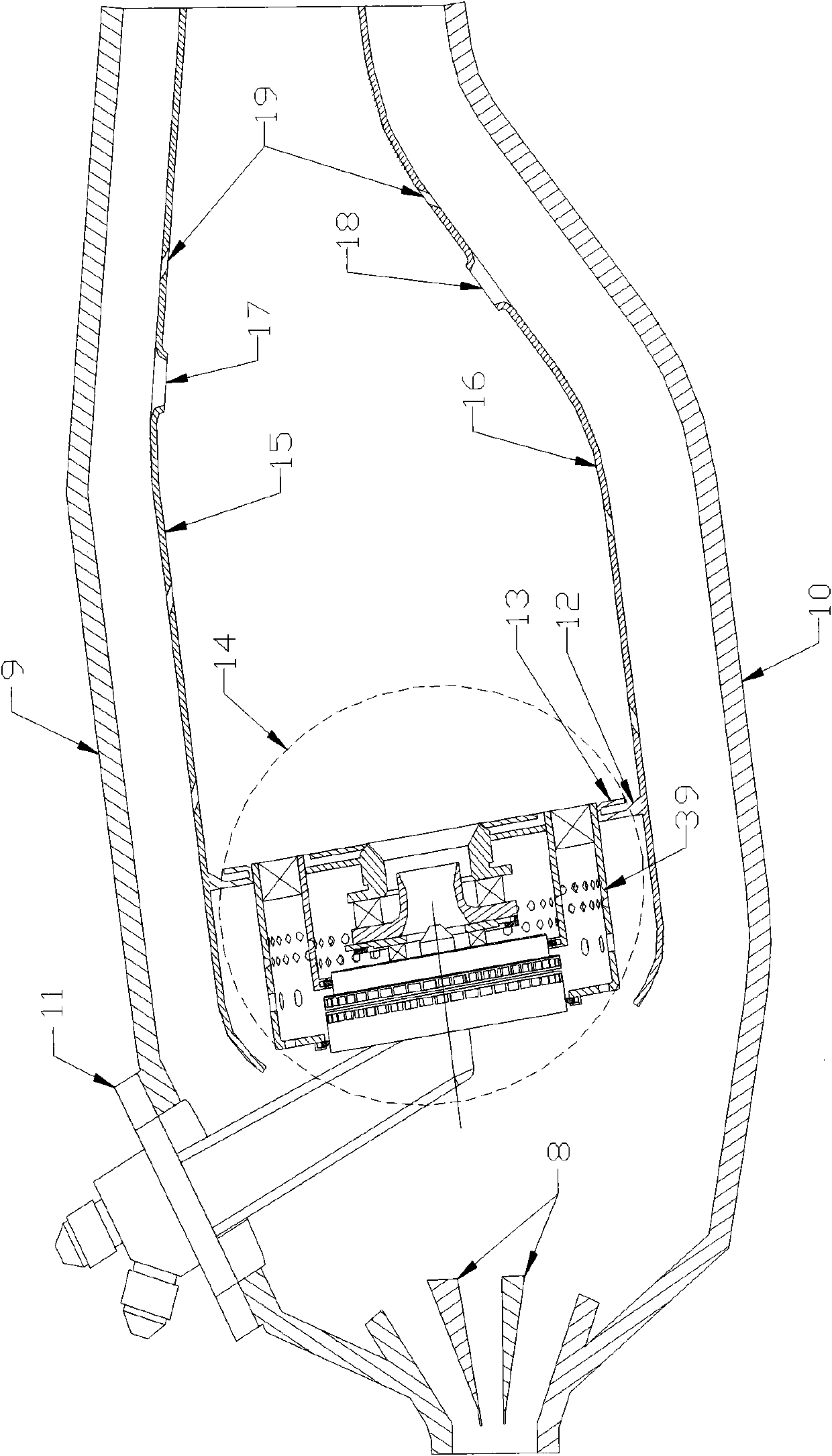

Premixing and pre-evaporating combustion chamber

ActiveCN101709884ASimple structureImprove efficacyContinuous combustion chamberDiffusion flameCombustion chamber

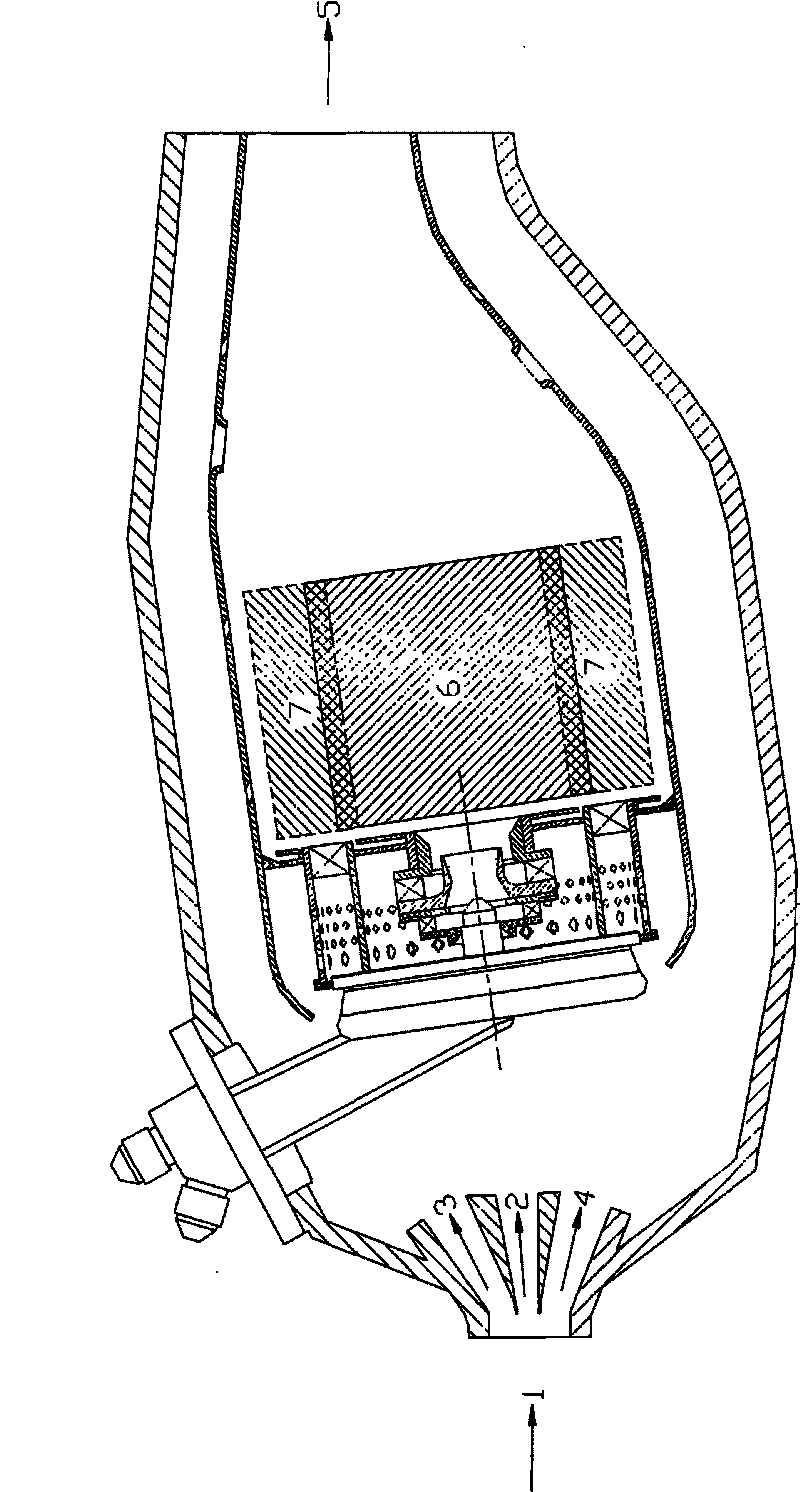

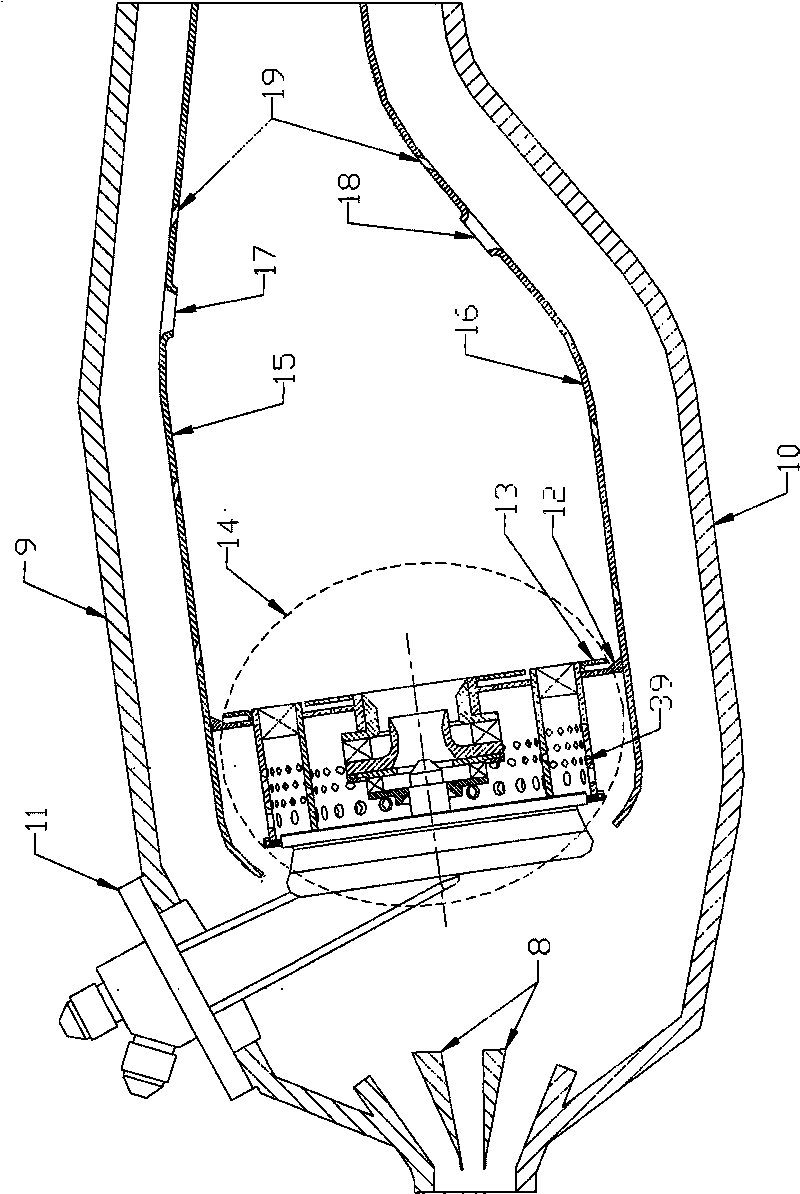

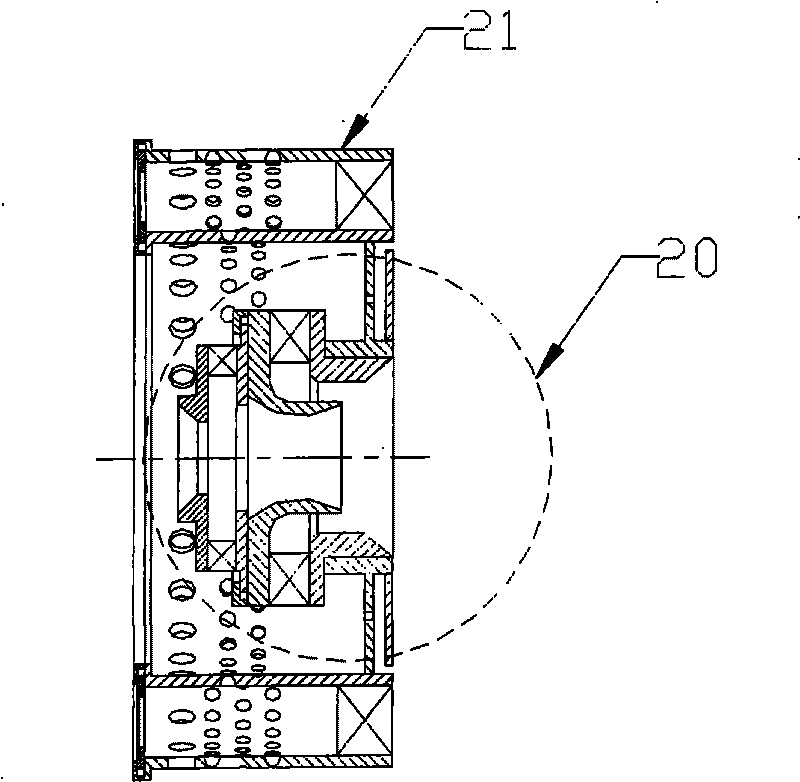

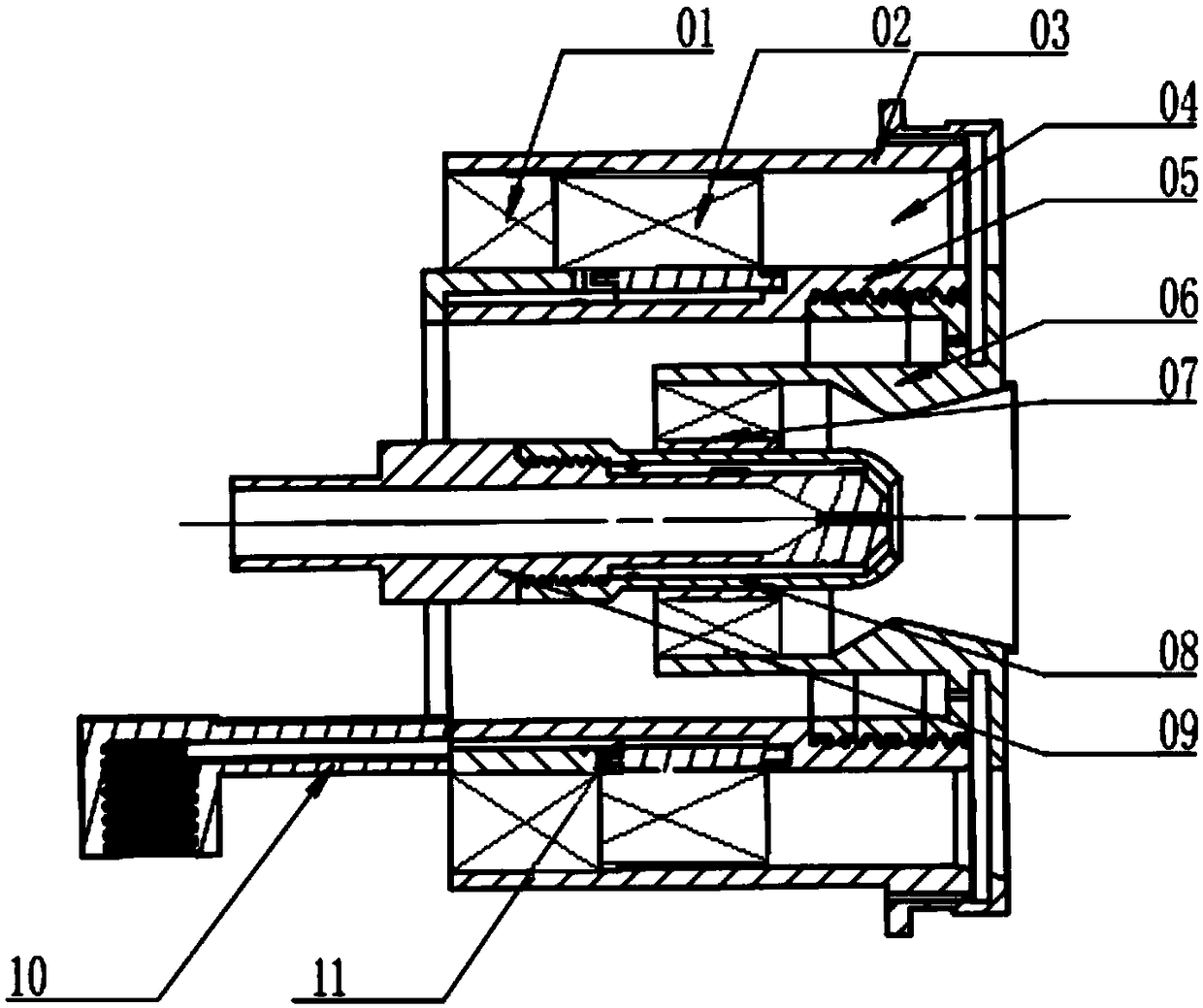

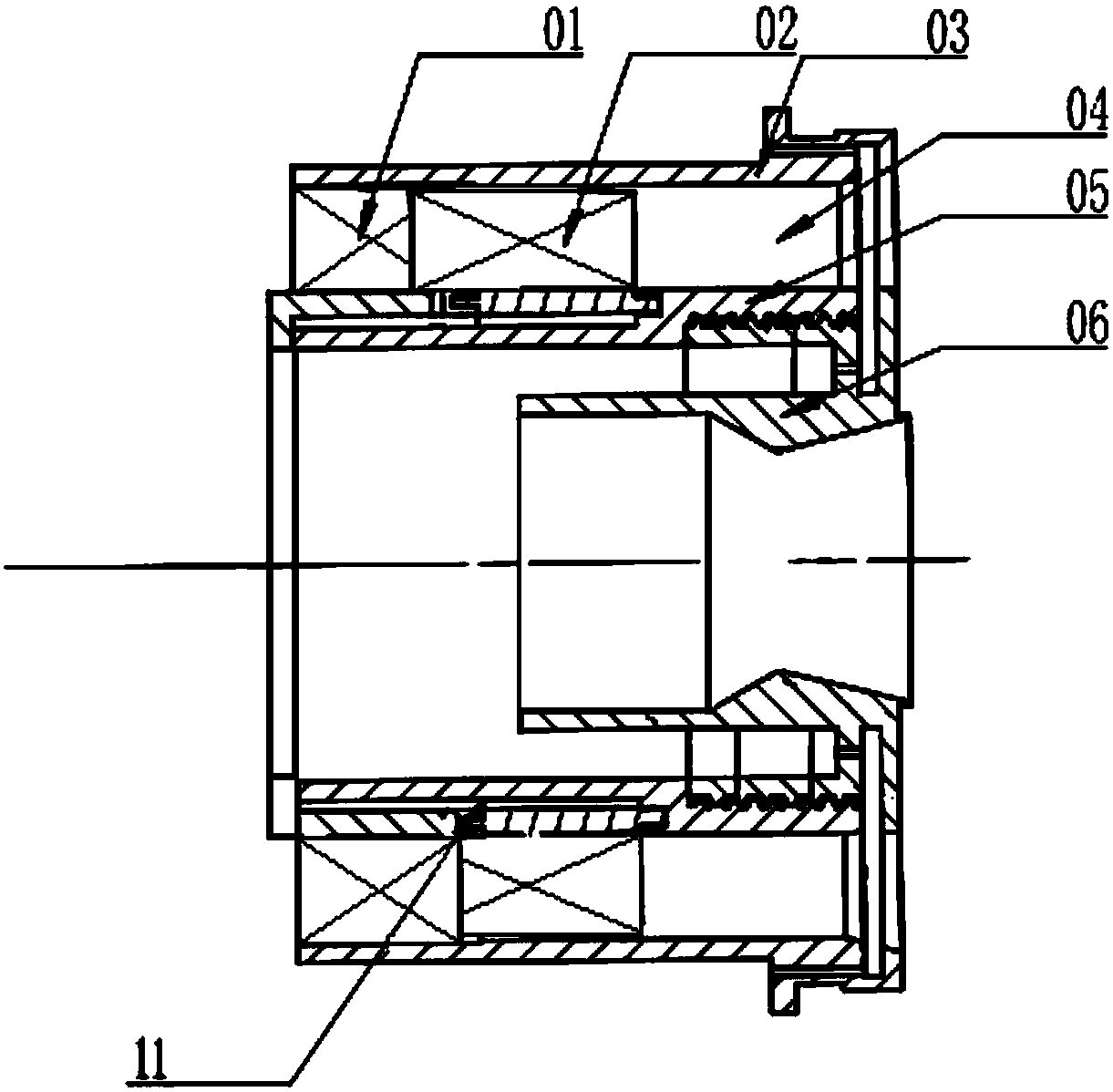

The invention discloses a premixing and pre-evaporating combustion chamber, which has a single annular chamber structure and adopts a conceptual design of fractional combustion. In the combustion chamber, the total combustion gas volume is supplied by a pre-combustion fraction and a main combustion fraction, the pre-combustion fraction adopts a swirl-flow stable diffusion flame combustion organization mode and the main combustion fraction adopts a premixing and pre-evaporating combustion organization mode. The combustion chamber mainly comprises a shunting diffuser, a combustion chamber outer casing, a combustion chamber inner casing, a fuel oil nozzle, the pre-combustion fraction, the main combustion fraction, a combustion liner outer wall and a combustion liner inner wall. The pre-combustion fraction stabilizes flame by using a low-speed refluxing zone generated by swirl air entering the combustion chamber from a pre-combustion fraction swirler; and after being sprayed out by a main combustion fraction nozzle, the fuel oil needed by the main combustion fraction first form an oil-gas mixed gas through atomization under the action of an air flow in a prefilming air ring in the main combustion fraction nozzle and then flows to the premixing and pre-evaporating fraction to be evaporated and further blended with the air, so a uniform oil-gas mixed gas jet flow is formed at the position of the outlet of the premixing and pre-evaporating fraction and enters the combustion liner to be ignited by flame in the pre-combustion fraction to combust. The combustion chamber is simple in structure and can effectively reduce pollutant discharge while ensuring an aeroengine works normally.

