Method for manufacturing aluminum alloy rotor with good wear resistance and rotor manufactured by the method

A manufacturing method and technology of aluminum alloy, applied in textiles and papermaking, anodizing, electrolytic coatings, etc., can solve the problems of poor bonding strength between wear-resistant layer and aluminum alloy substrate, low bonding strength of film layer, and low hardness of film layer. , to achieve high hardness and chemical stability, cost-effective, high bonding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

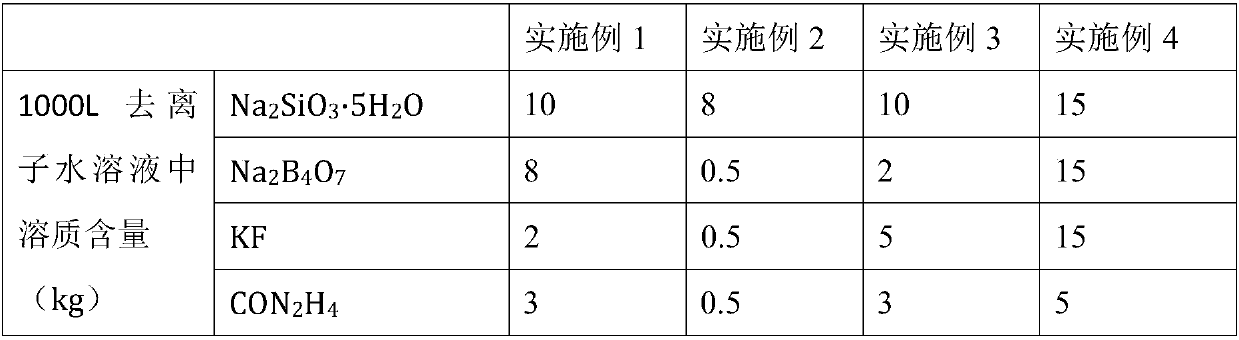

[0026] Example 1

[0027] The technical parameters of this embodiment 1 are shown in the corresponding data of embodiment 1 in Table 1.

