Patents

Literature

48results about How to "Uniform jet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heterogeneous Fenton reagent and preparation method and application thereof

InactiveCN103007753AMild reaction conditionsEasy to controlNitrous oxide captureDispersed particle separationPtru catalystFenton reagent

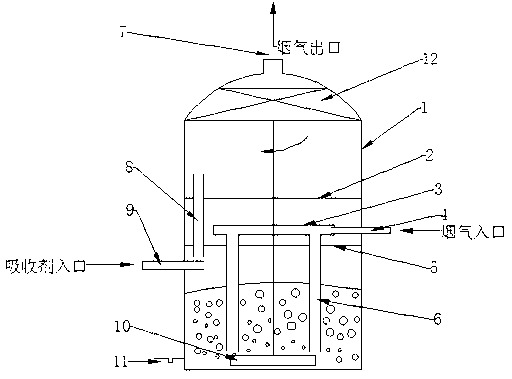

The invention discloses a heterogeneous Fenton reagent and a preparation method of the heterogeneous Fenton reagent and a method for removing NO out of smoke by wet oxidization by using the heterogeneous Fenton reagent. The heterogeneous Fenton reagent is a mixed solution which comprises an H2O2 water solution and an Al2O3 loaded Fe catalyst and has a pH of 5-6, wherein the concentration of the H2O2 waters solution in the mixed solution is 0.5-1.5mol / L, and the concentration of the Al2O3 loaded Fe catalyst is 2g / L. According to the method, NO is removed out of smoke by wet oxidization by using the heterogeneous Fenton reagent; particularly, the heterogeneous Fenton reagent is added in a conventional bubble tower, NO in the smoke is oxidized into HNO3, and thus the purpose of removing NO is reached. The method for removing NO out of the smoke by wet oxidization by using the heterogeneous Fenton reagent is low in denitration cost and does not cause secondary pollution.

Owner:上海电气电站环保工程有限公司 +1

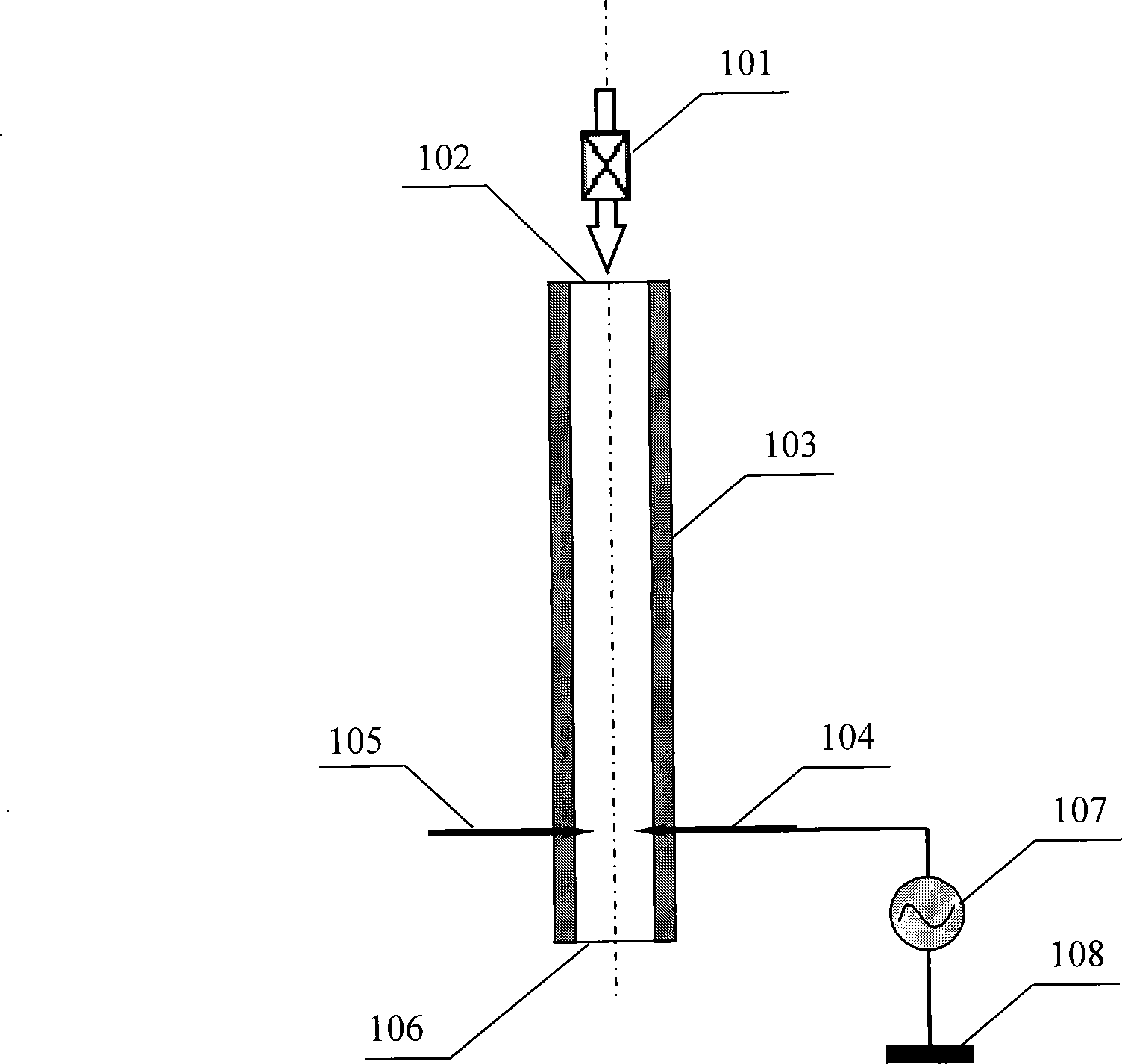

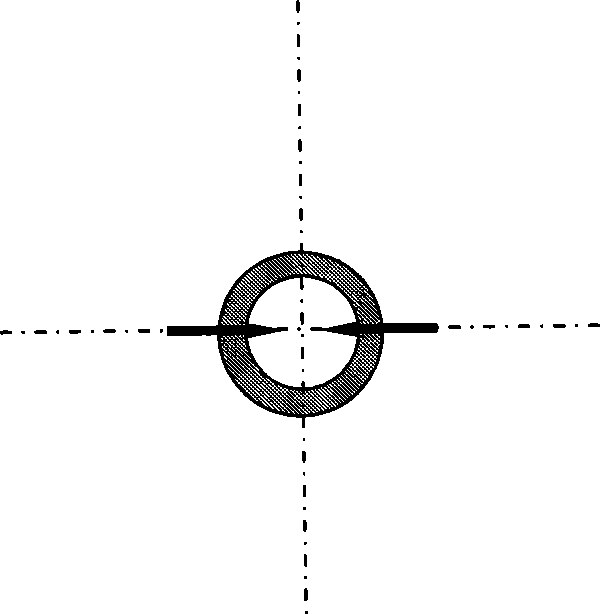

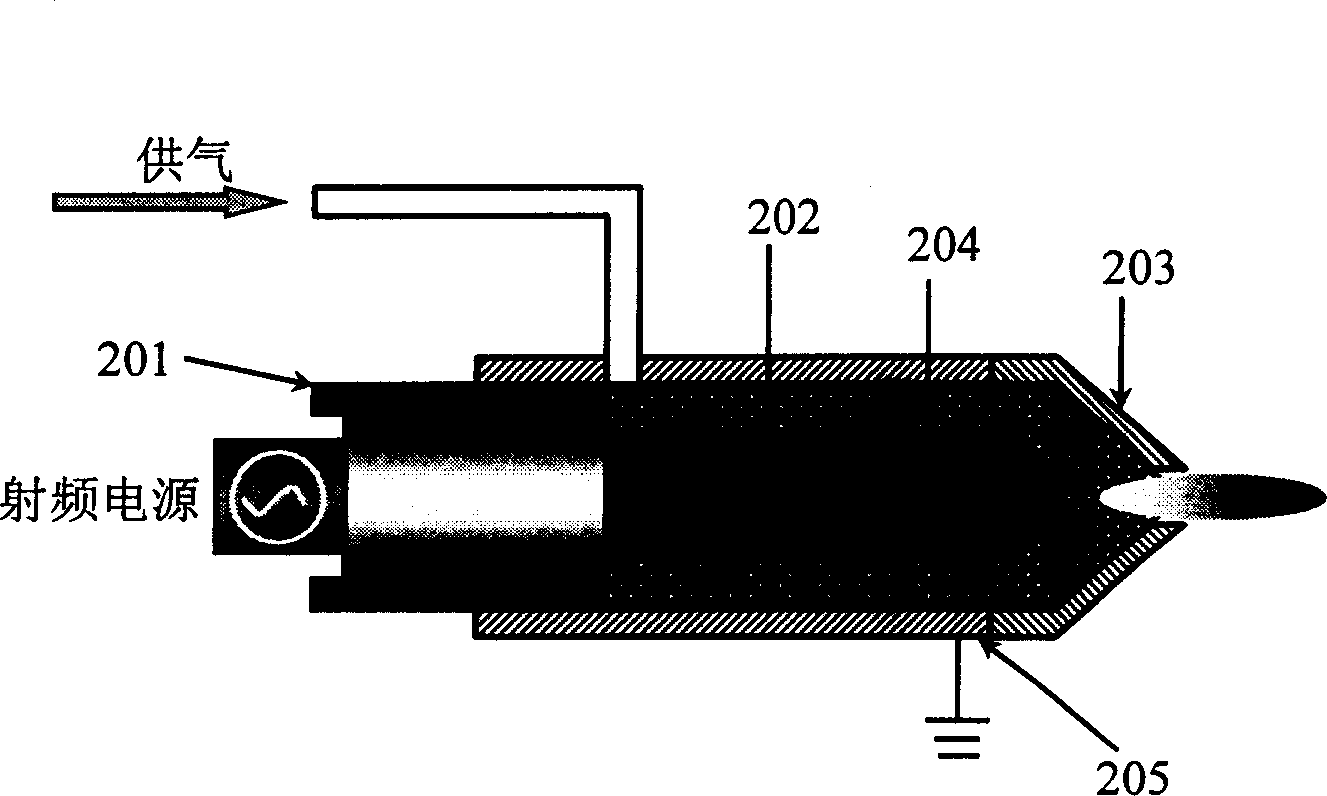

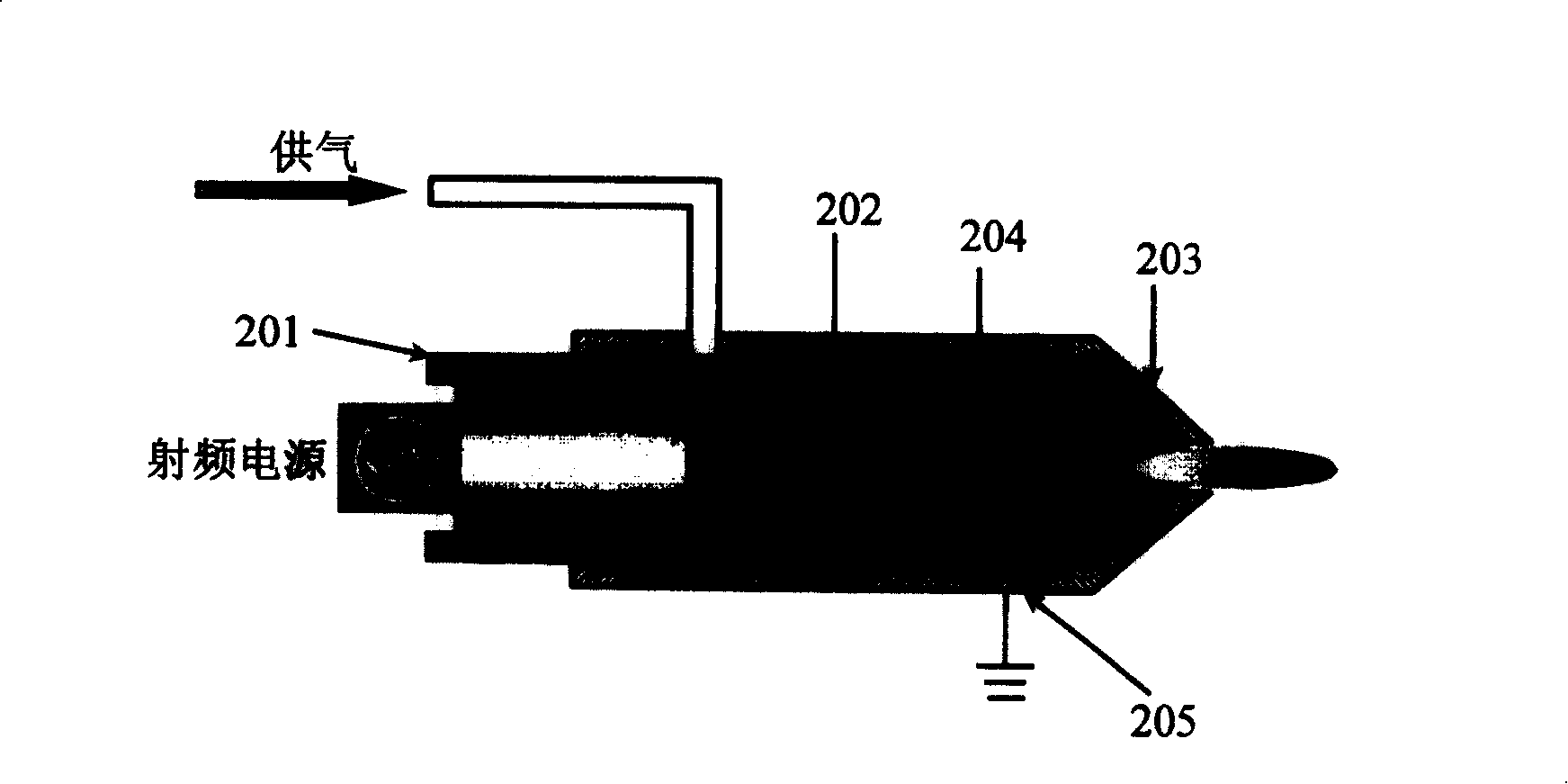

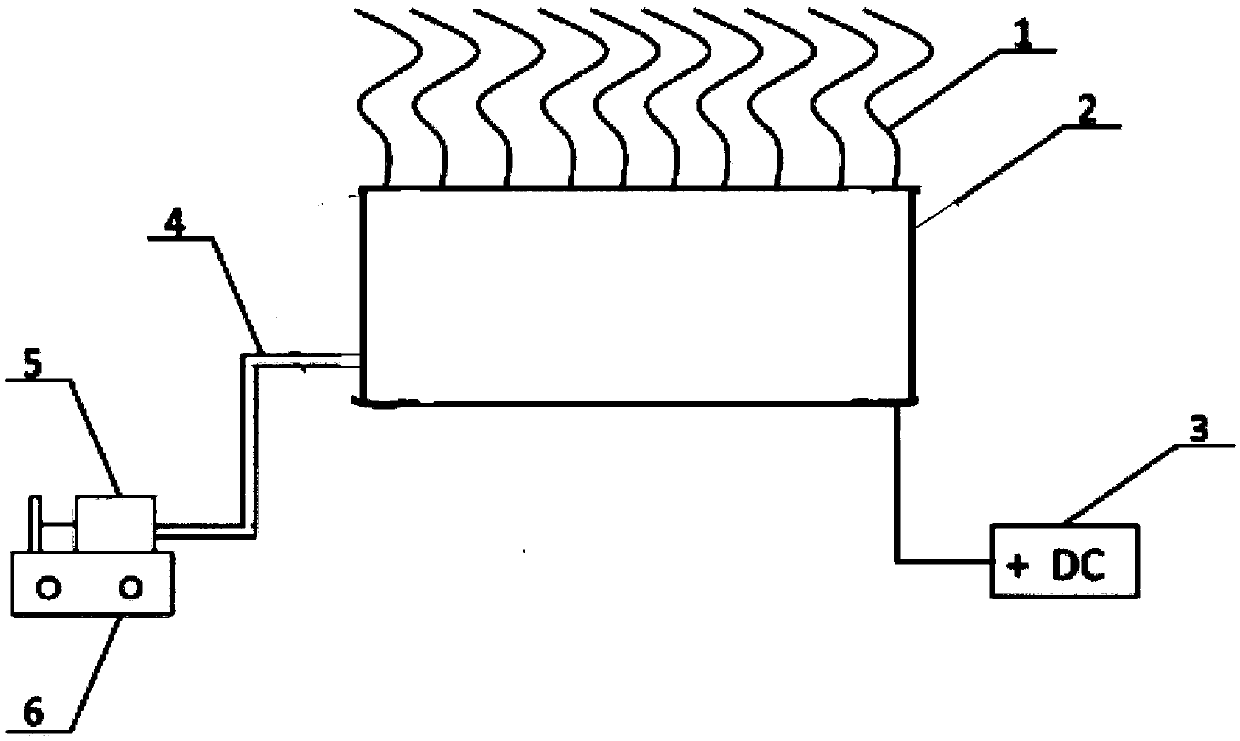

Simple atmosphere pressure suspending electrode cold plasma fluid generator

InactiveCN101252805AImprove jet propertiesJet stabilizationElectric discharge tubesPlasma techniquePlasma jetJet flow

The invention relates to a simple cold plasma jet flow generating device for the barometric suspended electrode, which belongs to the technical field of the plasma discharging reactor. The cold plasma jet flow generating device is characterized in that a main body of the device is a millimeter magnitude quartz tube, a gas inlet opening is arranged at one end connected with a gas supplying source, and a jet flow outlet opening is arranged at the other end; a pair of needle electrodes are embedded into the quartz tube above the jet flow outlet opening, both the electrodes are symmetrical in the radial direction, the needle electrode at one side connected with an alternating current power supply is adopted as a power electrode, and the other electrode at the other side is suspended in the air and adopted as the suspended electrode; through applying voltage, the electrodes discharge to generate plasmas which are sprayed out of the tube to form the jet flow through the action of flowing air. The jet flow generating device has the advantages that the needle electrode structure can reduce the generation of the jet flow and maintain the voltage; the suspended electrode is favorable not only for enhancing the utilization factor of the energy, but also for effectively controlling the discharging intensity and maintaining the stable discharging; the non-pressure plasma jet flow is characterized in low temperature, large length, low produced and maintained voltage, long continuous working time and simple structure.

Owner:DALIAN UNIV OF TECH

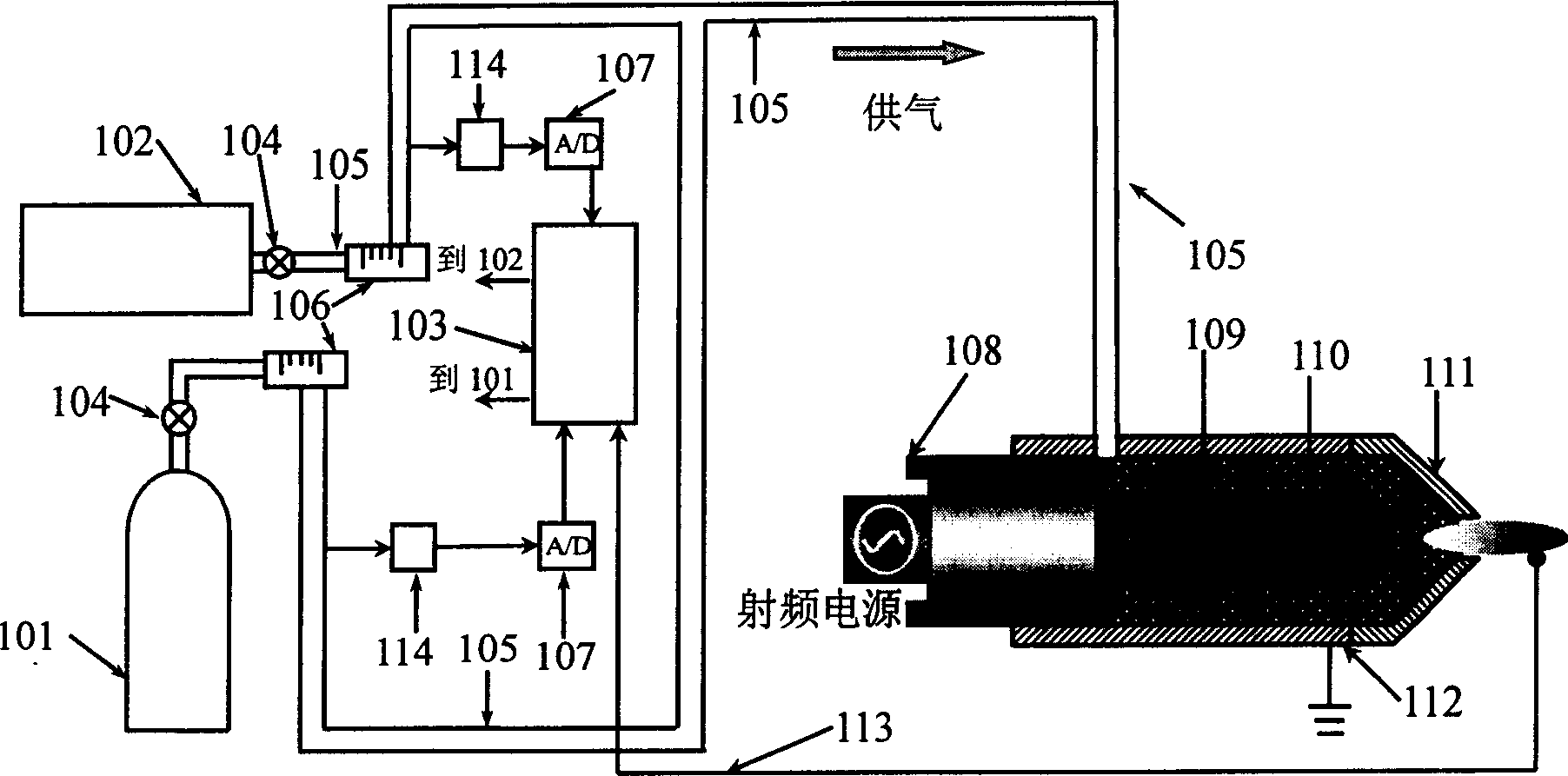

Atmospheric pressure discharge cold plasma generator based on double gas source

The present invention belongs to atmospheric pressure discharge cold plasma generator technology field. It features said generator gas supply system adopting double gas source gas supply system and uncover electrode structure, thereby constituting flat plate type or circle type or elliptic type atmospheric pressure discharge cold plasma generator. Said double gas source gas supply system can realize stabilizing gaseous discharge unable realized in inducing air or other atmospheric pressure, uncover electrode structure capable of avoiding electrode surface dielectric medium damage in current media blocking discharge.

Owner:TSINGHUA UNIV

Atmospheric pressure discharge cold plasma generator based on double gas source

The present invention belongs to atmospheric pressure discharge cold plasma generator technology field. It features said generator gas supply system adopting double gas source gas supply system and uncover electrode structure, thereby constituting flat plate type or circle type or elliptic type atmospheric pressure discharge cold plasma generator. Said double gas source gas supply system can realize stabilizing gaseous discharge unable realized in inducing air or other atmospheric pressure, uncover electrode structure capable of avoiding electrode surface dielectric medium damage in current media blocking discharge.