Owner:BEIHANG UNIV

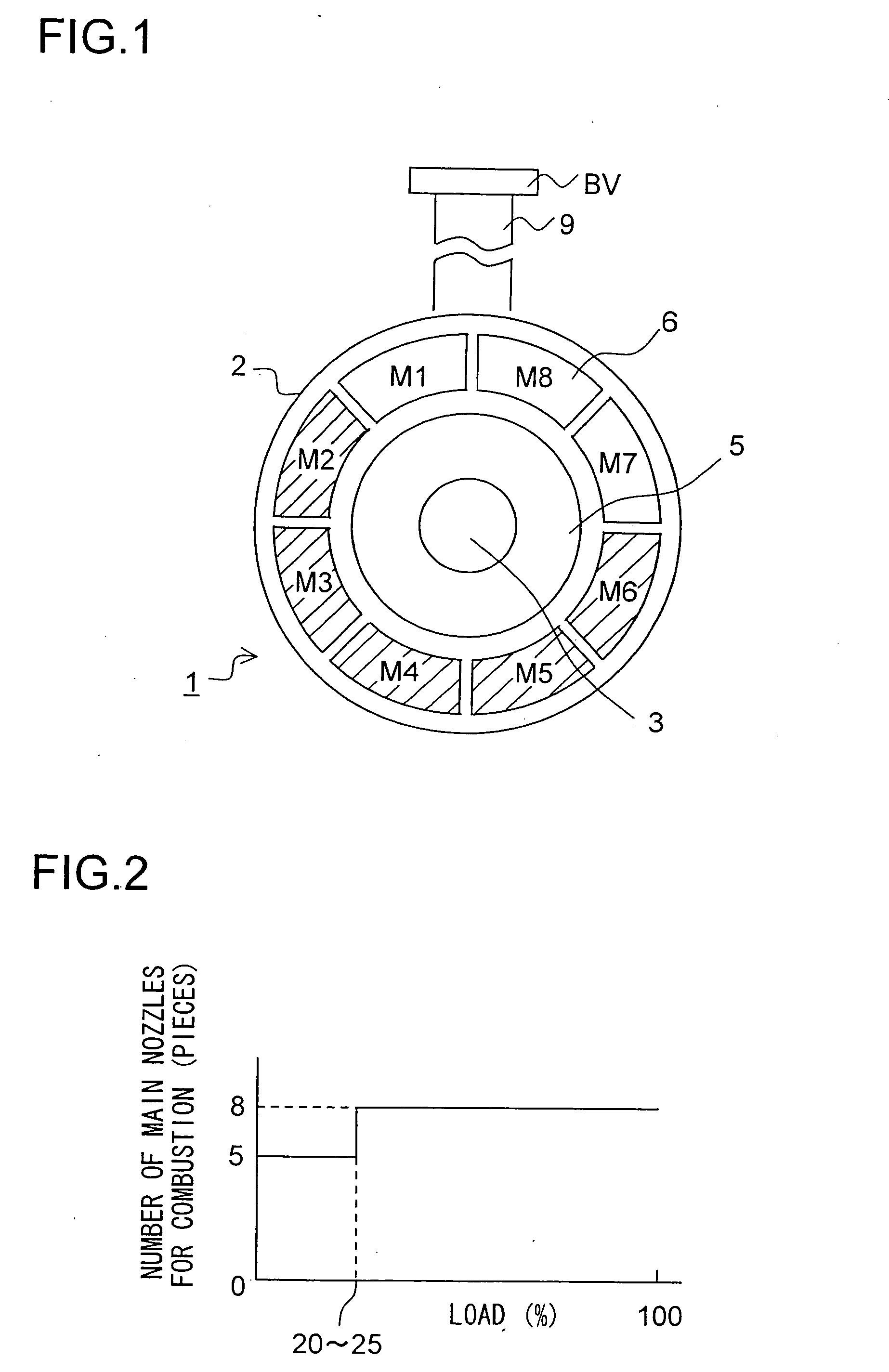

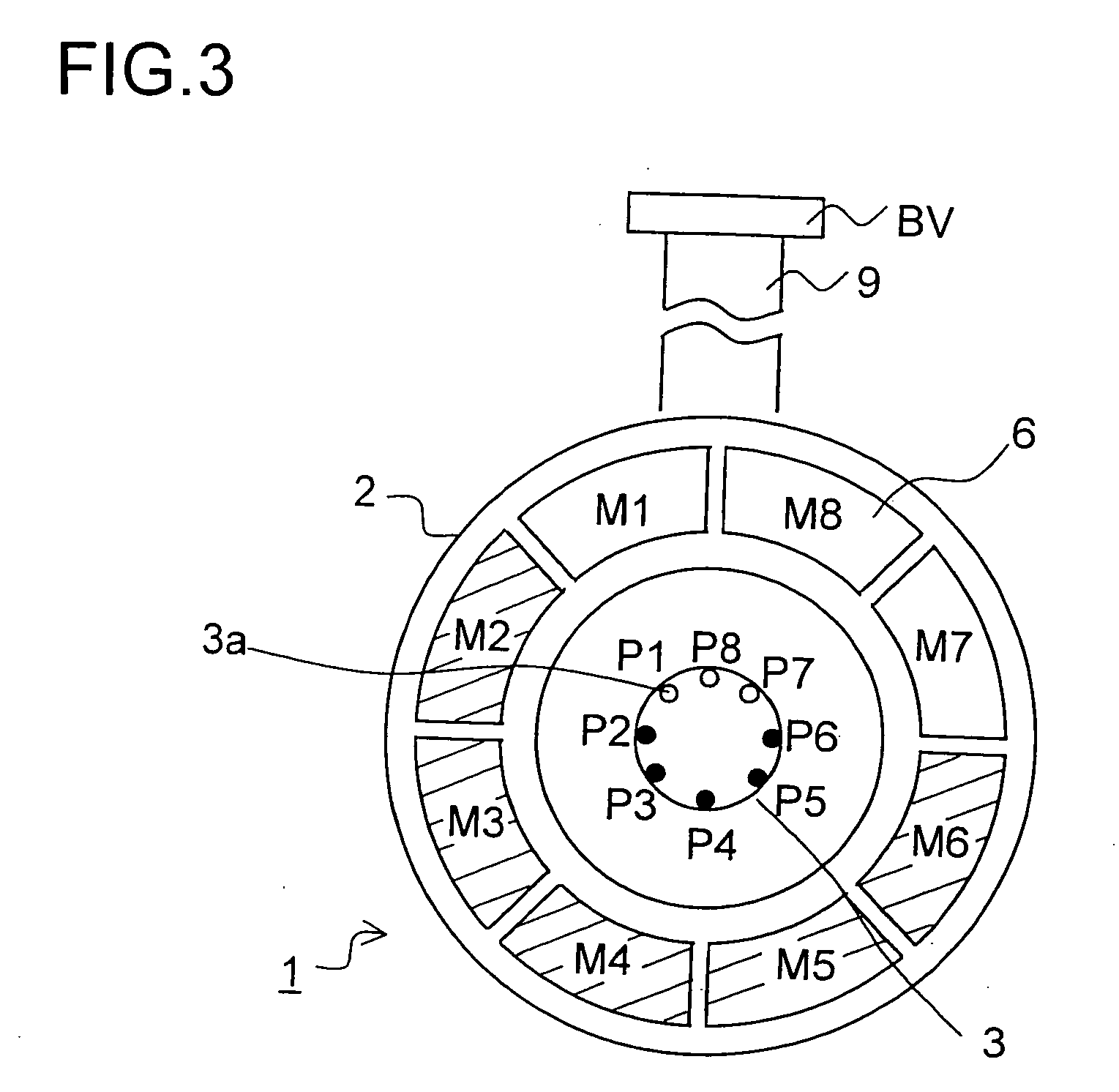

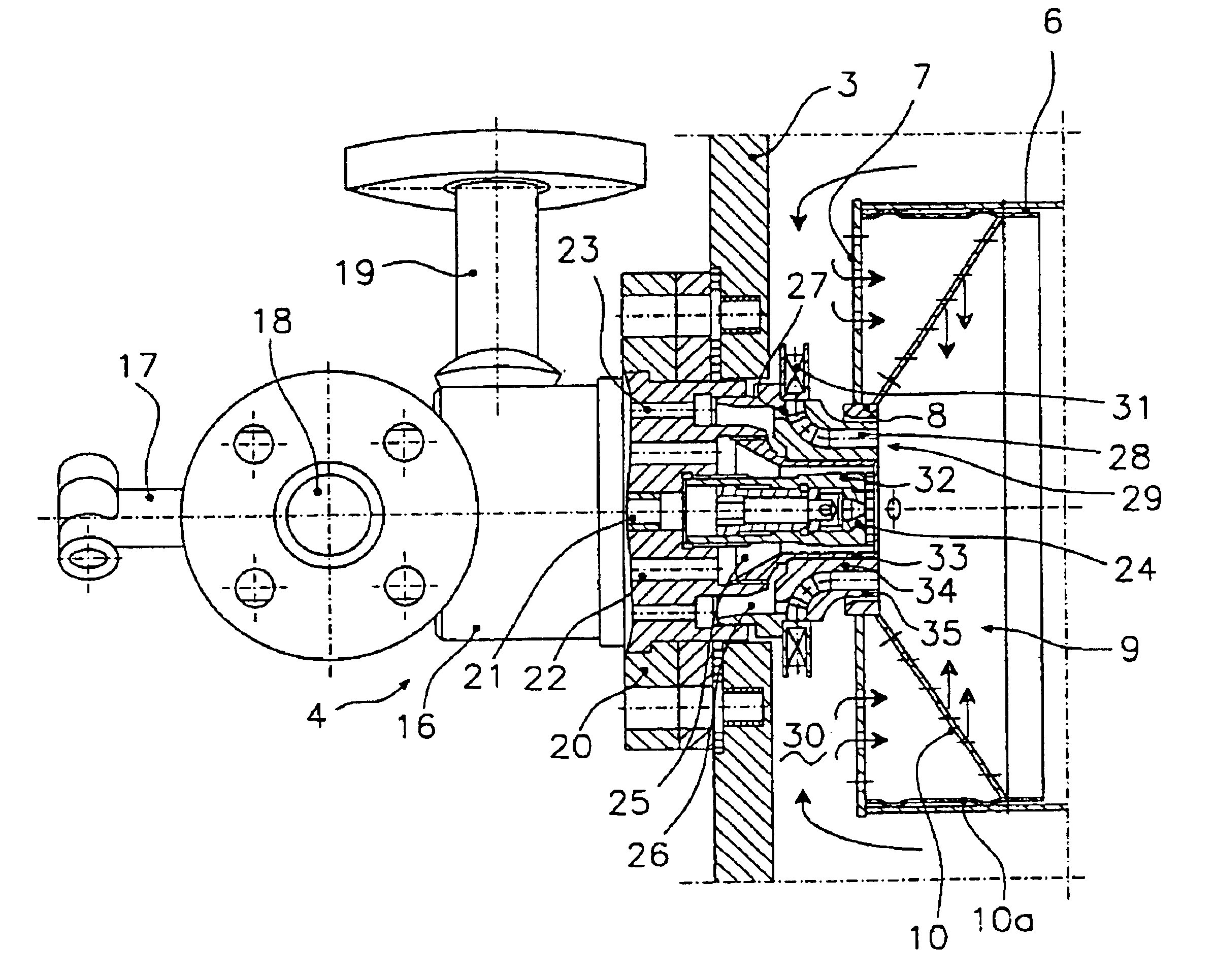

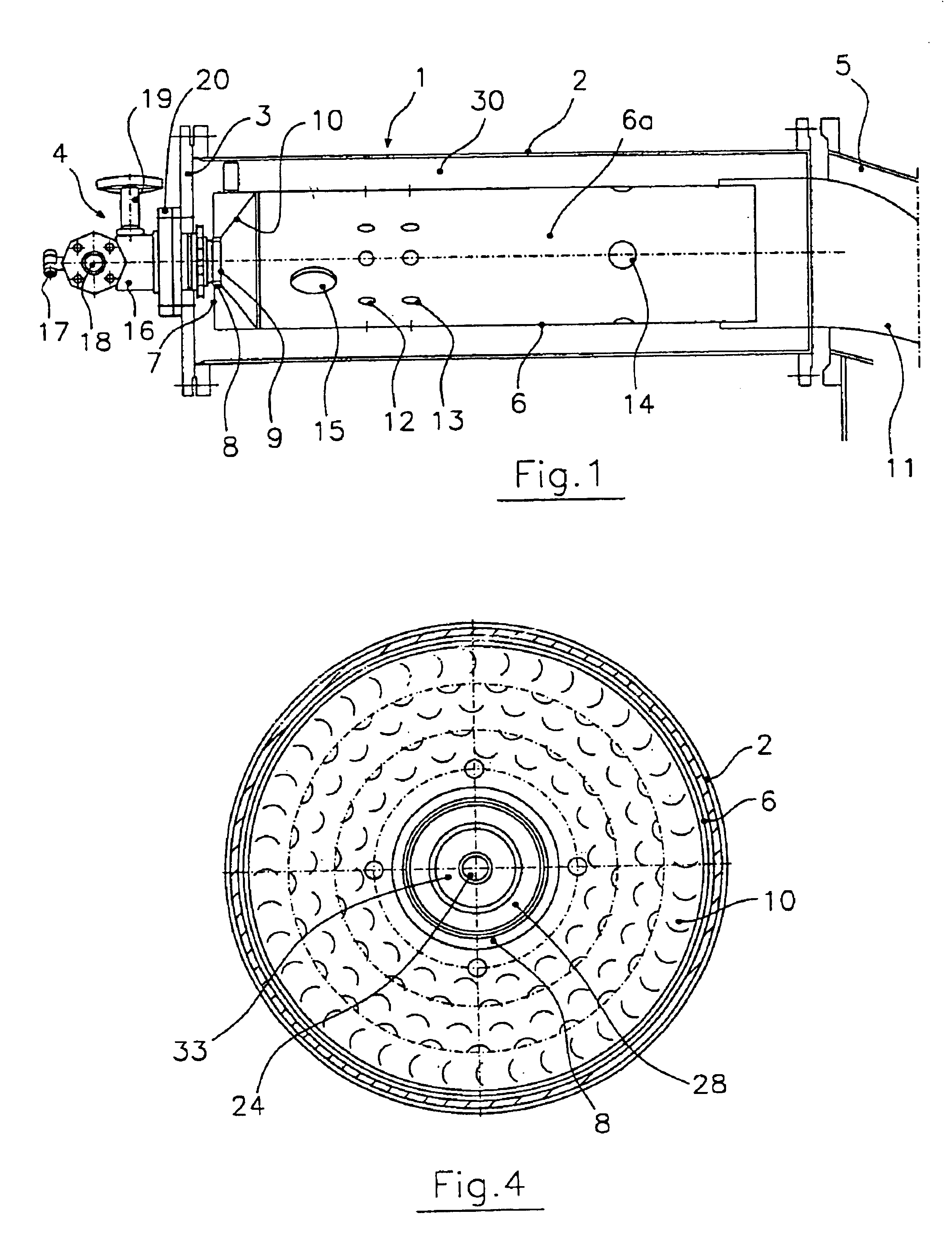

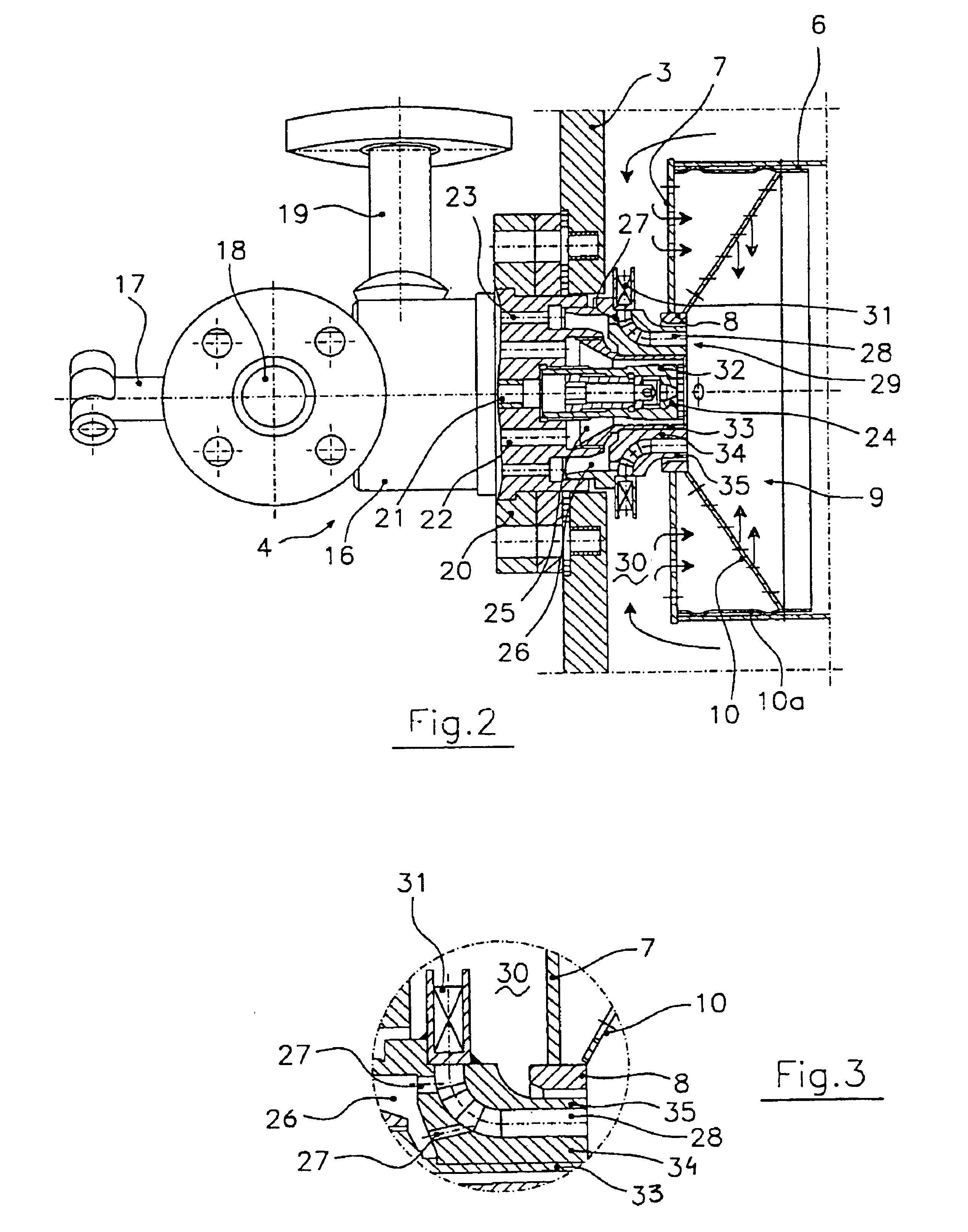

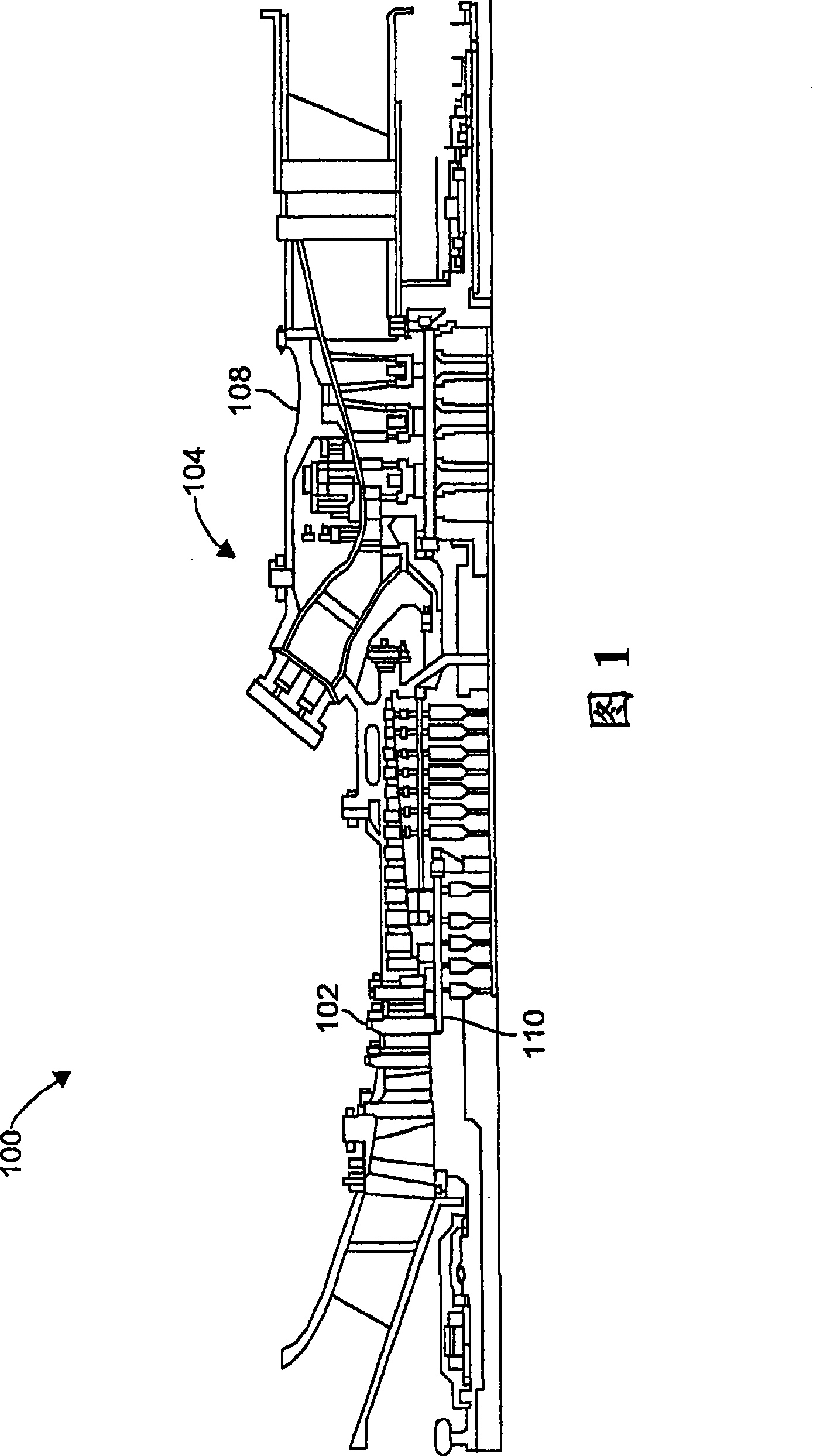

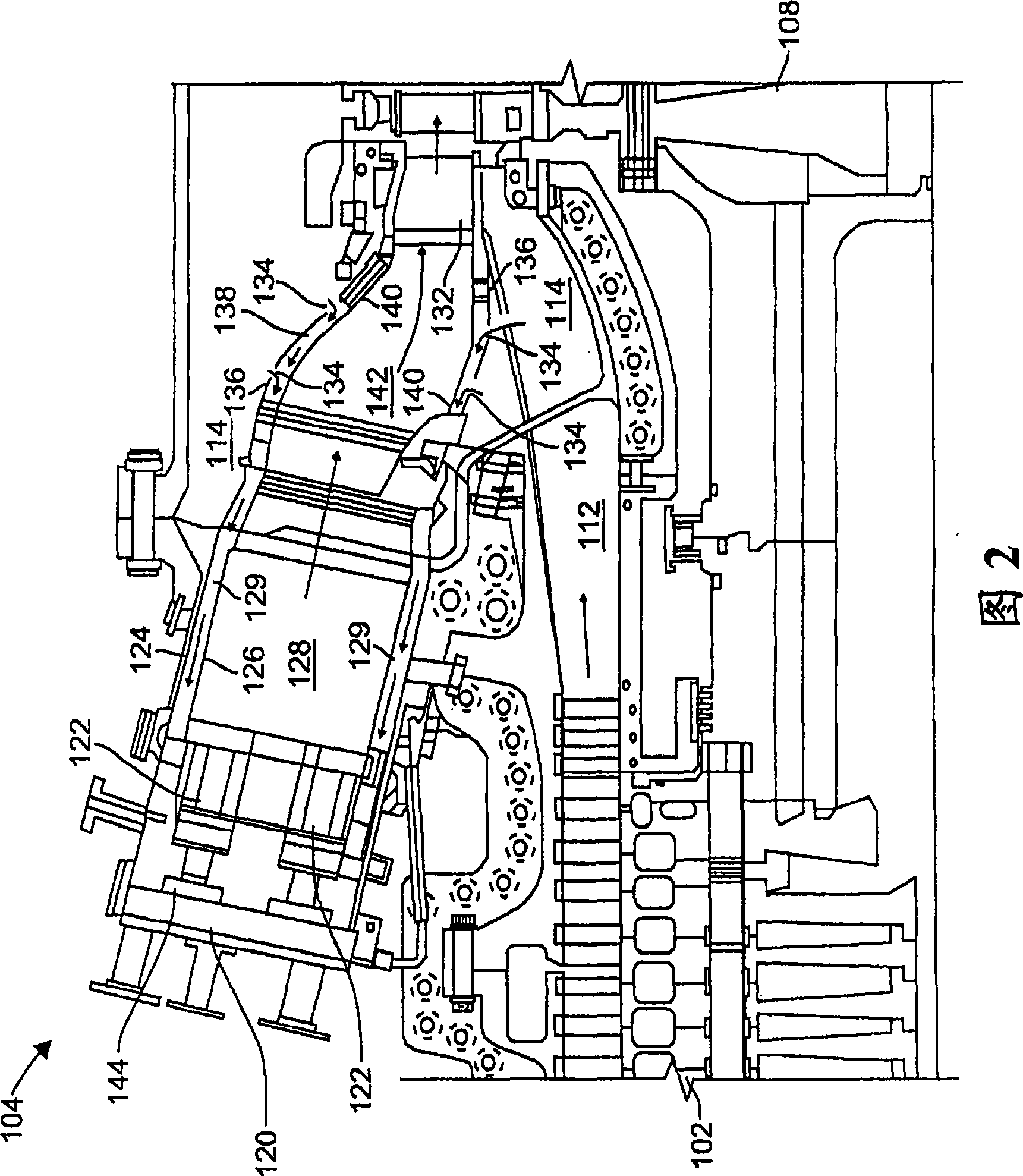

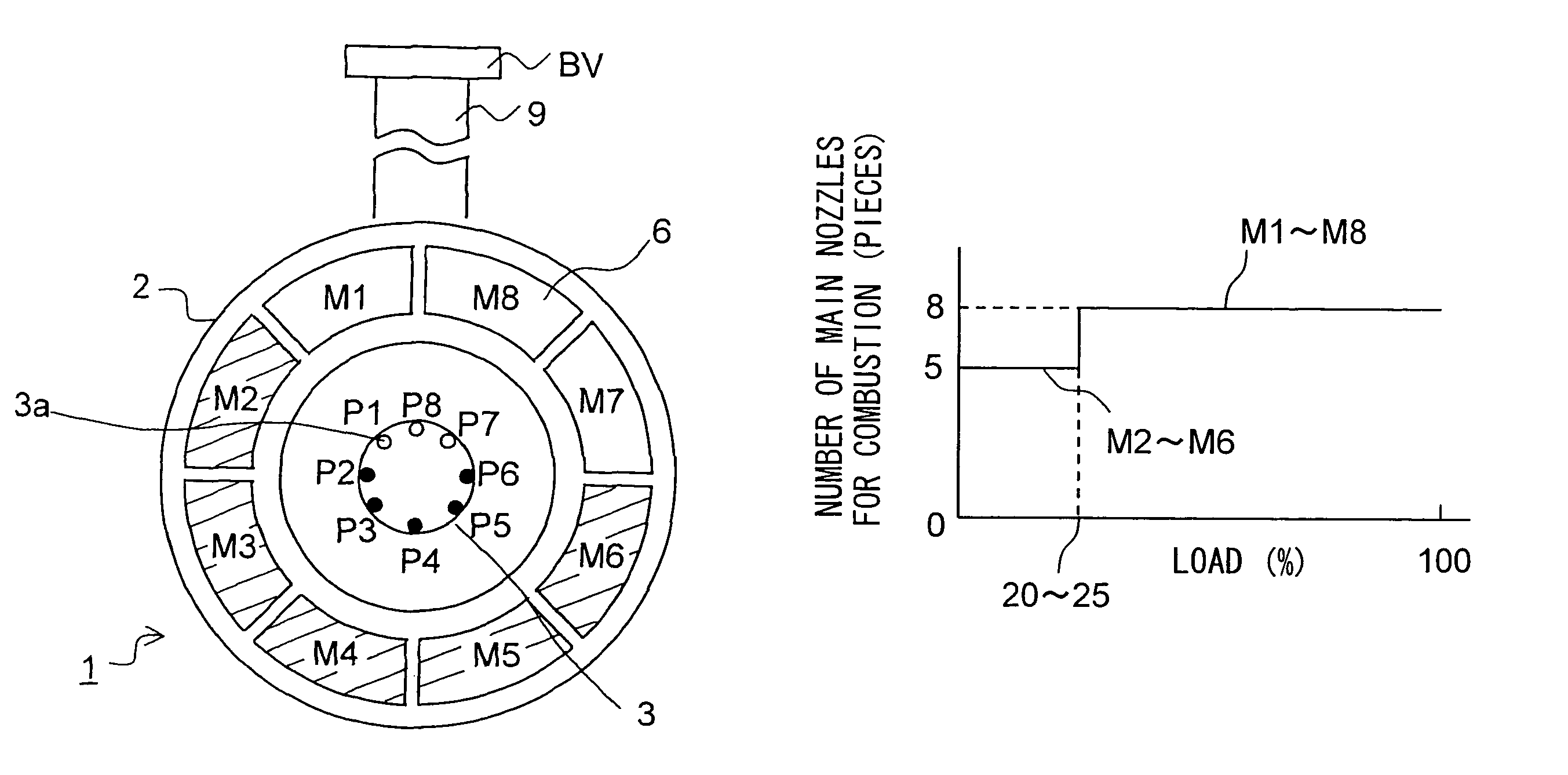

Combustor of a gas turbine

ActiveUS20060101814A1Improve featuresAchieve stablyContinuous combustion chamberTurbine/propulsion fuel supply systemsDiffusion flameCombustion chamber

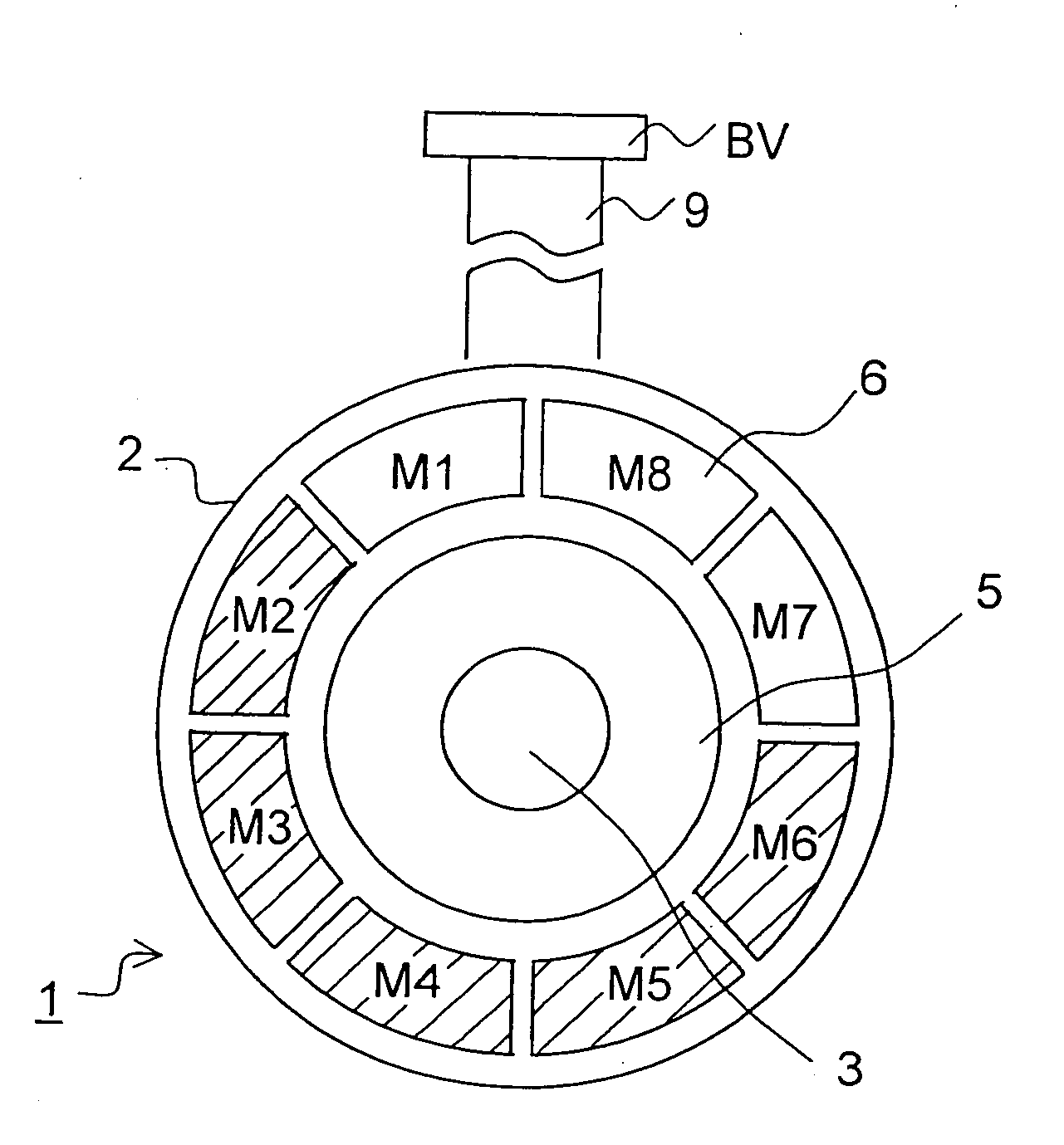

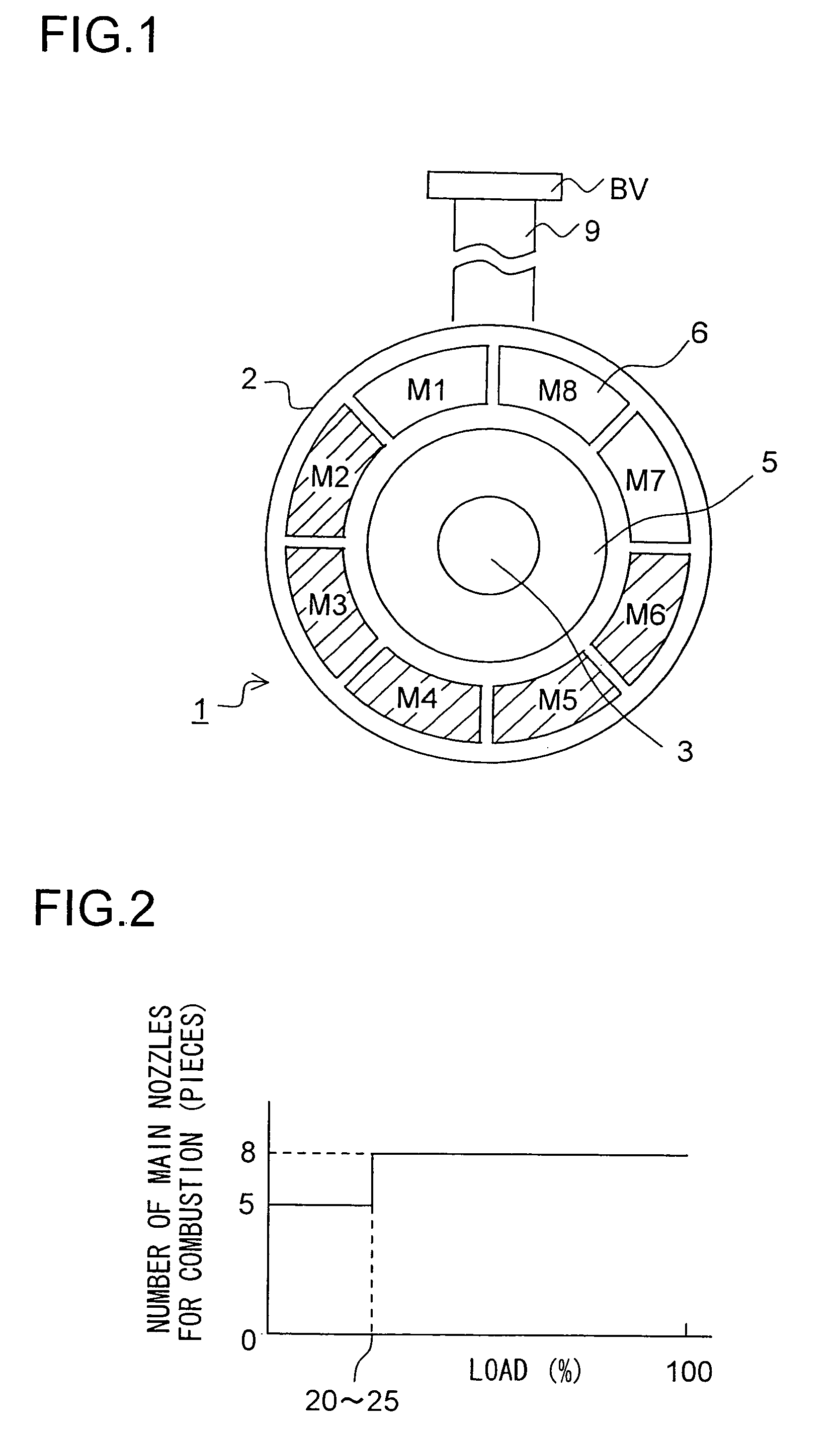

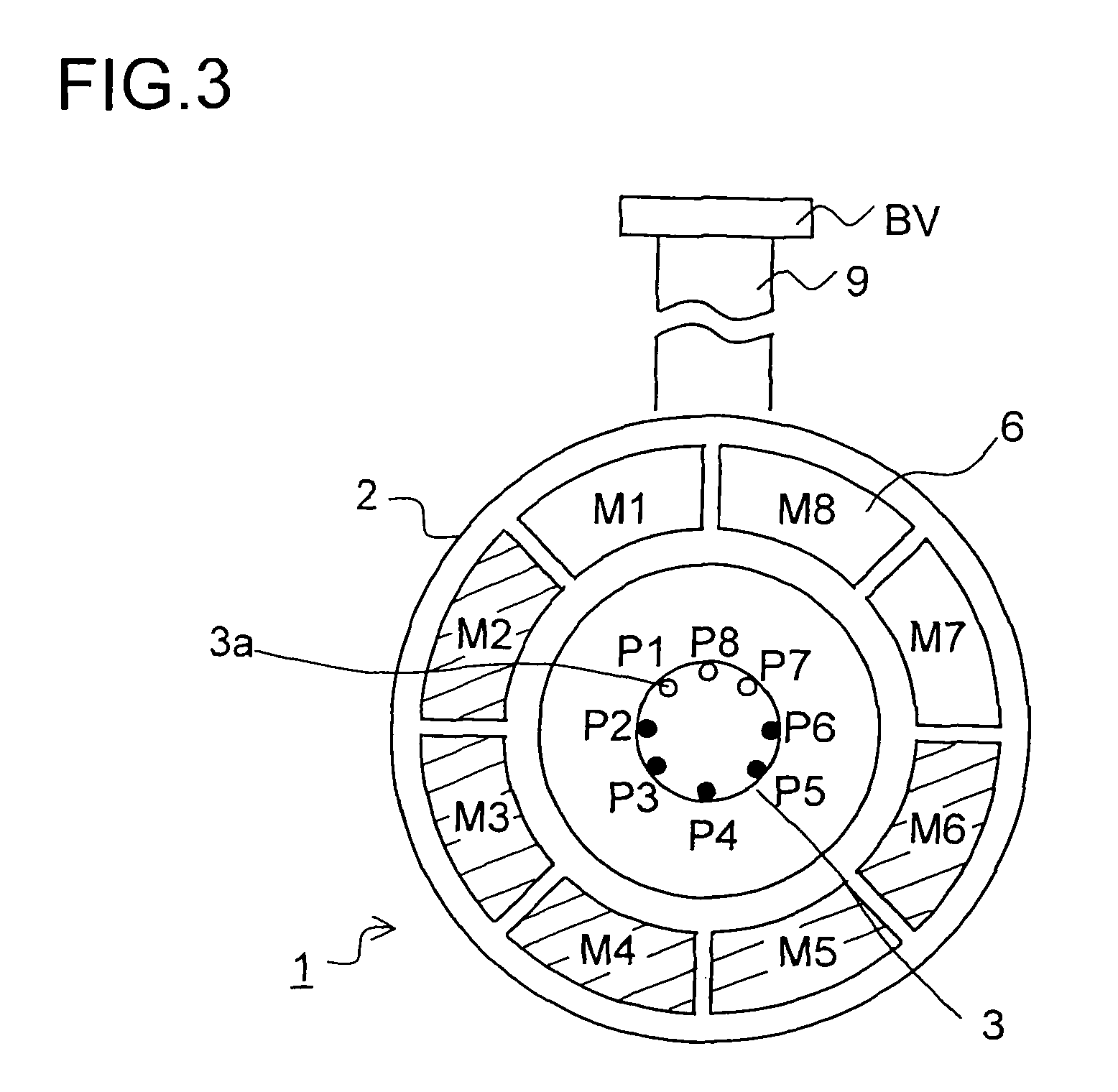

In a combustor of a gas turbine which has a pilot nozzle being installed to the center of the axis of a combustor basket and a plurality of main nozzles being installed to the vicinity of the pilot nozzle and provided with a premixing tool on the outer circumference thereof, wherein, fuel being injected as air-fuel pre-mixture from the main nozzle into the interior of a transition piece forming a combustion chamber downstream of the combustor basket is ignited by diffusion flame being generated by the pilot nozzle in the transition piece so as to generate a premixed flame in the transition piece, wherein combustion is performed by a part of the plurality of main nozzles from start-up until a predetermined load rate and then performed by adding the remaining portion of the plurality of main nozzles when the predetermined load rate is exceeded.

