Communication equipment metal shell and preparation method thereof

A technology for metal casings and communication equipment, applied to metal casings, casings/cabinets/drawer components, etc., can solve the problem of no integrated appearance effect, and achieve the effect of ensuring flatness and consistency and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

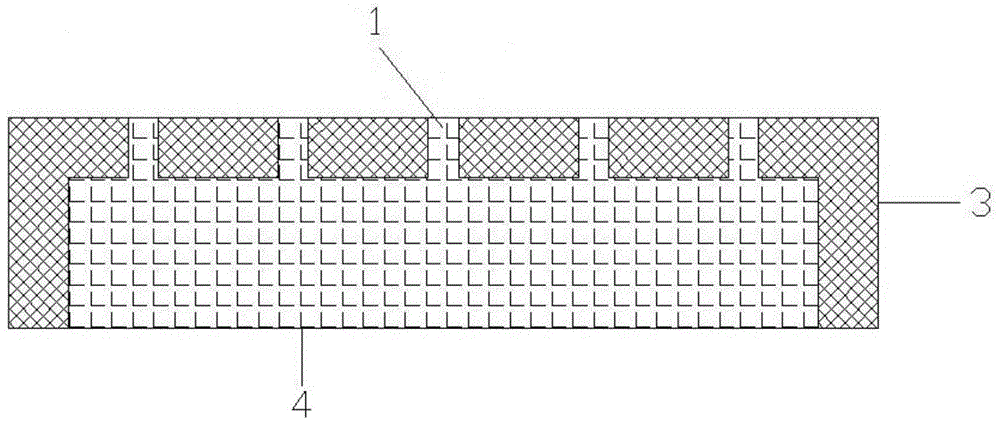

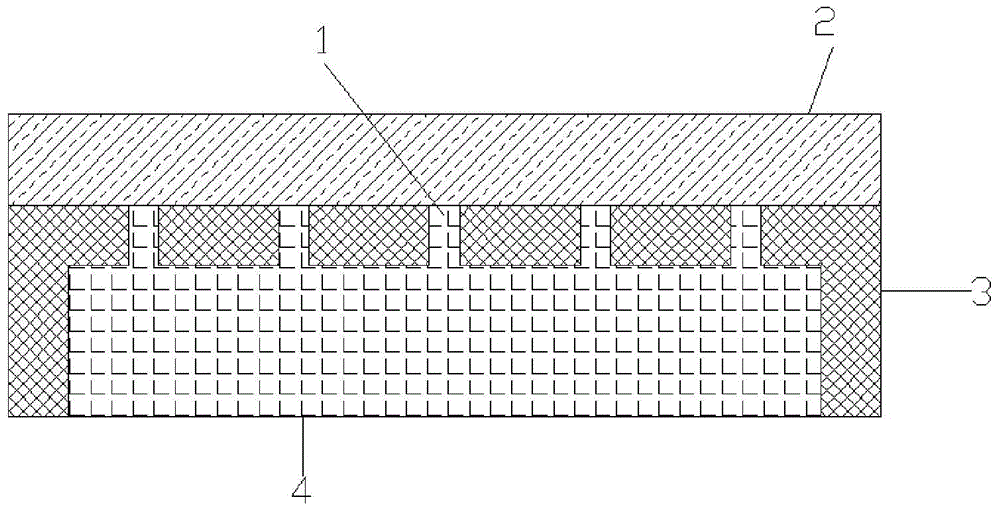

[0040] The invention provides a method for preparing a metal casing of a communication device, wherein the method includes the following steps,

[0041] 1) Provide a metal substrate, the metal substrate is provided with more than one slit;

[0042] 2) Paste reinforcing ribs in the area where slits are opened on the outer surface of the metal substrate;

[0043] 3) inject molding at least a part of the inner surface of the metal substrate;

[0044] 4) Removing the ribs from the metal substrate.

[0045] In the present invention, the region where the slit is opened on the outer surface of the metal substrate refers to the region on the metal substrate corresponding to the antenna of the communication device.

[0046] In the present invention, the thickness of the metal substrate is not particularly limited, and those skilled in the art can properly select it according to the specific communication equipment. For example, the thickness of the metal substrate may be 0.1-0.8 mm,...

Embodiment 1

[0079] 1) Form a slit

[0080] Aluminum alloy (purchased from Dongguan Gangxiang Metal Materials Co., Ltd., grade 6061, thickness 0.4mm) was cut into a size of 15mmx80mm as the metal substrate. Adopt laser machine (the model that Everbright Laser Technology Co., Ltd. produces is FM20D laser machine) to carry out slit processing (wherein, slit is 9, and shape is straight line) on metal substrate, and described slit width is 20 μ m, The length of the slit is 30 mm, and the distance between adjacent slits is 1 mm. The laser processing power is 50W, the speed is 50mm / s, the frequency is 20kHz, and the wavelength is 1064nm, and a metal substrate A11 with slits is obtained.

[0081] 2) Injection molding

[0082] Paste reinforcing ribs (stainless steel sheet, thickness 1mm, length 15mm, width 3mm) on the area where slits are opened on the outer surface of the metal substrate A11, and the pasting positions are the left, middle and right positions in the length direction of the slit,...

Embodiment 2

[0092] 1) Form a slit

[0093] Aluminum alloy (purchased from Dongguan Gangxiang Metal Materials Co., Ltd., grade 6061, thickness 0.6 mm) was cut into a size of 15 mm x 80 mm as the metal substrate. Adopt laser machine (the model that Everbright Laser Technology Co., Ltd. produces is FM20D laser machine) to carry out slit processing (wherein, slit is 9, and shape is straight line) on metal substrate, and described slit width is 40 μ m, The length of the slit is 100 mm, and the distance between adjacent slits is 2 mm. The laser processing power is 200W, the speed is 500mm / s, the frequency is 80kHz, and the wavelength is 300nm, and a metal substrate A21 with slits is obtained.

[0094] 2) Injection molding

[0095] Paste 8 reinforcing ribs (epoxy resin sheet, thickness 1.5mm, length 30mm, width 3mm) on the area where slits are opened on the outer surface of the metal substrate A21, paste them at equal intervals along the length direction of the slits, and the reinforcing ribs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com