Owner:TSINGHUA UNIV

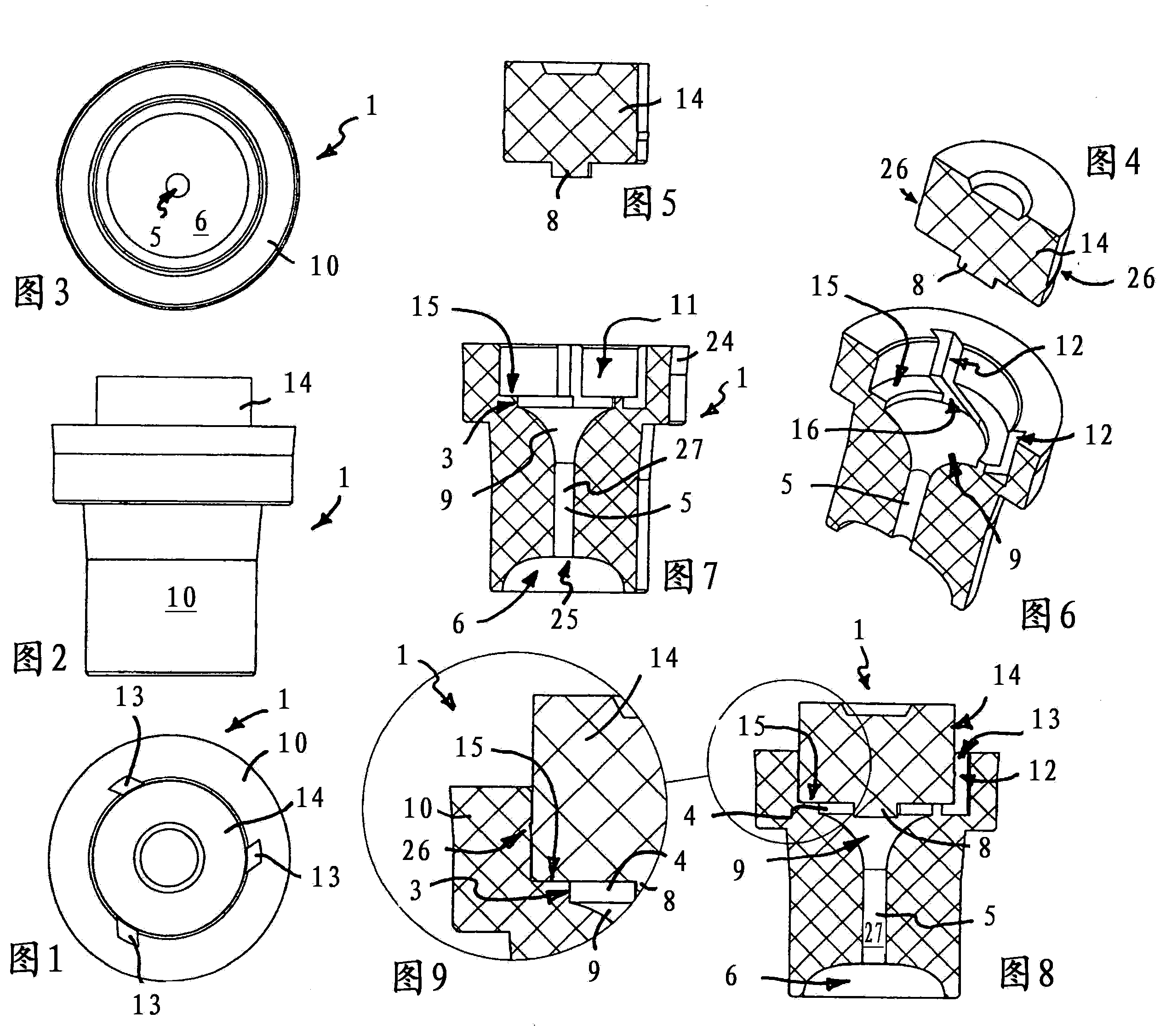

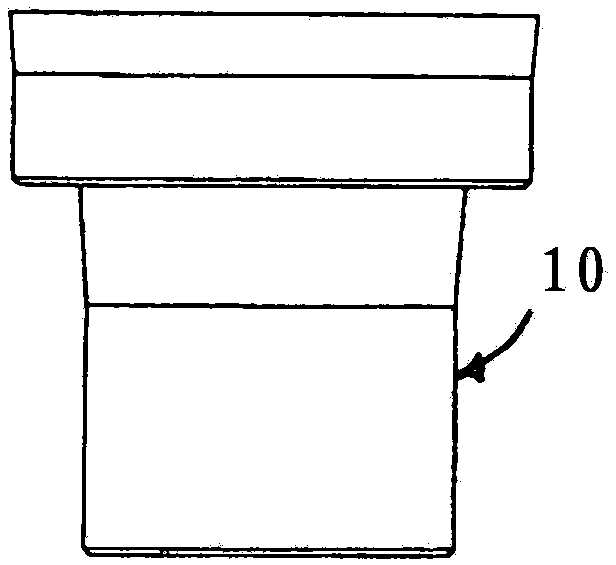

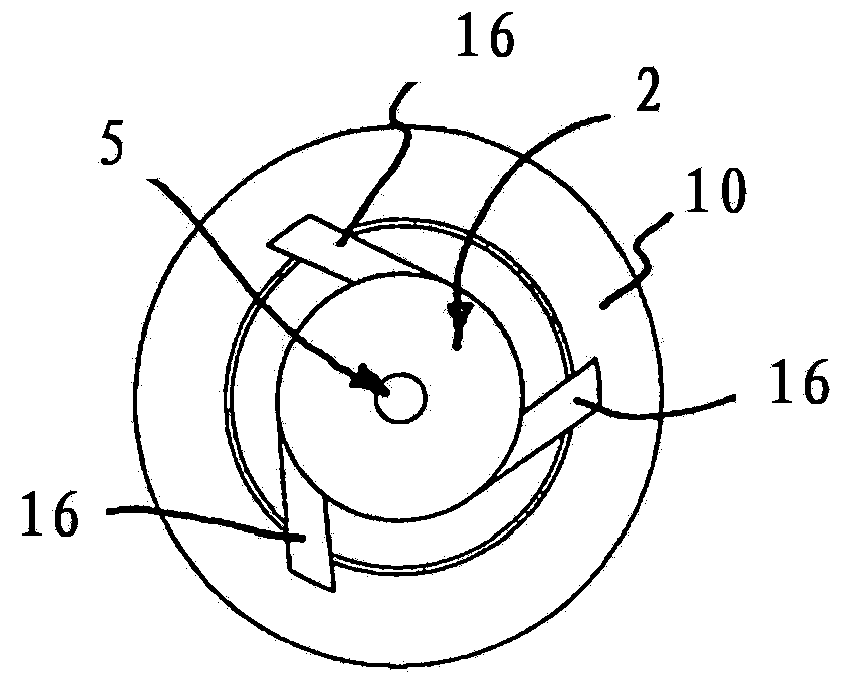

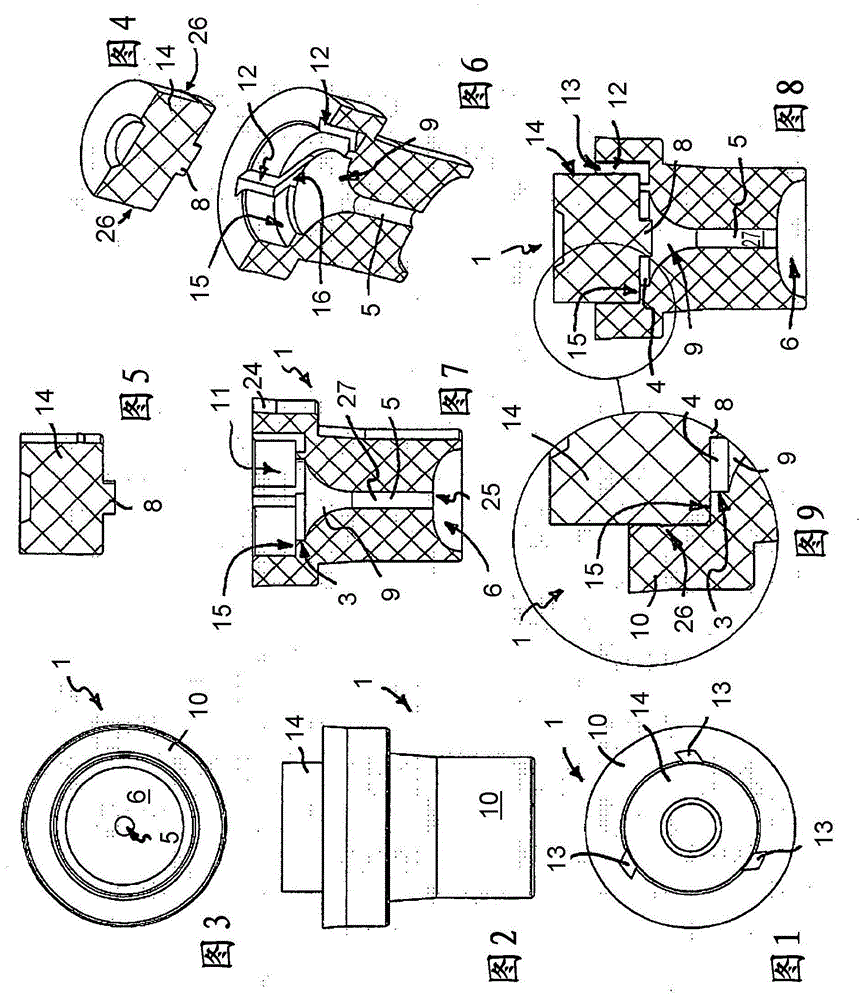

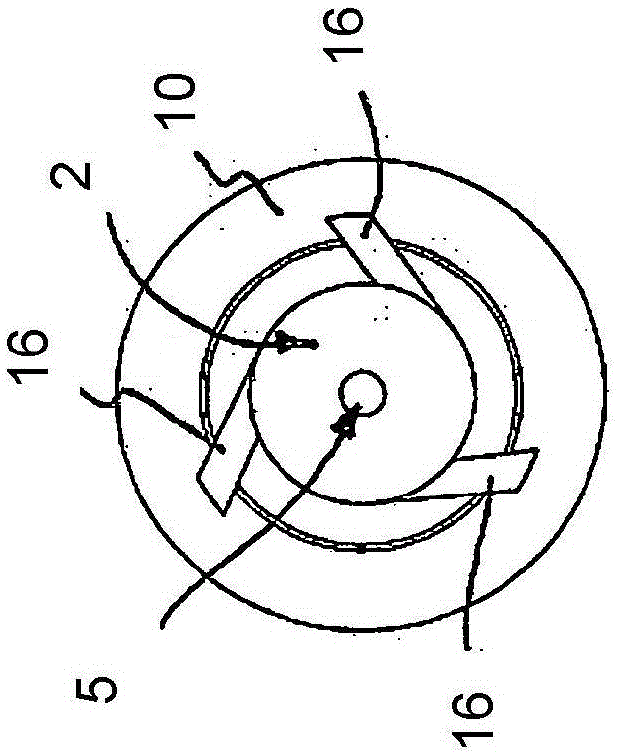

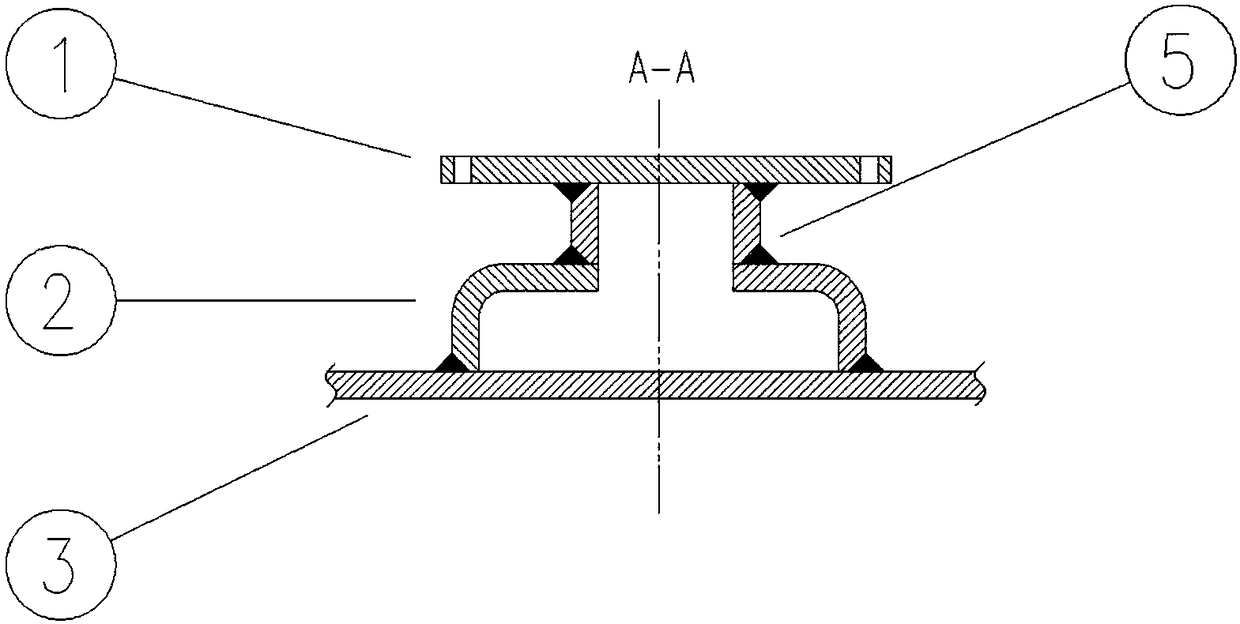

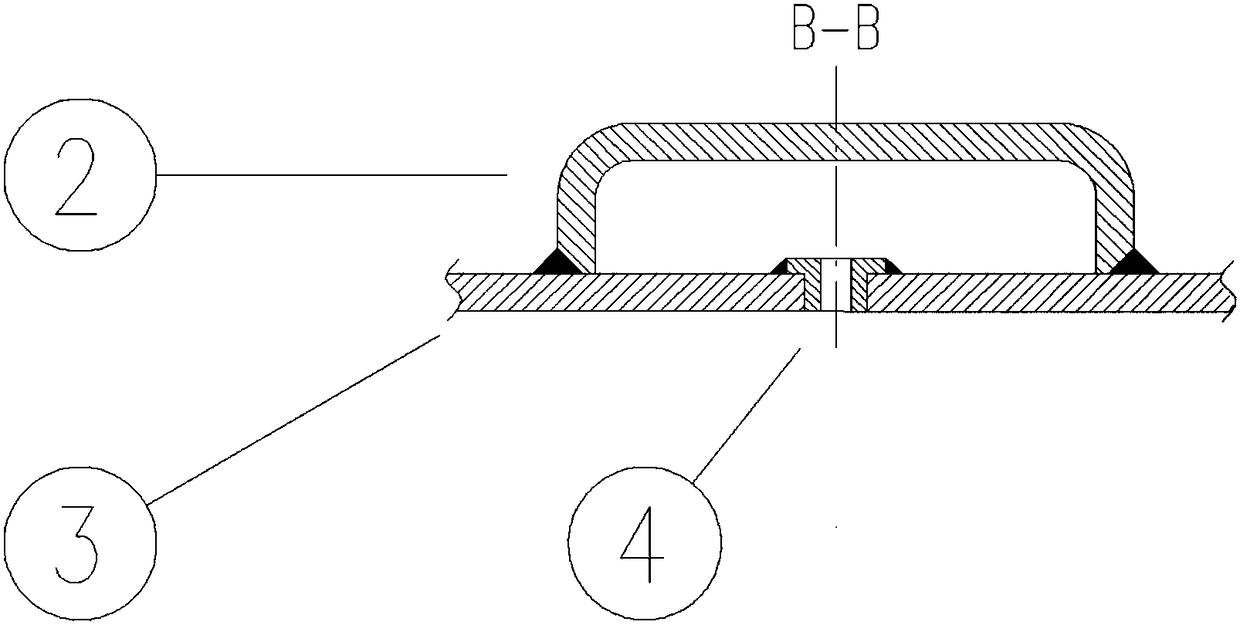

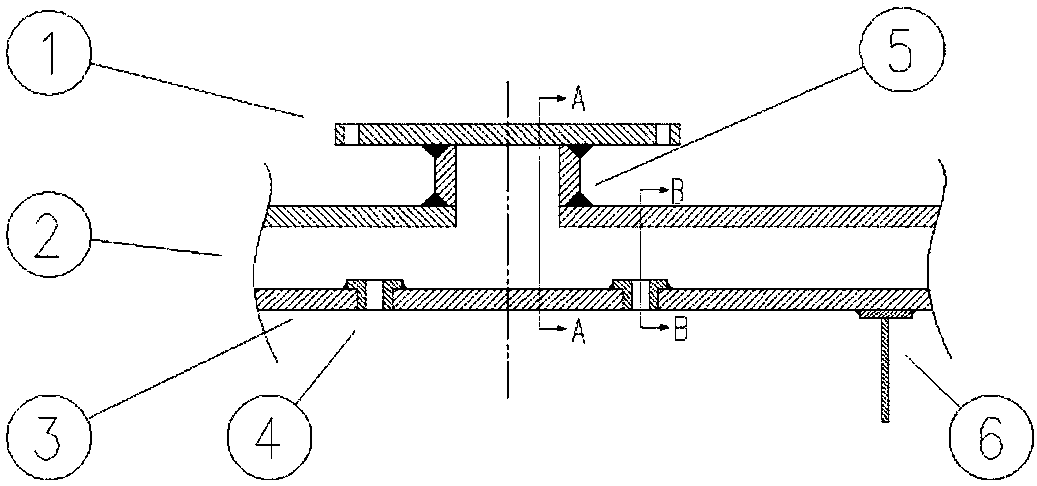

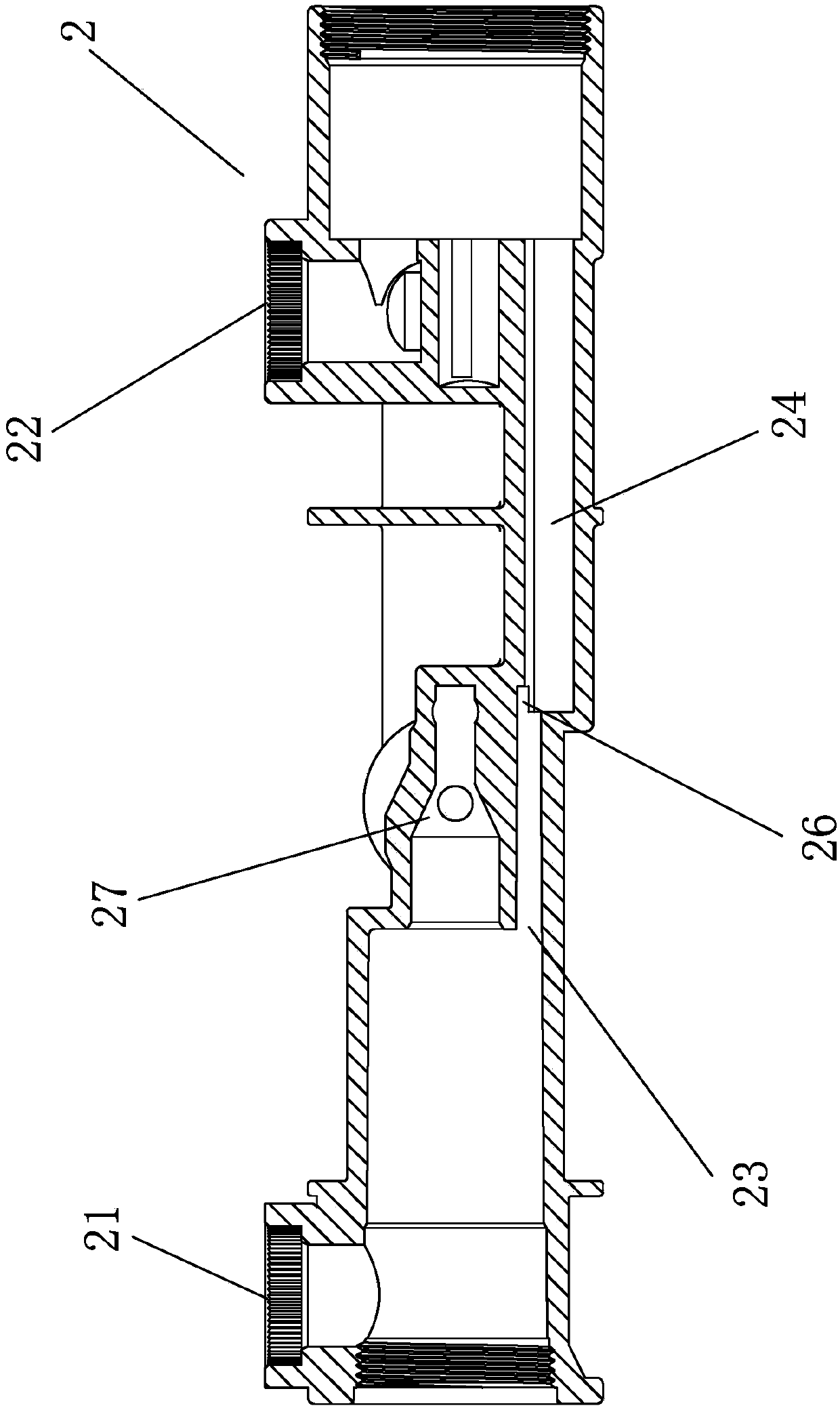

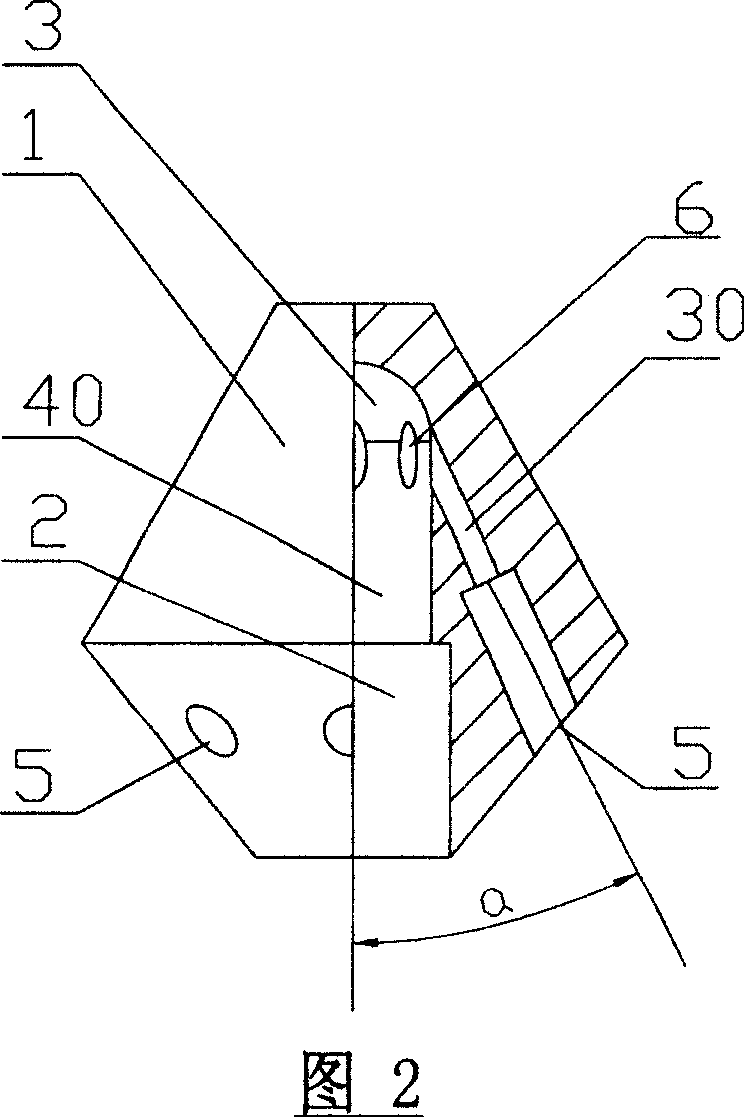

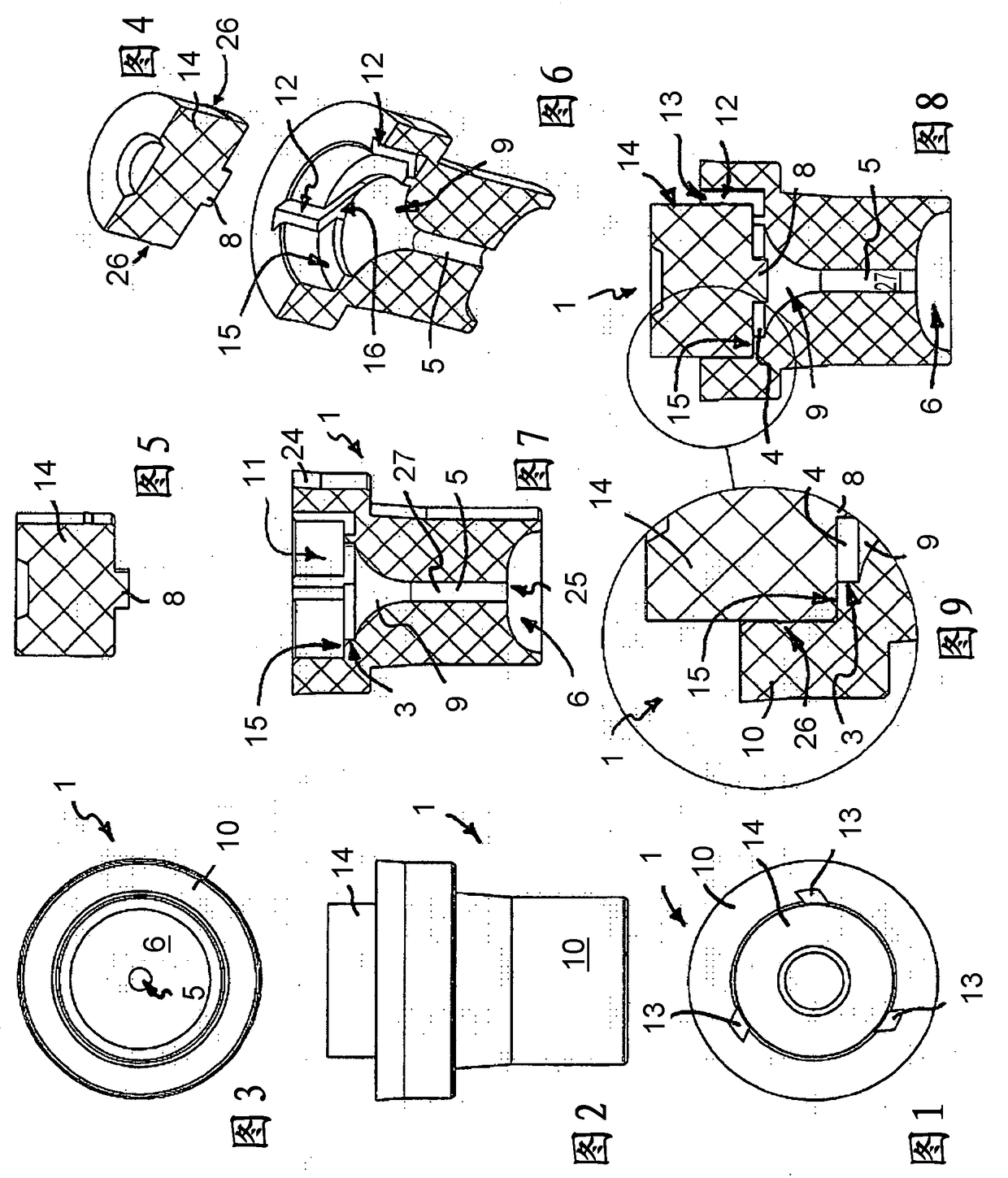

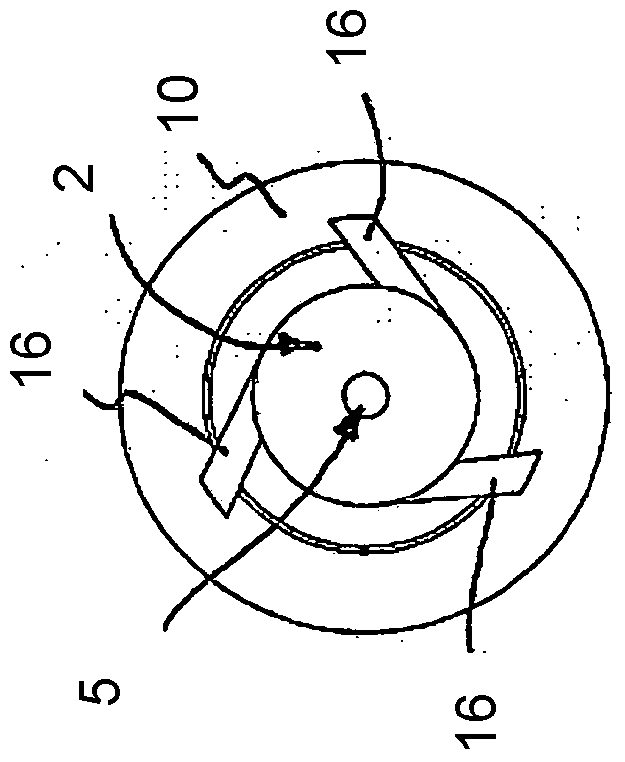

Atomizing nozzle used for sanitary water outlet unit and sanitary faucet with water outlet unit

ActiveCN104043544AUniform jetImproved jet mapValve arrangementsDomestic plumbingWater jetAtomizer nozzle

The invention relates to an atomizing nozzle (1) used for a sanitary water outlet unit, and the atomizing nozzle (1) is used for atomizing water under pressure. The atomizing nozzle (1) provided by the invention is characterized in that the atomizing nozzle (1) is provided with a swirl chamber (2), at least one supplying channel (4) which is parallel to the longitudinal axis of the nozzle and enters the swirl chamber (2) in an approximately-tangent manner is introduced into the swirl chamber, and the swirl chamber (2) becomes thinner along the outflow direction and towards a nozzle channel (5). By employing the atomizing nozzle (1), a uniform water jet can be generated in a jet figure, although the water jet is small in volume, the the water jet makes people think that the water jet is big in volume.