Owner:MITSUBISHI POWER LTD

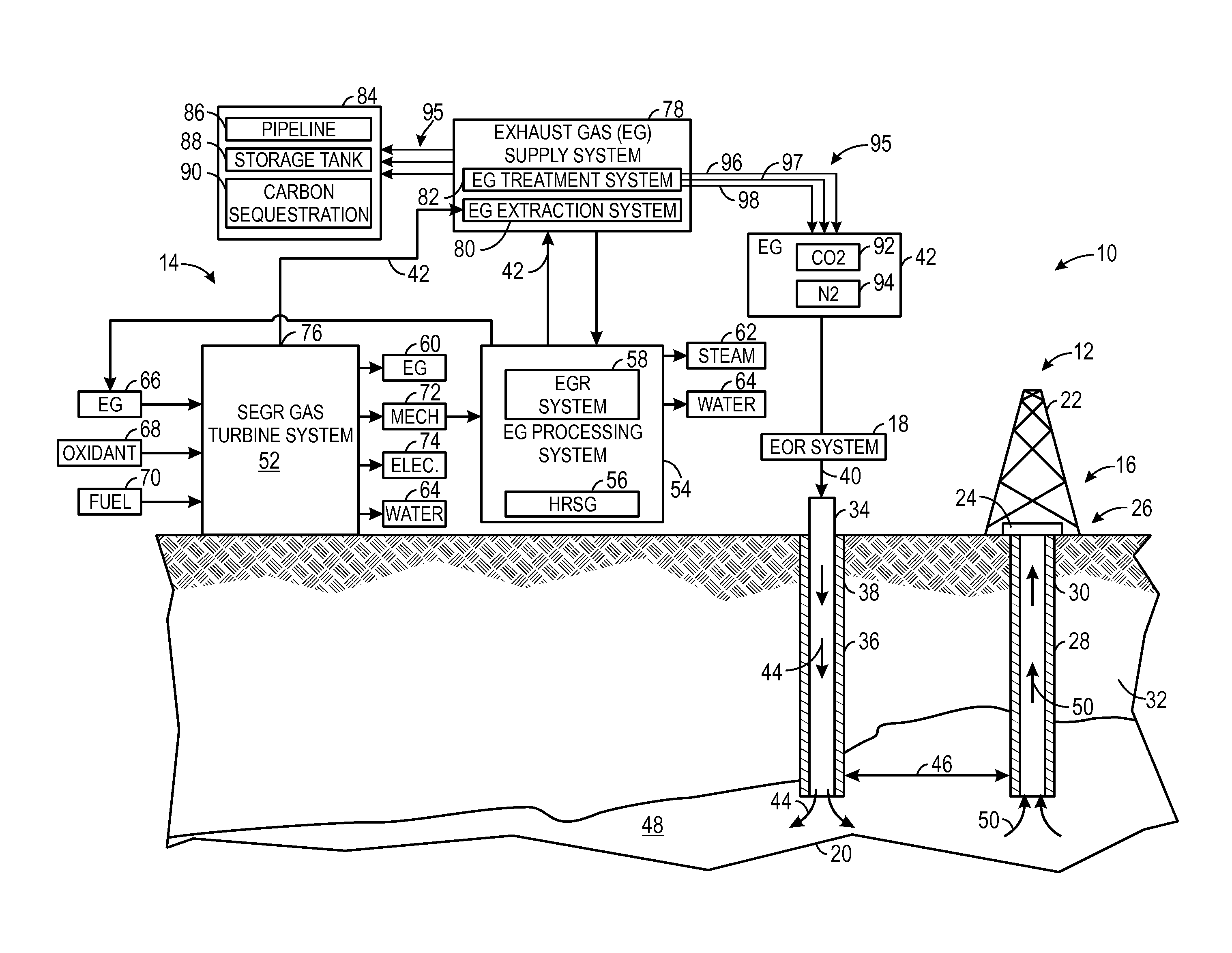

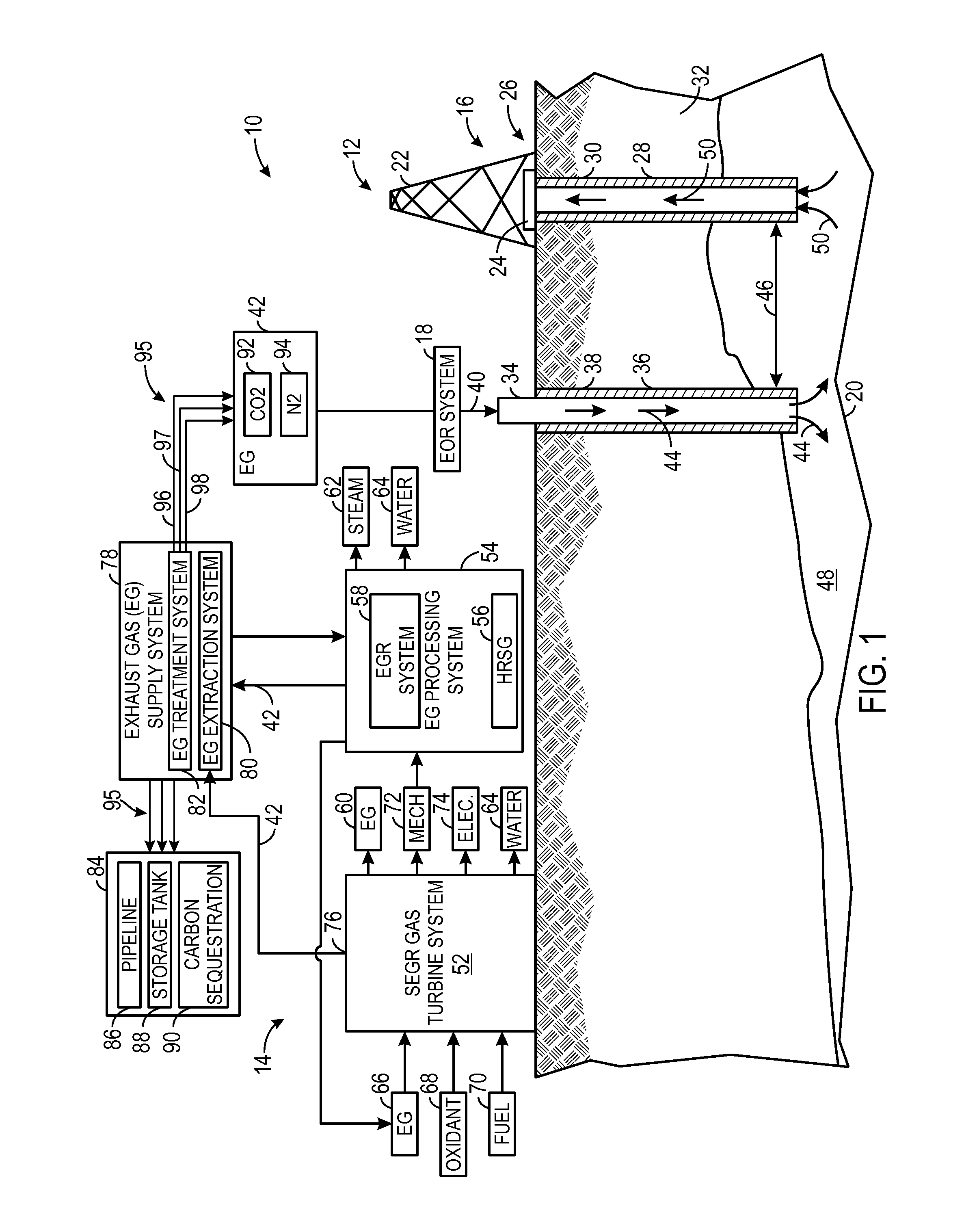

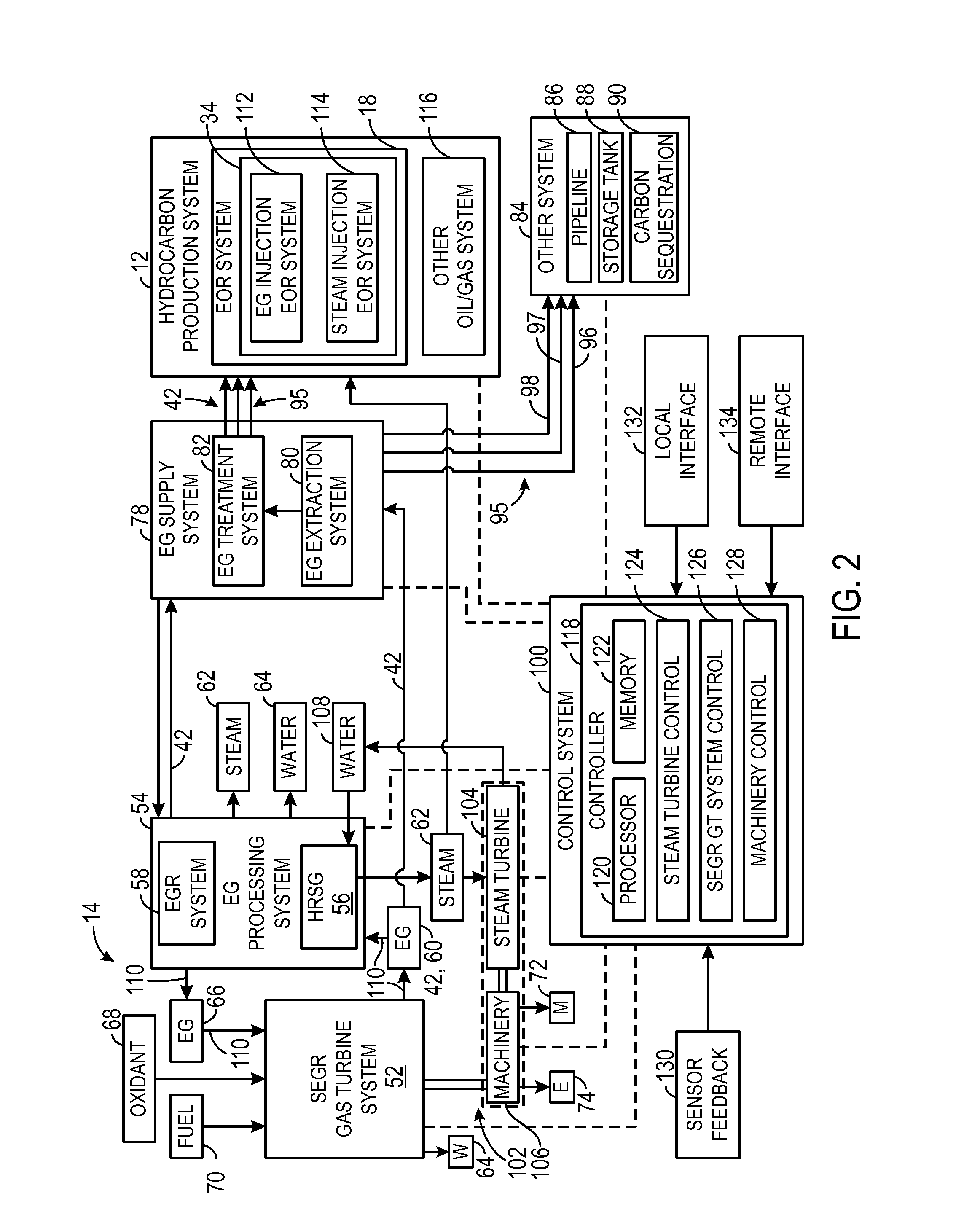

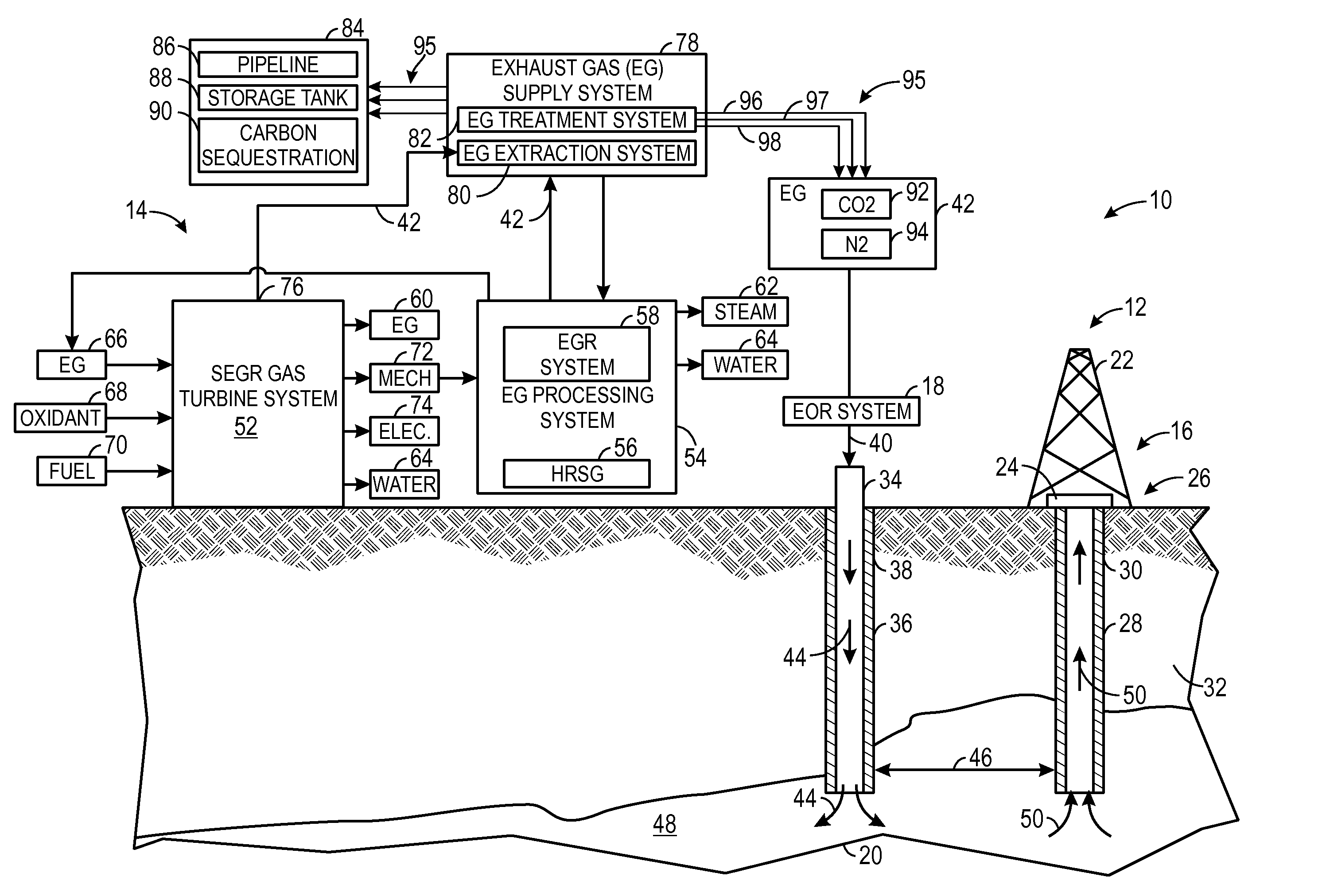

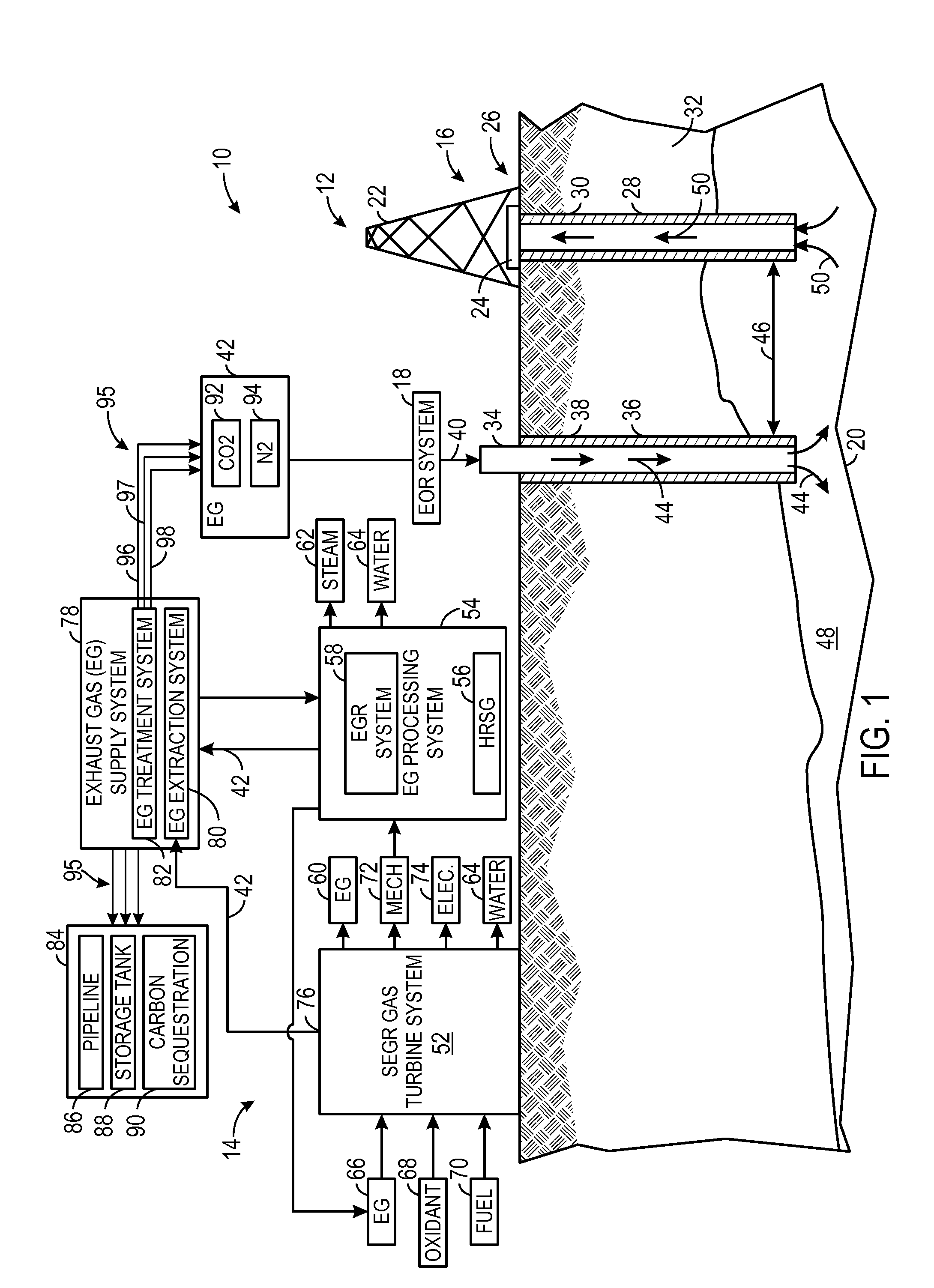

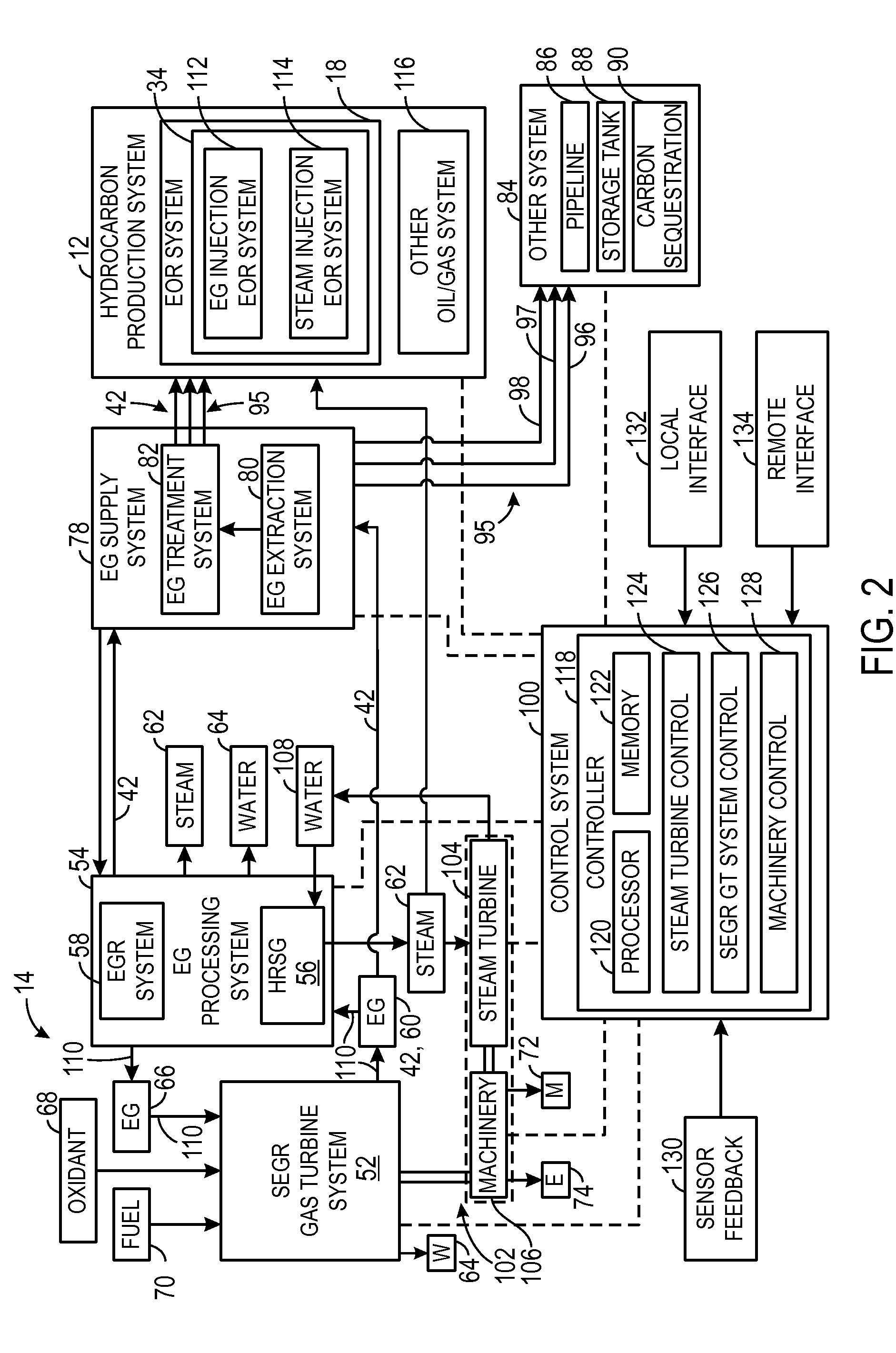

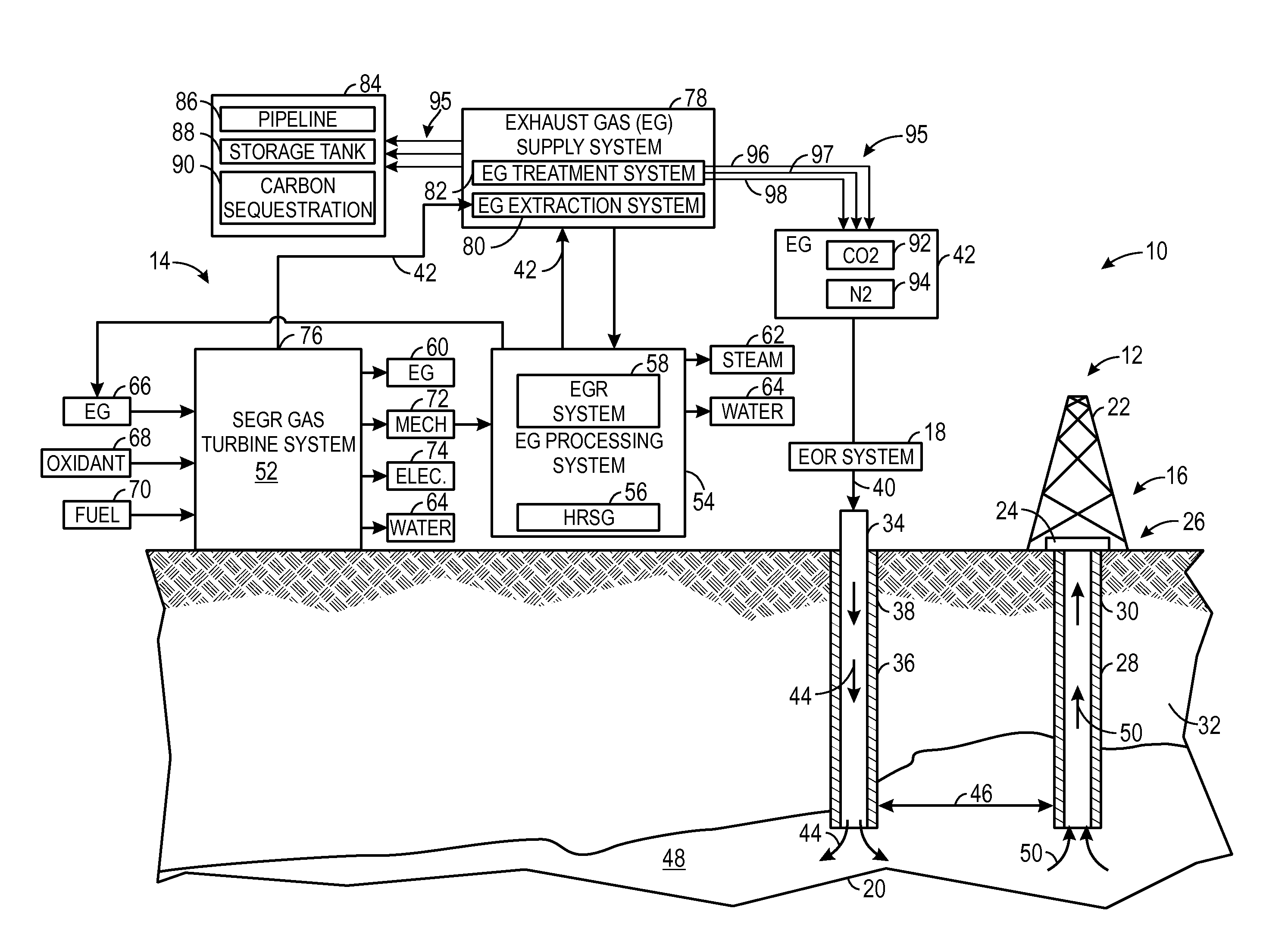

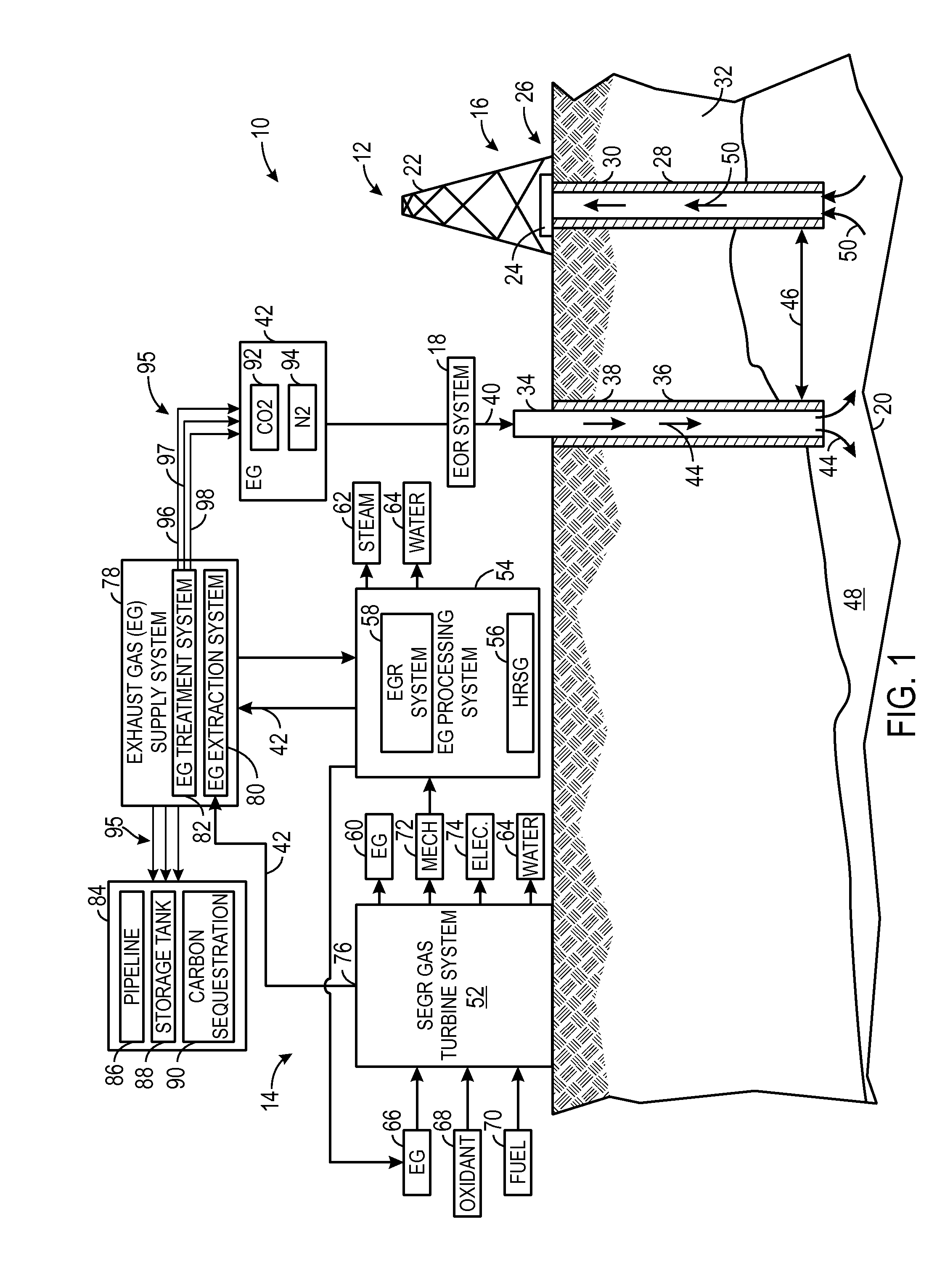

System and method for diffusion combustion in a stoichiometric exhaust gas recirculation gas turbine system

ActiveUS20140123672A1Low oxygenTurbine/propulsion fuel supply systemsGaseous fuel feeder/distributionDiffusion flameExhaust fumes

A system is provided with a turbine combustor having a first diffusion fuel nozzle, wherein the first diffusion fuel nozzle is configured to produce a diffusion flame. The system includes a turbine driven by combustion products from the diffusion flame in the turbine combustor. The system also includes an exhaust gas compressor, wherein the exhaust gas compressor is configured to compress and route an exhaust gas from the turbine to the turbine combustor along an exhaust recirculation path. In addition, the system includes a first catalyst unit disposed along the exhaust recirculation path.

