Patents

Literature

150results about How to "Even consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

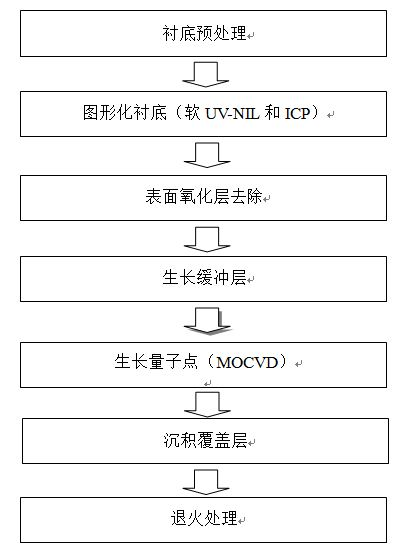

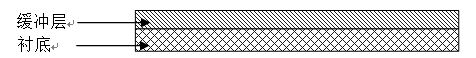

Manufacture method of large-area highly uniform sequential quantum dot array

InactiveCN101830430AReduce sizeSmall sizeNanostructure manufactureUltravioletInductively coupled plasma

The invention relates to a manufacture method of a large-area highly uniform sequential quantum dot array. The method comprises the following steps of: preparing a nanopore graphic array on a substrate by adopting soft ultraviolet nano imprint lithography (UV-NIL) and an inductively coupled plasma (ICP) technology; and growing quantum dots in a self-organizing way by using a prepared graphical substrate as a template and using a metal organic chemical vapor deposition (MOCVD) system. The invention realizes the low-cost, consistent and batched preparation of the large-area highly uniform sequential quantum dot array and can be applied to manufacture of devices such as quantum dot lasers, quantum dot memories, quantum dot solar batteries, quantum dot LEDs, single photon emitters, and the like.

Owner:SHANDONG UNIV

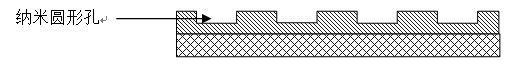

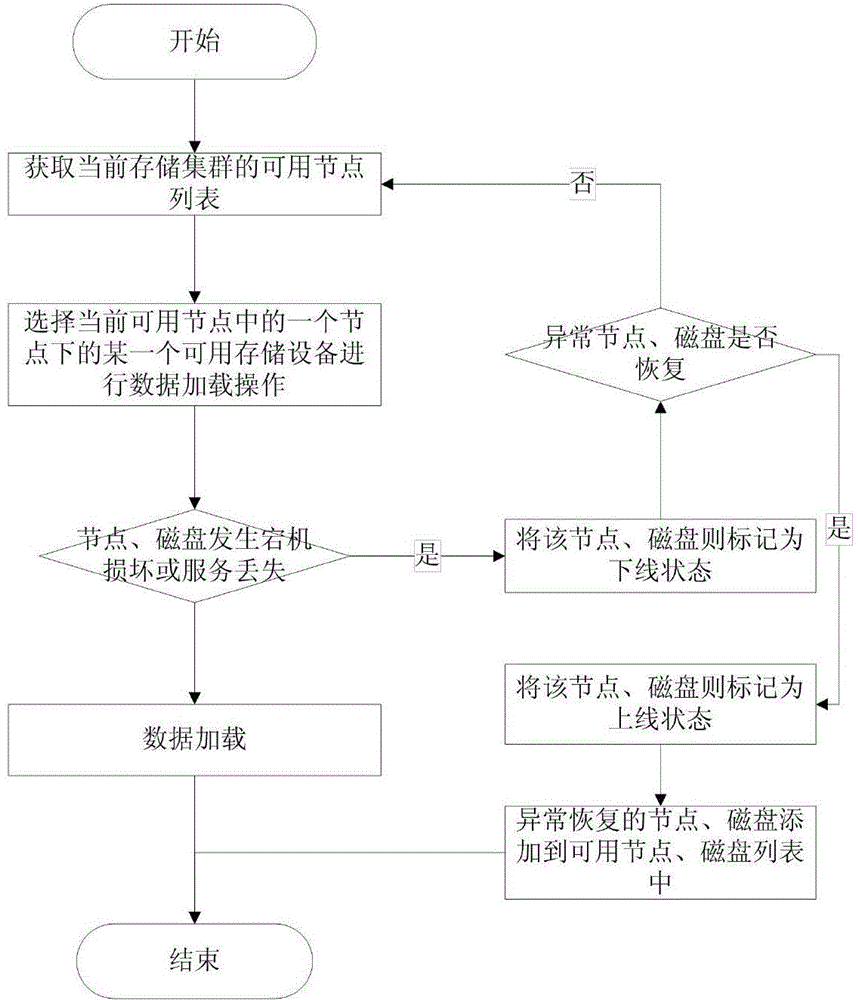

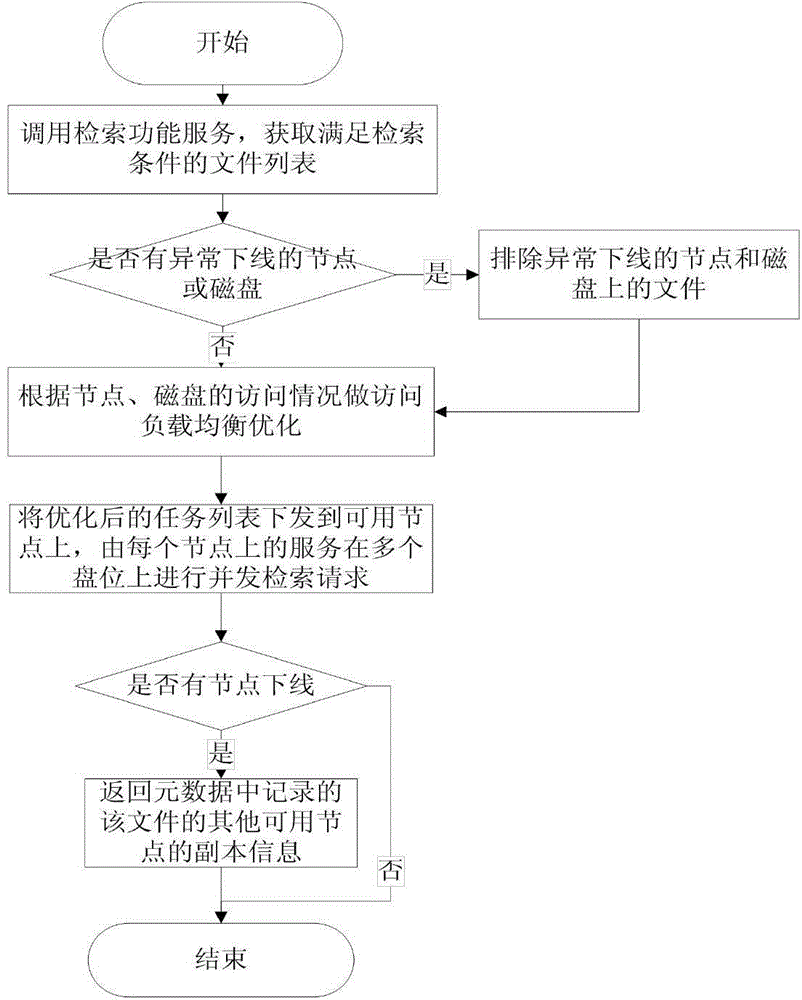

Massive data storage method based on file granularity

ActiveCN104657459AEnsure consistencyEven consistencyFile access structuresSpecial data processing applicationsOrganizational flexibilityMetadata management

The invention discloses a massive data storage method based on file granularity. The massive data storage method comprises the following steps of (1) dividing a data storage cluster into a plurality of partitions, wherein each partition is provided with a partition value; (2) creating a business data sheet for the record of each department, and setting a partitioning rule for the records of each business data sheet; (3) for each record in the to-be-stored business data, storing into a file of the corresponding partition according to the number and a partitioning rule, and creating an index file; storing the number of the record, the path of the file, the number of a storage node, and the number of storage equipment into a metadata file; furthermore, creating a view between the business data sheets; according to the metadata file, separating the business data sheet, the view, the record partition and the index information belonging to the same business scene into the same database, so as to obtain a massive metadata management model. The massive data storage method has the advantages that the data management accuracy is improved, and the data division and organization flexibility is improved.

Owner:INST OF INFORMATION ENG CAS

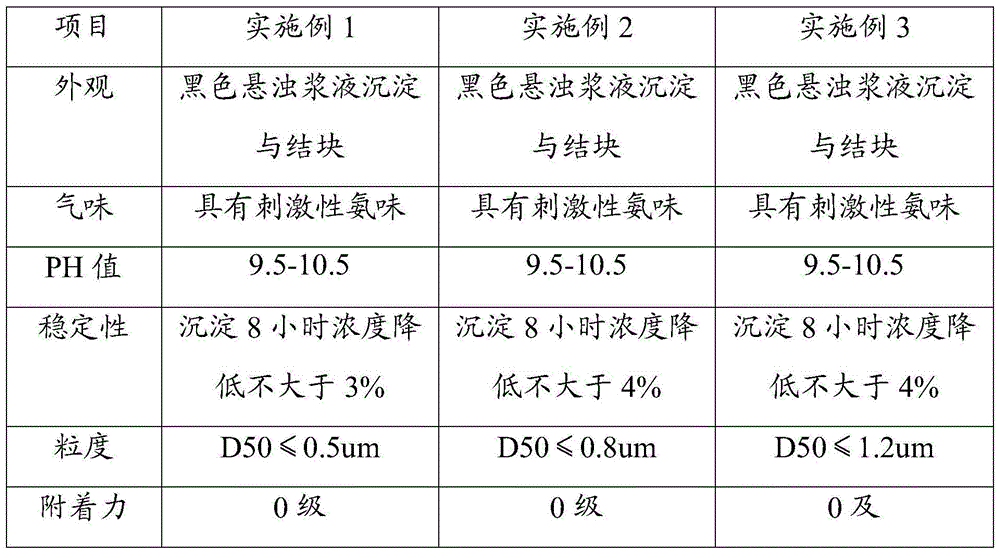

Heat resistant lubricant used for drawing refractory metal and preparation method thereof

InactiveCN104403771ALow impurity contentImprove the lubrication effectLubricant compositionPolymer scienceAdhesive

The invention discloses a heat resistant lubricant used for drawing refractory metal and a preparation method thereof. The heat resistant lubricant comprises the following components by weight: 10-30% of graphite, 0.1-2% of dispersant, 0.3-5% of thickening agent, 0.1-15% of emulsifier, 0.5-10% of film forming agent, 2-5% of ammoniacal liquor with concentration of 25%, 0.1-1% of antiseptic, 0.1-2% of adhesive, 0.3-3% of surfactant and balance of water. The heat resistant lubricant has good adhesive force under high temperature and can not generate explosion and shedding, lubricity, thermal conductivity and surface antioxidation performance between the drawing material and a mold can be effectively increased, heat due to friction can be reduced, and usage life of the mold can be prolonged.