Owner:NEOPERL

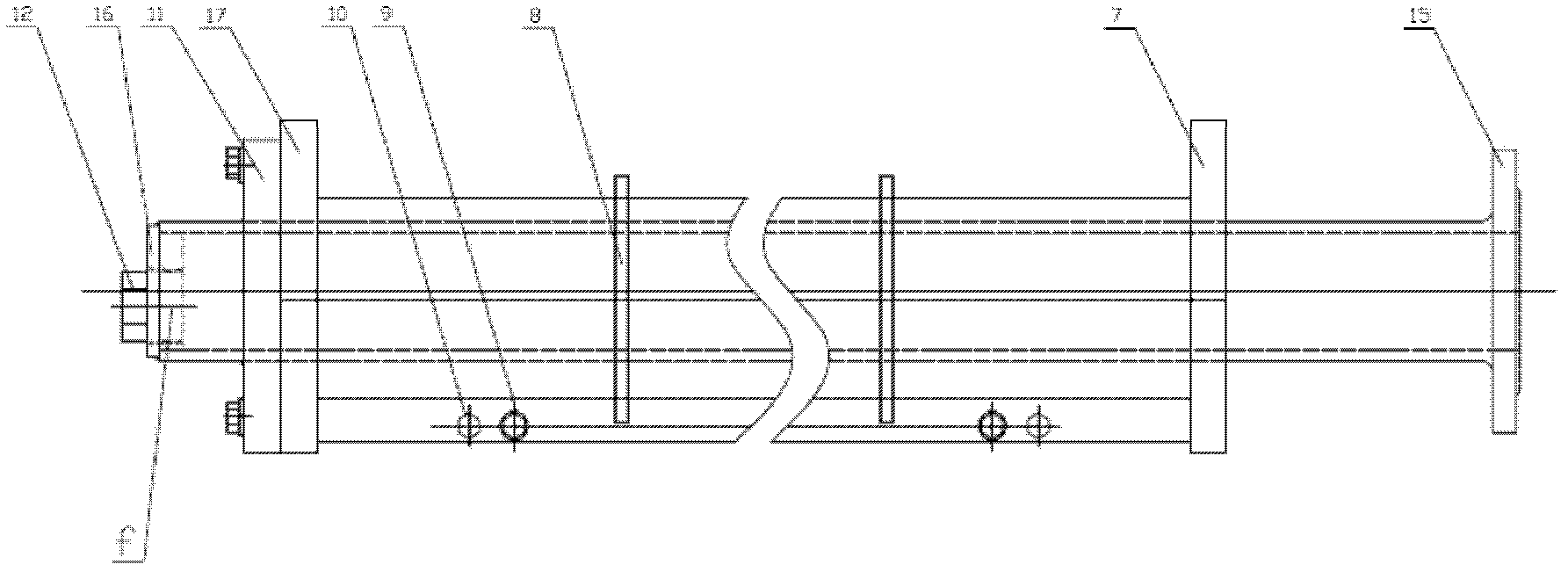

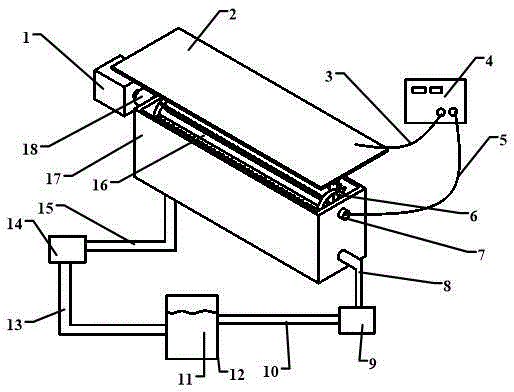

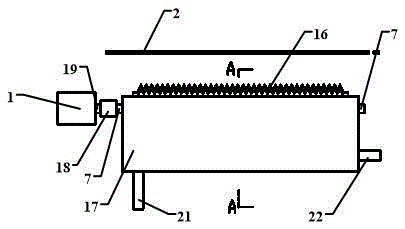

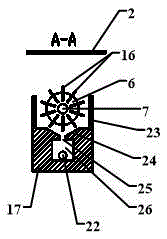

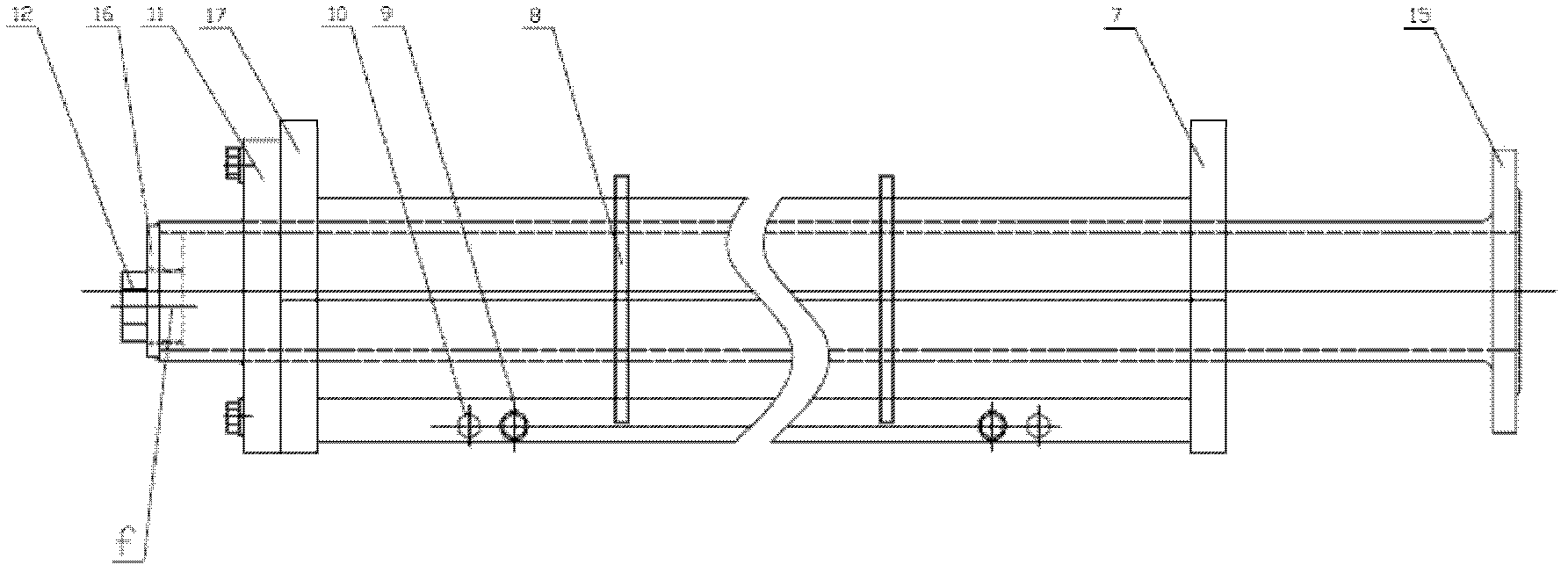

Cooling device generating flat jet and manufacturing method thereof

ActiveCN102319748AEasy to installAchieve uniformityWork treatment devicesMetal rolling arrangementsJet flowSewage outfall

The invention relates to a cooling device generating a flat jet and a manufacturing method thereof, the cooling device is characterized in that an inner pipe and an outer pipe of the cooling device are eccentrically fixed through a positioning strip for forming a cavity between the inner pipe and the outer pipe, a slit is formed in the axial direction, the width of the slit can be regulated through a tightening bolt and a compression bolt, a flange is welded at the inlet end of the inner pipe for connecting with a cooling medium pipeline, a steel plate is welded at the outlet end for sealing,and the cooling device is further provided with an inner cavity pollution discharge port. An end plate is welded at the inlet end of the cavity between the inner pipe and the outer pipe and used for sealing, the outlet end of the cavity and the flange are sealed through the end plate, and pollution can be discharged out of the cavity between the inner pipe and the outer pipe. Two rows of tidy flow through holes are formed on the inner pipe, and a cooling medium enters into the inner pipe via the flange at the inlet end, and then flows into the cavity between the inner pipe and the outer pipe via the flow through holes and further forms flat jet via the slit for cooling the steel plate. The eccentric arrangement of the inner pipe and the outer pipe of the device can form multiple damping effects for the cooling medium, the slit enables the cooling medium to form the uniform flat jet in the width direction of a rolling line, and multiple reinforcing ribs are welded outside the outer pipe in the radial direction for preventing deformation.

Owner:NORTHEASTERN UNIV

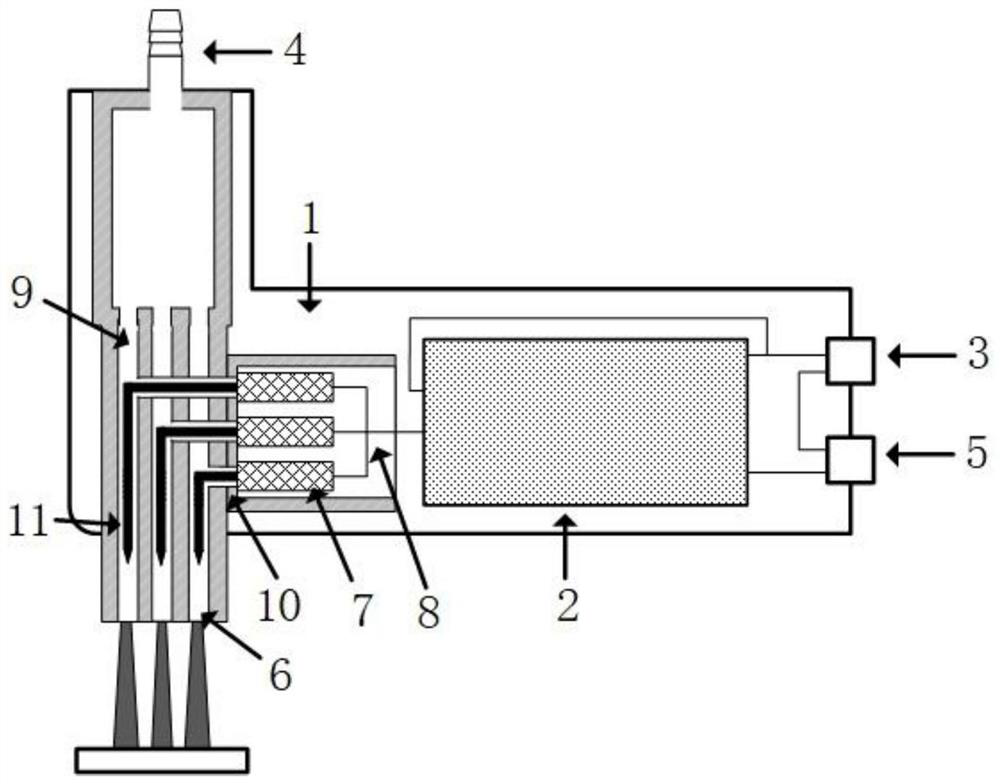

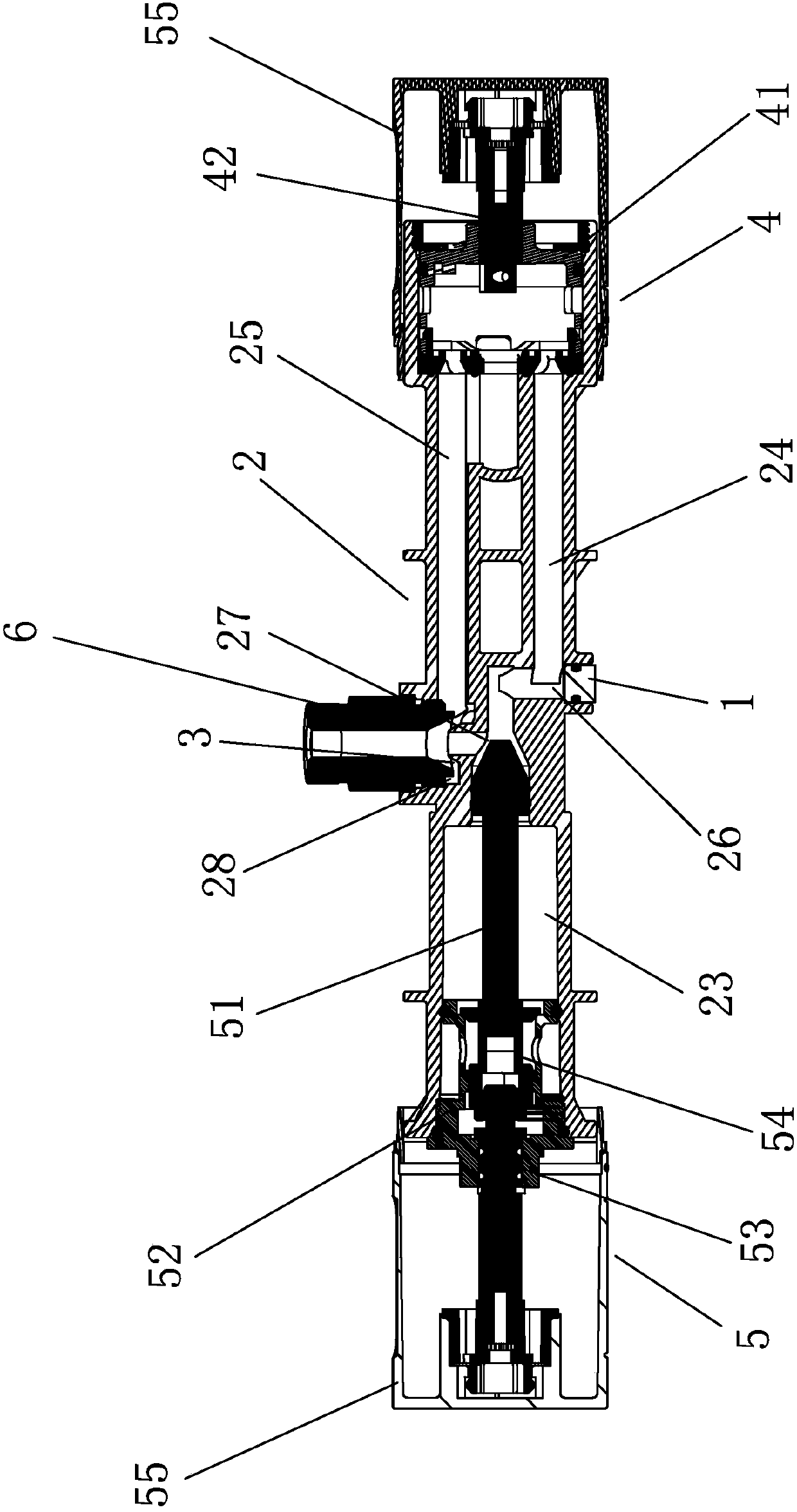

Portable large-area plasma jet device and system

The invention discloses a portable large-area plasma jet device and system, and belongs to the technical field of plasma generating devices, the portable large-area plasma jet device comprises a shell, a jet nozzle array, a pin electrode array, a resistor array, a high-voltage node and a boosting module; a fixing cavity of the boosting module and a main pipeline are arranged in the shell; one end of the main pipeline is provided with a gas inlet interface, and the other end is provided with a plurality of independent gas pipelines; each jet flow nozzle in the jet flow nozzle array is communicated with a corresponding gas pipeline, and a plurality of needle electrodes in the needle electrode array are positioned in a plurality of corresponding gas pipelines; a plurality of pin electrodes of the pin electrode array are electrically connected with a plurality of resistors corresponding to the resistor array respectively, and the plurality of resistors are electrically connected with the high-voltage node; and the high-voltage node is electrically connected with the high-voltage side of the boosting module. According to the invention, a distributed resistor-needle series array electrode structure is used, and an independent needle electrode-jet nozzle is communicated with a gas pipeline, so the electric field distribution is optimized, and the uniformity of large-area jet discharge is improved.

Owner:武汉海思普莱生命科技有限公司

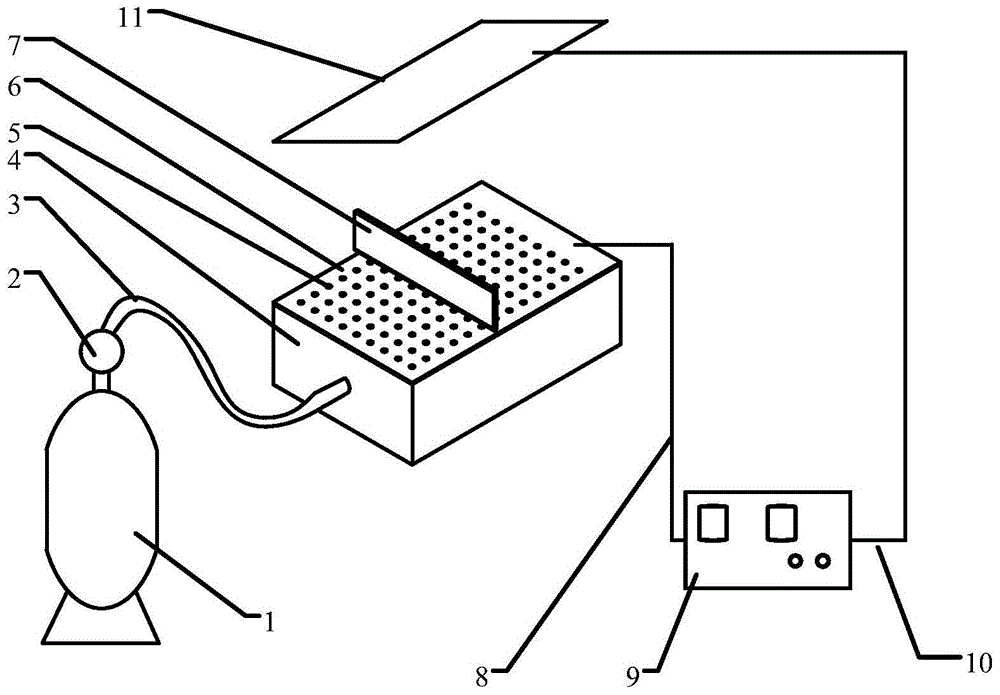

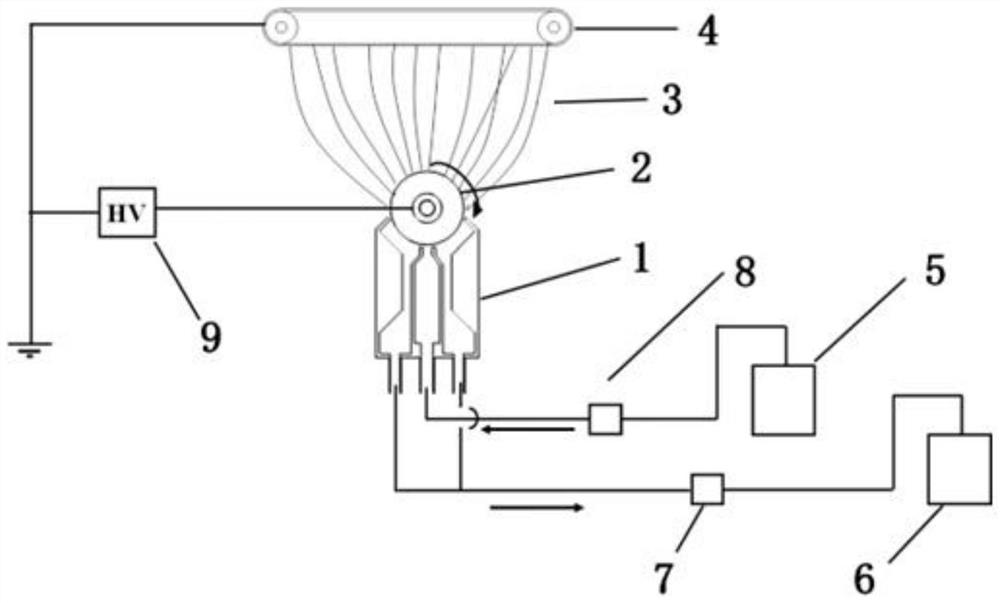

Electrospinning device, method and system for manufacturing nanofibers in batch

The invention relates an electrospinning device, method and system for manufacturing nanofibers in batch. The electrospinning device comprises an air chamber, an air supply unit, a conductive collector and a power supply, wherein one surface of the air chamber is provided with a plane electrode which is provided with multiple micro pores, the air supply unit supplies air for the air chamber, the conductive collector is arranged opposite to the plane electrode and located outside the air chamber, and the two poles of the power supply are connected with the plane electrode and the conductive collector respectively. According to the electrospinning device, method and system for manufacturing the nanofibers in batch, the plane electrode with the micro pores serves as an electrode on the air chamber; by means of the distribution of the micro pores, jet flow of spinning can be more even; in the spinning process, airflow in the air chamber jets from the micro pores, spinning can be induced more easily, further stretch is conducted on the jet flow under the airflow action before deposition is conducted, and fibrous deposition in the conductive collector is more even. The electrospinning device, method and system for manufacturing the nanofibers in batch can be applied to electropinning.