Owner:GENERAL ELECTRIC CO +1

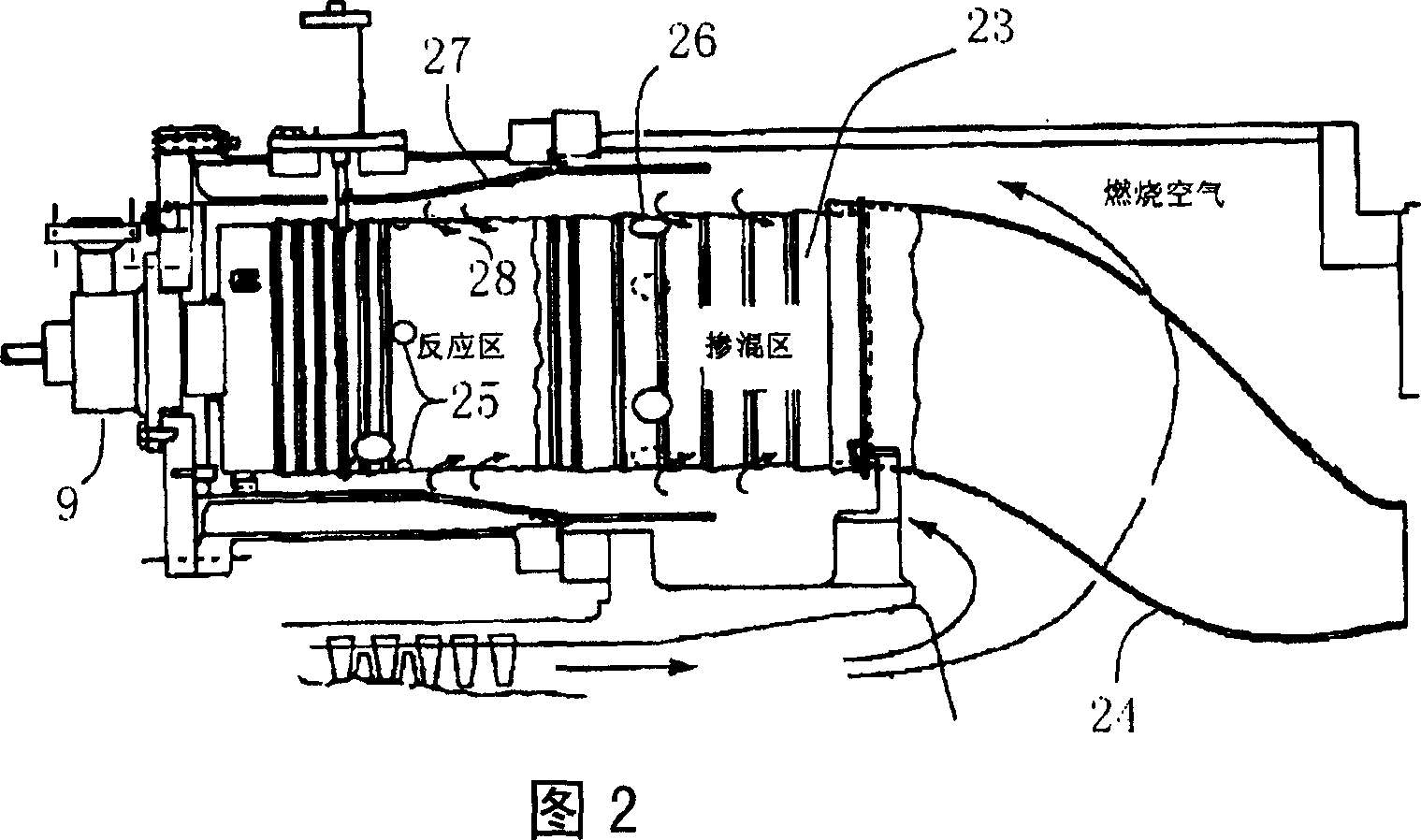

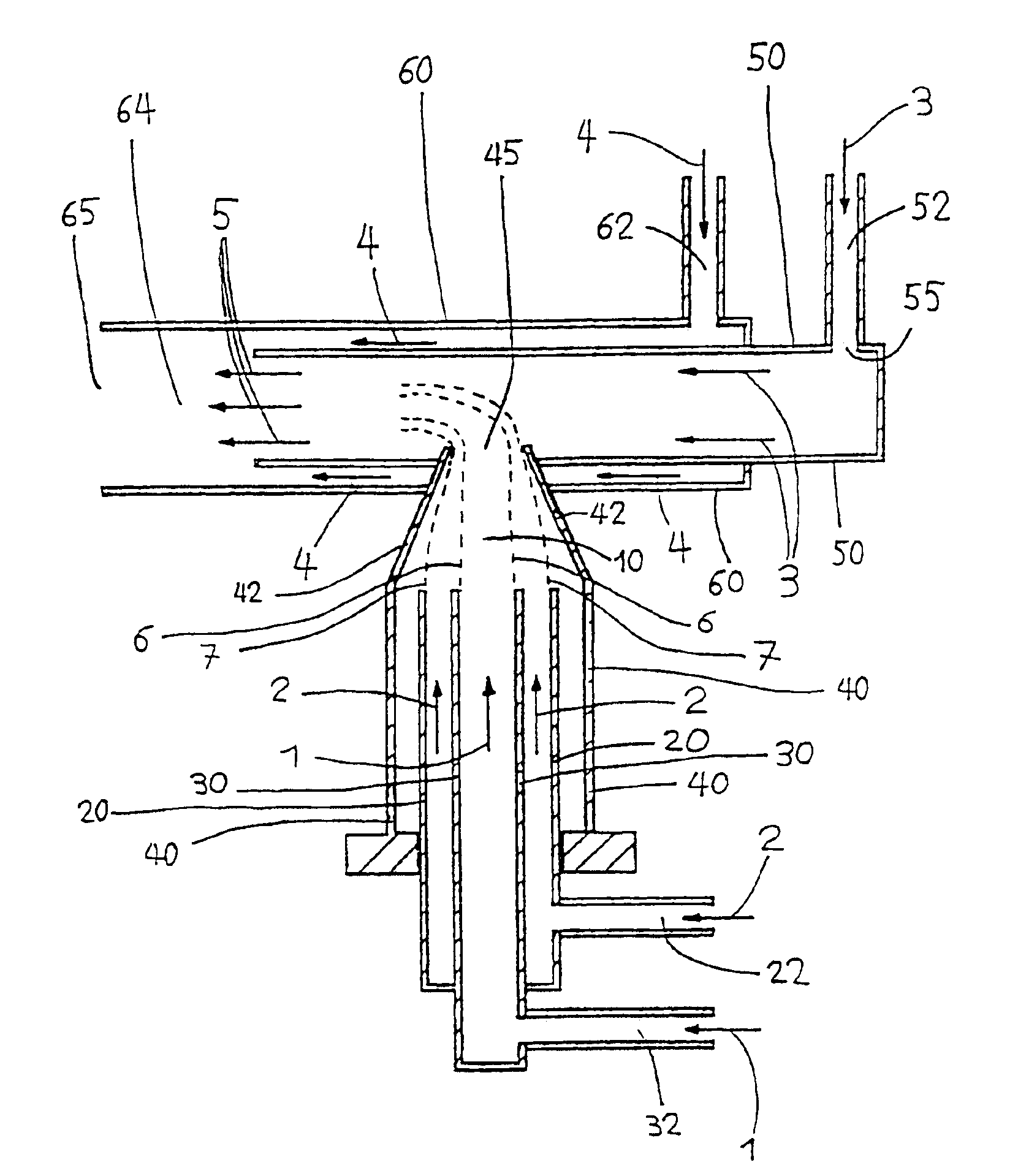

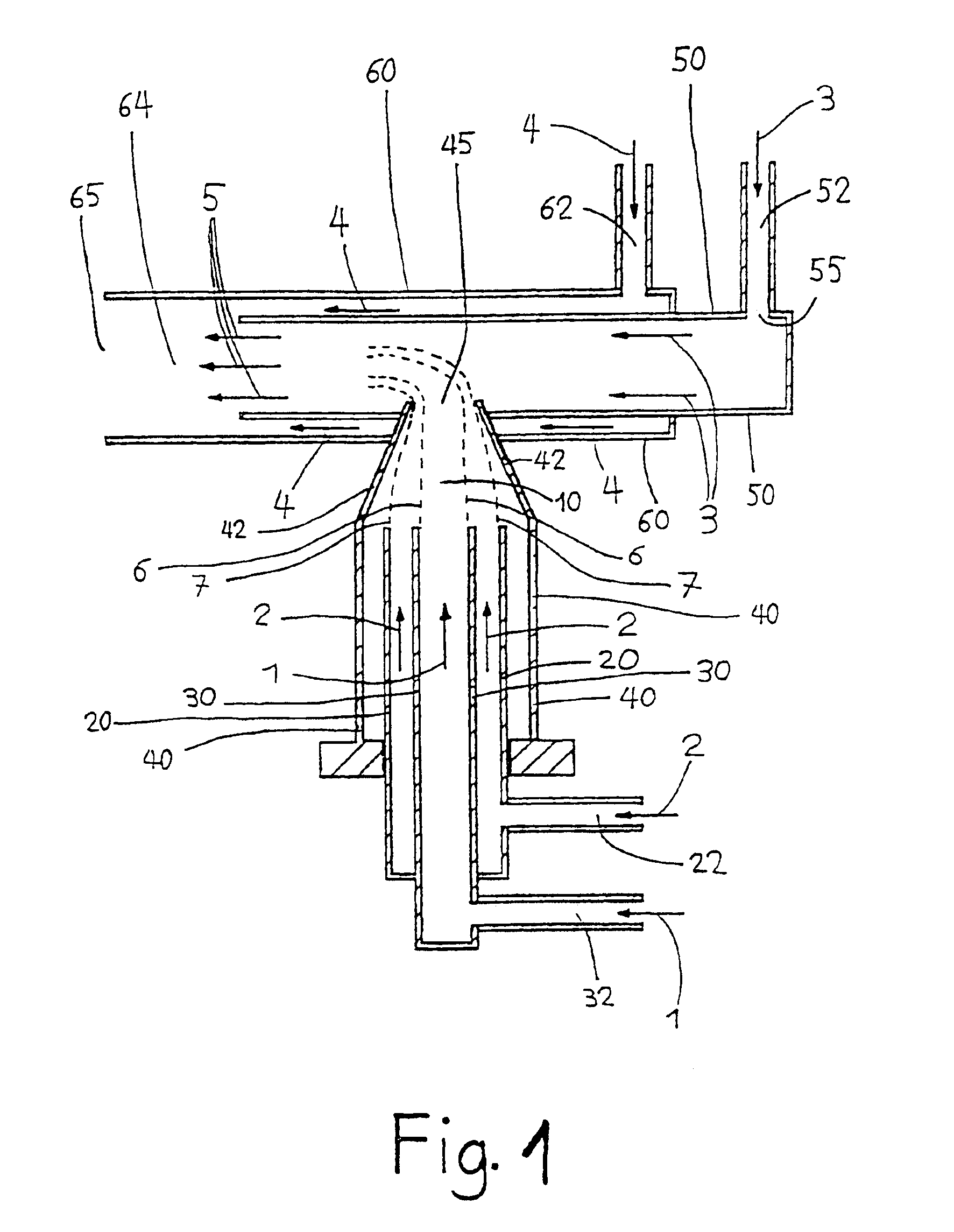

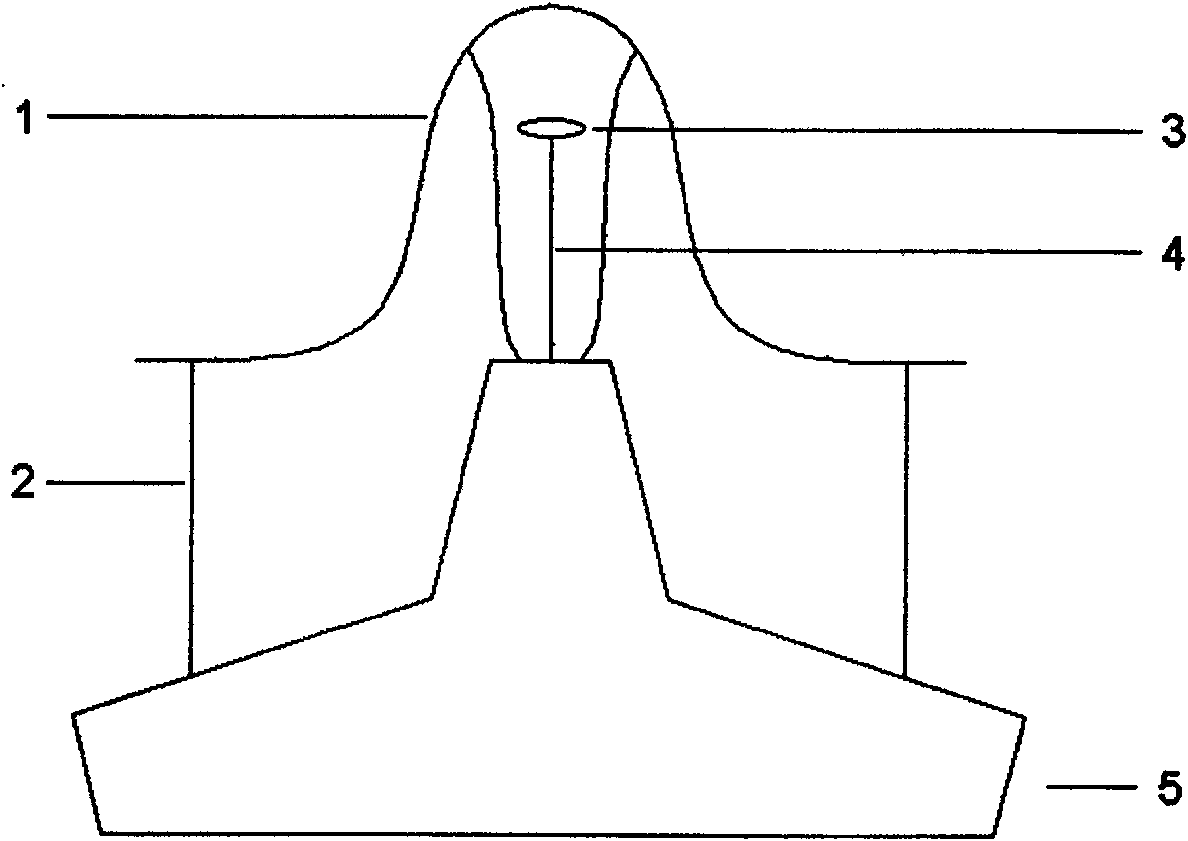

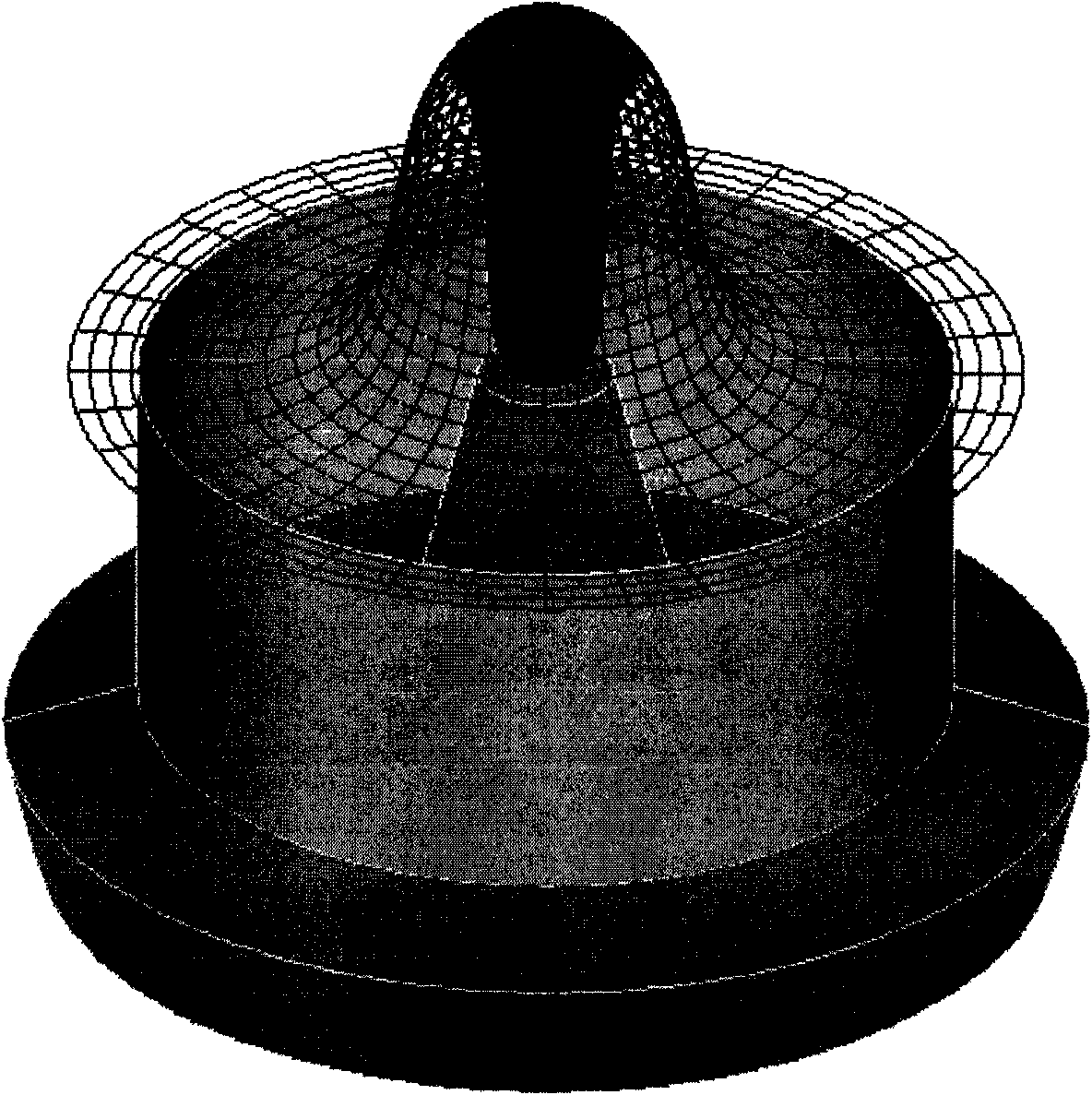

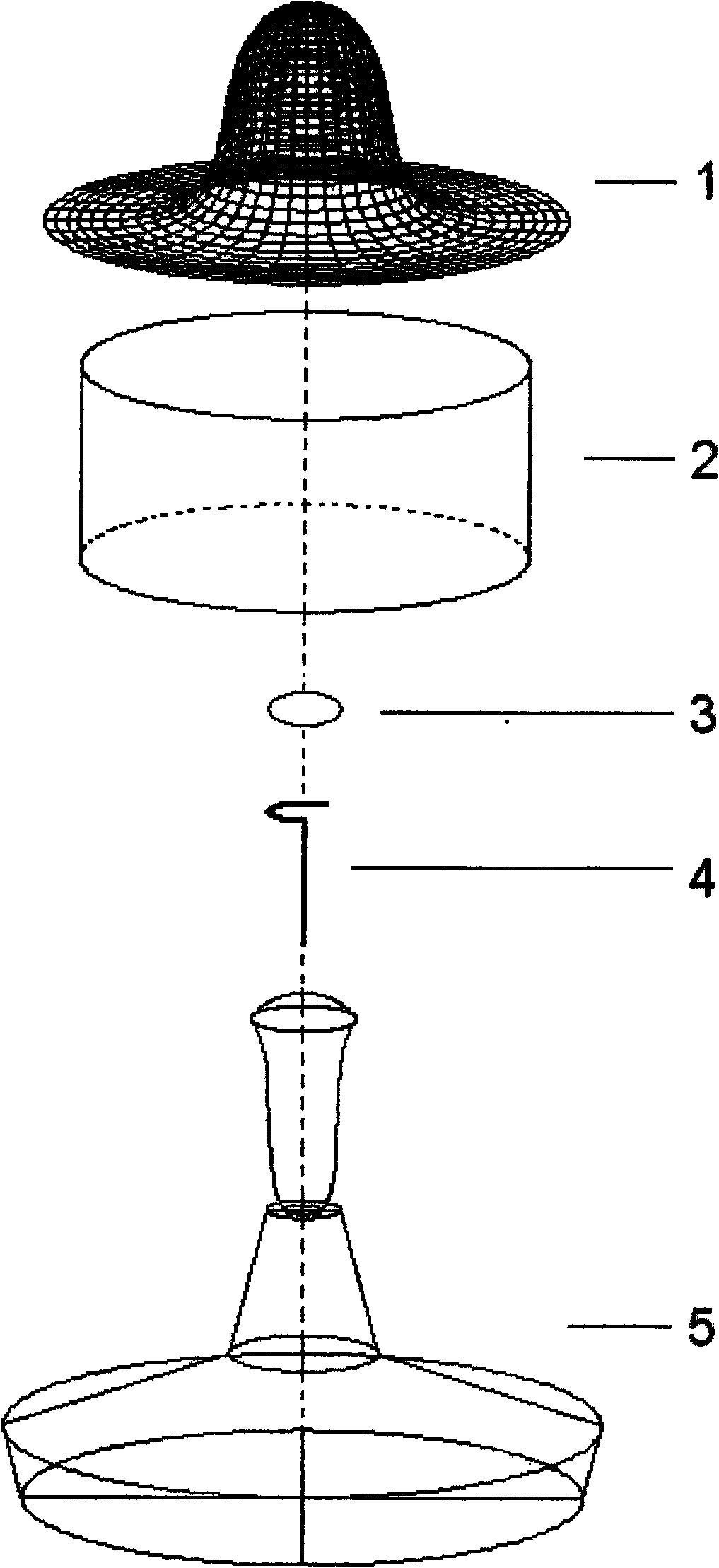

Premix and pre-evaporation combustion chamber

InactiveCN101949551ASimple structureImprove efficacyContinuous combustion chamberAviationDiffusion flame

The invention discloses a tangential premix and pre-evaporation combustion chamber. The combustion chamber has a single-ring cavity structure; and through a design by adopting a concept of staged combustion, combustion gas is totally supplied by a pre-combustion stage and a main combustion stage, wherein the pre-combustion stage adopts a steady-rotational flow diffusion flame combustion organization mode; and the main combustion stage adopts a premix and pre-evaporation combustion organization mode. The combustion chamber mainly comprises a flow-dividing diffuser, an outer casing of the combustion chamber, an inner casing of the combustion chamber, a fuel nozzle, the pre-combustion stage, the main combustion stage, a flame tube outer wall and a flame tube inner wall, wherein the pre-combustion stage stabilizes the flame by a low-speed return area generated by rotational flow air entering the combustion chamber from a pre-combustion stage swirler assembly; and the fuel needed by the main combustion stage is ejected from a nozzle of the main combustion stage, is atomized to form oil-gas mixed gas under the airflow action of a prefilming air ring of the nozzle of the main combustion stage, flows into a premix and pre-evaporation section to be evaporated, is further doped with the air to form a uniform oil-gas mixed air jet at an opening of the premix and pre-evaporation section to enter the flame tube, and is combusted under the ignition of a pre-combustion stage flame. The tangential premix and pre-evaporation combustion chamber has the advantages of simple structure and capacities of guaranteeing the normal working state of an aircraft engine and effectively reducing pollution discharge simultaneously.

Owner:BEIHANG UNIV

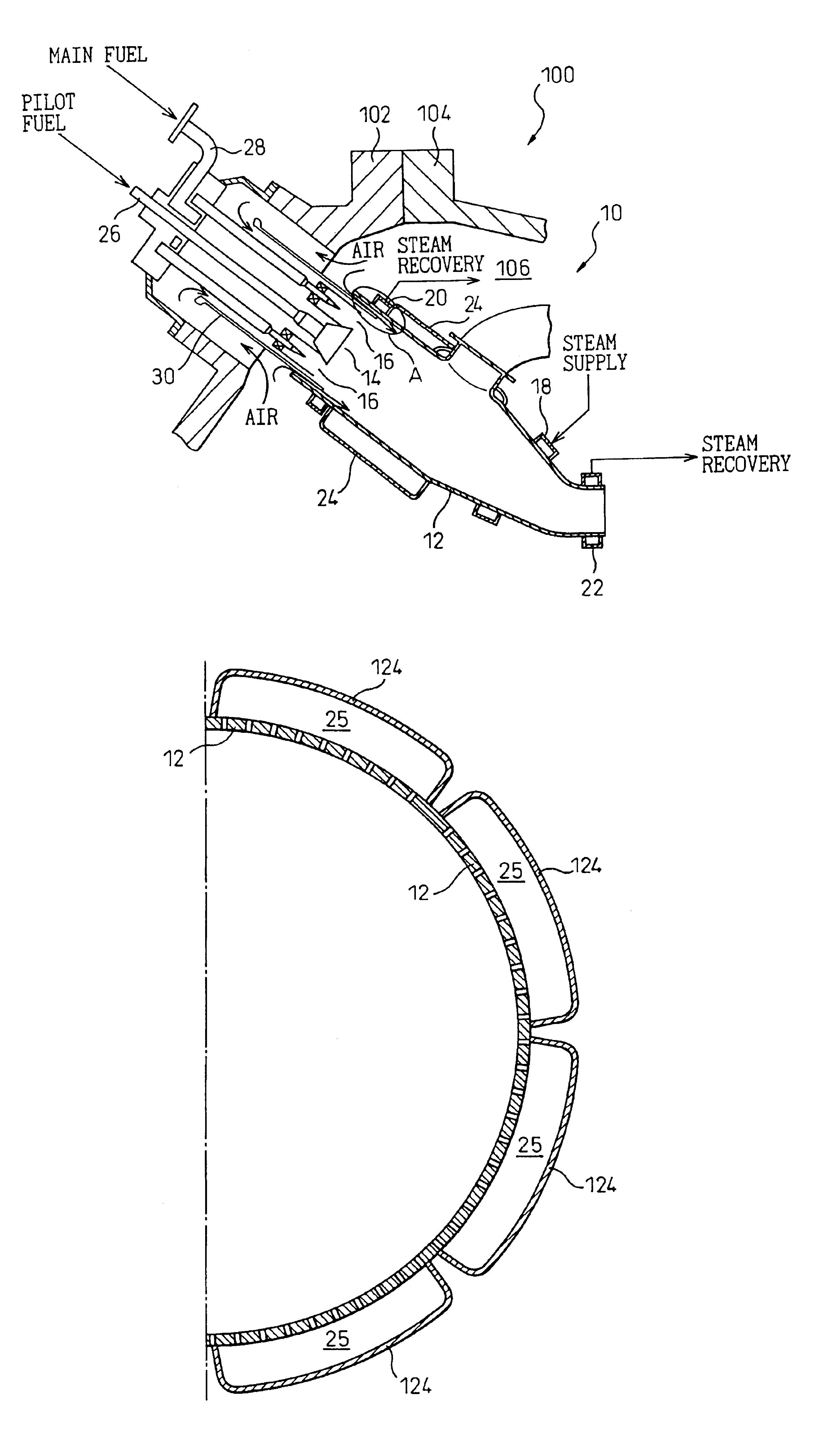

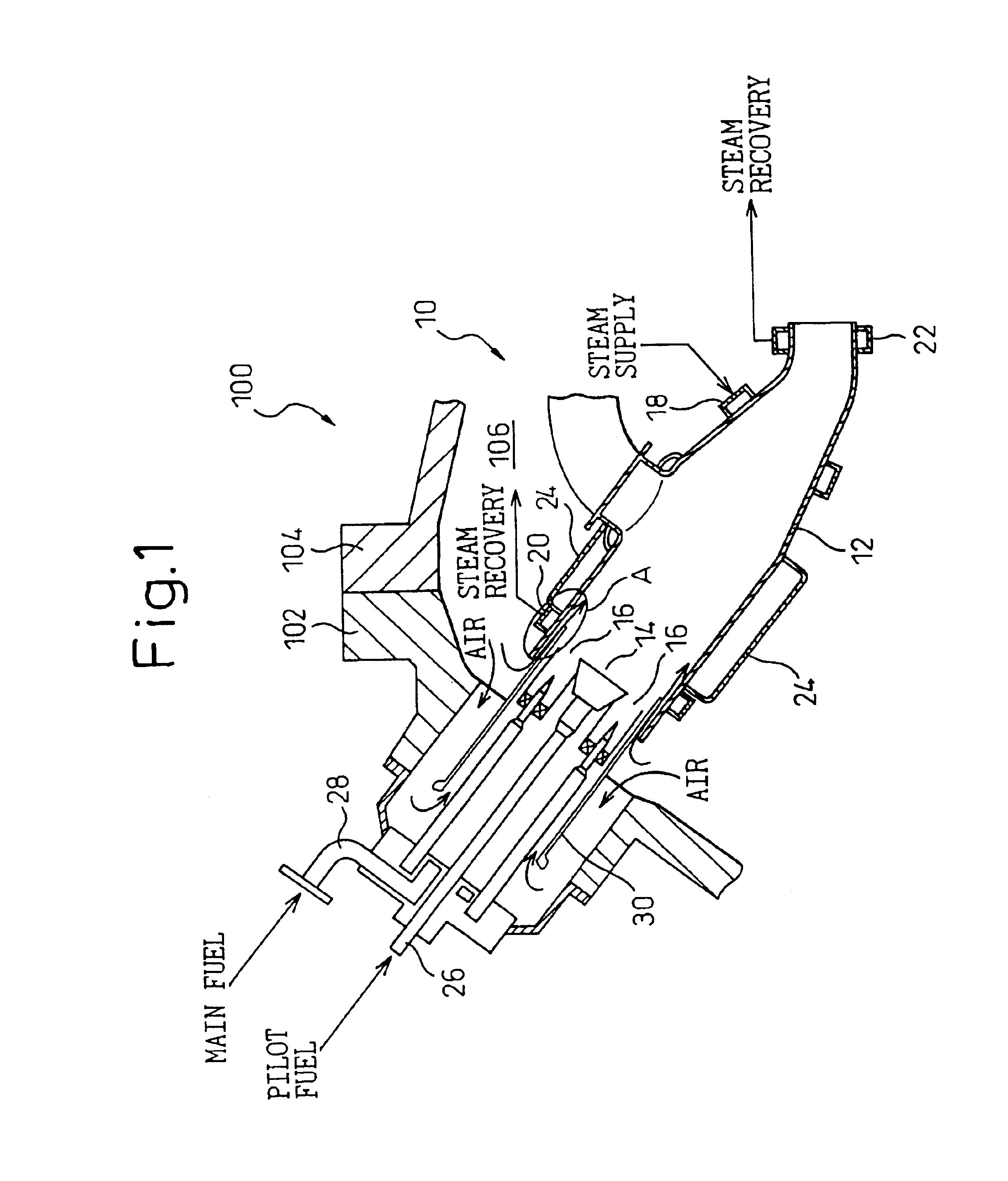

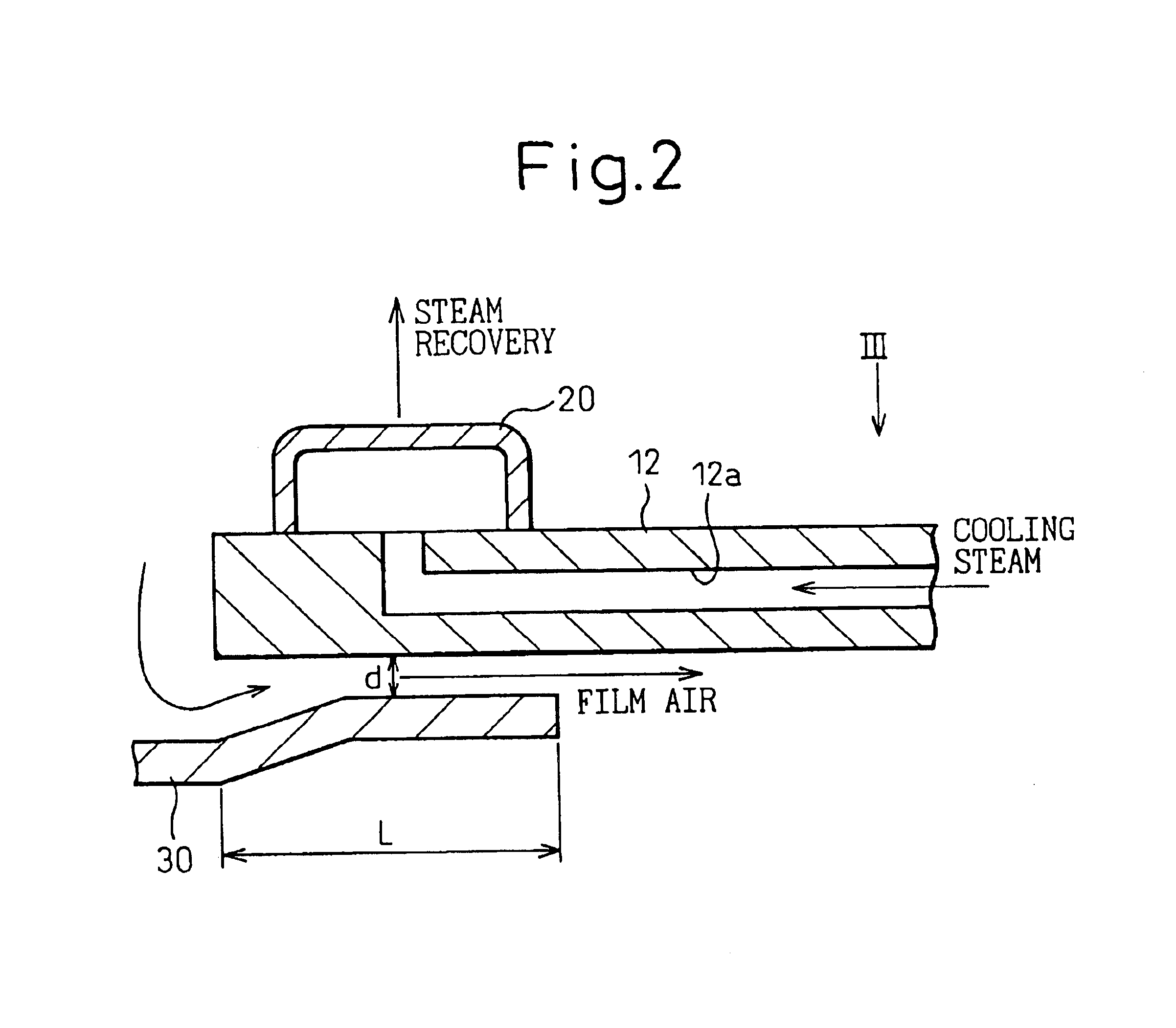

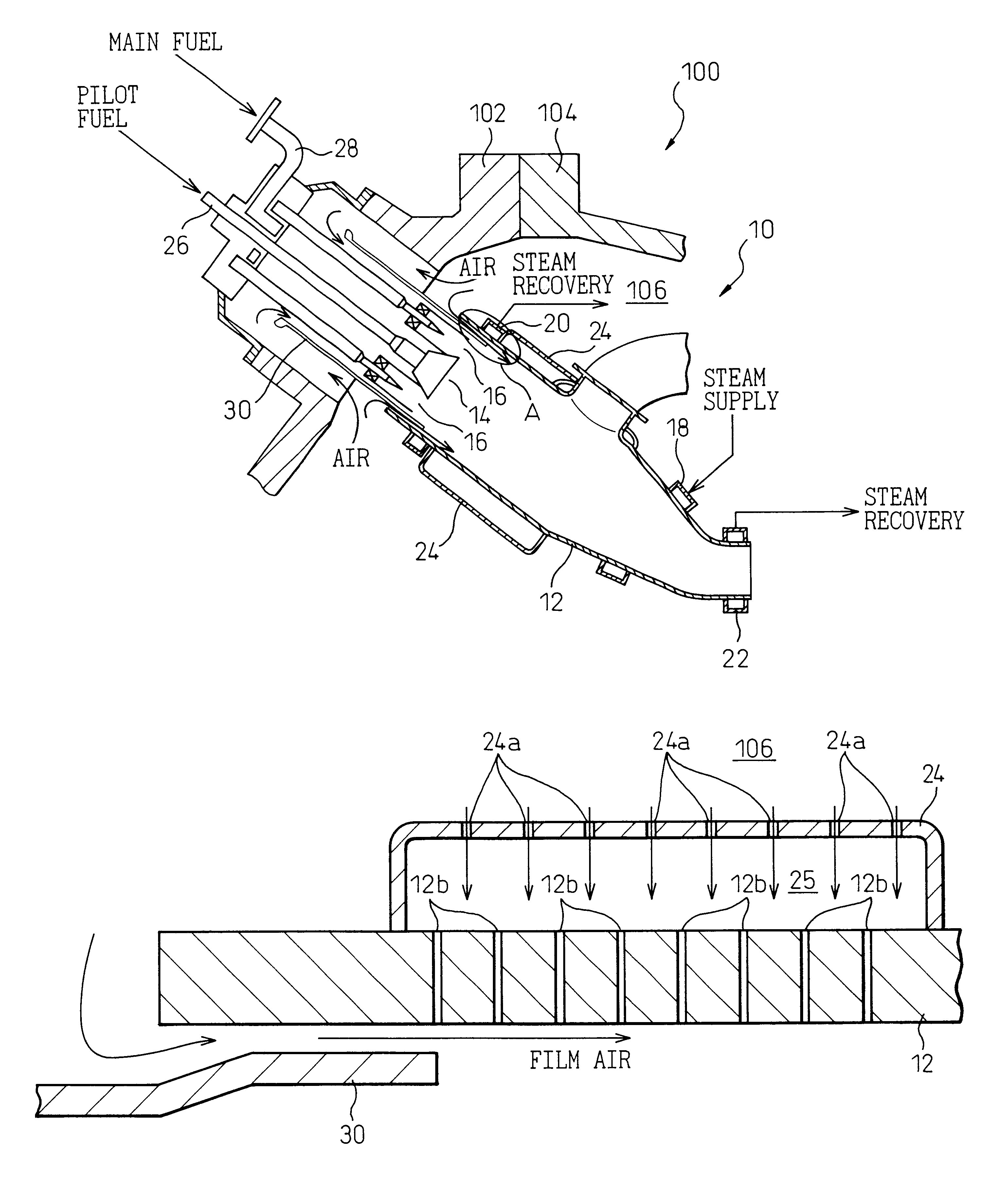

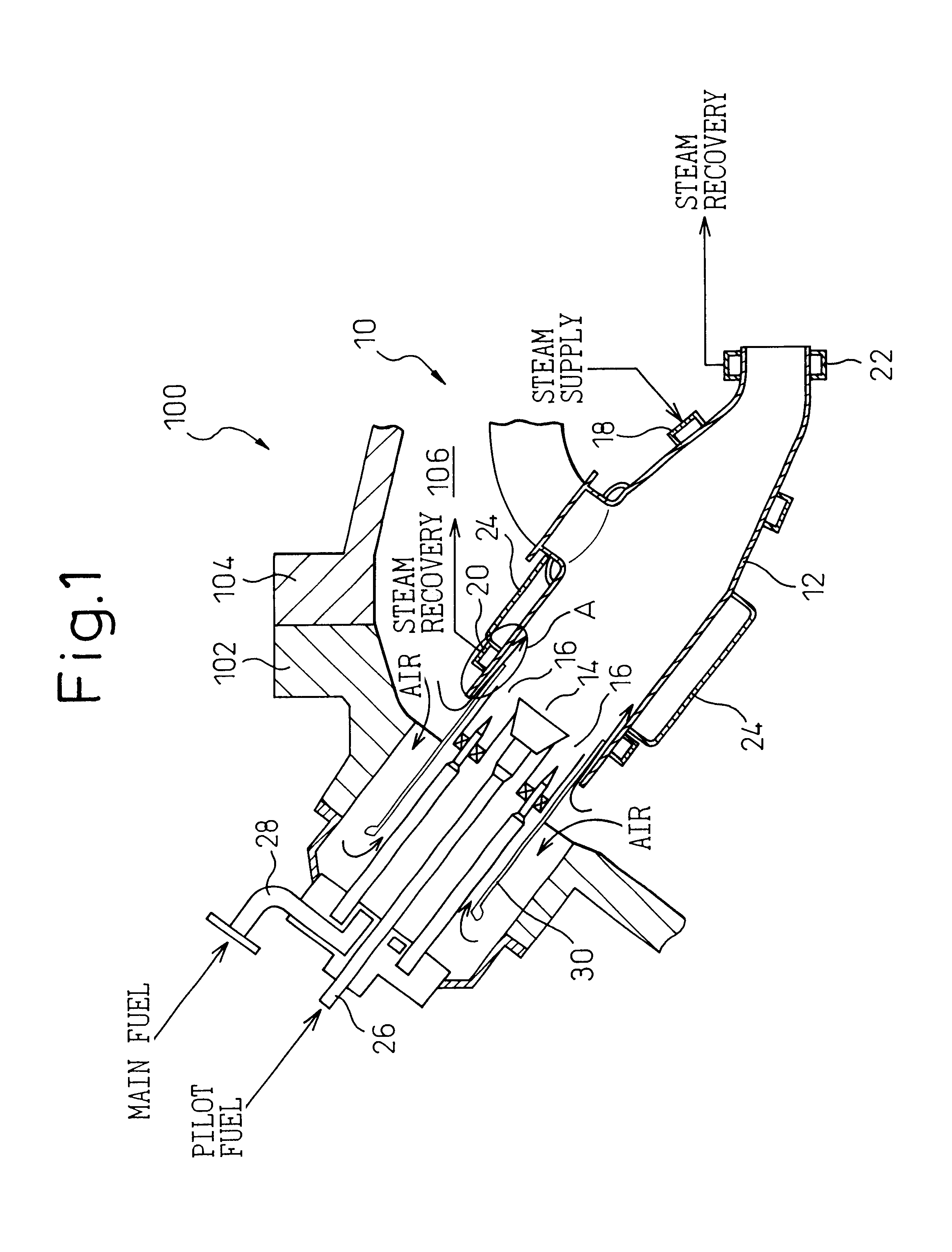

Gas turbine combustor

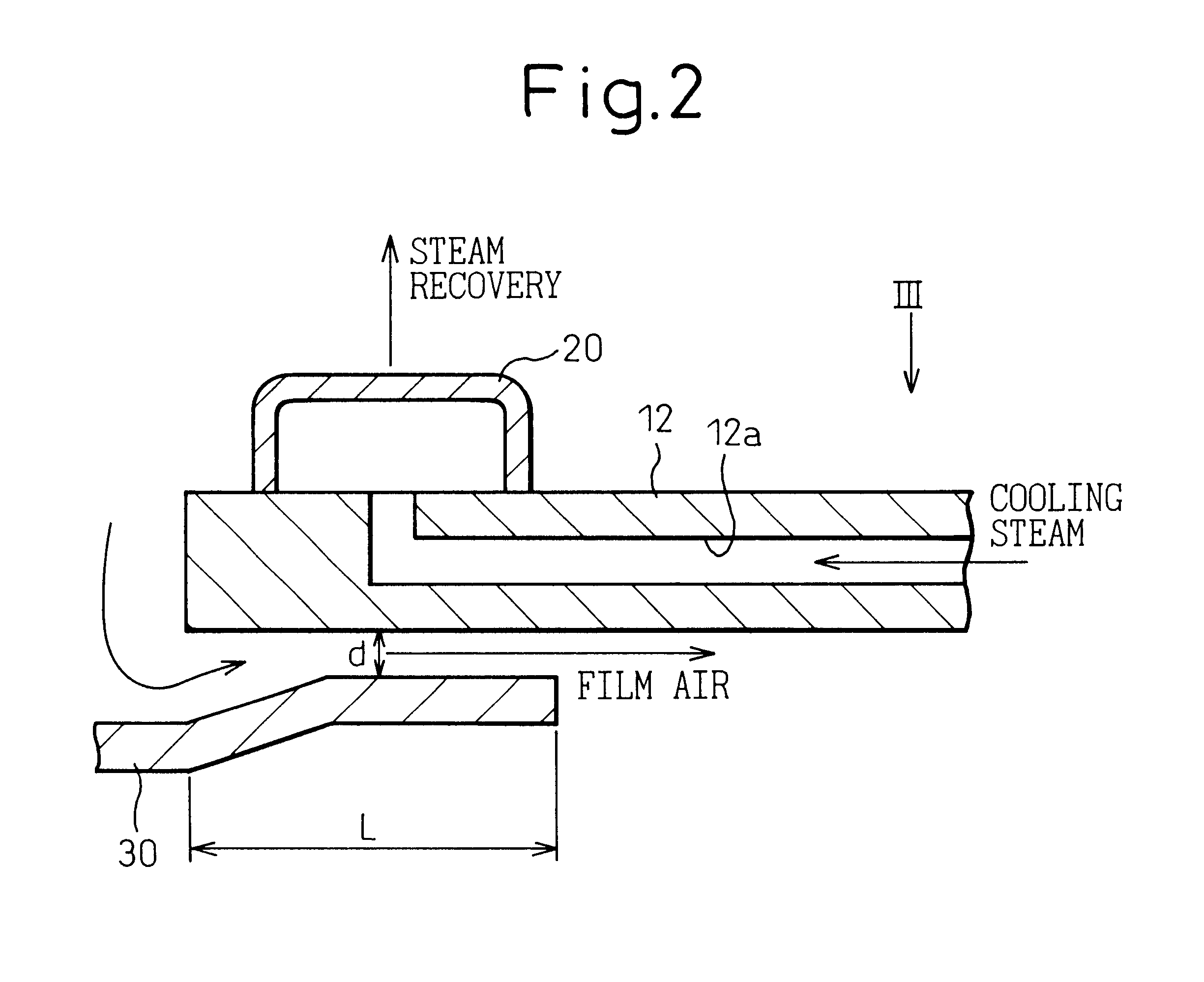

InactiveUS6837051B2Reduce fuel-air ratioRestrain combustion-drivenBurnersContinuous combustion chamberDiffusion flameCombustion chamber

A gas turbine combustor includes a side wall, for defining a combustion volume, having upstream and downstream ends, a pilot nozzle, disposed adjacent the upstream end of the side wall, for discharging a pilot fuel to form a diffusion flame in the combustion volume, and a plurality of main nozzles, provided around the pilot nozzles, for discharging a fuel-air mixture to form premixed flames in the combustion volume. Film air is supplied into the combustion volume downstream of the main nozzles along the inner surface of the side wall to reduce the fuel-air ratio in a region adjacent the inner surface of the side wall and to restrain a combustion-driven oscillation in the combustion volume.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

System and method for diffusion combustion with oxidant-diluent mixing in a stoichiometric exhaust gas recirculation gas turbine system

ActiveUS20140123669A1Low oxygenTurbine/propulsion fuel supply systemsGaseous fuel feeder/distributionDiffusion flameExhaust fumes

A system is provided with a turbine combustor having a first diffusion fuel nozzle, wherein the first diffusion fuel nozzle has first and second passages that separately inject respective first and second flows into a chamber of the turbine combustor to produce a diffusion flame. The first flow includes a first fuel, and the second flow includes a first oxidant and a first diluent. The system includes a turbine driven by combustion products from the diffusion flame in the turbine combustor. The system also includes an exhaust gas compressor, wherein the exhaust gas compressor is configured to compress and route an exhaust gas from the turbine to the turbine combustor along an exhaust recirculation path.