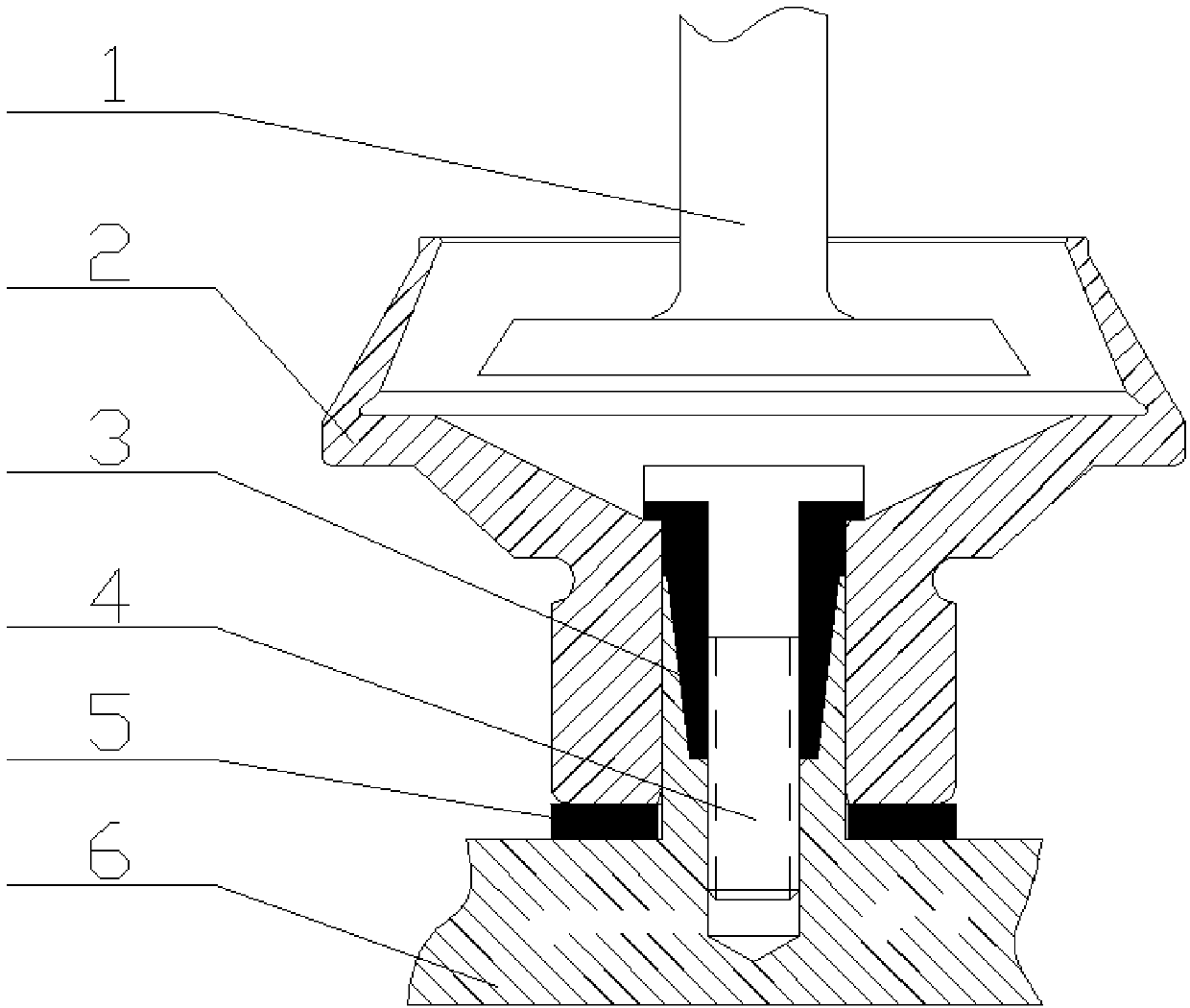

[0028] Step 1: Spinner processing

[0029] In the present invention, high-strength aluminum alloys such as 7 series and 6 series can be used as the base material. In this embodiment, the 6061 aluminum alloy is selected for blank forging, solid solution and aging treatment, and machined into the rotor shape required by the vehicle according to the drawings. , According to the existing technology or design requirements, the upper part of the general rotor cup body is an expanded cohesive groove, and the lower cylinder is an assembly hole. The cohesive groove is the key part that needs to be worn during spinning. The cup assembly hole needs to maintain the same dimensional accuracy.

[0030] Step 2: Partial protection and hoisting of the rotor

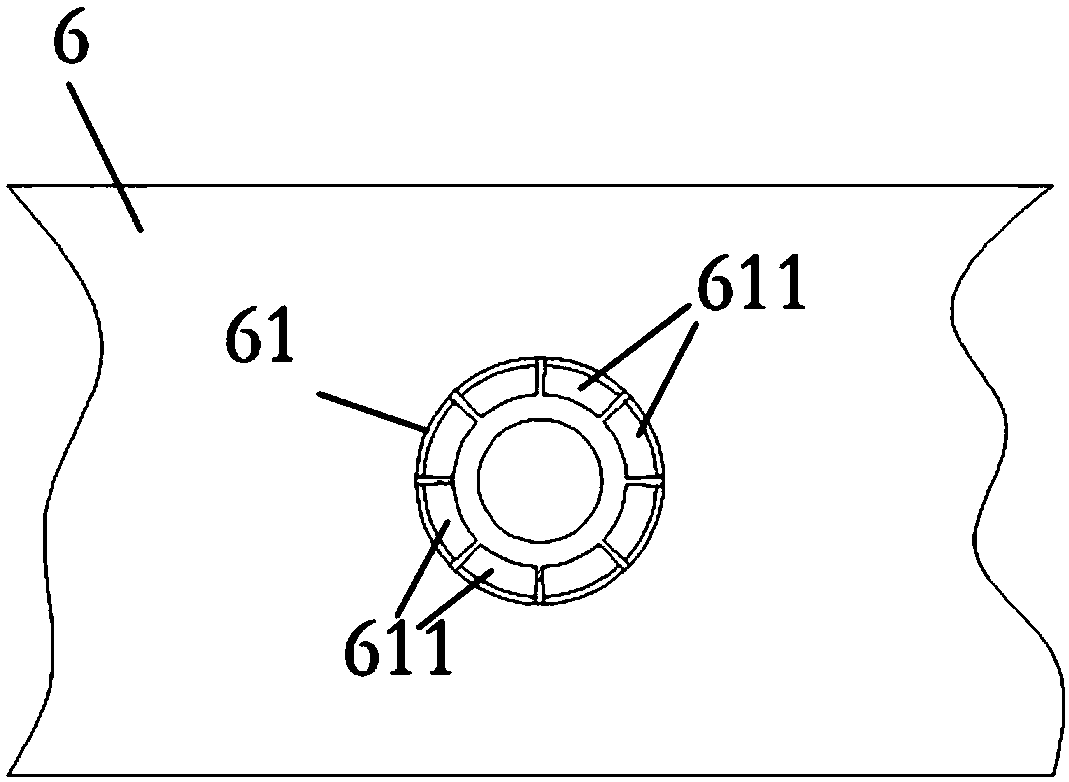

[0031] The assembly hole in the center of the rotor requires subsequent installation of the shaft, so it nee...

Example Embodiment

[0042] Example 2

[0043] The method steps in this embodiment 2 are the same as those in embodiment 1, except that the technical parameters corresponding to embodiment 2 shown in table 1 are used, and the wear-resistant layer obtained is also shown in the data corresponding to embodiment 2 in table 1, and is no longer Repeat.

Example Embodiment

[0044] Example 3

[0045] The method steps in this Example 3 are the same as those in Example 1, except that the technical parameters corresponding to Example 3 shown in Table 1 are used, and the wear-resistant layer obtained is also shown in the data corresponding to Example 2 in Table 1. Repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com