Owner:DONOGGUAN AIR GUARD MFG CO LTD

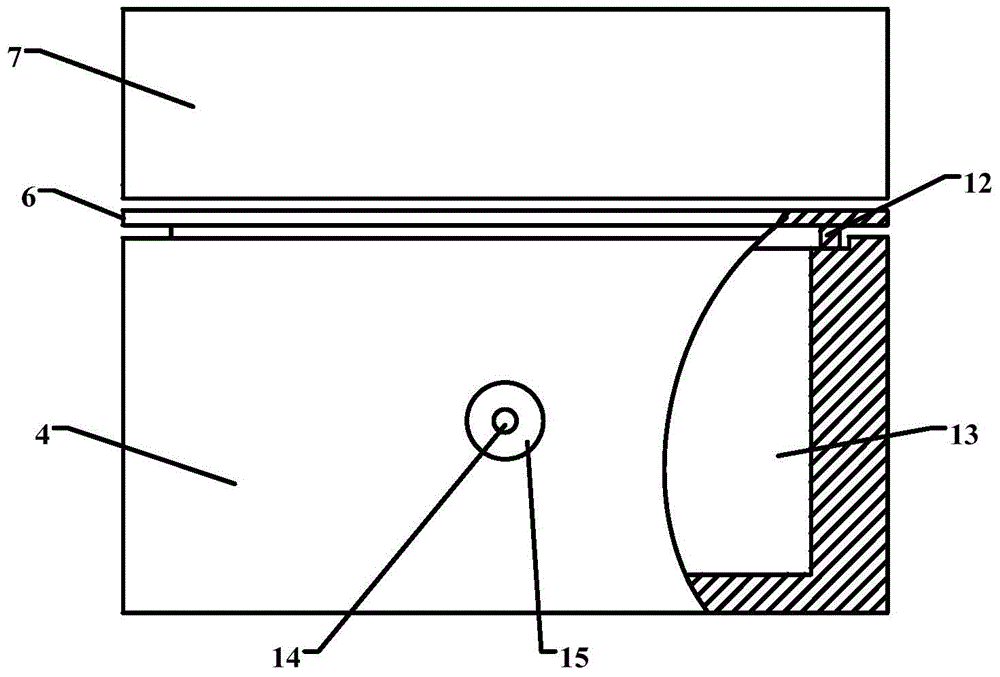

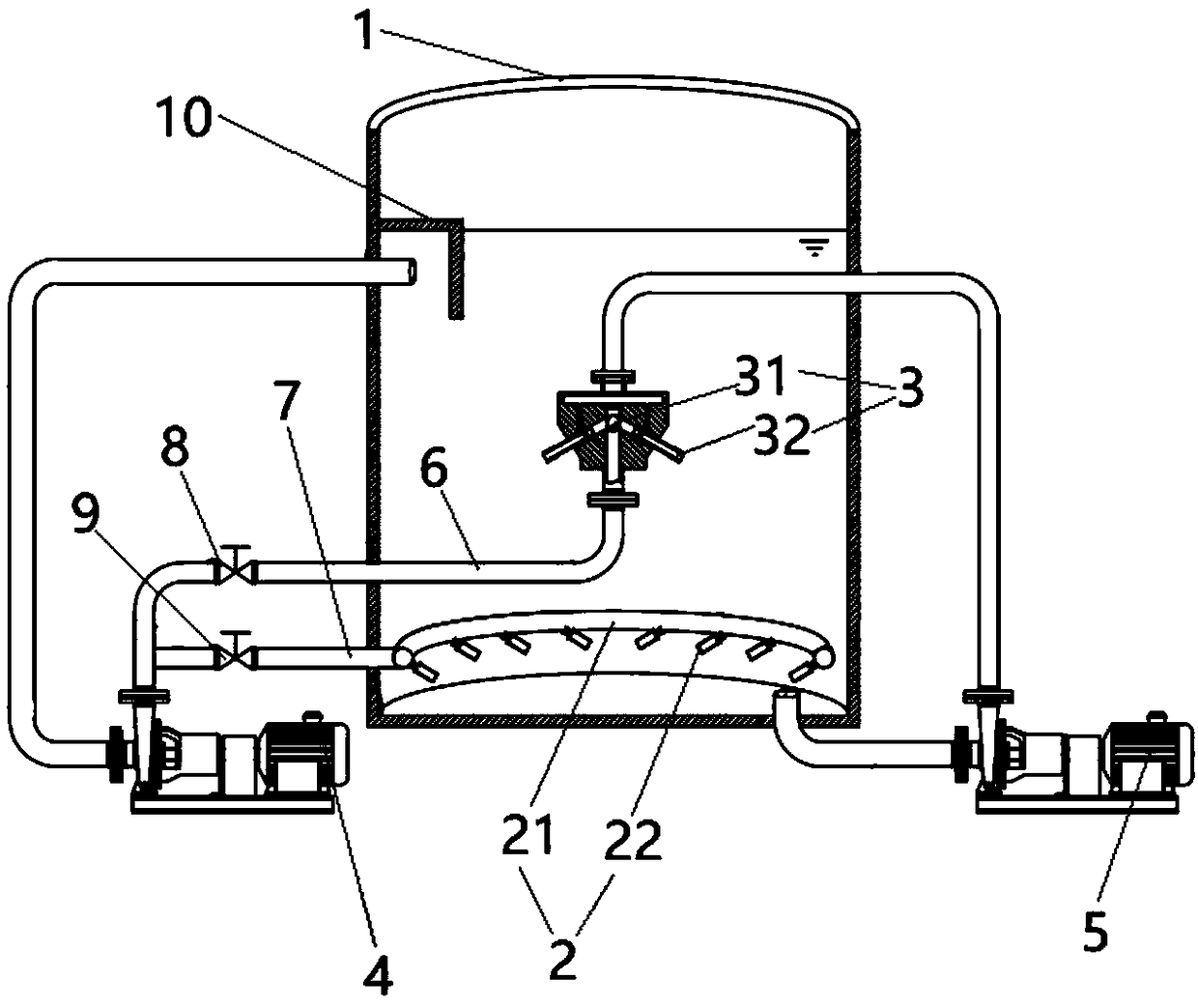

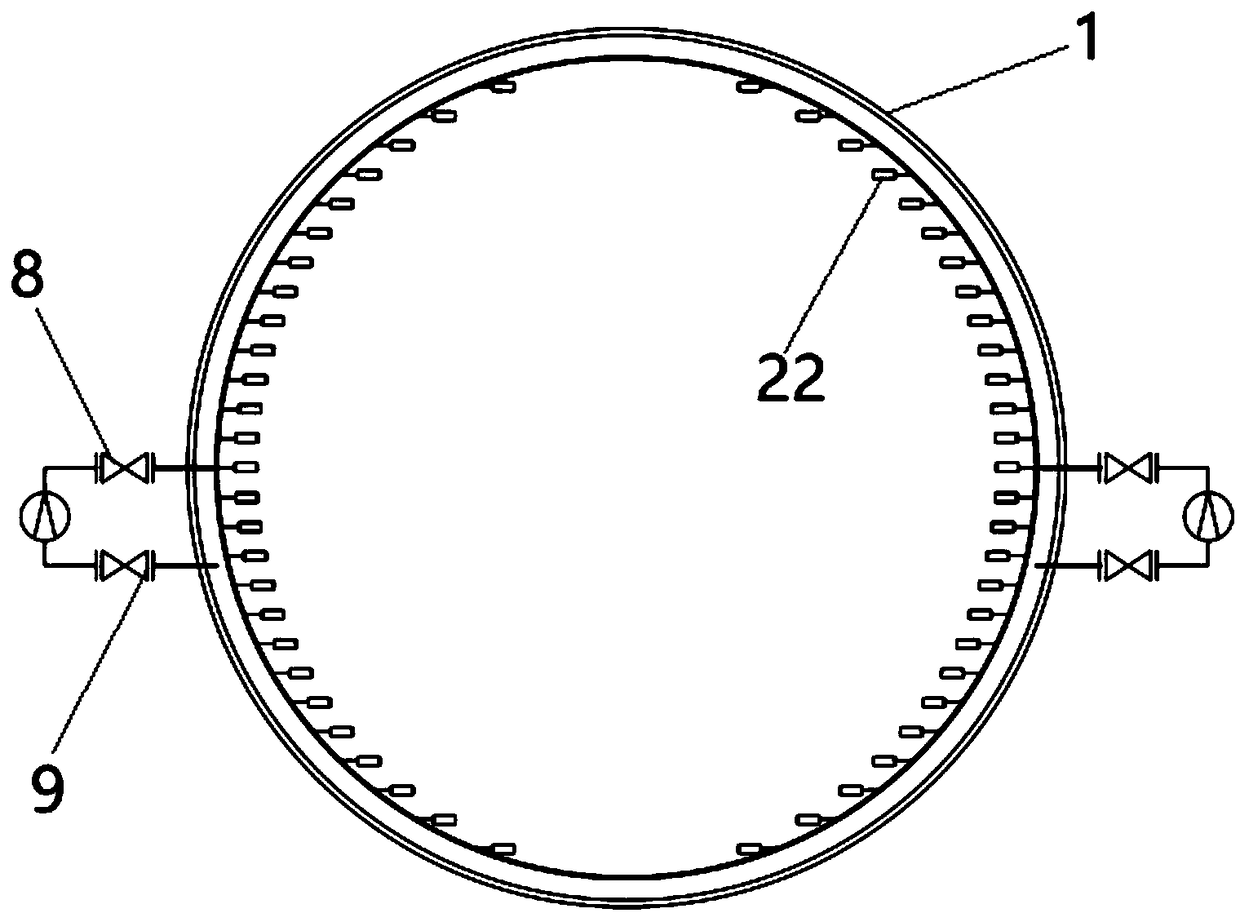

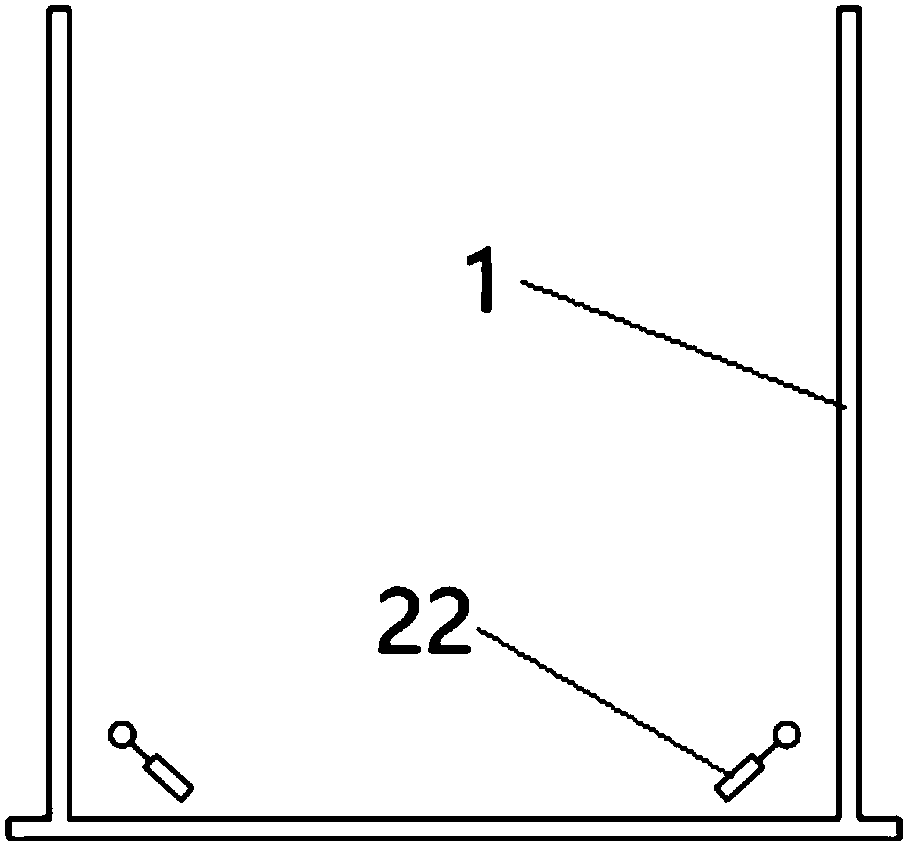

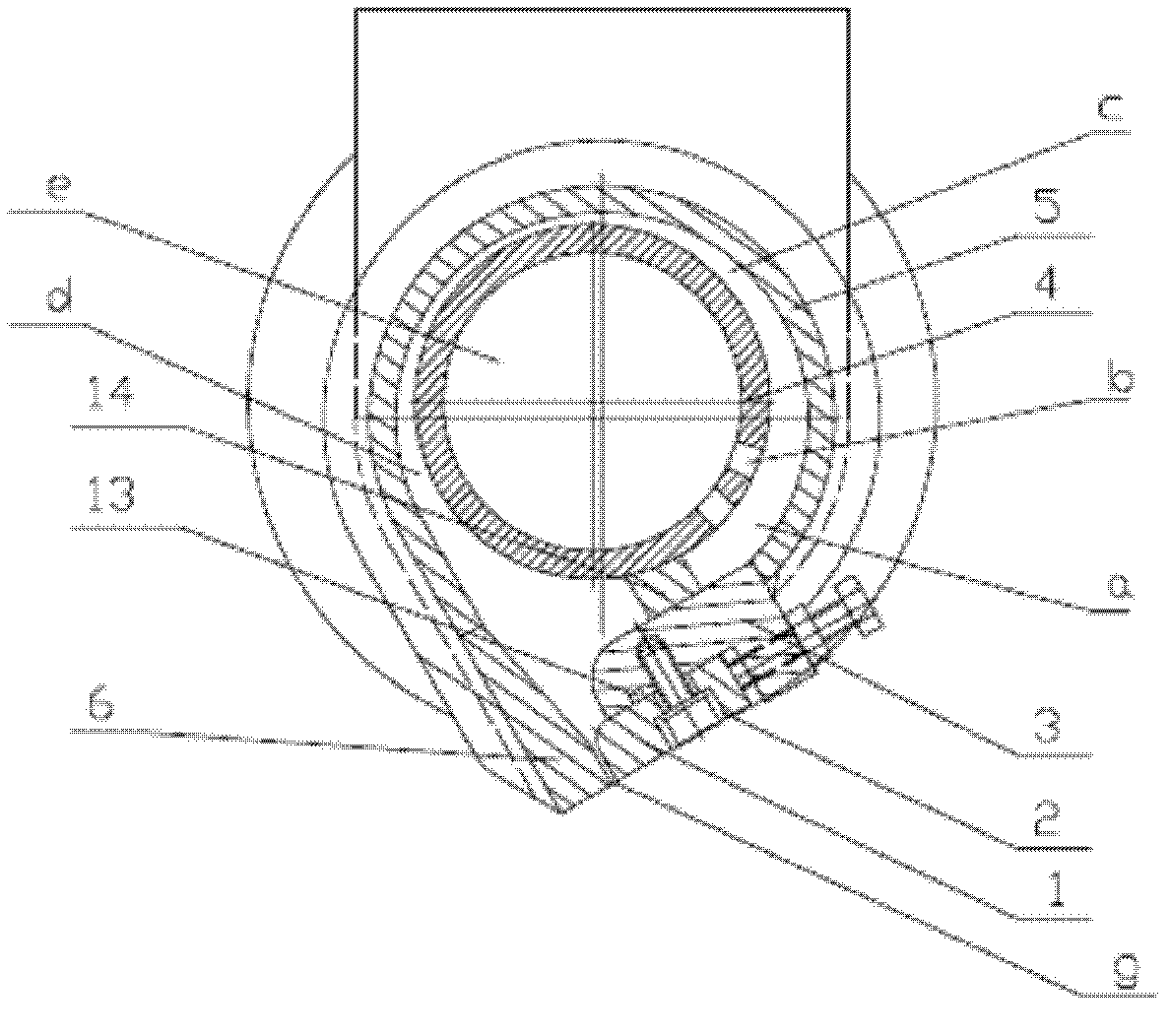

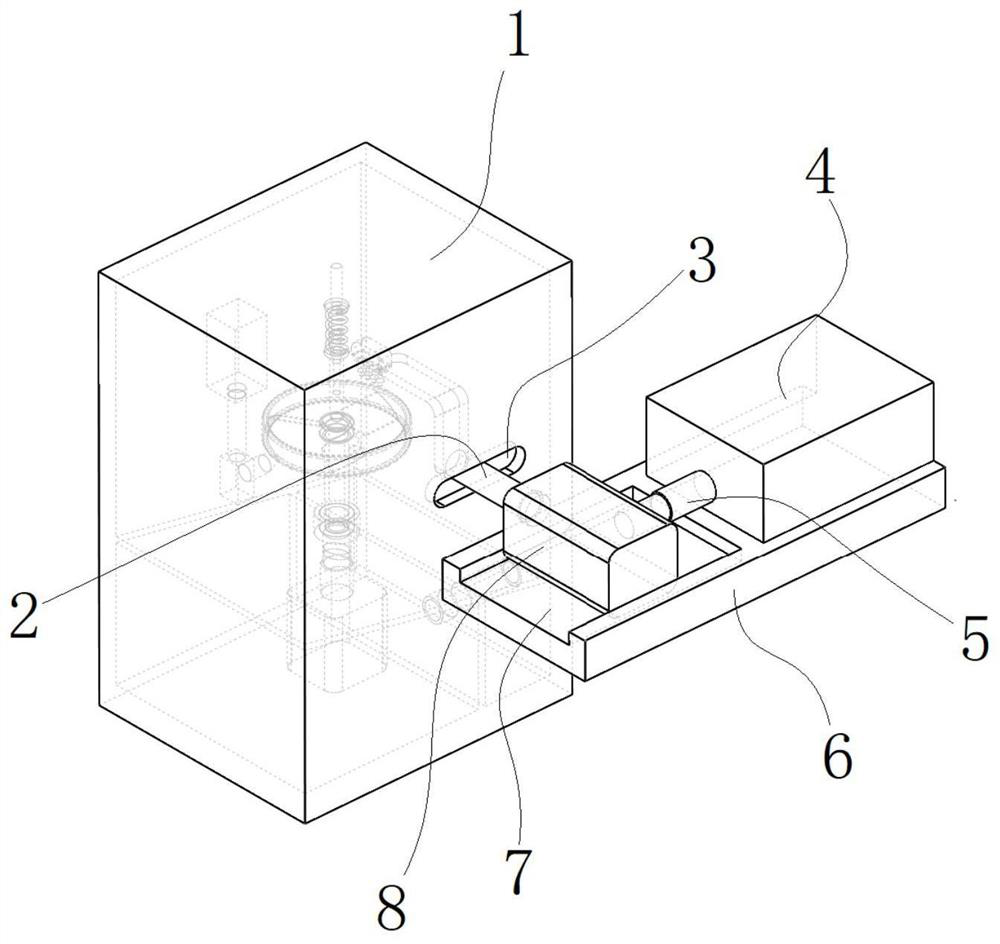

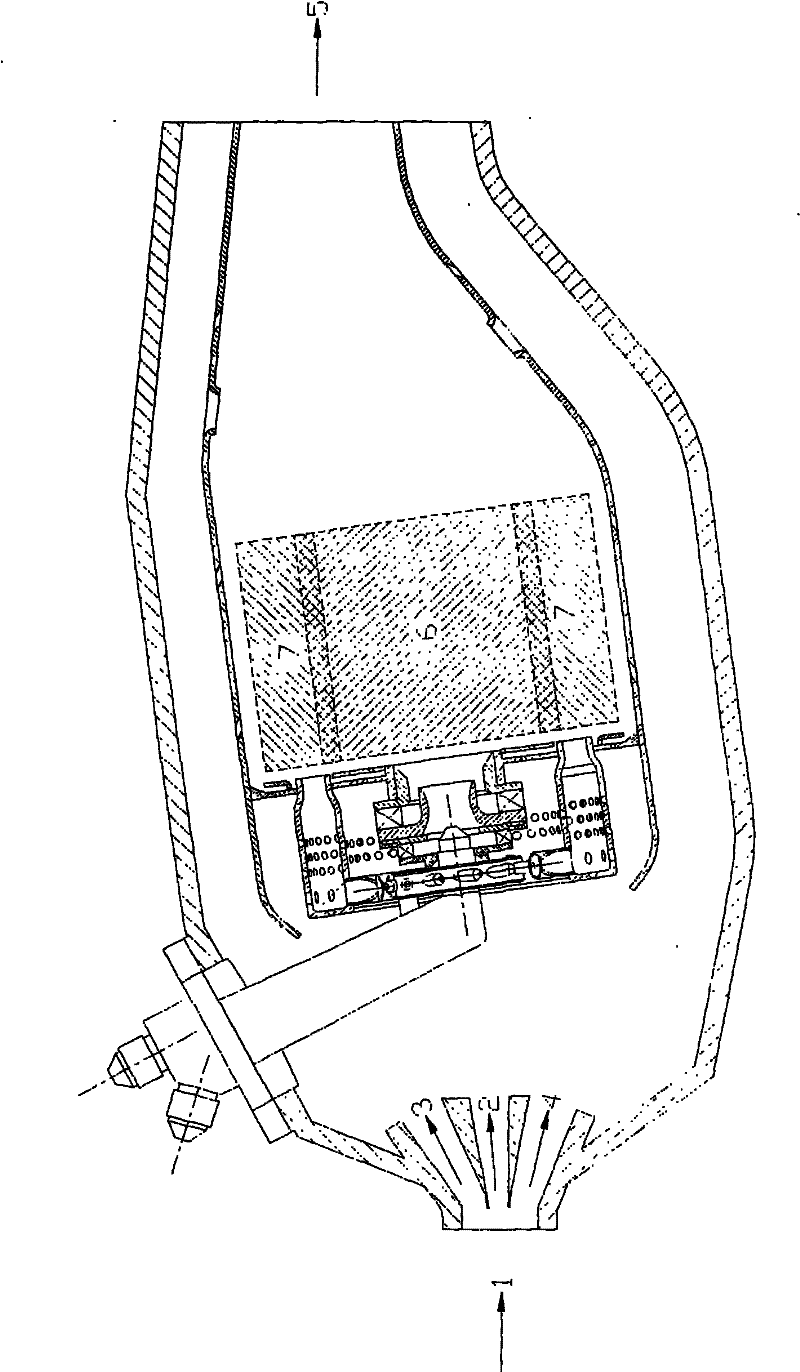

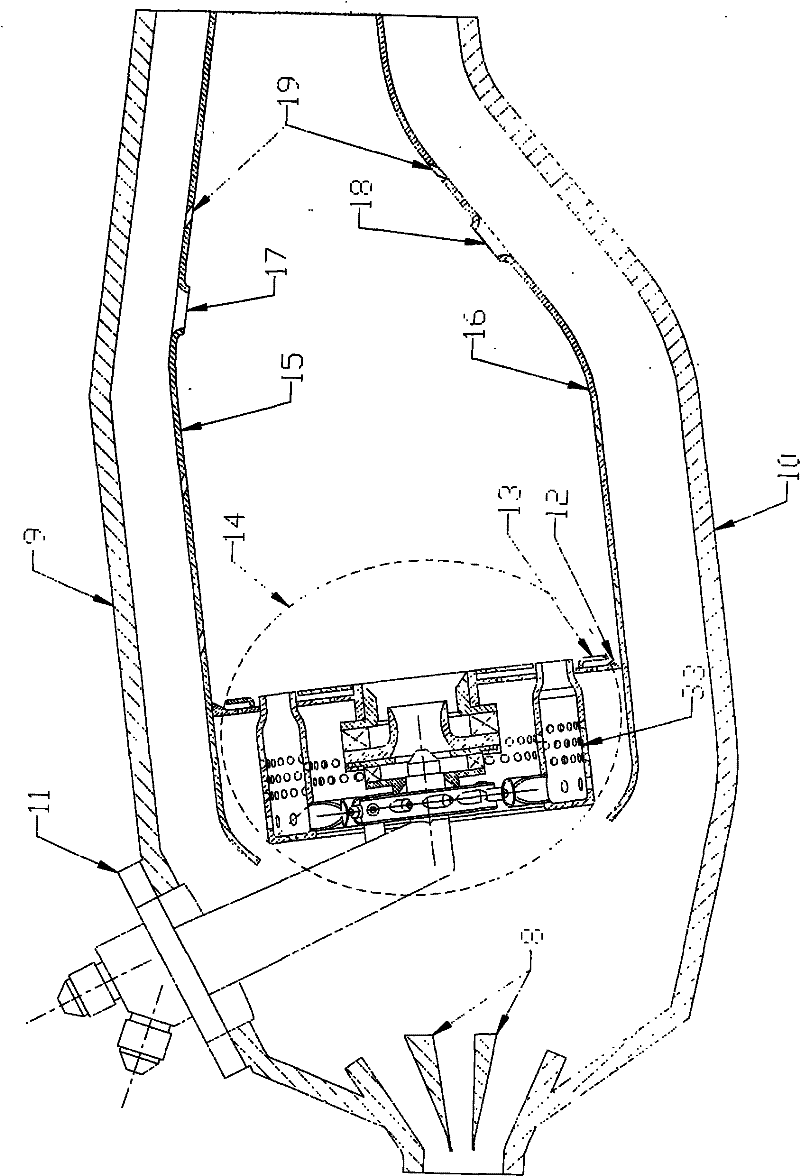

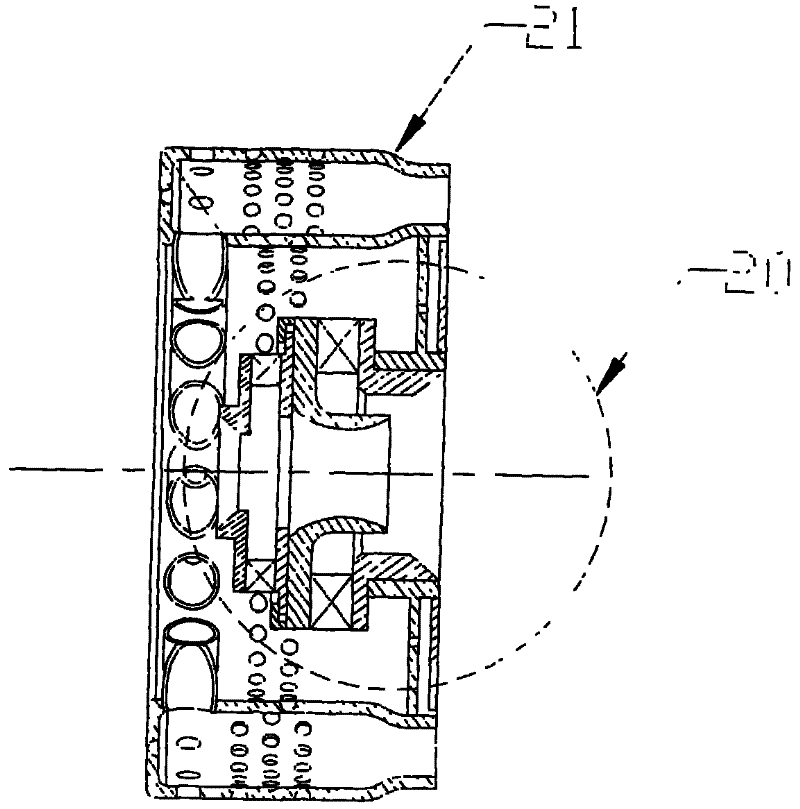

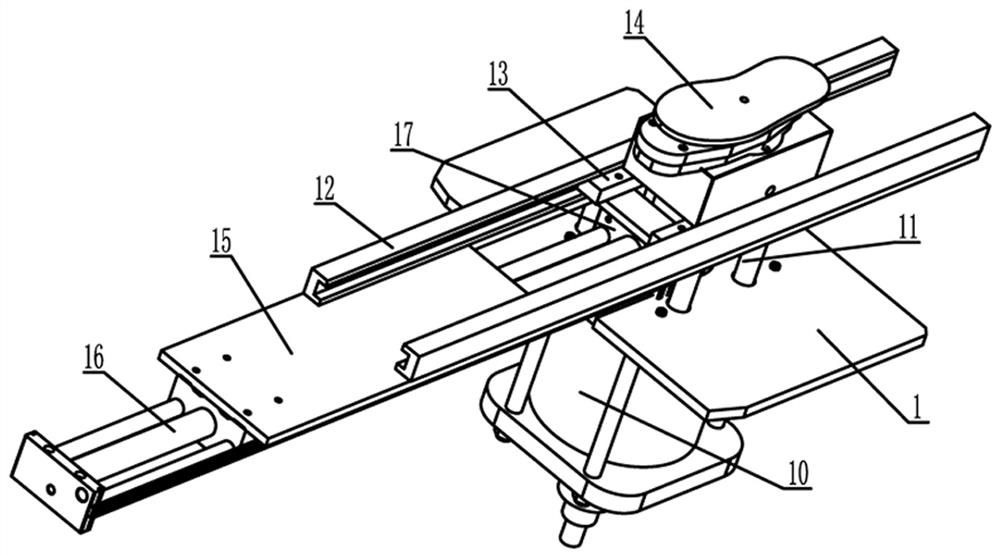

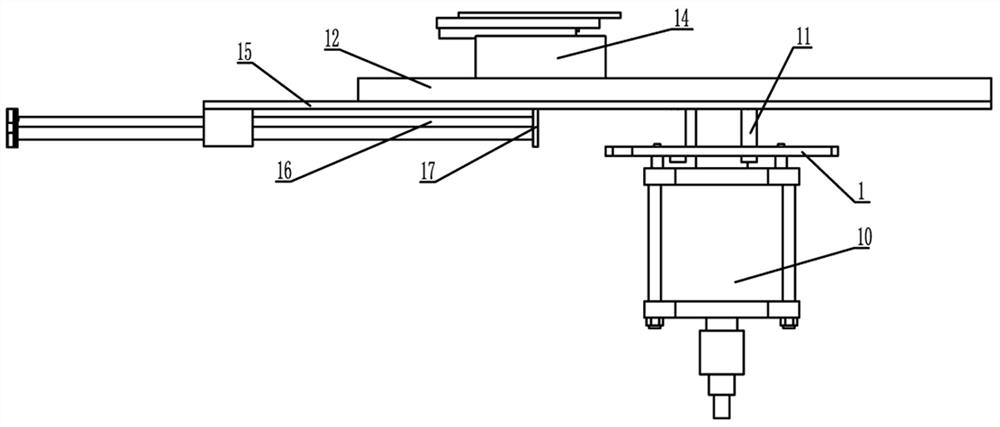

Combined type stirring system

PendingCN108854822APromotes circular mixed movementsUniform jetFlow mixersTransportation and packagingEngineeringCirculating pump

The invention discloses a combined type stirring system. The combined type stirring system comprises a stirring tank, a disc type jet system, a central jet system, a first circulating pump and a second circulating pump. According to the stirring system, the first circulating pump and the second circulating pump are served as a power source, power is provided for stirring of the stirring tank, so that the circulating mixing motion among fluid in the stirring tank is promoted, meanwhile, the disc type jet system is combined with the central jet system, the use is convenient, and the mixing effect is good; in addition, the composite structure realizes rapid mixing among the multiple fluid, and the working efficiency is high; no dead angle exists in the whole stirring process, the energy consumption is reduced, and the homogenization degree is high; and the mechanical faults are few, the service life is long, the maintenance is avoided in the later period, the cost is reduced, and the application range is wide.