Owner:GENERAL ELECTRIC CO +1

Gas turbine combustor

InactiveUS6837050B2Reduce fuel-air ratioRestrain combustion-drivenBurnersContinuous combustion chamberDiffusion flameCombustion chamber

A gas turbine combustor includes a side wall, for defining a combustion volume, having upstream and downstream ends, a pilot nozzle, disposed adjacent the upstream end of the side wall, for discharging a pilot fuel to form a diffusion flame in the combustion volume, and a plurality of main nozzles, provided around the pilot nozzles, for discharging a fuel-air mixture to form premixed flames in the combustion volume. Film air is supplied into the combustion volume downstream of the main nozzles along the inner surface of the side wall to reduce the fuel-air ratio in a region adjacent the inner surface of the side wall and to restrain a combustion-driven oscillation in the combustion volume.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

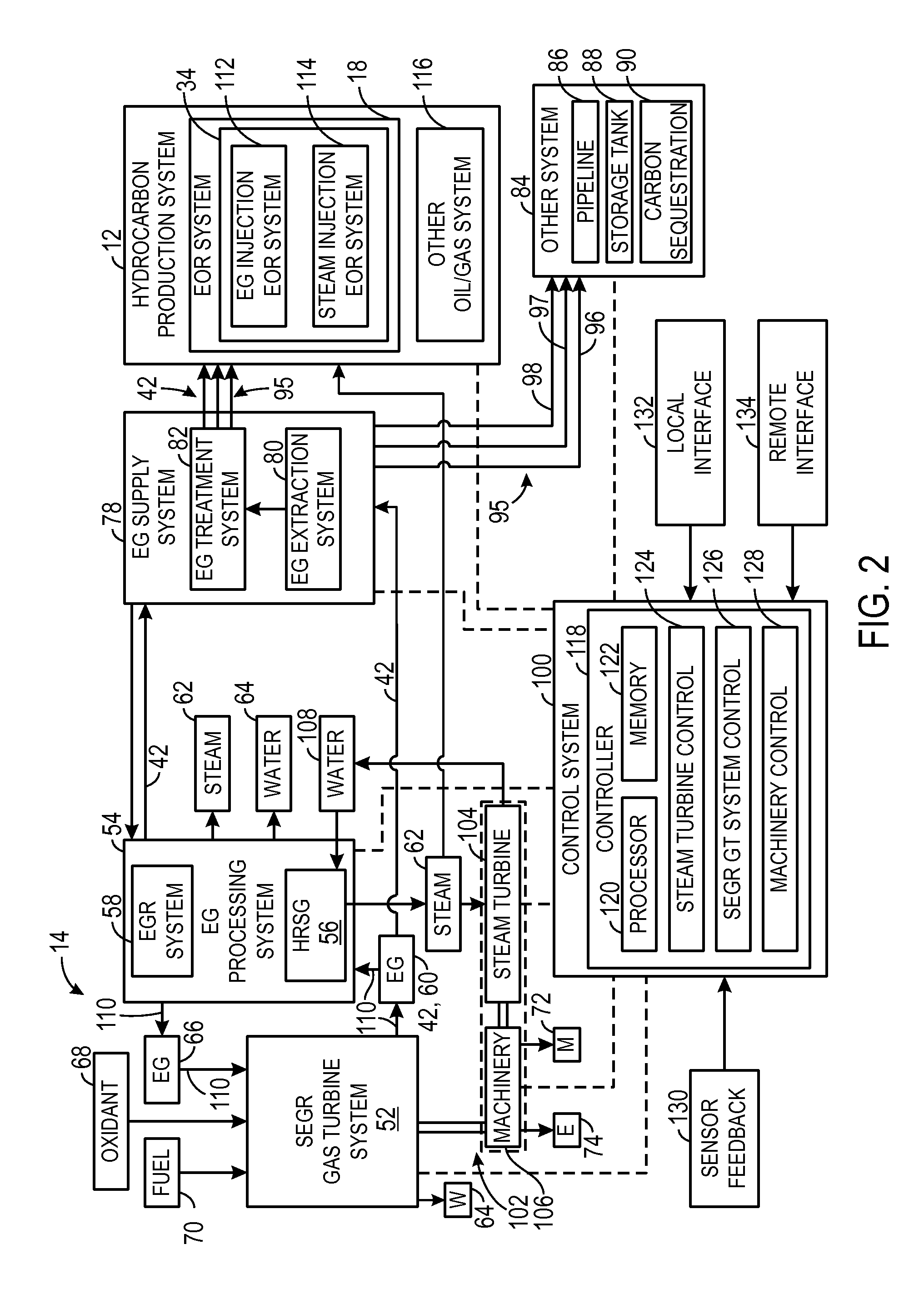

System and method for load control with diffusion combustion in a stoichiometric exhaust gas recirculation gas turbine system

ActiveUS20140150445A1Increase pressureLow oxygenTurbine/propulsion engine ignitionTurbine/propulsion engine startersDiffusion flameControl flow

A system is provided with a turbine combustor having a first diffusion fuel nozzle, wherein the first diffusion fuel nozzle is configured to produce a diffusion flame. The system includes a turbine driven by combustion products from the diffusion flame in the turbine combustor. The system also includes an exhaust gas compressor, wherein the exhaust gas compressor is configured to compress and route an exhaust gas from the turbine to the turbine combustor along an exhaust recirculation path. In addition, the system includes a control system configured to control flow rates of at least one oxidant and at least one fuel to the turbine combustor in a stoichiometric control mode and a non-stoichiometric control mode, wherein the stoichiometric control mode is configured to change the flow rates and provide a substantially stoichiometric ratio of the at least one fuel with the at least one oxidant, and the non-stoichiometric control mode is configured to change the flow rates and provide a non-stoichiometric ratio of the at least one fuel with the at least one oxidant.

Owner:GENERAL ELECTRIC CO +1

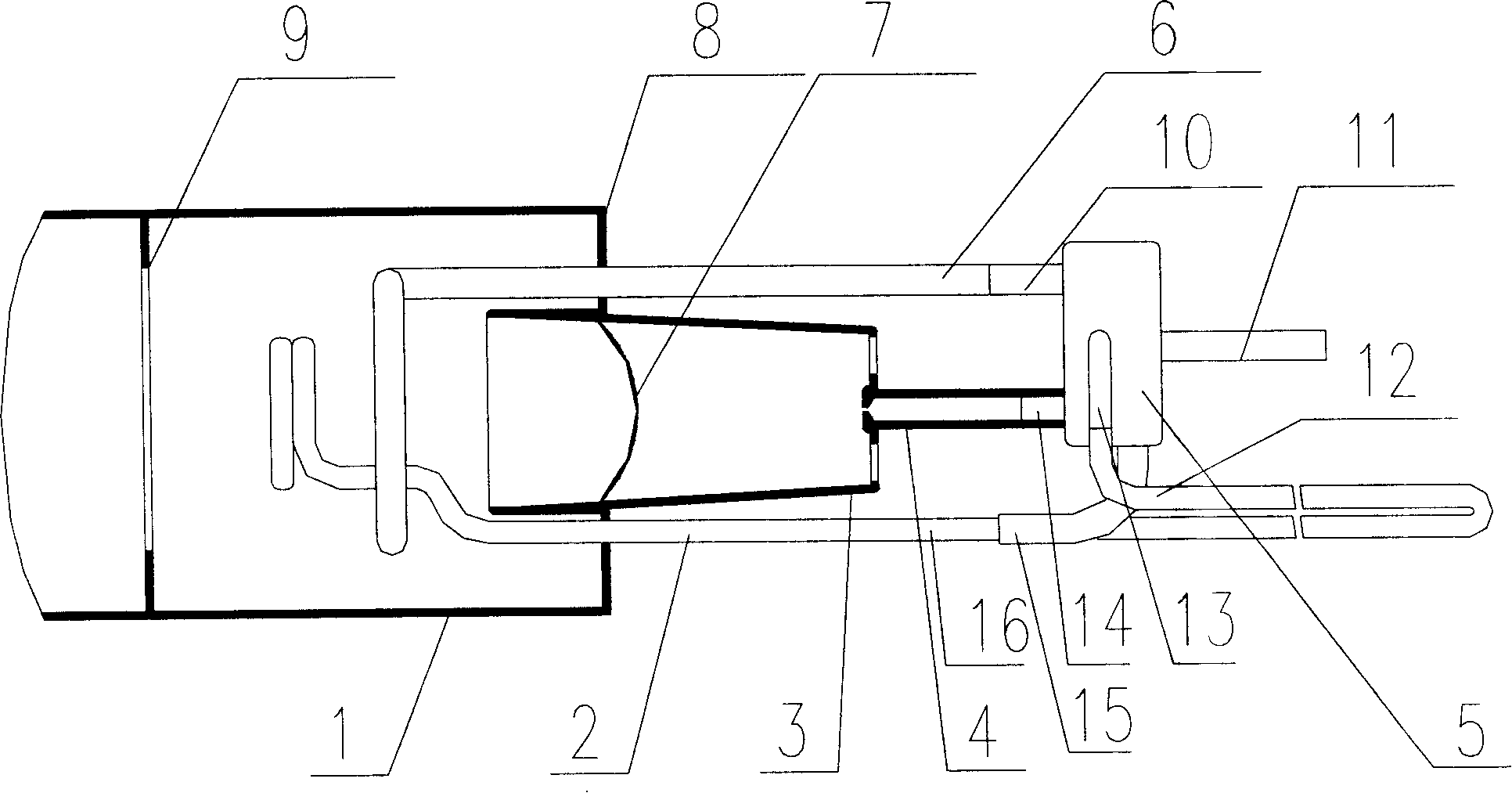

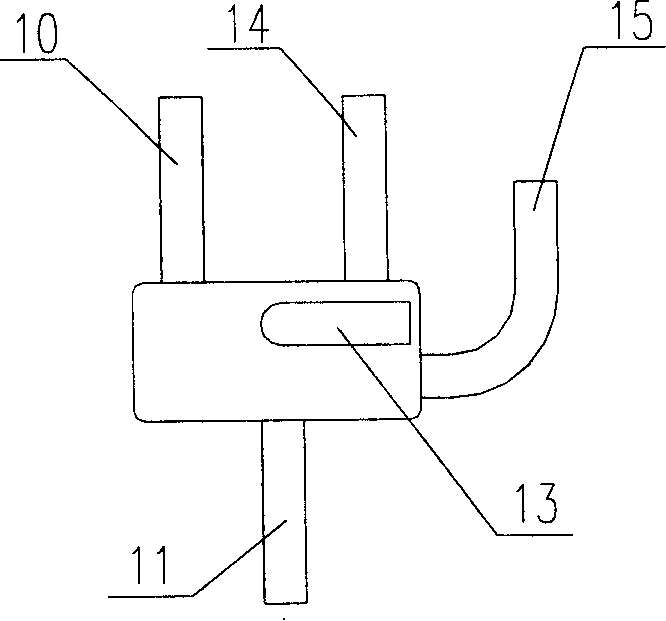

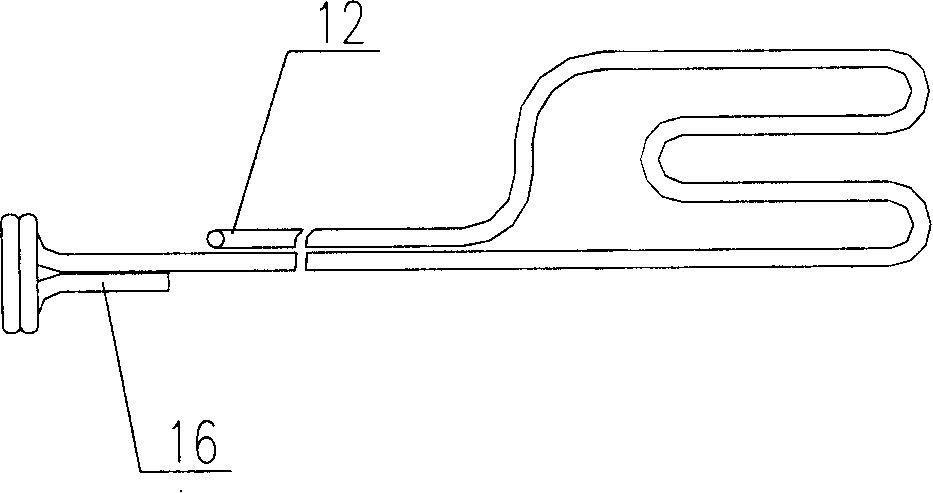

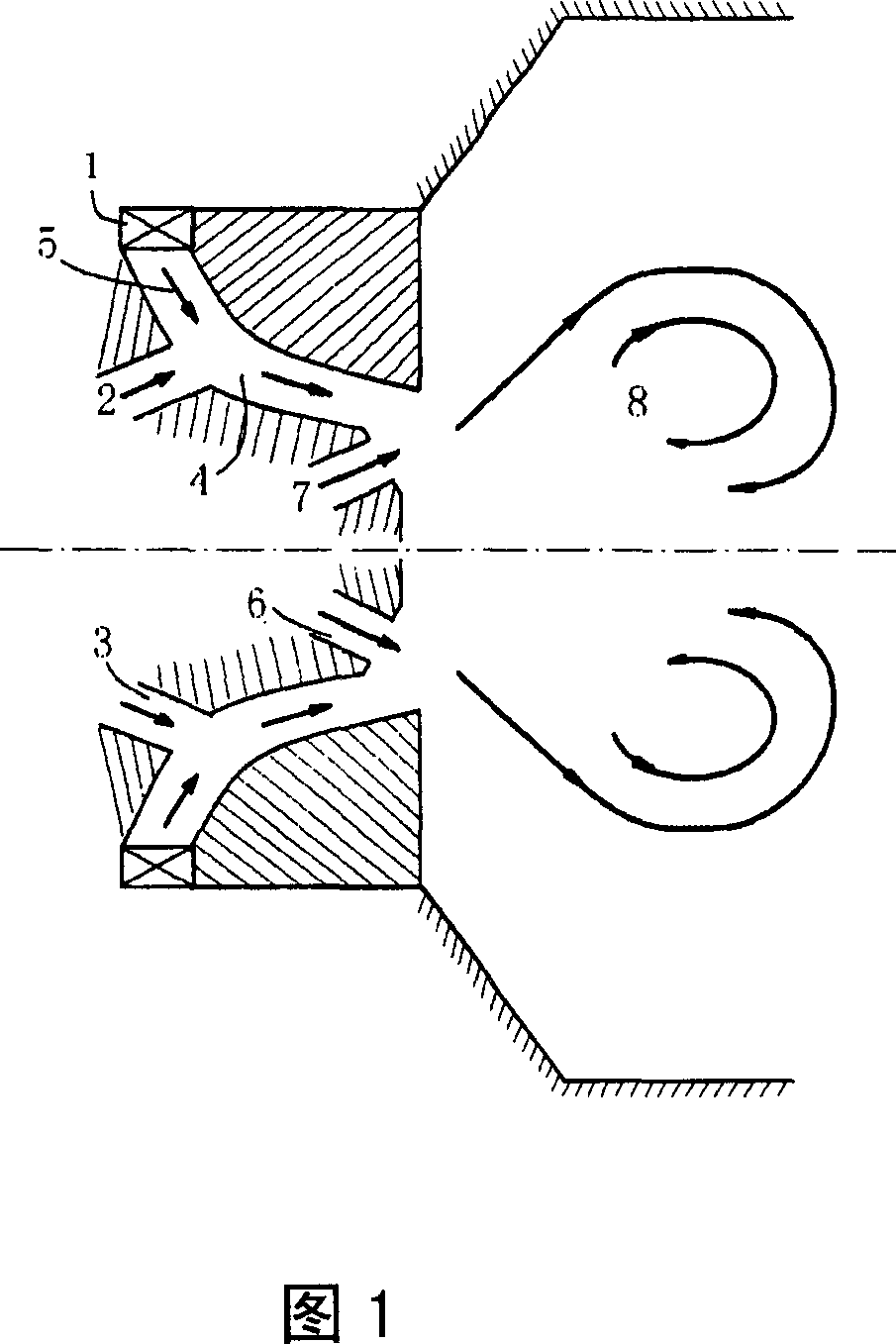

Device for combusting stably of gas flame torch

InactiveCN101201165AStable combustionBright colorCombustion ignitionGaseous fuel burnerDiffusion flameCombustion chamber

The invention provides an air flame type skyrocket steady burner which mainly comprises a maim combustion chamber housing (1), a heat return tube (2), a prechamber housing (3), a nozzle prechamber nozzle (4),a steady burning device (7) and a wind proofing device (9). The invention also comprises a five-channel for fuel distributing (5) and a main fuel ejection ring (6). The five-channel for fuel distributing (5) is connected with the main fuel ejection ring (6) and the nozzle prechamber nozzle (4). The body of the main fuel ejection ring (6) is arranged in the maim combustion chamber housing (1) and supplies fuel for the main combustion chamber. As the fuel for the prechamber and the main combustion chamber of the air flame type skyrocket steady burner of the invention is supplied respectively, the air is completely mixed, thus generating massive black smoke, the frame changes to be brighter. And as the five-channel for fuel distributing (5) realizes to supply the fuel in two ways, the frames are correspondingly divided into a premixing frame of the prechamber and a diffusion flame of the main combustion chamber; and cooperates the steady burning device (7) and the wind proofing device (9); thereby improving the wind proofing capacity as well as the stability of the frame.

Owner:THE 31TH INST OF THE THIRD ACAD OF RES CASIC

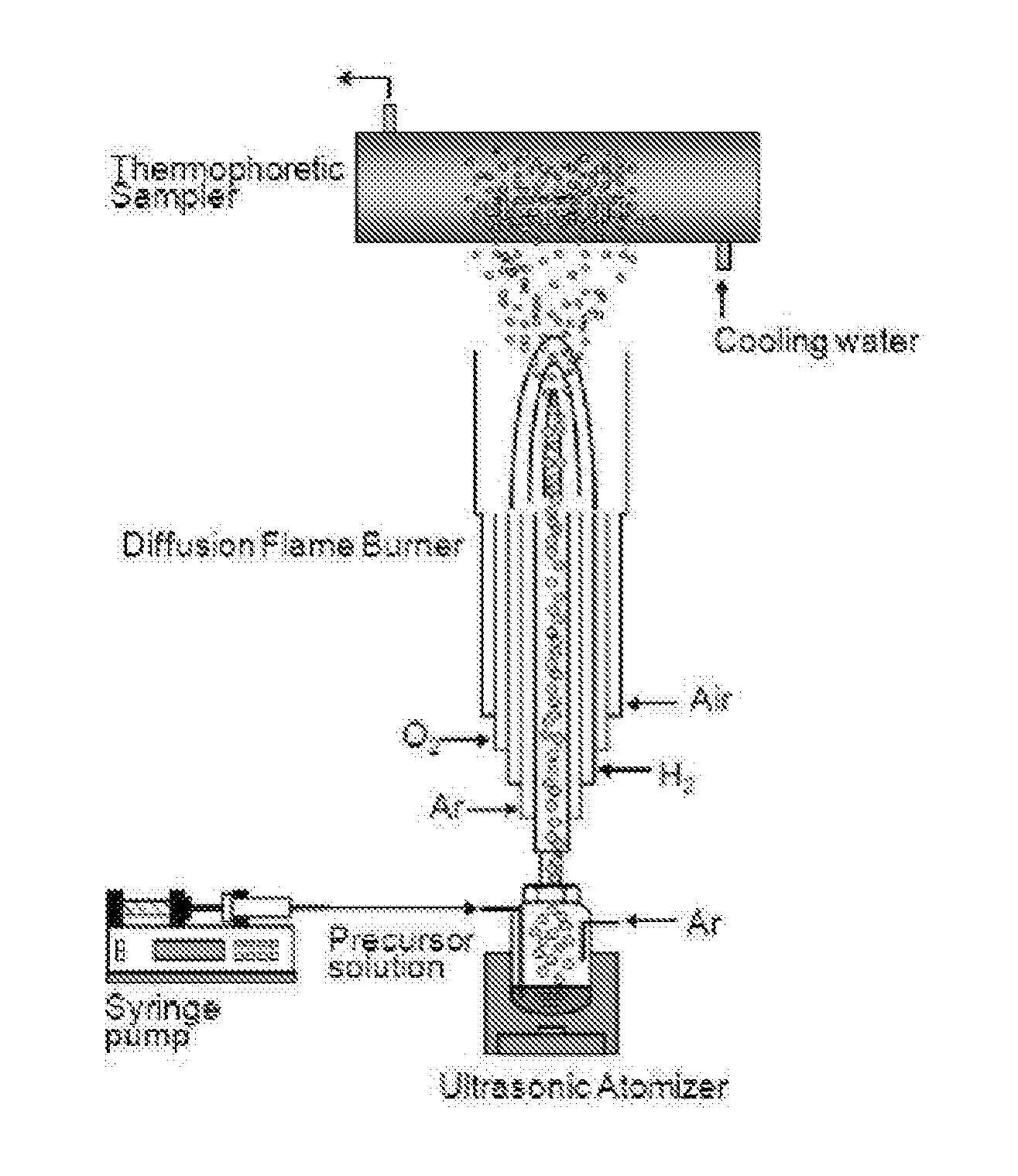

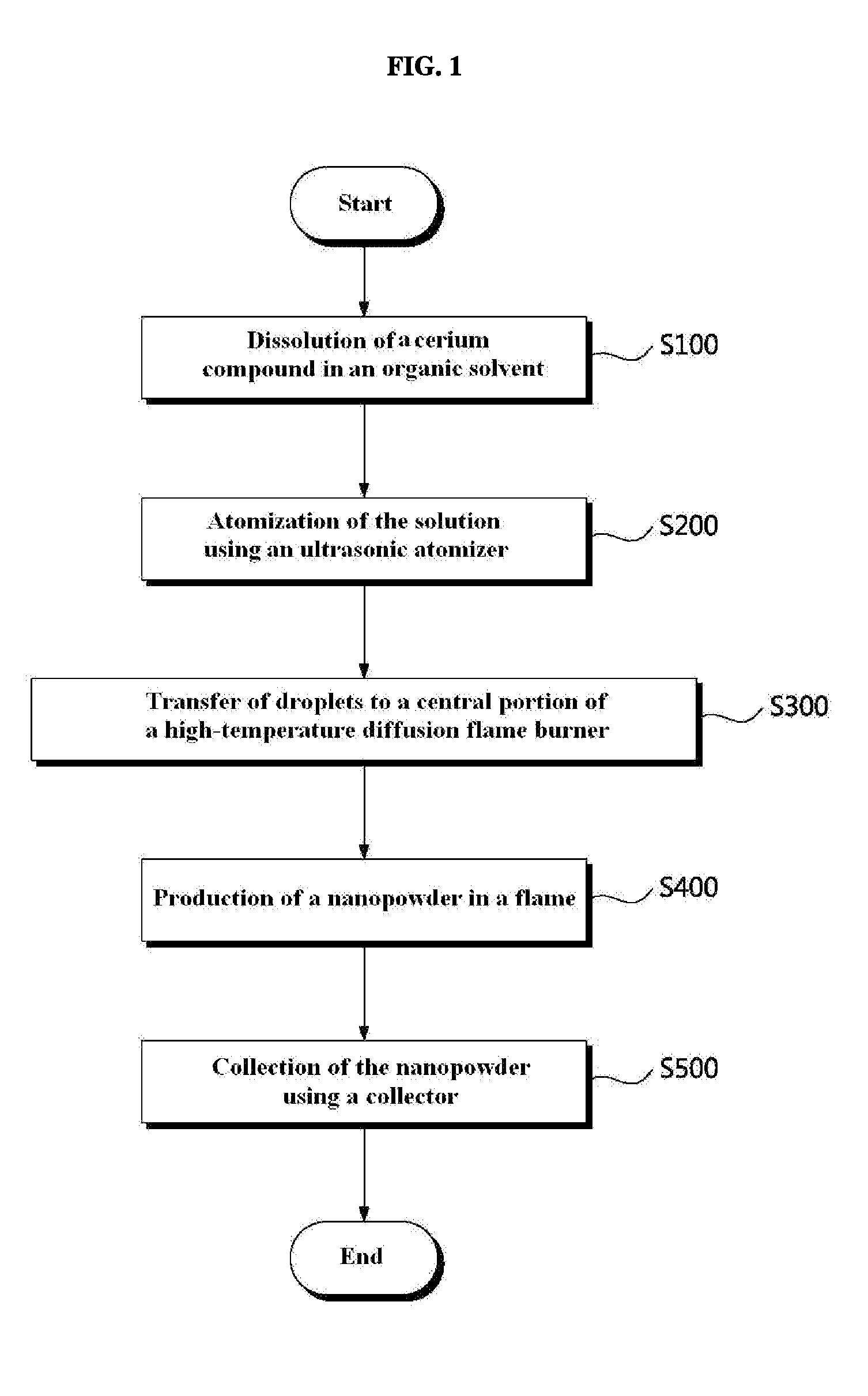

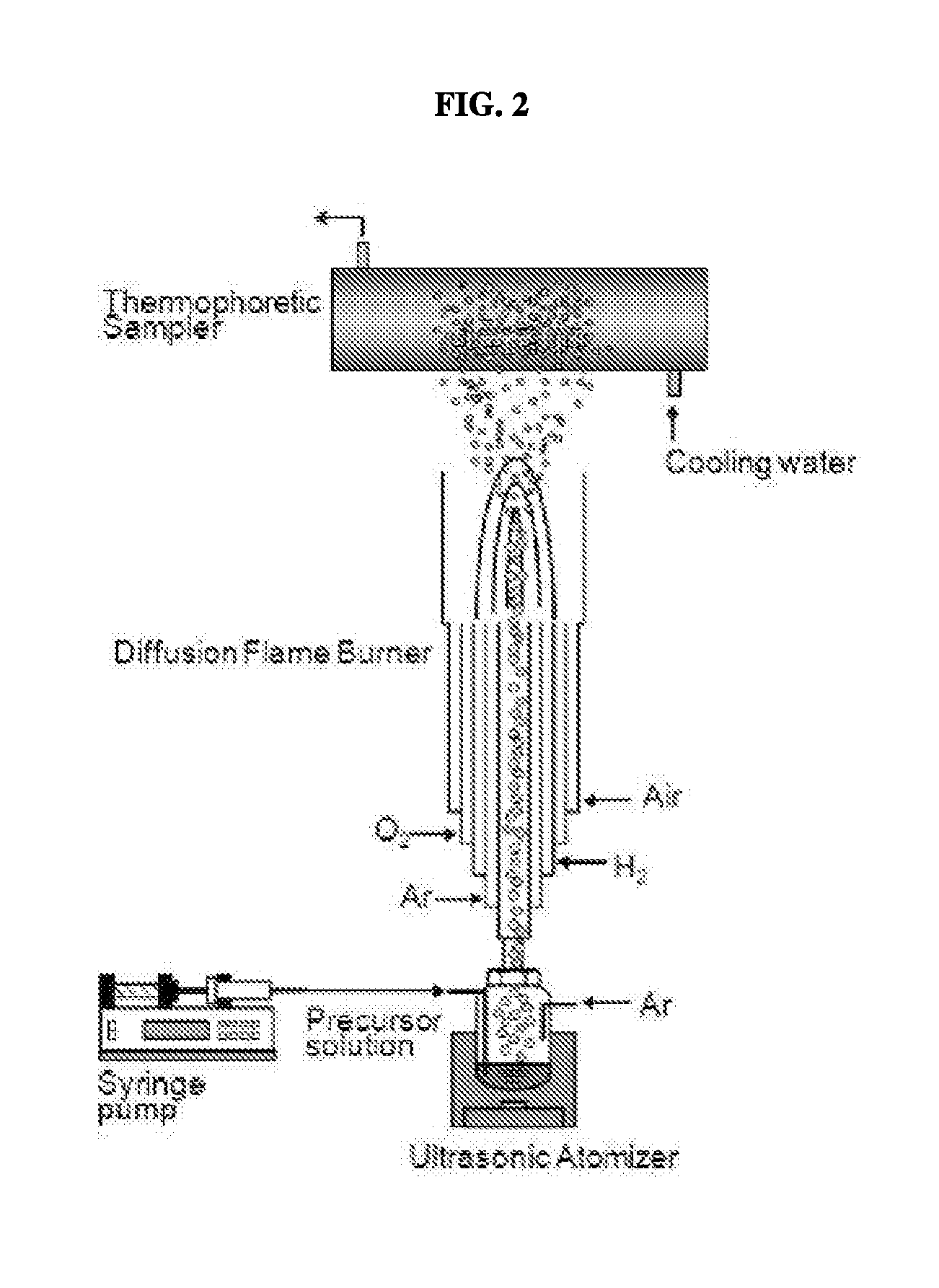

Method for producing cerium dioxide nanopowder by flame spray pyrolysis and cerium dioxide nanopowder produced by the method

ActiveUS20110281112A1Material nanotechnologySynthetic resin layered productsDiffusion flameOrganic solvent

Disclosed is a method for producing a cerium dioxide nanopowder by flame spray pyrolysis. The method comprises dissolving a cerium compound in an organic solvent to prepare a precursor solution, atomizing the precursor solution into microdroplets using an ultrasonic atomizer, transferring the microdroplets together with an argon gas as a carrier gas to a central portion of a high-temperature diffusion flame burner, subjecting the microdroplets to pyrolysis and oxidation in the central portion of the diffusion flame burner to produce a cerium dioxide nanopowder, and collecting the cerium dioxide nanopowder using a collector. According to the method, a cerium dioxide nanopowder can be continuously produced on a large scale by flame spray pyrolysis. In addition, the particle size and uniformity of the cerium dioxide nanopowder can be controlled by appropriately selecting the kind of the solvent and the concentration of the raw material. Furthermore, flame spray pyrolysis allows the cerium dioxide to have a fluorite crystal structure.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

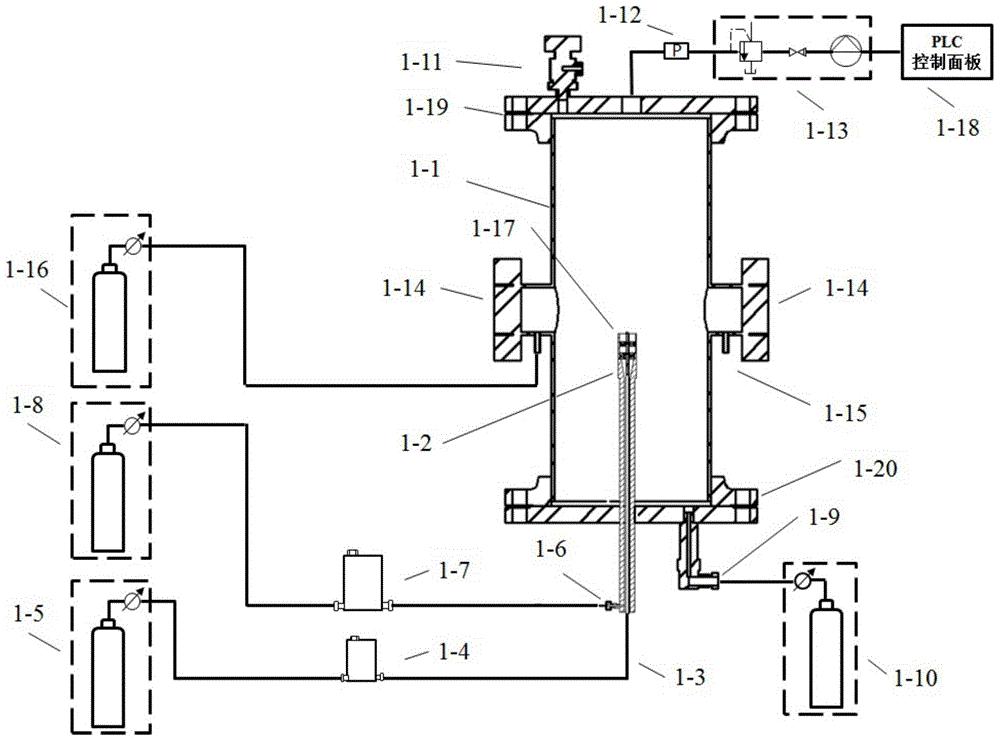

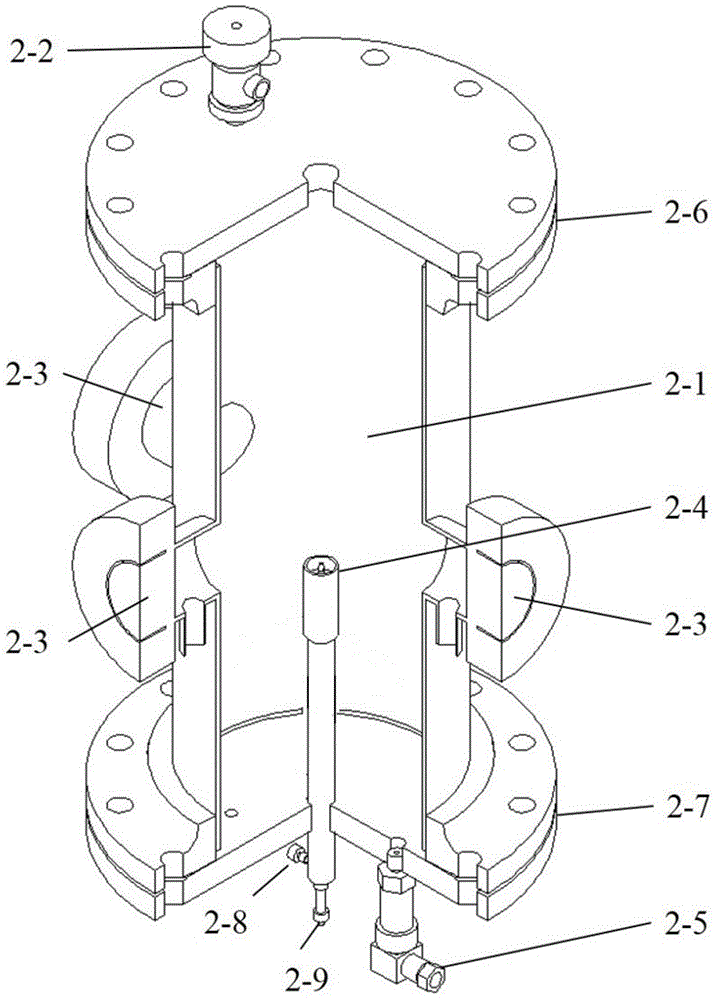

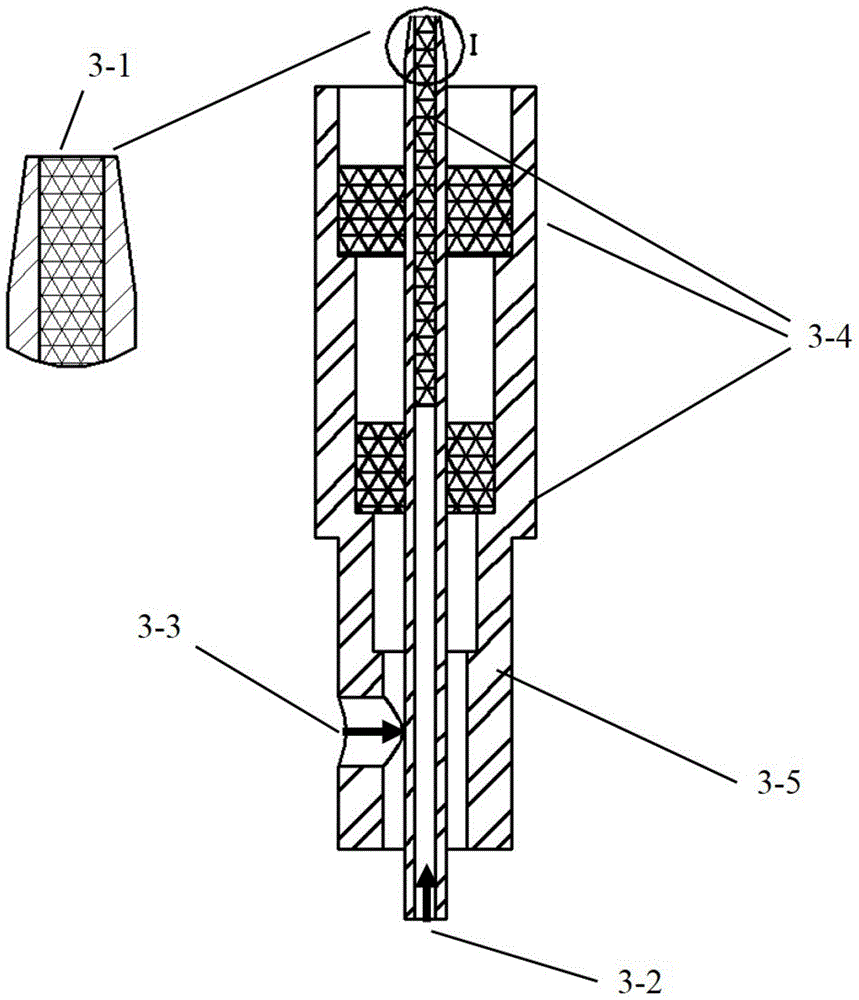

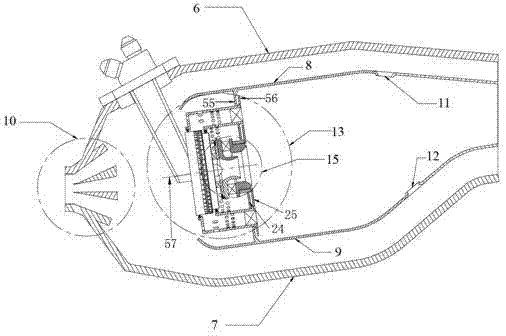

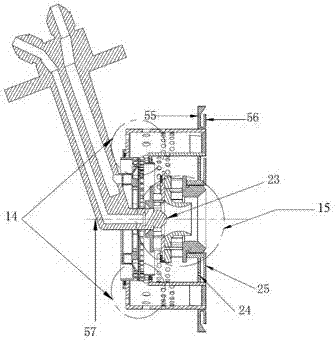

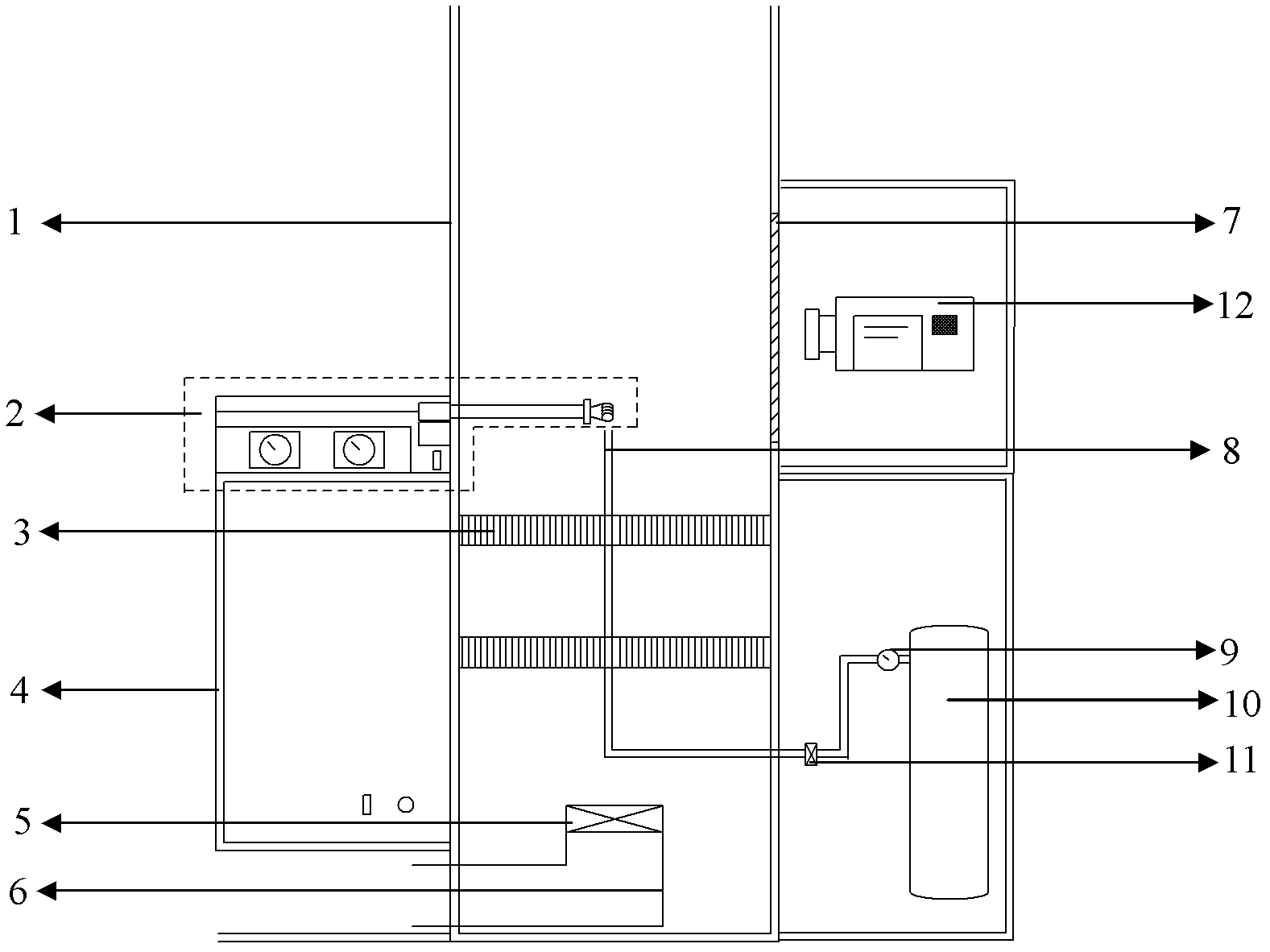

Combustion device for researching soot characteristics in low-pressure environment

InactiveCN103983738AAchieve pressure controlGuaranteed feasibilityChemical analysis using combustionDiffusion flamePressure stabilization

The invention provides a combustion device for researching soot characteristics in a low-pressure environment. The combustion device comprises a stainless steel low-pressure sealed cabin, a diffusion flame combustor, a gas mass flow control device, a high-voltage arc ignition device, an observation window, an auxiliary cleaning device, a digital display programmable logic controller (PLC), a vacuum pump group, an operating pressure stabilization device, a balance pressure air source and a detachable calibration tool clamping groove. The vacuum pump air exhaust and the balance pressure air source are simultaneously controlled through the control device in a low-pressure environment in the cabin, so that target pressure of the cabin is achieved. The inflow of two paths of gases of the combustor and the balance pressure air source is controlled by the gas flow controller, and after a pipeline is connected each time, the gas tightness at each joint of gas transport pipelines in the whole system is checked. A pressure meter is designed on a quick release upper flange plate. Operating pressure can be set and is dynamically monitored in real time through a PLC control interface, and the inflow of fuel gas, following wake air and the balance air source can be set.

