Steel heat treatment method, steel, creeper tread and excavator

A heat treatment method and steel technology, applied in the fields of steel heat treatment, steel, crawler shoes and excavators, can solve the problems of high cost, reduced impact toughness, easy fracture, etc., and achieve long service life, excellent impact toughness, and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

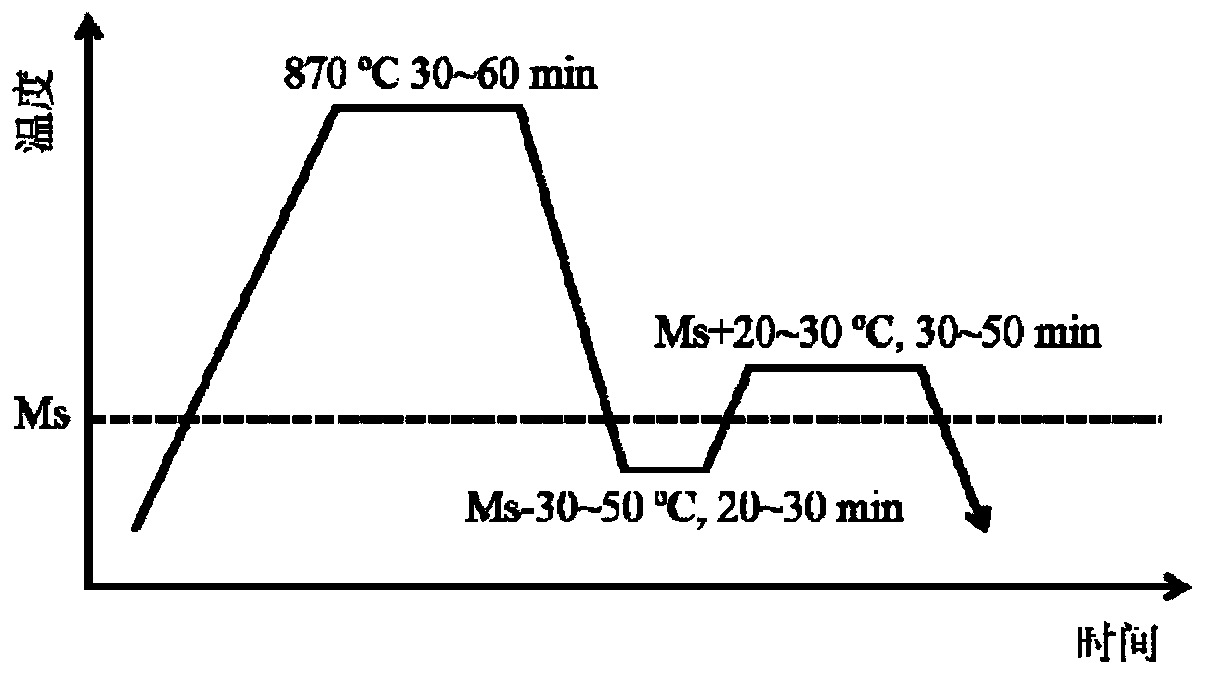

[0058] Heat treatment according to the following process steps:

[0059] (1) Austenitization: heat the casted track shoe to 870°C and keep it warm for 50 minutes;

[0060] (2) The first step isothermal quenching: Quench the austenitized track shoe to a salt bath (the mass ratio of potassium nitrate and sodium nitrate is 1:1), the temperature of the salt bath is 280°C, and keep it warm for 20 minutes;

[0061] (3) The second step of isothermal quenching: move the track shoes after the first step of isothermal quenching into a salt bath with a higher temperature (the mass ratio of potassium nitrate and sodium nitrate is 1:1), the temperature of the salt bath is 350 ° C, keep warm 40min;

[0062] (4) Air-cool the track shoes to room temperature.

[0063] It should be noted that due to the influence of the size of the experimental material, this application does not make additional requirements on the rate of heating or cooling of the material, and the conventional rate of heati...

Embodiment 2

[0069] Heat treatment according to the following process steps:

[0070] (1) Austenitization: heat the casted track shoe to 850°C and keep it warm for 60 minutes;

[0071] (2) The first step isothermal quenching: quench the austenitized track shoe to a salt bath (the mass ratio of potassium nitrate and sodium nitrate is 1:0.8), the temperature of the salt bath is 275°C, and keep it warm for 30 minutes;

[0072] (3) The second step of isothermal quenching: move the track shoes after the first step of isothermal quenching into a salt bath with a higher temperature (the mass ratio of potassium nitrate and sodium nitrate is 1:0.8), the temperature of the salt bath is 345 ° C, and keep warm 50min;

[0073] (4) Air-cool the track shoes to room temperature.

[0074] After testing, the average performance data of the crawler shoes obtained in Example 2 are: the hardness is 59HRC, and the impact toughness is 71J / cm 2 .

Embodiment 3

[0076] Heat treatment according to the following process steps:

[0077] (1) Austenitization: heat the casted track shoe to 900°C and keep it warm for 30 minutes;

[0078] (2) The first step isothermal quenching: Quench the austenitized track shoe to a salt bath (the mass ratio of potassium nitrate and sodium nitrate is 1:1.2), the temperature of the salt bath is 295°C, and keep it warm for 25 minutes;

[0079] (3) The second step of isothermal quenching: move the track shoes after the first step of isothermal quenching into a salt bath with a higher temperature (the mass ratio of potassium nitrate and sodium nitrate is 1:1.2), the temperature of the salt bath is 355 ° C, and keep warm 30min;

[0080] (4) Air-cool the track shoes to room temperature.

[0081] After testing, the average performance data of the crawler shoes obtained in Example 3 are: the hardness is 57HRC, and the impact toughness is 70J / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact toughness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com