Owner:LIAOYANG BOSHI FLUID EQUIP

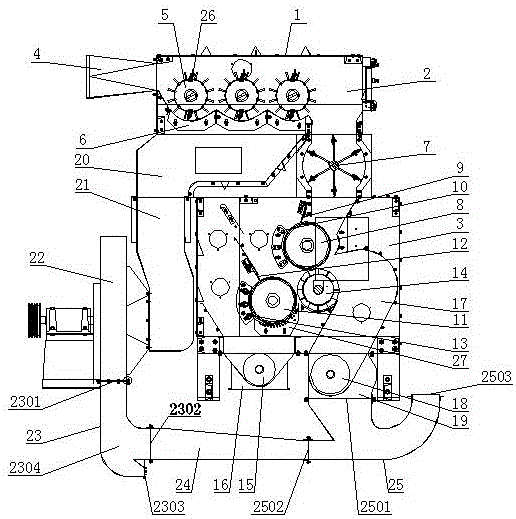

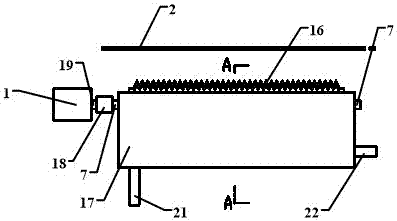

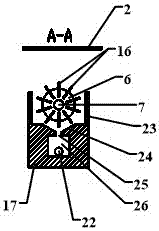

Scutcher

ActiveCN105133094AGood cleaning effectImprove cleaning effectFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by toothed membersAirlockBellows

The invention relates to a scutcher, wherein a group of barbed nail rollers distributed in parallel are arranged on a rack, close to a material feed hole, in an upper chamber, a separating net bottom is arranged below the barbed nail rollers, the upper chamber is communicated with a lower chamber through an airlock valve, an upper rack roller, a lower rack roller, a cotton brushing roller, an impurity discharge auger, a cotton discharge passage and a cotton discharge auger are arranged in the lower chamber, a negative pressure chamber is arranged in an enclosure on the other side of the lower part of the upper chamber, the upper chamber is communicated with the upper end of the negative pressure chamber through the separating net bottom, the lower end of the negative pressure chamber is connected with an air suction end of a fan through an air suction bellow, the inlet of a three-way elbow is connected with an air blow end of the fan, an upper outlet of the three-way elbow is connected with one end of a flat air pipe, the other end of the flat air pipe is communicated with a lower inlet of a cotton blow pipe, and a cotton discharge hole is communicated with an upper inlet of the cotton blow pipe. The scutcher is reasonable in structural design, convenient to use, and good in cotton cleaning effect, and the unginned cotton after scotching can be fed into a cotton storage box without an additionally arranged fan.