Owner:UNIV OF SCI & TECH OF CHINA

Nozzle structure of combustion chamber in low heat value of gas turbine, and combustion method

A burning method of nozzle of low heat value combustion chamber on fuel gas turbine applies combustion mode of combining expansion flame with partial premixture to solve problem of non-stable combustion and carbon monoxide residue when low heat value fuel gas is burned.

Owner:江苏中国科学院能源动力研究中心 +1

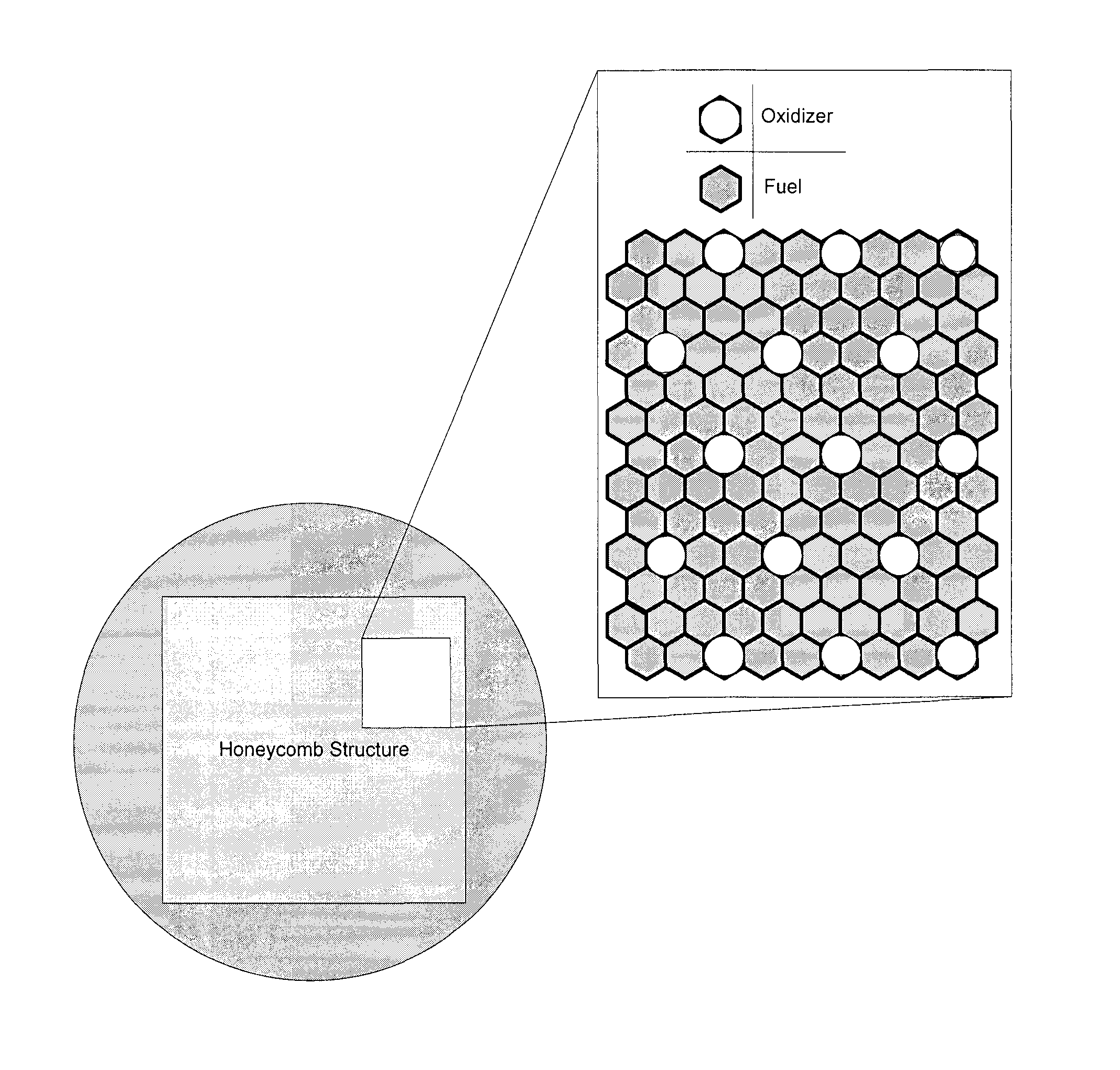

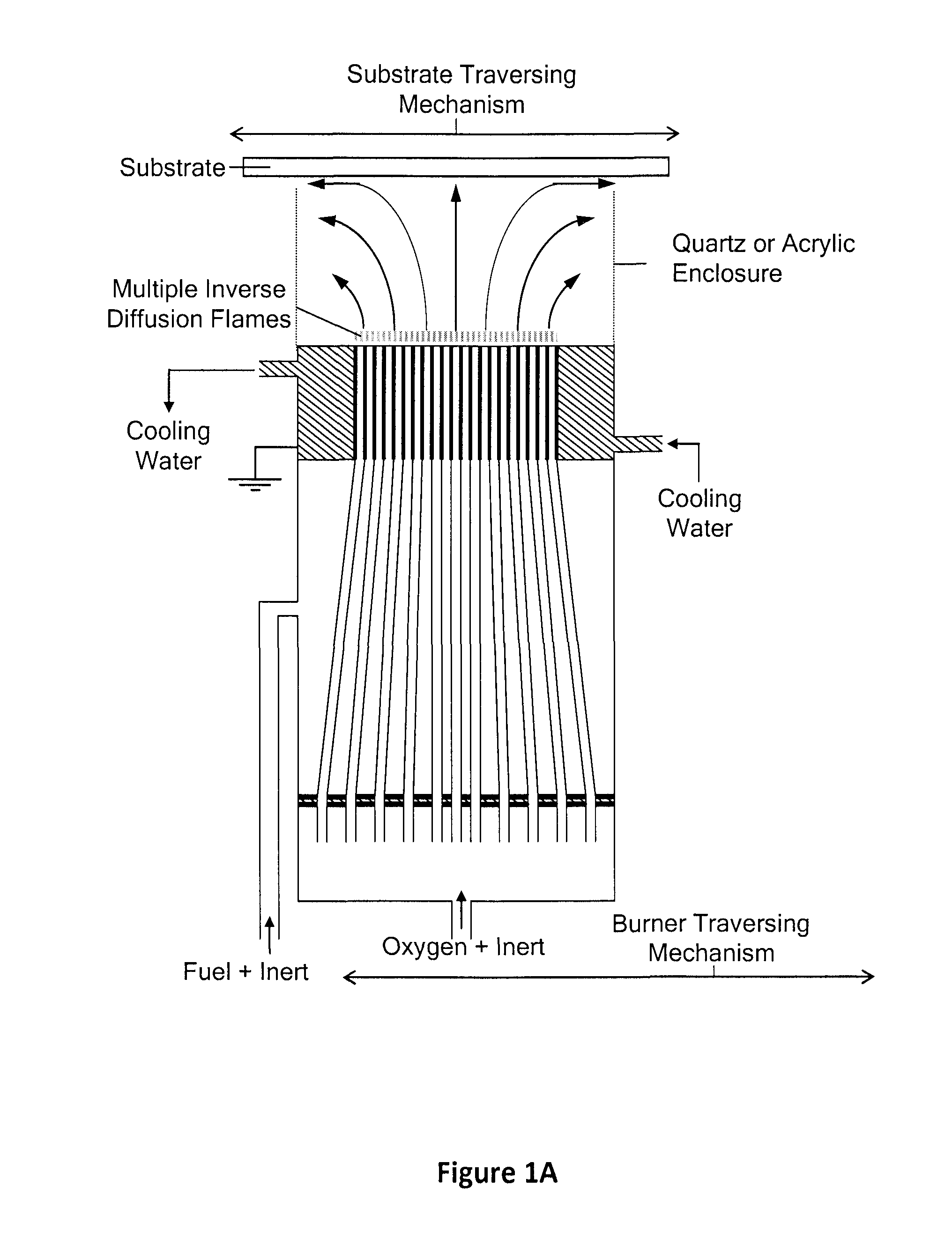

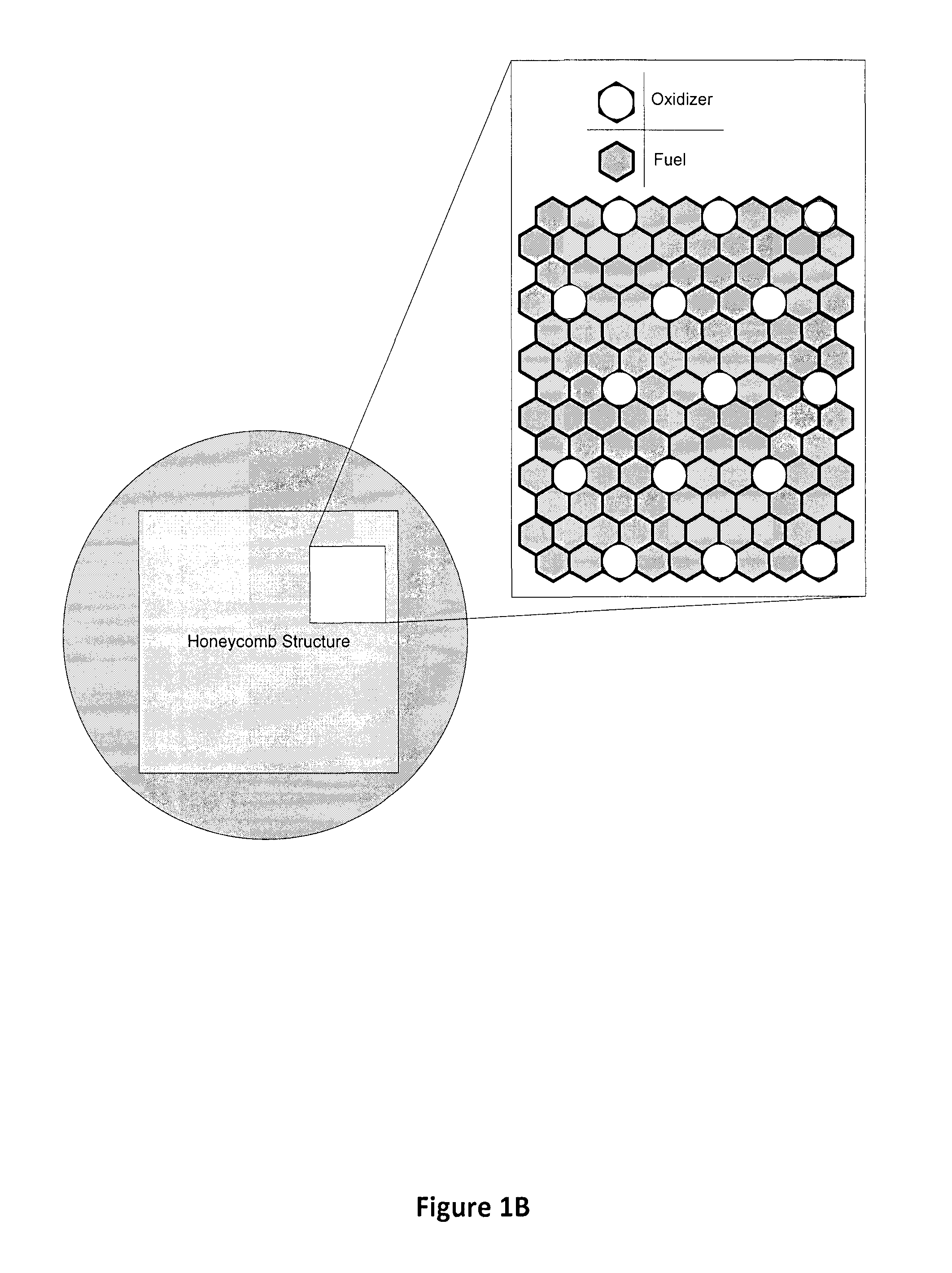

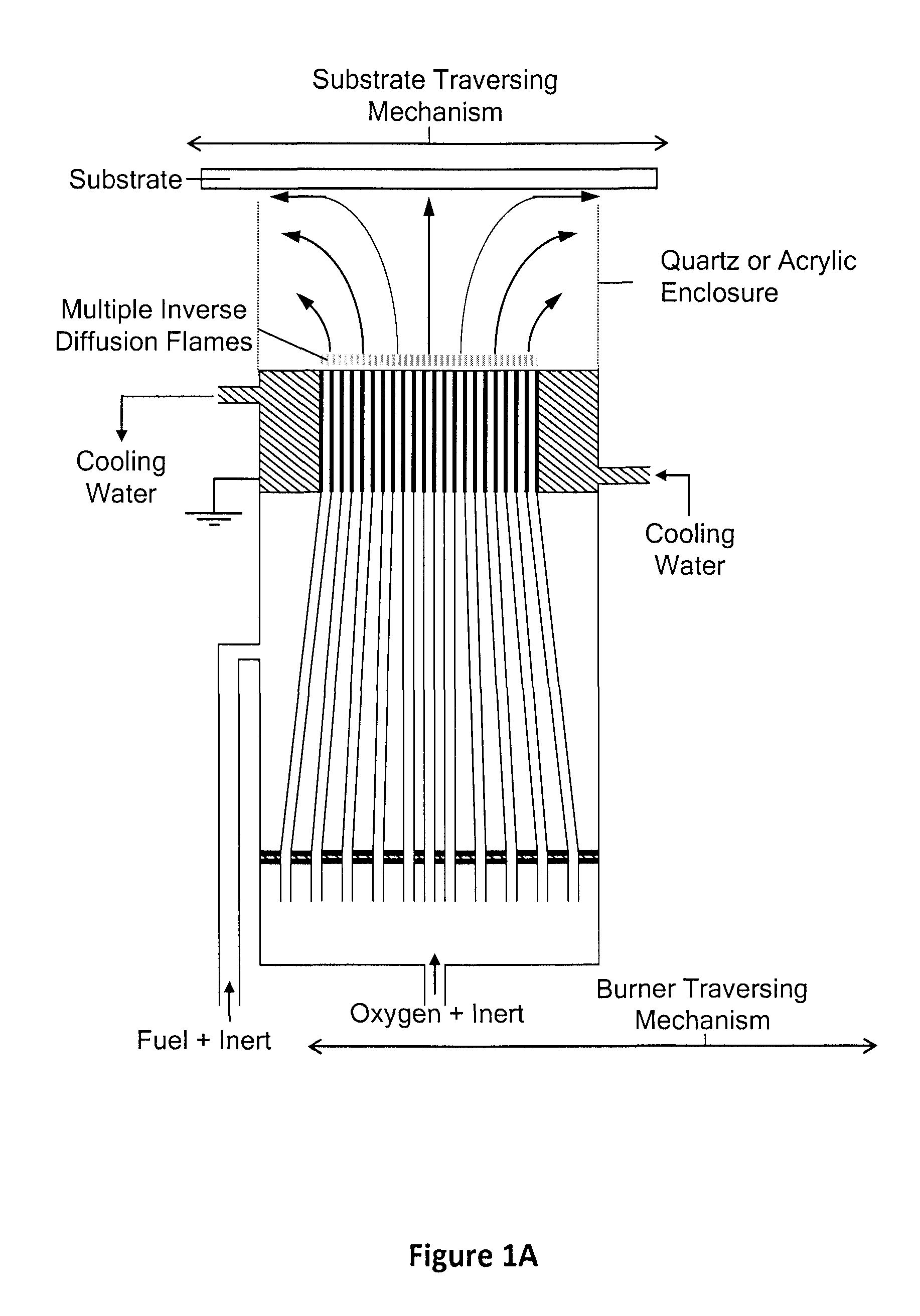

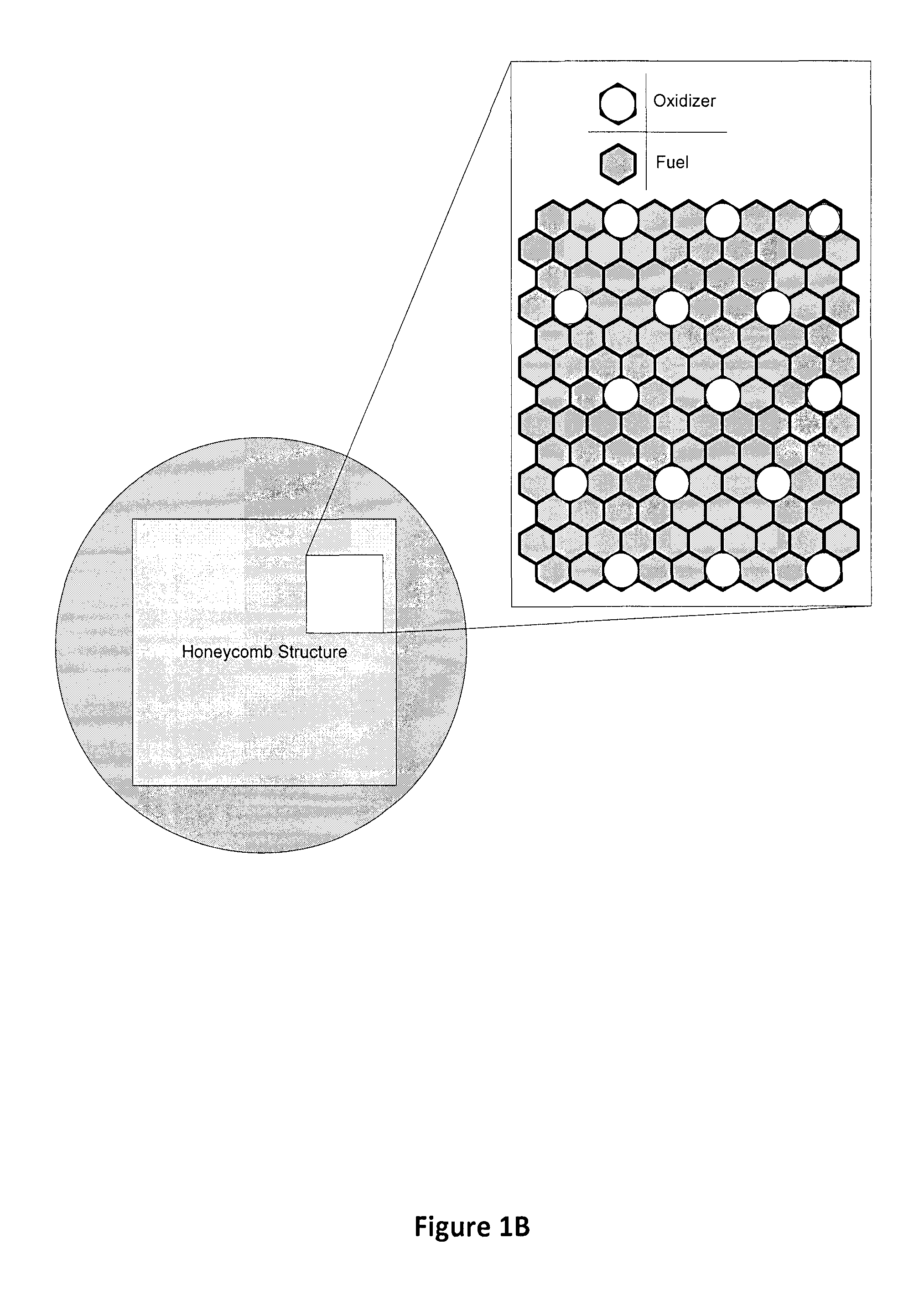

Scalable Multiple-Inverse Diffusion Flame Burner for Synthesis and Processing of Carbon-Based and Other Nanostructured Materials and Films and Fuels

ActiveUS20140054505A1Efficient hydrogen extractionImprove hydrogen permeabilityCyanogen compoundsThiosulfates/dithionites/polythionitesDiffusion flameNanostructured materials

Owner:RUTGERS THE STATE UNIV

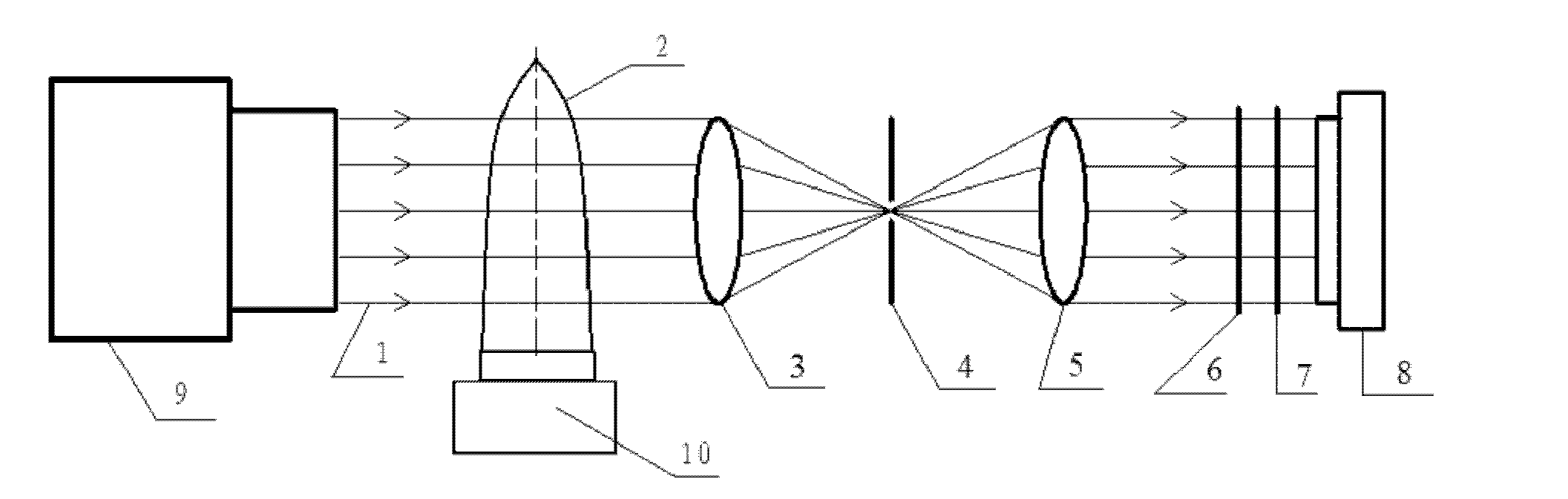

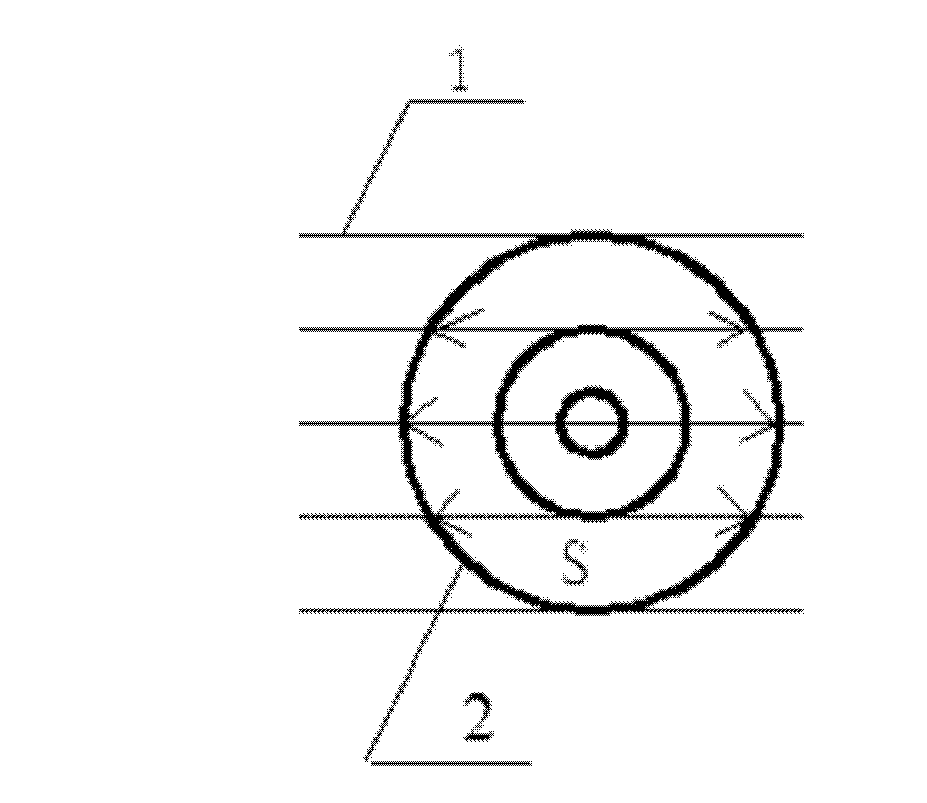

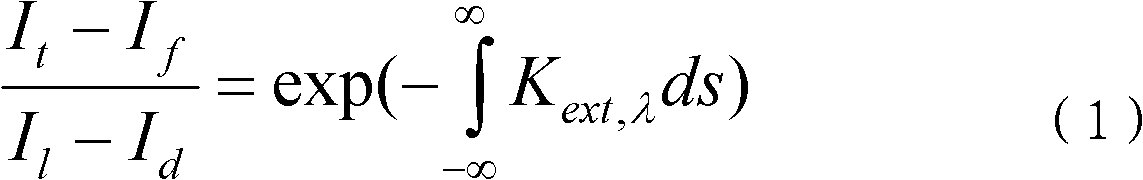

Device and method for rapidly measuring carbon black concentration in laminar flow diffusion flames based on parallel light

InactiveCN102680475ASimple structureGood repeatabilityInvestigating moving fluids/granular solidsParticle suspension analysisMeasurement deviceExtinction

The invention discloses a device and a method for rapidly measuring carbon black concentration in laminar flow diffusion flames based on parallel light. The measuring device comprises a xenon lamp, a burner, a convex lens A, a pore diaphragm, an attenuation group, a light filter, a charge coupled device (CCD) camera and a computer, wherein the xenon lamp is capable of shooting parallel light, the burner, the convex lamp A, the pore diaphragm, the attenuation group and the light filter are arranged successively behind the xenon lamp, the CCD camera is arranged behind the light filter, and the computer is connected with the CCD camera. Wavelength of the light filter is within the visible wavelength range of the xenon lamp. According to the device and the method, the xenon lamp is used for shooting parallel light with uniform brightness, the parallel light passes through test flames, changes of parallel light intensity before and after the parallel light passes through the test flames are measured, planar carbon black particle extinction coefficients are obtained, and planar laminar flow flame carbon black concentration distribution can be obtained further. The device and the method have the advantages of being convenient and rapid to measure, low in device requirements, fast in speed, changeable in flames, good in repeatability and the like; the method and the device can be applied in both the mechanism research on carbon black and the online measurement of carbon black concentration.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

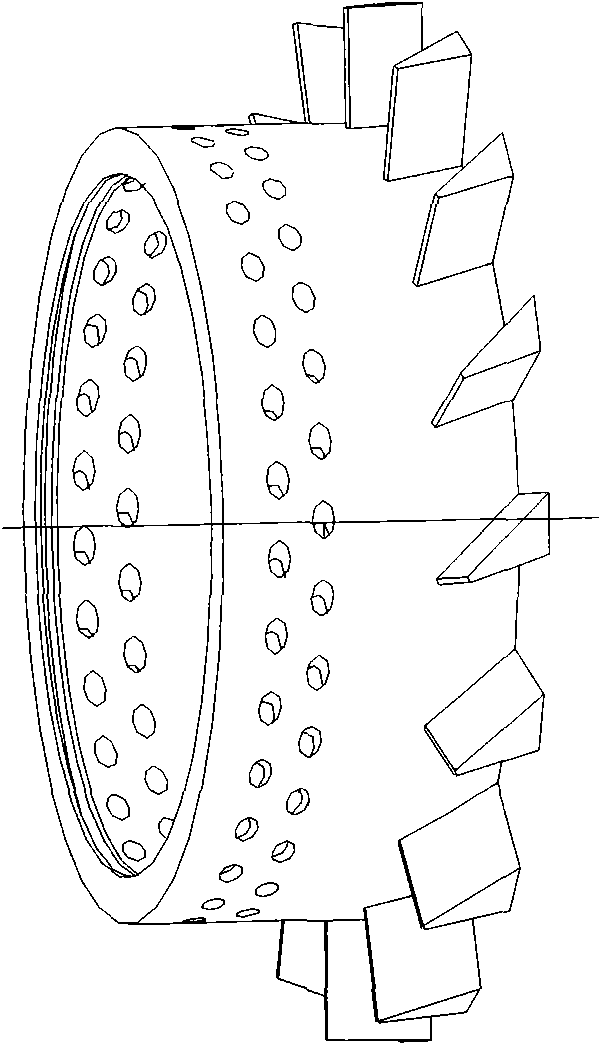

Burner for producing carbon black

InactiveUS6946101B1Improve stabilityImprove property stabilityChemical/physical/physico-chemical processesExtinguishing-devicesDiffusion flameCombustion chamber

A burner for producing carbon black, includes a combustion chamber which can be supplied with fuel gas and an oxidizing gas in such a way that a diffusion flame producing carbon black particles is generated in the combustion chamber. The burner is also provided with a carbon-black discharge line. Carbon black formed in the combustion chamber can be discharged via an opening in the combustion chamber which feeds into the carbon-black discharge line. The discharge line is also provided with an opening through which an extinguishing gas can be supplied to the carbon-line. The burner permits the stable and reproducible production of carbon black particles which present well defined chemical and physical characteristics.

Owner:JING LIANPENG

Method for preparing carbon nano-tube by diffusion flame with stable limited area

The invention discloses a method for preparing a carbon nano-tube by diffusion flame with a stable limited area, belonging to the technical field of preparation of nanometer materials. The method is characterized by comprising the following steps: preparing transitional metal salt ethylate solution and coating the transitional metal salt ethylate solution on a substrate; naturally drying and placing the substrate on a support inserted in a lamp wick; igniting flame, and covering a flame stable cover to obtain the diffusion flame with the stable limited area; keeping the substrate in the diffusion flame for 1-30 minutes and extinguishing the flame to obtain the carbon nano-tube. The method has the characteristics of simple apparatus and simple process, and obviously improves the repeatability and the consistency for preparing the carbon nano-tube due to the good stability of the diffusion flame with the stable limited area, thereby being hopeful to realize industrialization.