Owner:GUANGDONG DONGGUAN TEAMRUN ELECTRONICS MATERIAL

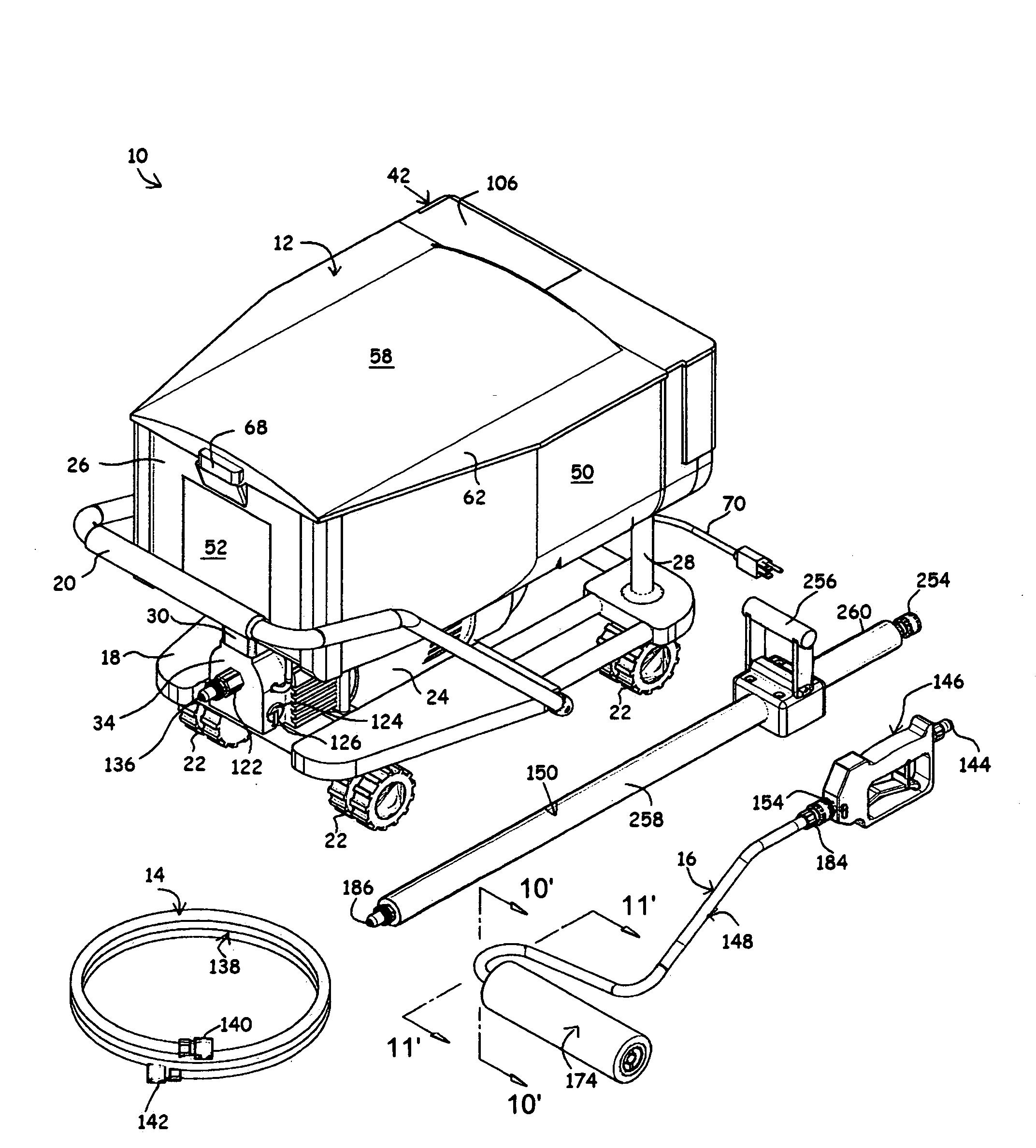

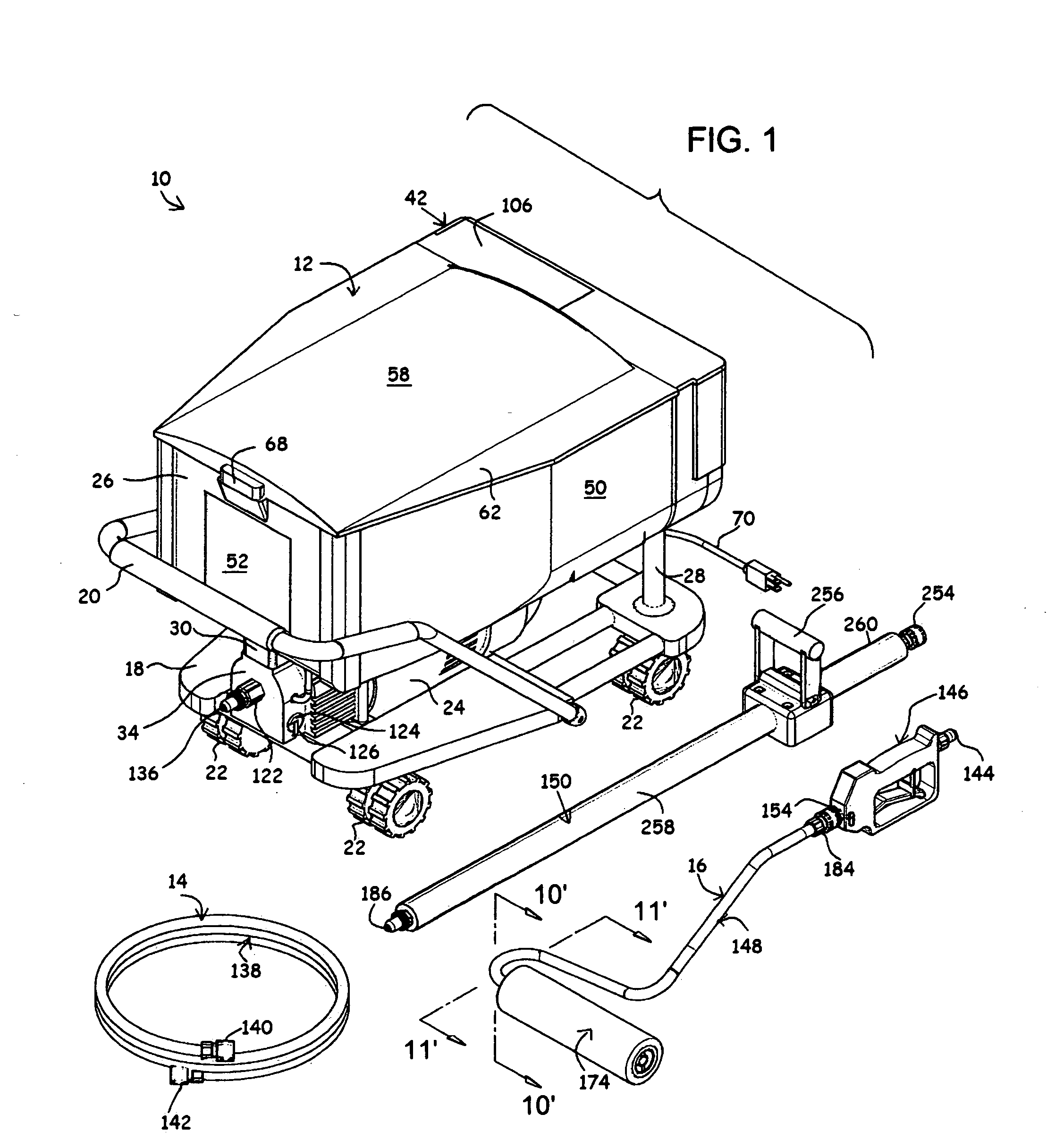

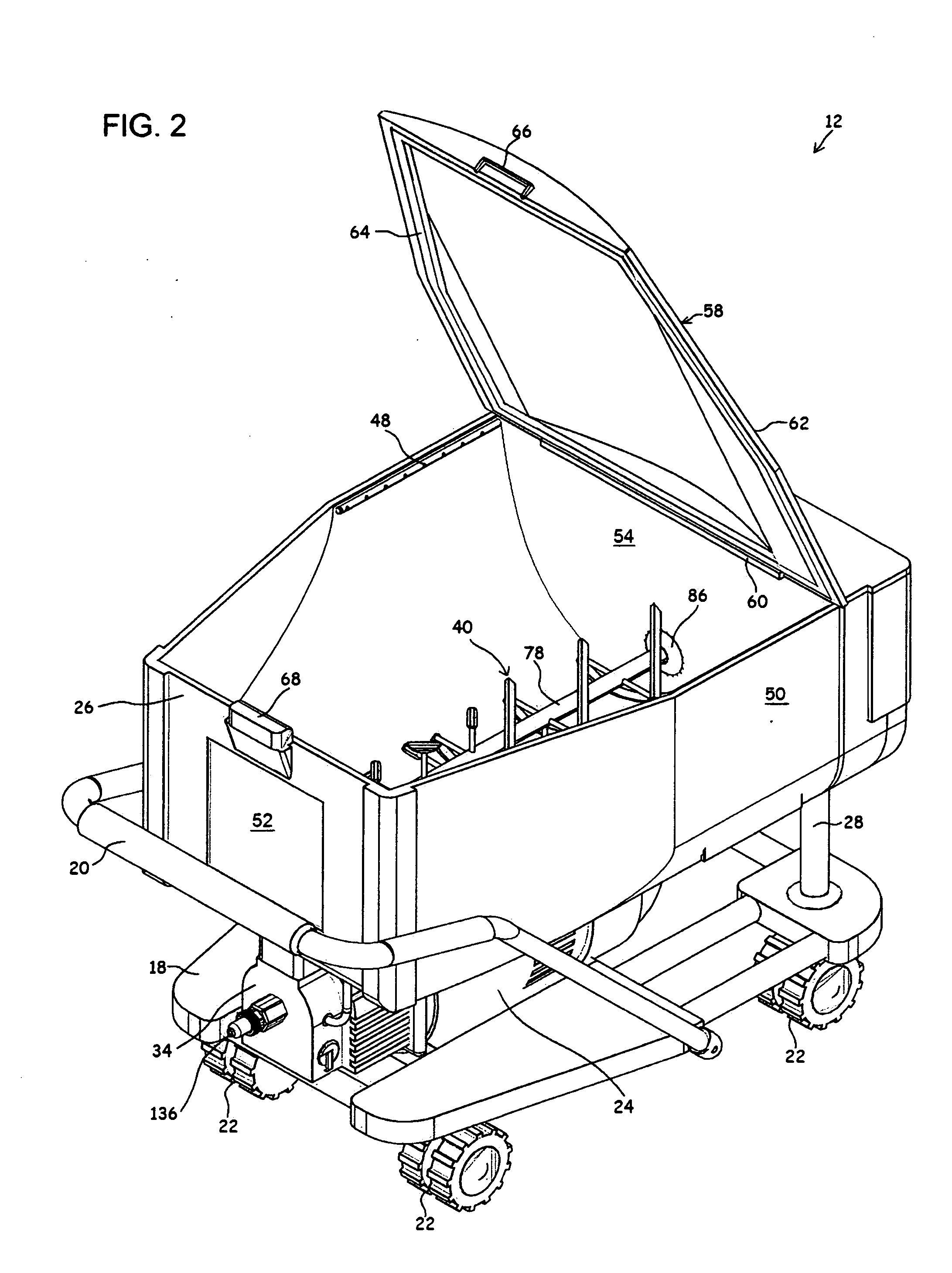

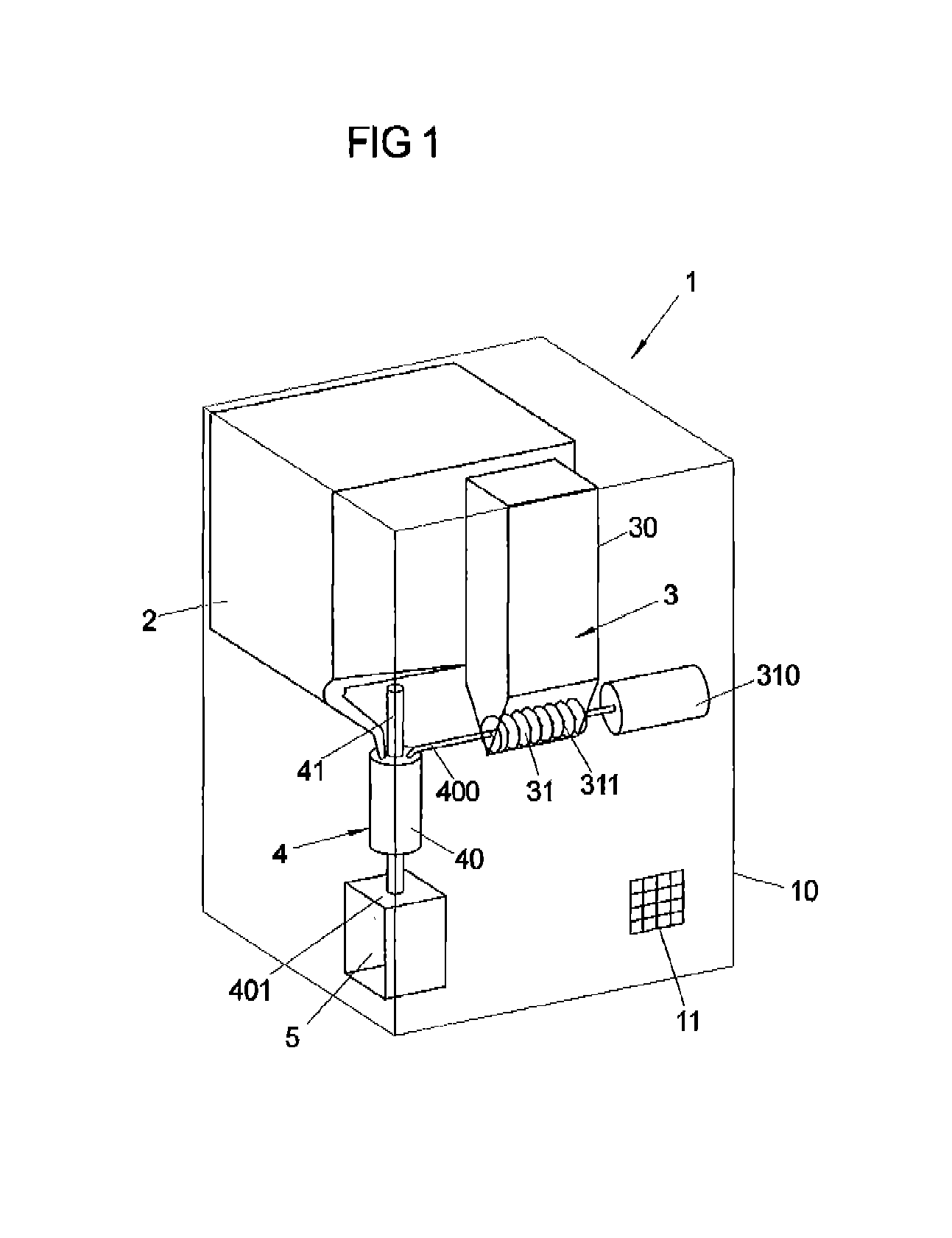

Joint compound tool

InactiveUS20100014908A1Eliminates messShorten the timeLiquid surface applicatorsBuilding constructionsDrive shaftJoint compound

A joint compound tool including a mixer, a hose, and an applicator. The mixer has a hopper and a beater positioned therein. The beater has a rotatable drive shaft that is journaled in the opposed ends of the hopper. A number of first support rods radiate outwardly from the drive shaft remote from the hopper outlet. A pair of intertwined, helical bands encircle the drive shaft and are affixed thereto by the first support rods. A number of second support rods radiate outwardly from the drive shaft adjacent the hopper outlet. A number of blades are secured to the second support rods. A motor is connected to the drive shaft for rotating the beater. A pump is connected to the hopper outlet for pressurizing joint compound received from the hopper. A hose connects the pump to a joint compound applicator having a valve assembly for controlling the flow of joint compound received from the hose and a roller assembly for applying joint compound to drywall.

Owner:CAMPBELL SHAWN O +1

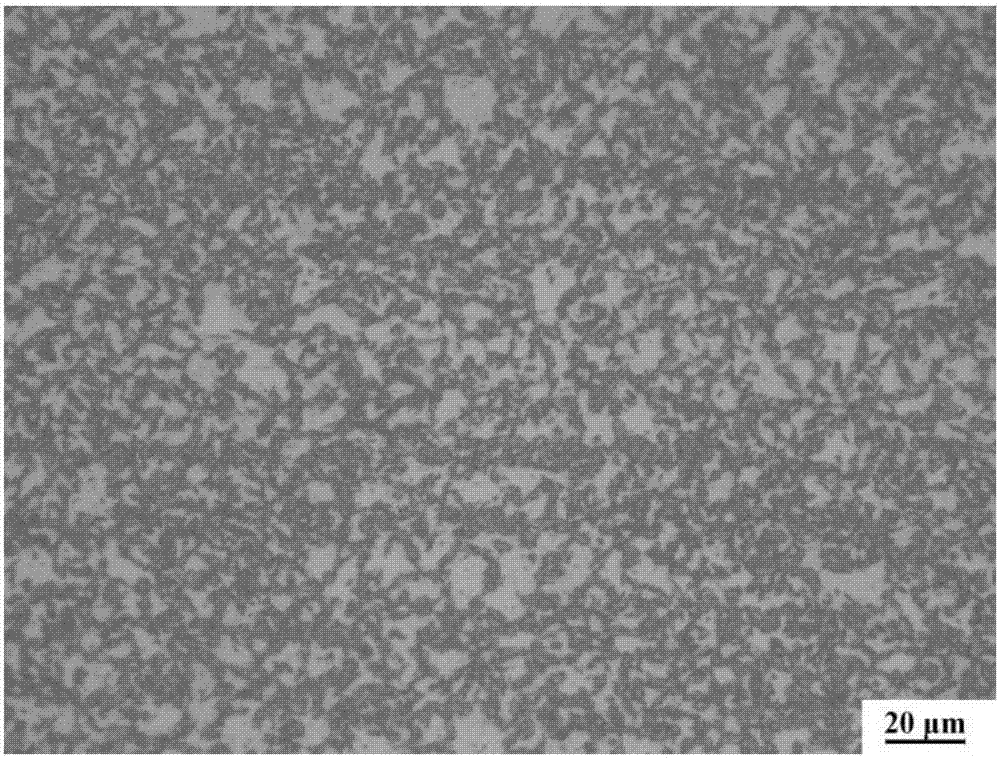

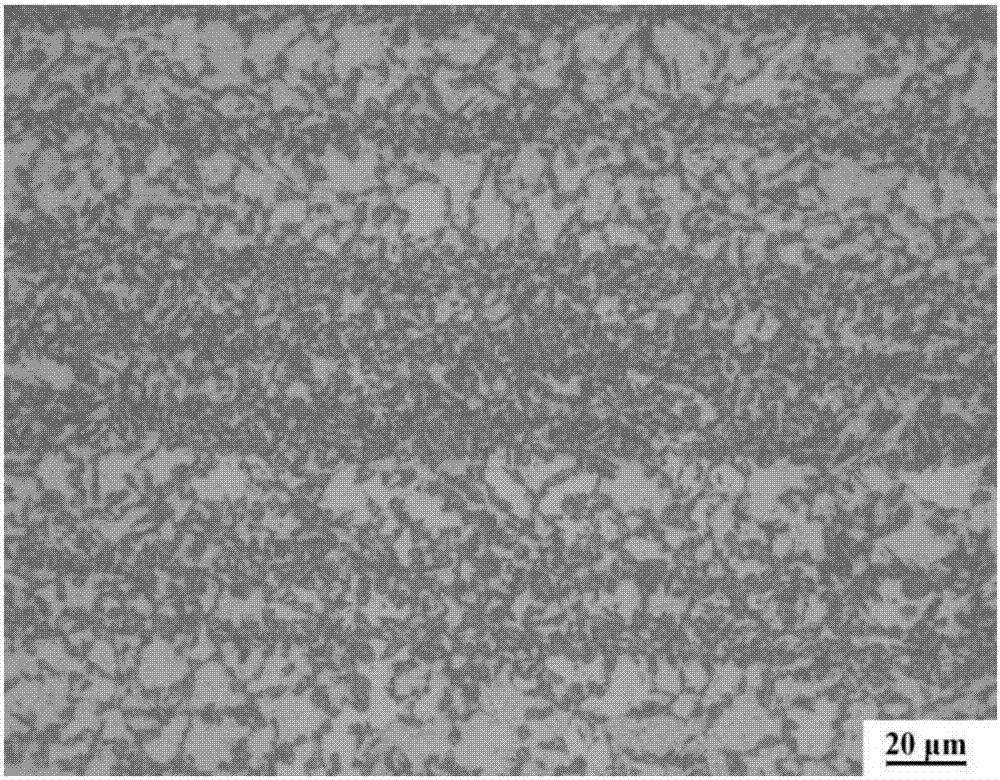

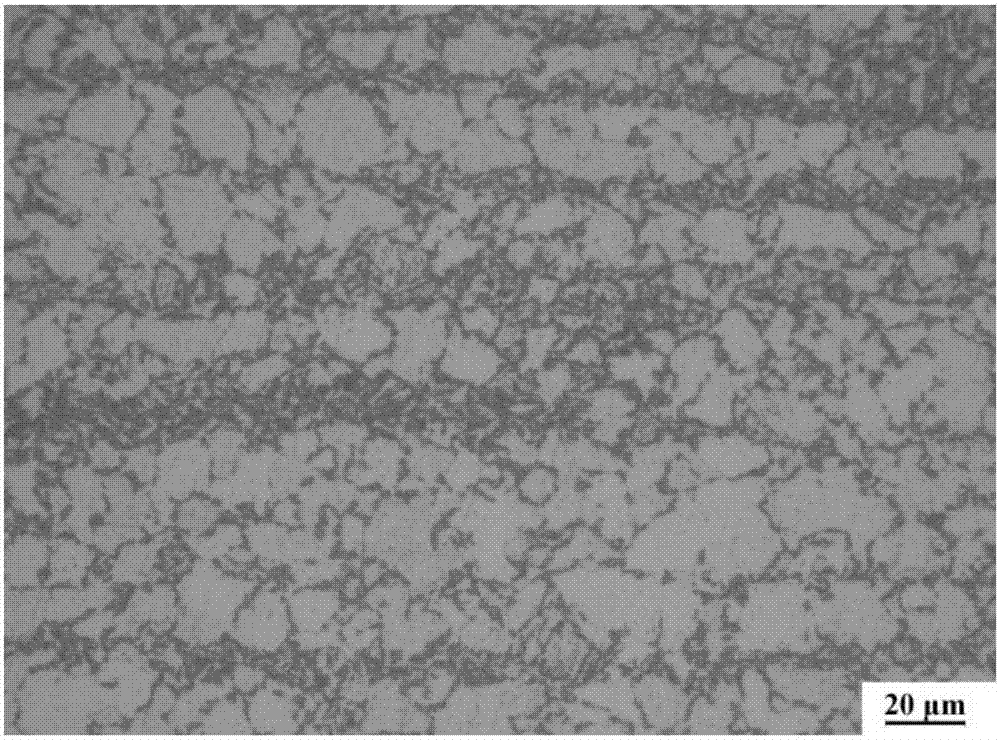

Toughening and deformation processing method of magnesium alloy

The invention discloses a toughening and deformation processing method of a magnesium alloy, which performs toughening and deformation processing on a melted and homogenized magnesium alloy billet. The method is combined by any more than two methods of metal plastic deformation processing methods containing forging deformation processing, extruding deformation processing, rolling deformation processing and stamping deformation processing, a latter deformation processing method is carried out on the magnesium alloy directly after the former deformation processing method or after the magnesium alloy is split when the former deformation processing method is finished, heating is not carried out between the two deformation processing methods, the magnesium alloy material after deformation processing is immediately subjected to water spray cooling or blow cooling when the last deformation processing method is finished, and the cooled magnesium alloy material is performed with aging heat treatment. The method in the invention can obviously and evenly refine the interior textures of the magnesium alloy material, improve the mechanical property and uniformity of the magnesium alloy material, avoid texture coarsening of a magnesium alloy deformation workpiece in reheating and heat insulation processes, and save energy.

Owner:GRIMAT ENG INST CO LTD

Fiber matrix composite material made from recycled carpet

InactiveUS20050233126A1Increase flexibilityFine surfaceSynthetic resin layered productsPlastic recyclingThermoplasticComposite construction

The invention relates to a composite structural material comprising a fiber dispersed in a fused matrix, wherein the fiber is derived from carpet, carpet recycle, carpet scrap, or mixtures thereof, and wherein the fused matrix comprises a thermoplastic comprising nylon, polyolefin, or mixtures thereof. The invention also relates to a method of manufacturing a rigid board composite structural material comprising the steps comminuting carpet to a predetermined particle size, adjusting the carpet feed stock to a form a balanced feed stock, introducing the feed stock into an extruder, and extruding the feed stock to form a structural composite comprising fiber dispersed in a fused matrix.

Owner:INNOVATION INC

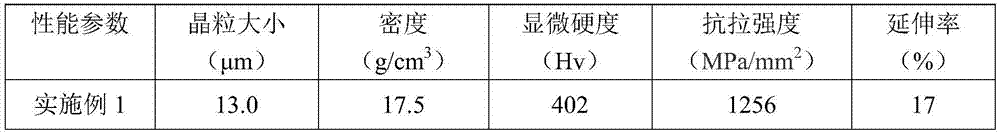

Missile heavy-gravity tungsten alloy and preparation method thereof

Owner:HENAN UNIV OF SCI & TECH

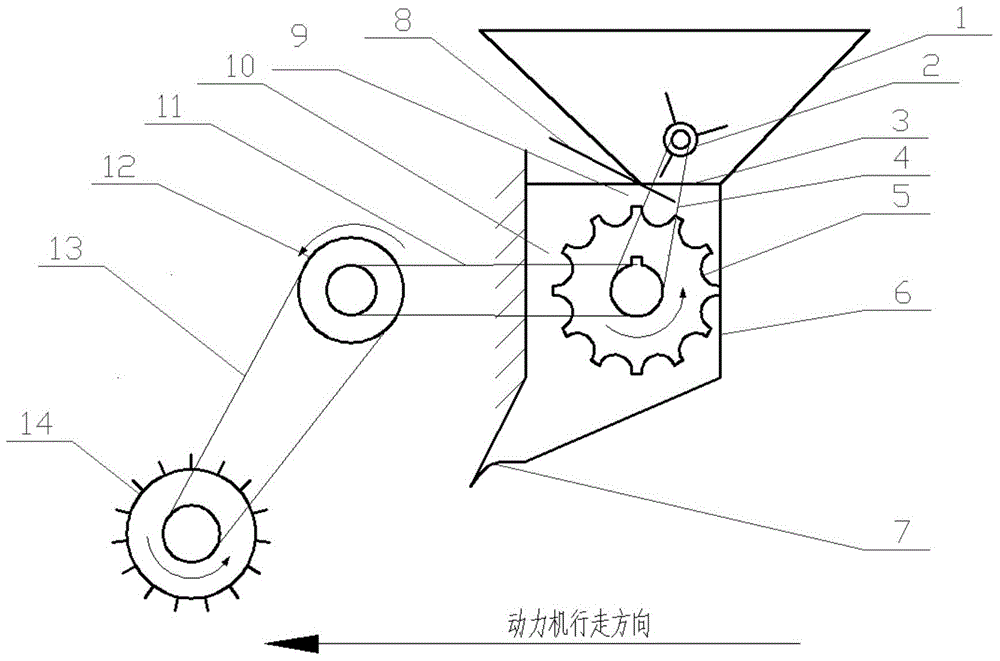

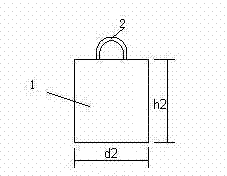

Fertilizer applying device

InactiveCN105165212APrecision fertilizationEven consistencyFertiliser distributersDrive wheelAgricultural engineering

The invention discloses a fertilizer applying device. A hopper is arranged above a casing of a fertilizer discharging device of the fertilizer applying device, a fertilizer discharging port is formed in the bottom of the casing of the fertilizer discharging device, a blanking port of the hopper is close to the side of a clamping wall of the casing of the fertilizer discharging device, a driving wheel is arranged in the casing of the fertilizer discharging device, two ends of the driving wheel are fixed on inner walls on two sides of the clamping wall of the casing of the fertilizer discharging device through a rotary shaft, a motion clearance exists between the driving wheel and the clamping wall only, and the driving wheel is driven by a power mechanism to rotate from one side of the clamping wall from bottom to top. The fertilizer applying device has the advantages that the principle that the driving wheel performs transfer and quantitative conveyance is adopted, accurate quantitation, simultaneous fertilizer application and mechanical walking as well as uniform and consistent fertilizer application can be realized, and the fertilizer discharging device is not blocked, can discharge fertilizer smoothly and can be adapted to different granular and compound fertilizer. Compared with a traditional operation manner, the device has the characteristics of accurate fertilizer application, good consistency, high working efficiency, low labor intensity, convenience in operation and the like.