Owner:胡玉白

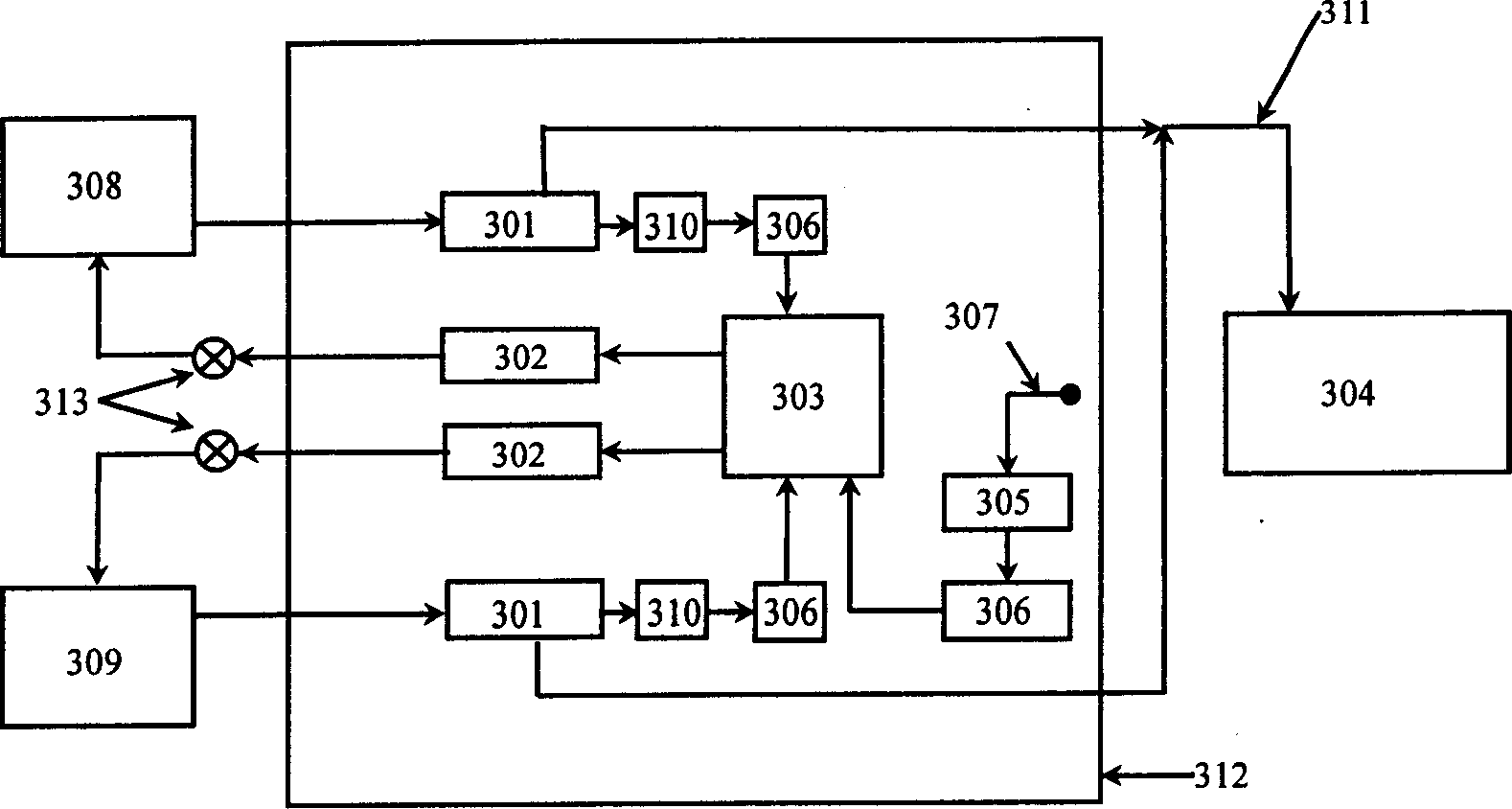

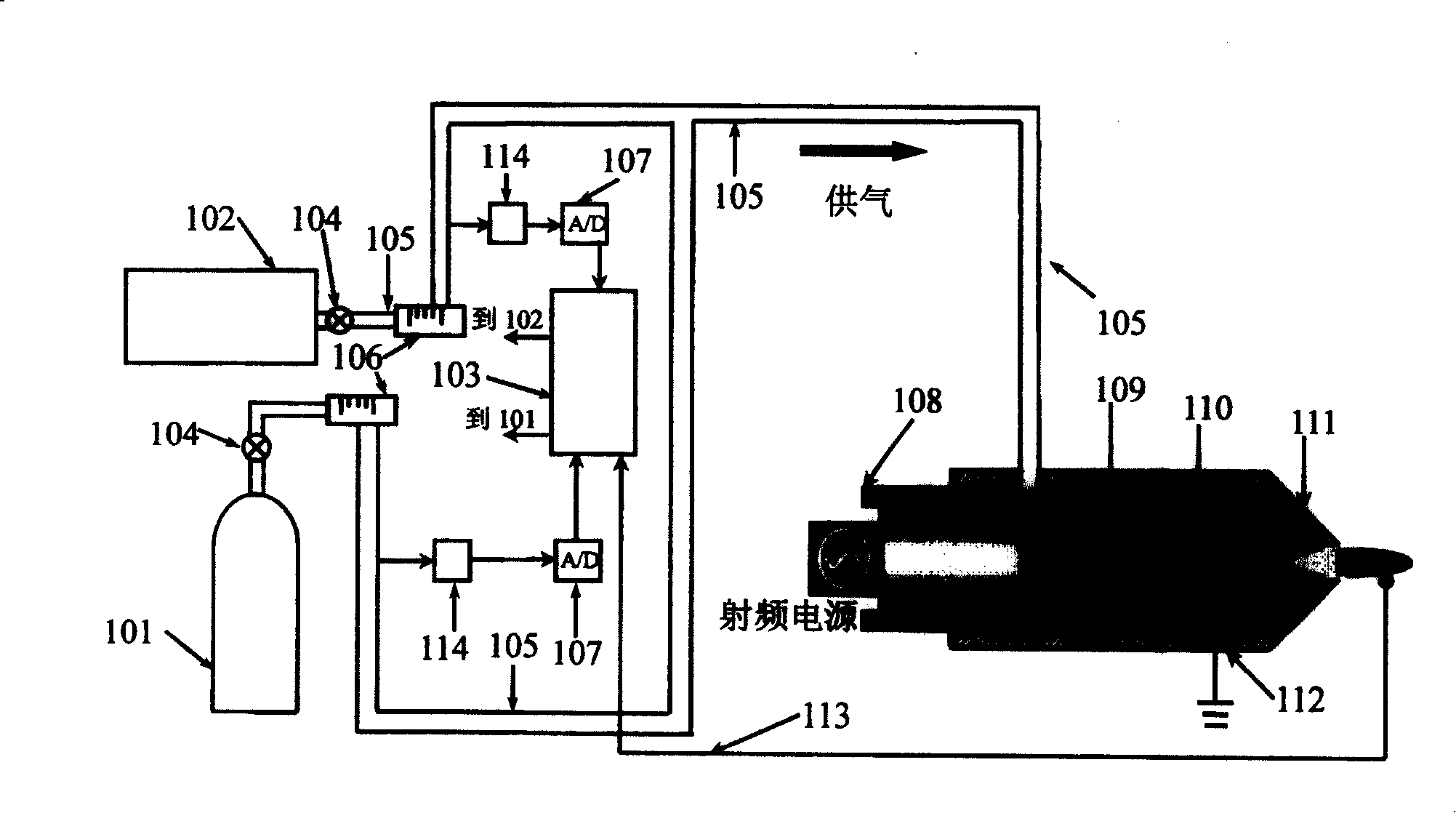

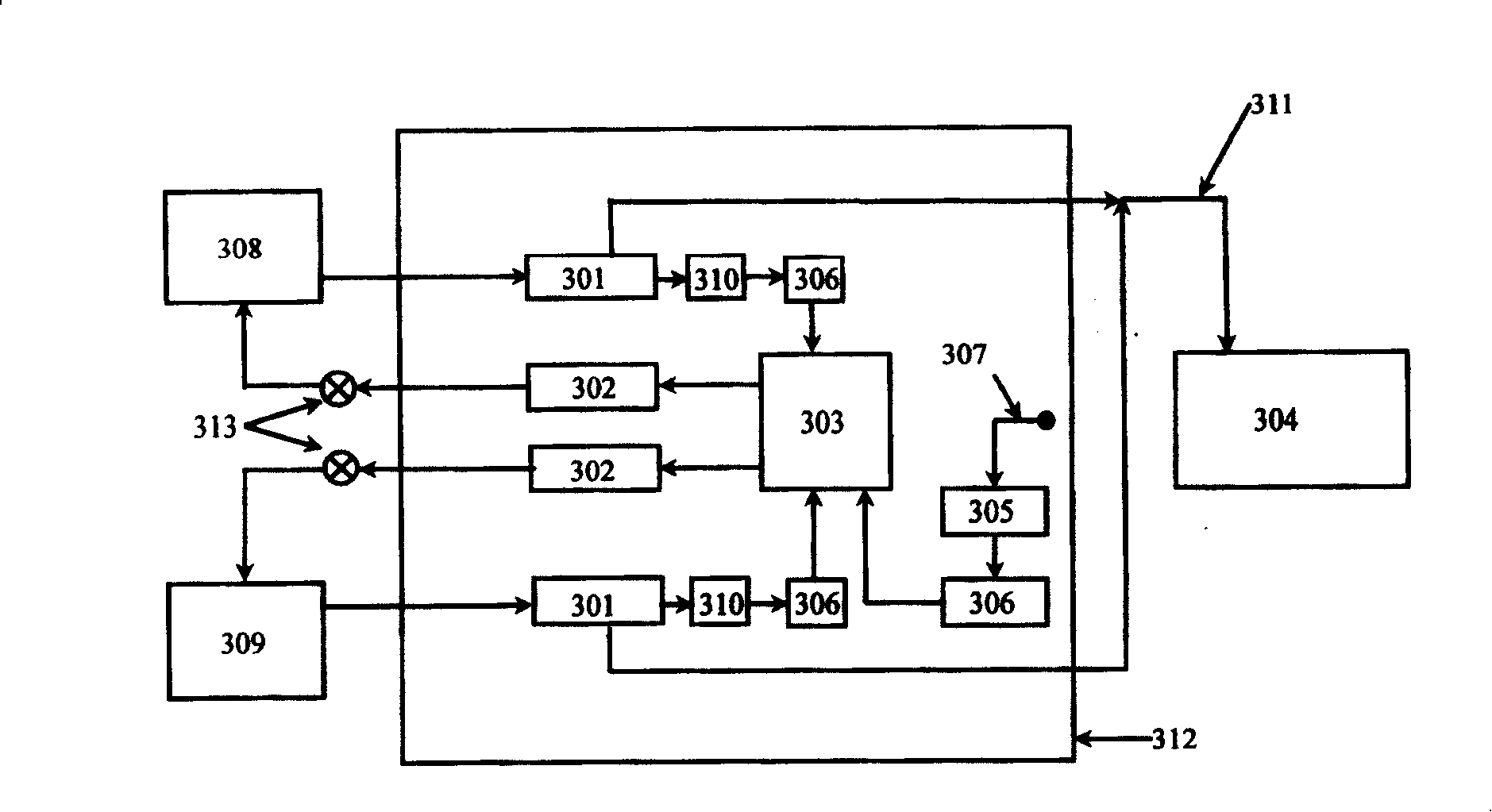

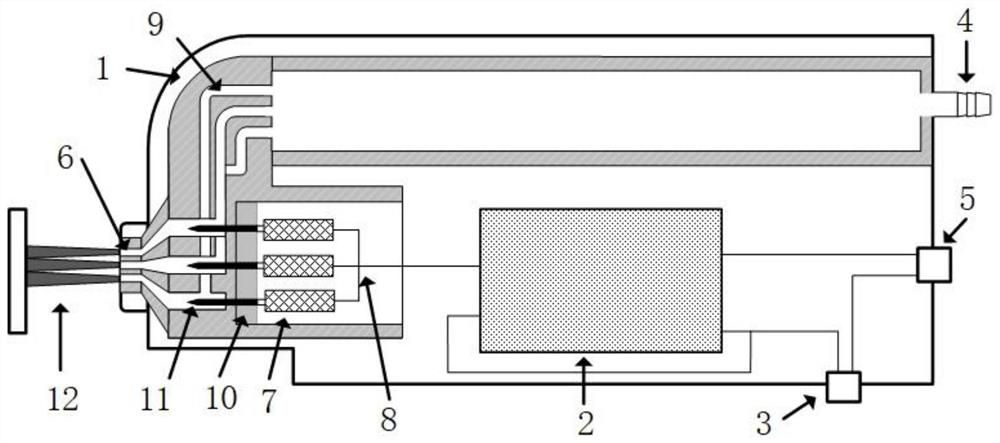

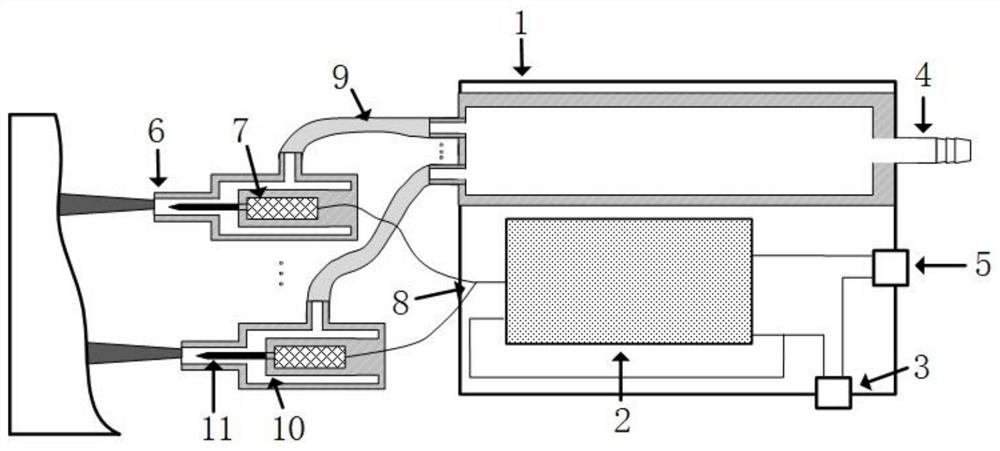

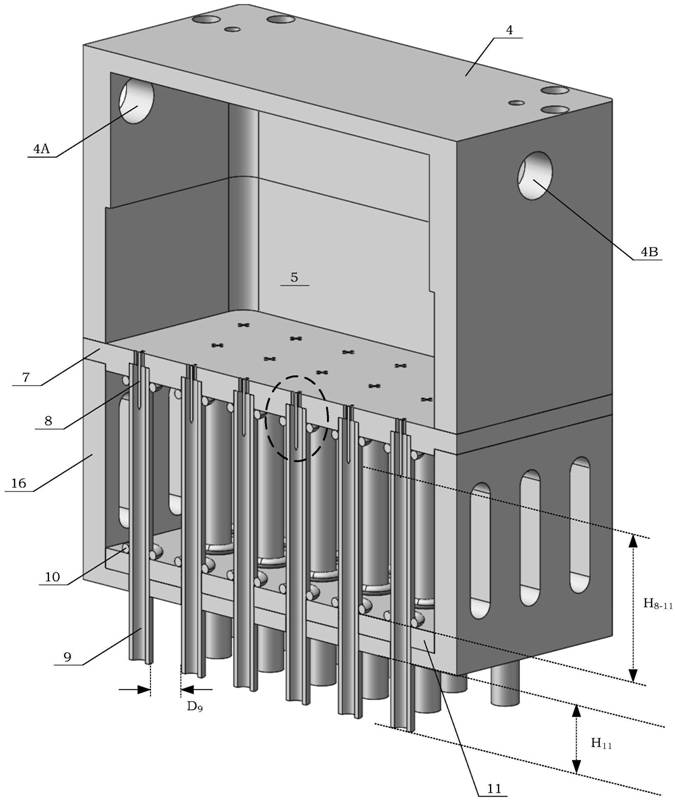

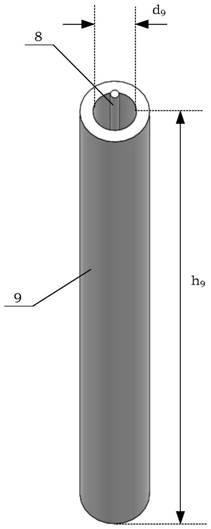

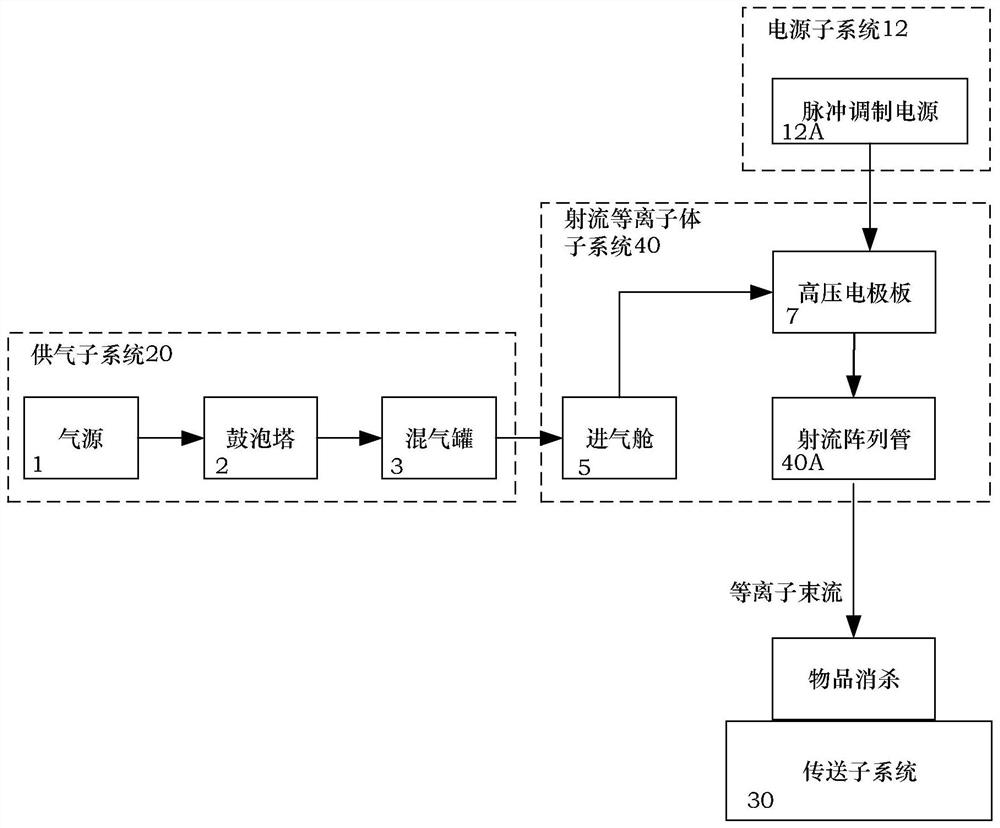

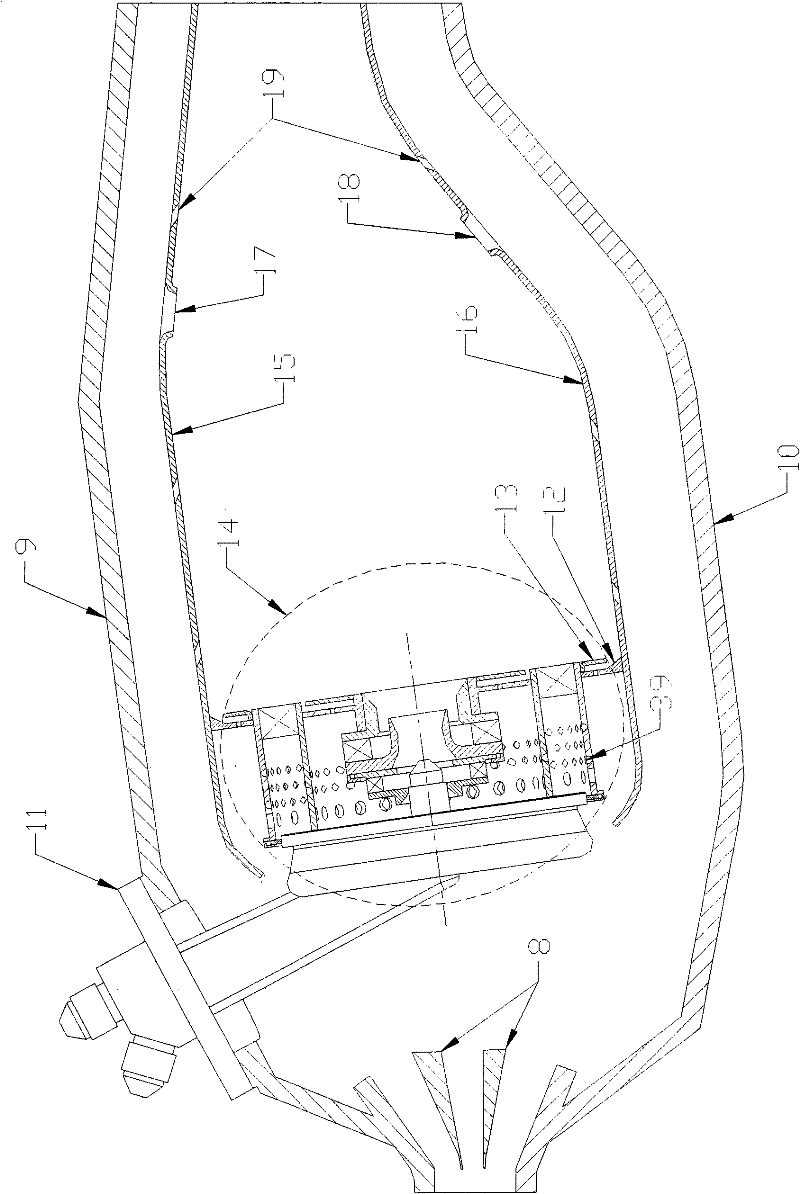

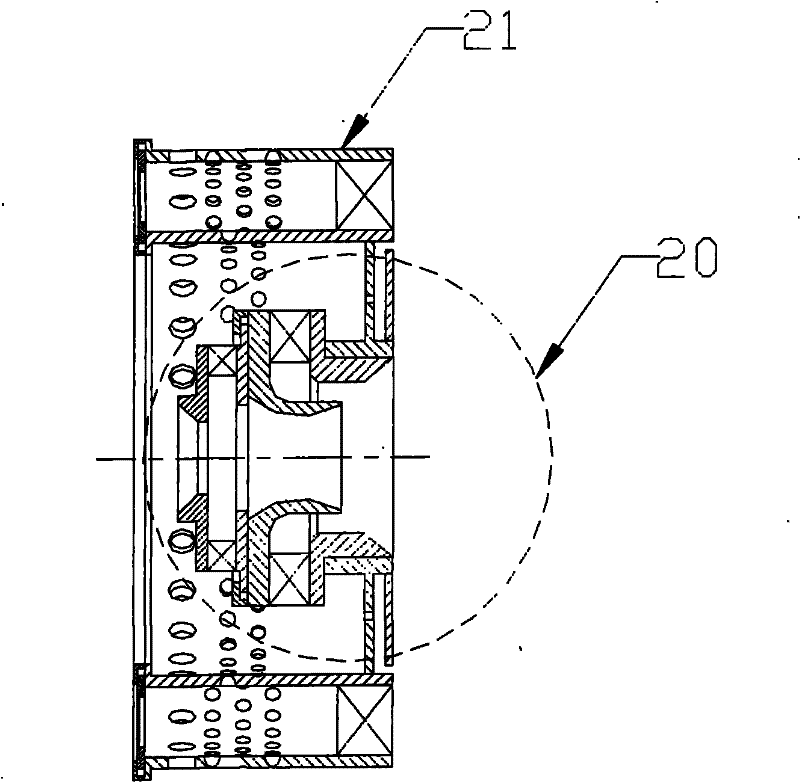

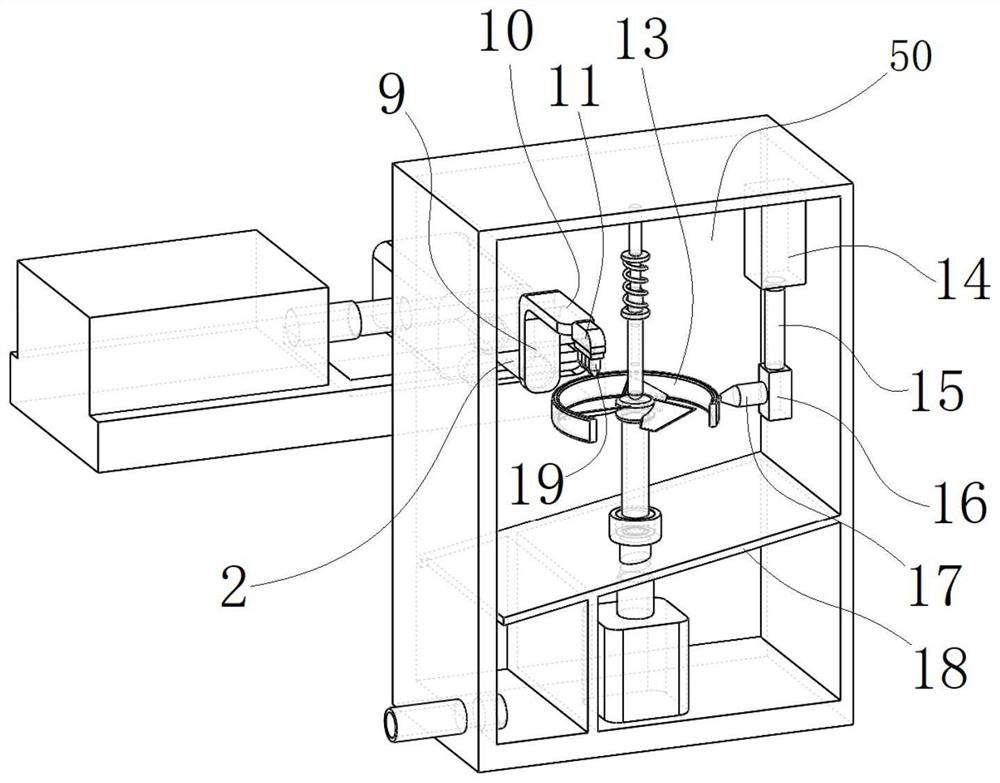

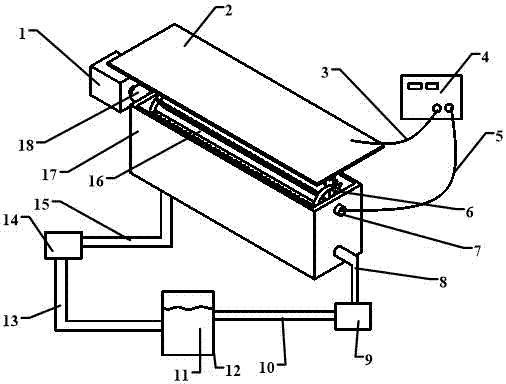

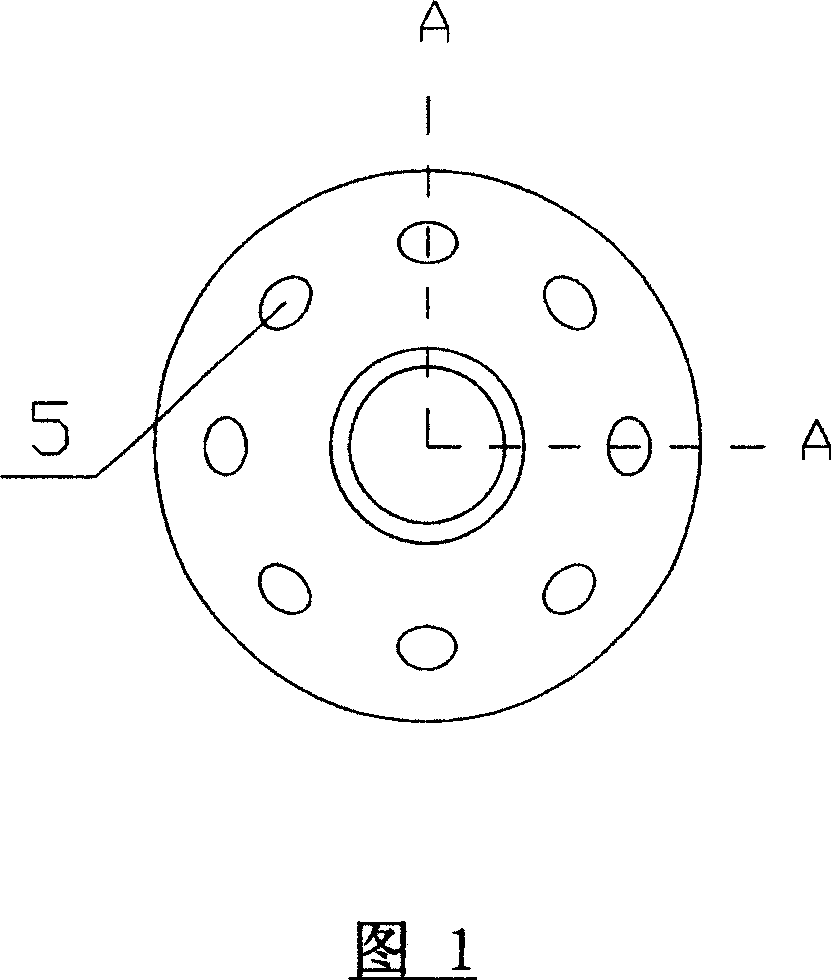

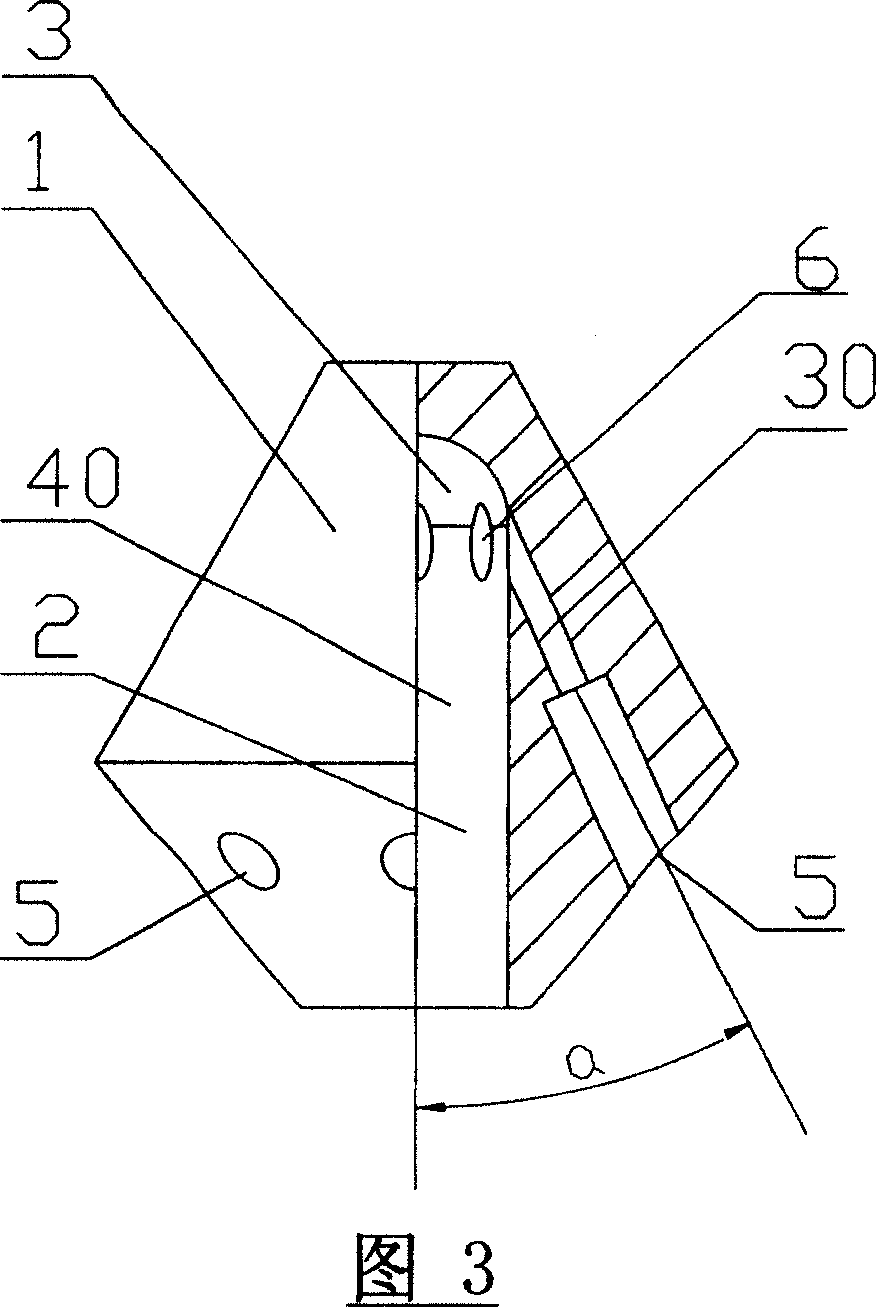

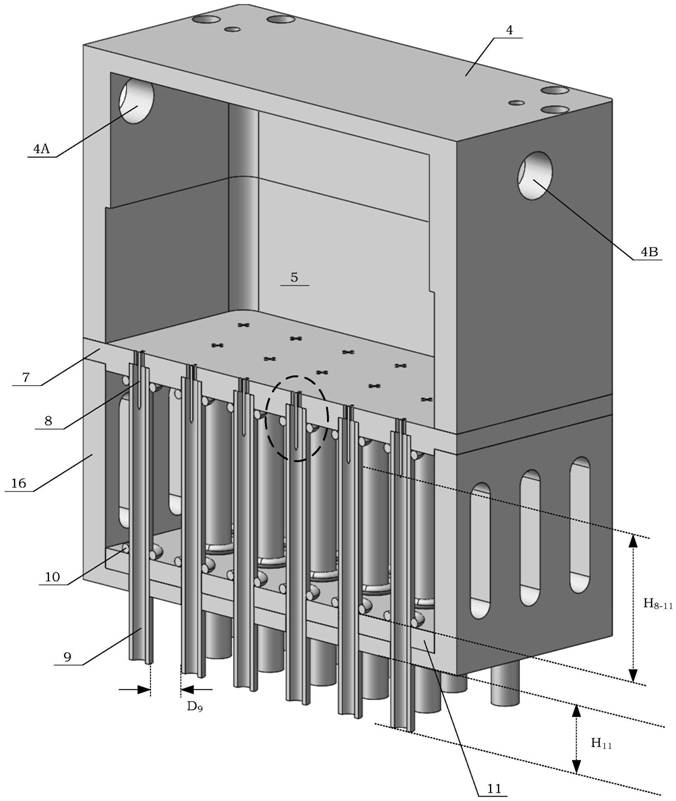

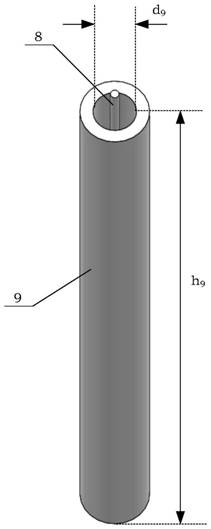

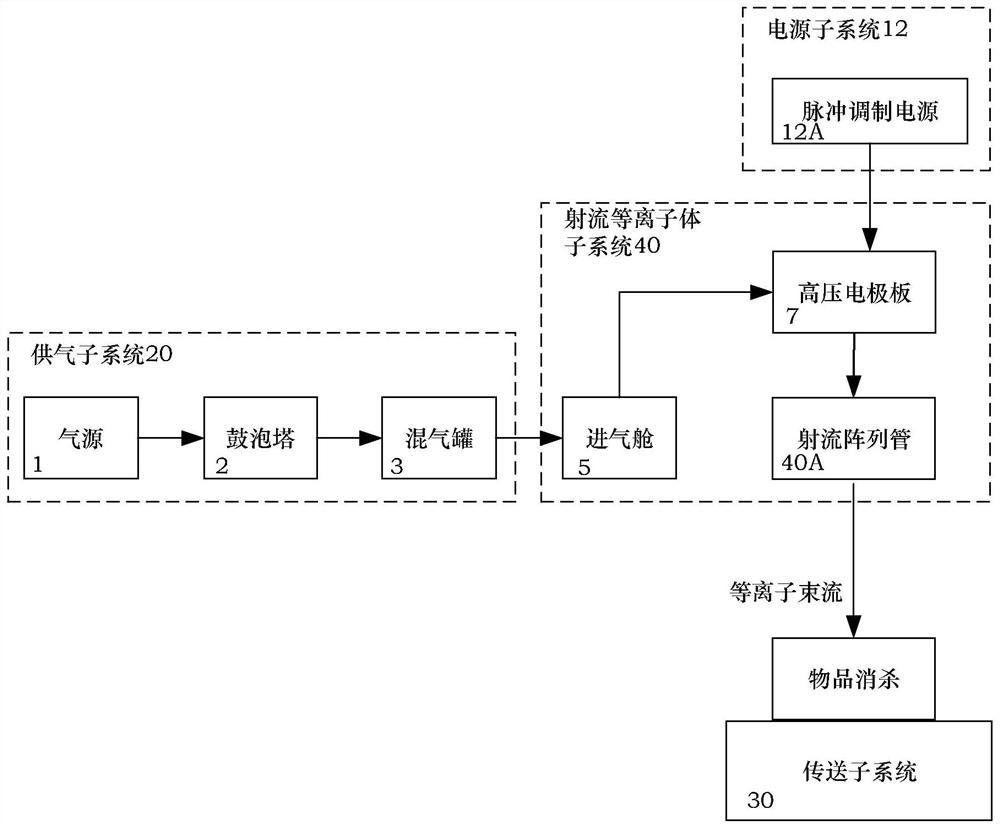

System and method for rapidly disinfecting surface pathogenic microorganisms by array jet plasma

The invention discloses a system and method for rapidly disinfecting surface pathogenic microorganisms by array jet plasma. A gas supply subsystem (20) in the system comprises a gas source, a bubble tower and a gas mixing tank; a jet plasma subsystem (40) comprises a gas inlet cabin (5), a high-voltage electrode plate (7), a grounding electrode plate (11), hollow medium tubes (9), metal needles (8) and a fixed silica gel pad; and a power supply subsystem (12) and a transfer subsystem (30) are comprised. Mixed gas is introduced into the gas inlet cabin (5) connected with a power supply, so that working carrier gas forms large-area and uniform-density plasma; multi-tube uniform flow distribution is implemented through flow limiting holes (6), and a needle-ring discharge type array electrode is formed; Useless power consumption is reduced by modulating a pulse source, the composition and concentration level of active components of a plasma flow are controlled through atmosphere composition, and disinfecting time is controlled through speed regulation and control of a transfer system. According to the device and the method of the invention, the pathogenic microorganisms on the surface of an object can be quickly disinfected in a large area with low energy consumption under the conditions of normal temperature, refrigeration and freezing.

Owner:BEIHANG UNIV

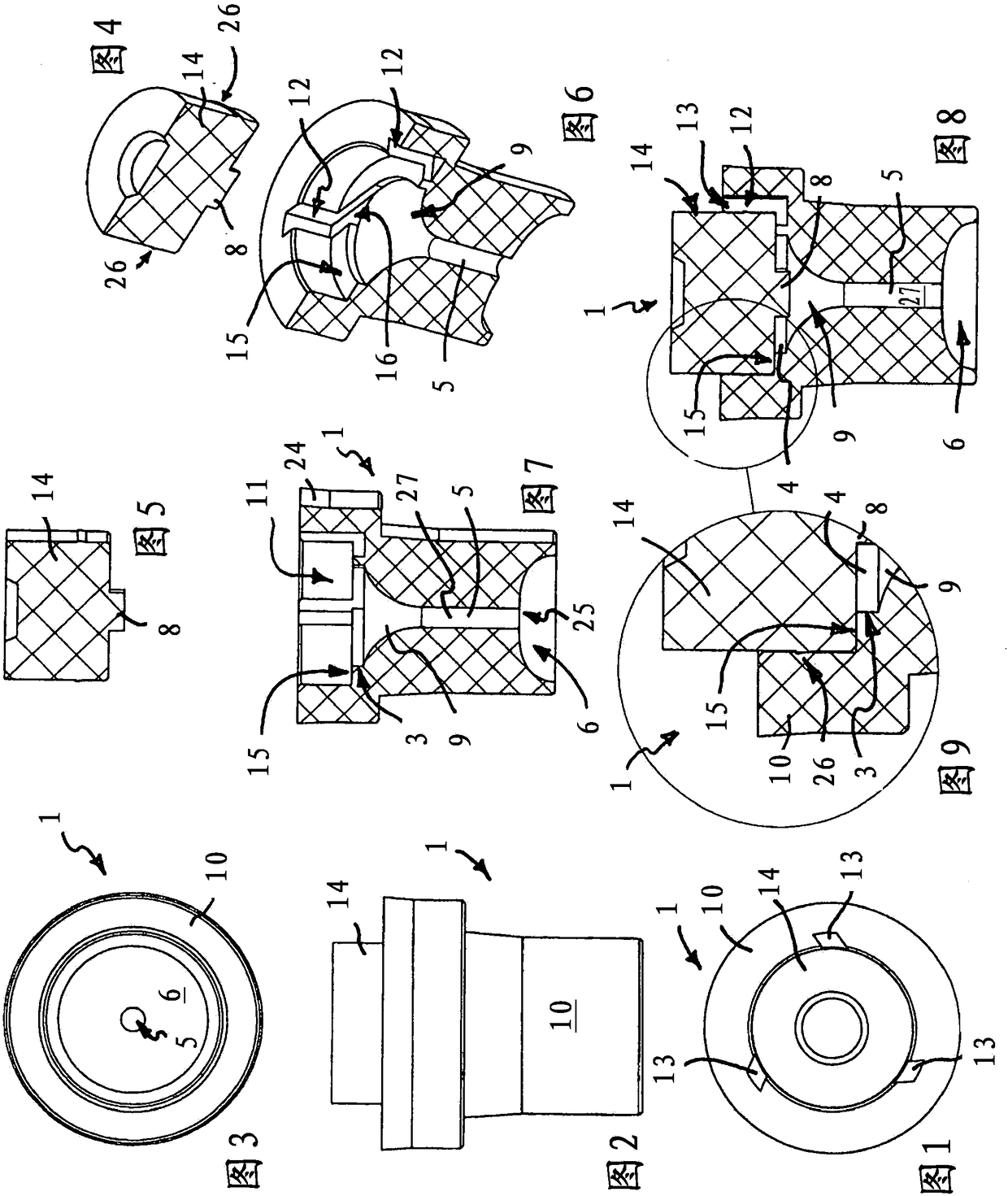

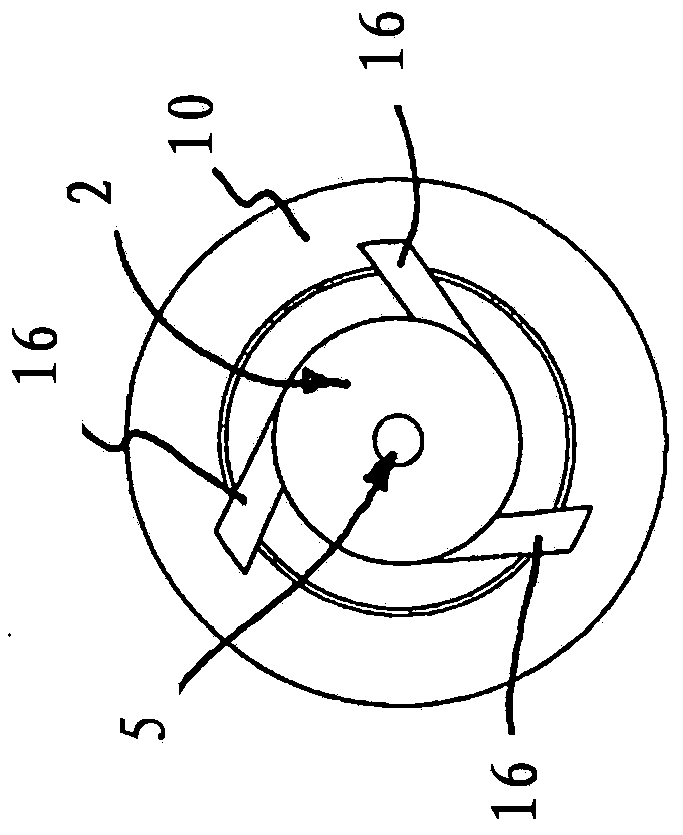

Atomizer nozzle for a sanitary water outlet and sanitary outlet fitting with a water outlet

The invention relates to an atomizer nozzle (1) for a sanitary water outlet, which atomizer nozzle (1) is intended for atomizing water under pressure. The characterizing feature of the atomizer nozzle (1) according to the invention is that the atomizer nozzle (1) has a swirl chamber (2), in which at least a feed channel (4) that is oriented transversely in relation to the longitudinal axis of the nozzle and runs approximately tangentially into the swirl chamber (2) opens out, wherein the swirl chamber (2) tapers in the outflow direction, in the direction of a nozzle channel (5). The atomizer nozzle (1) can be used to produce a water jet of a homogeneous jet pattern that gives the impression of a voluminous water jet in spite of having a low volumetric flow.

Owner:NEOPERL

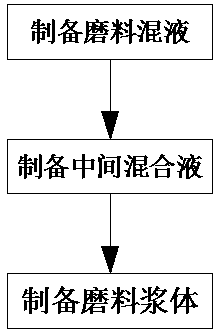

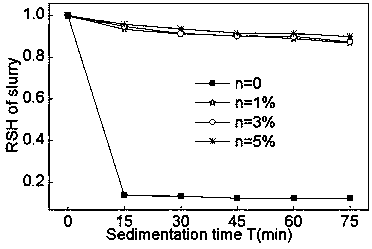

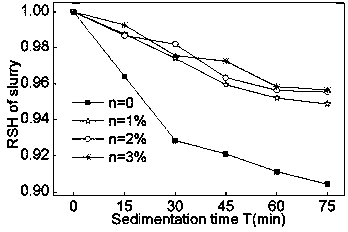

Abrasive slurry for abrasive slurry jet processing and preparation method thereof

PendingCN110240890AGood dispersionGood suspensionOther chemical processesPolishing compositions with abrasivesPolyvinyl alcoholSuspending Agents

The invention discloses abrasive slurry for abrasive slurry jet processing, prepared from water and an abrasive, wherein the particle size of the abrasive is 0.5 micrometer to 5 micrometers; the abrasive slurry is further prepared from a dispersing agent and a suspending agent, the mass concentration of the dispersing agent is 0% to 8% of that of the abrasive, the dispersing agent is an organic dispersing agent and / or an inorganic dispersing agent, the suspending agent is polyvinyl alcohol, and the mass concentration of the polyvinyl alcohol is 0% to 5% of that of the added abrasive. The abrasive slurry can solve the problem that the agglomeration and precipitation of the abrasive during jet slurry processing result in nozzle plugging and serious system wear, can increase the dispersibility and suspension of the abrasive in the slurry to make the abrasive be uniformly dispersed and not easy to precipitate over time, and can maintain the uniform consistency of slurry jet and high removal ability, so that the abrasive slurry jet processing has a very high polishing effect, meeting the actual production and reducing production cost.

Owner:GUANGDONG UNIV OF TECH

Gas gap pressure stabilizer

PendingCN108128401AUniform jetWell formedWatercraft hull designHydrodynamic/hydrostatic featuresPressure stabilizationGas lubrication

The invention provides a gas gap pressure stabilizer. A gas rectification and pressure stabilization device is designed for a gas lubrication, resistance reduction and energy saving device for a ship.The stabilizer comprises N pressure stabilization cavities in a ship baseplate, m gas jetting holes are formed in the bottoms of the pressure stabilization cavities, and the N pressure stabilizationcavities are connected with gas supply equipment separately and fixed in the inner side or the outer side of the ship baseplate in the width direction of the ship, wherein m is larger than or equal to3, and N is larger than or equal to 1; the spacing distance between every two pressure stabilization cavities is 5-150 m, the shape of the cross section is rectangular, square, semicircular, semi-oval or wing-shaped, the interiors of the N pressure stabilization cavities are smooth, the N pressure stabilization cavities are independent from one another, and the volume (V) of the pressure stabilization cavities is equal to the specific value of CPQ to N, wherein Cp is a gas compression coefficient, Q is a gas supply amount of gas supply equipment, and N is the number of the pressure stabilization cavities; the gas jetting holes are formed in the bottom planes, parallel to the water flow direction, of the pressure stabilization cavities or formed in the ship baseplate in the pressure stabilization cavities.