Owner:BEIJING INFORMATION SCI & TECH UNIV

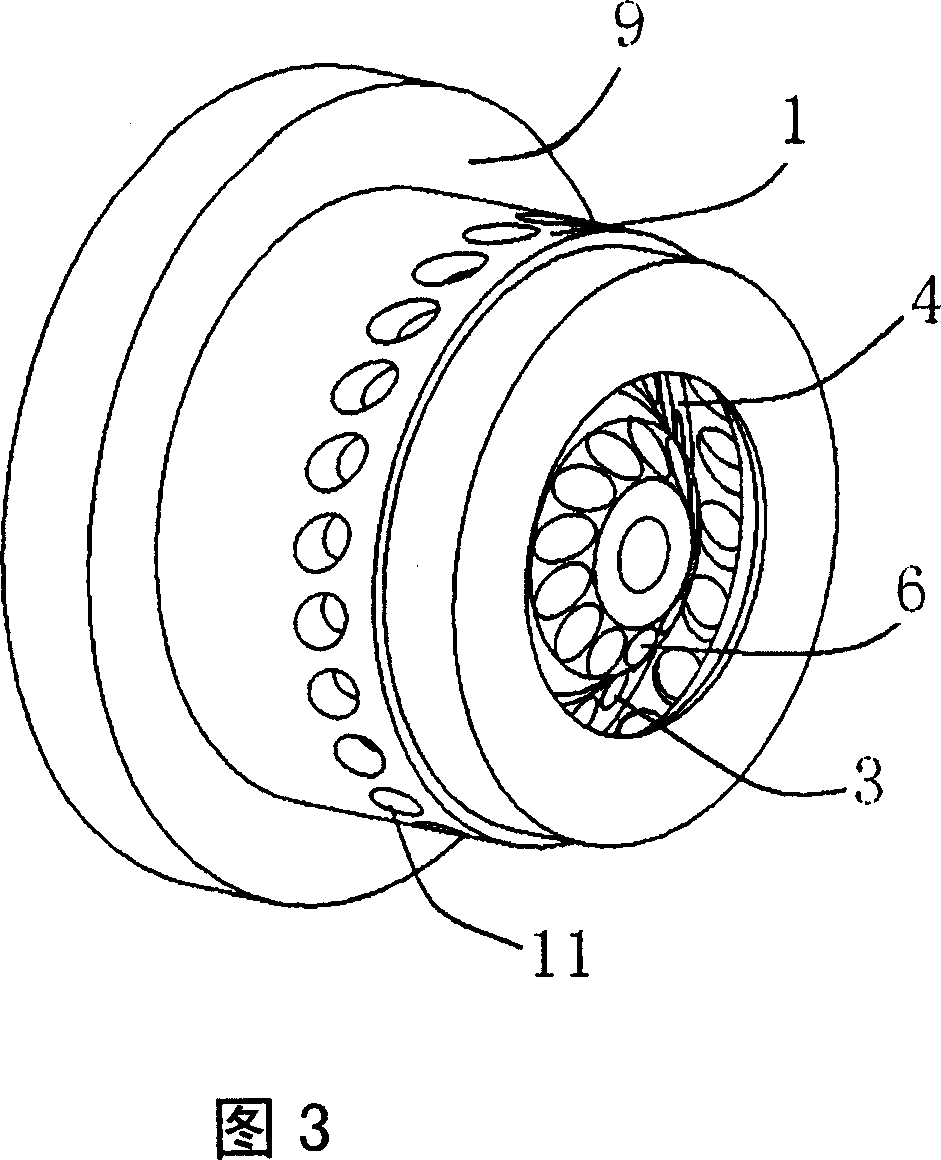

Premixing and pre-evaporation combustor for main combustion stage using radial film formation

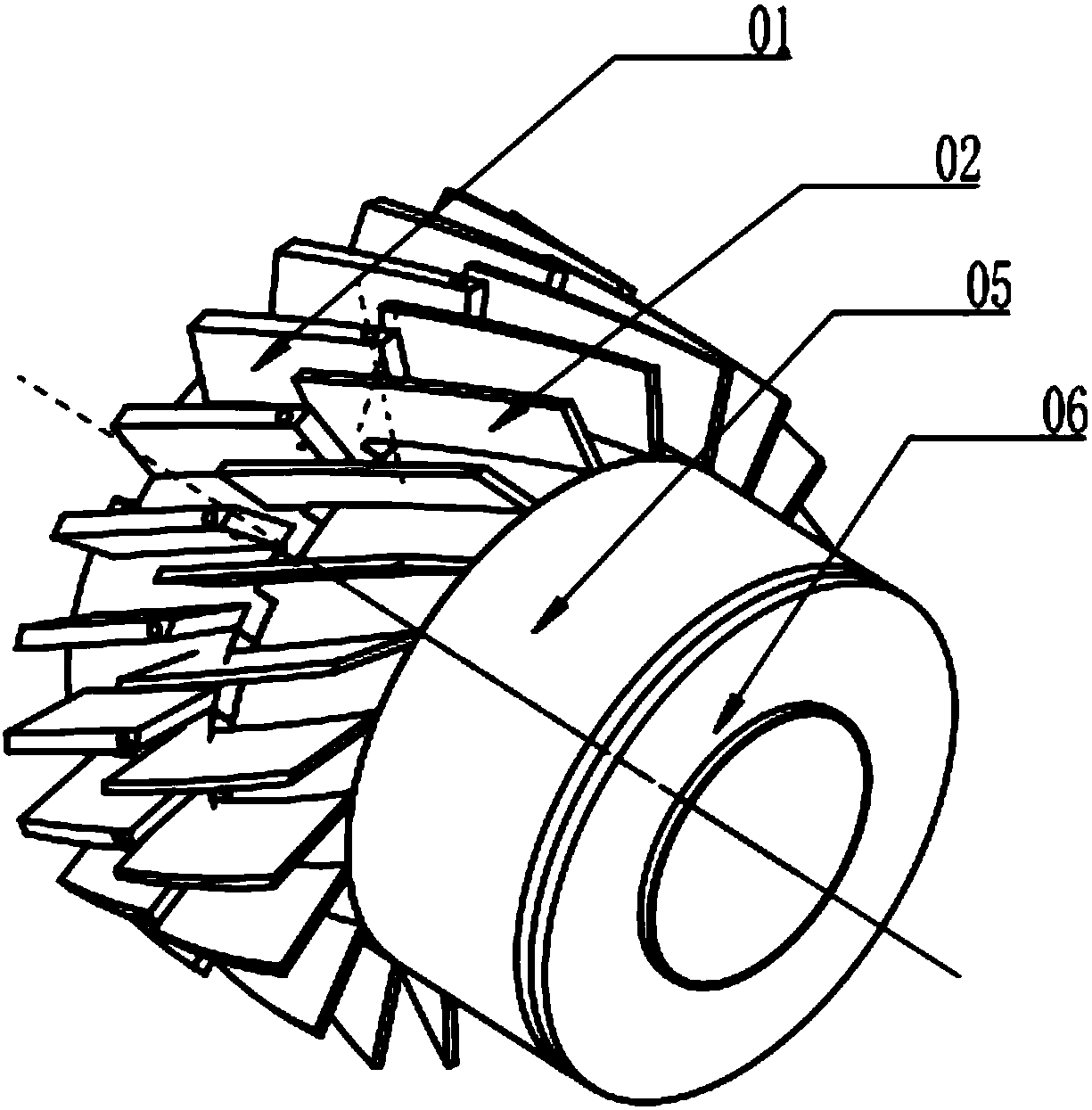

ActiveCN102889617ASimple structureHas a modular featureContinuous combustion chamberDiffusion flameCyclone

A premixing and pre-evaporation combustor for a main combustion stage using radial film formation consists of a diffuser, an outer combustor case, an inner combustor case, a pre-combustion stage, the main-combustion stage, a flame barrel outer wall and a flame barrel inner wall, wherein the flame of the pre-combustion stage is stabilized by a low-speed return flow zone formed by cyclone generated when a pre-combustion stage cyclone assembly enters the combustor; after being sprayed out by a plurality of tangential spraying openings of a main combustion stage nozzle, fuel oil of the main combustion stage spreads in a fuel oil film formation region and realizes connection, so that a peripheral continuous oil film is formed; the cyclone of an upstream cyclone ring of the main combustion stage nozzle and the cyclone of a downstream cyclone ring of the main combustion stage nozzle secondarily atomize the fuel oil, the fuel oil is brought to a premixing and pre-evaporation section to evaporate and is mixed with air, and uniform oil-gas mixtures are formed at an outlet of the premixing and pre-evaporation section, are jetted into a flame barrel, are ignited by the flame of the pre-combustion stage and then are combusted. The premixing and pre-evaporation combustor is simple in structure; and pollutant discharge can be effectively reduced while a normal working state of an aerial engine is guaranteed.

Owner:BEIHANG UNIV

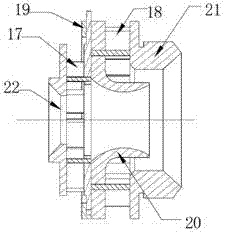

Low NOx emission diffusion flame combustor for gas turbines

InactiveUS6945051B2Reduce nitrogen oxide emissionsReduce impactBurnersContinuous combustion chamberDiffusion flameCombustion chamber

A diffusion flame combustor for a gas turbine comprising a flame tube that delimits a combustion chamber, the flame tube having a fuel injector unit mounted at one end, the other end of the tube being connected to a duct that conveys combustion gases to the turbine. The flame tube is mounted coaxially inside a generally tubular container that communicates with the discharge casing of an air compressor and, together with the tube, defines a space for combustion air. The injector unit comprises an injector head facing generally into the combustion chamber and provided with at least one fuel gas injection nozzle. The nozzle includes an air-gas premixing duct into which fuel gas is introduced. The premixing duct has an inlet section that communicates with the air space and is provided with a radial-fin air swirler generally upstream of a point at which the fuel gas enters the premixing duct. This partial premixing of combustion gas with combustion air reduces NOx emissions and production of un-combusted material.

Owner:ENEL PRODUZIONE

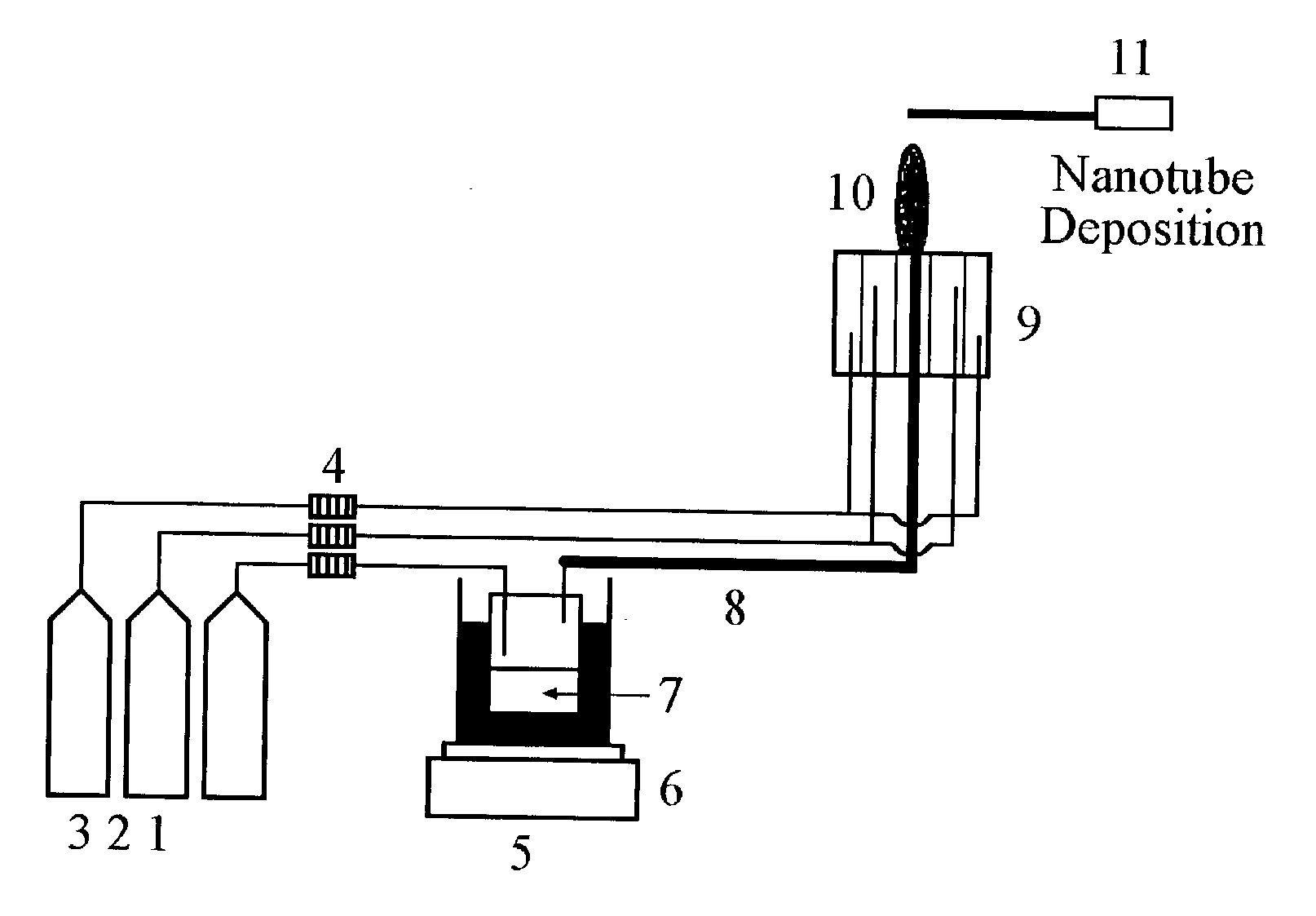

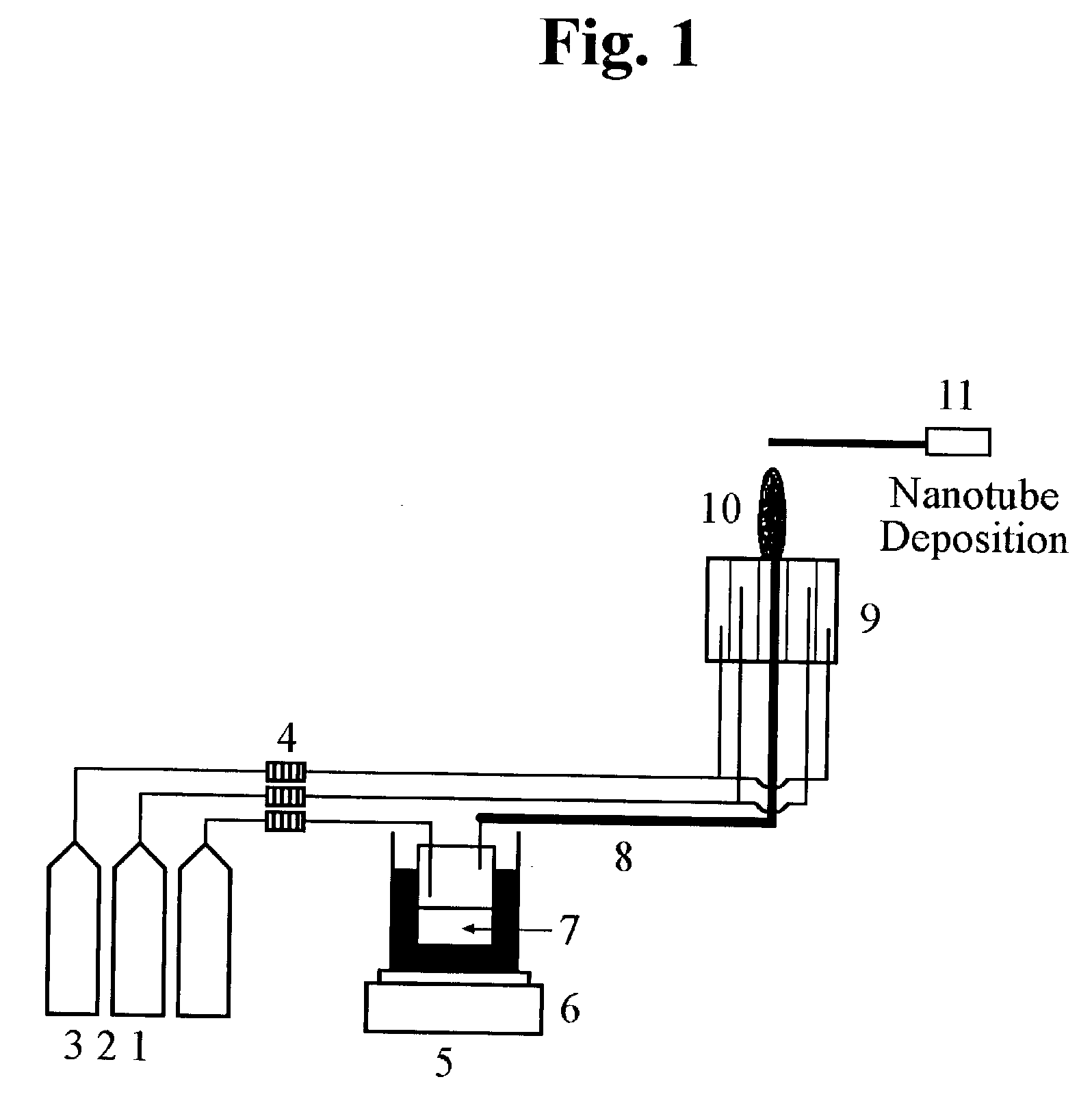

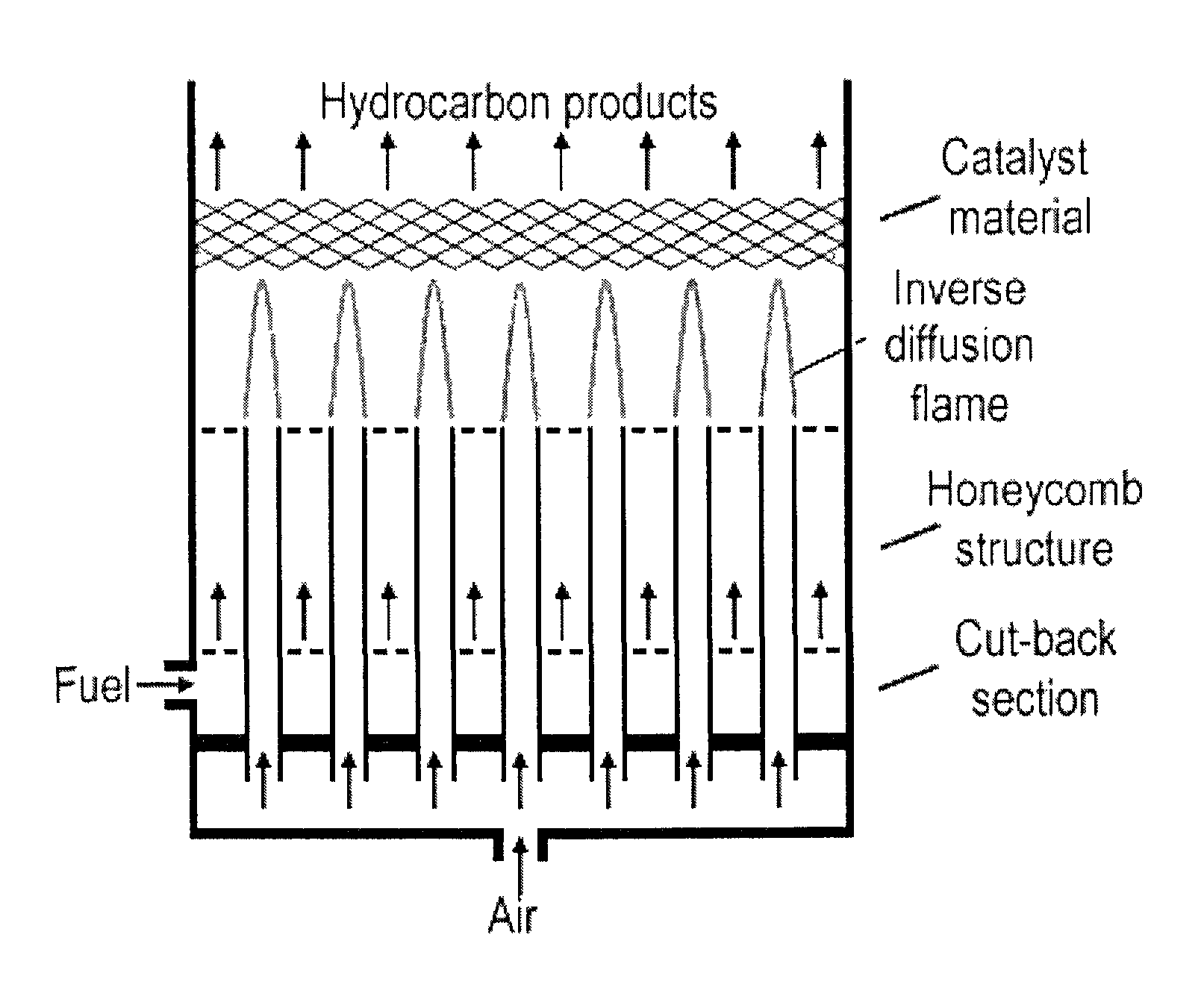

Apparatuses and processes for synthesis of carbon nanotubes using inverse diffusion flame

InactiveUS7157069B2Overcome limitationsMaterial nanotechnologyNanostructure manufactureDiffusion flameCarbon nanotube

Disclosed is an apparatus for the combustion synthesis of carbon nanotubes characterized with the combustor having an oxidizing agent inlet, a fuel inlet and an inert gas inlet, such that the inverse diffusion flame occurs within the combustor, thereby producing carbon nanotubes without using vacuum, and a method for the combustion synthesis of carbon nanotubes using the same. According to the present invention, it is possible to directly collect samples including carbon nanotubes without oxidation and a substrate may be installed with ease. Moreover, the manufacturing cost can be lowered to a level suitable for mass production so that the carbon nanotube technology can be extended to various applications.

Owner:KOREA INST OF SCI & TECH

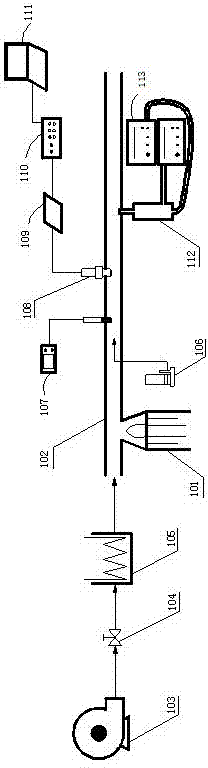

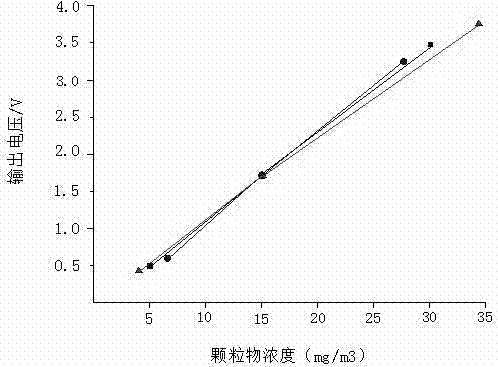

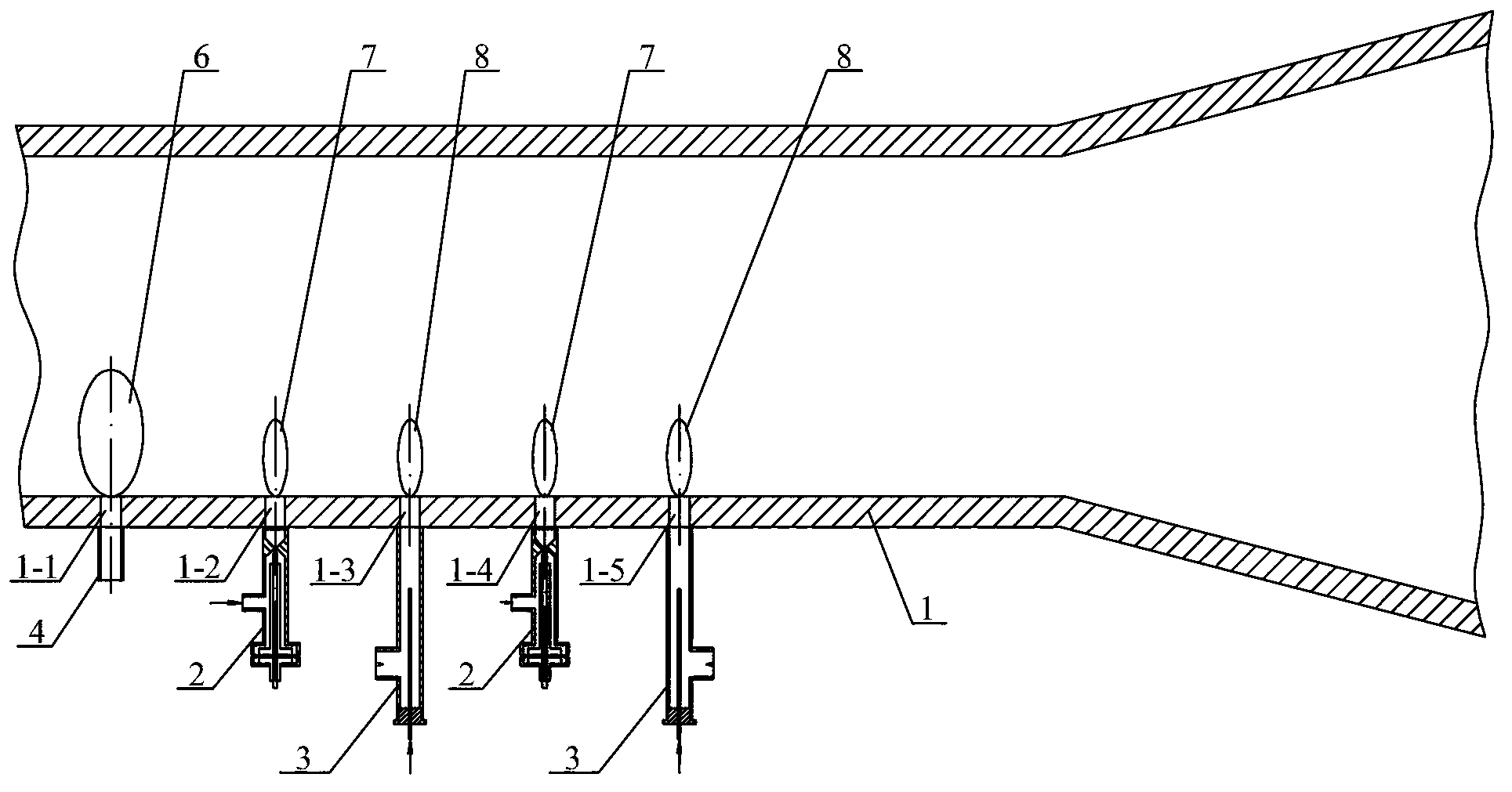

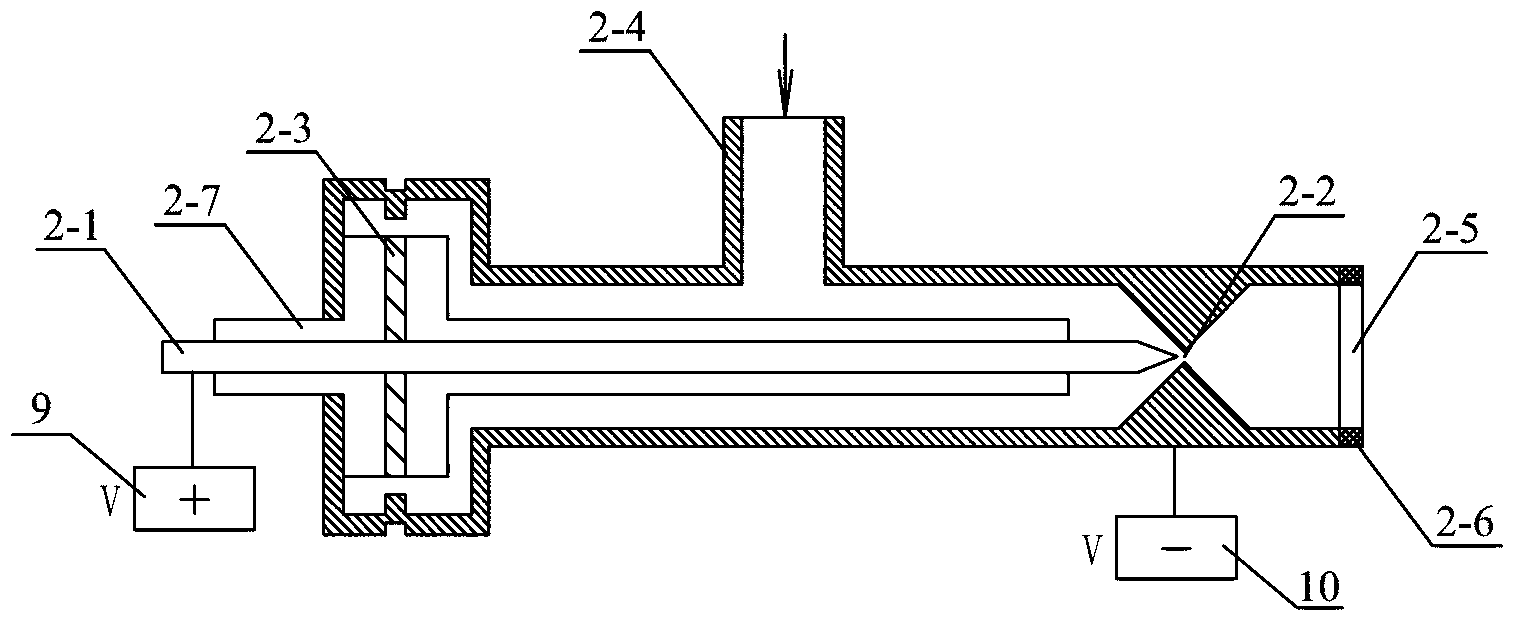

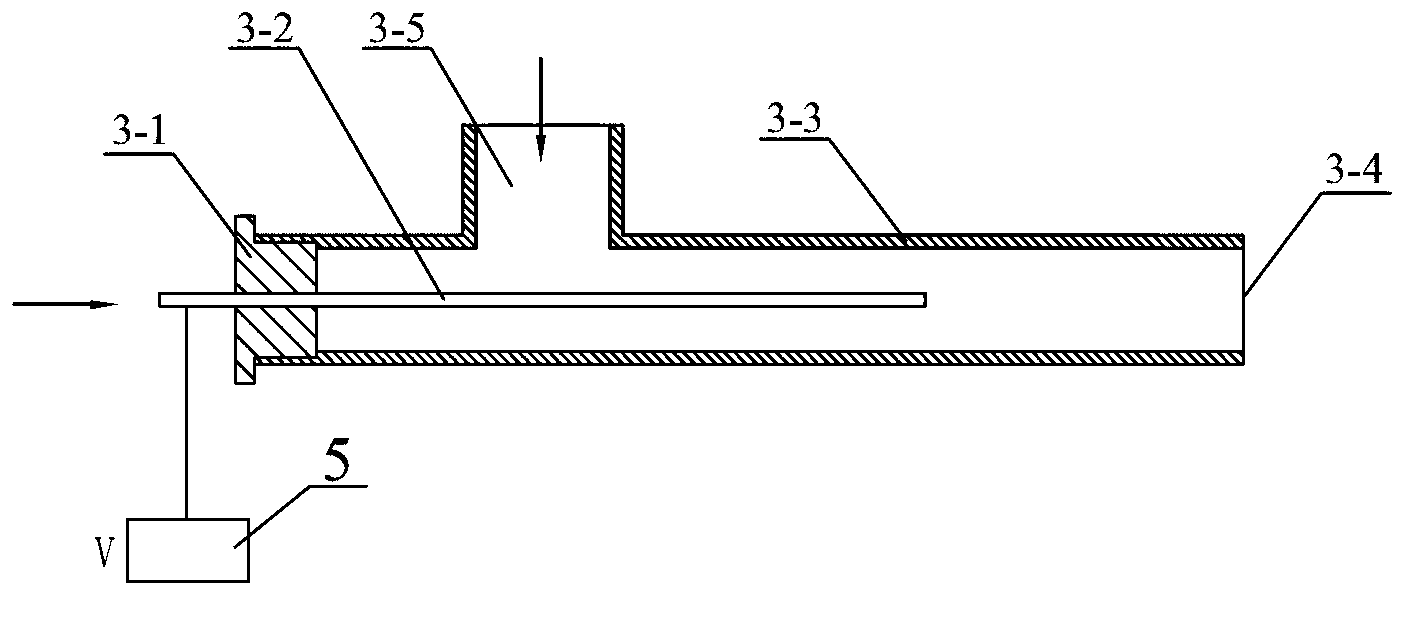

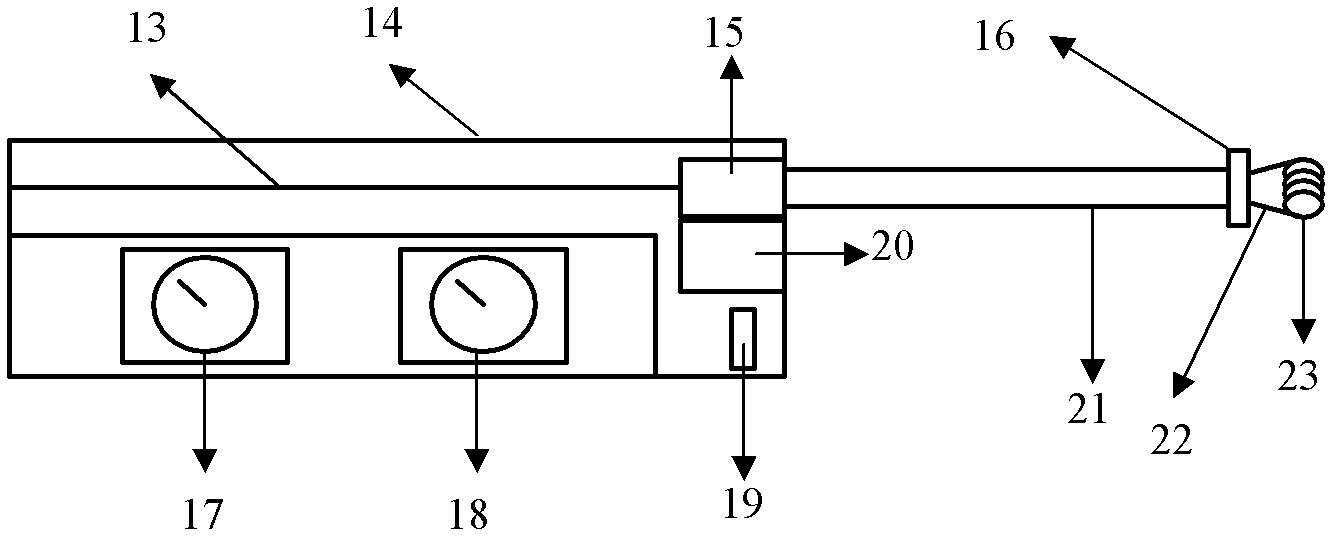

Particle sensor calibration system and measuring method

ActiveCN104849186AReduce oxidationReduce carbonizationParticle suspension analysisConvertersDiffusion flame

The invention discloses a particle sensor calibration system and a measuring method. A fuel is introduced into an inverse diffusion flame combustor, an upper combustor mouth is communicated with an exhaust pipe, a gas mixture is ignited, and stable soot is produced by combustion of the gas mixture; a compressor is started, and a stable quantity of air is introduced; air input is adjusted through a pressure-regulating valve, and the air is heated by a heater and then enters the exhaust pipe to dilute the soot produced by combustion; air input flow adjusted by the pressure-regulating valve is read by a flowmeter; a temperature sensor outputs the temperature of diluted particles; the soot enters a particle sensor, a current signal is output and then amplified and converted by a circuit board, then a voltage signal is output, an A / D converter is used to acquire a signal value, and a voltage value is read by a computer; a transient smokemeter is started in the moment when the soot enters the particle sensor, and transient soot concentration is measured and output; and the voltage values output by the particle sensor under different soot concentrations are recorded, a calibration curve representing the changes of the voltage values under different soot concentrations is drafted, and accurate particle concentration is obtained.

Owner:JIANGSU UNIV

Supersonic combustion method actuated by combination plasma

InactiveCN103216317AAvoid layoutAvoid technical requirements for placing ionization electrodesInternal combustion piston enginesCombustion-air/fuel-air treatmentDiffusion flameCombustion chamber

The invention discloses a supersonic combustion method actuated by combination plasma, relates to the supersonic combustion method for an engine combustion chamber, and solves the problems that by using an existing concave chamber type combustion method, the concave chamber dimensions are large, the flow loss is large, and the supersonic combustion performance is poor. The method comprises the steps that 1) a ceramic membrane is plated on the inner surface of each through hole; 2) the first through hole is connected with a fuel oil outlet pipe, the second through hole and the fourth through hole are connected with a thermal equilibrium plasma generator respectively, and the third through hole and the fifth through hole are connected with a non-thermal equilibrium plasma generator respectively; 3) fuel oil is injected into the combustion chamber through the first through hole; 4) a working medium is ejected from the thermal equilibrium plasma generator, is injected into a combustion area of the engine combustion chamber and ignites the fuel oil at the combustion area to form diffusion flame and realize ignition; and 5) jet cooling plasma is ejected from the non-thermal equilibrium plasma generator, and is injected into different positions of the combustion chamber through the third through hole and the fifth through hole for forming reliable combustion. The method provided by the invention is used for organizing supersonic combustion.

