Vanadium nitrogen system Q460 strength level steel plate for low-temperature container and production method of steel plate

A low-temperature container and production method technology, applied in the field of metallurgy, can solve problems such as high cost, low steel plate strength, and low impact toughness, and achieve the effects of improving production efficiency, low yield ratio, and excellent impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

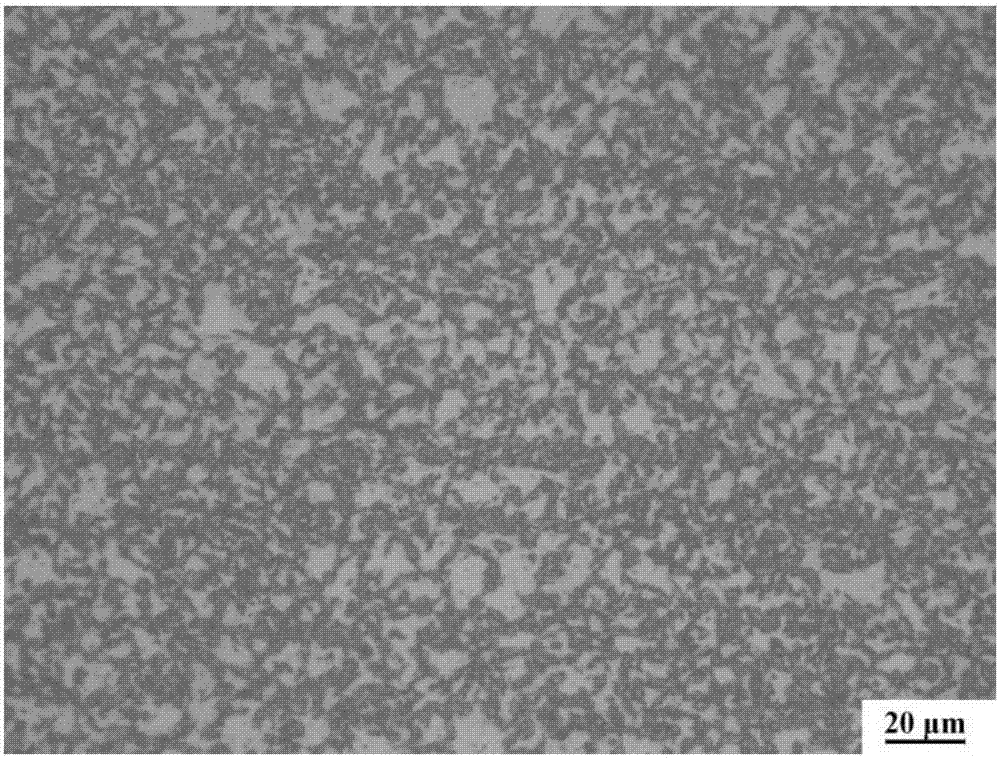

Embodiment 1

[0027] In this example, the thickness of the vanadium-nitrogen series Q460 steel plate for low-temperature vessels is 16mm, and its chemical composition and mass percentage are: C: 0.19%, Mn: 1.45%, P: 0.016%, S: 0.005%, Ni: 0.25%, Nb: 0.025%, V: 0.163%, Al: 0.035%, N: 0.0167%, and the rest are iron and unavoidable impurities.

[0028] The production method of the vanadium-nitrogen series Q460 strength steel plate for cryogenic vessels in this embodiment includes rolling, quenching, and tempering processes, and the specific process steps are as follows:

[0029] (1) Rolling process: Type II controlled rolling is adopted, the second-stage rolling temperature is 860-880 °C, the final rolling temperature is 790-810 °C, and the thickness of the steel is 60 mm;

[0030] (2) Quenching process: quenching in a roller hearth quenching furnace, the quenching temperature is 740 ° C ~ 770 ° C, the holding time is 1.5 ~ 2.5min / mm, after the holding is completed, the surface of the steel pl...