Owner:ANHUI WANNAN TOBACCO LEAF +2

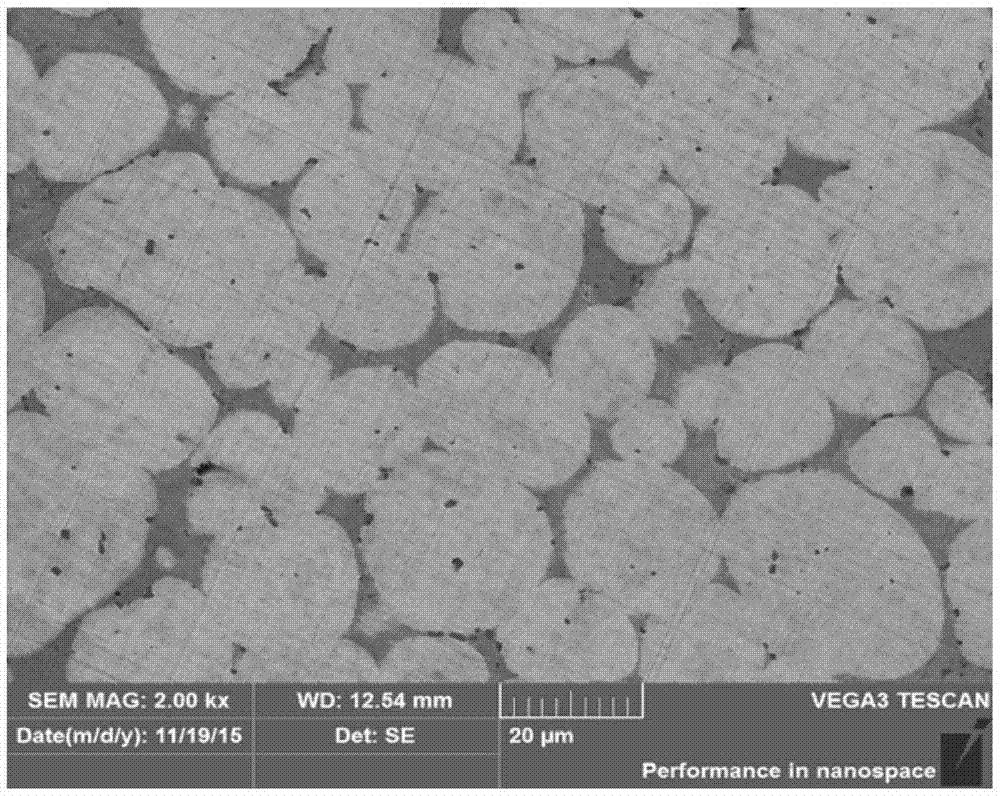

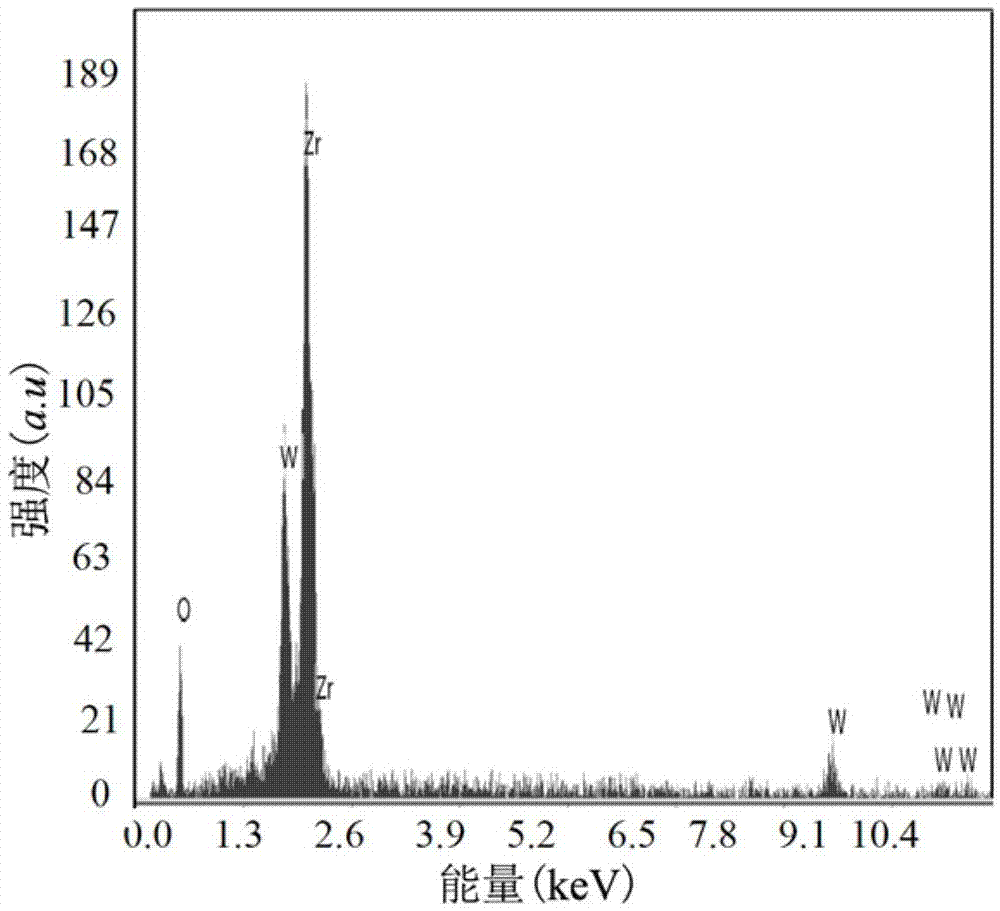

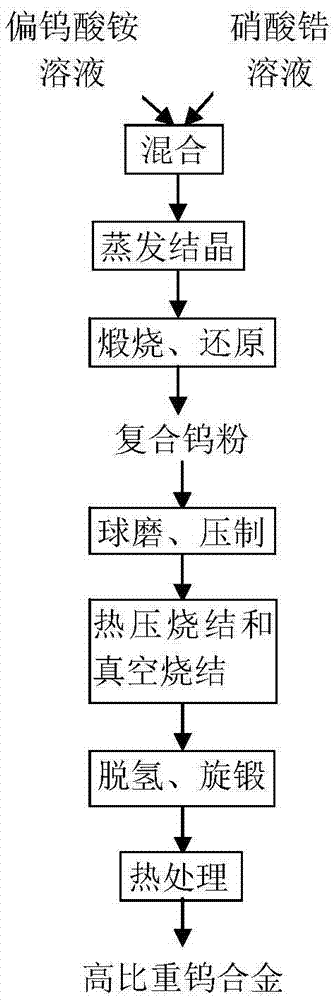

High-density tungsten alloy and preparation method thereof

The invention discloses a high-density tungsten alloy and a preparation method thereof, belonging to the field of metal materials. The tungsten alloy comprises the following components in percentage by mass: 95.0-99.0 percent of tungsten, 1.0-5.0 percent of zirconium oxide and inevitable impurities. The preparation method comprises the following steps: (1) respectively dissolving ammonium metatungstate and zirconium nitrate in water for mixing; drying the mixed liquid, and thus obtaining powder; calcining and reducing the powder, and thus obtaining composite tungsten powder; (2) after ball milling, carrying out compression molding and sintering for the composite tungsten powder, and thus obtaining a sintering billet; after dehydrogenation, carrying out deformation and thermal treatment for the sintering billet, and thus obtaining the high-density tungsten alloy. According to the preparation method, a ZrO2 strengthening phase is added in a tungsten matrix through a liquid-liquid doping method, and two segments of sintering processes, dehydrogenation and rotary swaging treatment are adopted to prepare the tungsten alloy. The preparation method solves the problems of uneven distribution of the strengthening phase of the traditional tungsten alloy, hydrogen embrittlement and low sintered density and provides a new direction for the application and development of the tungsten alloy in the new field.

Owner:HENAN UNIV OF SCI & TECH

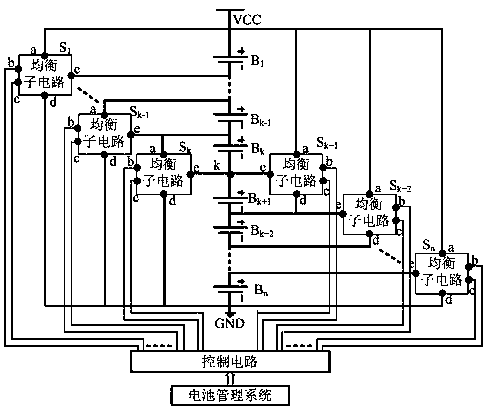

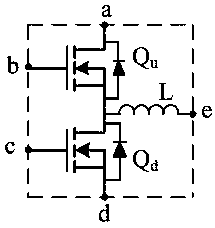

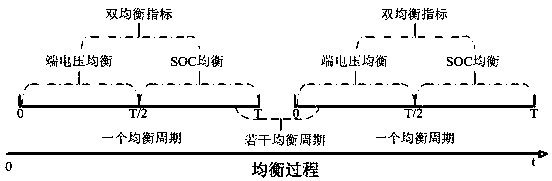

Dual-target direct equalization circuit and equalization method of battery pack

ActiveCN107733007AImprove safety and reliabilityImprove safety and reliability performanceCharge equalisation circuitCharging stationsMOSFETElectrical battery

The invention discloses a dual-target direct equalization circuit of a battery pack. A series battery pack comprises at least three single batteries and is divided into an upper part and a lower part,each single battery is connected with an equalization sub-circuit, the equalization sub-circuit comprises two metal-oxide-semiconductor field-effect transistors (MOSFETs) and an energy storage inductor, the series battery pack and the equalization sub-circuit bridge between VCC and GND, each equalization circuit is also connected with a control circuit to achieve direct equalization on an equalization target, the control circuit is used for equalizing end voltages and SOC of the single batteries in a stage way within an equalization period by simultaneously taking the end voltages and the SOCof the single batteries as equalization indexes, and dual-target equalization on the end voltages and the SOC of the single batteries is achieved by controlling on / off of the two MOSFETs of the equalization sub-circuit and by an energy storage effect of the energy storage inductor. The equalization circuit and an equalization strategy are applicable to an equalization management system of an energy storage device in a hybrid electric vehicle, a blade electric vehicle and an energy storage power station.

Owner:HENAN POLYTECHNIC UNIV

Communication equipment metal shell and preparation method thereof

InactiveCN105530787AAvoid deformationInfluence throughCasings/cabinets/drawers detailsMetal casingsMetal substrateNanotechnology

The invention discloses a communication equipment metal shell and a preparation method thereof. The communication equipment metal shell disclosed by the invention comprises a metal substrate, more than one slit and a plastic support layer, wherein the more than one slit runs through the metal substrate; and the plastic support layer covers at least one part of the inner surface of the metal substrate and fully fills the slits. The communication equipment metal shell which is suitable for various antennas and has an integrated effect in appearance can be provided.

Owner:BYD CO LTD

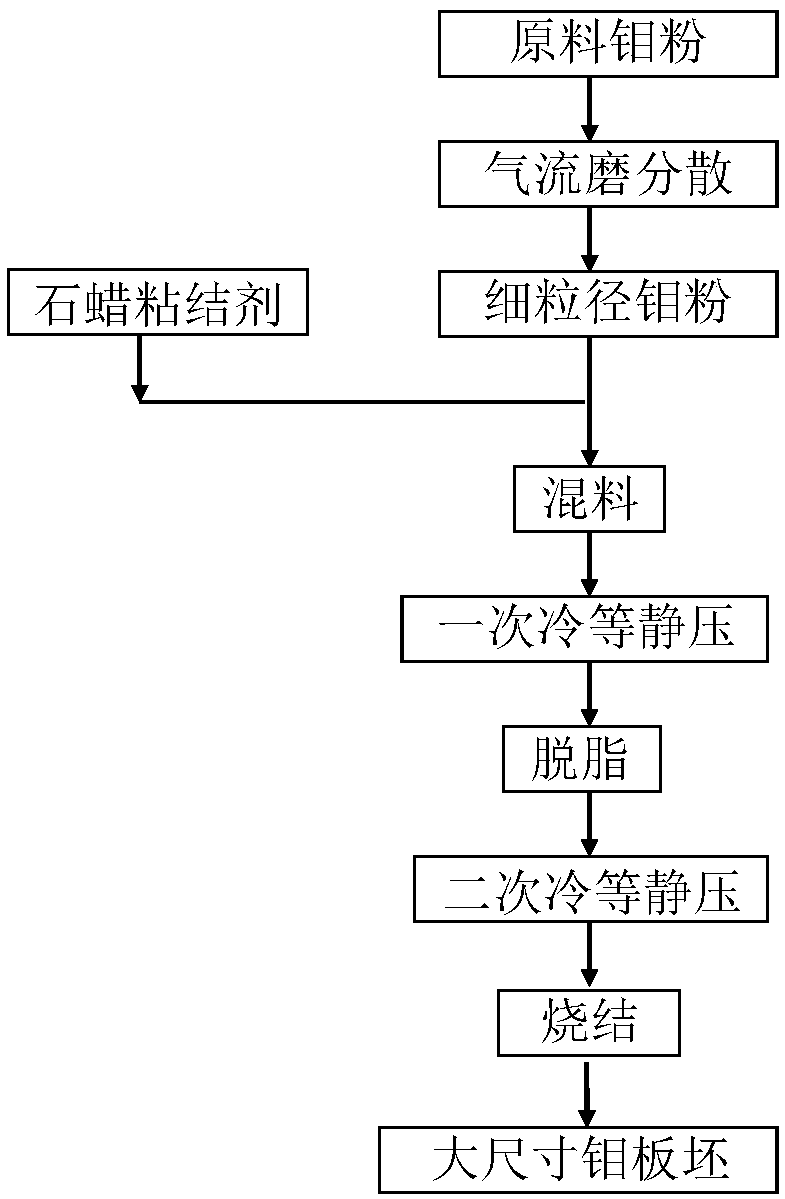

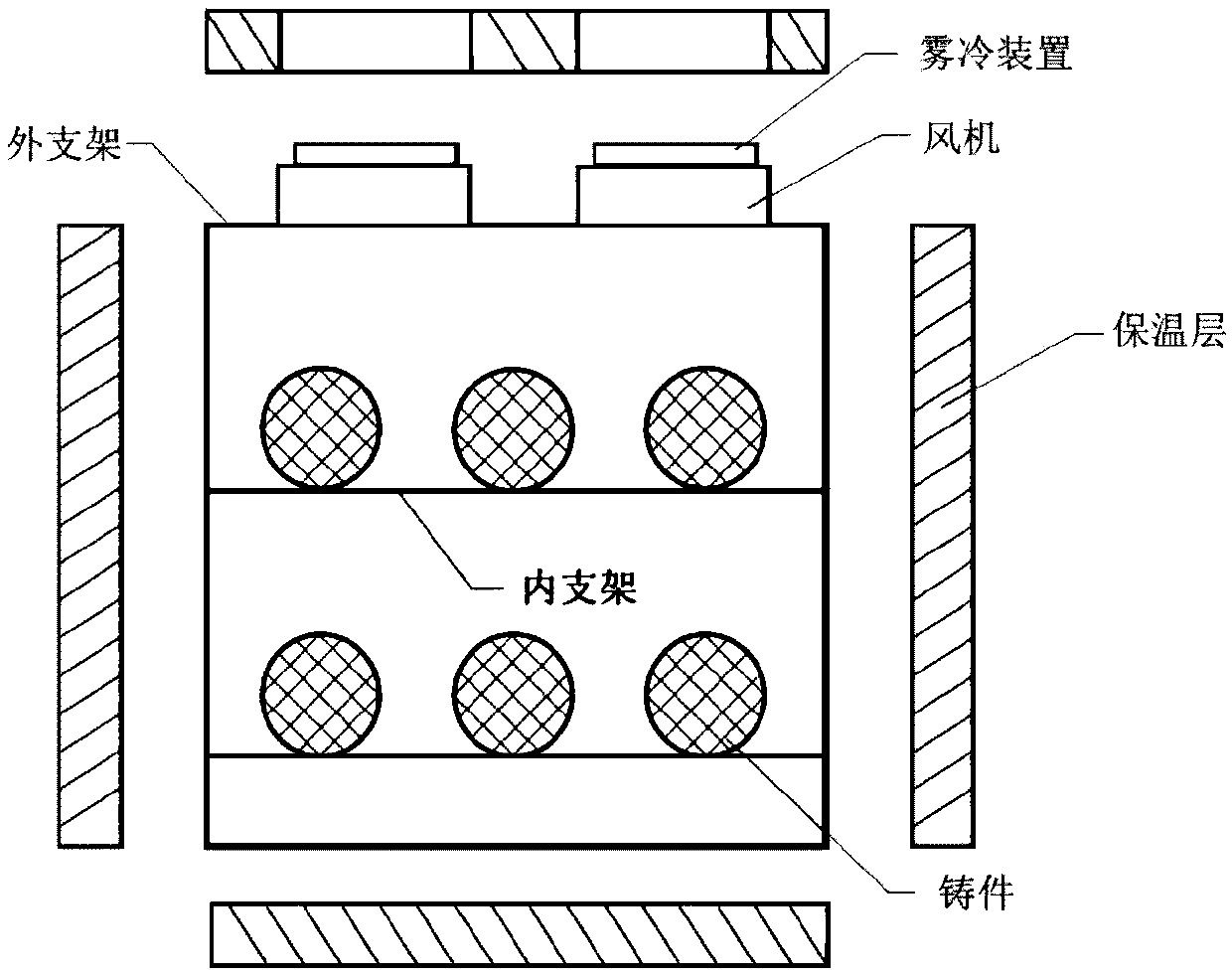

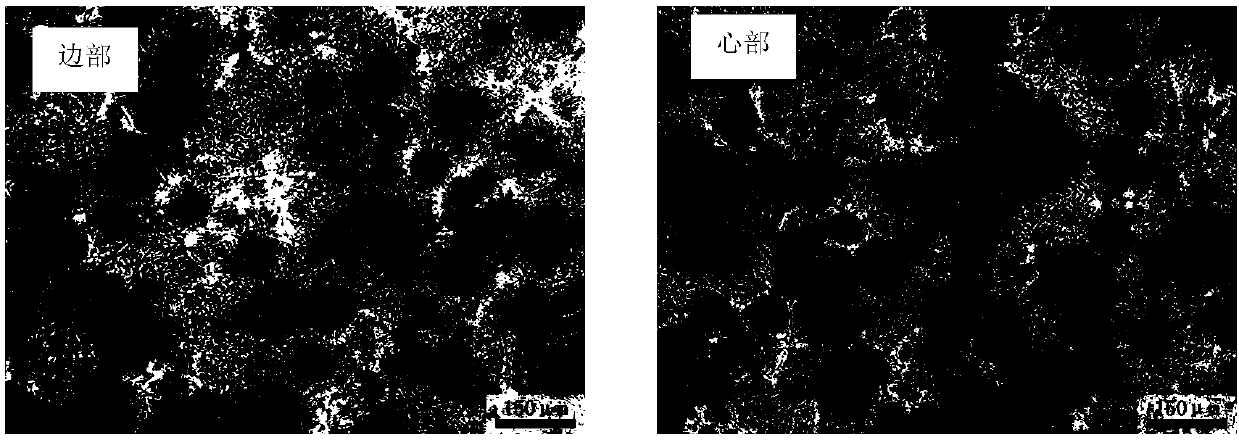

Method for preparing large-size molybdenum plate blank

ActiveCN108907211AGood dispersionUniform particle size distributionTransportation and packagingMetal-working apparatusHigh pressureMaterials science

The invention provides a method for preparing a large-size molybdenum plate blank, and belongs to the technical field of powder metallurgy. The method includes the steps that reducing molybdenum powder serves as a raw material, and small-granularity molybdenum powder which is evenly dispersed, has narrow granularity distribution and is nearly spherical is obtained through airflow milling treatment; then the small-granularity molybdenum powder and a paraffin binder are evenly mixed, and a mixture is obtained; and then by the adoption of a secondary isostatic cool pressing forming process, a degreased blank is isostatically pressed into a secondary blank under high pressure intensity. A sintering method of low-temperature slow heating and high-temperature rapid heating is adopted, specifically, slow heating is carried out at a low-temperature sintering stage, the blank is fully reduced in order to reduce the oxygen content in a blank body, and therefore the sintering activity of the blank is kept; and rapid heating is carried out at a high-temperature sintering stage, grain growth can be reduced, and after sintering is completed, the thick molybdenum plate blank with high density andhigh tissue uniformity can be obtained. By means of the preparation method, the problems that local looseness and cracks are easily generated in former large-size thick molybdenum plates are solved,the density of the prepared molybdenum plate blank reaches 99% or above, and the uniformity and the consistency of tissue of the surface and the center position of the plate blank can be guaranteed.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for producing deep-drawn cold-formed medicinal aluminum foil with cast-rolling billet in short process