Owner:CSIC SHANGHAI MARINE ENERGY SAVING TECH DEV CO LTD

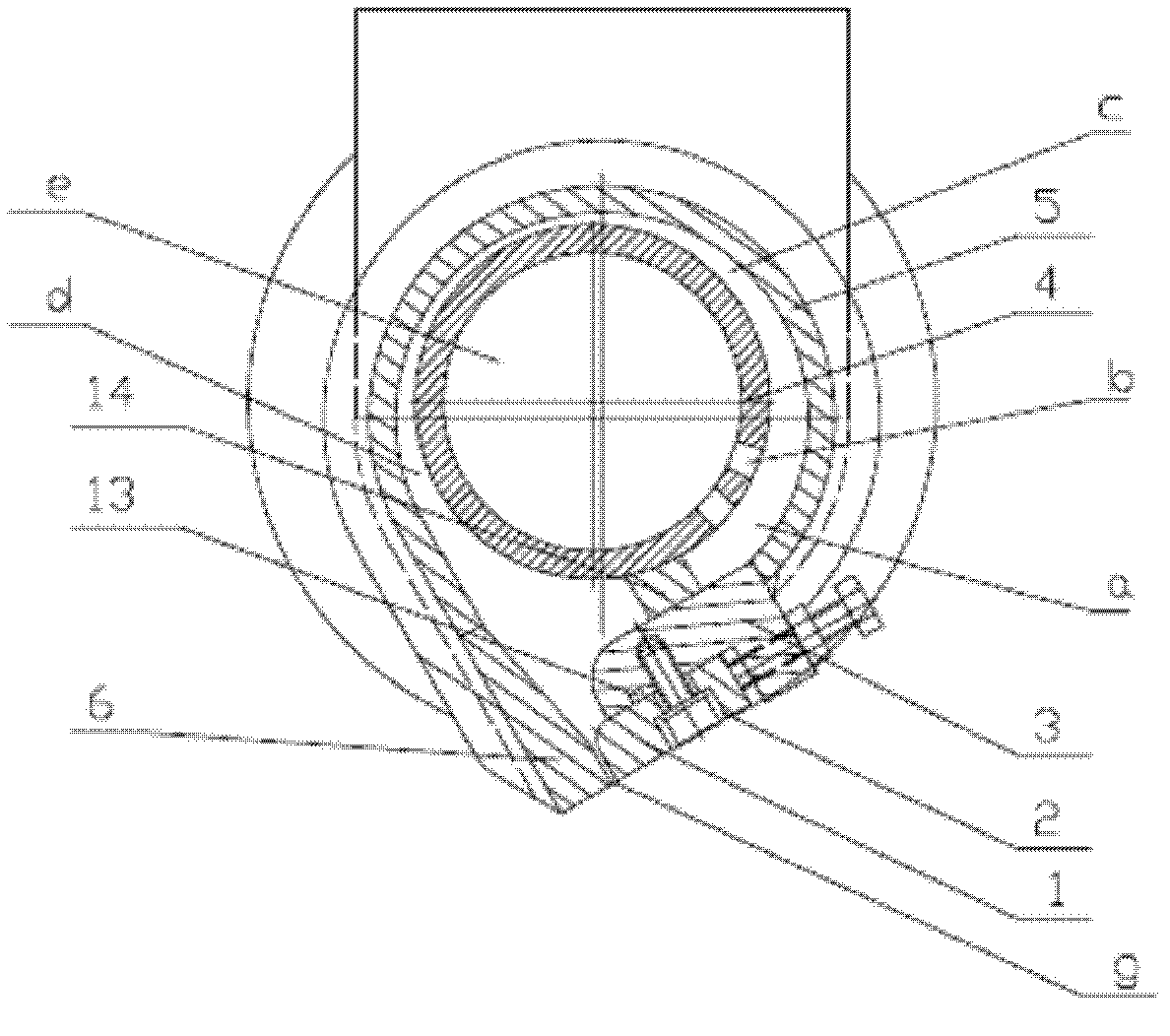

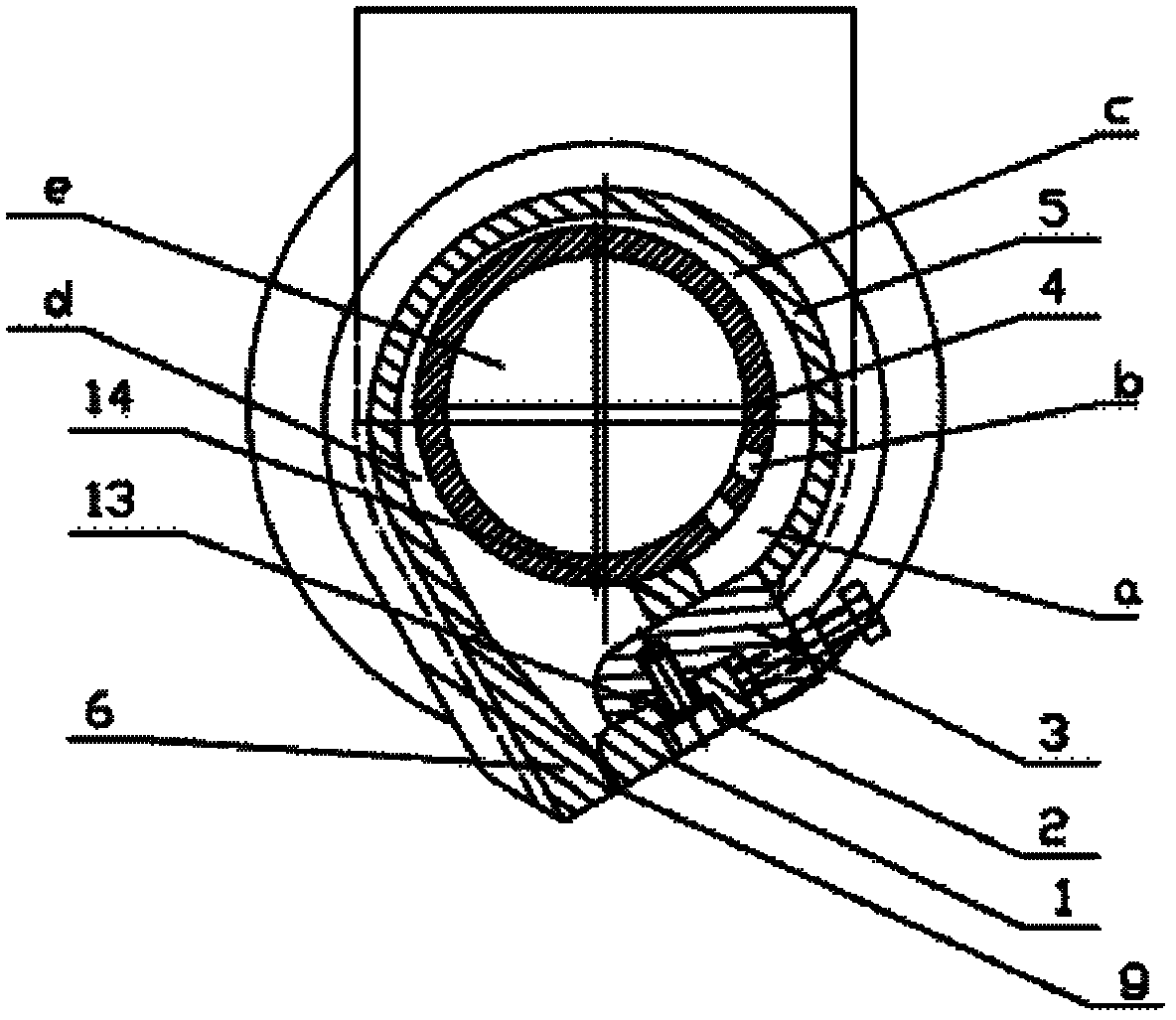

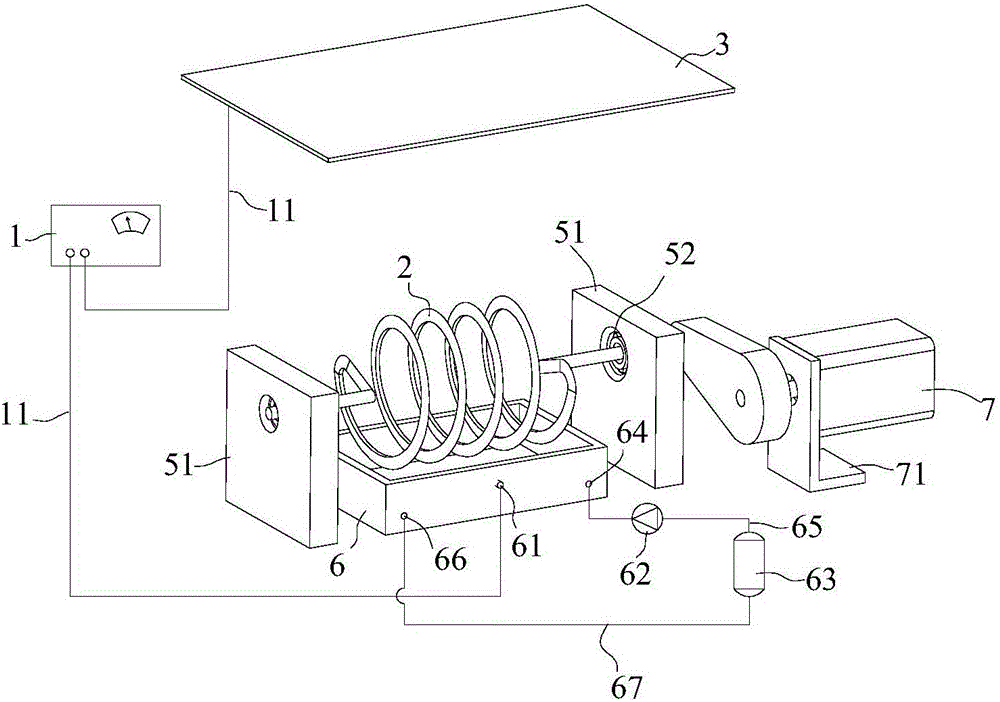

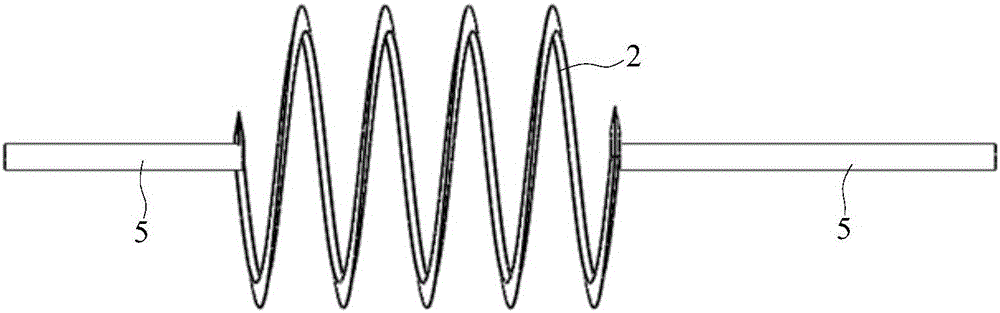

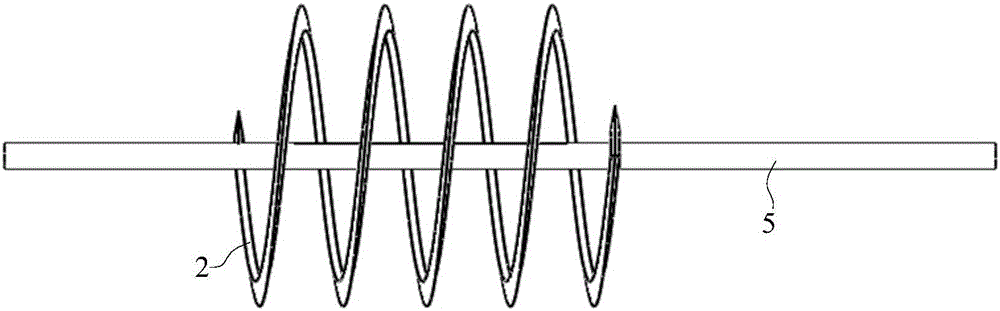

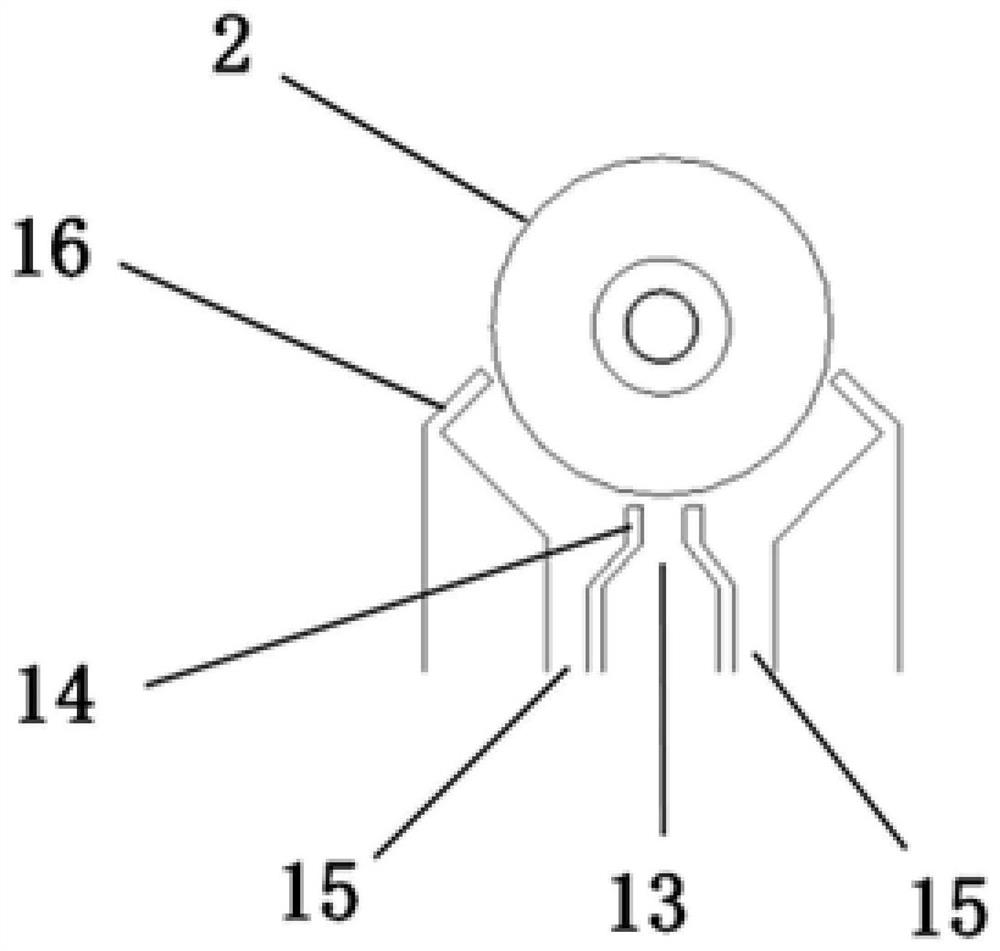

Spiral electrostatic spinning device with tip structure

The invention discloses a spiral electrostatic spinning device with a tip structure, and belongs to the technical field of electrospinning. The spiral electrostatic spinning device comprises a high-voltage power supply device, a spinning electrode and a receiving electrode. The spinning electrode is in a uniform-pitch cylindrical spiral line shape and is installed on a rotating shaft base through a rotating shaft coaxial with the spinning electrode, the spinning electrode has a sharp outer edge profile, and the high-voltage power supply device can form an electric field needed for generating jet flow between the spinning electrode and the receiving electrode. The sharp outer edge profile of the spinning electrode of the spiral electrostatic spinning device forms the tip structure, the tip part has the charge gathering effect, spinning induction can be prompted, spinning voltage can be reduced, the problem that spinning voltage is high in the needleless electrospinning technology can be solved, the fiber production quality can be further improved, and the fiber production yield can be further increased; the electrode tip structure is uniform in size and axial spacing, electric field distribution is uniform, jet flow can be uniformly generated, and uniform nanofibers can be deposited; the device is simple in structure and easy to machine, and industrial application is convenient.

Owner:FOSHAN QINGZI PRECISION MEASUREMENT & CONTROL TECH

Sharp tooth cage-shaped electrode electrostatic spinning device

The invention discloses a sharp tooth cage-shaped electrode electrostatic spinning device. The sharp tooth cage-shaped electrode electrostatic spinning device includes a sharp tooth cage-shaped electrode, a power supply, and a collecting device; the sharp tooth cage-shaped electrode includes two end plates and one or a plurality of sharp tooth linear type electrodes, the two end plates are provided with a rotation shaft, and the sharp tooth linear type electrodes are provided with a plurality of sharp teeth which are at a side edge away from the rotation shaft, have the identical distance relative to an axis of the rotation shaft, and are evenly distributed; and the power supply is electrically connected to the sharp tooth cage-shaped electrode and the collecting device, and an electric field required by jet flows is formed between all the sharp teeth and the collecting device after the power supply is on. The sharp tooth linear type electrodes can combined into the sharp tooth cage-shaped electrode, the structure is simple, the processing is convenient, and all the electrodes can be easily arranged on the same circle, so that the uniformity of the electric field can be ensured; and when the plurality of sharp tooth linear type electrodes are arranged between the two end plates, and uniform distribution operation of a solution on other sharp tooth linear type electrodes can be completed through rotation of the rotation shaft during spinning of one sharp tooth linear type electrode, so that spinning work can be continuously performed, and the efficiency of the spinning can be improved.

Owner:DONOGGUAN AIR GUARD MFG CO LTD

Cooling device generating flat jet and manufacturing method thereof

ActiveCN102319748BEasy to installAchieve uniformityWork treatment devicesMetal rolling arrangementsEngineeringFlange

The invention relates to a cooling device generating a flat jet and a manufacturing method thereof, the cooling device is characterized in that an inner pipe and an outer pipe of the cooling device are eccentrically fixed through a positioning strip for forming a cavity between the inner pipe and the outer pipe, a slit is formed in the axial direction, the width of the slit can be regulated through a tightening bolt and a compression bolt, a flange is welded at the inlet end of the inner pipe for connecting with a cooling medium pipeline, a steel plate is welded at the outlet end for sealing, and the cooling device is further provided with an inner cavity pollution discharge port. An end plate is welded at the inlet end of the cavity between the inner pipe and the outer pipe and used for sealing, the outlet end of the cavity and the flange are sealed through the end plate, and pollution can be discharged out of the cavity between the inner pipe and the outer pipe. Two rows of tidy flow through holes are formed on the inner pipe, and a cooling medium enters into the inner pipe via the flange at the inlet end, and then flows into the cavity between the inner pipe and the outer pipe via the flow through holes and further forms flat jet via the slit for cooling the steel plate. The eccentric arrangement of the inner pipe and the outer pipe of the device can form multiple damping effects for the cooling medium, the slit enables the cooling medium to form the uniform flat jet in the width direction of a rolling line, and multiple reinforcing ribs are welded outside the outer pipe in the radial direction for preventing deformation.

Owner:NORTHEASTERN UNIV LIAONING

Atomizing nozzles for sanitary outlets and sanitary taps with outlets

ActiveCN104043544BUniform jetImproved jet mapValve arrangementsDomestic plumbingAtomizer nozzleEngineering

The invention relates to an atomizing nozzle (1) used for a sanitary water outlet unit, and the atomizing nozzle (1) is used for atomizing water under pressure. The atomizing nozzle (1) provided by the invention is characterized in that the atomizing nozzle (1) is provided with a swirl chamber (2), at least one supplying channel (4) which is parallel to the longitudinal axis of the nozzle and enters the swirl chamber (2) in an approximately-tangent manner is introduced into the swirl chamber, and the swirl chamber (2) becomes thinner along the outflow direction and towards a nozzle channel (5). By employing the atomizing nozzle (1), a uniform water jet can be generated in a jet figure, although the water jet is small in volume, the the water jet makes people think that the water jet is big in volume.

Owner:NEOPERL

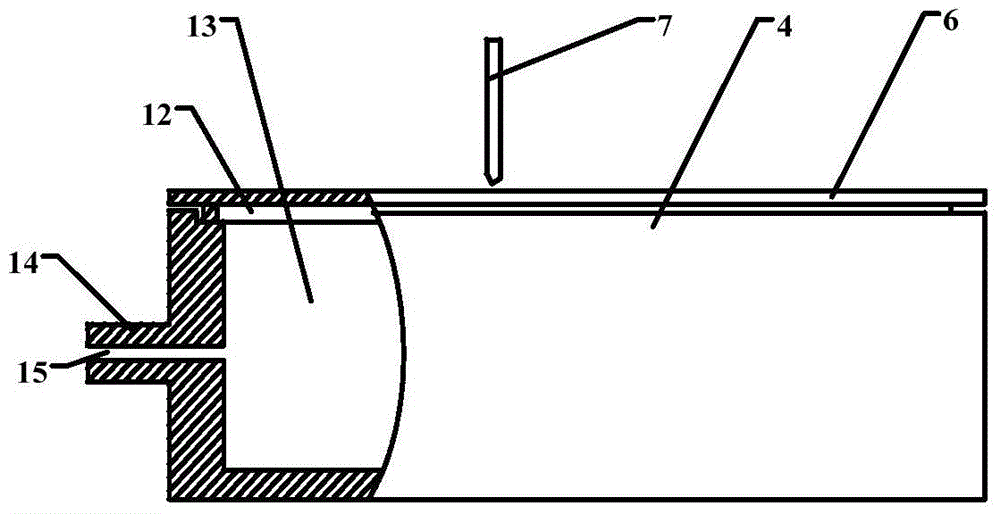

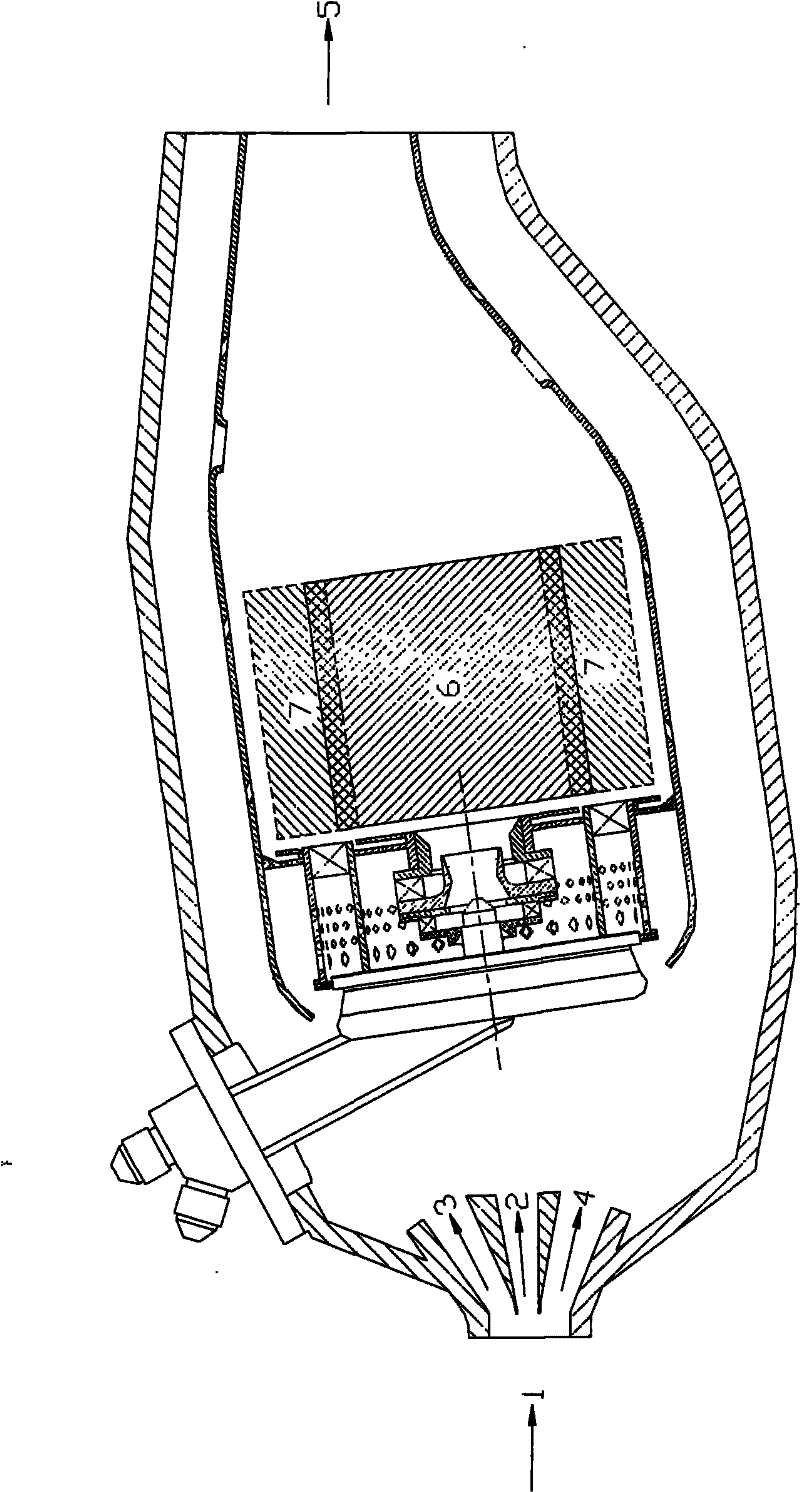

Premixing and pre-evaporating combustion chamber

ActiveCN101709884BSimple structureImprove efficacyContinuous combustion chamberDiffusion flameCombustion chamber

The invention discloses a premixing and pre-evaporating combustion chamber, which has a single annular chamber structure and adopts a conceptual design of fractional combustion. In the combustion chamber, the total combustion gas volume is supplied by a pre-combustion fraction and a main combustion fraction, the pre-combustion fraction adopts a swirl-flow stable diffusion flame combustion organization mode and the main combustion fraction adopts a premixing and pre-evaporating combustion organization mode. The combustion chamber mainly comprises a shunting diffuser, a combustion chamber outercasing, a combustion chamber inner casing, a fuel oil nozzle, the pre-combustion fraction, the main combustion fraction, a combustion liner outer wall and a combustion liner inner wall. The pre-combustion fraction stabilizes flame by using a low-speed refluxing zone generated by swirl air entering the combustion chamber from a pre-combustion fraction swirler; and after being sprayed out by a maincombustion fraction nozzle, the fuel oil needed by the main combustion fraction first form an oil-gas mixed gas through atomization under the action of an air flow in a prefilming air ring in the main combustion fraction nozzle and then flows to the premixing and pre-evaporating fraction to be evaporated and further blended with the air, so a uniform oil-gas mixed gas jet flow is formed at the position of the outlet of the premixing and pre-evaporating fraction and enters the combustion liner to be ignited by flame in the pre-combustion fraction to combust. The combustion chamber is simple instructure and can effectively reduce pollutant discharge while ensuring an aeroengine works normally.

Owner:BEIHANG UNIV

Rodlike electrospinning device and electrospinning method

InactiveCN109554771ASimple structureNarrow structureFilament/thread formingElectrospinningEngineering

The invention provides a rodlike electrospinning device and an electrospinning method. The rodlike electrospinning device is characterized by comprising a rodlike spinneret and a solution supply device which is connected with the rodlike spinneret to supply spinning solution to the rodlike spinneret, the spinning solution supplied by the solution supply device can be stored in the rodlike spinneret, and the rodlike spinneret is provided with a sawtoothed gap. The rodlike spinneret is connected with a high-voltage positive electrode, and when the voltage exceeds a critical value, various electrospinning jet flows can be generated in the sawtoothed gap. The rodlike electrospinning device is simple, the spinneret is less prone to blockage, jet flow interval uniformity, easiness in cleaning and high stability are realized, and spinning efficiency can be remarkably improved while electrospinning yield is greatly increased.

