Premix and pre-evaporation combustion chamber

A combustion chamber and pre-evaporation technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of low equivalent ratio in the combustion zone, high CO and UHC emissions, uneven local equivalent ratio, etc., and achieve low pollution emissions , Efficient and stable work, and the effect of reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

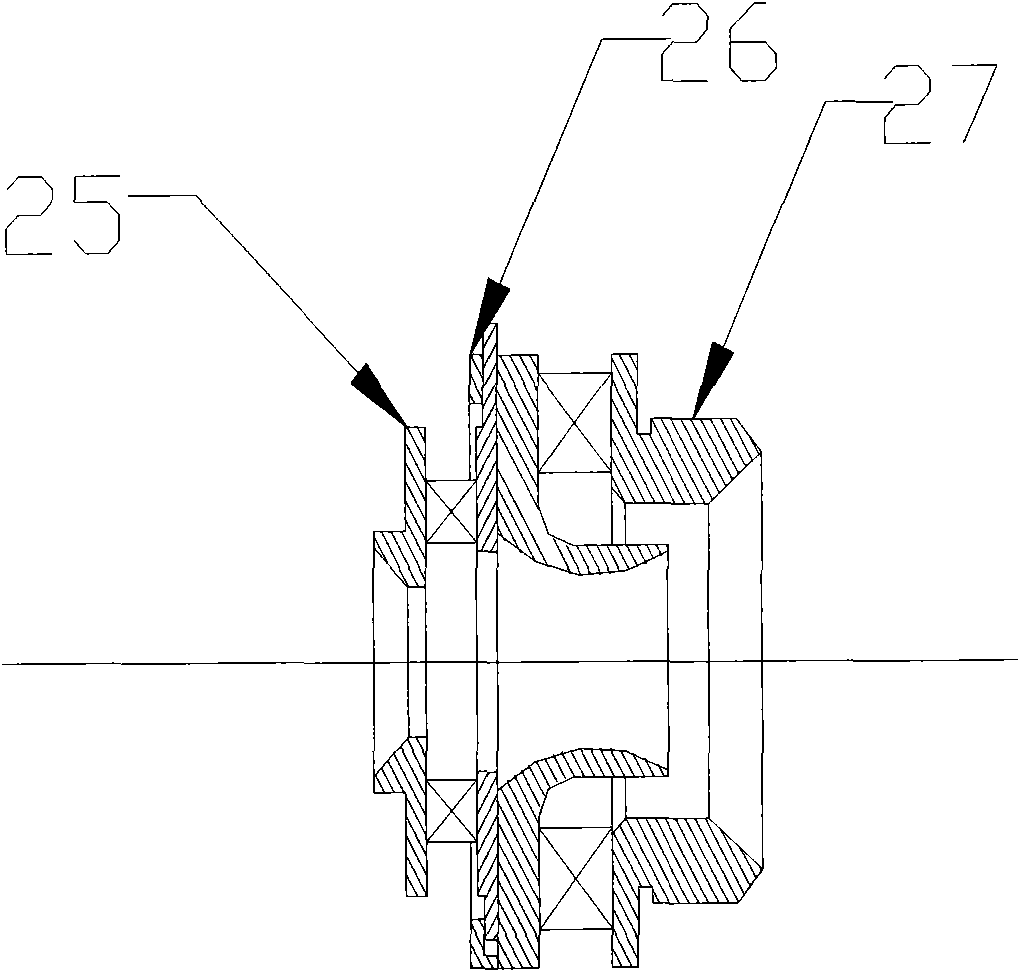

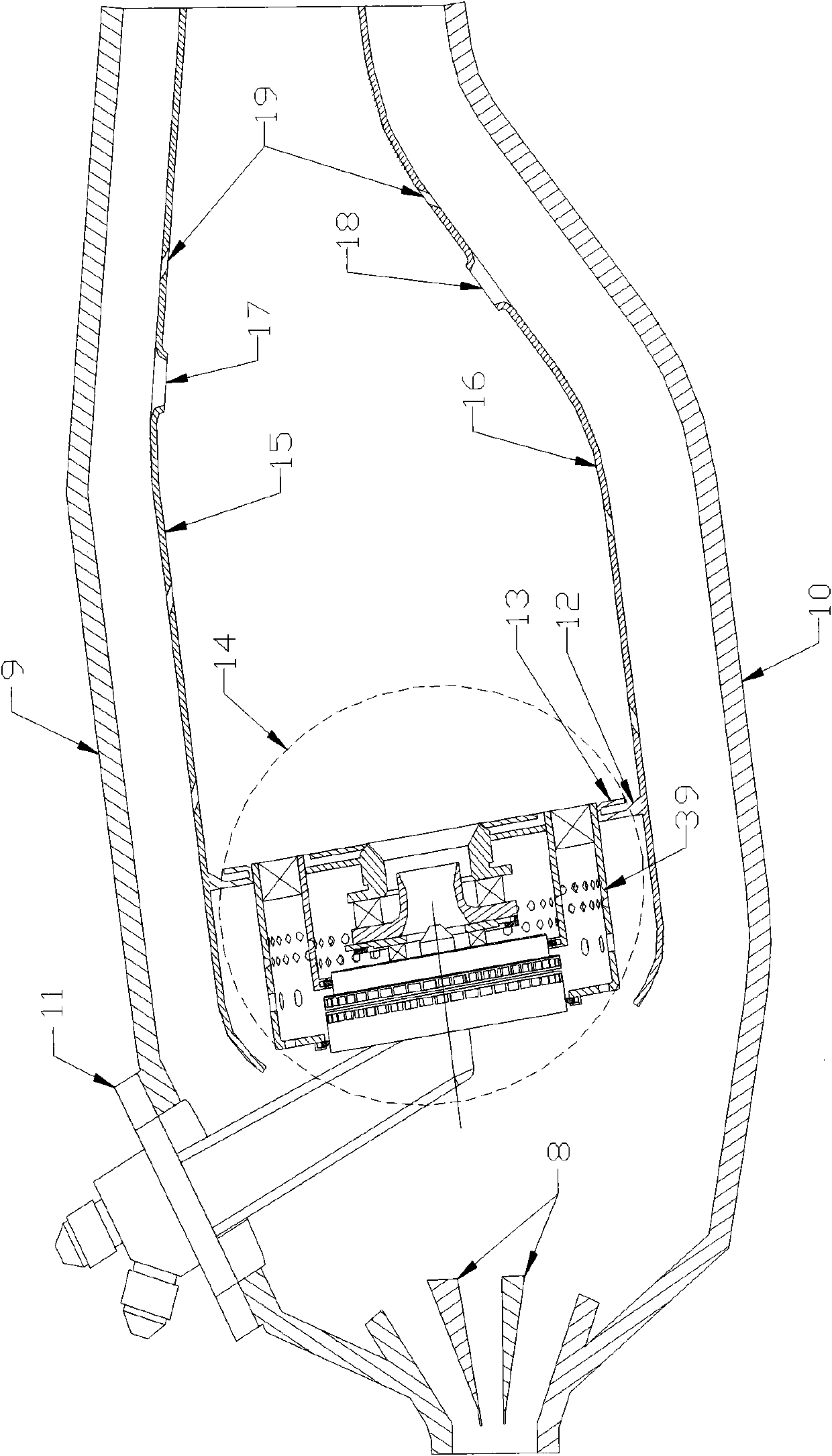

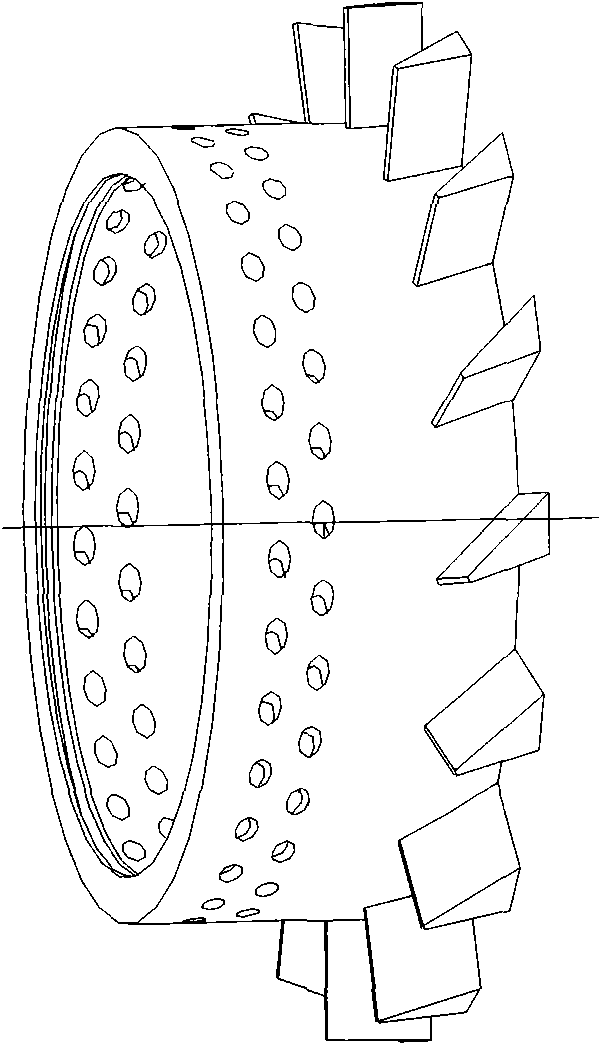

[0040] Such as figure 1 and figure 2 As shown, the tangential premixed pre-evaporation combustor designed by the present invention is a single-ring cavity structure, and adopts the conceptual design of staged combustion. The diffusion flame combustion organization mode, the main combustion stage adopts the premixed pre-evaporation combustion organization mode, and the cooling gas and the mixed gas are supplied from the flame tube. This combustion chamber comprises two combustion areas---the pre-combustion level combustion area 6 and the main combustion level combustion area 7, two combustion areas share the same inner and outer boundaries, the outer boundary of the combustion area is the outer wall 15 of the flame tube, and the inner boundary of the combustion area It is the inner wall 16 of the flame tube, and the outer wall 15 of the annular flame tube and the inner wall 16 of the flame tube are located between the annular casing 9 outside the combustion chamber and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com