Owner:HARBIN INST OF TECH

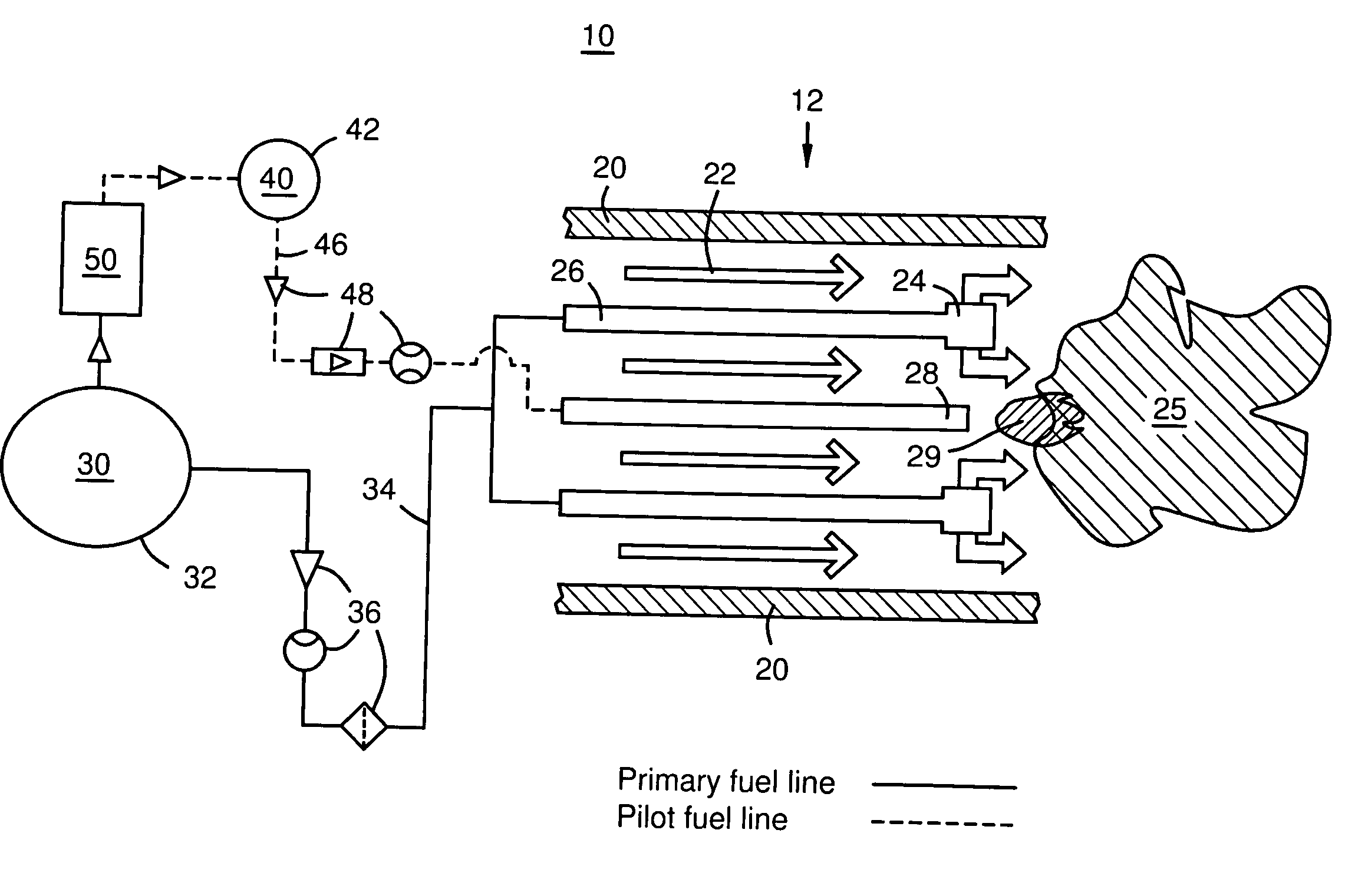

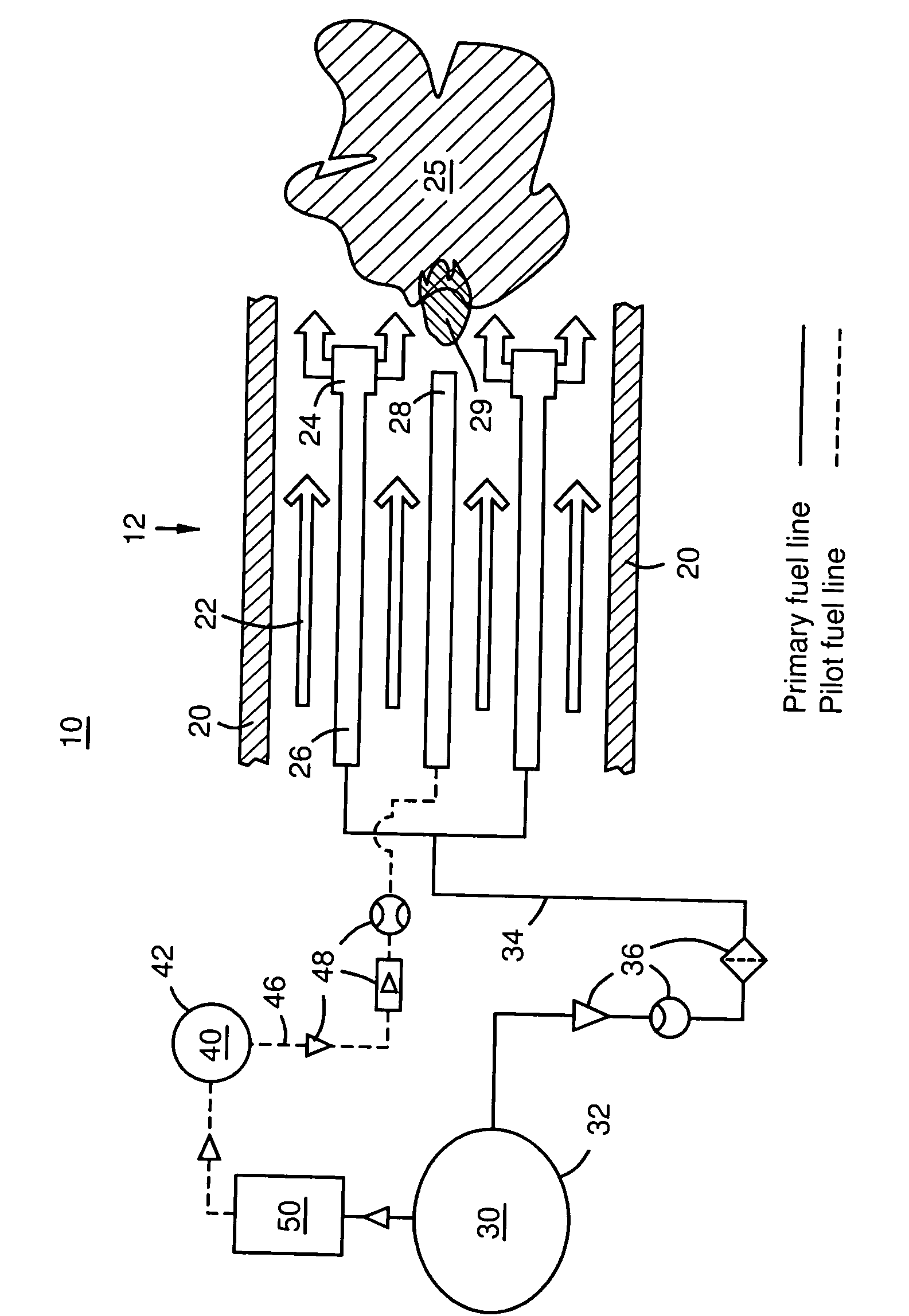

Combustion apparatus using pilot fuel selected for reduced emissions

InactiveUS20070289311A1Continuous combustion chamberTurbine/propulsion fuel supply systemsDiffusion flameEngineering

A combustion apparatus (10) incorporating a dry low NOx (DLN) combustor (20) that uses two different fuels (30, 40) simultaneously. One fuel (30) is premixed with air (22) for a primary combustion zone (25), and a second fuel (40) supplies a diffusion pilot flame (29). Each fuel may be selected for its specialized role, maximizing overall combustion efficiency while lowering emissions. A primary fuel (30) such as natural gas (NG) may be chosen for its economy and combustion characteristics in a lean premix. A pilot fuel (40) may be chosen for having a low diffusion flame temperature and a clean burn. An oxygenated pilot fuel such as dimethyl ether (DME) has a lower flame temperature than natural gas, thereby reducing NOx from the pilot flame. The pilot fuel (40) may be produced from the primary fuel (30) by a reformer (50) associated with the combustion apparatus.

Owner:SIEMENS ENERGY INC

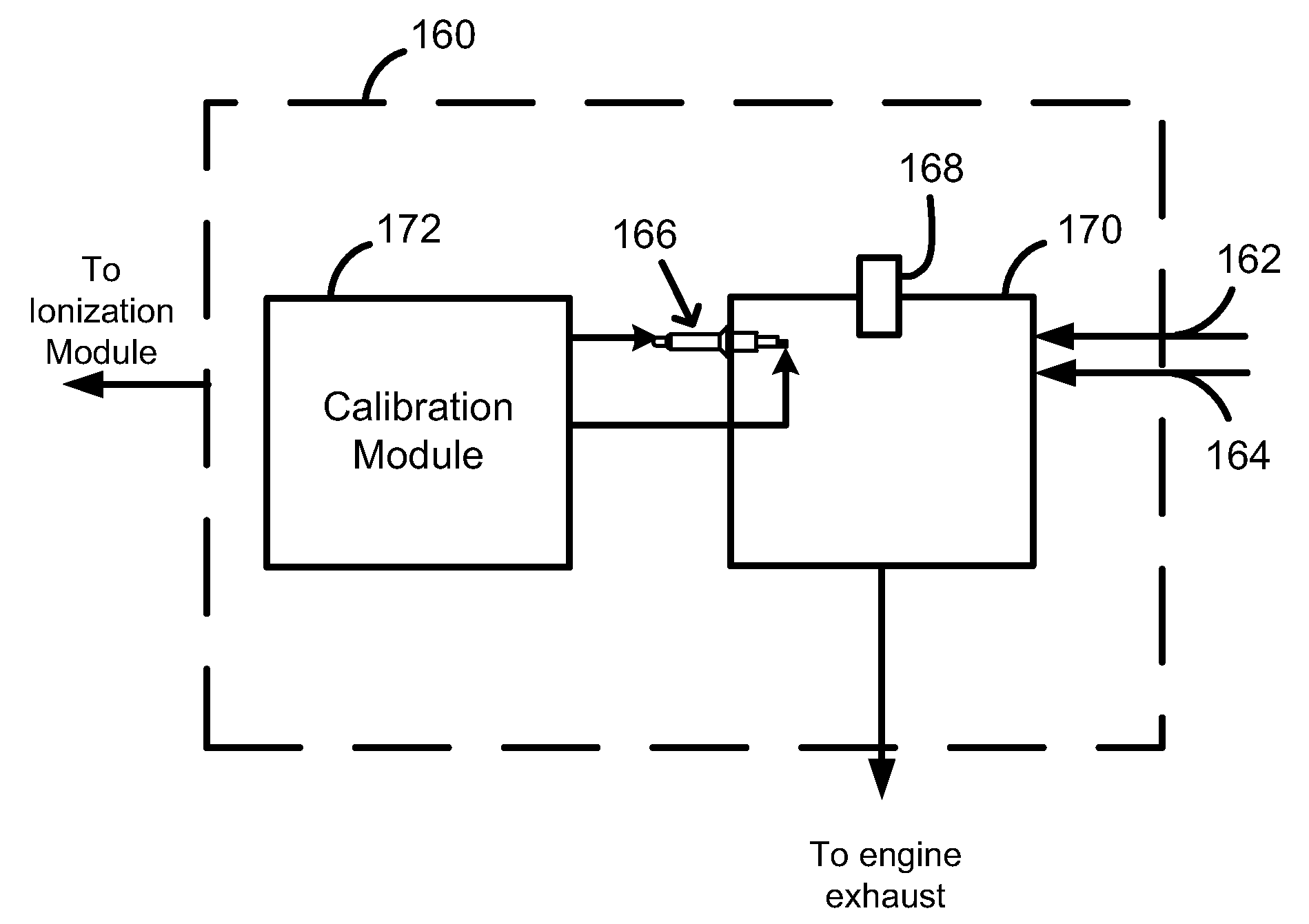

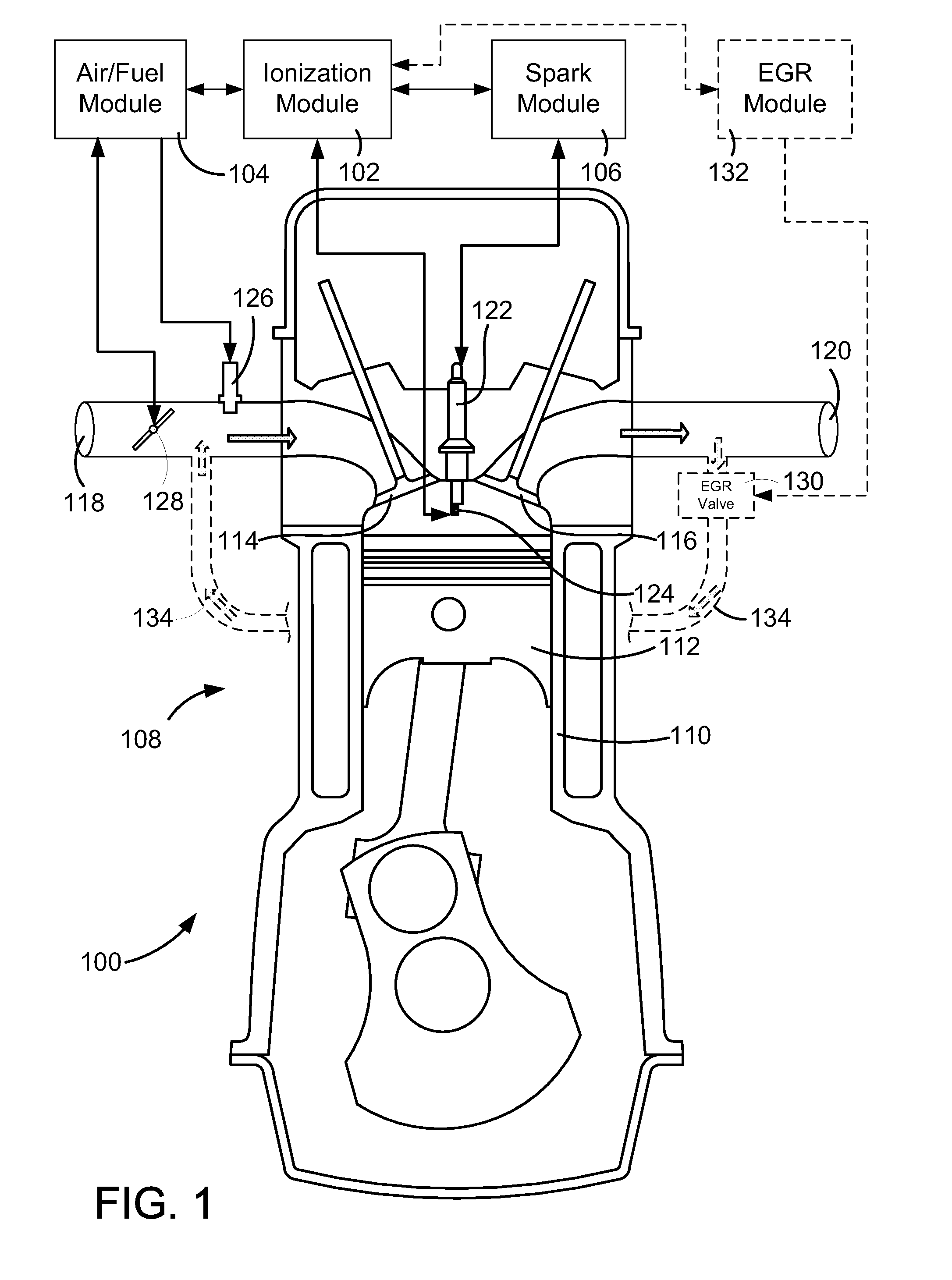

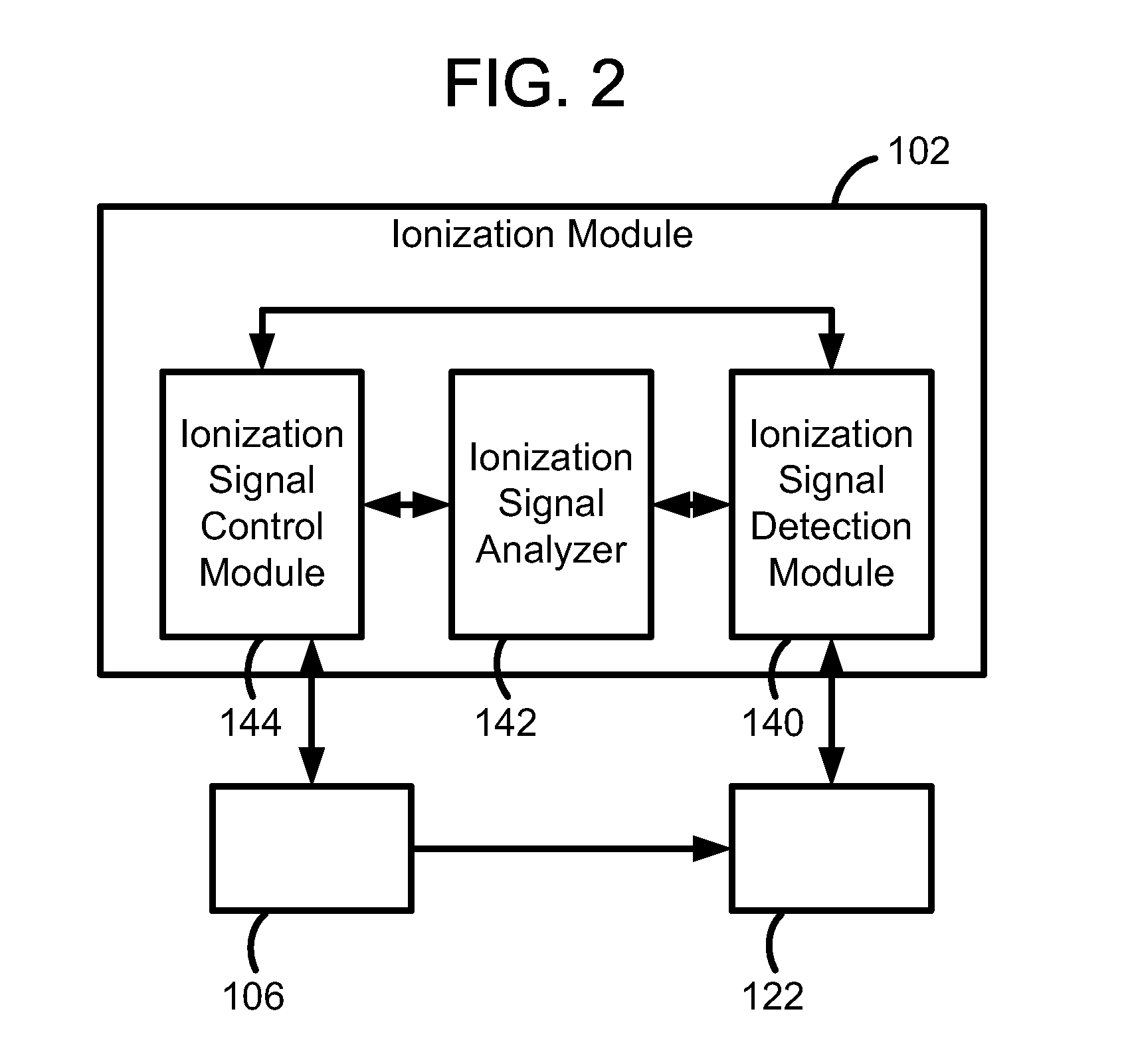

Compensating For Varying Fuel And Air Properties In An Ion Signal

ActiveUS20080053406A1Electrical controlNon-fuel substance addition to fuelDiffusion flameCombustion chamber

Presented is a device that provides a correction factor to compensate for varying fuel and air properties in an ion signal sensed in combustion chamber of reciprocating and continuous combustion engines, on a predetermined basis during the combustion of conventional petroleum-based fuels, other alternate fuels, and renewable fuels. The device uses an ion current reference sensor device and a processing module to provide a correction factor to the ion signal(s). The ion current reference sensor device is positioned near the chamber(s) of the engine and fuel provided to the chamber(s) is routed to provide a diffusion flame and the resultant ion current from the flame is measured and provided to the processing module at discrete intervals during the combustion process. Alternatively, a pre-mixed flame is used. The processing module provides a scaling factor to be applied to the ion signal and / or calibration points used to detect combustion conditions.

Owner:WOODWARD GOVERNOR CO

Method and system for controlling gas turbine

Owner:GENERAL ELECTRIC CO

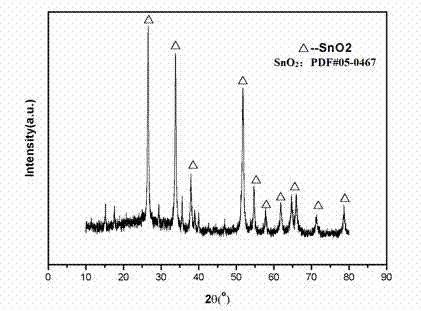

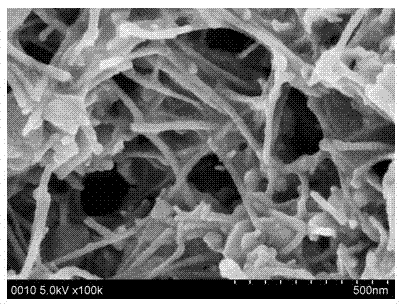

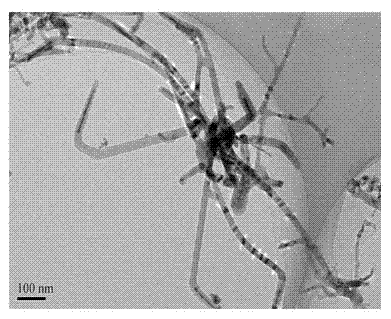

Method for preparing precious metal gold particle catalytically-grown stannic oxide nanowire

ActiveCN103043712AHigh purityHigh crystallinityMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsNanowireGas detector

The invention discloses a method for preparing a precious metal gold particle catalytically-grown stannic oxide nanowire. The method comprises the following steps of: introducing a precursor into a flame reaction chamber under the drive of an injection pump and atomization diffusion of the oxygen by using tetrachlorostannane pentahydrate and absolute ethyl alcohol solution of chloroauric acid as the precursor; assisting the burning of diffusion flame and precursor solution to provide heat energy at the reaction temperature of 1,600-2,000 DEG C to obtain a highly-crystallized stannic oxide nanowire under a catalytic induction function of the precious metal gold particles and high-temperature flame atmosphere. The stannic oxide nanowire prepared by the method, of which the sharp end is provided with the precious metal gold particles, can generate interface plasma resonance effect together with stannic oxide serving as a semiconductor and can be widely applied to the fields of dye-sensitized solar cells, gas sensitive sensors and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

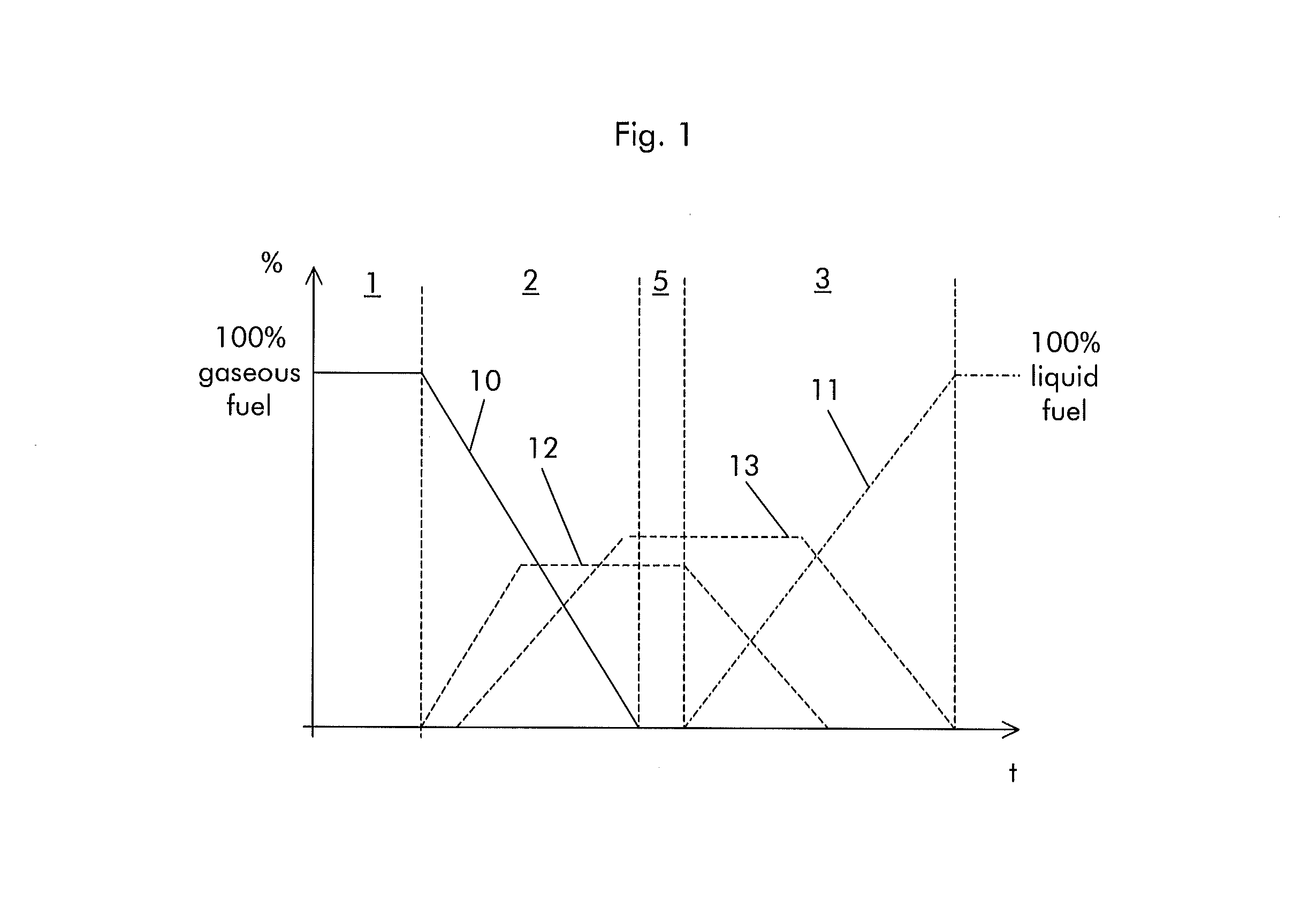

Method for switching over a combustion device

ActiveUS20130086918A1Continuous combustion chamberTurbine/propulsion engine ignitionDiffusion flameCombustion

An exemplary method for switching over a combustion device from operation with a first premix fuel to a second premix fuel includes reducing and stopping a first premix fuel supply and then starting a second premix fuel supply. In an intermediate phase, after the first premix fuel supply stop and before the second premix fuel supply start, the combustion device is operated with one or more pilot fuels generating diffusion flames.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Scalable multiple-inverse diffusion flame burner for synthesis and processing of carbon-based and other nanostructured materials and films and fuels

ActiveUS9388042B2High strengthEfficient extractionSemi-permeable membranesHydrogenDiffusion flameNanostructured materials

Owner:RUTGERS THE STATE UNIV

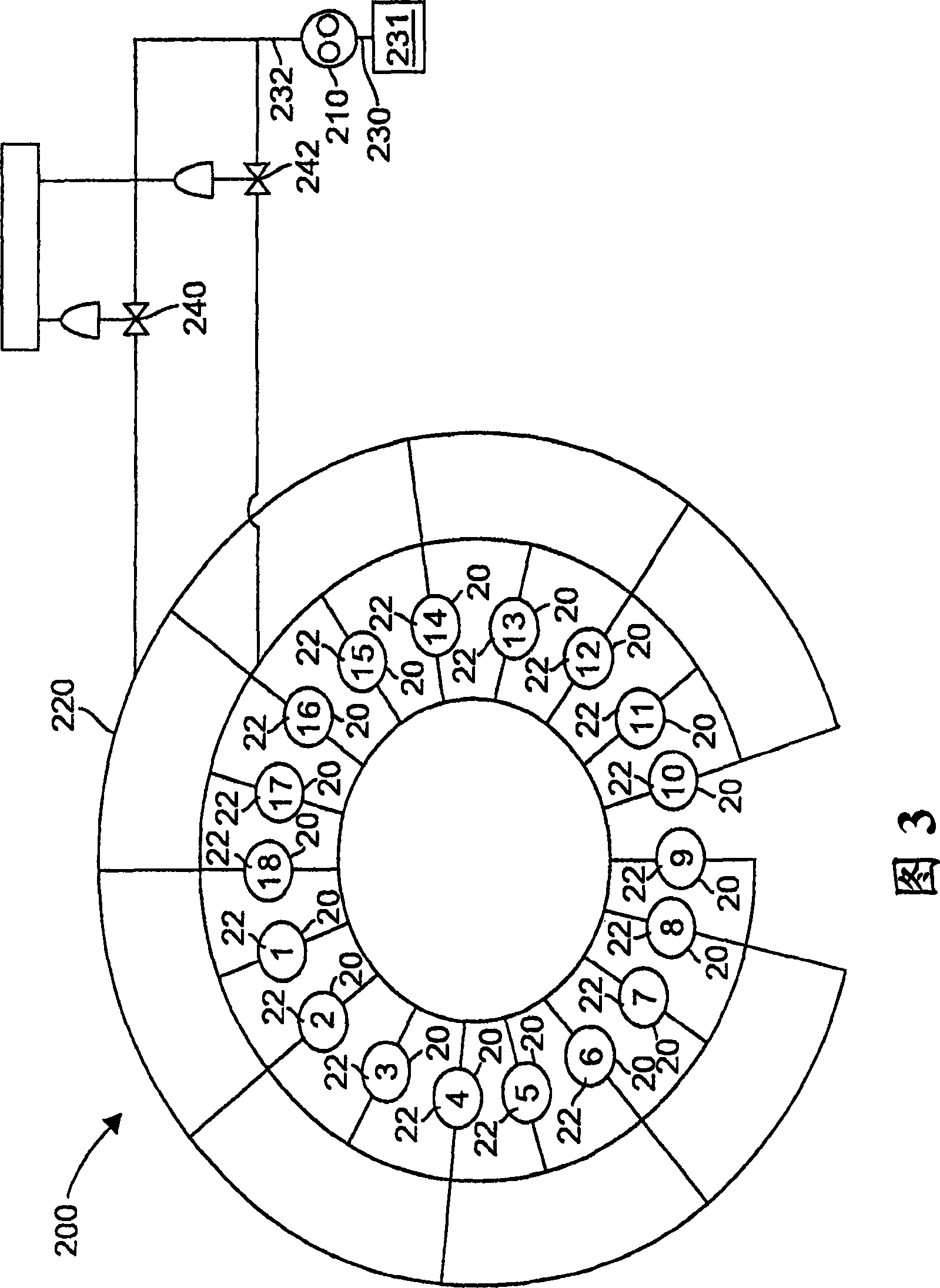

Gas turbine combustor having multiple independently operable burners and staging method thereof

ActiveUS7797942B2Improve featuresAchieve stablyContinuous combustion chamberTurbine/propulsion fuel supply systemsDiffusion flameCombustion chamber

Owner:MITSUBISHI POWER LTD

Low-emission combustion chamber head with main combustion stage adopting axial rotational flow pre-membrane plate matching with blade injection structure

ActiveCN108592084AGood premix effectGuaranteed ignition performanceContinuous combustion chamberDiffusion flameCombustion chamber

The invention discloses a low-emission combustion chamber head with a main combustion stage adopting an axial rotational flow pre-membrane plate matching with blade injection structure. According to the combustion chamber head, the head adopts a center grading design and consists of a main combustion stage and a pre-combustion stage; the main combustion stage is provided an axial rotational flow pre-membrane structure, the main functions of a main combustion stage swirler is that air is enable to generate rotational flow, moreover, fuel oil is injected into the air through small holes in blades, and the fuel oil is atomized and mixed in the swirling air; axial rotational flow pre-membrane blades are aligned with fuel oil injection holes in the swirler blades, and are used for carrying outpre-membrane atomization on the fuel oil, the atomization effect of main combustion stage fuel oil is improved, and therefore the relatively high low-emission performance is achieved; and the pre-combustion stage adopts diffusion flame to stabilized the flame, the main combustion stage adopts the structure in the chamber head to perform fuel oil atomization premixed combustion, so that the low-emission performance of the combustion chamber is further improved.

Owner:BEIHANG UNIV

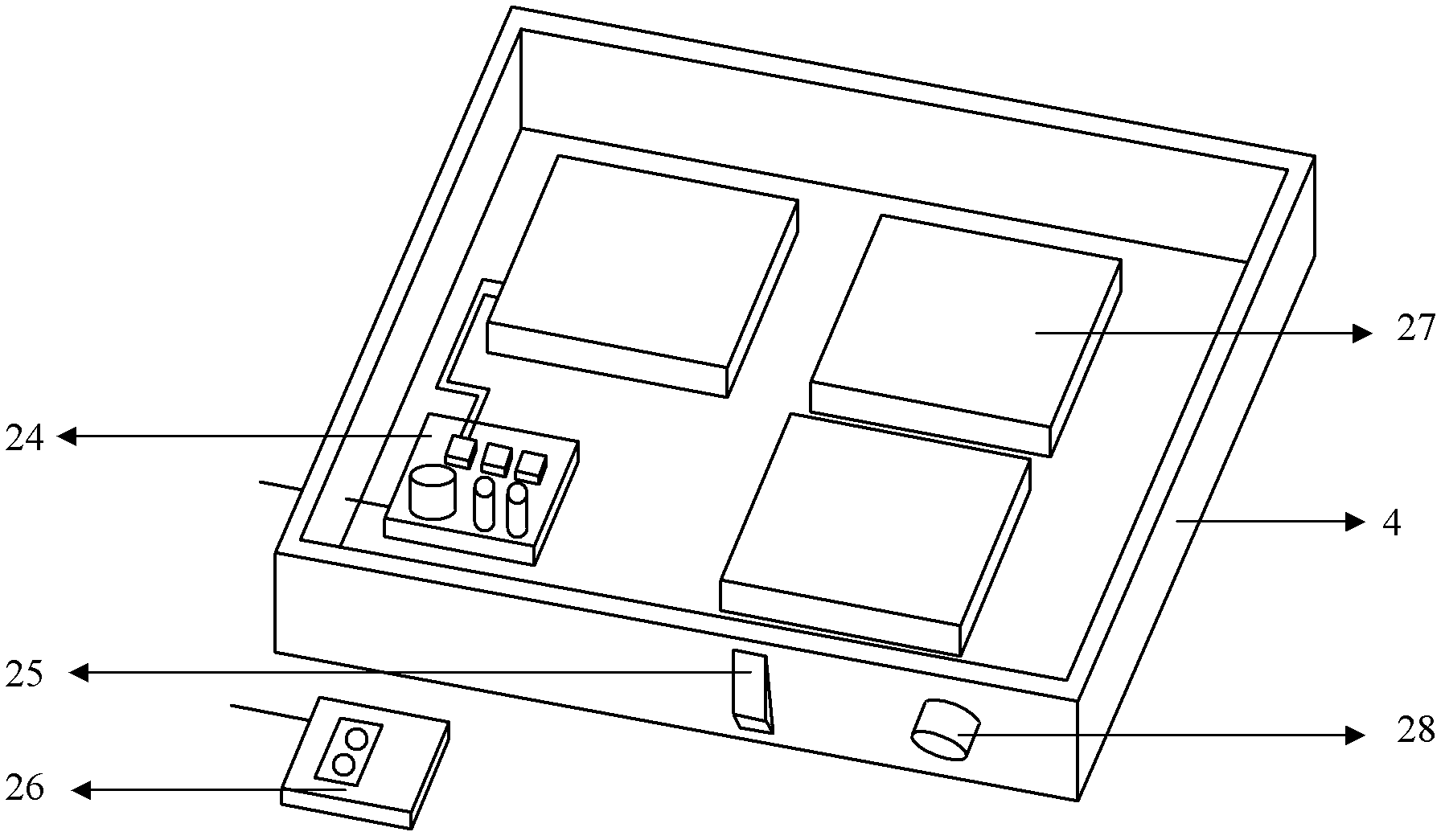

Experimental apparatus for diffusion flames in forced convection environment

InactiveCN102322739ADoes not affect forced convection environmentIncandescent ignitionFurnace typesDiffusion flameCombustion

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com