Owner:李瑞锋

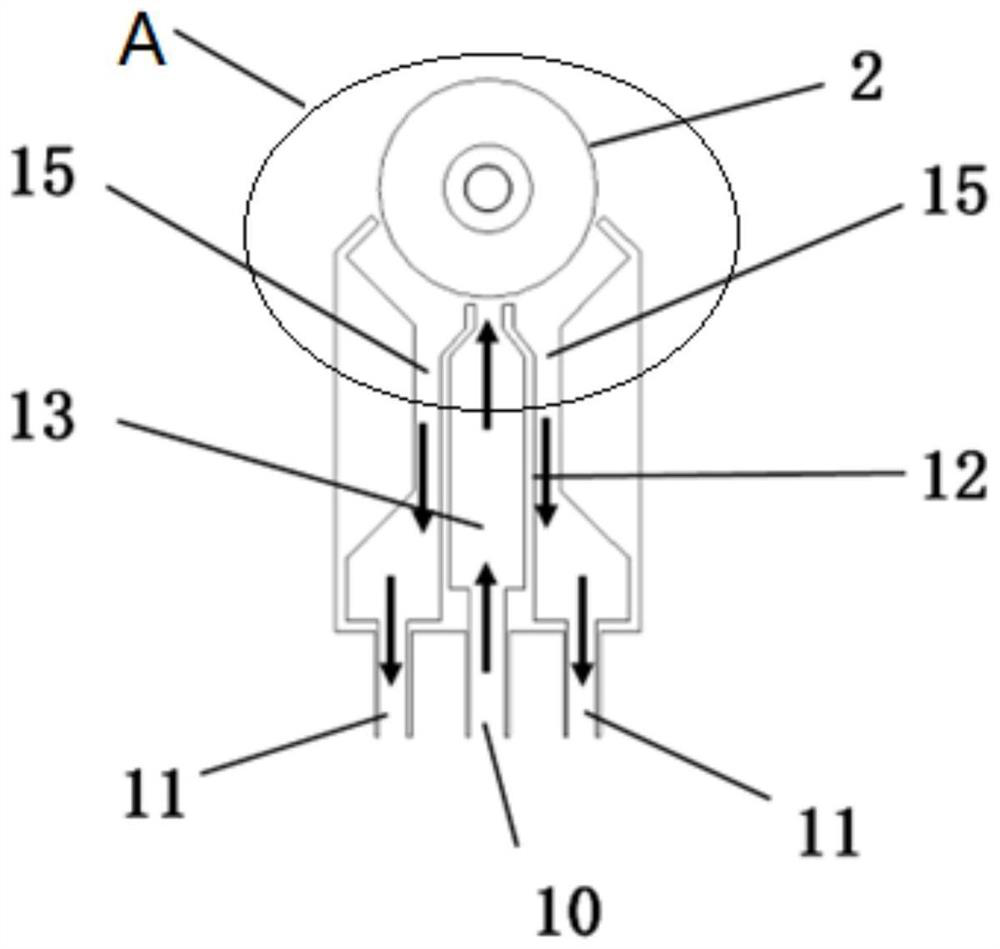

Needleless electrostatic spinning device

ActiveCN114855286AEvenly distributedControllable distributionFilament/thread formingTextile/flexible product manufactureNeedle freeSpinning

The needleless electrostatic spinning device comprises a spinning nozzle and a spinning electrode, the spinning nozzle is used for conveying and distributing a spinning solution, the spinning nozzle is provided with an opening, the spinning electrode is arranged at the opening, and the spinning electrode is used for rotating in the preset direction to excite the spinning solution to form a solution jet flow; the spinning nozzle comprises an inner shell and an outer shell, the inner shell is used for forming a liquid supply cavity for storing a spinning solution, the outer shell is used for forming a liquid return cavity for the spinning solution to flow back with the inner shell, and the liquid supply cavity is separated from the liquid return cavity. According to the needleless electrostatic spinning device, the spinning solution can be uniformly and controllably distributed on the spinning electrode; and meanwhile, the spinning solution which is not brought into the spinning area can be recycled, so that the yield, the uniformity and the quality stability of the nanofiber membrane can be ensured.

Owner:QINGDAO UNIV +1

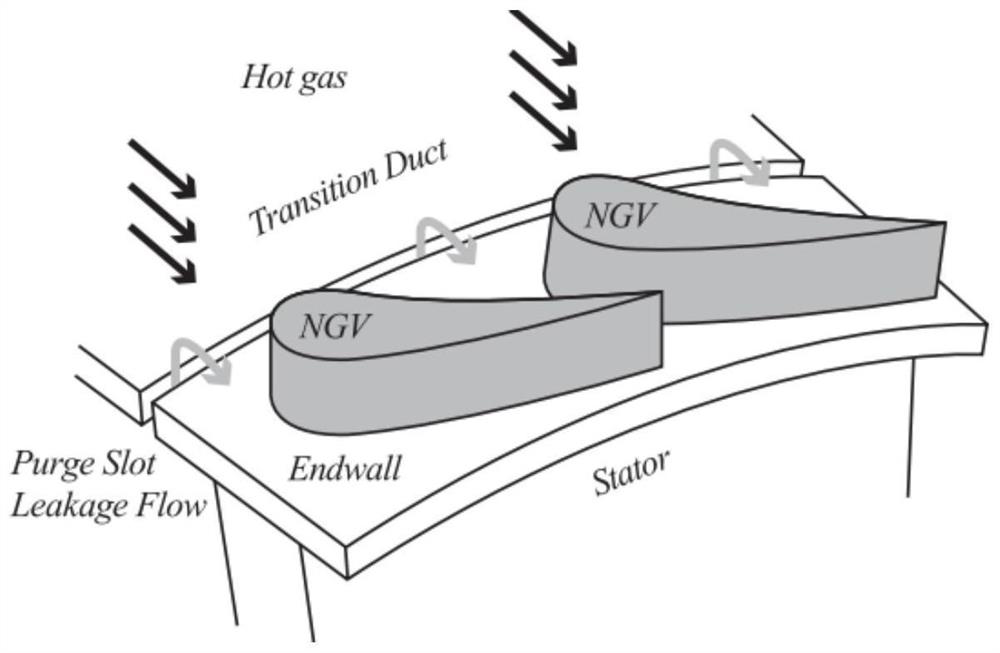

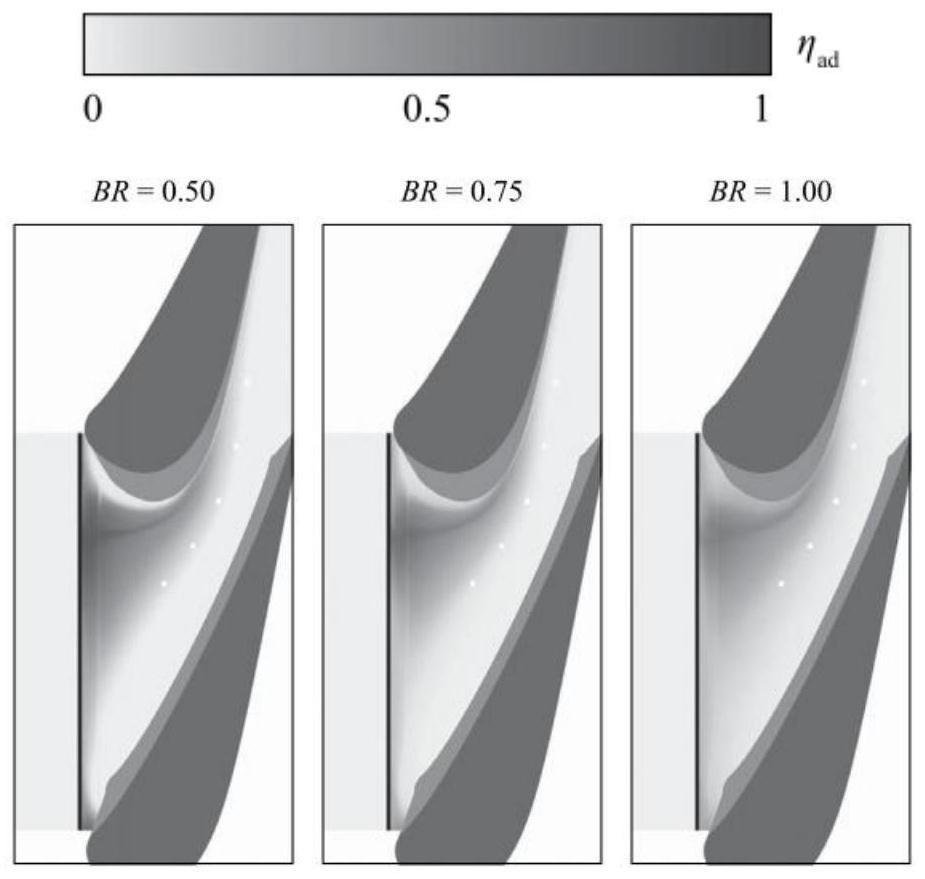

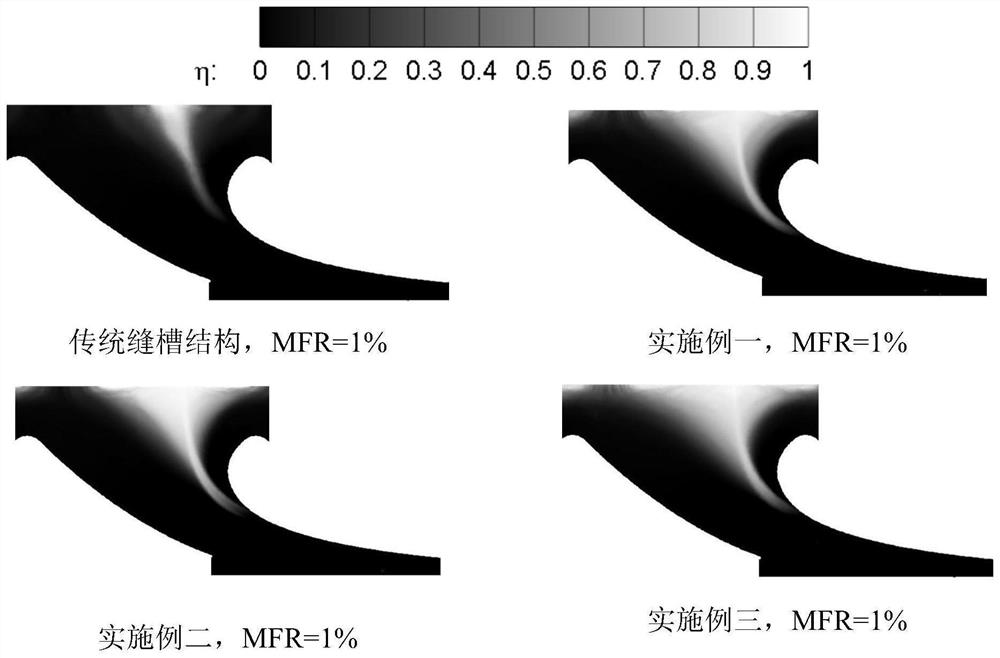

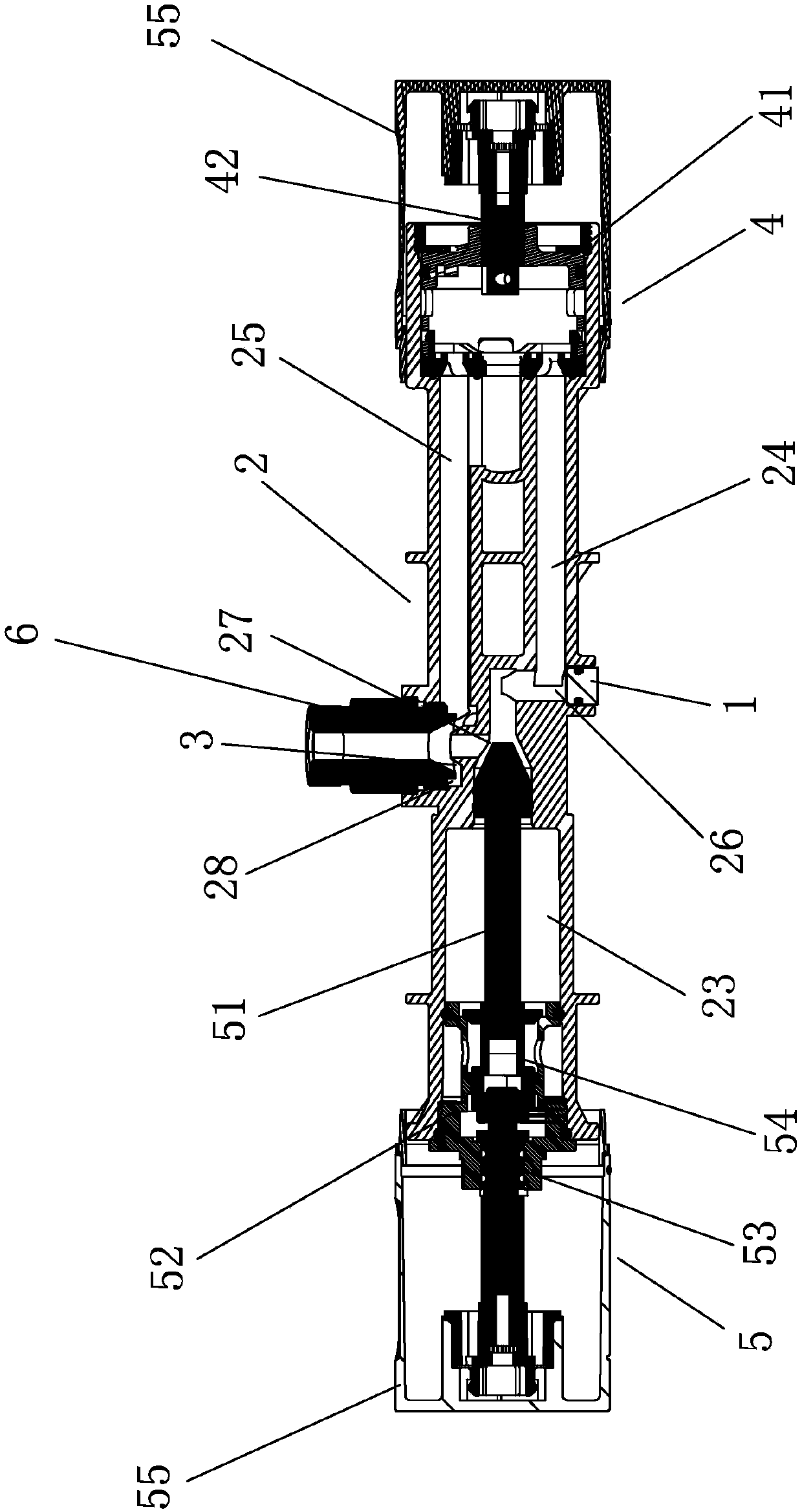

Leakage groove air film cooling structure used for turbine end wall and provided with protrusions and application of leakage groove air film cooling structure

PendingCN114562339AExpand coverageUniform coverageBlade accessoriesEfficient propulsion technologiesCold airSuction force

The invention discloses a leakage groove air film cooling structure used for a turbine end wall and provided with protrusions and application, and belongs to the technical field of cooling of turbine guide vane end walls of gas turbines. A leakage groove structure and a leakage groove air supply cavity are arranged on the upstream portion of the turbine end wall, and the leakage groove structure is located at an outlet of the leakage groove air supply cavity and serves as a cooling airflow channel. A plurality of protruding structures are evenly distributed on the inner wall of the side, away from the turbine blade, of the leakage groove structure in the spanwise direction, the protruding structures correspond to the front edge of the suction face of the turbine blade 4 in a one-to-one mode, so that most cooling airflow flows out of a channel between the adjacent protruding structures, and an air film is formed on the cooling wall face. Cooling airflow B flowing out of a leakage groove flows in the main flow direction under driving of main flow airflow A, and an air film is formed in a cooling wall face area; the structure can greatly weaken the influence of the pressure gradient C on the leaked cold air jet on the cooling wall surface, and secondly, the coverage area of the cold air of the leaked groove on the cooling wall surface is further uniformized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Pressure increasing valve body

InactiveCN109667960ARelieve pressureStable water pressureMultiple way valvesEngineeringThermal water

The invention discloses a pressure increasing valve body. The pressure increasing valve body comprises a main body sleeve, a main valve body fixedly connected into the main body sleeve, a water mixingcavity for supercharging, suction of hot water and uniform mixing of cold-hot water, a switch valve connected with an inner cavity of the main valve body and used for controlling a cold-hot water switch, and a temperature adjusting valve connected with the inner cavity of the main valve body and used for controlling the flow of the hot water; the main valve body comprises a hot water inlet, a cold water inlet, a first hot water cavity communicating with the hot water inlet, a cold water cavity communicating with the cold water inlet through rotation of the switch valve, a second hot water cavity communicating with the first hot water cavity and the water mixing cavity through rotation of the switch valve, a jet cavity communicating with the cold water cavity and the water mixing cavity and used for forming jet currents, and a water outlet; and the temperature adjusting valve comprises an ejector rod matched with the jet cavity, so that the cold-hot water can be uniformly mixed, and the water temperature, the water pressure and the water outlet quantity are stable.

Owner:何醒棠

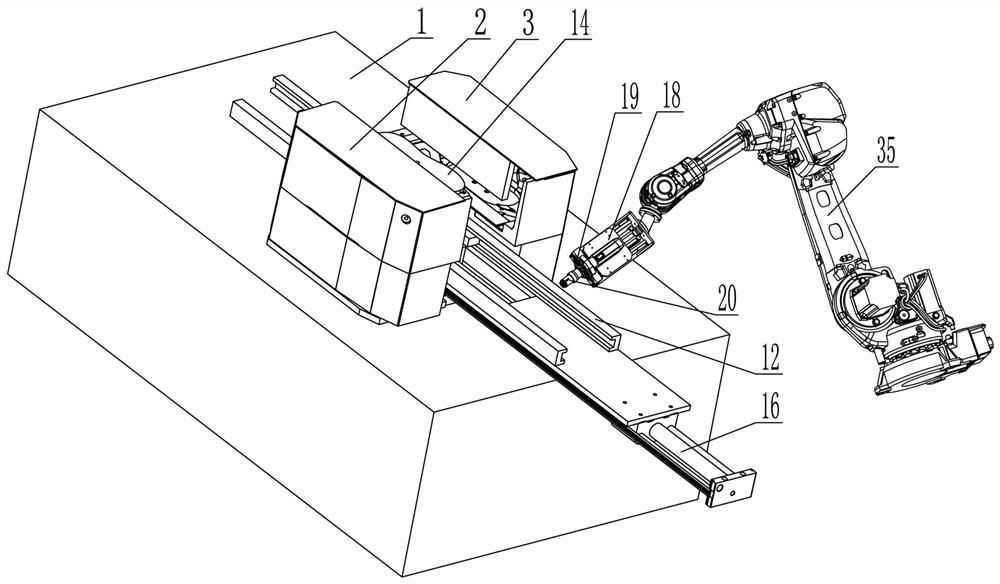

Surface treatment process system and process of automobile plastic parts

The invention discloses a surface treatment process system for automobile plastic parts, comprising a liquid sandblasting and grinding box, wherein an inclined guide plate is arranged in the liquid sandblasting and grinding box, and the upper side of the guide plate is a jet grinding cavity , the lower side of the baffle is provided with a vertical baffle, the left side of the baffle is a waste liquid cavity, and the right side of the baffle is a lifting motor cavity; the short end of the baffle is provided with Leakage hole; this scheme does not need to manually adjust the attitude of the workpiece to be sprayed, adjust the spray angle and other interventions in all processes, and improve the automation of the sandblasting process.

Owner:瑞安市强良塑料制品有限公司

An electrospinning device with a tine cage electrode

ActiveCN105401233BHas a sharp charge accumulation effectEasy to induceFilament/thread formingEngineeringElectric field

Owner:DONOGGUAN AIR GUARD MFG CO LTD

Main combustible stage tangential oil supply premix and pre-evaporation combustion chamber

ActiveCN101799174BSimple structureImprove efficacyContinuous combustion chamberCombustion chamberStaged combustion

The invention relates to a main combustion stage tangential oil supply premix and pre-evaporation combustion chamber. The combustion chamber is in a single-ring chamber structure and is designed by adopting the conceptual design of staging combustion, and all the used amount of gas for combustion is supplied by the precombustion stage and the main combustion stage. The combustion chamber mainly comprises a flow-dividing type diffuser, a combustion chamber outer case, a combustion chamber inner case, a fuel nozzle, the precombustion stage, the main combustion stage, a flame tube outer wall anda flame tube inner wall. The precombustion stage utilizes a low-speed flow returning zone generated by swirl air entering the combustion chamber by a precombustion stage swirler component; the fuel needed by the main combustion stage is ejected by the tangential main combustion stage nozzle, is atomized under the air flow effect generated by entering of atomized air of the main combustion stage nozzle into a pipe, then flows into a premix and pre-evaporation ring pipe for evaporation, and is further blended with air; and even oil-gas mixed gas formed at the outlet of the premix and pre-evaporation ring pipe enters a flame tube and combusts under the pilot combustion of the precombustion stage flame. The combustion chamber has simple structure, and can effectively reduce the discharge of pollution simultaneously while guaranteeing that an aeroengine is in normal working state.

Owner:BEIHANG UNIV

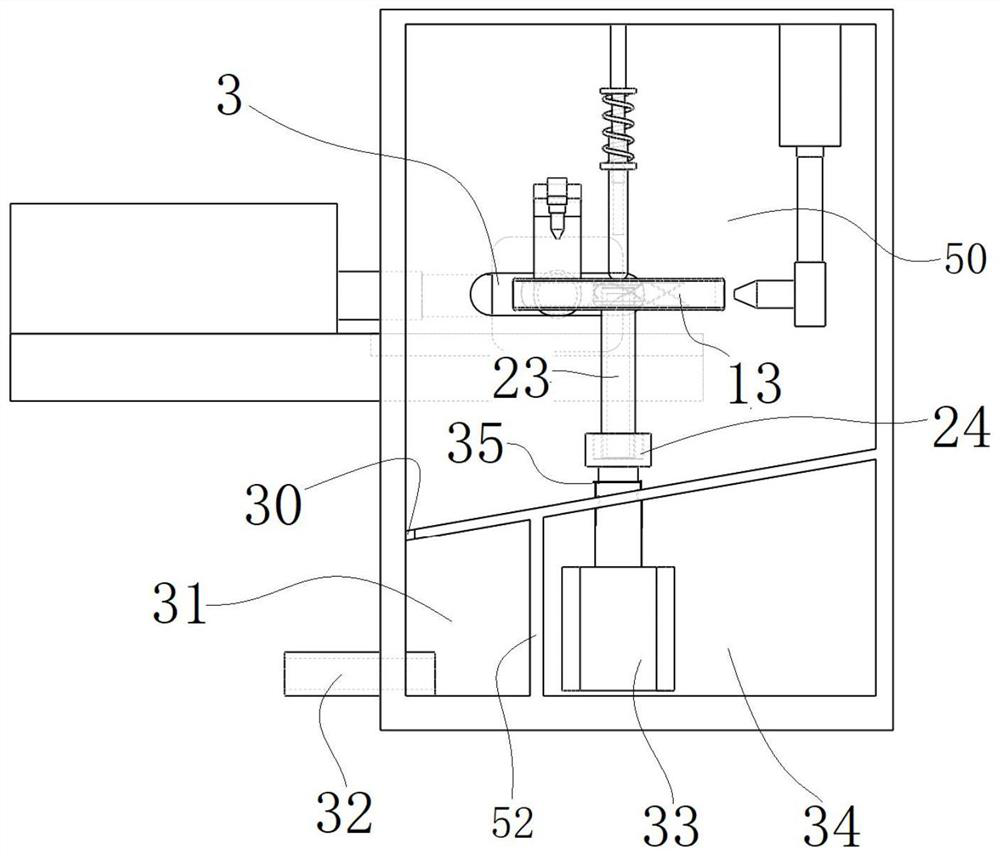

Spiral jet polyurethane upper-connected shoemaking device and preparation process thereof

The invention discloses a spiral jet polyurethane upper-connected shoemaking device. The device comprises a base, a bottom die device, a left side die and a right side die and further comprises a spiral jet device used for spraying raw materials. The invention further discloses a multi-component polymer mixed spiral jet flow shoemaking preparation process. The process comprises the steps: a bottom die moves to the outer portions of the left side die and the right side die; a plurality of polymer raw materials are added into a feeding mechanism of the spiral jet flow device and sprayed to the shoe sole in a spiral airflow mode, and a jet flow layer used for combining the shoe upper and the shoe sole is formed; and the left mold and the right mold press the shoe last to be combined with the bottom mold, and the polymer jet flow layer sprayed on the shoe sole expands and enters the shoe upper and the shoe sole in a diffusion and permeation mode, so that the shoe upper and the shoe sole can be combined. The bottom die can be conveniently and rapidly replaced and cleaned, the spiral jet flow device can conveniently spray raw materials on the bottom die, widened special shoes and boots can be produced, the jet flow amount is large, the edge track of a formed jet flow conical surface is clear, and the device is suitable for production of all the shoes and boots.

Owner:JIHUA 3514 LEATHER & FOOTWARE

Liquid divider

ActiveCN100473921CReduce the diffusion angleAvoid direct shuntingFluid circulation arrangementEngineeringRefrigeration

Owner:GREE ELECTRIC APPLIANCES INC

Array jet plasma system and method for rapidly disinfecting surface pathogenic microorganisms

Owner:BEIHANG UNIV

Atomizing nozzles for sanitary spouts and sanitary fittings with spouts

ActiveCN105008054BUniform jetEasy to manufactureSpray nozzlesDomestic plumbingAtomizer nozzleEngineering

The invention relates to an atomizing nozzle (1) for a sanitary water outlet, the atomizing nozzle (1) being used for atomizing water under pressure. The atomizing nozzle (1) according to the invention is characterized in that the atomizing nozzle (1) comprises a swirl chamber (2) into which at least one is oriented transversely to the longitudinal axis of the nozzle and enters approximately tangentially. The supply channel (4) opens into the swirl chamber, and the swirl chamber (2) tapers in the outflow direction towards the nozzle channel (5). With the aid of the atomizing nozzle (1), it is possible to generate a water jet with a uniform jet shape, which despite a low volume flow still gives the impression of a large-volume water jet.

Owner:NEOPERL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com