Remediation agent for cadmium contaminated soil and soil remediation method

A technology of cadmium-contaminated soil and remediation agent, which is applied in the restoration of contaminated soil, soil conditioning materials, chemical instruments and methods, etc., to achieve the effect of uniformity, strong ion exchange capacity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The preparation of embodiment 1 soil remediation agent

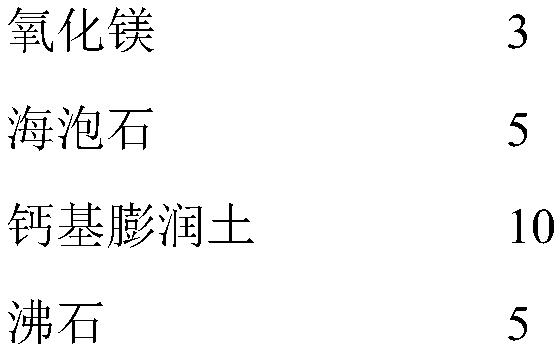

[0082] 1. Prepare raw materials according to the following ratio (×kg)

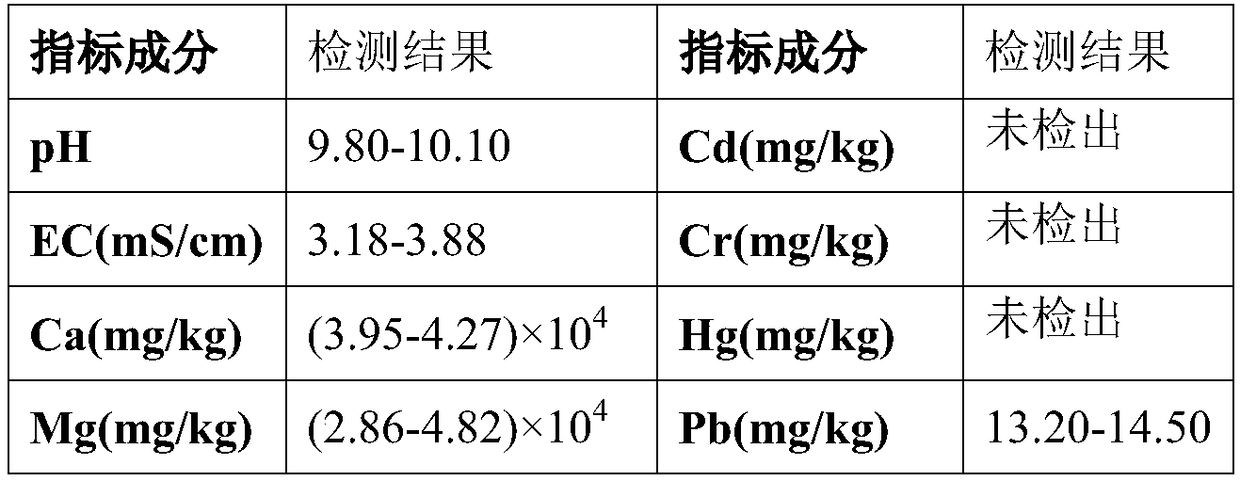

[0083]

[0084] 2. In an environment where the relative humidity is maintained at 30% (usually ≤ 30%, preferably 15-30%), the raw materials magnesium oxide, sepiolite, and calcium-based bentonite are respectively pulverized and sieved by a pulverizer to obtain Magnesium oxide powder, sepiolite powder, bentonite powder with a particle size of ≤100 mesh (usually ≤60 mesh, preferably 60-100 mesh);

[0085] Magnesium oxide, sepiolite and calcium-based bentonite all have strong hygroscopicity, and after absorbing water, they will rapidly expand, agglomerate, harden and lose their effect.

[0086] In the embodiment of the present invention, the particle size of magnesium oxide powder, sepiolite powder, and bentonite powder is 100 mesh as an example for illustration, and other powders ≤ 60 mesh are applicable to the present invention.

[0087] ...

Embodiment 2

[0103] The preparation of embodiment 2 soil remediation agent

[0104] 1. Prepare raw materials according to the following ratio (×kg)

[0105]

[0106]

[0107] 2. In an environment where the relative humidity is maintained at 20% (usually ≤ 30%, preferably 15-30%), the raw materials magnesium oxide, sepiolite, and calcium-based bentonite are respectively pulverized and sieved by a pulverizer to obtain Magnesium oxide powder, sepiolite powder, bentonite powder with particle size ≤ 80 mesh (usually ≤ 60 mesh, preferably 60-100 mesh);

[0108] 3. Mix the crushed magnesia powder, sepiolite powder, and bentonite powder with particle size ≤ 80 mesh evenly to make a magnesia-sepiolite-bentonite mixture, wherein the weight of magnesia, sepiolite, and calcium-based bentonite The ratio is 2:4:10 (ie 1:2:5);

[0109] 4) The zeolite is pulverized and sieved by a pulverizer to obtain a zeolite powder with a particle size of 10-20 mesh;

[0110] 5) Mix the magnesia-sepiolite-bent...

Embodiment 3

[0112] The preparation of embodiment 3 soil remediation agent

[0113] 1. Prepare raw materials according to the following ratio (×kg)

[0114]

[0115] 2. In an environment where the relative humidity is maintained at 25% (usually ≤ 30%, preferably 15-30%), the raw materials magnesium oxide, sepiolite, and calcium-based bentonite are respectively pulverized and sieved by a pulverizer to obtain Magnesium oxide powder, sepiolite powder, bentonite powder with a particle size of ≤100 mesh (usually ≤60 mesh, preferably 60-100 mesh);

[0116] 3. Mix the crushed magnesia powder, sepiolite powder, and bentonite powder with a particle size of ≤100 mesh evenly to make a magnesia-sepiolite-bentonite mixture, wherein the weight of magnesia, sepiolite, and calcium-based bentonite The ratio is 4:6:10 (ie 2:3:5);

[0117] 4) The zeolite is pulverized and sieved by a pulverizer to obtain a zeolite powder with a particle size of 10-20 mesh;

[0118]5) Mix the magnesia-sepiolite-bentonit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com