PendingCN111549261AHigh bursting strengthGood barrierMetal rolling arrangementsTemperature treatmentDeep drawing

The invention discloses a preparation method for producing deep-drawn cold-formed medicinal aluminum foil with a cast-rolling billet in a short process. The method sequentially includes the steps of smelting, cast rolling, cold rolling, homogeneous high-temperature treatment, intermediate rolling, slitting shear trimming, intermediate annealing, finish rolling, foil rolling, coil combining, finished product rolling, parting-off, and furnace loading for annealing. Raw materials of the deep-drawn cold-formed medicinal aluminum foil include an aluminum alloy and an Al-Fe intermediate alloy with amass content of 20% or a Fe-containing additive with a mass content of 75%, and elements in the aluminum alloy include 0.025-0.10% of Si, 1.25-1.65% of Fe, 0.001-0.10% of Cu, less than 0.05% of Mn, less than 0.05% of Mg, less than 0.05% of Cr, less than 0.05% of Zn, 0.01-0.04% of Ti and the balance A. By means of the recorded preparation method, final product detection shows that the end face layer offset after parting-off is less than or equal to 0.5 mm, the width of the corrugated edge is 3 mm, and the peak value is 1 mm; the surface cleanliness dyne value is greater than or equal to 65 dyn; as for mechanical properties, the tensile strength is 80-115 MPa, the elongation rate is 23%, and the yield ratio is 42%; and the Erichsen value is 5.0 mm, the deep drawing height is 2.0 mm, the surface hardness value is 22 HV, the bursting strength is 400-800 Ka, and the surface swabbing reaches level A.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

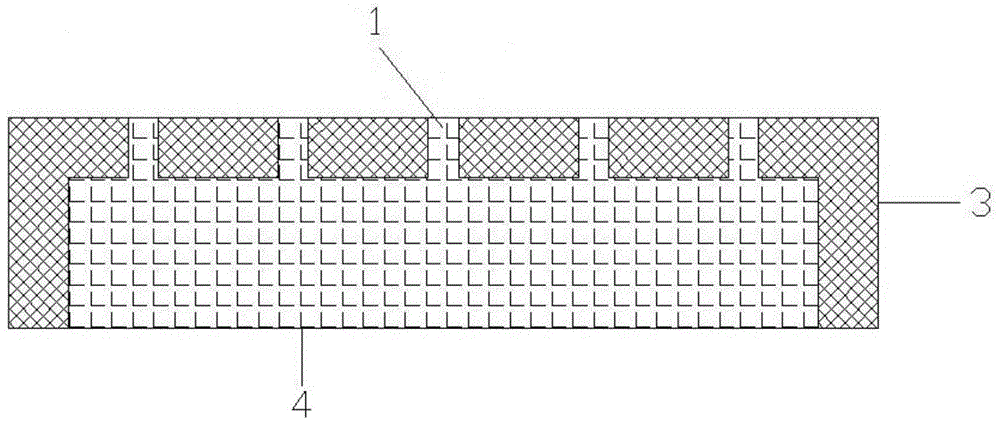

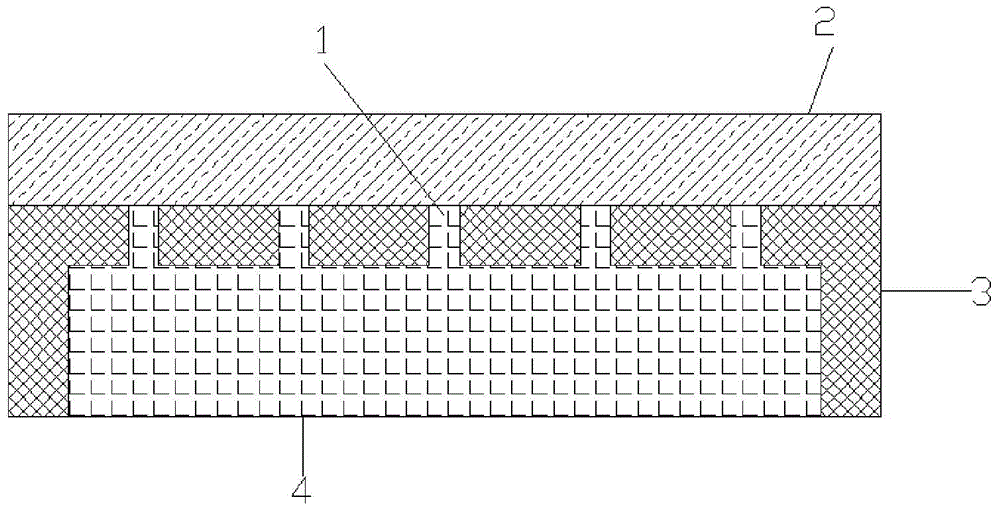

Polytetrafluoroethylene fiber tubular film

ActiveCN106669443AMeet a variety of functional needsEven consistencyDistillationFiberPore distribution

The invention relates to a polytetrafluoroethylene fiber tubular film, which comprises a polytetrafluoroethylene material body, wherein the polytetrafluoroethylene is fibrous, the diameter of the fiber is more than 200 nm and is less than or equal to 2000 nm, the polytetrafluoroethylene material body has pore cavities with a pore size of 10-2000 nm and cavity walls formed by surrounding the pore cavities in a three-dimensional space manner, the pore cavities are uniformly distributed and are communicated in a three-dimensional manner, various pore cavities present the uniform distribution on the porous material under any unit-scale volumes, and the porosity is more than or equal to 65%. According to the present invention, the uniform pore cavity distribution mode of the polytetrafluoroethylene fiber tubular film can be concretely and clearly measured, wherein the pore distribution uniformity of the porous material and the multi-level structure thereof are measured by using the small unit-scale volumes, such that the porous structure is highly uniform so as to ensure the uniformity of various performances of the porous material.

Owner:CHONGQING RUNZE PHARM CO LTD

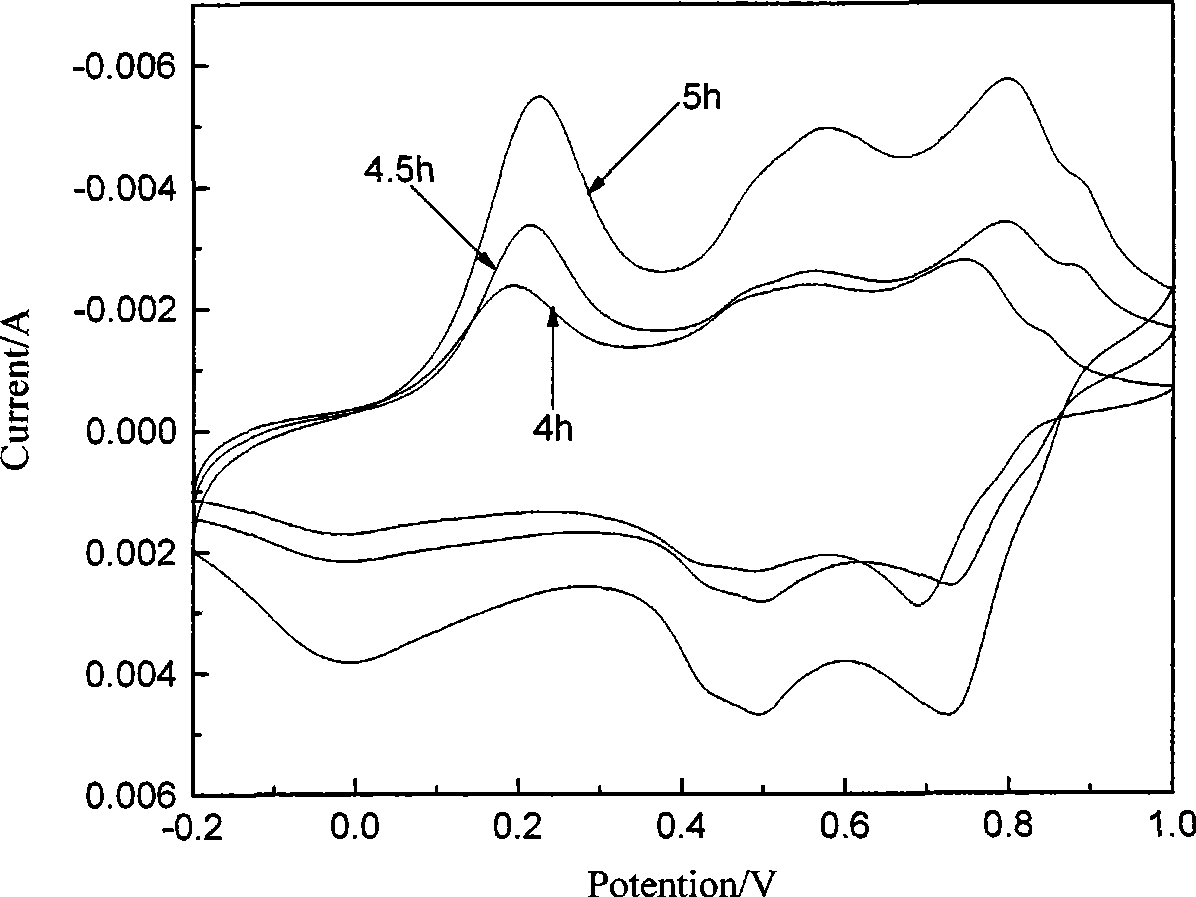

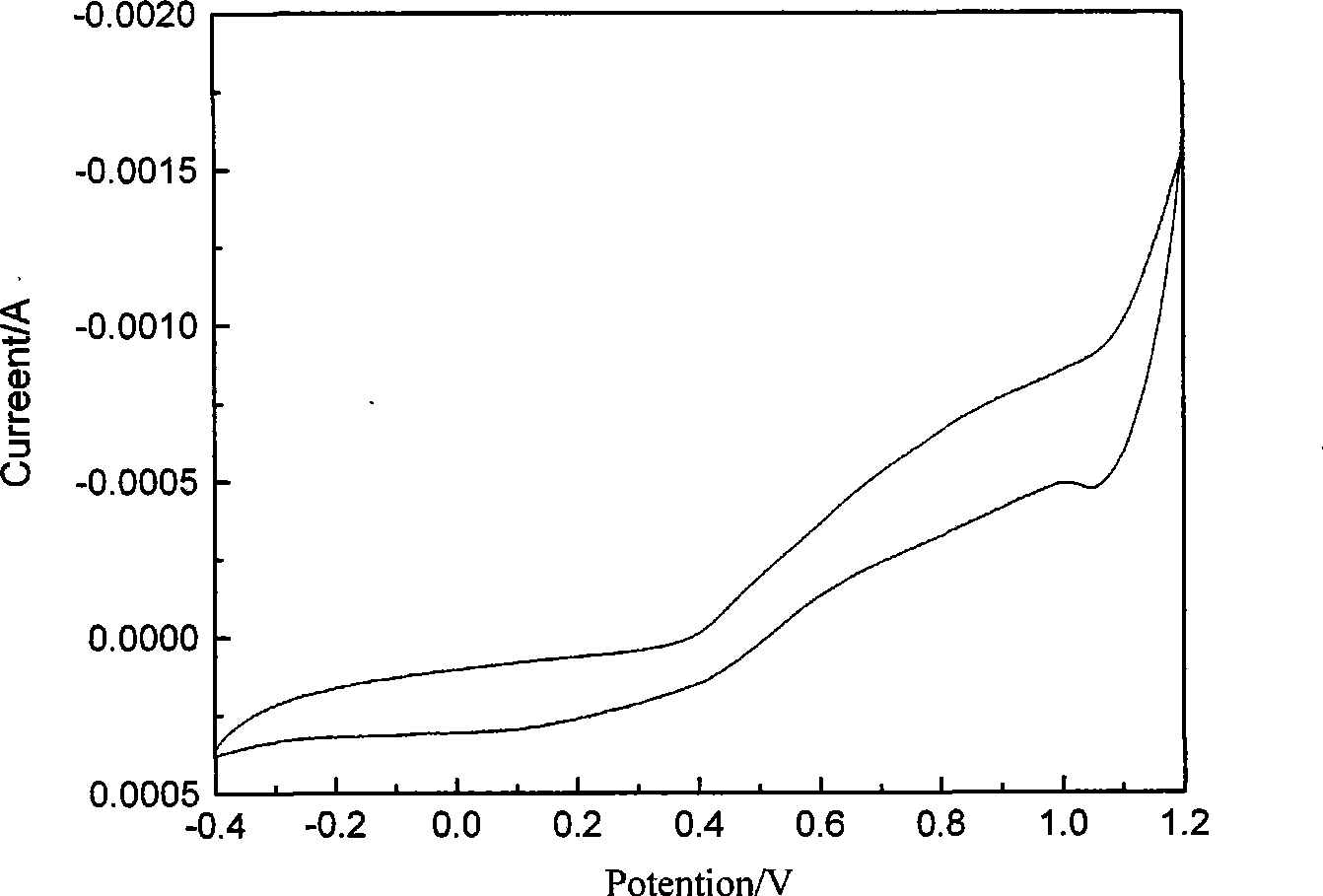

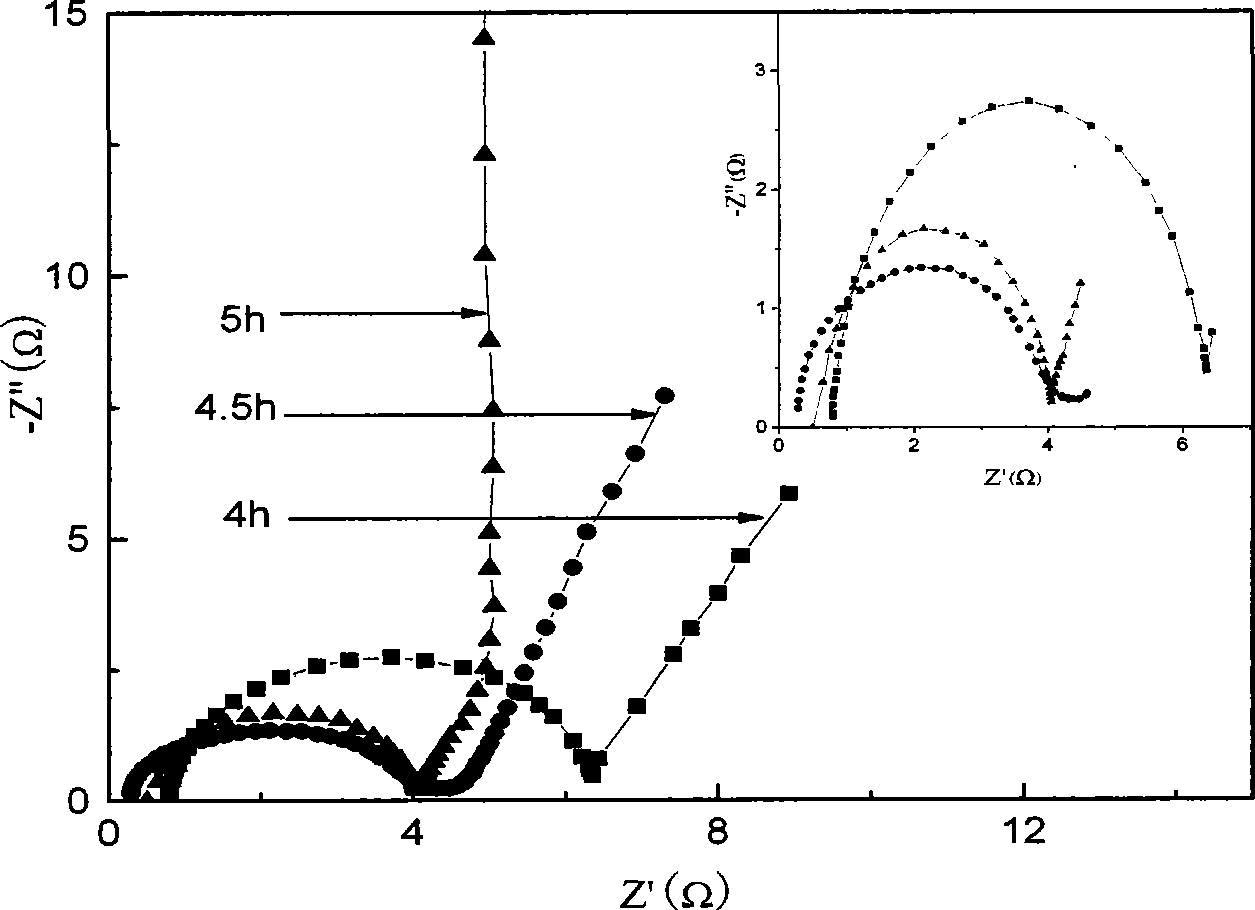

Method for testing electrochemical performance of polyaniline synthesized by chemical method

InactiveCN101545885AAvoid defectsEven consistencyMaterial electrochemical variablesElectrochemistryHigh polymer

The invention provides a method for testing electrochemical performance of polyaniline synthesized by a chemical method. The method comprises the following steps: when synthesizing the polyaniline by the chemical method, adding carbon paper before a polymerization reaction, and sufficiently moistening the carbon paper; adding initiator, such as ammonium persulfate solution, to make the polyaniline perform the polymerization reaction by taking the carbon paper as a center and evenly adsorbed on the surface on the carbon paper; at any time of the polymerization reaction, taking the carbon paper out; and using the carbon paper as an electrode to test the electrochemical performance of the polyaniline. The method adopts the carbon paper as a carrier to carry out testing on the electrochemical performance of the polyaniline, thereby effectively solving the problems of sensibility, accuracy and stability in the electrochemical test of the polyaniline. The method is simple and accessible, does not have pollution, has low cost, and has important reference significance and universality for the test of the electrochemical performance of high polymer.

Owner:CHONGQING UNIV

Vanadium nitrogen system Q460 strength level steel plate for low-temperature container and production method of steel plate

InactiveCN107326273AUniform and consistent overall performance and organizationGood impact toughnessSteel platesQuenching

The invention discloses a steel plate for a vanadium nitrogen series Q460 strength grade low-temperature container and a production method thereof. 0.005%, Ni: 0.25-0.35%, Nb: 0.025-0.033%, V: 0.15-0.20%, Al: 0.035-0.040%, N: 0.015-0.025%, the rest are Fe and inevitable impurities; the production method includes Rolling, quenching and tempering process. The overall performance and structure of the vanadium nitrogen series Q460 strength grade low-temperature container steel plate produced by the invention are uniform, the impact toughness is excellent at -40°C, the lower yield ratio greatly improves the safety factor of the product, the overall performance is uniform and stable, and the effective Improve production efficiency and reduce production costs.