Embodiment 2

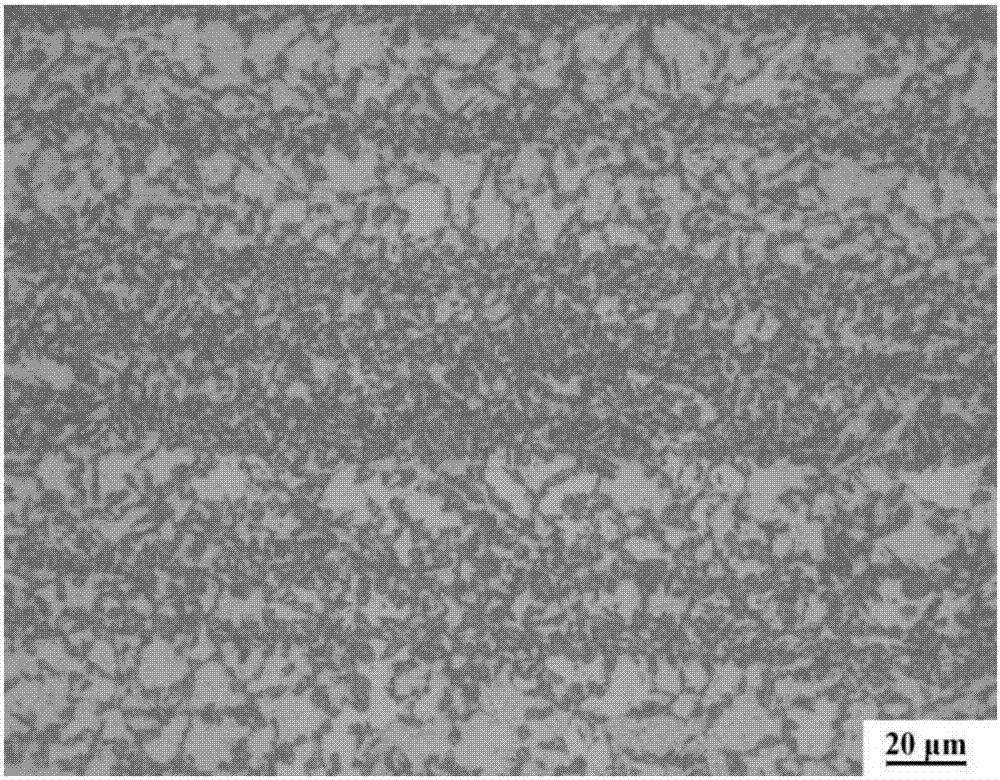

[0038] In this example, the thickness of the vanadium-nitrogen series Q460 steel plate for low-temperature vessels is 18.5 mm, and its chemical composition and mass percentage are: C: 0.19%, Mn: 1.50%, P: 0.013%, S: 0.002%, Ni : 0.28%, Nb: 0.028%, V: 0.176%, Al: 0.035%, N: 0.0190%, and the rest are iron and unavoidable impurities.

[0039] The production method of the vanadium-nitrogen series Q460 strength steel plate for cryogenic vessels in this embodiment includes rolling, quenching, and tempering processes, and the specific process steps are as follows:

[0040] (1) Rolling process: Type II controlled rolling is adopted, the second-stage rolling temperature is 870°C, the final rolling temperature is 800°C, and the thickness of the steel is 70mm;

[0041] (2) Quenching process: quenching in a roller hearth quenching furnace, the quenching temperature is 760°C, and the holding time is 2.0min / mm. After the holding, the surface of the steel plate is water-cooled to room temper...

Embodiment 3

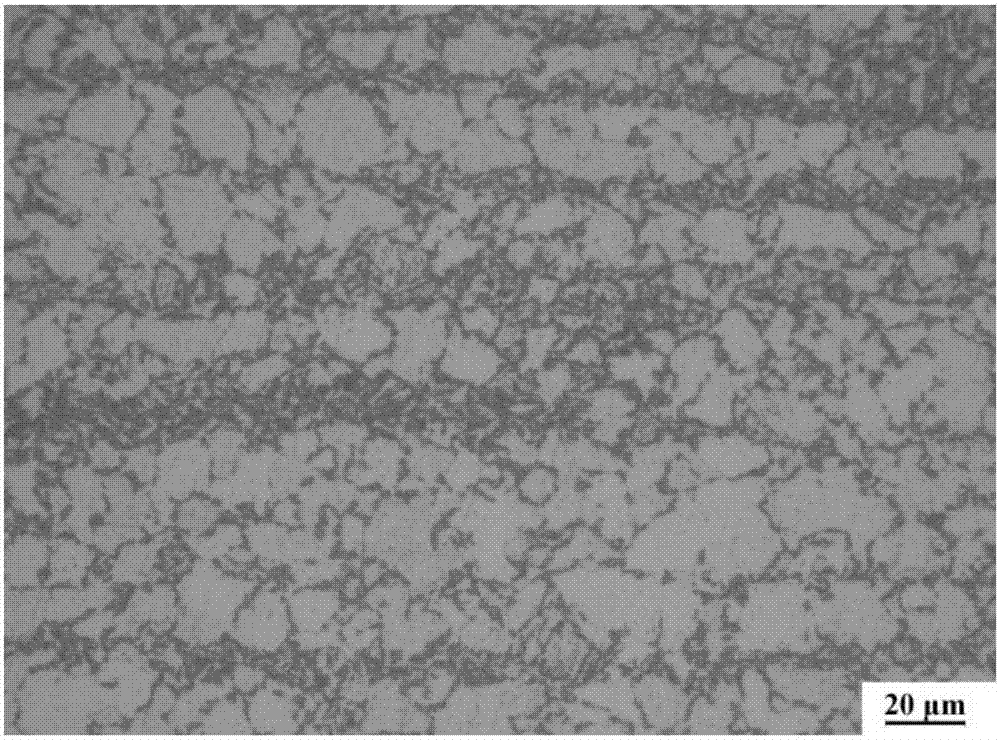

[0049]In this example, the thickness of the vanadium-nitrogen-based Q460-strength steel plate for low-temperature vessels is 20 mm, and its chemical composition and mass percentage are: C: 0.19%, Mn: 1.60%, P: 0.012%, S: 0.001%, Ni: 0.32%, Nb: 0.033%, V: 0.17%, Al: 0.040%, N: 0.0215%, and the rest are iron and unavoidable impurities.

[0050] The production method of the vanadium-nitrogen series Q460 strength steel plate for cryogenic vessels in this embodiment includes rolling, quenching, and tempering processes, and the specific process steps are as follows:

[0051] (1) Rolling process: Type II controlled rolling is adopted, the second-stage rolling temperature is 860°C, the final rolling temperature is 810°C, and the thickness of the steel is 70mm;

[0052] (2) Quenching process: Quenching in a roller hearth quenching furnace, the quenching temperature is 770°C, and the holding time is 1.5min / mm. After the holding, the surface of the steel plate is water-cooled to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact toughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com