Abrasive slurry for abrasive slurry jet processing and preparation method thereof

An abrasive slurry jet, abrasive slurry technology, applied in chemical instruments and methods, polishing compositions containing abrasives, other chemical processes, etc., can solve problems such as immaturity, achieve uniform dispersion and precipitation, reduce production costs, The effect of increasing dispersion and suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

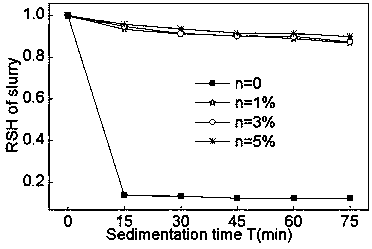

[0033] A kind of abrasive slurry that is used for abrasive slurry jet processing of the present embodiment, comprises water and abrasive material, and described abrasive grain diameter is 0.5 micron, and described abrasive slurry also comprises dispersant, and the mass concentration of described dispersant 0% to 5%, the dispersant is organic dispersant and / or inorganic dispersant, further, the model of the dispersant is SAM1112 dispersant, SAM dispersant is mainly used for grinding and dispersing various inorganic materials in water , the general dosage during wet grinding is 0.1% to 0.2% of the dry powder, the abrasive concentration is 50 to 70%, and can reach below 5 microns. If a finer particle size is required, the abrasive concentration can be appropriately reduced and the dispersant concentration can be increased. It is used for polishing processing of brittle and plastic materials, further, the brittle and plastic materials are die steel.

[0034] In a preferred embodim...

Embodiment 2

[0042] A kind of abrasive slurry that is used for abrasive slurry jet processing of the present embodiment, comprises water and abrasive material, and described abrasive grain diameter is 0.5 micron, and described abrasive slurry also comprises dispersant, and the mass concentration of described dispersant 0% to 5%, the dispersant is organic dispersant and / or inorganic dispersant, further, the model of the dispersant is SAM1112 dispersant, SAM dispersant is mainly used for grinding and dispersing various inorganic materials in water , the general dosage during wet grinding is 0.1% to 0.2% of the dry powder, the abrasive concentration is 50 to 70%, and can reach below 5 microns. If a finer particle size is required, the abrasive concentration can be appropriately reduced and the dispersant concentration can be increased. It is used for polishing processing of brittle and plastic materials, further, the brittle and plastic materials are die steel.

[0043]In a preferred embodime...

Embodiment 3

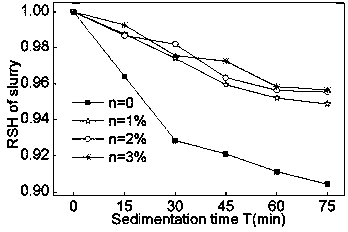

[0051] An abrasive slurry for abrasive slurry jet processing in this embodiment includes water and abrasives, the abrasive particle size is 0.5 micron, and the abrasive slurry also includes a suspending agent, and the suspending agent is polyethylene Alcohol, the mass concentration of the polyvinyl alcohol is 0.4% to 5%, and the abrasive slurry is used for polishing of brittle and plastic materials, further, the brittle and plastic materials are die steel.

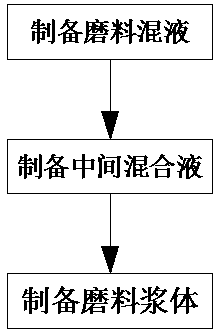

[0052] A method for preparing abrasive slurry for abrasive slurry jet processing, comprising the steps of:

[0053] (1) Take 50g of alumina abrasive, add it to 1L of water, mix and stir evenly to obtain the abrasive mixture, and set aside;

[0054] (2) Take 0.2 g of suspending agent, add it to the abrasive mixture prepared in step (1), mix and stir evenly, and prepare alumina abrasive slurry.

[0055] In a preferred embodiment, the suspending agent is polyvinyl alcohol suspending agent, and the suspending agent is polyvin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com