Owner:WUYANG IRON & STEEL

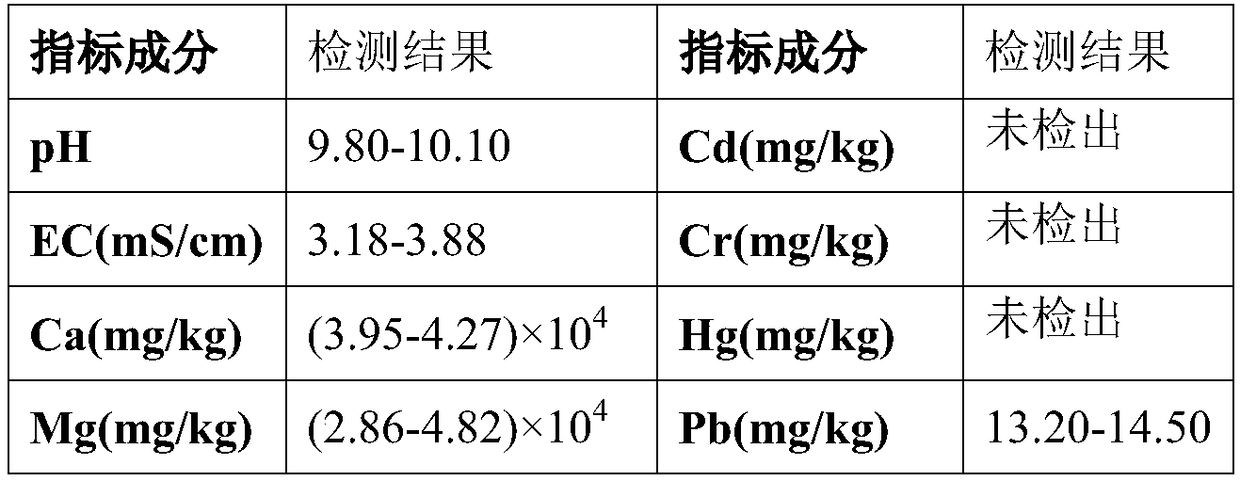

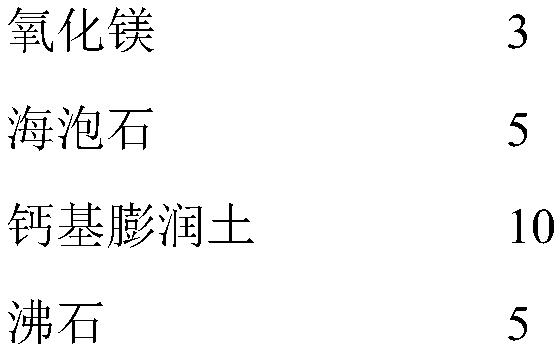

Remediation agent for cadmium contaminated soil and soil remediation method

PendingCN108795430AHigh ion exchange capacityImprove stabilityAgriculture tools and machinesOther chemical processesSelf purificationPollution

The invention provides a remediation agent for cadmium contaminated soil and a soil remediation method. The remediation agent comprises magnesium oxide, sepiolite, magnesium calcium-based bentonite, and zeolite, and can be used for in-situ remediation performed on the cadmium contaminated soil. The remediation agent takes magnesium oxide as a main passivator component for cadmium, additional threeclay minerals are added to serve as adsorbent and stabilizer components to form a mixture, after the remediation agent and the contaminated soil are uniformly mixed, the initial water content is adjusted to a saturated soil water content, and the remediation agent is left to stand for 3 to 10 days, so that normal plant seeding can be performed. The remediation agent reduces the bioavailability and transferability of heavy metal elements in the cadmium contaminated soil, improves soil self-purification capacity, and improves the soil fertility status, thereby guaranteeing the high quality, high yield and safety of agricultural products, ensures that the soil remediation is short in reaction period, good in effect, long in duration and wide in application range, and cannot cause secondary pollution.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

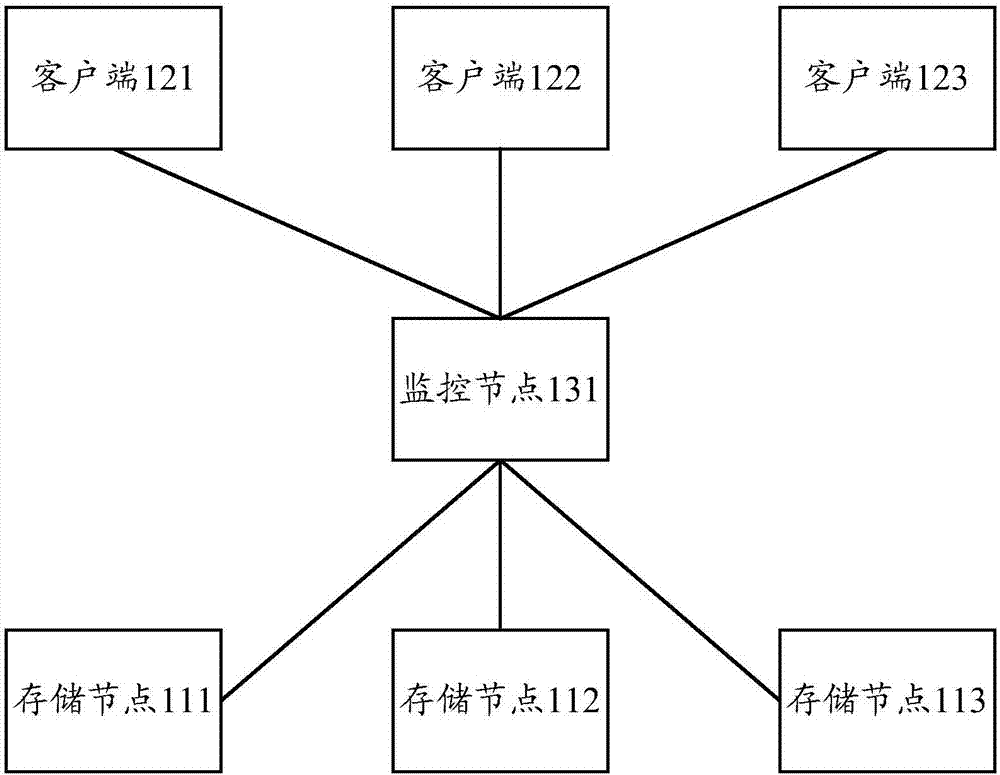

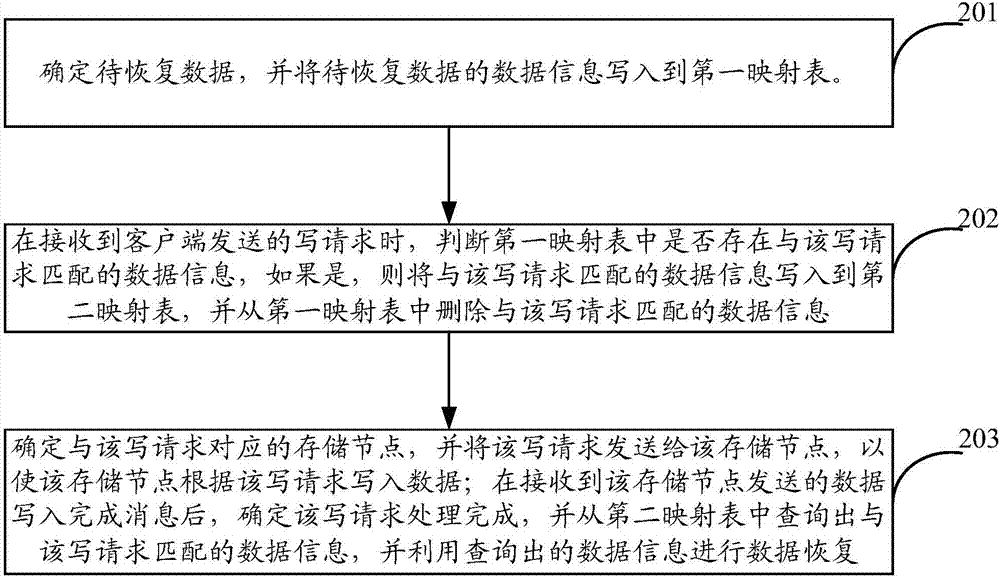

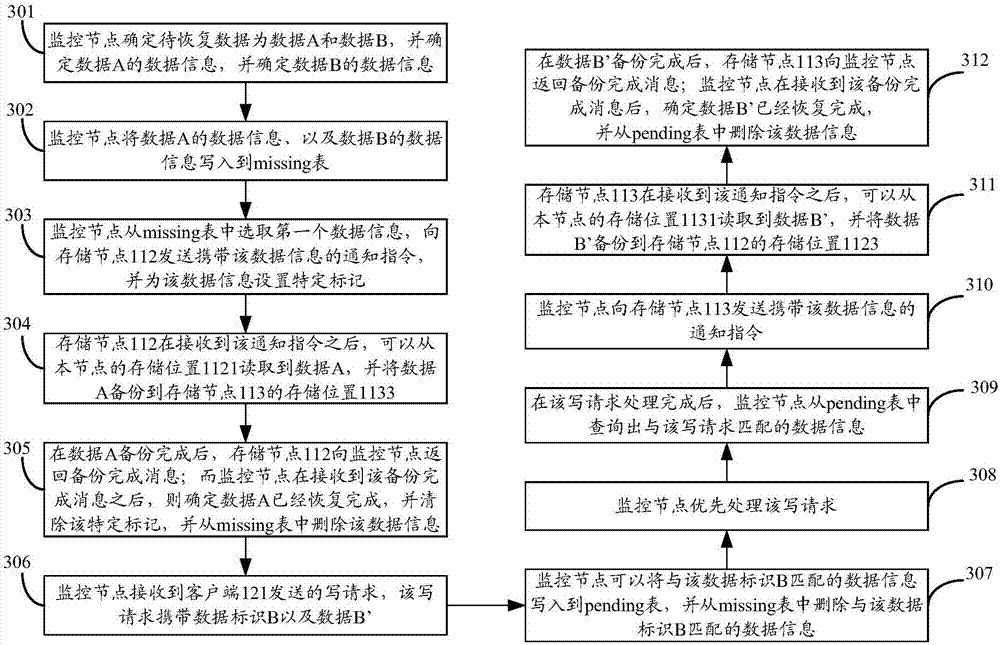

Data recovery method and device

ActiveCN107544869AGuaranteed reliabilityImprove usabilityInput/output to record carriersRedundant operation error correctionRecovery methodData information

The invention provides a data recovery method and device. The method comprises the steps that to-be-recovered data is determined, and data information of the to-be-recovered data is written into a first mapping table; when a write request sent by a client is received, whether or not the data information matched with the write request exists in the first mapping table is judged, if yes, the data information matched with the write request is written into a second mapping table, and the data information matched with the write request is deleted from the first mapping table; a storage node corresponding to the write request is determined, and the write request is sent to the storage node to enable the storage node to write data according to the write request; and after a data write completingmessage sent by the storage node is received, it is determined that processing of the write request is completed, the data information matched with the write request is queried out from the second mapping table, and data recovery is conducted by means of the queried-out data information. According to the technical scheme, the IO service availability can be improved, and the data reliability can beguaranteed.

Owner:NEW H3C TECH CO LTD

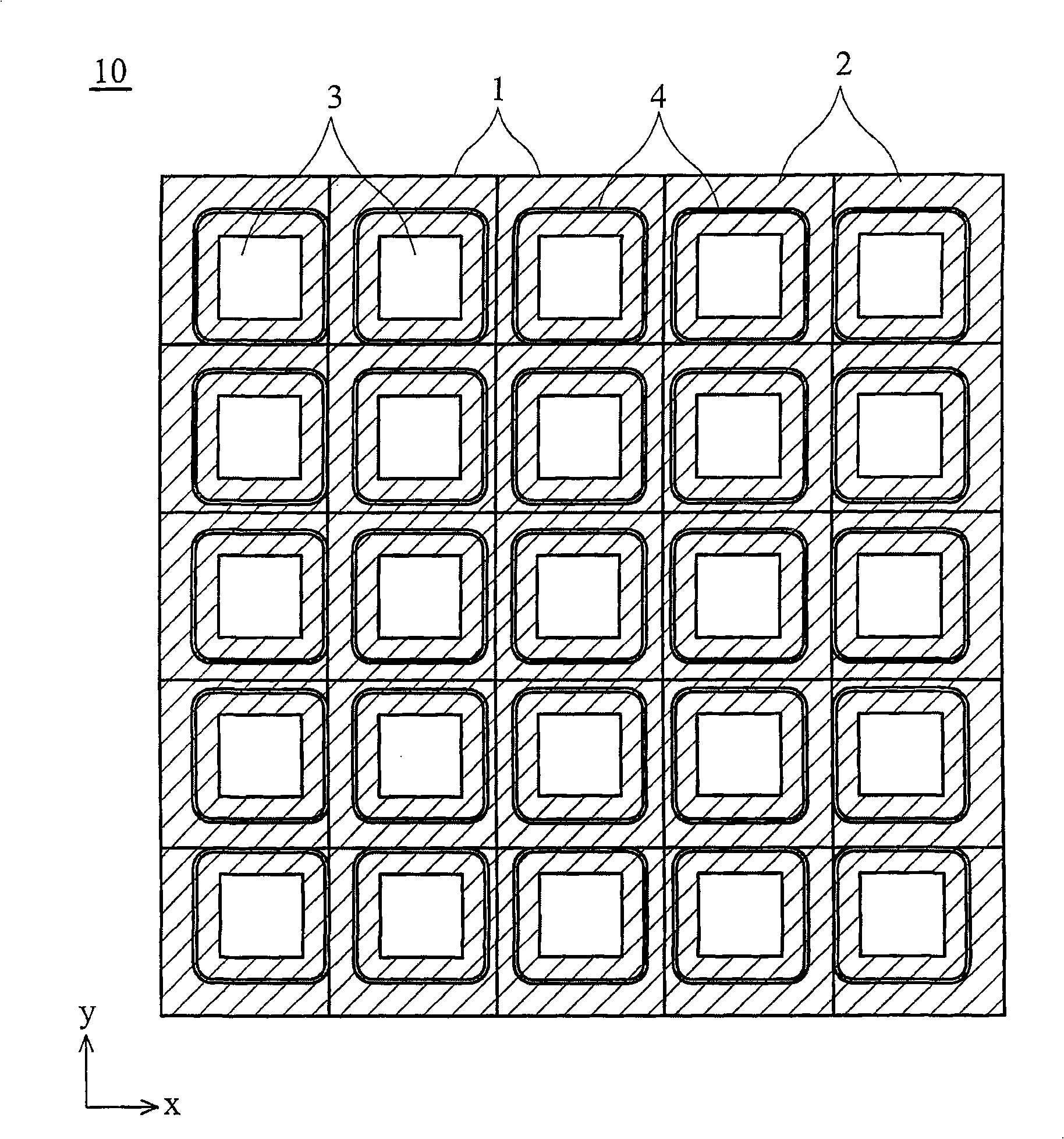

Color filter arrays and image sensors using the same

ActiveCN101355093AEven consistencyGood white balanceOptical filtersSolid-state devicesColor filter arrayComputer science

The present invention relates to a color filter arrays and image sensors using same. The color filter array includes a two-dimensional array including a plurality of first color filters, a plurality of second color filters, and a plurality of third color filters, wherein the first, second and third color filters are periodically arranged, and at least the first, second and third color filters formed in a first region of the two-dimensional array and the first, second and third color filters formed in a second region of the two-dimensional array are symmetrically mirrored. The embodiment of the invention provides an image sensing apparatus applying the color filter array. The invention can obtain symmetrical image with uniform color coherence and symmetrical characteristic, so that public known color dispersion phenomenon can be reduced or avoided and images with better white balance can be obtained.

Owner:VISERA TECH CO LTD

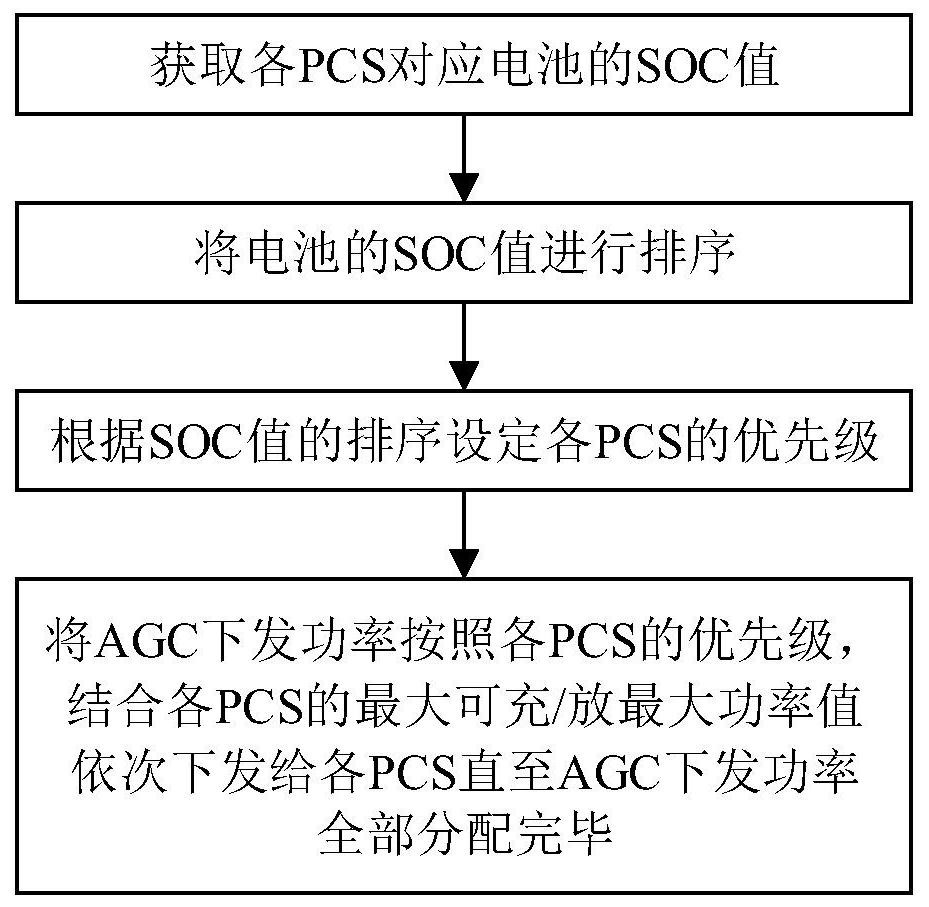

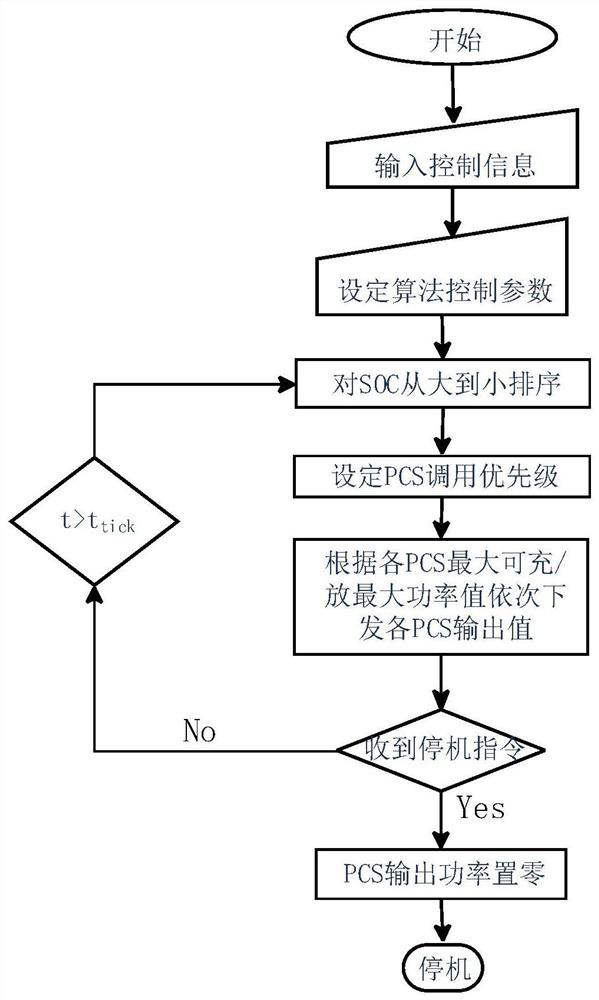

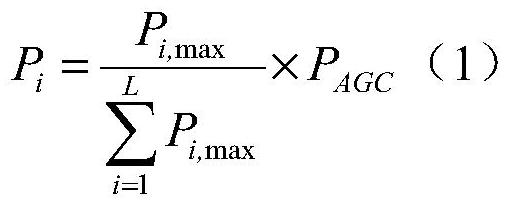

Method and system for distributing PCS active power by energy storage AGC considering SOC sorting

PendingCN113541174AReduce inconsistencyBalanceCircuit monitoring/indicationCharge equalisation circuitCharge and dischargeEngineering

The invention discloses a method and a system for distributing PCS active power by energy storage AGC considering SOC sorting. The method comprises the following steps: acquiring an SOC value of a battery corresponding to each PCS; sorting the SOC values of the batteries, and setting the priority of each PCS according to the sorting of the SOC values; and sequentially issuing the AGC issuing power to each PCS according to the priority of each PCS in combination with the maximum chargeable / dischargeable power value of each PCS until the AGC issuing power is completely distributed. According to the method, the requirements of power charging and discharging, battery consistency and SOC balance can be considered, the consistency of the batteries and the balance of the SOC in the charging and discharging process are considered under the condition that power dispatching is met, the inconsistency of the batteries is reduced, and the most accurate control information is provided for a power dispatching department.

