Metal loaded biomass semicoke catalyst and preparation method thereof

A biomass, supported technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the weak metal-support interaction and the decrease of catalyst specific surface area , large size of metal particles, etc., to achieve the effect of intermetallic electronic effect and geometric effect, strong ion exchange capacity, catalyst activity and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Take 1.487g Ni(NO 3 ) 2 •6H 2 O, 0.434g Fe(NO 3 ) 3 •9H 2 O, prepared as 45mL aqueous solution.

[0049] Weigh 10g of biomass particles, after pickling pretreatment, add to the above mixed aqueous solution, ultrasonically disperse and shake at room temperature for 1h, stir at 30°C for 24h to impregnate with equal volume.

[0050] Dry the impregnated sample at 105°C for 12h, N 2 Under the atmosphere, the temperature was raised from room temperature to 600° C. at a rate of 10° C. / min, and kept for 30 minutes to obtain a Ni-Fe / semi-coke catalyst.

[0051] The mass fractions of Ni and Fe in the catalyst were 10% and 2%, respectively.

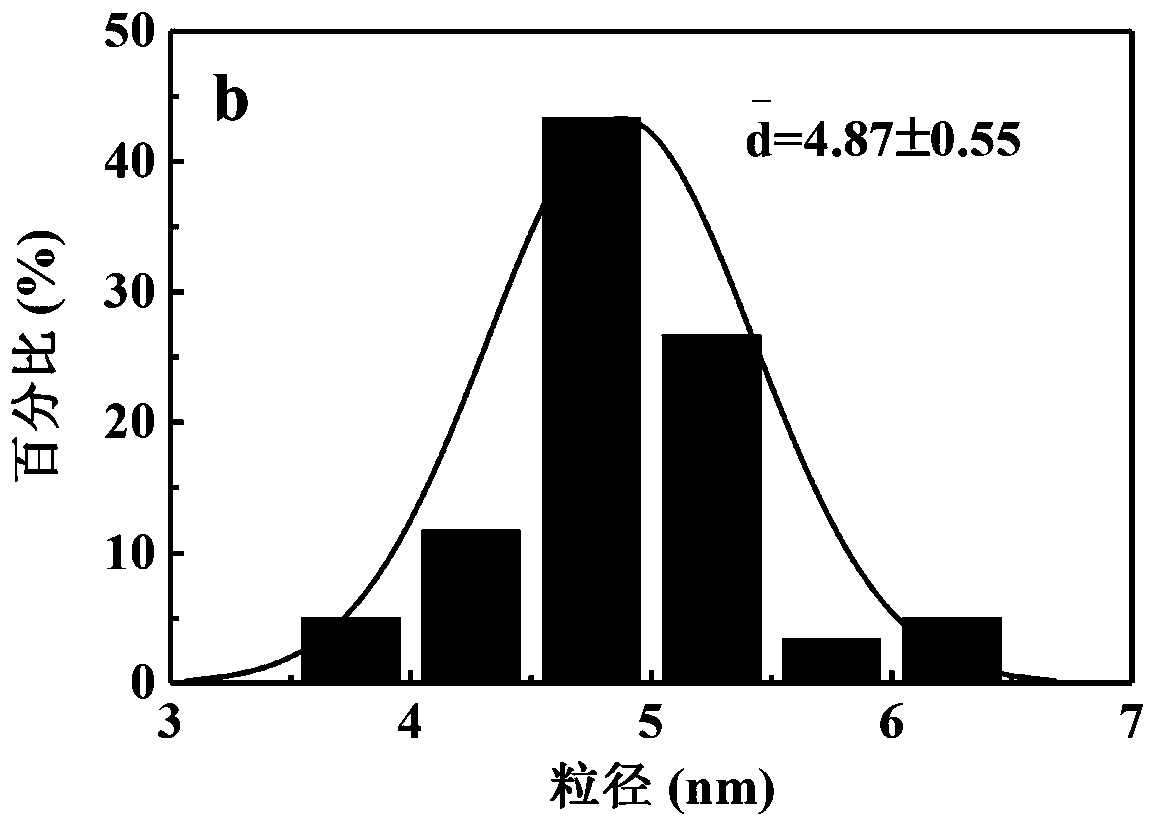

[0052] from figure 1 It can be seen from the SEM image that the obtained catalyst has a loose pore structure, and there are secondary pores on the pore wall. The rich pore structure is conducive to the dispersion of metal particles and the mass transfer of reactants. figure 2 The TEM image shows that the active metal nanoparticles a...

Embodiment 2

[0054] Take 2.974g Ni(NO 3 ) 2 •6H 2 O, 0.592g Co(NO 3 ) 2 •6H 2 O, prepared as 45mL aqueous solution.

[0055] Weigh 10g of biomass particles, after pickling pretreatment, add to the above mixed aqueous solution, ultrasonically disperse and shake at room temperature for 1h, stir at 40°C for 48h to impregnate with equal volume.

[0056] Dry the impregnated sample at 110°C for 12h, N 2 Under the atmosphere, the temperature was raised from room temperature to 700° C. at a rate of 8° C. / min, and kept for 60 minutes to obtain a Ni-Co / semi-coke catalyst.

[0057] The mass fractions of Ni and Co in the catalyst were 20% and 4%, respectively.

Embodiment 3

[0059] Take 4.461g Ni(NO 3 ) 2 •6H 2 O, 0.684g Cu(NO 3 ) 2 •3H 2 O, prepared as 45mL aqueous solution.

[0060] Weigh 10g of biomass particles, after pickling pretreatment, add to the above mixed aqueous solution, ultrasonically disperse and shake at room temperature for 1h, stir at 30°C for 24h to impregnate with equal volume.

[0061] Dry the impregnated sample at 110°C for 12h, N 2 Under the atmosphere, the temperature was raised from room temperature to 650° C. at a rate of 5° C. / min, and kept for 45 minutes to obtain a Ni-Cu / semi-coke catalyst.

[0062] The mass fractions of Ni and Cu in the catalyst were 30% and 6%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com