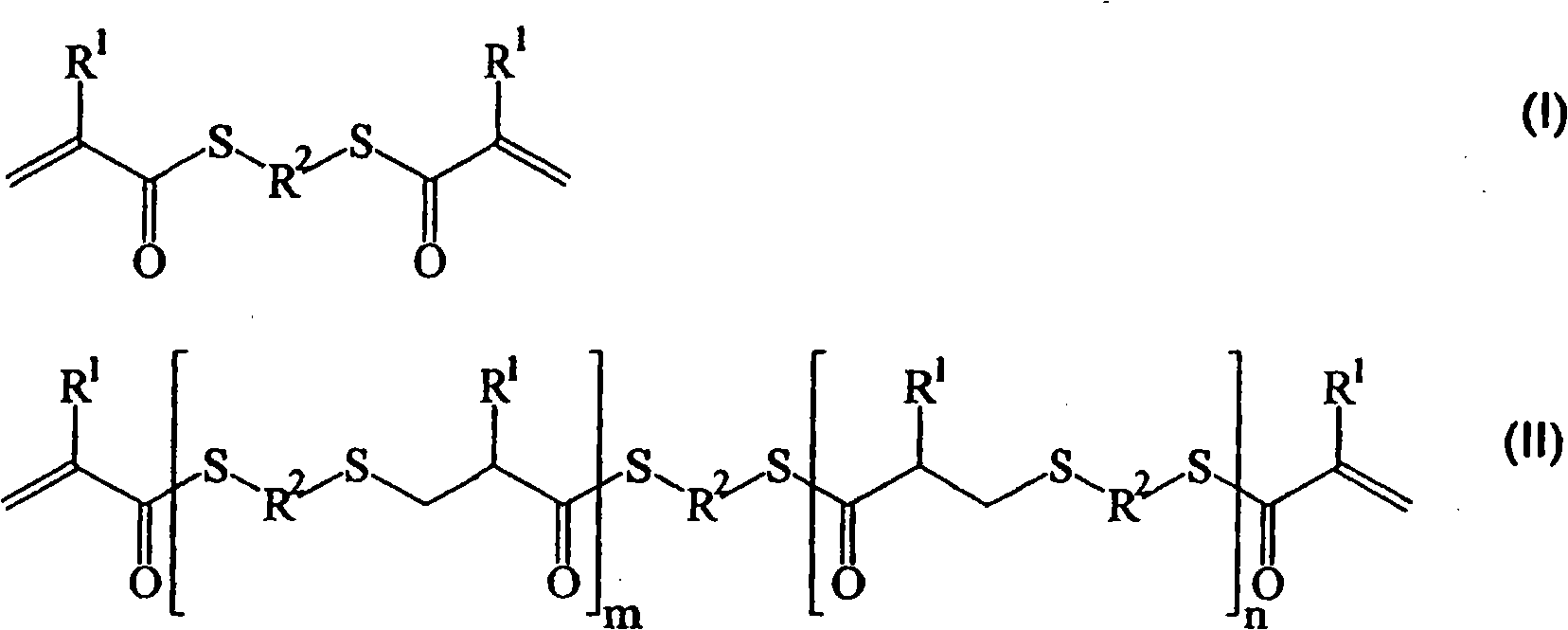

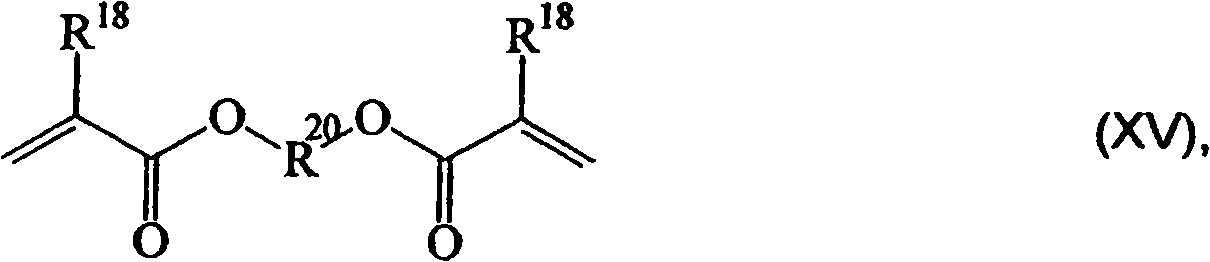

Highly transparent plastic for optical materials

A transparent and plastic technology, used in optics, optical components, organic chemistry, etc., can solve the problem of failing to give the data of plastic Vicat temperature, and achieve improved wearing comfort, good impact toughness, and prevention of damage or inoperability. The effect of repaired damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0294] 2 molar equivalents of TMDI (2,2,4- and 2,4,4-trimethylhexamethylene diisocyanate position isomer mixture (CAS-34992-02-4)) and thiomethyl in 81g 0.01-0.5% by weight DABCO in acrylate was weighed together and mixed to form a homogeneous solution.

[0295] At this point, 1 molar equivalent of 3,6-dioxa-1,8-octanedithiol was metered in at about 60-80° C. within 1 hour, followed by stirring at about 60-80° C. for 1 hour. This reaction step can also be carried out without a catalyst, if desired.

[0296] Subsequently, 2 molar equivalents of 2-hydroxyethyl methacrylate, a stabilizer (0.1% by weight of 4-methyl-2,6-di-tert-butylphenol), and again 0.01-0.5% by weight of The above-mentioned amines or tin compounds, such as dibutyltin laurate. The mixture was stirred at about 60-80°C for 1-5 hours.

[0297] The viscous casting resin was then injected into the mold and polymerized using 0.2 wt% AIBN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com