Owner:STATE GRID HUNAN ELECTRIC POWER +3

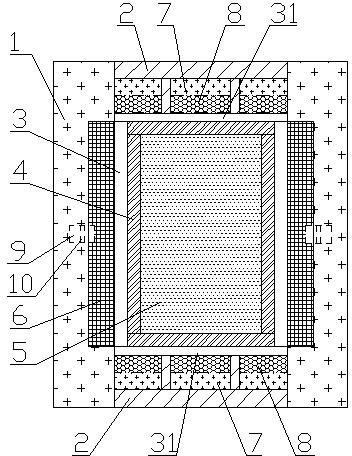

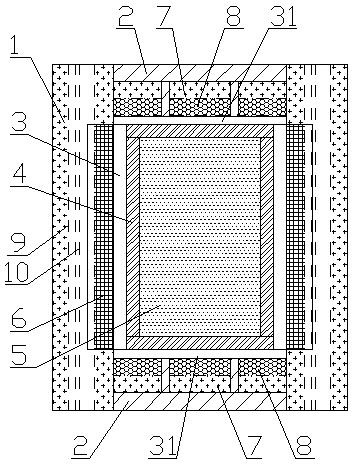

Sloping diamond synthesis block

InactiveCN102166498ACompression volume is smallReduce heat fatigueUltra-high pressure processesThermal fatiguePyrophyllite

The invention discloses a sloping diamond synthesis block, which comprises a graphite column, conductive steel rings at the two ends of the graphite column, and pyrophyllite blocks in the periphery of the graphite column and the conductive steel rings; the conductive steel rings are filled with pyrophyllite rings and dolomite rings; the periphery of the graphite column is provided with a heating element; an insulating element is arranged between the heating element and the graphite column; the pyrophyllite block consists of two half blocks buckled with each other; and a graphite column cavity is formed in the middle of the two buckled half blocks, and each half block is in a triangular prism shape. The sloping pyrophyllite blocks are formed, and a joint seam of the sloping pyrophyllite blocks is at the corner of the pyrophyllite blocks, and is staggered from the middle part of a non-heating top hammer; hot gas cannot rush to the non-heating top hammer, so that thermal fatigue of the non-heating top hammer can be obviously mitigated, and the top hammer is effectively protected; and the number of the broken non-heating top hammers is greatly reduced, the broken hammer accidents are reduced, the consumption of the hard alloy top hammer is greatly reduced, and the production cost is lowered.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

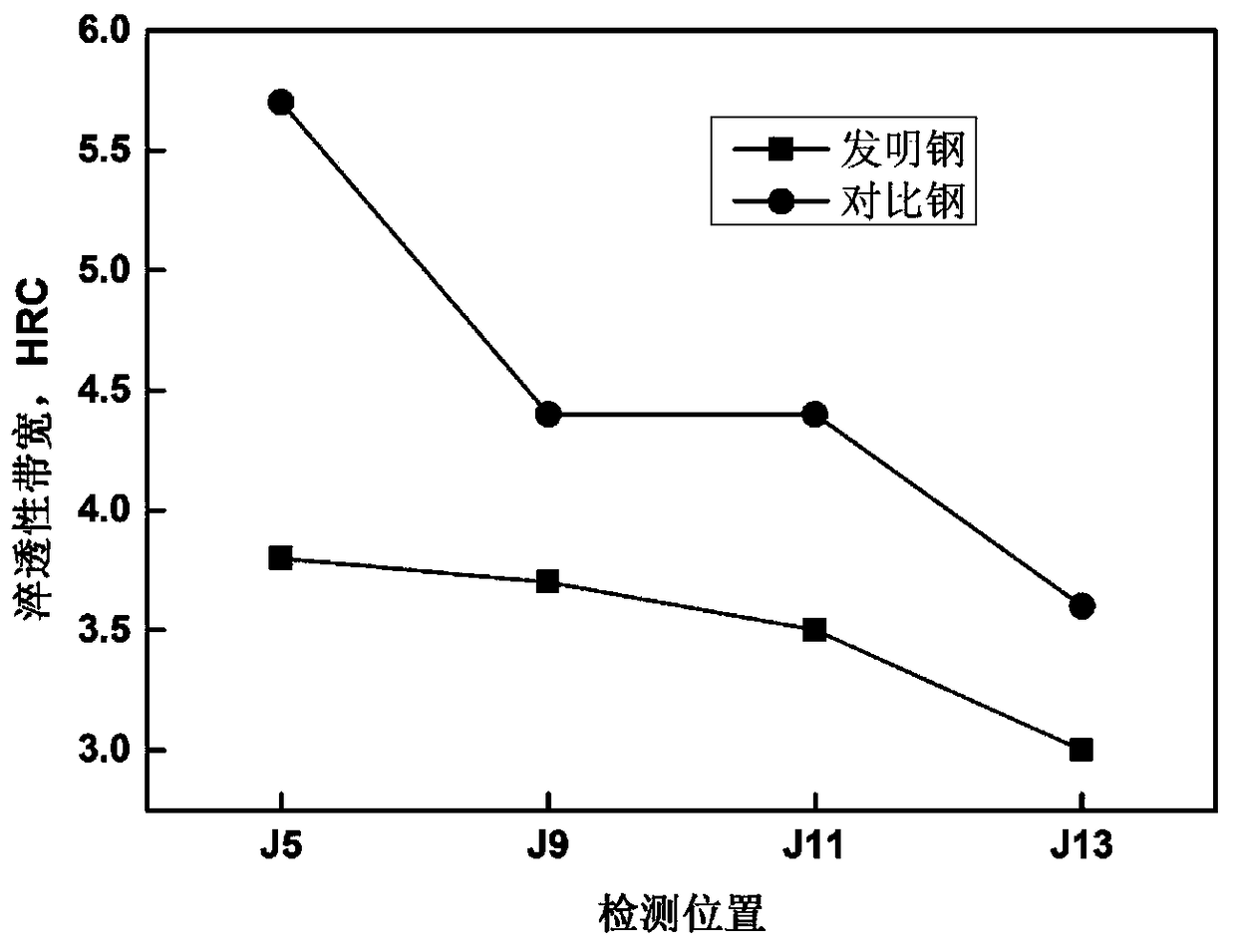

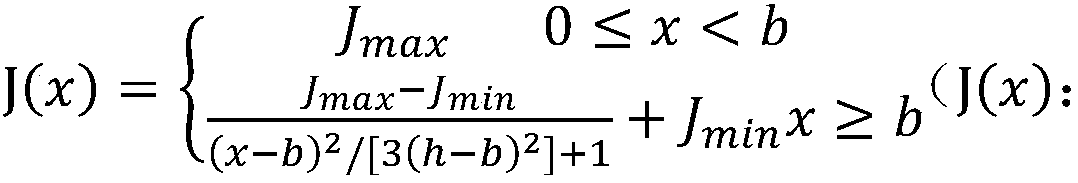

Control method for narrow hardenability bandwidth of gear steel

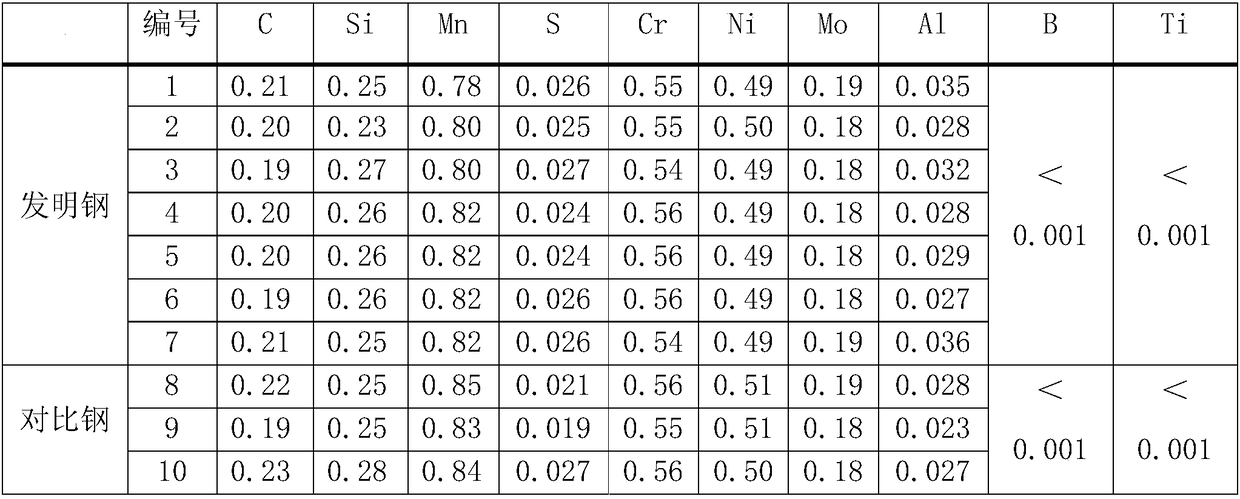

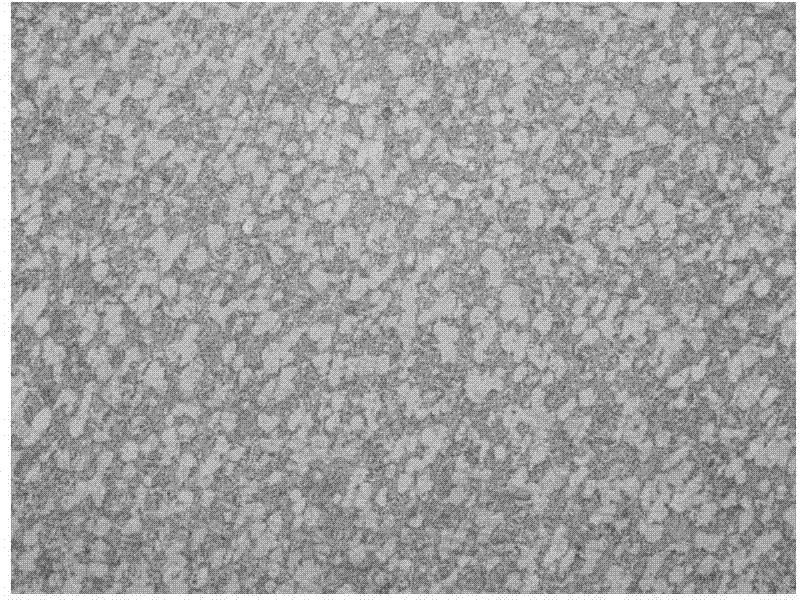

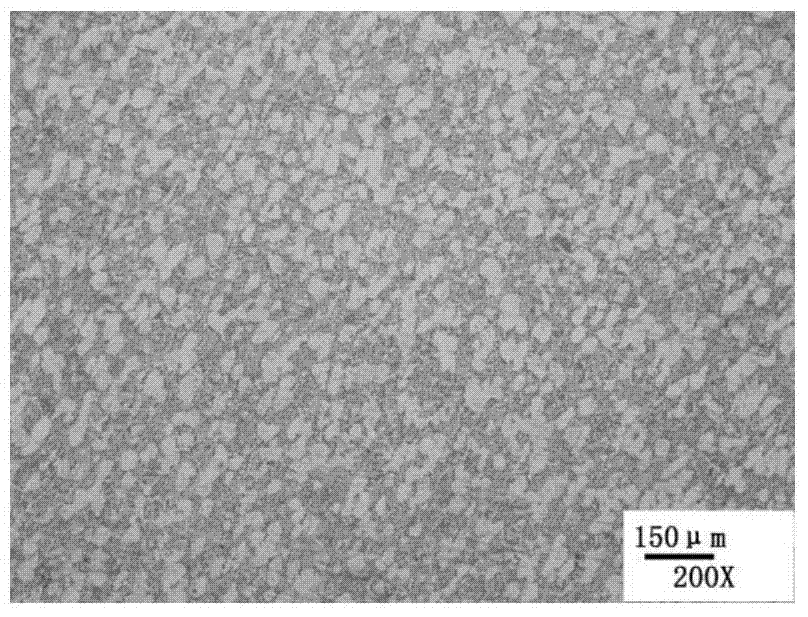

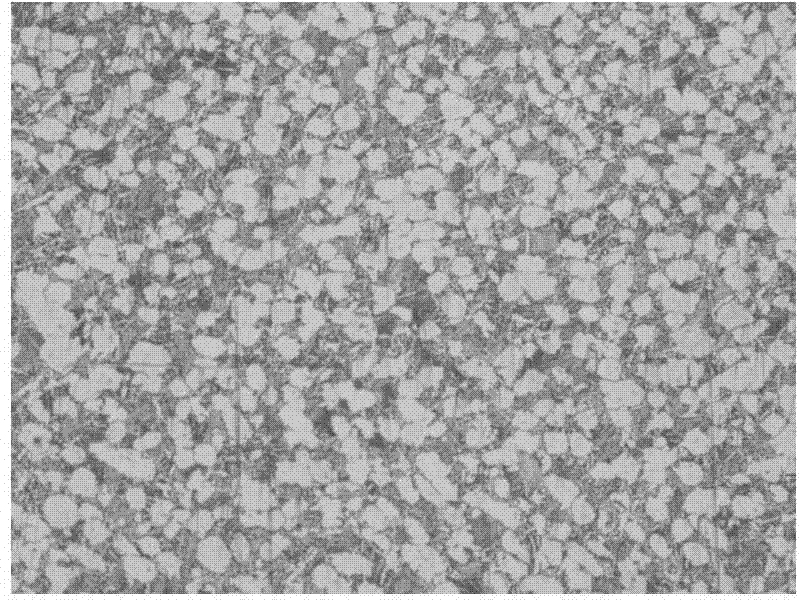

ActiveCN108193029AControl Hardenability BandwidthImprove consistencyHeat treatment process controlLower limitMetallurgy

The invention discloses a control method for narrow hardenability bandwidth of gear steel, and belongs to the technical field of gear steel. Accordring to the method, a calculation formula for the hardenability is optimized by adopting production data so as to obtain the calculation parameters suitable for the type of the gear steel, then the upper limit and the lower limit of the components of the elements of C, Si, Mn, Cr, Ni, Mo, Ti and B which influence the hardenability are calculated according to the optimized calculation formula, the hardenability bandwidth at J5, J9, J11 and J13 is required to be 3.5HRC or less, the range of the obtained components is compared with the deviation rage of the components, namely, delta C is smaller than or equal to + / -0.01%, delta Si is less than or equal to + / -0.02%, delta Mn is less than or equal to + / -0.02%, delta Cr is less than or equal to + / -0.01%, delta Ni is less than or equal to + / -0.01%, delta Mo is less than or equal to + / -0.01%, deltaTi is less than or equal to + / -0.01%, delta Al is less than or equal to + / -0.01%, delta B is less than or equal to + / -0.005%, delta S is smaller than or equal to + / -0.002%, finally the narrowest control range is determined as the component control range of the gear steel with the narrow hardenability bandwidth requirement, pouring of low degree of superheat of 10-20 DEG C is adopted, the heating temperature fluctuation of a continuous casting blank is guaranteed to be less than or equal to + / -7 DEG C, the heat preservation time fluctuation is guaranteed to be less than or equal to + / -5 minutes, and therefore a gear steel bar with the hardenability bandwidth of 4HRC or less is obtained.

