Mixtures for producing transparent plastics, transparent plastics, method for producing the same and the use thereof

A technology of transparent plastics and mixtures, which is applied in the production of optical lenses, ophthalmic lenses, and the preparation of transparent plastic mixtures. It can solve problems such as unsatisfactory impact strength, achieve excellent mechanical properties, good impact strength, and increase wearing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

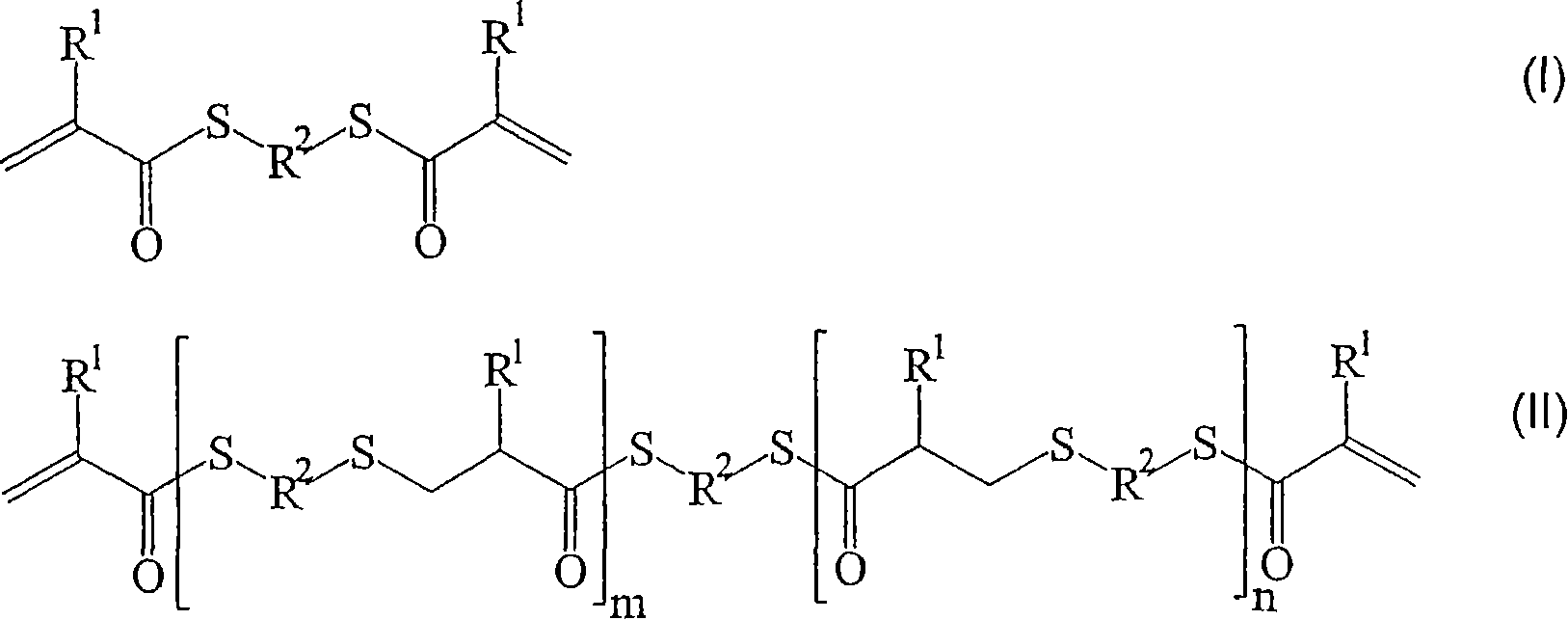

[0241] Synthesis of Thiomethacrylate Mixtures

[0242] 75.36 g of 1,2-ethanedithiol were weighed into an Erlenmeyer flask with protective gas introduction and stirred, and 416.43 g of a 13% strength NaOH solution were cooled in water at 25 to 30 °C within 30 minutes Add in the next meter. A clear brownish solution formed.

[0243] 178.64 g of methacrylic anhydride and Na thiol solution were subsequently metered in parallel at the desired metering temperature within 45 minutes to the stirred initial charge of ethyl acetate / water in the reaction flask. Here, if appropriate, protective gas is passed through the mixed batch. The contents of the flask were typically cooled by about 2°C at the start of the addition and a slightly exothermic reaction started after about 5-10 minutes, which meant subsequent cooling down accordingly to maintain the desired reaction temperature (35°C). After the addition had ended, the mixed batch was stirred for a further 5 minutes at 35°C and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com