Owner:CENT IRON & STEEL RES INST

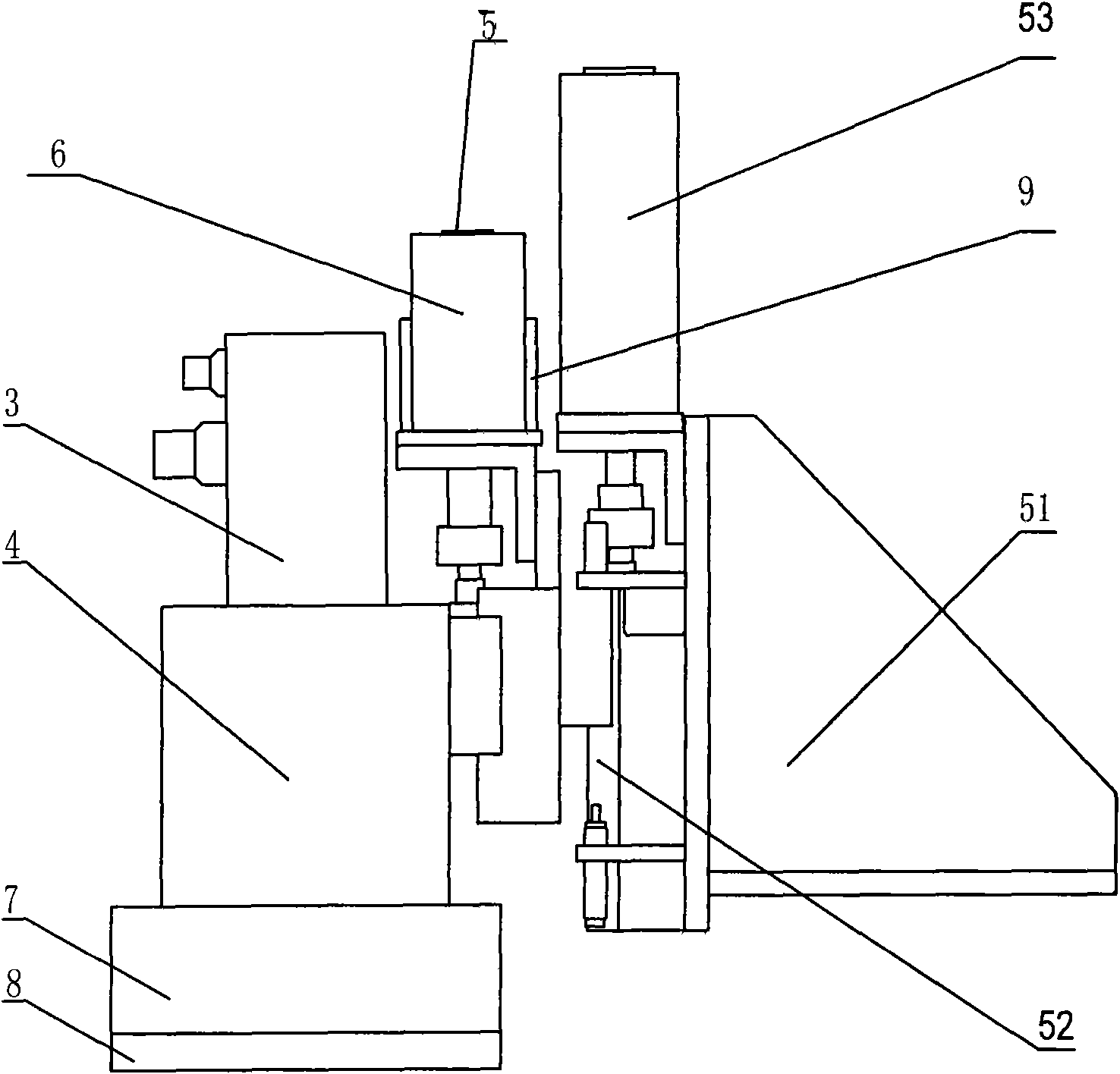

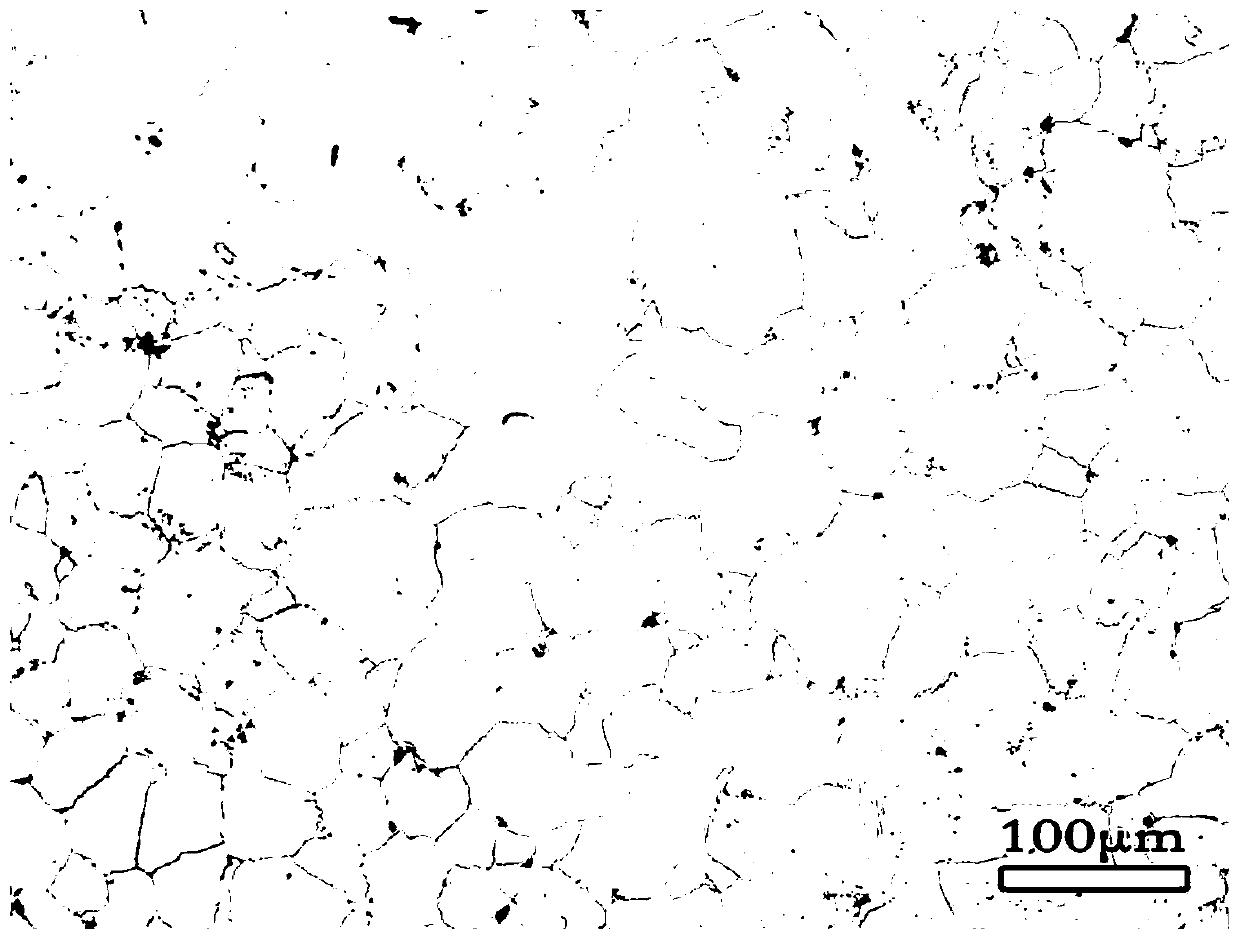

Machining method of TC4 titanium alloy thick-wall tubular product

ActiveCN103894441AIncrease lateral deformationControl the total forging ratioMetal-working apparatusThick wallTitanium alloy

The invention relates to a machining method of a TC4 titanium alloy thick-wall tubular product. The machining method comprises the following steps: heating by virtue of an electric furnace, forging a selected titanium alloy tube blank by virtue of a precision forging machine after the titanium alloy tube blank is subjected to heating and heat preservation, taking the tubular product out within 20 seconds after maintaining the temperature for 1-3 hours at 700-800 DEG C, arranging the tubular product in a fan region, and carrying out air cooling; finally straightening the tubular product on a seven-roll straightening machine, so as to obtain the TC4 titanium alloy thick-wall tubular product. The machining method has the beneficial effects that an existing rolling method is replaced by virtue of a radial forging method, the heating and forging temperatures are reasonably selected to match parameters such as forging rolling reduction and feeding quantity during machining, the transverse deformation of metal is increased, the total forging ratio of a phase region alpha and a phase region beta is controlled, then the TC4 titanium alloy thick-wall tubular product is obtained, and the production blank of a large-scale TC4 titanium alloy thick-wall tubular product is made up; the TC4 titanium alloy thick-wall tubular product has the characteristics that the tissue and the performance are uniform, the clutter level in ultrasonic flaw detection is high, the outer diameter phi is 90-150mm, the wall thickness is 10-30mm, and the length is 1000-5000mm.

Owner:宝鸡拓普达钛业有限公司

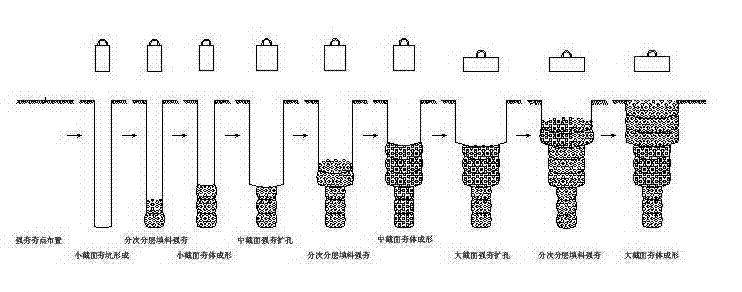

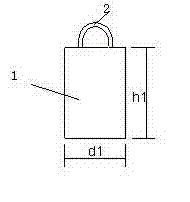

Multi-section type variable cross-section dynamic compaction method

The invention discloses a multi-section type variable cross-section dynamic compaction method, which is the method for treatment of a building foundation, clearing and leveling are firstly performed on a soft foundation space, and multi-section type variable cross-section dynamic compaction construction is further performed on dynamic compaction tamping points which are arranged according to the construction process flow and the technical specifications. During the process of forming a tamping pit and forming tamping bodies, more than two rams in cross sections which are increased gradually are adopted for ramming a soil body of a soft foundation from bottom to top respectively for forming the tamping pit or an expanded hole, dry soil or aggregate is further backfilled into the tamping pit and rammed, tamping of the tamping pit and the backfilled materials is completed section by section, then more than two sections of the dynamic compaction tamping bodies or replacement pier bodies in the cross sections which are gradually increased are formed from the bottom to the top and full compaction operation in a dynamic compaction region is finally performed. After the method is adopted for dynamic compaction and reinforcement, the overall compactness, the strength of the foundation and the bearing capacity are greatly improved, and the foundation is uniform at the upper part and the lower part. The stress stability, the uniformity and the overall rigidity of the foundation soil are significantly increased. The construction quality is more stable, the compression modulus of the foundation is high, and the settlement value and the settlement difference value are obviously reduced.

Owner:谢开生

Engraved intaglio plate polishing equipment and polishing process

ActiveCN101823227AFully automatedSolve the defect of roughness instabilityPolishing machinesPrinting pre-treatmentControl systemEngineering

The invention relates to engraved intaglio plate polishing equipment. The equipment comprises a control system, a pneumatic system, a frame capable of placing an intaglio plate, an X-axis servo mechanism, a Y-axis servo mechanism, a Z-axis servo mechanism and a polishing device, wherein the X-axis servo mechanism, the Y-axis servo mechanism and the Z-axis servo mechanism are arranged on the frame; the polishing device can be driven by the Z-axis servo mechanism to move along the Z-axis direction; the polishing device comprises a constant-pressure control cylinder, an electric device, a polishing head, a polishing pad and a polishing liquid supply system; the constant-pressure control cylinder is arranged on the Z-axis servo mechanism; the electric device is arranged on the constant-pressure control cylinder; the polishing head is arranged at the output end of the electric device; the polishing pad is arranged on the polishing head; and the polishing liquid supply system can provide polishing liquid for the polishing head. The engraved intaglio plate polishing equipment solves the technical problems of low safety, environmental-friendly and healthy hidden danger, low polishing efficiency and low polishing quality of the polishing method in the prior art and has the advantages of safety, environmental protection, high polishing efficiency and high polishing quality.

Owner:CHINA BANKNOTE PRINTING & MINTING +2

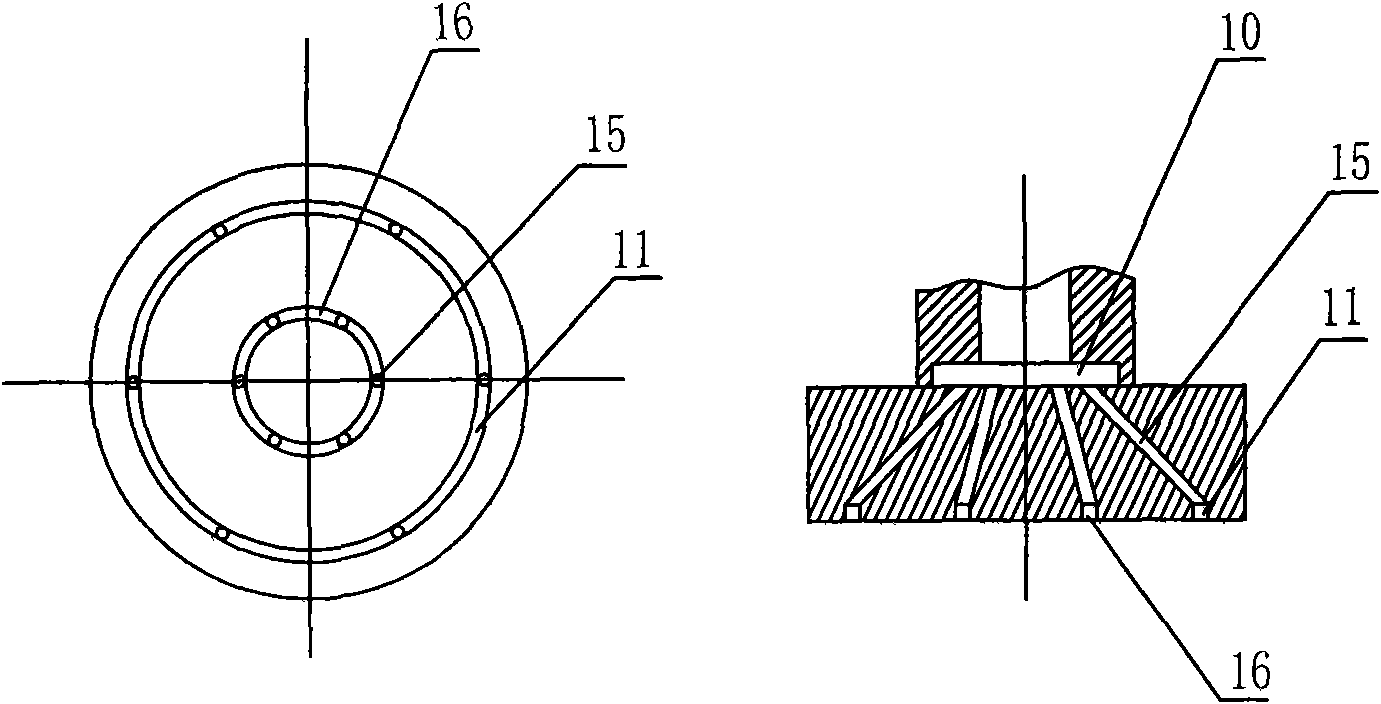

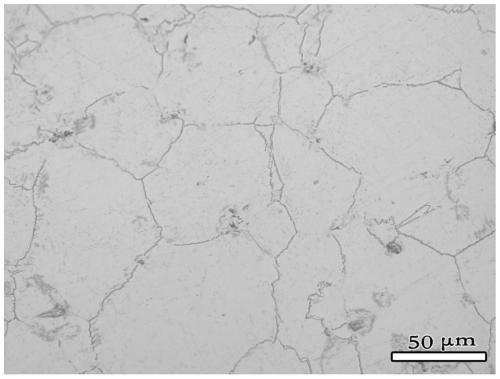

High-performance as-cast austenite-bainite ductile iron and production method and application thereof

ActiveCN107723583AFormation ability is controllableImprove uniformityCrankshaftsFoundry mouldsHardnessDuctile iron

The invention provides high-performance as-cast austenite-bainite ductile iron and a production method and application thereof. On the basis of ductile cast iron shell mold casting, the adding quantity ranges of bainite forming elements of Mo, Ni and Cu are defined according to the casting size and unshelling time, and through fine control over the deshelling time and the cooling and heat preservation processes, the production method suitable for the as-cast austenite-bainite ductile iron with complex shape characteristics is finally determined. The as-cast austenite-bainite ductile iron obtained through the method has excellent comprehensive mechanical properties, the tensile strength exceeds 900 MPa, the yield strength is not lower than 600 MPa, the elongation is larger than 4%, and theimpact toughness is larger than 65 J / cm<2>. The Brinell hardness of the austenite-bainite ductile iron obtained in the as-cast state is 250-310 HBS and meets the requirement of machining. The as-castaustenite-bainite ductile iron prepared through the method can be used for various metal components which bear large loads and have high safety coefficient requirements, and is particularly suitable for high-performance engine crankshafts.

Owner:辽宁华岳精工股份有限公司 +1

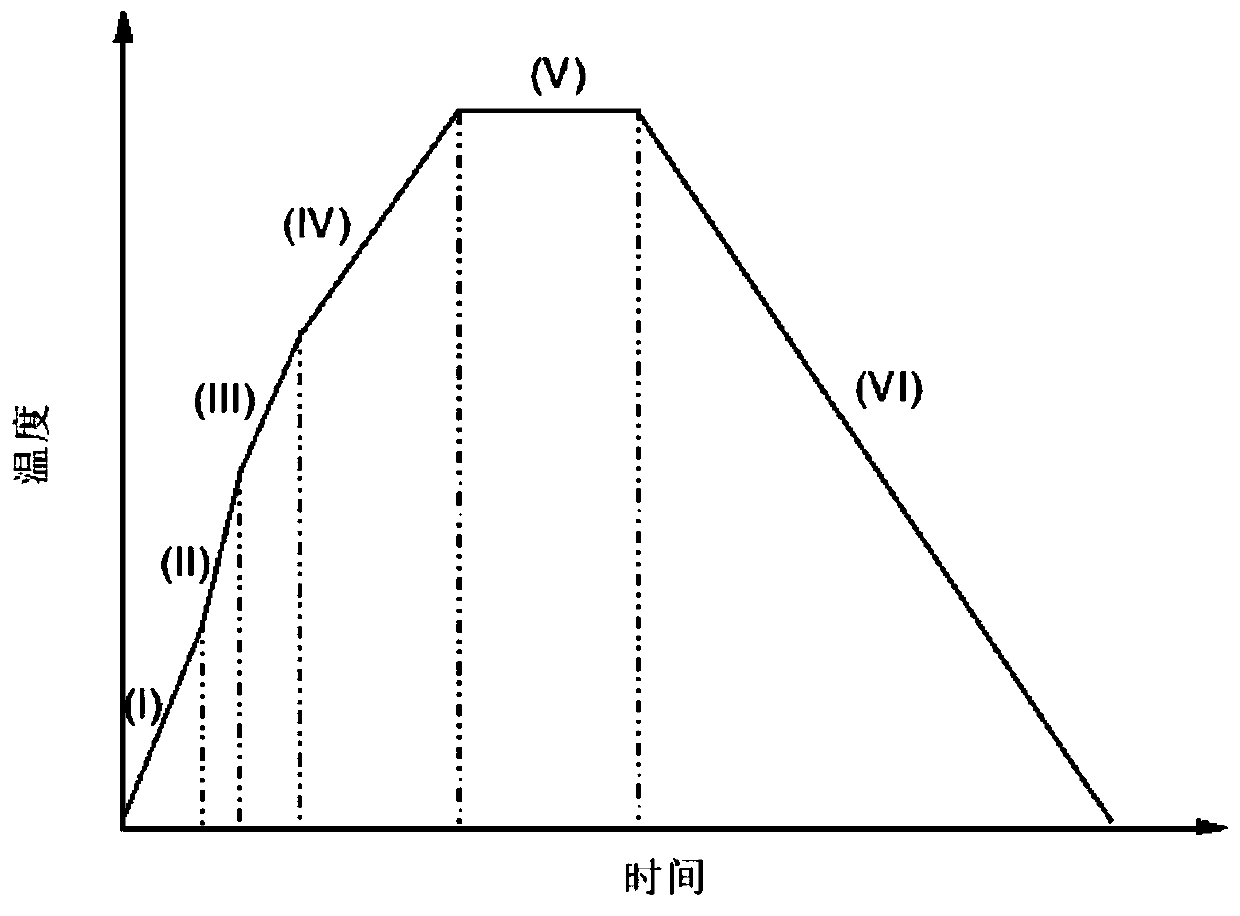

Normal-pressure multi-step sintering method for powder metallurgy of high-density Ti-Nb-Mo series alloy

ActiveCN111203531AHigh densityHomogeneous organizationTransportation and packagingMetal-working apparatusSintered titaniumCompressive strength

The invention provides a normal-pressure multi-step sintering method for powder metallurgy of a high-density Ti-Nb-Mo series alloy, and belongs to the technical field of alloys. According to the method, the multi-step sintering is carried out under normal pressure by adopting a temperature programming mode, and different protective atmospheres and gas flow rates are adopted at different temperature programming stages of the sintering, so that the capability of titanium hydride to improve the density of the powder metallurgy titanium alloy is maximally exerted, and the sintered titanium alloy is high in density and uniform and consistent in structure and performance. The results of the method show that the density of the Ti-Nb-Mo series alloy obtained by using the normal-pressure multi-stepsintering method can reach 99% or above, the average grain size is 30.2-39.7 microns, the yield strength of the alloy can reach 960 MPa, the compressive strength can reach 1287 MPa, and the criticalfailure strain is more than 0.7.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

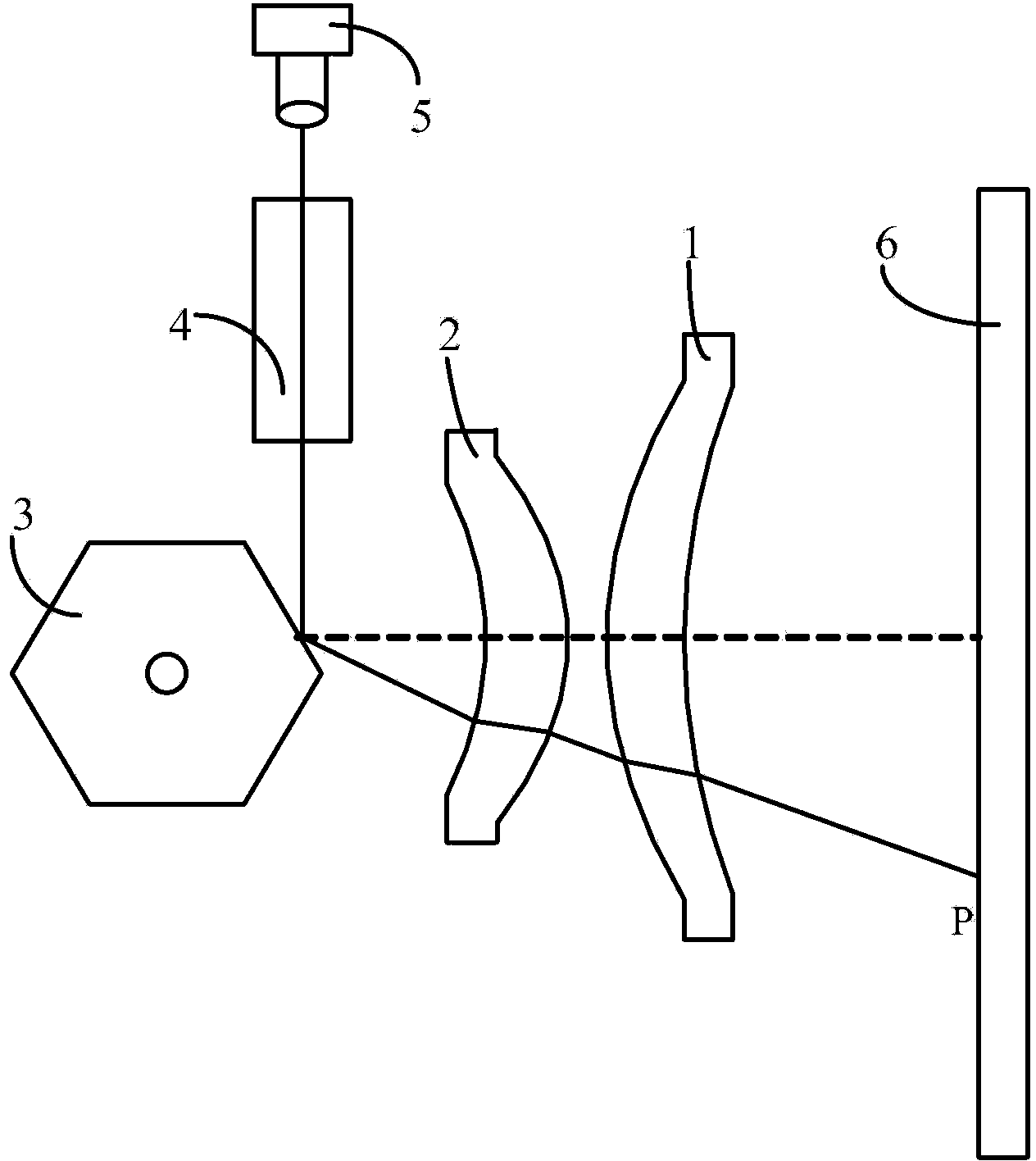

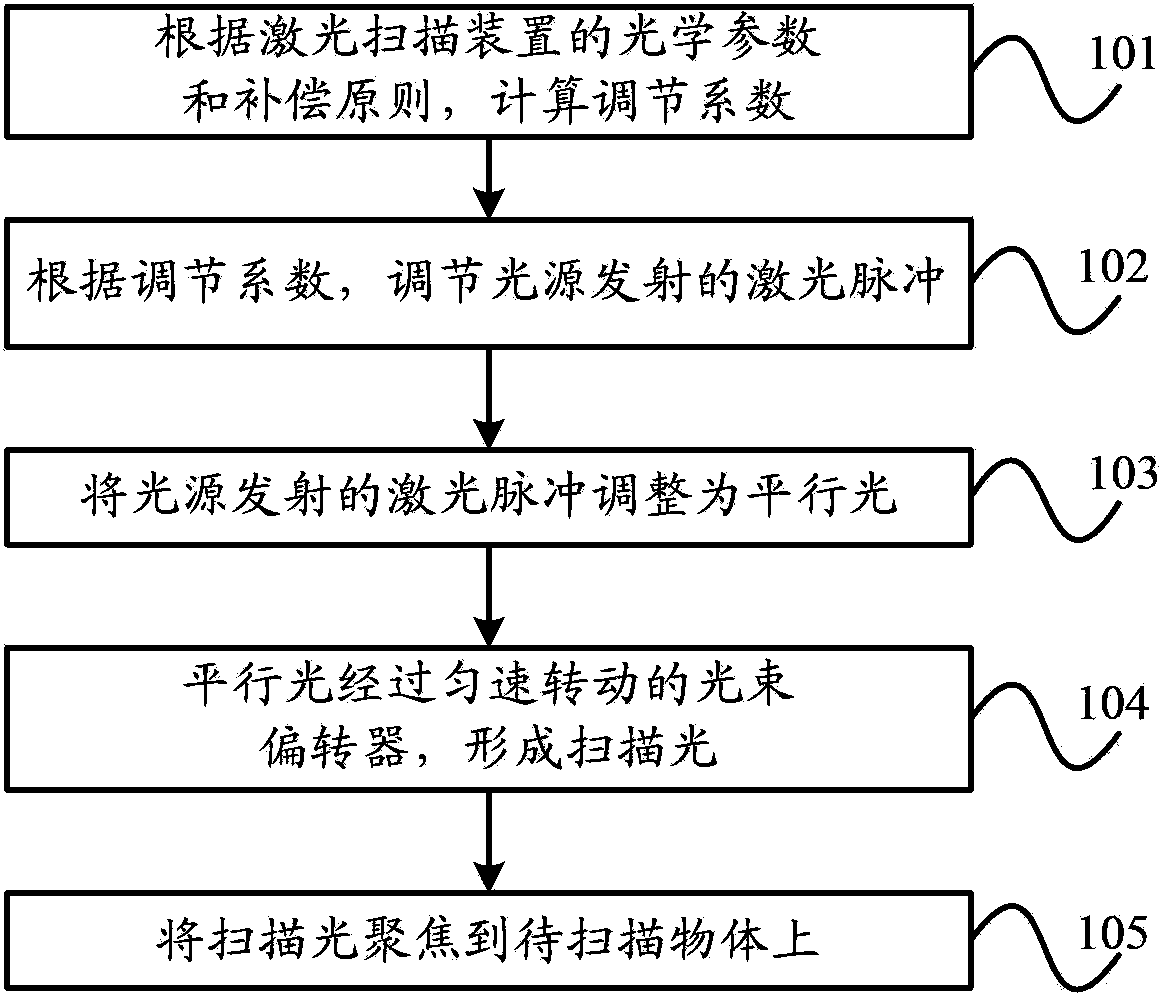

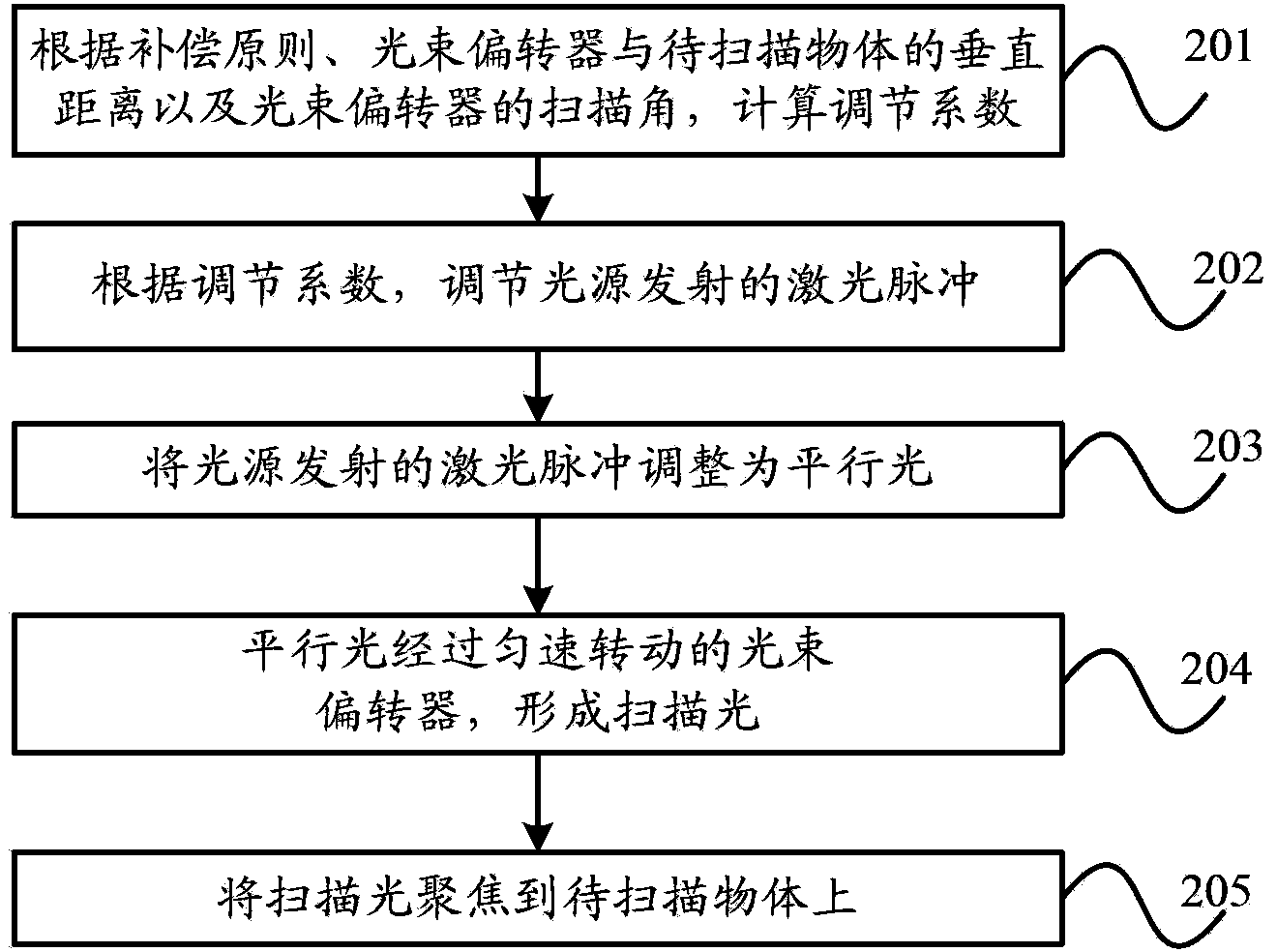

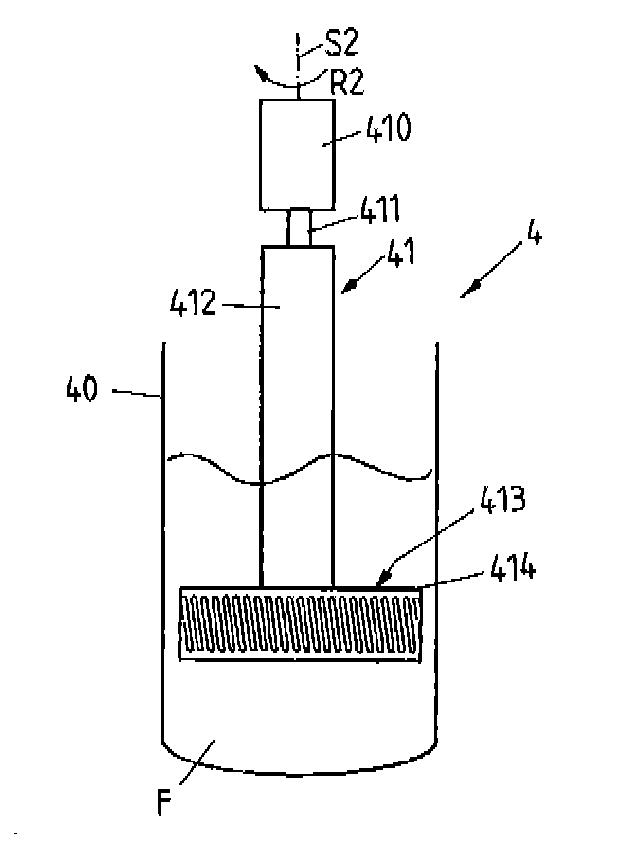

Laser scanning method, device and imaging equipment

ActiveCN103809288AEven consistencyFor accurate scanningElectrographic process apparatusOptical elementsLight spotLight beam

The invention provides a laser scanning method, a device and imaging equipment. The laser scanning method comprises steps that: adjusting coefficients are calculated according to optics parameters and a compensation principle of a laser scanning device; laser pulses emitted by a light source are adjusted according to the adjusting coefficients; the laser pulses emitted by the light source are adjusted to be parallel light; the parallel light is turned to be scanning light through a light beam deflector which uniformly rotates; the scanning light is focused on a scanned object. According to the method, the light source is adjusted through the adjusting coefficients, so light spots gathered on the object to be scanned have uniform consistency, and thereby accurate scanning for the scanned object can be realized.

Owner:APEX MICROELECTRONICS CO LTD

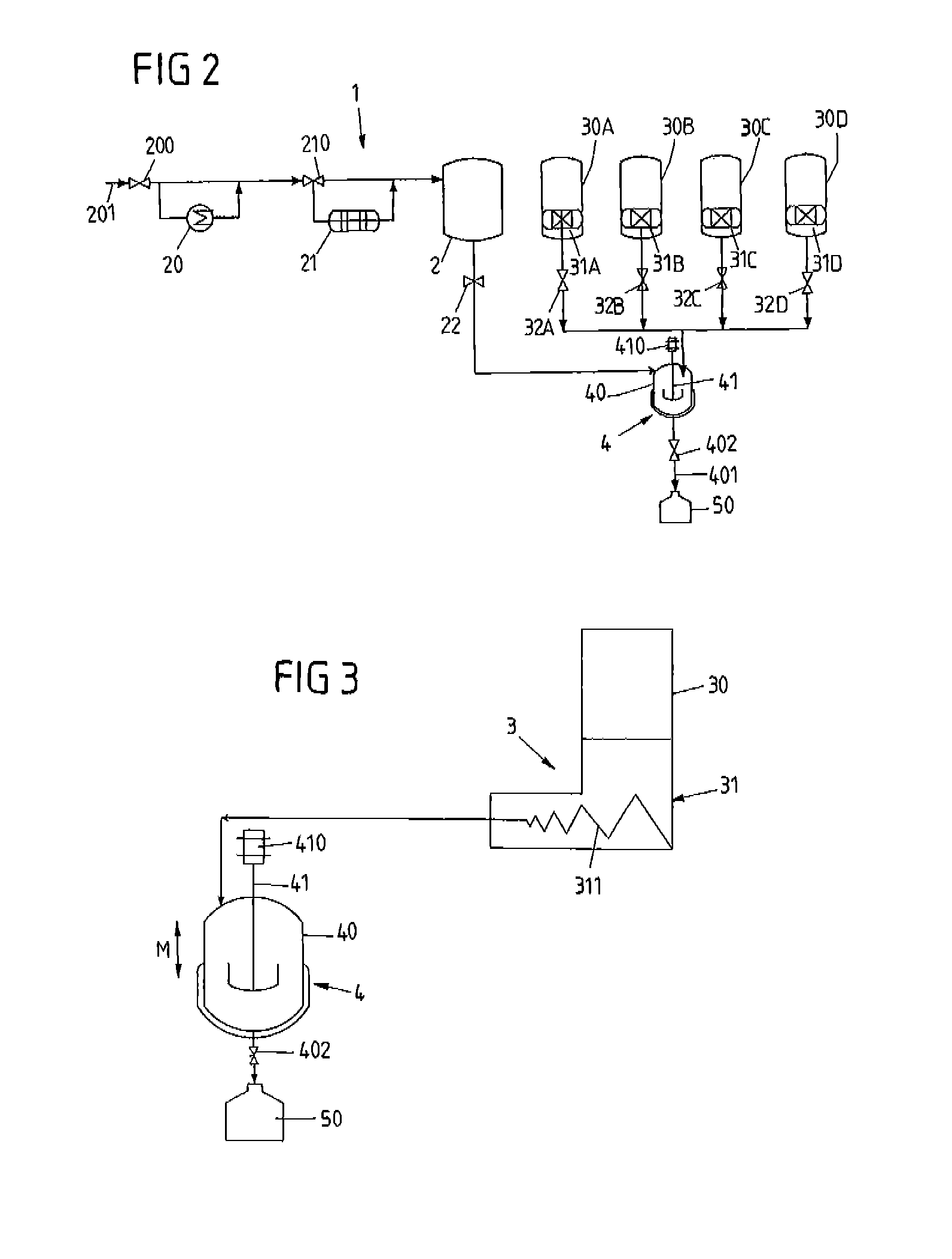

Device and method for preparing a fluid composition for complete or supplemental enteral nutrition

InactiveUS20140271548A1Sufficiently soluble/dispersibleEnsure consistencyBiocideShaking/oscillating/vibrating mixersAdditive ingredientEngineering

The invention relates to a device for preparing a fluid composition for complete or supplemental enteral nutrition, comprising a liquid feeding device, an ingredient feeding device and a mixing device for mixing a liquid fed from the liquid feeding device and at least one ingredient fed from the ingredient feeding device, the mixing device comprising a mixer and a mixing container in which the liquid and the at least one ingredient are mixed by the mixer. The device is operable to move the mixing container relative to the mixer during mixing of the liquid and the at least one ingredient of the fluid composition to be prepared. Also provided is a method for preparing a fluid composition for complete or supplemental enteral nutrition using the device.

Owner:FRESENIUS KABI DEUT GMBH

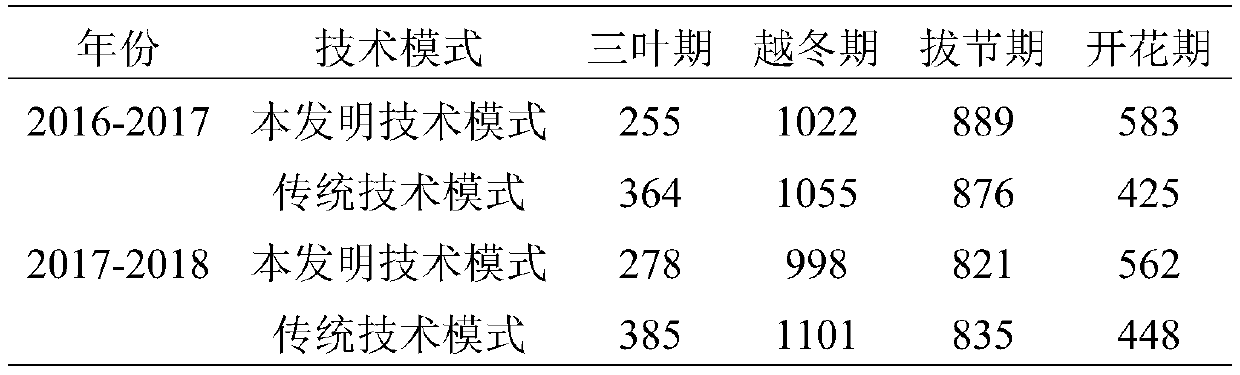

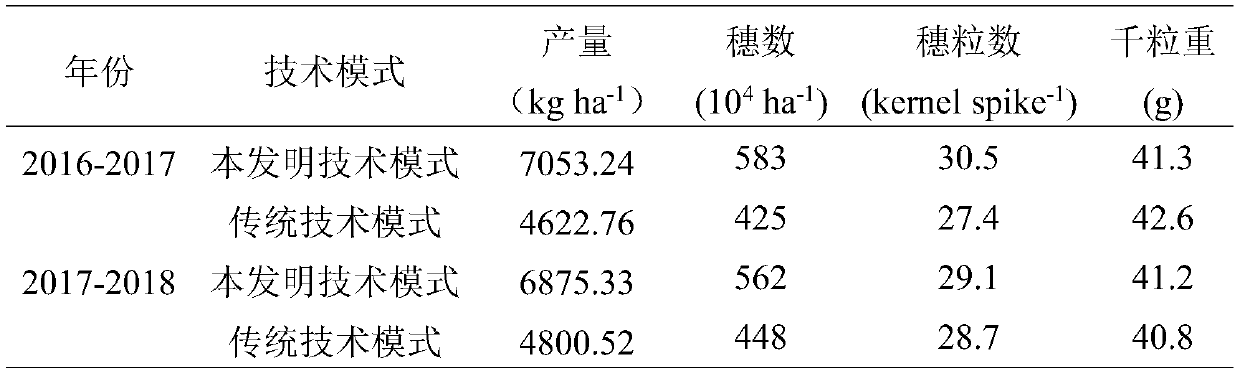

Full-mechanical cultivation method of wheat following rice

The invention discloses a full-mechanical cultivation method of wheat following rice and aims at a rice-wheat rotation system. The method includes the steps of firstly, sunning the field before rice harvesting, and mechanically harvesting rice; secondly, preparing soil before sowing, wherein different soil preparing manners are adopted according to soil water content; thirdly, using different seedprocessing manners to process selected seeds according to different-disease-degree regions; fourthly, determining an appropriate sowing period according to weather, varieties and soil moisture content, using a sowing machine which integrates sowing, fertilizing and compressing to perform sowing in the appropriate sowing period, and applying base fertilizer during sowing, wherein sowing depth is regulated according to soil moisture content; fifthly, performing filed management; sixthly, harvesting from the late dough stage of the wheat to the full ripe stage of the wheat, and returning crushedwheat straw to the field. By the method, the systematic mechanical cultivation technology can be built, the planting quality of wheat following rice can be increased, and high yield can be achieved.

Owner:HUAZHONG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com